Page 1

®

Modular

Jig & Fixture

it

System

Works wit h all INC RA Track & INCRA T-Trac k Compone nts and Accessori es

Platform System

Build-It

Components

• Large Build-It Panel

• Small Build-It Panel

• T-Slot Panel Connector

• 18” or 24” Miter Slider

• INCRA Build-It Clamp

• INCRA Build-It Bracket

• INCRA Build-It Knobs

• INCRA T-Track

• INCRA T-Track PLUS

• INCRA Track (not shown)

• INCRA Shop Stop

(not shown)

Sliding Cutoff Table Showing Major Components & Features of the System

Large Build-It Panel

INCRA Build-It Clamp

Build-It Bracket

(Includes all fasteners)

Miter Slider

Adjustable-width

aluminum runner

T-Slot Panel Connector

Interconnects Build-It Panels

(accepts 1/4” bolts and nuts)

Large Build-It Panel

INCRA T-Track Plus

INCRA T-Track

Wooden Fence

Pre -cut hol es and rabbet

to atta ch T-Slot Panel

Con nect ors on both sides

of Buil d-It Panels

Small Build-It Panel

Multiple rows of pre-drilled

holes for mounting INCRA

Miter Slider wherever needed

Build-It Knob

Counterbored holes on front and

back edges for mounting user

made fences and other accessories

The INCRA “Build-It“ Modular Jig & Fixture Platform System

The INCRA Build-It Modular Jig & Fixture Platform System is a highly versatile NEW method for quickly and easily creating an extremely wide

variety of common and special purpose jigs, fixtures and those one-of-a-kind work helpers that you typically find hanging on the walls and

rafters in just about any woodshop.

The Build-It System begins with INCRA’s Miter Slider adjustable aluminum runners. With hundreds of thousands of units already in circulation, these

tried and true jig and fixture runners have become a workshop staple for the production of sliding and fixed base jigs.

But it’s the NEW INCRA Build-It Panels and T-Slot Panel Connectors that put the punch in this system. The Build-It Panels are pre-cut and

pre-drilled to instantly accept all of the components of the system. You can add a Miter Slider in seconds and it’s automatically square to

your saw blade with no tedious measuring or drilling required, then mount a fence in moments using the counterbored mounting holes. The

glue that holds everything together is INCRA’s innovative NEW T-Slot Panel Connector. These specially designed aluminum components

serve to simultaneously interconnect the panels and provide a rock solid T-Slot for adding and holding jig accessories, fences, stops and

Build-It Clamps. With INCRA’s NEW Build-It Modular Jig & Fixture Platform System you just connect the parts with a screwdriver and the included

fasteners. The possibilities are endle ss!

Page 2

®

it

System

The INCRA Build-It assembly shown in the instructions that follow was chosen to illustrate a configuration using

all of the main components of the system and requiring each of the few simple assembly and trimming operations that are likely

to be encountered when putting the components together. Just remember that the example shown is by no means the only

configuration possible. By using different combinations of the Build-It Panels, T-Slot Panel Connectors and Miter Sliders,

hundreds of highly useful configurations are possible - like those shown on the opposite side of this instruction card. And

that’s just the beginning!

Also, keep in mind that while the table saw chosen to illustrate these instructions is an important candidate for sliding jigs

and fixtures, there are many other stations in the shop that will benefit from the increased safety, accuracy and repeatability

afforded by shop-made jigs. The NEW INCRA Miter Slider owner’s manual includes specific plans for some useful common and

specialty jigs that take advantage of the unique features of the Built-It System’s components. Don’t forget to check out the variety

of great books already available on the subject of beneficial jigs and fixtures for your workshop. Now let’s get started...

Left or Right Miter Slot?

While many tools in your shop like the band saw, router table or sanding

station have only one miter channel, the table saw has two, and often a

choice must be made to determine on which side of the blade the “business”

side of your jig will slide. In choosing, just remember that for any cut requiring

a tilted saw blade, you’ll want the blade to tilt safely away from the main

components of your jig, and most importantly, away from your hands. All of

the instructions to follow will illustrate only a left side of blade assembly.

1. Adjust Miter Slider and Attach Build-It Panel

Begin by adjusting an INCRA Miter slider at each of the expansion

mechanism locations for a good sliding fit in your table saw’s miter slot.

Now attach a small Build-It Panel to the Miter Slider as shown in Fig. 1 using

the (4) 10-24 x 3/4” flat head Phillips screws supplied with the Miter Slider.

2. Attach Panel Connectors

Using the supplied 10-24 x 1/2” flat head Phillips screws, attach a panel

connector to each side of the small Build-It panel, Fig. 2. CAUTION: Make

sure that no part of the aluminum Panel Connector overlaps the

projected line of cut!

This simple assembly can be used for a variety of jigs. The T-slots on the

twin Panel Connectors provide an easy and secure means of attaching

the components of your jig’s design to the sliding Build-It platform using

standard 1/4-20 hex bolts. Just take a look at the tenoning & raised

panel cutting fixture in Fig. 3, then let’s keep building.

Fig. 2 Attach Panel Connectors

10-24x1/2” Phillips screw

Left Side

Fig. 1 Attach Build-It Panel to the Miter Slider

10-24x3/4” Phillips screw

Small Build-It Panel

Miter Slider

Fig. 3 Tenoning Jig Using Basic Build-it Assembly

Specific plans for this jig can

be found in the new Miter

Slider owner’s manual

Right Side

Panel Connectors

Line of Cut

Page 3

®

it

System

3. Extend Build-It Panel to Blade

While the T-Slot Panel Connectors are a useful and important commod-

ity in attaching user made jig components, fences, stops and Build-It

Clamps, they also provide an easy means of adding additional Build-It

Panels to expand the size of your jig design. For example, you might

want to extend support for your jig design to the blade. A large Build-It

Panel is often a good choice here. Just attach the panel as shown in Fig.

4 with the supplied 10-24x1/2” f lat head Phillips screws. You’ll want

the area on the panel with the largest concentration of mounting

holes positioned away from the small panel. Now we’ll trim the panel

to your saw blade.

Fig. 4 Extend Build-It Panel to Blade

10-24x1/2” Phillips screw

Large Build-It Panel

4. Trim Build-It Panel to Blade

BLADE ANGLE NOTE: If the primary use for your jig’s design will be to make 90 deg. vertical cuts, be sure that the blade is set to 90 deg. before continuing.

Raise your blade about 3/4” and make a cut by sliding the Build-It assembly to remove the portion of the large Build-It Panel that extends across the line

of cut, Fig 5. Reserve the cutoff for later use as described in Step 6.

With a Build-It Panel extending all the way to the blade, your Build-It assembly can now be used to support a workpiece for crosscut operations like the

simple “shooter board” jig shown in Fig. 6. Now let’s add some size to our panel configuration for use with larger workpieces.

Fig. 5 Trim Build-It Panel to Blade

Build-It assembly

Fig. 6 “Shooter Board“ Jig

Large Build-It

Panel after cut

5. Increase Build-It Assembly Size

You can now add additional Build-It Panels and T-Slot Panel Connectors

as required to create a support platform to fit the size and scope of your

project needs. In Fig 7, we’ve added a large Build-It Panel to the left

edge of our assembly to increase workpiece support. Now, let’s take

a look at how you can use the cutoff reserved from Step 4 to extend

workpiece support beyond the blade.

Fig. 7 Increase Build-It Assembly Size

10-24x1/2” Phillips screw

Add Large Build-It Panel

6. Extend Build-It Panel Beyond the Blade

Some jig designs may benefit from workpiece or cutoff support on the

opposite side of the blade. A simple “drop panel” locked in place adjacent to the blade provides zero clearance and workpiece cutoff support.

Here’s how to add one to the Build-It assembly we’ve been working on.

Lower the blade and remove your Build-It assembly from the left hand

miter slot. Drop an INCRA Miter Slider into the right hand miter slot and

adjust for a good sliding fit. Using the row of mounting holes that allows

the least amount of overhang beyond the line of cut, attach the cutoff

reserved from Step 4 to the Miter Slider with the (4) supplied 10-24 x 3/4”

flat head Phillips screws. The rabbeted edge on the Build-It Panel should

be oriented away from the blade as shown in Fig. 8.

Fig. 8 Add “Drop Panel“ to Opposite Side of Blade

Cutoff reserved from Step 4

10-24x3/4” Phillips screw

Rabbeted edge of panel

Miter Slider

Page 4

®

7. Trim Build-It Panel to Blade

Raise the saw blade about 3/4” and make a cut to trim off the portion

of the panel that extends beyond the line of cut, Fig. 9. Now, when

you return the left hand Build-It assembly to the table saw, the right

hand “drop panel” can be positioned adjacent to the blade and locked

in place by tightening the two Miter Slider expansion mechanisms to

provide workpiece cutoff support.

it

System

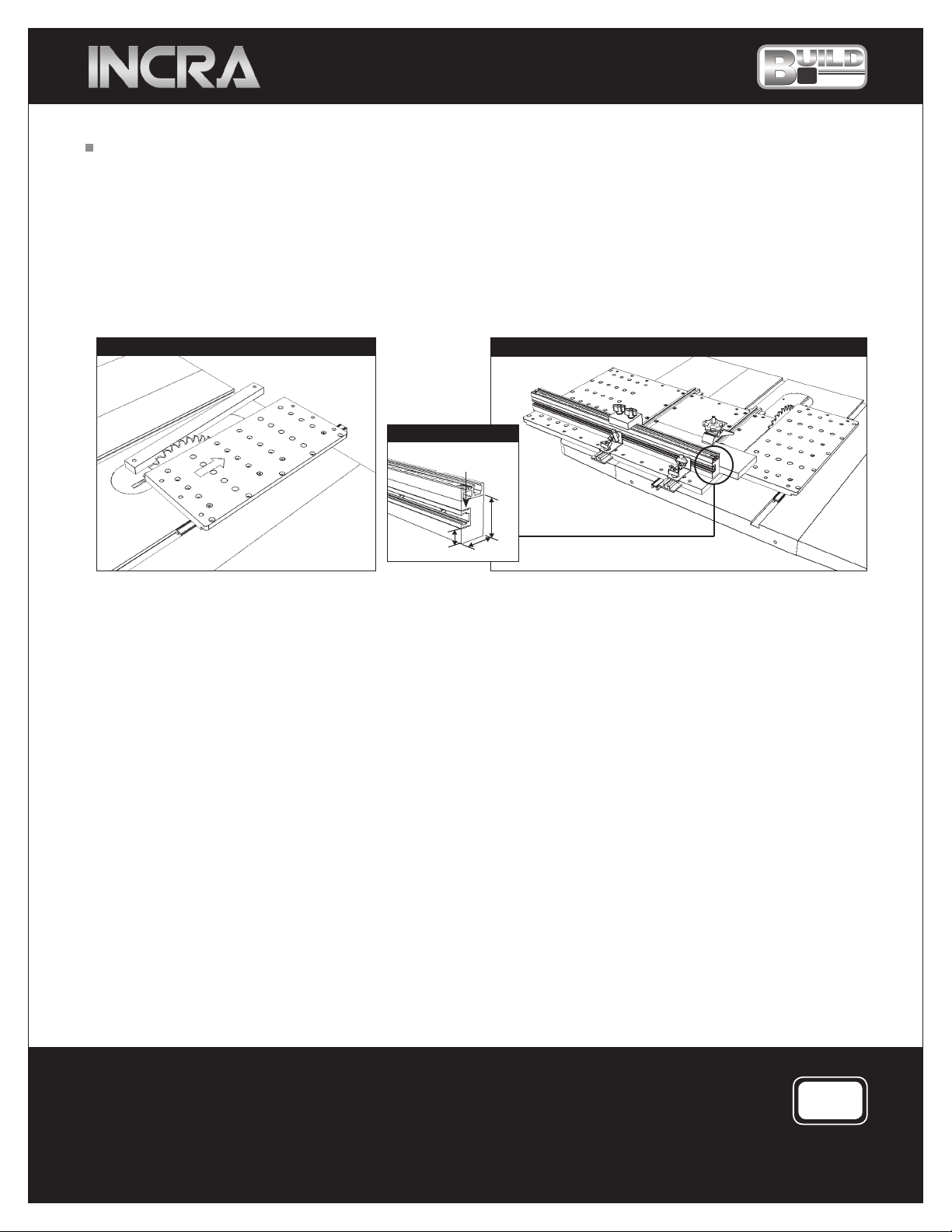

Fig. 10 shows the completed Build-It assemblies put together to create

a very useful sliding cutoff sled. The wooden fence shown includes the

addition of INCRA’s T-Track and T-Track Plus, see Fig. 11 for dimensions.

The fence is held in place with a pair of Build-It Brackets and the knobs

included with the brackets. This arrangement allows the fence to be

positioned at any location and at any angle on top of the sled. The

workpiece is positioned with a user made wooden stop and is securely

held in place with the INCRA Build-It Clamp.

Fig. 9 Trim Build-It Panel to Blade

Fig. 11 T-Track Fence

3/4” wide x 1/2”

deep groove

5

/8”

11/4”

Fig. 10 Sliding Cutoff Sled

13/4”

Manufactured by:

Taylor Design Group, Inc.

P.O. BOX 810262 Dallas, TX 75381

ww w.in cra.com

INCRA is a Registered Trademark of Taylor Design Group

©2007 Taylor Desig n Group, Inc.

MADE IN THE

USA

INCR A Tools are protect ed by one or m ore of the f ollowing US pat ents:

#4, 793,6 04, #4,930, 221, #5,195,730, #5 ,275,0 74, #5, 423, 360, #5,716,0 45, #6 ,237,4 57, #6,55 7,6 01, #6,67 2,190.

Oth er pat ents granted or p endin g.

Loading...

Loading...