Incon task sentinel TS-1001, task sentinel TS-504, task sentinel TS-508, task sentinel TS-750, task sentinel TS-2001 Programming Manual

Page 1

Tank Sentinel

®

Setup Programming

(T S -1001, 2001, 504, 508 & 750)

Automatic Tank Gauge

/

Leak Detection

System

Guide

Part Number: 000-1053, Rev. C

©

Copyright

January 2009

Page FC - 1

Page 2

NO TICE

INCON has strived to produce the finest possible manual for you, and to ensure

that the information contained in it is complete and accurate. However, INCON

makes no expressed or implied warranty with regard to its contents. INCON

assumes no liability for errors or omissions, or for any damages, direct or

consequential, that result from the use of this document or the equipment which

it describes.

This document contains proprietary information and is protected by copyright. All

rights are reserved. No part of this document may be reproduced in any form

without the prior written consent of INCON.

INCON reserves the right to change this document at any time without notice.

Need Help ? Contact INCON at:

INCON

INTELLIGENT CONTROLS, INC.

PO Box 638

SACO ME 04072

Office Hours: 8 a.m. to 5 p.m. EST Monday through Friday

Sales - Technical Service -

Phone: (800) 872-3455 Phone: (800) 984-6266

Fax: (207) 283-0158 Fax: (207) 282-9002

E-mail:

sales@incon.com

E-mail:

tech@incon.com

Visit our Website at: After Hours Cell Phone:

www.incon.com

(207) 229-4437

INCON is a wholly owned subsidiary of Franklin Electric and is a member of the

Franklin Fueling Systems Group

Tank Sentinel ® SCALD® Brite BriteBox® Britebus® BriteSensors

®

and INCON ® are registered trademarks of Intelligent Controls, Inc.

System Sentinel™ and System Sentinel ™ are trademarks of

Intelligent Controls, Inc.

Copyrighted 1997, 1998, 2003 Intelligent Controls, Inc. All rights reserved.

—

Tank Sentinel Setup Programming Guide

❖

—

Page 3

T able of Contents

P Preface................................................................................................... P - i

Graphic Symbol Conventions ..................................................................................... P - i

Page Numbering Convention................................................................................. P - i

Page Layout Convention ....................................................................................... P - i

Before You Begin – Read This ..................................................................................... P - ii

– Site Information Required ............................................................................. P - ii

– Other Sources of Information ....................................................................... P - ii

Scope of This Manual ................................................................................................. P - iii

Menu Conventions ......................................................................................... P - iii

Parent Menus ................................................................................................. P - iii

Key Action .................................................................................................................. P - iii

Alpha-Numeric Input............................................................................................ P - iv

Programming Alarms, Limits, or Inputs to Output Groups.......................................... P - v

Programming Output Devices: .................................................................................. P - vi

Example Applications: ......................................................................................... P - vi

Programming I/O Module Operation .............................................................. P - vii

Interfacing TS-LLD to Tank Gauge ............................................................................ P - vii

Leaving (Exit) Setup Programming .......................................................................... P - viii

After Programming is Done ...................................................................................... P - viii

Warranty Reminder .................................................................................................. P - viii

1 System Setup Programming................................................................ 1 - 1

System Menu .............................................................................................................. 1 - 1

2 T anks Setup Programming .................................................................. 2 - 1

Tanks Menu ................................................................................................................. 2 - 1

Tanks – TANK ALARM N Menu ................................................................................... 2 - 3

Tanks – SPECIAL TANK N Menu ................................................................................ 2 - 5

3 Lines Setup Programming................................................................... 3 - 1

Lines Menu .................................................................................................................. 3 - 1

Line Data Menu ........................................................................................................... 3 - 2

4 Probes Setup Programming ................................................................ 4 - 1

Probes Menu ............................................................................................................... 4 - 1

Probes – PRESSURE Probe Data Menu ................................................................... 4 - 3

Probes – SPECIAL Menu ........................................................................................... 4 - 4

Table of Contents Page TOC - 1

TOC

Page 4

5 Products Setup Programming............................................................. 5 - 1

Products Menu ............................................................................................................ 5 - 1

SPECIAL PRODUCTS Menu ..................................................................................... 5 - 2

6 Manifolds Setup Programming............................................................ 6 - 1

Manifolds Menu ........................................................................................................... 6 - 1

Manifolds ALARMS Menu ........................................................................................... 6 - 2

7 Reconciliation SETUP PROGRAMMING.............................................. 7 - 1

Reconciliation Menu .................................................................................................... 7 - 1

8 Dispenser Interface Module (DIM) SETUP PROGRAMMING .............. 8 - 1

DIM Menu .................................................................................................................... 8 - 1

9 Reports Setup Programming............................................................... 9 - 1

Reports Menu ............................................................................................................. 9 - 1

Reports Schedule Menu ............................................................................................. 9 - 2

Tank Inventory Detail Report: .................................................................... 9 - 2

Tank Inventory Summary Report: ............................................................. 9 - 2

Product Inventory Detail Report: ............................................................... 9 - 2

Product Inventory Summary Report:......................................................... 9 - 3

Product Usage Detail Report: ................................................................... 9 - 3

Product Usage Summary Report: ............................................................. 9 - 3

Delivery Detail Report: .............................................................................. 9 - 4

Delivery Summary Report: ........................................................................ 9 - 4

Active Alarm Report: ................................................................................. 9 - 5

Cleared Alarm Report: ............................................................................... 9 - 5

Alarm History Report: ................................................................................ 9 - 5

SCALD Leak Test: Report ......................................................................... 9 - 6

Sensor Status Report ................................................................................ 9 - 6

Vapor Sensor: ............................................................................................ 9 - 6

Regulatory Report: .................................................................................... 9 - 7

Line Compliance Report: ........................................................................... 9 - 7

Line Diagnostics Report: ........................................................................... 9 - 7

Line Test History Report: ........................................................................... 9 - 8

Line Test Report:....................................................................................... 9 - 8

Shift Reconciliation Report: ....................................................................... 9 - 8

Daily Reconciliation Report: ...................................................................... 9 - 9

Monthly Reconciliation Report: .................................................................. 9 - 9

Shift Reconciliation History Report: .......................................................... 9 - 9

Daily Reconciliation History Report:........................................................ 9 - 10

Shift Sales Report: .................................................................................. 9 - 10

Daily Sales Report: ................................................................................. 9 - 10

TOC

Page TOC - 2 Tank Sentinel Setup Programming Guide

Page 5

Monthly Sales Report: ............................................................................. 9 - 11

Shift History Report: ................................................................................ 9 - 11

Daily History Report: ............................................................................... 9 - 11

1 0 Leak T est Setup Programming.......................................................... 10 - 1

Leak Test Menu (Static Tank) .................................................................................... 10 - 1

Tank Leak Test Menu................................................................................................. 10 - 2

1 1 SCALD ® T ank Leak T est Setup Programming.................................. 11 - 1

SCALD Tank Leak Test Menu..................................................................................... 11 - 1

SCALD (tank leak) Test Menu ....................................................................................11 - 2

1 2 Line T ests Setup Programming .......................................................... 12 - 1

LN (Line) Tests Menu ................................................................................................. 12 - 1

Line Leak Test Requirements & Notes: .......................................................... 12 - 2

1 3 Clock / Calendar Setup Programming................................................ 13 - 1

Clock / Calendar Menu...............................................................................................13 - 1

1 4 Annunciator Setup Programming ...................................................... 14 - 1

Annunciator Menu (Console Alarm Horn) .................................................................. 14 - 1

Annunciator Time-out................................................................................ 14 - 1

Modulated Annunciator Output Group (alarm assignment)....................14 - 2

Solid Annunciator Output Group (alarm assignment) ............................ 14 - 2

1 5 Relays Setup Programming ................................................................ 15 - 1

Relay Menu ................................................................................................................15 - 1

Relay 1 Output Group (alarm assignment) ............................................ 15 - 2

TEST Relay 1 ........................................................................................... 15 - 2

Relay 2 Output Group (alarm assignment) ............................................ 15 - 3

TEST Relay 2 ........................................................................................... 15 - 3

1 6 TS-ROM Relay Output Module Setup Programming ......................... 16 - 1

TS-ROM Menu ...........................................................................................................16 - 1

Grace Period .................................................................................................. 16 - 1

TS-ROM Channel 1 Output Group (alarm assignment) ..................... 16 - 2

TS-ROM Channel 2 Output Group (alarm assignment) ..................... 16 - 2

TS-ROM Channel 3 Output Group (alarm assignment) ..................... 16 - 2

TS-ROM Channel 4 Output Group (alarm assignment) ..................... 16 - 3

TS-ROM Channel 5 Output Group (alarm assignment) ..................... 16 - 3

Table of Contents Page TOC - 3

TOC

Page 6

TS-ROM Channel 6 Output Group (alarm assignment) ..................... 16 - 3

TS-ROM Channel 7 Output Group (alarm assignment) ..................... 16 - 3

TS-ROM Channel 8 Output Group (alarm assignment) ..................... 16 - 4

1 7 Sensors (Leak Detection) Setup Programming ................................. 17 - 1

Sensors Menu ............................................................................................................17 - 1

Naming Sensors ....................................................................................... 17 - 1

Leak Detection Sensors ........................................................................... 17 - 3

Standard Sensors (below... all Alarms = STD N) ..................................... 17 - 3

BriteSensors & alarms (all 3 wire – below)...............................................17 - 3

1 8 Auxiliary Inputs Setup Programming................................................. 18 - 1

Aux. Input Menu .........................................................................................................18 - 1

1 9 Cathodic Protection Monitor (CPM) SETUP PROGRAMMING .......... 19 - 1

Remember:................................................................................................................. 19 - 1

CPM Menu Notes: ...................................................................................................... 19 - 1

2 0 I / O (Input/Output) Module Setup Programming.............................. 20 - 1

I O Module Menu ........................................................................................................20 - 1

Channel N Output Groups – Output Module Alarm Assignments ..............................20 - 4

2 1 Communication Ports Setup Programming....................................... 21 - 1

Comm Ports Menu .....................................................................................................21 - 1

COMM PORT 2 Menu................................................................................................21 - 3

DATA MODE Menu ..................................................................................................... 21 - 5

FAX MODE Menu ...................................................................................................... 21 - 8

2 2 Compliance Via Sensors (CVS) SETUP PROGRAMMING.................. 22 - 1

Remember:................................................................................................................. 22 - 1

Character input / editing: ............................................................................................22 - 1

Before Programming: .................................................................................................22 - 1

CVS Tanks Menu............................................................................................ 22 - 2

CVS Lines Menu ............................................................................................22 - 3

2 3 Upgrade Menu ..................................................................................... 23 - 1

TS-UPGRADE ........................................................................................................... 23 - 1

Upgrade Menu ................................................................................................ 23 - 2

TOC

Page TOC - 4 Tank Sentinel Setup Programming Guide

Page 7

2 4 Language Selection Menu................................................................... 24 - 1

Language Selection Menu ..........................................................................................24 - 1

Language Selection Notes .............................................................................24 - 1

2 5 Data Log Menu .................................................................................... 25 - 1

Data Log Menu ...........................................................................................................25 - 1

Data Logging Notes ........................................................................................ 25 - 1

2 6 Display Menu ....................................................................................... 26 - 1

Display Menu ............................................................................................................. 26 - 1

Display Notes .................................................................................................26 - 1

2 7 Problem Solving (Alarms & Errors) ................................................... 27 - 1

Problem Solving .........................................................................................................27 - 1

Outputs DON’T Turn On When Expected ....................................................... 27 - 7

A Appendix A Standar d T anks................................................................ A - 1

B Appendix B Standard Products.......................................................... B - 1

C Appendix C Typical Tank Leak Test Times........................................... C - 1

D Appendix D P art Number Codes......................................................... D - 1

Tank Sentinel Part Numbering .................................................................................... D - 1

Example Part Numbers .................................................................................. D - 1

Part Number Codes & Meaning...................................................................... D - 2

CFF Customer Feedback Form........................................................... CFF - 1

FCC Information & Requirements ........................................................ FCC - 1

Overall Information & Requirements ...................................................................... FCC - 1

INDUSTRY CANADA Information & Requirements ............................................ FCC - 2

CP-01 Issue 8, Part I, Section 14.1 ............................................................ FCC - 2

CP-01, Issue 8, Part I, Section 14.2 ........................................................... FCC - 2

Table of Contents Page TOC - 5

TOC

Page 8

T able of FIGURES and T ABLES

Page Layout Convention ................................................................................. P - i

Figure 2 - 1 Typical Tank Limits....................................................................... 2 - 3

TABLE 4.1 SPECIAL PROBE RTD POSITIONS .......................................... 4 - 5

TABLE 9.1 TYPICAL REPORT SCHEDULE ................................................. 9 - 1

TABLE 9.2 24 HOUR TIME INPUT FORMAT .............................................. 9 - 1

TABLE 10.1 TYPICAL TEST SCHEDULE ................................................. 10 - 3

TABLE 10.2 24 HOUR TIME INPUT FORMAT .......................................... 10 - 3

TABLE 12.1 24 HOUR TIME INPUT FORMAT ...........................................12 - 2

TABLE 13.1 24 HOUR TIME INPUT FORMAT ...........................................13 - 2

WORKSHEET 1-1 – OUTPUT GROUPS - SYSTEM LIMITS ....................... 1 - 6

WORKSHEET 2-1 – OUTPUT GROUPS - TANKS 1 THRU 4 ...................... 2 - 8

WORKSHEET 2-2 – OUTPUT GROUPS - TANKS 5 THRU 8 ...................... 2 - 9

WORKSHEET 6-1 – OUTPUT GROUPS - MANIFOLDS 1 THRU 4............. 6 - 4

WORKSHEET 10-1 – OUTPUT GROUPS - TANK LEAK TESTS .............. 10 - 5

WORKSHEET 12-1 – OUTPUT GROUPS - LINE LEAK TESTS ................. 12 - 5

WORKSHEET 17-1 – OUTPUT GROUPS - SENSORS 1 TO 8 .................. 17 - 4

WORKSHEET 17-2 – OUTPUT GROUPS - SENSORS 9 TO 16 ................17 - 5

WORKSHEET 17-3 – OUTPUT GROUPS - SENSORS 17 TO 24 ..............17 - 6

WORKSHEET 17-4 – OUTPUT GROUPS - SENSORS 25 TO 32 ..............17 - 7

WORKSHEET 17-5 – OUTPUT GROUPS - SENSORS 33 TO 40 ..............17 - 8

WORKSHEET 18-1 – OUTPUT GROUPS - AUX. INPUTS 1 AND 2........... 18 - 3

WORKSHEET 19-1 – OUTPUT GROUPS - LINE LEAK TESTS ................. 19 - 3

WORKSHEET 20-1 – OUTPUT GROUPS - EXTERNAL INPUTS .............. 20 - 6

WORKSHEET 20-2 – OUTPUT GROUPS - LINE INPUTS .........................20 - 7

TOC

Page TOC - 6 Tank Sentinel Setup Programming Guide

—

❖

—

Page 9

P PREF ACE

Contents:

Graphic Symbol, Page #

& Layout Conventions

Before you Begin

– Site Information Required

– Other Sources of Info.

Scope of This Manual

Menu Conventions, Key

Action, Alpha-Numeric Input

Programming Alarm, Limits,

or Inputs to Output Groups

Programming Output Devices

Graphic Symbol Conventions

NOTE

Important information, tips, and hints are highlighted by the NOTE graphic.

☞

CAUTION

instructions that must be followed to avoid faulty equipment operation, or hazards.

If ignored, equipment damage or personnel injury

WARNING

instructions that must be followed to avoid faulty equipment operation, or an explosion or

shock hazards. If ignored, severe injury or death

messages are highlighted by the

messages are highlighted by the

Programming I/O Module

Interfacing TS-LLD to Tank

Leaving (Exit) Setup

CAUTION

could

result!

WARNING

may

result !

Operation

Gauge

Programming

graphic and contain

graphic and contain

DANGER

messages are highlighted by the

that must be followed to avoid an explosion or electrical shock hazard. If ignored, severe

injury or death

will

result !

— ❖ — End of Chapter symbol

Page Numbering Convention – Example:

Page 4 - 1 = Chapter 4 page 1

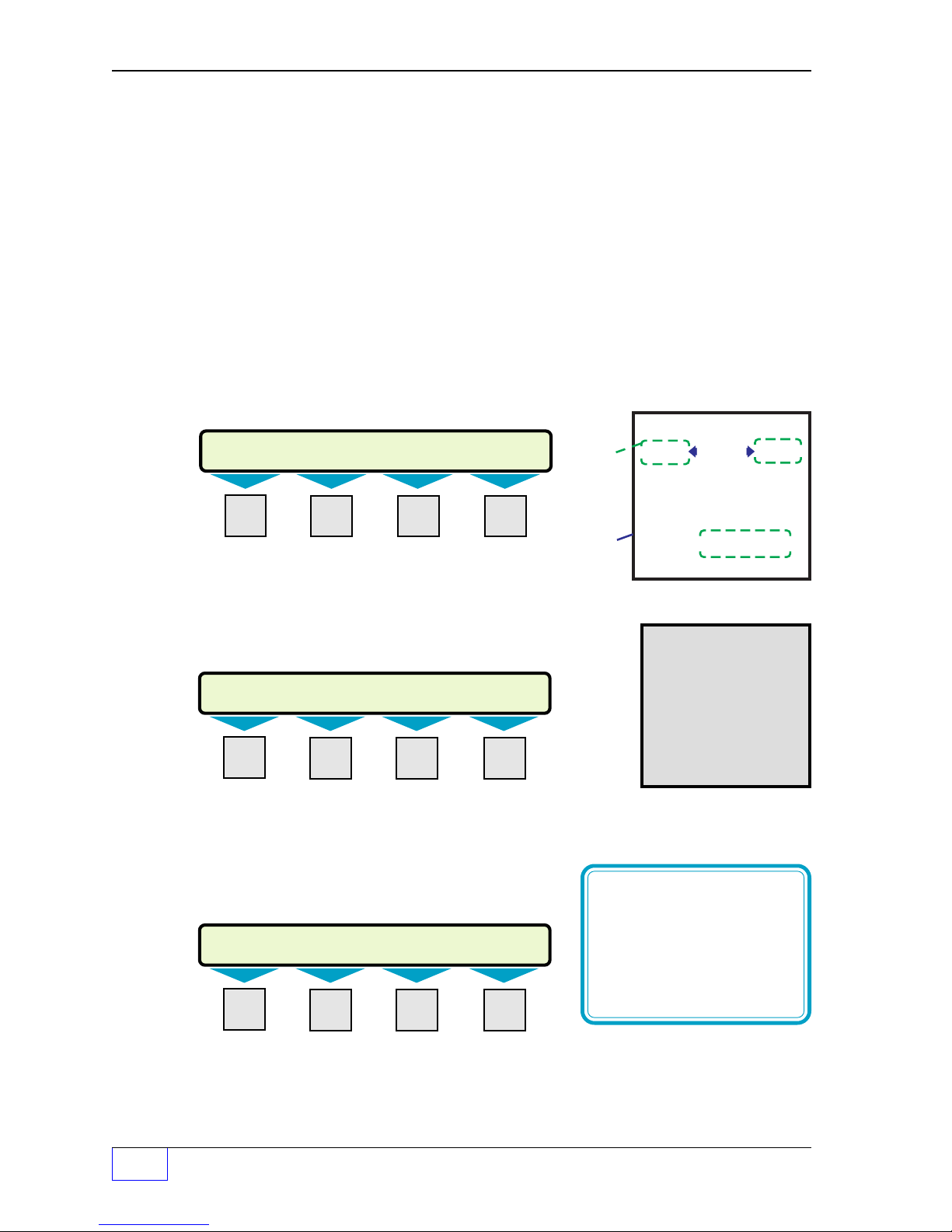

Page Layout Convention – Example:

Manual Name

(

EVEN NUMBERED

PAGES

)

Page Number

Chapter Number

DANGER

graphic and contain instructions

Chapter Number &

Name (

FIRST

Chapter Contents

Chapter Name

(

Page Number

Chapter Number

TOP LEFT

PA GE

)

ODD NUMBERED

PAGES

)

PREFACE Page P - i

P

Page 10

Before Y ou Begin – Read This

CAUTION

Leaking underground storage tanks ( USTs ) and fuel lines cause serious

environmental and health hazards. The Tank Sentinel

in tanks by tank tightness / leak testing with liquid level probes, and/or with leak detection

sensors. You must follow the instructions in this manual carefully to ensure that the

system is programmed properly and is effective in detecting leaks.

– Site Information Required

• Site Plan? — showing the location, size, and model #s of all tanks, probes and sensors

• Dispenser Manufacturer Documentation?

• Pump Manufacturer Documentation? — Type, Model #s, and suction inlet

the bottom

of each tank (to determine the lowest product level and highest water level)

• Pump Control Required ? — enable / disable pumping... TS-IEM Output modules (for

TS-2001/508 consoles only), or a TS-ROM1 BriteBox

• Remote Device Control Required? — use TS-IEM (see above), or a TS-ROM2 BriteBox

• Remote Tank Overfill Alarm / Acknowledge Installed ? — (TS-RA1 or TS-RA2 / TS-RK)

Type, Model, Size and Manufacturer of each Tank

• Tank Manufacturers’ Tank Chart / Strapping Table (s)? — for each tank or the diameter

and length of each tank

• Are any tanks identical ? — (tanks, probe data, and alarm limits can be copied)

• Standard Probe Data? — (model number, shaft length, gradient, serial number)

• Special Probe Data? — (ie RTD / Temperature sensor locations)

• Tank # & Probe # — model number assignments and input channels for each tank

• Leak Detection Sensors? — installed in or near or associated with each tank including

input channel number assignments

• Product? — in each tank (API specific gravity) and the type & number of float(s) / probe

• State and Local Regulations? — (testing requirements, reporting requirements, and

hotline numbers, and other information that you and/or the customer will need)

®

system is designed to detect leaks

distance off

– Other Sources of Information

Use the TOC (Table of Contents) to find information within this manual and see the

following INCON documentation:

•

Installation Guide

•

Leak Detection Sensor – Installation Guides (one per type / family of sensor)

•

Tech Service Bulletins • Application Bulletins

P

Page P - ii Tank Sentinel Setup Programming Guide

•

Operator’s Guide

•

TroubleShooting Guide

•

Application Notes

Page 11

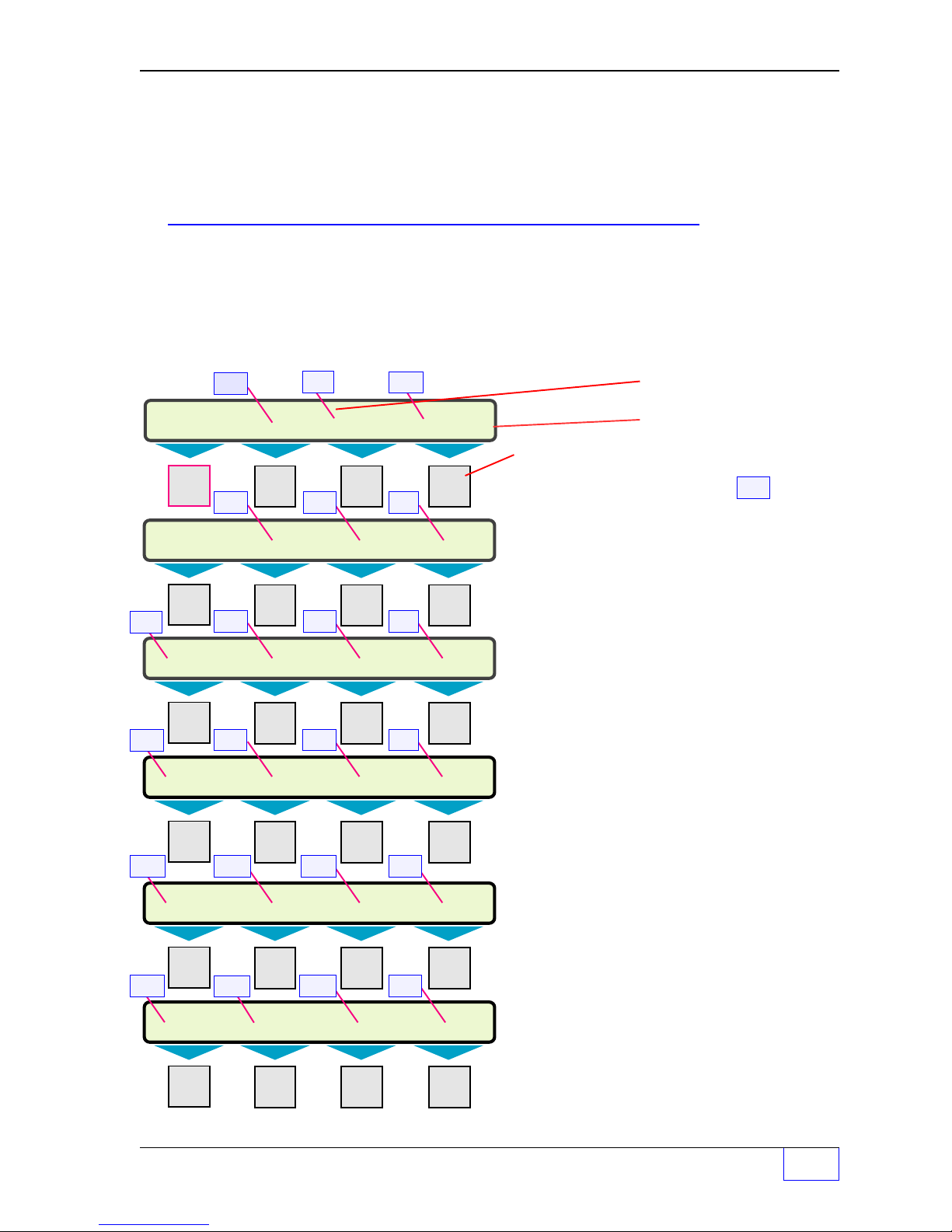

Scope of This Manual

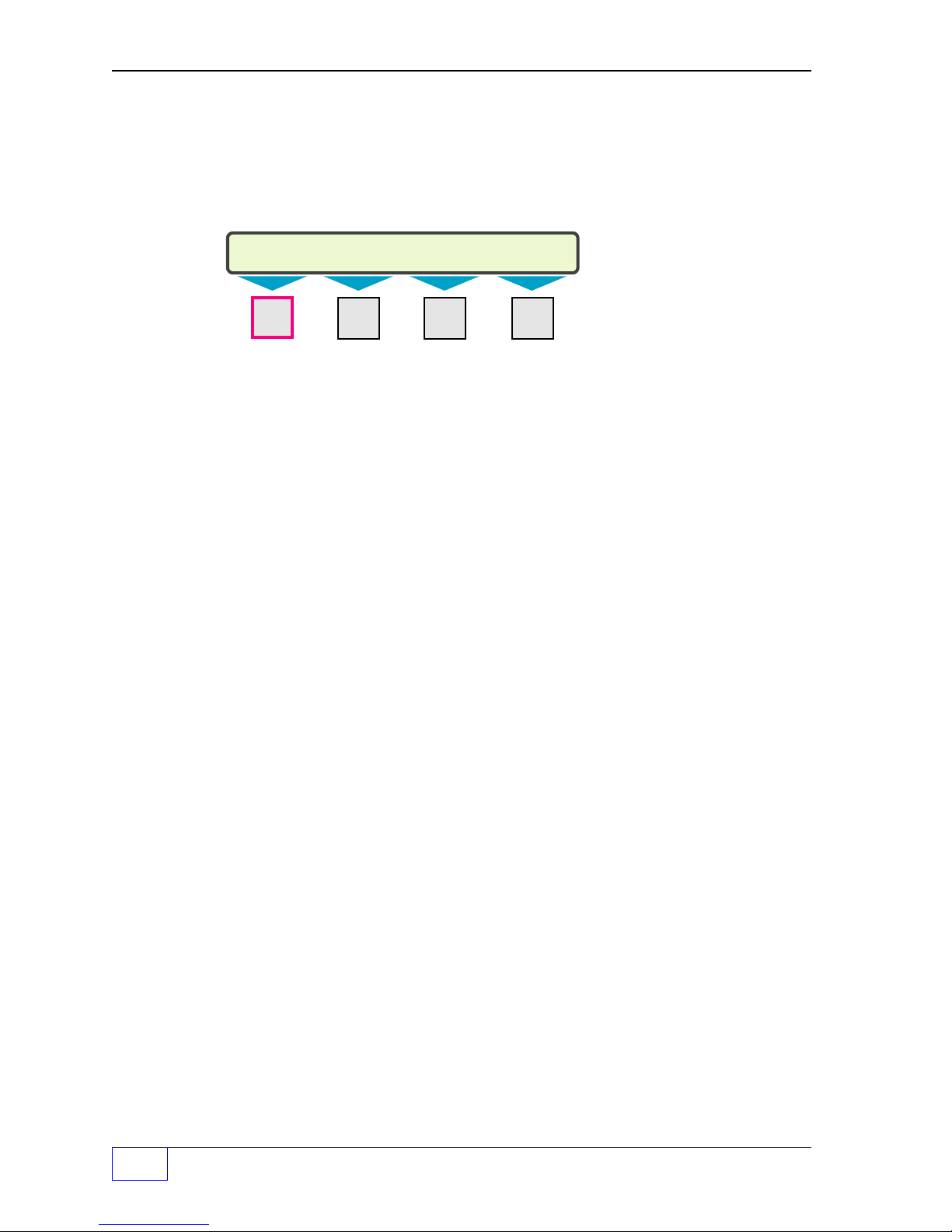

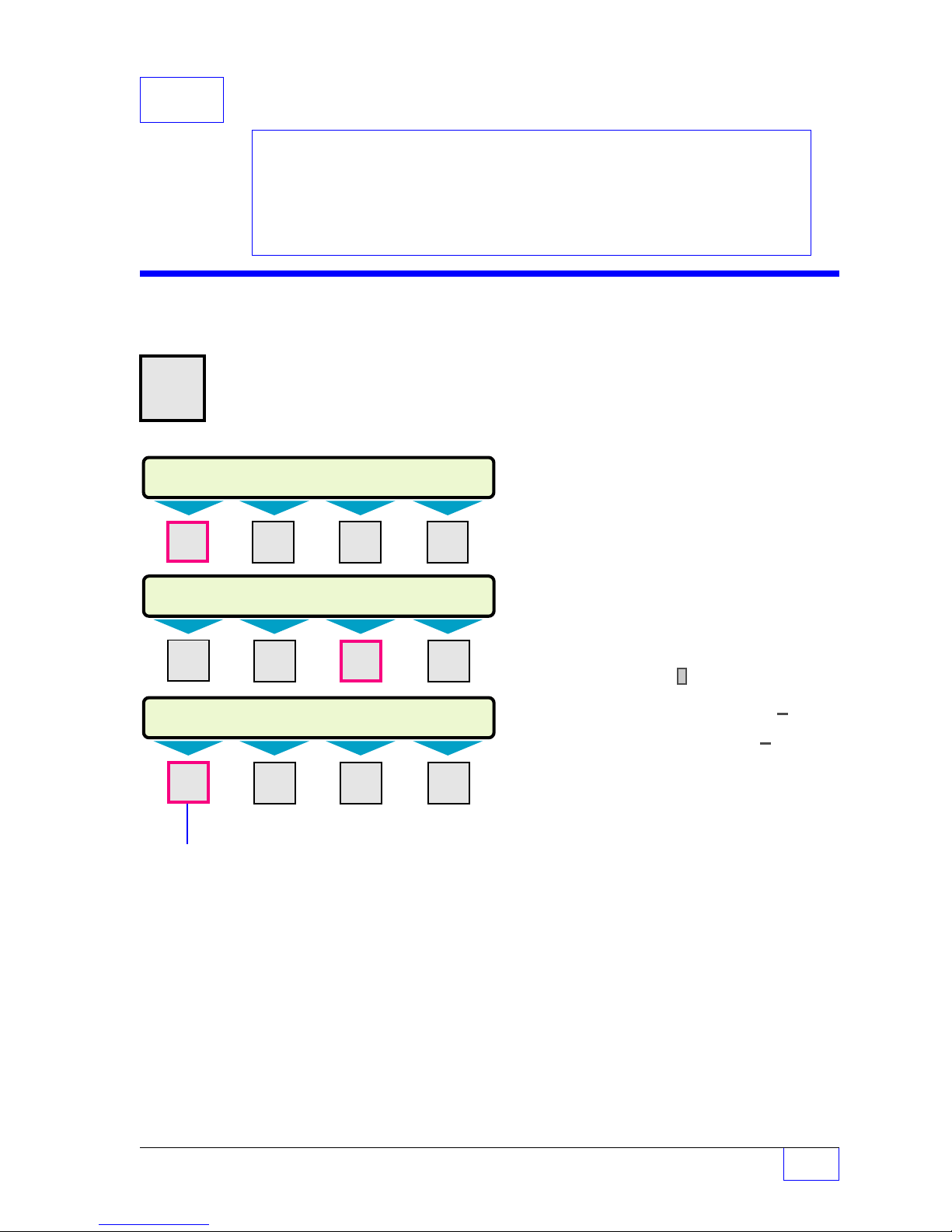

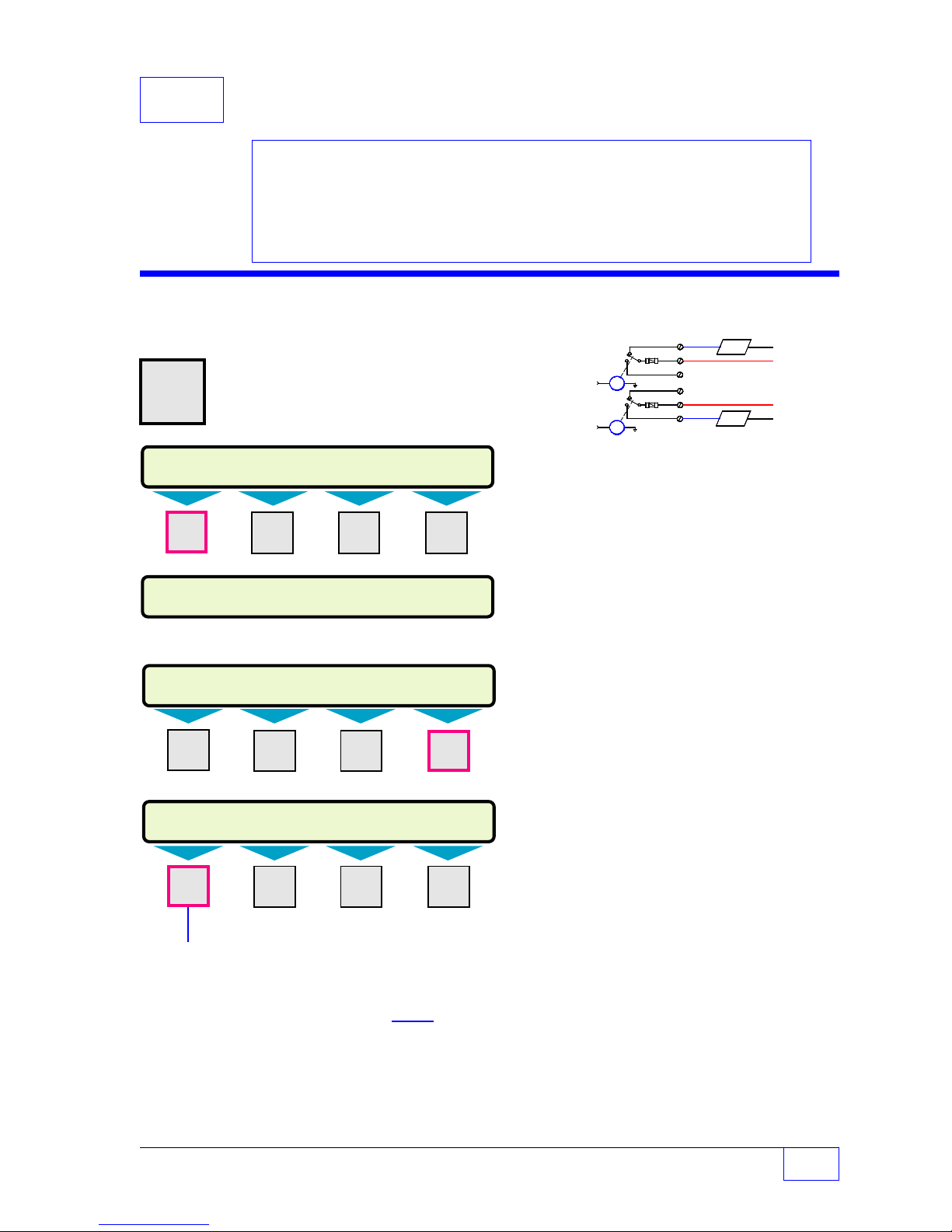

SELECT MENU OPTION (MORE)

SETUP UPGRADE LANGUAGE DATALOG

SETUP MENU (MORE)

EXIT SYSTEM TANKS LINES

SETUP MENU (MORE)

PROBES PRODUCTS RECONCILE DIM

SETUP MENU (MORE)

REPORTS LK TESTS SCLD TEST LN TESTS

SETUP MENU (MORE)

CLK/CAL ANNUNC RELAYS SENSORS

SETUP MENU (MORE)

AUX INPUT CPM COM PORTS CVS

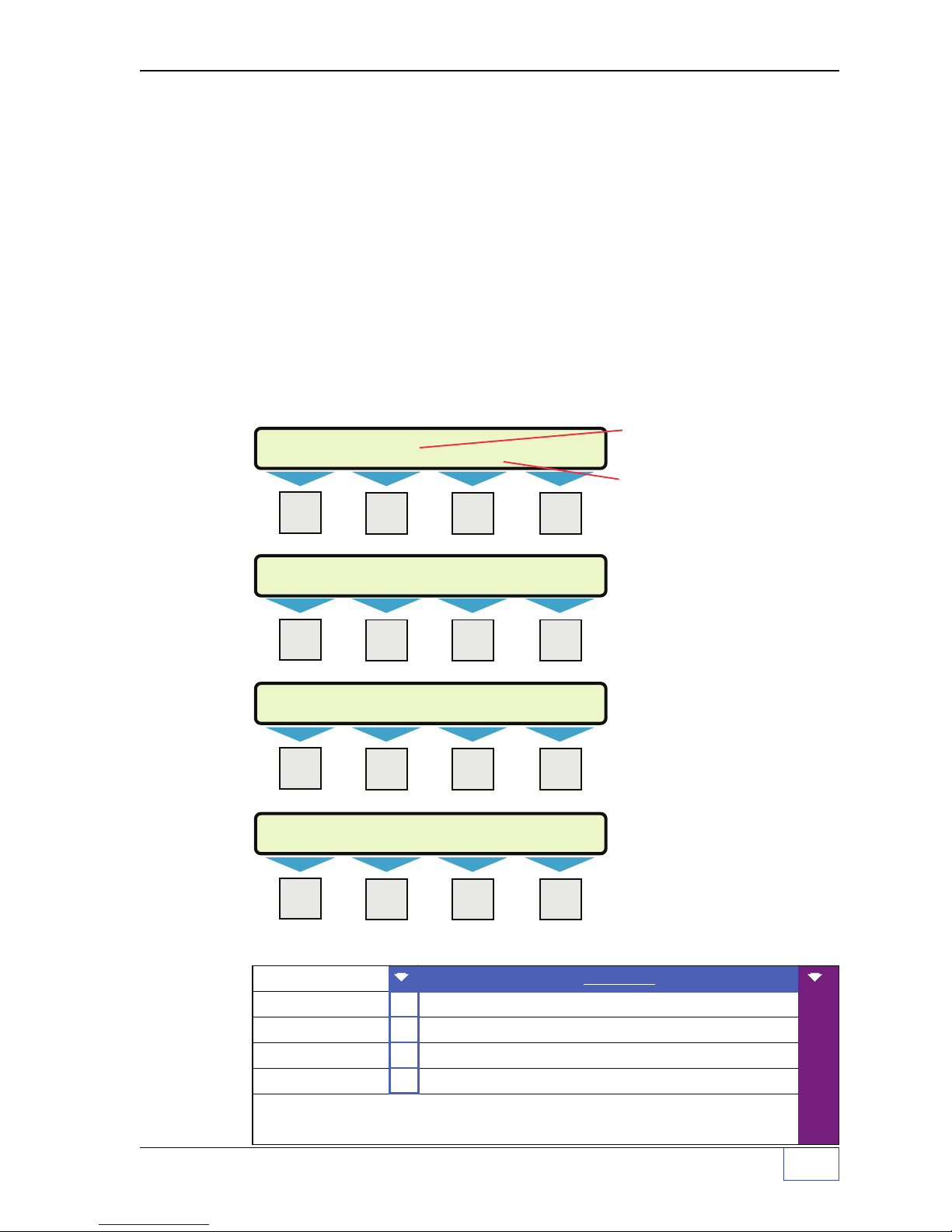

This manual shows the setup-programming of Tank Sentinel system. Each Chapter is

dedicated to a specific parent menu (see Parent Menus below).

Menu Conventions

The menu structure in this manual is shown in an indented format:

PARENT MENUs are above and to the left of sub-menus and

SUB-MENUs are below and to the right of parent menus.

Default

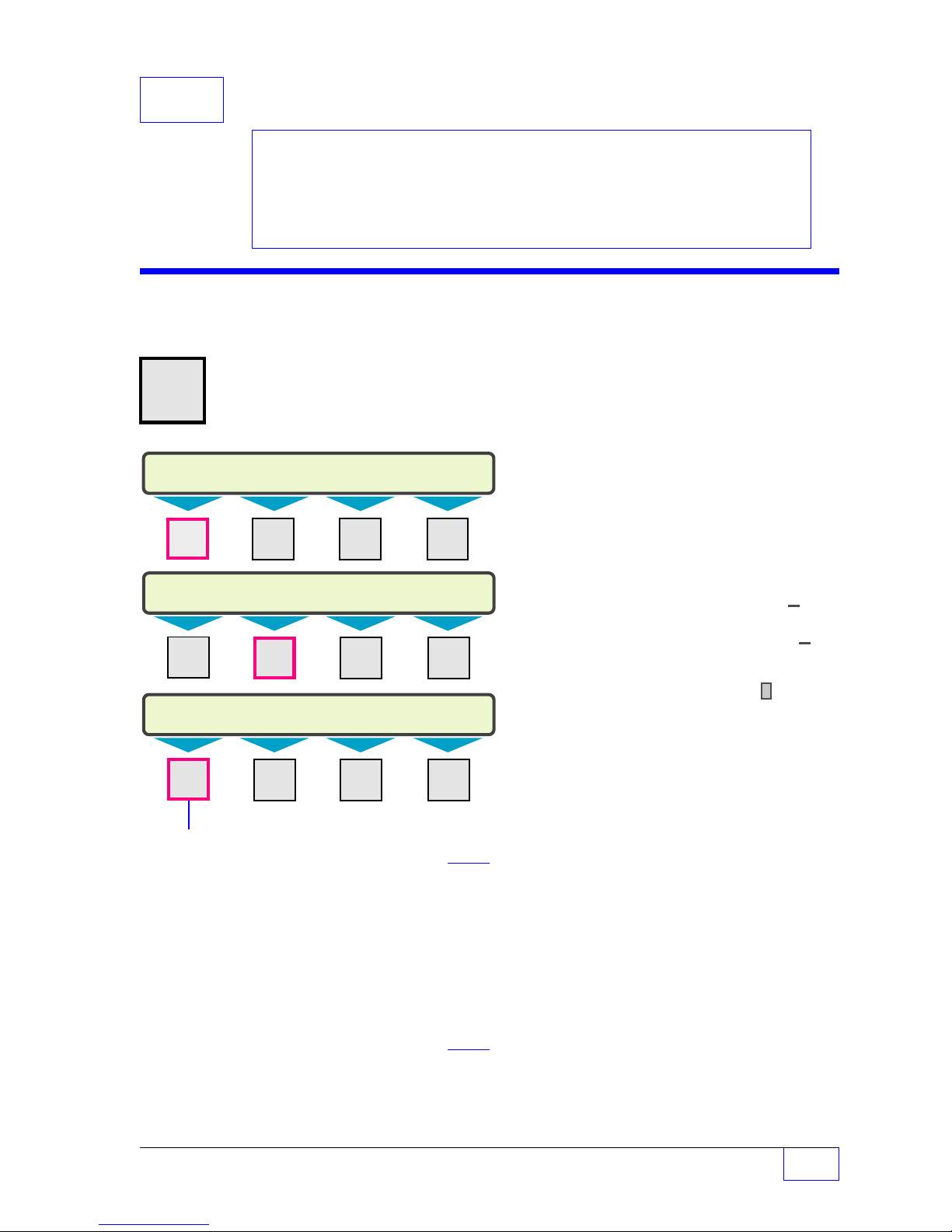

Parent Menus

VALUES, SETPOINTS, & LIMITS

are shown first and in

ITALIC

text.

20

M1 M2 M3 M4

1 2* 3***

M1 M2 M3 M4

4*

8***

12

16

5* 6* 7

M1 M2 M3 M4

9*** 10*** 11

M1 M2 M3 M4

13 15*

M1 M2 M3 M4

17**

M1 M2 M3 M4

21

14**

18

22

19

UPPER ROW – DISPLAY TEXT

LOWER ROW – DISPLAY TEXT

MENU keys M1 thru M4

NOTES

☞

Numbers within boxes

Chapter #s. Some parent menus, or

are

sub-menus will not appear unless:

*

a related setup menu / feature is selected

**

the accessory (hardware) is installed and the

system is powered up

***

the appropriate options have been purchased

Key Action

MENU keys

•

choose / display other menus or sub-menus

or exit SETUP mode

•

move the cursor left or right through a text

string (

•

backspace over / delete a character in a text

string (

KEY PAD keys

•

ï

of a menu

•

▲

when (MORE) is shown, or other selections

from a sub-menu when (UP/DN) is shown

•

Use the

choice or value for storage into setup memory

– use (press) to:

M1

=

left, M2

M4

backspaces from the right)

– use (press):

CANCEL

UP

to cancel an input or to exit out

or

DOWN

ENTER

= right)

▼ to display more menus

key to accept the displayed

PREFACE Page P - iii

P

Page 12

Key Action (C

LOCATION LINE 1 A...M

INCON BACKSPACE

LOCATION LINE 1 N...Z

A BACKSPACE

LOCATION LINE 1 NUMERIC

AN 0.1 BACKSPACE

NOTE

The shift

function

will remain in the

current input character

mode (or position) until

the ACK SHIFT key is

pressed again

.

•

ONTINUED FROM PREVIOUS PAGE

ACK SHIFT

shows either an

key is used to change the preconditioned

A...M

expected. Press the

to another type (look at the upper right corner of display while doing this).

Operator’s manual about using the

and to start an output grace period (programmable length of time).

Alpha-Numeric Input (example)

The example below is what you would see when

programming SYSTEM ID... (press keys:

MENU M1 M2 M2 M1

M1 M2 M3 M4

... )

input character type...

or the word NUMERIC when an alphanumeric or numeric input is

ACK SHIFT key N

) to display:

times

to change the current input character type

ACK SHIFT

key to silence and acknowledge alarms,

Press the

N

Upper right

DISPLAY

shows the

input

selection

...shown

here

within

dashed

lines

times to DISPLAY the

input character type ( #__ )

then press the

(

)

# 1

A...M

COMMAND

the display

See the

ACK SHIFT

Key of choice.

(

input a

letter

# 2

N...Z

key

)

A...M means that the system is conditioned to

Typical

Key

(# 3)

number or special character

N

UMERIC

input the upper left letter of any key (A B C D

E F G H I J K L M)... see below:

Press

ACK SHIFT

key once again to display:

A

PRODUCT

M1 M2 M3 M4

1

N...Z means that the system is conditioned to

input the upper left letter of any key (N O P Q R S T U V W X Y Z)

– conditions remain until changed – see below:

Press

ACK SHIFT

key once again to display:

N

M1 M2 M3 M4

NUMERIC means that the system is conditioned to input the lower character of

any key (numbers 1 2 3 4 5 6 7 8 9 0 . +/– or a SPACE)... see above.

P

Page P - iv Tank Sentinel Setup Programming Guide

Page 13

Programming Alarms, Limits, or Inputs to Output Groups

HIGH PRODUCT OUTPUT GROUP 1 (UP/DN)

NONE

HIGH PRODUCT OUTPUT GROUP 1 (UP/DN)

GROUP A

HIGH PRODUCT OUTPUT GROUP 1 (UP/DN)

ALL GROUPS

TANK ALARM 1 (MORE)

COPY HIGH LIM H LIM OG HIGH HIGH

The TS-1001/504 / 2001/508 / 750 Tank Sentinels includes a powerful setup feature called

Output Groups

(OGs). Alarms, limits, and inputs (Aux. or

assigned / programmed to output groups (OUT GROUP or OG). An output device will turn

on or off when an alarm is active in any of its assigned output group(s). Up to 32 output

group(s) can be assigned or programmed to any output device... also see Programming

Output Devices.

The

standard

optionally

output modules

output devices are annunciators and relays. Other

added to the system. These are: TS-ROM BriteBox

, and TS-IEM internal expansion PC Board

508 consoles only.

I/O

Module inputs) can be

output devices

relays,

TS-CIM BriteBox

output modules

— for TS-2001/

can be

Example:

TANK 1, ALARMS and the H LIM OG (high product level limit) menus:

M1 M2 M3 M4

M1 M2 M3 M4

M1 M2 M3 M4

M1 M2 M3 M4

The HIGH LIM (high product

level limit) has an associated H

LIM OG – high limit output

group near it.

NOTE

In an 8 tank system

there are 8

H LIM OG s (one under

each tank menu).

Each limit, alarm or input can

be assigned to one of the 34

Output Group choices —

GROUP A thru FF, or to ALL

output GROUPS, or to

NONE

( no output group = default )

Record output group

assignments for each alarm,

limit, or input in theprovided

OG Worksheets.

.

Example Output Group Assignment WORKSHEET

OG = Output Group

Example - System:

Output Devices:

(partial)

- Output Group Assignment WORKSHEET Output Group choices -

= default setting (others are: GROUP A thru FF & ALL GROUPS)

NONE

LEAK OG

THEFT OG

SYSFL OG

Modulated Annunciator, Solid Annunciator, Relay 1, Relay 2, I/O Output Module

Channel # 1 to # __ (record all OG Assignment

Tank Leak turns on Modulated Annunciator, Relay 2 for external leak light

A

T

Sentinel Mode Theft Limit (turns on external product theft light)

System Fail - software or hardware failures - (activates solid annunciator)

F

s in the vertical column)

PREFACE Page P - v

NONE

A

B

C

E

F

P

Page 14

Programming Output Devices:

After assigning alarms and limits to output group(s), program the appropriate

output devices to respond to any or all output groups (OGs)

Example Applications:

Turn on external Tank Overfill Alarm & solid console annunciator

(when a high or high high product level – alarm limit is reached)

Program the

LIM OG output groups to one alarm group for each tank

annunciator (alarm horn) and relay 1

(above)

alarm limits for each tank. Assign the associated H LIM OG or HH

(ie GROUP O).

output devices

to react to any

assignment... change GROUP O – (dash) to a Y. The external TS-RA2 or RA1 alarm unit

(wired to relay 1) will turn on / off

with relay 1.

This way a high level condition in any tank will activate the solid annunciator and the

external alarm connected to relay 1.

To disable a STP & turn on the modulated console annunciator

(when a low low product or high water – alarm limit is reached)

Program the

LIM OG output groups to a

1 & GROUP S for TANK 4)

N — OUT GRPS) to respond to a unique tank alarm

(above)

alarm limits for each tank. Assign the associated LL LIM OG and W

unique

. Program the TS-ROM channel relays

alarm group

for each tank (ie GROUP P for TANK

output device

GROUP __

. The line power, that

activates the STP motor relay, is wired between the TS-ROM relay contacts. When these

alarms occur, the unique output group activates the appropriate TS-ROM channel relay

which interrupts the STP power and disables dispensing.

Program the modulated annunciator (alarm horn)

output device

to activate and react to any

alarm by assignment... change GROUP P Q R S – (dash) to a Y.

Program the solid

GROUP O

alarm by

(CHANNEL

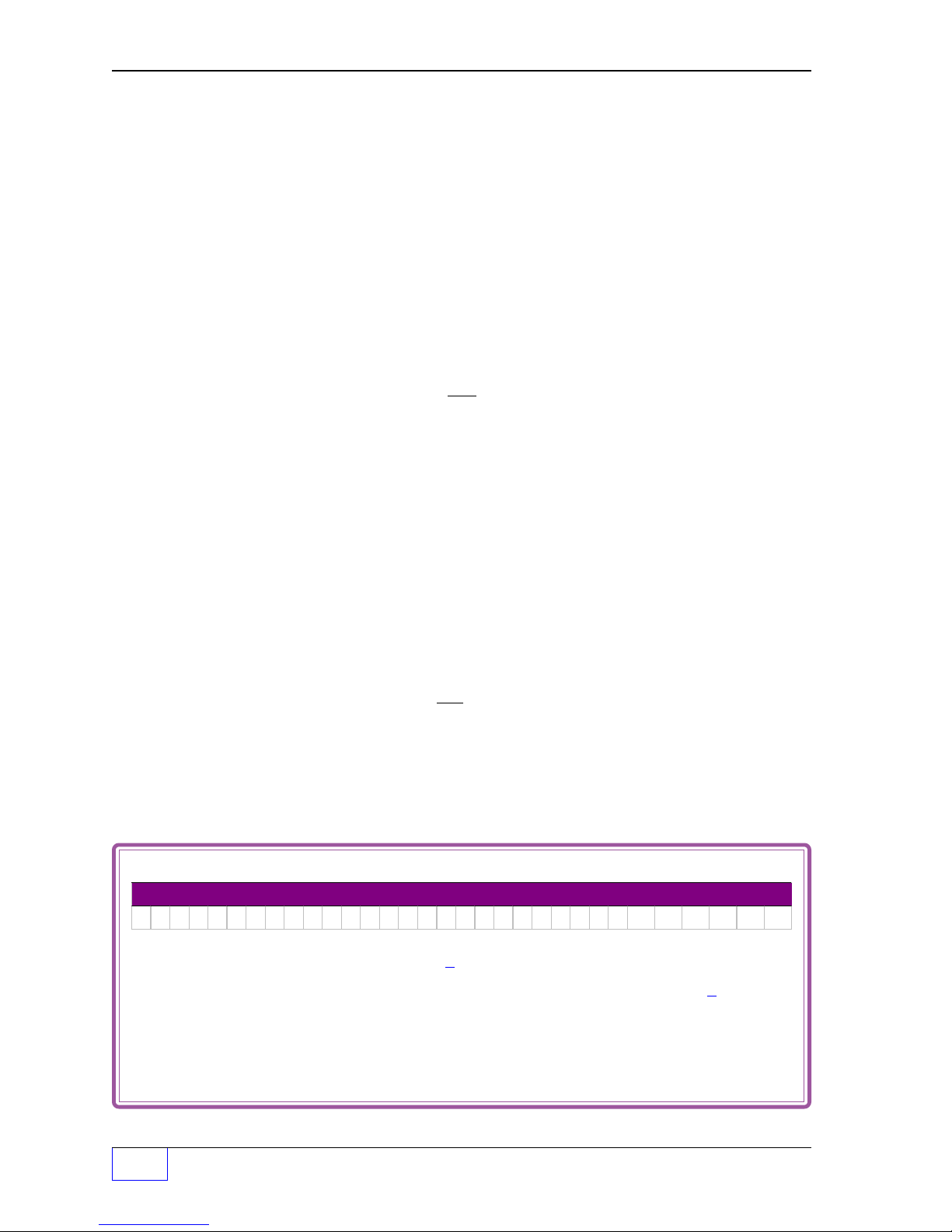

Example Output Device – OUTPUT GROUP Assignments

Output Device — OUTPUT GROUP Assignment

ABCDEFG H I J KLMNOPQRST UVWXYZA AB BC CD DE EF F

Y YYY YYYYY Y

OUTPUT GROUP GROUP

Y – – Y Y Y – –– – – – – –Y Y Y Y Y

132

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z AA BB CC DD EE FF

Press:M1 to move the cursor left

M2

NOTE

☞

P

Page P - vi Tank Sentinel Setup Programming Guide

to move the cursor right

UP / DOWN

ENTER

▲▼ to select (Y for yes assigned, or

to store the setup into the system memory

– – – – Y – – – – – – – – X

ï

ð

M4

to backspace (delete) one character to the left

–

(dash) for no not assigned)

(shown filled-in)

The 24TH group

(Group X) is shown

assigned

Y

ï

Page 15

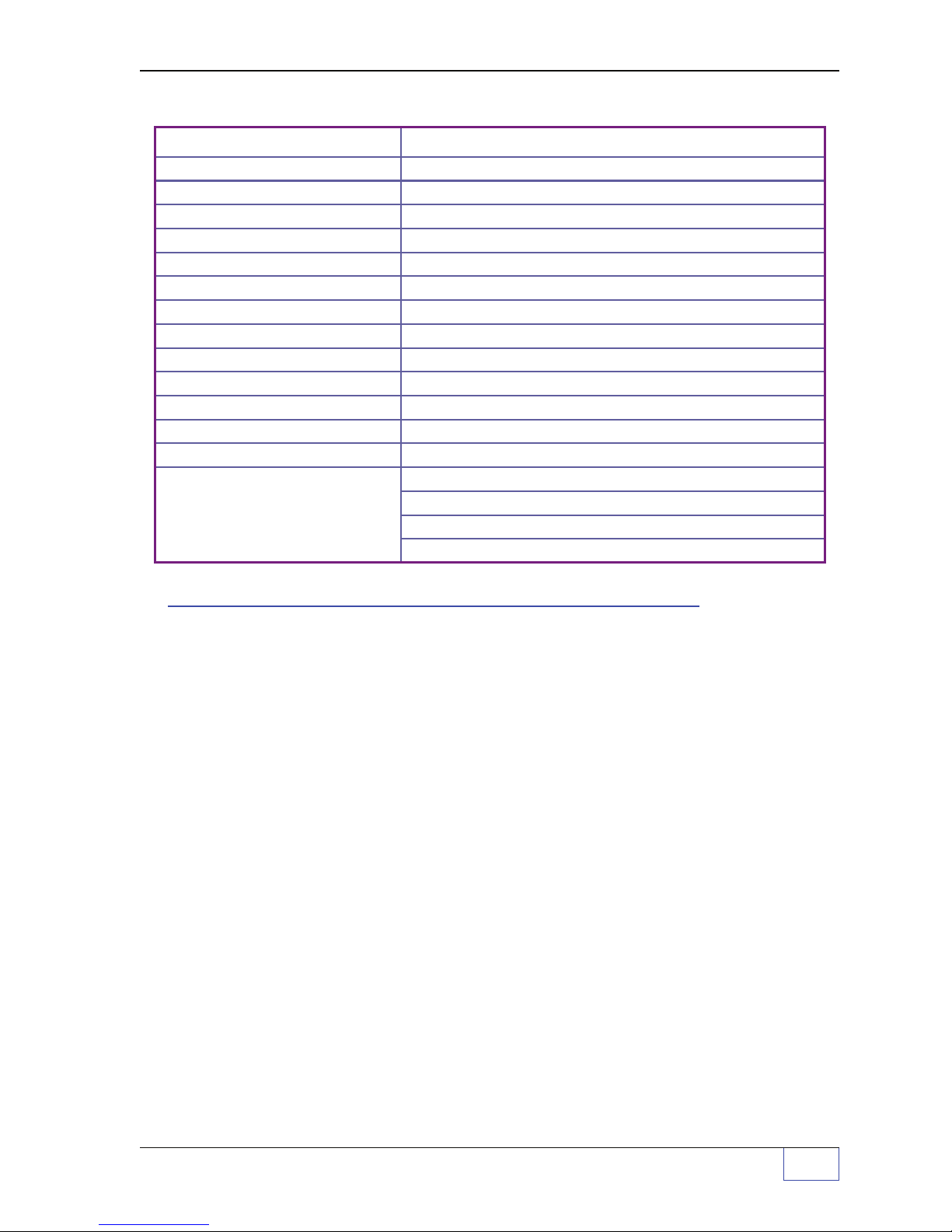

Standard and

Optional

Output Devices

Standard Output Devices:

Modulated Annunciator

Solid Annunciator

Relay 1

Relay 2

Optional Output Devices:

TS-ROM Relay 1

TS-ROM Relay 2

TS-ROM Relay 3

TS-ROM Relay 4

TS-ROM Relay 5

TS-ROM Relay 6

TS-ROM Relay 7

TS-ROM Relay 8

: The TS-2001 will list the

Note

TS-CIM Output Modules as I/0

Module - Output

#

24 (if installed).

s # 17 through

Optional (TS-CIM / TS-IEM) Output Devices

I/O Module Output 1*

I/O Module Output 2*

I/O Module Output 3*

I/O Module Output 4*

I/O Module Output 5*

I/O Module Output 6*

I/O Module Output 7*

I/O Module Output 8*

I/O Module Output # 9* I/O Module Output # 10*

I/O Module Output # 11* I/O Module Output # 12*

I/O Module Output # 13* I/O Module Output # 14*

I/O Module Output # 15* I/O Module Output # 16*

I/O Module Output # 17* I/O Module Output # 18*

I/O Module Output # 19* I/O Module Output # 20*

I/O Module Output # 21* I/O Module Output # 22*

I/O Module Output # 23*

I/O Module Output # 24*

:

Programming

I/O

Module Operation

The TS-CIM / TS-IEM channels * can function either as an input or an output module. The

mode menu option allows selection of the channel operation — this must correspond to the

type of module that is inserted into the channel. Input mode must be selected for input

modules, and output mode must be selected for output modules.

IO MODULE

NOTE

about

Aux. Inputs are always inputs and cannot be changed because the input circuitry

setup programming.

is hard-wired. Reference the Chapter about

Interfacing TS-LLD to Tank Gauge

In order to interface the INCON TS-LLD line leak detector(s) to the TS-1001/504 / 2001/

508 / Tank Sentinel consoles —

Use the

communication). The first TS-LLD is wired to the tank gauge and the others are connected

to each other (1 to 2, 2 to 3... ).

1.10 and higher ( check options – L must be in the part number ).

TS-LLD

interface terminals within the console (providing RS-485 bidirectional

LLD

is available with Tank Sentinel software version #

AUX INPUT

Reference the Chapter

setup programming.

PREFACE Page P - vii

P

Page 16

Leaving (Exit) Setup Programming

SETUP MENU (MORE)

EXIT

SYSTEM TANKS PROBES

There are two ways to leave the setup mode. These are:

NOTE

☞

1.) Use (press) the

exit the setup mode.

M1 M2 M3 M4

2.) Wait until the Tank Sentinel console

The unit will automatically leave / exit the setup mode

of inactivity (if no key is pressed). This feature prevents the unit from being left in the setup

mode for long periods of time...

CANCEL

key until the exit choice appears, then press the

– or –

M1

key to

autoexits

.

( autoexit )

after three or four minutes

leak testing and leak detection are not active while in

the setup mode.

While viewing data in the normal run mode, the display will also revert to the normal display

after shorter period of key inactivity (20 or 30 seconds).

After Programming is Done

After the system is custom-programmed and tested, printout or Fax a hard copy of the:

system setup report, and a setup report for each tank for your records. Please give a

copy of these reports to the customer for his records.

Warranty Reminder

After installation, make sure to sign the completed Warranty Registration form and

return it to INCON. This form validates the express warranty stated here !

—

❖

—

P

Page P - viii Tank Sentinel Setup Programming Guide

Page 17

1 System SETUP PROGRAMMING

SELECT MENU OPTION (MORE)

SETUP

UPGRADE LANGUAGE DATALOG

SETUP MENU (MORE)

EXIT

SYSTEM

TANKS LINES

SYSTEM INFO (MORE)

PASSWORDS SYSTEM ID UNITS NO. TAN KS

Contents:

System Menu

Worksheet 1-1 — System Output

Groups

System Menu

H U

MENU

7

× Press this key and follow the

highlighted sequence shown below

M1 M2 M3 M4

NOTE

☞

See the Table of Contents to find topics in

this manual. See the Preface for general

information about this manual. See the

Installation, Operator’s, TroubleShooting

Guides and Application Notes for other

reference sources.

The NO. (of) TANKS set in the system menu

is shown in the TANKS, PROBES and

PRODUCTS menus !

Remember:

• Use

• Press

• Use the

UP

or

DOWN

▲ ▼ key to display

more menus (MORE shown) or selec

tions (UP/DN shown)

CANCEL

ENTER

to cancel data entry

key to accept data

Character input / editing:

• Press

• Use

M1 M2 M3 M4

• Press

M1 M2 M3 M4

PASSWORDS

(none / empty)

(Secures access to setup mode or acknowledging alarms and/or starting grace periods.

A setup password is recommended for security.)

SETUP

SETUP PASSWORD

ACK

ACKNOWLEDGE PASSWORD

(none / empty)

enter up to 12 characters max.

Press

ENTER

(also see ANNUNC [IATOR] menu for time-out)

enter up to 12 characters max.

Press

ENTER

to accept this data.

to accept this data.

M1

to move the cursor left

M2

to move the cursor right

M4

to backspace (delete) one

or more characters to the left

ï

ð

ï

— Continued on next page —

System Setup Page 1 - 1

1

Page 18

S

YSTEM

Menu (C

ONTINUED

...

FROM PREVIOUS PAGE

)

SYSTEM ID

LINE 1

LINE 2

LINE 3

LINE 4

Default Report Header Ø

LOCATION LINE 1

INCON

LOCATION LINE 2

INTELLIGENT CONTROLS

LOCATION LINE 3

P. O. BOX 638

LOCATION LINE 4

SACO ME 04072

(enter new 5 line report header, see below)

enter up to 24 characters max.

Press

ENTER

to accept this data.

enter up to 24 characters max.

Press

ENTER

to accept this data.

enter up to 24 characters max.

Press

ENTER

to accept this data.

enter up to 24 characters max.

Press

ENTER

to accept this data.

............... LINE 1

:

:

:

..... LINE 5

LINE 5

LOCATION LINE 5

1-800-984-6266

UNITS

MEASUREMENT UNITS

VOLUME

VOLUME UNITS

GALLONS

LITERS

LEVEL

LEVEL UNITS

INCHES

CM

TEMP

TEMPERATURE UNITS

FAHRENHEIT

CELSIUS

NO. TANKS

NUMBER OF TANKS

1

enter up to 24 characters max.

Press

ENTER

to accept this data.

(Units are set in either US Standard or Metric)

(– change if not using the default US units)

(volume measurement units)

Use

UP/DOWN

Press

ENTER

▲ ▼ keys to choose units.

to accept this data.

(– change if not using the default US units)

(level and length units)

Use

UP/DOWN

▲ ▼ keys to choose.

(Metric - Centimeters)

Press

ENTER

to accept this data.

(– change if not using the default US units)

(Prints F for Fahrenheit, or C for Celsius on reports)

Use

UP/DOWN

Press

ENTER

▲ ▼ keys to choose units.

to accept this data.

(enter total number of tanks in the system)

enter number of tanks.

Press

ENTER

to accept this data.

1

Page 1 - 2 Tank Sentinel Setup Programming Guide

Page 19

YSTEM

S

Menu (C

ONTINUED

...

FROMPREVIOUS PAGE

)

NO. SENSORS

NUMBER OF SENSORS

12 (for TS-1001, 504, 750)

24 (for TS-2001, 508)

NO. METERS

NUMBER OF METERS

0

BUSY ENA

BUSY ENABLED

NO

YES

U THRESH

USER THRESHOLD

+0

LIMITS

LIMITS

LEAK LIM

LEAK LIMIT

+2.0

(enter the number of Leak Detection Sensors)

(0 thru N) enter the total number of Sensors.

(also enter all unused channels between the lowest to

highest channel (also see SENSORS menu)

Press

ENTER

to accept this data.

(devices used with TS-DIM)

enter number of meters.

Press

ENTER

to accept this data.

(dispenser supports ‘busy’ signal to ATG)

UP/DOWN

Use

Press

ENTER

keys to choose setting.

to accept this data.

(volume allowed pumped before Catastrophic Leak alarm)

1 to +9999 volume units.

Press

ENTER

to accept this data.

(set leak limits for after hours sentinel mode – also see

menu)

0.2 to +10.0 volume units.

Use keypad to input sentinel mode leak rate.

Press

ENTER

to accept this data.

LEAK OG

LEAK LIMIT OUTPUT GROUP

NONE

GROUP A

thru

FF

ALL GROUPS

THEFT LIM

THEFT LIMIT

+10.0

THEFT OG

THEFT LIMIT OUTPUT GROUP

NONE

GROUP A

ALL

thru

FF

GROUPS All OGs selected

(assign leak alarm to an OG (

NONE

, A to FF, or ALL)

(32 OGs available... see Worksheet #1-1 )

Not assigned to an Output Group (OG)

One OG selected ( A = 1ST OG, FF = 32

ND OG )

All OGs selected

UP/DOWN

Use

Press

ENTER

keys to choose an OG.

to accept this data.

(enter theft limit for all tanks)

1 to +9999 volume units.

ENTER

Press

(assign theft limit alarm to an OG (

to accept this data.

NONE

, A to FF, or ALL

Output Groups)(32 OGs available... see Worksheet #1-1 )

Not assigned to an Output Group (OG)

One OG selected ( A = 1ST OG, FF = 32

UP/DOWN

Use

Press

ENTER

keys to choose an OG.

to accept this data.

ND OG )

System Setup Page 1 - 3

1

Page 20

S

Input time in 24 hour format:

00.00.00 = midnight

22.00.00 = 10:00:00 pm

+ 12

(add 12 hours to pm times

from 1 pm to 11:59 pm

)

02.05.00 = 2:05:00 am

YSTEM

Menu (C

ONTINUED

...

FROM PREVIOUS PA G E

)

SENTINEL

SENTINEL MODE

MODE

SENTINEL MODE

OFF

SCHEDULED

START TIM

SENTINEL START TIME

00.00.00

END TIME

SENTINEL END TIME

00.00.00

DEL DELAY

DELIVERY DELAY

15

REP DELIV

REPORT DELIVERIES

ENABLED

DISABLED

(after hours theft monitoring / tank leak detection)

Use

UP/DOWN

Press

ENTER

Select SCHEDULED to enable Sentinel Mode —

up to 23.59.59

up to 23.59.59

(delay tank delivery reports by minutes)

(minutes) 1 to 240 minute input range.

Press

ENTER

Use

UP/DOWN

Press

ENTER

(enabled = yes, report deliveries)

(disabled = no, don’t report deliveries)

▲ ▼ keys to choose mode.

to accept this data.

to accept this data.

▲ ▼ keys to choose.

to accept this data.

REP ALARM

REPORT ALARMS

ENABLED

DISABLED

REP LEAK

REPORT LEAK TESTS

ENABLED

DISABLED

REP SCALD

REPORT SCALD TEST

DISABLED

ENABLED

1

Page 1 - 4 Tank Sentinel Setup Programming Guide

Use

UP/DOWN

Press

ENTER

(enabled = yes, report alarms)

disabled = no, don’t report alarms)

Use

UP/DOWN

Press

ENTER

(enabled = yes, report leak test results)

(disabled = no don’t report leak test results)

(Appears only if an S is present in the TS Part

Number (press CHECK and M4 to view OPTIONS)

Use

UP/DOWN

Press

ENTER

(disabled = no, don’t report SCALD leak tests)

(enabled = yes, report SCALD leak tests)

▲ ▼ keys to choose.

to accept this data.

▲ ▼ keys to choose.

to accept this data.

▲ ▼ keys to choose.

to accept this data.

Page 21

S

YSTEM

Menu (C

ONTINUED

...

FROM PREVIOUS PA G E

)

REP LINES

REPORT LINE TESTS

ENABLED

DISABLED

HIST SIZE

HISTORY REPORT LENGTH

50

SYSFL OG

SYSTEM FAIL OUTPUT GROUP

NONE

GROUP A

ALL

PRNT INTR

STRAPPING TABLE PRINT INTERVAL

+1.000

thru

FF

GROUPS All OGs selected

(Appears only if an L is present in the TS Part

Number (press CHECK and M4 to view OPTIONS)

Use

UP/DOWN

Press

ENTER

(enabled = yes, report LINE leak tests)

(disabled = no, don’t report LINE leak tests)

(Max. number of alarms in Alarm History Reports)

enter range from 1 to 50 alarms shown.

Press

ENTER

(assign system fail warnings to Output Group)

(32 OGs available... see Worksheet #1)

Not assigned to an Output Group (OG)

One OG selected ( A = 1ST OG, FF = 32

Use

UP/DOWN

Press

ENTER

(how many intervals to print)

enter strapping table print interval,

range = 1 to 100.0 level units.

Press

ENTER

▲ ▼ keys to choose.

to accept this data.

to accept this data.

ND OG )

▲ ▼ keys to choose an OG.

to accept this data.

to accept this data.

DATA INTR

DATA CAPTURE INTERVAL

1

DATA TANK

TANK TO DATA LOG

1

COLD BOOT (Will erase all program data / setup data to the

IF YOU CONTINUE, ALL SYSTEM

PROGRAMMING AND DATA WILL BE LOST...

PRESS ENTER IF YOU ARE SURE THAT

YOU WANT TO CONTINUE WITH COLD BOOT

ERASING SYSTEM MEMORY ...

SYSTEM WILL REBOOT WHEN (The ATG SETUP programming is returned to the default

COMPLETE settings and must be reprogrammed to match the site.)

(for diagnostic use)

data logging interval, range = 1 to 9999.

Press

ENTER

(for diagnostic use)

tank(s) to data log, range = 1 to NO. of TANKS.

Press

ENTER

original “factory” default values)

Press

ENTER

to accept this data.

to accept this data.

to proceed with the ‘COLD BOOT’.

System Setup Page 1 - 5

1

Page 22

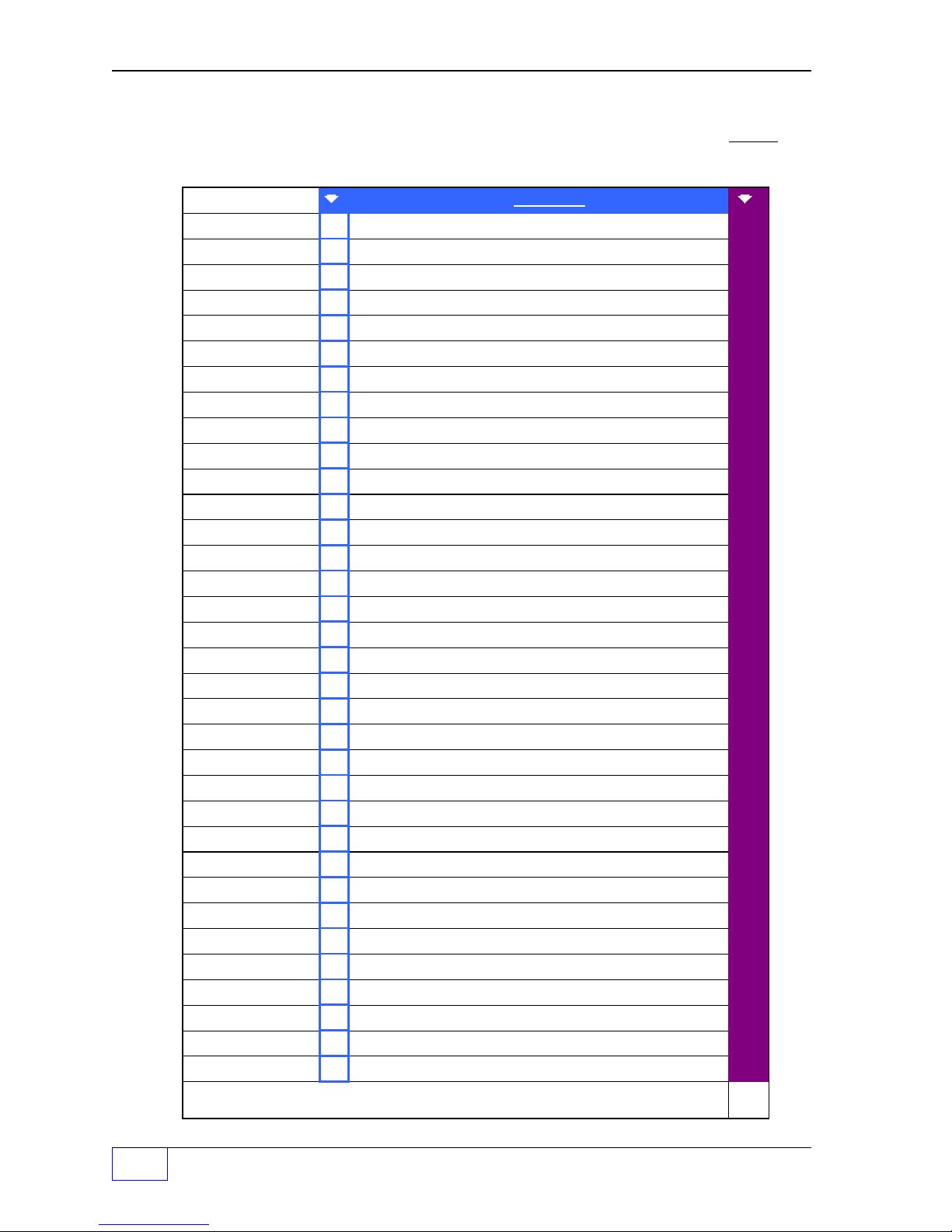

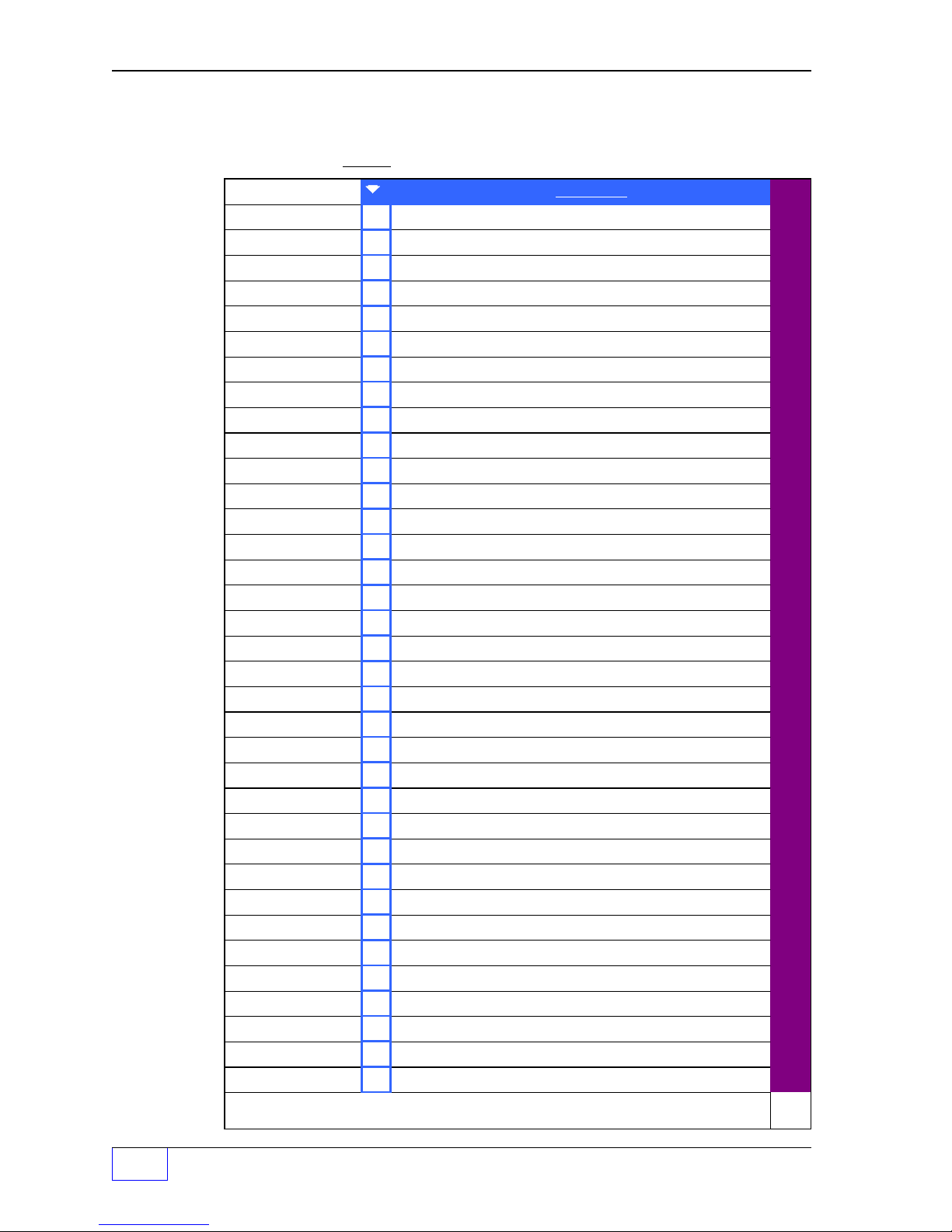

Worksheet #1-1 – Output Groups – System Limits

Fill-in the work sheet below and compare assignments to uncover conflicts before

programming output devices.

OG = Output Group

System Limits:

LEAK OG

THEFT OG

SYSFL OG

Example:

LEAK OG

THEFT OG

SYSFL OG

Output Devices: Modulated Annunciator, Solid Annunciator, Relay 1, Relay 2, I/O Output Module

Channel # 1 to # __ (record all OG Assignments in the vertical column)

- Output Group Assignment WORKSHEET Output Group choices -

Activates Modulated Annunciator & Relay 2 (turns on external tank leak light)

D

---

Sentinel Mode Theft Limit:

System Fail (software or hardware failures) Activate solid annunciator horn

A

none

assigned

NONE

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

ALL

1

Page 1 - 6 Tank Sentinel Setup Programming Guide

Page 23

— Your Notes —

—

System Setup Page 1 - 7

❖

—

1

Page 24

2 Tanks SETUP PROGRAMMING

SELECT MENU OPTION

SETUP

UPGRADE LANGUAGE DATALOG

SETUP MENU (MORE)

EXIT SYSTEM

TANKS

PROBES

TANKS

DATA ALARMS SPECIAL

Contents:

Tank Data Menu

Tank Alarm Menu

Special Tank Menu

Worksheet 2-1, 2-2

Tank Output Groups

Tanks Menu

H U

MENU

7

× Press this key and follow the

highlighted sequence below

M1 M2 M3 M4

NOTE

☞

See the Table of Contents to find topics

in this manual. See the Preface for

general information about this manual.

See the Installation, Operator’s,

TroubleShooting Guides and Application

Notes for other reference sources.

Only the NO. (of) TANKS set under the

system menu are shown here !

Remember:

• Use

▲UP

or

DOWN

▼ keys to display more

menus (MORE shown) or selections (UP /

DN are shown)

• Press

• Use the

CANCEL

ENTER

to cancel data entry

key to accept data

Character input / editing:

M1

to

• Press menu keys

(

M4

)

to access

menus.

M1 M2 M3 M4

• Press

• Use

• Press

M1 M2 M3 M4

TANK DATA N refers to / represents a tank number

TANK 1

TANK DATA N Tank 1 is shown selected (press

COPY

COPY FROM TANK DATA X TO N

COPY FROM TANK DATA N TO N

PRESS ENTER IF YOU ARE SURE? Press

TANK 2 ...... Select the tank number to program Data.

TANK 1 Select a tank to copy data from (use

ENTER

M4

to backspace (delete) one or more

characters to the left

M2

to move the cursor right

M1

to move the cursor left

to accept this data.

ï

M1

key).

M

key).

ð

ï

Use

UP/DOWN

Tank Setup Page 2 - 1

▲▼ keys to display tanks 5-8.

2

Page 25

Tanks – TANK DATA N Menu (C

NAME (Use SHIFT to change from A-M to N-Z to NUMERIC.)

TANK NAME N

TANK N

MANIFOLD

MANIFOLD FOR TANK N (selct only when tanks are part of a manifold)

NONE

MANIFOLD 1

MANIFOLD 2 Press

:

MANIFOLD 4

SHAPE (distinguishes between underground and aboveground)

TANK SHAPE 1

HORIZONTAL

VERTICAL Press

(aboveground storage tank)

TYPE (select STANDARD 1 thru XX... see Appendix A)

TANK TYPE N

SPECIAL #

ONTINUED

N refers to / represents a tank number

Press

(INCON recommends leaving the tank name as TANK N )

Use

UP/DOWN

Use

UP/DOWN

Use

UP/DOWN

Press

(for Standard Tank types, or SPECIAL 1 thru 8 or program

the special tank(s) under the SPECIAL TANK N menu )

...

FROM PREVIOUS PA G E

enter up to 7 characters max.

ENTER

ENTER

ENTER

ENTER

to accept this data.

▲ ▼ keys to display Manifold 1 thru 4.

to accept this data.

▲ ▼ keys to choose shape.

to accept this data.

▲ ▼ keys to choose type.

to accept this data.

)

PROBE

PROBE FOR TANK N

PROBE #

PRODUCT

PRODUCT FOR TANK N

PRODUCT #

NOTE

☞

Use

UP/DOWN

Press

ENTER

Select the correct Probe channel # for TANK N...

Any Probe # (input channel Number) can be used for any Tank.

For example, Probe 8 (the probe that is wired to probe input

channel #8) can be installed in Tank 1 ....BUT a Probe can not

be used (or programmed or assigned) to more than one

tank ! Assigning the same Probe #N to more than one Tank, will

display an alarm when exiting SETUP (to warn you that more

than one tank is referencing the same probe) ! The system will

remain in setup until this problem is fixed.

Set Probe data under the PROBE menu (Chpt. 3.)

Use

UP/DOWN

Press

ENTER

(select Product 1 thru 8 ...

present if a Manifold is selected / changed from

NONE

) ...Also see PRODUCTS menu for standard

products and Special product programming.

▲ ▼ keys to choose probe#.

to accept this data.

▲ ▼ keys to choose product#.

to accept this data.

the PRODUCT menu is not

2

Page 2 - 2 Tank Sentinel Setup Programming Guide

Page 26

Tanks – TANK DAT A N Menu (C

ONTINUED

...

FROM PREVIOUS PA G E

)

P OFFSET (to compensate product readings from tank tilts)

PRODUCT OFFSET N

+0.00000

+20 to -20

Use keypad to input level units.

Press

ENTER

to accept this data.

(see Installation Manual for offset values)

(Not available if Manifold or Pressure probe selected)

W OFFSET (to compensate product readings from tank tilts)

WATER OFFSET N

+0.00000

+20 to -20

Use keypad to input level units.

Press

ENTER

to accept this data.

(see Installation Manual for offset values)

(Not available if Manifold or Pressure probe selected)

DEL THRES (the minimum volume before a delivery is reported)

DELIVERY THRESHOLD N

+200.000

1.0 to 99999

Use keypad to input level units.

Press

ENTER

(

the Delivery Threshold menu is not present if a

Manifold is selected / changed from NONE

to accept this data.

)

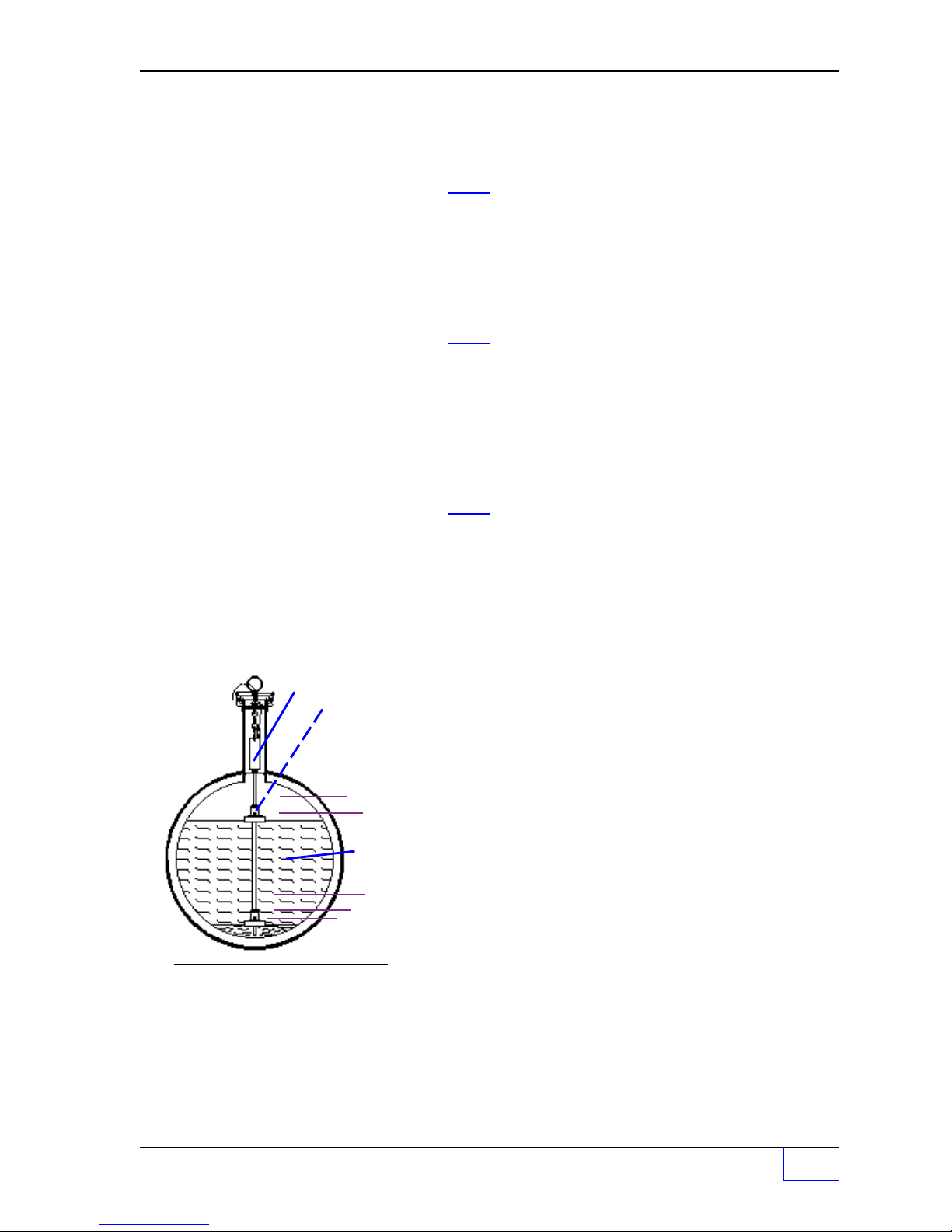

Tanks – TANK ALARM N Menu

Liquid Level Probe &

Floats

PROGRAMMED

TANK

RELATED

ALARM

LIMITS:

HIGH HIGH

HIGH

NOTES

☞

Product

LOW

LOW

LOW

HIGH

WATER

Figure 2 - 1 Typical Tank

Limits

ALARMS (To set Tank Alarm Limits)

TANK ALARMS Use

TANK 1

TANK 2 Use

M2

Select Tank N to program, using M1 - M4 keys.

UP/DOWN

:

TANK 8

See Figure 2 - 1 at left for typical alarm limit

settings.

N refers to / represents a tank number

• The alarm copy function copies all alarm limits

from Tank X to the current Tank # N. This is a

good function to use for identical sized tanks,

and may be adequate for similar sized tanks

but limit settings may require editing after the

copy operation.

• Also note, Water, High and High High limits

are set in length units, inches or centimeters

— while Low and Low Low limits are set in

volume units,gallons or liters.

key.

▲ ▼ keys to display Tanks 5-8.

Tank Setup Page 2 - 3

2

Page 27

Tanks – TANK DATA N Menu (C

ONTINUED

...

FROM PREVIOUS PA G E

)

TANK ALARM N To select Tank N ...

COPY (COPY is optional) Press the

M1

key.

COPY FROM TANK ALARMS X TO N

TANK 1 Select a tank to copy data from (use

: Use

UP/DOWN

▲▼ keys to display tanks 5-8.

M

TANK 8 (The alarm copy function copies all alarm limits

COPY TANK ALARMS X TO N from Tank X to the current Tank # N)

PRESS ENTER IF YOU ARE SURE? Press

ENTER

to accept this data.

HIGH LIM

HIGH PRODUCT LEVEL LIMIT N

+96.0000

0.0 to 9999.0

Use keypad to input limit in inches or centimeters.

Press

ENTER

to accept this data.

H LIM OG (assign Alarm Limits to Output Group)

HIGH PRODUCT OUTPUT GROUP N (32 OGs available... see Worksheet #2 or #3)

NONE

GROUP A-FF One OG selected (

Not assigned to an output Group (OG)

A = 1ST OG, FF = 32

ALL GROUPS All OGs selected

Use

UP/DOWN

Press

ENTER

▲ ▼ keys to choose an OG.

to accept this data.

key).

ND OG )

HIGH HIGH N N refers to / represents a tank number

HI HI PRODUCT LEVEL LIMIT N

+96.0000

0.0 to 9999. (enter alarm limit)

Press

ENTER

to accept this data.

HH LIM OG N (assign Alarm Limits to Output Group)

HI HI PRODUCT OUTPUT GROUP N (32 OGs available... see Worksheet #2 or #3)

NONE

GROUP A-FF One OG selected (

Not assigned to an output Group (OG)

A = 1ST OG, FF = 32

ND OG )

ALL GROUPS All OGs selected

Use

UP/DOWN

Press

ENTER

▲ ▼ keys to choose an OG.

to accept this data.

LOW LIM N N refers to / represents a tank number

LOW PRODUCT VOLUME LIMIT N

+0.0000

0.0 to 50000 (enter alarm limit)

Press

ENTER

to accept this data.

L LIM OG N (assign Alarm Limits to Output Group)

LOW PRODUCT OUTPUT GROUP N (32 OGs available... see Worksheet #2 or #3)

NONE

GROUP A-FF One OG selected (

(A to FF, or ALL) Not assigned to an output Group (OG)

A = 1ST OG, FF = 32

ND OG )

ALL GROUPS All OGs selected

Use

UP/DOWN

Press

ENTER

▲ ▼ keys to choose an OG.

to accept this data.

LOW LOW N

LOW LOW PRODUCT VOLUME LIMIT N

+0.0000

2

Page 2 - 4 Tank Sentinel Setup Programming Guide

+ 0 to 50000 (enter alarm limit)

Press

ENTER

to accept this data.

Page 28

Tanks – TANK ALARM N Menu (C

LL LIM OG N (assign Alarm Limits to Output Group)

L L PRODUCT OUTPUT GROUP N (32 OGs available... see Worksheet #2 or #3)

NONE

GROUP A-FF One OG selected (

ALL GROUPS All OGs selected

WATER LIM N

HIGH WATER LEVEL LIMIT N

+4.0000

W LIM OG N (assign Alarm Limits to Output Group)

HIGH WATER OUTPUT GROUP N (32 OGs available... see Worksheet #2 or #3)

NONE

GROUP A-FF One OG selected (

ALL GROUPS All OGs selected

ONTINUED

Not assigned to an output Group (OG)

Use

UP/DOWN

Press

ENTER

0.0 to 9999.0 (enter alarm limit)

Press

ENTER

Not assigned to an output Group (OG)

Use

UP/DOWN

Press

ENTER

...

FROM PREVIOUS PA G E

A = 1ST OG, FF = 32

▲ ▼ keys to choose an OG.

to accept this data.

to accept this data.

A = 1ST OG, FF = 32

▲ ▼ keys to choose an OG.

to accept this data.

)

ND OG )

ND OG )

NOTE

WATER LIM N and W LIM OG N are not available for PRESSURE probes, since they do

not measure water level.

☞

Tanks – SPECIAL TANK N Menu

NOTE

☞

• If

STANDARD tanks

• Correction Tables:

then you must program a correction table (100 correction points can be programmed).

Two values are required per point / position (POS #). These are level and volume, which

are found in the manufacturers’ tank table /chart, input these accurately. Always input 0

level and 0 volume for the first point, and max. level and max. volume for the last point.

The number of points in between determines the accuracy of the strapping table.

• Cylindrical Tanks:

set the length to the internal length of the tank (correction tables are usually not needed

with cylindrical tanks).

• V ertical or Rectangular tanks:

depth, and set its

max. level and max. volume for the last point.

• Correction Points

level is closest to the bottom of the tank.

length

are selcted, then these menu options will not be available.

If the Special Tank is not a perfect cylinder or has a domed end,

Select diameter and input the internal tank diameter value, and

Select diameter and input the internal tank diameter or

to zero

are automatically sorted from lowest to highest level. The lowest

( 0 )

. Input 0 level and 0 volume for the first point, and

SPECIAL

SPECIAL TANKS

SPECIAL 1

SPECIAL 2

: Use

SPECIAL 8

UP/DOWN

Tank Setup Page 2 - 5

▲▼ keys to display tanks 5-8.

2

Page 29

Tanks – SPECIAL TANK N Menu (C

SPECIAL TANK N N refers to / represents a tank number

COPY Press the

COPY FROM SPECIAL TANK X TO N Select a tank to copy data from (use

SPECIAL 1

COPY SPECIAL TANK N TO N

PRESS ENTER IF YOU ARE SURE? Press

Use

ONTINUED

M1

key.

ENTER

UP/DOWN

to accept this data.

)

M

key).

▲▼ keys to display tanks 5-8.

DIAMETER Press the

TANK DIAMETER N

+96.00

LENGTH Press the

TANK LENGTH N

+324.000

NOTE

(HEIGHT will replace LENGTH when VERTICAL is selected as the TANK DATA SHAPE)

0.0 to 999,999

Use the

Use the Keypad to input the special tank diameter.

Press

ENTER

0.0 to 999,999

Use the

Use the Keypad to input the special tank diameter.

Press

ENTER

can be added between inaccurate level positions.)

☞

HEIGHT Press the

TANK HEIGHT N

+324.000

0.0 to 1999.0

Use the

Use the Keypad to input the special tank diameter.

ENTER

Press

M2

key.

M4

key to use BACKSPACE.

to accept this data.

M3

key.

M4

key to use BACKSPACE.

to accept this data. (Correction points

M3

key.

M4

key to use BACKSPACE.

to accept this data.

CORR TABL Press the M4 key.

CORRECTION TABLE N (Position (POS #) ...see

ADD Press the

LEVEL

VOLUME

2

Page 2 - 6 Tank Sentinel Setup Programming Guide

+0

+0

NOTES

M1

key. POS 1 is the lowest value tank.

Two values (LEVEL and VOLUME) are required.

Use the Keypad to input level of strapping point.

Press

ENTER

Use the Keypad to input volume at that level point.

Press

ENTER

to accept this data.

to accept this data.

in this section)

Page 30

Tanks – SPECIAL TANK N Menu (C

DELETE

SELECT POSITION WITH UP/DN POS # Select the POS # to delete (

LEVEL

+X

VOLUME

+Y

ONTINUED

Press

ENTER

)

to accept this data.

UP/DOWN

▲▼).

ARE YOU SURE? Press

EDIT

SELECT POSITION WITH UP/DN POS # Select POS # to edit

LEVEL

DISPLAY

CORRECTION TABLE N POS N

LEVEL

+X

+X

VOLUME

VOLUME

+Y

+Y

ENTER

Press

ENTER

(correct the mistake and press

Use

UP/DOWN

to accept this data.

to accept this data.

(UP/DOWN

▲▼ keys to scroll thru list.

▲▼).

ENTER

again)

Worksheet 2-1 and 2-2 are shown on the next two pages

Tank Setup Page 2 - 7

2

Page 31

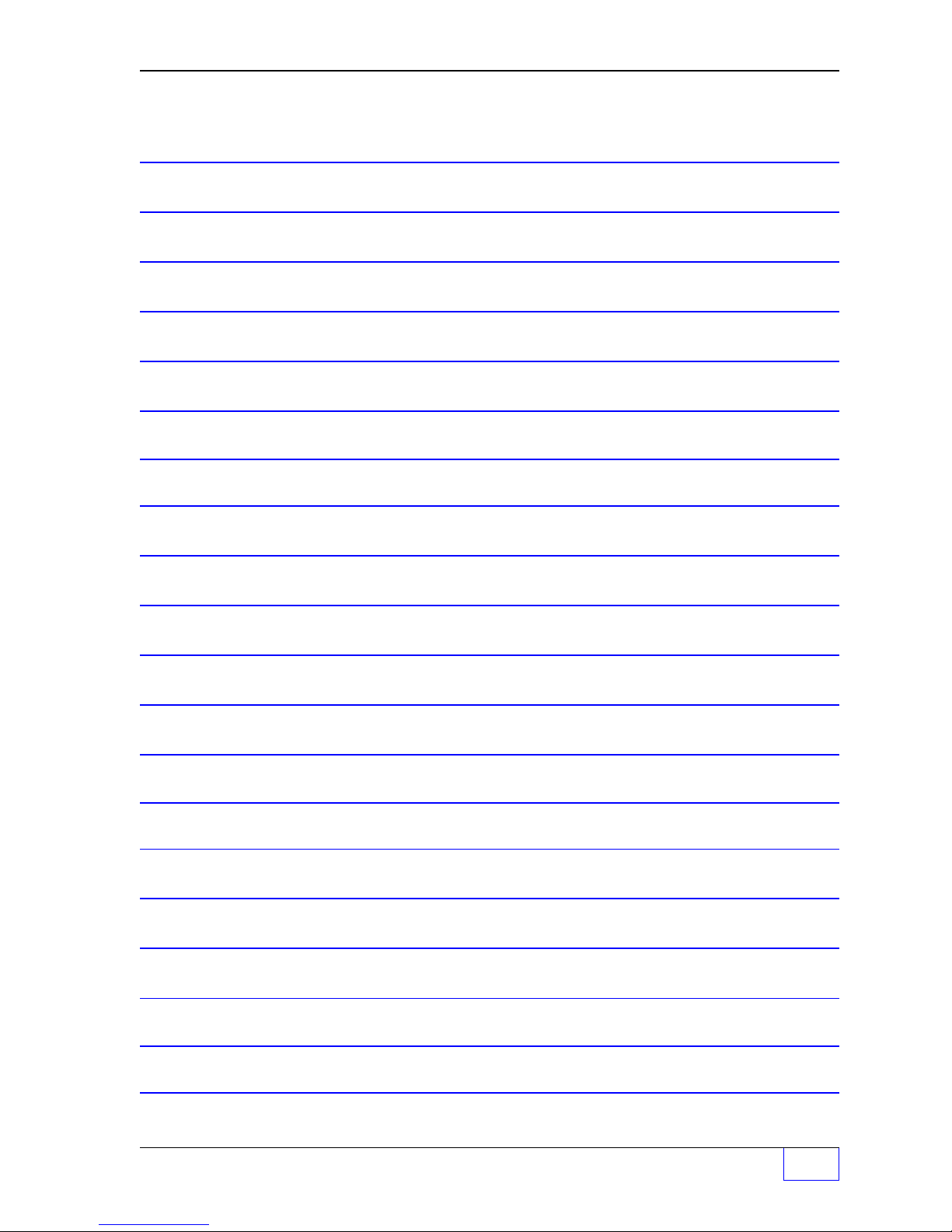

Worksheet #2-1 – Output Groups – Tanks 1 thru 4

ge,

,

)

)

)

Fill-in the work sheet below and compare assignments with other work-sheets to

uncover conflicts before programming output devices (for ALL ATG types).

OG = Output Group

Tank 1

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

Tank 2

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

Tank 3

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

Tank 4

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

- Output Group Assignment WORKSHEET Output Group choices -

Example: Tank #1

(High Limit Activates Relay 1 [for programmed timeout] to external Tank Overfill

H LIM OG

HH LIM OG

L LIM OG

LL Limit OG

W LIM OG

SYSFL OG

C

Alarm Acknowled

(High High Limit Activates Relay 2 [for programmed timeout] to activate external

D

Tank Overfill Alarm

(Low Limit Activates Output Module 2, turns on Reorder Product Light &

R

Modulated Annunciator

(Low Low Limit Activates TS-ROM Relay 1 to Disable Tank 5 STPump, and

S

Activates Modulated Annunciator

(Low Low Limit Activates TS-ROM Relay 1 to Disable Tank 5 STPump, and

S

Activates Modulated Annunciator

A

System Fail (software or hardware failures) Activate solid annunciator horn

& Activates Solid Annunciator)

& Activates Solid Annunciator)

Output Devices: Modulated Annunciator, Solid Annunciator, Relay 1, Relay 2, I/O Output Module

Channel # 1 to # __ (record all OG Assignments in the vertical column)

NONE

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

ALL

2

Page 2 - 8 Tank Sentinel Setup Programming Guide

Page 32

ge,

,

)

)

)

Worksheet #2-2 – Output Groups – Tanks 5 thru 8

Fill-in the work sheet below and compare assignments with other work-sheets to

uncover conflicts before programming output devices (for TS-2001 / 508 only).

OG = Output Group

TS-2001 only:

Tank 5

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

TS-2001 only:

Tank 6

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

Tank 7

TS-2001 only:

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

Tank 8

TS-2001 only:

H LIM OG

HH LIM OG

L LIM OG

LL LIM OG

W LIM OG

- Ou tput Group Assignment WORKSHEET Ou tput Group choices -

Example: Tank # 5

H LIM OG

HH LIM OG

L LIM OG

LL Limit OG

W LIM OG

(High Limit Activates Relay 1 [for programmed timeout] to external Tank Overfill

C

Alarm Acknowled

(High High Limit Activates Relay 2 [for programmed timeout] to activate external

D

Tank Overfill Alarm

(Low Limit Activates Output Module 2, turns on Reorder Product Light &

R

Modulated Annunciator

(Low Low Limit Activates TS-ROM Relay 5 to Disable Tank 5 STPump, and

W

Activates Modulated Annunciator

(Low Low Limit Activates TS-ROM Relay 5 to Disable Tank 5 STPump, and

W

Activates Modulated Annunciator

& Activates Solid Annunciator)

& Activates Solid Annunciator)

Output Devices: Modulated Annunciator, Solid Annunciator, Relay 1, Relay 2, I/O Output Module

Channel # 1 to # __ (record all OG Assignments in the vertical column)

NONE

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

AA

BB

CC

DD

EE

FF

ALL

Tank Setup Page 2 - 9

2

Page 33

— Your Notes —

2

Page 2 - 10 Tank Sentinel Setup Programming Guide

—

❖

—

Page 34

3 Lines SETUP PROGRAMMING

SELECT MENU OPTION

SETUP

UPGRADE LANGUAGE DATALOG

SETUP MENU (MORE)

EXIT SYSTEM TANKS

LINES

LINES

DATA

LINE DATA (MORE)

LINE 1 LINE 2 LINE 3

LINE DATA N (MORE)

NAME

LINE NAME N A...M

LINE 1

BACKSPACE

Contents:

Lines Menu

Line Data Menu

Lines Menu

H U

MENU

7

× Press this key and follow the

highlighted sequence below

M1 M2 M3 M4

NOTE

☞

See the Table of Contents to find topics in

this manual. See the Preface for general

information about this manual. And see the

Installation, Operator’s, TroubleShooting

Guides, and Application Notes for other

reference material.

Only the NO. (of) LINES programmed under the

system menu are shown here !

to consoles that have a L in the part number (

This menu applies

LLDI

enabled – CHECK OPTIONS).

Disregard this menu when it’s not displayed.

The purpose of this menu is to allow renaming of

the line to help identify its location. The new line

name will appear on reports and at the local tank

gauge display.

M1 M2 M3 M4

M1 M2 M3 M4

M1 M2 M3 M4

M1 M2 M3 M4

Changing the Line Name is optional.

Use the ▲

UP

or

DOWN

▼ key to display LINE 5

through LINE 8.

Use a menu select keys to choose a line.

Remember:

• Use ▲

UP

or

DOWN

▼ key to display more

menus or selections (when MORE or

UP/DN is shown)

• Press

• Use the

CANCEL

to cancel a data entry

ENTER

key to accept data

Character input / editing:

• Press

• Use

• Press

M4

to backspace (delete) one

character to the left

M2

to move the cursor right

M1

to move the cursor left

ï

ð

ï

M1 M2 M3 M4

Lines Setup Page 3 - 1

3

Page 35

Line Data Menu

LINE DATA Select a line.

LINE 1

LINE 2

: Use

LINE 8

LINE DATA N

NAME

LINE NAME N LINE N is shown typical for any line #

LINE N

UP/DOWN

Use keypad to input / edit name (9 characters max.).

Press

ENTER

▲ ▼ keys to display Lines 5 – 8.

— Your Notes —

to accept this data.

3

Page 3 - 2 Tank Sentinel Setup Programming Guide

—

❖

—

Page 36

4 Probes SETUP PROGRAMMING

SELECT MENU OPTION

SETUP

UPGRADE LANGUAGE DATALOG

SETUP MENU (MORE)

EXIT SYSTEM TANKS

PROBES

PROBES

DATA SPECIAL

Contents:

Probes Menu

Probe Data Menu

Special Probes Menu

TABLE 4.1 Special Probe RTD

Positions

Probes Menu

H U

MENU

7

× Press this key and follow the

highlighted sequence below

M1 M2 M3 M4

NOTE

☞

See the Table of Contents to find topics in

this manual. See the Preface for general

information about this manual. And see the

Installation, Operator’s, TroubleShooting

Guides, and Application Notes for other

reference material.

See the Installation Guide – Chapters 6 & 7 for

Probe Model & Serial numbers, Gradient values,

Float types, and RTD Locations).

Only the NO. (of) TANKS programmed under

the system menu are shown here !

Remember:

• Use ▲

UP

or

DOWN

▼ key to display more

menus or selections (MORE or UP/DN

shown)

• Press

• Use the

CANCEL

ENTER

to cancel data entry

key to accept data

M1 M2 M3 M4

• Press

character to the left

• Use

• Press

M1 M2 M3 M4

N refers to / represents any probe #

PROBE DATA Press (

Character input / editing:

PROBE

PROBE 2 Press

PROBE 8

1

: probes 5 – 8 (for TS-2001/508 only).

PROBE DATA N (Optional - used to copy probe data)

COPY Press

COPY FROM PROBE DATA X TO N Press (

PROBE 1

PROBE 2 Press

: probes 5 – 8 (for TS-2001/508 only).

PROBE 8

COPY FROM PROBE DATA X TO N

PRESS ENTER IF YOU ARE SURE? Press

M4

to backspace (delete) one

ï

M2

to move the cursor right

M1

to move the cursor left

M

) key to select probe # for setup.

UP/DOWN

M1

M

) key to select a probe # to copy.

UP/DOWN

ENTER

▲ ▼ keys to display

key.

▲ ▼ keys to display

to accept this data.

ð

ï

Probes Setup Page 4 - 1

4

Page 37

Probes – PROBE DATA Menu (C

ONTINUED

...

FROM PREVIOUS PA G E

)

PROBE DATA N PROBE # N shown typical for any probe # 1 – # 8

TYPE Press M2 key.

PROBE TYPE FOR PROBE N Press