Page 1

INSTALLATION AND

PROGRAMMING MANUAL

FOR MODEL

1250-LTC

PROGRAMMABLE POSITION MONITOR

Solid State Indicator for SynchroTransmitter

000-2072 Rev. C

1

Page 2

INTELLIGENT CONTROLS, INC.

PO Box 638

Saco, Maine 04072 USA

Phone: 207-283-0156 FAX: 207-283-0158

Toll Free: Technical Service & Sales 800-872-3455

Web Site: www.incon.com E-mail: sales@incon.com

This manual applies to all INCON model 1250-LTC monitors

Copyright 2008, Intelligent Controls, Inc. All rights reserved

.

2

Page 3

TABLE OF CONTENTS

Section: Page:

List of Figures…………………………………………………………………… 4

List of Tables……………..……………………………………………………… 4

Introduction……………………………………………………………………... 5

1.0 Installation……………………………………………………………..…… 5 - 8

2.0 Programming…………………………………………………………..…… 9 – 33

2.1 Front Panel Programming…………………………………………….. 9

2.2 Serial Port Programming – ASCII …………………………………… 13 - 17

2.3 Serial Port Programming – MODBUS……………………………….. 18 – 33

2.3.1 MODBUS Packet Format – Read……………………………….. 19

2.3.2 MODBUS Packet Format – Write………………………………. 20

2.3.3 MODBUS Packet Format – Error Exception Response……….. 21

2.4 Operating Modes………………………………………………………. 34 – 37

2.5 Programming Notes……………………………………………………. 38

3.0 Options…………………………………………………………………..….. 39 – 48

3.1 Analog Output……………………………………………………..…… 39

3.2 High / Low Relay Limits………………………………………..……… 40 – 45

3.2.1 Tap Change Acknowledgement.………………………………… 41

3.2.2 High Tap / Low Tap……………………………………………… 41

3.2.3 Total Tap Change Count………………………………………… 42

3.2.4 On-Tap Alarm……………………………………………………. 42

3.2.5 Up-To & Down-To Count………………………………….…….. 44

3.2.6 Pass-Through-Neutral Alarm…………………………….……… 44

3.2.7 One-Direction Change Count…………………………….……… 45

3.2.8 FA 25 & FA 27 Error Alarm…………………….…………….… 45

3.3 Serial RS-232…………………………………………………...……….. 46

3.4 Serial RS-485 .……………………………………...………………….... 47

3.5 Input Isolation…………………………………………………...……… 48

4.0 Field Calibration and Test………………………………………...…….…. 48 – 49

5.0 Error Codes…………………………………………………………….……. 50

6.0 Specifications…………………………………………………………….….. 51

3

Page 4

LIST OF FIGURES

Figure: Page:

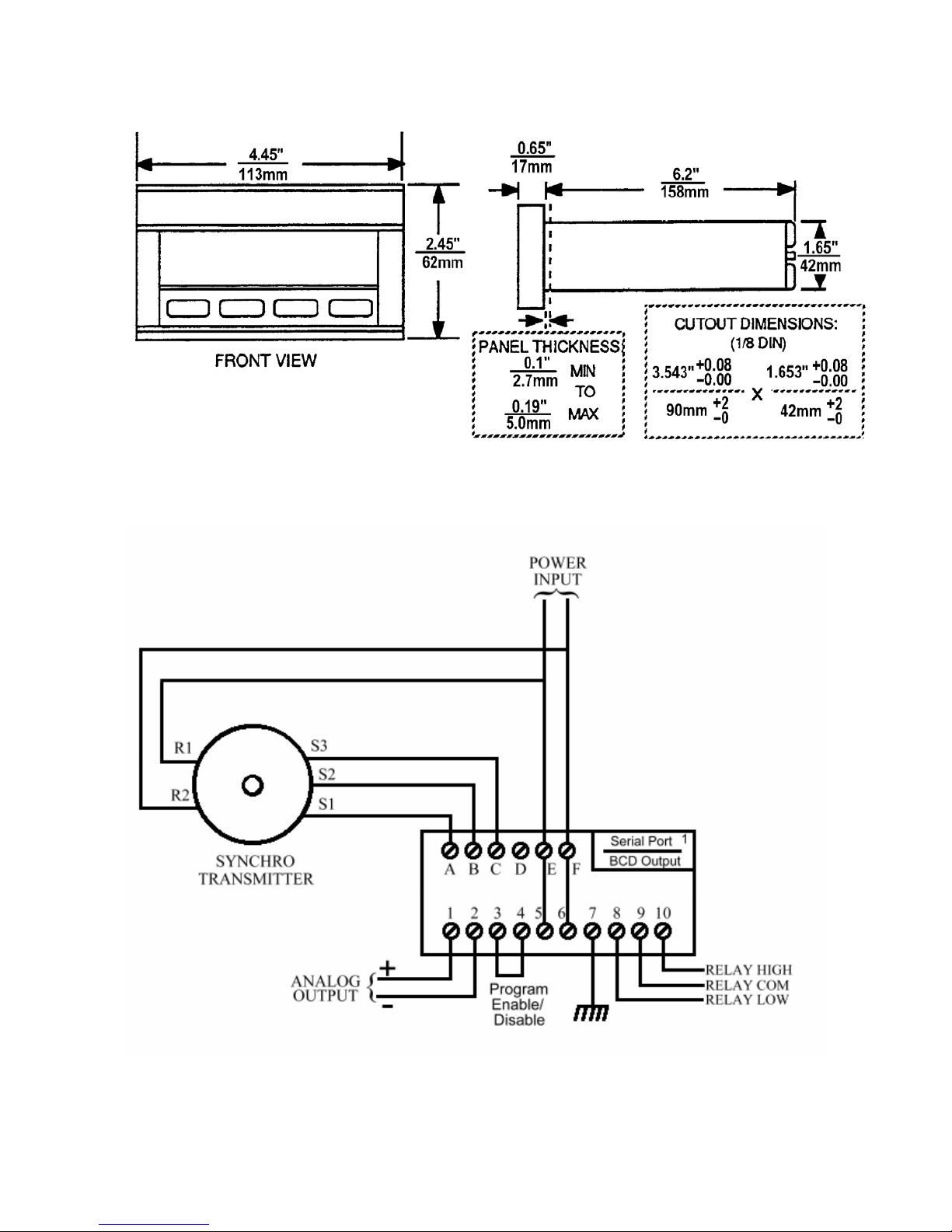

1.1 Mechanical Dimensions…………………………………………………………… 6

1.2 Field Wiring Diagram…………………………………………………………….. 6

1.3 Field Wiring Diagram with 4-20mA Option.…………………………………….. 7

2.1 Simplified Programming Flowchart…...…………………………………………. 12

2.2 Serial Data Dump Example……………………………………………………….. 17

2.3 Base 1 Uni-Polar Mode Analog Output………………………………………….. 35

2.4 Base 0 Uni-Polar Mode Analog Output………………………………………….. 36

2.5 Bi-Polar Mode Analog Output…………………………………………………… 37

3.1 Relay Field Wiring Diagram……………………………………………………... 40

3.2 On-Tap Example………………………………………………………………….. 43

4.1 Analog Output Adjustment Pots…………………………………………………. 49

LIST OF TABLES

Table: Page:

1.1 Terminal Functions……………………………………………………………… 7

1.2 DIP Switch Functions…………………………………………………………... 7

1.3 Analog Output Configuration Jumpers…………………………………………. 8

2.1 Numeric and Alpha-numeric Menu Items……………………………………… 9-12

2.2 Serial Programming ASCII Commands……………………………………….. 13-15

2.3 Read Registers Command Format..……………………………………………. 19

2.4 Read Registers Response Format.…………………………..………………….. 19

2.5 Write Registers Command Format……………………………………………... 20

2.6 Write Registers Response Format……………………………………………… 20

2.7 Error Exception Response Format……………………………………….…….. 21

2.8 RS-485 MODBUS Register Definitions...……………………………………… 22-33

3.1 Analog Output Load Limits……………………………………………………. 39

3.8 Wiring: Digital Connector Pin-Out……………………………………….…….. 47

5.1 Error Codes …………………………………………………………….….……. 50

4

Page 5

INTRODUCTION

The Model 1250-LTC Programmable Position Monitor is a highly advanced solidstate instrument, which measures the absolute position of a synchro transmitter. It provides

both a user definable visual panel indication and optional analog and digital signal outputs

suitable for a variety of monitoring and control applications.

The INCON 1250-LTC series is unique in its capability to monitor up to 40 userdefinable position segments. It is specifically designed for monitoring power transformer

load tap changer position, where the desired readout is in whole tap numbers. Its transmitter

can be attached to any operating shaft on the LTC and the 1250 programmed to read out in tap

positions. The display and all outputs follow a “stair step” function defined in the program.

The INCON 1250 has become the industry standard for LTC position monitoring.

In addition to basic LTC tap position, the 1250-LTC can provide useful information

about the movement of the LTC. Beginning with a momentary (optional) relay closure after

each successful tap change, the 1250-LTC keeps records on seven important issues relating to

LTC movement, including: total number of tap changes; number of days since last “pass

through neutral”; number of changes “up to” and “down to” each tap; and more.

Most LTC’s rotate about 9 to 11 degrees with each tap change. The 1250-LTC can

measure in increments of 1/10th of a degree. A special feature of the 1250-LTC is its ability

to monitor small discrepancies in tap position. A programmable limit can be set to give an

alarm when the discrepancy in tap position reaches the limit. Inaccurate tap position can be

an early indicator of wear in the LTC mechanism or possible impending failure.

The 1250-LTC may be wired in parallel with existing synchro transmitter/receiver

pairs or wired directly to the synchro transmitter. Additional 1250’s may be wired to the

same transmitter without compromising the accuracy or reliability of the system.

1.0 INSTALLATION

• The Model 1250-LTC is designed for use in any 50/60 Hz, five-wire synchro system

compatible with electrical specifications given in Section 6.0, page 51. These devices

include CX, TX, CDX, and TDX function synchros, as well as Self-Synchronous

Indicator devices. (INCON’s model 1292 Synchro is a highly specified robust

transmitter with a history of proven performance.)

• The panel-mount case is designed to snap-fit into a standard 1/8 DIN rectangular

cut-out of 44mm (1.73 in.) by 92mm (3.62 in.)

• Wiring is done to the rear of the case. #16 AWG (min.) type THHN, THWN, TFFN,

or equivalent wire is recommended for the five AC synchro lines. #20 AWG (min.)

shielded twisted pair wire is recommended for analog output wiring. Use appropriate

spade lugs (provided) when connecting to the case terminals.

• Contact INCON Technical Service (1-800-872-3455) for application assistance if the

synchro transmitter and the 1250-LTC monitor are separated by a wire run of more

than 1200 feet.

5

Page 6

Figure 1.1 Mechanical Dimensions

Figure 1.2 Field Wiring Diagram

6

Page 7

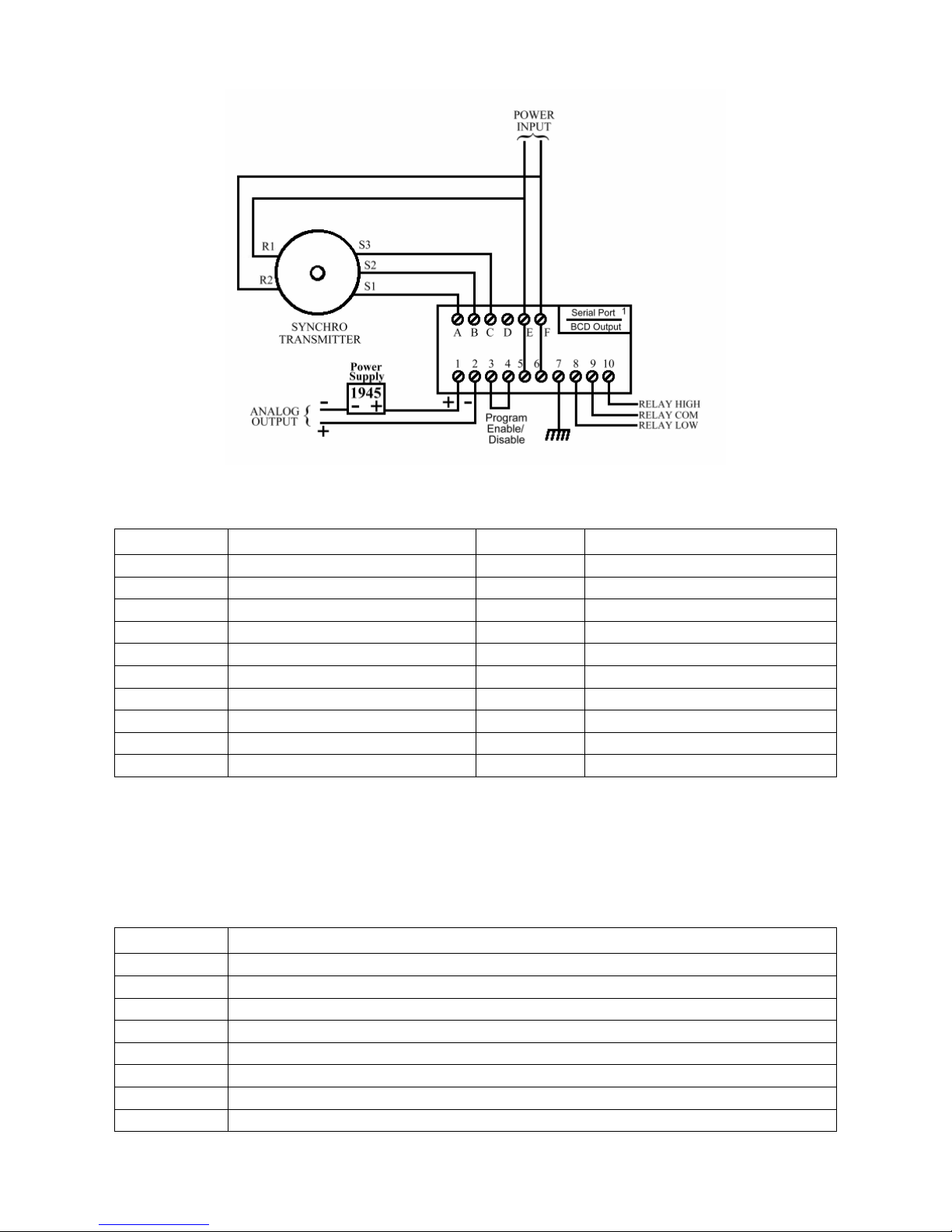

Figure 1.3 Field Wiring Diagram with 4-20mA Output

Table 1.1 Terminal Functions

Terminal Function Terminal Function

A S1 1 Analog Output +

B S2 2 Analog Output –

C S3 3 Program Mode Inhibit

D (Spare) 4 Inhibit Return

E R1 * 5 Line L1 *

F R2 * 6 Line L2 *

7 Chassis Ground

* Terminals E & F are 8 Relay Low Contact N.O.

jumpered to 5 & 6 9 Relay Common

respectively 10 Relay High Contact N.O.

A DIP switch tells the firmware which hardware options are installed, so their function

can be enabled. It is located on the top PCB, above the power transformer and is

accessible through a slot in the left side of the case, towards the rear of the instrument.

Table 1.2 DIP Switch Functions

Switch # Function

1 Serial Communications Option Enable

2 MODBUS Protocol Enable

3 Spare

4 High / Low Relay Limit Option Enable

5 Analog Output Option Enable

6 Spare

7 Spare

8 In-Factory Test & Calibration Menu Enable

7

Page 8

Installation Notes:

1) A resistor may be wired remotely across the analog output terminals to convert analog

output milliamp current to a voltage. Use Ohm’s Law to calculate the proper resistance

for the desired voltage based upon the 1250-LTC’s rated output current.

2) Maximum analog output load resistance: 0-1mA = 10K ohms; +/-1mA = 10K ohms;

0-2mA = 5K ohms; 4-20mA = 500 ohms.

3) Models with 4-20 mA analog output options must have an EXTERNAL LOOP POWER

SOURCE of 10.0 VDC minimum, 24.0 VDC maximum, in series with the current loop.

The INCON Model 1945 Power Supply is recommended for these installations,

(See Figure 1.3, page 7).

4) When additional remote indication is needed, several 1250-LTC’s may be wired in

parallel to the same transmitter. The 1250-LTC can also be connected via its serial port to

the INCON model RD-4 Remote Display unit.

5) The 1250-LTC and the synchro transmitter MUST BE WIRED TO THE SAME AC

SOURCE. Do not remove the jumpers from terminals E and F.

6) A wire jumper or keyswitch may be installed between terminals 3 & 4 to prevent the

program from being changed. When these terminals are jumpered the menu will read

“EP-x” instead of “OP-x”, which indicates that you can Examine each Parameter, but not

change them.

7) After installation and programming, install the rear terminal guard with screws provided.

8) For models with serial options, plug the cable onto the card edge with the red stripe

towards the outside of the case.

Application Bulletins:

1) If there is a large component of AC “ripple” present on the 1250 analog output, check the

isolation of all wiring with respect to earth ground. R1, R2, S1, S2, and S3 should

measure infinite resistance to earth ground. In applications where external isolation is not

sufficient, the Input Isolation Option (-I) is required to break the ground path that causes

this ripple. See Application Bulletin #000-1150 for more detailed information.

2) Analog outputs of 0-1mA, +/-1mA, and 0-2mA can be changed in the field to any one of

the other two (see Table 1.3). The configuration jumpers are located on the bottom PCB.

See Application Bulletin #000-1151 for more detailed information.

Table 1.3 Analog Output Configuration Jumpers

Output Signal: J8 J10 J12 J13

0-1mA Jumped Jumped Jumped

+/-1mA Jumped Jumped Jumped

0-2mA Jumped Jumped

8

Page 9

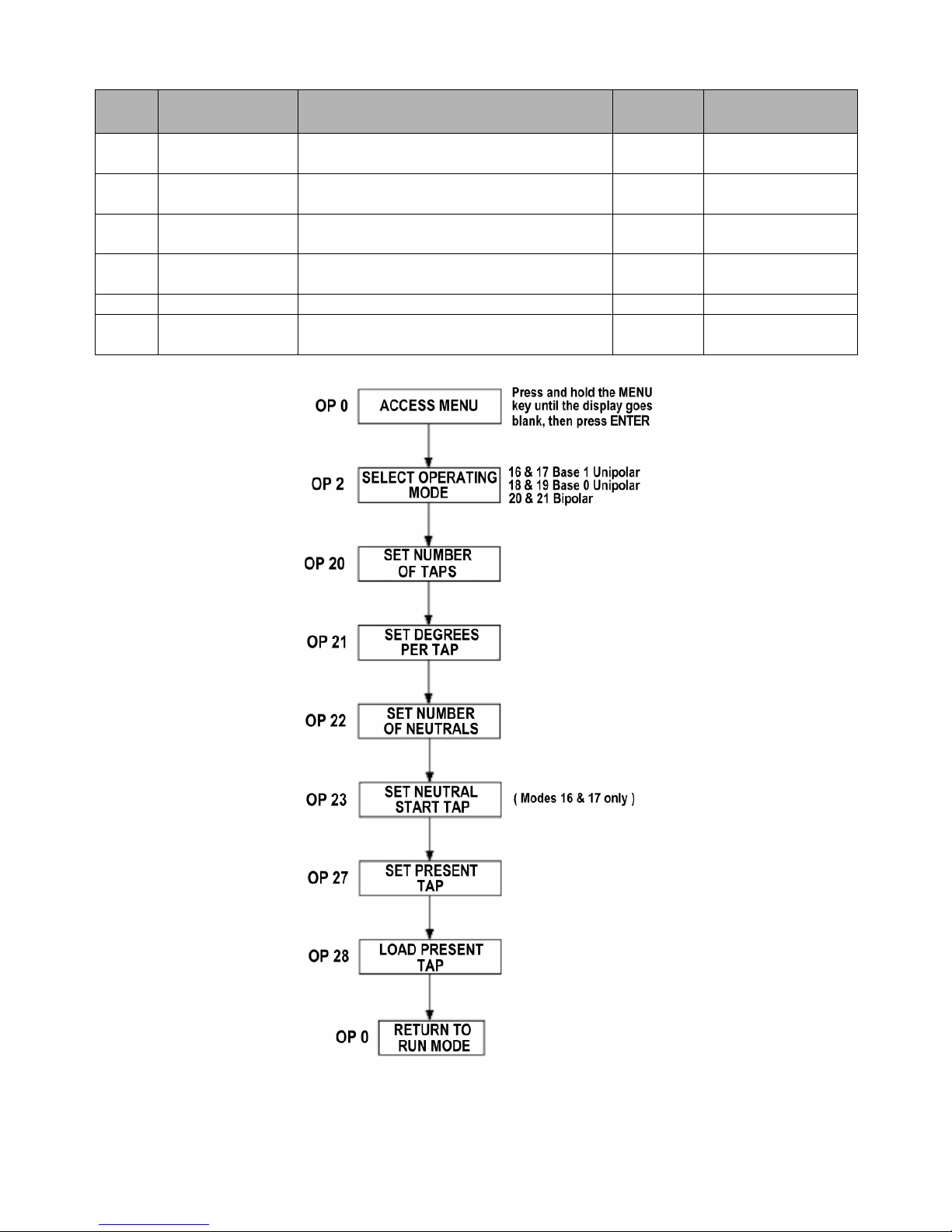

2.0 PROGRAMMING

The Model 1250-LTC has three methods of programming: numeric menu (traditional

1250); alphanumeric menu; and serial port programming commands. The 1250-LTC can be

ordered with either RS-232 or RS-485 serial port hardware. The serial programming

commands can be in the form of ASCII characters or MODBUS packets, depending upon the

position of DIP switch #2. See Tables 2.1, 2.2 & 2.3 for a full listing of all programming

menu items, commands, and syntax. See the simplified programming flowchart for tap

position on page 12, Figure 2.1.

2.1 Front Panel Programming

To access the numeric or alphanumeric programming menu, press the MENU key for

several seconds until the display goes blank, then press the SELECT/ENTER key. The

display should read “OP 0”. The default menu is the numeric menu. To choose the

alphanumeric menu, press the DOWN key to select OP 99. Press the SELECT/ENTER key,

the display should read “to OP”. Press the UP key. The display should read “run”. You are

now in the alphanumeric menu mode.

To change a parameter using the numeric or alphanumeric menus, select the parameter

to be changed from the menu, press the SELECT/ENTER key. The parameter’s present

setting will now be displayed. You can change the setting by pressing the UP or DOWN key.

To store the new setting, press the SELECT/ENTER key, the display will return to the menu.

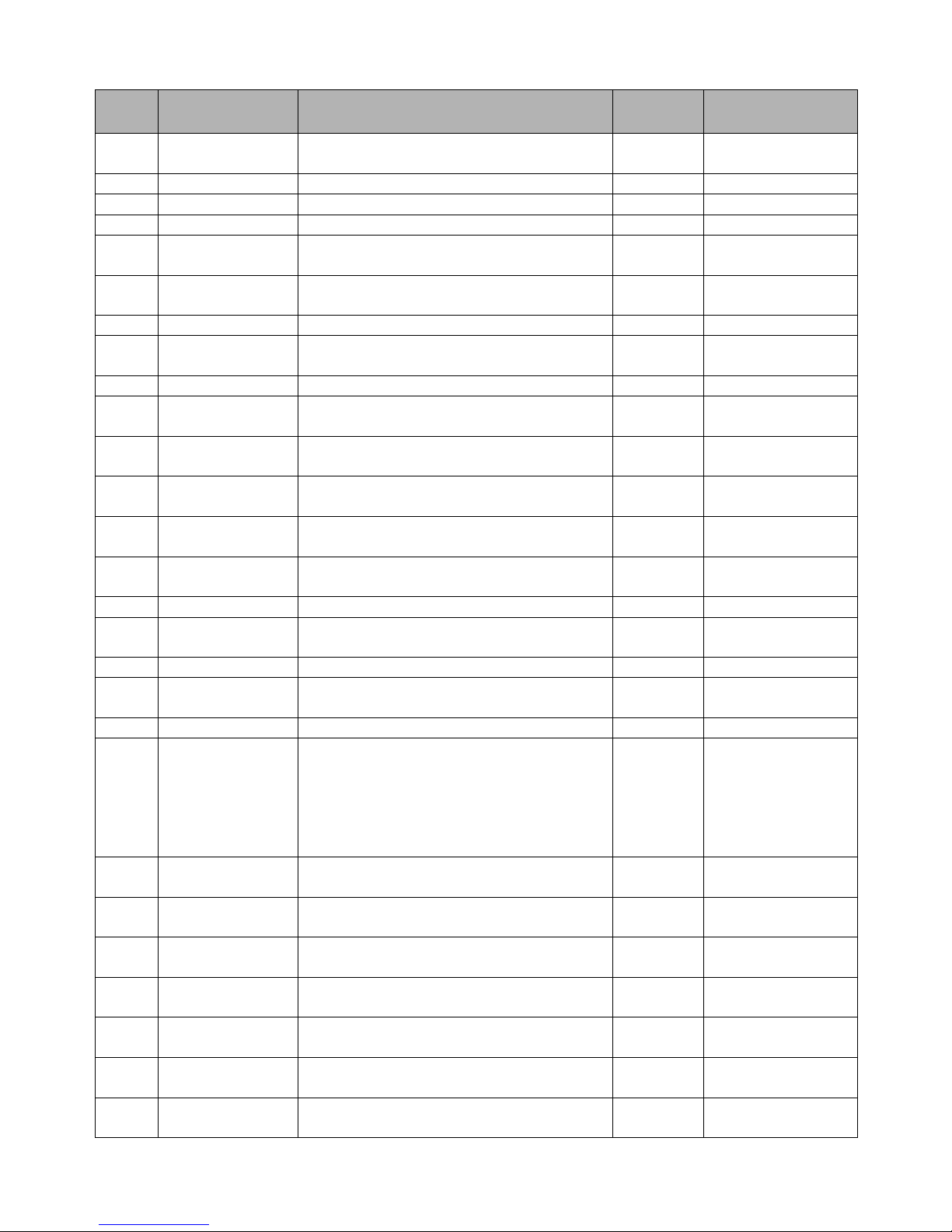

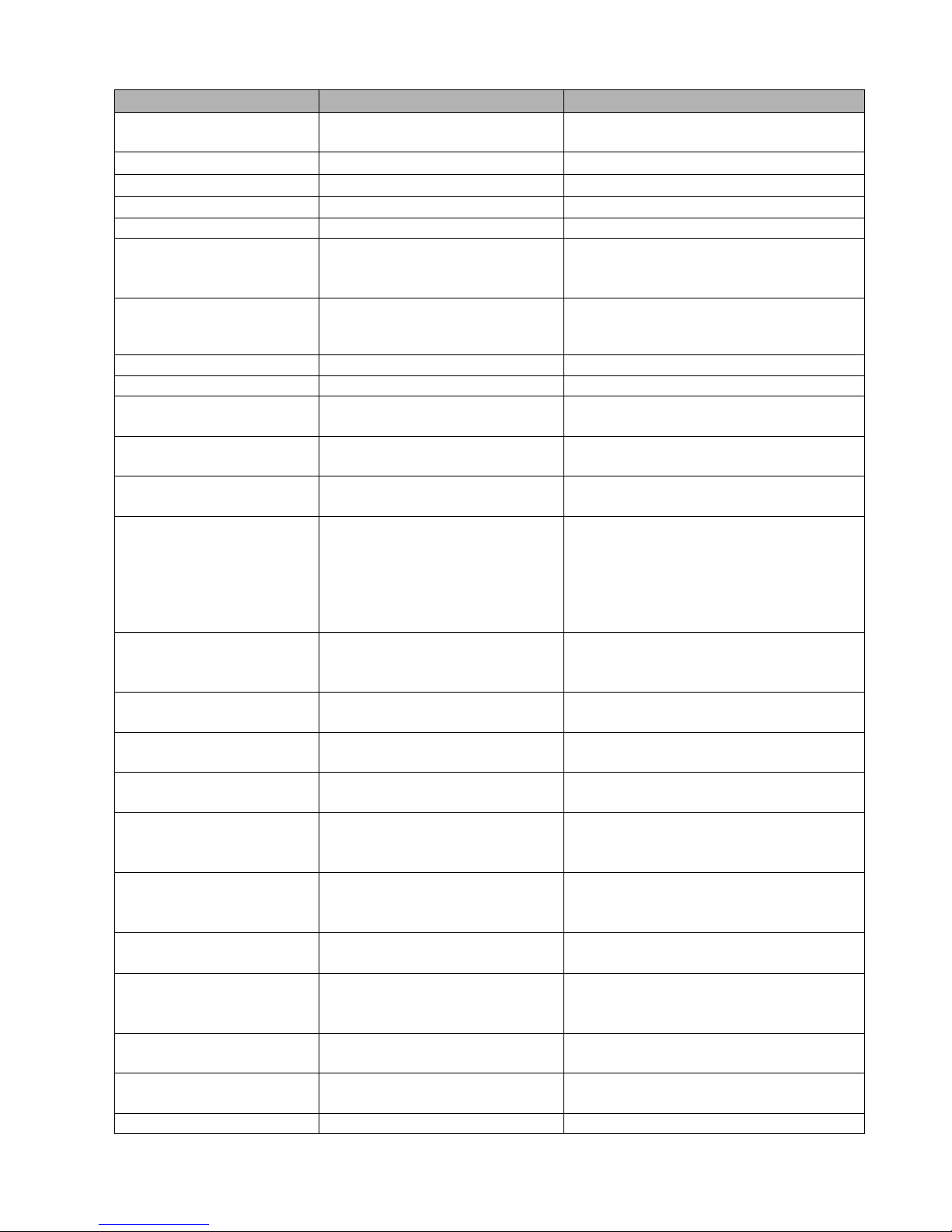

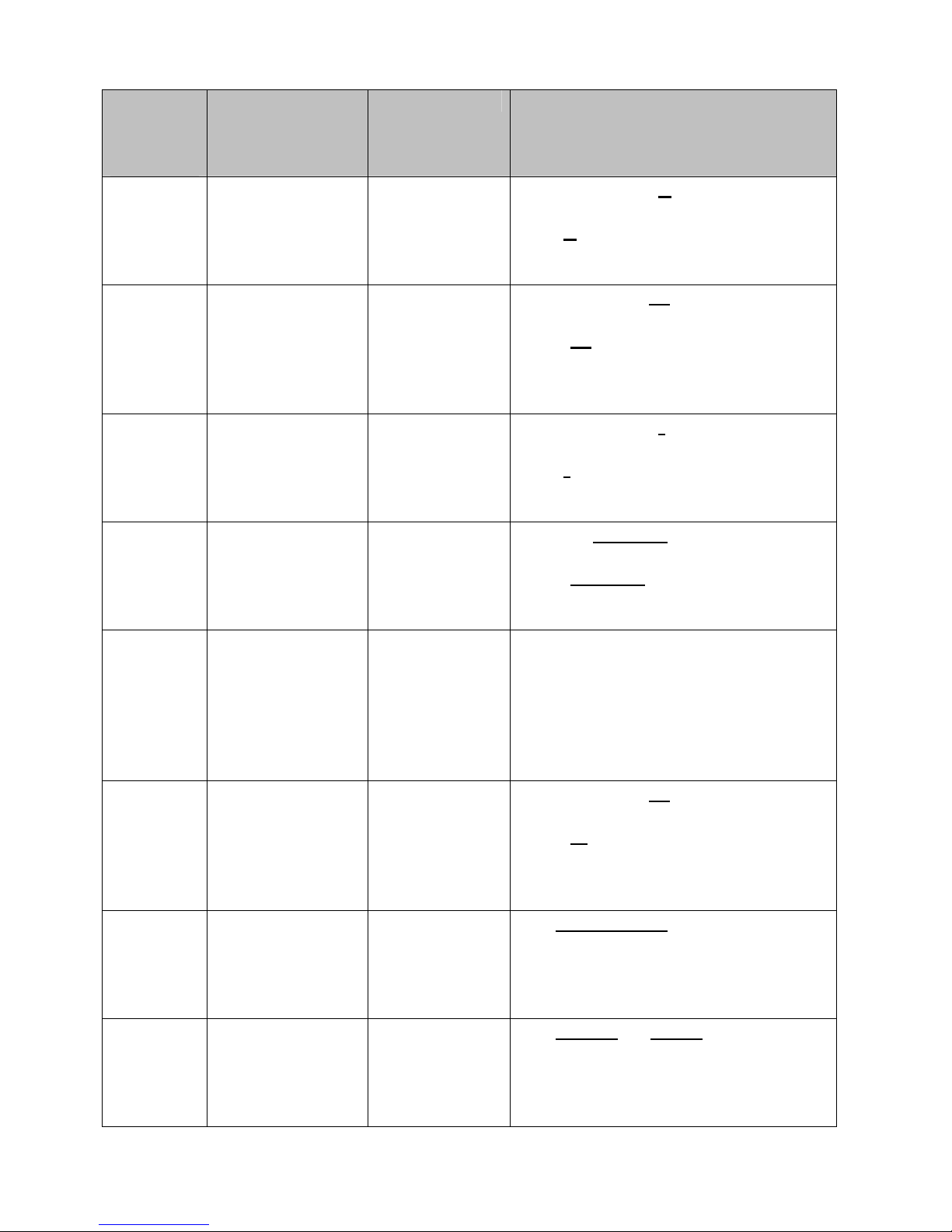

Table 2.1 Numeric and Alphanumeric Menu Items:

Numeric

OP 0 run Press the SELECT/ENTER key to exit the

OP 2 Func Select Operating Mode (see pages 34-37) 21 16, 17, 18, 19, 20,

OP 3 tCrLY Selects which relay will assert

OP 4 tCrdL Sets the delay time before Tap Change

OP 5 tCrLt Sets duration of time the Tap Change

OP 6 dHF-L Selects which visit to the Draghand

OP 10 LtCLr Low Tap Alarm Clear CL

OP 11 HtCLr High Tap Alarm Clear CL

OP 15 rL Lt Sets low relay limit tap -16 Any valid tap

OP 16

OP 17 rL Ht Sets high relay limit tap +16 Any valid tap

OP 18

Alpha-numeric

Protocol

LtrLY

HtrLY

Function: Default

Value:

Program mode

OFF OFF, LO, HI

momentarily, after each tap change

0.0 0.0 to 9.9

Acknowledge Relay turns on (Seconds)

0.0 0.0 to 9.9

Acknowledge Relay stays on (Seconds)

LASt “FirSt”, “LASt”

positions (first

the day counters

Selects which relay will assert when the

“Low Tap” alarm limit is reached

Selects which relay will assert when the

“High Tap” alarm limit is reached

time or last time) will begin

OFF OFF, LO, HI

OFF OFF, LO, HI

Programmable

Range:

21

number

number

9

Page 10

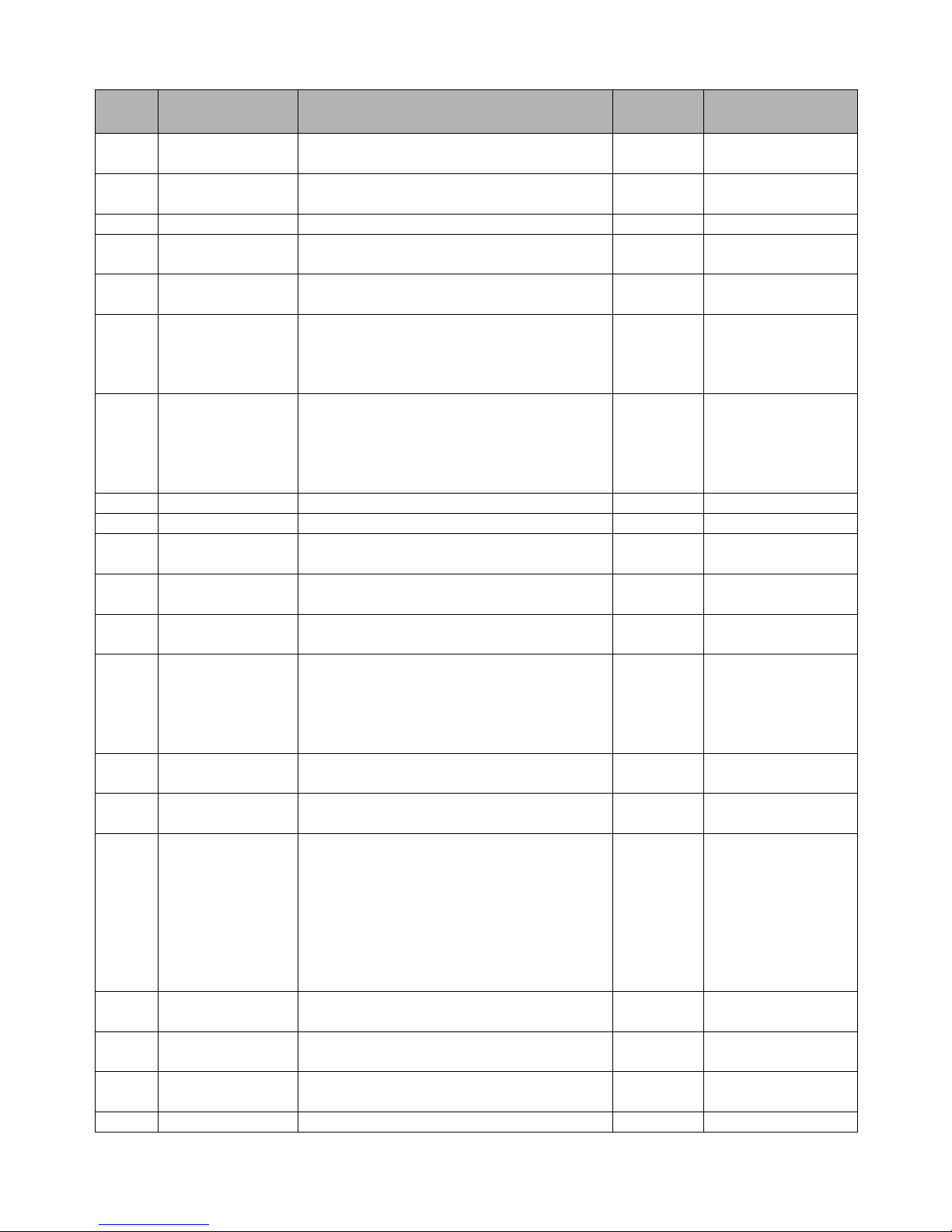

Numeric

OP 19

OP 20

OP 21

OP 22 nEu Number of neutral taps 1 0 to 8

OP 23 n St Sets lowest neutral tap 0-1 Any valid tap

OP 27 S Pt Sets present tap position 0 Any valid tap

OP 28 L Pt Loads present tap position into memory Ld

OP 29 dSPrL Enables display of “r” or “L” in Function

OP 30 CAL E Enables analog output Calibration Mode OFF On or OFF

OP 31 L CAL Forces the analog output to its lowest

OP 32 H CAL Forces the analog output to its high scale

OP 33 d CAL Forces the analog output to its mid scale

OP 34 t CAL Forces the analog output to alternate

OP 39 dOG t Forces a Watchdog Reset (Factory use

OP 40 LED t Display LED Test: Turns on all LED’s -8.8.8.8.8.

OP 41 rS t RS-232 Echo Test: Re-transmits characters

OP 42 InCAL Calibrates synchro input circuitry CAL

OP 43 rLY t Relay Test: UP and DOWN keys toggle

OP 50 dSPbL Causes the display to go blank after 60 sec. OFF On or OFF

OP 51 SEr Serial Communication Mode:

OP 53 Aut25 Auto-Reset after “FA 25” Loss of Synchro

OP 54

OP 55 ttCLt Sets Total Tap Change counter alarm limit

OP 56 ttrLY Selects which relay will assert when the

OP 57 ttPrE Presets the Total Tap Change counter in

OP 58 ttdtE Total Tap Change counter reference date

OP 59 ttCdS Displays Total Tap Change Count and

Alpha-numeric

Protocol

dEGrE

tAPS

d SEG

25rLY

Function: Default

Value:

Displays absolute synchro position in

degrees with one decimal place resolution

Number of taps 33 2 to 40

Degrees per tap 10.000 -99999 to +99999

Modes 20 and 21

signal output

signal output

signal outputs

between high and low scale signal outputs

only)

received through the RS-232 serial port

between LO and HI relays

0=Serial Disabled,

1=Data Logger Mode, 2=Polled Mode,

3=Sampled Mode, 4=Serial Command

Mode, 5=Reserved, 6= MODBUS Mode,

7=Remote Display Driver Mode

Signal Error (page 50)

Selects which relay will assert when the

“FA 25” error is active

in THOUSANDS

Total Tap Change counter limit is reached

THOUSANDS

Enter day, month, year

reference date Press ENTER to exit

OFF On or OFF

LO

HI

- -

LO then HI

<<Press ENTER>>

rS

LO then HI

0 0 to 4, and 6

OFF On or OFF

OFF OFF, LO, HI

000.01 000.01 to 999.99

OFF OFF, LO, HI

000.00 000.00 to 999.99

01–01–00

Programmable

Range:

number

number

10

Page 11

Numeric

OP 60 Aut27 Auto-Reset after “FA 27” Unstable

OP 61

OP 62 OtGLt Sets On-Tap guard band limit (Degrees) 0.1 0.1 to 9999.9

OP 63 OtrLY Selects which relay will assert when the

OP 64 OtdtE On-Tap reference date

OP 65 OtdIS Scrolls through the list of taps, to select,

OP 66 Otdtd Scrolls through the list of taps which have

OP 67 OtCLr Clears the On-Tap alarm CL

OP 68 OtrSt Resets all On-Tap logs & alarm rESEt

OP 70 udCLt Sets the alarm limit for the number of

OP 71 udrLY Selects which relay will assert when the

OP 72 uddtE UP TO & DOWN TO Change counter

OP 73 uddIS Scrolls through the list of taps to select,

OP 74 udCLr Clears an active Up-To and Down-To

OP 75 udrSt Resets all Change Up-To and Down-To

OP 80 POrt Sets serial port parameters: (press the UP

OP 85 PtnLt Sets the limit for number of days without a

OP 86 PtrLY Selects which relay will assert when the

OP 87 PtdIS Displays the number of days since the last

Alpha-numeric

Protocol

27rLY

Function: Default

Value:

OFF On or OFF

Synchro Signal Error (page 50)

Selects which relay will assert when the

“FA 27” error is active

On-Tap guard band limit is reached

Enter day, month, year

Press ENTER to display the highest

measured deviation, for that tap

Press MENU to escape back to the menu

exceeded the On-Tap alarm limit to select,

Press ENTER to display the highest

measured deviation, for that tap

Press MENU to escape back to the menu

changes UP TO any tap in THOUSANDS

“UP TO” change alarm limit is reached

reference date Enter day, month, year

Press ENTER to display the Change UpTo count Press ENTER to display the

Change Down-To count, for that tap

Press MENU to escape back to the menu

Change alarm

counters and alarm

or Down key to select a value, press the

enter key to move to the next parameter)

Baud rate

Word length

Parity (n=none, E=even, O=odd)

Stop bits

Address (for RS-485 Multi-drop)

“Pass Thru Neutral”

“Pass Thru Neutral” time limit is reached

“Pass-Through-Neutral”

OFF OFF, LO, HI

OFF OFF, LO, HI

01–01–00

Any valid tap

Any valid tap

000.01 000.01 to 999.99

OFF OFF, LO, HI

01–01–00

0 Any valid tap

CL

rESEt

9600

8

n

1

128

OFF Off, 0.1 to 365.0

OFF OFF, LO, HI

Programmable

Range:

number

number

number

2400, 4800, 9600,

14400, 19200,

28800,38400,

57600, 76800

7 or 8

n, E, O

1 or 2

0 to 255

11

Page 12

Numeric

OP 88 PtrSt Resets the “Pass-Through-Neutral”

OP 90 1dCLt Sets the limit for number of consecutive

OP 91 1drLY Selects which relay will assert when the

OP 92 1ddIS Displays the number of days since the

OP 93 1dCLr Clears “One Direction Change” alarm CL

OP 99 tO OP Toggles between Numeric and

Alpha-numeric

Protocol

Function: Default

Value:

rESEt

counter & alarm

2 2 to 30

tap changes in One Direction

OFF OFF, LO, HI

“One Direction Change” limit is reached

“One Direction Alarm” was asserted

tO OP

Alphanumeric menus

Programmable

Range:

Figure 2.1 Simplified Programming Flowchart

12

Page 13

2.2 Serial Port Programming - ASCII:

These commands require either the RS-232 (-S) or RS-485 (-M) hardware option. To use

the serial port programming commands, connect a computer terminal to the serial port cable. The

terminal must have the proper Comm port settings to communicate to the 1250-LTC (see Sections

3.3 and 3.4, pages 46 - 47). See Table 2.2 for a full listing of all Serial Programming Commands

and syntax. At the command prompt, type a command followed by the new parameter setting,

using proper syntax as shown in Table 2.2. Typing the command only, without a new para-

meter setting, will cause the 1250-LTC to transmit the present setting for that parameter.

Table 2.2 Serial Programming ASCII Commands:

◊=space ª=enter

Command Syntax: Function: Explanation:

SETUPª Enter the Setup Mode This command must be entered before

any other commands can be made.

EXITª Re-starts the serial connection Changes to comm. port settings will take

effect

RUNª Return to the Run Mode Changes to settings will take effect

DISPª Displays all setup parameters Each setup parameter command is dis-

played with the current value following it

DUMPª Displays all measured LTC

information

(See Figure 2.2, page 17)

POSª Displays present Tap #, synchro

position (in degrees) and current

On-Tap deviation degrees

MODE◊nnª

ACKRLY◊LOª

ACKDLY◊nn.nª

ACKHOLD◊nn.nª

DHCOUNT◊FIRSTª

DHLRST Low Draghand Reset Draghand value becomes present tap

DHHRST High Draghand Reset Draghand value becomes present tap

LTLMT◊nnª

LTRLY◊LOª

LTCLRª Clears Low Tap Alarm Also resets “Days Since Alarm” counter

HTLMT◊nnª

HTRLY◊LOª

HTCLRª Clears High Tap Alarm Also resets “Days Since Alarm” counter

TAPS◊nnª

Segmented modes See Section 2.4, page 34-37 for details

Selects which relay will assert

momentarily after each tap

change

Sets the delay time, in seconds,

before the ACK relay asserts

Sets the duration, in seconds,

that the ACK relay remains on

Selects which visit to the

Draghand position to begins the

day counter

Set Low Tap alarm limit n= an integer, any valid tap number

Selects which relay is associated

with the Low Tap alarm

Set High Tap alarm limit n= an integer, any valid tap number

Selects which relay is associated

with the High Tap alarm

Set number of taps n= an integer from 2 to 40

Lists: Total tap change count, Days since

Pass-Through-Neutral, High & Low

Draghand positions, Change Up-To and

Down-To counts for each tap, Maximum

On-Tap deviations for each tap, etc…

Reads Tap #, 0.0 to 359.9 degrees, with

one decimal place of resolution

Press ª (enter) to exit

Choose “OFF”, “LO” or “HI” relay to

assert momentarily after each tap change

n= a number from 0.1 to 9.9 with one

decimal place resolution

n= a number from 0.1 to 9.9 with one

decimal place resolution

Choose “FIRST” or “LAST” visit.

The number of days since the LTC

visited that extreme position the first or

last time

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

13

Page 14

Command Syntax: Function: Explanation:

DEGSEG◊n.nnnnª

NEUTRALS◊nª

NSTART◊nnª

SETTAP◊nnª

LDTAPª

DISPRL◊ONª

ANACALª

WDOGTESTª

LEDTESTª Turns on all display segments Press the enter key to stop the LED test

INCALª Self-calibrates the input circuitry Outputs “Pass” or “Fail” calibration

RLYTESTª Forces Hi / Lo relay output to

DSPBL◊ONª

SERIAL◊nª

AUTO25◊ONª

FA25RLY◊LOª

RESET25ª Manually clears the “FA 25”

TTCLMT◊nnn.nnª

TTCRLY◊LOª

TTCPRE◊nnn.nnª

TTCDATE◊mm-dd-yyyyª

AUTO27◊ONª

FA27RLY◊LOª

RESET27ª Manually clears the “FA 27”

Set degrees per segment n= a floating point number, 5 digits max,

average number of degrees between taps

Set number of neutral taps n= an integer from 0 to 8

Set lowest neutral tap number n= an integer, any valid tap number

Set present tap position n= an integer, any valid tap number

Load present tap pos. into memory

Enables the display of “r” (raised)

and “L” (lowered) tap numbers

Must be done for SETTAP to take effect

“ON” or “OFF” When enabled causes

the display to show “r” and “L” in

function modes 20 and 21 only

Enter analog calibration mode, the

1250 analog output will be forced

to Low / Mid / High signal output

Forces a Watchdog Reset This command is for factory use only.

Press the space bar to toggle between

Low / Mid / High analog output. Press the

enter key to stop calibration

result

Press the Space Bar to toggle between

close

Enables the display blanking

feature

Lo or Hi relay Press ª (enter) to exit

“ON” or “OFF” When enabled causes

the display to go blank after 60 sec.

Set serial communication mode 0=Serial Disabled, 1=Data Logger

Mode, 2=Polled Mode,

3=Sampled Mode,

4=Serial Command Mode, 5= Reserved,

6=MODBUS Mode, 7=Remote Display

Driver

Enables automatic reset of the

“FA 25” Loss of Synchro Signal

Error (page 50)

Selects which relay is associated

with the “FA 25” Error

“ON” or “OFF” When “ON”, the

“FA 25” alarm will automatically reset

when the condition clears

Choose “OFF”, “LO” or “HI” relay to

assert when the FA 25 Error is active

When AUTO25 is “OFF”, manually

alarm

Sets the Total Tap Change count

alarm limit in THOUSANDS

Selects which relay is associated

with the Total Tap Change count

clears the alarm and opens the relay

n= a number from 0.00 to 999.99 with

two decimal place resolution

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

alarm

Presets the Total Tap Change

counter

and clears the alarm

Sets the Total Tap Change

counter reference date

in THOUSANDS

Enables automatic reset of the

“FA 27” Unstable Synchro

Signal Error (page 50)

Selects which relay is associated

with the “FA 27” Error

n= a number from 0.00 to 999.99 with

two decimal place resolution

mm-dd-yyyy = Month <hyphen> Day

<hyphen>Year (4 digits)

“ON” or “OFF” When “ON”, the

“FA 27” alarm will automatically reset

when the condition clears

Choose “OFF”, “LO” or “HI” relay to

assert when the FA 27 Error is active

When AUTO27 is “OFF”, manually

alarm

clears the alarm and opens the relay

14

Page 15

Command Syntax: Function: Explanation:

OTGDLMT◊nn.nª

Sets the On-Tap guard band

limit in DEGREES

OTRLY◊LOª

Selects which relay is associated

with the On-Tap alarm

OTDVTNª Displays the tap with the greatest

On-Tap Deviation

OTDATE◊mm-dd-yyyyª

Sets the On-Tap reference date

OTCLRª Clears the On-Tap alarm Data is retained, the alarm is cleared

OTRSTª Resets all On-Tap logs & alarm All On-Tap data is erased, alarm cleared

UPDNLMT◊nnn.nnª

Sets the alarm limit for the

number of changes “Up-To”

and “Down-To” any tap

in THOUSANDS

UPDNRLY◊LOª

Selects which relay is associated

with the “Up-To / Down-To”

Change alarm

UPDNDATE◊mm-dd-yyyyª

Sets the Up To / Down To

Change counter reference date

UPDNCLRª Clears an active Up-To or

Down-To Change alarm

UPDNRSTª Resets all Change Up-To and

Down-To counters and alarm

PORT◊bbbb◊w◊p

◊s◊aª

Set comm. port settings: baud

rate, word length, parity, stop

bits, and address

SITEID◊Abcd-Xyz & 123ª

Identifies installation site on the

“DUMP” header

PTNLMT◊nnnª

Sets the alarm limit for the

number of DAYS without a

“Pass Through Neutral”

PTNRLY◊LOª

Selects which relay is associated

with the “Pass-Through-Neutral”

alarm

PTNRSTª Resets the “Pass-Through-

Neutral” counter & alarm

1DTCLMT◊nnª

Sets the alarm limit for the

number of consecutive tap

changes in One Direction

1DTCRLY◊LOª

Selects which relay is associated

with the “One Direction” alarm

1DTCCLRª Clears a “One Direction” alarm

MENU◊1ª

Set the keyboard button menu

type

n= a number of degrees from 0.0 to 99.9

with one tenth degree resolution

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

Displays Tap Number and Deviation

mm-dd-

yyyy = Month <hyphen> Day

<hyphen>Year (4 digits)

n= a number from 0.00 to 999.99 with

two decimal place resolution

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

mm-dd-yyyy = Month <hyphen> Day

<hyphen>Year (4 digits)

If a tap with an Up-To or Down-To Change

counter exceeding the programmed limit is

re-visited, the alarm will re-activate

All Up-To and Down-To counters are reset

to zero and an active alarm is turned off

b=

2400, 4800, 9600, 14400, 19200,

28800, 38400, 57600, 76800 baud

w= 7 or 8 bit word

p= n, E, O

s= 1 or 2 stop bits

a= 0 to 255

40 ASCII Characters – Upper / lower case

letters, numbers, punctuation marks

n= a number from 0.0 to 365.0 with one

decimal place resolution

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

n= an integer from 2 to 30, OFF

Choose “OFF”, “LO” or “HI” relay to

assert when the alarm limit is reached

“1” = Numeric “OP” menu or

“2” = Alpha-numeric menu

15

Page 16

HELP◊(command) ª

Provides on-line help on the

specific command entered or

lists all available commands

An explanation of a command and the

proper entry syntax is given. If no

command is entered, all commands will

be listed with syntax but no explanations

To prevent accidental or unwanted changes to the program parameters, a jumper wire

may be installed across terminals 3 & 4. With this jumper installed, the numeric menu will

read “EP nn” instead of “OP nn”. All parameters can be viewed but no changes can be made.

16

Page 17

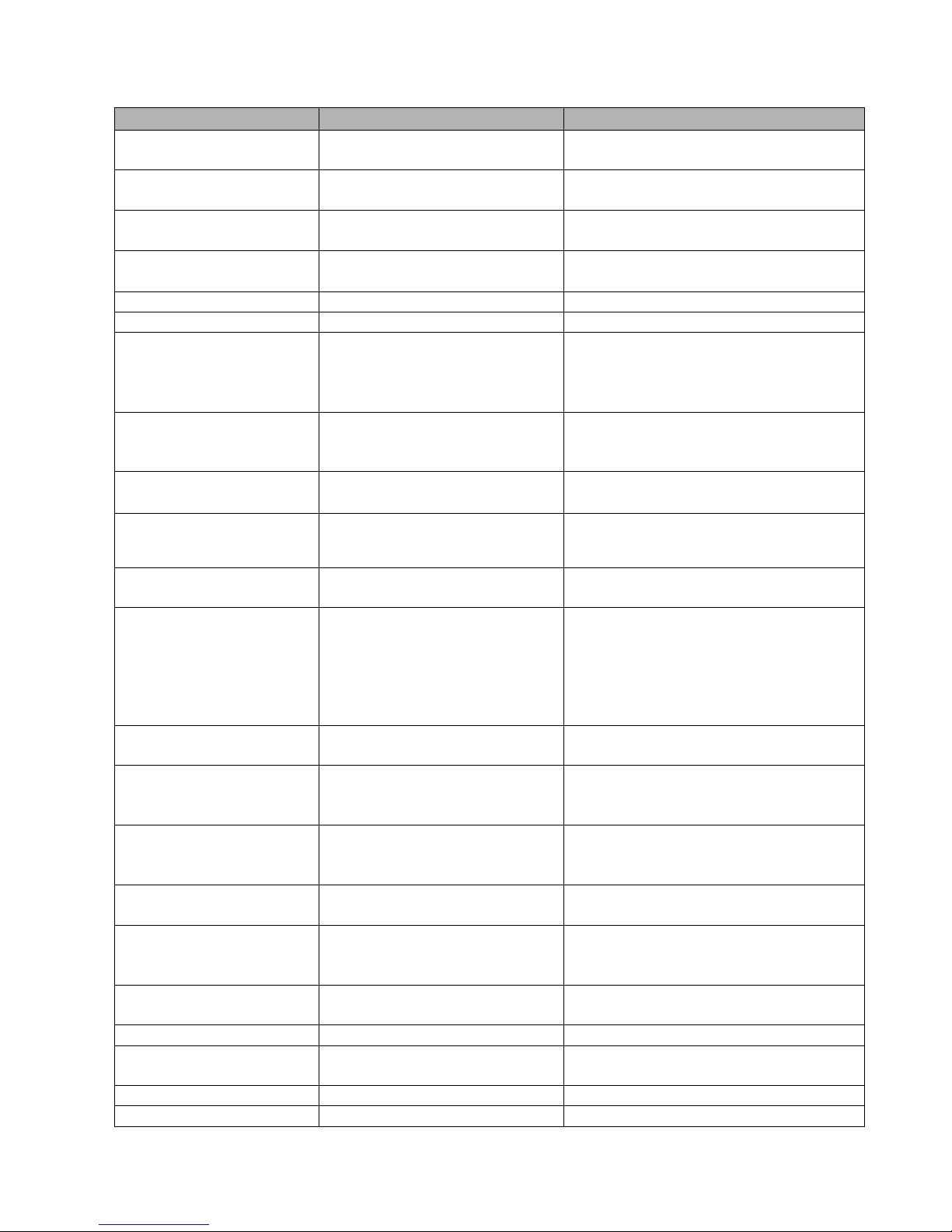

Site ID: Maplewood Sub LTC #2

INCON 1250-LTC Firmware Revision X.xx Copyright 2007

Present Tap: 5

Total Tap Changes: 5729

Low Draghand: -7 35.4 Days Since LAST

High Draghand: 8 17.6 Days Since LAST

ALARMS:

Since activated - Days: Limit: Ref Date:

On-Tap Deviation 0.65 3.0 08-30-2007

Instability -- --

Synchro Signal Lost -- - 1 Direction Change 0.86 04

Up Down Count -- 123456 08-30-2007

Total Tap Changes 0.66 1234567 08-30-2007

Low Tap -- -10

High Tap 0.86 12

Pass Through Neut 0.95 30.0

TAP STATISTICS:

Tap Max. Dev. Change Change

Num: Degrees: Up-To: Dn-To:

-16 + 0.0 0 0

-15 + 0.0 0 0

-14 + 0.0 0 0

-13 + 0.0 0 0

-12 - 0.4 0 1

-11 - 0.4 1 2

-10 - 0.3 2 3

-9 + 0.4 3 9

-8 + 0.5 9 85

-7 + 0.8 85 215

-6 + 0.9 215 608

-5 + 0.9 608 1935

-4 + 1.1 1935 5564

-3 + 1.2 5564 6258

-2 + 1.1 6258 7145

-1 + 1.3 7145 5199

0-1 + 0.0 5199 5199

0-2 - 1.3 5199 8064

0-3 + 0.0 8064 8064

1 + 1.4 8064 40792

2 + 2.2 40792 22186

3 + 1.9 22186 9420

4 + 1.4 9420 7384

5 + 1.2 7384 4008

6 + 0.9 4008 1523

7 + 0.7 1523 407

8 - 0.6 407 115

9 - 0.6 115 11

10 + 0.5 11 4

11 - 0.3 4 2

12 - 0.4 2 1

13 + 0.4 1 0

14 + 0.0 0 0

15 + 0.0 0 0

16 + 0.0 0 0

Visit

Visit

Figure 2.2 Serial Data Dump Example

17

Page 18

2.3 Serial Port Programming - MODBUS:

This type of serial communication require the RS-232 (-S) or RS-485 (-M) hardware option. To

communicate to the 1250-LTC with MODBUS protocol, connect a computer with the appropriate

MODBUS communication software and serial port hardware to the 1250-LTC’s serial port cable.

The computer must have the proper Comm port settings to communicate to the 1250-LTC (see

Section 3.3, page 46). See Table 2.3 for a full listing of all MODBUS Registers, the definition

and binary format for each.

In the following Table 2.3 the meanings of the columns is as follows:

Register: MODBUS register address as seen in a MODBUS command beginning with

register 40001 and ending with 45895. These addresses are in decimal.

Hex: The same register’s address in hexadecimal, this value is calculated by

subtracting 40001 from the register number. Thus register 40001 in decimal

becomes 0000 in hex, and 40257 in decimal becomes 0100 in hex.

Function: Defines what each register contains or does when written. Some registers

are read only and have no meaning when written. Others can be written

or read. Others are “write only” special functions and cause actions to be

performed when they are written.

Format: This column defines what a register contains bit-by-bit in binary. A row of 16

symbols shows what each of the 16 bits of the register contain MSB first

and LSB last. A BCD formatted floating point register is shown as

follows (two 16 bit binary words):

Bcdabcdbbcdcbcdd bcde000000vspppp

bcda, bcdb, bcdc, bcdd, bcde are each four-bit BCD digits, as it

would be seen on a display.

000000 are 6 unused bits that report as 0 when read and must be 0

when written.

v is an overflow bit that indicates that the number in the register is too

big to display when it is a 1. 0 indicates a valid register value.

is the sign bit and is 1 when the value in the register is negative. 0

s

indicates a positive number.

pppp

is the position of the decimal point within the bcd digits.

Most registers are not as complex as a floating-point register.

An alternate floating-point format is supported and selected by writing a 1 to

the 40256d (00ff h) register. This selects an IEEE floating-point format as

follows (two 16 bit binary words):

seeeeeeeemmmmmmm mmmmmmmmmmmmmmmm

The format of the IEEE floating-point number is as follows:

s is the sign bit,

is the exponent bits, and

e

m

are the mantissa bits.

18

Page 19

The MODBUS protocol is a master/slave packet based protocol with the 1250-LTC operating

as a RTU slave. The MODBUS function commands recognized by the 1250-LTC are “3”

(read multiple registers) and “16” (write multiple registers). By supporting these two

commands the 1250-LTC is in level 0 compliance. Using these two commands it is possible

to configure the 1250-LTC as well as monitor it for current position. MODBUS RTU

command and response packets are formatted as follows:

2.3.1 MODBUS Packet Format - Read

Reading from Holding Registers:

GAP = A gap in transmission of 3.5 character frames indicates to the slaves that a new packet

is to follow. No transmission gaps within a packet may exceed 1.5 character frames.

Byte 1 = Device Address: Address 0 is a broadcast address that all units respond to regardless

of programmed address. All other addresses can be programmed and used in this mode.

Byte 2 = Function Code: When reading holding registers, this byte is “03h”

Data Block = Begins with the number of the first register (two bytes) in a command packet,

or data from the first register (two bytes) in a response packet. Followed by the number of

registers to be read (two bytes) in a command packet, or by data from subsequent registers.

Last 2 Bytes = Error Checking CRC – Lo Byte & Hi Byte

Table 2.3 Read Registers Command Format

GAP

3.5

Char

Min. 80h 03h 01h 03h 00h 04h xx xx

Device

Address

Function

Code

# of First

Register

Hi

# of First

Register

Lo

# of

Registers to

Read Hi

# of

Registers to

Read Lo

CRC

Lo

CRC

Hi

Table 2.4 Read Registers Response Format

GAP

3.5

Char

Min. 80h 03h 08h 01h 03h 00h 03h

Device

Address

Function

Code

Byte

Count

Data from

First Register

Hi

Data from

First Register

Lo

Data from

Second

Register

Hi

Data from

Second

Register

Lo

…… …… Data from Last

Register Hi

Data from Last

Register Lo

CRC

Lo

CRC

Hi

…… …… 00h 02h xx xx

19

Page 20

2.3.2 MODBUS Packet Format - Write

Write to Holding Registers:

GAP = A gap in transmission of 3.5 character frames indicates to the slaves that a new packet

is to follow. No transmission gaps within a packet may exceed 1.5 character frames.

Byte 1 = Device Address: Address 0 is a broadcast address that all units respond to regardless

of programmed address. All other addresses can be programmed and used in this mode.

Byte 2 = Function Code: When writing to holding registers, this byte is “10h”

Data Block = Begins with the number of the first register to be written (two bytes), followed

by the number of registers to be written (two bytes), in either command or response packets.

In a command packet the programming data for the first register will be the next two bytes

followed by programming data for subsequent registers.

Last 2 Bytes = Error Checking CRC – Lo Byte & Hi Byte

Table 2.5 Write Registers Command Format

GAP

3.5

Char

Min. 80h 10h 10h 00h 00h 04h

Device

Address

Function

Code

# of First

Register to be

written to Hi

# of First

Register to be

written to Lo

# of Registers

to Write Hi

# of Registers

to Write Lo

Byte

Count

Program Data for

First Register

Hi

Program Data for

First Register

Lo

Program Data for

Second Register

Hi

Program Data for

Second Register

Lo

08h 00h 01h 03h 60h

……

……

Program Data for

Last Register Hi

Program Data for

Last Register Lo

CRC

Lo

CRC

Hi

…… …… 00 01 xx xx

Table 2.6 Write Registers Response Format

GAP

3.5

Char

Min. 80h 10h 01h 00h 00h 04h xx xx

Device

Address

Function

Code

# of First

Register to

be written to

Hi

# of First

Register to

be written to

Lo

# of

Registers

to Write

Hi

# of

Registers

to Write

Lo

CRC

Lo

CRC

Hi

20

Page 21

2.3.3 MODBUS Packet Format – Error Exception Response

When the master sends a command, the MSB bit in the Function Code is always clear. When

a slave responds to the command, the slave leaves the MSB bit in the Function Code clear if

the response is a normal response and sets MSB bit on if the response is an error exception

response.

GAP = A gap in transmission of 3.5 character frames indicates to the slaves that a new packet

is to follow.

Byte 1 = Device Address: Address 0 is a broadcast address that all units respond to regardless

of programmed address. All other addresses can be programmed and used in this mode.

Byte 2 = Function Code: This byte will be the last command sent plus the MSB set on.

Exception Code = Illegal Command = 01

Illegal Register = 02

Last 2 Bytes = Error Checking CRC – Lo Byte & Hi Byte

Table 2.7 Error Exception Response Format

GAP

3.5

Char

Min. 80h 90h 02 xx xx

Device

Address

Function

Code

Exception

Code

CRC

Lo

CRC

Hi

21

Page 22

Table 2.8 RS-485 MODBUS Register Definitions

Register

Class & Type Function: Binary Format:

Address:

Decimal

[hex]

40001

[0000]

40002

[0001]

Class:

Configuration

Type:

Read\write

Class:

AlarmClearing,

AlarmStatus

Type:

Setup / run

mode select

Synchro input

signal status

Read\write,

Write 0 to clear

40257,

40258

[0100,

0101]

Class: State

Type: Read-only

Angle

(cumulative)

[The value can

exceed +\- 360.0

degrees]

40264

[0107]

40513

[0200]

Class: State

Type: Read-only

Class:

Configuration

Type: Write-only,

Tap, neutral

Draghand reset

control

Write one to clear

40516

[0203]

Class: State

Type: Read-only

High tap

draghand

000000000000000s

LSB (s)

0 – run mode

1 – setup mode

This bit must be 1 before any

program parameter can be changed

000000000000000s

LSB (s)

0 – OK input signal is present

1 – ALARM input signal is lost

seeeeeeeemmmmmmm MSW

mmmmmmmmmmmm LSW

IEEE 754-1985 single precision float

MSW = [0100] LSW = [0101]

tttttttt0000nnnn

[“0000” are unused bits]

“t”= 8-bit tap number

“n”= 4-bit neutral number

(both in binary)

00000000000000HL

“H”= high draghand

“L”= low draghand

0 ignored

1 = reset

tttttttt0000nnnn

[“0000” are unused bits]

”= 8-bit tap number

“t

“n

”= 4-bit neutral number

(both in binary)

22

Page 23

Register

Class & Type Function: Binary Format:

Address:

Decimal

[hex]

40519

[0206]

Class: State

Type: Read-only

Low tap

draghand

tttttttt0000nnnn

[“0000” are unused bits]

“t

”= 8-bit tap number

“n”= 4-bit neutral number

(both in binary)

40520

[0207]

Class:

Configuration

Type: Read\write

Draghand

counter start

visit

000000000000000s

LSB (s)

0 – First

1 – Last

Selects whether time since first or last

draghand visit to a tap is reported.

40769

[0300]

Class: State

Type: Read-only

Internal relay

states

00000000000000HL

“H”= high relay

“L”= low relay

If relay is on, bit = 1, else bit = 0

40777,

40778

[0308,

0309]

Class: State

Type: Read\write

Total tap change

count

ssssssssssssssss MSW

ssssssssssssssss LSW

MSW = [0308] LSW = [0309]

[NOTE: Always write both the high

(MSW) and low (LSW) words with

consecutive writes; do not write any

other register address between these two

writes.]

40785

[0310]

Class: State

Type: Read-only

Tap, neutral

with greatest

on-tap deviation

tttttttt0000nnnn

[“0000” are unused bits]

”= 8-bit tap number

“t

“n

”= 4-bit neutral number

(both in binary)

40786,

40787

[0311,

0312]

Class: State

Type: Read-only

Max measured

on-tap deviation

seeeeeeeemmmmmmm MSW

mmmmmmmmmmmm LSW

IEEE 754-1985 single precision float

MSW = [0311] LSW = [0312]

23

Page 24

Register

Address:

Decimal

[hex]

40801

[0320]

40802

[0321]

40803

[0322]

40804

[0323]

40805

[0324]

40806

[0325]

Class & Type Function: Binary Format:

Class:

AlarmClearing,

AlarmStatus

Type:

On-tap alarm

state

000000000000000s

LSB (s

)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Type:

Read\write,

One-direction

alarm state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Type:

Instability alarm

state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Type

Loss-of-signal

alarm state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Type:

Change up-to

\ down-to alarm

state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Pass-throughneutral alarm

state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Type:

Read\write,

Write 0 to clear

24

Page 25

Register

Address:

Decimal

[hex]

40807

[0326]

40808

[0327]

40809

[0328]

40833

[0340]

40834

[0341]

40835

[0342]

40836

[0343]

40837

[0344]

40838

[0345]

Class & Type Function: Binary Format:

Class:

AlarmClearing,

AlarmStatus

Type:

Total tap change

alarm state

000000000000000s

LSB (s

)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Type:

Low tap alarm

state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class:

AlarmClearing,

AlarmStatus

Type

High tap alarm

state

000000000000000s

LSB (s)

0 – OK

1 – ALARM

Read\write,

Write 0 to clear

Class: AlarmStatus

Type: Read-only

Class: AlarmStatus

Type: Read-only

Class: AlarmStatus

Type: Read-only

Days since

asserting On-tap

alarm

Days since

asserting Onedirection alarm

Days since

asserting

Instability

dddddddddddddddd

“d” = 10ths of a day

dddddddddddddddd

“d” = 10ths of a day

dddddddddddddddd

“d” = 10ths of a day

Alarm

Class: AlarmStatus

Type: Read-only

Days since

asserting

Loss-of –Signal

dddddddddddddddd

“d” = 10ths of a day

Alarm

Class: AlarmStatus

Type: Read-only

Days since

asserting Upto\down-to

dddddddddddddddd

“d” = 10ths of a day

alarm

Class: AlarmStatus

Type: Read-only

Days since last

Pass–throughneutral

dddddddddddddddd

“d” = 10ths of a day

25

Page 26

Register

Address:

Decimal

[hex]

40839

[0346]

40840

[0347]

40841

[0348]

40842

[0349]

40843

[034A]

40865

[0360]

40869

[0364]

40870

[0365]

41025

[0400]

Class & Type Function: Binary Format:

Class: AlarmStatus

Type: Read-only

Days since

asserting Total

tap changes

dddddddddddddddd

“d” = 10ths of a day

alarm

Class: AlarmStatus

Type: Read-only

Class: AlarmStatus

Type: Read-only

Class: AlarmStatus

Type: Read-only

Class: AlarmStatus

Type: Read-only

Class:

AlarmClearing,

StatisticsResetting

Type:

Write-only,

Days since

asserting Low

tap alarm

Days since

asserting High

tap alarm

Days since Low

draghand hit

new extremum

Days since High

draghand hit

new extremum

dddddddddddddddd

“d” = 10ths of a day

dddddddddddddddd

“d” = 10ths of a day

dddddddddddddddd

“d” = 10ths of a day

dddddddddddddddd

“d” = 10ths of a day

On-tap reset 000000000000000s

LSB (s)

0 = reset

1 = ignored

Write 0 to clear

Class:

AlarmClearing,

StatisticsResetting

Type:

Up-to/down-to

reset

000000000000000s

LSB (s)

0 = reset

1 = ignored

Write-only,

Write 0 to clear

Class:

AlarmClearing,

StatisticsResetting

Type:

Pass-throughneutral reset

000000000000000s

LSB (s

)

0 = reset

1 = ignored

Write-only,

Write 0 to clear

Class: state

Type:

Analog output 0000aaaaaaaaaaaa

12-bit number (in binary)

Read-only

26

Page 27

Register

Address:

Decimal

[hex]

44097

[1000]

44353

[1100]

44354,

44355

[1101,

1102 ]

44356

[1103]

44357

[1104]

44358

[1105]

44867

[1302]

44868

[1303]

Class & Type Function: Binary Format:

Class:

Configuration

Type:

Operating mode

00000000000mmmmm

LSBs (mmmmm

)

(see list of modes on page 34)

Read\write

Class:

Configuration

Number of taps 000000000nnnnnnn

7-bit number (in binary)

Type:

Read\write

Class:

Configuration

Type:

Read\write

Degrees per

segment

seeeeeeeemmmmmmm MSW

mmmmmmmmmmmm LSW

IEEE 754-1985 single precision float

MSW = [1101] LSW = [1102]

Class:

Configuration

Type:

Read\write

Class:

Configuration

Type:

Read\write

Class:

Configuration

Type:

Read\write

Class:

Configuration

Number of

neutrals

Neutral start

segment

Display

“r”&“L”

Preset tap

000000000000nnnn

LSBs (nnnn)

Up to 8 neutrals, in binary.

If field value > 8, clamps to 8

ssssssssssssssss

16 bits, first neutral tap

000000000000000d

LSB(d

)

0 = disabled

1 = enabled

ssssssssssssssss

16 bits, preset tap no.

Type:

Read\write

Class:

Configuration

Type:

Write-only

Load/clear

preset control

00000000000000cc

LSBs (cc)

00 – no operation

01 – clear offset

10 – load preset

27

Page 28

Register

Address:

Decimal

[hex]

45121

[1400]

45122

[1401]

45155

[1422]

45156

[1423]

45633

[1600]

45634

[1601]

Class & Type Function: Binary Format:

Class:

Configuration

Type:

Read\write

Class:

Configuration

Type:

Read\write

Class:

Configuration,

AlarmClearing

Type:

Display blank 000000000000000b

LSB(b)

0 = disabled

1 = enabled [display will blank]

Menu mode 000000000000000m

LSB (m)

0= numeric

1=alphanumeric

Auto reset 27 0000000 e

LSB (e

)

0 = disabled

1 = enabled

Read\write

Class:

Configuration,

AlarmClearing

Type:

Auto reset 25 0000000 e

LSB (e)

0 = disabled

1 = enabled

Read\write

Class:

Configuration

Type:

Read\write

RS-232 mode 0000000000000rrr

LSBs (rrr)

000 = Serial disabled

001 = datalogger mode

010 = polled mode

011 = sampled mode

100 = command

101 = reserved N/A

110 = RS485 Modbus

111 = remote display driver

Class:

Configuration

Type:

Read\write

Baud 000000000000bbbb

LSBs (bbbb)

0000 = 300 0001 = 1200

0010 = 2400 0011 = 4800

0100 = 9600 0101 = 14400

0110 = 19200 0111 = 28800

1000 = 38400 1001 = 57600

1010 = 76800

28

Page 29

Register

Address:

Decimal

[hex]

45635

[1602]

45636

[1603]

45637

[1604]

45638

[1605]

45889,

45890

[1700,

1701]

45891

[1702]

45892

[1703]

45893

[1704]

Class & Type Function: Binary Format:

Class:

Configuration

Type:

Read\write

Class:

Configuration

Type:

Read\write

Word length 000000000000000w

LSB (w

)

0 = 7 bits

1 = 8 bits

Parity 00000000000000pp

LSBs (pp)

00 = none

01 = even

10 = odd

Class:

Configuration

Type:

Read\write

Class:

Configuration

Type:

Stop bits 000000000000000s

LSB (s)

0 = 1 bits

1 = 2 bits

Address 00000000aaaaaaaa

LSBs (aaaaaaaa)

8-bit serial multidrop address

Read\write

Class:

Configuration

Type:

Read\write

Total tap change

counter limit

seeeeeeeemmmmmmm MSW

mmmmmmmmmmmm LSW

IEEE 754-1985 single precision float

MSW = [1700] LSW = [1701]

(in thousands of counts)

Class:

Configuration

Type:

Read\write

Total tap change

count alarm

relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Type:

Reference year

for Total tap

change counter

0000yyyyyyyyyyyy

“y” = Year

(in binary)

Read\write

Class:

Configuration

Type:

Read\write

Reference date

for Total tap

change counter

0000mmmm 000ddddd

“m” = Month (January = 1)

“d” = Day (1-31)

(in binary)

29

Page 30

Register

Address:

Decimal

[hex]

46145

[1800]

46146

[1801]

46147

[1802]

46148

[1803]

46401,

46402

[1900,

1901]

46403

[1902]

46404

[1903]

46405

[1904]

Class & Type Function: Binary Format:

Class:

Configuration

Type:

On-tap guard

band limit

dddddddddddddddd

“d” = tenths of a degree

(in binary)

Read\write

Class:

Configuration

Type:

Read\write

On-tap alarm

relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Type:

Reference year

for On-tap

counter

0000yyyyyyyyyyyy

“y” = Year

(in binary)

Read\write

Class:

Configuration

Type:

Read\write

Class:

Configuration

Type:

Read\write

Reference date

for On-tap

counter

Change up-to /

down-to counter

limit

0000mmmm 000ddddd

“m” = Month

“d” = Day

(in binary)

seeeeeeeemmmmmmm MSW

mmmmmmmmmmmm LSW

IEEE 754-1985 single precision float

MSW = [1900] LSW = [1901]

(in thousands of counts)

Class:

Configuration

Type:

Read\write

Change up-to /

down-to counter

alarm relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Type:

Reference year

for up-to /

down-to counter

0000yyyyyyyyyyyy

“y” = Year

(in binary)

Read\write

Class:

Configuration

Type:

Read\write

Reference date

for up-to /

down-to counter

0000mmmm 000ddddd

“m” = Month

“d” = Day

(in binary)

30

Page 31

Register

Address:

Decimal

[hex]

46657

[1A00]

46658

[1A01]

46913

[1B00]

46914

[1B01]

47169

[1C00]

47170

[1C01]

47425

[1D00]

47426

[1D01]

Class & Type Function: Binary Format:

Class:

Configuration

Type:

Pass-throughneutral limit

dddddddddddddddd

“d” = tenths of a day

(in binary)

Read\write

Class:

Configuration

Type:

Read\write

Pass-throughneutral counter

alarm relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Type:

One-direction

counter limit

0000000000ssssss

LSBs(ssssss)

6-bits, number of taps

Read\write

Class:

Configuration

Type:

Read\write

One-direction

counter alarm

relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Low tap relay

limit

ssssssssssssssss

16-bit signed word, low tap limit

Type:

Read\write

Class:

Configuration

Type:

Read\write

Low tap alarm

relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

High tap relay

limit

ssssssssssssssss

16-bit signed word, high tap limit

Type:

Read\write

Class:

Configuration

Type:

Read\write

High tap alarm

relay

00000000000000 rr

LSBs (rr

)

00 – OFF

01 – LO Relay

10 – HI Relay

31

Page 32

Register

Address:

Decimal

[hex]

47938

[1F01]

47939

[1F02]

47940

[1F03]

48193

[2000]

48194

[2001]

48705

[2200]

Class & Type Function: Binary Format:

Class:

Configuration

Type:

Read\write

Tap change

acknowledge

relay

00000000000000 rr

LSBs (rr

)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Acknowledge

relay delay time

000000000sssssss

“s” = Delay in tenths of a second

Type:

Read\write

Class:

configuration

Acknowledge

relay duration

time

000000000sssssss

“s” = Duration in tenths of a second

Type:

Read\write

Class:

Configuration

Type:

Read\write

“FA 25” error

relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class:

Configuration

Type:

Read\write

“FA 27” error

relay

00000000000000 rr

LSBs (rr)

00 – OFF

01 – LO Relay

10 – HI Relay

Class: State

Type:

Read\write

Tap index select

00000000 uuuuuuuu

Unsigned byte Zero-based index of tap

( value <= 39 decimal)

** NOTE: ALWAYS initially write the

tap index select register before reading

any of the tap attribute registers 0x3001

through 0x3007; that single write will

suffice until it’s desired to select a

different tap index, at which time another

write of the new tap index to this register

is required. Also write this register if a

restart may have occurred since the last

write; i.e. the value of tap index select is

not retained over a reset.

32

Page 33

Register

Address:

Decimal

[hex]

48706

[2201]

48707

[2202]

48708

[2203]

48709,

48710

[2204,

2205]

48711,

48712

[2206,

2207]

Class & Type Function: Binary Format:

Class: State

Type: Read-only

Tap number

corresponding

to Tap index

ssssssssssssssss

Signed 16-bit word

select

Class: State

Type: Read-only

Neutral number

corrresponding

to Tap index

uuuuuuuuuuuuuuu

Unsigned 16-bit word

select

Class: State

Type: Read-only

Class: State

Type: Read-only

Max On-Tap

deviation

corresponding

to Tap index

select

Upper and lower

words of Up-to

count

corresponding

to Tap index

select

ssssssssssssssss

Signed 16-bit word denoting tenths of a

degree

uuuuuuuuuuuuuuuu MSW

uuuuuuuuuuuuuuuu LSW

Unsigned 32-bit longword denoting upto count.

MSW = [3004] (upper)

LSW = [3005] (lower)

** NOTE: To obtain a consistent 32-bit

value, ALWAYS read 0x3004 BEFORE

0x3005; DO NOT read or write any

other register address between these

reads.

Class: state

Type: Read-only

Upper and lower

words of

Down-to count

corresponding

to

Tap index select

uuuuuuuuuuuuuuuu MSW

uuuuuuuuuuuuuuuu LSW

Unsigned 32-bit longword denoting

down-to count

MSW = [3006] (upper)

LSW = [3007] (lower)

** NOTE: To obtain a consistent 32-bit

value, ALWAYS read 0x3006 BEFORE

0x3007; DO NOT read or write any

other register address between these

reads.

33

Page 34

2.4 Operating Modes:

The model 1250-LTC has six operating modes. Each mode causes the 1250-LTC to

function differently. Determine which of the following operating modes is best suited to your

application. The proper mode will depend upon the desired numbering of the taps and where

the neutral taps are located:

16 = Base 1 Uni-polar Segmented Linear Analog (Neutrals can be at any tap number)

17 = Base 1 Uni-polar Segmented Stepped Analog (Neutrals can be at any tap number)

18 = Base 0 Uni-polar Segmented Linear Analog (Neutrals always at “0”)

19 = Base 0 Uni-polar Segmented Stepped Analog (Neutrals always at “0”)

20 = Bi-polar Segmented Linear Analog (Neutrals always at “0”)

21 = Bi-polar Segmented Stepped Analog (Neutrals always at “0”)

34

Page 35

Modes 16 & 17: Base 1 Uni-polar Segmented

These modes are used for LTC monitoring when the lowest tap number is 1. There

may be multiple neutral taps. They can be located anywhere between the lowest and highest

taps as long as they are grouped together in one section. Mode 16 has a linear analog output

that continuously varies with LTC shaft position. Mode 17 has a stepped analog output that

jumps with each tap change. To select this operating mode use the OP 2, Func, MODE

command to change the value to “16” or “17”.

Figure 2.3 Base 1 Uni-polar Mode Analog Output

Programming Example:

A typical transformer Load Tap Changer application with taps numbered 1 to 32,

o

2 neutral taps (17-1 and 17-2), with 9.5

per tap, presently set on tap “18” would be

programmed as follows:

OP 2 Operating mode = 17

OP 20 Number of taps = 33

OP 21 Degrees per tap = 9.5000

OP 22 Number of neutrals = 2

OP 23 Lowest neutral tap = 17

OP 27 Present tap = 18

OP 28 Load present tap

35

Page 36

Modes 18 & 19: Base 0 Uni-polar Segmented These modes are used for LTC monitoring

when the lowest tap number is 0. There may be multiple neutral taps, but they can only be

located at tap 0. Mode 18 has a linear analog output that continuously varies with LTC shaft

position. Mode 19 has a stepped analog output that jumps with each tap change. To select

this operating mode use the OP 2, Func, MODE command to change the value to “18” or

“19”.

Figure 2.4 Base 0 Uni-polar Mode Analog Output

Programming Example:

A typical transformer Load Tap Changer application with taps numbered 0 to 16,

2 neutral taps, with 10.5o per tap, presently set on tap “9” would be programmed as follows:

OP 2 Operating mode = 19

OP 20 Number of taps = 18

OP 21 Degrees per tap = 10.500

OP 22 Number of neutrals = 2

OP 27 Present tap = 9

OP 28 Load present tap

36

Page 37

Modes 20 & 21: Bi-polar Segmented These modes are used for LTC monitoring when the

neutral tap(s) are in the center of the dial and there is an equal number of raised and lowered

taps. There may be multiple neutral taps, but they can only be located at tap 0. Mode 20 has

a linear analog output that continuously varies with LTC shaft position. Mode 21 has a

stepped analog output that jumps with each tap change. To select this operating mode use the

OP 2, Func, MODE command to change the value to “20” or “21”.

Figure 2.5 Bi-polar Mode Analog Output

Programming Example:

A typical transformer Load Tap Changer application with 16 raised and 16 lowered

o

taps, 3 neutral taps, with 10

per tap, presently set on tap “2L” would be programmed as

follows:

OP 2 Operating mode = 21

OP 20 Number of taps = 35

OP 21 Degrees per tap = 10.000

OP 22 Number of neutrals = 3

OP 27 Present tap = -2

OP 28 Load present tap

37

Page 38

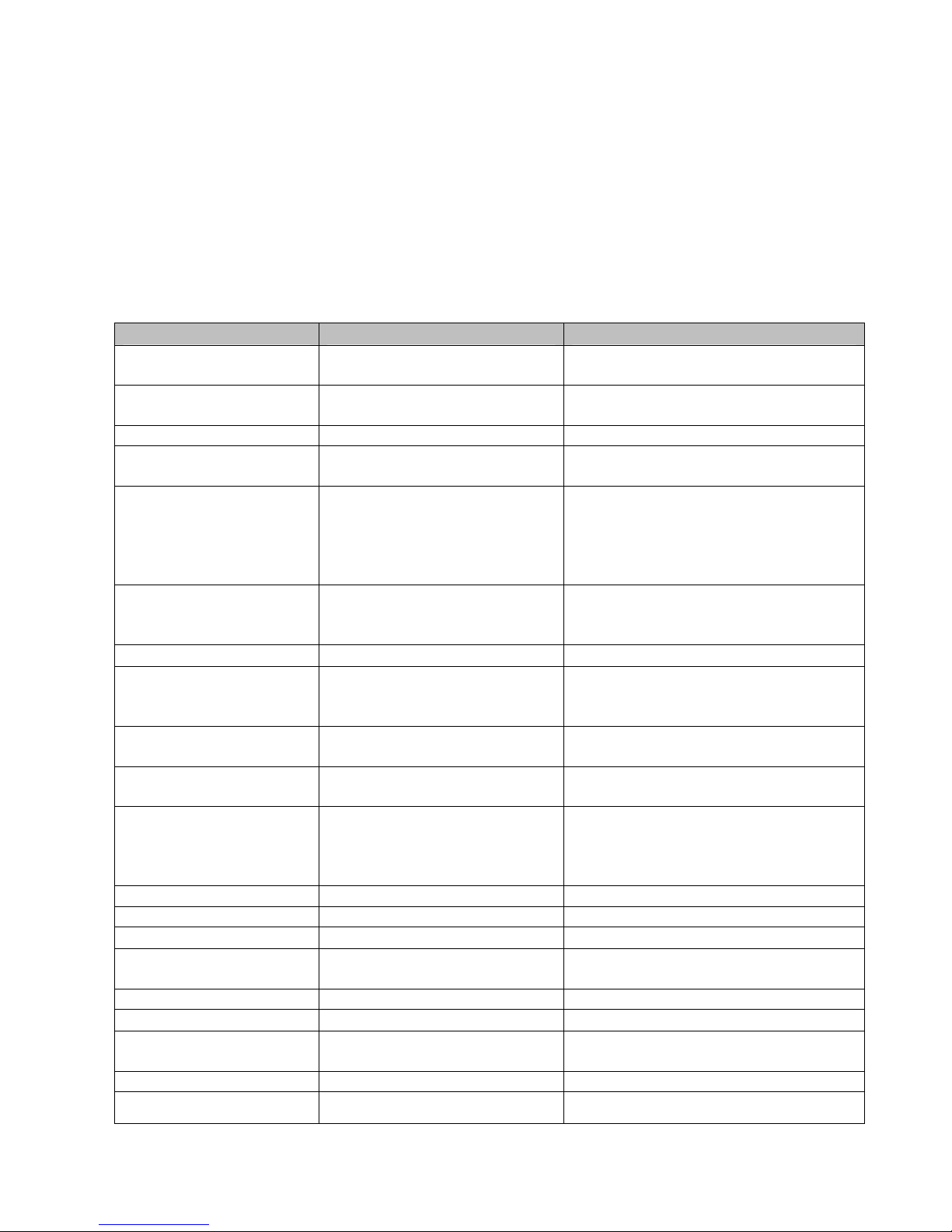

2.5 Programming Notes:

If the Degrees Per Tap value is not known, the 1250-LTC can be used to determine

this value. Follow these steps to determine the Degrees Per Tap value:

1) Enter the Programming Menu and select OP 19 (Degrees Mode) and press the ENTER

key.

3) The 1250-LTC should read a number from 0.0 to 359.9 with 1 decimal place.

4) Move the LTC to as many taps as possible. Record each tap number and the

corresponding degree reading displayed on the 1250-LTC in the table below.

5) Subtract one degree reading from the next, for each tap, and write it in the “Difference”

column in the table.

6) The differences should all be approximately the same. Take an average of the numbers in

the Difference column. The result is the Degrees Per Tap number that the 1250-LTC

needs for the OP 21, D SEG, or DEGSEG command.

7) Press the ENTER key to return to the Programming Menu.

Tap Number Degrees Difference Tap Number Degrees Difference

There is no programming required for the Analog Output. It automatically spans the full

range of taps, lowest tap to low output, highest tap to high output.

Programming for the High/Low Relays option is covered in Section 3.2, page 40.

Programming for the Serial ASCII Communication option is covered in Section 2.2, page 13.

Programming for the Serial MODBUS Communication option is covered in Section 2.3, page

18.

38

Page 39

3.0 OPTIONS

The standard Model 1250-LTC is configured with three options – Analog Output,

Hi/Lo Relays, and a Serial Port (RS-232 or RS-485). One more option is available – Input

Isolation. This section describes general use of each option, including wiring and

programming for each option.

3.1 Analog Output Option “-0”, “-1”, “-2”, “-4”

The analog output on the 1250-LTC may be used to feed position information to an

LTC Controller, a remote monitoring system such as SCADA, RTU or a remote indicator

such as the INCON model 1511-Z. In the all modes, the analog output automatically spans

between the highest and lowest taps.

Wiring:

The 4-20mA analog output option must be wired with an external power supply of

15.0 to 24.0 volts DC in series with the analog output current loop. (See Figure 1.3, page 7)

The INCON Model 1945 is available for this purpose. All other analog output options are

self-powered. Refer to Table 3.1 below for analog output load limits.

Table 3.1 Analog Output Load Limits

Analog Output: Load Minimum Load Maximum

0 to 1 mA Zero Ohms 10K Ohms

+/- 1 mA Zero Ohms 10K Ohms

0 to 2 mA Zero Ohms 5K Ohms

4-20 mA Zero Ohms 500 Ohms

Note:

If the presence of high voltage AC “ripple” is found on the analog output terminals, it

is generally not a problem with the 1250-LTC itself. Check the isolation of all field wiring

with respect to earth ground. All wiring should be completely isolated from ground. See

Section 3.5, page 48 Input Isolation Option. Contact INCON Technical Service for assistance

if the problem persists.

39

Page 40

3.2 High / Low Relay Limits Option “-R”

In the 1250-LTC, the High / Low Relays serve as alarm annunciators for the many

programmable limits associated with expanded LTC monitoring. The (two) relays are

normally open, dry contacts. Each relay may have one or more of the alarm limits assigned to

it. They may be used as feedback in a control system or as an alarm when the parameter has

reached its desired limits.

When the Tap Change Acknowledgement is not used, it is recommended that the

desired alarms be divided into two groups: Warning (LO) and Danger (HI). Less important

parameters should cause one relay (Warning) to turn on and more important parameters

should cause the other relay (Danger) to turn on. This way, the level of seriousness of an

alarm could be communicated, when remotely monitored. When the Tap Change

Acknowledgement is assigned to one relay (HI or LO), all other desired alarms must be

assigned to the other relay (LO or HI).

When the LO relay is asserted, the LED above the DOWN button, below the digital

display, will flash. When the HI relay is asserted, the LED above the UP button, below the

digital display, will flash. Note that the LED’s will flash even if the “-R” Relay Option is

not installed. This will alert an operator that an alarm limit has been reached, even on

an instrument without Relays. In addition to flashing the HI & LO Relay LED’s, an alarm

code(s) will be momentarily displayed, every 10 seconds, to explain which specific alarm(s) is

causing the alarm condition.

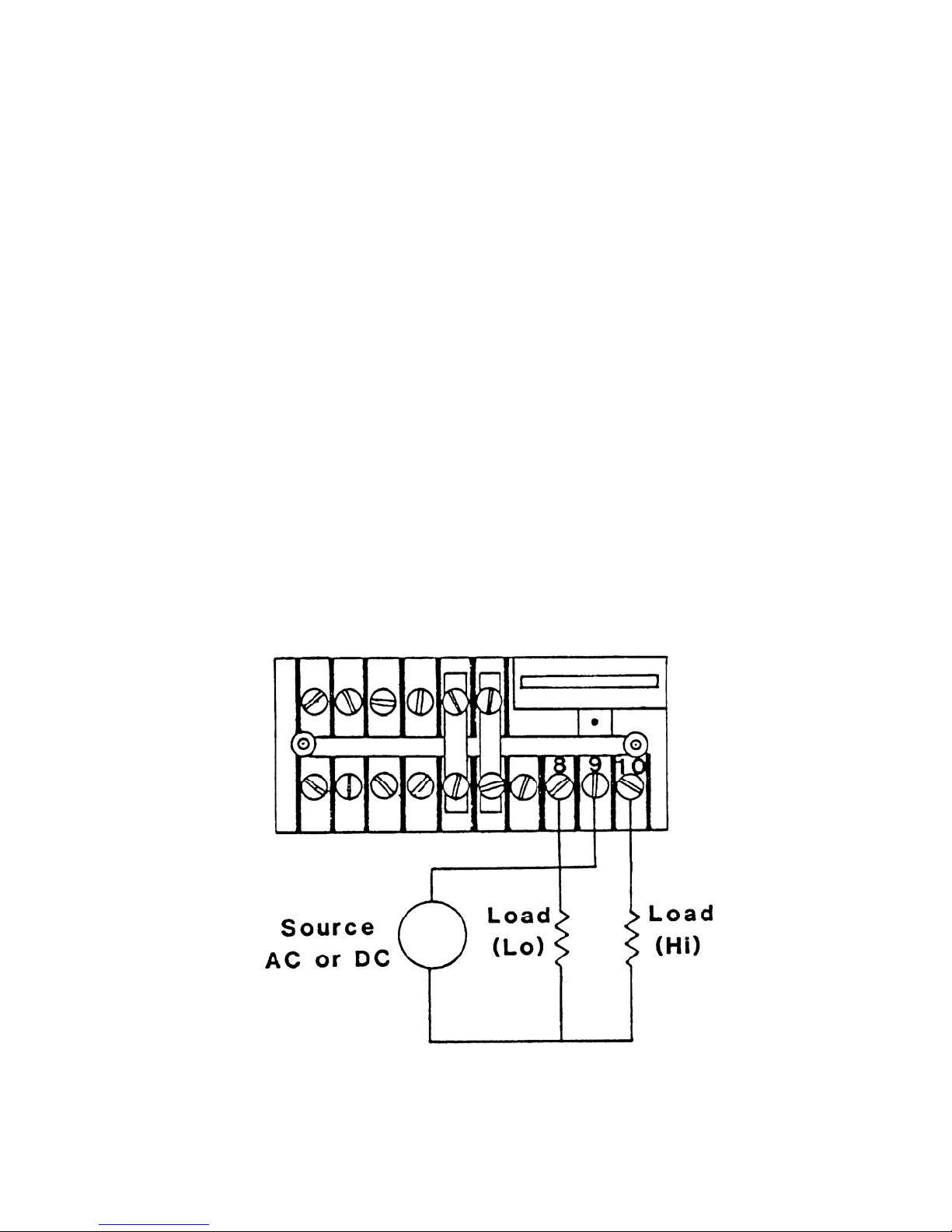

Figure 3.1 Relay Field Wiring Diagram

40

Page 41

Since the instrument has only two relays, and eight possible uses for those two relays,

there may be times when a relay is being asserted by more than one alarm. The relay actions

fall into three categories: Momentary; Transient; and Persistent. A Momentary action, as

the name implies, closes the relay for only a moment, then opens the relay. The Tap Change

Acknowledge is the only Momentary use of a relay. A Transient action is one that keeps the

relay closed as long as a condition remains valid. As soon as the condition goes away, the

relay will open. The High Tap & Low Tap Alarms and the FA 25 and FA 27 Error

Alarms are the only Transient uses of a relay. A Persistent action is one in which the relay

remains closed until it is manually reset by the operator. The Total Tap Change Count

Alarm, On-Tap Alarm, Up-To & Down-To Change Alarms, Pass Through Neutral

Alarm, One Direction Change Alarm are Persistent uses of a relay.

Relay Assertion Priority: Any Persistent relay action takes priority over any

Transient or Momentary action. The Tap Change Acknowledgement Relay can not be

assigned to the same relay as another alarm.

3.2.1 Tap Change Acknowledgement Relay

The 1250-LTC can momentarily close a relay contact following every detected tap

position change. The user can program a delay time of 0.1 to 9.9 seconds, which causes the

relay to wait before asserting. The user can also program a duration time of 0.1 to 9.9

seconds, which causes the relay to hold its assertion before turning off.

Use the OP 3, tCrLY, ACKRLY command to choose which relay output (OFF, LO

or HI) will be asserted following every tap position change. When this value is set to “OFF”

this function is disabled. Do not assign another alarm to the same relay assigned to for

Tap Change Acknowledgement. Use the OP 4, tCrdL, ACKDLY command to set the

delay time. Use the OP 5, tCrLt, ACKHOLD command to set the duration time.

3.2.2 High Tap Relay and Low Tap Relay

The 1250-LTC can close a relay contact when the LTC moves beyond programmable

upper and lower position limits. When the LTC tap position value reaches the Low Relay

limit, the assigned Low Tap Relay turns on, the appropriate Relay LED will light up, and the

alarm code “LOtAP” will be displayed momentarily. When the position value rises above the

Low Relay limit, the Low Tap Relay & LED will turn off and the alarm code will not be

displayed. When the tap position value reaches the High Relay limit the assigned High Tap

Relay turns on, the appropriate Relay LED will light up, and the alarm code “HItAP” will be

displayed momentarily. When the value falls below the High Relay limit, the High Tap Relay

& LED turn off and the alarm code will not be displayed. The user can separately program

which relays will assert for the upper and lower position limits.

Use the OP 15, rL Lt, LTLMT command to set the Low Tap Relay Limit and the

OP 17, rL Ht, HTLMT command to set the High Tap Relay Limit. Use the OP 16, LtrLY,

LTRLY command to select which relay (OFF, LO or HI) asserts when the Low Tap Relay

Limit is reached. Use the OP 18, HtrLY, HTRLY command to select which relay (OFF, LO

or HI) asserts when the High Tap Relay Limit is reached. These are Transient relay actions.

When these values are set to “OFF” this functions are disabled.

41

Page 42

3.2.3 Total Tap Change Count Relay

The 1250-LTC can count the number of tap position changes and turn on a relay and

LED when a programmed limit (10 to 999,990 counts) is reached. The alarm code “ttCLt”

will also be displayed momentarily. The counter can be pre-set to any number. A date can be

entered for reference purposes when the count is preset. (This date is stored in memory for

reference only, it will not increment as time passes. It can be read through the Front Panel or

the serial port.) The user can program which relay will assert when the Total Tap Change

Count limit is reached. Please note that the counter limit and pre-set values are set in

THOUSANDS of tap changes. For example, if an alarm is required at 125,000 operations,

set the alarm limit to “0125.0”. If it is known that the LTC already has 2,300 operations, preset the counter to “0002.3”.

Use the OP 55, ttCLt, TTCLMT command to set the Total Tap Change Count Limit.

Use the OP 56, ttrLY, TTCRLY command to select which relay (OFF, LO or HI) asserts

when the Total Tap Change Count Limit is reached. When this value is set to “OFF” this

function is disabled. Use the OP 57, ttPrE, TTCPRE command to pre-set the Total Tap

Change Counter value. If the alarm relay is asserted, it will be cleared when the counter is

preset to a value lower than the alarm limit. Use the OP 58, ttPdt, TTCDATE command to

enter a reference date. To do this using the programming menu: Select OP 58, ttPdt and

press the ENTER key. First, set the Day of the month value and press the ENTER key. Next,

set the Month value and press the ENTER key. Finally, set the Year value and press the

ENTER key. Use the OP 59, ttCdS, DUMP command to display the present counter value

and the reference date. The counter value will be displayed for 2 seconds, and then the date

will scroll across the display. This will repeat until the ENTER key is pressed, which will exit

the command.

3.2.4 On-Tap Alarm Relay

The 1250-LTC has the accuracy and resolution to monitor minute differences in LTC

tap position. Ideally, the LTC should always stop in the exact center of each tap position. A

properly functioning LTC should consistently stop within a tolerable band of degrees, with

every tap change. As the mechanism wears or if something breaks, the LTC may begin to

stop in positions further from the center of the tap position, on one or more taps.

The 1250-LTC can be programmed to give an alarm when it detects that the LTC has

stopped in a position that is outside the tolerable band of degrees. The width of this band of

tolerable error is programmable in degrees, with 0.1 degree resolution.

A three second time window is given for the LTC to be outside of the acceptable

Guard Band area. After three seconds, if the LTC is found in the “Error Zone”, the On-Tap

Alarm Relay will assert.

42

Page 43

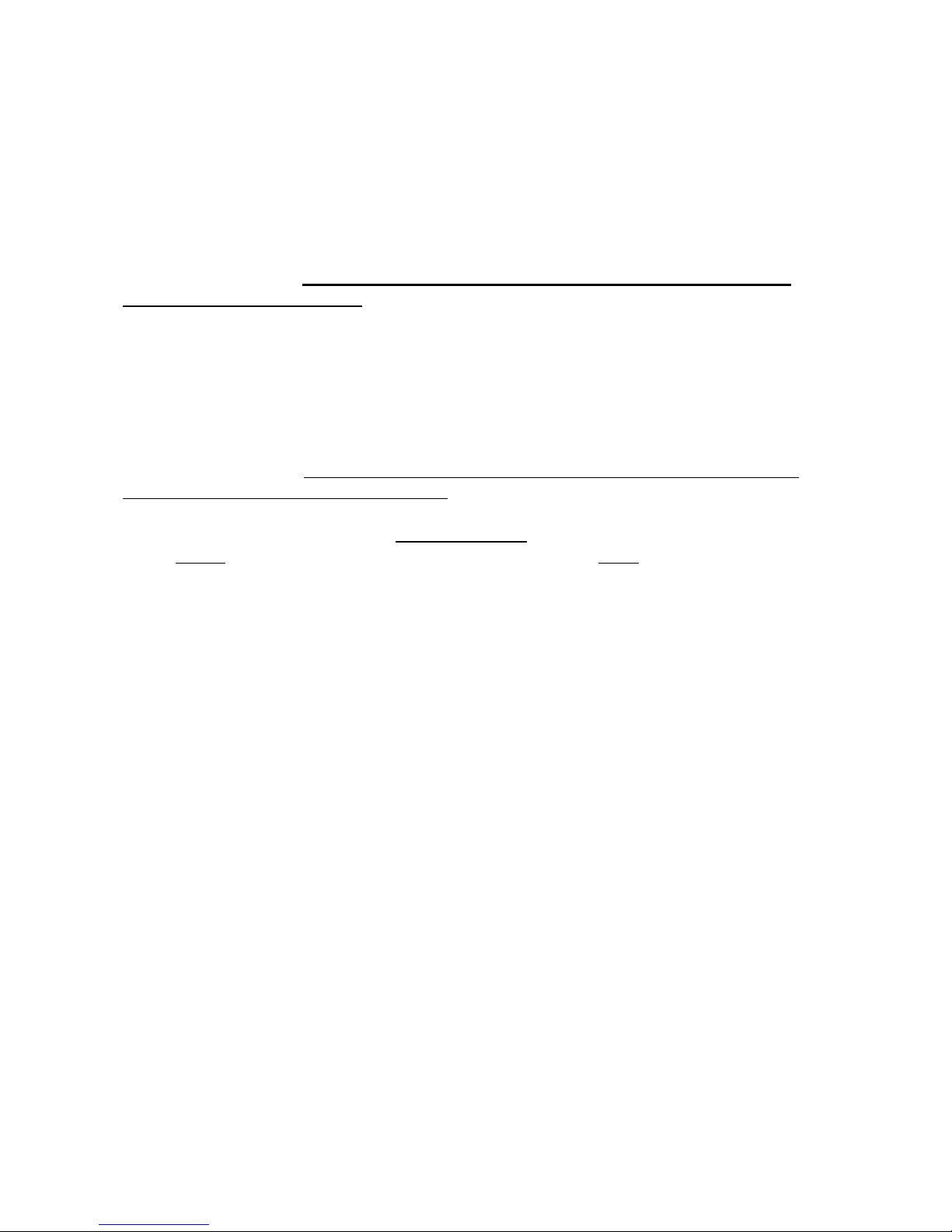

Figure 3.2 On-Tap Example

Figure 3.1 is an example of an LTC with 10.0 degrees per tap position. This LTC

should stop at the “zero degrees” center point on every tap, plus or minus a programmable

tolerance (“Guard Band”) of 1.5 degrees (green area). If the LTC ever stops more than 1.5

degrees from the center (red area) of any tap, the On-Tap Alarm Relay will be asserted and an

LED will flash. The alarm code “OtGLt” will be displayed momentarily.

Use the OP 62, OtGLt, OTGDLMT command to set the On-Tap Guard Band

tolerance in degrees, +/- from zero. Use the OP 63, OtrLY, OTRLY command to select