Page 1

SIGMA-CP Issue 1 November 2011

Conventional Fire Control Panel AFP-2516

Operation and Maintenance Manual

Page 2

Man-1078_Sigma_CP_AUS_12

Page 2 of 29

I

ndex Page

1 Warning ......................................................................................................................... 4

2 Introduction .................................................................................................................... 5

3 Safety and Mounting ........................................................................................................ 5

3.1 Safety .................................................................................................................................... 5

3.2 Mounting ................................................................................................................................ 6

4 Technical specification ..................................................................................................... 7

6 Using intrinsically safe barriers.......................................................................................... 9

7 Control panel fascia ....................................................................................................... 10

8 Connecting to the circuit board ....................................................................................... 11

9 Software revision number .............................................................................................. 11

10 Detection zone wiring .................................................................................................... 12

11 Sounder circuit wiring .................................................................................................... 13

12 Connection to remote control terminals ........................................................................... 13

13 Aux 24V DC supply ........................................................................................................ 14

14 Connection to relay contacts........................................................................................... 14

15 Connection to Accessory modules ................................................................................... 14

16 Panel operation ............................................................................................................. 15

16.1 Normal condition ................................................................................................................... 15

16.2 Fire condition ........................................................................................................................ 15

16.3 Silence/Sound Alarms ............................................................................................................ 15

16.4 Reset ................................................................................................................................... 15

16.5 Zone fault ............................................................................................................................. 15

16.6 Sounder fault ........................................................................................................................ 15

16.7 Power fault ........................................................................................................................... 15

16.8 System fault ......................................................................................................................... 15

16.9 Lamp test ............................................................................................................................. 15

16.10 Buzzer Silence ....................................................................................................................... 15

16.11 Disablements ........................................................................................................................ 16

16.12 Disable zones ........................................................................................................................ 16

16.13 Disable sounders ................................................................................................................... 16

16.14 Activate delays ...................................................................................................................... 16

16.15 Disable fault contact .............................................................................................................. 16

16.16 Test mode ............................................................................................................................ 16

17 Configuration options ..................................................................................................... 16

18 Watchdog reset switch ................................................................................................... 19

Page 3

Man-1078_Sigma_CP_AUS_12

Page 3 of 29

19 Processor reset switch ................................................................................................... 20

20 Internal indications – troubleshooting .............................................................................. 20

20.1 Mains fail .............................................................................................................................. 20

20.2 Batt fail ................................................................................................................................ 20

20.3 CPU fault .............................................................................................................................. 20

20.4 Aux 24V fault ........................................................................................................................ 20

20.5 Batt low ................................................................................................................................ 20

20.6 Earth fault ............................................................................................................................ 20

20.7 Sys fuse fault ........................................................................................................................ 20

20.8 S1 fault and S2 fault .............................................................................................................. 20

20.9 Comms fault ......................................................................................................................... 21

21 AIM – Australian Interface Module .................................................................................. 21

21.1 ACF – Ancillary Control Function............................................................................................. 22

21.1.1 Outputs ................................................................................................................................................. 22

21.1.2 Configuration: ...................................................................................................................................... 22

21.1.3 Controls – only available at Level 2 ..................................................................................................... 22

21.2 Door Holder Output ............................................................................................................... 23

21.3 ASE Outputs (Alarm Signalling Equipment) ............................................................................. 23

21.4 Installation ........................................................................................................................... 23

21.5 Configuration. ....................................................................................................................... 23

22 Power supply ................................................................................................................ 24

23 Maintenance ................................................................................................................. 25

24 Zone designation label ................................................................................................... 25

25 Record of Configuration ................................................................................................. 26

Page 4

Man-1078_Sigma_CP_AUS_12

Page 4 of 29

1 Warning

Sounders can only be used on detection circuits if H

ochiki YBO-R/6PA detector bases are

used.

To disable sounders on detector all lines, ensure that configuration mode 25 is not set.

To disable sounders on individual detector circuits, set configuration mode 25 and disable

individual circuits through the setting of C1 to C8.See Section 17Table 8.

DETECTOR BASES WILL BE DAMAGED IF THE INCORRECT

MODEL IS USED ON CIRCUITS WHICH HAVE SOUNDERS

ENABLED.

DAMAGE DUE TO INCORRECT CONFIGURATION WILL NOT

COVERED UNDER WARRANTY.

Page 5

Man-1078_Sigma_CP_AUS_12

Page 5 of 29

2 Introduction

The SIGMA CP conventional fire alarm control panel is designed to comply with AS7240-2 and AS7240-4 Fire

Detection and Fire Alarm systems - Control and Indicating Equipment.

The control panel has an integral, mains powered battery charger and power supply designed in accordance

with the requirements of AS7240-4.

In addition to the requirements of AS7240-2 the control panel has the following facilities:

Test condition to allow the automatic resetting of zones in alarm for testing purposes. AS7240-2

Section 11 option with requirements.

Delay of the actioning of fire alarm devices (sounders) so that an alarm may be verified before a

premises is evacuated. AS7240-2 Section 7.11 option with requirements.

Fire alarm devices to enable an audible warning to be sounded throughout a premises upon the

detection of a fire condition or the operation of a manual call point. AS7240-2 Section 7.8 option with

requirements.

Voltage free relay contacts for fire and local fire which operate upon fire condition. These are to be

used for local control and signalling.

3 Safety and Mounting

3.1 Safety

Suppliers of articles for use at work are required to ensure as reasonably as is practical that the article will

be safe and without risk to health when properly used.

An article is not regarded as properly used if it is used ‘without regard to any relevant information or advice’

relating to its use made available by the supplier.

This product should be installed, commissioned and maintained by trained service personnel in accordance

with the following:

(i) Local regulations for electrical equipment in buildings

(ii) Codes of practice

(iii) Statutory requirements

(iv) Any instructions specifically advised by the manufacturer

You are therefore requested to take such steps as are necessary to ensure that you make any appropriate

information about this product available to anyone concerned with its use.

This equipment is designed to be operated from 230V 50Hz mains supplies and is of class 1 construction. As

such it must be connected to a protective earthing conductor in the fixed wiring of the installation and a

readily accessible double pole disconnect device which disconnects live and neutral simultaneously shall be

incorporated in the fixed wiring.

Failure to ensure that all conductive accessible parts of this equipment are adequately bonded

to the protective earth will render the equipment unsafe.

This control panel is designed for indoor use only and at temperatures between -5

0

C (+/- 3) and +500C (+/-

2) and with a maximum relative humidity of 95%.

The IP rating for the enclosure is IP30.

Operation outside of these limits may render the equipment unsafe.

Page 6

Man-1078_Sigma_CP_AUS_12

Page 6 of 29

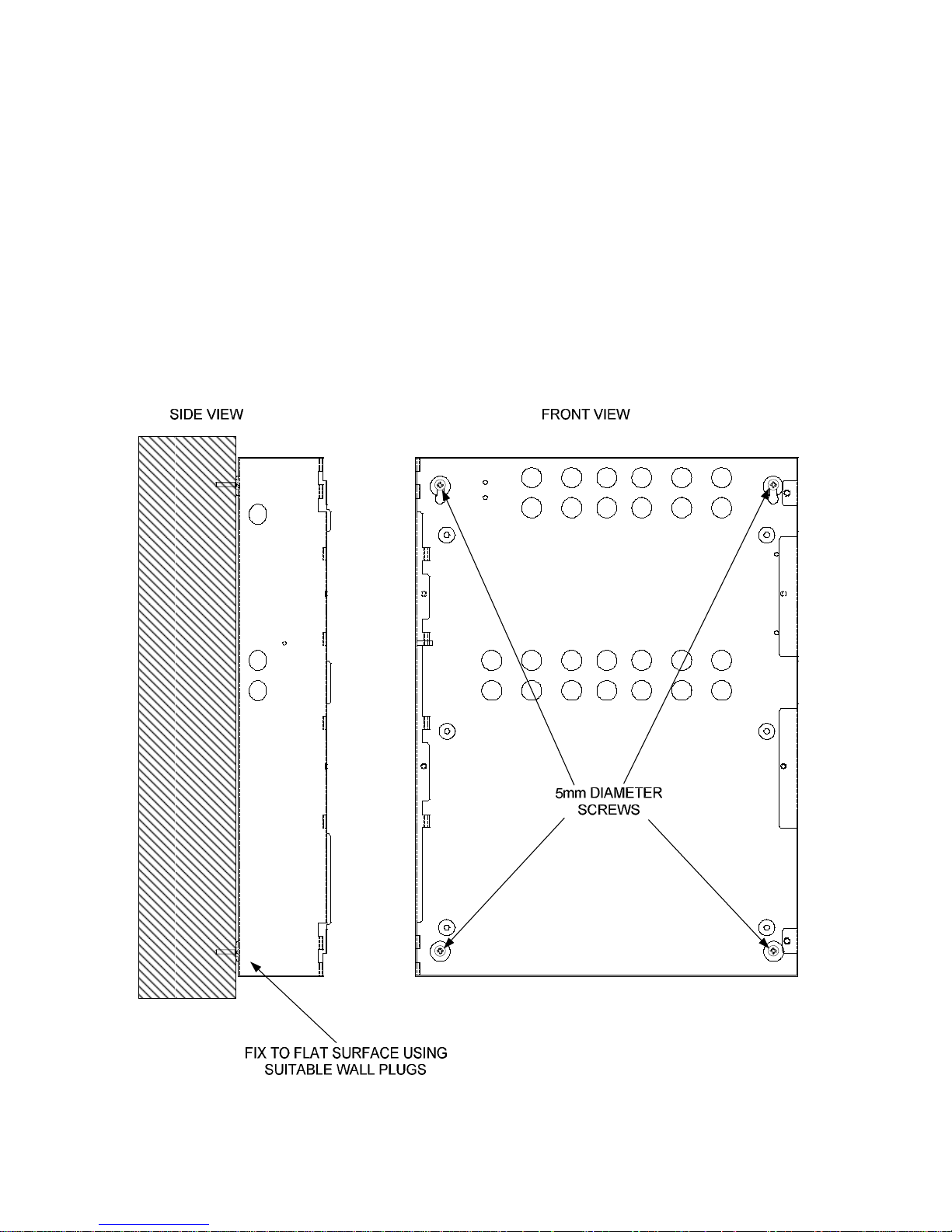

3.2 Mounting

The control panel should be mounted on a dry, flat surface, at eye height to the display and in a level

position such that the enclosure is not distorted.

Screws or bolts of a minimum of 5mm diameter must be used to mount the enclosure in all four mounting

points.

It should be positioned in an accessible position as agreed with the end user.

Suitable fixings should be used at all fixing points such that the control panel is securely mounted and is not

liable to move once fixed.

The control panel should not be mounted in another enclosure or near sources of excessive heat.

Cables should be connected using suitable cable glands fitted to the knockouts provided. If additional cable

entry points are required, all swarf and debris caused by drilling of additional cable entries must be cleared

before power is applied to the panel.

Page 7

Man-1078_Sigma_CP_AUS_12

Page 7 of 29

4 Technical specification

Table 1

Electrical Specifications

Mains supply

230V AC +10%

- 15% (100 Watts maximum)

Mains supply fuse

1.6Amp (F1.6A L250V)

Replace only with similar type

Power supply rating

3 Amps total including battery charge 28V +/ 2V

Maximum ripple current

1.5 Volts

Output voltage

18.5 to 29

V DC +/- 2% Imax a

400 milliamps

Imax b

2.3 Amps

Imin 0.065A

Battery type (Yuasa NP)

Two 12 Volt sealed lead acid (7Ah maximum)

See

Table

2

for capacities

Battery charge voltage

27.6VDC nominal (temperature compensated)

See

Table

3 Battery charge current

0.7A maximum

Battery lead fuse

20mm, 3.15A glass

Replace only with the same type

Battery high impedance warning

(Rimax)

1.35 ohms

max

Low battery voltage indication

21V +/

- 2%

Low battery shut off voltage

18.5V +/

- 2%

Maximum current draw from batteries

3 Amps

With main power source disconnected

R0V output

Fused at with electronic fuse

Dedicated sounder outputs

24V Fused at 500mA with electronic fuse

1.6 Amp total load over

all circuits

Zonal sounder outputs

24V

Fused at 500mA with electronic fuse

1.6 Amp total load

over

all circuits

Fault relay contact rating

30VDC 1A Amp maximum for each

Maximum ratings not to be exceeded

Fire relay contact rating

30VDC 1A Amp maximum for each

Maximum ratings not to be exceede

d Local fire relay contact rating

30VDC 1A Amp maximum for each

Maximum ratings not to be exceeded

Zone quiescent current

1.6mA maximum

See

Table

4

for detector types

Terminal capacity

0.5mm

2

to 2.5mm

2

solid or stranded wire

Number of detectors per zone

> 20 Dependent on type

Number of sounders per circuit

Dependent on type and curr

ent consumption

See

Table

6

for sounder types

Detection circuit end of line

6K8 5% ½ Watt resistor

Supplied in terminals

Sounder circuit end of line

10K 5% ¼ Watt resistor

Supplied in terminals

No.

of detection circuits

(see

Table

2

for number of zones for each model)

Dependent on model

No.

of

sounder outputs

2 (plus one per zone on T models)

SIL, AL, FLT, RST inputs

Switched

-

ve, max resistance 100 Ohms

Zone normal threshold

8K ohm TO 1K ohm

Detector alarm threshold

999 ohms to 400 ohms

Call point alarm threshold

399 ohms to 100 ohms

Short circuit threshold

99 ohms to 0 ohms

Head removal condition

15.5 to 17.5 volts

Zener clamp detector base to be used

Cabling

To Australian Standards (

maximum capacitance 1uF

maximum inductance 1 millihenry)

Metal cable glands must be used

Table 2

Standby battery capacity required for fully loaded system

Panel model

24 hours

standby

48 hours standby

72 hours

standby

Standby current

Max panel alarm

current

T11080

M3 (8 Zones)

3.75Ah

5.95Ah

8.2Ah 0.093A

0.63A

Table 3

Battery charge voltage versus temperature

Temperature

0

C

Battery charge voltage

0

29.2 10 28.56

20 27.99

30 27.55

40

27.13

Page 8

Man-1078_Sigma_CP_AUS_12

Page 8 of 29

Table 4

Compatible Detectors

Model Type Manufacturer Maximum Number per zone

SLV-AS OPTICAL HOCHIKI 40

DCD-A HEAT HOCHIKI 40

DCD-C HEAT HOCHIKI 35

DFJ-60B HEAT HOCHIKI 40

DFJ-90D HEAT HOCHIKI 35

DFG-60BLKJ HEAT HOCHIKI 40

DRD-AS FLAME HOCHIKI 25

SPC-AS BEAM HOCHIKI 6

Table 5

Compatible detector bases and call points

Model Type Manufacturer Comments

YBN-R/4C PLAIN BASE HOCHIKI

YBO-R/4A LED BASE HOCHIKI

YBO-R/6PA LED BASE HOCHIKI

MUS1A-R470SG-01 CALL POINT KAC

MUS1A-R470SF-01 CALL POINT KAC

Table 6

Compatible sounders

Model Type Manufacturer Comments

ROSHNI FULLEON

SQUASHNI FULLEON

SQUASHNI MICRO FULLEON

Table 7

Compatible I.S. barriers

Note: To use detectors and sounders within an intrinsically safe area, the detectors and sounders must be of

an intrinsically safe type and approved for use within the risk category.

Model

Type Manufac

turer

MTL5061

DETECTION ZONE GALVANIC ISOLATOR

MTL MTL778ac

SOUNDER CIRCUITS SI AND S2 ONLY

MTL

Page 9

Man-1078_Sigma_CP_AUS_12

Page 9 of 29

6 Using intrinsically safe barriers

SIGMA CP control panels support the use of I.S. barriers for connecting to equipment in hazardous areas.

Only certified detectors, call points and sounders may be used in hazardous areas and these

must be connected to the control panel via a compatible I.S. barrier as listed in Table 7.

Connection of the I.S. barrier changes the characteristics of the detection circuit, therefore zones that have

I.S. barriers connected, must be adjusted to work with them.

Programmable options C61 to C68 allow each zone to operate with I.S. barriers.

The amount of detectors and call points that can be connected to a zone is limited by the I.S. approval

system diagram which should be supplied by the detector manufacturer. The power rating of the end of line

resistor will be dependent upon the Zone classification rating (Gas class) this will be specified on the system

diagram.

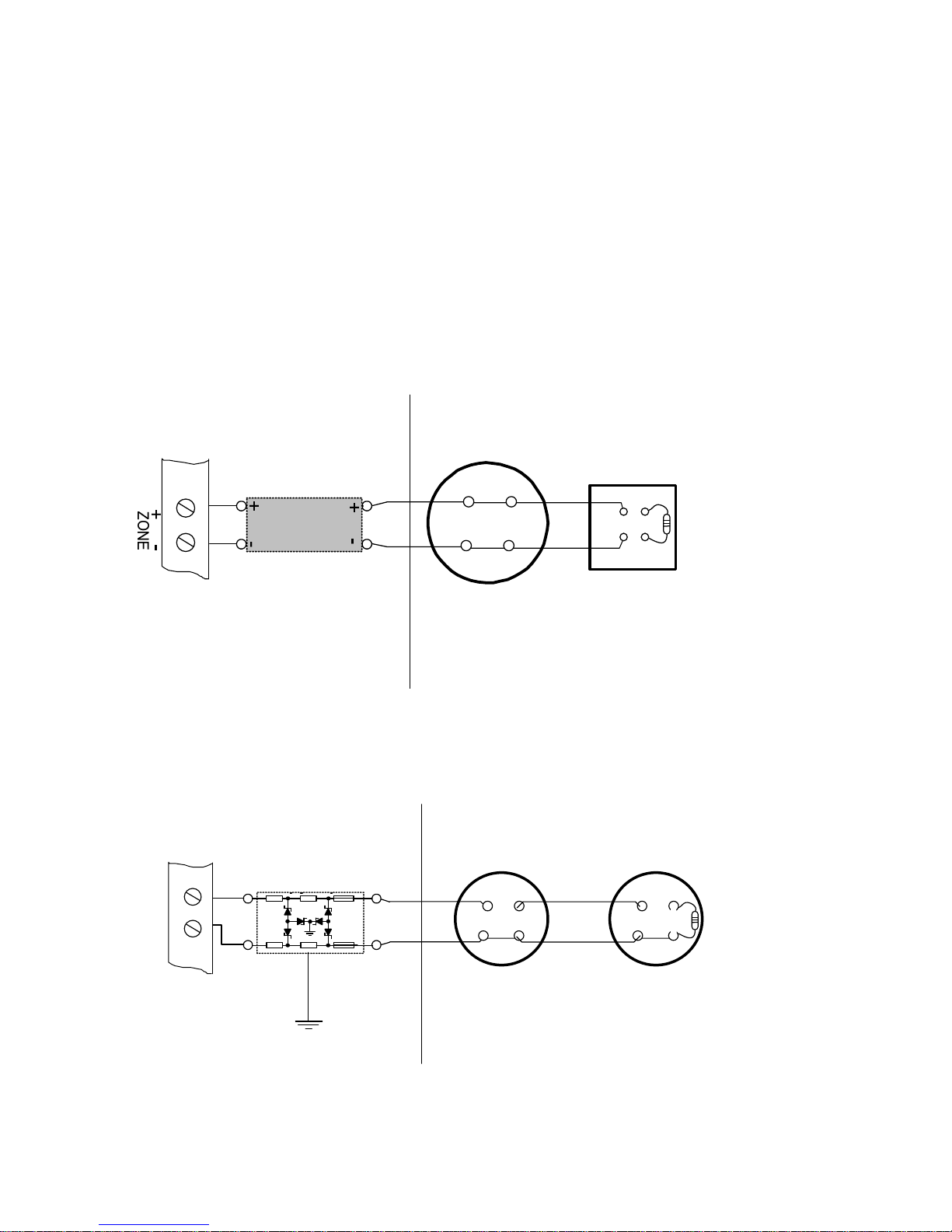

Figure 1. Detection zone wiring through an MTL5061 I.S .barrier

+ -

SOUNDER

OUTPUT

I.S .

POLARISED

SOUNDER

10K END OF LINE RESISTOR

MTL778ac

MAXIMUM OF TWO SOUNDERS PER SOUNDER CIRCUIT

I.S .

EARTH

POWER WILL DEPEND UPON

I.S. ZONE CLASSIFICATION

HAZARDOUS AREASAFE AREA

+ IN+

OUT

-IN-

OUT

I.S .

POLARISED

SOUNDER

+ IN+

OUT

-IN-

OUT

Figure 2. Sounder circuit wiring through an MTL778ac I.S. barrier

+

IN

+

OUT

-

IN

-

OUT

I.S. DETECTOR

I.S . CALL POINT

MTL5061

6K8 END OF

LINE RESISTOR

SAFE AREA HAZARDOUS AREA

POWER RATING WILL

DEPEND UPON I.S. ZONE

CLASSIFICATION

MAXIMUM NU MBER OF DEVICES ON ZONE

SPECIFIED IN SYSTEM DI AGRAM

Page 10

Man-1078_Sigma_CP_AUS_12

Page 10 of 29

7 Control panel fascia

In addition to the mandatory controls and indications required by the AS7240-2 standard, two sevensegment LED displays and MODE, SELECT and ENTER buttons are provided to allow easy entry and storage

of codes to configure the control panel to suit the requirements of the installation.

Opening the fascia

The fascia of the control panel is held in place by a screw on the right hand side. Undo the screw and lift

the plate from the right hand side.

Opening the fascia allows more room when mounting the cabinet and fitting cables.

Page 11

Man-1078_Sigma_CP_AUS_12

Page 11 of 29

8 Connecting to the circuit board

All connections for field wiring are to a single row of terminals along the top of the circuit board.

The connections for the power cables are to a pluggable terminal block which may be pulled off of the board

to remove power from the PCB assembly. Remove this pluggable terminal only with Mains Power OFF.

Cabling must comply with the relevant Australian Standards. The resistance of any core of any cable must

not exceed 25 ohms.

Wiring should enter the enclosure at the top of the panel using the knockouts provided and be formed tidily

to the appropriate terminals leaving only enough wire to ensure that there is no strain on the PCB.

Terminals are capable of accepting wires of up to 2.5mm2.

Terminal designations

Wiring must not go across the front of the circuit board plate or between the plate and the circuit board.

If cable entries need to be in positions other than at the knockouts provided, wiring must be fed behind and

well away from the surface of the circuit board.

The space at the bottom of the enclosure is largely occupied by the standby batteries so this must be borne

in mind when considering cable entries.

9 Software revision number

New features may be added to Sigma CP fire control panels from

time to time and when this is done the operating software of the

unit is updated. The software revision can be located on the main

processor by removing the plate holding the PCB from the

enclosure and turning it over. The software version will have a

number such as “Sig27.hex” and it is this number which will

determine which features the panel has installed and its

compatibility with Sigma CP ancillary board, sounders boards,

repeaters etc.

CORRECT

INCORRECT INCORRECT

SW1

SW2

SW4

SERIAL NUMBER

+

+

+

+

+

+

+

+

+

D 1008 ISSUE 06

C1

R1

R2

R

3

R

5

R

6

R7

R

8

R

9

C

3

0

C

3

1

R

1

1

R

1

2

R13

R

1

4

R

1

5

R

1

7

R

1

8

R19

R21

R51

R52

R53

R54

R55

R56

R57

R58

R60

R61

R62

R63

R64

R65 R66

R67

R69

R71

R72

R73

R74

R78

R80

R81

R85

R86

R87

R88

R90

R98

R99

R102

R103

R104

R109

R1

10

R111

R112

C2 C3 C4 C5 C7

C19

C20 C21 C22 C 23

C27

C37 C38 C39 C40

C43

C44

C55

C60 C61

R113

R114

R116

R117

C96

C33

R128

C73 C74

C75

C76

C34

C35 C 36

R130

R131

R132

R133

R134

R135

R137

R129

C42

C41

R89

R107

C81

R126

C83

C94

C95

R118

R4A R4B

R4C

R4D

R4E

R4F

R10A

R10B

R1

0C

R10D

R10E

R10F

R16A

R16B

R16C

R16D

R16E

R16F

R22A

C92

C93 C97

C98

C99

C100

C101

C102

C103

R155

R156

R157

C104

C105 R158

C106

C107

C108

C109

D1 D2 D3

D4

D9

D10

D11

D12

D13

D14

D15

D16

D22

D23

Z11

Z14

D30

F1

F2

F4

F9

F10

F11

TR1

TR2

TR3

TR9

TR26

TR19

TR24

TR28 TR25

IC4

IC5

IC10

IC1

IC2

D32 D33 D34

D35

IC6

REG1

J1

C24

C25

C65 C 66 C 67 C 68

C56

C82

D41

D20

F12

C51

RL2

RL3

RL1 RL 9

RL10

XTL1

LED3 LED4 LED5 LED6 LED7 LED17 LED35

VR1

TH1

TR23

L1

T3

REG3

FB5 FB6

FB7

FB

8

FB1

FB2

FB3

FB4

FB9

FB10

R70

R75

R76

X2X1

C45

VDR4

VDR3

VDR2

VDR1

FB20FB21

C128C127

LED8 LED11

LED15 LED12 LED10

LED16LED34LED9LED13LED14

C6

F3

R168

TR47

R167R166

Sig27.hex

Jason

SOFTWARE VERSION LABEL

Page 12

Man-1078_Sigma_CP_AUS_12

Page 12 of 29

+

IN

+

OUT

-

IN

-

OUT

DETECTOR

CALL POINT

6K8 END OF

LINE RESISTOR

+

IN

+

OUT

-

IN

-

OUT

DETECTOR

CALL POINT

6K8 END OF

LINE RESISTOR

POLARISED

SOUNDER

IN OUT

+

IN+OUT

_ _

NOTE: SOUNDER WIRED IN

REVERSE POLARITY

USE ONLY SA-WIRE BASES

ON “T” SERIES PANELS

Figure 4. – K Series detection zone wiring

Figure 5. - T series detection zone wiring

10 Detection zone wiring

The detection zones provide a nominal 24V DC to power compatible conventional detectors and call points.

The wiring is monitored for open and short circuit fault conditions. The 6K8 end of line monitoring resistors

that are factory fitted to the control panel’s terminals must be removed and placed across the last device

that is wired to the zone circuit.

Wiring can be conventional using standard detector bases (K series), or by the use of special detector bases

it is possible to wire the system such that detection devices and sounders are fitted to the same pair of

wires. (T series)

Detection zone circuits must be wired as a single, radial circuit with no spurs or T junctions to enable the

monitoring circuit to work correctly.

Polarised sounders may also be wired across the detection zone but in reverse polarity to that shown by the

zone terminals (see figure 5 below). Each zone can be configured individually as a 2-wire type zone or a

non 2-wire type zone using configuration options C1 to C8.

Page 13

Man-1078_Sigma_CP_AUS_12

Page 13 of 29

11 Sounder circuit wiring

All sounders must be of the polarised type. If non-polarised sounders are used the control panel will

permanently show a fault condition.

Sounder circuits are monitored for open and short circuit faults by placing a 10K end of line monitoring

resistor across the last device on the circuit.

Sounder circuits must be wired as a single, radial circuit with no spurs or T junctions to enable the

monitoring circuit to work correctly.

A maximum of 1.6 Amps is available for powering sounders with a maximum load of 0.41 Amps on any one

circuit.

12 Connection to remote control terminals

Some functions of the control panel can be controlled externally from the panel if required. Operation of

these inputs must be restricted by an access level 2 control as defined in AS7240-2.These are

abbreviated at the terminals block as follows:

a) Remote 0V supply – R0V

b) Silence Alarm – SIL

c) Sound Alarm – AL

d) Fault – FLT

e) Reset – RST

To activate these inputs, the remote 0 Volt (R0V) supply must be connected to the input via a normally open

switch or contact and via a resistance of no greater than 100 ohms.

All of the remote control inputs are non-latching.

+

-

S1

Figure 6. - Sounder circuit wiring

10K end of line

resistor

POLARISED

SOUNDER

IN OUT

+IN+

OUT

_ _

POLARISED

SOUNDER

IN OUT

+

IN+OUT

_ _

Page 14

Man-1078_Sigma_CP_AUS_12

Page 14 of 29

13 Aux 24V DC supply

An auxiliary 24V DC supply is provided to enable local signalling or control of ancillary systems such as door

release controllers. The terminals for the Aux 24V supply are labelled Aux 24V and ROV. The ROV terminal

is the negative terminal and is the same terminal that should be used to switch the remote control terminals.

It is possible to make the ROV terminal pulsing so that by connecting it to the AL terminal via a remote voltfree contact, it can be used to pulse the dedicated sounder circuits in response to a signal from another

system for example to give an alert. See programming code 24.

The supply is fitted with an electronic self-resetting fuse to protect the control panel’s 24V supply in the

event of a wiring fault.

Any standing load on the Aux 24V supply must be taken into account when calculating battery standby times

as standby time will be significantly affected by even modest standing loads. It is recommended that the

Aux24V output is not used to power standing loads and not used to supply loads of greater than 300

milliamps.

Where the Aux 24V supply is used to power electromechanical devices such as relays or door retainers it is

imperative that a suppression diode is fitted across the coil of the electromechanical device to prevent the

generation of high voltage transients back to the control panels power supply. The Aux 24V DC Supply is not

suitable for powering Sigma CP sounder boards, a separate power supply should be used for these.

14 Connection to relay contacts

Volt free changeover relay contacts are provided for local control and signalling if required. These contacts

are rated for switching signalling circuits only and the maximum ratings listed in Table 1should not be

exceeded under any circumstances.

Fault relay

The Fault Relay is normally energised and will de-energise upon any fault condition including total loss of power.

Local fire relay

The Local Fire Relay will energise upon activation of a fire condition on any of the zones or pressing of the

Sound Alarm Button on the front panel. The relay will remain activated until the alarm is silenced or the

panel is reset. This relay will not operate upon activation of the remote AL input or when a fire condition is

triggered on a zone that is in test mode.

Fire relay

The fire relay will energise upon activation of a fire condition on any of the zones. The relay will remain

activated until the control panel is reset. This relay will NOT operate upon activation of the remote AL input.

Individual zones can be configured not to operate the Fire relay by setting configuration options E1 to E8.

15 Connection to Accessory modules

Accessory modules include a Gas Module, Ancillary Relay Module, or an Australian Interface Module.

Accessory modules connect via a 2 core cable to the terminals marked RS485 + and – on the Sigma CP main

control panel PCB. Up to a total of 7 Accessory modules may be connected and each has terminals for the

incoming cables and outgoing cables. All except the last accessory module connected to the cable must

have the jumper links J2 removed.

The address of any accessory modules used within the system must have their address set using the DIP

switch on the module, ensuring that no two modules of the same type share the same address. NOTE: The

Australian Interface Module is fixed at Output unit address 7 and cannot be changed.

Apply power to main panel first and then all accessory modules. Turn ON the Enable Control keyswitch and

set the Write Enable switch to ON then briefly press the Processor Reset button on the main panel. Wait for

a few seconds and the main panel will show the addresses of the modules that were found on the display for

instance “r1” indicates that a module at address 1 has been found.

Turn the Write Enable switch OFF, then ON again and then press the Enter button to accept each module

that has been found. When all modules have been added, set the main panel Write Enable switch to OFF.

Press the Watchdog Reset switch on the main panel.

All modules are now configured and the main control panel will report a fault if any module, that has been

accepted, becomes faulty or goes off-line.

Page 15

Man-1078_Sigma_CP_AUS_12

Page 15 of 29

16 Panel operation

16.1 Normal condition

Under normal conditions, control panels will have only the green, Power On LED lit.

16.2 Fire condition

Upon receipt of a fire condition by activation of a detector or call point, the Common Fire indicator will light

and the Fire in Zone indicators will flash at around 2Hz.

The Fire and Local Fire relays will also operate and signal any systems to which they are connected.

Any sounders connected to the sounder circuits will operate in common, zonal or 2-stage mode as selected

by configuration options 10 to 12 (see Table 8).

16.3 Silence/Sound Alarms

The Silence/Sound alarm button can only be operated at access level two which means that the Enable

Control keyswitch must be activated.

To silence the sounders, activate the Enable Control keyswitch and press the Silence/Sound Alarm button.

When the sounders have been silenced, the Zone Fire LEDs will change from flashing to a steady state.

Pressing the Silence/Sound Alarm whilst the control panel is in this silenced condition will cause the sounders

to operate again.

The sounders can be toggled on and off with the Silence/Sound Alarm button as required.

16.4 Reset

To reset the panel, activate the Enable Control keyswitch then press the Reset button.

16.5 Zone fault

Removal of a detector from its base or a fault on any of the zone wiring will cause the Fault LED and Zone

Fault LEDs to light indicating the zone in which the fault has occurred. Zone fault is non-latching and will

automatically reset once the fault has been rectified.

16.6 Sounder fault

A fault on the wiring to sounder circuits will cause the Fault and Sounder Fault LEDs to light indicating a fault

on the wiring to the sounder circuits. Sounder fault is non-latching and will automatically reset once the

fault has been rectified.

16.7 Power fault

Failure of the mains power, disconnection of the standby battery or high impedance in the charging circuit

will cause the Fault and Power Fault LEDs to light indicating an abnormality in the power supply to the

control panel. Power fault is non-latching and will automatically reset once the fault has been rectified.

16.8 System fault

The System Fault LED will light if the configuration memory has not been set or has become corrupt.

System fault is non-latching and will automatically reset once the configuration has been rectified.

16.9 Lamp test

All LED indicators can be tested at any time by pressing the Lamp Test button. The Enable Control

keyswitch does not need to be activated to test the indicators.

16.10 Buzzer Silence

The buzzer can be silenced at any time by pressing the Alarm/Fault Warning Silence button. The Enable

Control keyswitch does not need to be activated to silence the buzzer.

Page 16

Man-1078_Sigma_CP_AUS_12

Page 16 of 29

16.11 Disablements

It is possible to disable parts of the system. This may be required if there are works going on in a building

which may cause the fire alarm system to operate in error.

16.12 Disable zones

To disable zones, the Enable Control keyswitch should be activated and the Mode button pressed until “d”

appears in the first of the two seven-segment LED displays. The Select button should then be pressed to

select the number of the zone which is to be disabled in the second of the two seven-segment displays.

Once the desired zone is displayed, the Enter button should be pressed to confirm the disablement.

The Disable LED will light and the Zone Fault LED will light for each disabled zone.

16.13 Disable sounders

To disable sounder outputs, press the Mode button to select “db” on the seven-segment display. Pressing

Enter will disable all sounders and cause the Disable and Sounder Fault LEDs to light.

16.14 Activate delays

To activate delays on zones as set in configuration options 31 to 48, press the Mode button until “Ad’

appears on the seven-segment LED display. When the Enter button is pressed any zones that are set as

delayed will have their alarm outputs delayed by the time set in configuration options 00 to 09.

16.15 Disable fault contact

The fault relay can be disabled by selecting configuration option 22.

16.16 Test mode

Fire alarm systems must be tested regularly to ensure that they are functioning correctly. The Sigma CP

range of panels enable the system to be tested single handed by using a test mode. When in test mode,

activation of a fire alarm will be automatically reset after a few seconds to eliminate the need to return to

the control panel to reset after every activation.

Test mode is entered in a similar way to disablements. With the Enable Control keyswitch activated, press

the Mode button until “t” appears in the first of the seven-segment displays. Then press the Select button

until the required zone number appears. Pressing the Enter button will cause the Test and Zone Fault LEDs

to illuminate indicating the zones which are in test mode.

Disablements and zone tests are cleared by repeating the sequence that is used to select them, i.e. the "db"

function (for example) toggles between sounders disabled and sounders enabled.

17 Configuration options

The Sigma CP range of control panels has many configuration options which can be set at the time of

commissioning to suit the requirements of the installation. These options are normally set once and will

rarely need to change. The configuration options are only available at access level 3. To access level 3,

CAREFULLY slide the Write Enable switch (located behind the aperture in the panel plate) to the right

position using a small screwdriver or similar. When the panel is at access level 3, the buzzer will “pip” three

times every few seconds as an indication that it is at this access level.

Page 17

Man-1078_Sigma_CP_AUS_12

Page 17 of 29

Configuration options are simple to enter using the codes in Table 8below. When the control panel is at

access level 3, the sub-text of the Mode and Select buttons is used to enter a number using tens (+10) and

units (+1).

When the required code number is displayed, pressing the Enter button will cause the dot on the units,

seven-segment display to flash. This indicates that a configuration option has been set.

To review which configuration options have been set previously, simply scroll through numbers 1 to 99, A1

to A8, C1 to C8 and E1 to E8 and those with a flashing dot indicate which options have been set.

DOT

FLASHING

NO DOT

ZONE 1 I.S. BARRIER

OPTION SET

ZONE 1 I.S. BARRIER

OPTION NOT SET

Figure 9

– Example display showing option set and not set.

Page 18

Man-1078_Sigma_CP_AUS_12

Page 18 of 29

Table 8

Configuration Codes

CODE

FUNCTION

COMMENTS

00

SOUNDER DELAY TIME = 30 SECONDS

Sets the time delay before sounders

operate in combination with

configuration codes 31 to 48 and access level 2 function AD.

01 SOUNDER DELAY TIME = 1 MINUTE

02

SOUNDER DELAY TIME = 2 MINUTES

03

SOUNDER DELAY TIME = 3 MINUTES

04

SOUNDER DELAY TIME = 4 MINUTES

05

SOUNDER DELAY TIME

= 5 MINUTES

06

SOUNDER DELAY TIME = 6 MINUTES

07

SOUNDER DELAY TIME = 7 MINUTES

08

SOUNDER DELAY TIME = 8 MINUTES

09

SOUNDER DELAY TIME = 9 MINUTES

10

COMMON ALARM MODE (default)

All sounders operate upon any fire condition

11 TWO-STAGE ALARM

MODE

Continuous sounders in activated zone, pulsing elsewhere

12

ZONED ALARM MODE

Only sounders connected to zone in alarm operate

21* DISABLE FIRE BUZZER

Buzzer will not operate on fire condition

22* DISABLE FAULT OUTPUT

Fault relay will not

operate except upon total power failure

23

DISABLE EARTH FAULT MONITORING

Connection of fire alarm wiring will not announce a fault

24

PULSED REMOTE CONTROL OUTPUT

Aux 24V supply pulses 1 sec on/1 sec off

25

ENABLE SOUNDERS ON DETECTION CIRCUITS

Set as

default if panel is two wire “T” series (detectors and call

points on same cables)

26 DISABLE FIRE OUTPUT

Fire relay will not operate upon any alarm

27

REMOVE AUX 24 UPON PANEL RESET

DO NOT SET

24V supply switches off for about 5 seconds when panel is

reset 28 I

NDICATE CALL POINT ACTIVATION

Activation of a call point

with a 270R resistance fitted

is

indicated by a flashing zone indicator and “Pu” on the 7 segment

display. Activation of a detector will be indicated by a steady

zone indicator and nothing on the 7 segment display.

29 DO NOT RE

-

SOUND ALARMS FROM ANOTHER ZONE

Silenced sounders will not re

-

sound upon further zone

activations

31

ZONE 1 ALARM FROM DETECTOR DELAYED

Sounder outputs will be delayed by time set at options

0-9 when selected zone(s) triggered by detector only.

Note: Access level 2 function Ad must be set for this to take

effect.

32 ZONE 2 ALARM FROM DETECTOR DELAYED

33 ZONE 3 ALARM FROM DETECTOR DELAYED

34 ZONE 4 ALARM FROM DETECTOR DELAYED

35 ZONE 5 ALARM FROM DETECTOR

DELAYED

36 ZONE 6 ALARM FROM DETECTOR DELAYED

37 ZONE 7 ALARM FROM DETECTOR DELAYED

38 ZONE 8 ALARM FROM DETECTOR DELAYED

41

ZONE 1 ALARM FROM CALL POINT DELAYED

Sounder outputs will be delayed by time set at options

0-9 when selected zone(s) triggered by call point only.

Note access level 2 function Ad must be set for this to take

effect.

42 ZONE 2 ALARM FROM CALL POINT DELAYED

43 ZONE 3 ALARM FROM CALL POINT DELAYED

44 ZONE 4 ALARM FROM CALL POINT DELAYED

45 ZONE 5 ALARM FROM CALL

POINT DELAYED

46 ZONE 6 ALARM FROM CALL POINT DELAYED

47 ZONE 7 ALARM FROM CALL POINT DELAYED

48 ZONE 8 ALARM FROM CALL POINT DELAYED

51

COINCIDENCE ZONE 1

Zone contributes to ancillary board coincidence O/P

.

Any

number of zones can be selected to contribute.

52 COINCIDENCE ZONE 2

53

COINCIDENCE ZONE 3

54

COINCIDENCE ZONE 4

55

COINCIDENCE ZONE 5

56

COINCIDENCE ZONE 6

57

COINCIDENCE ZONE 7

58 COINCIDENCE ZONE 8

61 CONFIGURE Z1 FOR I.S BARRIER

Detection threshold changed

for use with IS barrier

62

CONFIGURE Z2 FOR I.S BARRIER

63

CONFIGURE Z3 FOR I.S BARRIER

64

CONFIGURE Z4 FOR I.S BARRIER

65 CONFIGURE Z5 FOR I.S BARRIER

66

CONFIGURE Z6 FOR I.S BARRIER

67 CONFIGURE Z7 FOR I.S BARRIER

68

CONFIGURE Z8 FOR I.S

BARRIER

Page 19

Man-1078_Sigma_CP_AUS_12

Page 19 of 29

CODE

FUNCTION

COMMENTS

71* ZONE 1 SHORT CIRCUIT INDICATES ALARM

Changes the trigger threshold of

the zone

so that the control

panel can be used on older systems that had no short-circuit

monitoring.

72* ZONE 2 SHORT CIRCUIT INDICATES ALARM

73* ZONE 3 SHORT CIRCUIT INDICATES ALARM

74* ZONE 4 SHORT CIRCUIT INDICATES ALARM

75* ZONE 5 SHORT CIRCUIT INDICATES ALARM

76* ZONE 6 SHORT CIRCUIT INDICATES ALARM

77* ZONE 7 SHORT CIRCUIT INDICATES ALARM

78* ZONE 8 SHORT CIRCUIT INDICATES ALARM

81* ZONE 1 NON

-

LATCHING

Renders the zone self

-

resetting so

that it can be used to receive

signals from other systems and will reset when the input is

removed.

Note: It can take up to 20 seconds for zone to reset itself when

sounders are operating

82* ZONE 2 NON

-

LATCHING

83* ZONE 3 NON

-

LATCHING

84* ZONE 4 NON

-

LATCHING

85* ZONE 5 NON

-

LATCHING

86* ZONE 6 NON

-

LATCHING

87* ZONE 7 NON

-

LATCHING

88* ZONE 8 NON

-

LATCHING

91 ZONE 1 DOES NOT SOUND ALARMS

Prevents the zone from operating the

two common sounder

outputs.

92 ZONE 2 DOES NOT SOUND ALARMS

93 ZONE 3 DOES NOT SOUND ALARMS

94 ZONE 4 DOES NOT SOUND ALARMS

95 ZONE 5 DOES NOT SOUND ALARMS

96 ZONE 6 DOES NOT SOUND ALARMS

97 ZONE 7 DOES NOT SOUND ALARMS

98 ZONE 8 DOES NOT

SOUND ALARMS

A1* ZONE 1 ANY ALARM DELAYED

Zone needs to be triggered for 30 seconds

continuously before

an alarm is generated.

A2* ZONE 2 ANY ALARM DELAYED

A3* ZONE 3 ANY ALARM DELAYED

A4* ZONE 4 ANY ALARM DELAYED

A5* ZONE 5 ANY ALARM

DELAYED

A6* ZONE 6 ANY ALARM DELAYED

A7* ZONE 7 ANY ALARM DELAYED

A8* ZONE 8 ANY ALARM DELAYED

C1 ZONE 1 SOUNDERS INHIBITED

Enables individual zones to be configured not to operate zonal

sounders.

On 2 wire “T” series panels this enables individual zones to be

configured for use with conventional (non 2-wire) detector

bases.

C2 ZONE 2 SOUNDERS INHIBITED

C3 ZONE 3 SOUNDERS INHIBITED

C4 ZONE 4 SOUNDERS INHIBITED

C5 ZONE 5 SOUNDERS INHIBITED

C6 ZONE 6 SOUNDERS INHIBITED

C7 ZONE

7 SOUNDERS INHIBITED

C8 ZONE 8 SOUNDERS INHIBITED

E1* ZONE 1 WILL NOT OPER

ATE FIRE RELAY

Enables individual zones to be selected to not operate the fire

relay. This is sometimes combined with the non-latching

function to prevent ring around on interconnected panels.

E2* ZONE 2 WILL NOT OPERATE FIRE RELAY

E3* ZONE 3 WILL NOT OPERATE FIRE RELAY

E4* ZONE 4 WILL NOT OPERATE FIRE RELAY

E5* ZONE 5 WILL NOT OPERATE FIRE RELAY

E6* ZONE 6 WILL NOT OPERATE FIRE RELAY

E7* ZONE 7 WILL NOT

OPERATE FIRE RELAY

E8* ZONE 8 WILL NOT OPERATE FIRE RELAY

NOTE: Setting the options marked with asterisks does not comply with AS7240-2

Once the required configuration options have been set, the Write Enable switch must be returned to its

normal position to the left. The General Fault indicator will remain lit if the Write Enable switch is not turned

OFF.

18 Watchdog reset switch

If for any reason the microprocessor in the control panel fails to carry out its operation correctly it will

attempt to restart itself. This process is called a “watchdog” and the control panel must record and indicate

these events.

If a watchdog event occurs, the control panel will show the Fault and System Faultless on the front panel,

the CPU Faulted inside the panel.

Page 20

Man-1078_Sigma_CP_AUS_12

Page 20 of 29

This fault can only be cleared by pressing the Watchdog Reset button on the PCB inside the control panel.

The control panel buzzer cannot be silenced and will continue to sound until the watchdog activation is

reset.

19 Processor reset switch

Once started, the microprocessor controlling the panel should continue to run continuously without

interruption. If the microprocessor fails to run correctly it can be reset by pressing the Processor Reset

button on the PCB inside the control panel.

This should not normally be necessary but should be done as a matter of course if the system is behaving

abnormally. The system should resume normal operation within a couple of seconds of pressing the

Processor Reset button. Note: A Watchdog Reset should always be performed following a Processor Reset.

20 Internal indications – troubleshooting

To assist in identifying fault conditions which are not detailed on the front of the control panel, a number of

internal indicators are visible with the front cover removed as follows:

20.1 Mains fail

Indicates that the 230V AC supply is not present and the system is running on standby batteries.

If there is not a power cut, check the panels mains fuse.

20.2 Batt fail

Indicates that the standby battery has become disconnected, or that the charging circuit of the control panel

has a high resistance or has failed. Check that both batteries are connected and linked together. Test the

battery. Disconnect the battery and ensure that 28 Volts can be measured on battery charger leads.

20.3 CPU fault

Indicates that the central processor unit has failed to correctly execute code and has been re-started by the

system watchdog. The Watchdog Reset switch must be pressed to clear the CPU Fault condition.

If system does not return to normal after the Watchdog Reset switch is pressed then the panel is probably

damaged and the circuit board needs replacing.

20.4 Aux 24V fault

The Aux 24V and R0V terminals provide a 500 milliamp, 24V DC power supply for power fire alarm ancillary

equipment. This LED indicates that fuse protecting the R0V output has operated and the rating of this

output has been exceeded. The fuse is a self-resetting type and the supply will resume when the fault

condition is removed.

20.5 Batt low

Illuminates when the system is running on batteries and the battery voltage is lower than 21V +/-2% (the

minimum battery voltage).

20.6 Earth fault

Indicates that part of the system wiring is connected to earth. Remove all system wiring and re-connect

cables one at a time until the earth fault returns. This will indicate which cable the earth fault is present on.

20.7 Sys fuse fault

Indicates that the total power rating of the power supply has been exceeded and that the system fuse has

come into operation. Remove and review all loads and re-connect one at a time until over rated circuit trips

fuse to identify troublesome circuit.

20.8 S1 fault and S2 fault

Indicates a short or open circuit on sounder outputs. Remove wiring and refit end of line resistors. Check

sounder circuit wiring.

Page 21

Man-1078_Sigma_CP_AUS_12

Page 21 of 29

20.9 Comms fault

Indicates that communication has been lost with a repeater panel or ancillary board. Check for comms fault

at all repeaters and ancillary boards to identify the source of the problem.

21 AIM – Australian Interface Module

The AIM module is optional on the Sigma range of panels and can be utilised to provide:

ACF Output

Door Holder Output

ASE Outputs

Only one AIM is permitted on each control panel and has a fixed addressed at “o7”, output unit 7.

Page 22

Man-1078_Sigma_CP_AUS_12

Page 22 of 29

21.1 ACF – Ancillary Control Function

21.1.1 Outputs

The ACF has a 24V DC monitored output suitable for operating a remote, polarised and suppressed

relay. Monitoring is via an end of line resistor. This output is designated ACF O/P +/-

A clean contact relay rated at 30VDC 1Amp follows the monitored output.

The ACF outputs are activated by a non-silenceable fire signal from the Sigma control panel

section. A red LED indicator is lit when the output is active.

A fault on the ACF outputs is signalled at the Sigma panels as a General fault and on the AIM as

ACF fault.

21.1.2 Configuration:

The ACF can be configured as latching by setting the LATCH dipswitch to the On position.

The ACF can be configured as failsafe (Normally Energised) by setting the FAIL S. dipswitch

to the ON position.

21.1.3 Controls – only available at Level 2

When the ACF is set to “latching” the Reset switch on the AIM module, in order to reset the ACF,

firstly, the Alarm must be reset, and then the ACF can be reset using the Reset switch on the AIM.

When the ACF is set to “non-latching” the ACF output is deactivated when the alarm is reset or

disabled.

Page 23

Man-1078_Sigma_CP_AUS_12

Page 23 of 29

The Isolate switch on the AIM module allows the ACF output to be disabled and not operate on an

alarm condition. A yellow ACF Isolated LED indicates when the ACF is isolated, and signals a

General Disablement to the Sigma control panel section.

21.2 Door Holder Output

The door holder circuit allows magnetic fire doors to be automatically closed in the event of a fire,

thus limiting smoke and fire egress in an emergency situation.

Four terminals are provided:

DH 24V In A 24V supply to power the magnetic door holders.

Door Holders The 24V from the “DH 24V In” circuit appears at this output under

“Normal” condition. When an alarm occurs, power is disconnected from the “Door Holder” output.

The maximum output of the Door Holder circuit must be less than 1A.

The status of the door holder output follows that of the ACF output as described in section 21.1

and is isolated via the ACF Isolate facility. The only exception is when the DOOR D. dipswitch is

ON, the Door Holder Output activates after a 30 seconds delay.

21.3 ASE Outputs (Alarm Signalling Equipment)

Clean contact relay outputs, rated at 30VDC 1Amp, are provided to facilitate connection of the

Sigma fire panel to a variety of ASE depending on the installation. It is the responsibility of the

installer to ensure that the ASE being installed is compatible with the local fire station to which it is

being connected.

ALARM normally de-energisedactivates on a non-disabled Alarm

FAULT normally de-energisedactivates on a non-disabled Fault

ISOLATED normally de-energisedactivates on a non-disabled Disable

POWER FLT normally energised, de-activates when there is an abnormality with the power

supply.

COINC. normally de-energised activates on multiple alarms. This output will activate when

an alarm occurs any of the zones specified as being coincident zones. See options

51 to 58 in Section 0.

ENABLE normally de-energised activates when the Enable Control keyswitch is activated.

i.e. The panel enters the Level 2 state.

ACF O/P this output follows the state of the ACF monitored output.

21.4 Installation

See Section 15 for full installation instructions.

21.5 Configuration.

The AIM only has 3 configurable parameters which are set via dip-switches.

LATCH sets the ACF output to latching

FAIL S. sets the ACF output to normally energised.

DOOR D. sets the Door Holder Output to trip 30 seconds after the ACF output activates.

Page 24

Man-1078_Sigma_CP_AUS_12

Page 24 of 29

22 Power supply

The control panel requires a 230V (+10%/-15%), 50/60Hz, AC mains power supply which connects to the

fused terminal block labelled “230V”.

The fused terminal block contains a 20mm, F1.6A L250V fuse which should only be replaced with a similar

type.

The output voltage of the power supply is 28V DC +/- 2V and the total current rating including a maximum

0.7A for battery charging is 3 Amps. Fuse F12 mounted on the circuit board is a self-resetting electronic

fuse rated at 4 Amps.

The incoming mains cable should be routed well away from other lower voltage wiring by a distance of at

least 50mm.

Mains wiring should include an earth conductor which is securely bonded to the building earth and should

enter the enclosure as close as possible to the mains terminal block. Mains wires should be kept very short

inside the enclosure and secured together close to the mains terminal block with a cable tie.

The control panel can accept sealed lead acid rechargeable batteries of up to 7Ah maximum capacity (see

Table 2 for battery size required for each model).

The maximum current drawn from the batteries when the main power source is disconnected is 3 Amps.

Battery leads are supplied wired to the PCB along with a link to connect the two batteries in series. The PCB

is fitted with a 20mm, 3.15A T1 glass fuse (F13) in the battery charging circuit which must only be replaced

with one of the same type.

It is most important that the polarity of the batteries is carefully observed when connecting.

When the batteries are discharged to a level at which a low battery indication is given, the Batt Fail indicator

will also be lit.

WRONGLY CONNECTED BATTERIES COULD CAUSE DAMAGE TO THE CONTROL PANEL.

Figure 9 – Mains and battery connections

N N

L L

E

+ - + -

GREY LINK

BLACK BATTERY

LEAD TO

-

TERMINAL

RED BATTERY

LEAD TO

+

TERMINAL

MAINS

TERMINAL

KEEP MAINS WIRES AS SHORT AS POSSIBLE

AND SECURE ALL THREE WIRES CLOSE TO

THE TERMINAL BLOCK WITH A CABLE TIE

Page 25

Man-1078_Sigma_CP_AUS_12

Page 25 of 29

23 Maintenance

Sigma CP control panels do not require any specific maintenance but should the control panel become dirty

it can be wiped over with a damp cloth and should then be dried with a dry, lint free cloth. Detergents or

solvents should not be used to clean the panel and care must be taken that water does not enter the

enclosure.

The control panel contains sealed lead acid batteries to provide standby power in the event of a mains

failure. These batteries have a life expectancy of around 2 years. It is recommended that these batteries be

tested in accordance with the battery manufacturer’s recommendations annually to determine their

suitability for continued standby applications.

Routine testing of the fire alarm system in accordance with local standards will identify any malfunction of

the control panel and any malfunction should be reported to the fire alarm maintenance company

immediately.

Should the control panel become faulty the complete electronic assembly can be replaced.

To do this, any configured options should be noted then both mains and battery power should be removed

before the work is started. The field wiring should be carefully labelled and removed from the terminals.

The PCB can now be taken out of the panel by removing the screw and hinge pins holding the plate in

position.

Fitting the new PCB is the reverse of the procedure for removing the board.

24 Zone designation label

All Sigma CP control panels are supplied with a zone designation label onto which zone designations can be

written.

This enables each zone to be given a text description allowing easier identification of any zones showing an

abnormal condition.

Page 26

Man-1078_Sigma_CP_AUS_12

Page 26 of 29

25 Record of Configuration

Use the Table below to record the configuration codes that have been set on the control panel for future

reference. Place a tick in the grey band for any configuration options that are set.

It is recommended that a copy of this Table is left with the control panel under the supervision of the person

responsible for the fire detection system.

CODE

FUNCTION

COMMENTS

SET 00 SOUNDER DELAY TIME = 30 SECONDS

Sets the time delay before sounders operate in combination with

configuration codes 31 to 48 and access level 2 function AD.

01

SOUNDER DELAY TIME = 1 MINUTE

02 SOUNDER DELAY TIME = 2

MINUTES

03 SOUNDER DELAY TIME = 3 MINUTES

04 SOUNDER DELAY TIME = 4 MINUTES

05 SOUNDER DELAY TIME = 5 MINUTES

06 SOUNDER DELAY TIME = 6 MINUTES

07 SOUNDER DELAY TIME = 7 MINUTES

08 SOUNDER DELAY TIME = 8 MINUTES

09 SOUNDER DELAY TIME =

9 MINUTES

10 COMMON ALARM MODE

All sounders operate upon any fire condition

11 TWO-STAGE ALARM MODE

Continuous sounders in activated zone, pulsing elsewhere

12 ZONED ALARM MODE

Only sounders connected to zone in alarm operate

21* DISABLE FIRE

BUZZER

Buzzer will not operate on fire condition

22* DISABLE FAULT OUTPUT

Fault relay will not operate except upon total power failure

23 DISABLE EARTH FAULT MONITORING

Connection of fire alarm wiring will not announce a fault

24 PULSED REMOTE

CONTROL OUTPUT

Aux 24V supply pulses 1 sec on/1 sec off

25 ENABLE SOUNDERS ON DETECTION CIRCUITS

Set as default if panel is two wire “T” series (detectors and call

points on same cables)

26

DISABLE FIRE OUTPUT

Fire relay will not operate upon any alarm

27 REMOVE AUX 24 UPON PANEL RESET

24V supply switches off for about 5 seconds when panel is reset

28 INDICATE CALL POINT ACTIVATION

Activation of a call point with a 270R resistance fitted is indicated

by a flashing zone indicator and “Pu” on the 7 segment display.

Activation of a detector will be indicated by a steady zone

indicator and nothing on the 7 segment display

29 DO NOT RE

-

SOUND ALARMS FROM ANOTHER

ZONE

Silenced sounders will not re

-

sound upon further zone activations

31 ZONE 1 ALARM

FROM DETECTOR DELAYED

Sounder outputs will be delayed by time set at options

0-9 when selected zone(s) triggered by detector only.

Note access level 2 function Ad must be set for this to take

effect.

32

ZONE 2 ALARM FROM DETECTOR DELAYED

33

ZONE 3

ALARM FROM DETECTOR DELAYED

34 ZONE 4 ALARM FROM DETECTOR DELAYED

35

ZONE 5 ALARM FROM DETECTOR DELAYED

36

ZONE 6 ALARM FROM DETECTOR DELAYED

37

ZONE 7 ALARM FROM DETECTOR DELAYED

38

ZONE 8 ALARM FROM DETECTOR DELAYED

41

ZONE 1 ALARM FROM

CALL POINT DELAYED

Sounder outputs will be delayed by time set at options

0-9 when selected zone(s) triggered by call point only.

Note access level 2 function Ad must be set for this to take

effect.

42

ZONE 2 ALARM FROM CALL POINT DELAYED

43

ZONE 3

ALARM FROM CALL POINT DELAYED

44

ZONE 4 ALARM FROM CALL POINT DELAYED

45

ZONE 5 ALARM FROM CALL POINT DELAYED

46

ZONE 6 ALARM FROM CALL POINT DELAYED

47

ZONE 7 ALARM FROM CALL POINT DELAYED

48

ZONE 8 ALARM FROM CALL POINT DELAYED

51

COINCIDENCE ZONE 1

Zone contributes to ancillary board coincidence O/P

.

Any number

of zones can be selected to contribute.

52

COINCIDENCE ZONE 2

53 COINCIDENCE ZONE 3

54 COINCIDENCE ZONE 4

55 COINCIDENCE ZONE 5

56 COINCIDENCE ZONE 6

57 COINCIDENCE ZONE 7

58 COINCIDENCE ZONE 8

61 CONFIGURE Z1 FOR I.S BARRIER

Detection threshold changed for use with IS barrier

62 CONFIGURE Z2 FOR I.S BARRIER

63 CONFIGURE Z3 FOR I.S BARRIER

64 CONFIGURE Z4 FOR I.S BARRIER

65 CONFIGURE Z5

FOR I.S BARRIER

66 CONFIGURE Z6 FOR I.S BARRIER

67 CONFIGURE Z7 FOR I.S BARRIER

68 CONFIGURE Z8 FOR I.S BARRIER

Page 27

Man-1078_Sigma_CP_AUS_12

Page 27 of 29

CODE

FUNCTION

COMMENTS

SET 71* ZONE 1 SHORT CIRCUIT INDICATES ALARM

Changes the trigger threshold of

the zone

so that the control

panel can be used on older systems that had no short-circuit

monitoring.

72* ZONE 2 SHORT CIRCUIT INDICATES ALARM

73* ZONE 3 SHORT CIRCUIT INDICATES ALARM

74* ZONE 4 SHORT CIRCUIT INDICATES ALARM

75* ZONE 5 SHORT CIRCUIT

INDICATES ALARM

76* ZONE 6 SHORT CIRCUIT INDICATES ALARM

77* ZONE 7 SHORT CIRCUIT INDICATES ALARM

78* ZONE 8 SHORT CIRCUIT INDICATES ALARM

81* ZONE 1 NON

-

LATCHING

Renders the zone self

-

resetting so

that it

can be used to receive

signals from other systems and will reset when the input is

removed.

Note: It can take up to 20 seconds for zone to reset itself when

sounders are operating

82* ZONE 2 NON

-

LATCHING

83* ZONE 3 NON

-

LATCHING

84* ZONE 4

NON-LATCHING

85* ZONE 5 NON

-

LATCHING

86* ZONE 6 NON

-

LATCHING

87* ZONE 7 NON

-

LATCHING

88* ZONE 8 NON

-

LATCHING

91 ZONE 1 DOES NOT SOUND ALARMS

Prevents the zone from operating the two common sounder

outputs

92

ZONE 2 DOES NOT SOUND

ALARMS

93

ZONE 3 DOES NOT SOUND ALARMS

94

ZONE 4 DOES NOT SOUND ALARMS

95

ZONE 5 DOES NOT SOUND ALARMS

96

ZONE 6 DOES NOT SOUND ALARMS

97

ZONE 7 DOES NOT SOUND ALARMS

98

ZONE 8 DOES NOT SOUND ALARMS

99 A1* ZONE 1 ANY ALARM DELAYED

Zone needs to be triggered for 30 seconds

continuously before

an alarm is generated.

A2* ZONE 2 ANY ALARM DELAYED

A3* ZONE 3 ANY ALARM DELAYED

A4* ZONE 4 ANY ALARM DELAYED

A5* ZONE 5 ANY ALARM DELAYED

A6* ZONE 6 ANY ALARM DELAYED

A7* ZONE 7 ANY ALARM DELAYED

A8* ZONE 8 ANY ALARM DELAYED

C1 ZONE 1 SOUNDERS INHIBITED

Enables individual zones to be configured not to operate zonal

sounders.

On 2 wire “T” series panels this enables individual zones to be

configured for use with conventional (non-savwire) detector

bases.

C2

ZONE 2 SOUNDERS INHIBITED

C3

ZONE 3 SOUNDERS INHIBITED

C4 ZONE 4 SOUNDERS INHIBITED

C5

ZONE 5 SOUNDERS INHIBITED

C6

ZONE 6 SOUNDERS INHIBITED

C7

ZONE 7 SOUNDERS INHIBITED

C8

ZONE 8

SOUNDERS INHIBITED

E1* ZONE 1 WILL NOT OPER

ATE FIRE RELAY

Enables individual zones to be selected to not operate the fire

relay. This is sometimes combined with the non-latching function

to prevent ring around on interconnected panels.

E2* ZONE 2 WILL NOT OPERATE FIRE RELAY

E3* ZONE 3 WILL NOT OPERATE FIRE RELAY

E4* ZONE 4 WILL NOT OPERATE FIRE RELAY

E5* ZONE 5 WILL NOT OPERATE FIRE RELAY

E6* ZONE 6 WILL NOT OPERATE FIRE RELAY

E7* ZONE 7 WILL NOT OPERATE FIRE RELAY

E8* ZONE 8 WILL NOT OPERATE FIRE RELAY

NOTE: Setting the options marked with asterisks does not comply with AS7240-2

Page 28

Man-1078_Sigma_CP_AUS_12

Page 28 of 29

This page intentionally left blank.

Page 29

Man-1078_Sigma_CP_AUS_12

Page 29 of 29

Loading...

Loading...