Page 1

__________________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. IS 2451-P Issue E 19-02-10 Sheet 1 of 4 (1)

INSTRUCTION MANUAL (ATEX / IECEx)

BExDS120D and BExDS110D

Flameproof Sounders

For use in Flammable Gas and Dust Atmospheres

1) Introduction

The BExDS120D and BExDS110D are flameproof sounders

which are certified to meet the requirements of the ATEX

directive 94/9/EC and the IECEx scheme. The sounders

produce loud warning signals and can be used in hazardous

areas where potentially flammable gas and dust atmospheres

may be present. Thirty-two different first stage alarm sounds

can be selected by internal switches, and each one can be

externally changed to a second or third stage alarm sound

(see tone table on Page 4). The BExDS120D unit produces

output levels in the 117dB(A) range and the BExDS110D unit

produces output levels in the 110dB(A) range. Both sounders

can be used in Zone 1 and Zone 2 areas with gases in groups

IIA, IIB and IIC and temperature Classifications of T1, T2, T3

and T4. For ambient temperatures over +55ºC the gas groups

are limited to IIA and IIB. They can also be used in Zone 21

and Zone 22 areas for combustible dusts and have an IP rating

of IP 67 and a surface temperature rating of T100ºC up to

+55ºC and T115ºC over +55ºC.

2) Marking

All units have a rating label, which carries the following

important information:-

Input Voltage: DC Units 12V or 24V or 48V

AC Units 230V or 110V or 115V

Codes: Ex d IIC T4 for Ta –50°C to +55ºC

Ex d IIB T4 for Ta –50°C to +70ºC

Ex tD A21 IP67 T115°C based on max Ta of +70°C

Certificate No’s KEMA 99ATEX6312

IECEx KEM 10.0003

“Warnings” DO NOT OPEN WHEN AN EXPLOSIVE

GAS OR DUST ATMOSPHERE IS PRESENT

COVER BOLTS CLASS A4-80

USE HEAT RESISTING CABLES AND CABLE GLANDS

(Rated 110ºC) AT AMB. TEMPERATURES OVER 40ºC

Year of Construction /

Serial No. i.e. 10 / 1DS22000001

3) Type Approval Standards

The sounders have EC Type Examination and IECEx

certificates issued by KEMA and have been approved to the

following standards:-

EN60079-0:2006 IEC60079-0:2004 (Ed4) General Requirements

EN60079-1:2007 IEC60079-1:2007 (Ed6) Flameproof Enclosure ‘d’

EN61241-0:2006 IEC61241-0:2004 (Ed1) Dust General

Requirements

EN61241-1:2004 IEC60079-1:2004 (Ed1) Dust Enclosures tD

4) Installation Requirements

The sounders must be installed in accordance with the latest

issues of the relevant parts of the EN60079 standards or the

equivalent IEC standards – Selection, Installation and

maintenance of electrical apparatus for use in potentially

explosive atmospheres (other than mining applications or

explosive processing and manufacture):-

EN60079-14:2008 Electrical Installations in Hazardous

IEC60079-14:2007 (Ed4) Areas (other than mines)

EN60079-10:2003 Classification of Hazardous Areas

IEC60079-10:2008 (Ed1)

The installation of the units must also be in accordance with

any local codes that may apply and should only be carried out

by a competent electrical engineer who has the necessary

training.

5) Zones, Gas Group, Category, IP Rating and

Temperature Classification

The BExDS120D and BExDS110D sounders have been

certified Ex de IIC T4 for Ta –50°C to +55ºC and Ex de IIB T4

for Ta –50°C to +70ºC for gas and Ex tD A21 IP67 T115ºC

based on max. Ta of +70ºC for dust. This means that the units

can be installed in locations with the following conditions:-

Area Classification Gas:

Zone 1

Explosive gas air mixture likely to occur in

normal operation.

Zone 2

Explosive gas air mixture not likely to occur,

and if it does, it will only exist for a short time.

Gas Groupings:

Group IIA

Propane

Group II

B Ethylene

Group IIC

(Up to

+55ºC

only) Hydrogen and Acetylene

Temperature Classification:

T1 400

o

C T2 300

o

C T3 200

o

C T4 135

o

C

0518

II 2G/D

Epsilon x:

Equipment Group and

Category:

CE Marking:

Notified Body No.

Page 2

__________________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. IS 2451-P Issue E 19-02-10 Sheet 2 of 4 (2)

Area Classification Dust:

Zone 21

Explosive dust air mixture likely to occur in

normal operation.

Zone 22

Explo

sive dust air mixture not likely to occur,

and if it does, it will only exist for a short time.

IP Rating: IP67 T100ºC Ta < +55ºC

T115ºC Ta < +70ºC

Equipment Category: 2G/D

Ambient Temperature Range:

-50°C to +55°C Gas Groups IIA, IIB and IIC

-50°C to +70°C Gas Group IIA and IIB

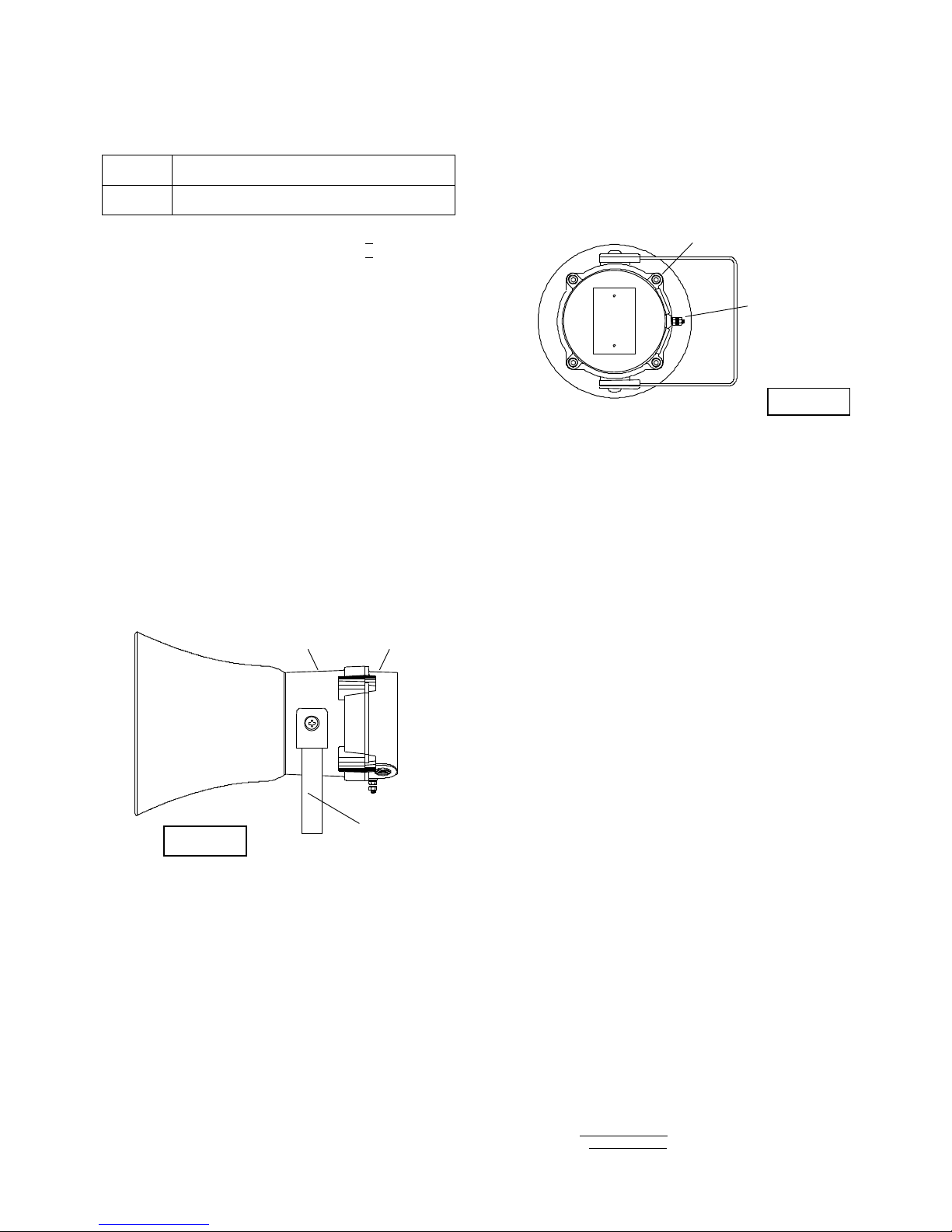

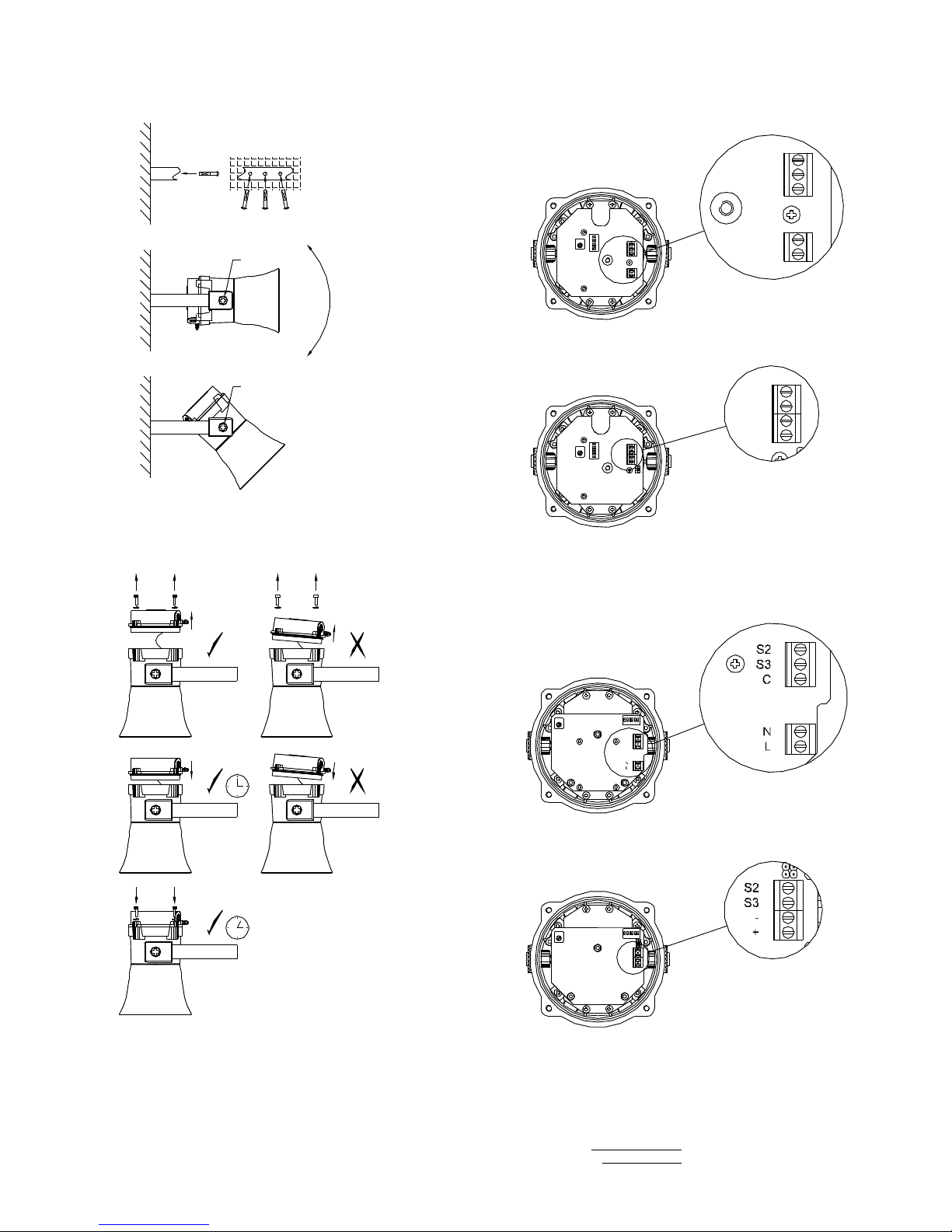

6) Sounder Location and Mounting

The location of the sounders should be made with due regard

to the area over which the warning signal must be audible. The

sounders should only be fixed to services that can carry the

weight of the unit.

The sounder should be securely bolted to a suitable surface

using the 7mm diameter boltholes in the stainless steel U

shaped mounting bracket (see figure 1). The angle can then be

adjusted in the direction that the sound is primarily required to

cover. This can be achieved by loosening the two large bracket

screws in the side of the unit, which allow adjustment in steps

of 18°. On completion of the installation the two large bracket

adjustment screws on the side of the unit must be fully

tightened to ensure that the unit cannot move in service.

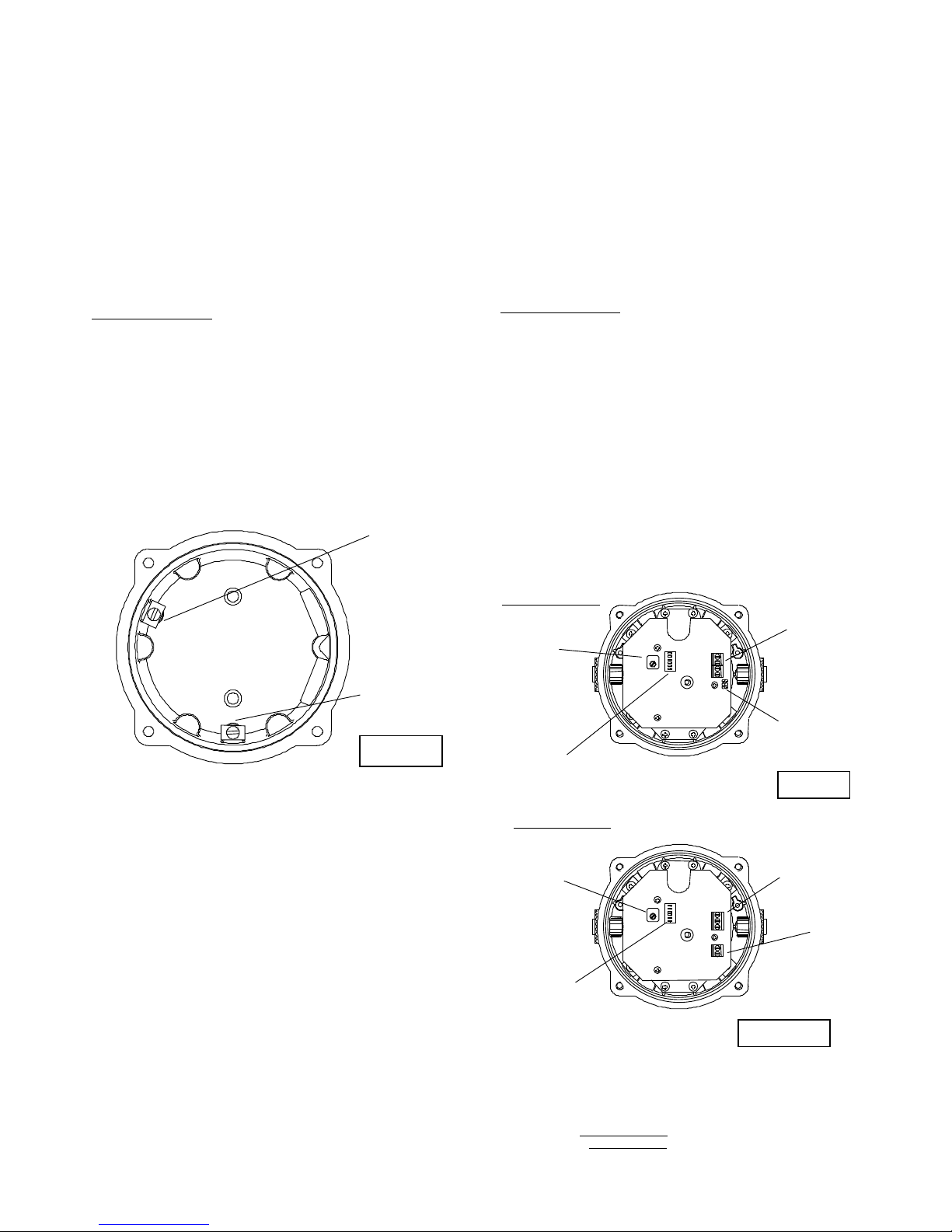

7) Access to the Flameproof Enclosure

In order to connect the electrical supply cables to the sounder

it is necessary to remove the flameproof cover to gain access

to the flameproof chamber. To achieve this remove the four M6

hexagon socket head screws (see figure 2) and withdraw the

flameproof cover taking extreme care not to damage the

flameproof joints in the process.

Note the four M6 screws are Class A4-80 stainless steel

and only screws of this category can be used on these

sounders. It is therefore important that these screws and their

spring washers are kept in a safe place during installation.

On completion of the cable wiring installation the flameproof

joints should be inspected to ensure that they are clean and

that they have not been damaged during installation. Also

check that the earth bonding wire between the two casting

sections is secure and the ‘O’ ring seal is in place.

When replacing the flameproof cover casting ensure that it is

square with the flameproof chamber casting before inserting.

Carefully push the cover in place allowing time for the air to be

expelled. Only after the cover is fully in place should the four

M6 Stainless Steel A4-80 cover bolts and their spring washer

be inserted and tightened down. If the cover jams while it is

being inserted, carefully remove it and try again. Never use the

cover bolts to force the cover into position.

8) Power Supply Selection

It is important that a suitable power supply is used to run the

sounders. The power supply selected must have the

necessary capacity to provide the input current to all of the

sounders connected to the system.

The following table shows the input current taken by the

various sounder units:-

Unit Type Input Input Max.

Voltage Current I/P Volts

BExDS120D 24V DC 800mA 30V

BExDS120D 12V DC 850mA 15V

BExDS120D 48V DC 420mA 58V

BExDS120D 230V AC 90mA 264V

BExDS120D 110V AC 200mA 121V

BExDS120D 115V AC 180mA 126V

BExDS110D 24V DC 265mA 30V

BExDS110D 12V DC 195mA 15V

BExDS110D 48V DC 130mA 58V

BExDS110D 230V AC 56mA 264V

BExDS110D 110V AC 93mA 121V

BExDS110D 115V AC 110mA 126V

The input current will vary according to the voltage input level

and the frequency of the tone selected. The current levels

shown above are for the 440Hz Continuous tone @ nominal

input voltage. The 24V and 48V DC units and the 230V AC,

115V AC and 110V AC units have a switching voltage

regulator circuit and therefore the input current level will

decrease slightly as the input voltage in increased and will

increase slightly as the input voltage is reduced. The 12V units

do not have a voltage regulator and therefore their input

current will increase when the input voltage is increased.

Figure 1

Plastic Acoustic Horn

(Anti-static Plastic)

Flameproof

Chamber

Flameproof

Cover

S/S Mounting

Bracket

Figure 2

4 off M6 Cover Screws

External Earth

Terminal

Page 3

__________________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. IS 2451-P Issue E 19-02-10 Sheet 3 of 4 (3)

The above table also shows the maximum voltages at which

the sounders can be operated.

9) Cable Selection

When selecting the cable size consideration must be given to

the input current that each unit draws (see table above), the

number of sounders on the line and the length of the cable

runs. The cable size selected must have the necessary

capacity to provide the input current to all of the sounders

connected to the line.

SAFETY WARNING: If the high output BExDS120D sounders

are used at high ambient temperatures, i.e. over +40ºC, then

the cable entry temperature may exceed +70ºC and therefore

suitable heat resisting cables must be used, with a rated

service temperature of at least 110ºC.

10) Earthing

Both AC and DC sounder units must be connected to a good

quality earth. The units are provided with internal and external

earthing terminals which are both located on the terminal

chamber section of the unit (see figures 2 and 3).

When using the internal earth terminal ensure that the

stainless steel M4 flat washer is between the incoming earth

wire and the enclosure.

When using the external earth terminal a cable crimp lug must

be used. The cable lug should be located between the two M5

stainless steel flat washers. The M5 stainless steel spring

washer must be fixed between the outer flat washer and the

M5 stainless steel nut to ensure that the cable lug is secured

against loosening and twisting.

The internal earth bonding wire ensures that a good quality

earth is maintained between the flameproof chamber casting

and the flameproof cover casting.

11) Cable Glands

The BExDS120D and BExDS110D sounders have dual cable

gland entries which have an M20 x 1.5 entry thread as

standard. Only cable glands approved for Ex ‘d’ applications

can be used, which must be suitable for the type of cable being

used and also meet the requirements of the Ex ‘d’ flameproof

installation standard EN60079-14:2008 / IEC60079-14:2007.

When only one cable entry is used the other one must be

closed with an Ex ‘d’ flameproof blanking plug, which must be

suitably approved for the installation requirements.

For combustible dust applications, the cable entry device and

blanking elements shall be in type of explosion protection

increased safety "e" or flameproof enclosure "d" and shall have

an IP 6X rating according to EN60529:1992.

SAFETY WARNING: If the high output BExDS120D sounders

are used at high ambient temperatures, i.e. over +40ºC, then

the cable entry temperature may exceed +70ºC and therefore

suitable heat resisting cable glands must be used, with a rated

service temperature of at least 110ºC.

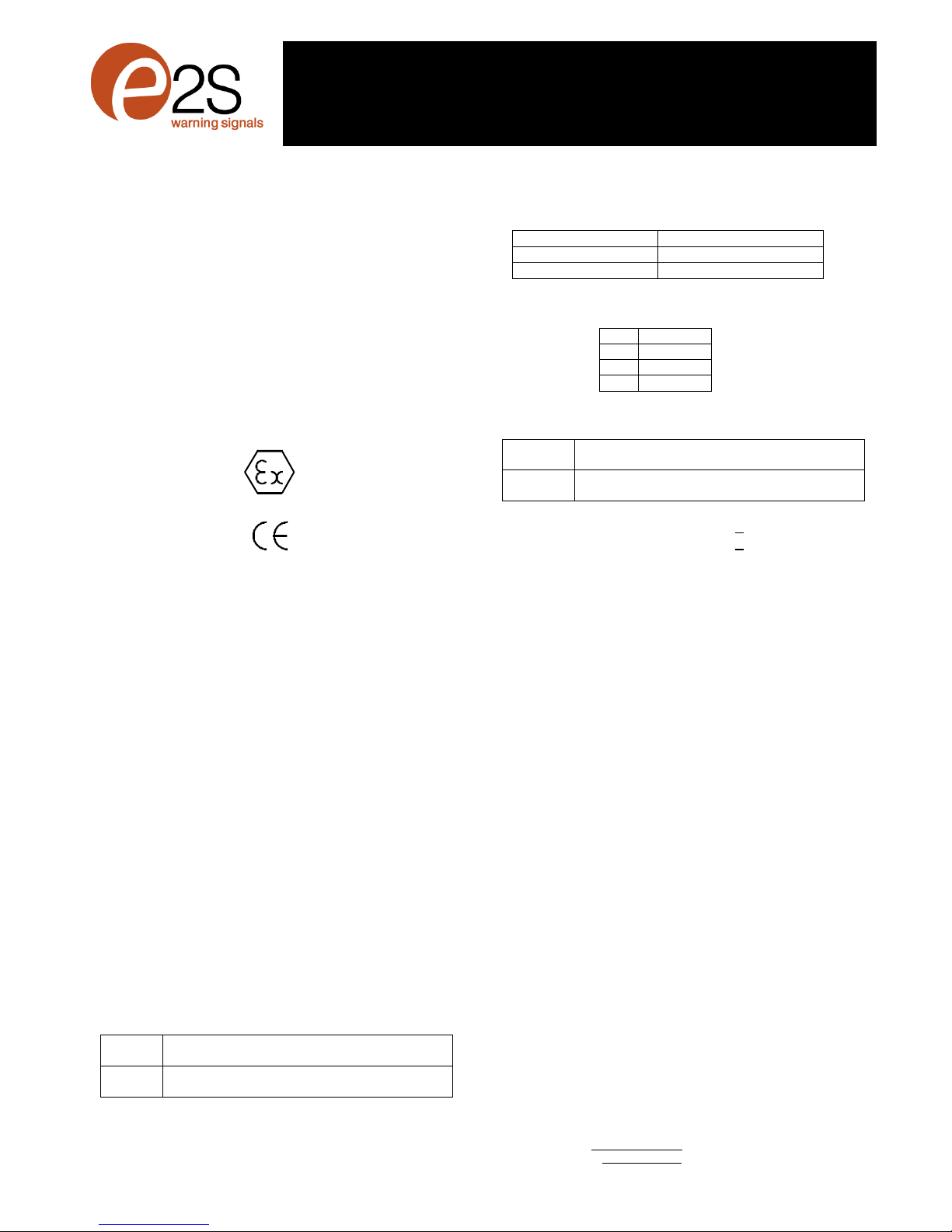

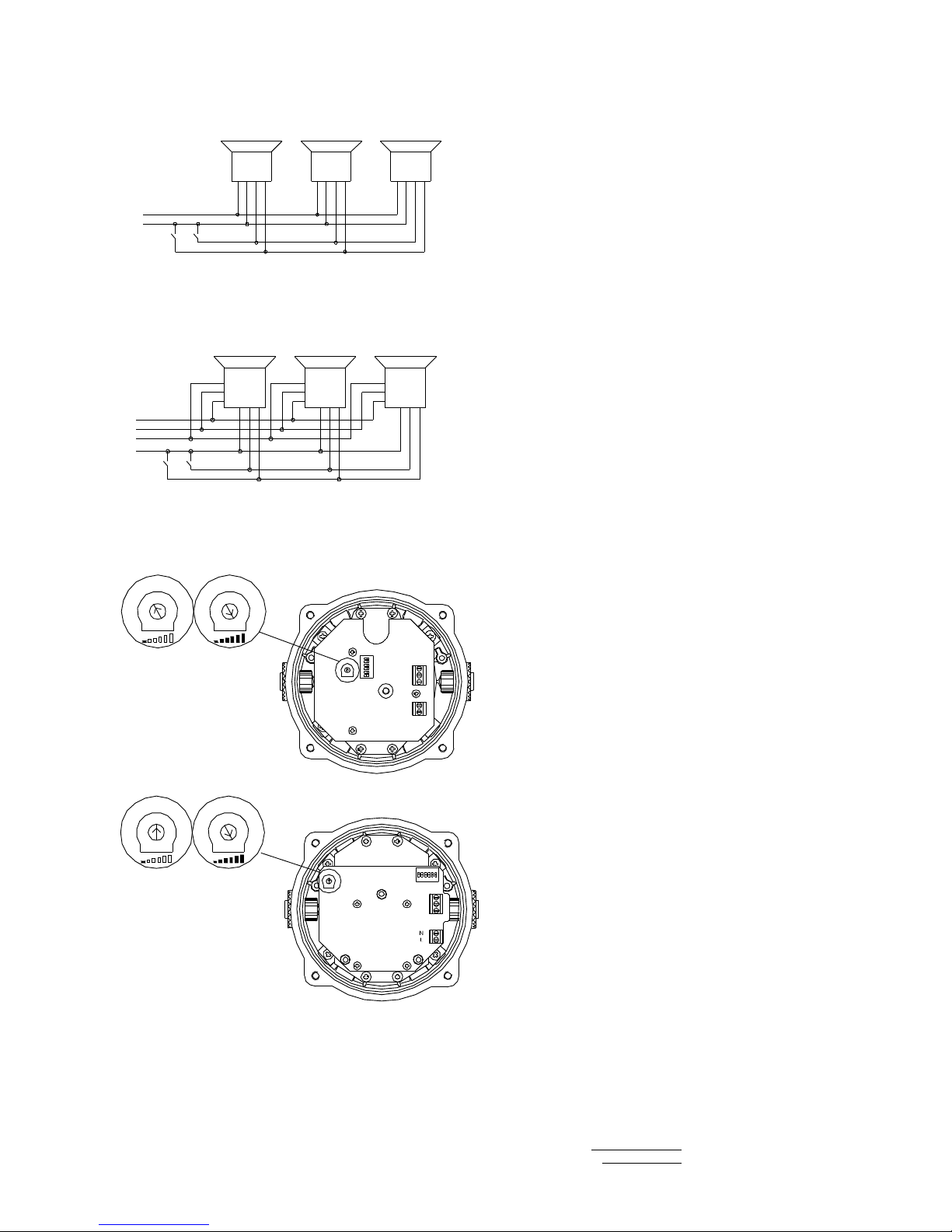

12) Cable Connections

The cable connections are made into the terminal blocks on

the electronic pcb assembly located in the flameproof

enclosure. See section 7 of this manual for access to the

flameproof enclosure. On the AC units a two-way terminal

block is provided for the live and neutral mains supply wires

and a three way terminal block is provided for linking the

second and third stages, (see figures 5 and 7). On the DC

units a four way terminal block is provided for +ve and –ve

supply input and second and third stage modes of operation,

(see figures 4 and 6).

A single wire with a cross sectional area of up to 4mm² can be

connected to each terminal way or if an input and output wire

is required two 2.5mm² wires can be connected to each

terminal way. When connecting wires to the terminals great

2 off M20

Cable Entries

Internal Earth Terminal

Figure 3

Internal Bonding

Wire Terminal

Figure 4

Figure 5

BExDS120D DC

BExDS120D AC

Volume Control

DIP Switch

DC Terminals

Stage Headers

Volume Control

DIP Switch

Stage Terminals

AC Terminals

C

S3

S2

N

L

+

-

S3

S2

Page 4

__________________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. IS 2451-P Issue E 19-02-10 Sheet 4 of 4 (4)

care should be taken to dress the wire so that when the cover

is inserted into the chamber the wires do not exert excess

pressure on the terminal blocks. This is particularly important

when using cables with large cross sectional areas such as

2.5mm² and above.

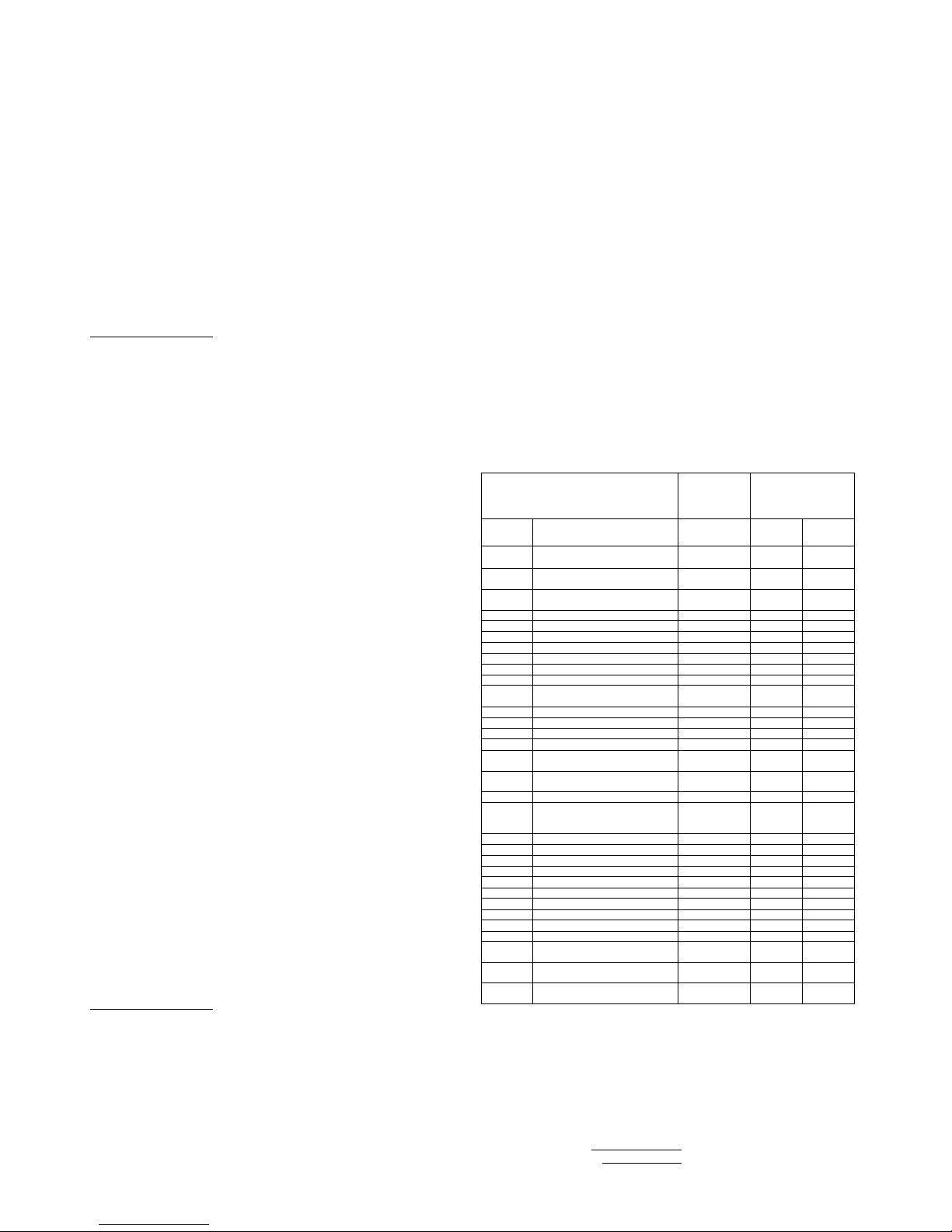

13) Tone Selection and 2nd and 3rd Stage Alarms

The BExDS120D and BExDS110D sounders have 32 different

tones that can be selected for the first stage alarm. The

sounders can then be switched to sound second and third

stage alarm tones. The tones are selected by operation of a

DIP switch on the pcb for both DC and AC units. The tone

table on page four shows the switch positions for the 32 tones

and which tones are available for the second and third stages.

To operate the sounder on stage one simply connect the

supply voltage to the normal supply terminals (+ve and –ve for

DC units, L and N for AC units).

The operation of the second and third stages is different for DC

and AC units.

DC Units Second and Third Stage Tone Selection

The BExDS120D and BExDS110D DC sounders have the

facility to use either +ve or –ve switching to change the tone to

the second and third stages. For –ve switching connect the two

headers on the pcb to the left-hand (marked –ve) and centre

pins. For +ve switching connect the headers to the right hand

(marked +ve) and the centre pins. To change to the second

stage tone, connect either a -ve or +ve supply line to terminal

S2, depending on which switching mode is being used while

maintaining the dc supply to the +ve and –ve terminals.

Similarly for the third stage tone, connect a -ve or +ve supply

line to terminal S3. The supply to the S3 terminal will

automatically override a supply to the S2 terminal.

AC Units Second and Third Stage Tone Selection

To select the second and third stage tones on the BExDS120D

and BExDS110D AC sounders the Common (C) terminal on

the three way terminal block on the pcb is connected to the S2

terminal for the second stage tone and the S3 terminal for the

third stage tone.

14) Volume Control

All BExDS120D and BExDS110D sounders, with the exception

of 12V DC units, have a volume control to adjust the output

level. To set the required output level, adjust the potentiometer

on the pcb. For maximum output level the potentiometer

should be set to the fully clockwise position.

15) End of Line Monitoring (DC Units)

On BExDS120D and BExDS110D DC units, dc reverse line

monitoring can be used if required. All DC sounders have a

blocking diode fitted in their supply input lines. An end of line

monitoring diode or an end of line monitoring resistor can be

connected across the +ve and –ve terminals. If an end of line

resistor is used it must have a minimum resistance value of

3k3 ohms and a minimum wattage of 0.5 watts or a minimum

resistance value of 500 ohms and a min. wattage of 2 watts.

TONE SELECTION TABLE Note Switch No. 6 is not used

Tone Selection

DIP Switch

Settings

Stage Selection

Stage 1 Frequency Description

1 2 3 4 5

Stage 2 Stage 3 1 Continuous 1000Hz

Toxic gas alarm

0 0 0 0 0

Tone 31 Tone 11 2 Alternating 800/1000Hz at 0.25s

intervals

1 0 0 0 0

Tone 17 Tone 5 3 Slow Whoop 500/1200Hz at 0.3Hz

with 0.5s gap repeated

0 1 0 0 0

Tone 2 Tone 5 4 Sweeping 800/1000 at 1Hz

1 1 0 0 0

Tone 6 Tone 5 5 Continuous at 2400Hz

0 0 1 0 0

Tone 3 Tone 27 6 Sweeping 2400/2900Hz at 7Hz

1 0 1 0 0

Tone 7 Tone 5 7 Sweeping 2400/2

900Hz at 1Hz

0 1 1 0 0

Tone 10 Tone 5 8 Siren 500/1200/500Hz at 0.3Hz

1 1 1 0 0

Tone 2 Tone 5 9 Sawtooth 1200/500Hz at 1Hz

0 0 0 1 0

Tone 15 Tone 2 10 Alternating 2400/2900Hz at 2Hz

1 0 0 1 0

Tone 7 Tone 5 11 Intermi

ttent 1000Hz at 0.5Hz

General alarm

0 1 0 1 0

Tone 31 Tone 1 12 Alternating 800/1000Hz at 0.875Hz

1 1 0 1 0

Tone 4 Tone 5

13 Intermittent 2400Hz at 1Hz

0 0 1 1 0

Tone 15 Tone 5

14 Intermittent 800Hz 0.25s on 1s off

1 0 1 1 0 Tone 4 Tone 5 15 Continuous at 800Hz

0 1 1 1 0

Tone 2 Tone 5 16 Intermittent 660Hz 150mS on,

150mS off

1 1 1 1 0

Tone 18 Tone 5 17 Alternating 544Hz

(100mS)/440Hz(400mS)

0 0 0 0 1

Tone 2 Tone 27 18 Intermittent 660Hz

1.8s on, 1.8s off

1 0 0 0 1

Tone 2 Tone 5 19 1400Hz to 1600Hz sweep up over

1s - 1600Hz to 1400Hz sweep down

over 0.5s

0 1 0 0 1

Tone 2 Tone 5 20 Continuous 660Hz

1 1 0 0 1

Tone 2 Tone 5 21 Alternating 554/440Hz at 1Hz

0 0 1 0 1

Tone 2 Tone 5 22 Intermittent 554Hz at 0.875Hz

1 0 1 0 1

Tone 2 Tone 5 23 800Hz pulsing at 2Hz

0 1 1 0 1

Tone 6 Tone 5

24 Sweeping 800/1000Hz at 50Hz

1 1 1 0 1

Tone 29 Tone 5

25 Sweeping 2400/2900Hz at 50Hz

0 0 0 1 1

Tone 29 Tone 5 26 Simulated bell sound

1 0 0 1 1

Tone 2 Tone 1 27 Continuous 554Hz

0 1 0 1 1

Tone 26 Tone 5 28 Continuous 440Hz

1 1 0 1 1

Tone 2 Tone 5 29 Sweeping 800/1000Hz at 7Hz

0 0 1 1 1

Tone 7 T

one 5 30 420Hz repeating 0.625s on, 0.625s

off Australian alert signal

1 0 1 1 1

Tone 32 Tone 5 31 1200/500Hz at 1 Hz

Prepare to abandon platform

0 1 1 1 1

Tone 11 Tone 1 32 Sweeping 500/1200Hz 3.75s on,

0.25s off 15Hz

1 1 1 1

1

Tone 26 Tone 1

Figure 7

Figure 6

BExDS110D DC Sounder

BExDS110D AC

Volume Control

DIP Switch

DIP Switch

Volume Control

DC Terminals

Stage Headers

Stage Terminals

AC Terminals

S2

S3

+

S2

S3

C

N

L

Page 5

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) English Issue E (Four Sheets) 19-02-10 (5)

INSTRUCTION MANUAL (ATEX / IECEx) (GBR)

BExDS120D and BExDS110D Flameproof Sounders

For use in Flammable Gas and Dust Atmospheres

2) Marking

All units have a rating label, which carries the following

important information:-

Unit Type No. BExDS120D or BExDS110D

Input Voltage: DC Units 12V or 24V or 48V

AC Units 230V or 110V or 115V

Codes: Ex d IIC T4 for Ta –50ºC to +55ºC

Ex d IIB T4 for Ta –50ºC to +70ºC

Ex tD A21 IP67 T115ºC based on max Ta of +70ºC

Certificate No’s KEMA 99ATEX6312

IECEx KEM 10.0003

“Warnings” DO NOT OPEN WHEN AN EXPLOSIVE

GAS OR DUST ATMOSPHERE IS PRESENT

COVER BOLTS CLASS A4-80

USE HEAT RESISTING CABLES AND CABLE GLANDS

(Rated 110ºC) AT AMB. TEMPERATURES OVER 40ºC

4) Installation Requirements

Sounders must be installed in accordance with the following

or equivalent standards.

EN60079-14:2008 Electrical Installations in Hazardous

IEC60079-14:2007 (Ed4) Areas (other than mines)

EN60079-10:2003 Classification of Hazardous Areas

IEC60079-10:2008 (Ed1)

Installation should only be carried by competent personnel

and any local codes of practice applied.

5) Zones, Gas Group, Category and Temperature

Classification

The units can be installed in locations with the following

conditions:-

Area Classification Gas:

Zone 1

Explosive gas air mixture likely to occur in

normal operation.

Zone 2

Explosive gas air mixtu

re not likely to occur,

and if it does, it will only exist for a short time.

Gas Groupings:

Group IIA

Propane

Group IIB

Eth

ylene Group IIC

< +55ºC

Hydrogen and Acetylene

Temperature Classification:

T1 400o C T2

300o C T3

200o C T4

135o C

Area Classification Dust:

Zone 21

Explosive dust air mixture likely to occur in

normal operation.

Zone 22

Explosive dust air mi

xture not likely to occur,

and if it does, it will only exist for a short time.

IP Rating: IP67 T100ºC Ta < +55ºC

T115ºC Ta < +70ºC

Equipment Category: 2G/D

Ambient Temperature Range:

-50°C to +55°C Gas Groups IIA, IIB and IIC

-50°C to +70°C Gas Group IIA and IIB

6) Sounder Location and Mounting

See drawing A

7) Access to the Flameproof Enclosure

See drawing B

Note the four M6 screws are Class A4-80 stainless steel

and only screws of this category can be used on these

sounders. It is therefore important that these screws and

their spring washers are kept in a safe place during

installation.

8) Power Supply Selection

The system power supply must have the necessary capacity

to provide the input current to all of the sounders connected

to the system.

The following table shows the input current taken by the

various sounder units:-

Unit Type Input Input Max.

Voltage Current I/P Volts

BExDS120D 24V DC 800mA 30V

BExDS120D 12V DC 850mA 15V

BExDS120D 48V DC 420mA 58V

BExDS120D 230V AC 90mA 264V

0518

II 2G/D

Epsilon x:

Equipment Group and

Category:

CE Marking:

Notified Body No.

Page 6

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) English Issue E (Four Sheets) 19-02-10 (6)

BExDS120D 110V AC 200mA 121V

BExDS120D 115V AC 180mA 126V

BExDS110D 24V DC 265mA 30V

BExDS110D 12V DC 195mA 15V

BExDS110D 48V DC 130mA 58V

BExDS110D 230V AC 56mA 264V

BExDS110D 110V AC 93mA 121V

BExDS110D 115V AC 110mA 126V

The above table also shows the maximum voltages at which

the sounders can be operated.

9) Cable Selection

Cables must be capable of handling the current drawn from

all of the units on the line.

SAFETY WARNING: If the high output BExDS120D sounders

are used at high ambient temperatures, i.e. over +40ºC, then

the cable entry temperature may exceed +70ºC and therefore

suitable heat resisting cables must be used, with a rated

service temperature of at least 110ºC.

10) Earthing

Both AC and DC sounder units must be connected to a good

quality earth. The units are provided with internal and

external-earthing terminals, which are, both located on the

terminal chamber section of the unit (see figures 2 and 3).

When using the internal earth terminal ensure that the

stainless steel M4 flat washer is between the incoming earth

wire and the enclosure.

When using the external earth terminal a cable crimp lug

must be used. The cable lug should be located between the

two M5 stainless steel flat washers. The M5 stainless steel

spring washer must be fixed between the outer flat washer

and the M5 stainless steel nut to ensure that the cable lug is

secured against loosening and twisting.

11) Cable Glands

The BExDS120D and BExDS110D sounders have dual cable

gland entries with M20 x1.5 entry threads. Only cable glands

approved for Ex ‘d’ applications can be used, which must be

suitable for the type of cable being used and also meet the

requirements of the Ex ‘d’ flameproof installation standard

EN60079-14:2008 / IEC60079-14:2007.

When only one cable entry is used the other one must be

closed with an Ex ‘d’ flameproof blanking plug, which must be

suitably approved for the installation requirements.

For combustible dust applications, the cable entry device and

blanking elements shall be in type of explosion protection

increased safety "e" or flameproof enclosure "d" and shall

have an IP 6X rating according to EN60529:1992.

SAFETY WARNING: If the high output BExDS120D sounders

are used at high ambient temperatures, i.e. over +40ºC, then

the cable entry temperature may exceed +70ºC and therefore

suitable heat resisting cable glands must be used, with a

rated service temperature of at least 110ºC.

12) Cable Connections

See drawing C and D

13) Tone Selection and 2nd and 3rd Stage Alarms

See wiring diagram E

14) Volume Control

See drawing F

15) End of Line Monitoring (DC Units)

On BExDS120D and BExDS110D DC units, dc reverse line

monitoring can be used if required. All DC sounders have a

blocking diode fitted in their supply input lines. An end of line

monitoring diode or an end of line monitoring resistor can be

connected across the +ve and –ve terminals. If an end of line

resistor is used it must have a minimum resistance value of

3k3 ohms and a minimum wattage of 0.5 watts or a minimum

resistance value of 500 ohms and a min. wattage of 2 watts.

TONE SELECTION TABLE

Tone Selection

DIP Switch

Settings

Stage Selection

Stage 1

Frequency Description

1 2 3 4 5

Stage 2

Stage 3

1

C

ontinuous 1000Hz

Toxic Gas Alarm

0 0 0 0 0

Tone 31 Tone 11 2 Alternating 800/1000Hz at 0.25s

intervals

1 0 0 0 0

Tone 17 Tone 5 3 Slow Whoop 500/1200Hz at 0.3Hz

with 0.5s gap repeated

0 1 0 0 0

Tone 2 Tone 5 4 Sweeping 800/1

000 at 1Hz

1 1 0 0 0

Tone 6 Tone 5 5 Continuous at 2400Hz

0 0 1 0 0

Tone 3 Tone 27 6 Sweeping 2400/2900Hz at 7Hz

1 0 1 0 0

Tone 7 Tone 5 7 Sweeping 2400/2900Hz at 1Hz

0 1 1 0 0

Tone 10 Tone 5 8 Siren 500/1200/500Hz a

t 0.3Hz 1 1 1 0 0

Tone 2 Tone 5 9 Sawtooth 1200/500Hz at 1Hz

0 0 0 1 0

Tone 15 Tone 2 10 Alternating 2400/2900Hz at 2Hz

1 0 0 1 0

Tone 7 Tone 5 11 Intermittent 1000Hz at 0.5Hz

General alarm

0 1 0 1 0

Tone 31 Tone 1 12

Alternating 800/1000Hz at 0.875Hz

1 1 0 1 0

Tone 4 Tone 5 13 Intermittent 2400Hz at 1Hz

0 0 1 1 0

Tone 15 Tone 5 14 Intermittent 800Hz 0.25s on 1s off

1 0 1 1 0

Tone 4 Tone 5 15 Continuous at 800Hz

0 1 1 1 0

Tone 2 Tone 5 16 Intermittent 660Hz 150mS on,

150mS off

1 1 1 1 0

Tone 18 Tone 5 17 Alternating 544Hz

(100mS)/440Hz(400mS)

0 0 0 0 1

Tone 2 Tone 27 18 Intermittent 660Hz 1.8s on, 1.8s off

1 0 0 0 1

Tone 2 Tone 5 19 1400Hz to 1600Hz

sweep up over

1s - 1600Hz to 1400Hz sweep down

over 0.5s

0 1 0 0 1

Tone 2 Tone 5 20 Continuous 660Hz

1 1 0 0 1

Tone 2 Tone 5 21 Alternating 554/440Hz at 1Hz

0 0 1 0 1

Tone 2 Tone 5 22 Intermittent 554Hz at 0.875Hz

1 0

1 0 1 Tone 2 Tone 5 23 800Hz pulsing at 2Hz

0 1 1 0 1

Tone 6 Tone 5 24 Sweeping 800/1000Hz at 50Hz

1 1 1 0 1

Tone 29 Tone 5 25 Sweeping 2400/2900Hz at 50Hz

0 0 0 1 1

Tone 29 Tone 5 26 Simulated bell sound

1 0 0 1

1

Tone 2 Tone 1 27 Continuous 554Hz

0 1 0 1 1

Tone 26 Tone 5 28 Continuous 440Hz

1 1 0 1 1

Tone 2 Tone 5 29 Sweeping 800/1000Hz at 7Hz

0 0 1 1 1

Tone 7 Tone 5 30 420Hz repeating 0.625s on, 0.625s

off Australian alert signal

1 0 1 1 1

Tone 32 Tone 5 31 1200/500Hz at 1 Hz

Prepare to Abandon Platform

0 1 1 1 1

Tone 11 Tone 1 32 Sweeping 500/1200Hz 3.75s on,

0.25s off 15Hz

1 1 1 1 1

Tone 26 Tone 1

Page 7

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) English Issue E (Four Sheets) 19-02-10 (7)

Drawing A

Tighten screw to

secure

Lossen screw

to adjust

Tighten screw to secure.

Spænd skruen for at fastgøre.

Schroef aandraaien om vast te zetten.

Serrer la vis pour une fixation sûre.

Zum Sichern Schraube anziehen.

Stringere la vite per il fissaggio.

Stram skruen for å feste.

Aperte o parafuso para fixar.

Apriete el tornillo para asegurar.

Dra åt skruven för att fästa.

Loosen screw to adjust.

Løsn skruen for at tilpasse.

Schroef losdraaien om af te stellen.

Desserrer la vis pour régler.

Zum Regulieren Schraube lockern.

Allentare la vite per poter effettuare la

regolazione.

Løsne skruen for å justere.

Desaperte o parafuso para ajustar.

Afloje el tornillo para ajustar.

Lossa skruven för att justera.

Drawing B

Drawing C

+

S3

S2

N

L

C

S3

S2

N

L

+

S3

S2

C

S3

S2

BExS120D AC

BExS120D DC

Drawing D

S2

S3

+

S2

S3

C

BExS110D AC

BExS110D DC

Page 8

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) English Issue E (Four Sheets) 19-02-10 (8)

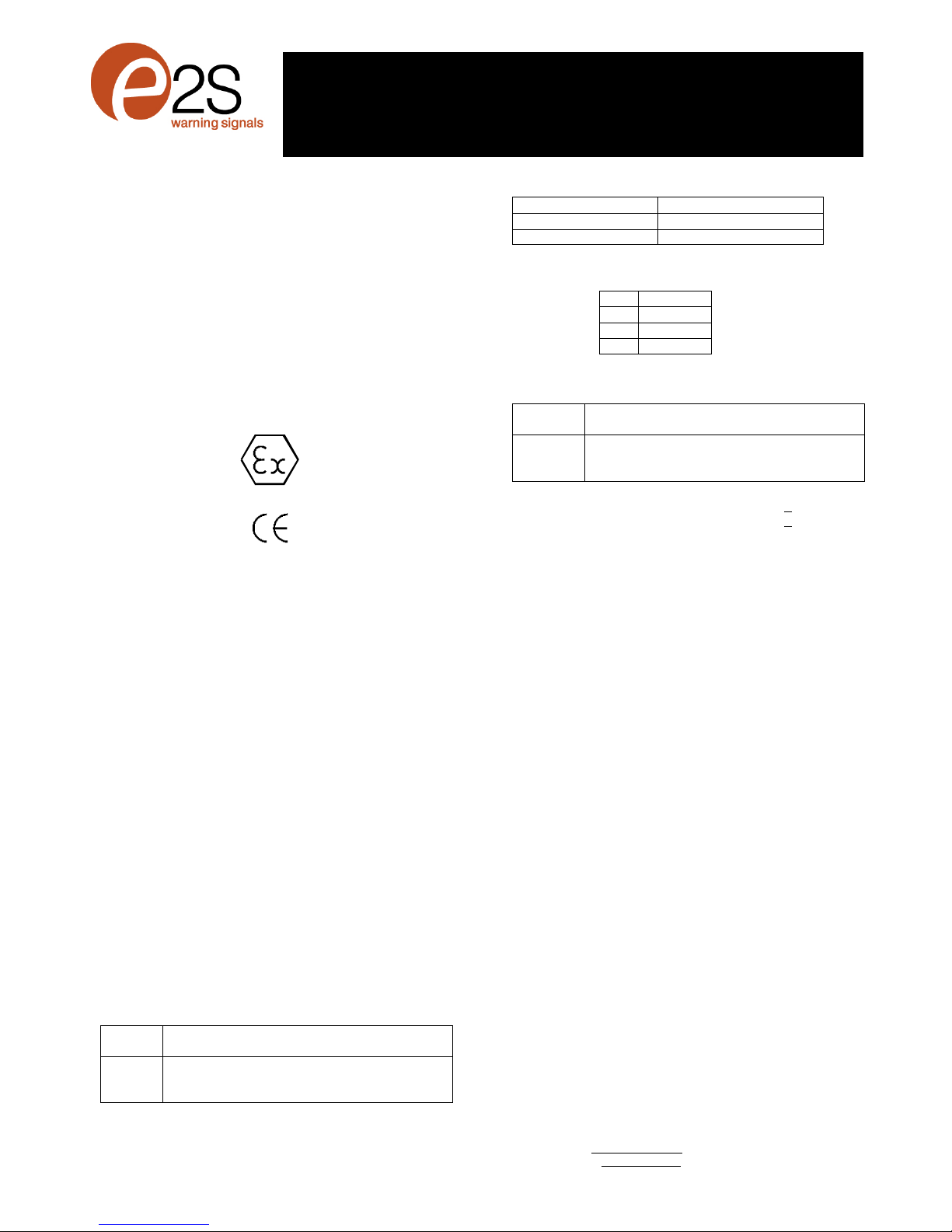

Wiring Diagram E

-

S3

S2

+

BExS120D and

BExS110D

DC Units

+ - S2 S3

+ - S2 S3 + - S2 S3

C

S3

S2

L

N

E

BExS120D and

BExS110D

AC Units

C S2 S3

N

C S2 S3

N

C S2 S3

E

E

L

L

E

N

L

Drawing F

BExS110D

BExS120D

S2

S3

C

C

S3

S2

N

L

Page 9

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) Danish Issue E (Two Sheets) 19-02-10 (9)

INSTRUKTIONSMANUAL (ATEX / IECEx) (DNK)

BExDS120D og BExDS110D Flammesikre soundere

Til brug i miljøer med brandfarlige gasser og

2) Mærkater

Alle enheder har en klassificeringsmærkat, der bærer

følgende vigtige oplysninger:

Enhedstypenr. BExDS120D eller BExDS110D

Indgangsspænding: DC-enheder 12V eller 24V eller 48V

AC-enheder 230V eller 110V eller 115V

Kodes: Ex d IIC T4 for Ta –50ºC to +55ºC

Ex d IIB T4 for Ta –50ºC to +70ºC

Ex tD A21 IP67 T115ºC based on max Ta of +70°C

Certifikatnr. KEMA 99ATEX6312

IECEx KEM 10.0003

”Advarsler” MÅ IKKE ÅBNES,

NÅR DER ER EKSPLOSIVE

GASSER ELLER STØV TIL STEDE

DÆKBOLTE KLASSE A4-80

BRUG VARMEBESTANDIGE KABLER OG PAKDÅSER

(Mærket 110ºC) VED OMGIVENDE TEMP. OVER 40ºC

4) Installationskrav

Soundere skal installeres i overensstemmelse med følgende

eller tilsvarende standarder.

EN60079-14:2008 Elektriske installationer i sundheds

IEC60079-14:2007 (Ed4) farlige områder (undtagen miner)

EN60079-10:2003 Klassifikation af sundhedsfarlige om

IEC60079-10:2008 (Ed1) råder

Installation bør kun udføres af kompetent personale og under

iagttagelse af lokale regler.

5) Zone-, gasgruppe-, kategori- og temperatur klassifikation

Enhederne kan installeres på områder med følgende forhold:

Klassificeringsareal for gasser:

Zone 1

Eksplosiv gas

- og luftblanding kan forekomme

ved normal drift.

Zone 2

Eksplosiv gas

- og luftblanding fore

kommer

sandsynligvis ikke, og hvis det sker, vil det kun

være for en kort tidsperiode.

Gasgrupperinger:

Gruppe IIA

Propan

Gruppe IIB

Ethylen

Gruppe IIC

< +55ºC

Hydrogen og acetylen

Temperaturklassifikation:

T1 400o C T2

300o C T3

200o C T4

135o C

Klassificeringsareal for støv:

Zone 21

En eksplosiv blanding af støv og luft kan

forekomme under den normale drift

Zone 22

En eksplosiv blanding af støv og luft vil

sandsynligvis ikke forekomme, og hvis dette

skulle ske, vil det kun vare et kort stykke tid.

IP dimensionering: IP67 T100ºC Ta < +55ºC

T115ºC Ta < +70ºC

Udstyrskategori: 2G/D

Omgivende temperatur:

-50°C til +55°C Gasgrupperinger IIA, IIB og IIC

-50°C til +70°C Gasgrupperinger IIA og IIB

6) Sounderplacering og -montering

Se illustration A

7) Adgang til flammesikker indkapsling

Se illustration B

Bemærk, at de fire M6 skruer er klase A4-80, rustfri stål,

og der må kun anvendes skruer af denne kategori på

sounderne. Det er derfor vigtigt, at skruerne og deres

fjederskiver opbevares på et sikkert sted under installation.

8) Strømforsyningsudvalg

Systemets strømforsyning skal have den nødvendige

kapacitet for at kunne yde indgangsstrøm til alle soundere

forbundet til systemet.

Nedenstående tabel viser indgangsstrømbehovet for forskellige sounderenheder:

Enhedstype Indgangs- Indgangs- Maks.

spænding strøm I/P Volt

BExDS120D 24V DC 800mA 30V

BExDS120D 12V DC 850mA 15V

BExDS120D 48V DC 420mA 58V

BExDS120D 230V AC 90mA 264V

BExDS120D 110V AC 200mA 121V

BExDS120D 115V AC 180mA 126V

0518

II 2G/D

Epsilon x:

Udstyrets gruppe

og kategori:

CE-mærke:

Noteret

myndighedsnr.

Page 10

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) Danish Issue E (Two Sheets) 19-02-10 (10)

BExDS110D 24V DC 265mA 30V

BExDS110D 12V DC 195mA 15V

BExDS110D 48V DC 130mA 58V

BExDS110D 230V AC 56mA 264V

BExDS110D 110V AC 93mA 121V

BExDS110D 115V AC 110mA 126V

Ovenstående tabel viser også maksimalspændingen, som

sounderne kan betjenes ved.

9) Kabeludvalg

Kablerne skal kunne håndtere den samlede strøm fra alle anvendte enheder.

SIKKERHEDSADVARSEL: Hvis de højtydende BExDS120Dsoundere anvendes ved høje omgivende temperaturer, dvs.

over +40ºC, kan kablets indgangstemperatur overstige

+70ºC, og der skal derfor anvendes passende

varmebestandige kabler med en nominel arbejdstemperatur

på mindst 110ºC.

10) Jordforbindelse

Både AC- og DC-sounderenheder skal være forbundet til en

jordforbindelse af høj kvalitet. Enhederne har indvendige og

udvendige jordklemmer, der begge befinder sig på enhedens

klemkammerdel (se figur 2 og 3).

Når den udvendige jordklemmel anvendes, skal der bruges

en kabelklemmesko. Kabelskoen skal befinde sig mellem to

flade M5-spændeskiverr af rustfrit stål. De rustfri stål M5spændeskiver skal fastgøres mellem den ydre flade skive og

M5-møtrikken af rustfrit stål for at sikre, at kabelskoen ikke

løsner eller vrider sig.

11) Kabelafslutning

Sounderne har dobbelte kabelafslutningsindgange med M20

x1,5 indgangsgevind. Kun kabelafslutninger godkendt til Ex

‘d’-applikationer må anvendes og skal passe til den type

kabel, der anvendes samt opfylde kravene i Ex ‘d’, standard

for flammesikker installation EN60079-14:2008 / IEC6007914:2007.

Når der kun anvendes en kabelindgang, skal den anden lukkes med en Ex ‘d’, flammesikker blindprop, der skal være

korrekt godkendt i overensstemmelse medl

installationskravene.

I forbindelse med letantændelige støvapplikationer skal

kabelindføringsanordningen og stansningselementerne være

med eksplosionsbeskyttelse for forhøjet sikkerhed af type “e”

eller et flammesikkert indelukke af type “d” og skal have en IP

6X dimensionering i overensstemmelse med EN60529:1992.

SIKKERHEDSADVARSEL: Hvis de højtydende BExDS120Dsoundere anvendes ved høje omgivende temperaturer, dvs.

temperaturer over +40ºC, kan kablets indgangstemperatur

overstige +70ºC, og der skal derfor anvendes passende

varmebestandige kabler med en nominel arbejdstemperatur

på mindst 110ºC.

12) Kabelforbindelser

Se illustrationen C og D

13) Tonevalg og 2. og 3. niveau alarmer

Se ledningsdiagram E

14) Volumenkontrol

Se illustration F

15) Linieslutovervågning (DC-enheder)

På BExDS120D og BExDS110D DC-enheder kan der

anvendes returlinieovervågning, efter behov. Alle DCsoundere har en spærrediode i strømindgangsledningerne.

En diode til linieslutovervågning eller en linieslutmodstand

kan forbindes på tværs af +ve- og –ve- klemmerne. Hvis en

linieslutmodstander anvendes, skal den have en minimum

modstandsværdi på 3k3 ohm og et minimum watt-tal på 0,5

watt eller en minimum modstandsværdi på 500 ohm og et

minimum watt-tal på 2 watt.

TONEVALGSTABEL

Tone Selection

DIP Switch

Settings

Stage Selection

Stage 1

Frequency Description

1 2 3 4 5

Stage 2

Stage 3

1

Continuous 1000Hz

Toxic Gas Alarm

0 0 0 0 0

Tone 31 Ton

e 11 2 Alternating 800/1000Hz at 0.25s

intervals

1 0 0 0 0

Tone 17 Tone 5 3 Slow Whoop 500/1200Hz at 0.3Hz

with 0.5s gap repeated

0 1 0 0 0

Tone 2 Tone 5 4 Sweeping 800/1000 at 1Hz

1 1 0 0 0

Tone 6 Tone 5 5 Continuous at 2400

Hz 0 0 1 0 0

Tone 3 Tone 27 6 Sweeping 2400/2900Hz at 7Hz

1 0 1 0 0

Tone 7 Tone 5 7 Sweeping 2400/2900Hz at 1Hz

0 1 1 0 0

Tone 10 Tone 5 8 Siren 500/1200/500Hz at 0.3Hz

1 1 1 0 0

Tone 2 Tone 5 9 Sawtooth 1200/500Hz a

t 1Hz 0 0 0 1 0

Tone 15 Tone 2 10 Alternating 2400/2900Hz at 2Hz

1 0 0 1 0

Tone 7 Tone 5 11 Intermittent 1000Hz at 0.5Hz

General alarm

0 1 0 1 0

Tone 31 Tone 1 12 Alternating 800/1000Hz at 0.875Hz

1 1 0 1 0

Tone 4 Ton

e 5 13 Intermittent 2400Hz at 1Hz

0 0 1 1 0

Tone 15 Tone 5 14 Intermittent 800Hz 0.25s on 1s off

1 0 1 1 0

Tone 4 Tone 5 15 Continuous at 800Hz

0 1 1 1 0

Tone 2 Tone 5 16 Intermittent 660Hz 150mS on,

150mS off

1 1 1 1

0

Tone 18 Tone 5 17 Alternating 544Hz

(100mS)/440Hz(400mS)

0 0 0 0 1

Tone 2 Tone 27 18 Intermittent 660Hz 1.8s on, 1.8s off

1 0 0 0 1

Tone 2 Tone 5 19 1400Hz to 1600Hz sweep up over

1s - 1600Hz to 1400Hz sweep down

over 0.5s

0 1

0 0 1 Tone 2 Tone 5 20 Continuous 660Hz

1 1 0 0 1

Tone 2 Tone 5 21 Alternating 554/440Hz at 1Hz

0 0 1 0 1

Tone 2 Tone 5 22 Intermittent 554Hz at 0.875Hz

1 0 1 0 1

Tone 2 Tone 5 23 800Hz pulsing at 2Hz

0 1 1 0

1

Tone 6 Tone 5 24 Sweeping 800/1000Hz at 50Hz

1 1 1 0 1

Tone 29 Tone 5 25 Sweeping 2400/2900Hz at 50Hz

0 0 0 1 1

Tone 29 Tone 5 26 Simulated bell sound

1 0 0 1 1

Tone 2 Tone 1 27 Continuous 554Hz

0 1 0 1 1

Tone 26 Tone 5 28 Continuous 440Hz

1 1 0 1 1

Tone 2 Tone 5 29 Sweeping 800/1000Hz at 7Hz

0 0 1 1 1

Tone 7 Tone 5 30 420Hz repeating 0.625s on, 0.625s

off Australian alert signal

1 0 1 1 1

Tone 32 Tone 5 31 1200/500Hz at 1 Hz

Prepare to Abandon Platform

0 1 1 1 1

Tone 11 Tone 1 32 Sweeping 500/1200Hz 3.75s on,

0.25s off 15Hz

1 1 1 1 1

Tone 26 Tone 1

Page 11

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) Dutch Issue E (Two Sheets) 19-02-10 (11)

INSTRUCTIEHANDLEIDING (ATEX / IECEx) (NLD)

BExDS120D en BExDS110D Vuurvaste alarmgevers

Voor gebruik in brandbare gas- en stofatmosferen

2) Labels

Alle eenheden zijn voorzien van een label, waarop de

volgende belangrijke informatie staat:

Typenr. eenheid: BExDS120D of BExDS110D

Ingangsspanning: DC-eenheden 12 V of 24 V of 48 V

AC-eenheden 230 V of 110 V of 115 V

Codes: Ex d IIC T4 for Ta –50ºC to +55ºC

Ex d IIB T4 for Ta –50ºC to +70ºC

Ex tD A21 IP67 T115ºC based on max Ta of +70°C

Certificate No. KEMA 99ATEX6312

IECEx KEM 10.0003

“Waarschuwingen” NIET OPENEN WANNEER

ER EEN EXPLOSIEVE GAS-

OF STOFATMOSFEER AANWEZIG IS

DEKSELBOUTEN KLASSE A4-80

BIJ OMGEVINGSTEMP. HOGER DAN 40ºC

HITTEBESTENDIGE KABELS EN KABELWARTELS

GEBRUIKEN (geschikt voor 110ºC)

4) Vereisten voor installatie

Alarmgevers moeten worden geïnstalleerd in

overeenstemming met de volgende of equivalente normen.

EN60079-14:2008 Elektrische installaties in gevaarlijke

IEC60079-14:2007 (Ed4) omgevingen (anders dan mijnen)

EN60079-10:2003 Classificatie van gevaarlijke

IEC60079-10:2008 (Ed1) omgevingen

Installatie mag alleen worden uitgevoerd door deskundig

personeel en met inachtneming van plaatselijke

gedragscodes en praktijkrichtlijnen.

5) Classificatie t.a.v. zones, gasgroep, categorie

en temperatuur

De eenheden kunnen worden geïnstalleerd op plaatsen waar

de volgende omstandigheden heersen:

Zoneclassificatie gas:

Zone 1

Ontplofbaar gas

-

/luchtmengsel is waarschijnlijk

bij normaal bedrijf.

Zone 2

Ontplofbaar gas

-

/luchtmengsel is

onwaarschijnlijk, en indien dit ontstaat zal het

waarschijnlijk slechts korte tijd aanwezig

blijven.

Gasgroeperingen:

Groep IIA

Propaan

Groep IIB

Ethyleen

Groep IIC

< +55ºC

Waterstof en acetyleen

Temperatuurclassificatie:

T1 400o C T2

300o C T3

200o C T4

135o C

Zoneclassificatie stof:

Zone 21

Explosief stof

-

luchtmengsel waarschijnlijk

aanwezig bij normaal functioneren.

Zone 22

Explosief stof

-

luchtmengsel waarschijnlijk niet

aanwezig, of alleen van korte duur.

IP-classificatie: IP67 T100ºC Ta < +55ºC

T115ºC Ta < +70ºC

Categorie van apparatuur: 2G/D

Omgevingstemperatuur:

-50°C tot +55°C Gasgroeperingen IIA, IIB en IIC

-50°C tot +70°C Gasgroeperingen IIA en IIB

6) Plaatsing en bevestiging van alarmgever

Zie tekening A

7) Toegang tot de vuurvaste behuizing

Zie tekening B

Houdt u er rekening mee dat de vier M6-schroeven van

Klasse A4-80 roestvrij staal zijn en dat op deze

alarmgevers alleen schroeven van deze categorie

kunnen worden gebruikt. Het is derhalve belangrijk dat

deze schroeven en de bijbehorende veerringen tijdens de

installatie op een veilige plaats worden bewaard.

8) Kiezen van voedingsbron

De voedingsbron van het systeem dient voldoende capaciteit

te hebben om alle alarmgevers die op het systeem zijn

aangesloten van elektrische voeding te voorzien.

In de onderstaande tabel staat vermeld welke ingangsstroom

de verschillende alarmgevers trekken:

Type eenheid Ingangs- Ingangs- Max.

spanning stroom I/P volt

BExDS120D 24 V DC 800 mA 30 V

BExDS120D 12 V DC 850 mA 15 V

BExDS120D 48 V DC 420 mA 58 V

0518

II 2G/D

Epsilon x:

Groep en categorie

van apparatuur:

CE-certificaat:

Instantienr.

Page 12

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) Dutch Issue E (Two Sheets) 19-02-10 (12)

BExDS120D 230 V AC 90 mA 264 V

BExDS120D 110 V AC 200 mA 121 V

BExDS120D 115 V AC 180 mA 126 V

BExDS110D 24 V DC 265 mA 30 V

BExDS110D 12 V DC 195 mA 15 V

BExDS110D 48 V DC 130 mA 58 V

BExDS110D 230 V AC 56 mA 264 V

BExDS110D 110 V AC 93 mA 121 V

BExDS110D 115 V AC 110 mA 126 V

In de bovenstaande tabel wordt tevens vermeld op welke

maximumspanningen de alarmgevers kunnen werken.

9) Kiezen van kabels

Kabels moeten bestand zijn tegen de stroom die door alle

eenheden op de lijn wordt getrokken.

VEILIGHEIDSWAARSCHUWING: als de BExDS120D

alarmgevers met hoge uitvoer worden gebruikt bij hoge

omgevingstemperaturen, m.a.w. hoger dan +40º C, dan kan

de temperatuur bij de kabelingang hoger zijn dan +70ºC en

moeten dus geschikte hittebestendige kabels worden

gebruikt, met een nominale werktemperatuur van ten minste

110º C.

10) Aarding

Zowel alarmgevers op wisselstroom als gelijkstroom moeten

worden aangesloten op aarding van goede kwaliteit. De

eenheden worden geleverd met interne en externe

aardaansluitingen, beide aangebracht op het gedeelte met de

aansluitkast op de eenheid (zie Afb. 2 en 3).

Bij gebruik van de externe aardaansluiting dient een

kabelkrimpkous te worden gebruikt. De kabelkous moet

worden aangebracht tussen de twee M5 roestvrijstalen platte

borgschijfjes. De M5 roestvrijstalen veerring moet worden

bevestigd tussen het buitenste platte borgschijfje en de M5

roestvrijstalen moer, zodat de kabelkous goed is vastgezet

en niet kan draaien of losraken.

11) Kabelwartels

De alarmgevers zijn voorzien van dubbele

kabelwartelingangen met M20 x 1,5 ingangsschroefdraad. Er

kunnen alleen kabelwartels worden gebruikt die zijn

goedgekeurd voor Ex ‘d’-toepassingen, geschikt zijn voor het

bekabelingstype dat wordt gebruikt en voldoen aan de

vereisten van de norm EN60079-14:2008 / IEC6007914:2007 ten aanzien van de Ex ‘d’ vuurvaste installatie.

Indien slechts een kabelingang wordt gebruikt, dient de

andere te worden afgesloten met een Ex ‘d’ vuurvaste

afdichtplug, die moet zijn goedgekeurd voor de

installatievereisten.

Voor brandbare stoftoepassingen zullen de kabelinvoer en

blokkeerelementen van het type explosiebescherming met

verhoogde beveiliging “e” of vuurvaste omhulling “d” zijn en

een IP 6X-classificatie hebben overeenkomstig

EN60529:1992.

VEILIGHEIDSWAARSCHUWING: als de BExDS120D

alarmgevers met hoge uitvoer worden gebruikt bij hoge

omgevingstemperaturen, m.a.w. hoger dan +40º C, dan kan

de temperatuur bij de kabelingang hoger zijn dan +70ºC en

moeten dus geschikte hittebestendige kabelwartels worden

gebruikt, met een nominale werktemperatuur van ten minste

110º C.

12) Kabelaansluitingen

Zie tekening C en D

13) Toonkeuze en alarmen in 2e en 3e fase

Zie bedradingsschema E

14) Volumeregeling

Zie tekening F

15) Bewaking aan einde van lijn (DC-eenheden)

Op BExDS120D en BExDS110D DC-eenheden kan

desgewenst omgekeerde gelijkstroomlijnbewaking worden

gebruikt. Alle DC-alarmgevers zijn uitgerust met een

blokkeringsdiode in de ingangslijnen voor de elektrische

voeding. Een bewakingsdiode of bewakingsweerstand aan

het einde van de lijn kan worden aangesloten op de +ve en –

ve contacten. Indien een weerstand aan het einde van de lijn

wordt gebruikt, dient deze een minimumweerstandswaarde

van 3k3 ohm en een minimumwattage van 0,5 watt te

hebben, of een minimumweerstandswaarde van 500 ohm en

een minimumwattage van 2 watt.

TABEL VOOR TOONKEUZE

Tone Selection

DIP Switch

Settings

Stage Selection

Stage 1

Frequency Description

1 2 3 4 5

Stage 2

Stage 3

1

Continuous 1000Hz

Toxic Gas Alarm

0 0 0 0 0

Tone 31 Tone 11 2 Alternating 800/1000Hz at 0.25s

intervals

1 0 0 0 0

Tone 17 Tone 5 3 Slow Whoop 500/1200Hz at 0.3Hz

with 0.5s gap repeated

0 1 0 0 0

Tone 2 Tone 5 4 Sweeping 800/1000 at 1Hz

1 1 0 0 0

Tone 6 T

one 5 5 Continuous at 2400Hz

0 0 1 0 0

Tone 3 Tone 27 6 Sweeping 2400/2900Hz at 7Hz

1 0 1 0 0

Tone 7 Tone 5 7 Sweeping 2400/2900Hz at 1Hz

0 1 1 0 0

Tone 10 To

ne 5 8 Siren 500/1200/500Hz at 0.3Hz

1 1 1 0 0

Tone 2 Tone 5 9 Sawtooth 1200/500Hz at 1Hz

0 0 0 1 0

Tone 15 Tone 2 10 Alternating 2400/2900Hz at 2Hz

1 0 0 1 0

Tone 7 Tone 5 11 Intermittent 1000Hz at 0.5Hz

General alarm

0 1 0 1 0

Tone 31 Tone 1 12 Alternating 800/1000Hz at 0.875Hz

1

1 0 1 0

Tone 4 Tone 5 13 Intermittent 2400Hz at 1Hz

0 0 1 1 0

Tone 15 Tone 5 14 Intermittent 800Hz 0.25s on 1s off

1 0 1 1 0

Tone 4 Tone 5 15 Continuous at 800Hz

0 1 1 1 0

Tone 2 Tone 5 16 Intermittent 660Hz 150mS on

,

150mS off

1 1 1 1 0

Tone 18 Tone 5 17 Alternating 544Hz

(100mS)/440Hz(400mS)

0 0 0 0 1

Tone 2 Tone 27 18 Intermittent 660Hz 1.8s on, 1.8s off

1 0 0 0 1

Tone 2 Tone 5 19 1400Hz to 1600Hz sweep up over

1s - 1600Hz to 1400Hz sweep down

over 0.5s

0 1 0 0 1

Tone 2 Tone 5 20 Continuous 660Hz

1 1 0 0 1

Tone 2 Tone 5 21 Alternating 554/440Hz at 1Hz

0 0 1 0 1

Tone 2 Tone 5 22 Intermittent 554Hz at 0.875Hz

1 0 1 0 1

Tone 2 Tone 5 23 800Hz puls

ing at 2Hz

0 1 1 0 1

Tone 6 Tone 5 24 Sweeping 800/1000Hz at 50Hz

1 1 1 0 1

Tone 29

Tone 5 25 Sweeping 2400/2900Hz at 50Hz

0 0 0 1 1

Tone 29 Tone 5 26 Simulated bell sound

1 0 0 1 1

Tone 2 Tone 1 27 Continuous 554Hz

0 1 0 1 1

Tone 26 Tone 5 28 Continuous 440Hz

1 1 0 1 1

Tone 2

Tone 5 29 Sweeping 800/1000Hz at 7Hz

0 0 1 1 1

Tone 7 Tone 5 30 420Hz repeating 0.625s on, 0.625s

off Australian alert signal

1 0 1 1 1

Tone 32 Tone 5 31 1200/500Hz at 1 Hz

Prepare to Abandon Platform

0 1 1 1 1

Tone 11 Tone 1 32 Sweeping 500/1200Hz 3.75s on,

0.25s off 15Hz

1 1 1 1 1

Tone 26 Tone 1

Page 13

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) French Issue E (Two Sheets) 19-02-10 (13)

MANUEL D’UTILISATION (ATEX

/

IECEx

) (F

RA

)

Alarmes sonores antidéflagrantes

BExDS120D et BExDS110D

Pour une utilisation dans des atmosphères poussiéreuses

et contenant des gaz inflammables

2) Marquage

Les caractéristiques nominales de toutes les unités figurent

sur une étiquette comportant les informations importantes

suivantes :

N° de type d’unité : BExDS120D ou BExDS110D

Tension d’entrée : Unités CC 12 V, 24 V ou 48 V

Unités CA 230 V, 110 V ou 115 V

Codes: Ex d IIC T4 for Ta –50ºC to +55ºC

Ex d IIB T4 for Ta –50ºC to +70ºC

Ex tD A21 IP67 T115ºC based on max Ta of +70ºC

Certificate No. KEMA 99ATEX6312

IECEx KEM 10.0003

Avertissements NE PAS OUVRIR EN PRESENCE D’UN

GAZ

EXPLOSIF OU DANS UNE ATMOSPHERE

POUSSIEREUSE

BOULONS DE COUVERCLE DE CLASSE A4-80

UTILISER DES CABLES ET DES PRESSE-ETOUPE

RESISTANTS A LA CHALEUR (Valeur nominale 110ºC)

A DES TEMPERATURES AMBIANTES

SUPERIEURES A 40ºC

4) Spécifications d’installation

Les alarmes sonores doivent être installées selon les normes

suivantes, ou des équivalents.

EN60079-14:20008 Installations électriques dans des

IEC60079-14:2007 (Ed4) zones dangereuses (autres que des

mines)

EN60079-10:2003 Classification des zones dangereuses

IEC60079-10:2008 (Ed1)

L’installation doit être effectuée uniquement par un personnel

compétent et conformément aux codes de pratique locaux.

5) Classification des zones, du groupe et de la

catégorie de gaz et des températures

Les unités peuvent être installées dans des endroits

respectant les conditions suivantes :

Classification de zone : gaz:

Zone 1

Mélange d’air et de gaz explosif pouvant

survenir en condition normale.

Zone 2

Mélange d’air et de gaz explosif ne pouvant

pas survenir et qui, dans le cas contraire,

serait présent que très brièvement.

Groupes de gaz :

Groupe IIA

Propane

Groupe IIB

Ethylène

Groupe IIC

< +55ºC

Hydrogène et Acétylène

Classification des températures :

T1 400o C T2

300o C T3

200o C T4

135o C

Classification des zones : poussière :

Zone 21

Mél

ange air

-

poussière explosif susceptible

de se former durant le cours normal des

opérations

Zone 22

Mélange air

-

poussière explosif non

susceptible de se former et qui, s’il se forme,

ne subsistera pas longtemps.

Indice IP : IP67 T100ºC Ta < +55ºC

T115ºC Ta < +70ºC

Classe de l’équipement: 2G/D

Plage de températures ambiantes :

-50°C à +55°C Groupes de gaz IIA, IIB et IIC

-50°C à +70°C Groupes de gaz IIA et IIB

6) Assemblage et emplacement de l’alarme sonore

Se reporter au schéma A

7) Accès au boîtier antidéflagrant

Se reporter au schéma B

Remarque : les quatre vis M6 sont en acier inoxydable de

classe A4-80 et seules des vis de ce type doivent être

utilisées sur ces alarmes sonores. C’est pourquoi il est

important de les conserver, ainsi que leurs rondelles à

ressort, en un endroit sûr pendant l’installation.

8) Sélection de l’alimentation électrique

L’alimentation électrique du système doit posséder la

capacité nécessaire pour procurer le courant d’entrée à

toutes les alarmes sonores connectées au système.

Le tableau suivant indique le courant d’entrée pour les

diverses unités d’alarme sonore :

II 2G/D

Epsilon x

:

Groupe et classe

de l’équipement :

0518

Marquage CE

:

N° de l’organisme notifié

Page 14

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) French Issue E (Two Sheets) 19-02-10 (14)

Type d’unité Tension Courant Volts I/P

d'entrée d’entrée max.

BExDS120D 24 V CC 800 mA 30 V

BExDS120D 12 V CC 850 mA 15 V

BExDS120D 48 V CC 420 mA 58 V

BExDS120D 230 V CA 90 mA 264 V

BExDS120D 110 V CA 200 mA 121 V

BExDS120D 115 V CA 180 mA 126 V

BExDS110D 24 V CC 265 mA 30 V

BExDS110D 12 V CC 195 mA 15 V

BExDS110D 48 V CC 130 mA 58 V

BExDS110D 230 V CA 56 mA 264 V

BExDS110D 110 V CA 93 mA 121 V

BExDS110D 115 V CA 110 mA 126 V

Le tableau ci-dessus indique également les tensions

maximales de fonctionnement des alarmes sonores.

9) Sélection des câbles

Les câbles doivent pouvoir prendre en charge le courant

utilisé par toutes les unités sur la ligne.

AVERTISSEMENT DE SECURITE : si les alarmes sonores

BExDS120D à haut rendement sont utilisées à des

températures ambiantes élevées, c’est-à-dire supérieures à

+40ºC, la température d’entrée du câble peut excéder +70ºC

et des câbles résistants à la chaleur doivent être utilisés,

d’une température de service assignée de 110ºC minimum.

10) Mise à la terre

Les unités d’alarme sonore CA et CC doivent être

connectées à un système de mise à la terre de bonne qualité.

Les unités sont fournies avec des bornes de mise à la terre

externe et interne qui sont toutes les deux situées sur la

section de chambre terminale de l’unité (se reporter aux

figures 2 et 3).

Lors de l’utilisation de la borne de mise à la terre externe,

employer une cosse à sertir. La cosse à sertir doit être située

entre les deux rondelles plates M5 en acier inoxydable. La

rondelle à ressort M5 en acier inoxydable doit être fixée entre

la rondelle plate externe et l’écrou M5 en acier inoxydable

afin que la cosse à sertir ne se desserre ni ne se torde.

11) Presse-étoupe

Les alarmes sonores ont deux entrées de presse-étoupe

avec des filetages d'entrée M20 x1,5. Seuls les presseétoupe approuvés pour les applications Ex ‘d’ peuvent être

utilisés, et ils doivent être adéquats pour le type de câble

utilisé et répondre aux exigences d'installation

d’antidéflagrant Ex ‘d’ de norme EN60079-14:2008 /

IEC60079-14:2007.

Lorsqu’une seule entrée de câble est utilisée, un bouchon

obturateur antidéflagrant Ex ‘d’, répondant aux exigences

d’installation, doit être appliqué sur l’autre entrée.

Pour les applications avec présence de poussière

combustible, le dispositif d’entrée de câble et les obturateurs

requièrent un type de protection antidéflagrante accrue « e »

ou un boîtier ignifugé « d » et doivent présenter un indice de

protection IP 6X conforme à EN60529:1992.

AVERTISSEMENT DE SECURITE : si les alarmes sonores

BExDS120D à haut rendement sont utilisées à des

températures ambiantes élevées, c’est-à-dire supérieures à

+40ºC, la température d’entrée du câble peut excéder +70ºC

et des câbles résistants à la chaleur doivent être utilisés,

d’une température de service assignée de 110ºC minimum.

12) Connexions de câble

Se reporter au schéma C et D

13) Sélection du timbre et alarmes de 2

ème

et 3

ème

étape

Se reporter au schéma de câblage E

14) Contrôle du volume

Se reporter au schéma F

15) Contrôle de fin de ligne (Unités CC)

Sur les unités CC BExDS120D et BExDS110D, un contrôle

de ligne inverse cc peut être utilisé si nécessaire. Toutes les

alarmes sonores CC possèdent une diode de blocage

installée sur leur ligne d’entrée d’alimentation. Une diode de

contrôle de fin de ligne ou une résistance de contrôle de fin

de ligne peut être connectée sur les bornes positive et

négative. En cas d’utilisation d’une résistance de fin de ligne,

celle-ci doit avoir une valeur de résistance minimum de 3k3

ohms et une puissance minimum de 0,5 watt ou une

résistance minimum de 500 ohms ainsi qu’une puissance

minimum de 2 watts.

TABLEAU DE SELECTION DU TIMBRE

Tone Selection

DIP Switch

Settings

Stage Selection

Stage 1

Frequency Description

1 2 3 4 5

Stage 2

Stage 3

1

Continuous 1000Hz

Toxic Gas Alarm

0 0 0 0 0

Tone 31 Tone 11 2 Alternating 800/1000H

z at 0.25s

intervals

1 0 0 0 0

Tone 17 Tone 5 3 Slow Whoop 500/1200Hz at 0.3Hz

with 0.5s gap repeated

0 1 0 0 0

Tone 2 Tone 5 4 Sweeping 800/1000 at 1Hz

1 1 0 0 0

Tone 6 Tone 5 5 Continuous at 2400Hz

0 0 1 0 0

Tone 3 Tone 27 6 Sweeping 2400/2900Hz at 7Hz

1 0 1 0 0

Tone 7 Tone 5 7 Sweeping 2400/2900Hz at 1Hz

0 1 1 0 0

Tone 10 Tone 5 8 Siren 500/1200/500Hz at 0.3Hz

1 1 1 0 0

Tone 2 Tone 5 9 Sawtooth 1200/500Hz at 1Hz

0 0 0 1 0

Tone 15 Tone 2 10 Alternating 2400/2900Hz at 2Hz

1 0 0 1 0

Tone 7 Tone 5 11 Intermittent 1000Hz at 0.5Hz

General alarm

0 1 0 1 0

Tone 31 Tone 1 12 Alternating 800/1000Hz at 0.875Hz

1 1 0 1 0

Tone 4 Tone 5 13 Intermittent 2400Hz a

t 1Hz 0 0 1 1 0

Tone 15 Tone 5 14 Intermittent 800Hz 0.25s on 1s off

1 0 1 1 0

Tone 4 Tone 5 15 Continuous at 800Hz

0 1 1 1 0

Tone 2 Tone 5 16 Intermittent 660Hz 150mS on,

150mS off

1 1 1 1 0

Tone 18 Tone 5 17 Altern

ating 544Hz

(100mS)/440Hz(400mS)

0 0 0 0 1

Tone 2 Tone 27 18 Intermittent 660Hz 1.8s on, 1.8s off

1 0 0 0 1

Tone 2 Tone 5 19 1400Hz to 1600Hz sweep up over

1s - 1600Hz to 1400Hz sweep down

over 0.5s

0 1 0 0 1

Tone 2 Tone 5 20

Continuous 660Hz

1 1 0 0 1

Tone 2 Tone 5 21 Alternating 554/440Hz at 1Hz

0 0 1 0 1

Tone 2 Tone 5 22 Intermittent 554Hz at 0.875Hz

1 0 1 0 1

Tone 2 Tone 5 23 800Hz pulsing at 2Hz

0 1 1 0 1

Tone 6 Tone 5 24 Sweeping

800/1000Hz at 50Hz

1 1 1 0 1

Tone 29 Tone 5 25 Sweeping 2400/2900Hz at 50Hz

0 0 0 1 1

Tone 29 Tone 5 26 Simulated bell sound

1 0 0 1 1

Tone 2 Tone 1 27 Continuous 554Hz

0 1 0 1 1

Tone 26 Tone 5 28 Continuous 440Hz

1

1 0 1 1

Tone 2 Tone 5 29 Sweeping 800/1000Hz at 7Hz

0 0 1 1 1

Tone 7 Tone 5 30 420Hz repeating 0.625s on, 0.625s

off Australian alert signal

1 0 1 1 1

Tone 32 Tone 5 31 1200/500Hz at 1 Hz

Prepare to Abandon Platform

0 1 1 1 1 Tone 11 Tone 1 32 Sweeping 500/1200Hz 3.75s on,

0.25s off 15Hz

1 1 1 1 1

Tone 26 Tone 1

Page 15

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) German Issue E (Two Sheets) 19-02-10 (15)

TECHNISCHE HINWEISE (ATEX / IECEx) (DEU)

BExDS120D und BExDS110D

Schwer entflammbare Sounder

Zum Einsatz in entflammbaren Gas- und

Staubatmosphären

2) Kennzeichnung

Alle Geräte sind mit einem Typenschild mit den folgenden

wichtigen Informationen versehen:-

Gerätetyp-Nr. BExDS120D oder BExDS110D

Eingangsspannung:

Gleichstromgeräte (DC) 12V, 24V oder 48V

Wechselstromgeräte (AC) 230V, 110V oder 115V

Codes: Ex d IIC T4 for Ta –50ºC to +55ºC

Ex d IIB T4 for Ta –50ºC to +70ºC

Ex tD A21 IP67 T115ºC based on max Ta of +70ºC

Certificate No. KEMA 99ATEX6312

IECEx KEM 10.0003

Warnung NICHT IN EXPLOSIONSFÄHIGEN GAS- ODER

STAUBATMOSPHÄREN ÖFFNEN

ABDECKSCHRAUBEN KLASSE A4-80

WÄRMEBESTÄNDIGE KABEL UND

KABELFLANSCHE VERWENDEN

(Nennleistung 110ºC) BEI UMGEB.-TEMP. ÜBER 40ºC

4) Installationsanforderungen

Die Sounder müssen gemäß den folgenden oder

vergleichbaren Standards installiert werden.

EN60079-14:2008 Elektrische Installationen in

IEC60079-14:2007 (Ed4) Gefahrenbereichen (außer

Bergwerken)

EN60079-10:2003 Klassifizierung von Gefahrenbereichen

IEC60079-10:2008 (Ed1)

Die Installation sollte nur von qualifiziertem Fachpersonal

vorgenommen werden. Örtliche anerkannte Verfahren sind

zu beachten.

5) Zonen, Gasgruppe, Kategorie und

Temperaturklassifizierung

Die Geräte können an Standorten aufgestellt werden, an

denen die folgenden Bedingungen vorliegen:-

Bereichseinteilung Gas:

Zone 1

Bei normalem Betrieb kann mit hoher

Wahrscheinlichkeit eine explosive Gas-LuftMischung vorliegen.

Zone 2

Explosive Gas

-

Luft-Mischung unwa

hrschein

-

lich und sollte sie doch auftreten, dann nur

kurzfristig.

Gasgruppen:

Gruppe IIA

Propan

Gruppe IIB

Äthylen

Gruppe IIC

< +55ºC

Wasserstoff und Azetylen

Temperaturklassifizierung:

T1 400o C T2

300o C T3

200o C T4

135o C

Bereichseinteilung Staub:

Zone 21

Explosionsgefährdetes Staub

-

/Luftgemisch,

das beim normalen Betrieb durchaus

auftreten kann

Zone 22

Explosionsgefährdetes Staub

-

/Luftgemisch,

dessen Auftreten unwahrscheinlich bzw. von

kurzer Dauer ist.

IP-Schutzklasse: IP67 T100ºC Ta < +55ºC

T115ºC Ta < +70ºC

Gerätekategorie: 2G/D

Umgebungstemperaturbereich:

-50°C bis +55°C Gasgruppen IIA, IIB und IIC

-50°C bis +70°C Gasgruppen IIA und IIB

6) Sounder-Standort und Montage

Siehe Zeichnung A

7) Zugang zum schwer entflammbaren Gehäuse

Siehe Zeichnung B

Hinweis: Die vier Schrauben M6 sind aus Edelstahl Klasse

A4-80 gefertigt. Für diese Sounder sind nur Schrauben

dieser Kategorie geeignet. Diese Schrauben und die

zugehörigen Federringe sind beim Einbau daher sorgfältig

aufzubewahren.

8) Stromversorgung

Die Stromversorgung der Anlage muss ausreichen, um alle

angeschlossenen Sounder mit Eingangsstrom zu versorgen.

Folgende Tabelle zeigt den von den verschiedenen SounderGeräten entnommenen Eingangsstrom:-

Gerätetyp Eingangs- Eingangs- Max. I/P

Spannung strom Spannung

BExDS120D 24V DC 800 mA 30V

BExDS120D 12V DC 850 mA 15V

BExDS120D 48V DC 420 mA 58V

BExDS120D 230V AC 90 mA 264V

BExDS120D 110V AC 200 mA 121V

BExDS120D 115V AC 180 mA 126V

BExDS110D 24V DC 265 mA 30V

0518

II 2G/D

Epsilon x:

Gerätegruppe und

–kategorie:

CE-Kennzeichnung:/

Bekannt gegebene Nr.

Page 16

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) German Issue E (Two Sheets) 19-02-10 (16)

BExDS110D 12V DC 195 mA 15V

BExDS110D 48V DC 130 mA 58V

BExDS110D 230V AC 56 mA 264V

BExDS110D 110V AC 93 mA 121V

BExDS110D 115V AC 110 mA 126V

Obige Tabelle zeigt auch die maximale Spannung an, mit der

die Sounder betrieben werden können.

9) Kabelwahl

Die Kabel müssen den Strom aller angeschlossenen Geräte

führen können.

SICHERHEITSHINWEIS: Wenn die BExDS120D HighOutput-Sounder bei hohen Umgebungstemperaturen

eingesetzt werden (d. h. bei über +40ºC), kann die

Kabeleingangstemperatur +70ºC übersteigen. Daher sind

geeignete hitzebeständige Kabel mit einer

Nennbetriebstemperatur von mindestens 110ºC zu

verwenden.

10) Erdung

Die Wechsel- und Gleichstrom-Soundergeräte müssen mit

einer hochwertigen Erdung verbunden werden. Die Geräte

sind mit internen und externen Erdklemmen (am

Klemmkammerteil des Geräts, siehe Abb. 2 und 3) versehen.

Bei Verwendung der externen Erdklemme ist ein

Quetschkabelschuh zu verwenden, der zwischen den beiden

flachen M5-Edelstahl-Unterlegscheiben eingesetzt werden

sollte. Die M5-Unterlegscheiben sind zwischen der äußeren

flachen Unterlegscheibe und der M5-Edelstahlmutter

einzusetzen, um zu gewährleisten, dass der Kabelschuh sich

nicht lösen oder verdrehen kann.

11) Kabelflansche

Die Sounder sind mit doppelten Kabelflanscheingängen mit

Eingangsgewinden von M20 x1.5 versehen. Es dürfen nur

Kabelflansche verwendet werden, die für Ex ‘d’Anwendungen zugelassen sind. Die Kabelflansche müssen

für den eingesetzten Kabeltyp geeignet sein und zudem den

Anforderungen der Ex ‘d’-Norm zur Installation schwer

entflammbarer Geräte EN60079-14:2008 / IEC6007914:2007 entsprechen.

Wenn nur ein Kabeleingang verwendet wird, muss der

andere mit einem schwer entflammbaren Ex ‘d’

Handlochverschluss, der für die Installationsbedingungen

zugelassen ist, verschlossen werden.

Bei Anwendungen in brennbaren Staubbereichen sind der

Kabelanschluss und die Abdeckelemente in einem Gehäuse

mit erhöhtem Explosionsschutz (Typ „e“) oder erhöhtem

Entflammbarkeitsschutz („Typ „d“) zu installieren und müssen

der Schutzklasse IP 6X gemäß EN60529:1992 entsprechen.

SICHERHEITSHINWEIS: Wenn die BExDS120D HighOutput-Sounder bei hohen Umgebungstemperaturen

eingesetzt werden (d. h. bei über +40ºC), kann die

Kabeleingangstemperatur +70ºC übersteigen. Daher sind

geeignete hitzebeständige Kabelflansche mit einer

Nennbetriebstemperatur von mindestens 110ºC zu

verwenden.

12) Kabelanschlüsse

Siehe Zeichnung Cund D

13) Tonwahl und Alarm der 2. und 3. Stufe

Siehe Schaltbild E

14) Lautstärkeregulierung

Siehe Zeichnung F

15) Überwachung des Leitungsendes

(Gleichstromgeräte)

Bei BExS120D- und BExS110D-Gleichstromgeräten kann bei

Bedarf eine Wechselstrom-Sperrleitungskontrolle eingesetzt

werden. Alle Gleichstrom-Sounder sind mit einer Sperrdiode

versehen, die in die Speise-Eingangsleitungen eingesetzt ist.

Eine Überwachungsdiode oder ein Kontrollwiderstand für das

Leitungsende können über die Klemmen +ve und –ve

miteinander verbunden werden. Wird ein Widerstand für das

Leitungsende verwendet, muss sein Widerstandswert

mindestens 3k3 Ohm und die Mindestleistung 0,5 Watt

betragen, oder aber es muss ein Widerstandswert von

mindestens 500 Ohm und eine Mindestleistung von 2 Watt

vorliegen.

TONEVALGSTABEL

Tone Selection

DIP Switch

Settings

Stage Selection

Stage 1

Frequency Description

1 2 3 4 5

Stage 2

Stage 3

1

Continuous 1000Hz

Toxic Gas Alarm

0 0 0 0 0

Tone 31 Tone 11 2 Alternating 800/1000Hz at 0.25s

intervals

1 0 0 0 0

Tone 17 Tone 5 3 Slow Whoop 500/1200Hz at

0.3Hz

with 0.5s gap repeated

0 1 0 0 0

Tone 2 Tone 5 4 Sweeping 800/1000 at 1Hz

1 1 0 0 0

Tone 6 Tone 5 5 Continuous at 2400Hz

0 0 1 0 0

Tone 3 Tone 27 6 Sweeping 2400/2900Hz at 7Hz

1 0 1 0 0

Tone 7 Tone 5 7 Sweeping

2400/2900Hz at 1Hz

0 1 1 0 0

Tone 10 Tone 5 8 Siren 500/1200/500Hz at 0.3Hz

1 1 1 0 0

Tone 2 Tone 5 9 Sawtooth 1200/500Hz at 1Hz

0 0 0 1 0

Tone 15 Tone 2 10 Alternating 2400/2900Hz at 2Hz

1 0 0 1 0

Tone 7 Tone 5 11 Intermittent 1000Hz at 0.5Hz

General alarm

0 1 0 1 0

Tone 31 Tone 1 12 Alternating 800/1000Hz at 0.875Hz

1 1 0 1 0

Tone 4 Tone 5 13 Intermittent 2400Hz at 1Hz

0 0 1 1 0

Tone 15 Tone 5 14 Intermittent 800Hz 0.25s on 1s off

1 0 1 1 0

Tone 4 Tone 5 15 Continuous at 800Hz

0 1 1 1 0

Tone 2 Tone 5 16 Intermittent 660Hz 150mS on,

150mS off

1 1 1 1 0

Tone 18 Tone 5 17 Alternating 544Hz

(100mS)/440Hz(400mS)

0 0 0 0 1

Tone 2 Tone 27 18 Intermitten

t 660Hz 1.8s on, 1.8s off

1 0 0 0 1

Tone 2 Tone 5 19 1400Hz to 1600Hz sweep up over

1s - 1600Hz to 1400Hz sweep down

over 0.5s

0 1 0 0 1

Tone 2 Tone 5 20 Continuous 660Hz

1 1 0 0 1

Tone 2 Tone 5 21 Alternating 554/440Hz at 1

Hz 0 0 1 0 1

Tone 2 Tone 5 22 Intermittent 554Hz at 0.875Hz

1 0 1 0 1

Tone 2 Tone 5 23 800Hz pulsing at 2Hz

0 1 1 0 1

Tone 6 Tone 5 24 Sweeping 800/1000Hz at 50Hz

1 1 1 0 1

Tone 29 Tone 5 25 Sweeping 2400/2900Hz at 5

0Hz 0 0 0 1 1

Tone 29 Tone 5 26 Simulated bell sound

1 0 0 1 1

Tone 2 Tone 1 27 Continuous 554Hz

0 1 0 1 1

Tone 26 Tone 5 28 Continuous 440Hz

1 1 0 1 1

Tone 2 Tone 5 29 Sweeping 800/1000Hz at 7Hz

0 0 1 1 1

Tone 7 Tone 5 30 420Hz repeating 0.625s on, 0.625s

off Australian alert signal

1 0 1 1 1

Tone 32 Tone 5 31 1200/500Hz at 1 Hz

Prepare to Abandon Platform

0 1 1 1 1

Tone 11 Tone 1 32 Sweeping 500/1200Hz 3.75s on,

0.25s off 15Hz

1 1 1 1 1 Tone 26 Tone 1

Page 17

_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH sales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

Document No. BExDS120D and BExDS110D (Gas-Dust) Italian Issue E (Two Sheets) 19-02-10 (17)

MANUALE DI ISTRUZIONI (ATEX / IECEx) (ITA)

Sirene antincendio BExDS120D e BExDS110D

Per l'utilizzo in atmosfere di gas e polveri infiammabili

2) Marchio

Tutte le unità sono dotate di etichetta contenente le seguenti

importanti informazioni:-

N. tipo unità BExDS120D o BExDS110D

Tensione in ingresso: Unità CC 12 V o 24 V o 48 V

Unità CA 230 V o 110 V o 115 V

Codice: Ex d IIC T4 for Ta –50ºC to +55ºC

Ex d IIB T4 for Ta –50ºC to +70ºC

Ex tD A21 IP67 T115ºC based on max Ta of +70ºC

N. certificato KEMA 99ATEX6312

IECEx KEM 10.0003

“Attenzione” NON APRIRE IN CASO DI PRESENZA DI

GAS O POLVERI ESPLOSIVE

COPRIRE I BULLONI CON UNA COPERTURA

CLASSE A4-80

USARE CAVI E PREMISTOPPA PER CAVI RESISTENTI AL

CALORE (temp. nominale 110°C) SE LA

TEMPERATURA AMB. È SUPERIORE A 40°C

4) Requisiti di installazione

Le sirene devono essere installate in conformità con i

seguenti standard o standard equivalenti.

EN60079-14:2008 Installazioni elettriche in aree

IEC60079-14:2007 (Ed4) pericolose (tranne che nelle miniere)

EN60079-10:2003 Classificazione delle aree pericolose

IEC60079-10:2008 (Ed1)

L'installazione deve essere eseguita da personale

competente e devono essere applicati tutti i codici

professionali l °Cali.

5) Classificazione delle zone, dei gruppi di gas,

delle categorie e delle temperature

Le unità possono essere installate in ambienti che

presentano le seguenti condizioni:-

Classificazione area Gas: