inbro IB-RSC1501, IB-RSC1201 Operating Instructions Manual

wNw.lnbrotech.com

«

IOPERATING

INSTRUCTIONS

For

ModeIIB-RSCI501

SAFETY

/

OPERATING

INSTRUCTIONS

Automatic Embroidery Machine

for model IB-RSC1201

*

Please

read

all of

these

instructioI1s carefully

before

you

operate

your

machine.

*

Save

this

iI1structioI1 for future

reference.

inbro

l"tC"Qr~'¢j

Emhroider.d

Page

Contents

1.

Introduction -..---

..

--~-..---~

...

~~--

..

--------

4

5

1-2.

\Varning

symboi

--------

_._._._-

6

1-3.

Stickers positions

~---

--~---.--

~-~

...

--

7

1-4.

Each

pa::t

name -

--

..

-.--~-

-

-------

...

-----~-

----.---- ,-

----.----..-------

8

1-5. Front cover

s/w

namE: -...

---

...

---

..

---

..

_--

..

_--

-

-~..-~----

9

2.

Carrying the machine -

..

~~.

~~

....

~-

..

-~-

..

-~.

10

2-1. Carrying the nachine by manpQWf.'f

-~-

..

---

..

------

..

-----

..

----

10

2-2. Carrying the machine

-.-----~---

-~.-------

10

3.

Installation

and

Assembly

-~--

11

3-

L Installation

El1viroment

-----~

..

------

.------.-------.---------------

...

~-

12

3-2. Electric Installation

Enviro!ller;t

-~----

..

---

..

--

..

----

..

----.-.-

12

13

3-4.

AdjllSting

the machine level

----------~.-------

14

3-5. Asserr.bling

rhe

frame

--

-------

'-~---

16

4.

Upper threading

and

How

to

assemble

the

tension

--.

17

.j-1. Upper threading

--

..

---

..

---.-

..

---

..

---

..

---

..

------

17

4-2,

Adj'Jsting the upper thread tens.ion

--

..

--.-

..

----

..

~--.---

..

--.--

20

5.

Lower threading

and

How

to

assemble the tension

--.-

21

5-!.

Ilanging a lower thread

--

--

..-.--

..

-

.-~

..

---

..

~-

-..-

21

6.

Selecting a thread

and a needle---···-----

22

6-1.

Se~ecting

a needle

...

--

..

---

...

--~

...

-.--

..

--~

..

---

..

--

22

6-2_

Changing a needte ~..

---

..

---

..

---

...

---

...

---

..

--~--

23

1)-3. Position adjust:ng

of

needle

and

threadjng hook -

..

---

..

-----~

24

7.

The relation between a needle

and a hook

~---~--

26

7-

L Adjusting tt,e

timing

of

a needle

and a hook

------

-------.----

...

-.--

..

-

26

7-2.

The type of thread loop made I;y the needle movement

-----

.-~--

---_.

--~

.--~

26

8.

Maintenance

and

checkup

of

the

machine

-.

~-

...

~

27

8-

I. The perionic checkpoint of the

machine

.-

..

----

..

~-

..

-~~-

..

-.

27

8-2. Cleaning

--.---.-~---.----

..

---

..

-~-.---

---

28

8~3.

Oil

supply

-~"-~~-----

29

8~4.

Supply of Grease

-----

..

----

..

~~--

..

--

30

8-'5.

How

to

empty

;rimmings

bin

-.---~-

.'.---------

..

~----

..-------..---

--

...

-

31

21

___

l_~ontent_s

Page

I

I

-----~---~-.~~.-

9.

How

to

adjust the

main

part

of

the

machine

-~--.--~

32

g-],

Adjustbg tl:e hook

-~.~~.---~..--~.--~

..

,~~.--~.,,--~~-~.~-----

33

0-2.

Adjusting

Lhe

upper dead point of needle and hook

pvim~--.----.----~--.-

34

9--3,

How

to

replace

re:::lprocator

-----

..

---~--

_.

__________.____.

____.___

h.

~._

36

Y-4.

The

relation between a

ptesser

foot

.and

2:

needle

~-.---~.-----------

38

9-5.

Adjusting

the

encorder

~-..-.--~--.--.-

...

--.--~.~.----

39

9-6.

Aciusting

the

movable

mes

entry

angle

and

positlon

---

..

-~.,,--.~~.---.-

41

9-7. Ad;usting

L"te

picker

-.-----.---.----.----.----.--

43

9-8.

Adjusting the belt tension

--.--.-~.--.----.---.--.--.-.----

44

9-9.

Adjusting the

take-up

lever position

.~--.-~-.~-~.---.~-~.---.--~.---

47

9-10.

Setting up the position of thread sensor

--.--.--.---.-~.--.-~.--

48

9-11. Pueumatk system f'aeh

name

and

layout

--.-.-.---.--.~~.--

..

--.

v

;:;0

10.

Trouble

and

repairing --

..

--.~-.~-~.-

-.~.~.-.-

..

~.-

53

10-1.

The

start

and operation error

~-.----.----~.~.----.----.

53

20-2. The stop pcsitiau err(lr

~------.~---~-~~.~~-,,~-.~--.~---.~~-----.~

'--'

::;5

10-3.

The

upper thread

sensor

error

-~.--.--.---.--.-~.-~,,--.---.-.-

56

10-4. The

Jwnping

error

~~-.--

..

--

•.

--.---

.-----~-.---------.-

57

lO-f).1'he twiste(l embroidery

---.----.-~-----.-----.-

•.

--.--~

58

10-6,

The

thread

b:--eak,

needle hreak, skipping over stitch

~-.-"---.~,-------.----,,

60

1(}-7.

The

cutting working

error

-.--~.~.~.--,,~.--

..

--.~-

..

-,

,,~.--

..

--

62

10-8 The threan can't

be

cut or get shorlen

-.--.-~.--.--.--.~-.--

63

even the mes retracting

sensor

"vorks normally

10-9, Tbe lower thread break

-""-.-.-,,.---,-

..

-------~.-.------.~.-----.~.-

u

1~5

10-10.

vY:--:en

the

u;=;per

thread

catcher

does not eperate

-.~."'---.-.~.--.--.~.-~

66

1.

INTRODUCTION

These

instructions

were

made

for a

user

and a technician

of

the

automatic

embroidery

machine (model:

IB-RSC120l)

to

explain

the

safety

contents

when

carrying, installing

and

maintaining

the

machine.

These

instructions

describe

the

operation

process

and

function

of

embroidery

machine

to

perform

efficient

and

correct

embroidery

working.

Please

read

all

of

these

instructions

carefully

before

you

operate

your

machine to

utilize

the

machine

suitable for working

use.

Always

save

these

instructions

within striking

distance

to

provide

for

the

future

necessary

case.

Do

not

operate

or

treat

this machine with

any

method

or

form in

accordance

with not specified

contents

and/or

prohibited

contents

especially

on

these

instructions.

Inbro will

not

bear

the

responsibility for

mechanical

trouble

and

accidents

may

occur

when a user

does

not

observes

the

instructions

specified

on

this

book.

These

instructions

may contain

the

differences

in

detailed

content

of

the

machine

such

as

operation,

maintenance

or

improvement

of

the

construction

according

to

the

modeL

Should

you

have

further

questions

about

these

instructions,

contact

with

the

Inbro's

agent

or

your

supplier.

1-1.

Safety Instructions

To

operate

the

machine

correctty,

understand

(he

important

safety

instructions

in

this

book

and

then

operate

the

machine.

Do

not

operate

the

machine

before

you

completely

tmderstand

the

contents

in

these

instructions.

A

WARNING

Physical

injury

may

be

caused

by

crev'1ce.

Donlt

put

your

finger

in a

greoove

on

the

table.

A

CAUTION

Surface

temperature

of main motor may be up

to

60Q C.

To

avoid

thenna!

hazard,

do

not

touch

the

surface

of

main

motor.

Allow

to

coo] it down

before

servicing.

A

WARNING

Turn

off

the main

power

before

service.

Fire

or

death

may

be

caused

by

high

voltage

electric

shock.

Don't

open

the

cover

except

for

service

rna

assigned

by

inbra

Wben open

the

cover,Power off and watt for 4 minutes.

A

WARNING

Ensure

that

the

machine

is

in a

stop

condition

before

changing,

threading,

or

rethreading of

needles

or

changing of needles.

(

stop:

Insulation

equipment

IS locking

and

pull

out

piug )

A

WARNING

Ensure

that

safety

cover

i;:;

attached

before

running,

Do

nor

aprroach

your

hands

to

the

moving

parts

during funning.

AVOID

EXPOSURE

Avoid

eye

and

skin

exposure

to

direct

or

scattered

radiation.

-5-

OVERTURN

HAZARD

Do

not

place

the

machine

on

an

unstable

cart,

stand,

bracket

or

tab]e.

The

machine

may

fall,

causing

serious

injury to a

person,

and

serious

damage

to

the

1113chine.

A

machine

and

carl

combination

should

be

moved

with

care.

Qllick

stops,

excessive

force,

and

uneven

surface

may

cause

the

machine

and

cart

combination

to

overtur.

1-2.

WARNING SYMBOL

The

content

required a user's

special

caution

when

operating

the

machine

is

specified

as

the

warning

symbol

below.

;!,\ CAUTION

This

mark

means

dangerous

consequences

wiH

arise,

with

the

possibility

of

death

or

serious

injury

to

the

user,

if

the

embroidery

machine

is

handled

incorrectly.

A.

DANGER

This

mark

means

dangerolls

consequences

could

arise,

with

the

possibility

of

death

or

serious

injury to

the

user

ar:d/or

damage

to

the

embroidery

maehine

and facilities, if

the

embroidery

machine

is

handled

incorrectly.

/1"\

WARNING

This

mark

means

dangerous

consequences

may

arise,

with

the

possibility

of

somewhat

serious

injury

to

the

user

and/or

damage

to

the

embroidery

machine

and facilities, if

the

embroidery

m2chine

is

handled

incorrec\ly.

& LIGHTING EQUIIPMENT

Should

do

work

under

lighting.

-6-

1-3.

Stickers

Position

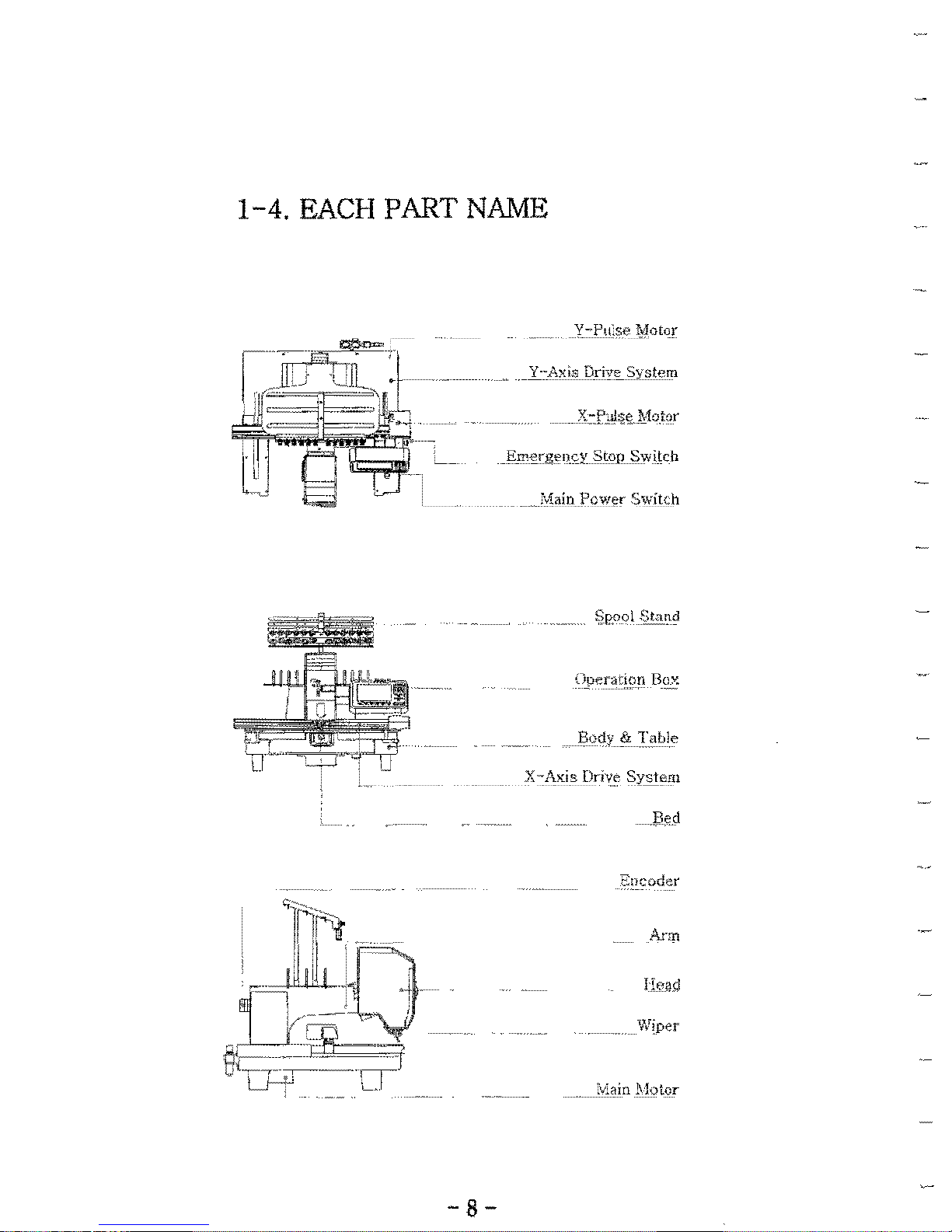

1-4.

EACH PART NAME

I

~

;\!Iain

Power

Switch

Operation

Box

l?ody

§z.

TaLle

encoder

VJjper

-8-

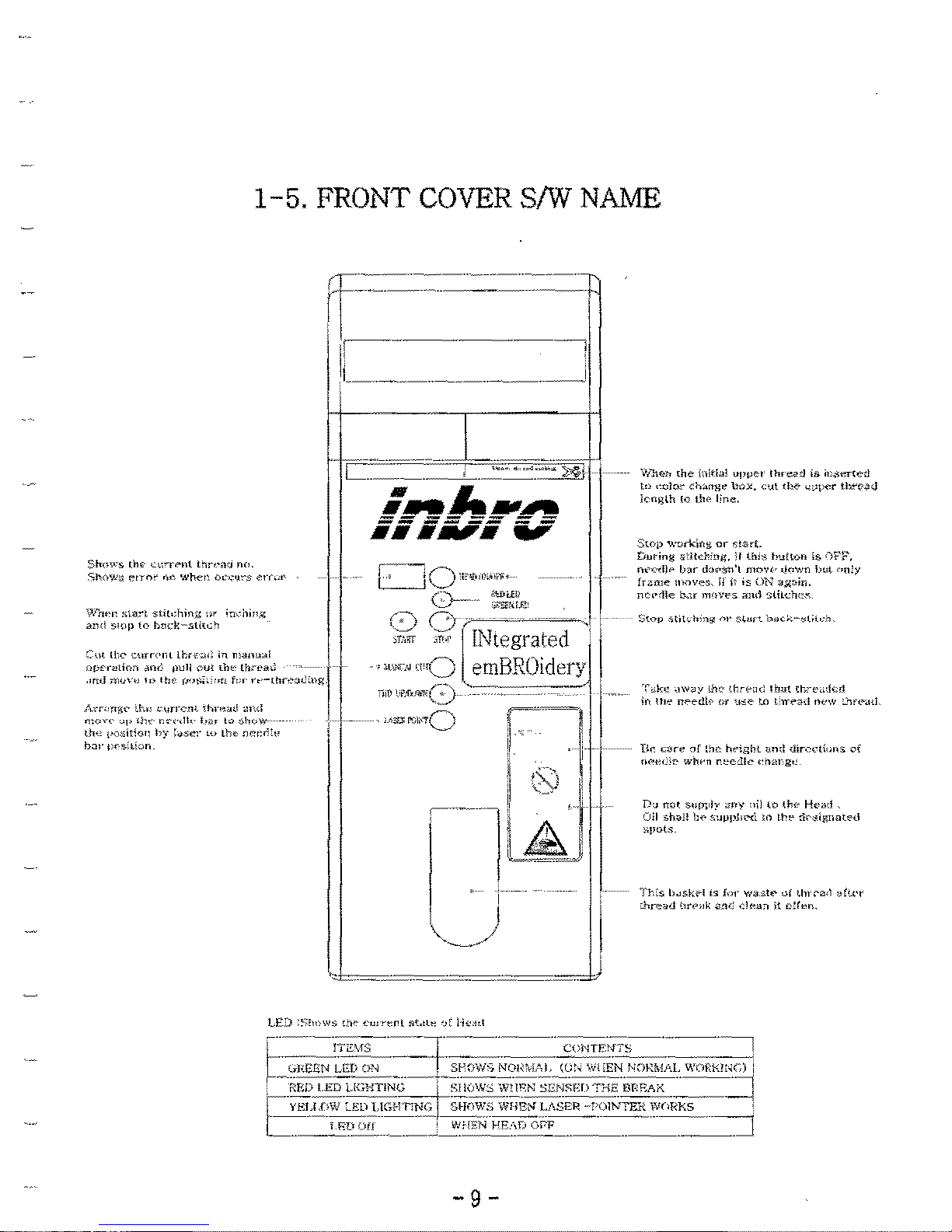

1-5.

FRONT COVER

8/W

NAME

Shows

til'"

c,,~rf'''t

t~n';n

'w,

Sh0','iU

e,r,.,t

<It",

whet~

()Cq'~$

;;-rr,A'

\Vh,·"

",ar,

stit,;hinz

'"

;m-hin,'I

ami

SI\)I'

to

b,w\(-"ti<c'l

C'm n,·:-

cmn'nllhtf;),;

in

ma""",i

nf>f'r>!l;""

M";

pull

em

th,"

tln'c'aJ

.",d

;-r,,,v,,

,,,

Hw

(NN.:·,n

f,;,'

r"-(t.r"'.H~~ng_

A''''fl,W

lL"

nm-cm

lhr",,,d

md

me""

~p

in",

F.r-",Ik

har

to

show

til"

(",,,ilion

by

:"SC]'

co

th"

n.;:,:r':"

b'l!"

p".,:.[on.

l

W1teh

(he

in!tial

"pret

lh.",,:!

is

j".~",(e:l

tn

"do:

ch:.ng"

box,

<:\tt

th&

<;;per

thtTll<J

knglh

!Q

Ihp

lin""

Swp

w[)rkirtg

Dr

~!srt.

During

s'lkh'!>".

if

tn'8

tn"rt""

is

nFP.

m-~",I)"

lnr do..

;m'l

moW-

,1<Iwn

bu,

"11;)1

frM!l~

I1hC1ve",;;

it

is

ON

"'>1"''',

mo",Ue

b.:r

m(>Y""

,md

slil{;h""

T

~k.:

,!\~~)'

01e:

(trp,,,:

Itmt

tkO',,:!n1

in

til'''

n"edk

G'

,-,~e

lO

t "-.,.,,,1

'ww

:':~fC¥.HL

n"

""re

a[

the

Iwight

und

tiir,-,eth,r>s

ef

n"'"":;,,

wtwn

r.""llt"

,'"a,-

&"

n"

m,( sum,ly

,my

"il

to

th<o

H~'"d

,

Oll

~h,.l!),,,

~'-'I-'I'LN\

;0

II'"

n""igIlflt"d

:>PG-ts.

'n-,:s

b~skH

I~

f"r

wa21

...

"I

Un ,,"a,l

u!\.('r

=--}",,,.d

\1r(',,1<

"tlr:

.:I"""

it

c!("".

-9-

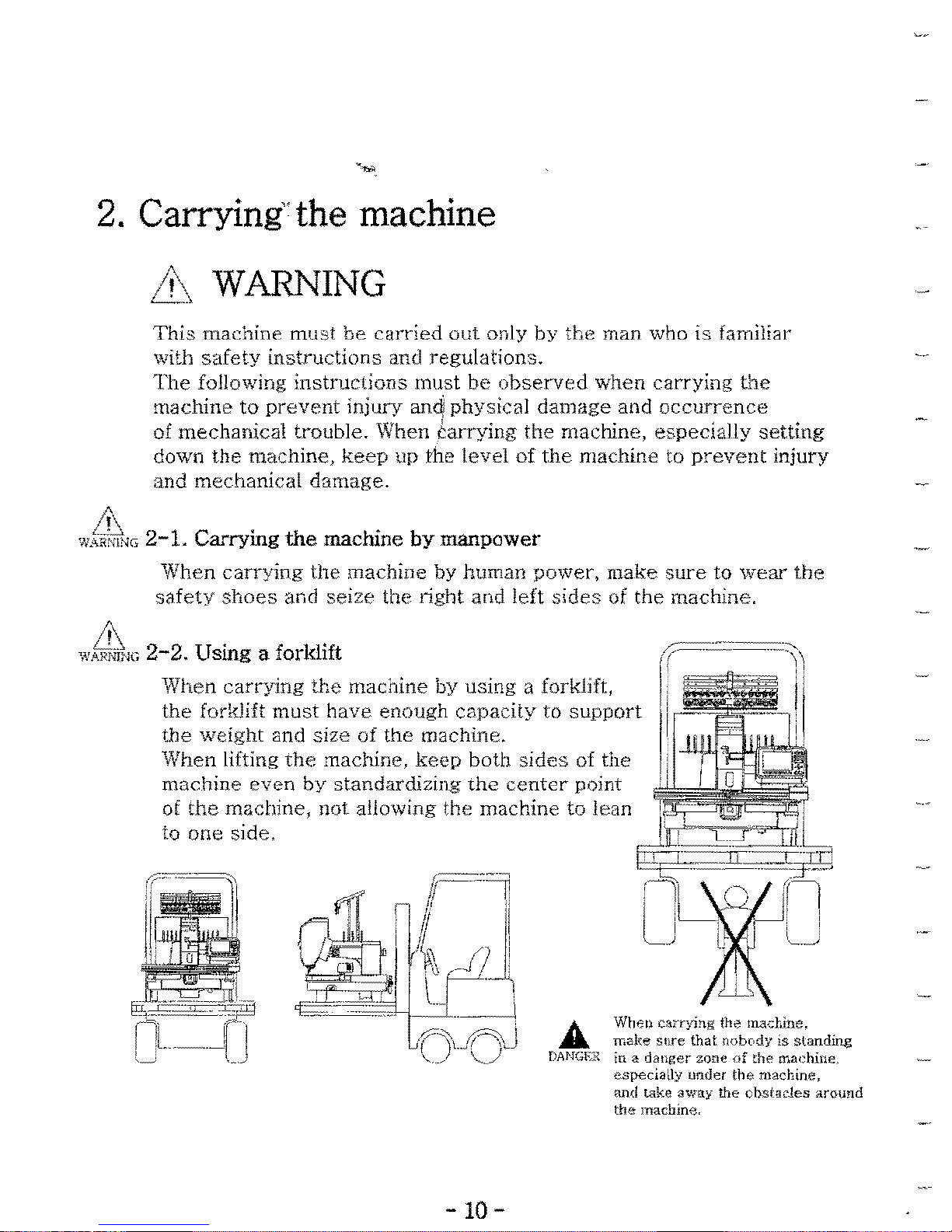

2.

Carrying" the machine

Ll\

WARNING

This

machine

must

be

carried

out

only

by

the

man

who

is

familiar

with

safety

instructions and regulations.

The

following

instruclions

must

be

observed

when

carrying

L~e

machine

to

prevent

injury

an~

physical

damage

and

occurrence

of

mechanical

trouble.

When

tarrying

the

machine,

especially

setting

down

the

machine,

keep

up

the

level

of

the

machine

to

prevent

injury

and

mechanical

damage.

&21C

'th

hibman

r

WAR;<lNG

-.

arrymg

e mac

ne

y

powe

\,ftlhen

carrying

the

machine

by

human

power,

make

sure

to

wear

the

safety

shoes

and

seize

the

light

and

left

sides

of

the

machine.

1\

w,~R;iiNG

2-2.

Using

a forklift

When

carrying

the

machine

by

using

a forklift,

the

forklift

must

have

enough

capacity

to

support

the

weight

and

size

of

the

machine.

When

lifting

the

machine,

keep

botb

sides

of

the

machine

even

by

standardizing

the

center

point

ot

the

machine,

not

allowing

the

machine

to

lean

to

one

side,

A

Wh€l~

canyjng

th0 mad-,inc.

rr.ake

SHe

that

nobody

is

standing

[lANGE:;:

in a danger zone

of

the machine,

especiaUy under the machine,

and

take

away

the

cbstades

around

the

machine,

-10-

3. INSTALLATION

AND

ASSEMBLY

&

CAUTION

When

installing

the

machine, follow

these

instructions

to

prevent

mechanical

damage

such

as

maUunction,

break

down,

etc.

or

physical injury,

A

DANGER

To

prevent

an

electrical

shock

caused

by a

short

circuit,

earth

the

ground

wire

of

the

machine

to the ground,

The

grounding

resistance

must be

100

ohms

II

or

less,

&

WARNING

Check

the

input

power

of

the

location

ior

installing

the

machine,

When installing

the

machine, do

not

change

arbitrarily

the

input

power,

'which

was

set

up at

the

factory. \Vhen a

user

changes

the

input

power

at will,

the

machine

may

cause

physical

damage

and/or

mechanical problems,

When

installing

the

power

cable, a

user

may

trip

OVer

the

cable,

therefore

install

the

cable

out

of

the

user's

working

space,

-11-

3-1.

INSTALLATION

ENVIRONMENT

L

The

machine

must

be

installed

on a

strong

floOf

that

can

bear

the

weight

of

the

machine

(marked

on

the

specifications)

sufficiently.

2. Do

not

install

the

machine

near

heat

sources

such

as

radiators,

heat

registers,

stoves.

or

other

appliances

that

produce

heat.

3. Install

the

machine

near

an

air

conditioning and

clean

up

the

machine

periodically,

as

dirt and

rust

may

cause

not

only

pollution

and

corrosion

of

the

machine

but

also

a fire and an

electric

shock,

4.

In

case

that

the

machine

is

exposed

to

direct

rays

of

light for a

long time,

it

may

cause

discoloration

and

transformation

of

the

machine. Install

the

machine

at

the

appropriate

place

away

from

direct

rays

of

light.

To

reduce

noise

of

operation,

complete

the

interior

work

of

the

factory

by

using

soundproofing

material

to

the

walls, ceiling and floor

inside

the

factory.

6.

Space

the

machine

at

least

50

em

from

the

left,

right

and

back

sides

of

the

machine

for

enough

mending

space

of

the

machine.

Ll\

3-2.

ELECTRIC

INSTALLATION ENVmONMENT

WA"NlNG

1. Input

Power

(adjusted

when

taking

out

of

the

factory)

:

Single

Phase

100V,llOV.120V,200V.220V,240V

(50/60Hz)

2. Approvable

voltage

range:

within ± 10%

of

rating voltage

,>.

Power

capacity

and

consumption

of

electricity: 450VA,

300W

4. Insulation

resistance:

more

than

lOMQ

(measured

by

500V

insdation

tester]

-12

-

&

3-3.

INSTALLATION ENVlROMENT FOR COMPRESSOR

"V?8NING

1.

NPUT

POWER :

llOv

, 220v l50/60Hz)

2.

APPROVED VOLTAGE

R,\NGE:

R,\TING VOLTAGE

±10%

3. STAND

SET

POSITION (FIG)

4. COMPRESSOR TUBE CONNECTION

Size:

8x5

, APPROX

1M

NOTICE : PlIt

the

marked A in

deeply

then

meet

the

pressure

of

air

with

,1,4

"4.5

Bar.

*

If

air leaks due

to

not complete insert.

Compressor

may be

overheated

or

abnormal working.

Make

compressor

automaticaHy

stop

at

the

pressure

point 5.5

bar

by using

aetomatic

pressure

adjuster.

(

if

the

pressure

drops around 4.5 bar.

compressor

3utomatica!iy works,)

Ill'

ill

CAUTION

3-4.

ADJUSTING

THE

MACHINE LEVEL

Wilen

the

machine

is

installed

on

the

unleveled

place,

it

may

cause

transfonnation

of

the

machine

and

misplacement

of

the

needle

bar.

Adjust

the

level

of

the

machine's

front-back

and

left-right

sides

by

using a precision

level

with

the

adjusting

bolts,

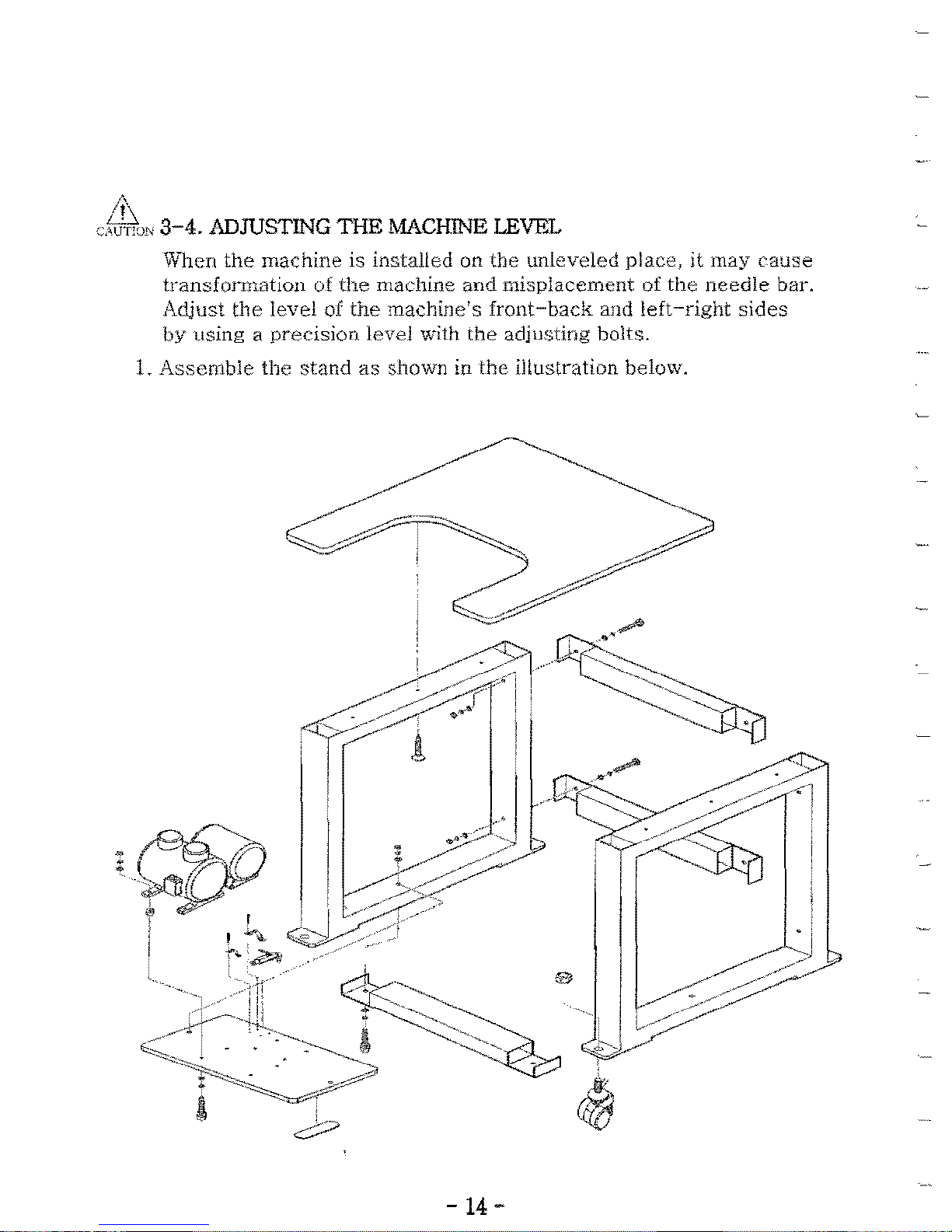

L

Assemble

the

stand

as

shown

in

the

illustration

below,

•

·

•

-14

-

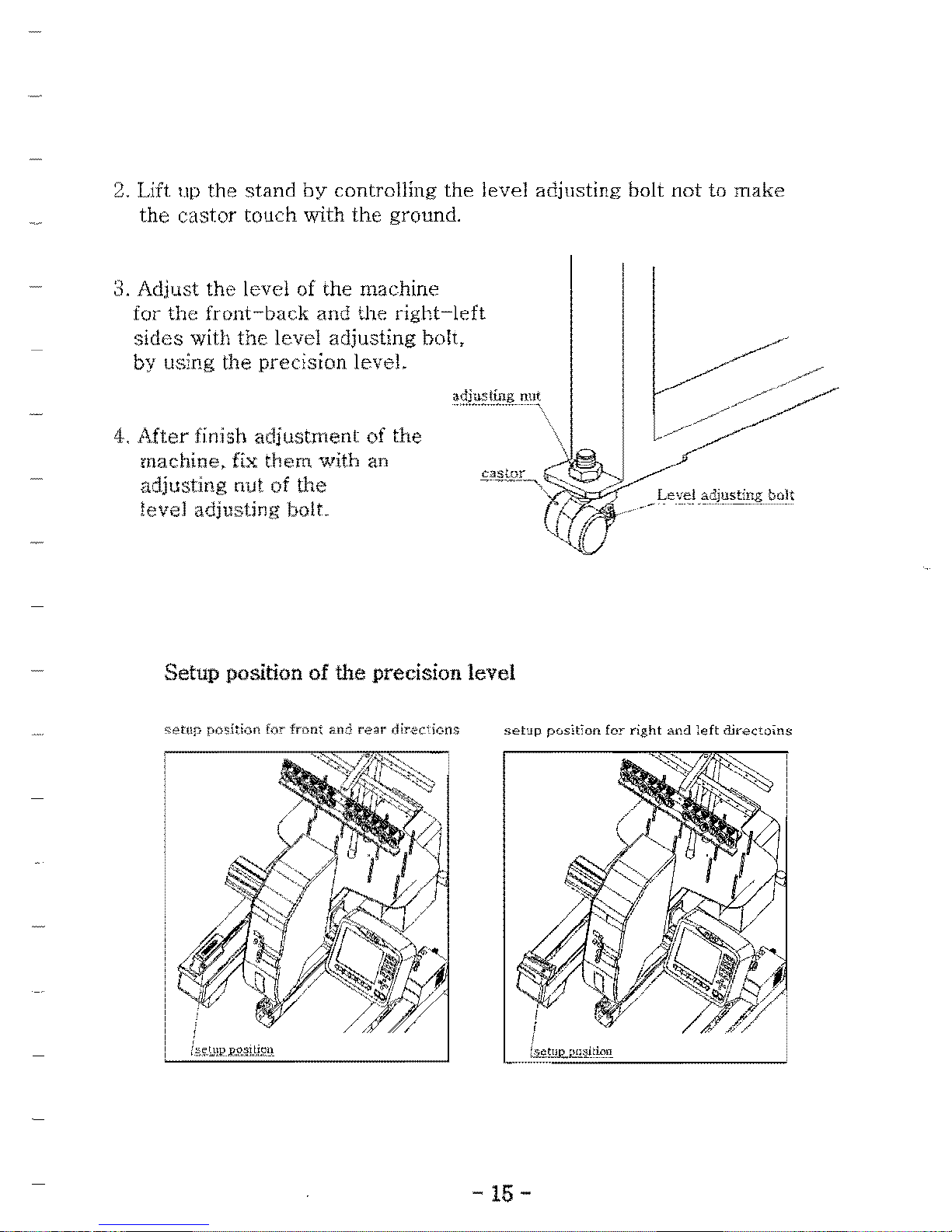

2,

Lift up the

stand

by

controlling

the

level adjusting bolt

not

to

make

the

castor

touch

with

the

ground,

3, Adjust

the

level of the machine

for

the

front-back

and the

right-left

sides

with

the

level adjusting bolt,

by using the

precision

leveL

adjusting nut

..

,

...

_._

..._....

- -

--"\

4,

After

finish

adjustment

of

the

\

"-

"?:;c=?

machine, fix

them

with an

castor

~-~~-~

adjusting nut of

the

"

_

Le':':t:~

,~djusting

bolt

level adjusting bolt.

Setup

position

of

the

precision

level

setu;:: position for front ano

fear

dir-ecions

setJp

pusifon

for

right

and

ieft

direcwins

"

-

15-

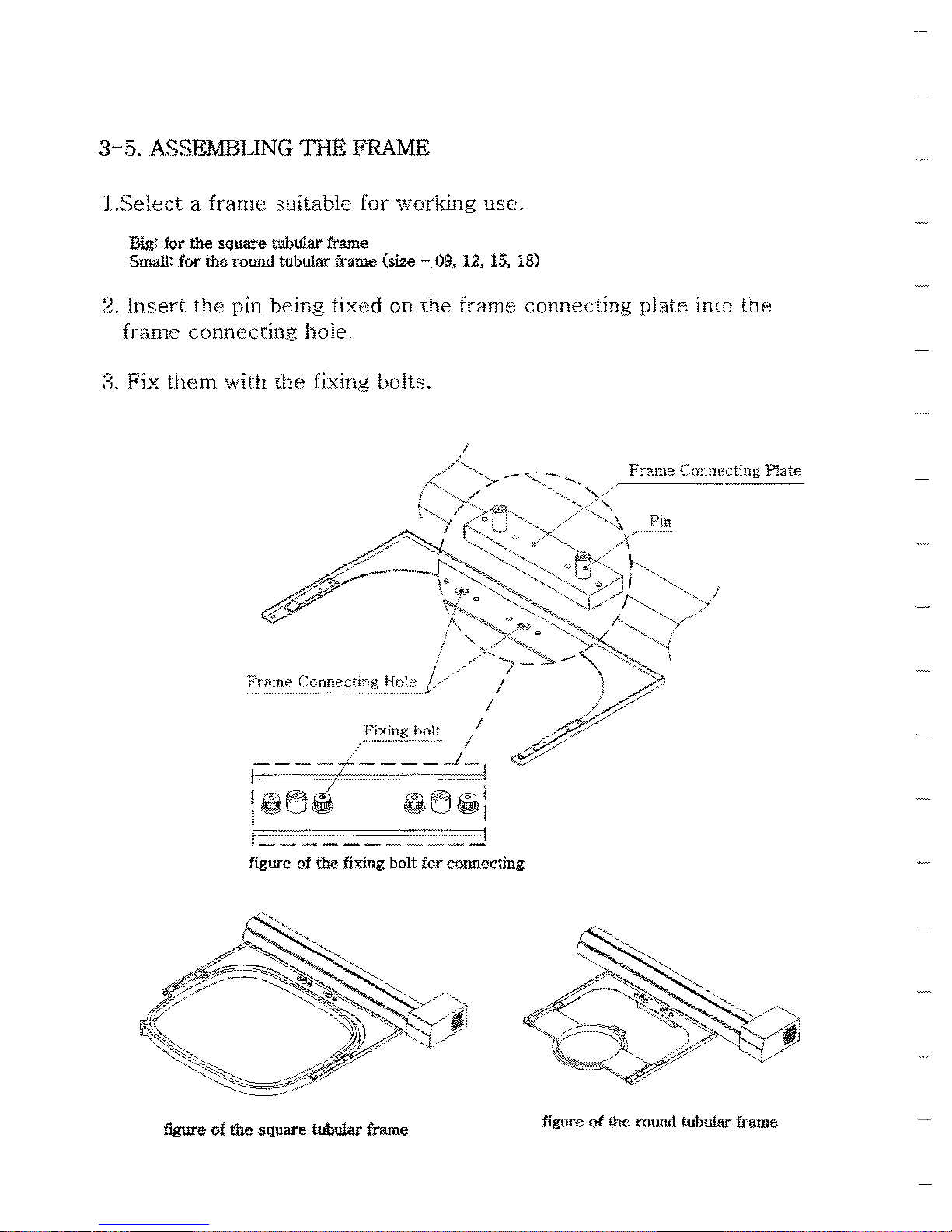

3-5.

ASSEMBLING

THE

FRAME

LSelect a frame

suitable

[or

working

use.

Big:

tor

the square tubular frame

Small:

for

the round tubular frame

(size

-.09.

12, 15, 18)

2.

Insert

the

pin

being

fixed

on

the

frame

connecting

plate

into

the

frame

connecling

hole.

3. Fix

them

\\~th

the

fixing bolts.

figure

Qf

the round tubular frame

figure

of

the square tubular frame

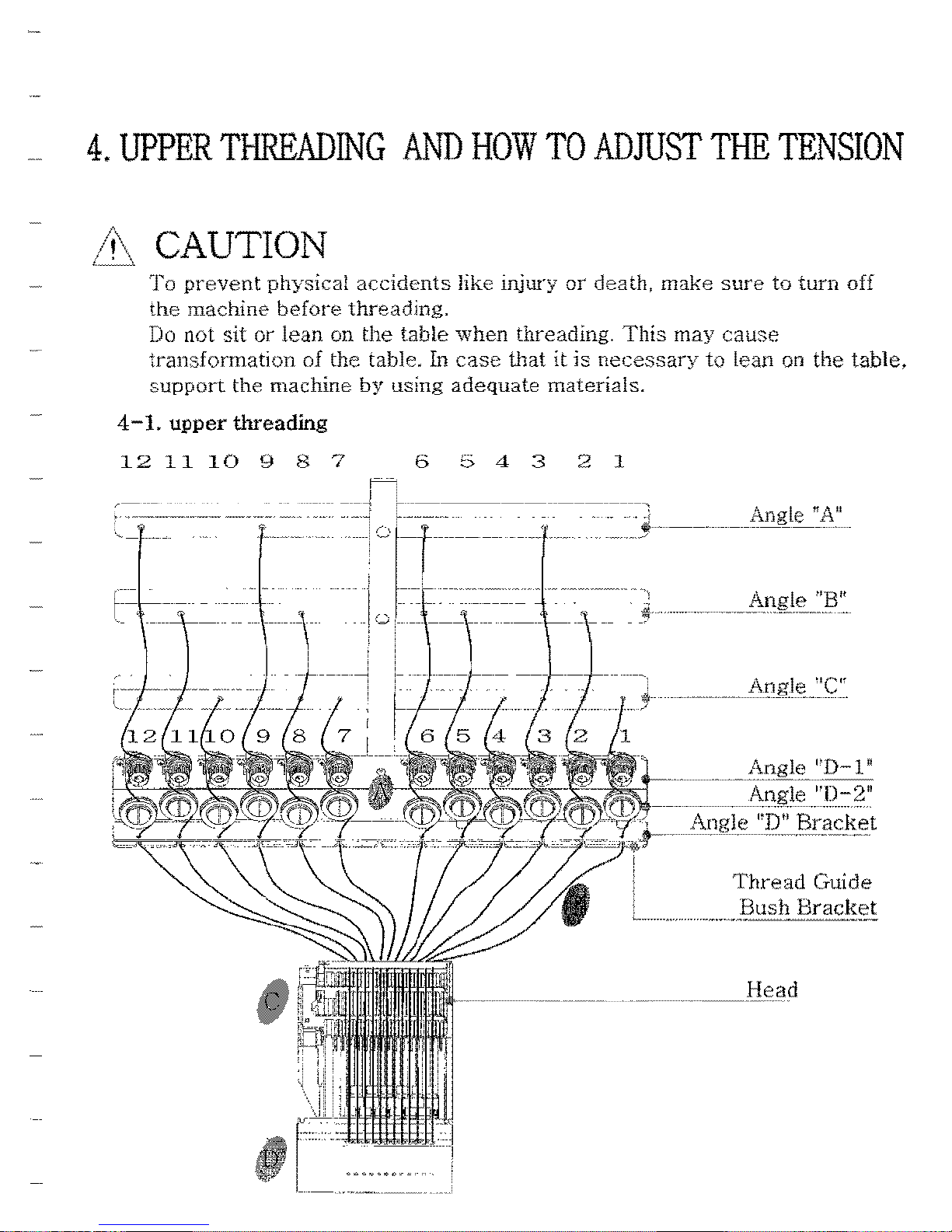

4.

UPPER

THREADING

AND

HOW

TO

ADmST

THE

TENSION

& CAUTION

To

prevent

physicat

accidents

like injury

or

death,

make

sure

to

turn

off

the

machine

before

threading.

Do not

sit

or

lean

on

the

table

when

threading.

This

may

cause

transformation

of

the

table. In

case

!hat

it

is

necessary

to

lean on

the

table,

support

the

machine

by

using

adequate

materials.

4-1.

upper threading

12

11

10

9 8 7

654321

p-=-

---------

-----1

-----------------,

,

'-;:------._-

_

..

_-

_

..

________

._

_. --•.

i Angle

ff

A

II

_______

0

_______

'" ----

------------

\--

-\

Ie

.',-

+'

-----\::-----:

---:

";~.----------~",

,.

l-tI0g1e

I'D-l

n

Anil:

1e

"[):::?"

Angle

"D"

Brack..et

Thread

Guide

~_!H,-"e

ad

,

i

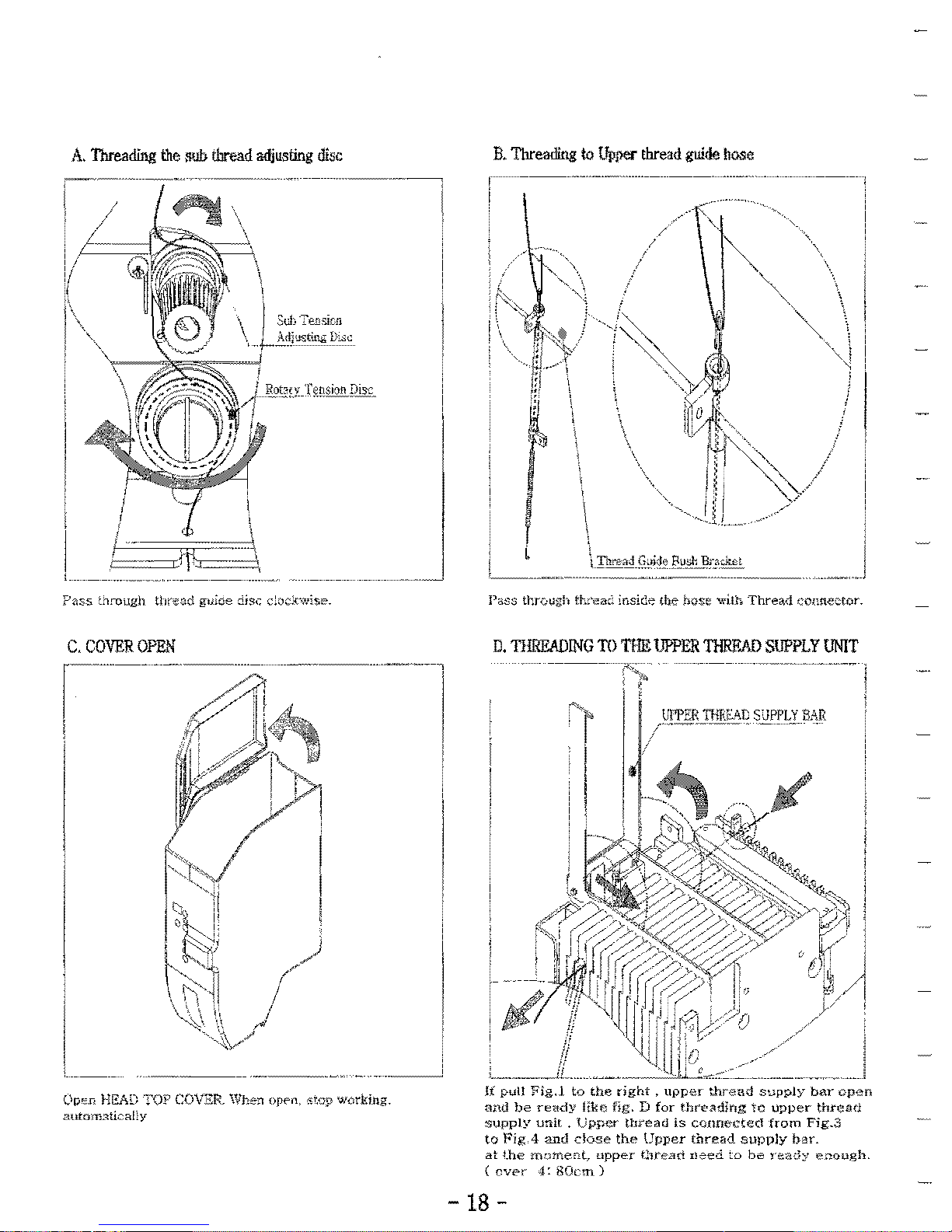

A,

Threading

the

IlUb

thread

adjusting

disc

B.

Threading

to

Upper

thread

guide

hose

,

I

3d)

--=-81;;lon

Atljsstill,i;

be

.1--

..

L

Pass

through tt.:"ea;;' insiG;;

the

hose

wilh

Thread

connector.

D,

TIlRllADlNG

TO

TIlE

UPPER

THllF.AD

SUPPLY

UNIT

UPPER

THRSA.t:

SliPPLY

EAR

?<1SS ::Jrough tlireuci

guiae

:ijs,~

c!oc]{wise.

C,

COVER

OPEN

r~~~~-~

I'

-

.-

-~---~-~

l\P"'Jl

HEAD

TOF

COV3:Ft

Whe-:l

open,

,ViJP

w(lrki:ng.

3UfOffi."Itic<iEy

18

-

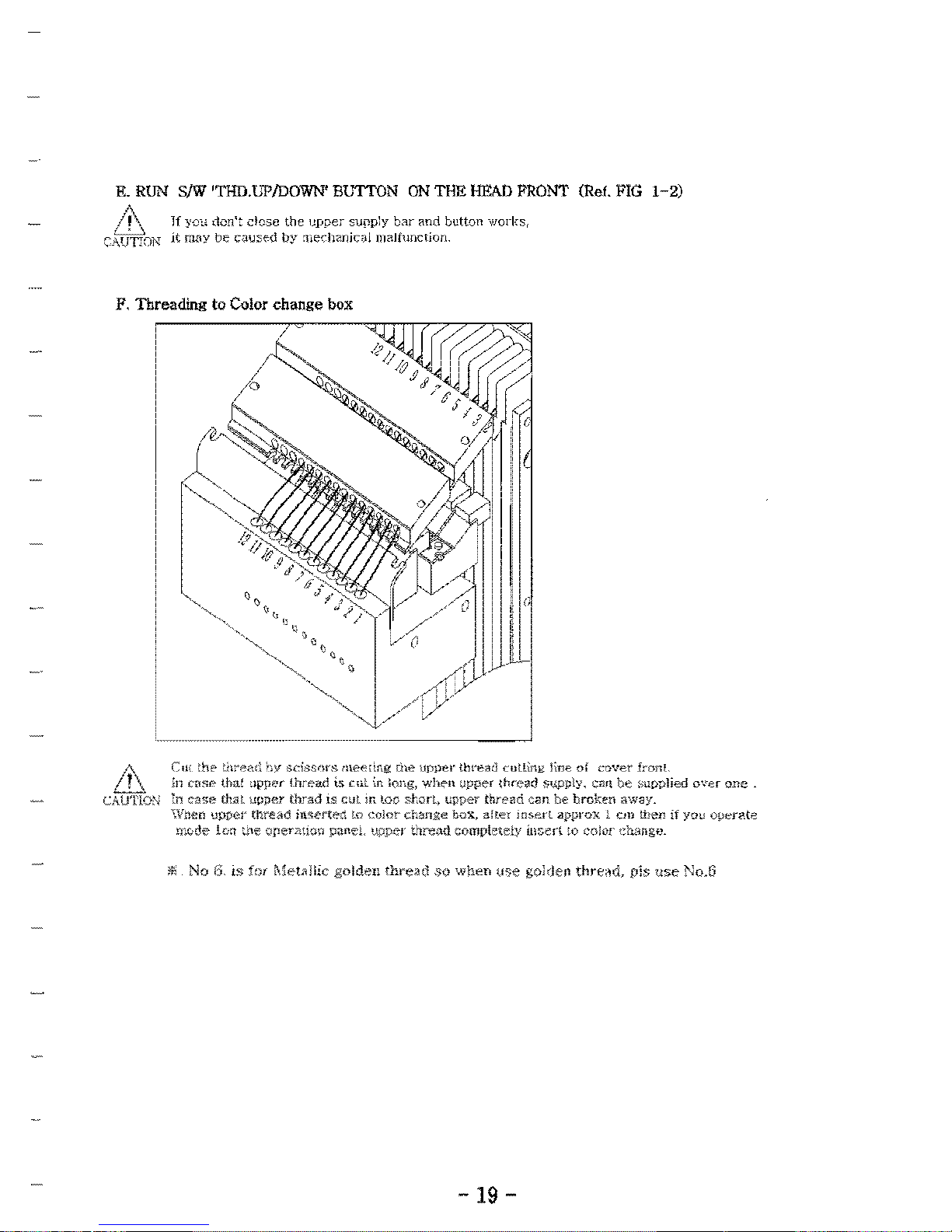

E.

RUN

S!W

'THD.\JPIDOWN'

BUTTON

ON

THE

HEAD

FRONT

(Ref.

FIG

1-2)

u

'A,

If

YDU

don':

dc-se

the

upper

S1JPP~Y

bar

ftnd

button

'works,

('_'''Xr.:)1\!"

jt

rrwy be c;lused by ;ne<:hc.niol malfunction.

p,

Threading

to

Color

change

box

&

em

:hi"

:h:0dl

'lY "dSYlrs.

mee:mg

[he

upper

tiweaci

cuning

line

o!

cover

ironL

;n

(T'$i'

tha~

:Ipper

lhread

is

cuL

il1

long,

wht'lt

:;pper

,nn:;,lIj 5<JPply,

em\

be

supplied

over

one.

CAUTiON

:11

case

thill

upper

thrad

IS

cut

111.

loe

shon,

upper

thread

e<ln

be

broken

away.

\Vnctl

upper

thre;.d

iW'l:ertect

LO

eolor

change

bex,

alter

insert

;approx i

em

lhen

if

you

0pen'.te

rL.0Ce

10:;

~"f'

Qperl!tl(i\) paneL upper thre;;td completely Loserl to

color

dunge.

-19

-

Loading...

Loading...