Technical Specifications:

- Function Limitations …….. ............................................................. 1

- Production capacity……… ............................................................. 1

- Dimensions .................................................................................... 2

- General Features ........................................................................... 2

General information and installation:

- Introduction .................................................................................... 3

- Unpackaging and inspection........................................................... 3

- Location and levelling….................................................................. 4

- Electrical connection ...................................................................... 4

- Drain and water connexions.. ........................................................ 4

Operation instructions

- Start-up…………….......................................................................... 5

- Verifying operation with the equipment working………………........ 5

Operation principle

- Water circuit….. ............................................................................. 7

- Cooling circuit…… ........................................................................ 8

- Components description……. ...................................................... 11

INDE

X

Process of adjusting, elimination and substitution of

components…............................................................................. 14

Electrical diagram ..................................................................... 19

Troubleshooting … .................................................................... 20

Diagnosis service....................................................................... 21

Cleaning and maintenance instructions

- General ........................................................................................ 22

- Cleaning the ice making equipment……...................................... 22

- Instructions for cleaning the water circuit………… ...................... 23

Control Panel ……..................................................................... 25

Components of Ice making equipment…............................. 26

Type of installation

- Installation in an adjacent room… ............................................... 28

- Installation in a false ceiling….. ................................................... 29

- Ice fountain semiannual maintenance

….. .................................. 30

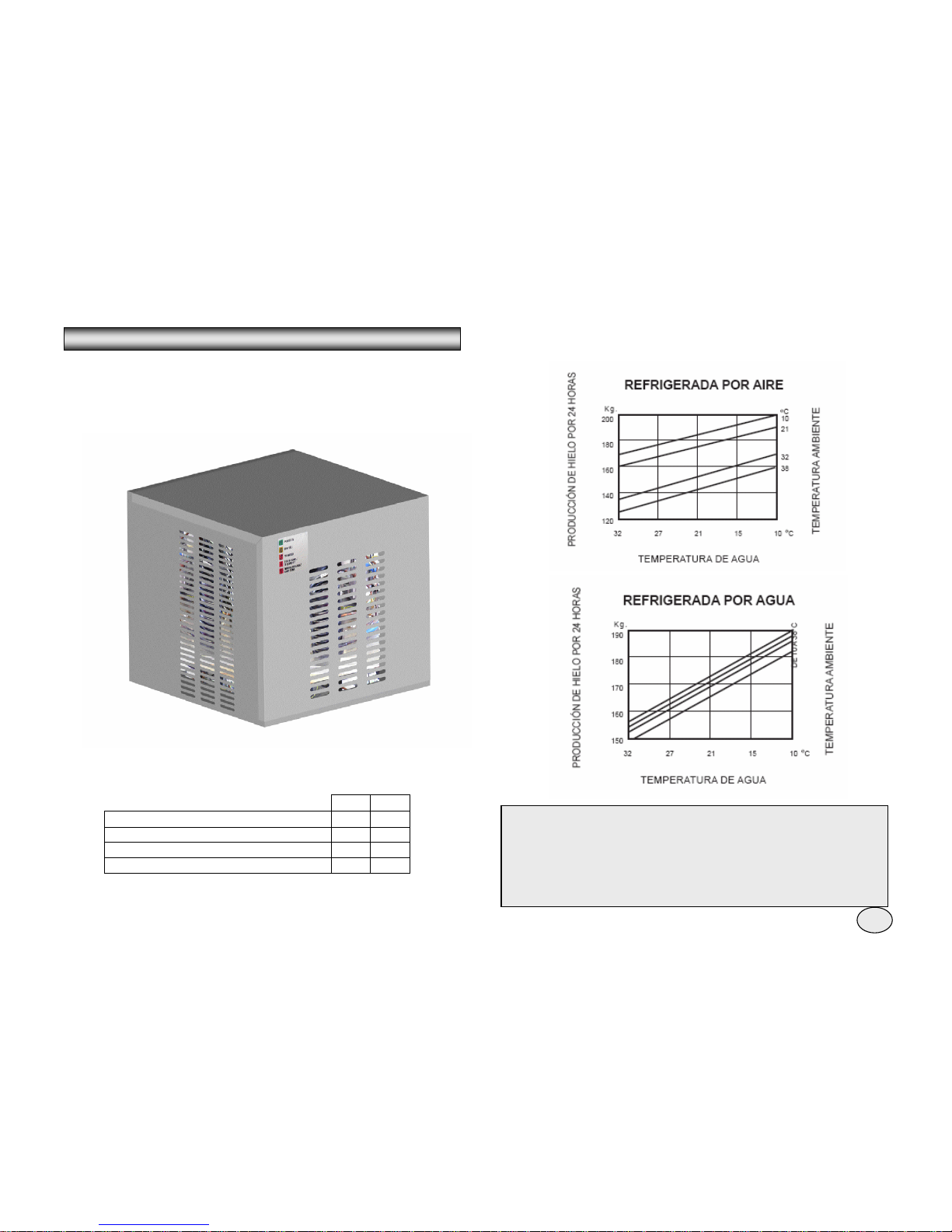

TECHNICAL SPECIFICATIONS

MODULAR ELECTRONIC ICE EQUIPMENT

mod. GEL-MF 30

¾ OPERATION LIMITS

MIN MAX

Environmental temperature

10º C 40º C

Water temperature

5º C 35º C

Water pressure

1 bar 5 bares

Variation with regard to plate tension

-10% 10%

¾ PRODUCTION CAPACITY

NOTE: The daily production capacity change when the environmental

temperature and the water supply change, a capacidad de producción

diaria varía al variar la temperatura ambiente y del agua de alimentación

, thus the space around the equipment..

So as to mantain the equipment in maximum efficient conditions, it is

necessary to do the periodic maintenance as explained in the

correspondence part of the manual

1

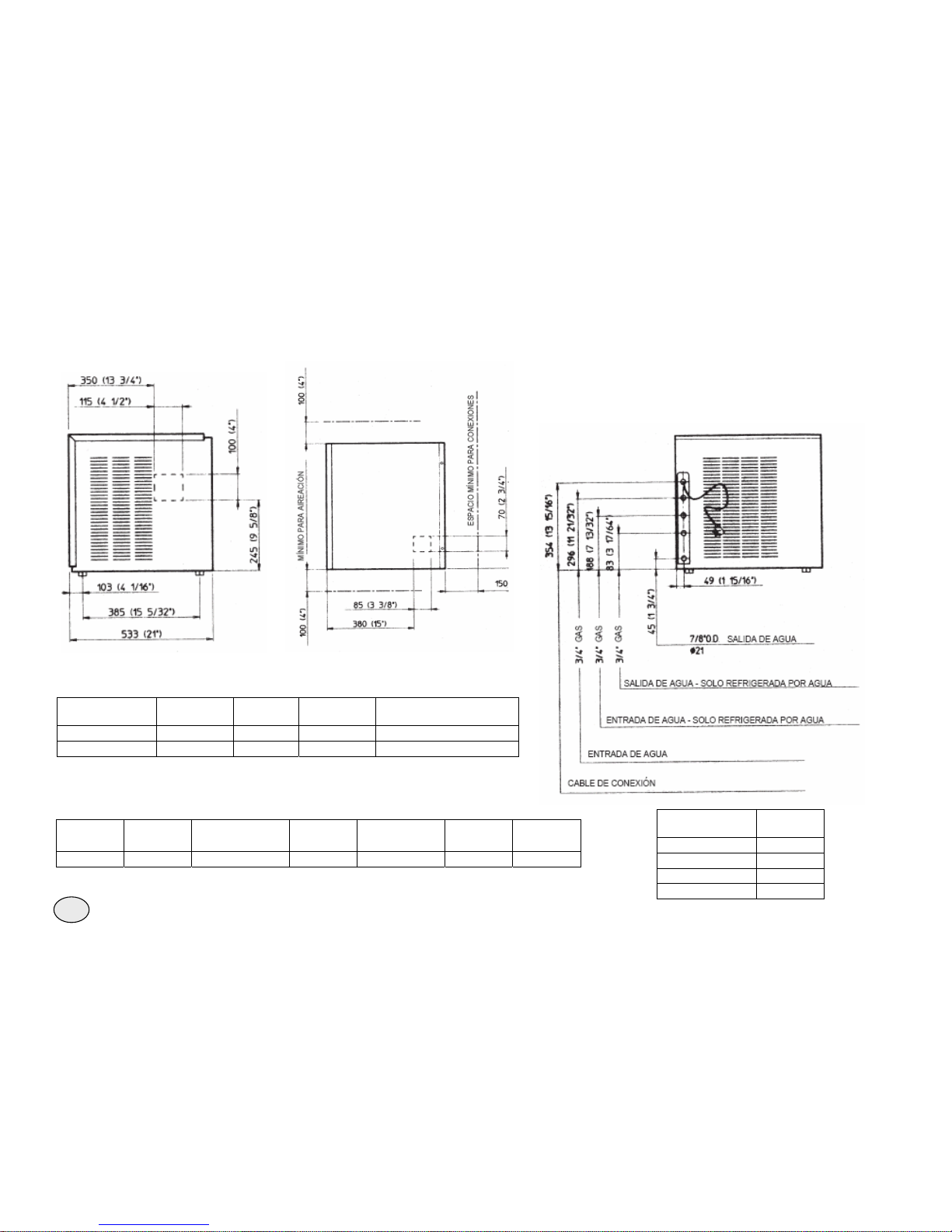

¾ DIMENSIONS OF THE EQUIPMENT

High (Whitout

base)

525 mm

High (with base)

542 mm

Wide

560 mm

Deep

533 mm

Weight

49 Kg.

¾ MF – 30 GENERAL FEATURES

Model Cooling Material Compr. CV

Water consumption (l/24

HR)

MF 30 AS Air Stainless 3/4 200

MF 30 WS Water Steel 3/4 850 *

Ampere Electrical cons. Cable Fuse

Tension Amperes Start-up Power Kw h by 24 HR Section Amperes

230 / 50 / 1 4 20 760 W 17 3 x 1 mm 2 10

* To 15º C of water temperature

2

¾ INTRODUCTION

¾

This operation manual has been writing to give the technical

specifications as well as all the instalation instructions, start-up,

operation, maintenance and cleaning the modular equipment of ice

crusher and super ice crusher of MF electronic range.

The electronic equipment of ice crusher and super ice crusher has been

designed and manufactured with high quality level.

The equipment is tested during several hours and reassure a maximum

performance in whatever use and situation.

2. Check the external cartoon packaging and the wood platform used for the

delivery. Whatever obvious damage in the external packaging has to be notify

to the transport; in this case check the equipment with a representative of the

transport agency.

3. a) Cut and take out the plastic ribbons that mantain seale the cartoon

packaging.

b) Take out the cramps that fix the cartoon in the platform.

c) Open the upper side of the packaging and take out the V

protective angular plate

d) Lift the cartoon taking it out of the equipment.

4. In models MF 22, MF 30, MF 41 Y MF 51 take out frontal panel / saque el

frontal / top panel , while in model MF 61 take out top and lateral panels and

check the unit so as to verify it has not been damage during transport.

5. Take out the inner supports used for the transport as well as adhesive

ribbons.

6. Check the pipe of the cooling circuit do not graze between them and it do

not touch other pipes or surfaces; make sure the fan spin freely.

7. Check the compressor it is free of swing above their own shock absorbers..

8. Observe the details of the plate located in the back part of the frame near

the water and electrical connexions and check that the voltage of the electric

net it is suitable for the equipment.

ATTENTION: A wrong voltage of electric supply will cancel

automatically the warranty.

9. Fill in the warranty coupon located inside the User manual, refer to the

model and the serial number of the unit located in the plate fixed to the frame.

Send the coupon to your local distributor.

INSTALLATION AND GENERAL INFORMATION

NOTA: It is recommended when making the installation and the maintenance

operation, follow this manual so as not to damage or reduce the quality and

security characteristics of the equipment.

- Store of ice

The equipment model MF do not have pile ice dispenser basin, thus it is

necessary to design and build one with the material most suitable according

the the decoration of the room. Having into account the following points:

The high of the basin has to be between 90 and 100 cm to make easy the

pick up of the ice.

The dimensions of the ice dispenser has to be approximately of 60 cm wide

x60 cm deep x20 cm high.

It has to have a drain to throw away the ice.

¾ UNPACKAGING AND INSPECTION

- Ice equipment

1. Ask the assistance of the official distributor for a correct installation.

3

Before connecting the ice equipment with the electric line, check the ampère

again of the unit, detail in the plate, with the correspondent ampère of the

electric supply.

¾ WATER AND DRAIN CONNEXION

- General

When choosing the water line for the modular crush and supercrush ice

equipment of model MF take care of the following: la serie MF,

a) Length of the line

b) Clear and pure water

c) Suitable pressure of the line.

¾ LOCATION AND LEVELLING

Water is the most simple and important ingredient for making ice, for this

resason the previous points are very important. A low pressure of water,

below 1 bar can origin problem with the operation of the unit.

Water that contains and excess of minerals can produce a residuum sheet

in the inner parts of the water system, meanwhile a soft water containing

lower mineral salts produce a granular ice too “dry”.

ATTENTION: this ice equipment has been designed to be installed in

areas where the room temperature do no exceed the maximum of 40 º C

nor the minimum of 10 º C

Prolonged period of operation with temperature different ot the

mentioned represents a wrong use of the equipment and suppose the

nullity of the guarantee.

¾ ELECTRICAL CONNEXIONS

To choose the kind and section of the cable observe the ampère indicated in

the plate of the equipment.

All the equipments has an electric supply cable, so it is needed a conection

to the electric line equipped with earth cable and with magnetothermic

switch with fuse appropriate as it is indicated in the plate of each equipment.

The maximum ampere variation permitted does not have to exceed a 10%

of the plate or be less than a 10% of the same.

A lower ampère can produce an anomalous operation and make damage

seriously the protection device and the electric winding.

NOTE: All the external connexions has to be perfect, according with the local

laws. In some cases it is needed the intervention of a qualified electrician..

A

TTENTION: Using soft water (lower mineral salt) with less electric

conductivity of 30 mS don’t let the low tension electricity to go

through between the sensors of water level, causing the stop or wrong

function of the unit.

Chlorine water or ironish water can be partially improve with active coal

filters.

- Inlet of water

Connect the male connector to the water inlet of 3/4" Gas to the water line

using a reinforced plastic pipe with non-polsonous material for food or a

copper pie with external diameter of 3/8".

The inlet water line has to have a stopcock located in an accessible place

near the unit. If water has a high level of impirites it is recommended to install

a fitler or a purifier to prepare it appropriately.

- Water inlet – Water cooling models

The models cooled with water need two separate inlet lines; one for the tank

and the other one has to go through one adjustment mechanic valve to the

cooling condenser.

Also for the water connection of the condenser use a reinforced plastic

flexible pipe or a copper pipe of 3/ 8 with female connector of+" Gas and a

separet bypass valve.

4

¾ CHECKING THE PERFORMANCE WITH THE UNIT WORKING

D. Take out the front panel and if it is needed put the high and low pressure

gauge in their corresponding tyre valve to check the condensation and air

intake pressure.

- Drain

It is recommended a rigid plastic pipe with internal diameter of 18 mm and

constant flow of 3 cm per meter. The draining of remainder water it is made

by gravity; it is necessary a drianing with vertical air inlet near the connector

and that it go to the open siphon for a constant flow.

- Drain – Model cooled with water

The equipment cooled with water need a new line of drain separet with a

male connector 3/4" Gas that comes with the indication “Drain- Only for

cooled with water".

C. After the compressor work 2 or 3 minutes, check that the ice go out

through the unloading hole and through the pipe go to the store.

NOTE: All the water connections has to be perfect and realise according to

the local laws. In some cases it is necessary the intervention of a qualified

plumber.

¾ STARTING

A

fter a correct electrical, water and drain installation, follow the next

instructions for the starting up:

A. Open the tap and connect the plug or electric general switch located in the

electrical connexion line. The first GREEN LIGHT will light, showing the unit

is under tension.

OPERATION INSTRUCTIONS

NOTE: When the unit has been some time disconnected, the RED LIGHT

it is flashing during 3 minutes; afther these minutes it will start the motor ot

the gear reduction and after 5 seconds the compresor.

B. After the 3 minutes, the unit will start up activating the

following components:

- MOTOR / S REDUCTION GEAR COMPRESSOR

- MOTOR / S OF FAN(if the unit is cooling with air), controled by the

temperature sensor of the condenser located in the wings of the same.

NOTE. The first ice granule present a scarce consistence because the

temperature of evaporation still have to reach the normal functioning

value. Wait 10 minutes so as the evaporation temperature go down to

the normal functioning values so as the ice has the correct consistence.

NOTE. If after 10 minutes of being working the equipment the

temperature of the evaporator has not reach below 1°C due to an

inadequate quantity of cooler, the temperature sensor of the evaporator

detects this abnormal situation and consequently stop the unit. In this

circumstance, the YELLOW LIGHT switch on.

After diagnosing and eliminating the problem of this poor

evaporation temperature due to inadequate quantity of

cooler or excessive condensation temperature, press the

boton RESET located in the lid of the control

After 3 minutes, with the RED LIGHT flashing, the unit will start working.

5

F. Check the correct function of ice level control electronic eyes, put the

hand between the two sensor located in the outlet pipe. (one in every

pipe in model MF61). In this way it is interrumped the beam and switch

off the RED LIGHT located in the front side of the electroic

Card. After 6 second the unit stops automatically and switch

On the YELLOW LIGHT showing the situation FULL CABIN.

The beam of light is retablished after 6 seconds, the unit will start up

Automatically (after de 3 minutes of delay) and the yellow

Light that has been switched on before.

NOTE: in the air cooled models, the condensation pressure remain

between two values preestablished throught the fan, sending

intermittently through the sensor located in the wings’ condenser.

If the condensation temperature reach to 70 º C due to

and obstruction in the condenser and/or the motor of the

fan do not work, the sensor temperature of the condenser

stop the unit and consequently a RED LIGHT of danger is

switch on.

After diagnosing and solving the problem, repit the operation indicated in

the previous “Note” to start up again the unit.

E. Check the correct functioning of the water level sensor, close the

stopcock. After some minutes when the level of water

Go down the sensor, the unit will stop and inmediately

switch on the YELLOW LIGHT showing the lack of water.

NOTE: The water level sensor detects the presence of inadequate quantity

of water in the tank and it confirms it to the microprocessor manintining an

electric low ampère flow through the sensors using the water as a

conductive material.

ATTENTION. To use demineralize water (water whitout or with little

salt) with a electric conductivity of less than 30 mS not allow the

lower tension electricity to pass making the unit to stop or not

functioning, a YELLOW LIGHT swith one showing a lack of water.

After open again the stopcock, the YELLOW LIGHT switch off automatically

and a RED LIGHT is flashing. After 3 minutes the unit start up again, first

the reduction gear and after 5 seconds the compresor.

NOTE. The control level of the ice (infrared system) is independent of the

temperature, otherwise it can be affected for the external light and the dirty or

lime deposits located directly in the eyes(infrared sensors).

For a correct operation of the unit it necessary to install it far away of direct

point of light and to scrupulously observe the points mentioned in the

maintenance of the eyesde los ojos.

G. If they are instaled take out the auxiliar manometers and install again the

frontal panel that have been taken before.

H. Explain to the owner the function of the ice equipment as well as the

cleaning and maintenance of the same.

6

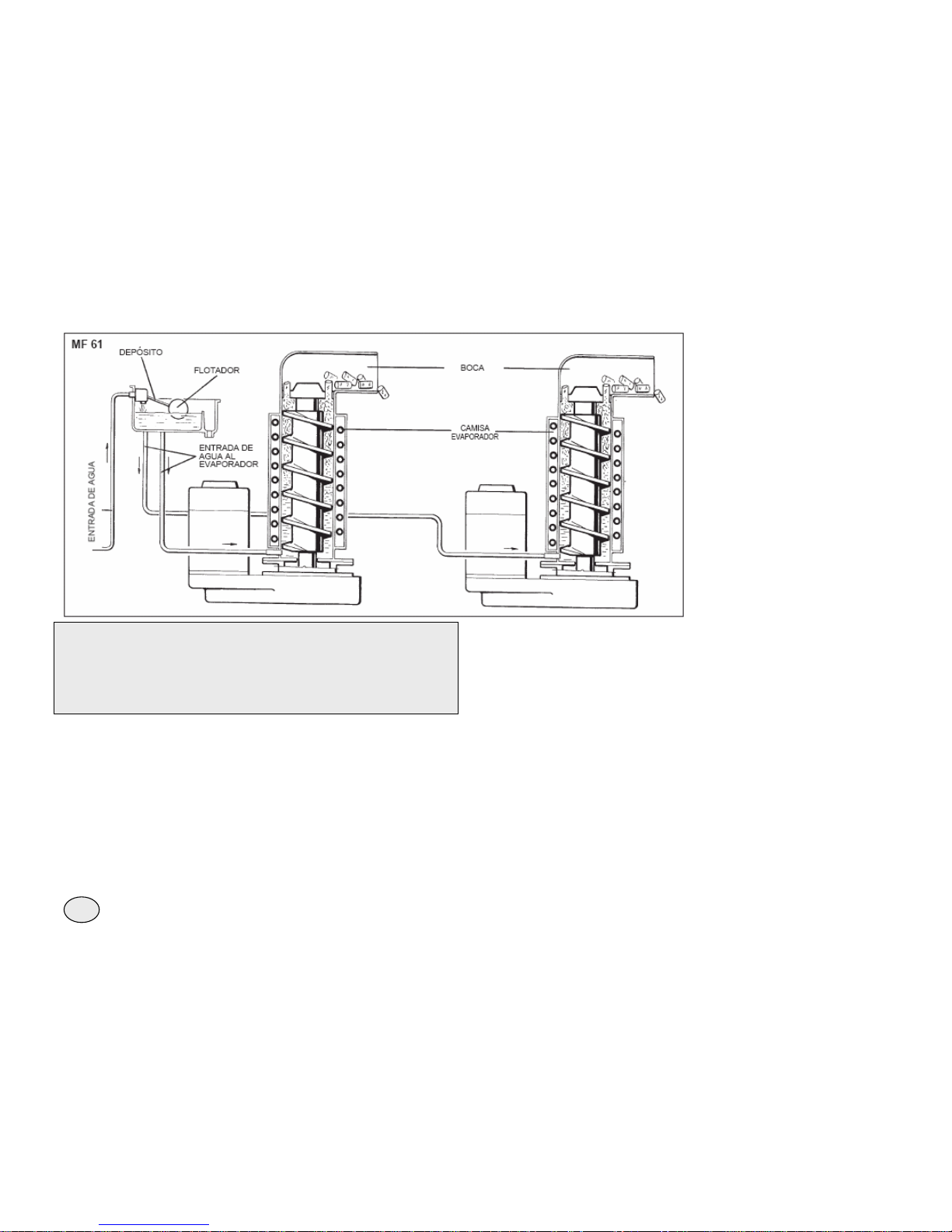

¾ WATER CIRCUIT

Water enter into the machine by the inlet line, where there is a small arille filer

located in the back side and here reach the wáter tank going through a float

valve.

PRINCIPLE OF OPERATION

NOTE: The presence of water in the tank is detected by a system of two

sensors that work together with the electronic board. Both sensors use the

water as a conductive to maintain a electric flow of low voltage that it is send

to the electronic board showing the presence of water in the tank. The lack of

water or the presence of soft water with an electrical conductivity with less of

30mS (demineralize waters)means the interruption of electrical flow to the

electronic boards and consequently the stop of the unit and the switch on of

the YELLOW LIGHT of ” lack of water”.

Tank of wáter is located allied of the evaporator case to a high that allows

through the communicative pipes, maintain constantly a correct level of

wáter inside the evaporator case.

Water enters from the tank through the conexion pipe inside the

evaporator case, where it is unfreeze and it is transformed in ice; this is

constantly mantained in movement by a stainless steel shaft that turn

inside the evaporator case.

The shaft, sumerge in water inside the evaporator turn in antitimetable

direction by the action of a reductive motor, pushing up the sheet of ice

that is formed in the internal cooled walls of the evaportor.

The ice, when it is push up by the shaft becomes more thick and when it

reach the crush it is compacted and cut into pieces, going through the outlet

pipe and falling into the ice keeper.

When the unit start up, it start up the continuous process of ice making,

process that continue until the ice keeper is full until the level sensors located

in the pipe of outlet ice.

When the ice interrumps the infrared beam of light between both electronic

eyes ( one or both in the model MF 61), the unit stops, the YELLOW LIGHT

switch on that shows the situation of full cabin.

7

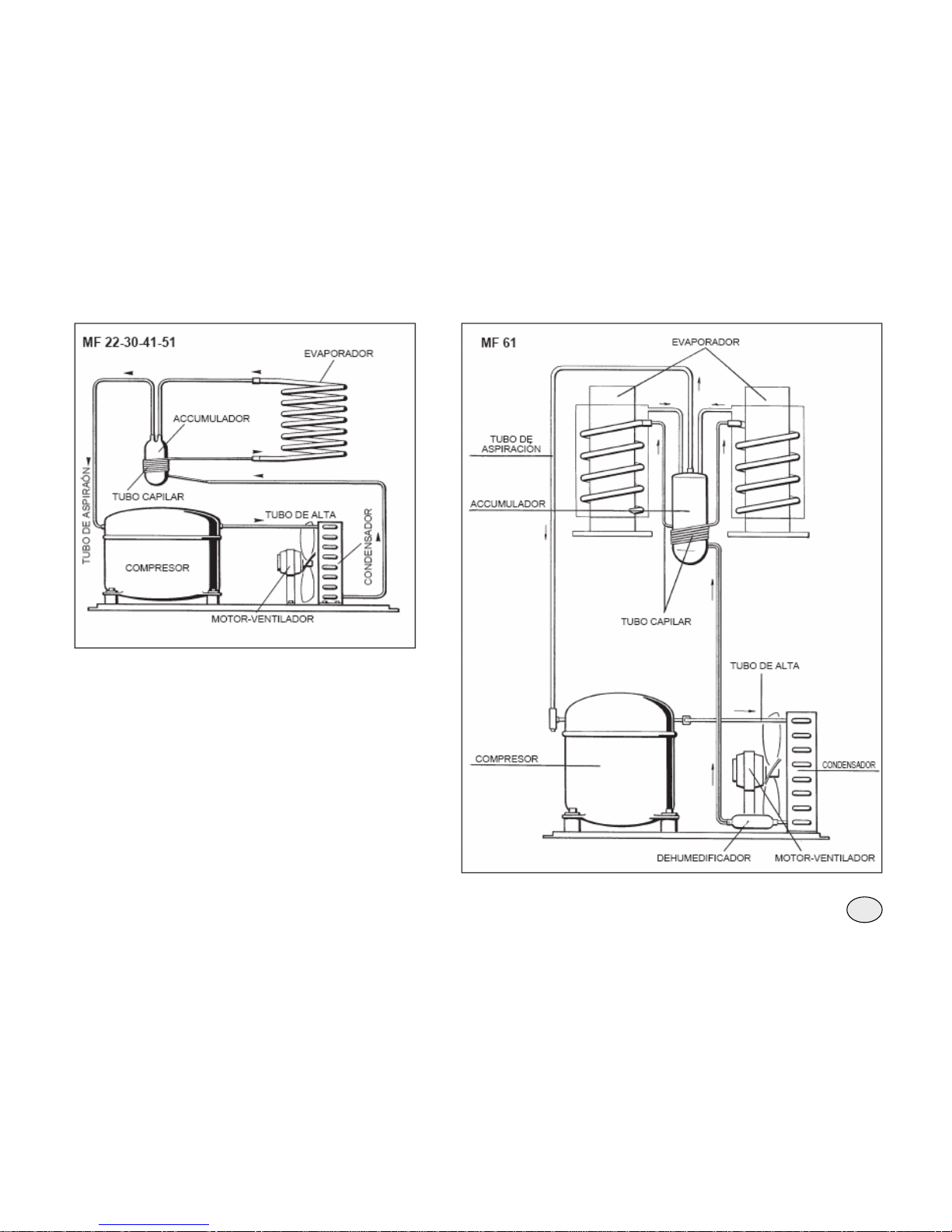

The liquid circuit lead the

refrigerant from the condenser

to the capillary tube through a

dehydrated filter.

When the refrigerant in liquid state

goes through the capillary tube

lose gradually a part of pressure

and a part of temperature.

Then it reachs and enter in the coil

evaporator. Water in contact with

the cooled walls of the evaporator

give heat to the refrigerant that

flow inside the coil, making its

evaporation and the consequent

change of liquid state into steam.

The regrigerant in steam state after

going through the accumulator it is

suck in again in the compressor

trhough the aspiration line.

NOTE: The interruption of the beam between the sensors is inmediately

showed by the switch off of the RED LIGHT located in the electronic board.

Afther the interrumption of the beam of light during 6 seconds, the unit stops

and the YELLOW LIGHT switch on. The 6 seconds of delay protect the unit

of unnecessary stops due to the eventual interruption of the beam of light,

that can be produced for the fall of the ice through the pipe.

When the ice is taken out of the store cabin and the outlet pipe get free, the

beam of light between the two sensors is inmediately reestablished and the

RED LIGHT is switch on in the centre of the board. After 6 seconds the unit

start up again, the YELLOW LIGHT of full cabin switch off and after 2-3

seconds the ice fall again through the pipe.

¾ COOLING CIRCUIT

The refrigerant in gaseous state and high temperature it is pumped from the

compressor, going through the condenser and it is transformed in regrigerant

in liquid state.

The pressure of push of the refrigerant system (high pressure) it is mantained

between the previously establish values (8/9 bar for MF 22 and 17/18 bar for

MF30, MF 41, MF 51 Y MF 61) through the temperature sensor of the

condenser that has the probe located inside the sheet of the condenser, in th

e

air cooled models.

This sensor notice the increase of temperature in the condenser above the

established limit, change its electric resistance and send low tension electricit

y

to the MICROPROCESSOR of the electronic board that supply through a triac

the fan motor in intermittend way ON – OFF.

8

In water cooled models, the high pressure of the system is constant

to 8.5 bar in model MF 22, and to 17 bar in models MF 30, MF 41, MF

51 Y MF 61, due to a quantity of water that goes through the

condenser, which flow is controled by the action of the presostate

valve that it is open to increase the water flow that cool the

condenser.

9

NOTE, In case the temperature sensor of the condenser detects 70ac ' in the

cooled air model or 62º Cin the water cooled version for one of these

reasons:

- DIRTLY CONDENSER (cooled by air)

- INADEQUATE CONDENSATION WATER (cooled by water)

- BURNT FAN OR STOPPED (cooled by air)

- HIGH ROOM TEMPERATURE (UP TO 43° C)

the unit stop inmediately so as to prevent to be working in extremely

abnormal and dangerous situation. When this happens it switch on the RED

LIGHT,that warn of high temperature.

After eliminating the cause of excessive temperature in the condenser,

push button RE-SET.

The RED LIGHT will flash and after 3 minutes the unit will start working. The

temperature sensor of the condenser has also another option for security, it

consist in preventing the start up of the unit if the room temperature (detected

by the sensor of the condenser) in where it is installed the unit is less than 10

C.

When the room temperature is up to 10º C, the electronic board start up

again the unit automatically after 3 minutes.

The pressure of air intake or low pressure in normal conditions is of 0.5 bar in

model MF 22 and 2.4+2.6 bar in model MF 31, MF 41, MF 51 Y MF 61 after

some minutes of operation. These valuer can change between 0.1 bar or 1.2

bar, in relation with the water temperature that supply the evaporator.

NOTE If after 10 minutes of operation not produce ice and the tempertaure

registered by the sensors of the evaporator do not reach -1 C, the unit stops

and switch on flashing the 5

th

YELLOW LIGHT

COOLING EXPANSION DEVISE:

Capillary pipe

PRESSURE OF OPERATION (With a room temperature of 21º)

Pressure of impuls: MF - 22 MF 30 - 41 - 51 - 61

Cooling by air 8 / 9 bar 17 / 18 bar

Cooling by water 8,5 bar 17 bar

Pressure of air intake:

0,5 bar 2.5 bar

COOLING CHARGE (R 134 A)

Cooling by air Cooling by water

MF 22

440 g 380 g

COOLING CHARGE (R 404 A)

Cooling by air Cooling by water

MF 30

540 g 410 g

MF 41

750 g 600 g

MF 51

880 g 820 g

MF 61

2200 g 1300 g

NOTE: Before charging the refrigerator system, check the technical data of

the identification plate of the unit for the kind of indentification of the

equipment as well as the kind of refrigerant and the quantity

10

¾ DESCRIPTION OF COMPONENTS

A.

TEMPERATURE SENSOR OF THE EVAPORATOR

The sensor of temperature of the evaporator, located inside a bulb pipe, it is

welded in the outlet of the freezer tube, register the temperature of the

refrigerant aspirated transmitting a signal (low tension electricity) to the

microprocessor.

Depending on the signal received, the microprocessor give green light to the

ice equipment to continue working (evaporation temperature below -1°C after

10 minutes working or in case there is a lack partially or totally of refrigerant in

the system, stops the equipment flashing the 5a YELLOW LIGHT

(evaporation temperature above -1°C after 10 minutes of operation).

B. SENSOR OF WATER LEVEL FLOAT TANK

The sensor of water level of the flowt tank it is composed of two stainless

steel sensors vertically anchored to the lid and connected electrically to the

low tension circuitry of the electronic board.

Its lower extreme is sumerged in the water tank and throught a current of flow

that it is transmitted through the mineral salt of the water, mark its presence to

the electronic board.

NOTE. The lack of water or the presence of water whitout mineral salt

(electrical conductivity below 30 mS)means the interruption or reduction of

the electric current transmitted to the electronic board, with the consequent

stop of the unit, show with the switch on of the YELLOW LIGHT.

In the models cooled by air, the probe of the condenser control also the

operation of the fan motor through a MICROPROCESSOR of the electronic

board. Using the TRIAC, tjos start up the motor of the fan removing the heat

of the condenser and consequently lowing the temperature.

If the temperature of the condenser is above 62°C to 70°C depending on the

position of the microswitch number 8, the signal that arrives to the

MICROPROCESSOR make to stop the unit.

C. SENSOR OF TEMPERATURE OF THE CONDENSER

The sensor of temperature of the condenser (located between the wings of

the air condenser or in contact with its coil in the case of water condenser)

registers the temperature of condensation and transmitt the variations

sending a signal to the electronic board.

In case the temperature of sensor of the condenser have a value below +3°C

(room temperature too low), the electronic board don’t start up the unit the

temperature of the probe gets to +10°C.

NOTE. So as the unit start up again, push the button REARM (after solving

the cause that has produce the stop) or unplug and plug again the unit.

D. SPEED SENSOR AND DIRECTION OF MOTOR IN THE REDUCTION

GEAR (Two in models MF 61)

The sensor of speed and the direction of rotation of the motor in the reduction

gear (one for each motor in model MF 61). Register through a magnetic

signal (effect hall) the speed and direction of rotation of the motor. When it is

below 1300 revolutions by minute, the signal transmitted to the

MICROPROCESSOR of the electronic board stop inmediately the unit and it

switch on a YELLOW LIGHT.

The same happens when the motor run in the incorrect direction avoinding

that the ice inside the evaportor make a unic body with the axis.

NOTE. To start up the unit in both cases ( slow don and attempt opposing

rotation) push button rearm (after solving the cause that has produced the

stop) or the switch and the electrical connexion.

11

E. OPTICAL SYSTEM OF ICE LEVEL CONTROL (Two in the models MF

61)

The optical system to control the level of ice (one for each discharge pipe in

model MF 61), installed inside the ice discharge pipe, stop the unit when the

level of ice interrumpt the beam of light(by infrared) transmitted between the

two electronic eyes.

When the beam of light stop, the RED LIGHT in the centre of the electronic

board switch off; the continuos stop of the beam of light during more than 10

seconds stop completly the unit switching on the second YELLOW LIGHT.

The 10 seconds of delay for the stop of the unit prevent that the unit stops by

a chance and undesired interrumption of the beam of light (pieces of ice that

fall for the discharge pipe)

En cuanto se quita el hielo para que el haz de luz pueda volver a pasar entre

los ojos electrónicos, la LUZ ROJA vuelve a encenderse inmediatamente

arrancando, después de 10

F. ELECTRONIC BOARD

The electronic board, located in a plastic box fix in the front part of the unit,

consists of two separate printed circuit, one of high voltage and the other one

of low voltage, protected by three fuses, integrated it by a button RE-SET

(REARM). There are also 5 lights indicating the operation of the unit, one

extra RED LIGHT , 8 DIP SWITCH of switching inlet and some connection

terminals with the inlet peripherals (sensors) and outlet peripherals (electric

components). The electronic board is the brain of the system and process

through the microprocessor, the signals received by the sensors to control

the functioning ot all the electric components of the unit (compresor,

reduction gear, etc).

The five LIGHTS in the front of the electronic board show the following

situations:

GREEN LIGHT:

Low tension unit / operation

YELLOW LIGHT:

Unit stop storage full

RED LIGHT FLASHING:

3 minutes of delay

RED LIGHT FIX:

Unit stop for high temperature of condensation

Unit stop for room temperature below 3ºC

YELLOW LIGHT:

Unit stop low level of water in the tank

YELLOW LIGHT FIX:

Unit stop rotation in the opposite direction of

The motor in the reduction gear

Unit stop for speed of rotation of the motor,

Reduction gear too low

YELLOW LIGHT FLASHING

Unit stop for high temperature of evaporation above – 1º C

after 10 minutes of working

12

G. TANK FOR THE FLOAT

The tank has a plastic box with a float with screw of adjustment in the top that

mantains a constant level of water in the tank and with communicating

vessels inside the evaporator.

In the lid there are two sensors to control the level of water that signs to the

electronic board the presence of water in the tank.

J. REDUCTION MOTOR (two in model MF 61)

It has an asynchrounous one-phase motor with a condenser installed in

reduction gear box of gears and pinions, the reduction motor activate through

a transmission connection the axis of elevation of ice located inside the

vertical evaporator.

The rotation of the motor, subjected by two ball bearing of permanent

lubrication, transmit the movement to a fibre gear (to reduce the fluid) of it,

with a pair of gears and pinions subjected by the roller gears located in the

upper and lower extreme of the outlet axis.

The reduction gear is seal, by the presence of thw retainers installed in the

hole of rotor axis and outlet axis and it is lubricated with specific grease

(MOBILPREX IP 44).

K. MOTOR OF THE FAN (Models cooled by air)

The motor of the fan is comanded through the TRIAC of the electronic board, by the

sensor of temperature of the condenser. It works making to flow the air thorugh the

sheets of the condenser. In conditions with a low room temperature, it can

intermittently work to maintain the condensation temperature between the

pressetablished values.

L. PRESOSTATIC VALVE (Model cooled by water)

The presostatic valve mantains a contant value of high pressure in the

cooling circuit changing the water flow in the condenser. When the pressure

increase the presostatic valve interiorily opens to increase the flow of water in

the condenser.

M. COMPRESOR

The hermetic compresor is the heart of the system and it makes the

refrigerant to circulate in the refrigerator. It intakes the refrigerant as a low

pressure and low temperature steam and it transforms it as high pressure

and high temperature steam, sending it to the circuit through the discharge or

high valve.

NOTE. It is very important to place correctly the lid in the tank of the float, so

as to the sensors be submerged and can transmit an electrical signal that

confirms to the electronic board the presence of water in the tank and avoid

inopportune stop of the ice equipment.

H. EVAPORATOR (Two in model MF 61)

The evaporator has a stainless steel vertical pipe in which external side it is

solded the evaporation chamber of the refrigerant and in which in the interior

there is the axis that turns and it is mantained in axis by the action of the top

and lower treads. In the lower part of the evaporator there is a retention ring

that hermetically seals it, while in the top part there is the ice crusher

machine.

I. CRUSHING RING OF ICE (Two in model MF 61)

The crushing ring of ice is on the top side of the evaporator and it has in

models MF 22-30, two cogs to crush the ice; with its inclined shape (the back

cogs to front) compress and force the ice to come out in horizontal direction.

In the other models, the ice crusher equipment has some rectangular holes

through the ones the ice is compressed. In this way, the ice loses the excess

of water and fall to the storage in compact and dried grains.

In the crush ice machine there is a top tread, and it has two stainless steel

rolling crowns located in a way that can support the axial and radial load of

the axis.

NOTE: It is recommended to check every 6 months the state of the lubricant

as well as the upper tread.

13

A. ADJUSTMENT THE WATER LEVEL IN THE EVAPORATOR

2. To drop the level of water make the same as before but putting down the

tank.

PROCESS OF ADJUSTMENT, REMOVAL AND

SUBSTITUTION OF THE COMPONENTS

NOTE: Reas carefully the following instructions before make a substitution or

adjustment process.

The correct level in the

evaporator is 25mm

below the outlet ice

hole (discharge hole).

A lower level of water

can cause a major

rubing of the ice and of

the axis due to a

quickly freese of water.

When the level of water is above or below than the normal level, the

regulation consists in raising and droping the level of water moving up or

down the tank

1 To raise the level of water act as following:

- a)Take out the screw that fix the support of water tank and raise it all

the necessary until it reach the level required.

- b ) Put the screw in the correspondent drill holes and tighten it.

ATTENTION. Before doing this regulation makes sure that the problem

is the level of water (check troubleshooting). Make sure the electric

supply is disconnected and the stopcock of water close so as to

prevent damages.

B. SUBSTITUTION OF THE SENSOR OF TEMPERATURE OF THE

EVAPORATOR

1.Take out the fornatl /upper panel.

2. Take out the isolation of pipes that connect the evaporator with the

storage heater to accede the bulb tub weld in the pipe of the cooling pipe

outlet and take out the inner sensor of temperature.

3. Look for the connection of the evaporator’s sensor in the back side of the

electric box and disengage it making prise with the anchored tab.

4. To install again the sensor of the evaporator follow this process on the

other way round.

C. SUBSTITUTION OF THE SENSOR OF TEMPERATURE OF THE

CONDENSER

1. Take out the frontal / upper panel and in model MF61 take out also the

right side panel.

2. Look for the sensible bulb of the condenser sensor placed between its

wings and in the models cooled by air and take it out. In models cooled by

water take the bulb out after open the plastic bracket (it can be used again)

that fix it to the pipe of the liquid.

3. Look for the connection of the sensor of the evaporator in the back side of

the electric box and disengage it making prise with the anchored tab.

4. To install again the sensor of the evaporator follow this process on the

other way round.

14

D. SUBSTITUTION OF OPTICAL CONTROL OF LEVEL OF ICE

1. Take out the upper /frontal panel in models MF 22, MF 30, MF 41 Y MF 51

and take out the frontal/ back panel in model MF 61.

2. Look for in the back side of the electric box the optical control conexión of

level of ice with 4 plugs of white colour and disengage it from its place making

prise with rubber anchored tab.

3. Take out the two electric eyes of its light port take them out of the drills

located in the two opposite side of the outlet discharge hole, making pressure

in the external part of the rubber elements, take attention so as not to

damage the sensible side (infrared reader)

4.To install again the optical control of ice level follow this instructions on the

other way round.

E. SUBSTITUTION OF CORRECT SENSOR OF ROTATION IN THE

MOTOR (HALL EFFECT)

1.Take out upper/frontal and side/back panel in models MF22, MF30, MF41

and MF51, while in model MF61 take out the left side/upper panel..

2. Unscrew the screws that fix the plastic lid in the place of the magnetic

sensor and take it out.

3. Unscrew the two screws that fix the sensor in the plastic space and take it

out.

4. Look for in the back side of the electric box the connection of the rotation

sensor of 4 red plugs and disengage of its place making prise with the

anchored tab.

5. To install again the sensor of correct rotation of the motor follow this

instructions on the other way round.

F. SUBSTITUTION OF SENSOR OF WATER LEVEL IN THE TANK

1. Take out the frontal/upper panel.

2. Unscrew the anchore nuts from the connection of cables of both stainless

steel bars –sensor of level of water-located in the float tank.

3. Look for in the back side of the electric box the connection of the sensor of

level of water from two red plugs and disengage it from its place making prise

with the anchored tab.

4. To install the new sensor of level of water follow this instructions on the

other way round.

G. SUBSTITUTION OF THE ELECTRONIC BOARD

1. Take out the frontal/upper panel.

2.Look for in the back side of the electric box the connections of the sensors

and disengage them of its location making prise with the anchored tab.

3. Disengage from the back side of the electronic board the terminal of the

electrical connections, after that take out the electronic board unscrewing the

4 screws that fix it to the plastic electric box.

4. To install the new electronic board follow this instructions on the other way

round.

H. SUBSTITUTION OF THE ICE DISCHARGE HOLE

1. Unscrew the nuts and take out the upper/frontal panel.

2. Take out hte nut and the cutting edge of the ice discharge taking attention

of not to damage the electronic eyes.

3. Slacken the two brackets that fix the polystyrene insulater in the upper part

of the evaportor and take out the two parts of the insulator.

15

6. Install the new entrance following this instructions on the other way round.

I. SUBSTITUTION OF THE AXIS, RETENTION RING, BALL BEARING

AND JOINT.

1. Unscrew the screws and take out the upper/frontal panel.

2. Follow the instructions detailed in point H to take out the ice discharge

entrance..

3. In models MF22-30 unscrew and take out the two screws and washer that

fix the support of the discharge entrance. In models MF41, MF51 and MF61

unscrew and take out the 4 nuts that fix the crushing ice euipment to the

upper clamp in the evaporator.

4. In models MF22-30 hold the ring located in the upper part of the ice

crusher in the evaporator and pull up to take out the axis, the lid and the ice

crusher. In models MF41, MF51 and MF61 introduce the end of screwdriver

in the space between the ice crusher and the upper clamp and turning rise

the axis/ice crusher. Take the ice crusher and take out the axis/ice rusher

taking it out from the evaporator.

4. In the models MF22-30 take out the stainless steel entrance of its bronze

part while in the other models inscrew the two nuts that fix it to the crush ice

equipment.

5. In the models MF22-30 unscrew the two screws taht fix the bronze

entrance to the evaporator and release it.

5. In models MF22-30 using a nipper of seeger take out the seeger washer

that fix the lid in the ice crusher while in the others models make prise with a

screwdriver and take out the lid of the ice crusher.

6. Unscrew and take out the head nut that fix the ice crusher to the bearing in

the axis, then take out the ice crusher from the nut.

7. Take out the exceed of grease inside the ice crusher and analise the state

of the binding and if it is not in good condition replace it.

8. Analise with attention the bearing located inside the ice crusher. If there is

a damage or lack of lubricant replace it.

NOTE. In models MF22-30 inspect the rectangular binding of the rubber

entrance and if it is damage substitute it.

NOTE. IF you can’t take out the axis/ice crusher f rom upper part, follow

instructions in points 10 and 11 as to do it from the interior side. Using a

wood hammer or plastic hammer, knock the inferior extreme side of the axis

to back off and take it out from the upper side of the evaporator..

ATTENTION. The upper ball bearing works in extreme condition making

reference to lubrication due to it is inside the ice crusherwhere there is

always so much condensation liquid. It is necessary to use fat and

water repellent to guarantee a correct lubrication.

9. Take out the inferior side of the axis, the turning washer from the gland

seal system..

ATTENTION. Every time you dismantle the axis to make a control or

substitution, take attention so as not to enter dirty inside the evaportor

and that the dirty don’t reach the surface carbon in the ring retention. If

you have doubts replace the ring.

10. Unscrew and take out ¾ nuts that fix the aluminium support in the inferior

side of the evaporator.

11. Raise the evaporator taking it out of its support then in models MF22-30

with a wood or plastic tool push the evaporator to the outward from the

inferior extrem as the retention ring as the inferior ball bearing. If it is

necessary use a hammer.

16

12In models of super crushing with the end of two screw drivers make prise

in the inferior extreme of the bronze ring.

18. Put lubricant and put the steel washer.

19. After substituting the O-ring in the rusher ice machine, install it in the

inner side of the axis and fix it to the upper nut.

20. Install the axis/crusher ice equipment in the evaporator following the

above instruction on the other way round.

J. SUBSTITUTION MOTOR OF THE REDUCTION GEAR

1 Take out the frontal/upper panel and back/side panel in models MF22,

MF30, MF41 and MF51 and in model MF61 the frontal panel and the left

upper panel.

2. Unscrew the ¾ nuts that fix the evaporator in the upper body of the

reduction gear.

3. Take out the sensor of rotation direction following instructions in section E,

unscrew the screws that fix the motor of the reduction gear in the framwork.

4. Disconnect the motor of the electrtical conexión of the unit. The reduction

gear now can be substituted.

5 To install the new motor of the reduction gear follows the instructions on the

other way round.

NOTE. It is recommended to substitute the mechanic retention ring, the

ball bearing upper and inferior as well as the bindings or every time the

evaporator is dismantled. There is one kit with these spare parts

number 001028.07 for MF22-30 and number 001028.08 for MF41-51-61

with a fat tube and water re

p

ellent.

13. From the interior of aluminium support, take out the components that

integrate the transmision connection.

14. Check the two half-connections, if they are not in good conditions replace

them.

15. Install the inferior ball bearing in its bronze place taking attention with the

plastic ring.

16 Install the upper ball bearing in the crush ice equipment starting from the

radial side that has to be installed with the flat side.

17. Put lubricant in the upper side, and install the ball bearing box with the

small holes upwards to give a free movement between the plastic box and

the flat area of the inner side of ball bearing (check picture).

NOTE. Drain carefully the cooking circuit to remove excess of humidity and

K. SUBSTITUTION OF WATER CONDENSER

1. Take out hte frontal/upper panel and side/upper panel in models MF22,

MF30, MF41 and MF51 and the frontal/right side panel in model MF61

2. Take from the condenser the sensitive bulb of the sensor.

17

3. Unscrew and take out the nuts that fix it in the base.

4. Unscrew the brackets of the tub and disconnect the plastic pipes from the

two end of the condenser.

5. Get the refrigerant out of the system and let it in a tank to use it again after

treat it.

6. Unweld the pipes of the cooling installation from the two end of the

condenser.

NOTE. Purge carefully the cooling circuit to remove the excess of humidity

and the no condensation of gas after the substitution of the presostathic

valve.

NOTE. Sustitue the dehydrate filter every time the cooling refrigerant is open.

Do not put the dehydrate filter until the reparation or substitution process is

finished..

7. To install a new condenser follow the instructions on the other way round.

NOTE. Purge carefully the cooling circuit to remove the excess of humidity

and the no condensation gas after the substitution of the condenser..

L. SUSTITUTION OF THE PRESOSTATHIC VALVE (UNIT COOLED BY

WATER)

1. Take out frontal/upper panel and back side panel in models MF22, MF30,

MF41 and MF51 and left side panel in model MF61.

2. Close the stopcock of water and disconnect the pipe from the presostathic

valve from the back side of the unit.

3. Get the refrigerant out of the ysstem and let it in a tank to use it again after

treat it.

4. Unscrew and take out the capillary pipe from the presostathic valve from

the refrigerator circuit.

5. To Install the new presostathic valve follow this instruction on the other way

roundl.

NOTE. The flow of water that go through the presostathic valve has to be

adjusted using the screw located in the upper side of its rod until the

condensation pressure is of 8.5 bar in MF22 and 17 bar in MF30,41,51,61..

M. SUBSTITUTION OF THE CONDENSER

1. Take out the forntal/upper panel and back lateral panel in models

MF22,MF30, MF41 and MF51 and frontal panel in model MF61.

2. Take out the lid and disconnect the electrical cable from the connections in

the condenser.

3. Get the refrigerant out of the system and let it in a tank for using it again

after drain it.

4. Unweld and disconnect the impulsion pipe and the aspiration pipe pof the

compresor.

5. Unscrew the screws that fix it in the base and take the compresor out of the

base of the unit.

6. Take out hte auxiliar/load pipe and reserve it to weld it again in the

compresor.

7. To install the new compresor follow these instructions on the other way

round .

NOTE. Sustitute the dehydrated filter every trime the refrigerator circuit is

open. Not install the new filter unit all the substitution or reparation process

has finished..

NOTE. Purge carefully the cooling circuit to remove the excess of humidity

and the no condensation gas after the sustitution of the condenser..

18

ELECTRICAL DIAGRAM MF 22 –30 (COOLED WITH AIR AND WATER

)

19

20

ELECTRICAL DIAGRAM MF 22 –30 (COOLED WITH AIR AND WATER

)

Connector probe

Connector probe

evaporator

Electric connector

Magnet turn of

reduction motor

Connector electrode

level of water

Connector cell

contro of ice

PROBLEM CAUSE MEASURE TO TAKE

Fuse of the board Sustitute the fuse and find out

Electronic blown The problem

Main switch unplug Connect the switch

The unit doesn’t work

(any light switch on)

Electronic board Sustitute the electronic board

Damage

Electric cables cut Check the cables

(Yellow light of tank full Optical control of filling dirty Clean or substitue the optical

switch on) Or damage Control

Water not arrive to the tank Check solution for the lack of

Water

Yellow light of lack of water Demineralized water Install a dosing for mineral salts

Switch on

Sensors with lime Remove lime descaling

Product

Excessive condensation Condenser dirty. Clean

temperature Fan motor burnt substitue

(Red light switch on)

Room temperature Move the unit to a suitable room

Very low (+ of 1º ©)

3 minutes of delay Wait 2 minutes

(Red light flashing)

(Yellow light of turn High evaporation temperature Check the refrigerant

flashing) Lack of refrigerant

PROBLEM CAUSE MEASURE TO TAKE

(Yellow light of turn The gear motor turn on Check the stator and the condenser

Flashing) The other way round Of work in the reduction gear

Check the circuit for overwork

Check the power supply

Low voltaje If there is low voltage check with

The electric company

The compresor works

intermittently Rusty contacts in the contactor Clean or substitute

No condense gases in the Discharge the refrigerant, and

system Charge again

Cable in the compressor Check all the connections

Loose

Check the circuit if there is overwork

Check power supply

Capillary pipe parcially If there is low voltage check with

Obstruct The electric company

Humidity in the system Make the same as in thebefore section

Lack of water in the evaporator Check solution for lack of water

Few production of

Ice Lack of refrigerant Look for leak of refrigerant a nd

Charge again

Excess of refrigerant Check and adjust the refrigerant

Level of water tank very low Raise the tank or water level

Shaft / Evaporator dirty Substitute axis/evaporator

Or damage

TROUBLESHOOTING

21

TROUBLESHOOTING

PROBLEM CAUSE MEASURE TO TAKE

Room temperature too high Install unit in a more fresh room

Temperature

Enough or two much quantity Control the refrigerant

Of regriferant

Ice very Water tank level too high Low the tank or the level of water

Ineficient compresor Sustitute the compresor

Axis profile wear away Sustitute the axis

Water doesn’t enter into Tubo de alimentación de agua al

The evaporator evaporador obstruido. Desatascar el

Tubo de alimentación. Limpiar

The unit works

But it doesn’t produce ice Gear teeths of the reductor Substitute the gear teeths

Wear away

Humidity in the system Discharge and charge

Broken water seal substitue

Supply pipe to the evaporator Check the brackets

Damage or free

Lose of water

Float valve doesn’t close Adjust the screw of the float

Joint broken in the outlet Substitute the joint in the outlet

discharge discharge

PROBLEM CAUSE MEASURE TO TAKE

Lime deposit or minerals in the interior Unistall axis and clean it with emeril felt

Of the evaporator or axis Clean the inner surface of the

Evaporator brushing vertically

Aspiration pressure to low Add refrigerant

Water pipe supply to the Check and clean.

Noise and excessive creak Evaporator partially obstruct

Water level tank too low Raise the level

Ball bearing in the evaporator Check and substitue

broken

Ball bearing in the motor Check and substitue

Wear out

Not enough lubricant in the reduction Check lose of lubricant, substitute the

Noisy reduction motor motor Sels and add lubricant

MOBILPREX IP 44

Ball bearing or gear teeth of the Check and substitue

Reduction motor seize up

Inlet water filter obstructed Clean the filter

Nozzle of the water tank obstructed Clean the nozzles after taking out

Lack of water The float

Water supply pipe Check and substitue

From the evaporator partially

obstruct

22

10. Check eventually lose of refrigerant and check the aspiration line it is frost

until 20 cm from the compresor.

11. If there are doubts about the refrigerant, connect the manomter with the

connectors Schrader and check that the working pressure it is the ones

indicated in page 24.

12. Check that the fan turn freely.

13. After taking out polyesthirene insulating from the outlet ice and the lid of

the crusher ice, check the state of the lubricant in the upper ball bearing. IF

there is water or they are partially solidify, check the ring O R and the ball

bearing located inside the ice crusher.

¾ GENERAL

The periods and procedement of maintnenace and cleaning represent a guide

and has no to be consider as absolutes and invariables. The cleaning

depends a lot of the environmental conditions and the water used, as well as

the quantity of ice produced. Every unit has to have its own manteinance in

accordance with its place.

¾ CLEANING THE ICE MAKING EQUIPMENT

The following manteinance operations has to be done twice a year by the

supplier company of the equipment.

1. Check and clean the filter grille located inside the connecter of water inlet..

2. Check the unit is leveled in both direction. IF it isn’t leveled use the nuts to

level it.

3. Take out the lid of the tank taking attention of not damaging the water level

sensors and pressing the float and clean its nozzles.

4. Make sure the level of water in the tank is below the top and that it is

enough to guarantee a good performance.

5. Clean the tank and the inner area of the evaporator using a descaling

product. Make references the cleaning instruction of the water circuit

mentioned in section “C”, after the cleaning it is possible to evaluate the

frequency and process the follow in the future depending on the place where

it is installe.

6. Use a part of the descaling product in concentrate state to remove rest of

limes in the water level sensor in the tank.

7. With the ice equipment stoppes in models cooled by air , clean the

condenser using a hoover or no metalic bruch taking attention not to damage

the room temperature sensors and hthe condenser.

8. Check if there is leakages in the water circuit. Put water in the ice keeper to

assure the outlet pipe is free.

9. Check the performance of the optical control of ice level putting one hand

between the electronic eyes to interrupt the infrared beam of light. In this way

the RED light switch off, it is located in the frontal side of the electronic board

and after some seconds all the unit stops and it switch on a YELLOW LIGHT.

The unit start up again automatically taking out the hand.

CLEANING AND MAINTENACE INSTRUCTIONS

NOTE: The need of cleaning depends on the water condition and use of the

equipment..

NOTE: The control of ice level by infrared it is composed by two light, the

transmitting and the receiver, between them the beam of light it is transmited

so as to the unit performance properly, it is necessary to clean once a month,

with a clean cloth

23

NOTE: Use only foot fat or water repellent for the upper ball bearing of the

evaporator.

Check the quality of the ice.

NOTE: It is usual that with the ice come out a little of water.

The ice come out from the outlet too wide, but, letting it in the storage, lose

the excess of water.

¾ INSTRUCTIONS TO CLEAN THE WATER CIRCUIT

1. Swith off the unit whit the general switch.

2. Put below the outlet of ice (two in models MF61) some tanks to pick up the

ice mixed with the descaling solution that it is produced to avoid that the

storage ice get contaminated with the descaling solution.

3. Close the stopcock of water in the supply line.

4. Take out the upper panel to get the float tank.

5. Take out hte float tank and connect with electric cables the two bars of

water level sensor supplying low tension.

NOTE. Not support one or both bars of water level sensor in the body othe

unit, because, in this way, the condenser sensor transmit tension to the

electronic board, making the unit to stop due to a high temperature.

6. Disconnect the inferior extrem of the tube that conect the float tank with the

evaporator and pick up with a recipient the water, after it connect it again.

7. In a clean bucket prepare the descaling solution diluting 2-3 liter of warm

tap water (45-50°C) with 0.2-0.3 litros de desincrustante

ATTENTION: The descaling product for ice equipment, contains

phosporic acid and hidroxiacid. This solution is corru Dicha solución es

corrosive and in case of ingest can produce intestinal damage. Do not

provoce vomiting. In this case it is necessary to drink a lot of water and

milk and go directly to the doctor. In case of external contact it is

enough with cleaning the are with water. KEEP OUT OF CHILDREN.

8. Pour the descaling solution in the tank float, after that give current to the

unit connecting the external switch.

9. Wait until the unit start to work to continue pouring the descaling solution

trying to mantain the level below the top tube.

NOTE: The ice produced with the descaling solution it is presented yellowish

and soft. In this phase it can be produce strong creaking in the evaportaion

due to the rubbing between the ice and the surface of the evaporator.

In this case it is recommended to stop the unit during some minuts so as to

the descaling solution can dissolve the lime inside the evaporator.

10. Once it is finished the descaling solution, open the stopcock and make to

work the unit until the ice will be again compact and clean.

11. Stop again the unit and dissolve the ice produced pouring some bottles of

warm water inside the container; then with a sponge with antibacterial product

clean the inner walls of the container. Take out the electric cables of the water

level sensor and install again the lid of the tank float, then install again the

upper panel.

ATTENTION: Do not use manufactured ice produced with the cleaning

NOTE. Remember that for avoiding bacterial accumulation you have to clean

the inner area of the container every week with an antibacterial solution

diluted with water.

24

CONTROL BOARD

CONTROL CELL

BASIN ICE

CELL CONNEXION

Respect colours:

Blue –

Brown +

Black return +

INLET POWER

220 V

TIMING DEVICE

STOP OF

EQUIPMENT

POWER SUPPLY

24 V

F N

CONNEXION ICE

EQUIPMENT

25

COMPONENTS OF THE ICE EQUIPMENT

26

POWER

INLET OF

PREFILTER

PRESSURE

DRAIN

EMERGENCY

SONDA

COMPRESSOR

CONDENSER

ROTATION

WATER LEVEL SENSOR REDUCTION GEAR

CONDENSER SENSOR

FLOAT TANK

27

PRIOR INSTALLATION

¾ INSTALLATION IN A FALSE CEILING

Maquina de hielo

Desague de 32 mm

Celula de control de

nivel de la pileta

Desague de PVC de 40 mm

Toma de agua fria de

1

2

"

(si el agua tiene cal , instalar

un descalcificador)

Tubo coarrugado

Linea electrica monofasica de

220 V y 1000W

Min. 70 cm

Falso techo

Techo

¾ INSTALLATION IN AN ADJACENT ROOM

Desague de

32 mm

Desague de PVC de

40 mm

Toma de agua fria de

1

2

"

(si el agua tiene cal ,

instalar un

descalcificador)

Tubo coarrugado

Linea electrica

monofasica de 220 V y

1000W

Celula de control de

nivel de la pileta

Maquina de hielo

Pared contigua

KIND OF INSTALLATION

¾ INSTALLATION IN AN ADJACENT ROOM

This installation consists in install the unit in an adjacent room and the ice

keeper in antoher room.

Ceilin

g

Adjacent

wall

Ice making equipment

Subjection

square

Ice keeper

PVC pipe

Stainless steel

pipe

28

¾ INSTALATION IN A FALSE CEILING

This installation consists in install the equipment in a false ceiling to hide

it.

Ceilin

g

False

Ice making equipment

Subjection

square

Ice keeper

Wall

29

IC E FOUNTAIN SEMIANNUAL MAINTENANCE

IN THIS ANNEX WE DESCRIBE STEP B Y STEP HOW TO CARRY OUT A SEMIANNUAL

MAINTENANCE INTERVENTION WHICH IS ESSENTIAL FOR THE

WELL-FUNCTIONING OF THE ICE CRUSHER AS WELL AS FOR THE MAINTENANCE

OF THE MACHINERY PARTS.

THIS MAINTENANCE IS OBLIGATORY IN ORDER TO UPKEEP THE WARRANTY.

PROCEDURES TO FOLLOW:

1. TAKE OUT THE INSULATING CORK FROM THE CRUSHER.

2. TAKE OUT THE COVER AND SEEGER WASHER WITH

THE HELP OF SOME POINTED PLIERS OR SIMILAR.

3. UNSCREW THE SCREW TOGETHER WITH THE WASHER TO ACCESS THE BEARING, TO CARRY OUT THIS PROCESS WE

HAVE TO STOP THE REDUCTIVE BOX FROM TURNING TO BE ABLE TO LOOSEN THE SCREW. HOW SHOULD WE DO IT?

WE INTRODUCE A SCREWDRIVER OR SOMETHING SIMILAR IN THE CROSSES OF THE ENGINE VENTILATOR,

WE INTRODUCE A SCREWDRIVER OR SIMILAR IN THE LOWER PART OF THE EVAPORATOR, SO THAT THESE

DON’T GO UP.

WE UNSCREW THE SCREW, TOGETHER WITH THE WASHER AND WE DISCOVER THE BEARING.

AXIAL BALL BEARING

1.

CLEAN THE OLD GREASE WITH A RAG AND OIL 6 IN 1, TO GREASE THE BEARIN G WITH GREASE OF

"ALIMENTATION AND WATER R EPELENT".

INVERT THE PROCESS AGAIN, TAKE INTO ACCOUNT THAT IT IS POSSIBLE THAT ONCE THE BEARING HAS BEEN

GREASED, THE ICE CAN COME OUT THE FIRST TIME A LITTLE DARK DUE TO THE GREASE.

THIS "PROCESS IS OBLIGATOR Y EVERY SIX MONT HS", WE, IN THIS WAY, MANAGE TO PROLONG T HE LIFE OF THE

MACHINERY, ESPEC IALLY, PREVENT THE BREAKING OF THE EVAPOR ATOR AND THE CRUSHER, SINCE THESE

PIECES ARE REAL LY EXPENSIVE.

TO THIS REVIEW OF THE MACHINERY, WE SHOULD DO A VISUAL INSPECTION TO MAKE SURE THAT THERE ARE NO OIL

REMAINS UNDER THE REDUCTIVE ENGINE.

POSSIBLE REMAINS OF VALVULINA

IN SUCH CASE, STOP THE MACHINE AND PROCEED TO CHANGE THE RETAINER RING AND FILL WITH VALVULINA, IN

THE FOLLOWING WAY:

1. REMOVE THE SUPERIOR COVER FROM THE REDUCTIVE MOTOR.

2. REMOVE THE PL ASTIC STORAGE O F THE MOVEMENT SENSOR.

3.

UNSCREW THE MAGNET SCREW AND TAKING IT OUT.

4.

TAKE OUT THE SUPER IOR METALIC COVER OF THE REDUCTIVE ENGINE.

POINT 2 POINT 3

POINT 4

PUNTO 4

5. EXTRACT THE ROTOR

6. DISPLACE THE STATOR TO A SIDE TO BE ABLE TO WORK BETTER WHEN TAKING OUT THE RETAINER RING (REF.002899)

7.

WITH THE HELP OF A SCREWDRI VER TO TAKE OUT THE RETAINER RING.

8.

WITH THE HELP OF AN INDUSTRIAL SYRINGE TO EXTRACT THE VALVULINA THAT IS AVAILABLE AND TO FILL IN AS

MUCH AS WE HAVE EXTRACTED AGAIN, PLUS A LITTLE BIT MORE. (IT FITS ABOUT 180ML. MORE OR LESS).

9.

CLEAN THE AREA WITH REMAINS OF VALVULINA AND INT RODUCE THE NEW RETAINER RING, WITH THE HELP OF A

SOCKET WRENCH 12/13 TO FINISH POSITIONING THE RETAINER RING.

POINT 7 POINT 8 POINT 9

POINT 9

10.

ONCE THE MAINTENANCE IS FINISHED GO AHEAD AND INSTALL ALL THEPARTS IN REVERSE DIR ECTION AGAIN.

TURN ON THE MACHINE AND OBSERVE TH AT THE FUNCTIONING IS CORRECT. CL EANING THE BASE OF THE

MACHINERY FROM ANY OIL REMAINS, SO THAT THEY COULD NOT HIDE ANY POSSIBLE DAMAGE.

Loading...

Loading...