10. Avoid using front and rear washing functions excessively or for long periods of time as

such overuse may increase the possibility of washing away desirable resident bacteria and

causing an imbalance of bacteria in your body. If you are pregnant, are being treated for a

gynecological condition, develop excessive irritation in the area of use, or if you have

questions, please speak to your doctor before beginning or continuing use of the product.

2. Product description

This product provides features to enhance personal toilet hygiene and comfort. This product features

include a posterior wash, a bidet, a warm air dryer, and a seat heater, as well as controls for these

functions.

This product consists of a body (with heated toilet seat, toilet seat lid, warm water tank, and power cord),

hardware to mount the body on a toilet and connect it to the toilet water supply and this installation and

use manual.

This product is equipped with the following features:

posterior wash with water flow strength controls

•

bidet with water flow strength controls

•

warm air dryer with air temperature controls

•

seat heater with heat level control

•

wash and bidet water temperature control

•

seat and water temperature indicators

•

wash and bidet nozzle self-cleaning

•

stop button for the wash, bidet, and dryer

•

Note:

When carrying the product, take care not to inadvertently bump or drop it.

•

This product has been already inspected using tap water. A small amount of water may be

•

detected when installing the unit; this should not be a cause for concern.

5

3. Installing this product

Installation requirements

Before installing this product, ensure that each of the following installation requirements is met.

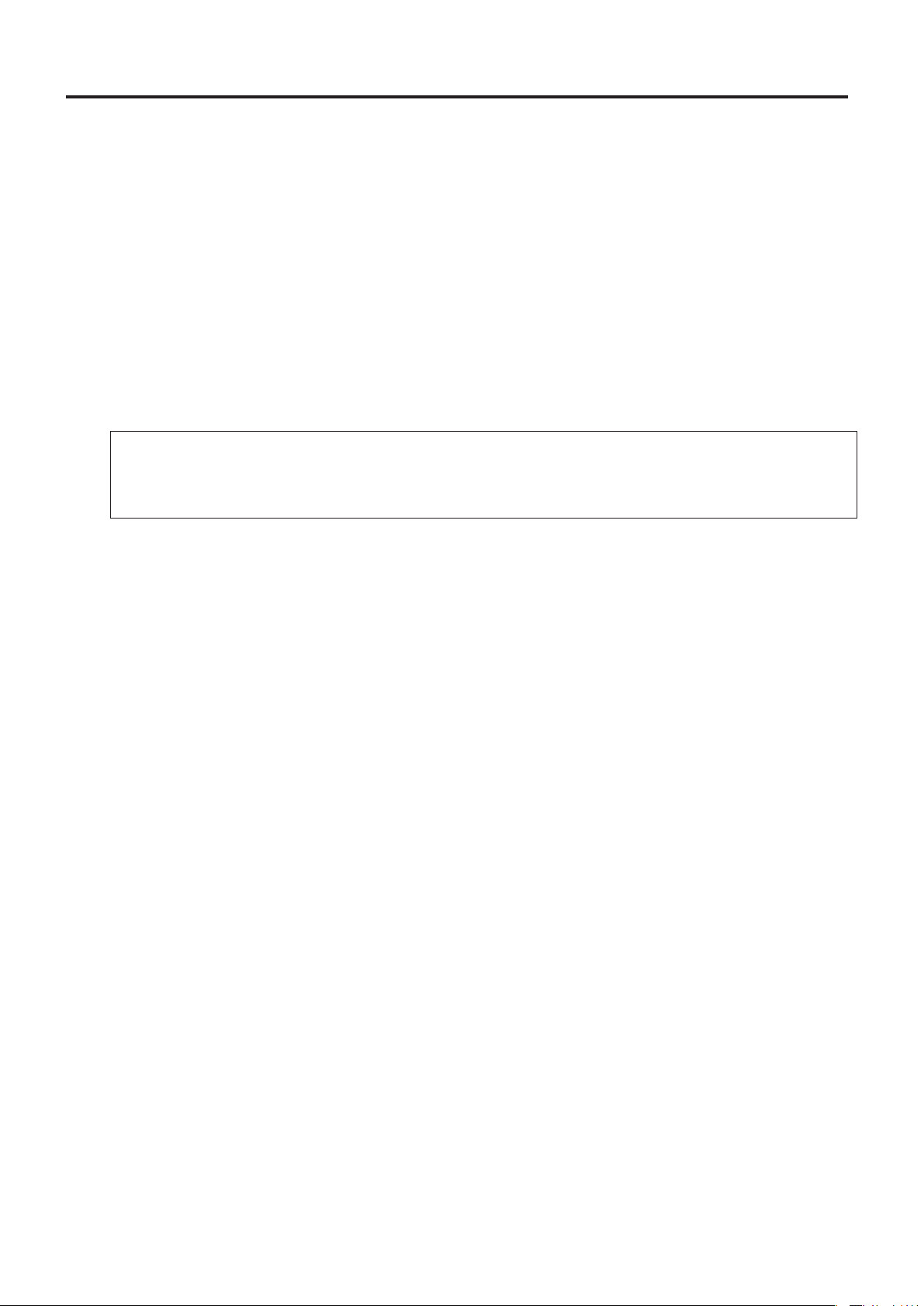

Product carton contents

Remove the parts from the product carton and make sure all the parts in the parts list (below) are

present. Inspect the parts carefully to make sure they are in good condition.

If any part is damaged or missing, do not install this product. Contact the nearest sales outlet for the

part(s) you need.

This product carton should contain the following parts:

Body (with heated toilet seat, toilet seat lid and power cord)

•

Slide plate

•

Manual set

•

Mounting bolts, washers, and bushings (2 pieces each)

•

Junction fitting (with a packing)

•

Body water supply hose (with 2 clips)

•

*Remote control unit and bracket are

packed in the box of the parts.

Body

Manual set

Slide plate

(This plate attaches to the body.)

Mounting bolt

Washer

Bushing

Remote control unit

Bracket

For remote control unit

Batteries (2) Wood screw Plastic anchor

Junction fitting

Clip

Clip

Water supply hose

(95 cm long)

Packing

(2 mm) thick

6

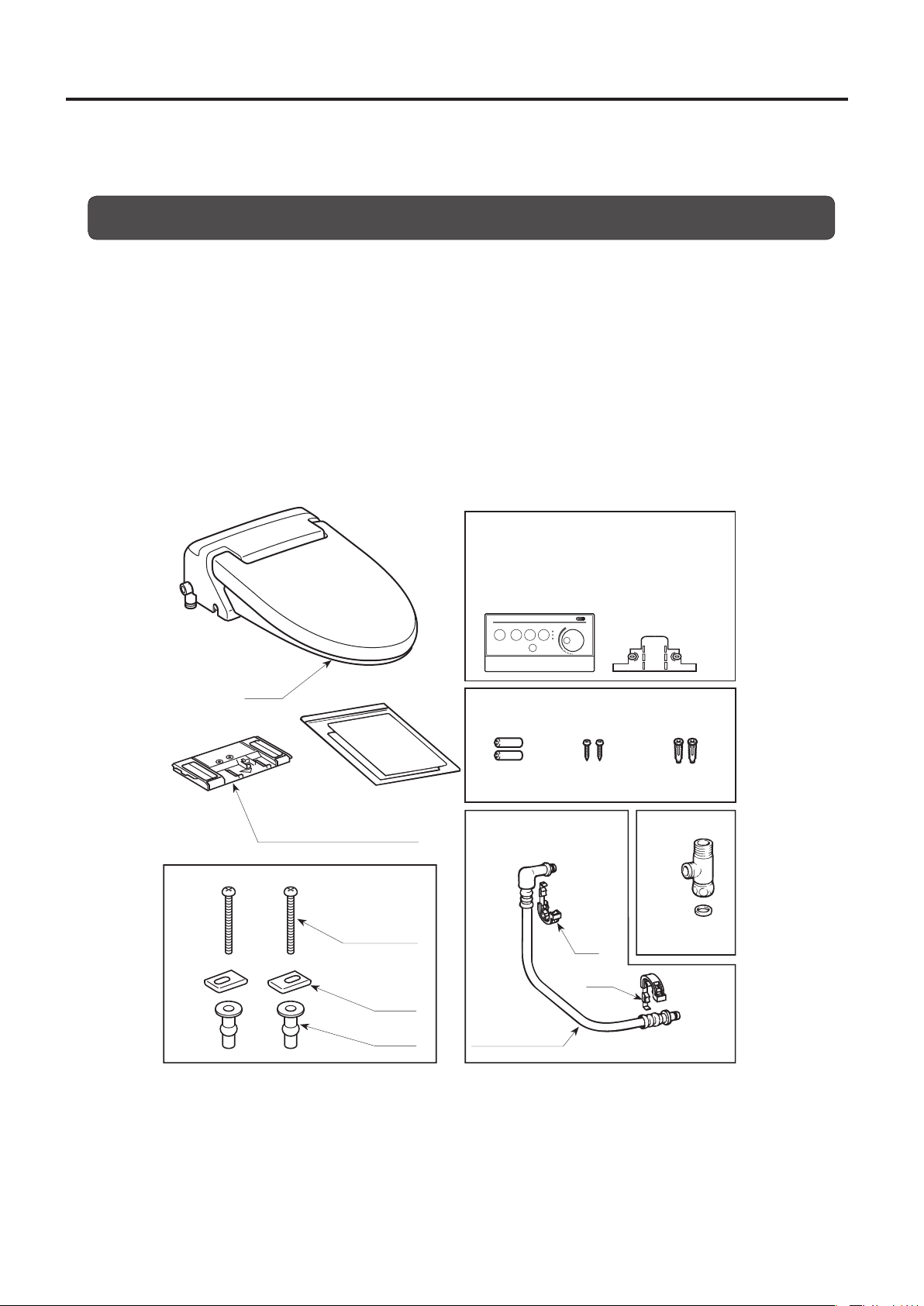

Ground fault circuit interrupter

A ground fault circuit interrupter must be installed in the circuit that supplies power to this product.

Power supply

This product is for use on a nominal 220 V circuit. Use a 220 V, 50 Hz power supply. The maximum

power consumption is 305 W. Electrical wiring must be installed that meets these conditions. The plug

outlet shall be placed in accessible location after installation.

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk

of electric hazard by providing an escape wire for the electric current. The power cord has a grounding

wire and a three-blade grounding plug (shown below). Do not use an adapter with the product's power

plug, or use any other method to connect the plug to an improperly configured outlet.

The outlet to which the product is connected must be 220 V, 50 Hz, with a minimum electrical rating of 3

A. The outlet must be properly installed and grounded, and have a three-slot outlet (shown below).

DANGER:Improper use of the grounding plug can result in a risk of electric hazard.

If it is necessary to use an extension cord, use only a three wire extension cord that has a three-blade

grounding plug. The extension cord must be rated for at least 220 V, 50 Hz, 3 A.

220V

Installation location

This product is manufactured for family or personal use. In order to avoid damage to the electronic

components, prevent the body of this product from getting wet by drops or splashes of water. In

extremely humid conditions, please provide adequate ventilation by operating an exhaust fan or opening

a window (or door).

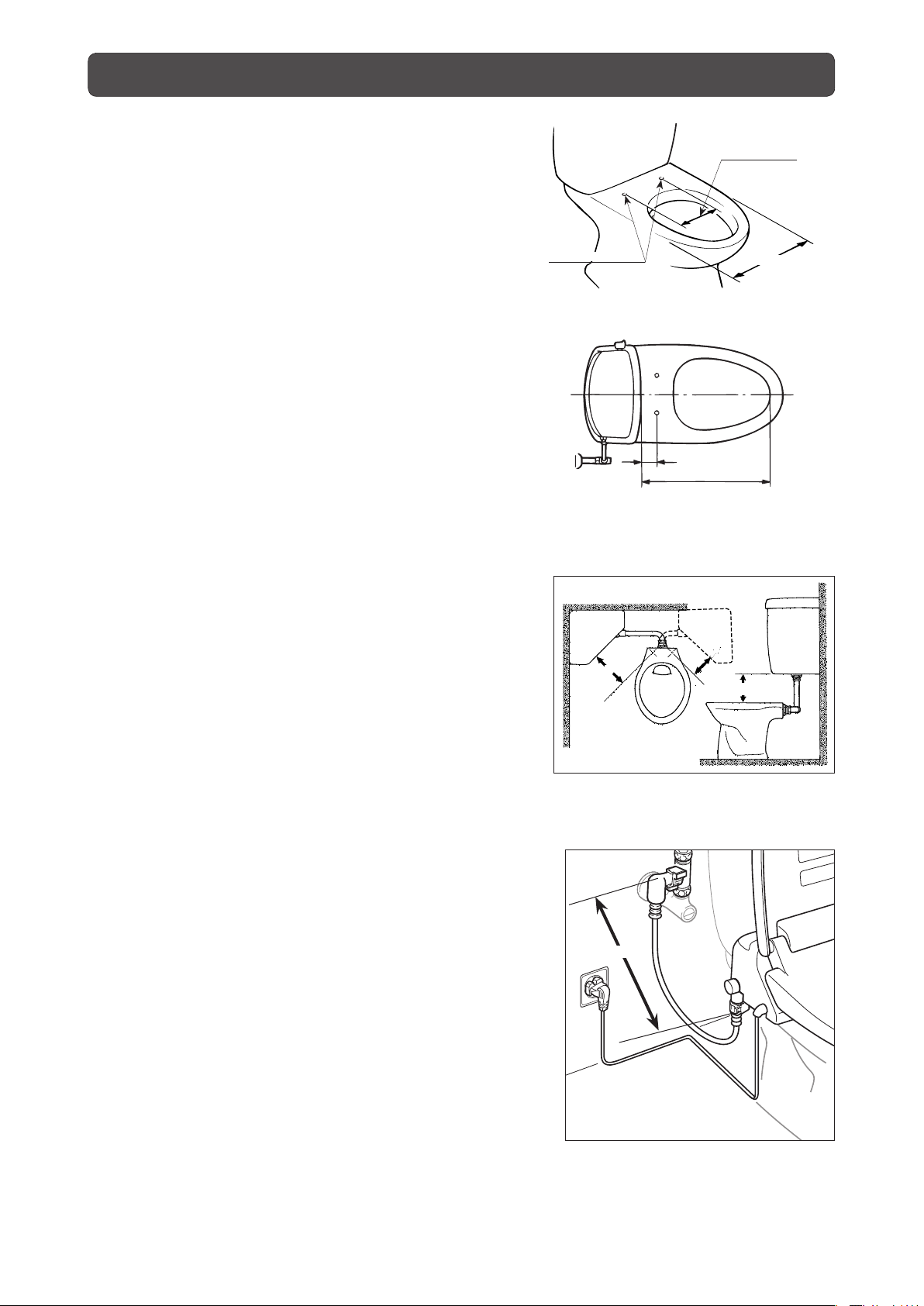

Water supply

Use only the tap water line to supply water to this product. There is danger of ground water or other

water that is not tap water causing trouble with this product.

The tap water pressure must be 0.06 to 0.74 MPa (0.6 to 7.5 kgf/cm

2

).

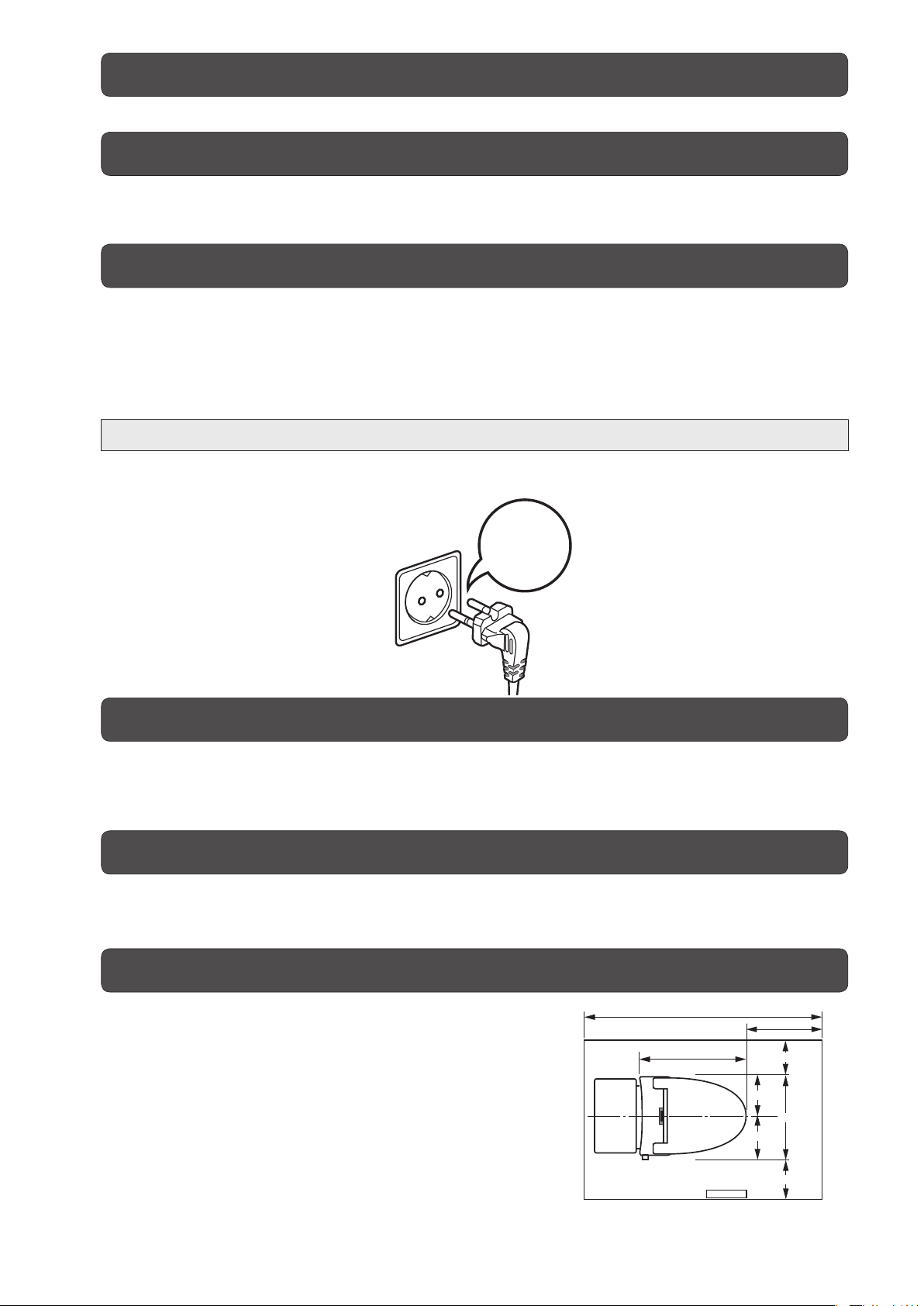

Checking the toilet room

The dimensions required for mounting this product on a

toilet are as shown in the figure below. Check to make

sure there is sufficient space inside the toilet room and

that there are no obstructions in the way.

120 or more

55.8

40 or more

3 or more

20.7

42.6

21.9

3 or more

Unit : cm

7

Checking the toilet

1. Measure the size of the toilet.

Depending on the toilet, it may not be possible to mount

this product on it.

Make sure the toilet's dimensions are as shown in the

figure at right.

14 to 15.7 cm

2.

In the case of a toilet with a corner

mounted tank, decide which is more

satisfactory, (1) or (2).

In the case of a corner mounted tank type toilet, it is

possible to mount this product if the dimensions A and B

meet the conditions in either (1) or (2) below.

(1) A: 17 cm or more

(2) A: 13 cm or more and

B: 17 cm or more

(3) A': 17 cm or more

(4) A': 13 cm or more and

B: 17 cm or more

If the measured dimensions satisfy neither (1) or (2),

(3) or (4), take measures such as raising the position

of the tank. (Please consult with the store where you

purchased this product.)

φ1.5 cm or more

A

80 cm or less

39 cm or less

5 cm or more

47 cm or more

A'

B

3. Conditions for use of this product's water

supply hose (packed with this product)

The length of the water supply hose shipped with this

product is 95 cm, but a length within 80 cm from the

junction fitting to the body's water supply socket is

appropriate. (See the figure at right.)

8

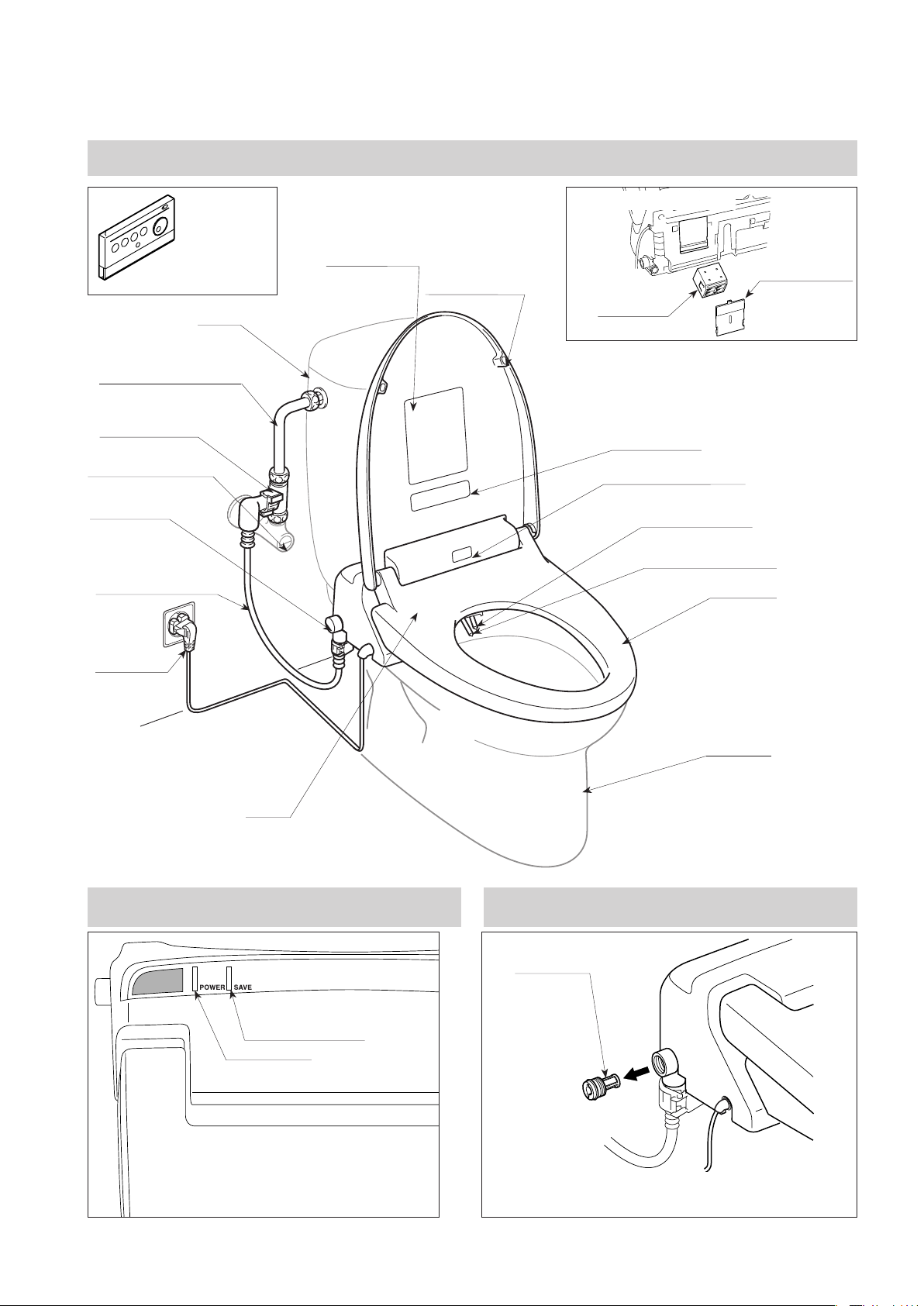

Names of parts

Overall view

<Bottom of body>

Remote control unit

(See page 10.)

Tank

Tank water supply pipe

Junction fitting

Water shutoff valve

Strainer

(See below.)

Water supply hose

Power plug

Caution label

Toilet seat lid

Deodorizer

cartridge cover

Deodorizer

cartridge

Marking label

Occupied seat sensor

Nozzle (for bidet)

Nozzle (for posterior)

Toilet seat

Body

Indicator panel

Power save lamp

Power lamp

Toilet bowl

Strainer

Strainer

* The strainer removes impurities and foreign matter in the

tap water. (See page 31.)

9

Operation panel

STOP

Stops posterior washing,

bidet washing, and drying

operations.

MASSAGE

Alternates spray strength

between strong and weak.

POWER

Pressing the stop switch

for 2 seconds or longer

turns the power on or off.

(See page 22.)

SHOWER

Use for posterior washing.

POWER SAVE

Pressing the toilet seat

switch and warm water

switch together for 2

seconds or longer turns off

the power to the toilet seat

heater and warm water

heater. (See page 26.)

BIDET

Use for bidet washing.

STRENGTH

Adjusts the spray strength

during posterior and bidet

washing. (See page 23.)

WATER TEMP.

Adjusts the water

temperature. (See page 22.)

DRY

Use when drying wet parts.

(See page 25.)

SEAT TEMP.

Adjusts the toilet seat

temperature. (See page 22.)

Warm water tank drain plug

<Bottom of body>

* Remove the warm water tank drain plug when draining the

water from the warm water tank. (See page 37.)

10

Warm water tank drain plug

Body locking plate

Body locking plate

Body

Lock lever

(See pages 33 and 34.)

Installation

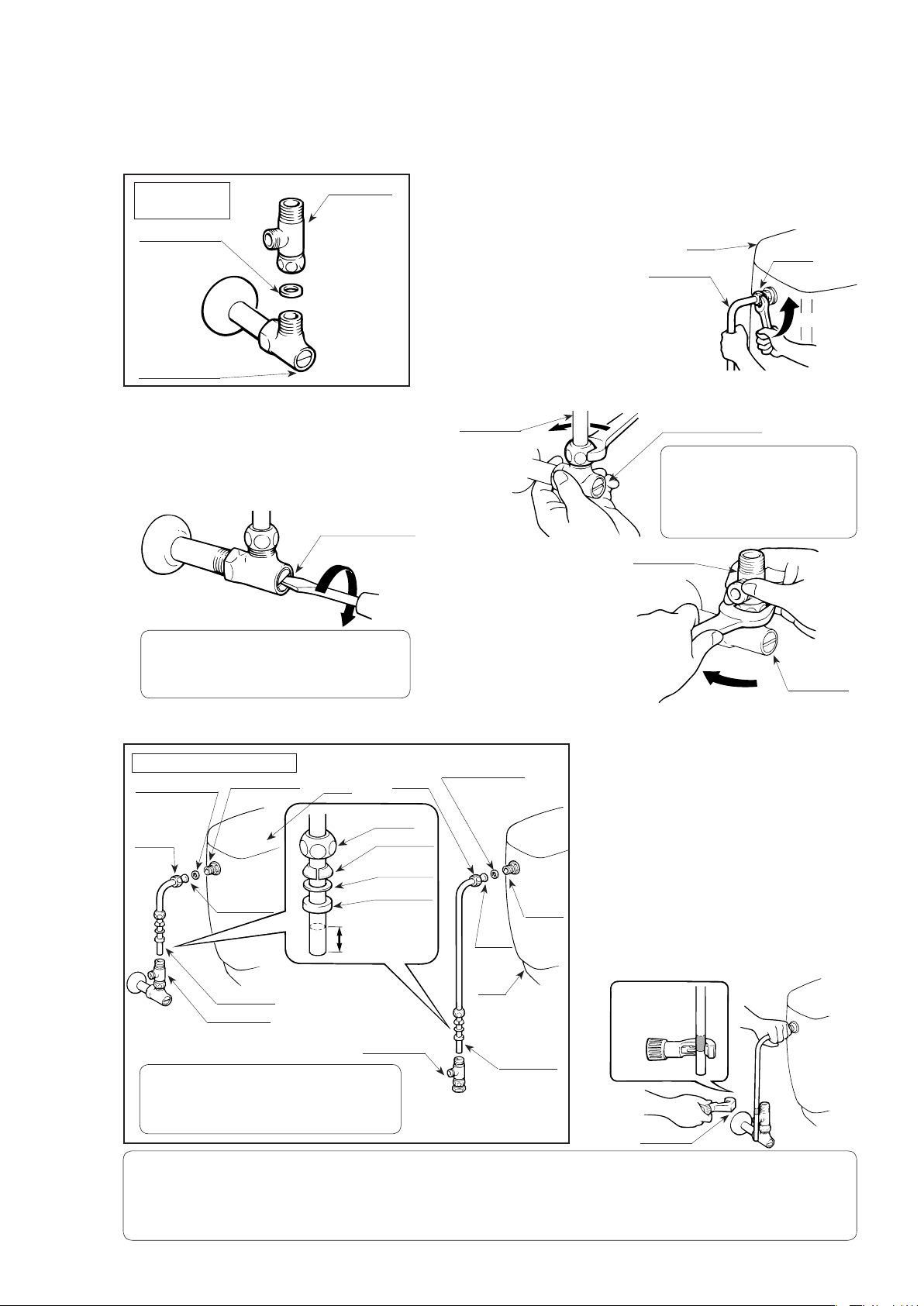

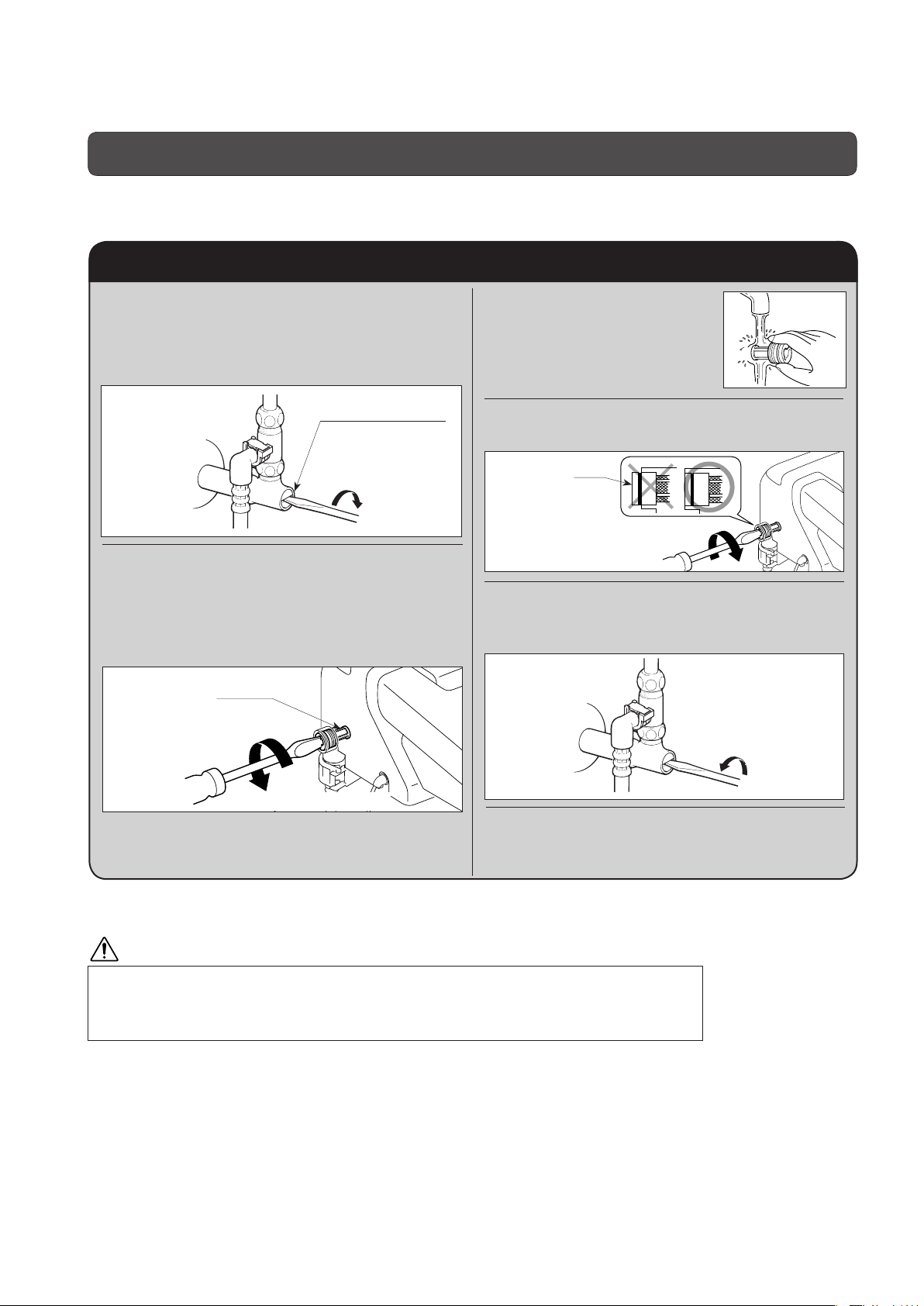

1. Installation of branch fitting

Installation

Branch fitting

diagram

Packing

(color: black,

thickness: 2 mm)

Water shutoff valve

(1) Close the water shutoff valve.

Close the water shutoff valve

for the toilet very tightly with a

flathead screwdriver (or the valve

handle, if available) and shut off

the water supply.

Water shutoff valve

Close

CAUTION

Close the water shutoff valve before performing any

•

operations.

* If you perform operations without closing the valve,

you may experience water leaks.

(2)

(3) Attach the

Remove the existing water supply pipe.

1) Loosen the cap nut at the tank.

A small amount of water

may spill from the pipe

when loosening the cap

Tank

Supply pipe

Cap nut

nut. If this is a concern,

please place a rag

underneath to catch

Loosen

the spilled water before

loosening the nut.

2) Loosen the cap nut at the water shutoff valve and

remove the water supply pipe.

Supply pipe

Loosen

Water shutoff valve

CAUTION

Do not apply unnecessary force

•

on the water shutoff valve or water

supply pipe.

* Doing so may break the

connections and cause water leaks.

Branch fitting

branch fitting.

Set the gasket seat

packing (color:

black, thickness: 2

mm) in the branch

fitting and attach

the fitting to the

water shutoff valve.

Water shutoff

valve

2. Installation of water supply pipe

Installation diagram

Gasket packing

(color: blue,

thickness: 2 mm)

Cap nut

Water supply from the wall

CAUTION

Please verify the orientation and the installation

•

sequence for each part.

* If you attach the parts in an incorrect sequence or

inappropriately, it may cause water leaks.

CAUTION

Please do not cut the guard area of the supply pipe.

•

•

Use a pipe cutter when shortening the supply pipe. Please connect the shortened pipe only after cleaning the cutting burrs by rinsing it with water or

some other method.

•

If the water shutoff valve can move vertically 5 mm or more, first please securely affix the stop valve.

* This may cause water leaks.

Ball tap

(or ball valve)

Guard area

Supply pipe

Branch fitting

Tank

Cap nut

Cap nut

Split compression

ring

Slip washer

Gasket packing

(color: black,

thickness: 4 mm)

Insertion tolerance

(10 to 15 mm)

Branch fitting

Gasket packing

(color: blue,

thickness: 2 mm)

Ball tap

(or ball

valve)

Guard

area

Tank

Supply pipe

Water supply from the floor

(1) Shorten the water supply pipe.

1) Mark the end of the water supply

pipe (on the side without the

guard) for a cutting position which

is suitable for attachment to the

branch fitting and then increase

that amount by an additional

10 to 15 mm for some insertion

allowance.

2) Cut the water supply pipe at the

position determined above with a

pipe cutter.

Add 10 to 15

mm for insert

allowance.

Pipe cutter

11

(2) Attach the water supply pipe.

1) Place the cap nut for the tank and branch fitting, split

compression ring, slip washer, and packing (color: black,

thickness: 4 mm) on the shortened water supply pipe and

insert the pipe into the branch fitting. (Please see the

above installation diagram of the water supply pipe.)

Supply pipe

Branch fitting

2) Place the gasket packing (color: blue, thickness: 2 mm)

between the ball tap and the supply pipe, and attach the

Hose connection socket

supply pipe to the tank with the cap nut.

3) The cap nut for the branch fitting should be fingertightened as much as possible, and then, additionally

tighten it with a wrench for another 3/4 to one full turn. Do

not over-tighten the nut.

(Tightening torque: 10 to 15 Nm ( 8-11 ft-lbs) or 100 to

150 KgF/cm)

While tightening the nut with a wrench, place a spanner

(monkey wrench) around the hexagonal area of the

branch fitting to hold it firmly, and then tighten the cap nut.

CAUTION

Tighten the cap nut

•

while securely grasping

the ball tap to prevent it

from turning.

* If the ball tap is rotated

out of position, the float

ball may make contact with the inside wall of the tank

and cause a water stoppage failure.

• Please be careful not to break or damage the hose

connection.

* Doing so may cause water leaks.

• Please firmly connect the water supply pipe.

* If the cap nut is not sufficiently tightened, it may

cause water leaks.

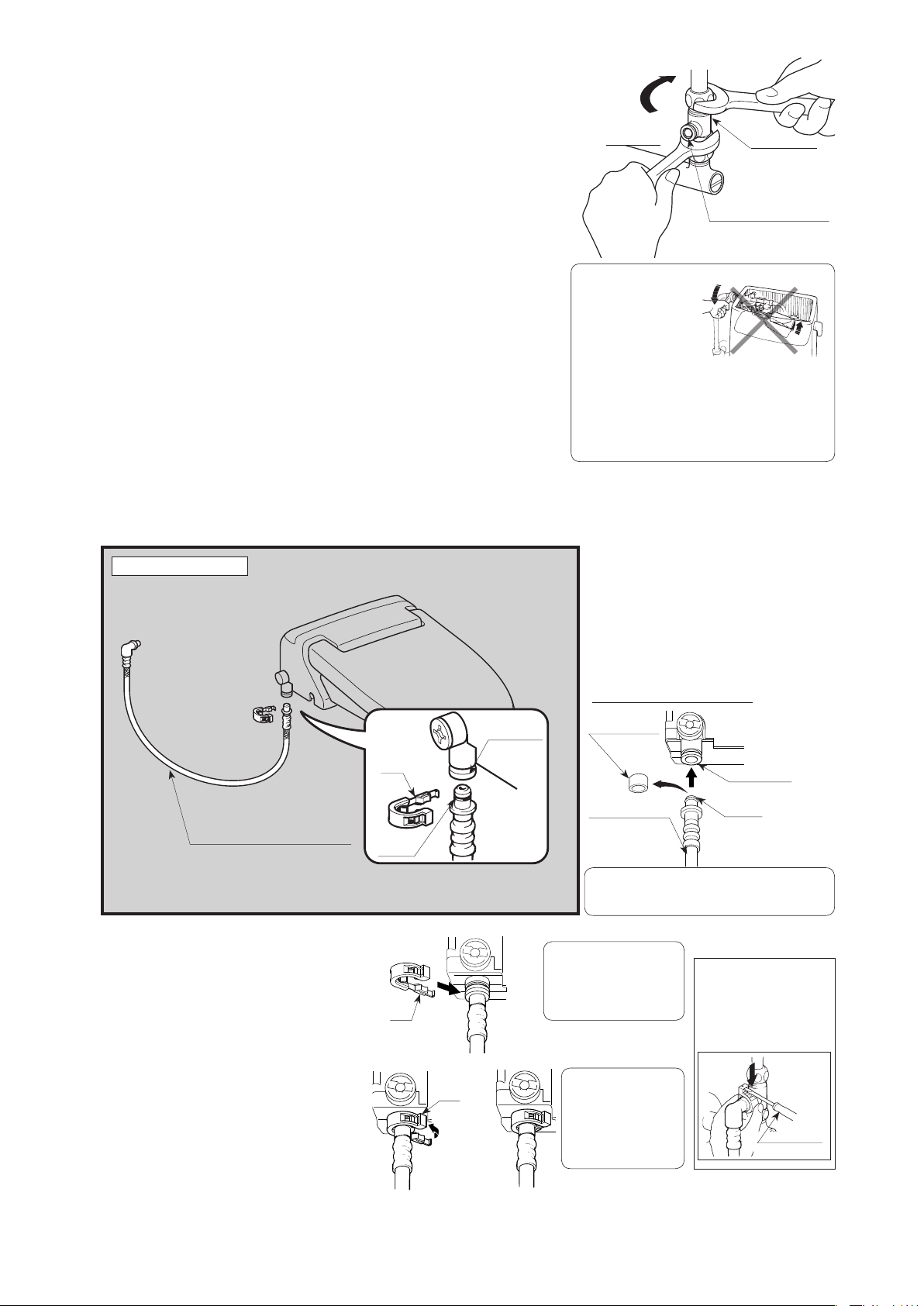

3. Installation of water supply hose to the shower

toilet (at the shower toilet body)

1)

Remove the protective cover

Installation diagram

from the end of the water supply

hose, and pull out the cap from the

water supply connection socket.

2) Connect the water supply hose

for the shower toilet into the water

supply connection socket.

Water supply connection socket

Water supply hose for shower toilet

3) Insert the attachment clip onto the

water supply hose to attach it to

the shower toilet and water supply

connection socket.

* The attachment clip can be attached in

any direction.

4) Bend the clip end and firmly clip

together both the feeding hose for

the shower toilet and the feeding

socket. After you install the clip,

twist it in both directions to verify

that it is firmly attached.

Clip

O-ring

Clip

Clip

Bend here

Water supply

socket

Protective cover

Water supply

socket

Water supply

hose for the seat

CAUTION

Please be careful not to damage the O-ring.

•

*If the O-ring is damaged, it may cause water leaks.

CAUTION

Please firmly insert the clip.

•

* If the clip is not firmly

inserted, it may cause

water leaks.

CAUTION

Please insert the clip

•

until you feel a click

from the clip edge.

* If not firmly inserted,

it may cause water

leaks.

O-ring

•

When removing the clip, hold

the clip with your fingers, set

the flathead screwdriver and

push the clip downward to

remove it as shown in the

figure below.

Flathead

screwdriver

12

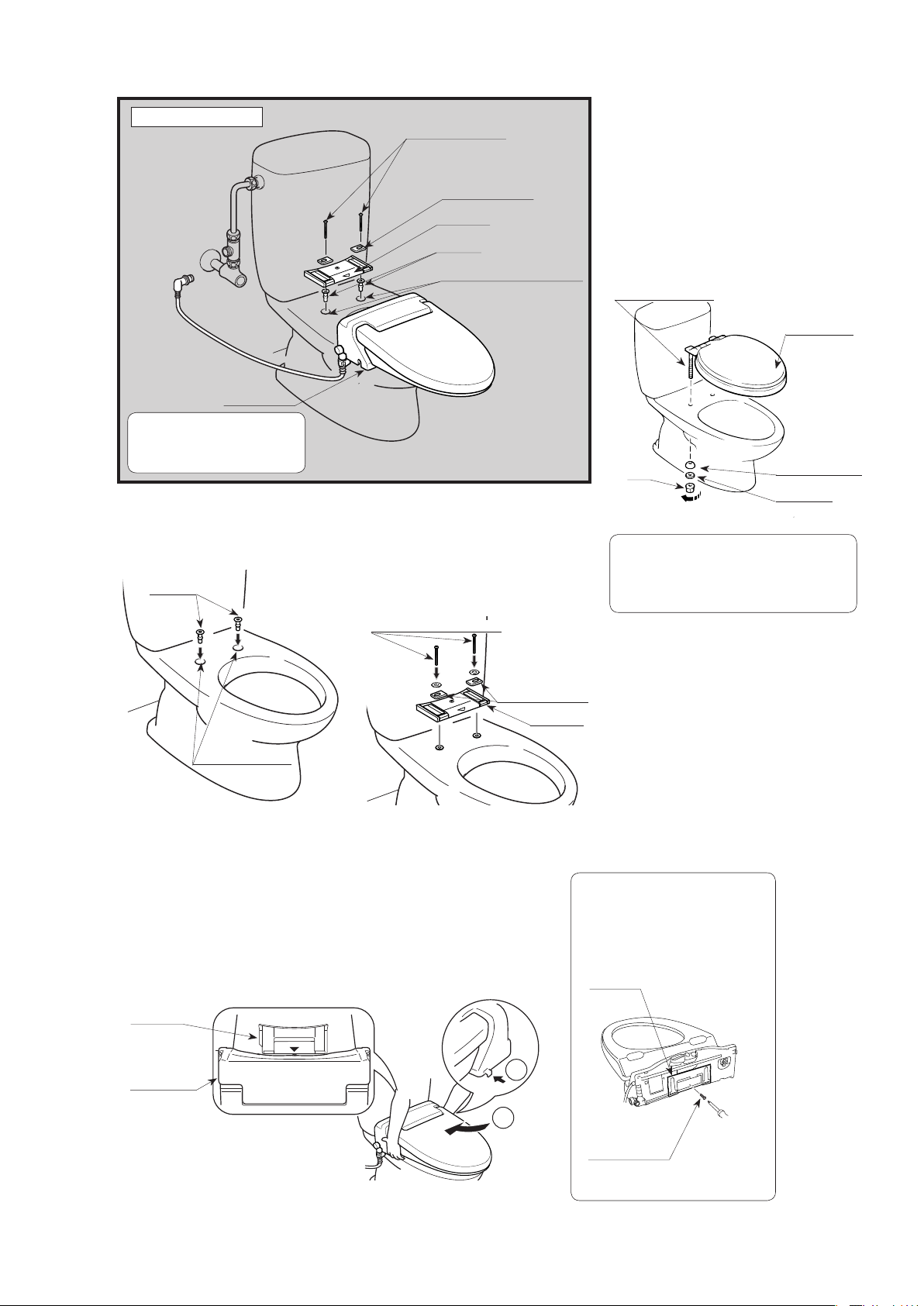

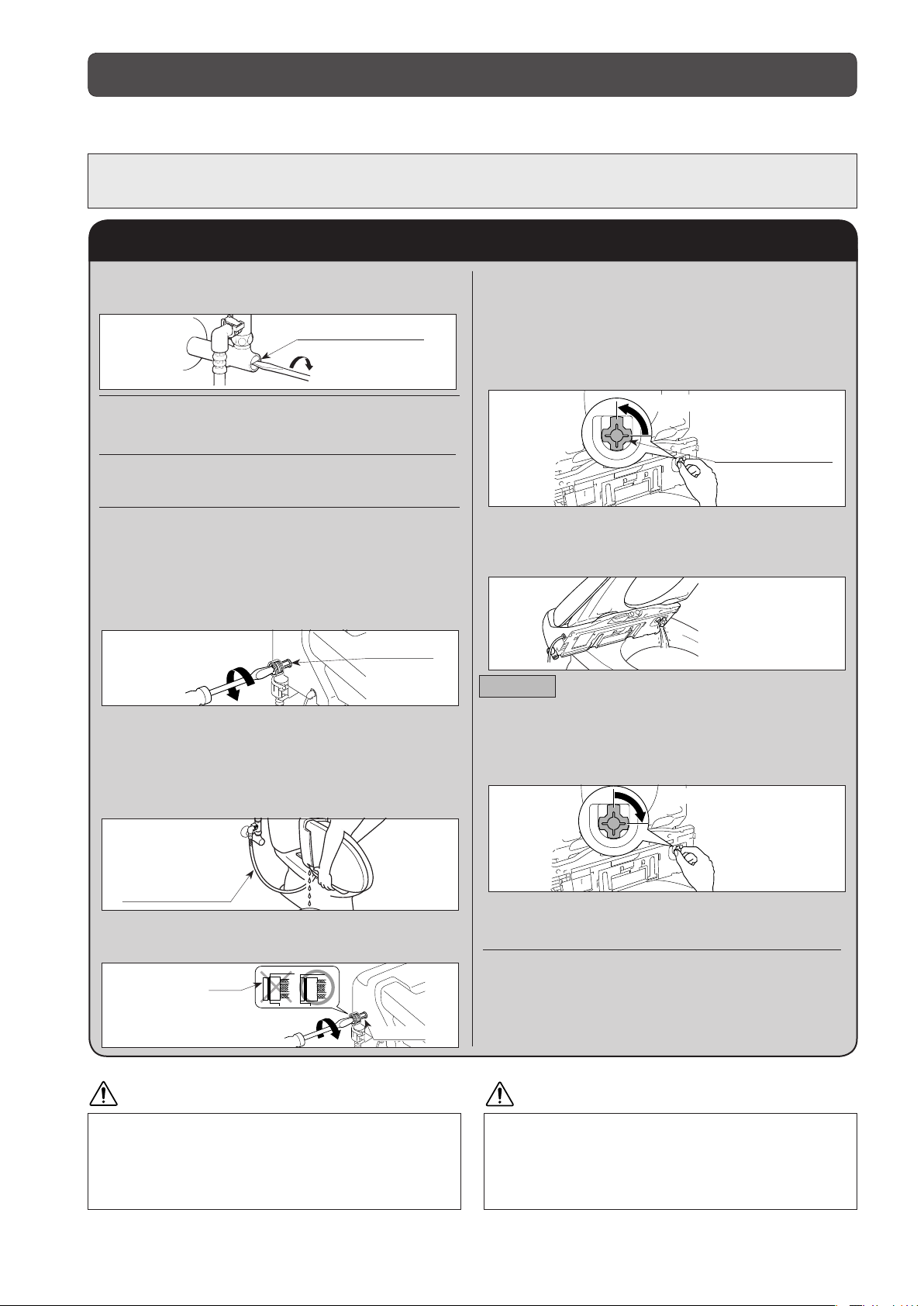

4. Installation of the shower toilet

Installation diagram

Shower toilet

Caution

•

When installing the shower

toilet, make sure to use the parts

provided in the installation kit.

(2) Attach the slide plate onto the seat.

1) Insert the bushings into

the seat mounting holes.

Bushings

Seat mounting bolts

Mounting brackets

Slide plate

Bushing

Toilet seat mounting guide holes

2) Insert the mounting

brackets into the slide

plate and attach the slide

plate with the mounting

bolts on the seat.

Mounting bolts for the toilet

(1) Remove the existing

seat.

1) Remove the nuts from the

seat mounting bolts, the

slip washers, and rounded

packing.

2) Raise the seat and remove

it by lifting the seat mounting

bolts.

Seat mounting bolts

Existing seat

Nut

Loosen

References

Some toilet seats may require different methods

•

of removal that differ from our explanation.

•

The removed toilet seat should be stored in your

home in case you remove the shower seat.

Rounded packing

Slip washer

Mounting brackets

Seat mounting holes

(3) Attach the shower toilet.

1) Place the shower toilet on the toilet and align the ▽

mark on the slide plate with the △ mark on the rear

section of the shower toilet.

2) Slightly raise the front side of the shower toilet, slide it

until the slide plate is fully inserted, and then press the

locking lever to secure the shower toilet.

Slide plate

Shower toilet

1

2

Slide plate

* For the attachment lacations of

the mounting brackets, please see

"Checking the toilet seat."

CAUTION

When use of the slide plate is not

•

necessary, please retain the slide

using the attaching screw included in

the installation kit to prevent it from

moving or becoming lost.

Slide plate

Attaching screw

13

5. Attachment of the water supply hose for the shower

toilet (at the branch fitting)

Installation diagram

O-ring

Water supply hose

for the shower toilet

CAUTION

Please be careful not to damage the O-ring.

•

* If the O-ring is damaged, it may cause water leaks.

•

Please firmly insert the clip.

* If the clip is not firmly inserted, it may cause water leaks.

•

Please insert the clip until you feel a click from the clip edge.

* If not firmly inserted, it may cause water leaks.

Branch

fitting

Clip

Example of water supply from the floor

(1) Remove the

protective covers

from the ends of

the water supply

hose and insert

the hose into the

branch fitting.

(2) Attach the clip in the same manner as

it is attached on the shower toilet, and

then attempt to twist the clip from side

to side to make sure that it is firmly

attached.

When removing the clip, hold

•

the clip with your fingers, set

the flathead screwdriver and

push the clip downward to

remove it as shown in the

figure below.

Clip

Branch fitting

Protective

covers

Bend here

O-ring

Water supply hose

Clip

Flathead

screwdriver

6. Confirming water flow

Branch fitting area

Water supply socket area

CAUTION

• When water supply into the tank does not stop, or the

tank does not fill at all, please check if the float ball is

making contact with the inside wall of the tank.

• If so, please reposition it using the following procedure:

(1) Loosen the inside nut on the side of the tank and

vertically straighten the ball tap.

(2)

While holding the ball tap with your hand, tighten the nut.

• Please do not remove the strainer while the water shutoff valve is open.

• Doing so may cause water leaks from the strainer area.

(1) Turn the water shutoff valve

counterclockwise to open the supply

of water to the tank and shower toilet.

Branch fitting

Water shutoff valve

Turn counterclockwise.

(2) Operate the flush handle attached on

the tank and check each joint to see if

there are any water leaks.

* If water is leaking, further tighten the

connections, or re-install the shower toilet.

(3) Confirm that the water flow stops after

the tank is filled with water.

* If the tank does not fill with water, or the

water flow does not stop, please check

whether the ball tap and float ball are

functioning.

14

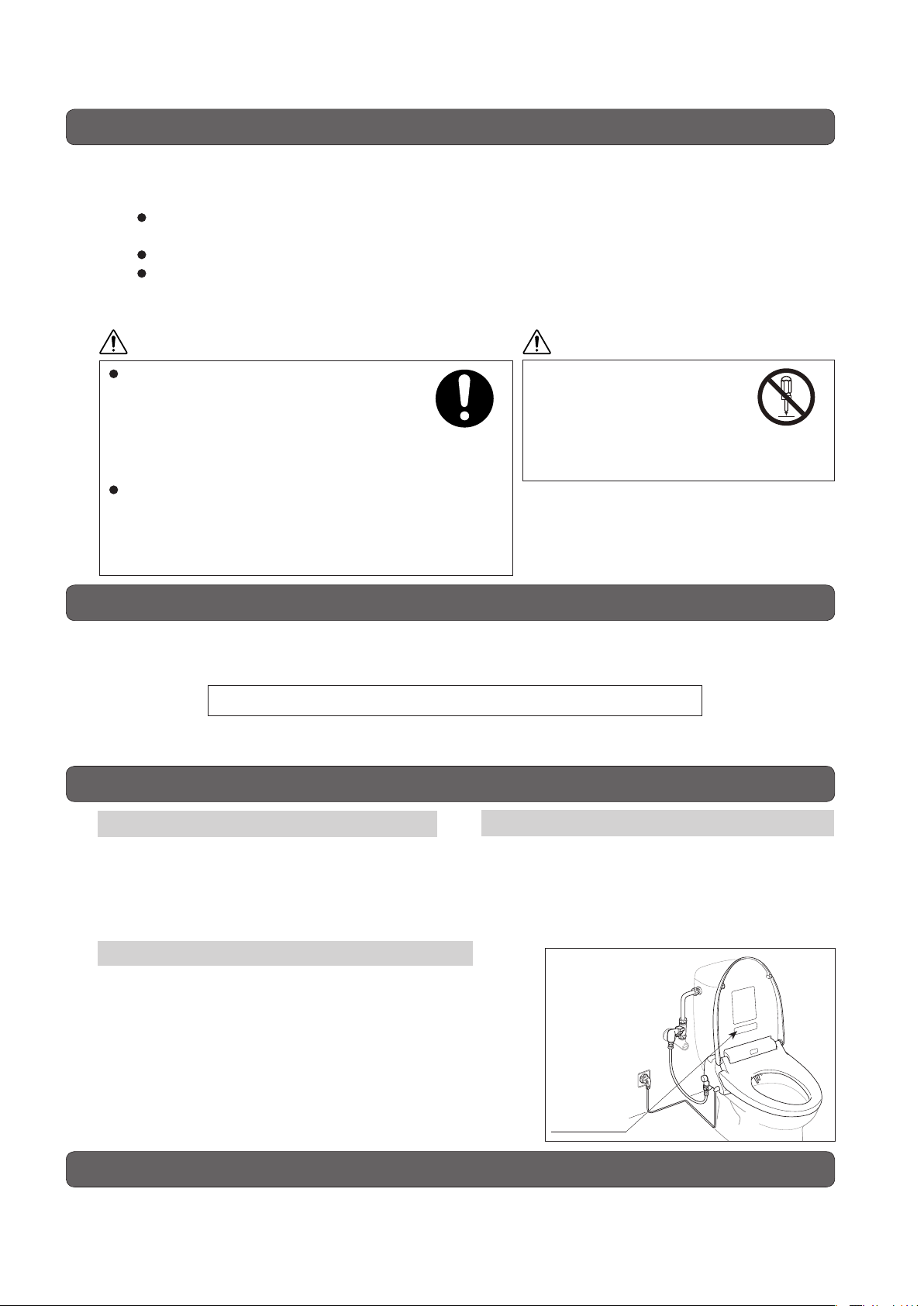

7. Positioning the remote control unit

(1) Open the back cover of the remote control

unit and insert the batteries (two AA size

batteries).

(2) Place the remote control unit in the position

you would like it to be in, sit down on the toilet

seat and press the stop switch.

CAUTION

•

Install the batteries with the positive and negative poles facing the

correct direction in accordance with the marks on the remote control unit

case.

•

Do not use old and new batteries together.

•

Use the batteries in the pack.

8. Mounting the remote control

(1) Place the bracket on the wall depending on the

wall material as follows, then mount it in the

desired mounting position.

• If mounted in plywood paneling 5 mm or

greater in thickness:

Fasten the bracket to the wall with the wood

screws.

• If mounted either in plywood paneling 5

mm or less in thickness or in gypsum

board:

Back cover

Battery

Wood screw

Bracket

6 mm dia.

Plastic anchor

A) In plywood paneling, drill holes with a

diameter of 6 mm; in gypsum board, drill

holes with a diameter of 5 mm.

B) Using a hammer, gently drive the plastic

anchors into the holes.

C) Fasten the bracket securely to the

anchors using wood screws. As you

tighten the screws, they are hard to turn at

fi rst, then gradually get easier to turn, and

then are hard to turn again.

(2) Align the remote control unit with the bracket

and then push it down onto the bracket.

CAUTION

Water will spray from the nozzle if the Shower or Bidet switch is pressed,

•

so exercise caution.

•

Check to make sure there is enough space above the remote controller to

mount or remove the controller at its mounting position.

•

After you make sure the power lamp blinking, pull the power plug out of the

receptacle at once.

33 mm

Remote

control unit

Bracket

Wood screw

Plastic anchor

φ6mm

Bracket

Wood screw

Bracket

15

Trial operation

(Follow the procedure below after installation work is completed.)

1. Insert the power plug in the outlet.

Confi rm that the power lamp on the body is lit.

220V

Power plug

2.Check the shower and bidet spray.

(1) Check the shower washing operation.

1) With your forearm resting on the toilet

seat, press the SHOWER button.

The shower automatically stops in two

minutes after the switch is turned on.

2) When the nozzle extends, cover the tip

of the nozzle with your hand to catch the

spray when the shower begins spraying.

3) Press the STOP button to stop the shower

spray.

Roll up your sleeve and

bring your bare arm in direct

contact with the toilet seat.

(2) Perform the same check with the bidet spray

function.

STOP

Stops posterior washing,

bidet washing, and drying

operations.

MASSAGE

Repeats washing

strength weak-strong

cycle.

POWER

Flushes the toilet

automatically when you

rise from the toilet seat.

POWER SAVE

Saves power by lowering

the toilet seat temperature.

DRY

Used to dry the parts

that became wet during

washing.

WATER TEMP.

Adjusts the temperature of

the shower and bidet water.

*Since there is an occupied seat sensor, the

product’s shower, bidet and deodorizing functions

will not operate if you don't touch the seat.

STRENGTH

Adjusts the spray strength

during posterior and bidet

washing.

SEAT TEMP.

Adjusts the heated toilet

seat temperature.

CAUTION

When removing the strainer, be sure

to close the water shutoff valve. When

attaching the strainer, firmly tighten it until

the end of the strainer is hidden in the body.

* Water will leak from the strainer.

Strainer

End

Warning

Please make certain to

securely attach the ground wire.

* If not connected, there is the

risk of electric shock in case of a

failure.

* If there is no ground terminal

on the electrical outlet, please

consult an electrician.

16

3. If flushing begins to weaken,or if the shower spray

seems to be getting weaker, clean the strainers.

(1) Turn the water shutoff valve to the right to close it.

As the water shutoff valve is pre-adjusted, remember the

original position (how much it is turned).

(2) Remove the strainer on the left side of the body.

Place a wash bowl or similar underneath the strainer.

(3) Clean the strainer.

(4) Firmly tighten the strainer.

(5) Turn the water shutoff valve to the original position to open it.

4.

If freezing weather is anticipated before handing the

Water Shutoff

Valve

Strainer

Turn

clockwise.

product to the customer, drain the water.

(1) Turn the water shutoff valve to the right to stop water supply to

the tank.

(For cold area drain type, operate the indoor drain plug.)

(2) Press the flush lever on the tank to drain water from the tank.

(3) Remove the power plug from the outlet.

(4) Drain water from the hot water tank and the water supply hose

connected to the body.

1) Pull the lock lever on the right side of the body and slide the

body forward to remove it from the toilet bowl.

2) Remove the strainer on the left side of the body. Place a wash

bowl or similar underneath the strainer.

3) Tilt the body to the left to drain water from the water supply

hose through the strainer hole.

4) After water drainage, firmly attach the strainer.

5) Turn the drain plug on the bottom of the body to the left

(counterclockwise) 90 degrees to loosen it.

6) Tilt the body forward, pull out the drain plug and drain water

from the hot water tank completely.

7) After water drainage, push and turn the drain plug to the right

(clockwise) 90 degrees to tighten it.

8) Place the body on the toilet bowl, and engage the ▽ mark on

the mounting plate with the convex part at the lower rear of the

body.

9) Slide the body backward and push the lock lever to secure the

body.

Lock Lever

Strainer

Turn

clockwise.

Drain Plug

Loosen

mark of the Fixing Plate

▽

Convex part of the

back of the body

17

4.

Using this product

Safety precautions

Observe these precautions to prevent possible injury or damage.

Do not pull the power plug out of the wall

outlet by pulling on the power cord. This could

damage the power plug or power cord and

cause an electrical hazard.

Do not climb or seat on top of the toilet seat

lid or body. Doing so could damage it.

For care of plastic parts, do not use any

cleansers which are not safe to use on

toilet seats. (Do not use toilet bowl cleaner,

household cleaner, bleach, benzene, paint

thinner, polishing powder, or cresol.)

Do not open or close either the toilet seat lid

or the toilet seat with great force. Doing so

could crack or otherwise damage it, causing

an electrical hazard.

Do not lean against the toilet seat lid during use.

Doing so could damage it.

Do not forcefully pull on the nozzle or turn it.

Doing so could damage it.

18

Do not cover the warm air outlet or insert a

foreign object into it. Doing so could cause

product failure.

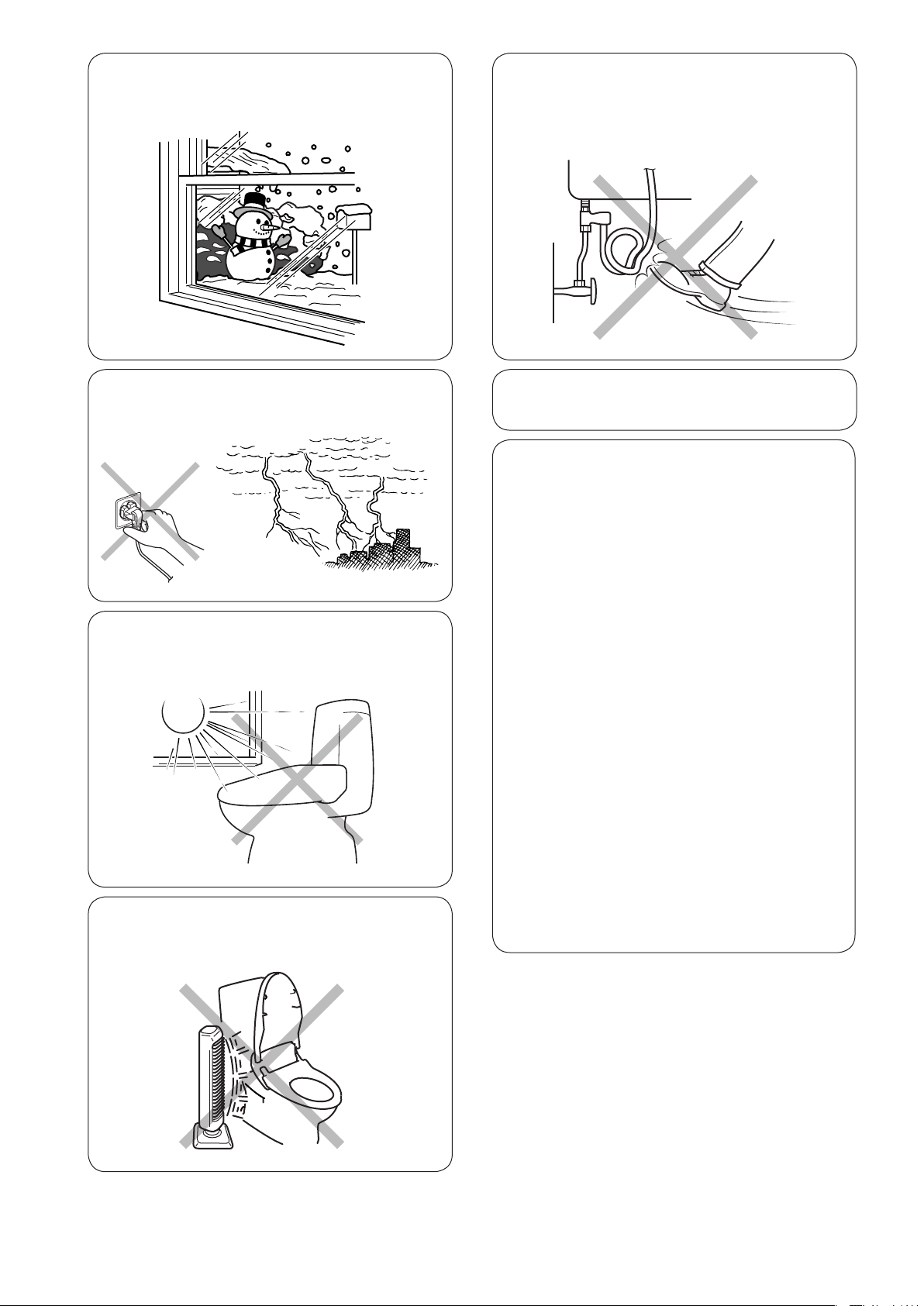

If there is risk of water lines freezing,

implement the freeze prevention methods to

prevent damage. (See page 35.)

Do not apply unnecessary force to the body

water supply hose. Doing so could damage it

and cause water to leak.

In a thunderstorm, do not touch the power plug.

Doing so could cause an electrical hazard.

Do not expose this product to the direct

rays of the sun. Plastic parts could become

discolored by the sunlight.

Do not place a stove or heater close to

the body. Doing so could cause product

discoloration or failure.

Do not urinate on the nozzle. Doing so could

cause nozzle damage or failure.

If you are using this product for a long period of

time, set the seat temperature switch

on "Off".

For the following persons, be sure to set the

seat temperature switch on "Off" when they are

using this product.

(Children, elderly persons, persons who are

sick, persons who cannot adjust the temperature

themselves, persons with weak skin, persons

who are taking medicines that make them

drowsy, such as sleeping medications, deeply

intoxicated persons, or persons who are

extremely fatigued.)

* If this product is being used for a long

period of time with the seat temperature switch

on any setting other than "Off", there is

danger of low temperature burns.

About Low Temperature Burns

A burn occurs when the skin has been

exposed to high temperatures. However, a low

temperature burn may occur when the skin

has been in contact with an object at relatively

low temperature (about 40ºC). Susceptibility

to burns also depends on an individual’s skin

sensitivity and other factors.

19

Other references

A toilet seat cover or toilet seat lid cover can

cause the occupied seat sensor to either remain

on continuously or not go on at all, leading to

faulty operation. In this event, remove the cover.

• The capacity of the warm water tank is 0.88 L.

Water temperature gradually drops when the

wash or bidet is used. If the water drops below

a comfortable temperature, press the stop

button and wait about 3 minutes for the water to

reheat.

• The water temperature range is preset to the

following temperatures:

Low: Approx. 36 °C,

Medium: Approx. 38 °C,

High: Approx. 40 °C.

It takes approximately 10 minutes to heat

cold water (at about 5 °C) to the appropriate

temperature (about 38 °C).

To prevent the toilet seat and toilet seat lid

from slamming down, a damping mechanism is

provided to lower them gradually. If the toilet seat

or toilet seat lid is closed roughly or too forcefully,

this product could be damaged or fail.

Before and after washing and when the water

temperature adjustment button is pressed, etc.,

water is sprayed out around the nozzle, but this

is necessary due to this product's construction

and is not a sign of breakdown.

If water sprays under any other circumstances,

or sprays constantly, close the water shutoff

valve and remove the power plug from the

wall outlet. Then, contact the store where you

purchased this product.

This product is equipped with an occupied seat

sensor that prevents the water from spraying

and the dryer from operating if nobody is sitting

on the toilet seat. This prevents activation if the

wash, bidet, or dry button is pressed when the

toilet seat is unoccupied.

Occupied seat sensor

This product is constructed to use the tap water

pressure to extend the nozzles and spray water

from them. Where the tap water pressure is

extremely low, the nozzles may not spray water

at all with the spray strength at the weakest

setting. In this case, turn the STRENGTH dial

clockwise. (See page 23.)

While this product is still new, there may be a

slight odor when using the drying function. As

the toilet is used, the odor will disappear.

This product may interfere with radio or

television reception. In this case, move the radio

or television away from this product until the

interference ceases.

The occupied seat sensor uses light reflection

to function and may not operate in the following

cases:

• You are leaning forward or sitting on the front of

the seat.

Sit back fully on the toilet seat, or change the

way you sit on the toilet.

• You are wearing clothing that is black, napped,

or otherwise inhibits light reflection.

Cover the sensor with your hand or arrange

your clothing so that your skin is sensed by the

sensor.

• Dirt or water is on the sensor.

Remove the dirt or water from the sensor.

Sit back fully on the toilet seat and arrange your

clothing so it does not get wet when using the

wash or bidet functions.

20

Using this product functions

《Remote control unit》

■

Main operation panel

SHOWER

Use when washing your

posterior.

Press again for wide range

washing.

(See page 23.)

BIDET

Use for bidet washing.

Press again for wide range

washing.(See page 23.)

Top

Front

Dependingonthemodel,somefunctions(markedwithastar,☆ )maynotbeincluded.

DRY

Blows air for drying.

(See page 25.)

Remote control transmitter

STOP

Stops the

SHOWER, BIDET

and DRY functions.

■

Sub-operation panel

POWER

Turns the power to the

Shower Toilet main unit ON/

OFF.

(See page 22.)

MASSAGE

Alternates spray

strength between

strong and weak.

(See page 24.)

Open the cover of the remote control unit.

POWER SAVE

Saves power by lowering

the toilet seat and water

temperatures.

(See page 26.)

SPRAY STRENGTH

Adjusts the spray strength

during posterior or bidet

washing.

(See page 23.)

WATER TEMP.

Adjusts the water

temperature.

(See page 22.)

* The deodorizer fan operates automatically. (See page 25.)

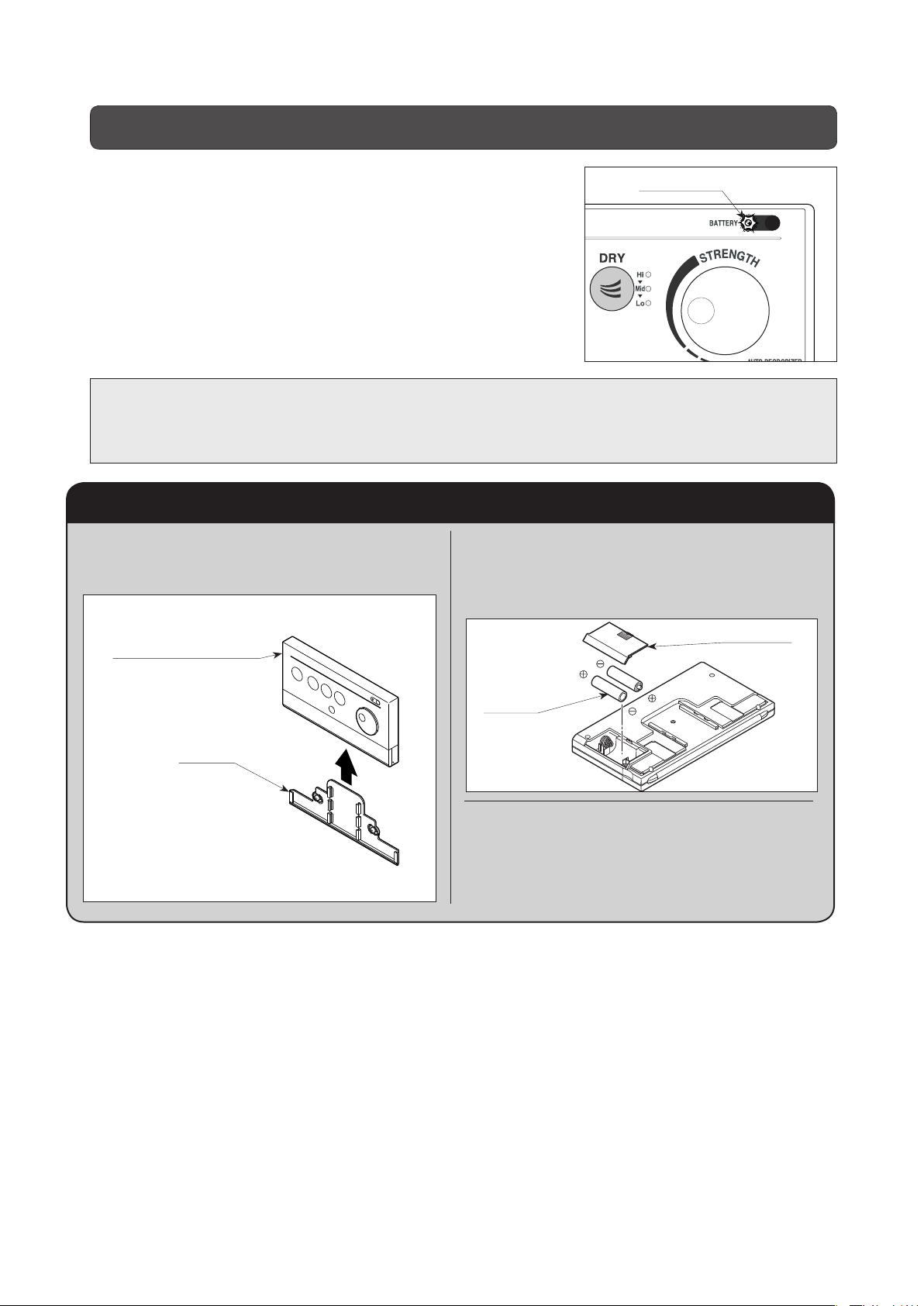

Battery indicator

This picture appears when

the battery power is low.

(See page 38.)

SEAT TEMP.

Adjusts the temperature of

the heated toilet seat.

(See page 22.)

21

《Preparations before use》

For an even more comfortable use, check the

following operations before using this product.

■

POWER

Press the POWER button to turn the power ON or OFF.

*

If the power is ON, the power lamp on the indicator panel will light

up.

* When you insert the power plug into the power outlet for the first

time after purchasing this product, the power is automatically set to

"ON".

(Turning the power on/off)

■

WATER TEMP.

(Heating the

shower)

Adjust the temperature of the shower

using the WATER TEMP. switch.

The water temperature can be set to one of 4

settings: HI, MID, LO and OFF. Set it to your

preferred temperature.

WARNING

•

If you are using this product for a long period of time, set

the seat temperature to OFF.

• For the following persons, be sure to set the seat

temperature to OFF when they are using this product.

(Children, elderly persons, persons who are sick,

persons who cannot adjust the temperature themselves,

persons with weak skin, persons who are taking

sleeping medications or other medicines that make them

drowsy, deeply intoxicated persons, or persons who are

extremely fatigued.)

* If this product is being used for a long period of time with the

seat temperature set to any setting other than OFF, there is

danger of low temperature burns.

■

SEAT TEMP. (Heating the toilet seat)

Adjust the temperature of the toilet seat

using the SEAT TEMP. switch.

The seat temperature can be set to one of 4 settings:

HI, MID, LO and OFF. Set it to your preferred

temperature.

Reference

• The toilet seat will not become warm instantly. If

you turn the SEAT TEMP. switch 10 to 15 minutes

before use, the toilet seat temperature will be at a

comfortable level during use.

• This product is equipped with a "Seat Heater AutoOff" function that prevents low temperature burns

by automatically switching the toilet seat heater off

when it is occupied.

(See page 27.)

• The toilet seat temperature (set at medium) can be

decreased (2°C). (See page 27.)

22

《How to use basic functions》

■

Shower

A shower is sprayed from the tip of the nozzle,

and washes your posterior.

Press the shower button.

1 1

■

Bidet

A shower is sprayed from the tip of the

nozzle, and sprays the more delicate female

parts.

Press the BIDET button.

Press the STOP button to stop

3

CAUTION

• In places with low tap water pressure, the nozzles may

• Please sit fully on the toilet seat. If you sit fully on the

the spray.

* An automatic self-stop function is included

which stops both posterior and bidet washing

automatically after 2 minutes.

not spray water far enough if the spray strength is set

to LO. In such cases, try setting the spray strength to

HI first.

seat, there will be less water splashing.

Turn the STRENGTH dial to

2

adjust the spray strength.

The STRENGTH dial has 5 levels. Set it at the

strength you prefer.

To make the

strength weaker,

turn the dial

counterclockwise.

Reference

You can make the washing strength much weaker or

stronger beyond the dial range.

(See page 28.)

To make the

strength

stronger,

turn the dial

clockwise.

23

■

Posterior massage washing

Spray strength is alternated between strong and weak during posterior washing to provide a

massaging effect.

Press the MASSAGE button

1

during posterior washing.

To stop the massage spray, press

2

the MASSAGE button again.

* Massage effect varies depending on the washing strength. This is high and low when the washing strength is High and

Low respectively.

24

■

Drying

Warm air will be blown out, and dry the parts which were wet by the shower.

Press the DRY button again to

Press the DRY button.

1

* Deodorizing is stopped temporarily while the drying

function is used.

change the temperature of the

2

warm air.

The warm air temperature setting is arailble

in 3 steps of "Hi" "Mid" "Lo". Set it at the

temperature tou prefer.

*

Each time the button is pressed, the indicator changes

from “High” to “Medium” to “Low,” then back to “High.”

WARNING

•

If you are using the drying function for a

long period of time, set the DRY mode to

LO.

• For the following persons, be sure to

set the DRY mode to LO when they

are using this product:

(Children, elderly persons, persons who are

Press the STOP button to stop

3

the drying function.

* An automatic self-stop function is included that stops

drying automatically after 4 minutes.

Reference

• To speed up the drying process after using one of the wash functions, wipe lightly with toilet paper to remove any drops

of water, and then press the DRY button.

• This product is equipped with a "low drying temperature start" function which switches the drying temperature from the

high temperature starting pattern to the low temperature starting pattern. (See page 27.)

sick, persons who cannot adjust the temperature

themselves, persons with weak skin, persons who

are taking sleeping medications or other medicines

that make them drowsy, deeply intoxicated

persons, or persons who are extremely fatigued.)

* If the drying function is being used for a long period of

time with the DRY mode on any setting other than LO,

there is danger of burns.

COMPULSORY

■

Deodorizing

Deodorizing starts when a

1

person sits on the toilet seat.

* This product is equipped with a deodorizer cartridge

which absorbs odors from the toilet. (See page 30.)

* Deodorizing is stopped temporarily while the drying

function is used.

Deodorizing automatically stops

2

1 minute after you stand up.

Stops after 1 minute

■

To disable the deodorizing function

Press the STOP and BIDET buttons

simultaneously for 2 seconds or longer.

* When operation is accepted, the power lamp on

the body blinks momentarily and the deodorizing

fan is not activated even when you are seated on

the toilet.

* To continue to use the function, again press the

STOP and BIDET buttons simultaneously for 2

seconds or longer.

Press the buttons simultaneously for 2 seconds or longer.

25

25

《How to use convenient functions》

Set

Temperature

8:00

10:00

12:00

14:00

16:00

18:00

20:00

22:00 24:00

Set

Reheat

Power Save

Temperature

Seat Temperature

OFF

8 hours

■

Power save

One-Touch Power Save: Controls power consumption by turning off the toilet seat heater for a

period of 8 hours overnight or during other extended periods when this

product is not being used. The settings automatically revert after 8 hours.

One-touch power save (8 hours)

Press the POWER SAVE button.

1

(The power save lamp will light up.)

For example: when One-Touch Power Save is set for 10:00

* Once 8 hours have passed, the settings will automatically return to their original state, and the power save lamp will

change from blinking to off.

* Pressing the One-Touch POWER SAVE button sets the timer for 8 hours. This highly convenient function allows as

many settings daily as desired, e.g. morning setting, nighttime setting, etc.

* When the One-Touch Power Save

function is running, the power save

lamp lights up.

To cancel the One-touch power save

function, press the POWER SAVE

2

button again.

(The power save lamp will go out.)

* You can use the toilet even when the power save function is operating. However, you may feel water is cold as the

heater for water and the toilet seat is turned off. If you feel so, cancel the power save function.

* Even when the power save functions are not operating, leaving the toilet lid closed is an effective way to save power.

26

■

Other convenient functions

Seat heater auto-off

This product is equipped with a function that

prevents low temperature burns by automatically

switching the toilet seat heater OFF when it is

occupied. Follow the procedure below.

■

Setting and canceling

• Press the STOP button and the POWERFUL

shower button simultaneously for 2 seconds or

longer.

(Once the function has been set, you will hear a

"beep, beep" sound.)

• This function can be canceled by following the

same procedure.

If you use the toilet continuously with this function enabled, you may feel the toilet seat is lukewarm.

* The toilet seat heater automatically turns ON when you stand up.

Press the buttons simultaneously for 2 seconds or longer.

Changing the (medium) temperature setting of the seat

The seat temperature (medium) can decreased by

2°C in the following procedure.

■

Setting or canceling

•

Press the STOP button and POWERSAVE

button simultaneously for 2 seconds or longer.

(Once set, an indicator on the body will blink as

soon as the function has been set.)

• Medium temperature change can be cancelled in

the same method.

Press the buttons simultaneously for 2 seconds or longer.

Low drying temperature start function (when equipped with drying function).

The dry function can be set to start on the low temperature setting. This function is convenient

for elderly persons, handicapped persons or persons who are particularly sensitive to heat. Use

the following procedure to enable or cancel the toilet seat heater auto off function.

■

Setting or canceling

•

Press the STOP button and DRY button

simultaneously for 2 seconds or longer.

(Once set, an indicator on the body will blink as

soon as the function has been set.)

• Medium temperature change can be cancelled

in the same method.

* Each time the button is pressed, the indicator changes

from “Low” to “High” to “Medium,” then back to “Low.”

Press the buttons simultaneously for 2 seconds or longer.

27

Making the spray strength still milder

If the "LO" setting for the shower spray is still too strong, adjust the spray strength using the

following procedure.

■

Setting and canceling

• Press the BIDET button and the POWER SAVE

ON/OFF button simultaneously for 2 seconds or

longer.

The power lamp on the body blinks momentarily

and the spray strength will weaken one step.

There are two weak settings. Adjust the spray to

your preferred strength.

To make the spray strength weaker, press the

The spray strength weakens one step

each time the buttons are pressed.

The original spray strength will be

restored on the third time.

buttons simultaneously for 2 seconds or longer.

* In places with low tap water pressure, the nozzles

may not extend or it takes time longer than usual

for the nozzle to extend, if the spray strength is

set to the lowest.

• To restore the original spray strength, repeat the process of pressing the BIDET button and the

POWER SAVE ON/OFF button simultaneously for 2 seconds or longer. The original spray strength

will be restored on the third time.

* Operate the buttons twice when weakened one step; once when weakened two steps.

The power lamp on the body blinks momentarily each time the buttons are pressed.

For persons who would like to make the spray strength much stronger

Persons who think the "strong" setting for the shower spray is still too weak can adjust the spray

strength using the following procedure.

The “strong” setting can be further strengthened.

■

Setting and canceling

• Press the SHOWER button and the POWER SAVE

ON/OFF button simultaneously for 2 seconds or

longer.

The power lamp on the body blinks momentarily

and the spray strength will be strengthened one

step.

Press the buttons simultaneously for 2 seconds or longer.

• To restore the original spray strength, press the SHOWER button and the POWER SAVE ON/OFF

button simultaneously for 2 seconds or longer.

The power lamp on the body blinks momentarily each time the buttons are pressed.

28

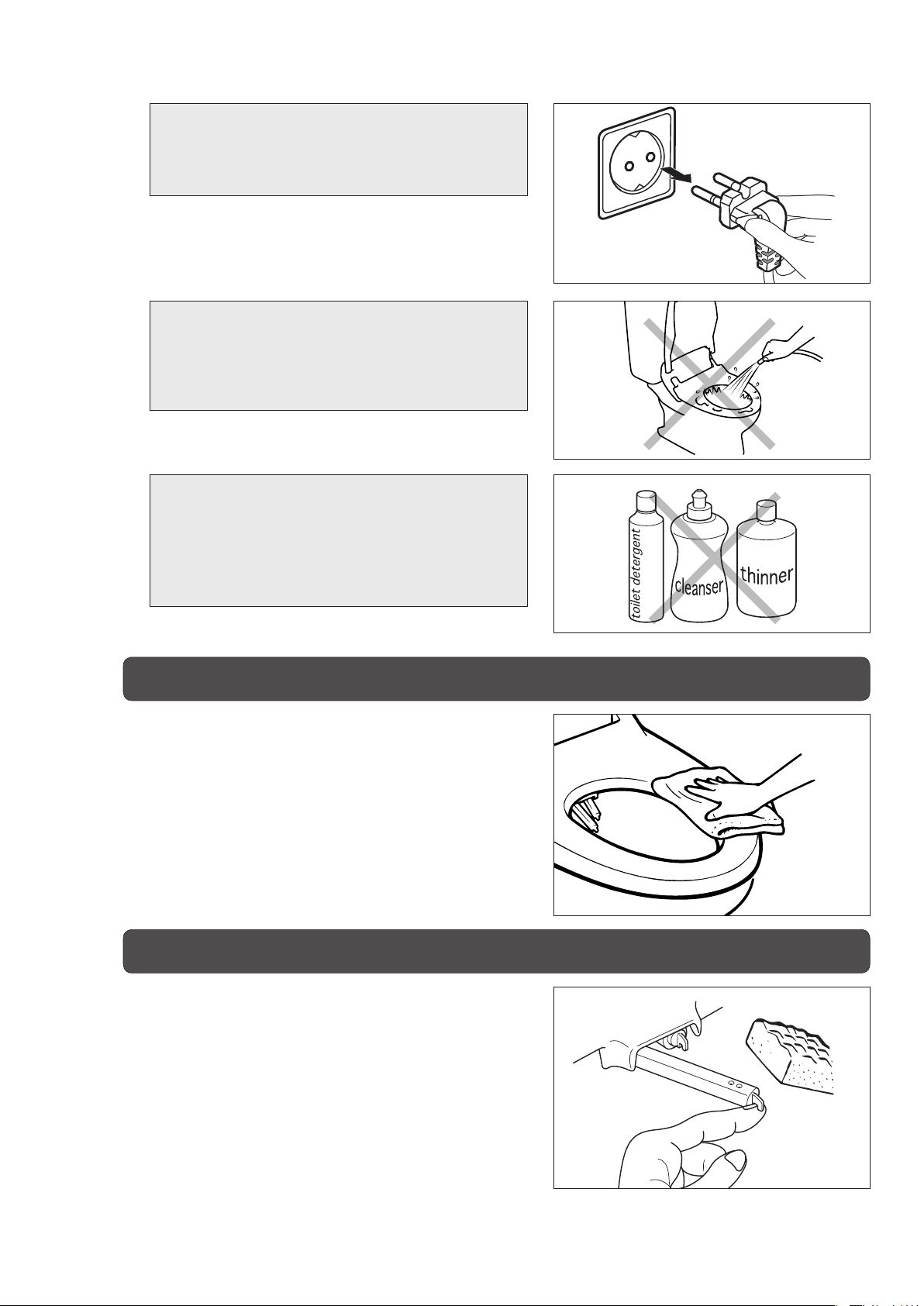

Maintaining this product

WARNING: When maintaining this product,

remove the power plug from the

wall outlet. Failure to do so could

result in electric hazard or fire.

WARNING: Do not pour water or cleanser in

the body. Do not splash water or

cleanser on the body or on the

power plug. Doing so could result

in electric hazard or fire.

WARNING: For care of plastic parts, do not

use any cleansers which are not

safe to use on toilet seats.

use toilet bowl cleaner, household

cleaner, bleach, benzene, paint

thinner, polishing powder, or cresol.)

(Do not

Cleaning the body

Periodically, wipe off the body with a soft cloth

dampened with water.

Cleaning the nozzles

Pull out the nozzle and clean it with a sponge.

Do not forcefully pull on the nozzle or bend it.

2929

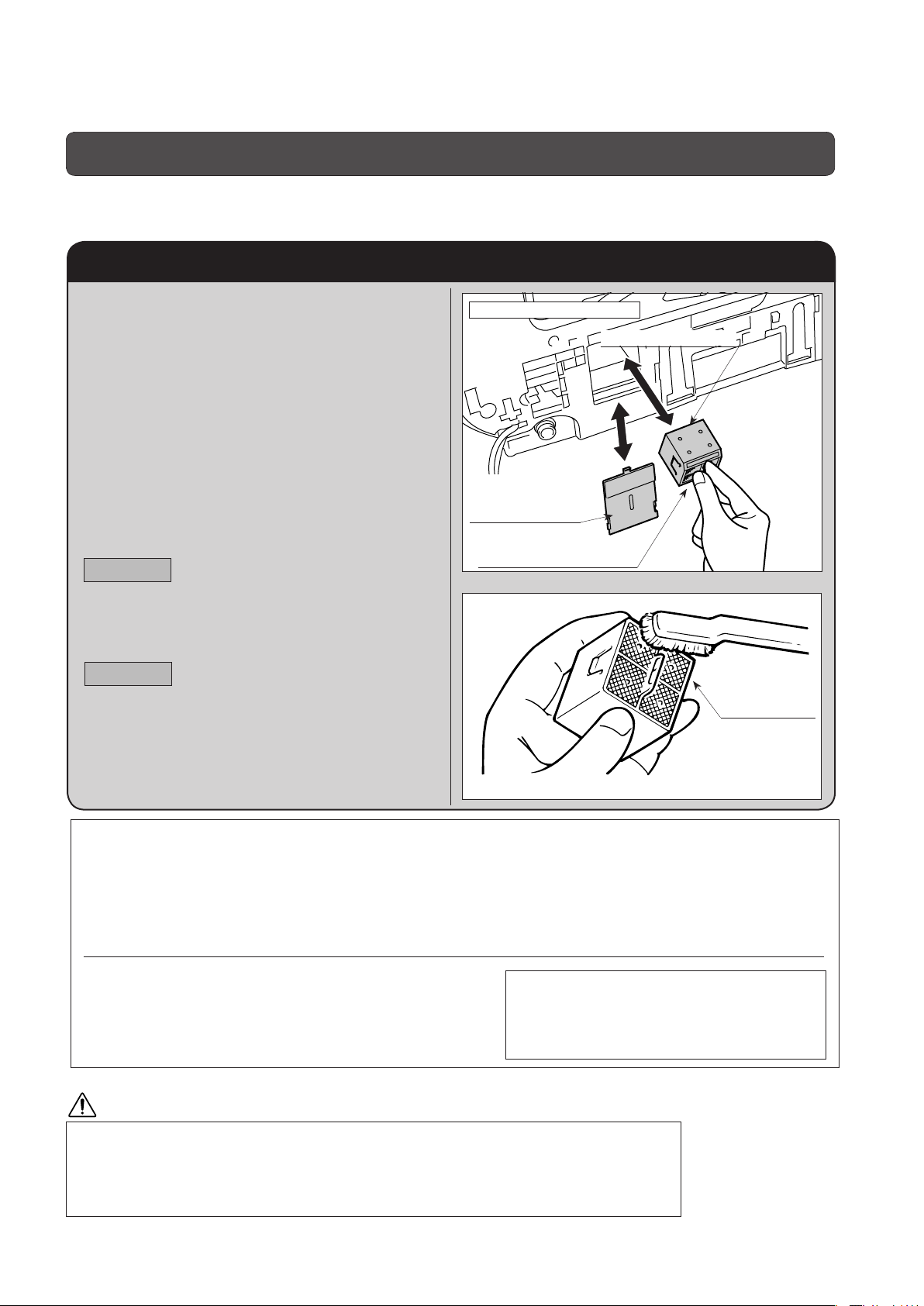

How to clean the deodorizing cartridge

The deodorizing cartridge may perform poorly if covered with dust. If odors start to bother you, please

clean the cartridge.

How to clean the deodorizing cartridge

1. Disconnect the power plug from the

outlet.

2. Remove the seat from the toilet (see

page 13).

3. Open the cover that is over the

deodorizing cartridge, which is

installed on the underside of the

seat.

4. Remove the deodorizing cartridge.

5. Clean off any dust covering the

cartridge filter with a tool such as

toothbrush.

CAUTION

Be careful! Do not wash the deodorizing

cartridge or allow it to become wet!

6. Hold the deodorizing cartridge with

your fingertips and insert it into the

opening, and then replace the cover.

CAUTION

Caution: Please insert the deodorizing

cartridge into the opening using the

orientation positioning as shown in

the diagram to the right. (Position the

rounded corners up.)

Underside of the toilet seat

Deodorizing cartridge

Cover of the opening

that contains the

deodorizing cartridge

Please make sure the

cartridge orientation is correct.

Cartridge filter

7. When cleaning is complete, reinstall

the toilet seat (see page 13).

Replacing the deodorizing cartridge

If odors still bother you after cleaning the cartridge filter, the deodorizing cartridge has expired. Please

replace it with a new cartridge. The useful life of the deodorizing cartridge is approximately seven

years under normal use.

* The useful life of the deodorizing cartridge is based on average hours of use by a family of four, two males and two

females.

First, please record the date you begin using the shower

toilet in the box to the right, and use this as a guide for

replacing the deodorizing cartridge.

Please record the date you replace the deodorizing

cartridge on the label attached to the cartridge.

Please write down the date you started using the shower toilet.

Year Month Day

CAUTION

The deodorizing fan is installed behind the opening for the deodorizing cartridge.

Please do not place your finger or anything other than the deodorizing cartridge into the

opening.

*Doing so may cause a finger injury or an equipment failure.

3030

Cleaning the strainer

If the spray strength weakens over time, clean the strainer using the following procedure.

Cleaning the strainer

1. Close the water shutoff valve to cut

off the water supply.

Since the water shutoff valve is adjusted beforehand,

keep the original position (to what extent you turned

the valve) in mind.

Water shutoff valve

Turn clockwise.

2. Turn the strainer on the bottom left of

the body with a screwdriver or similar

tool and remove it.

A small amount of water will pour out at this time.

Place a wash bowl or similar container underneath to

catch the water.

Strainer

3. Remove the dirt

adhering to the inside of

the strainer by rinsing it

with water.

4. Install the strainer, tightening it fully

with a screwdriver or similar tool.

End

Tighten the strainer

until the end is hidden

inside the body.

5. Open the water shutoff valve by

turning the water shutoff valve back to

the original position.

Turn counterclockwise.

Turn counterclockwise.

6. Finally, perform a trial operation.

(See page 16.)

CAUTION

When removing the strainer, be sure to close the water shutoff valve. When installing

the strainer, tighten it fully until the line is hidden by the body.

* Failure to do so could result in water leakage.

3131

Cleaning the hidden portions of the toilet seat lid

CAUTION

When cleaning this product, be sure to pull the power plug out of the wall outlet.

Removing the toilet seat lid

1. Move the pin hole on the right side

of the toilet seat lid to the outside and

remove it from the pin.

Toilet seat lid

Pin

Move to the outside.

Pin hole

2. Hold the toilet seat up on the right

side and slide it to the left, removing it

from the pin on the left side.

CAUTION

If you try to pull hard to remove the toilet seat

lid, it could crack or otherwise damage it.

Slide.

Lift up.

Installing the toilet seat lid

1. Align the pin hole on the left side

of the toilet seat lid with the pin on

the left side of the body and fit the lid

onto the pin.

Pin hole

Toilet seat lid

Pin

Fit together.

After cleaning, insert the power plug in the outlet and check to make sure the water temperature and

toilet seat temperature indicator lamps are lighted up again.

2. Move the toilet seat lid to the right,

opening it so the pin hole on the right

side is outside the pin, and then fit

the pin hole onto the pin to install

the toilet seat lid.

3232

Cleaning the portions of the toilet that are hidden by the body

1. Removing the body

1. Remove the power plug from the wall

outlet. (See caution 1.)

3.

Pull the lock lever on the right side of the body. 4. Carefully place the body on the

1

Slide this product forward so that it can be raised

2

slightly, and remove it from the toilet. (See caution 2, 3

and 4.)

2

Slide

forward you.

2. Close the water shutoff valve to cut off the water

supply. (See caution 2.)

Since the water shutoff valve is adjusted

beforehand, keep the original position (to what

extent you turned the valve) in mind.

Water shutoff valve

Turn clockwise.

rim of the toilet bowl.

1

Lock lever

* When removing this product, slide the unit slowly without holding the

toilet seat or toilet seat lid. Do not use an excessive force.

CAUTION

1. Do not fail to remove the power plug from the wall outlet.

* If the water heater operates with no water in the tank, it could

cause smoke or fire.

2. Be sure to drain the water out of the warm water tank.

* If there is still water in the tank, it could cause current leakage.

3. Do not pull any cord or water supply hose.

* Doing so may lead to damage or water leak.

4. Carefully handle the body when removing or cleaning.

* Failure to do so may lead to water leak or disorder.

5. Never reverse the body while it is connected to the

power supply.

* It could cause damage to this product.

* Do not pull.* Do not reverse.

* Do not place on the

floor.

3333

2. Cleaning 3. Assembling the body

Wipe out the body using a soft

cloth dampened with water.

Wipe out here.

* For cleaning of the toilet bowl, see the

user's manual for toilet bowl.

DANGER

Do not pour water or cleanser inside

this product. Do not splash water on

the body or the power plug.

* There is danger of electric shock or fire.

CAUTION

1. Place the body on the toilet bowl. Align the inverted triangle mark

( ) on the body locking plate with the protrusion on the rear of the

body .

" " mark on the body locking plate

2

1

Protrusion on the

rear of the body

2. Raise up the front end of this product slightly, slide it back

onto the body locking plate until the body locking plate can no

longer be seen, and push the lock lever in to lock this product in

place.

* If this product is not pushed all the way back, the lock lever cannot be

pushed back in.

After fastening this product in place, shake it slightly back and

forth and left and right, making sure it is fastened securely .

When cleaning the toilet bowl, take

care not to splash the body with

detergent. Before installing the

body , wipe detergent away from the

toilet bowl using a cloth damped

with water.

* Detergent sticking to the body may lead

to product failure.

Do not put your hand or any object

into the air outlet or around the

nozzle.

* Doing so may injure your hand or lead to

product failure.

3. Open the water shut-off valve

to its original position and run

water into this product.

* Make sure water is not leaking

from any of the joints.

Turn

counterclockwise.

4. Insert the power plug into the outlet.

At this time, check to make sure the water temperature and

seat temperature indicator lamps are lighted up again.

5. Make a trial operation after the completion of assembly.

(See page 16.)

CAUTION

Check that the body has been completely locked.

* If not, the body may come off the toilet bowl.

Do not bend any hose with an excessive force.

* Doing so may permanently deform it or suspend the water supply.

3434

Preventing freezing

In freezing conditions, the water in this product may freeze and cause damage. If there is danger of

water lines freezing, implement the following freeze prevention method to prevent damage.

Leave the power plug in the wall outlet.

General freeze prevention measures

Remove the body from the toilet. (See page 33.)

1. Set the water temperature on Hi, the seat

temperature on Hi, and close the toilet seat lid.

③

Tilt the body and drain out the water from inside

④

the body water supply hose through the strainer

installation opening.

2. Heat the toilet room.

If the toilet room cannot be heated, drain the water out of

the water supply hose by the following procedure.

(1) Close the water shutoff valve to cut off the water supply.

Since the water shutoff valve is adjusted beforehand, keep the

original position (to what extent you turned the valve) in mind.

Water shutoff valve

Turn clockwise.

(See caution on next page.)

(2) Drain the water from the water supply hose.

(If you cannot heat the toilet room)

① Place a wash bowl or similar container underneath

the strainer.

②

Remove the strainer with a screwdriver or similar tool.

Turn counterclockwise.

Strainer

3. Cover the occupied seat sensor with

After approximately 5 seconds, press

4. When using the toilet again, be sure to

Water supply hose

⑤

After draining out the water, install this product onto

the toilet bowl. (See page 34.)

⑥

Tighten the strainer securely with a screwdriver or similar

tool.

End

Strainer

Tighten the strainer

until the end is hidden

inside the body.

your hand and press the wash button.

(Drain the water from the valve in the

body .)

the stop button.

perform a trial operation. (See page 16.)

WARNING

If there is risk of water lines freezing, implement the

freeze prevention methods to prevent damage.

* The water in this product could freeze and cause

damage, resulting in electric shock, fire and water

leakage.

COMPULSORY

CAUTION

When removing the strainer, be sure to close

the water shutoff valve. When installing the

strainer, tighten it fully until the line is hidden by

the body.

* Failure to do so could result in water leakage.

COMPULSORY

3535

Thawing frozen water supply

If the water in the body water supply hose or in the water supply connection freezes, and the wash or

bidet does not spray water, the hose or connection must be thawed. To thaw the hose or connection

gradually, increase the air temperature in the room. To thaw the hose or connection more quickly, apply

a cloth dipped in warm water directly to the hose or connection.

CAUTION: Do not apply hot water or hot air to the water supply hose. This could damage the

water supply hose, causing it to leak.

3636

Draining this product for periods of extended disuse

If this product will not be used for an extended time (such as when you are away on a long trip), use the

following procedure to drain the water from of this product.

CAUTION

:

Water left in this product for an extended period can become contaminated and clog this

product, or can freeze. In either case, this product could be damaged.

Draining the water and disconnecting the power

1. Close the water shutoff valve to stop

the flow of water.

Water shutoff valve

Turn clockwise.

2. Drain the water from the tank using

the flush lever.

3.

Remove the power plug from the wall

outlet.

4. Drain the water from the water supply

hose.

Place a wash bowl or similar container underneath

①

the strainer.

Remove the strainer with a screwdriver or similar tool.

②

5. Remove the warm water tank drain

plug and drain the water from the

warm water tank.

① Loosen the water drain plug on the body of this

product by turning it counterclockwise 90 degrees.

Turn counterclockwise 90°

Warm water tank

drain plug

② Pull out the water drain plug, tilt the body forward,

and drain all the water out of the warm water tank.

Turn counterclockwise.

Remove the body from the toilet. (See page 33.)

③

Tilt the body and drain out the water from inside

④

the body water supply hose through the strainer

installation opening.

Water supply hose

⑤ After draining out the water, close the strainer

tightly with a screwdriver or similar tool.

Line

Tighten the strainer until the

line is hidden inside the body.

Strainer

Strainer

WARNING

CAUTION

③ After draining out the water, turn the water drain

④ Install this product onto the toilet bowl. (See page

Do not attempt to drain the water out of this

product with the body sitting as it is.

* Water could penetrate inside this product

mechanism and cause damage.

plug clockwise 90 degrees to close it.

Turn clockwise 90°

34.)

6. When using the toilet again, be sure to

perform a trial operation (See page 16.)

CAUTION

When not using this product for an extended time, be sure to

drain the water from this product.

* The water in this product could freeze and cause damage,

resulting in electric shock, fire and water leakage.

* The water could become dirty and cause skin inflammation.

When removing the strainer, be sure to close the

water shutoff valve. When installing the strainer,

tighten it fully until the line is hidden by the body.

* Failure to do so could result in water leakage.

3737

Replacing batteries in the remote control

As the batteries weaken, the battery lamp will begin to blink.

* Usually, this battery lamp turns off.

* The batteries provided with this product have been used to check

operations during construction, and so may have a useful life

shorter than commercially available batteries.

* Depending on the size of the room, the wall finish and color

(particularly dark colors), the remote control unit may stop

functioning before the battery lampstarts blinking.

Replace the batteries with new ones using the following procedure.

CAUTION: Correctly install the batteries with the positive (+) and negative (-) terminals

Battery lamp

facing the directions as shown on the remote control unit case.

Do not mix old and new batteries.

Only use alkaline batteries.

Replacing batteries in the remote control

1. Lift the remote control unit and

Remote remove it from its bracket.

2. Remove the back cover and replace

the batteries with new ones (four 1.5V

AA alkaline batteries).

Remote Control Unit

Bracket

Back Cover

Bracket

3. Replace the back cover, and set the

remote control unit back in its bracket.

38

Troubleshooting

You can easily correct some of the problems with this product. Before requesting repairs, please check

the following items.

If you are unable to correct the problem using the remedies shown below, contact the store where you

purchased this product.

All functions

Symptom

The system will not

operate at all.

Cause

Electricity is not being supplied to

the power outlet.

The power switch is off. The water

temperature and seat temperature

indicator lamps are off.

The power plug is not inserted into

the wall outlet.

Current is leaking.

Remote control’s light transmitter

or body’s light receiver is dirty.

The batteries in the remote control

are weak.

Remedy

Check for a power failure or tripped breaker,

etc.

Press the stop button for 2 seconds or longer

and get the water temperature and seat

temperature indicator lamps on the body to

light up. (See page 22.)

Insert the power plug securely into the wall

outlet.

Remove the power plug from the wall outlet,

let it sit for a while, and insert the plug in the

outlet again. If it still does not operate, pull

the power plug out and request repairs.

Remove the dirt.

Replace the batteries with new batteries. (See

page 38.)

Posterior cleaning and bidet cleaning

Symptom

Water does not spray

out.

The water shutoff valve is closed. Turn the water shutoff valve counterclockwise.

The strainer is clogged. Clean the strainer. (See page 31.)

Dirt or water drops are adhering to the

occupied seat sensor.

Tap water pressure is low. Spray

strength is set to “Lo”.

The occupied seat sensor is not

on.

Certain clothing is difficult for the

occupied seat sensor to detect

even if the seat is occupied.

The warm water tank is not full of

water.

Cause

Remedy

Remove the dirt or water drops from the

sensor. (See page 20.)

Set the spray strength to a higher level.

(See page 23.)

Sit back fully on the toilet seat, or change the

way you sit on the toilet. (See page 20.)

Place your hand close to the occupied seat

sensor. (See page 20.)

Carry out a trial operation. (See page 16.)

39

Posterior cleaning and bidet cleaning (continued)

Symptom

Spray water is not

warm.

Warm air drying

Symptom

Drying function does not

operate.

Dryer air is not warm.

Cause

Water temperature is not set to an

appropriate temperature.

The wash or bidet function was

used for a long period of time.

Power save is activated. Cancel power save. (See page 26.)

Cause

The occupied seat sensor is not

on.

Certain clothing is difficult for the

occupied seat sensor to detect

even if the seat is occupied.

Air temperature is not set to an

appropriate level.

Press the water temperature button

and adjust the water temperature to the

appropriate level. (See page 22.)

The water takes about 3 minutes to warm

back. (See page 20.)

Sit back fully on the toilet seat, or change the

way you sit on the toilet. (See page 20.)

Place your hand close to the occupied seat

sensor. (See page 20.)

Press the dry button and adjust the air

temperature to the appropriate level. (See

page 25.)

Remedy

Remedy

Warm air stops suddenly

before finishing.

The drying function has been used

for 4 minutes or longer.

Deodorizing

Symptom

The deodorizing fan

does not switch off.

Is any paper covering the seat

sensor?

Heated toilet seat

Symptom

Seat temperature is not set to an

The toilet seat is not

warm.

Toilet seat becomes

less warm when

seated long.

appropriate level.

Power save is activated. Cancel power save. (See page 26.)

The toilet seat heater auto off

function is operating.

Cause

Cause

Press the dry button again. (See page 25.)

Remedy

Please remove any paper blocking the seat

sensor.

Remedy

Press the seat temperature button and adjust

the seat temperature to the appropriate level.

(See page 22.)

Cancel the toilet seat temperature auto off

function. (See page 27.)

40

Others

Symptom

The body chatters and

deviates from correct

position.

The rear feet

(projections from the

rear) do not touch

the toilet (they are

floating).

The power lamp is

blinking.

Cause

The body is not locked.

There is trouble with the function

related with the blinking lamp.

There is trouble either with the

warm water or the toilet seat

functions.

Or it is time to check the shower

toilet.

Remedy

Push the body farther back and lock it in

position. (See page 34.)

It is not out of order.

The rear feet (projections from the rear)

were designed to float. Use the toilet as it

is.

It is broken. Pull the power plug from the

wall outlet and request repairs.

There is a malfunction or the maintenance

time. Unplug the power plug from the power

outlet, and call for repairs.

WARNING: A damaged or overheated power plug or cord, or a loose or overheated

wall outlet, could cause injury or damage the product. Under any of these

circumstances, remove the power plug from the wall outlet, contact us, and

discontinue using this product until the circumstances have been corrected.

WARNING: Do not allow anyone except an authorized service technician to disassemble,

repair, or modify this product. Doing so could result in electric hazard or fire, or

cause this product to malfunction and cause injury to users.

41

After-sales service

1. Before Requesting Repairs

If this product breaks down, see "Troubleshooting" on page 39. If the trouble is not repaired even after that,

contact the store where you purchased this product. Furthermore, even if there is no actual trouble, make

inquiry in the following cases.

If there are any points that are unclear even though the product is used in accordance with the

user's manual.

If the power cord is damaged or the outlet is loose.

The outlet or the power plug and power cord are overheating.

In the above cases, if it is left as it is without correction, there is danger of some unforeseen accident

occurring, so please get some advice.

WARNING

If the main unit, power plug, or power

cord are damaged (abnormal noise, odor,

smoke, high temperatures, cracking),

unplug the power plug from the power outlet

immediately, and have the part repaired.

* Failure to do so could cause electric shock or fire.

If water is leaking from the main unit or from the water

supply system, unplug the power plug from the power

outlet and close the water shutoff valve.

* Failure to do so could cause an electric shock or fire, or it

may cause the room to be flooded.

COMPULSORY

WARNING

Only authorized service

technicians are permitted to

disassemble, repair or modify

this product.

* There is a danger of electric

shock, fire, and injury.

DO NOT

DISASSEMBLE

2. Read the Warranty Certificate

This product comes with a Warranty Certificate. You will receive your Warranty Certificate once the

store where you purchased this product has completed the relevant information.

Check the details of the Warranty Certificate, and keep it in a secure place.

The warranty period is 2 years from the date of installation.

Even during the warranty period, there are some repairs for which you will be charged. Check the

details of your Warranty Certificate carefully.

3. Requesting repairs

Repairs within the warranty period

When requesting repairs, be sure to present

the Warranty Certificate. Repairs will be

performed in accordance with the provisions of

the warranty.

Details you will be asked

1. Address, Name, Telephone No.

2. Type, Product No., Color No., Serial No.

(See the Product No. label on the reverse side of the

toilet lid.)

3. Date of installation (See your Warranty Certificate.)

4. Description of malfunction or abnormal condition. (Be as

detailed as possible.)

5. Preferred date for house call

4.

If you want to know anything about the product or after-sales service

Consult the shop where you purchased this product.

42

Repairs after the warranty period has expired

If repairing the product will keep it functioning,

then, at your request, the repairs will be made

on a chargeable basis.

Charges for repairs include: Technical service

fee + Travel expenses + Parts costs.

Typ e

Product No.

Color No.

Serial No.

Specifications

Type CW-RS3-W

Water supply method Direct connection to tap water

Tap water pressure range 0.06 to 0.74 MPa (0.6 to 7.5 kgf/cm2)

Maximum rating AC 220 V, 305 W, 50 Hz

Product dimensions Width 426 mm x Depth 557.5 mm x Height 162 mm

Product weight Approx. 4.0 kg

Posterior and bidet cleaning

Warm water tank capacity Warm water storage 0.88 L

Nozzles Exclusive posterior, bidet nozzles, auto slide type

Nozzle holes

Posterior cleaning spray volume

Bidet cleaning spray volume 0 to 0.9 L/min. (adjustable in 5 stages)

Warm water heater capacity 250 W

Warm water internal control temperature

Safety devices Thermal fuses, High temperature sensor switch, Tank empty sensor circuit

Air volume 0.3 m3/min.

Drying

Air heater capacity 200 W

Air temperature adjustment Low (room temp.), Middle, High

Safety device Thermal fuses

Toilet seat

Heater capacity 45 W

Surface temperature

Temperature adjustment 4-steps selectable (micro-computer controlled)

Safety device Thermal fuse

Deodorization

Deodorizing method Chemisorption using a deodorizing cartridge

Deodorizing capacity 0.11 m3 / min.

Deodorizing cartridge life Approximately 7 years

Power save function One-touch power save (auto recovery after 8 hours)

Power cord Effective length: 1.0 m

Ambient operating temperatures 0 °C to 40 °C

Off (water temp.), Low (approx. 36 °C), Middle (approx. 38 °C), High (Approx. 40 °C)

Off (room temp.), Low (Approx. 28 °C), Middle (Approx. 36 °C), High (Approx. 40 °C)

* Occupied seat sensor

φ

1.3 mm x 2 holes, For bidet: φ0.9 mm x 10 holes.

0 to 0.9 L/min. (adjustable in 5 stages)

For posterior:

* Toilet seat lid one-touch removal

Other functions

* Body sliding removal mechanism

* Toilet seat heater auto off

* Toilet seat/toilet seat lid slow-down

* Adjustable side-lined toilet seat

mechanism

* Power switch

*

Included remote controller

* Posterior massage washing

CAUTION

This product is admitted to use only in your country. Do not use in any other countries.

43

Dealer (Store name, Address, Tel.)

GCW-1220A-W(11040)

Website: http://www.lixil.co.jp/

Loading...

Loading...