Instruction Manual

PSG 10N/15N/ 25N

MSG 6/10/15 /25

STORAGE

WATER HEATER

1

Dear Customer,

Congratulations on the purchase of your INALSA Storage Water Heater !

This has been designed to include many superior features. You are now on the

threshold of a whole new world.

At INALSA, we have a reputation of manufacturing innovative, high quality

appliances such as Food Processors, Mixer Grinders, Juicer Mixer Grinders,

Cooking Ranges, Juice Extractors, Cooktops, Microwave Ovens, Oven

Toaster Grillers, Hand Blenders, Electric Kettles, Rice Cookers, and Electric

Chimneys. Your newly acquired INALSA Storage Water Heater bears the

same distinctive hallmark of excellence.

It is all the result of vigorous quality consciousness in INALSA's design and

development where uncompromising standards are maintained and rigid

quality control measures are exercised on raw materials, components and

finally, the finished product.

Your INALSA Storage Water Heater has a lot of thoughtful features built in

to make your working convenient. Please read these instructions carefully, so

that you may get the best out of the power packed features in your INALSA

Storage Water Heater.

Welcome to the INALSA world of living pleasure!

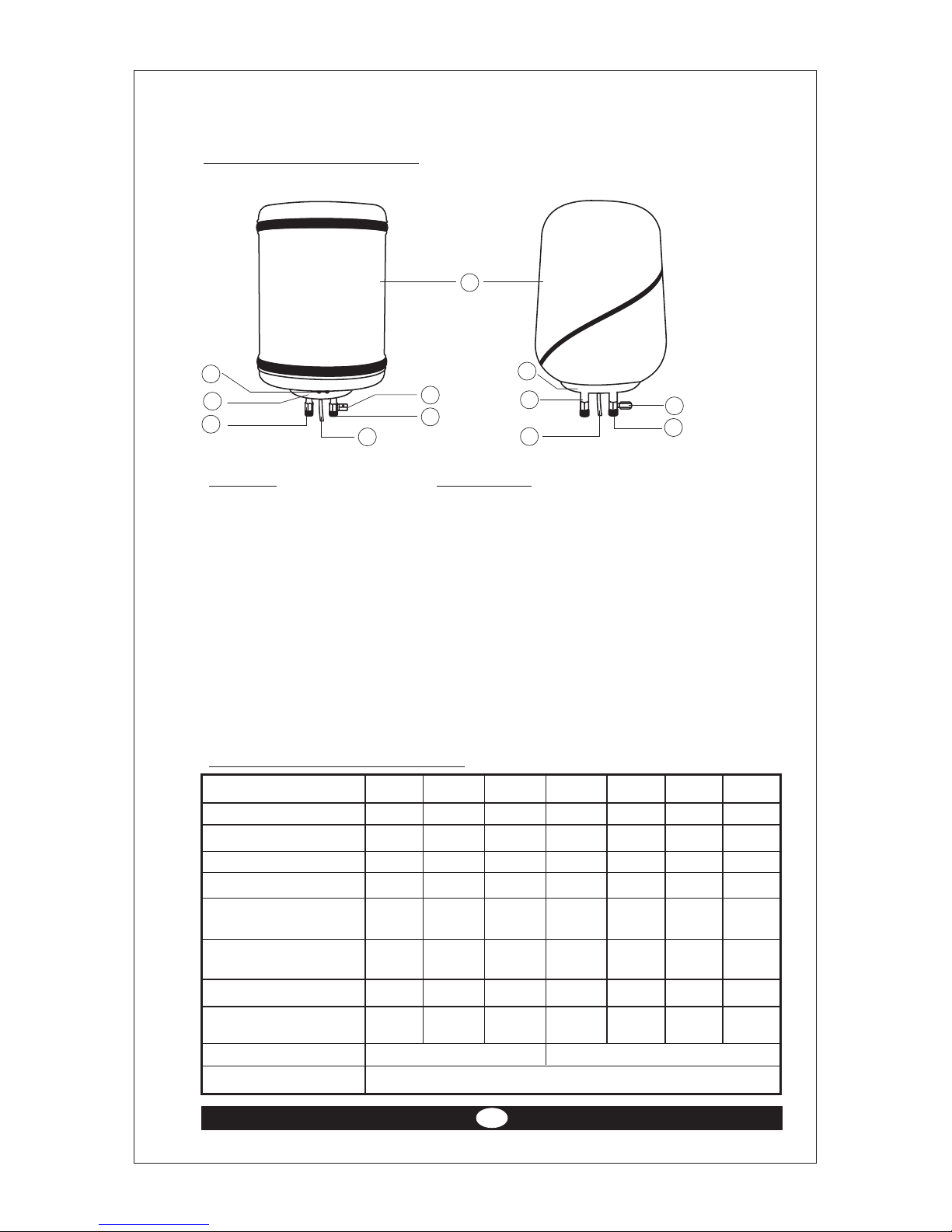

Parts Identification

Part No. Parts Name

1. Outer casing

2. Inspection cover

3. Water inlet (Blue)

4. Water outlet (Red)

5. Drain pipe

6. Indicator lamps

7. Pressure relief valve (PRV)

Technical Specifications*

Model No. PSG10N PSG 15N PSG 25N MSG6 MSG10 MSG 15 MSG 25

Capacity (in lt.) 10 15 25 6 10 15 25

Wattage (in kW) 2.0 2.0 2.0 2.0 2.0 2.0 2.0

Star rating NA 5 Star 5 Star NA NA 5 Star 5 Star

Max. pressure rating (psi) 90 100 100 90 90 100 100

Normal working pressure 30 30 30 30 30 30 30

rating (psi)

Minimum hot water 40 40 40 40 40 40 40

output temperature (C)

Max. mixing factor (%) 35 40 40 35 35 40 40

Max. Reheating time for

50°C temperature (in min.) 55 70 90 45 55 70 90

Outer casing Plastic MS Power coated

Power supply 230V, 50Hz, AC, Single Phase

2

Metal casing Plastic casing

1

2

4

5

3

7

6

4

3

7

5

2

3

Indicator Red:- Heating

Green:- Cut-out

Water tank Stainless Steel

Heating element - Two U, embedded type, copper sheathed, tubular

with mineral filling. (All models except MSG 6).

- Single element, embedded type, copper sheathed,

tubular with mineral filling ( Model MSG 6).

Thermostat Stem-type Pre-set at 60°C

Thermal cutout Stem type, Reset type to operate at 90°C

Fusible plug Operate at 98°C

* Due to continuous improvements in product, specifications are subject to

change without prior notice.

Features

1. Reset type automatic thermal cut-out for safety

2. Pressure relief valve for high pressure built-up

3. Siphon hole for low water pressure

4. Fusible plug for total safety

5. High grade stainless steel tank

6. Thermostatically controlled

7. Drain pipe to drain out the water when the heater is not in usage

8. Two U heating element. (All models except MSG 6)

9. Nonagonal tank protection.

Important Instructions

Please read operating instructions before using the appliance to ensure

safe and reliable performance.

Do's

1. Before plugging in the socket ensure that the mains voltage complies

with the rated one.

2. Qualified service personnel shall do periodic drainage of water from the

heater. This reduces the chances of scaling of heating element and tank.

3. Switch Off the power supply and drain out the remaining water in the

tank. This prevents scaling of both element and tank.

4. The gate valve at the inlet shall be kept open.

5. Servicing should be done at least once a year.

6. Make sure that no other appliance(s) is (are) plugged into the same

circuit with heater, as this may overload the circuit.

4

7. If the main cord of the heater is damaged, authorized service personnel

must only replace it.

Don'ts

1. Do not switch ON the heater till it is completely filled with water.

2. Do not install a pressure reducer valve at the inlet.

3. Safety devices are pre-set and are sensitive. Do not temper with them.

This could be hazardous.

5. Do not use outdoors. This product is for household use only.

6. In case of any abnormality during operation, immediately switch OFF

the main power supply and contact the nearest service center.

How to Install

1. Installation should be done by a qualified plumber / electrician.

2. There should be enough space around the heater for easy installation and

servicing.

3. Make sure that the supporting walls or fixtures are strong enough to

carry the weight of the heater when it is completely filled with water.

4. Fix the water heater in perfectly straight position at a suitable height

from the floor.

5. There should be a minimum space of 50 cm between the heater unit and

roof. This is to ensure that heater can be removed easily when required.

6. The heater should be saved from being damaged by splashing water. For

this keep a minimum distance of 1.8 M between the floor and bottom of

the heater.

7. During installation and plumbing (generally by flexible metal pipes)

connect the plumbing by bending the flexible pipes or elbow.

Installation Positions

Mounting Dimensions (in mm)

Model A B C D Approx. Weight Pipe connection

of water Heater (in mm)

with Water (in kg)

PSG10N 175 185 475 310 15.0 12mm (½")

PSG15N 228 215 550 365 24.0 12 mm (½")

PSG25N 235 250 605 435 36.0 12 mm (½")

MSG 6 160 200 400 265 11.0 12 mm (½")

MSG10 270 195 490 270 17.0 12mm (½")

MSG15 222 307 505 340 25.0 12 mm (½")

MSG25 288 307 640 370 37.0 12 mm (½")

5

Mounting diagram

Water supply

1. You can connect the water heater directly to the overhead water supply

tank. Do not connect the water heater directly to water lifting pumps.

2. The water should not be too low. The minimum height between the

heater and water supply should be at least 2M.

Water connections

1. Do not connect the cold and hot water pipelines directly to the heater.

Instead connect them using flexible copper pipes. Never use plastic

tubes especially at the outlet, as it cannot withstand heat over extended

usage. In case of direct pipe connections, tightening of couplings using

wrench can damage the heater unit. Always use control / gate valves at

the inlet and outlet. Ensure that the valve at the inlet is always open.

Electrical wiring

Make sure that connections in the plug & socket are secure and proper

earthing is provided to the unit.

A

C

D

B

Wiring diagram

6

How to Use

1. Do not switch ON the power supply before filling the heater with water.

2. Leave the hot water outlet open and open the inlet valve to allow the

heater unit to be filled with water. When the heater is full the water will

start flowing out from the outlet.

3. Now close the gate valve at the outlet. Always keep the inlet valve open.

4. Switch ON the power supply. Red neon lamps will glow 'ON' to indicate

that water is getting heated.

5. When the water is heated to the pre-fixed temperature, red lamp will get

OFF. This indicates that the thermostat has operated. You can now take

the hot water out through the outlet.

6. It is advisable to switch OFF the power supply when the unit is not in

use.

Note: In case green light glow ON, this indicates that thermostat has failed

and needs to be replaced.

Safety Devices

Thermostat

An adjustable ISI marked bimetallic stem type snap action thermostat

with temperature range between 25 C to 75 C, generally set at 60 C

cuts the electric power supply as soon as the water temperature rises

above the set temperature and restarts automatically when the

temperature goes low.

Reset type thermal cutout

It is bimetallic type snap action devices set to operate at 90 C. In

abnormal conditions, if the water temperature inside the tank exceeds

90 C or if the water heater is switched on with water the thermal cut the

power supply and protects the system.

Fusible Plug

Accidentally if the thermostat and the thermal cutout fails to operate, the

fusible plug melts at around 98 C reducing the water steam pressure

inside the tank.

Pressure relief valve

2

The PRV is set at 3.5 Kg/cm (50PSI). It prevents the pressure built up

inside the tank by bleeding out the water through the PRV when the

2

incoming pressure exceeds the set pressure of 3.5 Kg/cm

Non- Return Device

There is a siphon hole on the inlet pipe inside the inner tank of water

heater. At low pressure, the siphon prevents back flow of the water. It

acts as a non-return device upto a certain level of low pressure and

prevents vacuum formation that can lead to tank collapse and thus

leakage.

Cleaning and maintenance

Routine Inspection/Maintenance Chart

S.No. Inspection item Frequency Remarks

1. Pressure relief Every 3 If the water quality is

valve (PRV) months/1 yr. bad because of

of seasonal use hardness & suspended

impurities .

2. Fusible plug Every 3

months/1 yr.

of seasonal use

3. Heating element 18 months/6 yrs. In case of bad water

of seasonal use quality, inspect after

every 6 months of

continuous use or

every 2 yrs. of

seasonal use.

7

Loading...

Loading...