HA1600A

Power and Harmonics Analyzer with Flickmaster

INSTRUCTION MANUAL

Table of Contents

Introduction 2

Specification 3

Safety 5

EMC 7

Installation 8

Connections 9

Front Panel Connections 9

Rear Panel Connections 9

Initial Operation 10

Power Meter View 12

Power Meter Set-up 14

Waveform Graph View 15

Waveform Graph Set-up 16

Harmonics View 19

Harmonics View Set-up 20

Display Format - Histogram 20

Display Format – Tables 23

Test Control View 25

Test Control Set -up (Harmonics) 26

EN61000-3-3 Flicker and Fluctuations 31

Test Control Set -up (Flicker) 33

Meter View (Flicker) 35

Flicker Meter Page 35

Voltage Variation Page 36

Peak Inrush Current Measurement 38

Test Control Set -up (Peak Inrush Current) 40

Report View 41

Report Formats 42

Report Set-up 45

Compliance Measurements with the HA1600 47

Overview of Harmonics Measurements 47

Taking Harm onics Measurements 48

Taking Flick er and Fluctuation Measurements 50

HA-PC Link Plus Software 51

Software Installation 51

Operation of the HA-PC Link Plus Software 51

Installation of USB drivers 54

Maintenance & Calibration 55

Software Updates 56

Note: The latest revision of this manual, firmware, device drivers and software

tools can be downloaded from: http://tti1.co.uk/downloads/ha1600-download.htm

This manual is: 48511-0400 - Iss 12

1

High performance power analyser

The HA1600 is a high speed, high accuracy AC power analyser for single phase supplies of up to

16 Amps rms.

The supply to be measured is connected via a dedicated input cable independently of the supply

to the instrument. The output to t he load is via a fr ont panel mounted 'standard' mains connector.

A wide range of power connectors is available including most European national types.

The HA1600 can measure Watts, VA, Volts rm s , Volts peak, Amps rms, Amps peak, Crest

factors, THD, Power fac t or, Frequency and Inrush current .

The large display can show multiple parameters simultaneously along with graphical

representations of voltage and current waveforms.

Dual 16 bit Analog to Digital converters continuously sample both voltage and current and g ive a

wide dynamic range. A fast Dig ital Signal Processor gives the performance needed for

continuous real-time analysis of the data. Advanced algorithms yield accurate results, using

extended precision or floating point arithmet ic wherever necessary.

Compliance-quality harmonics analyser

Introduction

The HA1600 has been designed to make harmonics m easurements both quick and simple.

It measures harmonics from the 1

It is suitable for pre-compliance measurements using a normal mains supply and is capable of

full compliance measurements to EN61000-3-2 in conjunct ion with a suitable power source (such

as the AC1000).

Capabilities include continuous monitoring of the supply voltage, continuous comparison to

harmonic limits and timed test sequences with analysis of f luct uat ing harmonics.

Compliance-quality flicker meter

The HA1600 has the capability to operate as a compliance quality voltage variation and flicker

meter in conformance with EN61000-3-3 and EN61000-4-15.

Flicker severity can be measured in terms of P

analysis of voltage variations, including the calculation of the maximum value d

between steady states d

and the change characteristic d(t).

c

For pre-compliance testing, a curr ent measurement method can be used, rat her than voltage

measurement, to eliminate the need for a clean power generator and a reference im pedance.

A full range of interfaces

A parallel printer interface is included, for r ec or d keeping and archiving, and also a high speed

RS-232 interface is provided for use with either a print er or r emote control software running on a

PC. The HA1600A also has a USB port for use with the HA-PC Link Plus software.

st

to the 40th and updates the display in real time.

and P

st

while simultaneously performing full

lt

max

, the difference

The internal software of the instr um ent is stored in flash memory and can be updated through the

serial port as the requirements of the measurement standards evolve.

HA1600 and HA1600A

The two versions of the instrument are in diff er ent cases, with slightly different front panel

layouts. The HA1600A has a USB port. In all other respects the operation and performance of the

two types is identical. Both use the same firmware, and this manual applies to eit her t ype if fitted

with firmware version 2.80 or later.

2

Measurement Circuit:

Single Phase with standard mains connector.

Current Rating:

16A rms continuous, or national connector rating if lower.

Voltage Ranges:

115V (± 200V pk) and 230V (± 400V pk).

Current Ranges:

± 24mA pk to ± 400A pk in fifteen 2:1 ranges.

Frequency Range:

43 – 67 Hz.

3mΩ.

Sampling Rate:

300 points per cycle.

Basic Accuracy:

Better than 0.2% ±1mA, up t o 16A.

Peak Inrush current.

Display Modes:

Tabular display of all parameters including lates t and highest inrush current.

accumulate and multiple cycle display modes.

Monitor Outputs:

Re-constructed Voltage and Current Signals.

harmonics.

Current Rating:

16A rms continuous, or national connector rating if lower.

Voltage Ranges:

115 (± 200V pk) and 230V (± 400V pk).

Current Ranges:

± 24mA pk to ± 400A pk in fifteen 2:1 ranges.

Frequency Range:

43 – 67 Hz.

Shunt Resistance:

3mΩ (less than 150mV across shunt up to 50 Amp peak).

Transform W indows:

Continuous 4, 10, 12 or 16 cycle Discrete Fourier Transforms.

±1mA.

frequency against req uirem ents defined in EN61000-3-2.

Histogram or tabular display of supply voltage harmonics.

3-2), with Min. hold, Max. hold and percentage of limit display options.

limit and pass or fail assessment for each harmonic.

Specification

MAINS ANALYSER

Shunt Resistance:

Measured Parameters: Vrms, Vpk, Arms, Apk , Cr est factors, THD, W, VA, Power factor, Frequency,

Waveform Graph display of Voltage and Current with normal, Max hold,

HARMONICS ANA LYSER

Measurements: 1st harmonic to 40th harmonic.

Measurement processing to EN61000-3-2. and EN61000–4–7

Continuous calculation, analysis and assessment of unfilter ed, filtered,

average, minimum and maximum current har m onic levels and limits.

Continuous measurement and assessment of supply waveform and

Basic Accuracy: Better than 5% of limit or 0.2% of selected range (whichever is the great er )

Display Modes: Display of load supply assessment for voltage, harmonics, crest limits and

Histogram display of current harm onics with limits (calculated from EN61000-

Tabular display of curr ent har m onics showing present values, limits, average

values, average as percent of limit, maximum values, maximum as per cent of

3

Test Control:

Untimed, manually timed or automatically timed tests; user -defined test time.

user.

appropriate limits. Facility for insetting tes t limits.

supply voltage assessment and current harmonic analysis and assessment.

to EN61000-3-3 and EN61000-4-15.

Current Rating:

16A rms continuous, or national connector rating if lower.

Voltage Ranges:

115V (± 200V pk) and 230V (± 400V pk).

Fluctuation Range:

25% max (relative to nominal voltage).

Equivalent to 6400 pu on 8.8 Hz sinewave.

Flickermeter AGC:

Up to ±5%.

Flickermeter Accuracy:

Better than 5% for Pst range 0·7 to 10·0.

Frequency Range:

50Hz (operates over 43 – 67 Hz).

st

st

Display:

320 x 240 pixel backlit LCD.

Real−time clock for time and dat e−stamping of Report data.

Interfaces:

Parallel Printer, RS-232 (for printer or PC); also USB (for PC) on HA1600A.

different supply voltage and/or frequency f r om that used to supply the load.

Operating Range:

+5°C to 40°C, 20-80% RH.

Storage Range:

–10°C to +60°C.

Environmental:

Indoor use at altitudes up to 2000m, Pollution Degr ee 2.

Safety:

Complies with EN61010-1.

EMC:

Complies with EN61326-1.

Dimensions (WxHxD):

HA1600A: 357 x 132 x 235mm; HA1600: 305 x 148 x 220mm.

Declaration of load class. Limits automatically determined f rom EN61000-3-2

for appropriate class; Class C and Class D limits can be automatically

calculated from power measurements or from ratings declared by the user.

Minimum and maximum power thresholds for limits can be changed by the

Facility for declaring supply voltages other than 230V and deriving

Report Printing: Direct printer connection for har d-copy report with user-entered narrative,

VOLTAGE FLUCTUATIONS & FLICKER METER

Measurements:

Voltage fluctuations d

, d(t) and d

c

and flicker P

max

and P

st

lt

Flickermeter Range: Voltage change up to 20% (sinewave change) or 10% (low repetition rat e

rectangular change) relative to AGC level.

Report Printing:

Tabular listing of voltage variations, P

classifier and P

in each Plt interval.

GENERAL

Clock:

Instrument Supply: 220V–240V or 110V–120V ±10%, 48 to 65Hz. Installation Category II.

Maximum instrument power 25VA. The instrument can be operated at a

Weight: HA1600A: 4.4kg; HA1600: 4.2kg.

4

operation may damage the instrument.

Safety

This instrument is Safety Class I accor ding to IEC classification and has been designed to meet

the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Categ or y II inst r um ent intended for operation

from a normal single phase supply.

This instrument has been tested in accordanc e with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some informat ion and warnings which have to be

followed by the user to ensure safe operation and to r etain the inst r um ent in a safe condition.

This instrument has been designed f or indoor use in a Pollution Degree 2 environment in the

temperature range 5°C t o 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5° and -10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not spec ified by these instructions may impair the safety

protection provided. Do not operate the instrum ent outside its rat ed supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int entional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to either supply, terminals may be live and opening the covers

or removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, m aint enanc e or r epair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be

avoided as far as possible and, if inevitable, shall be carried out only by a skilled person who is

aware of the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive

moisture or chemical corrosion the safety protection may be impaired and the apparatus should

be withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rat ed c ur r ent and of the specified type are used f or

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

This instrument uses a Lithium button c ell for the real-time clock and non-volatile memor y battery

back-up; typical life is 3 years. In the event of replacement becoming necessary, replace only

with a cell of the correct type, i.e. 3V Li/Mn0

20mm button cell type 2032. Exhausted cells must

2

be disposed of carefully in accordance with local regulations; do not cut open, incinerate, expose

to temperatures above 60°C or attempt to recharge.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window. The f ollowing symbols are used on the inst r ument and in this manual:-

Caution -refer to t he accompanying documentation, incorrect

Terminal connected t o c hassis ground.

Alternating current.

5

Performance levels achieved are detailed in the user manual.

EC Declaration of Conf ormity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

HA1600A Power & Harmonics Analyser

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Comm unit ies.

EMC

Emissions: a) EN61326-1 (2013) Radiated, Class B

b) EN61326-1 (2013) Conducted, Class B

c) EN61326-1 (2013) Harmonics, referr ing to EN61000-3-2 (2006)

Immunity: EN61326-1 (2013) Immunity Table 1, referring to:

a) EN61000-4-2 (2009) Electrostatic Dischar ge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2009) Conducted RF

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS W ILDING

TECHNICAL DIRECTOR

1 May 2014

6

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of t he following standards:

Emissions

EN61326-1 (2013) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harm onics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2013) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performanc e achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (2009) Electrostatic Discharge : 8k V air, 4kV contact, Perfor m anc e A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (signal connections),

Performance A (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2009) Conducted RF, 3V, 80% AM at 1kH z (AC lin e on ly; s ignal

connections <3m, therefor e not tested), Performance A (A).

According to EN61326 the definitions of per formance criteria are:

Performance criterion A: ‘During test normal performance within the specif icat ion limits.’

Performance criterion B: ‘During t es t , temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During t est, temporary degradation, or loss of function or

performance which requires operator int er vention or s ystem r es et occ ur s.’

Cautions

To ensure continued com pliance with the EMC directive the following precautions should be

observed:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance A (A) and 1.4G Hz to 2GHz:

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Perf or m ance A (A).

25 cycles, 70%: Performance B (C); 250 cycles, 0% : Per formance C (C).

a) After opening the case for any reason ens ur e t hat all signal and ground connections

are remade correctly before replacing the cover. Always ensure all case screws are

correctly refitted and tightened.

b) In the event of part replacement becoming nec ess ar y, only use components of an

identical type, see the Service Manual.

Note that the conducted emissions measured on t he LO AD POWER connection of the

HA1600 will be those of the load itself since the HA1600 contains no filtering on this

connection. W hen m aking measurements on a non-compliant load, ther efore, care must be

taken to ensure that its emissions do not interfere with other equipment.

7

BROWN

-

MAINS LIVE

BLUE

-

MAINS NEUTRAL

GREEN/YELLOW

-

EARTH

Mains Operating Voltage – Instrument Power

Before making connections t o the AC line source ensure that the operating voltage of the

instrument is correctly set. The operating voltage is indicated by the or ientation of the fuseholder.

When the 230V mar king is upwards, the unit is set for operation over the range 198V to 264V.

When the 115V marking is upwards, the unit is set for operat ion over the range 99V to 132V. To

change the operating voltage range, remove the AC line plug, pull out the fuse holder, replace

the fuse with one of the appropriate r at ing (see below) and rotate the fuse holder before pus hing

it firmly back into place.

Safety Note: To fully disconnect the Instr um ent Power from the AC supply, unplug the mains

cord from the INSTRUMENT POWER inlet or from the AC supply outlet.

Mains Operating Voltage – Load Power

The fixed LOAD POWER mains lead is an independent connection, which provides power to the

appliance connector on the front panel; it can be at a different voltage and frequency fr om the

instrument power. The maximum permitted load power voltage is 264Vrms and the frequency

range is 43 - 67Hz.

For full compliance measurements to EN61000-3-2 the load power lead should be connected t o

an AC supply that meets the voltage, frequency and harmonics r equirements defined in the

standard; the AC1000 low distortion power source can be used for this pur pose.

Installation

Safety Note: To fully disconnect the Load Power from t he AC supply unplug the mains cord

from the AC supply outlet.

Fuse – Instrument Power

The correct time-lag fuse must be fitted for the selected operating voltage.

For 230V operation use 250mA (T) 250V time-lag HBC

For 115V operation use 500mA (T) 250V time-lag HBC

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders are prohibited.

Fuse – Load Power

A high voltage, high breaking current, fuse is fitted int er nally in the load power circuit. The correct

fuse type is: 20A 500V HBC Type aM or gL.

Make sure that only fuses with the required rated current and of t he specified ty pe ar e used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders are prohibited.

Mains Lead

When a three core mains lead with bare ends is provided this should be connected as follows:

Any interruption of the protective conductor inside or outside the instrument will make the instrument

dangerous. Intentional interruption is prohibited

8

WARNING ! - THIS INSTRUMENT MUST BE EARTHED

.

Pin

Name

Direction

Description

Passively asserted (+10V through 10kΩ)

2

TXD

O

Transmitted data to computer

3

RXD

I

Received data from computer

4

DTR

I

Computer can receive

5

GND

Signal ground

6

DSR

O

Passively asserted (+10V through 10kΩ)

7

RTS

( I )

Assumed asserted

8

CTS

O

Computer may send

9

RI

No connection

Front Panel Connec tions

Appliance Connector

The load under test should be plugged into the front panel appliance connector. Power to the

connector is supplied from the f ixed

which is controlled by the

instrument power (e.g. the

from the appliance socket.

A wide choice of national appliance connectors is available but the connector is factory fitted and

cannot be changed by the user. The maximum load current that can be supplied is the rating of

the connector, or 16Arms, whichever is lower.

Voltage and Current Monitor

The Voltage Monitor and Current Monitor BNC sockets output reconstructed, scaled versions of

the load power voltage and current waveforms referenced to inst rument ground, permitting direct

connection to other instruments such as an oscilloscope. The output voltage is approximately

2.5V pk-pk for a full-scale signal on any current or voltage range.

LOAD switch. If the LOAD switch is in the OFF position, or if there is no

POWER switch is OFF) then the load power supply is disconnected

Connections

LOAD POWER cable via an internal 20A fuse and a relay

Rear Panel Connections

Instrument Power and Loa d Power

The IEC inlet supplies power for the instrument only; t he fixed lead supplies the load power to the

front panel appliance connector. Refer to the Installation section.

USB

The USB interface is intended for c om m unicat ion with a PC running t he HA-PC Link Plus

software. See software installation section for information about device driver requirements.

RS232

The RS232 interface should be connected to a standard PC port using a fully wired 1-1 malefemale cable without any crossover connections. It may also be used with a serial printer.

The 9-pin female D-connector has t he following pin-out:

1 DCD O

The signal ground is connected to instr um ent ground. The Baud rate is fixed at 115,200.

Printer

25-way female D-connector configured as a standar d parallel (Centronics) printer port. Connect

directly to a suitable printer using a standard shielded cable.

9

Initial Operation

This section is a general introduction to the organisation of the instrument and is intended to be

read before using it for the first time. It is important to recognise that compliance q uality

measurements cannot be taken by relying on the instrument defaults. A full understanding of the

various configuration options must be g ained by studying t he detailed descript ions of each

function which follow in the sections of this manual below, starting with Power Meter.

In this manual front panel keys and connectors ar e shown in capitals, e.g .

MONITOR; all soft-key labels, messages and data values displayed on the LCD are shown in a

different type font, e.g. Setup Range, Load Declared Class A.

Switching On

With both t he PO WER and LOAD switches in the OFF position connect t he INSTRUMENT

POWER

distortion AC source as described in the Installation section.

Switch the POWER switch to ON to t urn the instrument power on; the display will show the

Initialisation screen for a few seconds followed by the Select screen. A 20 second time-out is

started, with a count down shown on the display. If no key is pressed during this time out, or if the

Resume Operation soft-key (F5) is pressed, the instrument will continue operation using the

Test and Report parameters automatically stored at the last power−down; the parameter settings

stored are given in the table at the end of this chapt er. The instrument will start up with the LCD

showing the Waveform Graph display. The display will show the load voltage waveform, which

will appear to be unstable for 4 to 5 seconds or more until the sampling clock synchronises

exactly with the incoming supply; the display will then show a single cycle of the voltage

waveform with the rising zero-crossing point at the lef t edge.

The second soft-key option on the Select scr een is Restore Defaults; t his continues

operation with all parameters defaulted to their orig inal factory setting. The stored parameter s

and their default settings ar e list ed in the table at the end of this chapter.

METER, VOLTAGE

lead to the standard AC supply and connect the LOAD POWER lead t o a suitable low

The final soft-key option is Setup, which gives access to a f ur ther screen where the soft-keys

are Restart and Update Software. Restart returns the instrument to the Initialisation

screen. Update Software selects the mode in which the instrument’s software can be

updated from a PC via its RS232 port; see the section of t he Maintenance chapter for details.

If the load is now connected and the

will also show in the display; the instrument will auto-range to show the current waveform at the

best resolution achievable. Load power is disconnected, even if the LOAD switch is ON, when

INSTRUMENT POWER is turned off.

Safety Note: Neither the POW ER switch, nor t he LO AD switch, fully disconnect their respective

AC supplies when switched to the OFF position. To fully disconnect from t he AC supply unplug

the mains cords from the AC supply outlets; make sure that the means of disconnection are

readily accessible. Disconnect from the AC supplies when not in use.

Display Contrast

The contrast of the LCD may vary a little with changes of ambient temperature or viewing angle

but can be optimised for a particular environment by using t he front panel contrast control. Ins er t

a small screwdriver or trimmer tool throug h t he adjustment aperture mark ed LCD and rotat e t he

control for optimum contrast.

LOAD switch also turned to ON the load current waveform

10

Parameter

Default Setting

Nominal Voltage and tolerance

230V ± 2%

Nominal Frequency and tolerance

50Hz ± 0.5%

Test Duration

Standard value for each mode.

Assessment inset

1.00

Operating Mode

EN61000-3-2:2006 Harmonics

Load Classification

Class A

Class C Limit basis, current and PF

Automatic (maximum fundamental current)

Class D Limit basis and power

Automatic (maximum power)

Class A, B or D minimum power

75W

Class D − A cross−over power (1995)

600W

Flicker sensing method

Voltage

Simulated Flicker Reference Impedance

0.4 + j 0.25 Ω

d

max

limit

d(t) limit

* < 500 ms above 3.3%

d

c

limit

Steady State Def inition

* > 1000 ms within ±0.32%

Switching sequence On and Off time

1000 cycles

Switching sequence On and Off phase

0 degrees

Left Margin (of Report)

5 characters

Report No.

1

Keyboard

The keys on the front panel can be considered in the following groups:

• The five keys beneath the LCD. When the green VIEW lamp is lit these are used to direct ly

• The four cur sor keys marked and are used to move the edit zone (shown as an

• Numeric keys permit direct entry of values in certain set-up displays. ENTER confirms a

•

call each of the five main display views (

METER for Power Meter, WAVE for Waveform Gr aph,

etc.). In addition, when the set-up scr een for each of these views is displayed (by pressing

the

SET-UP / VIEW key to light the red SET-UP lamp) they become 'soft-keys' which take the

functions shown immediately above them in boxes on the LCD.

outline box) around the editable fields of a set-up display. For each position of the edit zone

the keys below the display have the functions shown immediately above them in boxes on the

LCD; the functions change as the edit zone is moved which is why they are called 'soft' keys.

The cursor keys auto-repeat when held down.

numeric entry and

CANCEL terminates the entry without changing the paramet er t o the new

value.

START TEST and STOP TEST have specific f unc t ions det ermined by the type of test selected

on the Test Control set-up display; f ull details are g iven in the Test Control section.

• The

LOCAL key switches the instrument between remot e and local ( keyboard) control.

Stored S ettings and their Factory Defaults

The following parameters have their present sett ing stored at power−down; these are recalled at

power−up if Resume Operation is selected. If Restore Defaults is selected instead, the

settings are those shown in the Defaults Setting column.

* These values reflect the 2001 Amendment to EN 61000-3-3 and also apply to later issues.

Note that the Report’s Header, Title and Footer text is not restored to the orig inal form by the

Restore Defaults choice; the text can only be changed by entering new characters.

11

4 %

* 3.3 %

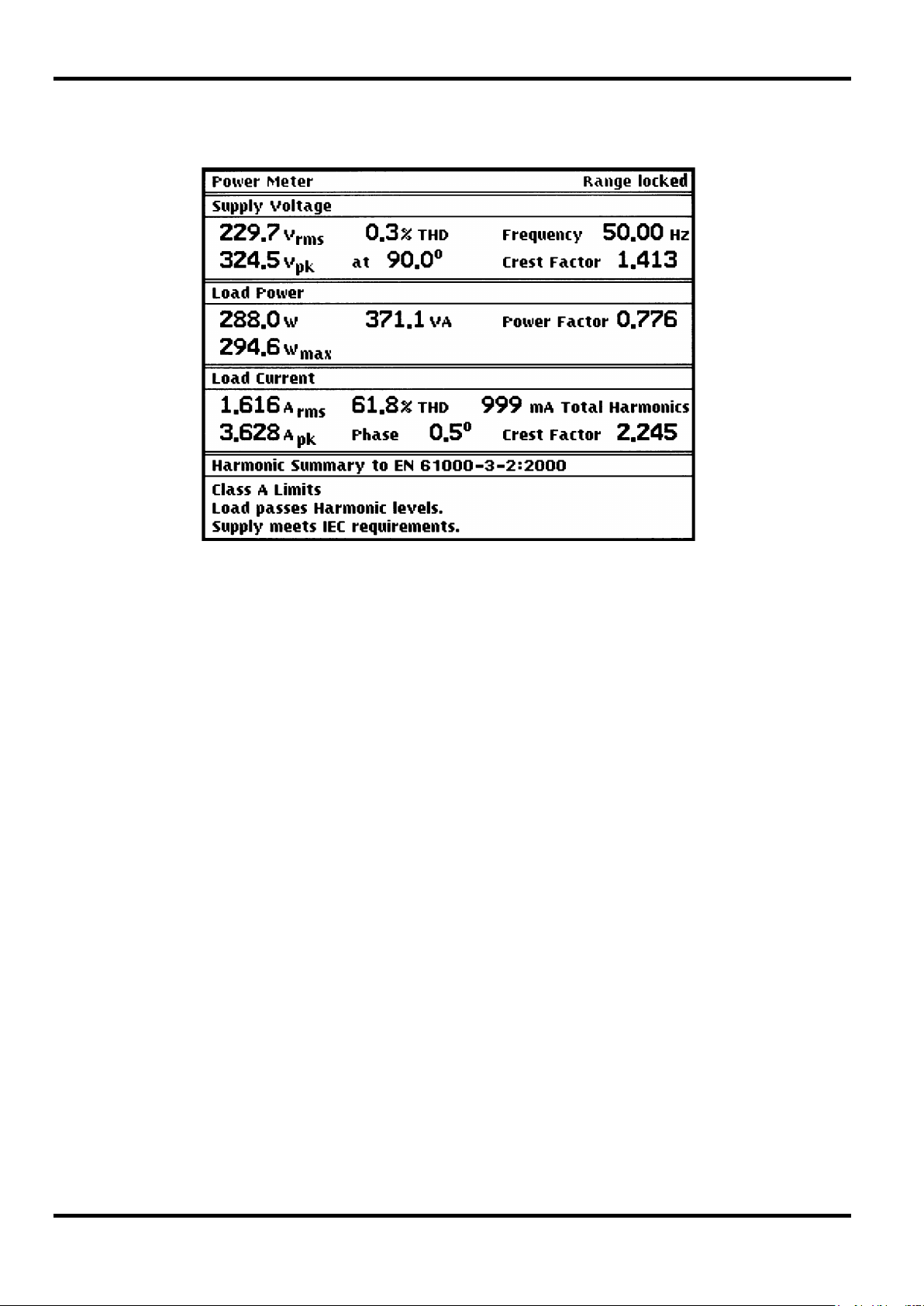

Power Meter View

With the green VIEW lam p lit, pr es s the METER key to display the Power Meter view.

The Power Meter view gives a continuously updated display of the major parameters of the

supply voltage and load current, together with an instantaneous summary of whether t he supply

and load meet the limits of the harmonics standard.

The Supply Voltage group shows the Vrms and frequency of the load power supply,

together with its total harmonic distortion (THD), peak voltage (Vpk), the phase of the peak with

respect to the zero-crossing point and t he calculat ed crest factor (Vpk/ Vrms).

For compliance quality measurements, the load power supply must meet the following

requirements:

Harmonics (max % of fundam ental) 0.9% : 3

0.4% : 5

0.3% : 7

0.2% : 9

0.1% : even 2

0.1% : all 11

rd

th

th

th

nd

– 10th

th

– 40th

Voltage 230 Vrms ± 2%

Frequency 50Hz ± 0.5%

Crest Factor (Vpk/Vrms) Between 1.40 and 1.42

Phase of Vpk Between 87° and 93° after zero crossing

All the above parameters are continuously monitored. All supply parameters are compared

against the limits and a pass or fail indication is given in the Harmonic Summary section of t he

display.

12

The Load Power group shows the true power (Watts), apparent power (V.A) and power factor

(W/V.A). The maximum value of the true power is also shown.

The Load Current group shows the rms and peak load curr ents, t ogether with the total

harmonic distortion (THD), the phase of the current peak, t he c alculated c r est factor (Ipk / Irms)

and the total harmonic current (this is t he r m s sum of all the harmonics between 2 and 40 and

can be used to find a worst case operating condition of the load under test). When testing

harmonics for a Class C equipment the total harmonics display is replaced by the value of the

fundamental current

The Harmonic Summary group gives a simple overview of the supply and load harmonic

status. It states whether the supply passes or fails the specified requirements; compliance quality

measurements can obviously only be made with a supply that meets the harmonics, voltage,

frequency, crest factor and phase requirements described earlier. It also states the load class as

declared by the user and any power related exclusions detected by the analyser; refer to the Test

Control section. Lastly the display states whether the load current passes or fails the harmonics

limits of the Class shown.

When the instrument is operated in Inrush or Flicker m ode t he region at the bottom of t he s cr een

is used to display a summary of those measurements instead of the Harmonic Summary. In

Flicker mode two further display pages are available: one showing Voltage Variations and the

second Flicker Results. For full details, see the relevant chapter s in t his m anual.

13

With the Power Meter view displayed, pressing SET-UP shows the Power Meter set-up screen,

which gives access to the Setup Range soft-key. In Flicker mode, it also gives access to the

Flicker and Voltage Variations result pages. See the Flicker Meter chapter for details.

Set-up Range

Pressing the Setup Range soft-key (on either the Meter or Waveform Graph views) changes

the display to a graphical view of the current waveform with three fur ther soft-keys: Up, Down

and Lock Range. Pressing any of these turns off aut o-ranging; the Lock Range key keeps

the present measurement rang e, while the Up and Down keys change the range in x2 and ÷2

steps respectively. The scaling of the waveform display changes to reflect t he peak capability of

the new range and the maximum current is shown in the bottom left-hand corner of the display;

for example, 1500mA peak means that the top of the display represents +1500mA and the

bottom represents –1500mA with respect to the centre zero line.

The range can be set fr om 24m A peak to 400A peak in 2:1 steps. The waveform display on this

set-up screen is always updated every cycle, regardless of the mode set up for the Waveform

Graph view.

Important Note: To take compliance quality measurements the range must not change during

the test. The user must select a range that will accommodate the highest waveform peak t hat will

be encountered during the load’s operating cycle. It is therefore recommended t hat a preliminary

assessment of the load should be made, with t he inst r um ent in auto-range mode, to determine

the highest peak current operating condition. The instrument s hould then be lock ed on t his r ange

to ensure that harmonics measurem ents ar e cor r ec t and t hat the derived values (Average, Max

Hold and Min Hold etc.) are meaningful.

Power Meter Set-up

If too low a range is chosen, no damage will be done, but all the m easurement results will be

invalid and the message Overload will show in the status line at the top of the Meter View display.

It is more important to maintain adequate ‘headroom’ for the measurement, i.e. to avoid overload,

than it is to maximise the vertical resolution on t he Wavefor m Graph view; measurement

accuracy is maintained even when the vertical scaling of the display is well below optim um .

Once the range is locked, the Lock Range soft-key label becomes Auto Range; pressing

this key releases the lock and allows the instrument to aut o-range on the present waveform.

Several other soft-keys 'toggle' between alternate choices in this way; it is only necessary to

remember that at any time the sof t -key box shows what will happen when the key is pressed.

Having set the range (or selected auto-range), the previous view can be recalled by pressing the

VIEW key.

Auto-ranging is only available in Harmonics operating mode (see the Test Control section). Note

that auto-ranging is disabled while the LOAD switch is OFF to prevent the instr um ent autoranging to the most sensit ive rang e when there is no load current. At switch-on the default range

is 3A peak if the LOAD switch is OFF; at other times, switching the LOAD to OFF lock s the range

at the setting currently in use.

In Flicker mode with voltage sensing, the current range can be manually changed, but should be

left at a setting that avoids overload at any time during t he test (otherwise the test will be

needlessly aborted). When the current sensing method is selected, the range is fixed to suit the

requirements of the reference impedance calculations and cannot be changed.

14

On selecting Peak Inrush mode, t he highest current range is initially set, but it c an be m anually

changed as required.

The Voltage range is determined by the Nominal Voltage value which must be declared on the

Test Control set -up menu to match the actual supply voltage.

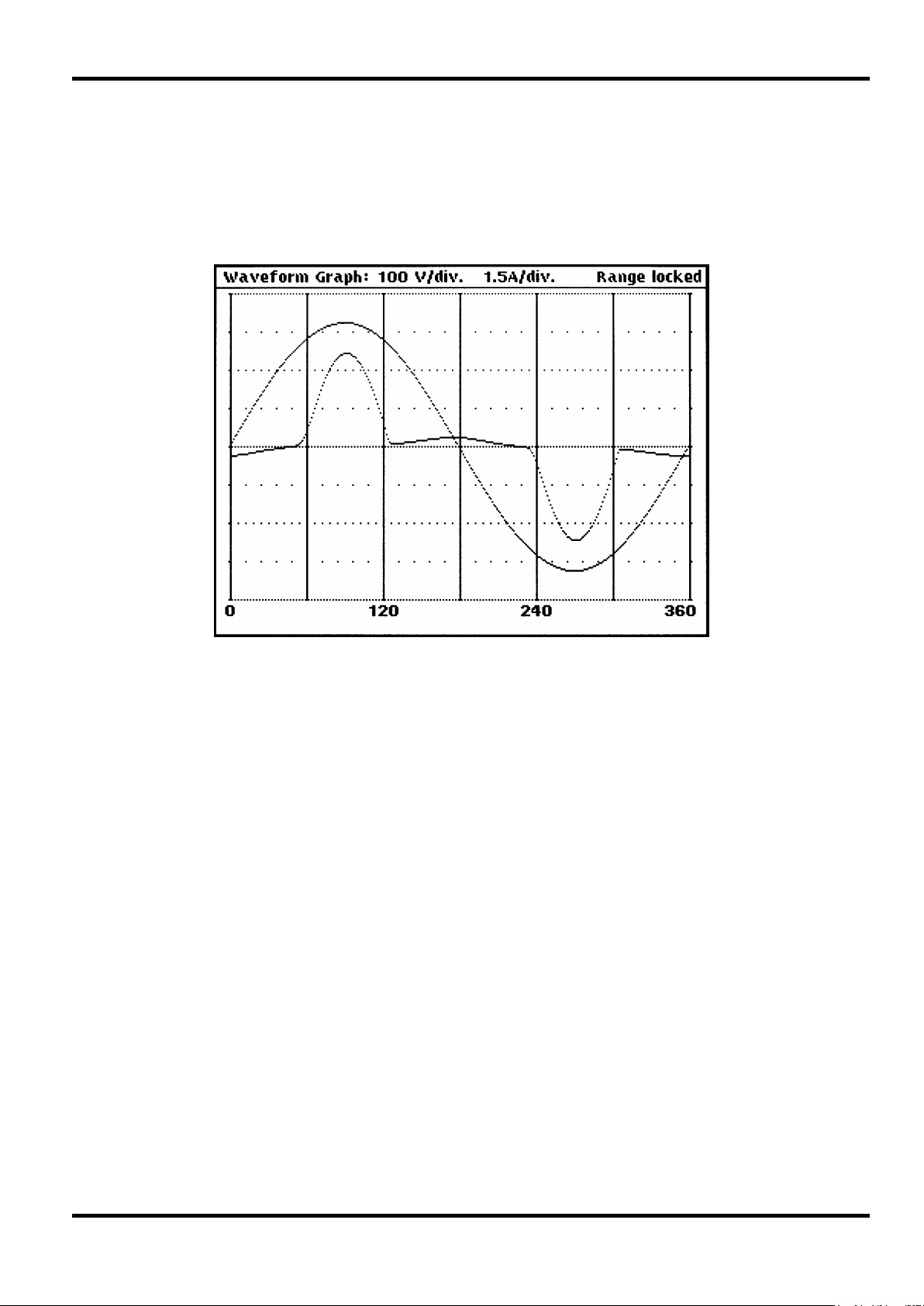

Waveform Graph View

The Waveform Graph display (which is the default display at instr um ent switch on) can be

selected by pressing the WAVE key whenever the green VIEW lamp is lit. The default form at of

the display is a full-screen view of both the voltage and current waveforms. The f or m at of the

display can be changed in various ways as described in the Waveform Graph Set-up sec t ion

below.

At the top of the display the scaling f or bot h voltage and cur r ent are given. There are 8 divisions

vertically, t hus 100mA/div is the sc aling shown if t he ± 400mA peak range has been selected

on the set-up screen. In auto-r ange mode (the default condition) the m ost sensitive range that

gives an in-range display is automatically selected. To avoid excessive range changes when the

measurement is near a range boundary the instr ument auto-ranges up at full-scale and aut oranges down at about 0.44 times full-scale.

The voltage display has two ranges only: 100V/div, for nominal 230V supplies, and 50V/div for

nominal 115V supplies; the voltage range is set from the value of t he nominal voltage which

must be declared on the Test Contr ol set-up display.

The X-axis of the single cycle display is divided into 6 divisions, each representing 60° of phase.

The rising zero-crossing point of the single voltage waveform cycle displayed is positioned at the

left edge of the display for t he default selection of voltage as the Trigger Source; this will change

if alternative Trigger Sources are selected, see Trigger Source section.

The X-axis is marked every 180º of the 2 cycle display and every cycle of the 4 and 10 cycle

displays.

When measur ing low power lighting eq uipm ent < 25 Watts to the Class C rules specifying

waveform phase angle requirements, the bot t om line of this screen reports the phase angles of

the start of conduction, the last current peak and the end of conduct ion. There are also t wo

graphical markers (short vertical lines above and below the centre line) showing the assessed

position of the last current peak in each half cycle.

15

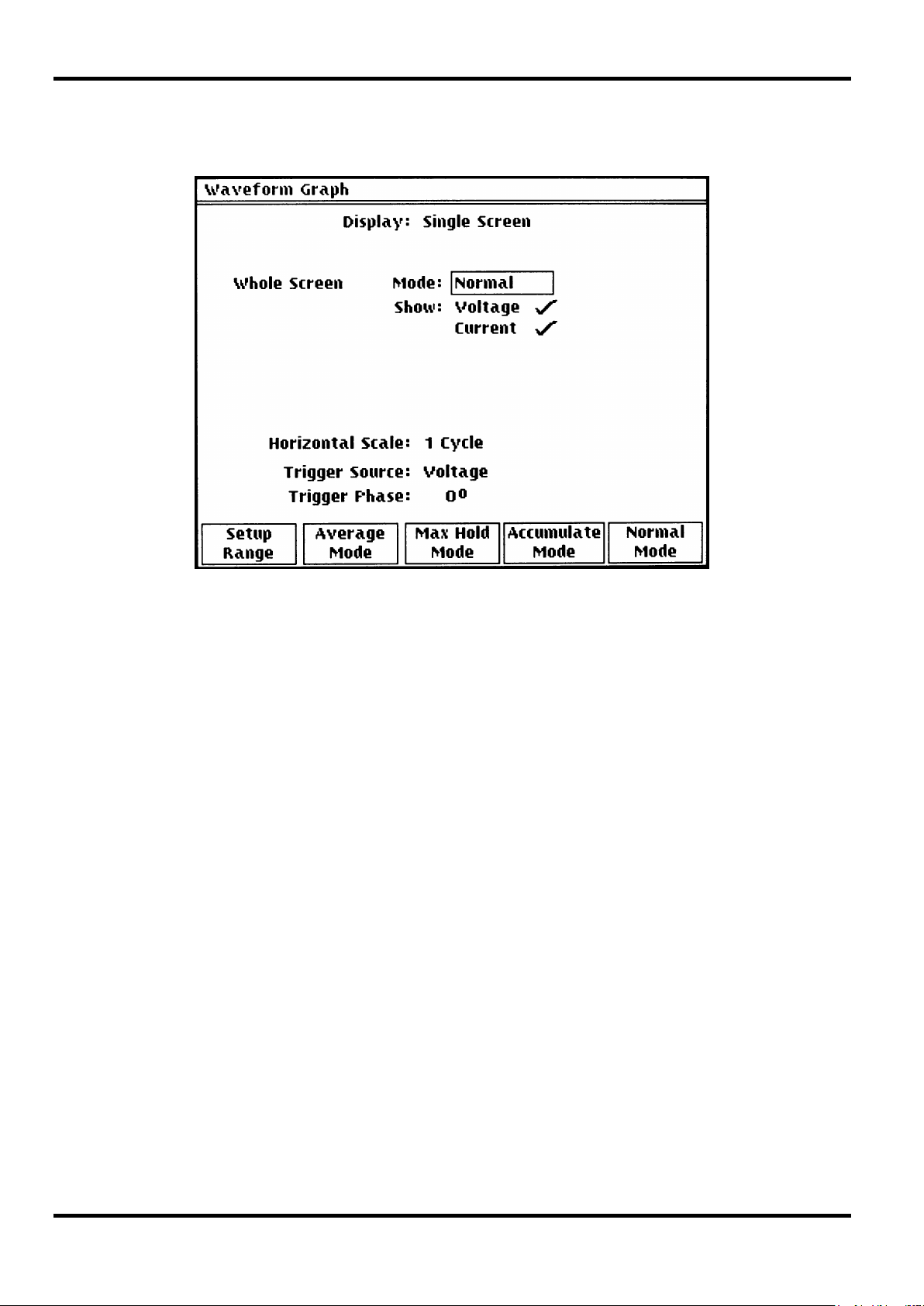

Waveform Graph Set-up

With the Waveform Graph view displayed, pressing SET-UP shows the Waveform Graph set-up

screen.

With the exception of the Setup Range key, the functions of the soft-keys change as the edit

zone is moved through the editable fields of the display using the

described below. Pressing the VIEW key returns the display to the W avef orm Graph view.

Set-up Range

Pressing the Setup Range soft-key (on either the Meter or Waveform Graph views) changes

the display to a graphical view of the current waveform with three fur ther soft-keys: Up, Down

and Lock Range. Pressing any of these turns off aut o-ranging; the Lock Range key keeps

the present measurement rang e, while the Up and Down keys change the range in x2 and ÷2

steps respectively. The scaling of the waveform display changes to reflect t he peak capability of

the new range and the maximum current is shown in the bottom left-hand corner of the display;

for example, 1500mA peak means that the top of the display represents +1500mA and the

bottom represents –1500mA with respect to the centre zero line. The range can be set from

24mA peak to 400A peak in 2: 1 s t eps. The waveform display on this set-up screen is always

updated every cycle, regardless of the mode set up for the Waveform G r aph view.

Important Note: To take compliance quality measurements the range must not change during

the test. The user must select a range that will accommodate the highest waveform peak t hat will

be encountered during the load’s operating cycle. It is therefore recommended t hat a preliminary

assessment of the load should be made, with t he inst r um ent in auto-range mode, to determine

the highest peak current operating condition. The instrument s hould then be lock ed on t his r ange

to ensure that harmonics measurem ents ar e cor r ec t and t hat the derived values (Average, Max

Hold and Min Hold etc.) are meaningful.

keys; each field is

16

If too low a range is chosen, no damage will be done but all the m easur em ent results will be

invalid and the message Overload will show in the status line at the top of the Meter View display.

It is more important to maintain adequate ‘headroom’ for the measurement, i.e. to avoid overload,

than it is to maximise the vertical resolution on t he Wavefor m Graph view; measurement

accuracy is maintained even when the vertical scaling of the display is well below optimum.

Normal:

The display is updated every waveform cycle. This is the default mode.

(see Traces section below).

necessary to lock the current range, see Set-up Range section above.

8 cycles. This mode offers a degree of noise reduction.

Screen

Once the range is locked, the Lock Range soft-key label becomes Auto Range; pressing

this key releases the lock and allows the instrument to aut o-range on the present waveform.

Several other soft-keys 'toggle' between alternate choices in this way; it is only necessary to

remember that at any time the sof t -key box shows what will happen when the key is pressed.

Auto-ranging is only available in Harmonics operating mode (see the Test Control section). Note

that auto-ranging is disabled while the LOAD switch is OFF to prevent the instr ument autoranging to the most sensit ive rang e when there is no load current. At switch-on the default range

is 3A peak if the LOAD switch is OFF; at other times, switching the LOAD to OFF lock s the range

at the setting currently in use.

In Flicker mode with voltage sensing, the current range can be manually changed, but should be

left at a setting that avoids overload at any time during t he test. W hen cur rent sensing is

selected, the range is fixed to suit t he r equirements of the calculations and cannot be changed.

On selecting Peak Inrush mode, t he highest current range is initially set; it can be manually

changed as required.

Having set the range (or selected auto-range), the Wavefor m G r aph view can be recalled by

pressing the VIEW key.

With the edit zone in the Screen field, the soft-key choices are Single Screen and

Split Screen. The default mode is Single Screen, which uses the whole display with

8 vertical divisions. Split Screen chang es t he sc r een int o 2 separat e displays, each with

4 vertical divisions; this is particularly useful when the current waveform is essentially in phase

with the voltage and displaying both together would cause confusion. At the same time the

Waveform Graph set-up display changes to add extra editable fields (mode and Traces) for the

second display, s ee below.

Mode

With the edit zone in the mode field the soft-key choices are as follows:

Accumulate:

Max Hold:

The display is written with every waveform cycle, without erasing the previous

data. A history of the waveform is built on t he s cr een, which means that shortterm aberrations can be captured.

The Accumulated display is lost when the view is changed, and can be

manually cleared at any time by pressing the VIEW key twice. Since it is also

automatically cleared at every range change it may be necessary to lock t he

current range, see Set-up Rang e s ect ion above. For clar ity, it is recommended

that only one waveform be accumulated, by selecting either Voltage or Current

The display is updated every waveform cycle with the greater of the new and

existing value at every point on the display.

The Max Hold algorithm keeps the largest amplitude (posit ive or neg at ive) for

each pixel. This often results in an apparent small discontinuity in the

maximum hold waveform at the zero-crossing point.

The Max Hold data can be manually reset at any time by pressing the START

key. It is also automatically reset at every range change, so it m ay be

Average:

The display is updated every waveform cycle with a rolling average of the last

When split screen is selected, the modes for the upper and lower screens can be set

independently. Changing between single screen and split screen will also change the

modes to those last used for that screen set-up. The modes are maintained when the

view is changed.

17