pag 1 of 201

SERVICE AND INSTALLATION MANUAL

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 2 of 201

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 3 of 201

Index:

1. Safety.................................................................................................... 10

1.1. Convensions ..................................................................................................... 10

1.2. Safety systems .................................................................................................. 15

1.3. Resuming operation after an emergency stop .................................................. 17

1.4. General Safety precautions............................................................................... 19

1.5. Protection and safety regulation ........................................................................ 19

1.6. Warnings and precaustions............................................................................... 19

1.7. General safety warning ..................................................................................... 21

1.8. Radiation protection warnings ........................................................................... 21

1.9. Electrical safety device ..................................................................................... 21

1.10. Exsplosion hazard ............................................................................................. 22

1.11. Risk associated witj cleaning the device ........................................................... 22

1.12. X-ray emission safety ........................................................................................ 22

1.13. Regulations, laws and normative reference ...................................................... 22

2. General Information............................................................................. 23

2.1. Labels ............................................................................................................... 23

2.2. Technical data ................................................................................................... 31

3. Panoramic view of the system ............................................................ 60

3.1. Description of the system .................................................................................. 60

4. Transport and moving ......................................................................... 65

4.1. Contents of the delivery .................................................................................... 65

4.2. Packing characteristic ................................ ....................................................... 65

4.3. Components inside the gantry packing ............................................................. 66

4.4. Components inside the AWS packing ............................................................... 67

4.5. Lifting and moving of packing ............................................................................ 68

4.6. Storage of packed equipment ........................................................................... 69

4.7. Removing the gantry from the pack .................................................................. 71

4.8. Removing the AWS from the pack .................................................................... 72

4.9. Disposal of the packing ..................................................................................... 72

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 4 of 201

4.10. Instructions for the handling, storing and packing of digital detector ................. 73

5. Installation ........................................................................................... 77

5.1. Ambient requirements conditions ...................................................................... 77

5.2. Preliminary radiology room inspection .............................................................. 78

5.3. Preliminary mechanical clamping inspection..................................................... 78

5.4. Installation procedure ........................................................................................ 79

6. Preliminary operating check ............................................................... 87

6.1. Checks before using the unit............................................................................. 87

6.2. Initial start-up .................................................................................................... 88

6.3. Troubleshooting before initial start-up ............................................................... 90

6.4. Quality checks before clinical application .......................................................... 92

6.5. Connection to the DICOM ntework ................................................................... 92

6.6. Operator instructions ......................................................................................... 93

7. Method of use ...................................................................................... 94

7.1. Equipment ......................................................................................................... 94

7.2. Acquisizione Work Station .............................................................................. 109

7.3. System Messages ........................................................................................... 114

7.4. Patient Registration ......................................................................................... 115

7.5. Exposure data setting ..................................................................................... 117

7.6. Performing the exposure ................................................................................. 118

7.7. Printing the exam images ............................................................................... 122

7.8. Concluding the exam ...................................................................................... 122

7.9. Manually sending images to other DICOM workstation .................................. 122

8. Image quality assessment ................................................................ 124

8.1. AEC Test for Installation ................................................................................. 125

8.2. Dose Calibration check ................................................................................... 133

8.3. Image Honogeneity and defective element evaluation .................................... 134

9. Components diagnosis ..................................................................... 140

9.1. Geometry of acquisition setting ................................................................ ....... 140

9.2. Detector .......................................................................................................... 141

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 5 of 201

9.1. X-ray tube ....................................................................................................... 151

10. Electronic boards .......................................................................... 161

10.1. Electronic boards topographic diagram ........................................................... 161

10.2. I008 – Collimator board ................................................................................... 162

10.3. I009 Compressor board .................................................................................. 163

10.4. I009PB Compressor Piggy Back board ........................................................... 164

10.5. I010 Detector .................................................................................................. 165

10.6. I011 Biopsy board ........................................................................................... 166

10.7. I011AC Biopsy cabling switching .................................................................... 167

10.8. I012 Gantry boards ......................................................................................... 167

10.9. I013 SELEMA actuation .................................................................................. 168

10.10. I014 Gantry keyboard ..................................................................................... 168

10.11. I015 Tube keyboard ........................................................................................ 168

10.12. I017 Wireless foot pedals power board ........................................................... 169

10.13. I020 Power switching board ............................................................................ 169

10.14. I021 Operator control table command board .................................................. 170

10.15. I022 Operator control table Cabling switching board ...................................... 170

11. Maintenance .................................................................................. 171

11.1. Warnings on routine maintenance .................................................................. 171

11.2. Cleaning .......................................................................................................... 172

11.3. Preventive maintenance program ................................................................... 173

11.4. Disposal and scrapping of the obsolete equipment ......................................... 175

12. Breakdowns and diagnosis .......................................................... 176

12.1. Introduction ..................................................................................................... 176

12.2. Alarms management ....................................................................................... 177

12.3. List of alarms ................................................................................................... 180

13. Interventions on the equipment ................................................... 181

13.1. Introduction ..................................................................................................... 181

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 6 of 201

IMS S.r.l. All rights reserved.

No part of this manual can be reproduced, transmitted, transcribed or filed in a retrieval system or

translated into other languages in any form with any means without written consent from IMS S.r.l.

The buyer may reproduce copies for personal use.

This manual is considered an integral part of the equipment. It must be immediately replaced with

another copy if any part of it is ruined or illegible.

Before performing any type of operation on the equipment, IMS S.r.l. requires that anyone of any

title involved in using the equipment carefully read the entire contents of this manual, paying

special attention to the important warnings.

IMS S.r.l. may not be held responsible for the improper use of the equipment, and for damages

caused by unreasonable operations.

The equipment must only be used to meet the needs for which it was expressly designed. Any

other improper use is considered dangerous.

IMS S.r.l. is considered responsible for the equipment only if it is in its original configuration

determined in the design phase. Any modifications to the structure and the equipment’s operating

cycle must by expressly authorized by the IMS S.r.l. Technical Department.

IMS S.r.l. recommends that only original replacement parts be used and therefore cannot be held

responsible for any damages caused after the use of non-original replacement parts.

IMS S.r.l. reserves the right to modify the design and to make marketable improvements without

forewarning customers who already possess similar models.

IMS S.r.l. is considered responsible for the descriptions written in Italian. The translations cannot

be fully verified, therefore if the buyer finds a discrepancy in the text, this person should refer to the

Italian version and possibly contact our Technical Documentation Office, which will make any

necessary changes.

IMS S.r.l. would like to thank you for choosing one of our machines and we are sure that it will fully

satisfy your needs for a long period of time.

IMSS.r.l.

Internazionale Medico Scientifica

Via Sagittario 5 - 40037 Pontecchio Marconi - Bologna - Italy

Tel ++39 051 846851 - Fax ++39 051 846856

e-mail: Export Dept.: imscomm@imsitaly.com

Tecnical Dept.: imstech@imsitaly.com

http://www.imsitaly.com

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 7 of 201

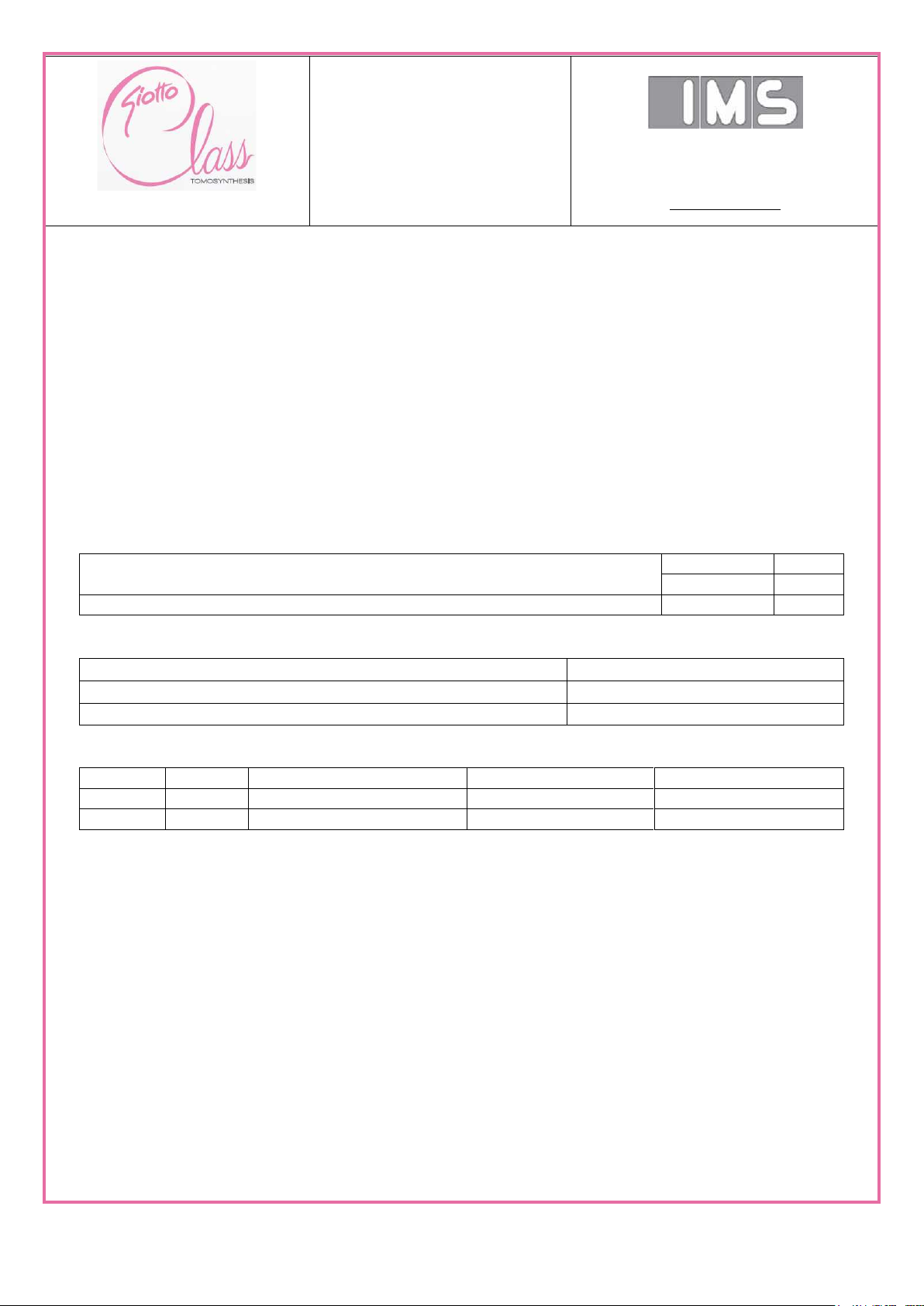

IEC 60601-1

Class

I

Type

B

Medical Device Directive 93/42/CE

Class

II B

DOCUMENT N°:

M189_EN

REVISON:

0.1

DATA:

01/07/15

N° REV.

DATE

Purpose of the revisions

Modified PAGES

Modified SECTION

01

01/07/15

Initial release

Intended use

The Giotto Class and its accessories are designed and built mammography examination for the

screening in modality of Full-Field Digital mammography (FFDM) and for diagnosis in modality of

Digital-Breast Tomosynthesis (DBT) for breast cancer detection and cannot be used for other

examinations or for purposes other than those specified by the Manufacturer. Its practical use is

therefore exclusively limited to personnel with medical training.

Using the accessory devices Smart Finder and Flexi table the system is able to perform

stereotactic biopsy examination with the optional possibility to perform the examination with patient

in prone position.

CE: 1936

CLASSIFICATION AND COMPLIANCE

REVISIONS OF THE MANUAL

Please comply with that reported in Section 1 - “Safety”.

Carefully read Section 1 - “Safety” before operating the equipment.

MANUFACTURER’S WARNINGS

This product has the CE marking in conformance with the provisions outlined in Annex II of

93/42/EEC of 14 June 1993 concerning medical devices.

The CE marking is only valid for technical medical products/medical devices put on the market

during the validity of the EC directive indicated above.

If modifications are made to the product without our authorization, the declaration will no longer be

valid.

The original version of this manual was drafted in Italian.

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 8 of 201

DO YOU HAVE ANYTHING TO REPORT WITH REGARD TO THIS MANUAL?

Your opinion means a great deal to us!

We strive to constantly improve the documentation of our equipment. To help do this, we give you

the opportunity to directly inform us of any need, suggestion or comment relating to this instruction

manual.

Use the following number to send notices via FAX:

• +39 051 846851.

If you prefer to communicate via e-mail, please use this address:

• imstech@imsitaly.com

In this case, please indicate the complete print reference code reported on the third page.

Thank you for your collaboration.

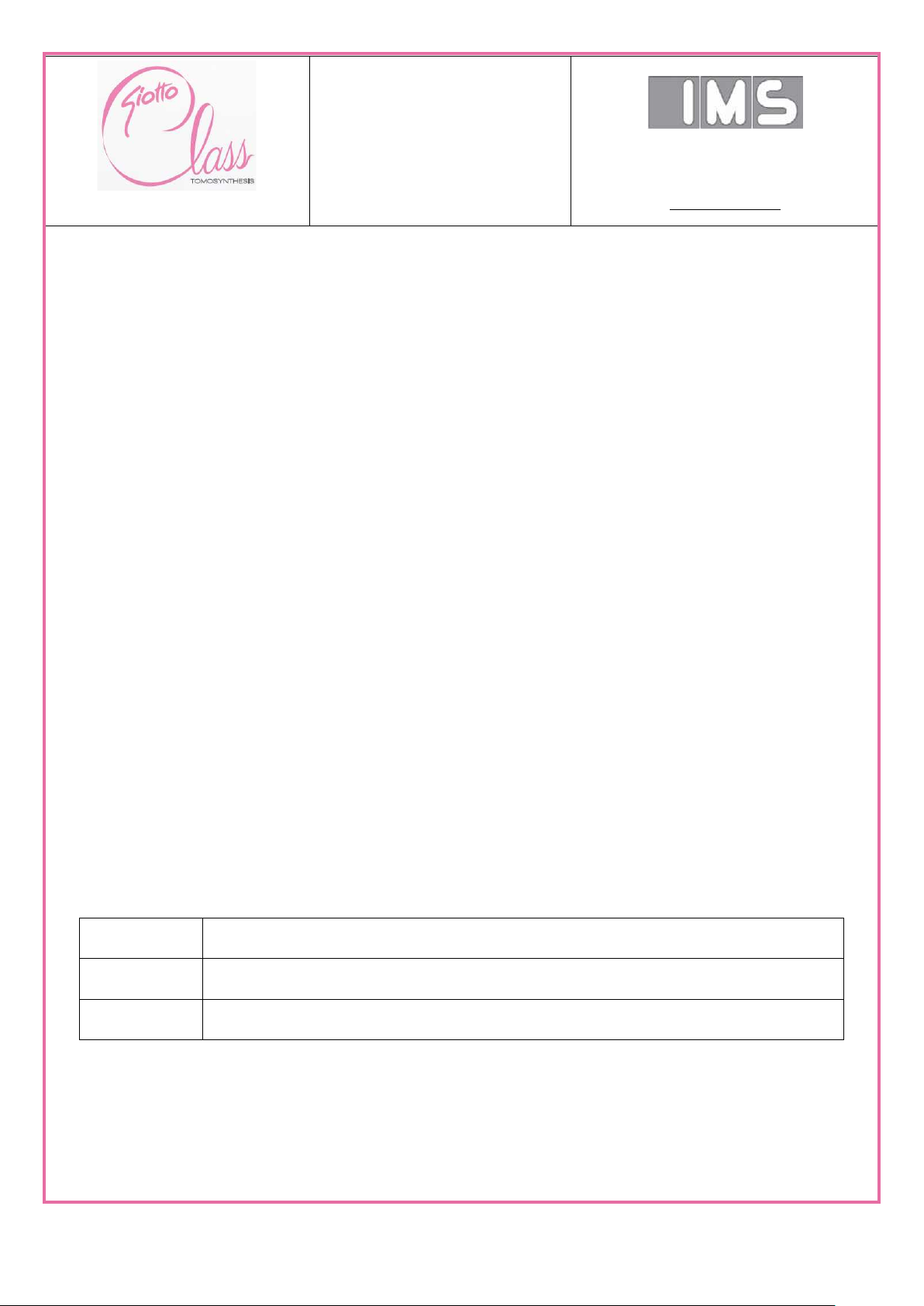

What I would like to report:

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Non-mandatory data

Name _________________________________________________________________________

Hospetal_______________________________________________________________________

City/Country ____________________________________________________________________

E-mail _________________________________________________________________________

Tel./Fax _______________________________________________________________________

Number of Fax pages ____________________________________________________________

M189_EN:

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 9 of 201

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 10 of 201

Sections

This manual is made up of various sections, the titles of which are reported in the

heading.

Paragraphs

Every section can have one or more paragraphs, the title of which is reported in

the text below the heading.

Page

numbers

The page footer shows the progressive page numbers.

1. Safety

1.1. Conventions

In order for the manual to be read quickly and rationally, symbols have been employed for

highlighting practical advice, simple information or situations in which great care must be taken.

Said symbols can be found alongside a section of text (and therefore refer only to that text),

alongside a figure (and refer to the subject illustrated in the figure and to the relative text) or at the

top of the page (in which case they refer to all the subjects treated on that page).

Pay maximum attention to the meaning of the symbols: their aim is not to have to repeat technical

concepts or safety warnings and therefore should be considered as proper “reminders”.

Thus, refer to the list of symbols whenever doubts arise as to their meaning. The symbols shown

in the following pages are not found on the device or its accessory parts; they are only present

in this manual. The series of the manuals supplied with the device usually contains some

documents not made up by I.M.S. S.r.l., which could use edition symbols that are graphically

different from the ones shown in this publication. Therefore, it is advisable to consult all the

documents supplied in order to “store” all the subjects for which the symbols themselves have

been used.

It is important not to confuse the edition symbols on the device with the “safety” plates, which are

applied in predetermined points on the device, auxiliary units, etc...

1.1.1. Structure of the manual

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 11 of 201

Instruction

Fornisce istruzioni sul corretto utilizzo dell’apparecchiatura.

Questo testo è preceduto da un rombo.

LIST OF

EXPLANATORY

TEXT

–

This text is preceded by a dot.

Divides an instruction or a list into various sub-parts.

This text is preceded by a dash.

REFERENCE

Refers to more detailed instructions reported in another page

of the manual or another document.

This text is marked by an arrow.

NOTE

This is used in two ways:

highlights important safety information, without which there is an

immediate risk

contains a summary of the main information regarding a subject matter

This text is highlighted inside a grey box.

Menu

The names of the menus are in bold type.

WARNING

Firstly, the source of the danger is indicated.

The possible consequences are then reported.

Finally, you are informed on how to avoid the danger.

LIFT ONLY FROM THE TOP

Operations that require the use of qualified personnel and specific equipment, and the

respect of the conditions stated by the Manufacturer and current regulations.

1.1.2. Text formatting

This manual contains certain text formats that are helpful in understanding the function of the text

more quickly.

The following characters were used:

1.1.3. Warning, caustions and information

The icons in a box give information .

The symbols in a triangle are DANGER/WARNING symbols.

The symbols in a circle represent an OBLIGATION/PROHIBITION..

1.1.3.1. Warning

Warnings indicate the possible presence of risks for the health and safety of patients, operators

and third parties.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 12 of 201

CAUTION

Firstly, the source of the danger is indicated.

The possible consequences are then reported.

Finally, you are informed on how to eliminate the danger.

NO!

Operations to be absolutely avoided.

INFORMATION

Il relativo testo è scritto in corsivo dentro il box grigio

EQUIPMENT TURNED OFF

With electrical power supplies isolated

OBLIGATION symbols

Use PROTECTIVE GLOVES

This symbol indicates that the maintenance engineer must wear protection

gloves to avoid injuries.

Use PROTECTIVE GLASSES

This symbol indicates that the maintenance engineer must wear protective

glasses to avoid injuries

PROHIBITION symbols

No MAINTENANCE/REPAIRS ON MOVING MEMBERS

It is forbidden to repair, adjust, clean or lubricate moving members of the

machine

HAZARD/CAUTION symbols

CAUTION: ELECTRIC SHOCK HAZARD

It indicates the presence of electric devices and powered components and

warns the operator against electric shock hazards.

The electric maintenance engineer is the only operator that is qualified to carry

out adjustments or maintenance of the electric cabinets and junction boxes

CAUTION!

It indicates the presence of ionizing radiation.

1.1.1.1. Caution

This indication reports that an incorrect command could cause minor injuries or damage to the

equipment.

1.1.1.1. Information

This indication provides further explanations about an issue.

1.1.1.1. Safety symbols

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 13 of 201

SYMBOLS FOR THE MANUALS

THIS OPERATOR MANUAL

Descriptions inherent to this manual.

SUBCONTRACTING MANUALS

Consult the attached documents relating to subcontracting.

OPERATORS

Radiological technician: the person in charge of preparing the equipment,

positioning the patient and performing the mammography examination,

according to the indications given by the doctor.

Doctor: the person who visits the patient in advance in order to decide the

examination method. This person observes the plates taken by the radiological

technician. He/she carries out the invasive operations (biopsy) on the patient.

Mechanical maintenance personnel: qualified technician able to intervene

on the mechanical parts of the equipment to perform any necessary

maintenance interventions and repairs. This person is not qualified to work

on live-electrical circuits.

Electrician: qualified technician able to carry out any necessary interventions

of an electrical or electronic nature. This person is qualified to work on live-

electrical circuits.

Manufacturer’s technician: qualified personnel provided by the Manufacturer

to perform complex operations under particular situations or when agreed

upon with the Buyer

1.1.1.1. Manuals symbols

1.1.1.1. Qualification of the personnel in charge with operation of the

equipment

The operators that have access to the equipment must be specifically qualified, trained and

responsible for the tasks they are in charge with.

A description of the professional qualifications of the operators and maintenance personnel is

given below. Each profile is graphically described by an icon.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 14 of 201

INFORMATION

In some figures the equipment may be highly equipped or outfitted with optional

accessories.

INFORMATION

A test report shall be filed in I.M.S. S.r.l. archive.

The names and data of all the patients and devices used in this manual as examples are fictitious.

Any similarity or correspondence to the actual names of people or institutions are purely

coincidental.

All the parameters and images reported in this manual are examples. The parameters seen in your

system are determining factors.

1.1.1. Regulations and laws

If there are regulations with legal implications for the installation and/or use of the device, the

installer and user must respect them. The national standards must be respected in every country.

With the exception of that given in this manual, the values can be set based on the national

standards.

This product has the CE marking in conformance with the provisions contained in directive

93/42/EEC of 14 June 1993 concerning medical devices,

Personal data are protected.

Please respect the regulations pertaining to this matter. During the manufacturing phase, the

equipment is checked according to applicable product standards.

The tests to be performed at the equipment installation site are the responsibility of the customer.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 15 of 201

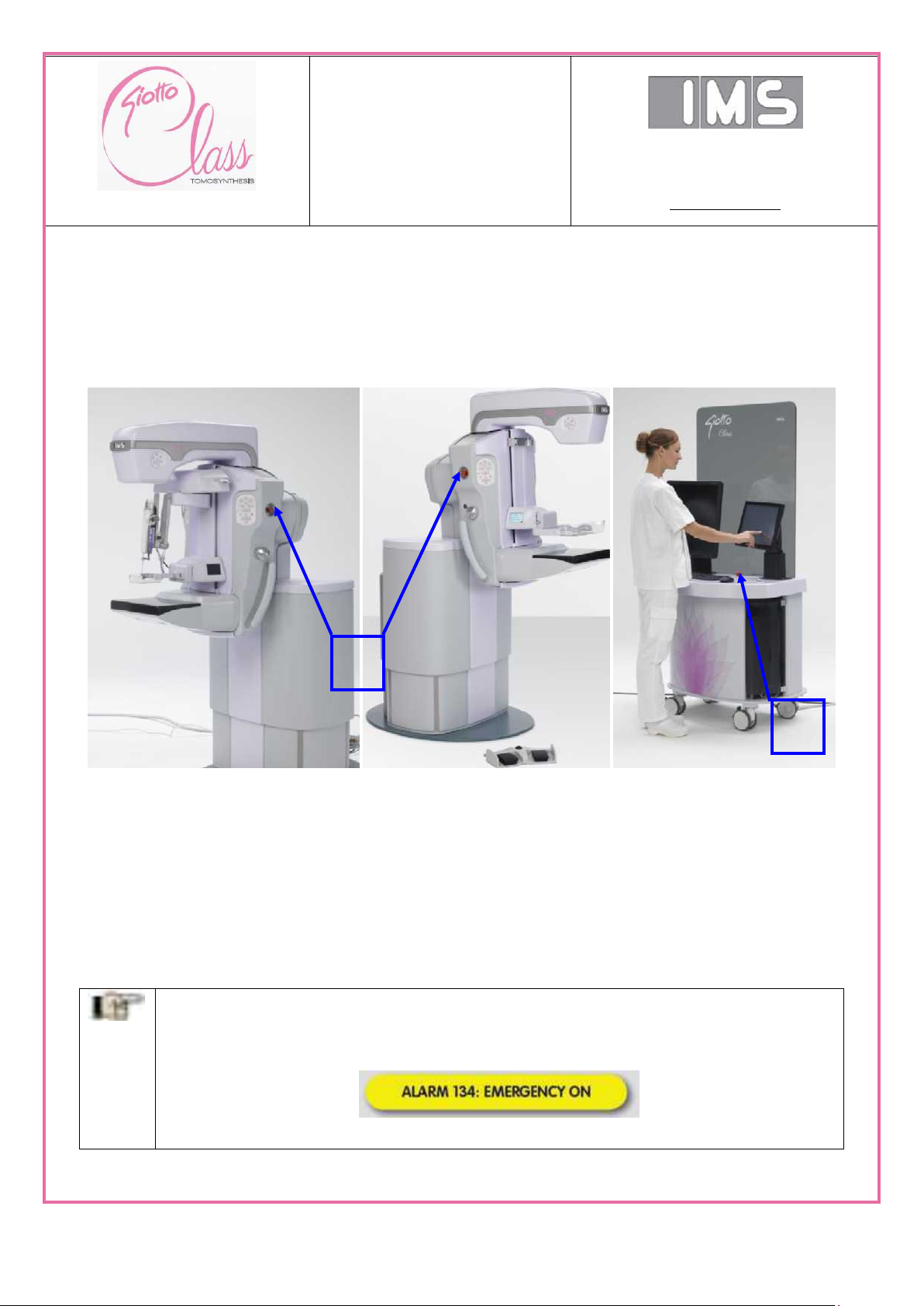

INFORMATION

After pressing one of these three emergency stop buttons, the following message

appears on the touchscreen panel

and an acoustic signal is simultaneously emitted.

1

2

1.2. Safety systems

1.2.1. Emergency stop buttons

Three emergency stop buttons are installed on the equipment described in this manual. If

pressed, they immediately stop all equipment functions.

1) EMERGENCY STOP button located on both sides of the vertical X-ray unit (GANTRY) near two

columns push-button panels.

2) EMERGENCY STOP button located on control table of the acquisition workstation (AWS).

Never use the emergency stop button as a normal stop device to immediately stop all functions of

the equipment, but only in cases of an actual emergency and if malfunctions occur.

After the EMERGENCY STOP button has been activated, keep in mind the following:

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 16 of 201

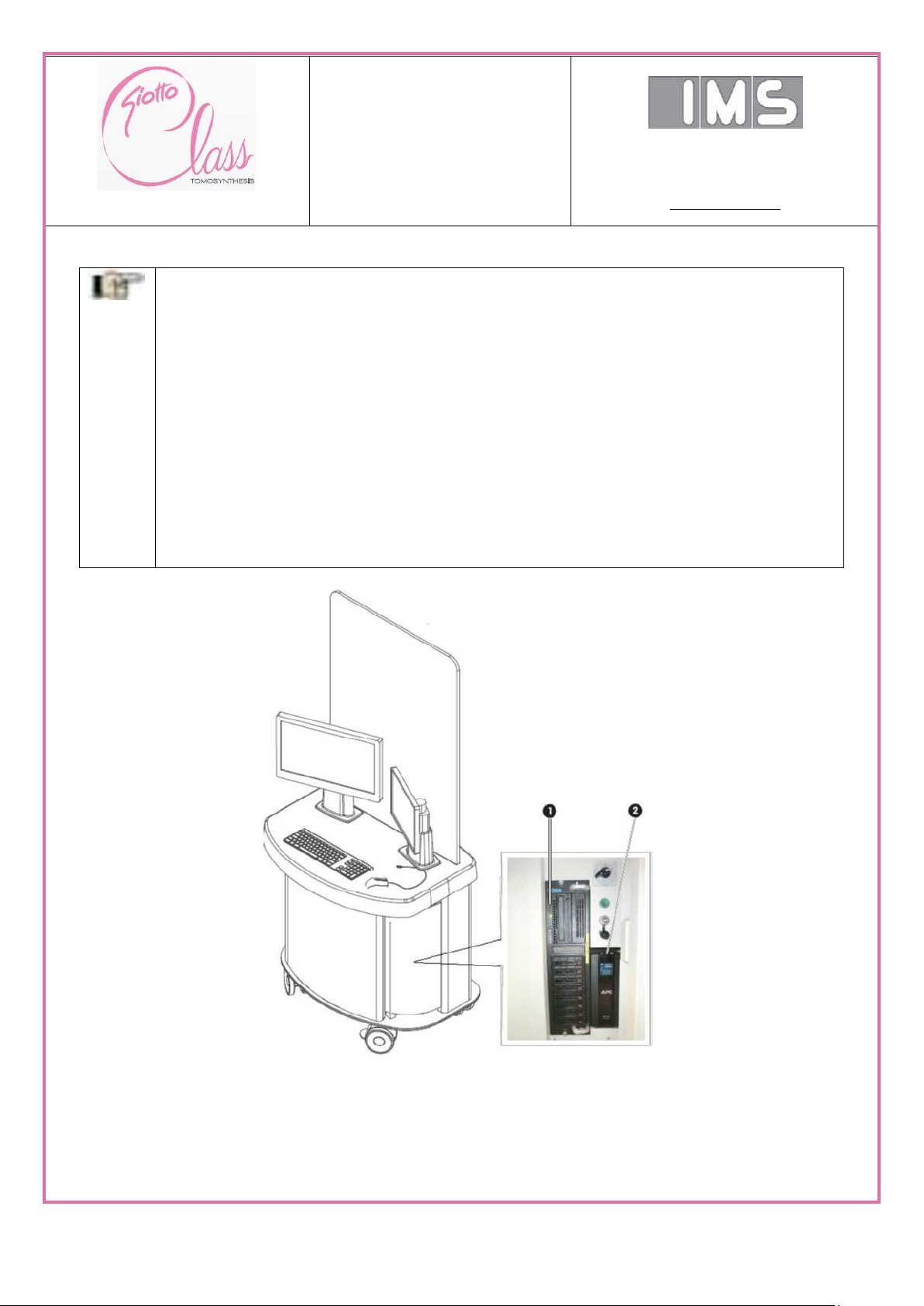

INFORMATION

The emergency stop button does not cut power to the workstation 1. The workstation

is also protected by an uninterruptible power supply UPS 2. The UPS takes power

from the equipment’s circuit; thus turning on “0” position the main switch, the UPS

switches to the batteries and the operator is informed of this operation by an acoustic

signal.

In the case of a power interruption, only the AWS acquisition workstation is powered

by the UPS for a few minutes (depending on the state of the battery). When the

battery of the uninterruptible power supply reaches 20%, the workstation

automatically turns off, following the operating system’s safety sequence.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 17 of 201

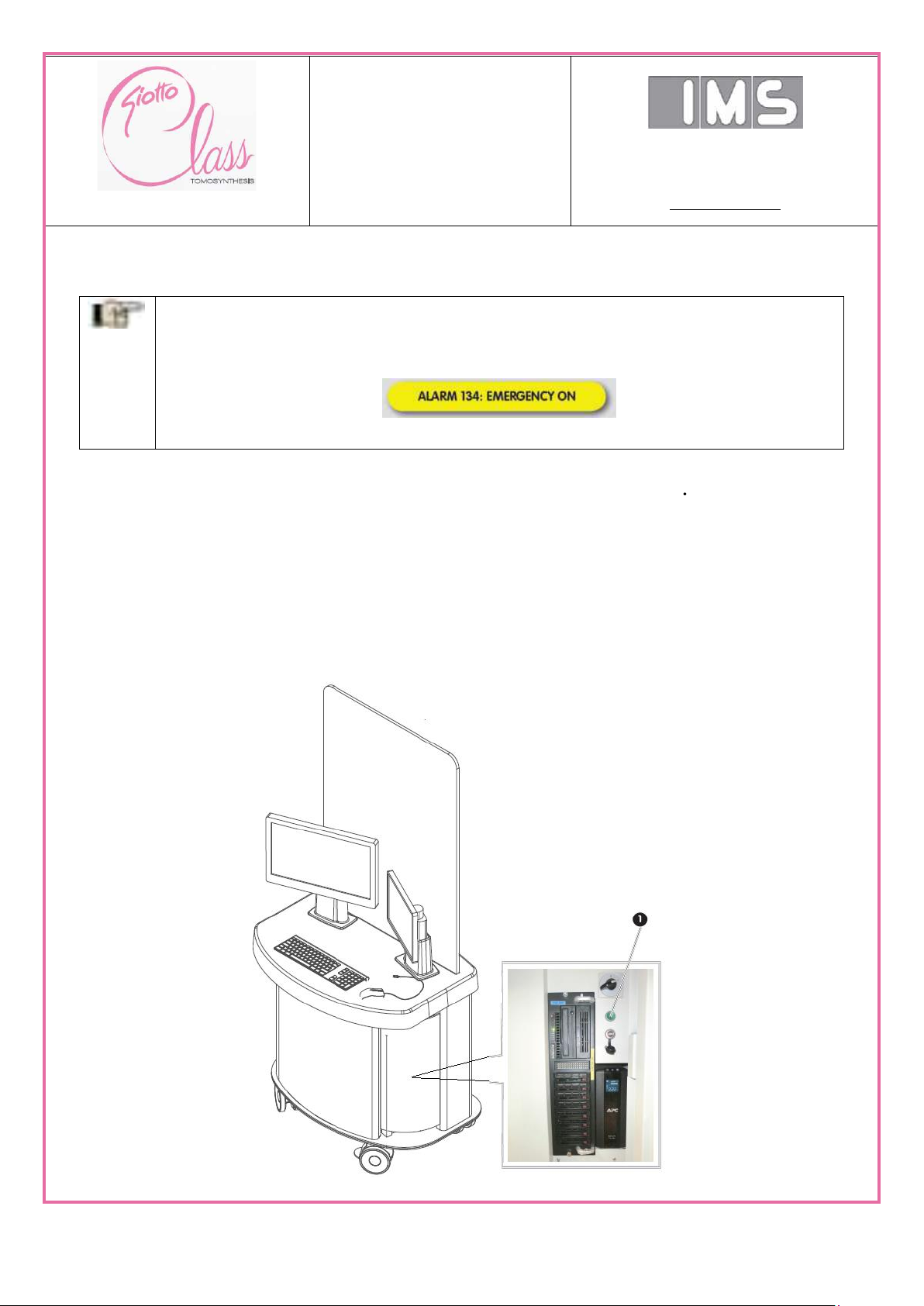

INFORMATION

After pressing one of these three emergency stop buttons, the following message

appears on the touchscreen panel

and an acoustic signal is simultaneously emitted.

1.3. Resuming operation after an emergency stop

Release the pressed emergency stop button by turning it (slightly). The acoustic signal will be

silenced and the alarm message on the touch screen panel will disappear ( see Section 12 -

“Breakdowns and diagnosis”).

To resume operations, press the engage circuits push-button 1 sited on the acquisition

workstation control table switching it to the “OFF” position (LED off). What a few seconds and

then press the engage circuits pushbutton 1 again, switching it to the “ON” position (LED on).

If the cause of the stop has been eliminated, the device will then be operational again.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 18 of 201

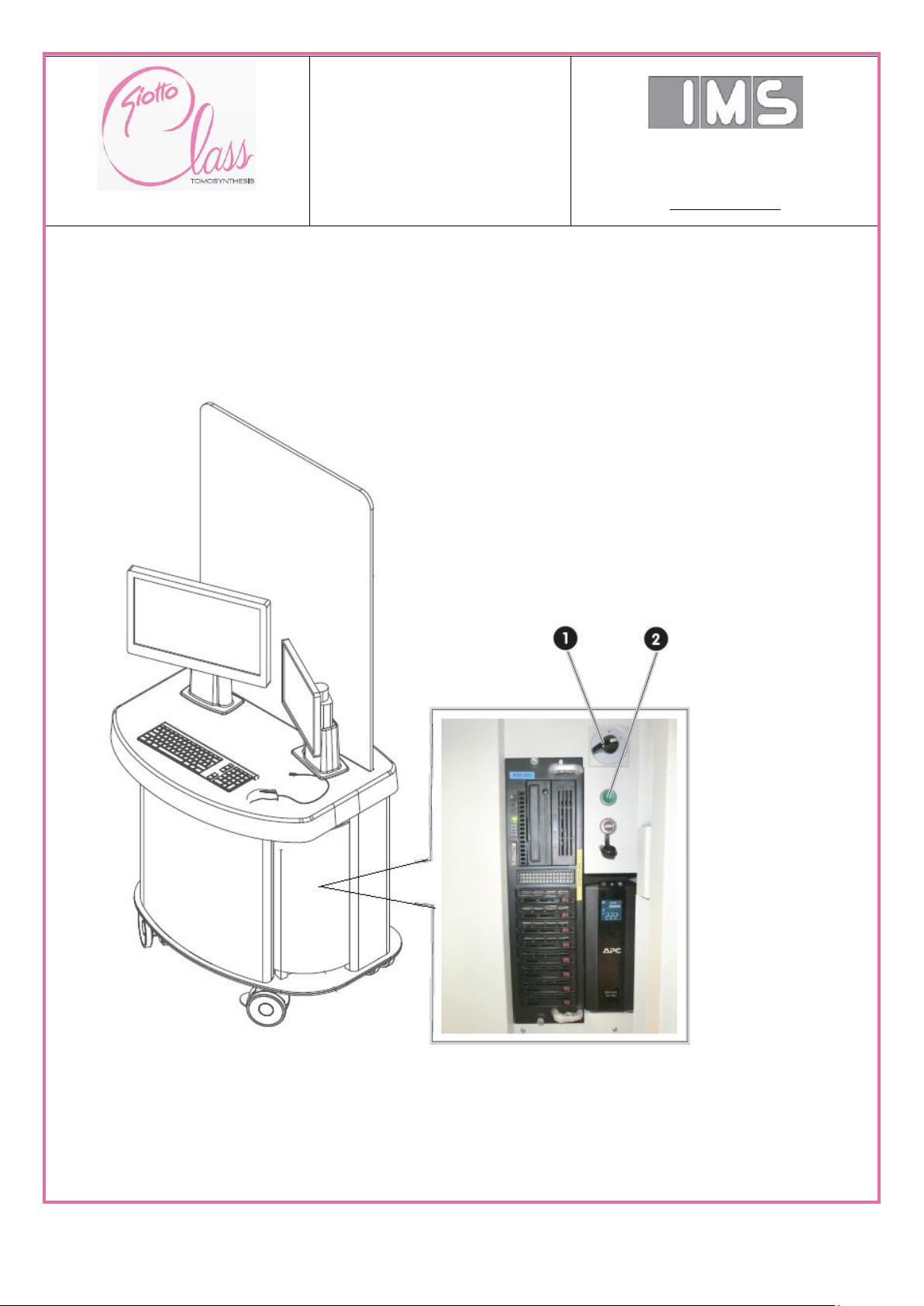

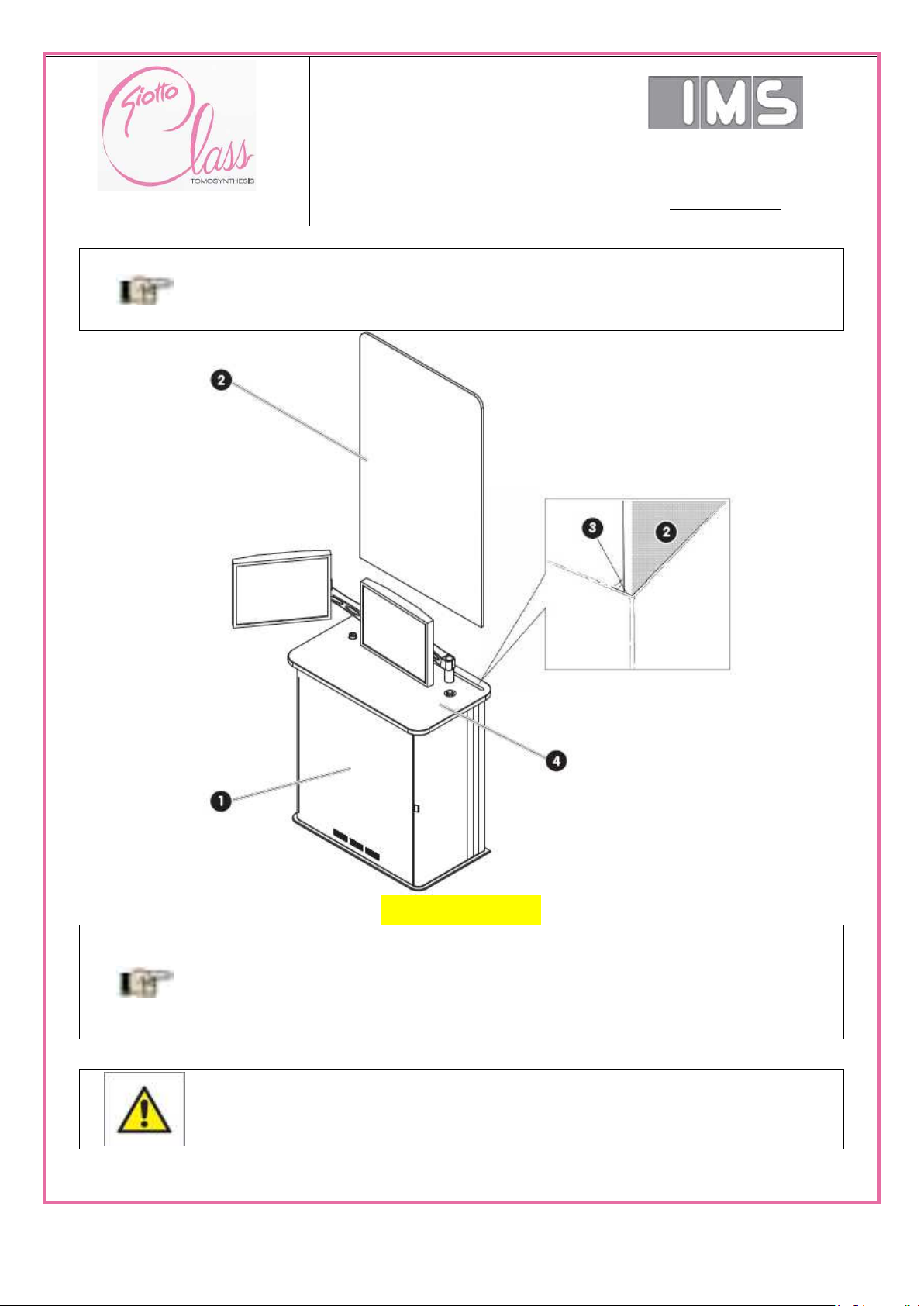

1.3.1. Control and signals

The acquisition workstation has a main switch 1, an engage circuits push button 2 and a touch

screen panel 3 that is used to control and monitor the appliance. The touch screen panel displays

set parameters and alarm messages.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 19 of 201

1.4. General Safety precautions

• The device may be dangerous to the patient and operator if the X-ray exposure values and

operating instructions are not respected. Observe all operating and safety instructions before

performing an X-ray exam.

• Check the following before installation: observance of minimal safety regulations, location and

operating efficiency of the equipment, measuring ambient conditions (temperature, humidity and

lighting) and checking the suitability of the work space.

• Always work with suitable clothing and the required personal protective equipment.

• While X-rays are being emitted, the operator must remain shielded behind the X-ray lead glass

panel supplied with the vertical X-ray unit (GANTRY).

1.5. Protection and safety regulation

• The person who is about to activate the radiological device must check that nobody else is in the

room, that the doors are closed and that all those present are protected by walls or by shielded

doors.

• During X-ray emissions, always stay behind the X-ray lead glass panel.

• Whenever necessary, always wear the personal dose-meter.

• Reduce the size of the beam and the value of the radiological parameters to a minimum (voltage,

current and radiography time) in so far as they are compatible with the diagnostic needs.

1.6. Warnings and precaustions

• The following is strictly forbidden: tampering with the equipment, controls and safety devices.

• Any modifications or tampering, however slight. The use of non-original spare parts, or spare

parts that are not compatible with the quality standards and electro-mechanical characteristics

specified by the Manufacturer, shall relieve the Manufacturer of all liability and shall void the

warranty rights.

• It is strictly forbidden to place and/or leave objects or anything else not foreseen by the

Manufacturer on the equipment that is potentially harmful to the safety of persons or the integrity of

the equipment.

• Carefully read the steps in this manual that are marked: “INFORMATION” and “CAUTION”.

• If you have any requests, always indicate the model and serial number of the equipment.

• Access to the workstation is password protected.

• It is forbidden to modify the configuration of the workstation.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 20 of 201

CAUTION!

It is strictly forbidden to operate the equipment if it is not permanently fixed to

the floor. Refer to the relative Section.

Mechanical group

List of screws

Reference draw

• It is forbidden to install software different from the original software that was installed by I.M.S.

S.r.l. service personnel.

• The workstation can be connected to a LAN/WAN network, but the user is responsible for

protecting against viruses, intrusions or data leaks.

• The AWS acquisition workstation TFT monitor can only be used for QA before diagnosis. No

clinical evaluation is allowed.

• Diagnosis can be done both through analysis of laser printed images and the images on the

workstation of reporting workstation (RWS) (optional). The monitor type and performance must

comply with the I.M.S. S.r.l. specifications.

• The “DICOM CD” function of the “Raffaello” appliction software is not built for the permanent

filing of data.

This function is only used for data transfer.

• The “Raffaello” application software installed on the AWS acquisition workstation is able to

store a certain number of examinations (the number depends on the capacity of the hard disks).

This archive is not a legal archive, so any lost data is not the responsibility of I.M.S. S.r.l..

1.6.1. Mechanical safety

The assembly procedure of some part of the device can be critical for the functionality of the device

itself and to assure the safety performance of fine movement.

Following the list of screws and bolt must be used for each critical mechanical group.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 21 of 201

CAUTION!

X-ray machines can be extremely dangerous to the patient and the operator if

the specified protective measures are not scrupulously observed

1.7. General safety warning

The device was designed and built in compliance with the most severe safety Regulations and left

our production plant in perfect working order. In order to ensure that these conditions are

maintained and that the device is used correctly, the technician must follow the instructions

contained in this manual.

RESIDUAL RISKS

• Although the equipment described in this manual was built in full compliance with the most

severe safety Regulations, the emission of X-rays is a potential hazard and the equipment

therefore cannot be used or handled by unappointed, unqualified, or unauthorized personnel.

• Over-exposure to X-rays can cause serious damage to the human body.

• Although X-ray radiation is in itself dangerous, the GIOTTO TOMO equipment does not cause

any dangerous conditions if used correctly.

• It is therefore essential that all technical and healthcare personnel be suitably informed and

instructed with regard to the hazards of X-ray exposure.

1.8. Radiation protection warnings

• Exposure to X-rays is a health hazard, and therefore great care should be taken in using

adequate means of protection. Radiation can accumulate over time and its effects can be

manifested after many years.

• Primary radiation is the most dangerous kind, therefore, avoid exposure; any object stuck by

primary radiation produces secondary radiation, which is also highly dangerous.

• The unit is equipped with an protective X-ray temperate glass screen coupled to the console,

which protects people against diffused radiation.

1.9. Electrical safety device

• The device must have an electrical supply line equipped with an earth circuit complying to current

Standards.

For any type of simple maintenance, such as cleaning the equipment, always disconnect it from

the mains to avoid damage to persons and/or the electrical - electronic part of the mammography

equipment.

• To ensure the isolation integrity for the system, use only I.M.S. S.r.l. approved accessories on the

equipment. Any changes to the interconnections must be performed by I.M.S. S.r.l. authorized

personnel.

• To ensure proper isolation maintain a 1.5 meter distance between the patient and any

devices not approved for use in the Patient Area. Devices not approved for use in the patient

area (such as the data management computer, the medical recording workstation, laser printers)

must not be installed in this area (see IEC 60601-1-1).

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 22 of 201

CAUTION!

In accordance with EN 60601-1, the unit must be permanently connected to

the electrical mains.

(The protective earth conductor must be connected directly to the protective

earth terminal of the electrical panel).

INFORMATION

A test report shall be filed in I.M.S. S.r.l. archive.

1.10. Exsplosion hazard

• Gas or flammable vapors cannot be used with this equipment.

• Some types of disinfectants could vaporize, thus forming an explosive mixture. If used, they must

be allowed to disperse before powering up the equipment.

1.11. Risk associated witj cleaning the device

• Gas or flammable vapors cannot be used with this equipment.

• Some types of disinfectants could vaporize, thus forming an explosive mixture. If used, they must

be allowed to disperse before powering up the equipment.

1.12. X-ray emission safety

The device uses two separate methods to assure that the generator doesn’t exceed the maximum

exposure limit.

a) A software counter that includes the anode current over time and stops the exposure when the

maximum time has been reached; the counter is protected by a watch dog circuit.

b) A hardware counter that cuts off the electrical power supply to the generator if the maximum

allowed exposure time is exceeded.

1.13. Regulations, laws and normative reference

If there are regulations with legal implications for the installation and/or use of the device, the

installer and user must respect them. The national standards must be respected in every country.

With the exception of that given in this manual, the values can be set based on the national

standards.

This product has the CE marking in conformance with the provisions contained in directive

93/42/EEC of 14 June 1993 concerning medical devices,

Personal data are protected.

Please respect the regulations pertaining to this matter. During the manufacturing phase, the

equipment is checked according to applicable product standards.

The tests to be performed at the equipment installation site are the responsibility of the customer.

M189_EN:Safety

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 23 of 201

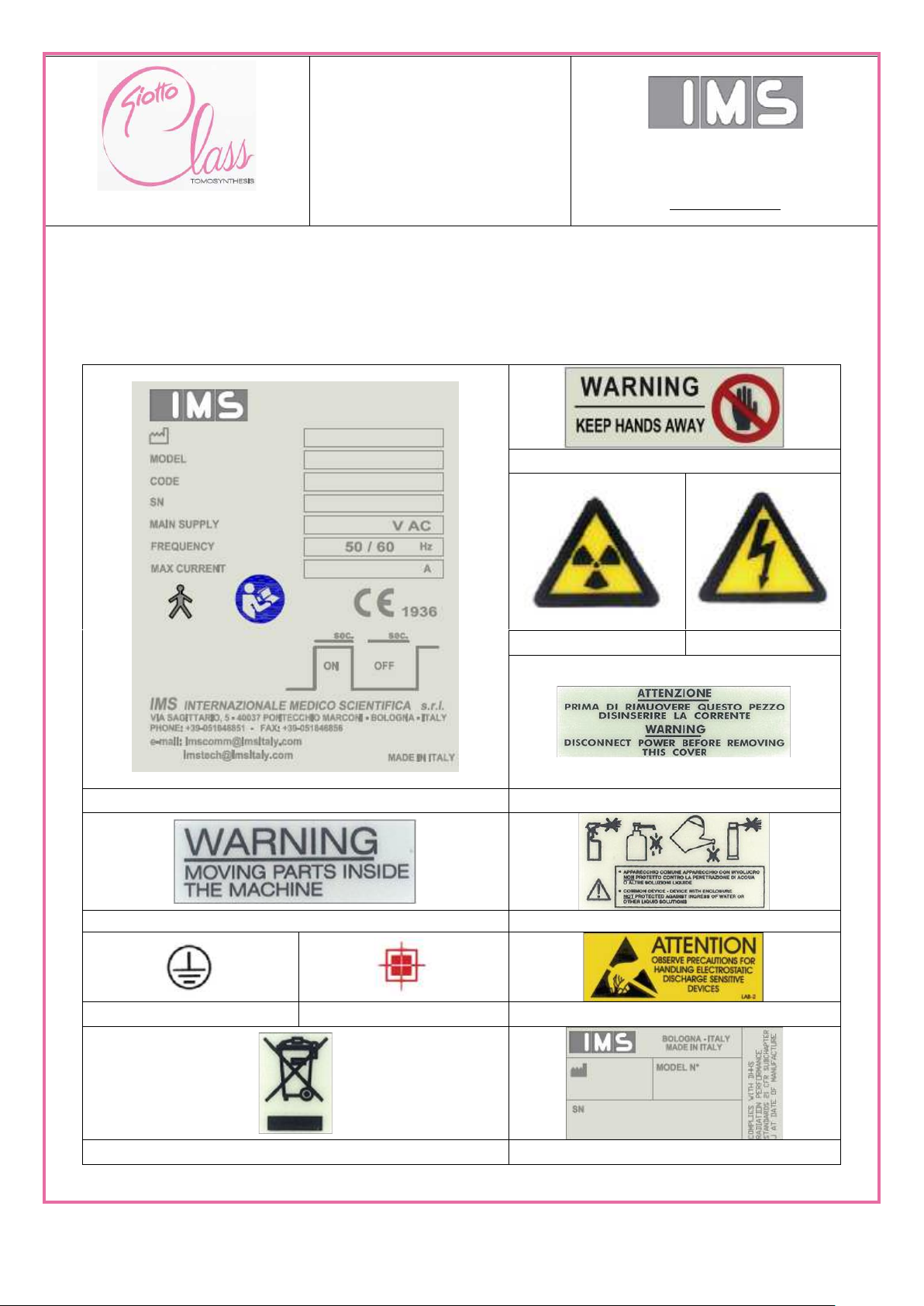

Keep the hands away

Radiation

High Tension

Main Identification label

Parts under voltage

Moving part

IPX0 Protection class label

Earth point

Focal Spot

Electrostatic discharge

WEEE Label

Component Identification

2. General Information

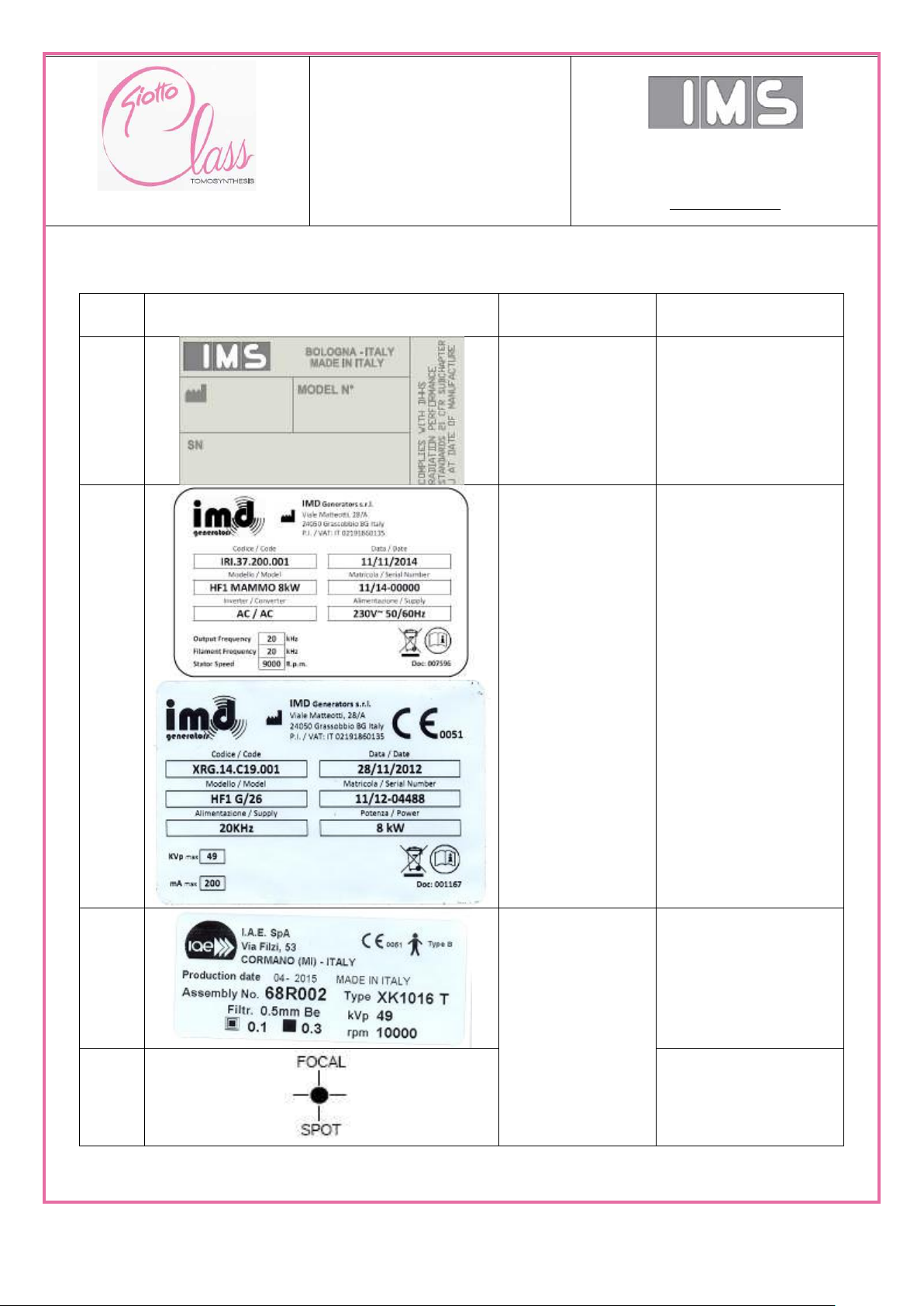

2.1. Labels

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 24 of 201

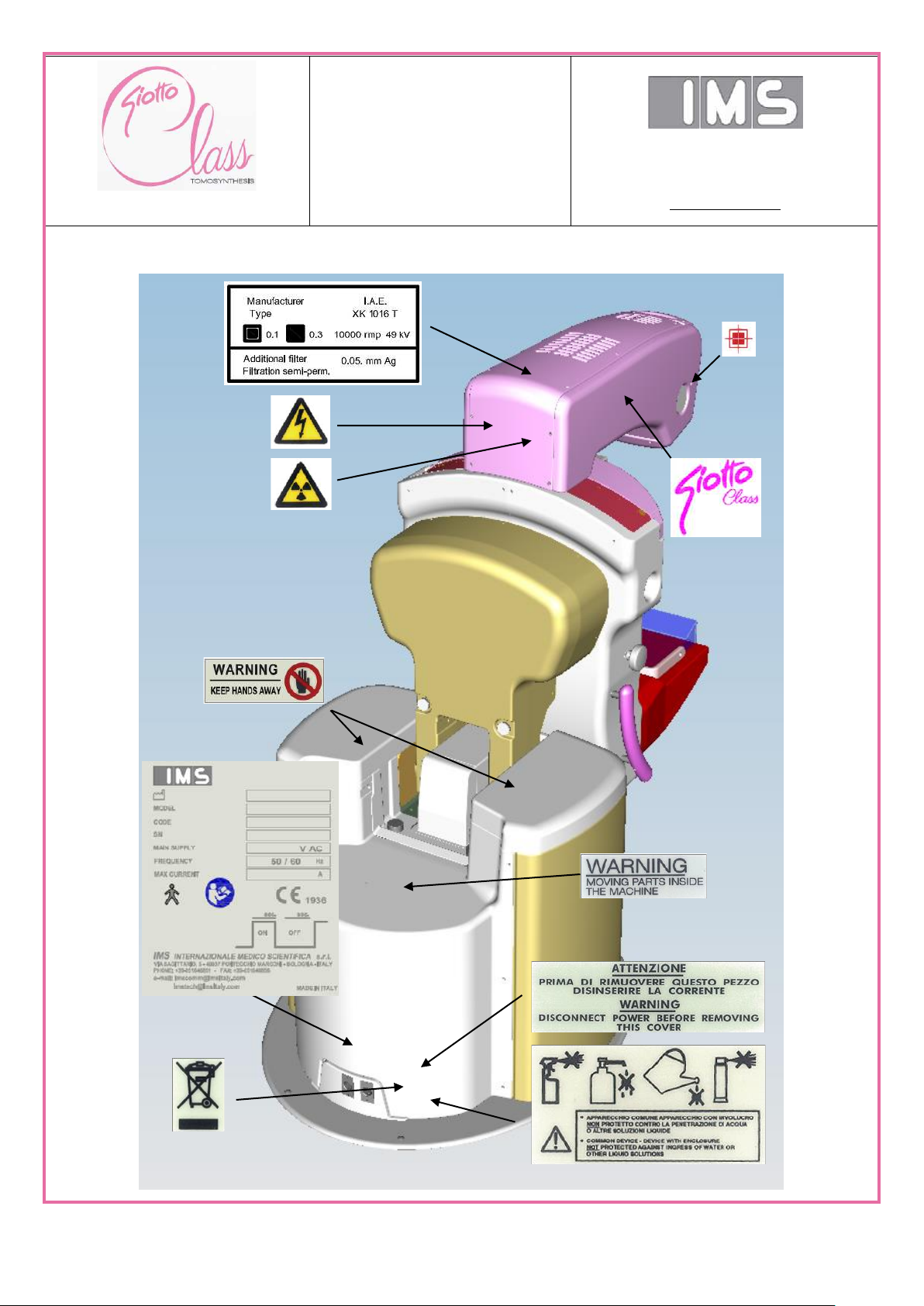

2.1.1. Labels on the X-ray unit

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 25 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 26 of 201

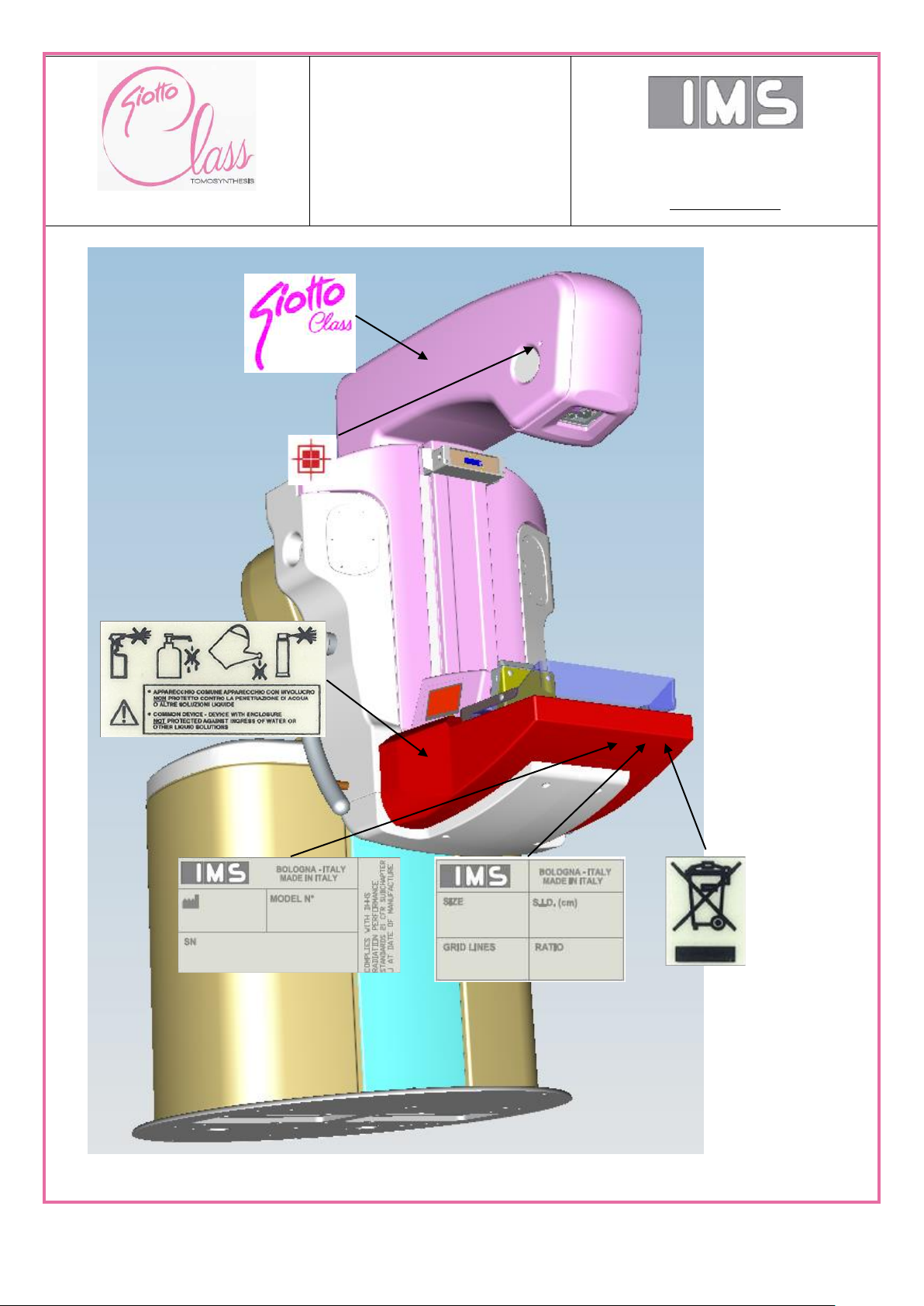

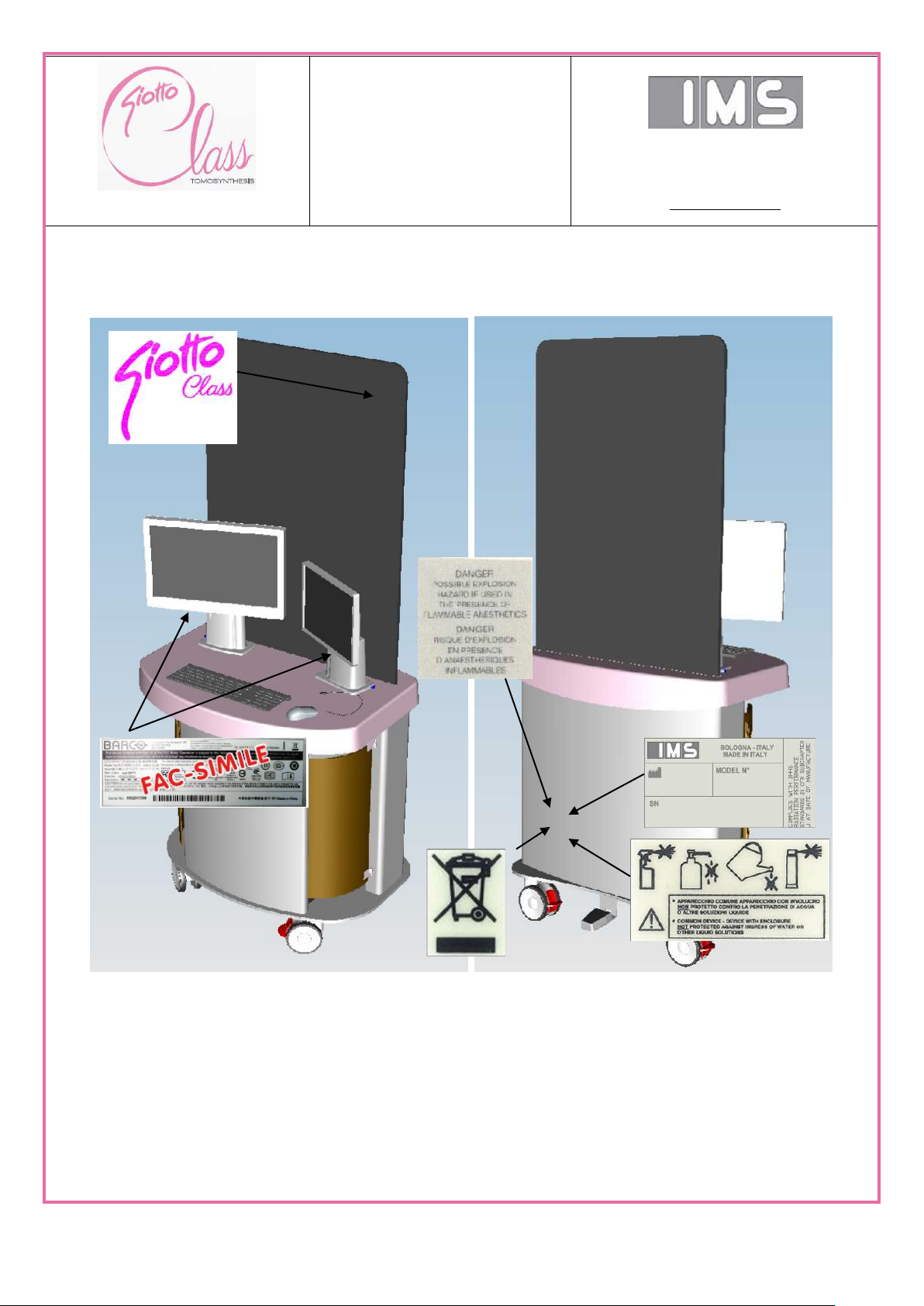

2.1.2. Labels on the operator console (AWS)

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 27 of 201

Label

ID

Label

Component

Description

1

IMS accessory

Identification data

2

High-Voltage

Generator

Identification data

3

X-ray tube:

Identification data

4

Focal spot position

2.1.3. Labels on the internal component

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 28 of 201

Label

ID

Label

Component

Description

4

Earth point

5

Vertical

movement motor

Identification data

6

Anti-scatter grid

Identification and

specifications data

7

INSERIRE IMMAGINE CON

IDENTIFICAZIONE E HVL

Collimator

Identification and

specifications data

8

Monitor

Identification data

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 29 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 30 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 31 of 201

Min

Max

Humidity

10%

80%

Temperature

-10 °C = 14 °F

80 °C = 176 °F

Atmospheric pressure

700 hPa

1060 hPa

WARNING

If the equipment is stored while packed, do not stack the packing crates on top of one

another.

Min

Max

Humidity

10%

95%

Temperature

5 °C = 41 °F

45 °C = 113 °F

Atmospheric pressure

700 hPa

1060 hPa

WARNING

If the equipment is stored while packed, do not stack the packing crates on top of one

another.

CAUTION

Do not stack other crates on top of the digital detector crate!!!

CAUTION

If the temperature is below 5 °C or is over 45 °C, there is a risk of permanent damage

to the digital detector.

2.2. Technical data

The equipment can only be used in rooms designed for medical use.

The current national standards apply. In order to ensure the safety of users, patients and third

parties, it is recommended that you fully comply with the standards mentioned in this document

(unless they are inconsistent with the national standards).

THIS IS A DRAFT VERSION; ALL THE DATA WITH THE * MARK ARE UNDER REVISION.

2.2.1.1. X-ray unit and operator console storage conditions

2.2.1.1. Digital image receptor storage conditions

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 32 of 201

Temperature range

From +12 °C to +27 °C.

If the detector internal temperature drops below 5 °C or exceeds

45 °C, there is a risk that the detector may be permanently

damaged.

Maximum ratio

0 °C in 20 minutes

Relative humidity

range

Up to 95% non condensing

Maximum warm-up

time for operation

10 minutes

Tension

230 VAC ± 10%, 50/60 Hz ± 5%,

single phase, permanent connection

Maximum Power

25 A – 230 VAC duty cycle 3s ON 60s OFF*

Fuses

40 A*

Permanent connection with

protective conductor

Required network filter with minimum attenuation of 10

dB*

2.2.1.2. Operating conditions

2.2.1.3. Enclosures protection class

The Giotto Class is a IPXO protection class device. Device is not sealed, not suitable for

use in the presence of flammable anesthetic mixture from the air, oxygen, or nitrogen

oxides.

2.2.1.4. Electrical power supply

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 33 of 201

Vertical movement

Total 630 mm (850 mm with consequence of inclination

movement)

Potter/Bucky - Floor:

(unit in vertical position)

Min: 630 mm

Max: 1260 mm

Potter/Bucky - Floor:

(unit in horizontal position)

Min: 1360 mm

Max: 1990 mm

Gantry rotation range

- 177.0° / + 177.0° (Motorized)

Gantry inclination range

- 15.0° / + 90.0 ° (Motorized)

Angular range of emission

- 14.5° / + 14.5 ° (Motorized)

Source-to-Image Distance (SID)

685 mm

Source-to-Breast Support Distance

668 mm

Magnification factor

1.8 X (optional)

Dimension of x-ray unit

(H x W x D)

147.6 x 80.0 x 149.8 cm (in vertical position)

Dimension of operator console unit

(H x W x D)

195.0 x 88.6 x 66.0 cm *

Weight of x-ray unit

270 kg

Weight of operator console unit

120 kg

Weight of Flexi Table

250 kg

2.2.1.5. X-ray unit specifications

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 34 of 201

SOURCE-to-IMAGE DISTANCE (SID), DIRECT FOCAL DISTANCE, and SOURCE-to AXIS

ROTATION DISTANCE (SAD)

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 35 of 201

Actuator type

Stepper Motor - Pedal or Manually with control knob

Maximum compressor force

200 N (motorized) 300 N (manual)

Minimum Force for AEC activation

5 N

Compression Force accuracy

± 1 kg

Compression Thickness

± 2 mm

Release after exposure

Automatic or manually in case of inhibition by operator

Compression velocity

2 mm/s during approaching 1 mm/s during compression *

Compressor plates material

PET-G

Compressor plate maximum flexion

< 5 mm for asymmetric compression

Compressor plate absorption

16.5% ÷ 0.003 mm Al for 28 kV W/Ag

2.2.1.6. Breast compression system

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 36 of 201

Manufacturer

IMD Generators

Model

HF1 Mammo 8kW

Input power supply

(Inverter + Filament +

Stator power supply)

Single phase 230VAC 50/60Hz

Rated input max power

11 kVApk (max 32Apk) Depending on the exposure

parameters

Max input current

protection breakers

32A 400 Vac aM 20 kA

Recommended thermomagnetic circuit breaker

Un = 230 Vac 50/60 Hz

In = 32 A;

Number of poles = 2

Protection class

C as per IEC-EN 60898

Power output

Single phase 20 kHz (Max 210 VAC

rms

)

Filament power board

output:

Single phase 16 kHz (Max 5.5 A

rms

)

Stator driver power board

output:

Single phase + shifted phase 150 Hz (Max 230 VAC

rms

/ 7Apk)

Inverter

Pulsed load output power

8 kW (200mA @ 40 kV 0,1 sec)

kV Range

22 - 49 kVDC

Max Ripple

< 1%

Max RAD mode load

output

200 mA @ 40 kV (0,1 sec)

Max frame per second rate

30 fps

Filament

Max load output power

65VA (5A @ 13V)

Stator driver

Steady state nominal

power

280 VA

Maximum surge power

(launch max 1msec)

1600 VA

2.2.1.7. High Voltage Generator specifications

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 37 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

High Voltage Generator Electrical connections

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 38 of 201

Terminals

Input / Output characteristic

CP1-1,2

Input power supply

(Inverter + Filament + Stator power

supply)

Single phase

230Vac 50/60Hz

Rated input max power

11kVApk

(max 32Apk)

Depending on the exposure

parameters

Max input current protection breakers

32A 400Vac aM 20kA

Recommended thermo-magnetic

circuit breaker

Un = 230Vac 50/60Hz

In = 32A

Number of poles = 2

Protection class = C

as per IEC-EN 60898

GND Screw

GND

Connected to the

Control unit chassis

CP2-1,2

Power output

Single phase

20kHz

(Max 210Vacrms )

CP3,1: (LF)

CP3,2: (SF)

CP3,3: (CM)

CP3,4: GND

Filament power board output:

(LF) = Large Focus

(SF) = Small focus

(CM) = Common

Single phase

16kHz

(Max 5.5Arms)

CP3,5: (P)

CP3,6: (S)

CP3,7: (C)

CP3,8: GND

Stator driver power board output:

(P) = Main phase

(S) = Shifted

(C) = Common

Single phase +

shifted phase

150Hz

(Max 230Vacrms / 7Apk)

2.2.1.8. High Voltage Generator Electric characteristics and I/O (power and

signals)

All the control unit interface connectors are from Molex (except power GND).

In order to connect the unit, following headers are needed:

CP1 = 2ways Minifit SR 42816 series connector

CP2 = 3ways Minifit SR 42816 series connector

CP3 = 8ways (4x2) Minifit Jr 5557 series connector

CP4 = 3ways Microfit 43645 series connector

CP5 = 4ways (2x2) Microfit 43645 series connector

CP6 = 6ways (3x2) Microfit 43020 series connector

GND = M5 brass nut

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 39 of 201

Terminals

Signal

Block diagram

1,3

(CP4-2: GND)

INPUT

CAN BUS

CP5-1,2

INPUT

Digital*

Command

X-Ray

CP5-3,4

OUTPUT

Digital*

HV > 85%

CP6-4,5

INPUT

Digital

Thermal safety

switch

This input manages the normally closed contact which comes

from the safety switch in the HV transformer.

CP6-1 mA+

CP6-2 mA-

INPUT

Analog

Feedback Anodic

mA

These inputs have to be connected to the load as indicated in

the chapter 8.3

Transport and storage conditions

Range of temperature

0° – 50° C

Relative humidity (non condensing)

20 – 90 %

Atmospheric pressure

700 – 1060 hPa

Working conditions

Range of temperature

10° – 40° C

Relative humidity (non condensing)

30 – 75 %

Atmospheric pressure

700 – 1060 hPa

2.2.1.9. High Voltage Generator: conditions of storage and usage

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 40 of 201

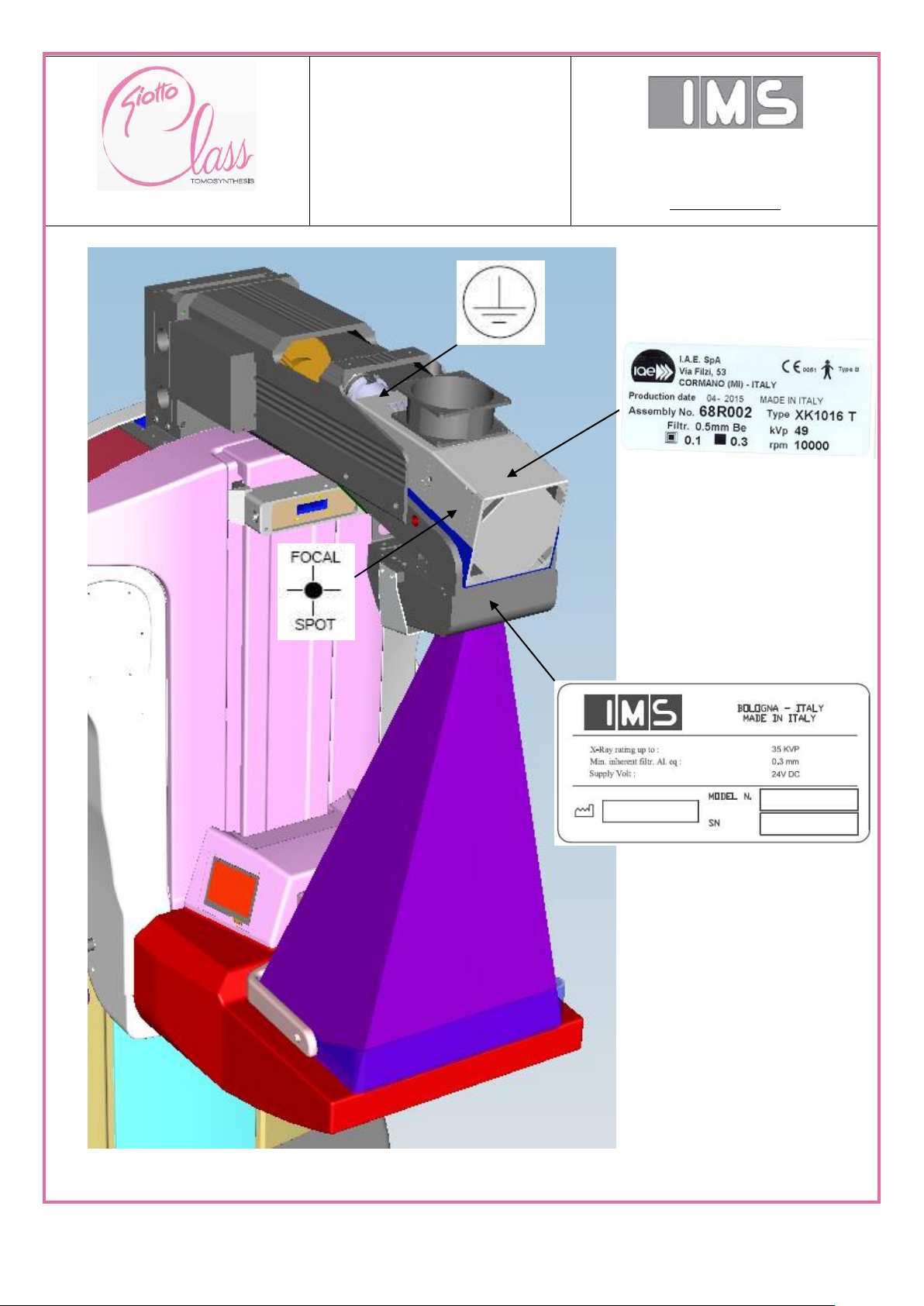

2.2.1.10. X-ray tube assembly

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 41 of 201

Manufacturer

I.A.E.

Model

XK116T

Focal Spot dimension

0.1-0.3 mm

Anode Angles

10°-16°

Anode rotation speed

3000-10000 rpm

Anodic Material

RT-TZM

Inherent Filtration

0.5 mm Be

Termal Anodic capacity

225 kJ - 300 kHU

Continuous anode heat dissipation

715 W

Maximum anode heat dissipation

750 W

Equivalent anode input power

100 W - 38% of max

Dimensions

110 x 155 x 305 mm

Weight

5.5 kg

Temperature condition

for transportation and storage

-10 / + 80 °C

Humidity condition

for transportation and storage

max 80 %

Maximum High Tension

49 kV

Maximum heat dissipation with fan

300 W

Maximum leakage radiation

at 1 m from focal spots

63 uGy/h - 7 mR/h

93/42/CEE Classification

IIb

IEC 60601-1 equipment class

I

IEC 60601-1 equipment type

B

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 42 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 43 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 44 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 45 of 201

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 46 of 201

kV

Large Focus (0.3mm2) - mA

Small Focus (0.1mm2) - mA

22

110

41

23

115

42

24

120

43

25

125

44

26

130

45

27

135

46

28

140

47

29

145

46

30

150

45

31

155

44

32

150

43

33

145

42

34

140

41

35

135

40

Range kV/mA

* Data under revision

Range current-time product (mAs):

- LARGE FUOCUS (0.3 mm2) 2-600 mAs with steps of 1 mAs

- SMALL FOCUS (0.1 mm2) 2-185 mAs with steps of 1 mAs

The Giotto Class unit does not apply the loading factors from TABLES R10 – R20.

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 47 of 201

Material

Silver (Ag)

Thickness

0.0050 ± 5 mm

Purity

≥ 99.9 %

Half-Value Layer (HVL)

W/Ag (50 m)

25 kV = 0.48 ± 0.02 mm Al *

28 kV = 0.53 ± 0.02 mm Al *

31 kV = 0.57 ± 0.02 mm Al *

Reproducibility

< 5%

Linearity

R2> 0.999

kV accuracy

± 1 kV of nominal value

mAs accuracy

± 5% o ± 1mAs of nominal value

Dose output

~ 1 mGy for 26 kV W/Ag 20 mAs at SID distance

(~ 7.0 mGy/s at 685 mm from source); *

Light field source

LED + mylar mirror

Light field intensity

> 160 lux

Light field activation

Single pressure of keyboard button or when compressor is moving

with pedal

Light field duration

20 s

X-ray field / Light field

misalignment

< 2 % of SID according to IEC 60601-2-45

2.2.1.11. X-ray beam filtration

2.2.1.12. Radiation Output

2.2.1.13. Beam Limiting device

Automatic collimation depending on the compressor format and angle of emission.

The image dimension is depending on the collimation format (collimation diaphragm never

visible)

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 48 of 201

Operator protection

Anti-X ray Protective barrier

Anti-X ray protective barrier

material and dimension

Temperate glass 760 x 1960 x 5 mm

Equivalent filtration

The protective barrier installed on the control cabinet guaranties an

equivalent absorption of 0.1 mm Pb as required by IEC 60601-1-3

and IEC 60601-2-45 standards.

Patient protection

Patient face protection

Automatic collimator

AEC system

Operating system

WINDOWS 7 Embedded SP1

Processor

INTEL DUAL- CPU

Memory RAM

24 GB

Capacity hard drive

1TB or superior, DVD READER/BURNER

Graphic board

Integrated display port

LCD Display

1600x1200 – 20” da 180 cd/m

2

Optional Diagnostic 3 MP

Network interface

3GB Ethernet

Remote diagnostic

Internet

G.U.I.

Machine state

Work-list modality

Patient data management

Brightness and contrast control

Magnification Lens

Tomosynthesis scroll tools with kinetic modality

Q.A. test tools

Biopsy examination modalities

Digital Images Formats

DICOM 3.0

– See Informance Statement

DICOM Functions

Verification SCU/SCP Store SCU/SCP Query /retrieve SCU Print

SCU WORKLIST CU STORAGE COMMITMENT SCU MPPS SCU *

Image processing and

reconstructions

RAFFAELLO software

2.2.1.14. Radiation Protection

2.2.1.15. Acquisition Work Station (AWS)

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 49 of 201

Manufacturer

Analogic

Model

AXS-2430

Sensor Physical

Dimensions

239.36 x 304.64 mm

Active Area

2816 x 3584 pixels

Image matrix

2812 x 3580 pixels

N.B. The first two lines and columns at the edge of the active area are declared dead

Pixel size

0.085 x 0.085 mm

Geometric Fill Factor

88%

Detection Method

Direct Conversion (DR) using Amorphous Selenium (a-Se)

Read out technology

TFT array

Saturation Dose

~ 3.0 mGy (mammographic context)

~ 0.7 mGy (tomosynthesis context)

Response

Linear (R2 > 0.99)

DQE @ 1lp/mm

> 50 %

DQE @ 5.8 lp/mm

> 20 %

MTF @ 1lp/mm

> 90 %

MTF @ 5.8 lp/mm

> 40 %

Lag

< 0.005 after 30 s

Ghost

0.05 (Euref Method)

ACR Mammography

Accreditation Phantom

≥ 4 Masses

≥ 3 Fibres

≥ 3 Speck goups

For every modality of acquisition

(MAMMO, TOMO, COMBO) using the AEC system

ADC Bit depth

16 bits min

Image bit depth

13 Bit for mammographic and projections images

14 Bit for reconstruction

Image dimension

19 MB for mammographic and projections images

Depending on the volumetric reconstruction dimension

Maximum defective pixels

< 5000

Maximum correctable

defective lines/columns

< 10

Maximum correctable

defective cluster

150 cluster (max 8 pixel)

2.2.1.16. Digital image receptor

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 50 of 201

Principle of function

The compressed breast thickness determinate the optimum values

of the kV and mAs for the pre-exposure (for tomosynthesis scan the

first exposure id used as pre-exposure) Analyzing the image

received the AWS determinates the maximum density inside the

breast and select the mAs needed.

Sensible areas

The analysis area is rectangular, aligned with chest wall and laterally

centered.

1. 2D Mammo : 15 cm x 19 cm

2. 3D Tomo : 10 cm x 19 cm

3. Biopsy : 4 cm x 1 cm

Techniques

- Manual: manual selection of kV, filter, mAs

- Automatic: automatic selection of Focus type, kV, filter, mAs

Short term reproducibility

< ± 5%

Long term reproducibility

< ± 10%

Manufacturer

JPI Healthcare solution

Model

2100

Type

linear focused grid

Ratio

4 : 1

Line density

31 lp / cm

Focal Distance

65 cm

Interspace material

Pure carbon ( C )

Absorbed material

Lead alloy ( Pb )

Cover material

CFRP

Application limit (f1 ~ f2)

43 ~ 180 cm

Transmission of primary

radiation (Tp)

73%

Transmission of scatter

radiation (Ts)

26%

Transmission of total

radiation (Tt)

58%

Grid selectivity (Σ)

2.81 ± 5%

Contrast improvement

fator (K)

1.26 ± 5%

Grid exposure factor (B):

1.72 ± 10%

2.2.1.17. Automatic Exposure Ccontrol (AEC) system

2.2.1.18. Anti-scatter grid

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 51 of 201

Max Height

2320 mm

Isocentric height

30 mm over the detector support

Breast support height

70 - 145 (± 2) cm

Source-to-image distance (SID)

690 mm

Gantry rotation range

+180° (in anticlockwise) -120° (in clockwise)

Weight

450 kg

2.2.1.19. Dimension of the X-ray unit

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 52 of 201

Dimension (H x W x D)

1982 x 886 x 660 mm

Weight

180 kg

2.2.1.20. Dimension of the opreator console unit

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 53 of 201

2.2.2. Electrical connections

M189_EN:General Information

Draft version_0.1 del 01/07/15

Temporary images (is not the final version)

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 54 of 201

CAUTION

In accordance with EN 60601-1, the unit must be permanently connected to the

electrical mains.

(The protective earth conductor must be connected directly to the protective earth

terminal of the electrical panel).

CAUTION

THE UNIT AND IT’S ACCESSORIES MUST ONLY BE INSTALLED AND USED IN

SHIELDED ROOMS (MINIMUM SHIELDING RATIO 20 dB).

INFORMATION

The fixed cables for systems and devices that cannot be disconnected by the user

are not listed. These cables are part of the system and were always taken into

consideration when measuring the EMC. The device or system would not function

without these cables.

CAUTION

Use of accessories, transformers or cables different than those indicated.

Possible increase in the emissions or reduction in the resistance to

disturbances for the device or system!

Use only transformers and cables sold by the manufacturer of the device or system

as replacement parts for the internal components.

2.2.3. Warning on electromagnetic compatibility (EMC)

The unit is certified as a fixed installation electro medical device and was built in conformity with

the applicable provisions of directive 93/42/EEC concerning medical devices modified by directive

2007/47/EC.

The unit is built in compliance with the IEC 60601-1-2 standard.

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 55 of 201

Measurement of the

emission

disturbances

Compliance

Guidelines - Electromagnetic Environment

Conducted RF

Radiated RF

CISPR 11

Group 1

The system uses HF energy only for its internal

functioning. Therefore its HF emissions are very low and

are not likely to cause any interference in nearby

electronic equipment.

Conducted RF

Radiated RF

CISPR 11

Class A

The unit/system is suitable for use in all environments

other than domestic and those directly connected to

the public low voltage power supply network that

supply buildings used for domestic purposes.

The system has a nominal input current greater than 16 A

per phase.

Harmonic emissions

IEC 61000-3-2

Not applicable

Voltage

fluctuations/flicker

IEC 61000-3-3

Not applicable

2.2.4. Manufacturer’s declaration and guidelines - Electromagnetic emissions

The system is intended for operation in an electromagnetic environment indicated below. The

customer or user of the system must ensure that it is used within this environment.

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 56 of 201

Electromagnetic

interference tests

Test level -

IEC 60601

Compliance

level

Electromagnetic environment -

guidelines

Electrostatic discharge

(ESD)

IEC 61000-4-2

±6 kV

Contact

discharge

±8 kV

Air discharge

±6 kV

Contact

discharge

±8 kV

Air discharge

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic

material, the relative humidity should be at

least 30%.

Electrical fast transient/

burst

IEC 61000-4-4

±2 kV

for power

supply cables

±1 kV

for input and

output cables

±2 kV

for power

supply cables

±1 kV

for input and

output cables

The mains power quality must be that of a

typical commercial or hospital environment.

Surge

IEC 61000-4-5

±1 kV

differential

mode

±2 kV

Common

mode

±1 kV

differential

mode

±2 kV

Common

mode

The mains power quality must be that of a

typical commercial or hospital environment.

Voltage drops, short

term interruptions and

fluctuations in the

supply voltage

IEC 61000-4-11

<5% UT

(> 95% drop

in UT) for 0.5

cycle

40% UT

(> 60% drop

in UT) for 5

cycles

70% UT

(> 30% drop in

UT) for 25

cycles

<5% UT

(> 95% drop

in UT) for 5 s

Not applicable

<5 % UT (>95

% dip in UT)

for half cycle

40 % UT (>60

% dip in UT)

for 5 cycles

70 % UT (>30

% dip in UT)

for 25 cycles

<5 % UT (>95

% dip in UT)

for 5 s

The mains power quality must be that of a

typical commercial or hospital environment. If

the user of the system requires continuous

operation during power outages, it is

recommended that it be powered with an

uninterruptible power supply.

The system has a nominal input current greater

than 16A per phase.

Magnetic field at the

supply frequency (5060 Hz)

IEC 61000-4-8

3 A/m

3 A/m

The magnetic fields at mains frequency should

correspond to the typical values seen in a

typical business or hospital environment.

Note: UT is the alternative current voltage before the application of the test level.

2.2.5. Manufacturer’s declaration and guidelines - Immunity to

electromagnetic interferences

The system is intended for operation in an electromagnetic environment indicated below. The

customer or user of the system must ensure that it is used within this environment.

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 57 of 201

CAUTION

Use of the device or system immediately next to other devices or stacked

on top of other appliances.

Proper operation cannot be guaranteed!

If the device or system must operate alongside other appliances or be

stacked on top of them, it should be execute a functional test to check

that it functions properly in this layout.

Portable and mobile HF communication devices should be used no closer to any part of the

equipment, including cables, than the recommended separation distance. The separation distance

is calculated based on the applicable transmission frequency equation.

P is the maximum nominal power rating of the transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation distance in meters (m).

The field strength from the stationary RF transmitter, as determined by a local electromagnetic site

survey a should be less than the compliance level b at each frequency range. Interference may

occur near equipment marked with the following symbol

Electromagnetic

interference tests

Test level - IEC

60601

Compliance

level

Recommended separation

distance:

Conducted HF

interference

IEC 61000-4-6

3 Vrms

from 150 kHz to

80 MHz

3 Vrms

d = 1, 2√P

Radiated HF

interference

IEC 61000-3-2

3 V/m

from 80 MHz to

2,5 GHz

3 V/m

d = 1, 2√P per 80 MHz - 800

MHz

d = 2, 3√P per 800 MHz - 2,5

GHz

Note 1: The higher frequency range applies at 80 MHz and 800 MHz.

Note 2: These guidelines may not be applicable in all cases. The spread of electromagnetic

emissions is affected by the absorption and reflection by buildings, objects and people.

A) The field strengths of stationary transmitters, e.g. base stations for radio telephones

(mobile/cordless) and mobile radio equipment, amateur radio stations, AM and FM radio and television

transmitters cannot be predicted theoretically with accuracy. In order to determine the electromagnetic

environment with regard to stationary transmitters, a study of the location should be carried out. If the

field strengths measured at the location where the system will be used exceed the compliance level

given above, the system should be monitored to see that it operates properly. If unwanted performance

characteristics are observed, additional measures may be necessary, such as reorienting or

repositioning the system.

B) At the frequency range from 150 kHz to 80 MHz, the field strengths should be lower than 3 V/m.

CAUTION

PORTABLE AND MOBILE RADIO COMMUNICATION DEVICES CAN

INFLUENCE THE OPERATION OF THE UNIT AND ITS

ACCESSORIES.

M189_EN:General Information

Draft version_0.1 del 01/07/15

SERVICE AND

INSTALLATION

MANUAL

Via Sagittario 5 - 40037

Pontecchio Marconi (Bo)

Tel. ++39 051 846851

Fax. ++39 051 846856

www.imsitaly.com

pag 58 of 201

Maximum rated output power of

transmitter (W)

Separation distance according to frequency of the

transmitter [m]

da 150 kHz a 80

MHz

d = 1, 2√P

da 80 MHz a 800

MHz

d = 1, 2√P

da 800 MHz a

2,5 GHz

d = 2, 3√P

0,01

0,12

0,12

0,23

0,1

0,38

0,38

0,73

1

1,2

1,2

2,3

10

3,8

3,8

7,3

100

12

12

23

For transmitters rated at a maximum output power not listed above, the recommended separation