IMR EX660

Portable Multi-Gas Detector

Operation Manual

IMR Environmental Equipment, Inc.

3634 Central Ave.

St. Petersburg, FL 33711

Phone: 727-328-2818

E-mai: info@imrusa.com

IMR EX660

SAFETY INFORMATION

Incorrect operation or unsuitable using environment may attenuate the instrument’s performance. Therefore, please first

read the below safety information carefully before using and then operate this device.

Please don't use the defective device. Before using, please check if there is crack or spare part missing. If yes,

please contact the seller immediately.

It's suggested that the user carry out the "Bump Test" by following Clause 5.3 of this manual before using the

device. If the device reading is beyond the specified range, please calibrate the device by following Clause 5.7 and

5.8 of this manual.

Periodic Bump test will test the response feature of the sensor. Please make sure that the visual, audible and

vibrative alarm signals are ok.

Only accessories which are specified for IMR EX660 or permitted by the seller are allowed to be used.

Only the charger which is specified for IMR EX660 is allowed to be used. It's forbidden to charge the device in

the dangerous environment.

Please don't expose the device to the exceeding-range gas environment for long time. Otherwise, it will badly

influence the performance and even damage the device.

If exposed to the environment consisting of leaded compound, sulfocompound, organic phosphorus compound or

silicon, the gas sensor will be poisoned. Please don't use the device in the above environment.

Please don't expose the device to the environment which consists of H2S, hydrocarbons gas or high corrosive gas

for long time. Otherwise, it will restrain the response of the gas sensor and reduce the sensitivity. If the device has

to be used in the above environment, please follow Clause 5.3 to carry out the Bump Test before using it.

Please don't expose the device to the environment which has electric shock, strong magnetic field or serious

continuous mechanic shocking.

There is a lithium battery inside the device. Please don't place the useless battery together with the rubbish. The

useless battery should be discarded by qualified withdrawers.

It's forbidden to disassembly, adjust or repair the device without permission.

Please avoid the device falling from high place or serious shocking.

Any other operation beyond this manual, please contact the seller.

IMR Environmental Equipment, Inc.

2

IMR EX660

1. Brief Introduction

IMR EX660 is a compact and lightweight multi gas detector that continuously measures combustibles, O2, CO, H2S and

other toxic gases in ambient air. By using 6 sensors, it can detect at most 7 gases at the same time. Its functional and

watertight design (IP 66) incorporates a Bump proof, rubberized housing to meet the toughest requi rements of harsh

environments.

2. Main Features

Advanced 16 digit MCU with low consumption

Ultra-wide angle LCM screen

Adjustable 2-level alarm points

Adjustable calibration point

Self-protection design for com bus tible gas sensor

Battery low voltage alert function

With real-time clock

Interchangeable smart sensor module design

Self-adjustment design

Audible, visual and vibrate alarm signals

Data communications function

STEL/TWA alarm for toxic gases

Design of self-test, self-diagnose and self-repairing

Password management

Intrinsically safe design

3. Technical Specification

Detecting method: Natural diffusion

Target gas: Refer to the Annex-1 in the end of this manual

Communication: RS 232

Response time:

Semi-conduct, catalytic, thermal conduct sensor ----------T90<30s

O2, CO, H2S sensor---------------------------------------------- T90<30s

Other sensors -----------------------------------------------------T90<120s

Indication error range:

Combustible gas----------------------------------------------------- ±5% F.S.

Toxic gas------------------------------------------------------------------±5ppm

Working condition:

Temperature: -20℃~50℃ Humidity: <95%RH

Power source: Lithium battery (DC3.6V, 6600mAh)

IMR Environmental Equipment, Inc.

3

IMR EX660

Working time per charging: ≤ 30 hours continuously (no alarm)

Charging time: ≤ 6 hours

Explosion –proof grade: Exia IIC T4 Ga

Ingress protection: IP66

Dimensions and weight: 168mm×91mm×45mm about 500g

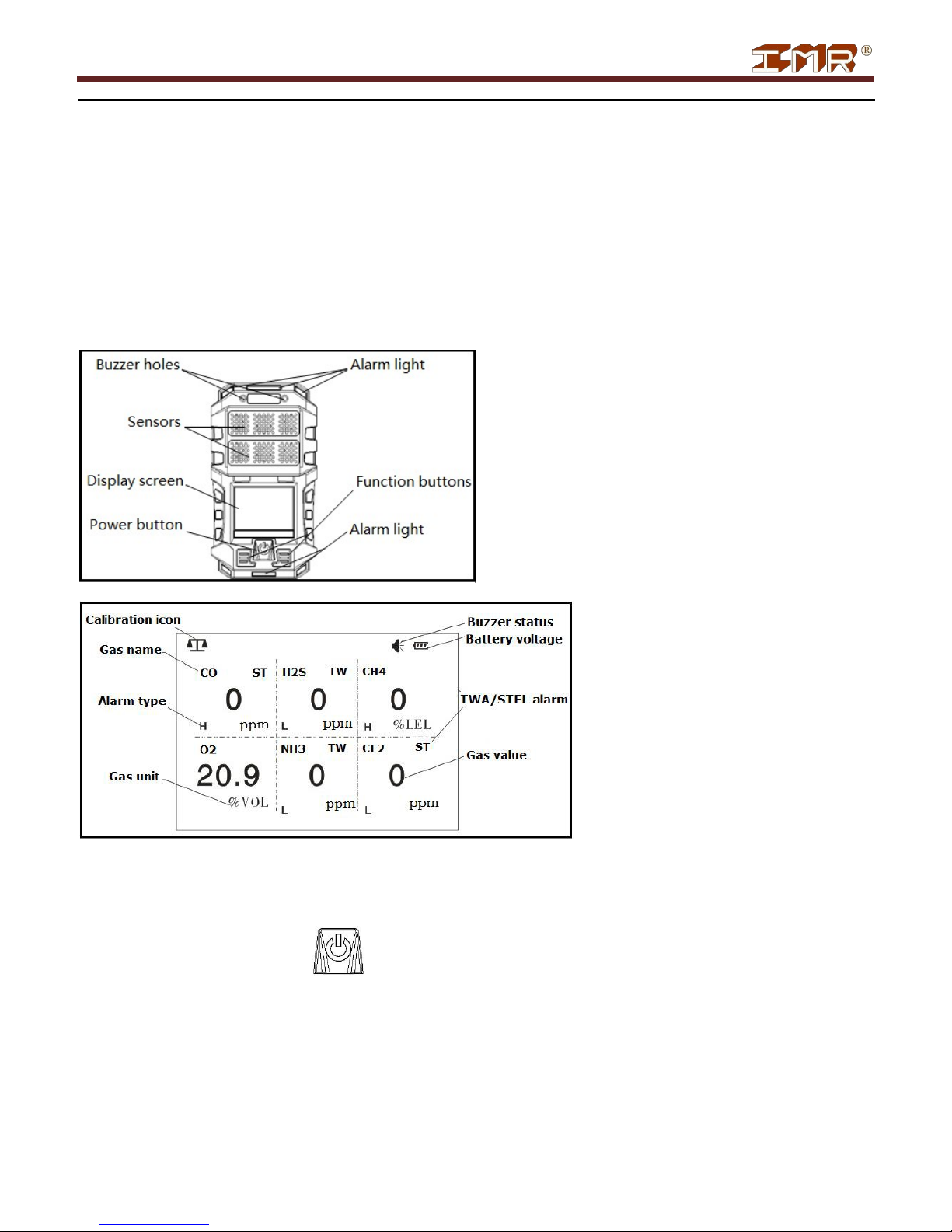

4. Structure and Functions

Appearance Display

information

5. Operation Instructions

5.1 Power on

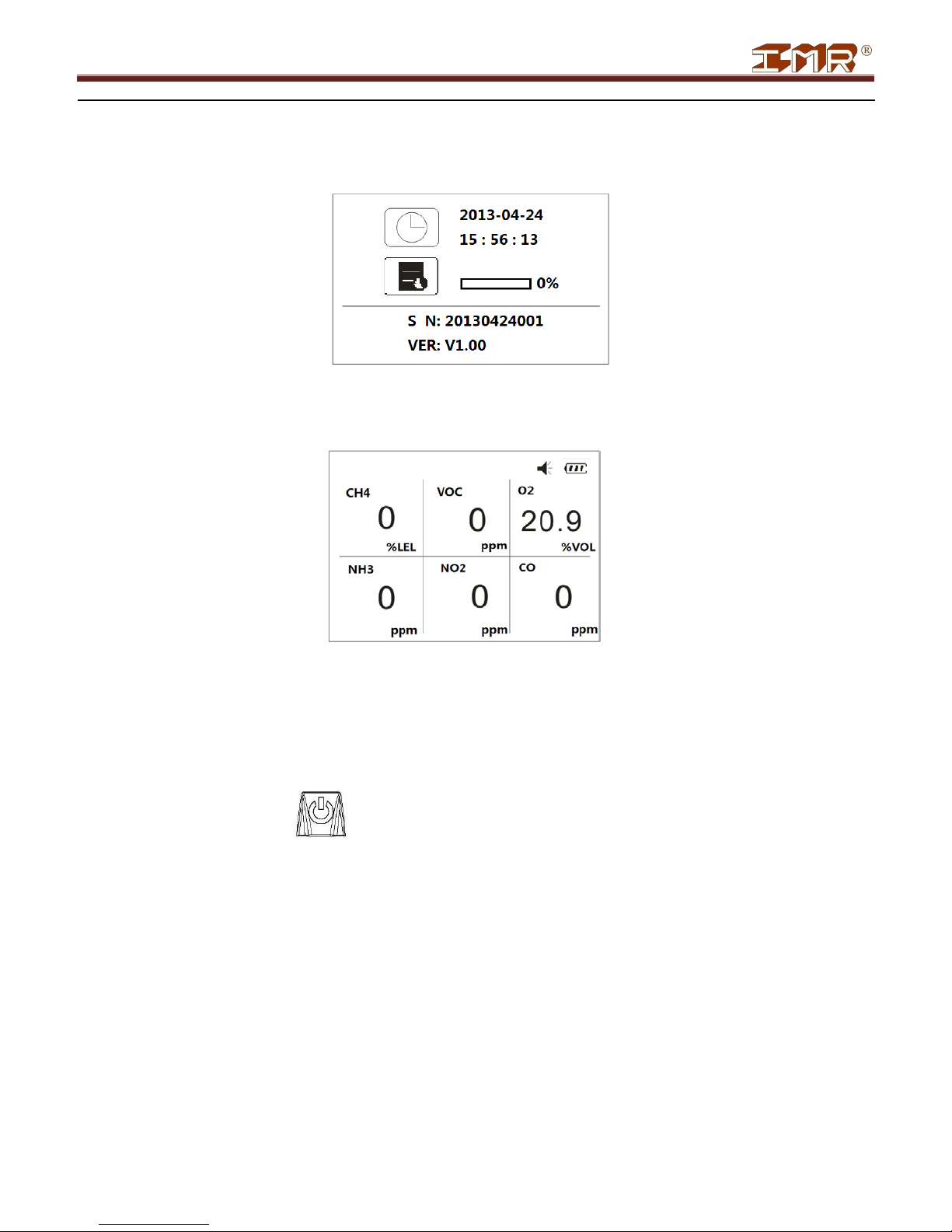

When machine is power off, hold for more than 3s and the device will be power on. The screen shows as

below.

IMR Environmental Equipment, Inc.

4

IMR EX660

After power on, the detector will proceed self-test and display is as below drawing.

The device will make self-test on the buzzer, alarm lights and vibrator automatically. After self-test, the device enters

into normal detection status and the screen displays as below.

Note:

If self-test fails, related information will be displayed. For details, please refer to Clause 10 Troubleshooting of

this manual.

If self-test succeeds, the device enters into warm-up period of 3-30s, which depends on the sensor type.

5.2 Power off

In normal detection status, hold for 3 seconds and the screen will show “Shutting down…”. Meanwhile, the

buzzer will give out intermittent beep twice. Then machine is power off.

5.3 Bump test

Every day before using the device, the user is suggested carry out Bump test, so as to check if the device is working

normally.

Test method:

When the device is power on, put it into high level gas environment, which is higher than the preset high alarm point of

the device. If the entire device’s function is ok, then device can be used in the working area.

Note:

If any reading on the screen is beyond the prescribed display error range, please follow Clause 5.7 and 5.8 of this

manual to re-calibrate it.

IMR Environmental Equipment, Inc.

5

IMR EX660

If detector does not response or showing errors, please contact the seller for re pai rin g .

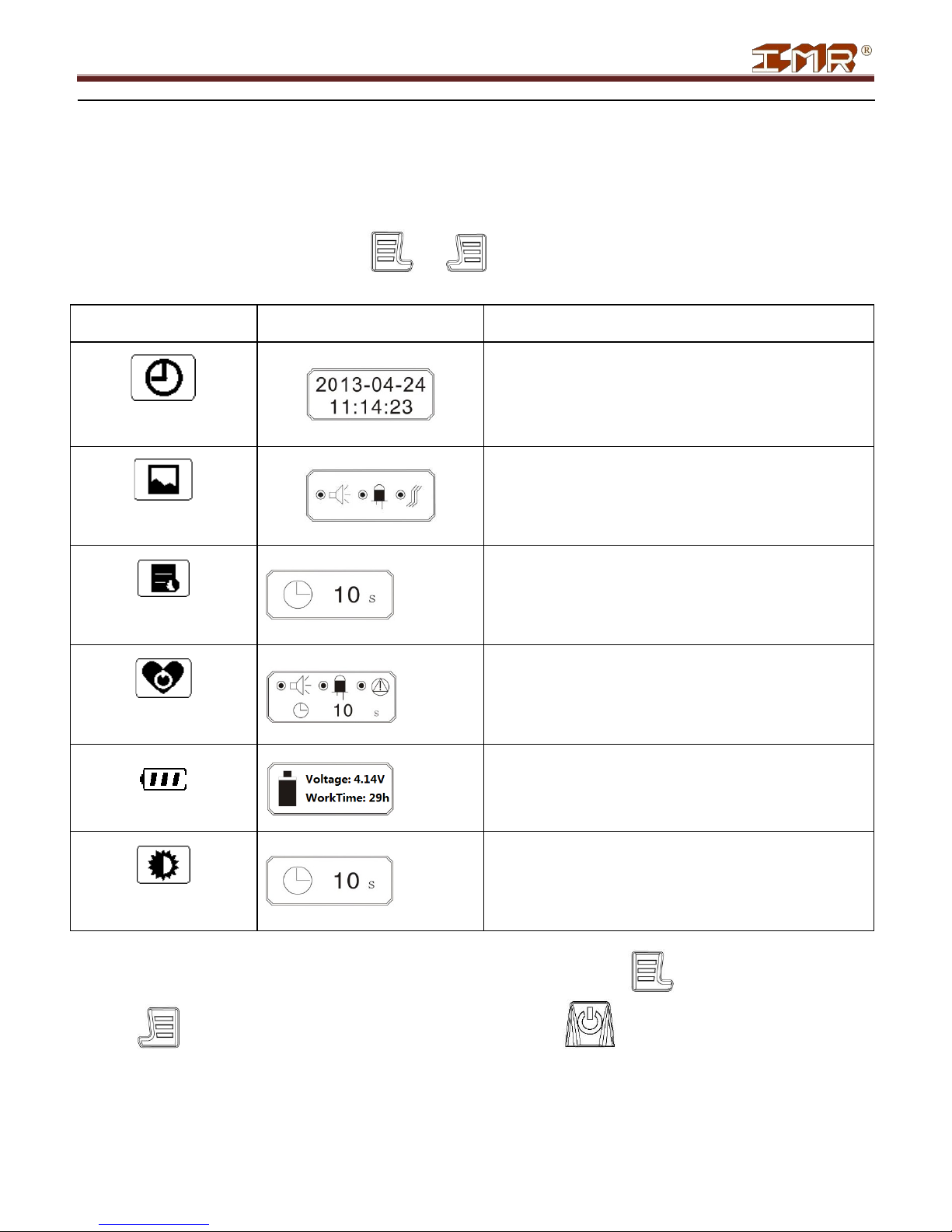

5.4 Menu explanation

5.4.1 Common menu

In the normal detection interface, press both and simultaneously and the device enters into common

menu setting interface. Below is the button function:

Menu Submenu Remarks

When changing the date or time, the selected bit will

blink.

When changing the mode, the selected bit will blink.

DATE

TIME

ALARM

MODE

RECORD

GAP

CAUTION

MESSAGE

BATTERY MESSAGE

BACKLIGHT

TIME

Set time gap for record saving.

Black box means this item is selected.

Display battery voltage and remaining work time

Backlight time will be increased

by 5s each time.

After enterin g into certain submenu, the user can change the item value by pressing and save the setting by

pressing . The user can also exit without saving changes by pressing .

IMR Environmental Equipment, Inc.

6

IMR EX660

Remarks

CAL.

MANAGE

5.4.2 Advanced menu

In the interface of common menu interface, press both and simultaneously twice. The screen shows

password inputting interface. Input the password by pressing to increase the bit value and press to

confirm the in put password. After inputting the correct password, press to enter into advanced menu interface.

Select the submenu item by pressing and enter into selected submenu by pressing .

Menu Submenu

SAFETY

DEPLOY

ZERO

To set user’s ID.

Zero calibration

DATA

UPLOAD

PERIPHE CONFIG.

Data upload

One mode must be selected

Activate the other function

POWER

One mode must be selected.

LANGUAGE

SELECT

Note: Initial password for entering advanced menu is “0000”.

5.5 Gas detection

The device monitors and displays gas concentration in real time. Once the gas concentration reaches the preset alarm

point, it will initiate alarms.

IMR Environmental Equipment, Inc.

7

IMR EX660

Note:

Do not block sensors in detecting process.

To prolong life span, external filters are suggested in detecting process.

Long time storage, serve physical shock and excessively high concentration may cause zero drift of the gas

sensors. If finding the reading in clean air is not zero, please make zero calibration by following Clause 6.7 and

6.8 of this manual.

5.6 Status review

In normal detection mode, press button in normal operation mode and the screen will show automatically

current temperature, time, STEL value①, TWA value①, the maximum leval of gas②, the minimum level of gas②

since power on.

Note:

① Only for toxic gas.

② Only for o xygen.

5.7 Auto zero calibration

In normal detection mode, hold both and buttons for about 1 second. The device asks for inputting

password. After inputting correct password, the device enters into advanced menu interface.

Move the cursor to icon and press button. The device will make zero calibration automatically. In the

end, a “√” icon displays for gas succeed and “×” for gas failed.

5.8 Calibration

WARNING!

Calibration must be carried out by qualified person. Otherwise,

the device may work wrongly.

5.8.1 Enter the setting interface

While the device is power off, hold both and buttons simultaneously for about 3 seconds. Then, the

device first performs a self test as after power on and after a short delay, the device asks for inputting the password.

After inputting correct password, the device enters into the setting interface shown as below.

IMR Environmental Equipment, Inc.

8

IMR EX660

Press

to move the cursor and the selected icon turns black. Then press

to enter the submenu.

5.8.2 Zero calibration

Select icon and press to enter auto zero calibration interface, shown below. When finished, a “√” icon

displays for gas succeed and “×” for gas failed.

In the auto zero calibration mode, press and the device enters manual zero calibration interface, shown as

below.

When the AD value of the sensor is stable, press to make zero calibration manually. After that, a “√” icon

displays for gas succeed and “×” for gas failed, shown as below.

IMR Environmental Equipment, Inc.

9

IMR EX660

5.8.3 Span Calibration

After zero calibration, the device displays a countdown interface, shown as below.

After that, it displays the calibration gas level, shown as below:

If the level needs to be changed, press to enter the below interface:

Press to move the cursor and press to change the figure. After changing

the figure, press button to save and enter the gas inputting mode, shown as below:

When the device senses the input gas, it displays as below:

IMR Environmental Equipment, Inc.

10

IMR EX660

During this period, if needing to change to manual calibration mode, press . Below is the manual calibration

interface.

Press again to confirm manual calibration. The below 2 drawings show the succeeded and failed manual

calibration.

Once finishing calibration one sensor, the device starts to calibrate the next sensor one by one. The operation is same as

above.

During calibration period, press and the user can skip calibration for some specific sensors.

5.9 Alarm point setting

IMR Environmental Equipment, Inc.

11

IMR EX660

Press

to move the cursor to the

icon and press

button to enter the submenu. Screen shows as

below.

Press to move the cursor to the figure which needs to be adjusted

and press when the figure flashes. Then it enters into the setting interface, shown as below.

Press button to adjust the figure and press to move the cursor. After adjusting, press button to

save. Then the device enters setting interface of the next alarm point.

Note:

H---High alarm point L---Low alarm point

ST---STEL alert point TW---TWA alert point

5.10 Channel setting

Press to move the cursor to icon and press to enter the sumenu. The screen displays as below.

Press to move the cursor to the target channel and this channel box flashes. Press to select or not. If

selected, the center is black; if cancelled, it’s white.

Note:

Select---means this channel is open.

Cancel---means this channel is closed.

Keep pressing until all the channels have been set. The device will save the setting and exit to the normal

detection mode. Closed channels will have a displayed in the channel box. Otherwise, it is open.

IMR Environmental Equipment, Inc.

12

IMR EX660

5.11 Password setting

Move the cursor to the icon and press button to enter the submenu, shown as below.

Press to adjust the figure and press button to move the cursor. After setting, press to save the new

password.

WARNING!

After setting the new password, please remember it clearly.

6. Battery Charging

If low voltage alert is activated or the device cannot be power on, please charge the device immediately in safety area.

Correct the charger connector first to the charge port of the device when power off. Then, connect the plug of the

charger to the suitable power source. The device will be power on automatically and a battery symbol

WARNING!

It’s forbidden to charge the device in working area.

During charging, the detector has no detection function.

Avoid charging when device is power on. Otherwise, the

charging speed will be influenced.

is displayed on the screen. The symbol shows the charging status. When the symbol is all black and no changes, the

charging is finished. When charged enough, the battery symbol is full of black color. Then please disconnect the

charger from both the device and power source.

7. USB Communications (Optional Function)

This function is only available for the device which includes CD and USB data cable.

Connect the USB data cable correctly between the device and computer. Then, run the matching program as instructed

in the manual for the software.

For details, please refer to the software manual.

IMR Environmental Equipment, Inc.

13

IMR EX660

Hand ring

1 pc

Alligator clip

1 pc

Calibration cover

1 pc

Operation manual

1 copy

Charger

1 pc

Normal problem

Possible reasons

Solution

Not power on

Too low voltage

Charge it immediately

System breakdown

Contact the seller

Circuit fault

Contact the seller

Warm-up not finished

Wait till it finishes

Circuit fault

Contact the seller

Sensor overdue

Contact the seller

Sensor drift

Re-calibrate it

Battery voltage has been

Intense electromagnetic

Too much sensor drift

Sensor drift

8. Using and Replacement of Sensor Modules

The device adopts smart sensor modules, which are suggested be calibrated every 6 months If life span is overdue,

please contact the seller for replacement.

9. Standard Accessories

How to use the clips and hand ring?

Belt clip, alligator clip and hand ring could be screwed to the back of the instrument when necessary.

If belt clip is used more frequently, the user can remove the alligator clip first and then install the instrument.

10. Troubleshooting

No response

to gas

Reading of gas level

not accurate

Time and date are

not correct

Zero calibration

function not

available

Display “-0” in

normal detection

status

used up

interference

Charge it and re-set the

time and date

Reset the time and data

Re-calibrate or replace

the sensor module

Make zero calibration

IMR Environmental Equipment, Inc.

14

IMR EX660

11. NOTICE OF USE

Do not drop it from high place and protect it from server shocking.

The instrument may not function properly in an atmosphere with gas of excessively high concentration level.

Please follow this manual to operate the device. Otherwise, it will cause incorrect readings or damage to the

device.

Do not store or operate the device in an environment containing corrosive gas or vapor (for example chlorine of

high concentration). Do not expose the device to other harsh environments (including excessive cold, heat,

humidity, electromagnetic field and intense light).

Clean the housing of the device by using damp cloth. Do not use corrosive agents or hard object which may cause

damage or scuffing on the housing.

Operations of disassembly, replacement and must be carried qualified person.

It’s suggested re-calibrate the device once every 6 months.

Considering environmental protection, do not throw away the old batteries and sensors freely. Please send them to

the specified place.

It’s forbidden to charge the device and upload data to the computer in the hazardous area.

For any application or trouble beyond description in this manual, please the seller for advice.

IMR Environmental Equipment, Inc.

15

IMR EX660

PID

PID Sensor Module for VOC

MOS

MOS Sensor Module for VOC

HCN

0-100 ppm

5 ppm

10 ppm

5 ppm

10 ppm

Gas Detection Range L-Alarm Point H-Alarm Point TWA (ppm) STEL (ppm)

CH4/CO/H2S/O2

LEL

CO/H2S/O2

CH4

C3H8 0-100% LEL 20% LEL 50% LEL N/A N/A

O2 0-30% vol. 19.5% vol. 23.5% vol. N/A N/A

H2S 0-100 ppm 10 ppm 15 ppm 10 ppm 15 ppm

CO 0-1000 ppm 35 ppm 200 ppm 35 ppm 200 ppm

CO 0-2000 ppm 35 ppm 200 ppm 35 ppm 200 ppm

NH3 0-100 ppm 25 ppm 50 ppm 25 ppm 35 ppm

CL2 0-20 ppm 5 ppm 10 ppm 0.5 ppm 1.0 ppm

SO2 0-100 ppm 2 ppm 5 ppm 2 ppm 5 ppm

CO2 0-5000 ppm 1500 ppm 2000 ppm N/A N/A

CH4 0-5% vol. 0.5% vol. 1% vol. N/A N/A

H2 0-100% LEL 20% LEL 50% LEL N/A N/A

H2 0-1000 ppm 35 ppm 250 ppm N/A N/A

NO 0-100 ppm 25 ppm 50 ppm 25 ppm 50 ppm

NO2 0-20 ppm 5 ppm 10 ppm 5 ppm 10 ppm

N/A

0-100% LEL

N/A

0-100% LEL

Annex1—Gas List

N/A

20% LEL

N/A

20% LEL

N/A

50% LEL

N/A

50% LEL

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PH3 0-20 ppm 5 ppm 10 ppm 5 ppm 10 ppm

HCI 0-20 ppm 5 ppm 10 ppm 5 ppm 10 ppm

IMR Environmental Equipment, Inc.

16

IMR EX660

IMR Environmental Equipment, Inc.

3634 Central Ave.

St. Petersburg, FL 33711

Phone: 727-328-2818

E-mail: info@imrusa.com

The manufacturer observ es t he ri g ht of amending the

operation manual without informing the users in advance.

IMR Environmental Equipment, Inc.

WARNING!

17

Loading...

Loading...