Page 1

Industrial

Devices

Corporation

The Only Microstepping Drive with:

Open Loop Stall Detect

Multi-Stepping

Dynamic Smoothing

Xtreme Smoothness

TM

(OLSD™)

TM

TM

TM

Motion Node

User’s Manual

P/N PCW-5181 Version 1.0

Page 2

Page 3

Revision History

Version: 1.0

April 2001

Industrial Devices Corporation (IDC) strives to maintain effective communication with all

users and potential users of our products. If you have any questions or concerns regarding

this technical manual or the product it covers, please contact:

Industrial Devices Corporation

3925 Cypress Dri ve

Petaluma, CA 94954

TEL: (800) 747-0064

FAX: (707) 789-0175

FROM OUTSIDE THE U.S. CALL (707) 789-1000

WEB SITE: www.idcmotion.com

EMAIL: info@idcmotion.com

Page 4

Page 5

Table of Contents

Table of Contents

CHAPTER 1 - IMPULSE OVERVIEW ...............................................................................................1-1

CHAPTER 2 - SHIPPING CONTENTS .............................................................................................2-1

CHAPTER 3 - CONNECTING AND INSTALLING YOUR IMPULSE ...............................................3-1

ONNECTING A MOTOR TO THE IMPULSE

A. C

B. S

ERIAL COMMUNICATION CONNECTIONS

.................................... ...... ....... ...... ....... ...... ....... ...... ...3-3

...................................................................................3-4

Making RS-232/RS-485 Connections ...................................................................................3-4

Daisy-Chaining Impulse Drives ............. ...... ....... ...................................................................3-5

Multi-Dropping with RS-485 ..................................................................................................3-5

Troubleshooting RS-232C Communication Problems ...........................................................3-6

ONNECTING AN

C. C

IDC K

EYPAD

..................................... .................................................... .........3-7

Using a Keypad with Impulse RS232C .................................................................................3-7

Using a Keypad with Impulse RS485 ....................................................................................3-7

ONNECTING

D. C

E. LED DIAGNOSTIC

F. CONNECTING

OUNTING THE IMPULSE DRIVE

G. M

OWER

AC P

I

NPUTS AND OUTPUTS

I

...................................... ................................................... ................3-8

NDICATIONS

................................................................................................. 3-8

.........................................................................................3-9

................................... .......................... .......................... ....... 3-10

Environmental and Installation Requirements .....................................................................3-10

Mounting Arrangements ......................................................................................................3-10

Impulse Dimensions ........................................... .................................................................3-11

Inserting and Removing Mounting Brackets from the Impulse ............................................3-12

Impulse DIN-Rail Mounting ................................ ...... ...........................................................3-13

CHAPTER 4 - CONFIGURING IMPULSE WITH APPLICATION DEVELOPER™ ..........................4-1

I

NSTALLING APPLICATION DEVELOPER ON WINDOWS

SING APPLICATION DEVELOPER

U

F

INE-TUNING YOUR APPLICATION

A

XIS SETUP

OTOR

M

M

ECHANICS

C

OMMAND

MOOTHNESS

X-S

A

DVANCED

I/O S

I/O D

S

TORED MOVE SETUP

F

ILE MENU

DIT MENU

E

S

ETUP MENU

C

OMMUNICATIONS MENU

UN MENU

R

V

IEW MENU

U

PDATING YOUR IMPULSE OPERATING SYSTEM

...................................... ...... ....... ...... ....... ...... ...... ....... ...... ........................................4-10

.......................................................................................................................................4-11

...................................... ...................................... ....................................... ..............4-12

................................. ................................................................. .................................4-13

TREME SMOOTHING

(X

DVANCED TUNING

(A

ETUP

................................. ............................................. .............................................. .......4-18

ESCRIPTIONS

.................................. ................................ ................................. .................... 4-18

- E

..................................................................................................................................4-23

....................................... ...... ....... ...... ....... ...... ...... ....... ...... ........................................4-23

..............................................................................................................................4-23

.............................................................................................................4-24

....................................... ................................................... ........................................4-25

...................................... ................................ ................................ ...........................4-26

...................................................................................................4-2

...................................... .......................... .......................... ....... 4-10

™) ...................................................................................4-15

) ....................................... .................................................... .......4-17

DITING STORED MOVES

95/98/2000/ME/NT ................. ...... ....... ...... ...4-1

........................................................................4-21

: ................................... ........................................ 4-27

CHAPTER 5 - CONFIGURING IMPULSE WITH AN IDC KEYPAD .................................................5-1

i

Page 6

Table of Contents

ECTION

S

S

ECTION

NTRODUCTION TO THE

1 - I

ONFIGURING IMPULSE WITH AN

2 - C

FP100 I

MPULSE KEYPAD

EYPAD

IDC K

....................................... .................... 5-11

................................... ...... ....... ...... ...5-1

Configuring Impulse with the Keypad ..................................................................................5-12

Open a File ..........................................................................................................................5-12

Using the EDIT > SETUP Menus to Configure the Impulse ................................................5-12

MOTOR SETUP ..................................................................................................................5-12

COMMAND SETUP ............................................................................................................5-13

MECHANICAL SETUP ........................................................................................................5-15

MOTOR TUNING SETUP (X-Smoothness) ........................................................................5-16

ADVAN CED SE TUP ...................... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... .......5-17

I/O SETUP ..........................................................................................................................5-20

Move Menus - Using Stored Moves ......................... ...... ....... ..............................................5 -2 2

UNIT# ....................................... ............................................. ..............................................5-24

CHAPTER 6 - HARDWARE REFERENCE .......................................................................................6-1

I

MPULSE SPECIFICATIONS

R

EMOTE MOUNTING YOUR KEYPAD

E

XTENDING THE CABLE LENGTH TO YOUR KEYPAD

EYPAD MOUNTING TEMPLATE

K

I

MPULSE

O

PTIONAL ACCESSORIES FOR YOUR IMPULSE

MPULSE-APPLICABLE

I

I/O S

CHEMATICS

..............................................................................................................6-1

................................... ............. ............. ............. ............. .........6-2

...................................... ................... ................6-2

.................................... ............ ............. ............. ............. ............. ...6-3

.................................... .......................... .......................... ...................... 6-4

................................. ............. ............. ............. .........6-7

IDC M

OTORS

............................................................................................... 6-9

CHAPTER 7 - TROUBLESHOOTING THE IMPULSE ......................................................................7-1

ROUBLESHOOTING TABLE

T

IMITS TABLES

L

..............................................................................................................................7-3

................................... .......................... .......................... ...................... 7-1

CHAPTER 8 - PRODUCT SUPPORT ............................................................................................... 8-2

ARRANTY

W

& R

EPAIRS

.................................. ....................................................................... .........8-3

APPENDIX A: RECOMMENDED WIRING PRACTICES FOR IDC CONTROLS ............................ A-1

APPENDIX B - IMPULSE ADVANCED PROGRAMMING ..............................................................B-1

APPENDIX C - USING NON-IDC MOTORS WITH THE IMPULSE .................................................C-1

USTOM OR USER-DEFINED MOTORS

C

........................................................................................... C-2

INDEX........................................................................................................................END OF MANUAL

ii

Page 7

Chapter 1 - Impulse Overview

The Impulse is the latest microstepping drive from Industrial Devices Corporation and this

innovative drive will move your appli cati ons with a combi nation of features previously unheard of

in the motion control industry.

The Impulse is a self-contained microstepping drive designed to operate permanent-magnet linear

and rotary hybrid step-motors. Its internal control hardware is based on a digital signal processor

(DSP) operating a pair of IGBT power amplifiers. The Impulse is fully protected against shortcircuits and overheating.

Responding to users who demand the ultimate in value and reliability, the Impulse employs the

following features and performance enhancements:

Feature Function

TM

Open Loop Stall Detect

Dynamic Smoothing

Multi-Stepping

Motion Node

Xtreme Smoothing

IDeal Performance Probe Automatic fine-tuning of the Impulse for optimum performance with the con-

I/O Capabilities 4 configurable inputs and one configurable output provide the user with

Configurable I/O Polarity I/O polarity can be set to Active High or Active Low ensuring compatibility

Diagnostic LED Green for power ON/ENABLED, flashing green for DISABLED, red for ON/

Ultra-Compact Packaging Top-notch performance, while consuming a minimal amount of space

Resolution Up to 100,000 steps/rev

FLASH Firmware Downloadable software facilitates quick upgrades over the internet

Current Reduction Modes Enable Stop (current reduced to 75% of drive setting if no motion occurs

Anti-Resonance Provides optimum torque and nulls mid-range instability

Integrate d C ooling Tunnel For maximum performance and multiple drive mounting capability

Regenerative Circuit Dumps excessive power during deceleration

TM

TM

TM

Allows a motor to run without an encoder and still be able to detect a stall

Move profiles are smoothed to minimize jerk

For full-stepping with the smoothness of microstepping

7 simple moves can be stored in the Impulse and activated via inputs or

serial port. This feature is optional.

6 component “gain” settings for low-speed smoothness, reduced vibration,

and more usable torque

figured motor

flexibility

with a wide range of controls

UNCONFIGURED, flashing red for FAULTS

during a user-programmed amount of time)

Enable Idle (user-defined current reduction percentage if no motion occurs

during a user-programmed amount of time)

Chapter 1 - Impulse Overview

This manual will enable you to 1) quickly setup and verify that your Impulse is operational, 2)

configure and program the Impulse for your specific application, and 3) successfully troubleshoot

possible performance problems.

1-1

Page 8

Chapter 1 - Overview

This page intentionally left blank

1-2

Page 9

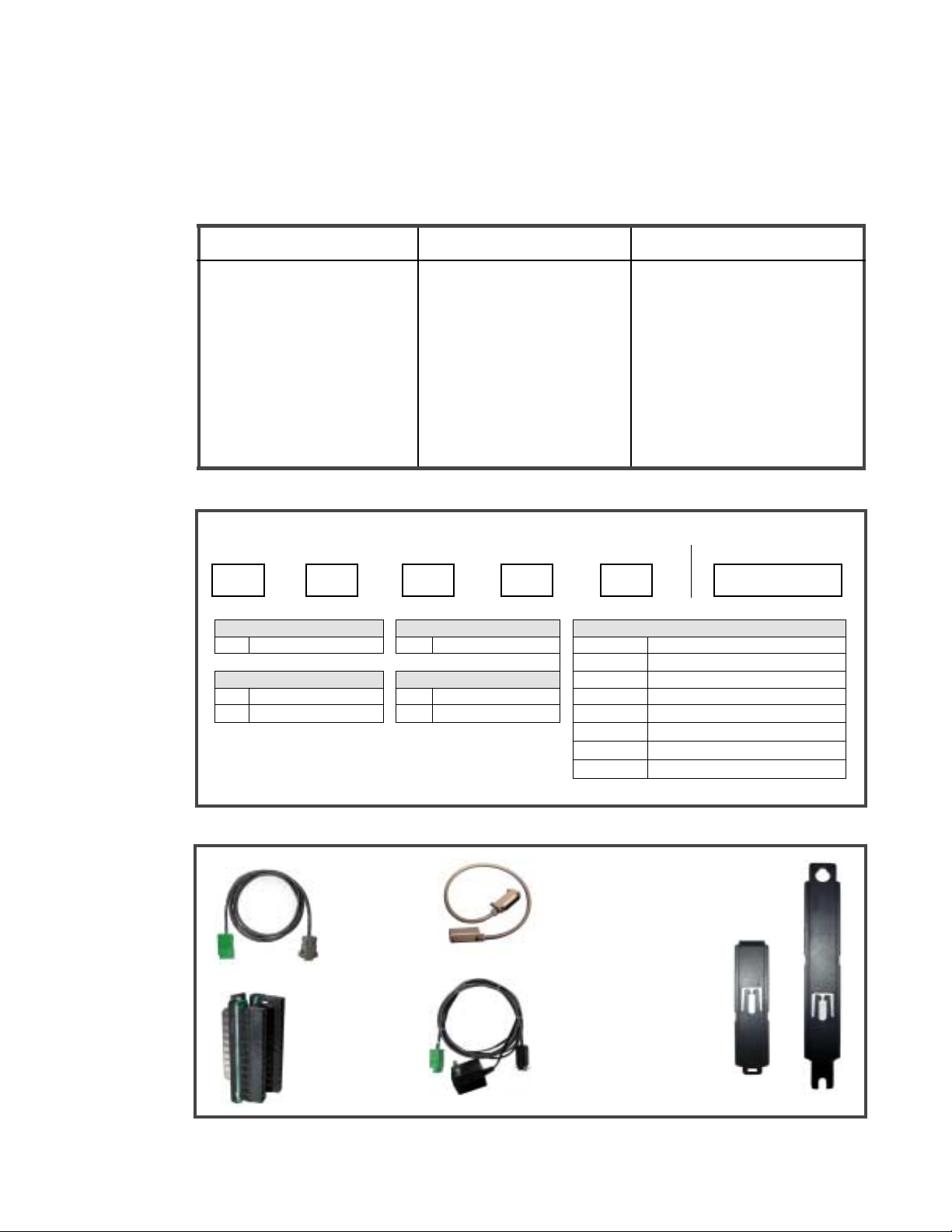

Chapter 2 - Shipping Contents

Your Impulse will arrive equipped as listed in section #1. If any parts or accessories are missing, please call

IDC Custome r Support at: (800) 747-0064. Sections 2 and 3 are provided as reference material.

1

- What You Will Receive if You Ordered the Following:

Chapter 2 - Shipping Contents

Impulse + FP100

(or FP220) Keypad

1. Impulse Microstepping Drive 1. Impulse Microstepping Drive 1. Impulse Microstepping Drive

2. AC power cord for Impulse 2. Motor Connector 2. AC power cord for Impulse

3. Motor Connector 3. AC power cord for Impulse 3. Motor Connector

4. FP100 (or FP220) Keypad 4. IDCMotion Software 4. FP100 (or FP220) -RS48 5 Keypad

5. Remote cable for Keypad 5. Impulse Quick Setup/Ref. Guide 5. Keypad Power Supply

6. Keypad mounting gasket 6. Impulse User’s Manual 6. Remote cable for Keypad

7. Keypad mounting template 7. Keypad mounting gasket

8. IDCMotion Software 8. Keypad mounting template

9. Impulse Quick Setup/Ref. Guide 9. IDCMotion Software

10.

Impulse User’s Manua

2

- Ordering and Identifying an Impulse

Using the tables below, fill in the boxes and you will be able to order or identify your Impulse:

IMPULSE Input Power Capability Drive Type Communication Accessories

l

Impulse Only

Impulse + FP100-RS485

(or FP220-RS485) Keypad

10. Impulse Quick Setup/Ref. Guide

11.

Impulse User’s Manua

l

IM L T4

Input Power Drive Type Accessories (order separately)

L Line Voltage 120 VAC T4 Stepper Drive, 4 A *FP_ _ _-_ _ Keypad Configuration

DB25BO 25 pin D-Shell Breakout Board

Capability Communication SS-IO 25 pin I/O Cable - 2 ft.

M Motion Node Version 2 RS232 SS-IO-6 25 pin I/O Cable - 6 ft.

D Drive Version 4 RS485 SS-RS232 Serial Comm. Cable

PCS-5004 Keypad to PC Cable

PCS-5110 Screw-Mounting Bracket

PCS-5111 DIN Rail Mounting Bracket

*FP100, FP220, FP100- R S485, or FP220-RS485

3

- Accessories Currently Available for the Impulse

SS-RS232

Impulse to

PC Cable

DB25BO

Screw Terminal

Breakout Board

SS-IO (2ft. cable)

SS-IO-6 (6ft. cable)

PCS-5004

Keypad to PC

Cable

PCS-5110

Screw-Mount

Bracket

PCS-5111

DIN Rail

Mounting

Bracket

2-1

Page 10

Chapter 2 - Shipping Contents

This page intentionally left blank

2-2

Page 11

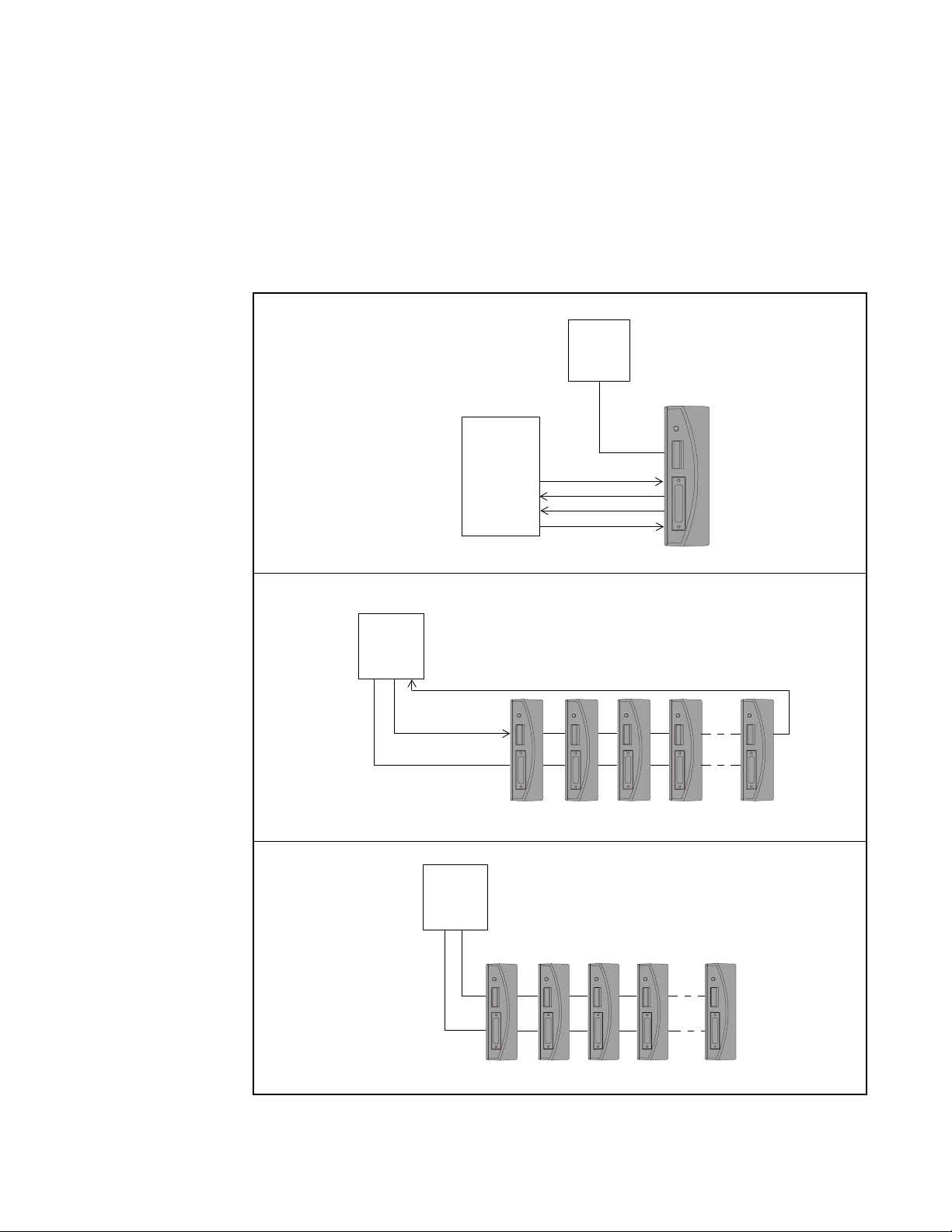

Chapter 3 - Connecting and Installing Your Impulse

Chapter 3 - Connecting and Installing Your Impulse

The purpose of this chapter is to provide information that will help you connect and install your

Impulse drive in its intended application.

The Impulse drive easily interfaces with a PC, PLC, Step & Direction Motion Controller, or IDC

keypad. Block diagrams of several Impulse-based applications are shown below.

Typical Impulse Applications

PC

or

Keypad

PC

or

PLC

I/O TX RX

RS232C

1 - 7 Stored Moves

961/962

Indexer

Single or

Multi-Axis

Unit #1

RS232C

or

RS485

Digital Inputs (4)

Digital Output (1)

Fault Output

Step/Dir/Shutdown

Impulse

Unit #99

PC

or

PLC

I/O

RS485

Unit #1

Unit #32

3-1

Page 12

Chapter 3 - Connecting and Installing Your Impulse

Read This Page Bef ore Your Begin!

Always use cau ti on

•

driven cylinders are capable of exerting trem endous force agai ns t an obstruction.

Always en sure that power to yo u r system is OFF

•

mainten ance activity, or making any con nections or adjus t m ents.

Do not insert objects into the Impulse drive

•

sonal injury, and equipment could be damaged beyond repair.

when working with mechanica l syste ms. Ge a rs an d s crew-

CAUTION!

before performing any

. High volt ages could cause per-

Do not open the Impulse drive.

•

is opened.

The factory warranty will be voided if the drive

3-2

Page 13

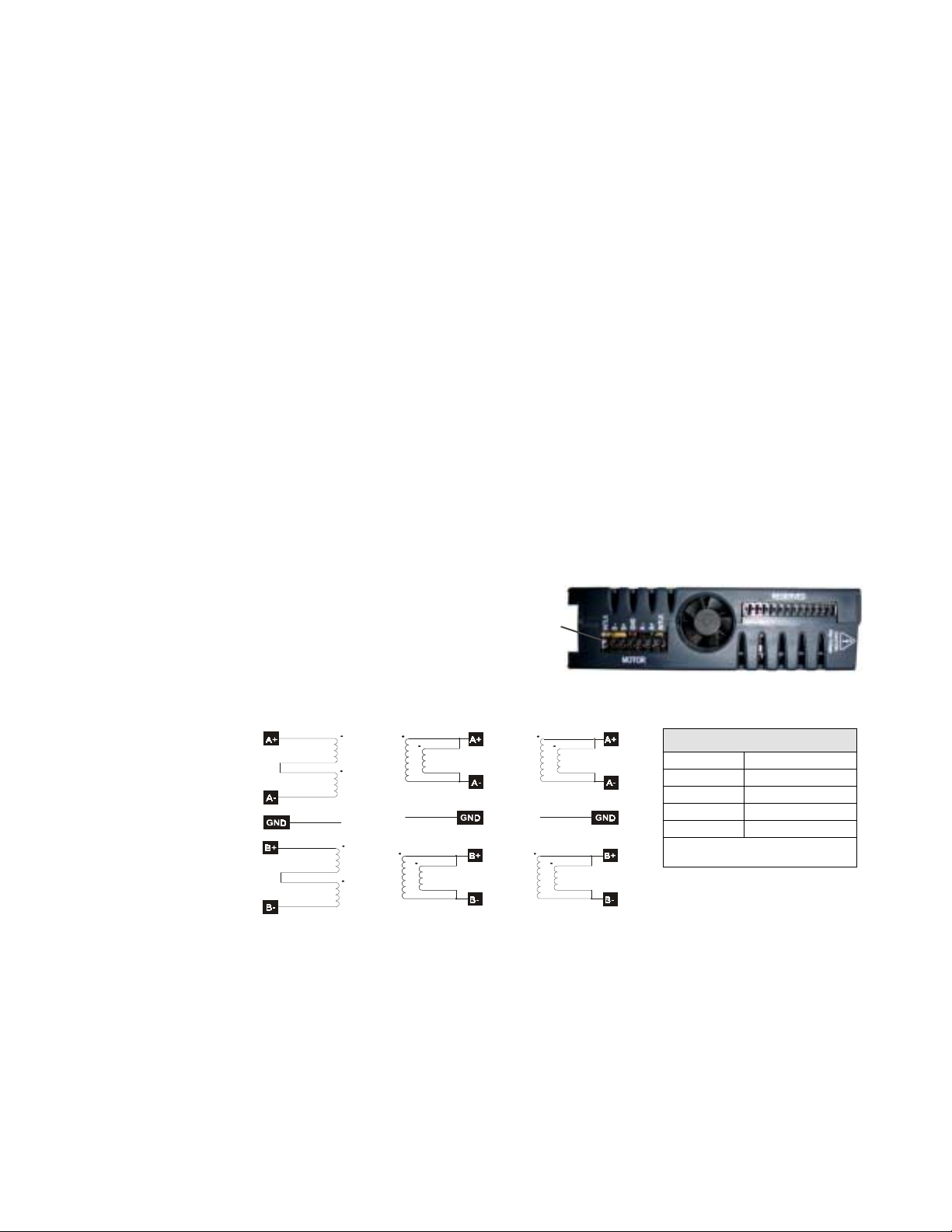

A. Connecting a Motor to the Impulse

Connecting an IDC Motor

The A+, A-, B+, and B- phase outputs power the motor windings.

Connect motor wires to the motor connector (supplied) and plug the wir ed con nector into the dr ive.

Drawings below provide color codes for IDC motors.

GND is internally connected to the earth pin on the power connector. This provides a convenient

terminal for grounding the motor frame and a motor cable shield. Note: If the motor is mounted on

a machine that is grounded, do not connect the motor to GND.

The two INTLK pins must be jumpered together on the motor connector to allow power to the

motor.

CAUTION! Do not remove the motor connector from the Impulse drive while power is

applied. Removing the connector while power is applied could damage the connector pins.

Do not extend the interlock jumper wire to provide protection for anot her connector interface. The

interlock circuit is susceptible to trips caused by noise-pickup in cables (20 kHz switching).

Chapter 3 - Connecting and Installing Your Impulse

Note: This is a high-impedance safety-interlock circuit. If the interlock wire breaks, or the connector

is removed, the current to the motor is immediately stopped, the drive faults (latches) and the LED

on the front panel of the Impulse will flash five times (see LED Diagnostics on p. 3-8).

IDC Motor Wiring/Color Codes

Series Parallel Parallel

YELLOW

WHT/YEL

WHT/RED

RED

SHIELD

BLACK

WHT/BLK

WHT/ORG

ORANGE

WHT/YEL

SHIELD

WHT/BLK

Connecting a Non-IDC Motor

YELLOW

WHT/RED

RED

BLACK

WHT/ORG

ORANGE

Motor

Connector

GREEN/YEL

P31/32/33S12/21/23/32/33 P21/22, S21/23

YELLOW

WHT/RED

RED

WHT/YEL

BLACK

WHT/ORG

ORANGE

WHT/BLK

Quick Disconnect Cable Wire Color

A+ Red

A- Red/Yellow

*GND Green

B+ Red/White

B- Red/Black

*Gray-colored Quick Disc. cables are

shielded - connect shield to GND.

One of the Impulse drive’s more advanced features, Open Loop Stall DetectTM, is guaranteed only

when matched with one of IDC’s S or P-series motors.

IDC’ s S and P series motors have cust om windi ngs to pro vide optimu m dynami c performan ce with

the Impulse. If you use another manufacturer’s motor, refer to Non-IDC Motors in Chapter 6,

Hardware Reference, for more information.

3-3

Page 14

Chapter 3 - Connecting and Installing Your Impulse

B. Serial Communication Connections

Making RS-232/RS-485 Connections

The standard Impulse drive uses a 3-wire implementation of RS-232C. The RX, TX, and COM lines

are the serial signals supported. No hardware handshaking is required. Note that some RS-232C

devices require handshaking, such as R TS and C TS. It is the respons ibility of the user to disable this

handshaking via software or hard ware (see Troubleshooti ng RS -232C Com munica tion P roblems on

page 3-6 for more information).

If you will be using RS-485 communication, the typical 5-wire interface connection to a “host” is

shown below. See “Multi-Dropping Impulse Drives with RS-485” on the next page for information

on using termination resi stors. Note: the maximum cable length for RS-485 communication is 4,000

feet.

Make your RS-232C connecti on as shown below . The PC Cable (IDC P/N SS-RS 232) shown below,

is an ideal choice for making trouble-free RS-232C connections to the Impulse.

IDC P/N

SS-RS232

Comm Port Settings

RS-232C/RS-485

Baud Rate 19200 (fi xed)

Stop Bits 1

Data Bits 8

Parity None

XON/XOFF Yes

9-Pin

Connector

RS-485 Host

3 (TX)

2 (RX)

5 (COM)

TX-

TX+

RX-

RX+

COM

COM PORT

RS-232C

COM PORT

RS-485

3-4

Page 15

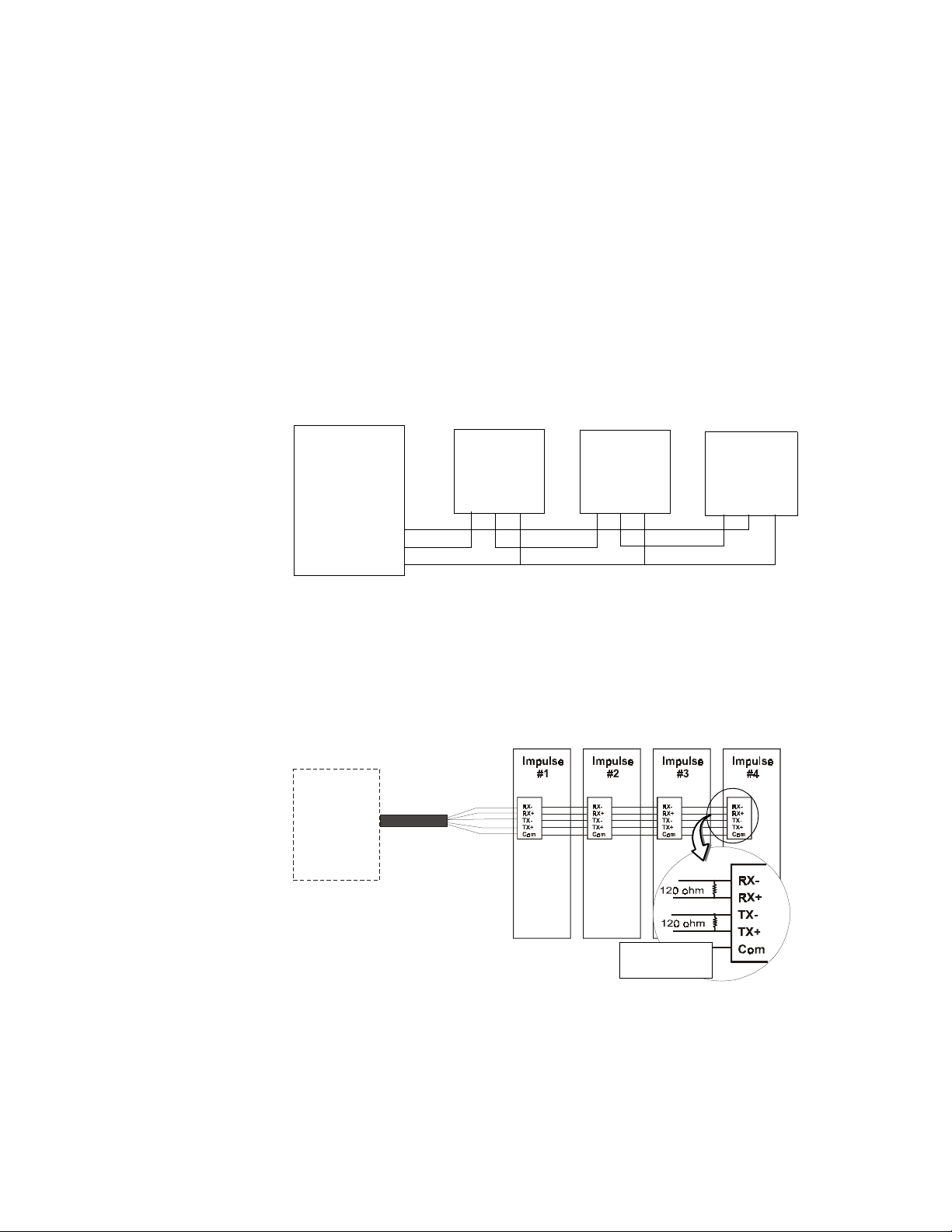

Daisy-Chaining Impulse Drives

Your Impulse also supports daisy chaining. The unit address (range 1-99) can be set via the keypad

or in Application Developer.

Rules for Daisy Chain Operation

1. Units on a daisy chain must be “d evice add ressed ’ (nu mber ed) in o rder for commu nications to

work properly. A unit’s address should increment upward as you move down the daisy chain

from the PC (see illustration below).

2. Do not duplicate unit addresses.

3. Any loose RS-232C connections or miswiring along the daisy chain will cause communications

to fail. Please double check wiring if communication problems arise.

4. Please call IDC if you need to daisy chain more than 99 drives.

5. The hardware diagram below shows how to connect the daisy chain.

Chapter 3 - Connecting and Installing Your Impulse

PC/Host

RS-232C

Device

RX

TX

COM

Multi-Dropping with RS-485

If you will be “multi-dropping” Impulse drives with RS485, add 120-ohm termination resistors

across RX and TX connections of the last unit as shown below:

RS-485

Host

Impulse

Unit 1

RX TX COM

.

Impulse

Unit 2

RX TX COM

.

Impulse

Unit 3

RX TX COM

Add resistors as

shown here:

3-5

Page 16

Chapter 3 - Connecting and Installing Your Impulse

Troubleshooting RS-232C Communication Problems

If communications between computer and Impulse are unsuccessful, one or more of the following

procedures will usually solve the problem:

1. Host transmit (TX) must be con nected to receive (RX) of the dr ive unit, and receive ( RX) of the

host must be connected to transmit (TX) of the drive. If communication fails, try switching

connections on either the host or the drive.

2. Some serial ports may require handshaking.

Jumper R TS to C TS, and DSR to DTR (s ee tab le).

3. Check your ground connections. The COM

Jumpers 9 pin D 25 pin D

RTS to CTS 7 to 8 4 to 5

DSR to DTR 4 to 6 6 to 20

terminal should be isolated from earth gro und. Use

DC common or signal ground as your reference - do not use earth ground or shield.

4. Voltage between TX and COM should be -8.0 to -12.0 VDC. Voltage between RX and COM

should be 0 to -0.5 VDC. Consult factory if measured voltages are outside these ranges.

5. For RS-232C only: If any cable is more than 50 ft. long, you should use a line driver, optical

coupler, or shield. Shields must be connected to earth ground at one end only.

6. Reminder for PDA Users: Prog rams such as Palm’s Hotsync Manager take over a comm. port.

Be sure to close/exit these types of programs if you are using serial communication with your

Impulse.

7. Important Application Note Regarding PC Com Port: PC FIFO (First In First Out) Buffers

should be used and adjusted t o the highe st settings f or fastest pe rformance. This applies to bot h

Receive and Transmit Buffers.

• In your Windows operating system, go to Start > Settings > Control Panel > System >

Device Manager > Ports (Com 1, Com 2) > Port Settings > Advanced > Buffer.

3-6

• Select Use FIFO Buffers, and ensure both Buffers (Receive and Transmit) are adjusted to

the High setting for best performance.

Page 17

C. Connecting an IDC Keypad

Two versions of IDC keypads can be used with the

Impulse drive. The FP100 works only with the

Impulse, while the FP220 can be used with the Impulse

as well as IDC’s Smart Drives (see keypad-specific

information below).

Chapter 3 - Connecting and Installing Your Impulse

COM

PORT

COM

PORT

The COM PORT on the front panel of the Impulse is

used for connecting either version of keypad.

Power is applied to either version of keypad when

power is connected to the Impulse.

Using a Keypad with Impulse RS232C

FP100 Keypad

Connect the FP100 Keypad to the Impulse with the

cable supplied with the keypad.

FP220 Keypad (Version 3.0 or higher)

Only FP220 Keypad ver sions 3.0 an d higher will wo rk

with the Impulse drive.

T o use an FP220 keypad with your Impulse, y ou mu st

set DIP-switch #3 to the ON position and switch #s 1,

2, and 4 to OF F.

The FP220 uses the same keypad cable as the FP100.

I/O

Keypad with Impulse RS232C

Keypad

Using a Keypad with Impulse RS485

Impulse RS485 requires either the FP100-RS485 or

FP220-RS485 keypad.

On the FP220-RS485 keypad only, set DIP switches as

described above. Both FP100-RS485 and FP220RS485 keypad are connected as follows:

1. Connect the keypad cable to the keypad and to the

Impulse.

2. Connect the keypad power supply cable to the

keypad as shown in the illustration.

3. Plug in the AC adapter.

Keypad with Impulse RS485

Keypad

3

2

1

3-7

Page 18

Chapter 3 - Connecting and Installing Your Impulse

D. Connecting AC Power

There is no ON/OFF switch on the Impulse. AC power is

applied by plugging the *power cord (included) into the

connector on top of the Impulse.

Input voltage must be in the range of 120 VAC ± 10%, single

phase, 50/60 Hz, 500 VA max @ 4 Amps. Operation outside

these specifications will result in reduced performance, drive

faults, and may damage the drive.

When power is applied, the LED on front of the drive should

briefly turn red, then steady green. If a red light is present, see

Section E of this chapter for more information on fault detection

codes.

*Note: If the AC power cord requires replacement, the

replacement must be rated for Hard Usage or Extra Hard

Usage.

To AC

Power

Supply

E. LED Diagnostic Indications

The Impulse drive detects and resolves fault conditions (see table below). Faults are signaled by

either a steady red or a flashing red LED on the front panel. A solid green LED indicates normal

operation. A slowly flashing green LED indicates a shutdown (disabled), while a rapidly flashing

green LED signals a regen dump. Faults are cleared by either 1) cycling power, 2) sending a RESET

command via the serial port or configurable logic input, or 3) probing the motor if the LED is steady

red.

For more detailed explanation of faults refer to Chapter 7, Troubleshooting the Impulse.

Diagnostic LED Indications

LED Signal Indication

Green (steady) Normal Operation

Slow Flashing Green Shutdown

Quick Flashing Green Regen Dump

Red (steady) Motor Not Probed

1 Flash Red Stalled

2 Flashes Red Undervoltage Fault

3 Flashes Red Overvoltage Fault

4 Flashes Red Overcurrent Fault

5 Flashes Red Interlock Fault

6 Flashes Red Overtemperature Fault

7 Flashes Red EEPROM Checksum Fault

LED

3-8

Page 19

F. Connecting Inputs and Outputs

Connect your inputs and outputs to IDC’s 961/962 Indexer according to the information below.

Schematics for Impulse I/O circuits can be found in Chapter 6, Hardware Reference

Application Notes

1. On 961/2, ensure that Step/D irection and Dif ferential Jumpers are installed (see 961/2 manu al).

2. If using IDC P/N SS-I/O or SS-I/O-6 cable, cut one end of the cable if necessary (see table

below for SS-I/O cable color-code). If making your own cable, or using a non-IDC indexer,

refer to the Impulse I/O Schematics (Chap. 6) and the 25-pin Connector drawing below.

3. Use a shielded cable, and connect the shield only at the Impulse. Connect shield to pin 9.

4. IDC offers a 25-pin screw-terminal breakout board (shown below) to add convenience and

flexibility to your application. Terminals on the breakout board match the pins of the 25-pin

connector on the Impulse.

5. When wiring TTL signals to other manufacturer’s indexers, the Step TTL command signals

from the controller should be wired to Step +, the Direction signal to Dir + , and the Shut down

signal to SD + (Step -, Dir -, and SD - should not be connected). Remember, th e drive common

must be connected to the controller common.

Chapter 3 - Connecting and Installing Your Impulse

6. Activating the Shutdown input disables the drive amplifier and de-energizes the motor. Wh en

this input is OFF the drive is enabled and the motor is energized. The polarity of this input is

configurable.

7. The open-collector Fault Output turns ON (Active High) when any one of the LED- indicated

conditions occur (see Section E, LED Diagnostic Indicators). The output stays ON while the

LED flashes.

IDC Indexer

(962 Dual-Axis Shown)

1

Breakout

Board

P/N DB25BO

IDC Cable P/N: SS-IO/SS-IO-6

Pin Impulse Signal Wire Color Pin Impulse Signal Wire C ol o r Pin Impulse Signal Wire Color

1 STEP + Brown 10 COM Gray 19 COM Black/White

2 STEP - Red 11 COM White 20 Reserved Red/Black

3 DIR + Orange 12 Reserved Black 21 Reserved Orange/Black

4 DIR - Pink 13 Reserved Brown/White 22 COM Yellow/Black

5 SD + Yellow 14 INPUT 1 Red/White 23 Output 1 Green/Black

6 SD - Green 15 INPUT 2 Orange/White 24 Reserved Gray/Black

7 FAULT + Light Green 16 INPUT 3 Green/White 25 Reserved Pink/Black

8 FAULT - Blue 17 INPUT 4 Blue/White

S

T

U

P

T

U

O

COM

COM

S

T

U

P

N

I

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Note: Cable SHIELD is internally connected to the

DB25 metal housing.9 Drain Violet 18 COM Violet/White

SHLD

FLT-

1

FLT+

E

V

SD-

I

R

SD+

D

DIR-

O

DIR+

T

STEPSTEP+

SHLD

COM

+5

ZZ+

BB+

AA+

3-9

Page 20

Chapter 3 - Connecting and Installing Your Impulse

G. Mounting the Impulse Drive

This section includes installation requirements, Impulse dimensions, installing and removing

mounting brackets, and mounting the Impulse on a DIN rail.

Environmental and Installation Requirements

• Operating Ambient Temperature: Max. 50º C (122º F) @ 4 Amps

• Storage Temperature: Max. 65º C (149º F)

• Not intended for use in humidity above 95% (non-condensing), or at altitudes greater than

3,048 meters [10,000 ft.]

• Heat Dissipation @ 4 A (typical): 32 Watts

• Leave 6 inches above and below drives for airflow and wiring.

• Leave 0.1 inch between drives for easier mounting.

• Air supplied to the Impulse must be uncontaminated.

Mounting Arrangements

The illustration on the right shows an example

of an acceptable mounting arrangement.

COM

PORT

I/O

COM

PORT

COM

PORT

I/O

COM

PORT

I/O

COM

PORT

I/O

I/O

6.0 in.

COM

PORT

I/O

COM

PORT

COM

PORT

I/O

COM

PORT

I/O

COM

PORT

I/O

I/O

3-10

Page 21

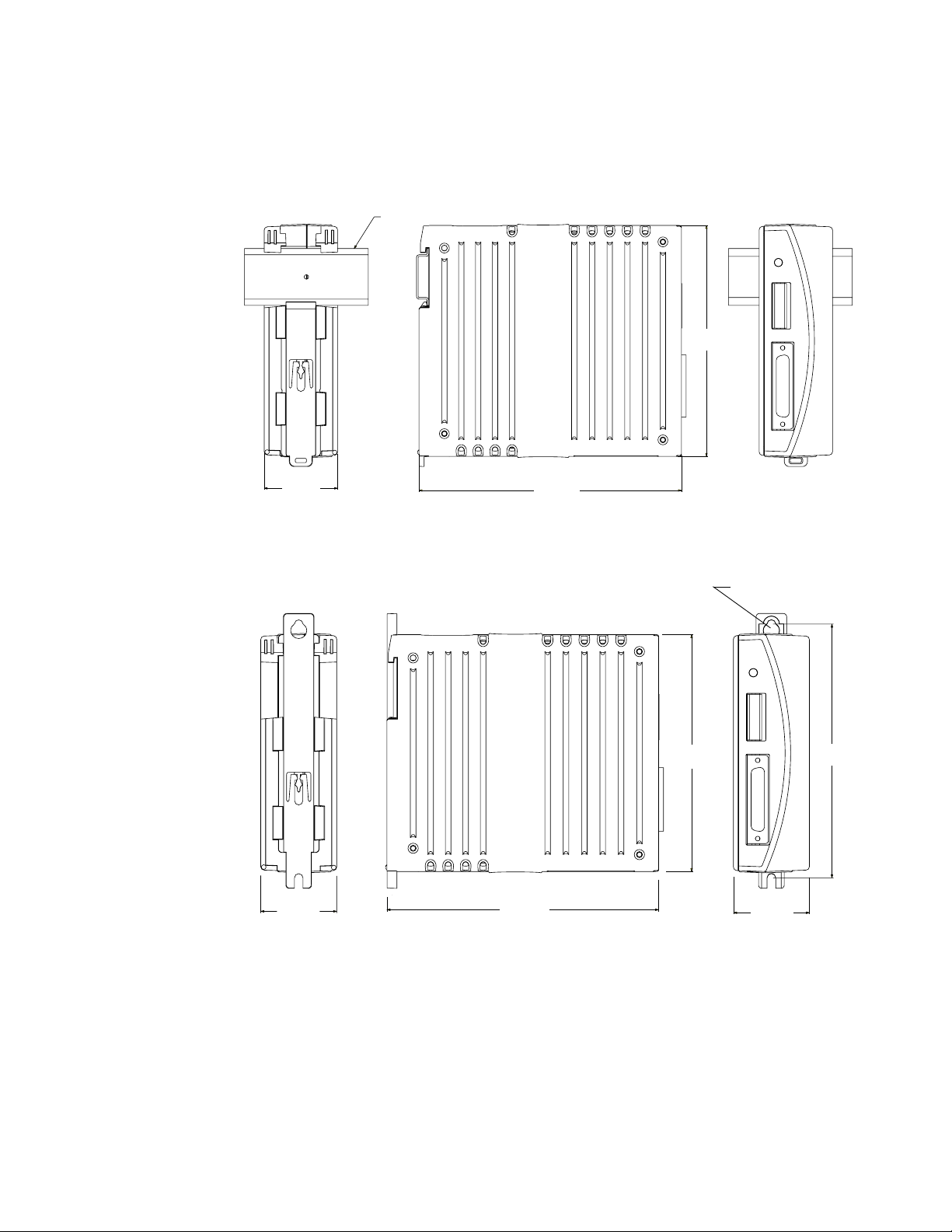

Impulse Dimensions

Impulse with DIN-rail Mounting Bracket (P/N PCS-5111

Chapter 3 - Connecting and Installing Your Impulse

TS 35 DIN RAIL

5.599

1.779

6.365

Impulse with Screw-type Mounting Bracket (P/N PCS-5110)

1.779

6.365

5.599

10-32 screw with

.305'' head ∅

6.000

1.779

3-11

Page 22

Chapter 3 - Connecting and Installing Your Impulse

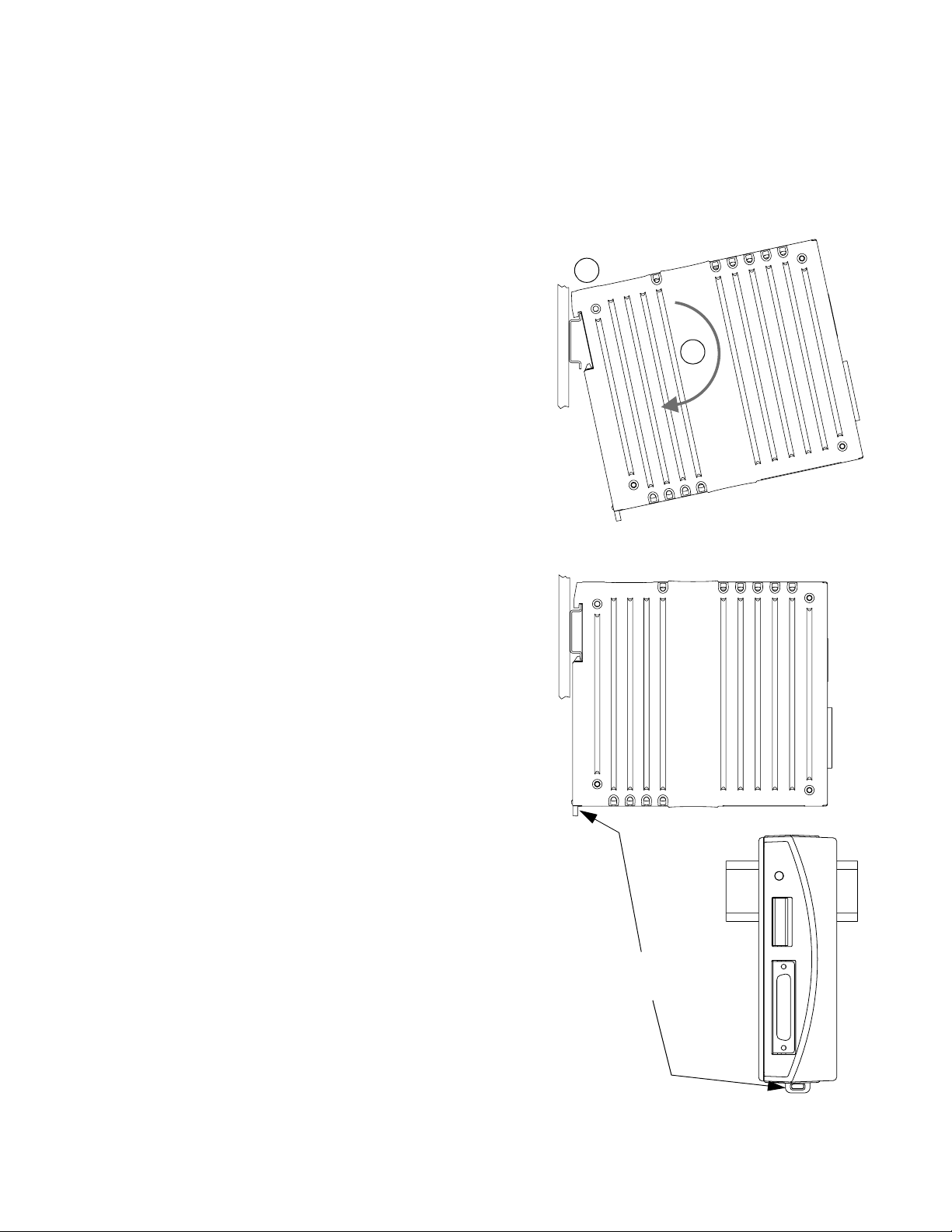

Inserting and Removing Mounting Brackets from the Impulse

Both Impulse mounting brackets are interchangeable and each is inserted or removed according to

the following procedures. No tools are required to insert a bracket, however a flat-bladed

screwdriver is required for removal. If additional brackets are required, see Chapter 2, Shipping

Contents, for part numbers.

Installation of Bracket

1. Insert the bracket into the bracket housing from the

top side of the Impulse as show n in the drawing on

the right.

2. Slide bracket downward until a single click is felt

(detent position). The bracket will be seated in the

position shown at righ t. Note: If you push the bracket

beyond the detent position (second click), it will be

necessary to push the bracket back to the detent

position.

Do not attempt to remove the bracket by pulling it

from the bottom of the bracket housing. Both brack et

and bracket housing coul d be per manent ly damaged.

(DIN Rail Bracket Shown)

Installation

2

Slide Bracket into

Position as

Shown Here

1

Insert

Bracket

Removal of Bracket

(DIN Rail Bracket Shown)

1. Insert the tip of a flat-bladed screwdriver between

the bracket-release arms as shown in the drawing at

right.

2. Gently twist the tip of the screwdriver until the arms

are spread apart enough to clear the detent

mechanism on the housing. Maintain this position.

3. While holding the arms apart with the screwdriver,

push the bracket toward the top of the bracket

housing as shown in the drawing.

Do not attempt to remove the bracket by pulling it

from the bottom of the bracket housing. Both brack et

and bracket housing coul d be per manent ly damaged.

Removal

1

Insert screwdriver

blade perpendicular

to bracket (profile of

blade shown in

spread position)

2

Twist until arms are

spread apart - hold

in position

Push bracket free of

3

arms and out the

bracket housing

3-12

Page 23

Impulse DIN-Rail Mounting

The DIN-rail mounting system is a combination of 1) a removable mounting bracket, which locks

the drive onto the DIN-rai l (ins tallation on pr evious p age), plus 2) the DIN-r ail hang er on t he upper

rear part of the housing that suspends the weight of the drive on the rail.

Chapter 3 - Connecting and Installing Your Impulse

Mounting the Impulse on the DIN-Rail

1. Hook the top of the DIN-rail hanger

over the top of the DIN-rail.

2. Rotate the Impulse drive downward

until it locks into place on the rail.

3. Pull back slightly on the drive to ensure

it is securely fastened to the rail.

Removal of Impulse from the DIN-Rail

Mounting

1

2

Impulse Securely Mounted on DIN-Rail

1. Ensure power to the drive is OFF.

2. Remove the motor connector.

3. Insert tip of flat-bladed screwdriver into

slot provided on the bottom of the

mounting bracket (see drawings on the

right).

4. Gently pry down ward unti l the brack et

disconnects from the rail. Note: The

bracket will fall approximately 1 inch,

but will still be retained by the Impulse

housing. Do not attempt to remove the

bracket by pulling it from the housing.

5. The bracket can be reset to the detent

position by pushing upward until a click

is felt (see “Installation of Bracket” on

the previous page).

Removal

Insert screwdriver blade

and pull downward

3-13

Page 24

Chapter 3 - Connecting and Installing Your Impulse

This page intentionally left blank

3-14

Page 25

Chapter 4 - Configuring Impulse with Applic ation Developer

Chapter 4 - Configuring Impulse with Application Developer™

This chapter covers the installation and use of IDC’s Application Developer software to configure

your Impulse drive.

Installing Application Developer on Windows 95/98/2000/ME/NT

1. Place the IDC CD in your CD-ROM drive and click on the Start button.

2. Click on Run.

3. Type the following in the Command Line box that appears (replace “x” with your CD drive

letter if different): x:\App_Dev\Setupex.exe

4. Click OK and follow the onscreen instructions.

5. Restart Windows (recommended).

There are no known installation problems with Application Developer, but please call the IDC

Applications Department at (800) 747-0064 or (707) 789-1000 (from outside U.S.) if you need

assistance installing this software.

4-1

Page 26

Chapter 4 - Configuring Impulse with Application Developer

Using Application Developer

Application Developer’s graphic user interface allows you to configure and program your Impulse

using an appropriately equipped computer. Upon starting Application Developer you will be given

four options for beginning the configuration of your application (see window below).

1 2 3

page 4-5

4

Select from one of the following options to begin configuring your Impulse:

1. Upload Project. If your drive has already been configured, this option allows you to upload a

project file from the drive for editing (modification), troubleshooting, etc. See Upload Project

on the next page for more information on using this option. The Project Wizard is the best

method for initial drive configuration and building a new project file.

2. Launch Now - Allows you to go directly to the main menu or tool bar buttons to quickly

configure or change project parameters. See Launch Now on page 4-4 for more information.

3. Project Wizard - Clickin g on the Project Wizard button will take you through the

quickest, most accurate method of configuring the initial setup parameters for your

project file (see page 4-5 for details).

4. Open an Existing Project. To bypass the Project W izard and select a stored file from the Open

File window, click on the Open an Existing Project button (see page 4-4).

4-2

Page 27

Upload Project

1. Begin by clicking the Upload Project button on the

Application Developer Startup window. Yo u will see the

Control Type Selection menu (shown right).

2. Configuration begins by selecting your Impulse from the

list of Steppers. Click OK.

3. Select the Port you will use to connect the Impulse.

Chapter 4 - Configuring Impulse with Applic ation Developer

Comm Port Settings

(for reference only)

RS-232C/RS-485

Baud Rate 19200 (fixed)

Stop Bits 1

Data Bits 8

Parity None

XON/XOFF Yes

4. Select the Unit Number (from 1 - 99) of the Impulse being configured.

5. To test communication u sing the current setup, click on Test Connection. Click OK.

OR

6. Skip the section on Using the Project Wizard and go to Fine Tuning Your Application.

Note: Echo and Mode are not available; they have no effect on the Impulse drive.

4-3

Page 28

Chapter 4 - Configuring Impulse with Application Developer

Launch Now

This method of begi nning Application Develo per is typically used by more experienced users o f IDC

products. Select your Impu l se vers ion and press OK. You can now go directly to the Main Menu or

tool bar buttons to configure the Impulse (see Fine-Tuning Your Application).

Open an Existing Project

If you want to open a project file which has been st ored on disk (not in the Impu lse), select Open an

Existing Project. Select the desired file and click on the Open button. After opening an existing

project file, it is still possible to use the Project W izard at any time by simply clicking on the W izard

toolbar button. See Fine-Tuning Your Application if you do not wish to use the Project Wizard.

4-4

Page 29

Using the Project Wizard

1. Click the Project Wizard button on the Application Developer Startup window.

• Select the product you are configuring, Impulse in this case, and click on Next.

• The Wizard Navigator (left side of window) allows you to quickly locate your current posi-

tion in the setup process. The column of boxes represents the parameter being configured.

A box’s color r epresents its configuration status, i.e. gray indicates a parameter not yet configured, yellow indicates the parameter currently being configured, and black indicates

completed configuration of the parameter.

Wizard

Navigator

Chapter 4 - Configuring Impulse with Applic ation Developer

2. Click on the Next button and the Motor setup window will appear . The configuration pro cedure

in Motor Setup differs slightly depending upon whether you are using IDC or Custom (userdefined) motor (see A ppendix C t o configur e a custom mo tor). IDC -supplied motors hav e been

precisely characterized in motor files which reside in an Application Developer directory . These

files cannot be altered or deleted. User-defined (custom) motor files must be created by the user.

If you want to change the operational characteristics of an IDC m otor, you can do so b y selecting

an IDC motor from the scrollable list and saving it under a new file name in the Motor Editor

(the original motor file remains unchanged under its original file name).

• From the pull down menu, s elect the IDC mot or you will be us ing, or click on Add Custom

Motor and see Appendix C for information on configuring a custom motor file.

4-5

Page 30

Chapter 4 - Configuring Impulse with Application Developer

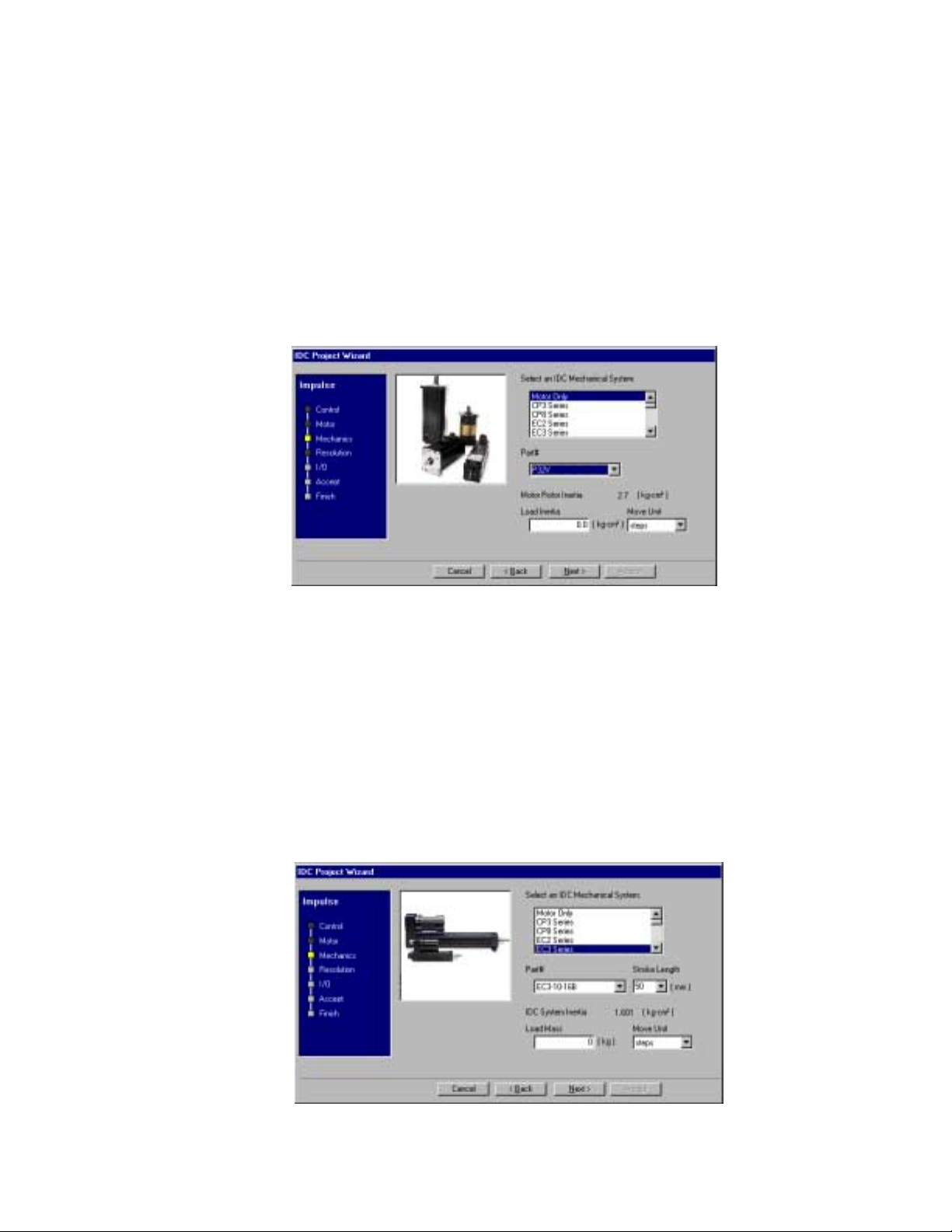

3. Click Next and the first of three possible Mechanics setup windows will appear. The

Mechanics window that appears depends on the selection made in the Select an IDC

Mechanical System list.

Mechanics window A (shown below) appears when a Motor Only is being configured. This

window shows the IDC motor or user-defined file name in the Part # text input box, and the

Motor Rotor Inertia (in kg-cm

• Select Motor Only.

• Load Inertia - Enter Load Inertia in the text input box.

• Move Unit - Choose your move unit from the pulldown menu.

2

) of the motor being configured.

A

Mechanics window B (below) will appear if an IDC Mechanical System (other than Motor

Only) is selected. This window allows you to select an IDC Mechanical System, the Part # of

the system, and the Stroke Length, Travel, Gear Ratio, or Table Diameter of the system.

• Select the category of IDC Mechanical System you are using.

• Select the Part # of the system.

• Select the Stroke Length (cylinders), Travel (tables), Gear Ratio (gearmotors), or Table

Diameter (rotary tables).

• Enter the Load Ma ss (cylinders and ta bles), o r Load Inertia (gearmo tors and rotary tables).

• Select the Move Unit for the system.

B

4-6

Page 31

Chapter 4 - Configuring Impulse with Applic ation Developer

Mechanics window C will appear if you select Non-I DC Mechanics from the “system” list.

• Enter your Total System Inertia (Load + Mechanics + Motor).

• Select your Move Unit (steps, revs, mm, or inches) from the pulldown menu.

• Enter you r Distance Ratio (only if in ches or mm a re the selected Move Un its ). You cannot

enter Distance Ratio if either steps or revs has been selected.

C

4. Click Next and the Resolution setup window will appear

• Select your Step Resolution from the pulldown menu, or enter a step resolution in increments of 200.

5. Click on Next and the I/O (Input/Output) setup wi ndow will appear . Using the pull down menus,

select configurations for up to fou r (4) Discrete Inputs and one (1) Discrete Output. The buttons

to the right of the inputs and outputs are provided for toggling between Active High (A.H.) and

Active Low (A.L.).

4-7

Page 32

Chapter 4 - Configuring Impulse with Application Developer

Discrete Inputs (see pulldown menu)

Discrete Outputs (see pulldown menu)

6. When all parameters h ave been configured, click Next and the Accept window will appear . This

display allows you to review the se ttings made earlie r, or gives you an opportunit y to return

(Back button) to any parameter you may want to chan ge.

• When satisfied with the setup of your system, click on Accept. The Wizard Navigator

should now indicate that all setup parameters have been configured. Use the scroll.bar/buttons to review the project file.

4-8

Page 33

Chapter 4 - Configuring Impulse with Applic ation Developer

7. Your basic project file has now been configu red b ut the f our “Finish” step s must b e comp leted

in order to send the project file to the drive and probe the motor.

• Click on Config. Comm Port (#1) and select the Port to which you are connecting the

Impulse. Next, select a Unit Number (from 1 - 99) f or the Impuls e being configu red. To test

communication using the current setup, click on Test Connection. Click OK.

• Click on Send All (#2) to send the project setup parameters to the drive.

• Click on Probe Motor (#3). Pressing this button tells the drive to execute an electronic

probe of the motor to determine a host of proprietary, internal settings for use in the antiresonance/stall detect features. Any time the drive is connected to a different type of motor,

or if a new motor file is selected, the motor must be re-probed. When the drive is probing

the attached motor, a 1 kHz tone will be heard emanating from the motor. Depending on

motor type, this tone may persist for up to 15 seconds. Motor probe is not required each

time the Impulse is powered on. .

• Click on Set Tuning Values (#4) and enter the values from your IDC motor label.

• The project fi le has been sent to the drive and your appli cation can n ow be fine-tun ed using

the Axis Setup menu (starting on the next page).

4-9

Page 34

Chapter 4 - Configuring Impulse with Application Developer

Fine-Tuning Your Application

Your basic system setup parameters have been configured by the Project Wizard, and though the

system is functional, your application will probably require further configuration and fine-tuning.

The remainder of this chapter provides information on configuring your Impulse with Application

Developer’s setup and I/O menus. In addition to the parameters configured by the Project Wizard,

these menus provide additional features for more control of your system and greater capacity for

applications. Also covered in this chapter is the Motion Node or Stored Move option.

The Project Wizard remains available at any time by clicking on the Project Wizard button. The

Toolbar Buttons provide access to the setup parameters and other features that will be covered in

the remainder of this chapter.

Toolbar Buttons

The Application Developer toolbar buttons allow quick access to most of the menu s available on the

menu bar. The toolbar buttons shown below are available when configuring an Impulse drive. If a

button or item on the menu bar is grayed-out, that function is not available to Impulse users.

Axis Setup

•The Axis Setup menus consists of five configurable sub-menus. Click on the Axis Setup but-

• The first menu to appear will be the Motor menu tab (begins on the following page).

• Important! After making changes in the Axis Setup menu, remember to perfor m

New

Project

Open

Project

Save

Project

Print

Project

Wizard

Axis

Setup

I/O

Setup

Edit

Stored Moves

View

Configuration

Send

All

Receive

All

ton or go to File > Axis Setup on the main menu bar.

a Send All command (Send All button or Communications > Send All) to send

newly configured parameters to the drive.

Reset

Impulse

4-10

Page 35

Motor

Chapter 4 - Configuring Impulse with Applic ation Developer

• Motor Name - Select your motor from the list, or click on the Edit Motor button to create a

custom motor file or edit an existing IDC motor file.

• Electrical - These text input boxes display the electrical characteristics of the selected motor.

If a text input box displays a zero (0), that particular electrical characteristic has not been configured as part of the motor file. To create or change a motor file, see Edit Motor.

• Mechanical - These text input boxes display the mechanical characteristics of the selected

motor. If a text input box displays a zero (0), that particular mechanical characteristic has not

been configured as part of the motor file. To create or change a motor file, see Edit Motor.

• Edit Motor - See Appendix C for information on using this feature. The “Advanced” tuning

feature is also covered in Appendix C.

See Appendix C

to Edit a Motor

4-11

Page 36

Chapter 4 - Configuring Impulse with Application Developer

Mechanics

Move Unit and Total Inertia (kg-cm

2

) are displayed on this tab, but they are not editable

parameters. Click on the Change Mechanical System/Units button to edit your mechanical

parameters.

• Change Mechanical System/Units - The text input-box parameters (in each available Setup

Mechanical System window) are dependent upon the selection you make from the Select

Mechanical System list. Examples of different mechanical parameters are shown below.

Windows for Configuring IDC Mechanical System Parameters

4-12

Parameters for

non-IDC Mechanics

Notes:

• Motor Rotor Inertia is pr ov id e d fo r

reference only.

• Enter your Total System Inertia

(Load + Mechanics + Motor).

• Ensure all units have been con-

verted to kg-cm

2

.

Page 37

Command

Chapter 4 - Configuring Impulse with Applic ation Developer

The Command Tab allows you to configure the Command Signal and Jog I nput parameters, and

to select the level of Numeric Precision that Application Developer will use to build the project file.

Command Signal Configuration

• Drive Resolution - Enter the operating step resolution in integer multiples of four times the

tooth count of the motor (50 tooth count x 4 = 200), or select a resolution from the scrollable list. Note: the default resolution is 25,000 and the valid range is 200 to 100,000.

• Stop Rate - Enter the deceleration rate of the motor when a STOP or EOT input is acti-

vated (see Limits Tables in Ch. 9, Troubleshooting the Impulse). Notes: (1) The Stop Rate

units are user-defined (selected). (2) The Stop Rate should be a value that ensures enough

torque to control deceleration while not allowing the motor to stall.

• Direction - Sets motor direction. Toggle the Direction button to select Direction + (CW) or

Direction - (CCW).

• Shutdown Polarity - Toggle the Shutdown Polarity button to select Shutdown Active

Low or Shutdown Active High.

Jog Input Configuration

This option allows you to modify the jog parameters (Jog Accel, Jog Low, Jog High) to be

used by the Jog Inputs (JOG+, JOG-, JOG SPEED). These values will be in displayed in units

selected in the Project Wizard (Mechanical Setup Move Units) or in Axis Setup > Mechanics

> Change Mechanical Sytem/Units.

Note: Numeric entries made in the Jog Input Configuration section of the Command tab

are applied using the user-defined units shown. If the units are changed (Setup > Axis >

Mechanical > Change Mechanical System/Units), the user must edit the Jog Input

Configuration values to obtain the intended velocities and acceleration in terms of the new

units. Application Developer does not automatically translate the numeric values when the

units are changed.

Enter Jog values directly in the text input boxes or use default values (shown below).

• Jog Accel (Jog Accel/Decel) - Default = 20.00 (user-defined units)

• Jog Low (Jog Low Speed) - Default = 0.50 (user-defined units)

4-13

Page 38

Chapter 4 - Configuring Impulse with Application Developer

• Jog High (Jog High Speed) - Default = 2.00 (user-defined units)

Numeric Precision

• Select Standard to limit the decimal precision of accelerations, decelerations, velocities,

and distances to the following:

Accels and Decels: #.x (One decimal place)

Velocities: #.xx (Two decimal places)

Distances: #.xxx (Three decimal places)

The Standard decimal precision is sufficient for most applications. Standard is the default

setting.

Note: The keypad (FP100 or FP220) only supports Standard decimal precision, therefore

project files intended to be used in conjunction with the keypad must be created using the

Standard setting. Attempting to load a project file into the keypad without Standard

decimal precision will result in an error.

• Select Extended to limit the decimal precision of accelerations, decelerations, velocities

and distances to the following:

Accels and Decels: #.xxx (Three decimal places)

Velocities: #.xxxxx (Five decimal places)

Distances: #.xxxxx (Five decimal places)

Project files created with Extended decimal precision may be edited only in Application

Developer.

4-14

Page 39

X-Smoothness (Xtreme Smoothing™)

The X-Smoothness tab is the most advanced low-speed tuning feature currently available on any

microstepping drive. The benefits of low-speed smoothness are 1) reduced vibration, and 2) an

increase in torque, which was typically lost to vibration before the arrival of the Impulse drive.

Achieving this revolutionary smoothness is easily and quickly accomplished by following the

simple procedure below. Note: the motor must be disconnected from its load while performing

Xtreme Smoothing™.

Chapter 4 - Configuring Impulse with Applic ation Developer

• X-Smoothness Sliders - Click and drag the indicator to change a value.

• Test Speed - This text input box displays the Recommended T est Speed and may be edited

if necessary.

• Recommended Test Speed - This value has been either 1) pre-configured for IDC motors,

or 2) calculated when a custom motor file was created in the Advanced Mo tor Editor. V erify

that this value has been entered in the Test Speed display.

• Run Test/Stop Test Button - Toggles between Run Test and Stop Test.

•Restore - Restores each X-Smoothness to the previous values.

Adjusting X-Smoothness #1, #2, #3

Important: Whether using an IDC motor or a non-IDC (custom) motor, all six X-Smoothness

values (L1, L2, M1, M2, H1, H2) must be adjusted in the order described in the following

procedure. Note: Slider bars L1 and L2 are interactive, as are M1 and M2, and these interactive

sliders should be alternately adjusted until the deepest null setting is achieved.

X-Smoothness #1

Recommended values for L1 and L2 have been pre-configured for IDC motors, but we

recommend that these settings be verified and adjusted if necessary by the following procedure.

If you are using a custom motor file, these values wer e calculated in the Advanced Motor Editor .

1. Press the Run Test button.

2. Move slider L1 left and right until the smoothest running condition is reached.

3. Move slider L2 left and right until the smoothest running condition is reached.

4. Press Stop Test.

4-15

Page 40

Chapter 4 - Configuring Impulse with Application Developer

X-Smoothness #2

Recommended values for M1 and M2 have been pre-configured for IDC motors, but we

recommend that these settings be verified and adjusted if necessary by the following procedure.

5. Press the Run Test button.

6. Move slider M1 to approximately 8,000.

7. Move slider M2 left and right until the smoothest running condition is reached.

8. Move slide M1 left and right until the smoothest running condition is reached.

9. Press Stop Test.

X-Smoothness #3

10. Press the Run Test button.

11. Move slider H1 left and right until the smoothest running condition is reached.

12. Move slider H2 left and right until the smoothest running condition is reached.

13. Press Stop Test.

14. Click OK.

4-16

Page 41

Advanced (Advanced Tuning)

The Advanced tab allows you to enable/disable and modify various advanced perfor mance features

of the Impulse drive.

Anti-Resonance

Chapter 4 - Configuring Impulse with Applic ation Developer

Note: Observe decrease in

Gain when Multi-Stepping is

Enabled.

• Enable this feature by selecting the Enabled check box. Ensure that both Damping Gains

are configured if Anti-Resonance is enabled.

Current Reduction Mode

•Select Stop to enable the stop mode current reduction time-out period. Stop Mode reduces

current by 25%. This time-out period is directly entered in milliseconds. The valid range is

6 to 19,656 ms.

•Select Idle to set the idle mode current reduction time-out period. This time-out period is

directly entered in seconds. The valid range is 0 to 3600 seconds (0 = disabled).

•In the % box, enter the percentage that current will be reduced after the idle mode time-

out has expired. The valid range is 0 to 100%.

Profiling

•Select Dynamic Smoothing Enabled by clicking on the check box and entering the recom-

mended gain in the input b ox. D ynamic Sm oothin g™ is an IDC pro prietary method o f auto matically reducing “jerk” (sudden change of acceleration) which is often inherent in move

sequences generated by indexers. Dynamic Smoothing™ is similar in effect to so-called Scurve profiles. The softening of accel/decel transients sharply reduces ringing in the motor

and various attached structures.

•Select Multi-Stepping En abled for more aggressive dynamic smoothing. Gain will be

1/10 of the recommended gain when Dynamic Smoothing is enabled. Multi-Stepping™ is

an IDC proprietary method of obtaining very smooth motion from step motors when using

low resolution indexers, i.e. 200, 400, 1000 steps/rev. The Multi-Stepping™ feature, when

enabled, executes coarse stepping regimens by using microsteps to fill-in between the

widely-spaced, low-resolution steps. This is a form of interpolation that produces smooth

motion in an otherwise coarse and noisy stepping system.

4-17

Page 42

Chapter 4 - Configuring Impulse with Application Developer

Stall Detection

• Select Stall Detection to enable the Open Loop Stall Detect™ encoderless stall detection

feature.

• Stall detection becomes active at velocities of 0.5 RPS and greater.

Remember to perform a “Send All” command to send the modified project file to

the drive.

I/O Setup

After configuring the Axis Setup parameters, the discrete inputs (4 ea.) and output (1 ea.) will need

to be configured for your application. See I/O Descriptions below for details.

• Click on the I/O Setup tool bar button.

• Select up to four Discrete Inputs and one Discrete Output from the pulldown menus.

• Use the toggle button s to right of the inputs to select between Active Low (A.L.) and Active

High (A.H.).

I/O Descriptions

Input Descriptions

EOT (End of Travel): Activation of an End of Travel input during any motion (external steps or

internal move engine) will terminate motion at the rate specified by the Stop Rate parameter, and

latch the direction. Motion is only allowed in the direction opposite of the latched EOT direction

until a negative edge (activation on to activation off) is made. This guards against the switch

activator becoming “trapped” if the Stop Rate was insufficient to stop motion in the activation

region. The EOT input is also required in the execution of Home type moves. See Stored Move

4-18

Page 43

Chapter 4 - Configuring Impulse with Applic ation Developer

Setup - Editing Stored Moves later in this chapter for more information on Home moves.

Jog +: Activation of a Jog+ input will jog the motor at the acceleration rate specified by the Jog

Accel parameter and the velocity specified by the current state of a Jog Speed input in the positive

direction. If a Jog Speed input has not been configured, the motor is jogged at the velocity specified

by the Jog-Low parameter.

Jog -: Activation of a Jog- input will jog the motor at the acceleration rate specified by the Jog Accel

parameter and the velocity specified by the current state of a Jog Speed input in the negative

direction. If a Jog Speed input has not been configured, the motor is jogged at the velocity specified

by the Jog-Low parameter.

Jog Speed: The Jog Speed input toggles between the low and high velocities for the Jog+ and Jog-

inputs as specified by the Jog-Low and Jog-High parameters. If the state of Jog Speed input is

changed while a Jog+ or a Jog- input is asserted, the motor will accel or decel at the Jog Accel r ate

to the high or low velocity respectively.

Kill: Activation of a Kill input terminates any motion (external steps or internal move engine)

instantly without a deceleration ramp.

Move Select: The Move Select input is used to trig ger on e of the 7 poss i ble stor ed moves (Mot ion

Node option only). Each configured Move Select input serves as a bit in a 3-bit binary number

therefore allowing the binary representation of numbers 0-7. The Move Select configuration option

is only available on inputs #1-#3 with input #1 being the least significant bit (LSB) and input #3

being the most significant bit (MSB). Note that the bit places are fixed with respect to the input

numbers. For example, if input #1 were configured as an EOT and input #2 were configured as a

Move Select, asserting input #2 would run stored move #2 not stored move #1. Below is a Move

Select assertion table:

Move Select Inputs

Input #3 State Input #2 State Input #1 State Result

Inactive Inactive Inactive Idle

Inactive Inactive Active Run Stored Move #1

Inactive Active Inactive Run Stored Move #2

Inactive Active Active Run Stored Move #3

Active Inactive Inactive Run Stored Move #4

Active Inactive Active Run St ored Move #5

Active Active Inactive Run Stored Move #6

Active Active Active Run Stored Move #7

T o guard against inadvertently selecting moves during input transitions, all Move Select inputs must

be stable for the time specified by the Mov e Select Input Scan T ime. See the “Editing Stored Moves”

section for more information on setting the Move Select Input Scan Time.

Stop: Activation of a Stop input terminates any motion (external steps or intern al move engine) at

the rate specified by the Stop Rate parameter.

Warm Boot: Activation of a Warm Boot input resets the drive and clears any latched fault

condition. To g uard against a Warm Boot input being inadvertently held asserted, the Warm Boot

input is negative edge triggered (activation on to activation off). To insure the negative edge is

latched, the Warm Boot input must be held asserted for at least 500µs before releasing.

4-19

Page 44

Chapter 4 - Configuring Impulse with Application Developer

Output Descriptions

Brake: The Brake output is activated on any fault condition. This provides a control signal to

engage a brake when the Impulse loses torque due to a fault. The Brake output also provides a

polarity-configurable fault output since the ded icated fault output is fixed as an active high, si nking

output. Note: The Brake output is not intended nor designed as a power source for a mechanical

brake.

In Motion: The In Motion output is activated upo n receiving incoming step pulses or when a stored

move (Motion Node option) is running. The minimum step frequency that the internal velocity

tachometer can render is 156.25 Hz (156.25 / Step Resolution in RPS). Input step freq uencies below

156.25 Hz will not activate the In Motion output.

Stall: The Stall output is activated when OLSD™ (Open Loop Stall Detect) detects a motor stall.

4-20

Page 45

Chapter 4 - Configuring Impulse with Applic ation Developer

Stored Move Setup - Editing Stored Moves

If your Impulse is equipped with the Motion Node option you will be able to access the Stored

Move Setup menu shown below. The Impulse will store seven (7) moves which can be invoked

through binary inputs, by serial commands (see Appendix B), or via the Run > Stored Move

window . Moves are edited in the Stored Move Setup window via Edi t > Stored Move or the Edit

Stored Moves tool bar button.

• Click on the Edit Stored Moves button.

• Use the information provided below to configure your Stored Moves in the St ored Move Setup

menu.

Stored Moves are defined by the parameters Accel (acceleration rate), Decel (deceleration rate),

Velocity, Position/Distance, and Move Type. Distance Units pertaining to the four dynamic

parameters are selected in the Project Wizard or the Axis Setup tab (Setup > Axis > Mechanics >

Change Mechanical System/Units). The three move types are Incremental, Absolute, and Home,

each selectable by a radio button.

Incremental moves are indexed to the commanded position from the current position.

Absolute moves are indexed to the commanded distance.

Home moves function as follows:

1. The drive moves at the specified velocity (direction selected by velocity sign) until it sees an

EOT input go active.

2. On the active going transition, the drive decelerates according to the specified Stop Rate

parameter.

3. The drive reverses direction and moves at 1/16 of the specified Velocity until it sees an activeto-inactive transition on the EOT input. This locates the inside edge of the EOT sensor precisely .

4. The drive stops the slow mov e and executes an incremental move defined by the Distance entry .

This final move is always in the opposite direction to the initial search direction specified by the

sign of the V elocity parameter . This move constitutes an offset from the edge of the EOT sensor.

5. After the final position is reached, the drive zeros its position counter. All subsequent “absolute”

moves will be relative to this Home position.

4-21

Page 46

Chapter 4 - Configuring Impulse with Application Developer

Note: Homing is predicated on the assumption that the system is positioned somewhere

between the EOT switches when the home move is invoked. If the system is initially outside the

interval between the EOT switches, the homing routine will fail in one of two ways: (1) carriage

will be driven against mechanical end-stop. (2) carriage will end up “homed” outside the

interval between the EOT switches.

Digital inputs are configurable as EOT (Active High/Active Low) on the Setup > I/O menu.

More than one Home move can be specified and stored simultaneously if it serves a purpose.

Input Scan Time - This is the time the drive requires the binary input selection to be stable prior to

triggering a move. Its primary purpose i s for debou nci ng input s. Scan time can be conf igured from

0 to 19,656 milliseconds.

4-22

Page 47

File Menu

Edit Menu

Chapter 4 - Configuring Impulse with Applic ation Developer

• Selecting New Project will take you to the Project Wizard.

• The default file suffix is *.idc.

• Project files may be stored on disk as DOS files.

• All other selections under the File menu are generic to all Windows applications.

• Stored Move and Motor File Editor s , both discussed previously, can also be accessed from

Setup Menu

• I/O, Axis, and Project Wizard, accessible from toolbar buttons, have been discussed previ-

• Select Controller Type as the first step in starting a new project file. You must select a con-

the menu bar.

oulsy.

troller before you can build a new project file.

4-23

Page 48

Chapter 4 - Configuring Impulse with Application Developer

Communications Menu

•Use Send All to download a project file to the drive. A Send All toolbar button is also avail-

able.

•Use Retrieve All to upload a project file from the drive for modification.

• Project Update allows you to accelerate the configuration of multiple drives when all drives

have the same setup configuration. After configuring your first drive with the Project Wizard,

select Project Update and follow the onscreen prompts for each additional drive.

• Change Unit Num ber is used to set the unit address of each

drive to be used on a daisy chain. Each drive must have its own

unique software address. The unit nu mber must b e set before the

units are connected in the daisy chain.

Press Query Address if the address is unknown. This feature

can only be used with a single drive connected to the computer.

An attempt to Query Address of a unit on a daisy chain will

result in an error message.

• Setup Comm Port is us ed to s elect a C omm Port when you r PC

has multiple serial ports. This dialog box also contains a Comm Port test utility to verify proper

RS-232/485 operation.

• Select Test Connection to command an instant communication test (also available in Setup

Comm Port).

• For information on Load Flash Memory, see Updating Your Impulse Operating System at

the end of this chapter.

4-24

Page 49

Run Menu

Chapter 4 - Configuring Impulse with Applic ation Developer

•The Run > Stored Move menu is available only on drives equipped with the Motion Node

option and can only be accessed from the menu bar. This menu allows you to view all stored

move profiles and to run and stop each stored move.

• No editing of moves is available on this menu. During the execution of any stored m ove, the

Impulse ignores the step and direction inputs. Any activity on those inputs is completely lost.

In other words, stored moves are not added in with incoming step commands. Typically, it is

not a useful control stratagem to trigger a stored move while engaged in motion commanded

via the step and direction inputs.

• Binary inputs (digital inputs 1, 2, and 3) may be configured as Move Inputs (Active High/

Active Low) for triggering stored moves (Setup > I/O).

• Serial Commands - A host system may trigger moves over the serial RS-232/485 connection.

This procedure involves the transmission of Unit Addressing, Parameter Indexes, Data and

Checksum. The advanced topic of serial communications protocol is covered separately in

Appendix B.

•Click on Probe Motor to probe th e motor at any time. Probe th e motor when a st eady re d LED

is present.

• Select Jog Motor to access the jog utility shown below. Jog Low and Jog High may be

changed for immediate effect but the configured input speeds (set in the Axis Setup > Command menu) will not be changed. The center button toggles between High and Low speeds,

and the arrow buttons change motor direction.

•Click on Reset Impulse to clear a fault. Reset is a warm boot.

4-25

Page 50

Chapter 4 - Configuring Impulse with Application Developer

View Menu

• Select Configuration Text File to see your system

configuration status. All configuration parameters are

listed and may be viewed by scrolling the list.

• Select Control Status for a quick look at current I/O configuration, motor position and veloc-

ity, fault history, and basic internal drive information (i.e. firmware version, etc.).

4-26

• Click Drive Info for a look at hardware and firmware versions. In the unlikely event that

the Impulse sustains an EEPROM Fault (7 red LED flashes) the Restore Factory Settings

button is used to clear the current memory contents and restore the factory default configuration of the Impulse.

• Click Fault History to look at the eight most recent drive faults, accumulated hours of

operation, and the number of power cycles.

• Click Refresh to get a quick snapshot of the Drive Status.

•Press the Poll button to continuously check drive status. Stop Polling turns polling off and

restores the Refresh button.

Page 51

Chapter 4 - Configuring Impu lse with Application Developer

Updating Your Impulse Operating System:

Your Impulse drive contains FLASH memory technology allowing the flexibili ty and convenience

of upgrading the operating system using Application Developer and a PC RS232 or RS485 serial

connection. The latest released Impulse operating system version is available for download at our

web site http://www.idcmotion.com

.

WARNING:

the factory. The potential for FLASH corruption exists if the operating system upgrade is

interrupted while in progress. If the FLASH memory becomes corrupted, it will need to be

reprogrammed at the factory.

NOTE:

sure to save the drive setup as a .idc file or in a keypad before upgrading the ope rating system.

Upgrading the operating system should only be performed when instructed by

Upgrading the operating system will reset the drive setup to factory default settings. Be

Loading the Operating System

WARNING: DO NOT

RS485 bus. Attempting to load multiple units simultaneously will result in a FLASH corruption of all units.

1. Obta in th e n ew op erating system file fro m http://www.idcmotion.com or directly from the

factory.

2. With a

from Application Developer.

3. Use the Open File dialog box to select the desired .hex operating system file.

4. Applic ation Deve loper wil l est ablish a FL ASH memory conne ction and begi n the trans fer. The

warning and progress screens (shown below) will appear when the FLASH transfer begins.

Impulse drive connected, select

single

attempt to load the operating system over an RS232 daisy chain or

Communications > Load FLASH Memory

4-27

Page 52

Chapter 4 - Configuring Impulse with Application Developer

This page intentionally left blank

4-28

Page 53

Chapter 5 - Configuring Impulse with an IDC Keypad

Chapter 5 - Configuring Impulse with an IDC Keypad

Section 1 of this chapter is intended primarily to familiarize new IDC keypad users with the FP100

Impulse Keypad, and we recommend th is section be reviewed by those expe rienced with the FP220

keypad as well. If you are u sing an FP220 keypad (vers ion 3.00 and above) t o configure the Impulse,

it is imperative that the keypad DIP-switches be set as shown on the next page.