Page 1

PLC-16.PCI User Manual

Part Number 8011

www.sealevel.com PO Box 830 Liberty, SC 29657 864.843.4343

Page 2

Table of Contents

INTRODUCTION......................................................................................................................... 1

OTHER SEALEVEL PCI DIGITAL I/O PRODUCTS.........................................................................................................1

BEFORE YOU GET STARTED................................................................................................. 2

WHAT’S INCLUDED....................................................................................................................................................2

OPTIONAL ITEMS .......................................................................................................................................................2

SOFTWARE INSTALLATION.................................................................................................. 3

WINDOWS 98/ME/NT/2000/XP INSTALLATION ........................................................................................................3

LINUX INSTALLATION................................................................................................................................................4

PHYSICAL INSTALLATION....................................................................................................5

PROGRAMMING THE PLC-16.PCI ........................................................................................ 6

PROGRAMMING FOR WINDOWS .................................................................................................................................6

PROGRAMMING FOR LINUX .......................................................................................................................................6

DIGITAL I/O INTERFACE ............................................................................................................................................6

INPUT PORT ...............................................................................................................................................................7

INPUT PORT PIN ASSIGNMENTS (HD44 FEMALE) ......................................................................................................8

OUTPUT PORTS (FORM C RELAYS)............................................................................................................................8

OUTPUT PORT PIN ASSIGNMENTS (HD44 FEMALE)...................................................................................................8

DIRECT HARDWARE CONTROL..................................................................................................................................8

READING THE INPUTS ................................................................................................................................................8

WRITING THE OUTPUTS .............................................................................................................................................9

READING THE OUTPUTS.............................................................................................................................................9

REGISTER DESCRIPTION ............................................................................................................................................9

INTERRUPT CONTROL................................................................................................................................................9

HD44 FEMALE PIN ASSIGNMENT ............................................................................................................................10

OPTIONAL TERMINAL BLOCK KIT (ITEM# KT108)..................................................................................................11

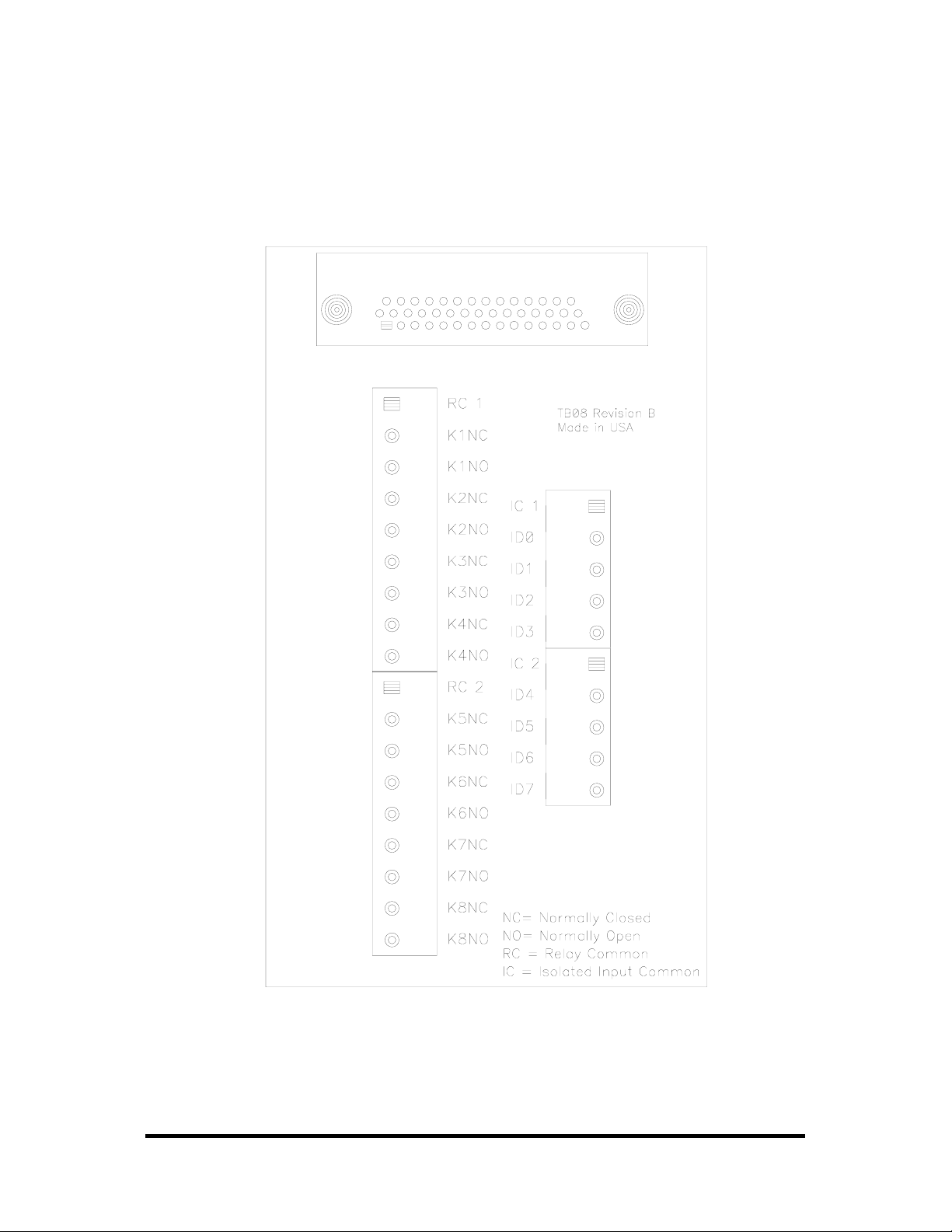

SILK SCREEN – TB08 TERMINAL BLOCK.................................................................................................................12

OPTIONAL CABLE PIN ASSIGNMENTS (ITEM# CA184) ............................................................................................13

INPUT PORT PIN ASSIGNMENTS (DB37 FEMALE) ....................................................................................................13

OUTPUT PORT PIN ASSIGNMENTS (DB37 MALE) ....................................................................................................13

ELECTRICAL CHARACTERISTICS.................................................................................... 14

FEATURES................................................................................................................................................................14

SPECIFICATIONS.......................................................................................................................................................14

EXAMPLE CIRCUITS.............................................................................................................. 15

APPENDIX A - TROUBLESHOOTING ................................................................................. 16

APPENDIX B - HOW TO GET ASSISTANCE ...................................................................... 17

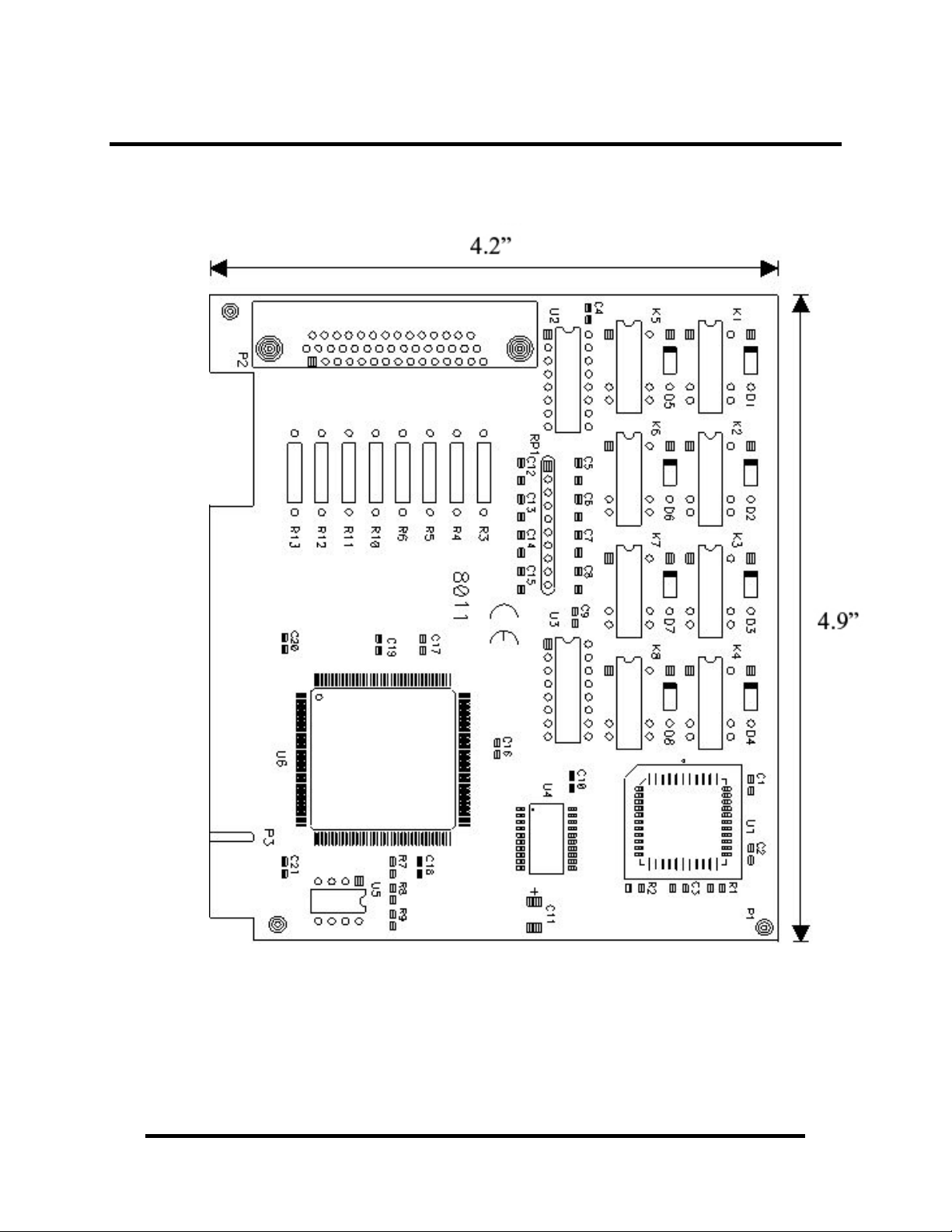

APPENDIX C – SILK SCREEN – 8011 PCB.......................................................................... 18

APPENDIX D - COMPLIANCE NOTICES............................................................................ 18

FEDERAL COMMUNICATIONS COMMISSION STATEMENT.........................................................................................19

WARRANTY............................................................................................................................... 20

© Sealevel Systems, Inc.

SL9014 Revision 7/2006

PLC-16.PCI User Manual

Page 3

Introduction

The PLC-16.PCI provides 8 Form C relays that can switch and carry 2A loads

making it suitable for latching power, data or other electronic signals for control

applications. Eight optically isolated inputs (rated for 5-30V) are also provided to

allow monitoring of off board switch closures, relays or for any other general

purpose monitoring needs. The PLC-16.PCI is optimized for 24V DC/AC usage.

The board is PCI bus specification 2.1 compliant.

The PLC-16.PCI is designed to be used with a variety of Operating Systems

including Windows 98/NT/ME/2000/XP, Linux and DOS. The SeaI/O API

(Application Programmer Interface) included on CD with the PLC-16.PCI provides

a variety of useful high-level function calls implemented as a Windows dynamic

link library (DLL) and as a Linux kernel module and library. In addition to the API,

SeaI/O includes sample code and utilities to simplify software development.

Other Sealevel PCI Digital I/O Products

PIO-24.PCI (P/N 8008) - 24 TTL Inputs/Outputs

PIO-32.PCI (P/N 8010) - 32 TTL Inputs/Outputs

PIO-48.PCI (P/N 8005) - 48 TTL Inputs/Outputs

PIO-96.PCI (P/N 8009) - 96 TTL Inputs/Outputs

DIO-16.PCI (P/N 8002) - 8 Reed Relay Outputs/8 Opto-isolated Inputs

REL-16.PCI (P/N 8003) - 16 Reed Relay Outputs

DIO-32.PCI (P/N 8004) - 16 Reed Relay Outputs/16 Opto-isolated Inputs

ISO-16.PCI (P/N 8006) - 16 Opto-isolated Inputs

REL-32.PCI (P/N 8007) - 32 Reed Relay Outputs

© Sealevel Systems, Inc.

- 1 -

PLC-16.PCI User Manual

Page 4

Before You Get Started

What’s Included

The PLC-16.PCI is shipped with the following items. If any of these items is

missing or damaged please contact Sealevel for replacement.

PLC-16.PCI Adapter

Sealevel SeaI/O Software CD

Optional Items

Depending upon your application, you are likely to find one or more of the

following items useful for interfacing the PLC-16.PCI to real-world signals. All

items can be purchased from our website (http://www.sealevel.com

(864) 843-4343.

DB44 Male to DB44 Female 6’ Cable (Part Number CA185)

− High Density DB44 Male to Female extension cable.

DB44 Male Terminal Block (Part Number TB08-KT)

− The TB08-KT, designed for use with the Sealevel 8011, eases field

wiring of 8 optically isolated inputs and 8 Form C relay outputs. The

terminal block has an HD44 male connector that breaks out to 28

screw terminals.

Cable and Terminal Block Kit (Part Number KT108)

− Includes CA185, TB08-KT, 6” Snap Track, and DIN rail clips.

) or by calling

DB44 Male to DB37 Male/Female V-Cable (Part Number CA184)

− Optional cable for 8011 with a DB44 connector that breaks out to one

DB37 Female connector for Inputs and one DB37 Male connector for

Outputs.

DB37 Male/Female Terminal Block (Part Number TB02-KT)

− Break out serial and digital connectors to 37 screw terminals for easy

field connection. The TB02 terminal block is designed with both

DB37 male and female connectors, therefore; it can be used with any

DB37 board regardless of the board's port gender.

Cable and Terminal Block Kit (Part Number KT109)

− Includes CA184, two TB02-KT, 6” Snap Track, and DIN rail clips.

© Sealevel Systems, Inc.

- 2 -

PLC-16.PCI User Manual

Page 5

Software Installation

Windows 98/ME/NT/2000/XP Installation

Do not install the Adapter in the machine until the software has been fully

installed.

1. Start Windows.

2. Insert the Sealevel Systems CD in to your CD drive.

3. If ‘Auto-Start’ is enabled for this drive the software will automatically

launch. Otherwise, point your browser to the ‘Index.htm’ on the root

directory of the CD

4. Select ‘Install Software’.

5. Select the Part Number for your adapter from the listing.

6. Select ‘Windows 98/ME/NT/2000/XP’. The setup file will automatically

detect the operating environment and install the proper components. Next

(depending on your browser) select the ‘Run this program from its current

location’ or ‘Open’ option. Follow the information presented on the screens

that follow.

7. A screen may appear with the declaration: “The publisher cannot be

determined due to the problems below: Authenticode signature not found.”

Please select the ‘Yes’ button and proceed with the installation. This

declaration simply means that the Operating System is not aware of the

driver being loaded. It will not cause any harm to your system.

8. During setup the user may specify installation directories and other preferred

configurations. This program also adds entries to the system registry that are

necessary for specifying the operating parameters for each driver. An

uninstall option is also included to remove all registry/INI file entries from

the system.

Windows NT Card Installation: After accomplishing the above steps, bring up the

Control Panel and double-click on the SeaIO Devices icon. To install a new card,

click "Add Port". Repeat this procedure for as many SeaIO cards as you wish to

install.

© Sealevel Systems, Inc.

- 3 -

PLC-16.PCI User Manual

Page 6

Linux Installation

Note: You MUST have "root" privileges to install the software and drivers.

Note Your cdrom may not be /dev/hdc it could be /dev/hda, /dev/hdb, /dev/hdd, or if

you have a SCSI drive /dev/sda, /dev/sdb, /dev/sdc, etc. You may mount the

CDROM to any location, the /cdrom is just a common example.

Note: The syntax is case sensitive.

1. Login as "root".

2. Mount the CDROM by typing:

mount -t iso4860 /dev/hdc /cdrom

3. Next change to the directory where you mounted the CDROM:

Ex. cd /cdrom/software/SeaIO/Other/linux

4. Copy seaio .tar.gz to your home directory by typing:

cp seaio .tar.gz ~

5. Change to your home directory by typing:

cd

6. Unmount the drive and then Unzip and Untar the drivers and software by

typing:

umount /cdrom

tar -xvzf seaio .tar.gz

7. Change to the SeaIO directory by typing:

cd SeaIO

8. Now compile and prepare the drivers for use:

make install

9. With the system off and unplugged, install your SeaIO PCI card.

10. Plug system back in and boot Linux.

Login as "root".

11. Load the driver by typing:

SeaIO -load

The driver has enabled the card and is ready to use, and you now have the option to

run a test utility on it. Skip to section "Using the test software" if you wish to do so

at this time.

To set up Linux to automatically load the driver; refer to a Linux manual concerning

your specific distribution for help.

© Sealevel Systems, Inc.

- 4 -

PLC-16.PCI User Manual

Page 7

Physical Installation

The adapter can be installed in any 5V PCI expansion slot.

Do not install the Adapter in the machine until the software has been fully

installed.

1. Turn off PC power. Disconnect the power cord.

2. Remove the PC case cover.

3. Locate an available 5V PCI slot and remove the blank metal slot cover.

4. Gently insert the PCI adapter into the slot. Make sure that the adapter is

seated properly.

5. After the adapter has been installed, the cables should be routed thru the

opening in the bracket. This bracket also features a strain relief function that

should be used to prevent un-expected cable removal.

6. Replace the screw you removed for the blank and use it to secure the adapter

into the slot. (This is required to ensure FCC Part 15 compliance.)

7. Replace the cover.

8. Connect the power cord

The PLC-16.PCI is now ready for use.

© Sealevel Systems, Inc.

- 5 -

PLC-16.PCI User Manual

Page 8

Programming the PLC-16.PCI

Sealevel’s SeaI/O software is provided to assist in the development of reliable

applications for the Sealevel Systems family of digital I/O adapters. Included on the

SeaI/O CD are driver functions for use in accessing the I/O as well as helpful

samples and utilities.

Programming for Windows

The SeaI/O API (Application Programmer Interface) provides a variety of useful

high-level function calls implemented in a Windows dynamic link library (DLL).

The API is defined in the help file (Start/Programs/SeaIO/SeaIO Help) under

“Application Programmers Interface”. This help file also includes detailed

information dealing with installation / removal of the software and information

about latency, logic states, and device configuration.

For C language programmers we recommend using the API to access the PLC-

16.PCI. If you are programming in Visual Basic, using the ActiveX control

included with SeaI/O is advised.

Samples and Utilities

A variety of sample programs and utilities (both executable and source code) are

included with SeaI/O. Further documentation on these samples can be found by

selecting “Start/Programs/SeaIO/Sample Application Description”. Information

about where the files are physically stored on your disk is also included in this same

file.

Programming for Linux

SeaI/O for Linux consists of two major parts: a kernel module and a library. The

kernel module is a simple IO pass-through device, allowing the library to handle the

more sophisticated functions provided to SeaI/O users. It is provided in a ‘tarball’

format and can easily be compiled and included in the kernel build.

Digital I/O Interface

The PLC-16.PCI provides two parallel input/output (I/O) ports. The ports are

organized as ports A, B, C, and D. Port A is an input port interfaced to optically

isolated inputs, while port C is the relay output port.

© Sealevel Systems, Inc.

- 6 -

PLC-16.PCI User Manual

Page 9

Input Port

Port A is an eight bit input port connected to optically isolated input sensors. Each

sensor can be used to interface a voltage input and then sense whether the voltage is

on or off. Each sensor is isolated (with respect to a common ground) from every

other sensor, and also isolated with respect to the host PC ground. This means that

signals such as low-level AC line voltage, motor servo voltage, and control relay

signals can be ‘sensed’, or read by the PC, without the risk of damage due to ground

loops or ground faults.

Each sensor input pair has a current limiting resistor that is used to limit the input

current to the opto-isolator. The opto-isolator has two ‘back-to-back’ diodes

internally. This allows AC or DC signals to be sensed, regardless of polarity. When

the applied voltage is high enough to cause the led in the opto-isolator to turn-on, the

output of the opto-isolator goes low (0 volts) and the signal is read as a low logic

level (binary 0) by the PC. When the input signal is too low to turn on the optoisolator, the output goes high and the port bit is read by the PC as a high logic level

(binary 1).

The input impedance of each isolated input is approximately 1K ohms

(factory default). The opto-isolator requires approximately 3mA to turn on. The

maximum input current is 50mA. There are two things to consider when selecting

the input resistor. The first is turn on voltage for the circuit to sense, and second is

the maximum input voltage. Maximum input voltage must not provide too much

power to the input resistor, and must also not overdrive the opto-isolator input

current specification. The following formulas apply:

Turn on Voltage = diode drop + (turn on current) x (resistance)

[Ex: 1.1 + (.003) x R]

Input Current = ((input voltage)-1.1V) / (resistor value)

Maximum voltage = 1.1 + square root of (.25(resistor value))

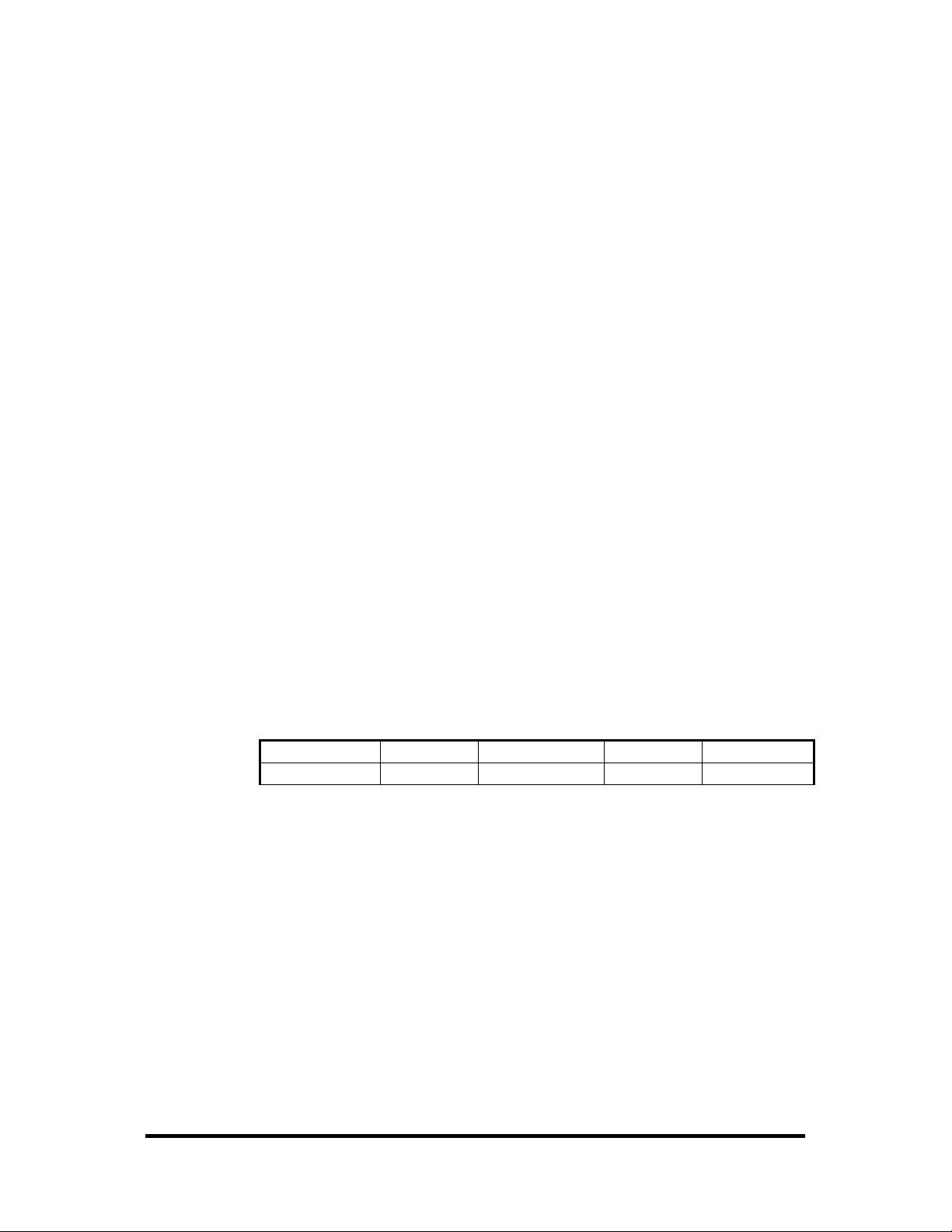

The following table shows the ranges associated with the resistor.

Input Resistor Turn-On Input Range Max Input Max Current

1KΩ

3.0V 5.0 – 24.0V 30V 29mA

Note: The turn-off voltage for all resistors is less than 1V.

Because through hole resistors are utilized, they cannot be easily replaced. If

modification is necessary, Sealevel can do this for an additional charge.

Important: The input circuits are not intended for monitoring 120-volt AC circuits.

In addition to being too high a voltage for the circuits, it is dangerous to have that

high a voltage on the card.

© Sealevel Systems, Inc.

- 7 -

PLC-16.PCI User Manual

Page 10

Input Port Pin Assignments (HD44 Female)

The inputs are not polarized and can be wired in either direction.

Port A Bit P1

D0 9,10

D1 11,12

D2 13,14

D3 23,24

D4 25,26

D5 27,28

D6 29,30

D7 40,41

Output Ports (Form C Relays)

The PLC-16.PCI provides 8 Form C (SPDT) Electro-mechanical relays. These

relays have three connections: Normally Open (NO), Normally Closed (NC) and a

Common. The relays are all de-energized at power-on. Data to the relays is latched

by a write to the base+2 address. On/off status of the relays can be read back by a

read at the base+2 address.

Output Port Pin Assignments (HD44 Female)

Port C Bit Normally Closed Common Normally Open

D0 (K1) 1 16 31

D1 (K2) 2 17 32

D2 (K3) 3 18 33

D3 (K4) 4 34 35

D4 (K5) 5 19 36

D5 (K6) 6 20 37

D6 (K7) 7 21 38

D7 (K8) 8 22 39

Direct Hardware Control

In systems where the user’s program has direct access to the hardware (i.e. DOS) the

table below gives the mapping and functions that the PLC-16.PCI provides.

Function Available Port Address Hex Port Type

RD A Base+0 Input Port (Opto Input)

B Base+1 Not Assigned

RD/WR C Base+2 Output Port (Reed Relays)

D Base+3 Not Assigned

RD = Read, RD/WR = Read or Write

Reading the Inputs

The inputs are active Low. If no voltage is applied across one of the differential

inputs it returns a binary one (1) on that bit. If an AC or DC voltage is applied it

returns a binary zero (0) on that bit.

© Sealevel Systems, Inc.

- 8 -

PLC-16.PCI User Manual

Page 11

Writing the Outputs

The output ports are the only ports that can be written. The relays on a standard

PLC-16.PCI are normally open. To close a relay a binary one (1) must be written to

the appropriate bit.

Reading the Outputs

The relay ports can also be read to determine the status of the various relays. A read

will return the ones complement (or opposite) of the value that is currently written to

the port.

Register Description

All ports are set to input after reset or power up.

Address Mode D7 D6 D5 D4 D3 D2 D1 D0

Base+0

Base+1

Base+2

Base+3

Base+4

Base+5

Base+6

Base+7

RD/WR PAD7 PAD6 PAD5 PAD4 PAD3 PAD2 PAD1 PAD0

RD {0} {0} {0} {0} {0} {0} {0} {0}

RD/WR PCD7 PCD6 PCD5 PCD4 PCD3 PCD2 PCD1 PCD0

RD {0} {0} {0} {0} {0} {0} {0} {0}

RD {0} {0} {0} {0} {0} {0} {0} {0}

RD/WR IRQEN IRQST {0} {0} {0} {0} IRC1 IRC0

RD {0} {0} {0} {0} {0} {0} {0} {0}

RD {0} {0} {0} {0} {0} {0} {0} {0}

Interrupt Control

When enabled, interrupts are generated on Port A bit D0.

IRQEN

IRC0

IRC1

Interrupt enable 1 = enabled 0 = disabled ( 0 on power up )

Interrupt Mode Select Table

Interrupt source is Base+0 bit D0. When selecting the Interrupt Type, always disable

interrupts prior to changing or setting states. This will help prevent inadvertent or

unexpected interrupts from occurring.

IRC1 IRC0 Interrupt Type

0 0 Low Level

0 1 High Level

1 0 Falling Edge

1 1 Rising Edge

Warning: When using the High and Low Level interrupts, an interrupt occurs when

input D0 changes to either a High or Low state. This will cause the computer to

remain in an interrupt state until the input state changes.

Interrupt mode select, see table below

Interrupt mode select, see table below

Interrupt Read

Reading the Interrupt Status port (Base+5) clears any interrupt pending.

IRQST (D0) Interrupt Status 1 = interrupt pending, 0 = none

© Sealevel Systems, Inc.

- 9 -

PLC-16.PCI User Manual

Page 12

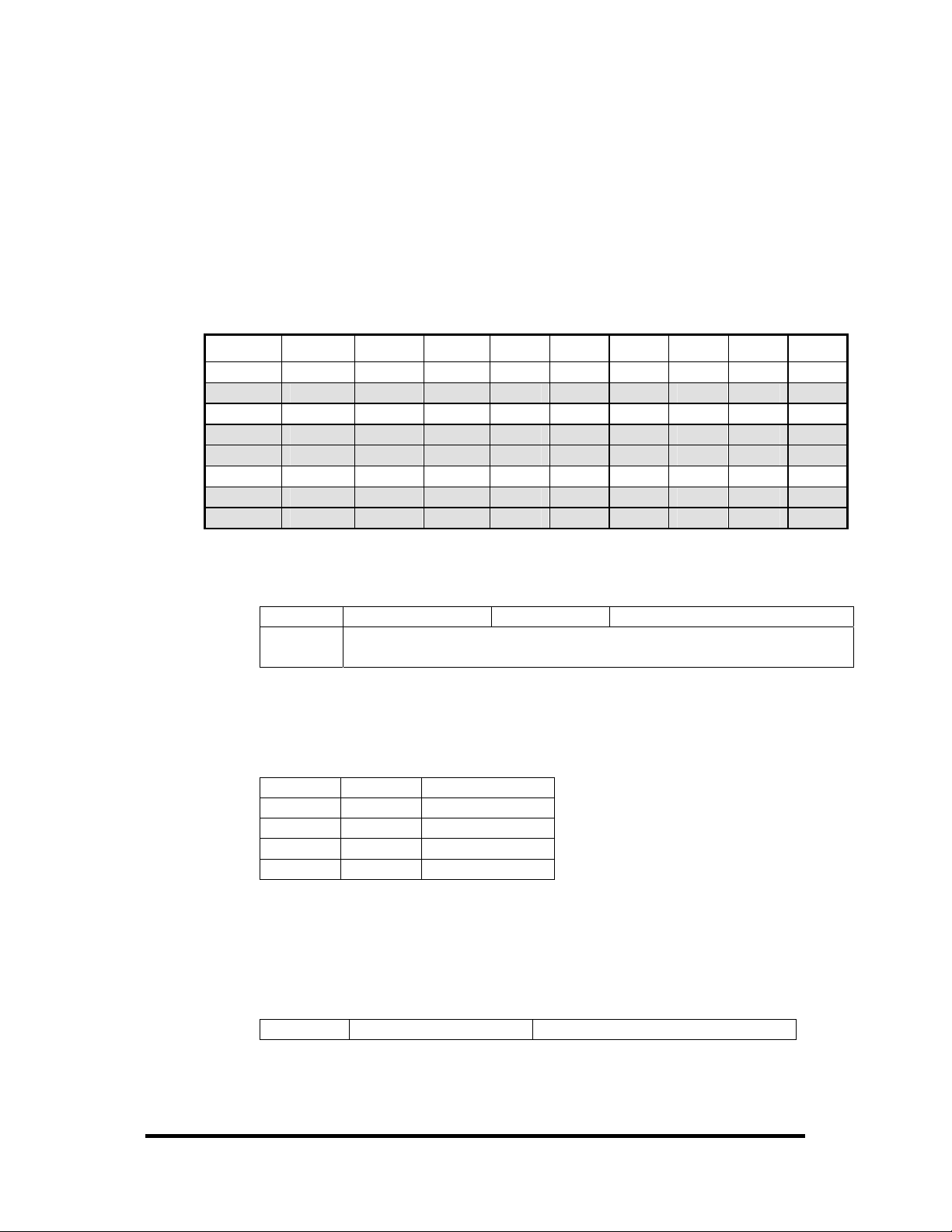

HD44 Female Pin Assignment

The table below describes the pin out for the HD44 Female connector on the 8011

board. The previous pages explain Port A (Inputs) and Port C (Form C Relay

Outputs) addressing and how to read and/or write to them.

Pin# Port Bit Type Pin# Port Bit Type

C D0 (K1) Relay NC

1

C D1 (K2) Relay NC

2

C D2 (K3) Relay NC

3

C D3 (K4) Relay NC

4

C D4 (K5) Relay NC

5

C D5 (K6) Relay NC

6

C D6 (K7) Relay NC

7

C D7 (K8) Relay NC

8

A D0 Input 1

9

10

11

12

13

14

15

16

17

18

19

20

21

22

A D0 Input 1

A D1 Input 2

A D1 Input 2

A D2 Input 3

A D2 Input 3

- - No Connect

C D0 (K1) Relay Common

C D1 (K2) Relay Common

C D2 (K3) Relay Common

C D4 (K5) Relay Common

C D5 (K5) Relay Common

C D6 (K6) Relay Common

C D7 (K7) Relay Common

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

A D3 Input 4

A D3 Input 4

A D4 Input 5

A D4 Input 5

A D5 Input 6

A D5 Input 6

A D6 Input 7

A D6 Input 7

C D0 (K1) Relay NO

C D1 (K2) Relay NO

C D2 (K3) Relay NO

C D3 (K4) Relay Common

C D3 (K4) Relay NO

C D4 (K5) Relay NO

C D5 (K6) Relay NO

C D6 (K7) Relay NO

C D7 (K8) Relay NO

A D7 Input 8

A D7 Input 8

- - No Connect

- - No Connect

- - No Connect

© Sealevel Systems, Inc.

- 10 -

PLC-16.PCI User Manual

Page 13

Optional Terminal Block Kit (Item# KT108)

Another option for termination of the PLC-16.PCI is the Terminal Block Kit (Item#

KT108). This kit includes an HD44 Male to HD44 Female six-foot cable (Item#

CA185) and a 28-Pin Terminal Block (Item# TB08-KT). The silk screen with

diagram is shown on the following page.

The CA185 cable is wired straight through, one-to-one.

The terminal block groups the common connections of the PLC-16.PCI into groups

of four as shown:

RC1 (Relay Common 1) ties together the ground pins for physical relays K1 –

K4 (logical D0 – D3) e.g.: HD44 pins 16,17,18 and 34 are connected to simplify

field wiring

RC2 (Relay Common 2) ties together the ground pins for physical relays K5 –

K8 (logical D4 – D8) e.g.: HD44 pins 19,20,21 and 22 are connected to simplify

field wiring

The other eight screw terminals in each group (16 total) are used to wire to the

NO (Normally Open) or NC (Normally Closed) side of the relays. These are

labeled K1 – K4 and K5 – K8

IC1 (Input Common 1) ties together one side of the input pins for D0-D3 and IC2

(Input Common 2) ties together one side of inputs D4-D7 to simplify field wiring

The other four pins in each group (8 total) are used to wire to the inputs. These

are labeled ID0 – ID3 and ID4 – ID8

© Sealevel Systems, Inc.

- 11 -

PLC-16.PCI User Manual

Page 14

Silk Screen – TB08 Terminal Block

The silk screen for the TB08 terminal block shows how the connections are labeled

for ease in wiring and troubleshooting.

© Sealevel Systems, Inc.

- 12 -

PLC-16.PCI User Manual

Page 15

Optional Cable Pin Assignments (Item# CA184)

Part Number CA184 is an optional cable for use with the PLC-16.PCI. The CA184

has an HD44 connector that breaks out to one DB37 Female connector for Inputs

and one DB37 Male connector for Outputs. This cable was designed to make our

products more easily integrated into systems that may have previously used Sealevel

legacy I/O interface products. The CA184 cable mimics several of the pin-out

options found on Sealevel PCI and ISA legacy products and provides a direct

connection to the 37 pin Terminal Block, Part Number TB02-KT. The following

tables show the pin out for this cable.

Input Port Pin Assignments (DB37 Female)

Port A Bit Input

D0 3,22

D1 4,23

D2 5,24

D3 6,25

D4 7,26

D5 8.27

D6 9,28

D7 10,29

Output Port Pin Assignments (DB37 Male)

Port C Bit Normally Closed Common Normally Open

D0 (K1) 1 2 3

D1 (K2) 4 5 6

D2 (K3) 7 8 9

D3 (K4) 10 11 12

D4 (K5) 22 23 24

D5 (K6) 25 26 27

D6 (K7) 28 29 30

D7 (K8) 31 32 33

© Sealevel Systems, Inc.

- 13 -

PLC-16.PCI User Manual

Page 16

Electrical Characteristics

Features

8 SPDT Form C relays

Eight optically isolated inputs

DB44 Female connector

PCI 2.1 Bus compatible

Specifications

Input Ports

Turn On Current: 3mA

Isolator Diode Drop: 1.1 VDC

Resistor Power Max: 1 W

Maximum Input Range: 5 – 30 VDC/VAC

Output Relays

Type: Bifurcated, Gold clad, silver palladium

Contact Max Power Rating: 30 W DC / 60 VA AC

Contact Voltage Maximum: 60 VDC/VAC

Contact Current Maximum: 2A AC/DC RMS

Contact Resistance, Initial: .10 Ω

Rated Life:

• Mechanical, Minimum: 10 Million Closures

• Electrical, Minimum: 5 Million Closures (Full Load)

Contact Speed:

• Operate: .2 mS

• Release: .1 mS

• Bounce: .7 mS

Temperature Range

Operating: 0°C – 70°C

Storage: -50°C – 105°C

Power Requirements

+5VDC @ 380mA

Physical Dimensions

PCB Length: 4.9” (12.4 cm)

PCB Height: 4.2” (10.7 cm, including Gold fingers)

Manufacturing

All Sealevel Systems Printed Circuit boards are built to UL 94V0 rating and are

100% electrically tested. These printed circuit boards are solder mask over bare

copper or solder mask over tin nickel.

© Sealevel Systems, Inc.

- 14 -

PLC-16.PCI User Manual

Page 17

Example Circuits

Input Circuit

Form C Output Circuit

© Sealevel Systems, Inc.

- 15 -

PLC-16.PCI User Manual

Page 18

Appendix A - Troubleshooting

Following these simple steps can eliminate most common problems.

1. Install software first. After installing the software then proceed to adding the

hardware. This places the required installation files in the correct locations.

2. Read this manual thoroughly before attempting to install the adapter in your

system.

3. Use Device Manager under Windows to verify proper installation.

4. Use the SeaIO Control Panel applet or the Device Manager’s property page for

card identification and configuration.

5. If these steps do not solve your problem, please call Sealevel Systems’ Technical

Support, (864) 843-4343. Our technical support is free and available from

8:00AM-5:00PM Eastern Time Monday through Friday. For email support

contact support@sealevel.com

.

© Sealevel Systems, Inc.

- 16 -

PLC-16.PCI User Manual

Page 19

Appendix B - How To Get Assistance

Begin by reading through the Trouble Shooting Guide in Appendix A. If assistance

is still needed please see below.

When calling for technical assistance, please have your user manual and current

adapter settings. If possible, please have the adapter installed in a computer ready to

run diagnostics.

Sealevel Systems provides an FAQ section on its web site. Please refer to this to

answer many common questions. This section can be found at

http://www.sealevel.com/faq.asp

Sealevel Systems maintains a Home page on the Internet. Our home page address is

http://www.sealevel.com

available via our FTP site that can be accessed from our home page.

Technical support is available Monday to Friday from 8:00 a.m. to 5:00 p.m. eastern

time. Technical support can be reached at (864) 843-4343.

RETURN AUTHORIZATION MUST BE OBTAINED FROM SEALEVEL

SYSTEMS BEFORE RETURNED MERCHANDISE WILL BE ACCEPTED.

AUTHORIZATION CAN BE OBTAINED BY CALLING SEALEVEL

SYSTEMS AND REQUESTING A RETURN MERCHANDISE

AUTHORIZATION (RMA) NUMBER.

. The latest software updates, and newest manuals are

© Sealevel Systems, Inc.

- 17 -

PLC-16.PCI User Manual

Page 20

Appendix C – Silk Screen – 8011 PCB

© Sealevel Systems, Inc.

- 18 -

PLC-16.PCI User Manual

Page 21

Appendix D - Compliance Notices

Federal Communications Commission Statement

FCC - This equipment has been tested and found to comply with the limits for Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in such case the user will be required to correct the interference at the

users expense.

EMC Directive Statement

Products bearing the CE Label fulfill the requirements of the EMC directive

(89/336/EEC) and of the low-voltage directive (73/23/EEC) issued by the European

Commission.

To obey these directives, the following European standards must be met:

EN55022 Class A - “Limits and methods of measurement of radio interference

characteristics of information technology equipment”

EN55024 – “Information technology equipment Immunity characteristics Limits and

methods of measurement”.

EN60950 (IEC950) - “Safety of information technology equipment, including

electrical business equipment”

Warning

This is a Class A Product. In a domestic environment, this product may cause

radio interference in which case the user may be required to take adequate

measures to prevent or correct the interference.

Always use cabling provided with this product if possible. If no cable is provided or

if an alternate cable is required, use high quality shielded cabling to maintain

compliance with FCC/EMC directives.

© Sealevel Systems, Inc.

- 19 -

PLC-16.PCI User Manual

Page 22

Warranty

Sealevel's commitment to providing the best I/O solutions is reflected in the Lifetime

Warranty that is standard on all Sealevel manufactured products. We are able to

offer this warranty due to our control of manufacturing quality and the historically

high reliability of our products in the field. Sealevel products are designed and

manufactured at its Liberty, South Carolina facility, allowing direct control over

product development, production, burn-in and testing.

Sealevel Systems, Inc. (hereafter "Sealevel") warrants that the Product shall conform

to and perform in accordance with published technical specifications and shall be

free of defects in materials and workmanship for life. In the event of failure,

Sealevel will repair or replace the product at Sealevel's sole discretion. Failures

resulting from misapplication or misuse of the Product, failure to adhere to any

specifications or instructions, or failure resulting from neglect or abuse are not

covered under this warranty.

Warranty service is obtained by delivering the Product to Sealevel and providing

proof of purchase. Return authorization must be obtained from Sealevel Systems

before returned merchandise will be accepted. Authorization is obtained by

calling Sealevel Systems and requesting a Return Merchandise Authorization

(RMA) number. The Customer agrees to insure the Product or assume the risk of

loss or damage in transit, to prepay shipping charges to Sealevel, and to use the

original shipping container or equivalent. Warranty is valid only for original

purchaser and is not transferable.

Trademarks

Sealevel Systems assumes no liability for any damages, lost profits, lost savings or

any other incidental or consequential damage resulting from the use, misuse of, or

inability to use this product. Sealevel Systems will not be liable for any claim made

by any other related party.

This warranty applies to Sealevel manufactured Product. Product purchased through

Sealevel but manufactured by a third party will retain the original manufacturer's

warranty.

Sealevel Systems, Incorporated

2779 Greenville Highway

P.O. Box 830

Liberty, SC 24857 USA

(864) 843-4343 FAX: (864) 843-3067

www.sealevel.com

email: support@sealevel.com

Technical Support is available Monday - Friday from 8 a.m. to 5 p.m. Eastern time

Sealevel Systems, Incorporated acknowledges that all trademarks referenced in this

manual are the service mark, trademark, or registered trademark of the respective

company.

© Sealevel Systems, Inc.

- 20 -

PLC-16.PCI User Manual

Loading...

Loading...