Page 1

SeaI/O User Manual

www.sealevel.com PO Box 830 – Liberty, SC 29657 864.843.4343

Page 2

Table of Contents

INTRODUCTION......................................................................................................................... 1

SEAI/O HARDWARE DESCRIPTION..................................................................................... 3

SEAI/O BASE AND EXPANSION MODULES ................................................................................... 3

SEAI/O MODULE COMMON FEATURES ........................................................................................ 4

SEAI/O CONFIGURATIONS & SPECIFICATIONS............................................................................. 5

410 Series – 16 Optically Isolated Inputs/16 Reed Relay Outputs......................................... 5

420 Series – 16 Optically Isolated Inputs/8 Form C Outputs................................................. 6

430 Series – 32 Optically Isolated Inputs............................................................................... 7

440 Series – 32 Reed Relay Outputs....................................................................................... 7

450 Series – 16 Form C Relay Outputs .................................................................................. 8

462 Series – 96 Channel TTL DB-78......................................................................................9

463 Series – 96 Channel TTL 50-Pin.................................................................................... 11

470 Series – 16 A/D, 2 D/A, 8 24V Outputs, 8 Isolated Inputs.............................................14

520 Series – 8 Optically Isolated Inputs/8 High-Current Form C Outputs.......................... 15

POWER OPTIONS .................................................................................................................... 16

BASE MODULE POWER CONNECTION......................................................................................... 16

SEAI/O EXPANSION POWER CONNECTION ................................................................................. 16

SeaI/O Max Power Requirements.........................................................................................16

TTL Power Requirements ..................................................................................................... 16

Sample Power Calculation ................................................................................................... 17

HARDWARE CONFIGURATION .......................................................................................... 18

SeaI/O-463 Ribbon Cable Installation Instructions ............................................................. 18

SeaI/O-470 Jumper and Dipswitch Settings Instructions..................................................... 21

SeaI/O-470 Jumper Locations .............................................................................................. 22

WIRING OPTIONS ................................................................................................................... 24

EAI/O PASS-THROUGH CONNECTOR........................................................................................24

S

I/O WIRING – SEAI/O-410, 420, 430, 440, AND 450 MODULES ................................................25

I/O WIRING – SEAI/O-462 AND 463 MODULES......................................................................... 26

I/O W

I/O W

IRING – SEAI/O-470 MODULES........................................................................................ 29

IRING – SEAI/O-520 MODULES........................................................................................ 32

CONNECTOR PIN OUTS............................................................................................................... 33

MOUNTING OPTIONS............................................................................................................. 34

ACCESSORIES .......................................................................................................................... 35

SEAMAX APPLICATION SUITE........................................................................................... 37

S

EAI/O ARCHITECTURE............................................................................................................. 38

EVICE ADDRESS CONFIGURATION ........................................................................................... 39

D

Setting Device Address (Slave ID)........................................................................................39

Setting Termination & Pull-Up/Pull-Down Resistors .......................................................... 40

CONFIGURING THE “BASE” SEAI/O MODULE ............................................................................ 41

© Sealevel Systems, Inc.

SL9049 Revision 8/2006

SeaI/O User Manual

Page 3

CONFIGURING N-SERIES EXPANSION MODULES........................................................................ 42

CONFIGURING AN ETHERNET MODULE (E-SERIES).................................................................... 43

MAXSSD CONFIGURATION & DIAGNOSTICS UTILITY............................................................... 46

Host PC Configuration Tab.................................................................................................. 46

SeaI/O Configuration Tab..................................................................................................... 47

Digital I/O Tab...................................................................................................................... 49

Programmable I/O Tab......................................................................................................... 50

A/D Inputs Tab...................................................................................................................... 51

D/A Outputs Tab................................................................................................................... 52

Diagnostics ........................................................................................................................... 53

COMMUNICATING VIA MODBUS ................................................................................................ 54

Modbus Commands............................................................................................................... 54

Modbus RTU......................................................................................................................... 55

Modbus TCP ......................................................................................................................... 55

EXTENDED MODBUS COMMAND SET......................................................................................... 56

DEVELOPING CUSTOM APPLICATIONS USING SEAMAX API .................................................... 64

SEAMAX API ........................................................................................................................... 65

NON OBJECT-ORIENTED SEAMAX API .................................................................................... 70

IOCTL CALLS AND FUNCTIONALITY......................................................................................... 73

USING SEAMAX WITH VISUAL C++ 6.0 ................................................................................... 79

USING SEAMAX WITH VISUAL BASIC 6.0................................................................................. 81

EXAMPLE SEAMAX PROGRAMMING TASKS.............................................................................. 82

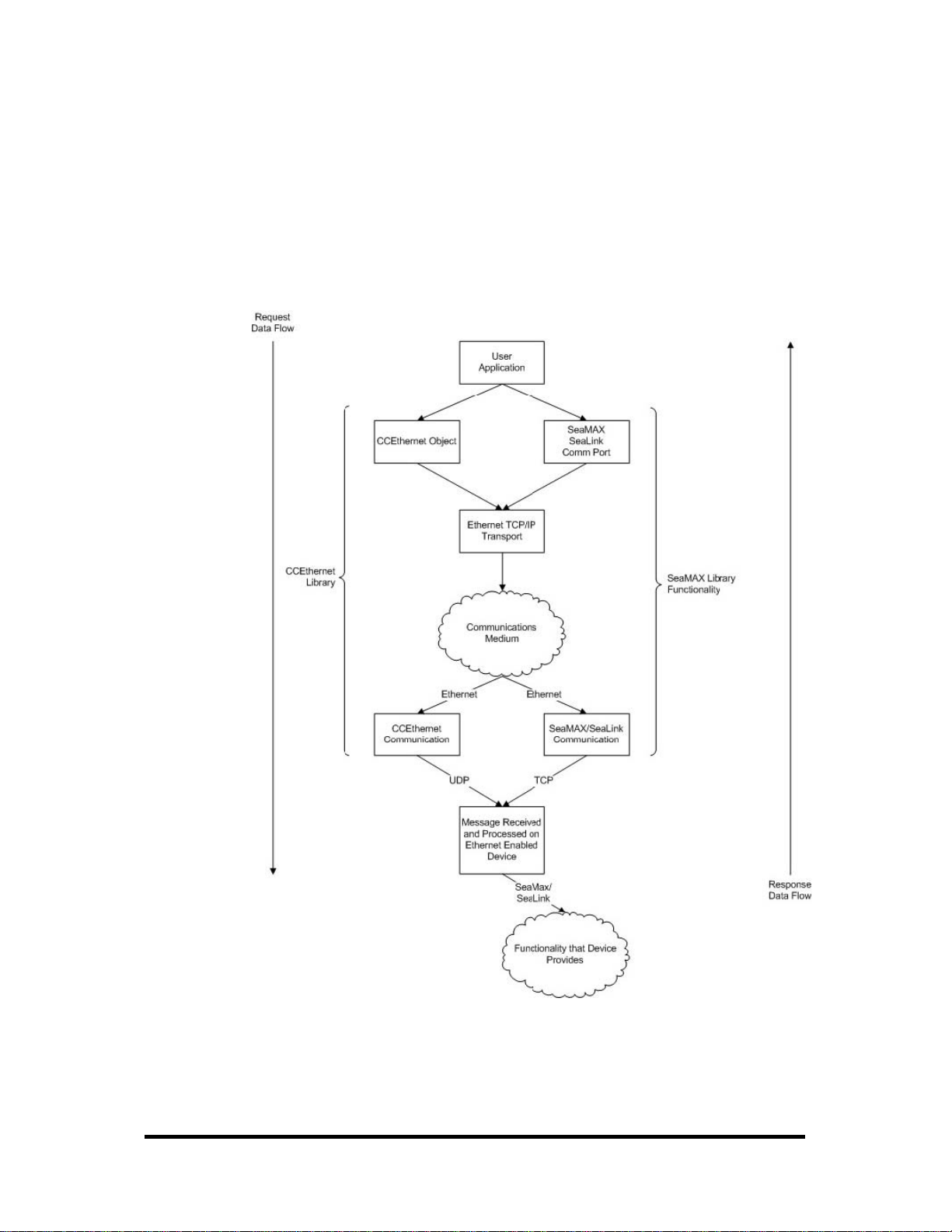

CETHERNET API...................................................................................................................... 87

APPENDIX A – DATA ENCODING TABLES....................................................................... 95

APPENDIX B – CRC CALCULATION................................................................................... 96

APPENDIX C – SEAIO MODEL 462/463 HOLDING REGISTER SET............................. 97

APPENDIX D – SEAMAX DATA TYPES AND STRUCTURES......................................... 98

APPENDIX E – TROUBLESHOOTING............................................................................... 102

APPENDIX F – HOW TO GET ASSISTANCE.................................................................... 104

APPENDIX G – COMPLIANCE NOTICES......................................................................... 105

WARRANTY............................................................................................................................. 106

© Sealevel Systems, Inc.

SL9049 Revision 8/2006

SeaI/O User Manual

Page 4

Introduction

SeaI/O

TM

modules provide a powerful way to add I/O to a variety of computers,

controllers, and PLCs. Each SeaI/O model is designed for maximum flexibility and

easy field wiring. Ordering options allow connection to the host device via Wireless

802.11b/g (Coming Soon!), Ethernet, USB, RS-485, or RS-232, and multiple units

can be daisy chained together using convenient pass-through connectors. For easy

software integration, application programs or 3

SeaMAX

TM

library or industry standard Modbus protocol.

rd

party software can use the Sealevel

This manual covers the installation and operation of these SeaI/O products:

Ethernet 10/100 BaseT

SeaI/O-410E – 16 Optically Isolated Inputs/16 Reed Relay Outputs

SeaI/O-420E – 16 Optically Isolated Inputs/8 Form C Outputs

SeaI/O-430E – 32 Optically Isolated Inputs

SeaI/O-440E – 32 Reed Relay Outputs

SeaI/O-450E – 16 Form C Relay Outputs

SeaI/O-462E – 96 Bit TTL I/O (DB-78)

SeaI/O-463E – 96 Bit TTL I/O (50-Pin IDC)

SeaI/O-470E – 8 Inputs/8 Outputs/2 D/A & 16 A/D

SeaI/O-520E – 8 Optically Isolated Inputs/8 High-Current Form C Outputs

USB

SeaI/O-410U – 16 Optically Isolated Inputs/16 Reed Relay Outputs

SeaI/O-420U – 16 Optically Isolated Inputs/8 Form C Outputs

SeaI/O-430U – 32 Optically Isolated Inputs

SeaI/O-440U – 32 Reed Relay Outputs

SeaI/O-450U – 16 Form C Relay Outputs

SeaI/O-462U – 96 Bit TTL I/O (DB-78)

SeaI/O-463U – 96 Bit TTL I/O (50-Pin IDC)

SeaI/O-470U – 8 Inputs/8 Outputs/2 D/A & 16 A/D

SeaI/O-520U – 8 Optically Isolated Inputs/8 High-Current Form C Outputs

RS-485

SeaI/O-410M – 16 Optically Isolated Inputs/16 Reed Relay Outputs

SeaI/O-420M – 16 Optically Isolated Inputs/8 Form C Outputs

SeaI/O-430M – 32 Optically Isolated Inputs

SeaI/O-440M – 32 Reed Relay Outputs

SeaI/O-450M – 16 Form C Relay Outputs

SeaI/O-462M – 96 Bit TTL I/O (DB-78)

SeaI/O-463M – 96 Bit TTL I/O (50-Pin IDC)

SeaI/O-470M – 8 Inputs/8 Outputs/2 D/A & 16 A/D

SeaI/O-520M – 8 Optically Isolated Inputs/8 High-Current Form C Outputs

RS-232

SeaI/O-410S – 16 Optically Isolated Inputs/16 Reed Relay Outputs

SeaI/O-420S – 16 Optically Isolated Inputs/8 Form C Outputs

SeaI/O-430S – 32 Optically Isolated Inputs

SeaI/O-440S – 32 Reed Relay Outputs

SeaI/O-450S – 16 Form C Relay Outputs

SeaI/O-462S – 96 Bit TTL I/O (DB-78)

SeaI/O-463S – 96 Bit TTL I/O (50-Pin IDC)

SeaI/O-470S – 8 Inputs/8 Outputs/2 D/A & 16 A/D

SeaI/O-520S – 8 Optically Isolated Inputs/8 High-Current Form C Outputs

Expansion Units (Connect to Base Unit via RS-485)

SeaI/O-410N – 16 Optically Isolated Inputs/16 Reed Relay Outputs

SeaI/O-420N – 16 Optically Isolated Inputs/8 Form C Outputs

SeaI/O-430N – 32 Optically Isolated Inputs

SeaI/O-440N – 32 Reed Relay Outputs

SeaI/O-450N – 16 Form C Relay Outputs

SeaI/O-462N – 96 Bit TTL I/O (DB-78)

SeaI/O-463N – 96 Bit TTL I/O (50-Pin IDC)

SeaI/O-470N – 8 Inputs/8 Outputs/2 D/A & 16 A/D

SeaI/O-520N – 8 Optically Isolated Inputs/8 High-Current Form C Outputs

© Sealevel Systems, Inc.

- 1 -

SeaI/O User Manual

Page 5

Software Installation

SeaI/O modules can be used with industry standard Modbus protocol or easily

controlled from application programs using the supplied SeaMAX software libraries.

Included are two diagnostic and configuration tools: MaxSSD and Ethernet Config.

The SeaMAX library features an object-oriented and functional interface for use with

C++ and Visual Basic. Also included is the CEthernet API library for programmatic

discovery and configuration of Ethernet enabled SeaI/O modules. Refer to the

SeaMAX Application Suite section of this manual for detailed information.

Industry Segments

SeaI/O modules are perfect for a wide variety of applications and environments

including:

Process Control

Data Acquisition

Broadcast Automation

Security

Facility Management

Features

Choice of Connectivity:

o Wireless (802.11b/g) – coming soon!

o Ethernet

o USB

o RS-485

o RS-232

Supports Industry Standard Modbus TCP & RTU Protocols

Models Offering Choice of:

o Optically Isolated Inputs

o Reed Relay Outputs

o Form C Relay Outputs

o TTL Interfaces

o Analog A/D & D/A

Status Indicator LEDs for Communication, Fault, and Status

Field Removable Terminal Block Connectors (most models)

9-30VDC Power Input

Power Input via Terminal Block or DC Jack

Daisy Chain up to 247 Modules

Extended Temperature Available (-40°C to +85°C)

Rugged Metal Enclosure

Compact Size - 7.5"(L) x 5.1"(W) x 1.3"(H)

Din Rail or Table Mount

© Sealevel Systems, Inc.

- 2 -

SeaI/O User Manual

Page 6

SeaI/O Hardware Description

SeaI/O Base and Expansion Modules

Base Modules connect to the host via one of the following interfaces:

E-Series - Ethernet Modbus TCP

U-Series - USB Modbus RTU

M-Series - RS-485 Modbus RTU

S-Series - RS-232 Modbus RTU

After the Base unit is installed, up to 246 additional SeaI/O N-Series Expansion

Units can be added to create an I/O network. These expansion modules interface via

RS-485 and can be located local to the Base SeaI/O device or remotely located up to

4000 feet away. Local installations should use the 5” CAT5 RS-485 pass-through

cable (Item number CA239) shipped with each N-series module to connect. Remote

expansion modules should use RS-485 twisted pair wiring from the Base unit

connected via the removable screw terminal connector.

For local installations power to the expansion modules is supplied from the Base unit

via the pass-through connectors. For remote devices, separate power is required at

each expansion unit. Refer to the Power Options section of this manual for more

information on SeaI/O power requirements and power supply sizing.

Included Communications and Expansion Accessories

SeaI/O modules are shipped with the following accessories:

E-Series (Ethernet) Item# CA246 – 1 x 7’ straight through Ethernet cable, for

connection to a hub or switch.

Item# CA251 – 1 x 7’ crossover cable, for direct connection to a

computer’s Ethernet port.

U-Series (USB) Item# CA179 – 6’ A to B USB cable.

M-Series (RS-485)

S-Series (RS-232) Item# KT119 – RS-232 DB9/RJ45 Kit, includes a DB9F to RJ45

N-Series (Expansion) KT122 – Expansion & Strap Kit, includes 5” CAT5 RS-485

All Models

No cable is included. RS-485 twisted-pair wiring connects to screw

terminals.

adapter with RS-232 pinout (Item# DB109) and a 7’ CAT5 patch

cable (Item# CA246) for connecting SeaI/O modules to both

Sealevel and standard RS-232 serial ports.

interconnect cable, four metal straps, and four #4-40 metal screws,

for connecting two or more SeaI/O modules together in a “stack”.

Each SeaI/O unit is shipped with 4 adhesive rubber feet that can be

attached to the bottom of the enclosure to enhance stability in table

mount applications.

© Sealevel Systems, Inc.

- 3 -

SeaI/O User Manual

Page 7

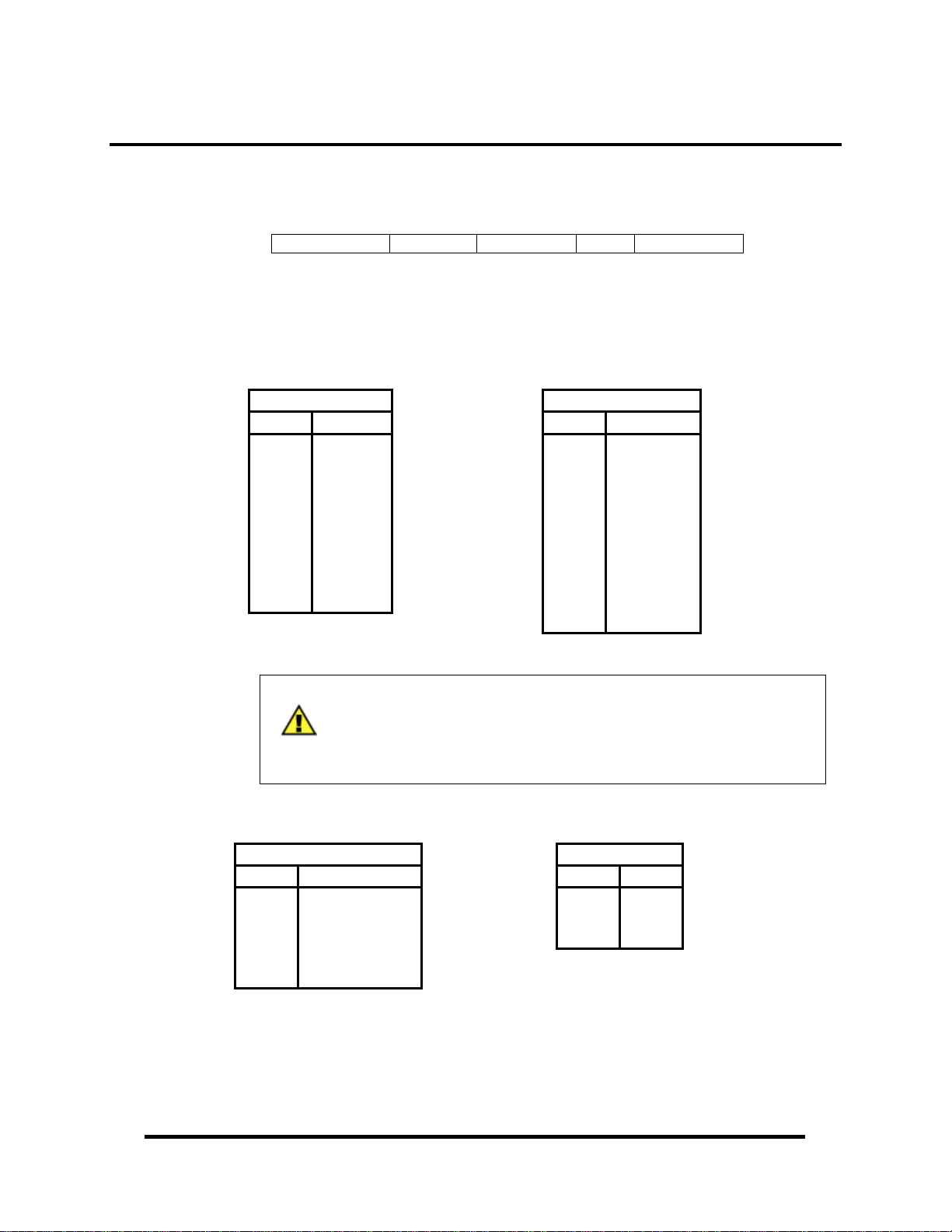

SeaI/O Module Common Features

All SeaI/O modules include the same connectors and configuration options on the

side of the unit:

NOTE:

RS-485 networks should have termination enabled on each end of

the network. Pull-up and pull-down resistors should also be enabled

on the last device on the network.

The 9-30VDC input barrel connector is center positive.

Status LEDs are included on the front of all SeaI/O devices to indicate

Communication (Yellow), Fault (Red), and Status (Green).

© Sealevel Systems, Inc.

- 4 -

SeaI/O User Manual

Page 8

SeaI/O Configurations & Specifications

410 Series – 16 Optically Isolated Inputs/16 Reed Relay Outputs

SeaI/O-410 modules provide 16 optically isolated inputs and 16 Reed relay outputs.

Inputs can range from 5-24VDC, while the Reed relays provide long life switch

closures that are well suited for low current applications. Inputs and outputs are

grouped into four-bit segments. Each group shares a common for easy wiring via

removable 3.5mm terminal blocks.

Inputs

Type: 16 non-polarized optically isolated inputs

Voltage Range: 5-24VDC

Isolation: 300V

Input Resistance: 6.2K Ohms in series

Response Time: 4 microseconds

Outputs

Type: 16 SPST Form A Reed relays

Power: 10VA max.

Contact Voltage: 60VDC max.

Contact Current: 500mA max.

Operate Time: 0.5ms max.

Bounce Time: 0.5ms max.

Release Time: 0.2ms max.

© Sealevel Systems, Inc.

- 5 -

SeaI/O User Manual

Page 9

420 Series – 16 Optically Isolated Inputs/8 Form C Outputs

The SeaI/O-420 provides 16 optically isolated inputs and 8 SPDT Form C relay

outputs. Inputs can range from 5-24VDC and provide 300V isolation to ground. Each

output offers normally open and normally closed contact connections via 3.5mm field

removable terminal blocks.

Inputs

Type: 16 non-polarized optically isolated inputs

Voltage Range: 5-24VDC

Isolation: 300V

Input Resistance: 6.2K Ohms in series

Response Time: 4 microseconds

Outputs

Type: 8 SPDT Form C relays

Power: DC 30W/ AC 60 VA

Contact Voltage: 60VDC max.

Contact Current: 2A max.

Operate Time: 2ms max.

Bounce Time: 7ms max.

Release Time: 1ms max.

© Sealevel Systems, Inc.

- 6 -

SeaI/O User Manual

Page 10

430 Series – 32 Optically Isolated Inputs

SeaI/O-430 modules provide 32 optically isolated inputs with 300V external isolation

and high channel-to-channel isolation. Ideal for low voltage monitoring applications,

connection to real world signals is made via 3.5mm convenient removable screw

terminal connectors.

Inputs

Type: 32 non-polarized optically isolated inputs

Voltage Range: 5-24VDC

Isolation: 300V

Input Resistance: 6.2K Ohms in series

Response Time: 4 microseconds

440 Series – 32 Reed Relay Outputs

The SeaI/O-440 provides 32 SPST Form A dry contact Reed relays. Reed relays offer

long life performance and fast response time. Convenient removable 3.5mm screw

terminal blocks compatible with 14-22 AWG wiring allow reliable connection to real

world I/O.

Outputs

Type: 32 SPST Form A Reed relays

Power: 10VA max.

Contact Voltage: 60VDC max.

Contact Current: 500mA max.

Operate Time: 0.5ms max.

Bounce Time: 0.5ms max.

Release Time: 0.2ms max.

© Sealevel Systems, Inc.

- 7 -

SeaI/O User Manual

Page 11

450 Series – 16 Form C Relay Outputs

Control a variety of low voltage, low current devices with the SeaI/O-450. The

module’s 16 channels of highly reliable SPDT Form C relay outputs are rated for up

to 60VDC @ 2A. Each output offers normally open and normally closed contact

connections via 3.5mm field removable terminal blocks.

Outputs

Type: 16 SPDT Form C relays

Power: DC 30W/ AC 60 VA

Contact Voltage: 60VDC max.

Contact Current: 2A max.

Operate Time: 2ms max.

Bounce Time: 7ms max.

Release Time: 1ms max.

© Sealevel Systems, Inc.

- 8 -

SeaI/O User Manual

Page 12

462 Series – 96 Channel TTL DB-78

Perfect for driving industry-standard solid-state relay (SSR) racks, the SeaI/O-462

provides 96 bits of buffered drive TTL I/O. Each DB-78 connector brings out 48 I/O

bits addressable as six, eight-bit ports. For easy connection to relay racks, Sealevel

offers a six-foot cable (Item# CA237) that terminates each DB-78 connector to two

industry standard 50-pin IDC connectors. Order part number 462x-KT and receive

two CA237 cables with each unit.

Power Requirements

Max Output Power: +5VDC @ 1A (5W)

Inputs

Logic High: Min 2VDC

Logic Low: Max 0.8VDC

Outputs

Logic High: Min 2VDC @ 32mA

Logic Low: Max 0.5VDC @ 64mA

© Sealevel Systems, Inc.

- 9 -

SeaI/O User Manual

Page 13

SeaI/O-462 Optional Items

Depending upon your application, you are likely to find one or more of the following

items useful for interfacing the SeaI/O-462 to real-world signals. All items can be

purchased from our website (http://www.sealevel.com

For high-current, high-voltage applications:

DB-78 to Dual IDC 50 Pin Ribbon Cable (Item Number CA237)

− 60” cable connects each SeaI/O-462’s DB-78 connectors to solid-state

relay racks equipped with 50-pin header interface.

Solid-State Relay Racks:

• Quad six position relay rack (Part Number PB24HQ)

− Relay rack can accept up to six QSSRs for a total of 24 channels.

Features a 50-pin header connector for easy interface via 50conductor ribbon cables.

• Quad four position relay rack (Part Number PB16HQ)

− Relay rack can accept up to four QSSRs for a total of 16 channels.

Features a 50-pin header connector for easy interface via 50conductor ribbon cables.

Quad Solid-State Relay Modules:

• AC Input (Part Number IA5Q) – Provides 4 channels of discrete I/O

interface to monitor AC inputs up to 140V @ 10mA.

• DC Input (Part Number IB5Q) – Provides 4 channels of discrete I/O

interface to monitor DC inputs from 3.3V to 32V.

• AC Output (Part Number OA5Q) – Provides 4 channels of discrete I/O

interface to control AC outputs up to 140V @ 3A.

• DC Output (Part Number OB5Q) – Provides 4 channels of discrete I/O

interface to control DC outputs up to 60V @ 3A.

Simulation/debug module (Part Number TA01)

− Module simulates the operation and load characteristics of a standard 24-

channel relay rack. An LED corresponding to each port bit illuminates to

indicate state. Eight position DIP-switches are used to generate input status

changes.

) or by calling 864-843-4343.

© Sealevel Systems, Inc.

- 10 -

SeaI/O User Manual

Page 14

463 Series – 96 Channel TTL 50-Pin

The SeaI/O-463 offers 96 bits of buffered drive TTL I/O via four internal industrystandard 50-pin header connectors. The interface module addresses the 96 channels

of I/O as 12 eight-bit ports, each programmable as input or output. Using standard

50-pin IDC ribbon cables, connect up to four industry standard relay racks for PC

based control and automation of equipment including sensors, switches, security

control systems, and other industrial automation systems. A metal strain relief

bracket is included to secure the cables after installation.

Power Requirements

Max Output Power: +5VDC @ 1A (5W)

Inputs

Logic High: Min 2VDC

Logic Low: Max 0.8VDC

Outputs

Logic High: Min 2VDC @ 32mA

Logic Low: Max 0.5VDC @ 64mA

© Sealevel Systems, Inc.

- 11 -

SeaI/O User Manual

Page 15

SeaI/O-463 Optional Items

Depending upon your application, you are likely to find one or more of the following

items useful for interfacing the SeaI/O-463 to real-world signals. All items can be

purchased from our website (http://www.sealevel.com

For TTL applications:

Terminal Block Kit - (Item# KT107)

− Kit includes the TB07 screw terminal block and CA167 ribbon cable for

connecting one of the SeaI/O-463’s 50-pin header connectors to your I/O.

6” Snap track and DIN rail clips are included for DIN rail mounting.

IDC 50 to IDC 50 Pin 40" Ribbon Cable (Item# CA167)

− Interfaces each of the SeaI/O-463’s 50-pin header connectors.

Simulation/debug module (Item# TA01)

− Module allows monitoring status of output pins and controlling state of

input pins. An LED corresponding to each port bit illuminates to indicate

state. Eight position DIP-switches are used to generate input status

changes.

) or by calling 864-843-4343.

© Sealevel Systems, Inc.

- 12 -

SeaI/O User Manual

Page 16

For high-current, high-voltage applications:

IDC 50 to IDC 50 Pin Ribbon Cable (Item# CA167)

− 40” cable connects the SeaI/O-463 to solid-state relay racks equipped with

50-pin header interface.

IDC 50 to IDC 50 Pin Ribbon Cable (Item# CA135)

− 40” cable connects the SeaI/O-463 to solid-state relay racks equipped with

50-pin edge connector.

Solid-State Relay Racks:

• Quad six position relay rack (Item# PB24HQ)

− Relay rack can accept up to six QSSRs for a total of 24 channels.

Features a 50-pin header connector for easy interface via 50conductor ribbon cables.

• Quad four position relay rack (Item# PB16HQ)

− Relay rack can accept up to four QSSRs for a total of 16 channels.

Features a 50-pin header connector for easy interface via 50conductor ribbon cables.

Quad Solid-State Relay Modules:

• AC Input (Item# IA5Q) – Provides 4 channels of discrete I/O interface to

monitor AC inputs up to 140V @ 10mA.

• DC Input (Item# IB5Q) – Provides 4 channels of discrete I/O interface to

monitor DC inputs from 3.3V to 32V.

• AC Output (Item# OA5Q) – Provides 4 channels of discrete I/O interface to

control AC outputs up to 140V @ 3A.

• DC Output (Item# OB5Q) – Provides 4 channels of discrete I/O interface to

control DC outputs up to 60V @ 3A.

Simulation/debug module (Item# TA01)

− Module simulates the operation and load characteristics of a standard 24-

channel relay rack. An LED corresponding to each port bit illuminates to

indicate state. Eight position DIP-switches are used to generate input status

changes.

© Sealevel Systems, Inc.

- 13 -

SeaI/O User Manual

Page 17

470 Series – 16 A/D, 2 D/A, 8 24V Outputs, 8 Isolated Inputs

Designed using the Maxim MAX197 successive approximation-type A/D chip, the

SeaI/O-470 provides eight differential or 16 single-ended 12-bit inputs. The A/D

inputs can be individually configured for sensing 4-20mA current loop signals.

Additionally, the module provides two 12-bit D/A output channels, eight optically

isolated inputs, and eight open collector outputs, ideal for driving 24V devices

commonly found in industrial environments. Perfect for a variety of data

acquisition/control and test & measurement applications, the SeaI/O-470 includes

removable screw terminals, which simplify field-wiring connections.

Optically Isolated Inputs

Input Range: 5-30VDC

Open Collector Outputs

Output Voltage: Max. 30VDC

Output Current: Max. 500mA (single output)

Output Current: Max. 580mA (all outputs)

A/D Inputs

Number of Channels: 8 differential or 16 single-ended

Resolution: 12-bits

Sampling Rate: 100K/s

A/D Input Range

Software Selectable: 0-5V, 0-10V, +/-5V, +/-10V

Hardware Selectable: 0-20mA current loop (for 4-20mA devices)

D/A Outputs

Number of Channels: 2 single-ended

Resolution: 12-bits

Output Range: 0-5V, 0-10V

Load Resistance: Min. 2K

© Sealevel Systems, Inc.

- 14 -

SeaI/O User Manual

Page 18

520 Series – 8 Optically Isolated Inputs/8 High-Current Form C Outputs

The SeaI/O-520 provides 8 optically isolated inputs and 8 SPDT high-current Form C

relay outputs. Inputs can range from 5-30VDC and provide 300V isolation to ground.

Each output offers normally open and normally closed contact connections via

3.5mm field removable terminal blocks.

Inputs

Type: 8 non-polarized optically isolated inputs

Voltage Range: 5-30VDC

Isolation: 300V

Input Resistance: 6.2K Ohms in series

Response Time: 4 microseconds

Outputs

Type: 8 SPDT High-Current Form C relays

Contact Voltage: 250VAC/100VDC max.

Contact Current: 6A max.

Operate Time: 10ms max.

Release Time: 10ms max.

© Sealevel Systems, Inc.

- 15 -

SeaI/O User Manual

Page 19

Power Options

Base Module Power Connection

Base modules are powered from a 9-30VDC source using either the DC jack or screw

terminals on the side of the unit. Sealevel offers several power supply choices to

make connection easy (see Accessories chapter at the end of this document).

SeaI/O Expansion Power Connection

Each SeaI/O product, including the expansion modules, contains an onboard

switching regulator power supply rated for 9-30VDC. For local installations (less

than 10’ apart), expansion unit power is usually supplied from the Base unit via the

pass-through connectors. The number of expansion modules that can be driven from

the Base unit depends on the power source and number/type of expansion units.

Refer to the chart below for power requirements. For expansion modules mounted

remotely (greater than 10’ apart), separate power is required at each expansion unit.

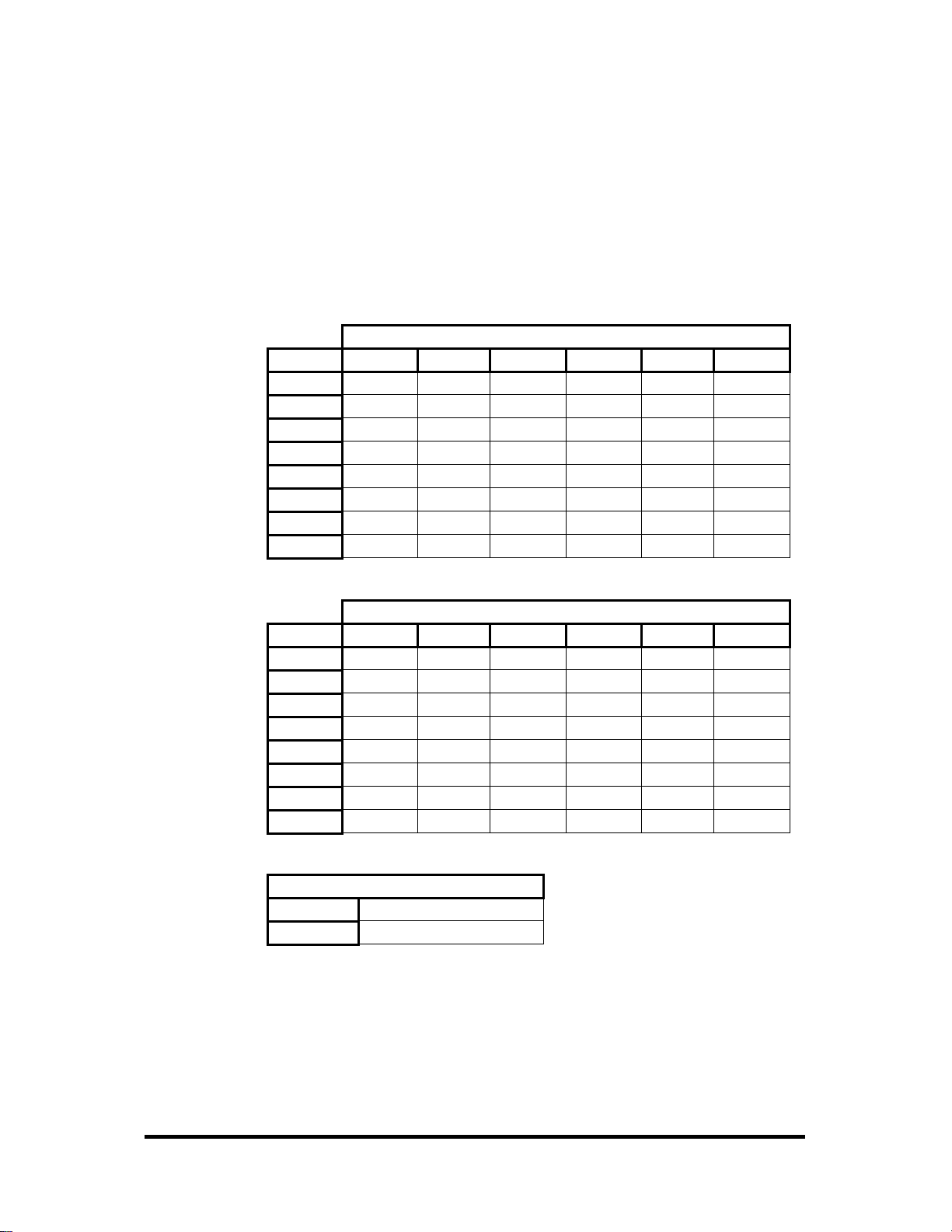

SeaI/O Max Power Requirements

SeaI/O-410 2.9W 1.7W 1.4W 1.6W 1.4W

SeaI/O-420 3.5W 2.3W 2.0W 2.2W 2.0W

SeaI/O-430 1.9W 0.7W 0.4W 0.6W 0.4W

SeaI/O-440 4.0W 2.8W 2.5W 2.7W 2.5W

SeaI/O-450 5.3W 4.1W 3.8W 4.0W 3.8W

SeaI/O-470 3.0W 1.8W 1.5W 1.7W 1.5W

SeaI/O-520 5.0W 3.8W 3.5W 3.7W 3.5W

TTL Power Requirements

The SeaI/O-462 and SeaI/O-463 use 74ABT245 octal bi-directional transceivers to

provide TTL input/output capabilities and can sink 64mA and source 32mA. Each

bit is pulled to +5V through a 10K ohm pull-up resistor to insure each bit is at a

known state when not driven. The supply current and maximum output power are

shown below.

SeaI/O-462 2.0W 0.8W 0.5W 0.7W 0.5W

SeaI/O-463 2.0W 0.8W 0.5W 0.7W 0.5W

Output Power +5VDC @ 1A (5W) Maximum

E-Series U-Series M-Series S-Series N-Series

E-Series U-Series M-Series S-Series N-Series

© Sealevel Systems, Inc.

- 16 -

SeaI/O User Manual

Page 20

Sample Power Calculation

A typical application for SeaI/O products would use one Base module and several Nseries units in a local expansion configuration. In this arrangement, with power

applied to the Base module through either the DC jack or screw terminal connector

and passed-through to the expansion units, attention should be given to ensure the

input power to the Base module is adequate.

Example:

Power (W)

Base Unit: SeaI/O-430U 0.7

Expansion 1: SeaI/O-410N 1.4

Expansion 2: SeaI/O-440N 2.5

4.6W Power Required

In this application, the Sealevel Item# TR112 “wall wart” power supply is a good

choice since it is low-cost and supplies 24VDC @ 250mA (6W).

NOTE:

A complete listing of recommended power supplies is provided in

the Accessories section of this manual.

© Sealevel Systems, Inc.

- 17 -

SeaI/O User Manual

Page 21

Hardware Configuration

The SeaI/O-463 and SeaI/O-470 are the only two modules that require you to open

the enclosure. On all SeaI/O modules, most device settings can be configured on the

left side of the SeaI/O module. Refer to the SeaI/O Hardware Description section

of this manual for a list of common features available and settings that can be

changed on the left side of the SeaI/O module.

When connecting more than one SeaI/O module to a host computer, you will need to

set the device address (Slave ID). This can be done in software or by using a rotary

switch on the left side of the enclosure. Refer to the SeaMAX Application Suite

section where you can find instructions for configuring the device address (Slave ID)

and setting the termination pull up and pull down resistors.

SeaI/O-463 Ribbon Cable Installation Instructions

A copy of these instructions are included with the SeaI/O-463 module and can also

be downloaded from the SeaI/O-463 product page on the Sealevel website.

NOTE:

Do not perform these instructions with the power connected. Be

sure to follow proper ESD procedures by grounding yourself and the

SeaI/O module.

What you will need:

SeaI/O-463 module

Phillips head screwdriver

Slotted screwdriver

50-pin IDC ribbon cable* (up to four)

*Ribbon cable accessories available:

• CA167 – 40” IDC 50-pin to IDC 50-pin ribbon cable

• CA197 – 18” IDC 50-pin to IDC 50-pin ribbon cable

• CA135 – 40” IDC 50-pin to 50-pin edge connector ribbon cable

Step 1

Remove the terminal block from the left side and

then remove the two black screws from each side

of the module as shown in the image.

© Sealevel Systems, Inc.

- 18 -

SeaI/O User Manual

Page 22

Step 2

On the front right side of the module, wedge a

slotted screwdriver between the top and bottom

halves as shown. Pry upwards – a pem in the top

half must clear the metal lip in the bottom half of

the enclosure.

Step 3

Remove the two screws from the metal strain

relief, as shown.

Step 4

Remove the three screws from the bottom of the

module and remove the front plate.

Step 5

Install up to four industry standard ribbon cables

in the 50-pin header connectors. A list of optional

cable part numbers is listed on the previous page.

Step 6

Replace the front plate and install the three screws

in the bottom of the module as shown.

© Sealevel Systems, Inc.

- 19 -

SeaI/O User Manual

Page 23

Step 7

Replace the metal strain relief. Start both screws

and tighten only until snug. Do not over-tighten.

Step 8

Replace the top half by starting it on the left side

over the connectors and then snapping the right

side down into place. Be careful not to pinch

fingers. Replace both screws on each side and

then replace the terminal block on the left side.

Step 9

Continue with the installation of the SeaI/O-463

module. The SeaI/O Hardware Description

section of this manual contains information on

TTL applications and optional accessories. The

SeaMAX Application Suite section walks you

through setting up the hardware address (Slave ID)

and software installation.

© Sealevel Systems, Inc.

- 20 -

SeaI/O User Manual

Page 24

SeaI/O-470 Jumper and Dipswitch Settings Instructions

The SeaI/O-470 module ships factory configured with the D/A outputs set for 0-10V

and current loop mode on the A/D inputs disabled. If you need to enable current loop

mode or set the D/A outputs to 0-5V, you will need to open the enclosure and access

the jumpers (shown on the next page).

NOTE:

Do not perform these instructions with the power connected. Be

sure to follow proper ESD procedures by grounding yourself and the

SeaI/O module.

What you will need:

SeaI/O-470 module

Phillips head screwdriver

Slotted screwdriver

Step 1

Remove the terminal block from the left side and

then remove the two black screws from each side

of the module as shown in the image.

Step 2

On the front right side of the module, wedge a

slotted screwdriver between the top and bottom

halves as shown. Pry upwards – a pem in the top

half must clear the metal lip in the bottom half of

the enclosure.

Jumpers and dipswitch locations are shown on the

following page.

© Sealevel Systems, Inc.

- 21 -

SeaI/O User Manual

Page 25

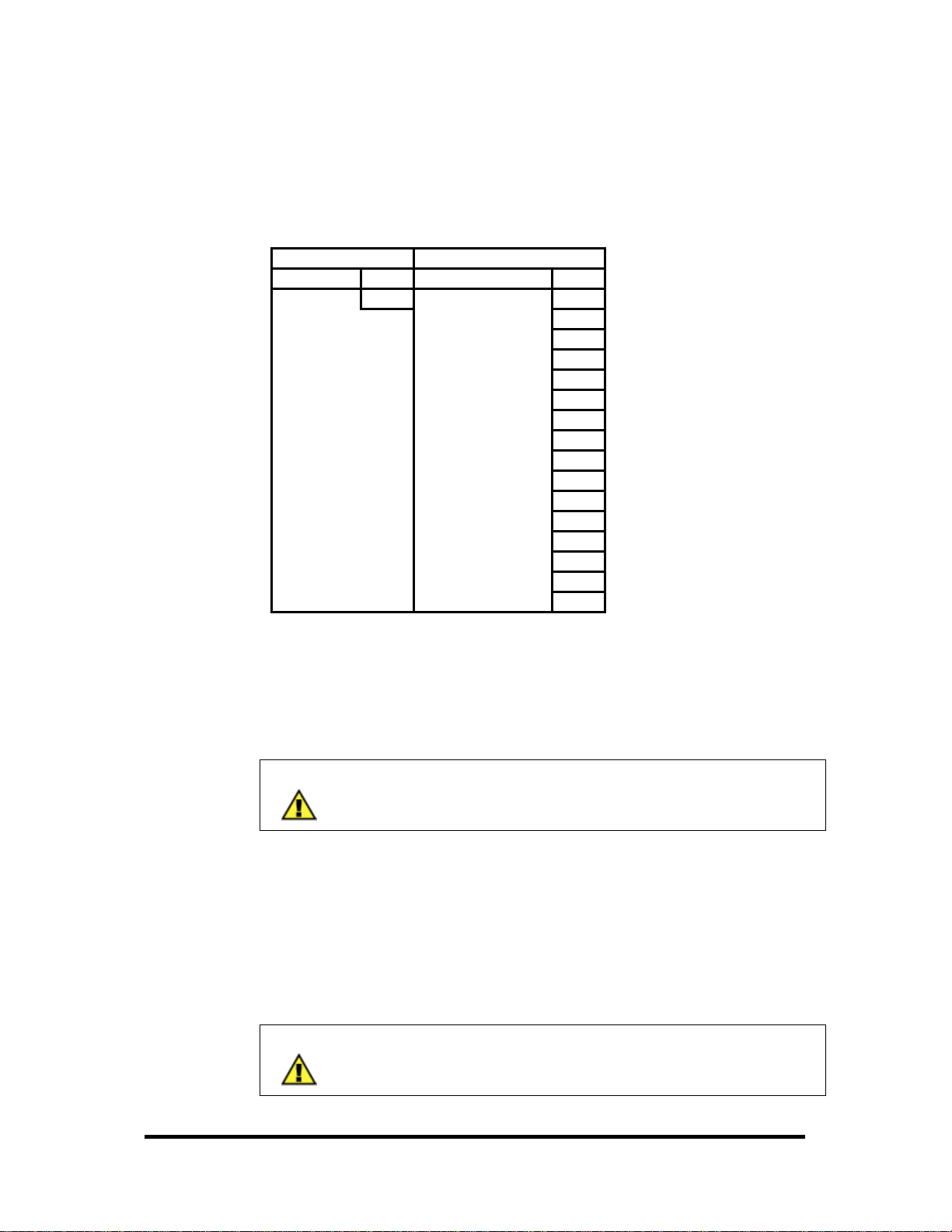

SeaI/O-470 Jumper Locations

This detail image of the right side of the SeaI/O-470 circuit board shows the locations

of the user configurable jumpers and dipswitches. Refer to the following pages for

instructions on properly configuring the jumpers and switches. The colored boxes

are shown here for clarity and are not visible on the actual circuit board.

© Sealevel Systems, Inc.

- 22 -

SeaI/O User Manual

Page 26

D/A Settings

The (E1) and (E2) jumpers (shown in the orange boxes on the previous page)

configure the D/A outputs for 0-5V or 0-10V. Both channels can be configured

independently. The D/A outputs do not support negative voltages. You must also set

the correct output voltage in your application or MaxSSD. Refer to the SeaMAX

Application Suite section of this manual for help configuring software to work with

the SeaI/O-470.

A/D 10X Gain

The A/D 10X gain (E3) jumper (shown in the green box on the previous page) is

disabled at the factory. Position the hardware jumper on both pins to enable this

functionality, which allows smaller voltages to be measured more accurately (e.g., a

0-1V input signal can be measured more accurately by enabling the 10x hardware

gain jumper and setting the SeaI/O-470 A/D input channel for 0-10V range). You

can also set the A/D input channel for 0-5V to sense voltages smaller than 0.5V.

When the jumper is enabled, the “10X Hardware Gain” checkbox will also be

enabled on the A/D Inputs tab in MaxSSD. Refer to the SeaMAX Application Suite

section of this manual for information on using MaxSSD.

A/D and Current Loop Dipswitches

The (SW3) and (SW4) dipswitches (shown in the yellow box on the previous page)

configure the A/D inputs for current loop mode and are disabled at the factory. Since

current loop mode is differential, the corresponding dipswitch on both (SW3) and

(SW4) should be properly set (e.g., ‘CH1’ on both dipswitches needs to be set to

‘ON’ to enable current loop mode).

SW3 – enables the current-loop sensing resistor

SW4 – ties the other half of connection to ground

© Sealevel Systems, Inc.

- 23 -

SeaI/O User Manual

Page 27

Wiring Options

SeaI/O Pass-Through Connector

All SeaI/O modules include two RS-485 pass-through connectors on the left side of

the unit that are internally connected to the same pins on the screw terminals. This

offers two convenient options for adding additional expansion modules.

For connecting several SeaI/O modules together in a “stack”, all N-series expansion

modules ship with an expansion and strap kit (item# KT122) that includes four metal

straps, four #4-40 screws, and a 5” RJ45 RS-485 interconnect cable (item# CA239).

The metal straps allow you to securely connect multiple SeaI/O modules together.

The interconnect cable can be used to connect SeaI/O modules together via the RJ45

pass-through connectors, providing an easy method to cascade RS-485 signals and

power from one module to the next.

For expansion modules that are less than ten feet from a base unit, a standard RJ45

CAT5 patch cable may be used. For SeaI/O modules greater than ten feet apart, use

twisted-pair cable connecting the data lines to the screw terminals instead. If RJ45

connectors are preferred, be sure to connect only the data lines (pins 4 & 5).

NOTE:

Modules greater than ten feet apart must have separate power

supplies. Refer to the Power Options section of this manual for

recommendations.

© Sealevel Systems, Inc.

- 24 -

SeaI/O User Manual

Page 28

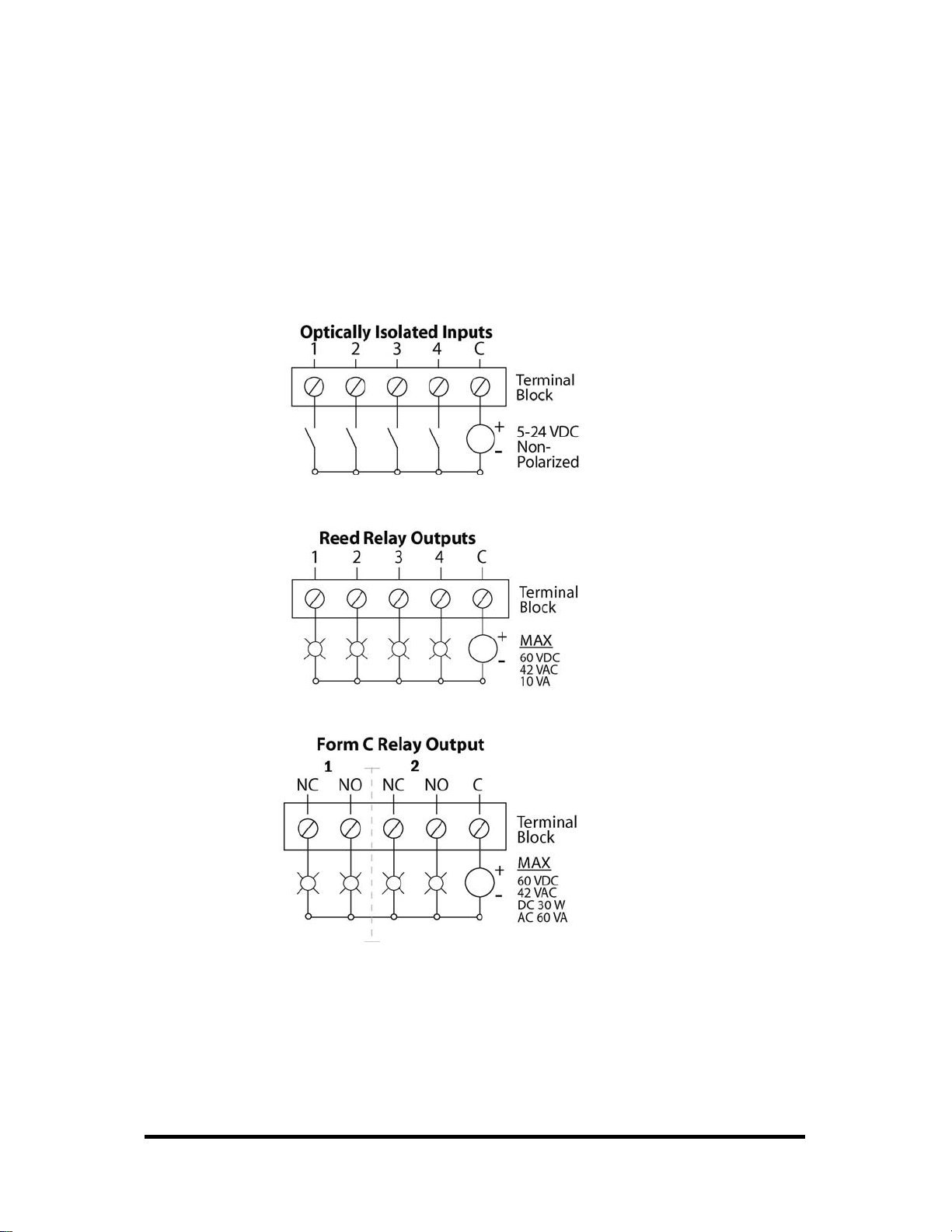

I/O Wiring – SeaI/O-410, 420, 430, 440, and 450 Modules

Optically isolated inputs are arranged such that each group of four shares a single

common. The four I/O points and shared common are connected via a five-position

removable screw terminal. Input voltage range is 5-24VDC. Like the inputs, each

group of four Reed relays also shares a single common and connects via a fiveposition removable screw terminal. Form C Relay outputs are arranged such that each

group of two relays shares a common. The NC and NO contacts of each relay along

with the common are brought out via a five-position removable screw terminal.

© Sealevel Systems, Inc.

- 25 -

SeaI/O User Manual

Page 29

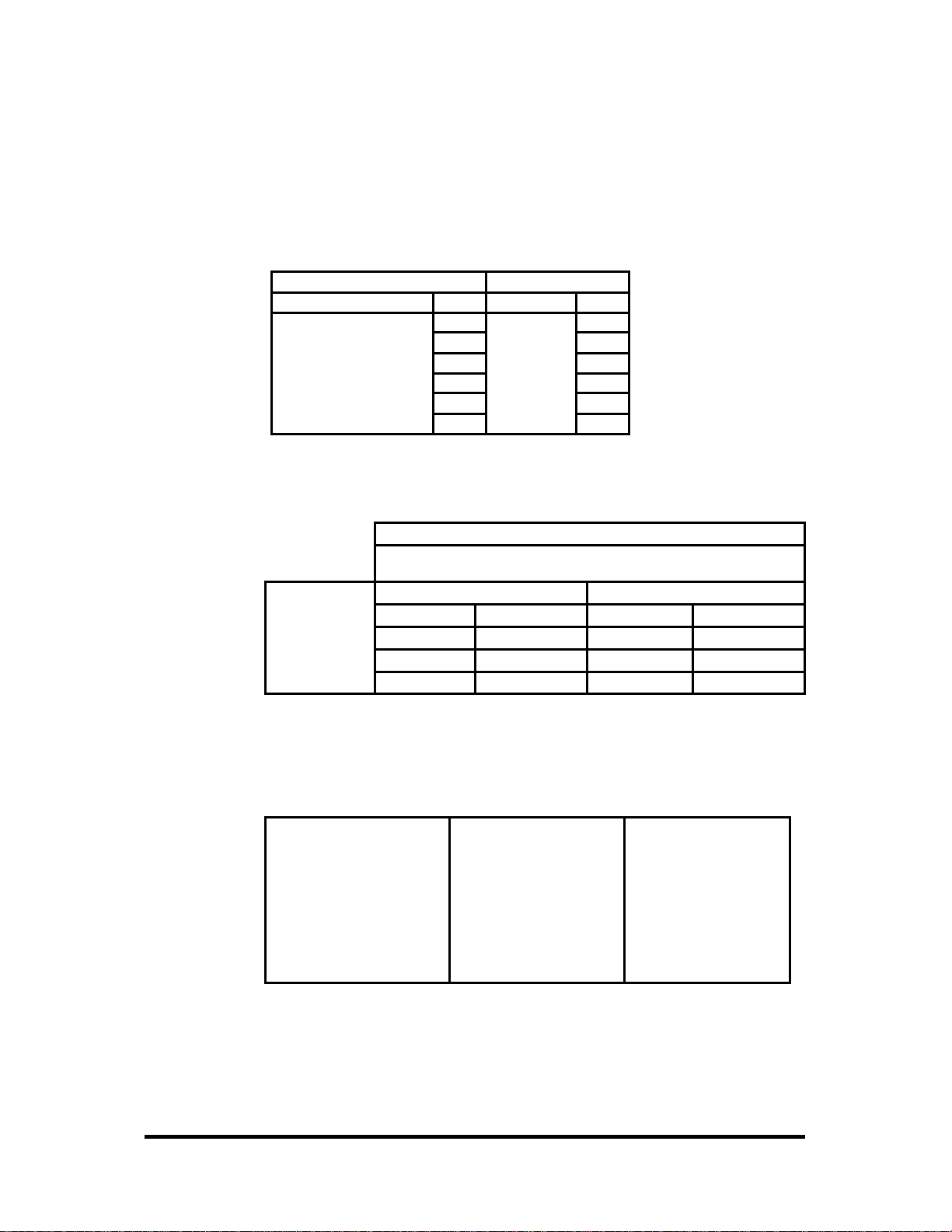

I/O Wiring – SeaI/O-462 and 463 Modules

SeaI/O-462 DB-78F Connectors

The SeaI/O-462’s 96 digital I/O channels are brought out to two DB-78 Female

connectors on the front of the enclosure (pinout shown below). Each connector

provides 48 bits of digital I/O divided into six eight-bit ports. Each port may be

individually configured via software command as an input or an output.

Bits A1 B1 C1 A2 B2 C2

D0

D1

D2

D3

D4

D5

D6

D7

Bits A3 B3 C3 A4 B4 C4

D0

D1

D2

D3

D4

D5

D6

D7

+5V

Commons 41 – 58, 64 – 73

75 38 18 10 30 2

76 37 17 9 29 1

77 36 16 8 28 22

78 35 15 7 27 21

59 34 14 6 26 40

39 33 13 5 25 60

20 32 12 4 24 61

19 31 11 3 23 62

75 38 18 10 30 2

76 37 17 9 29 1

77 36 16 8 28 22

78 35 15 7 27 21

59 34 14 6 26 40

39 33 13 5 25 60

20 32 12 4 24 61

19 31 11 3 23 62

Power & Commons

63, 74

Bits 1-48

Bits 49-96

© Sealevel Systems, Inc.

- 26 -

SeaI/O User Manual

Page 30

SeaI/O-462 Optional Cable (Item# CA237) Pinout

For easy connection to industry-standard solid-state relay racks, Sealevel

manufactures a 6’ cable, Item# CA237, that terminates the DB-78 to two industry

standard 50-pin header connectors. Two cables and a SeaI/O unit can be order

together as a kit using Item# 462x-KT. The pinout for the two 50-pin headers is

shown below.

© Sealevel Systems, Inc.

- 27 -

SeaI/O User Manual

Page 31

SeaI/O-463 50-Pin Header Connectors

The SeaI/O-463’s 96 digital I/O channels are accessed via four industry-standard 50pin header connectors. Each header provides 24 bits of digital I/O divided into three

eight-bit ports. Each port may be individually configured via software command as

an input or an output.

You will need to open the SeaI/O-463’s enclosure to access the four header

connectors: P2, P3, P4, and P5. The connector designators are silk-screened onto the

PCB for easy identification. Once cables are connected to the headers, route them

through the opening in the front of the enclosure, attach the included strain-relief

bracket to secure the cables and reassemble the enclosure. Refer to the ribbon cable

installation instructions included with the SeaI/O-463.

Each of the four 50-pin connectors has the following pinout, which is compatible

with a wide variety of industry-standard solid-state relay racks:

© Sealevel Systems, Inc.

- 28 -

SeaI/O User Manual

Page 32

I/O Wiring – SeaI/O-470 Modules

A/D Wiring Connections

The SeaI/O-470 supports single-ended, differential, and current loop A/D inputs.

Single-ended and differential modes can be configured in software. Current loop

mode requires configuring dipswitches inside the enclosure. Refer to the Hardware

Configuration section of this manual for instructions on configuring the current loop

dipswitches.

The SeaI/O-470 can be configured for up to sixteen 12-bit single-ended A/D inputs.

Each input is referenced to a common ground. The user selectable voltage ranges are

0-5V, 0-10V, +/-5V, and +/-10V.

The SeaI/O-470 can be configured for up to eight 12-bit differential A/D inputs. The

inputs are not referenced to ground. The user selectable voltage ranges are 0-5V, 010V, +/-5V, and +/-10V.

© Sealevel Systems, Inc.

- 29 -

SeaI/O User Manual

Page 33

The SeaI/O-470’s A/D channels can also be configured to provide up to eight 12-bit

current loop inputs. Each input has two terminals – one positive and one negative.

The input current range is 0-20mA for interfacing commonly used 4-20mA devices.

The dipswitches inside the enclosure must be properly configured for each current

loop input.

D/A Wiring Connections

The SeaI/O-470 provides two 12-bit D/A output channels, configured for 0-10V.

0-5V mode requires different jumper settings inside the enclosure. Refer to the

Hardware Configuration section of this manual for instructions on configuring the

D/A jumpers.

The SeaI/O-470 module’s D/A output channels can be independently configured for

0-5V or 0-10V. The D/A outputs do not support negative voltages.

© Sealevel Systems, Inc.

- 30 -

SeaI/O User Manual

Page 34

Digital I/O Wiring Connections

The SeaI/O-470 modules include eight optically isolated inputs that are arranged such

that each group of four inputs shares a single common. The four I/O points and

shared common are connected via a five-position removable screw terminal.

The SeaI/O-470 modules provide eight open-collector digital outputs. The outputs

do not source any current and must be connected to an external power source, max

30VDC. The outputs act as a switch and the circuit is open until energized. When

the output circuit is energized in software, the output sinks the current to ground,

closing the circuit.

© Sealevel Systems, Inc.

- 31 -

SeaI/O User Manual

Page 35

I/O Wiring – SeaI/O-520 Modules

Optically isolated inputs are arranged such that each group of two shares a single

common. The four I/O points and shared common are connected via a six-position

removable screw terminal. Input voltage range is 5-30VDC. Like the inputs, each

group of two Form C relays also shares a single common. The NC and NO contacts

of each relay along with the commons are brought out via a six-position removable

screw terminal.

© Sealevel Systems, Inc.

- 32 -

SeaI/O User Manual

Page 36

Connector Pin Outs

SeaI/O (RS-232) S-Series Modules

SeaI/O S-Series (RS-232) modules have an RJ45 connector on the face of the

enclosure. Each S-series module includes a kit (item# KT119) to convert the RJ45

RS-232 pin out to a standard DB9 RS-232 pin out. The kit ships with a DB-9F to

RJ45 modular adapter (item# DB109) with RS-232 pin out and a standard 7' CAT5

patch cable (item# CA246). This kit allows SeaI/O S-series modules to be easily

connected to a standard DB9 RS-232 serial port. For other interfacing options, the

RJ45 pin out is shown below.

© Sealevel Systems, Inc.

- 33 -

SeaI/O User Manual

Page 37

Mounting Options

SeaI/O Mounting Kit

Expanding your I/O count is as simple as adding

N-Series expansion units to the Base SeaI/O

module (or other N-series modules). Each NSeries module includes an expansion and strap kit

(Item# KT122), which includes a 5” CAT5

interconnect cable, four metal straps, and four #440 metal screws. The image shows a SeaI/O stack

configuration using the expansion kit.

DIN Rail Mounting

All SeaI/O modules are available with a factoryinstalled DIN-rail mounting clip. Alternatively

DIN-rail mounting clips can be ordered as a field

upgrade kit (Item# DR104). The bracket with clip

is easily attached using two included #4-40

Phillips head machine screws.

Table/Wall Mounting

The flush mount bracket kit (Item# KT123) is

extremely versatile and can be used to mount

SeaI/O modules from the top, bottom, or back

edge. Individual modules or a stack of SeaI/O

modules can be mounted flat to a tabletop,

underneath a counter, or inside an enclosure. The

kit can be used to mount SeaI/O modules flat to a

wall, or along the back edge, similar to DIN-rail

mounting options.

Universal Mounting Bracket

The universal mounting bracket (Item# KT125)

can be used as a “backpack” to mount power

supplies and other devices to SeaI/O modules. The

bracket has holes for both 75mm and 100mm

VESA mounting options. The universal

arrangement of slots and holes accept bolt sizes to

M4 and can be used for virtually any mounting

configuration.

© Sealevel Systems, Inc.

- 34 -

SeaI/O User Manual

Page 38

Accessories

Power Supplies

US Options

TR112 – 120VAC to 24VDC 250mA “Wall Wart” Power Supply with 1.3mm Plug

(for single SeaI/O module)

TR109 – 120VAC to 24VDC 500mA “Wall Wart” Power Supply with 1.3mm Plug

(for multiple SeaI/O modules)

TR108-US – 100-250VAC to 24VDC 36W 1.5A “Desktop” Power Supply with

1.3mm Plug, includes (CA248) Nema 5-15P 6’ US Power Cord

PS101 – 100-240VAC to 24VDC 7.5W 300mA DIN Rail Mount Power Supply

(connects via screw terminals, no wire included)

PS103 – 100-240VAC to 24VDC 50W 2.1A DIN Rail Mount Power Supply

(connects via screw terminals, no wire included)

International Options

TR108-AU - 100-250VAC to 24VDC 36W 1.5A “Desktop” Power Supply with

1.3mm Plug, includes (CA187) “AS 3112” 6’ Australian Power Cord

TR108-EC - 100-250VAC to 24VDC 36W 1.5A “Desktop” Power Supply with

1.3mm Plug, includes (CA188) “Schuko” 6’ Continental European Power Cord

TR108-UK - 100-250VAC to 24VDC 36W 1.5A “Desktop” Power Supply with

1.3mm Plug, includes (CA189) “BS 1363” 6’ UK Power Cord

TR108 – 100-250VAC to 24VDC 36W 1.5A “Desktop” Power Supply with 1.3mm

Plug, requires IEC country-specific Power Cord

Mounting Options

KT122 – Expansion & Strap Kit. Includes 5” RS-485 Interconnect Cable (item#

CA239), four metal straps, and four #4-40 metal screws, for connecting two SeaI/O

modules together in a “stack”

KT123 – Flush Mount Bracket Kit. Includes two metal brackets and four #4-40

metal screws, for mounting SeaI/O modules or stacks in a variety of positions and

locations

KT125 – Universal Mounting Bracket. Includes metal mounting bracket and four

#4-40 metal screws, for mounting devices to SeaI/O modules or mounting SeaI/O

modules to VESA mounts and other devices.

DR104 – DIN Rail Mounting Assembly. Connects to the back edge of SeaI/O

modules to facilitate an easy DIN rail mounting option and a cleaner installation

RK1U – 1U 19” Rack Tray

RK2U – 2U 19” Rack Tray

RK-CLAMP – Securely holds SeaI/O modules to rack trays

© Sealevel Systems, Inc.

- 35 -

SeaI/O User Manual

Page 39

Cabling Options

CA239 – 5” CAT5 RS-485 Interconnect Cable, used to connect SeaI/O modules

together in a stack (included in 4xxN SeaI/O expansion modules)

CA246 – 7’ Blue Ethernet Patch Cable. Can be used to connect SeaI/O Ethernet

modules to a hub (included with 4xxE SeaI/O Ethernet modules). Can be used to

connect SeaI/O RS-232 modules to both Sealevel and standard RS-232 serial ports

(included with 4xxS SeaI/O RS-232 modules as part of p/n: KT119). Optionally, it

can be used as an RS-485 interconnect cable to cascade additional SeaI/O modules

via the RS-485 In/Out ports on the side of SeaI/O modules

CA251 – 7’ Yellow Crossover Cable. Used to connect SeaI/O Ethernet modules

directly to a computer’s Ethernet port without having to go through a hub or switch

CA247 – 10’ Blue Ethernet Patch Cable. Can be used to connect SeaI/O Ethernet

modules to a hub, or can be used as an RS-485 interconnect cable to cascade SeaI/O

modules via the RS-485 In/Out ports

CA179 – USB 6’ A to B Cable (included with 4xxU SeaI/O USB modules)

KT119 – RS-232 DB9/RJ45 Kit, includes (DB109) DB9F to RJ45 adapter with RS-

232 pinout, and (CA246) 7’ CAT5 patch cable. For connecting SeaI/O modules to

both Sealevel and standard RS-232 serial ports (included with 4xxS SeaI/O RS-232

modules)

KT120 – RS-422 DB9/RJ45 Kit, includes (DB110) DB9F to RJ45 adapter with RS422 pinout, and (CA246) 7’ CAT5 patch cable. Optional accessory for connecting

SeaI/O modules to Sealevel RS-422 serial port products

KT121 – RS-485 DB9/RJ45 Kit, includes (DB111) DB9F to RJ45 adapter with RS485 pinout, and (CA246) 7’ CAT5 patch cable. Optional accessory for connecting

SeaI/O modules to Sealevel RS-485 serial port products

© Sealevel Systems, Inc.

- 36 -

SeaI/O User Manual

Page 40

SeaMAX Application Suite

Introduction

The SeaMAX Suite is a collection of software libraries, and configuration and

diagnostic utilities that facilitates rapid application development. The following

libraries and utilities are included in the SeaMAX Suite:

MaxSSD Configuration & Diagnostics utility

Ethernet Config utility

SeaMAX API

CEthernet API

Sealevel SeaI/O modules are available in various I/O configurations, each designed

for maximum flexibility and easy field wiring. Host devices can communicate with

SeaI/O modules using Modbus TCP (Ethernet) or Modbus RTU (RS-232, RS-485,

and USB). Up to 246 expansion modules can be daisy chained together via RS-485

using convenient pass-through connectors. Coupled with the SeaMAX Suite,

Sealevel SeaI/O modules offer powerful data acquisition solutions, perfect for a

range of applications and environments, and easy interfacing to a variety of

computers, controllers, and PLCs.

The source code referenced in this document is designed to offer a high-level

overview of how to utilize the libraries contained on the Sealevel software CD-ROM

that ships with all SeaI/O modules. These code samples are meant as examples to

assist in your application development. Any questions about the code samples may be

emailed to technical support at support@sealevel.com

.

© Sealevel Systems, Inc.

- 37 -

SeaI/O User Manual

Page 41

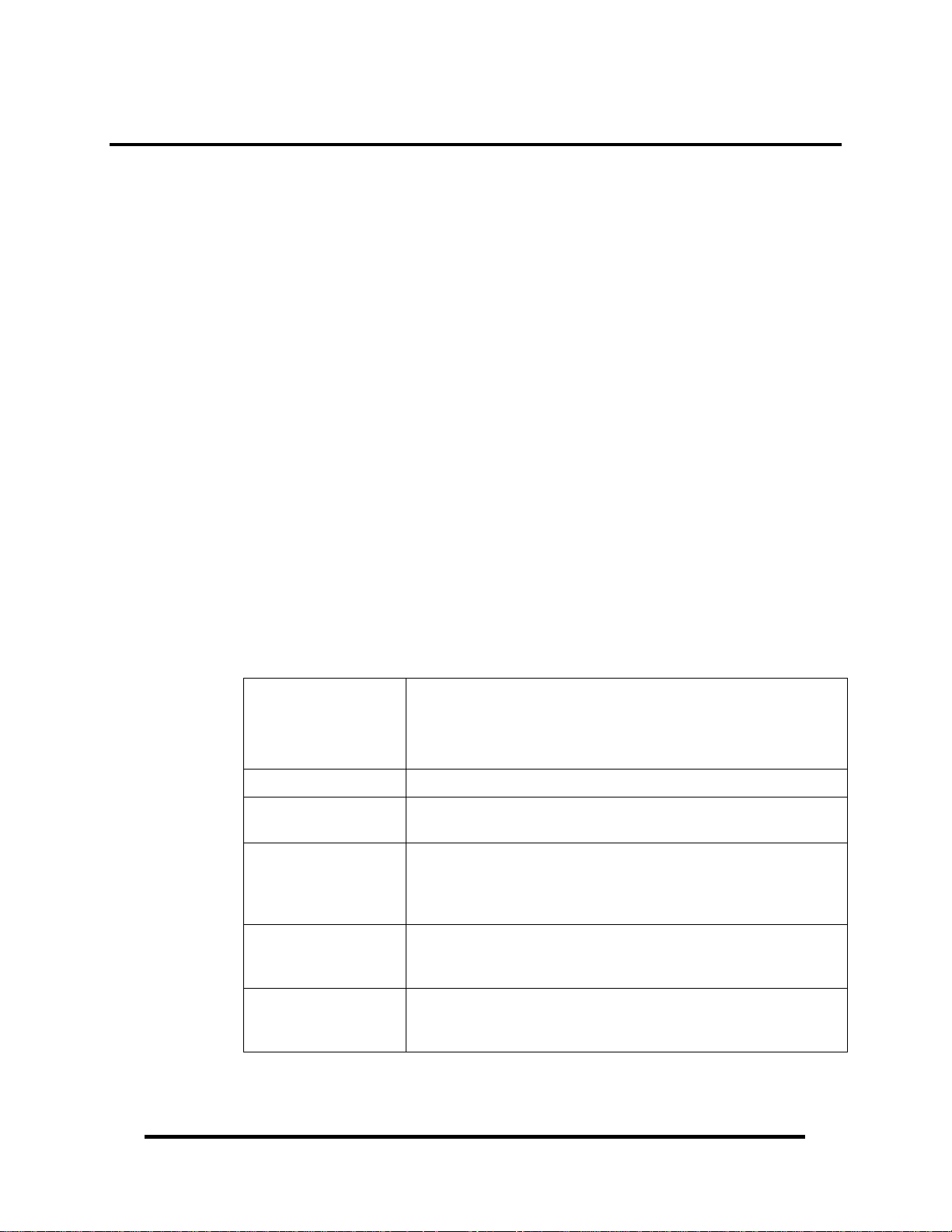

SeaI/O Architecture

The memory map for the I/O listed in the table below describes how to address the

SeaI/O modules in both Modbus compliant applications as well as through the

SeaMAX API library.

SeaI/O

Model

410

420

430

440

450

462

463

470

Opto. Inputs 8 0x02 0 – 7 Bit

D/A Outputs 2 0x06 0 – 1 16 Bits

A/D Inputs 16 0x04 0 – 15 16 Bits

520

Opto. Inputs 8 0x02 0 – 7 Bit

Type No.

Reed Relays 16 0x01 0 – 15 Bit

Opto. Inputs 16 0x02 0 – 15 Bit

Form C Relays 8 0x01 0 – 7 Bit

Opto. Inputs 16 0x02 0 – 15 Bit

Opto. Inputs 32 0x02 0 – 31 Bit

Reed Relays 32 0x01 0 – 31 Bit

Form C Relays 16 0x01 0 – 15 Bit

Programmable I/O 96 0x41

Programmable I/O 96 0x41

Outputs 8 0x01 0 – 7 Bit

Form C Relays 8 0x01 0 – 7 Bit

Modbus

Function

0x42

0x42

Modbus

Range

– –

– –

Access

When communicating with SeaI/O modules, the users needs to be aware of the

following:

When accessing multiple I/O points, they must be addressed linearly.

The output memory space is separate from the input I/O space; therefore

individual reads must be issued for each type of I/O (i.e., a 16-input and 16output module has two unique spaces. A program that wants to read all 32 digital

I/O points must issue two sixteen position reads for each I/O space).

In terms of Modbus, digital outputs are mapped into coil space and digital inputs

are mapped into discrete input space.

© Sealevel Systems, Inc.

- 38 -

SeaI/O User Manual

Page 42

Device Address Configuration

Before configuring SeaI/O modules using MaxSSD, you must first select a device

addressing method. Next, you must properly set termination and pull-up/pull-down

resistors. Finally, you must configure the SeaI/O modules one at a time before

MaxSSD and any subsequent applications (using the SeaMAX API) will be able to

successfully communicate.

Setting Device Address (Slave ID)

SeaI/O modules have a rotary switch, labeled “ADDR”, located on the left side of the

device that is used to set the device address (slave ID). The default position for all

SeaI/O modules is position “0” (zero). Each SeaI/O module must be set to a unique

slave ID in order to properly communicate with the host device, which can be a

computer or Modbus device. The slave ID can be set by hardware using the rotary

switch, which is recommended for most users. The slave ID can also be set in

software by leaving the rotary switch at position “0” and using MaxSSD to set the

slave ID. The rotary switch has three functions:

Set Address (slave ID) via Hardware – If the rotary switch is set to a position

between “1” and “15” (F), then the SeaI/O module will always respond to

commands issued at that slave ID. This is useful when there are fewer than 16

SeaI/O modules in a chain and the slave ID is not required to change. This

method is recommended for most users.

Set Address (slave ID) via Software – If the rotary switch is left in the “0”

(zero) position, the SeaI/O module uses a default slave ID of 247 for

communications. By using MaxSSD (or the SeaMAX libraries), it is possible to

set the slave ID to a software address between 1 and 247. This is useful when

there are more than 16 SeaI/O modules in a chain, or when the slave ID of a

module needs to be frequently changed.

Hardware Reset – If you have an existing SeaI/O module set to an unknown

slave ID or baud rate, you may wish to reset the device. If the rotary switch is

rotated clockwise one full revolution, the SeaI/O module will be reset to factory

defaults (slave ID 247, 9600 bps, and no parity).

NOTE:

A Hardware Reset will not reset the communication rate of an

Ethernet (E-series) module. Rotate the rotary switch clockwise one

full revolution, and then use the MaxSSD utility to broadcast a set

baud rate command to 9600 bps and no parity.

© Sealevel Systems, Inc.

- 39 -

SeaI/O User Manual

Page 43

Setting Termination & Pull-Up/Pull-Down Resistors

A “stack” or “chain” of SeaI/O modules, connected via the pass-through connectors

or screw terminals on the left side of the enclosure, communicates via an RS-485 bus,

which must be properly terminated to work correctly. A set of three dipswitches is

located on the left side of enclosure, next to the “ADDR” rotary switch. These

switches control line termination and the RS-485 pull-up and pull-down resistors.

The pull-up and pull-down resistors ensure that the input ports are at a known state

when not being driven by the RS-485 line. In most cases, all three of the dipswitches

on each SeaI/O module should be in the down position, except the two end modules.

The first and last SeaI/O modules in the chain should have all three dipswitches in the

up (enabled) position.

NOTE:

Make sure that only the first and last SeaI/O modules have line

termination enabled (up position). Improper termination settings

can result in invalid data or communication failures.

© Sealevel Systems, Inc.

- 40 -

SeaI/O User Manual

Page 44

Configuring the “Base” SeaI/O Module

After you have decided which address (slave ID) method you intend to use, proceed

with installing the SeaMAX Software Suite (discussed in the following section).

Once SeaMAX has been installed successfully, start by connecting the E-, U-, M-, or

S-series module to your computer. This module will be referred to as the “base”

module.

If you are chaining multiple SeaI/O modules together, only one SeaI/O module in the

chain can be the “base”. All other SeaI/O modules connected to the “base” module

are referred to as expansion modules. Multiple “base” modules can be directly

connected to a host computer, but expansion modules must be connected (daisy

chained) to a “base” module.

NOTE:

If you are configuring an Ethernet SeaI/O (E-series) module, skip

ahead to the Configuring an Ethernet Module section for

additional information on installing an Ethernet module.

For all other SeaI/O modules (U-series, S-series, or M-series), locate the COM port

by expanding the ‘Ports’ list in Windows Device Manager.

Start MaxSSD (Start Æ All Programs Æ Sealevel SeaMAX Æ MaxSSD) and choose

the correct port (IP address or COM port) to communicate with the “base” module.

Ensure a successful Get operation (refer to the MaxSSD section on the following

pages for more information).

Set the slave ID of the “base” module using the rotary switch or software selection

method discussed in the Setting Device Address section on the previous pages. This

guarantees that any expansion modules connected next will not conflict with the

“base” module. Perform another Get operation to verify that you can communicate

with the “base” module at the new slave ID.

NOTE:

Configure the SeaI/O modules one at a time. Set the address to a

hardware slave ID other than “0” or a software slave ID other than

247, which avoids device conflicts during setup.

After the “base” module is successfully communicating via MaxSSD, you can

proceed with adding SeaI/O expansion modules (N-series), as required.

NOTE:

If the “base” module doesn’t respond as expected, turn the rotary

switch (ADDR) clockwise one full revolution to reset. Configure the

PC to communicate at 9600 bps and no parity and then try again.

© Sealevel Systems, Inc.

- 41 -

SeaI/O User Manual

Page 45

Configuring N-Series Expansion Modules

Once you have successfully connected and communicated with a “base” module, you

can begin adding expansion modules (N-series). Connect a single expansion module

to the “base” module via the RJ45 pass-through connectors or screw terminals on the

left side of the enclosure. Expansion modules include a convenient 5” interconnect

cable (item# CA239) to simplify daisy-chaining SeaI/O modules together.

Alternately, you can use standard network patch cables to chain expansion modules

to a “base” module.

NOTE:

The RJ45 pass-through connectors are NOT Ethernet connectors.

Do not connect the ports to Ethernet enabled devices else damage to

Ethernet devices WILL result.

Ensure a successful Get operation (refer to the MaxSSD section on the following

pages for more information). Set the slave ID of the expansion module using the

rotary switch or software selection method discussed in the Setting Device Address

section on the preceding pages. Perform another Get operation to verify that you can

communicate with the expansion module at the new slave ID.

Continue adding expansion modules (N-series), one at a time, until all modules have

been successfully daisy-chained together and respond to a Get operation in MaxSSD.

Once all SeaI/O modules are configured and communicating successfully, they are

ready to communicate with your application.

© Sealevel Systems, Inc.

- 42 -

SeaI/O User Manual

Page 46

Configuring an Ethernet Module (E-Series)

NOTE:

Verify that SeaMAX has been installed successfully and that an Ethernet SeaI/O

module is connected to your computer. This module will become the “base” module.

All Ethernet SeaI/O (E-series) modules are shipped with DHCP enabled. When you

first connect an Ethernet SeaI/O module to the network, the status LEDs on the front

of the module will blink while it searches for a DHCP server. Once it receives an IP

address, the status LEDs will remain on.

If no DHCP server is available, the Ethernet SeaI/O module will default to a random

IP address in the range 169.254.x.x. To discover the Ethernet SeaI/O module’s IP

address, start the Ethernet Config utility (Start Æ All Programs Æ Sealevel

SeaMAX Æ Ethernet Config) installed with SeaMAX.

This section applies only to Ethernet SeaI/O (E-series) modules.

For all other SeaI/O modules, refer to the Configuring a “Base”

SeaI/O Module and Configuring Expansion Modules sections on

the previous pages.

Click on the “Search for SeaI/O Devices” button and the ‘Available SeaI/O Devices’

pane should refresh with any Ethernet SeaI/O modules that are found on the network.

Select one of the modules in the list by clicking on it. You can update the settings in

the Device Network Settings pane and then confirm these changes by clicking the

“Apply Changes” button. The module list should refresh, indicating that your

changes were successful.

© Sealevel Systems, Inc.

- 43 -

SeaI/O User Manual

Page 47

Configuring an Ethernet Module (Continued)

NOTE:

If the module does not change or respond, the PC and the module

may be on different subnets. Proceed to the Recover Module

section on the following page.

Start MaxSSD (Start Æ All Programs Æ Sealevel SeaMAX Æ MaxSSD) and choose

the correct IP address to communicate with the “base” Ethernet SeaI/O module.

Ensure a successful Get operation (refer to the MaxSSD section on the following

pages for more information).

Set the slave ID of the “base” Ethernet SeaI/O module using the rotary switch or

software selection method discussed in the Setting Device Address section on the

previous pages. This guarantees that any expansion modules connected next will not

conflict with the “base” module. Perform another Get operation to verify that you

can communicate with the “base” Ethernet SeaI/O module at the new slave ID.

NOTE:

Configure the SeaI/O modules one at a time. Set the address to a

hardware slave ID other than “0” or a software slave ID other than

247, which avoids device conflicts during setup.

After the “base” Ethernet SeaI/O module is successfully communicating via

MaxSSD, you can proceed with adding SeaI/O expansion modules (N-series). Refer

to the Configuring Expansion Modules section on the previous pages.

© Sealevel Systems, Inc.

- 44 -

SeaI/O User Manual

Page 48

Resetting an Ethernet SeaI/O Module

An Ethernet SeaI/O module may become no longer visible in the module list in the

Ethernet Config utility if the Ethernet SeaI/O module has been configured to use a

different subnet than the host computer.

In other cases, the Ethernet SeaI/O module doesn’t appear in the module list due to a

DHCP discovery failure. In either case, clicking on the “Recover Module” button

(see image on previous page) in the Ethernet Config utility will bring up the

“Module Reset” window shown below.

Before recovery begins, make certain that the PC and Ethernet SeaI/O module are on

the same network segment – they should be connected with an Ethernet crossover

cable, through a hub, or through a non-routing switch. Ethernet SeaI/O modules are

shipped with both an Ethernet patch cable (blue) and an Ethernet crossover cable

(yellow).

Enter the MAC address found on the label on the bottom of the SeaI/O enclosure. A

MAC address is made up of six pairs of hex digits separated by dashes (i.e., xx-xxxx-xx-xx-xx). While entering the MAC address, the indicator to the right of the field

will turn red if the MAC address entered is invalid. Once a MAC address is

successfully entered, the indicator light will turn green and the “Network Settings”

options will be enabled.

Contact your network administrator if you are unsure of the proper network settings

to choose. If a DHCP server is available, select the “Enable DHCP Configuration”

checkbox. Otherwise, complete the network settings and click the “Recover Module”

button to complete the configuration changes.

Proceed with configuring expansion modules, explained in the previous section, or

refer to the Troubleshooting section at the end of the manual for more information.

© Sealevel Systems, Inc.

- 45 -

SeaI/O User Manual

Page 49

MaxSSD Configuration & Diagnostics Utility

The Sealevel Systems configuration utility, MaxSSD, is designed to simplify the

installation, configuration, and diagnostics of Sealevel SeaI/O modules. MaxSSD is a

Microsoft Windows application and has been tested with Windows 2000 and XP.

Host PC Configuration Tab

The first time you run the MaxSSD utility (Start Æ All Programs Æ Sealevel

SeaMAX Æ MaxSSD) it will default to the “Host PC Configuration” tab. This tab

allows the user to set the initial communication settings. The “COM Port” dropdown

box allows the selection of a serial COM port (from COM1 to COM256) or Ethernet.

Once a COM port is selected, the baud rate and parity can be selected.

NOTE:

The baud rate and parity of the PC must match the settings of the

SeaI/O module to be configured. The factory default settings for all

SeaI/O modules are 9600 baud and no parity.

To use an Ethernet connection, select “ETHERNET” from the “COM Port”

dropdown box. When Ethernet is selected, MaxSSD searches for any SeaI/O Ethernet

modules on the network and displays their IP addresses in the “Available Ethernet

Devices” list box (not shown). When an IP address is selected from the list box, a

socket is opened to the SeaI/O module and it is ready for communication.

NOTE:

If no IP address is shown when using Ethernet modules, review the

previous Hardware Configuration section, or proceed to the

Troubleshooting section at the end of this manual.

© Sealevel Systems, Inc.

- 46 -

SeaI/O User Manual

Page 50

SeaI/O Configuration Tab

Once the host computer is configured correctly, the “SeaI/O Configuration” tab

becomes available.

Before communicating with a SeaI/O module, the configuration utility must

determine if there is a SeaI/O module at that slave ID address, and if so, what type of

module it is. This is the purpose of the Get operation.

To perform a Get operation, first select the slave ID to which the module is

configured. SeaI/O modules are shipped at hardware setting 0 (labeled “ADDR” on

the left side of the module) and slave ID 247 by default. All other slave ID addresses

(from 1 to 246) are available. However, each daisy chained SeaI/O module must have

a unique slave ID address - no duplicates are allowed.

Once a slave ID is selected, click the “Get SeaI/O Device Settings” button. After a

short delay, the information for that SeaI/O module should be displayed. If no

information appears, verify the host settings and baud rates are correct and make

changes, if necessary. Check the hardware settings (on the left side of the module)

and try again.

© Sealevel Systems, Inc.

- 47 -

SeaI/O User Manual

Page 51

After the Get command is executed, the “SeaI/O Configuration” tab will display

colored labels showing the SeaI/O model number and interface type. The “Set Device

Settings” and “Change Slave ID” buttons will also be enabled for this module. In the

example shown, the module found at slave ID 247 is a SeaI/O 410 module with an

RS-485 interface.

After a successful Get operation, additional tabs may be displayed in MaxSSD,

depending on the found device model. These tabs display device I/O and allow easy

configuration for the entire SeaI/O family of devices.

The “Broadcast to Multiple SeaI/O Devices” checkbox, along with the “Set Device

Settings” button can be used to change the baud rate and parity on multiple SeaI/O

modules at once. MaxSSD broadcasts a set data rate and set parity command to all

devices on the RS-485 bus, but only those modules listening at the current baud rate

will be able to receive and respond. For example, if you have five SeaI/O modules

chained together and two are set to 9600 bps and no parity and three are set to 115.2k

bps and the PC is set to 9600 bps, only the two modules set to 9600 bps will receive

the broadcast set data rate and parity message.

NOTE:

Important note regarding SeaI/O Ethernet (E-series) modules

The broadcast feature sets the Ethernet SeaI/O (E-series) module’s

TCP/IP to RS-485 translation data rate independently of the SeaI/O

module itself. Therefore, if you have an Ethernet SeaI/O module

and you set the data rate to 115.2K bps via a MaxSSD broadcast

command, both the RS-485 port and the Ethernet port will respond

thereafter to 115.2K bps, as expected. However, if you reset the

SeaI/O module by rotating the rotary switch clockwise one complete

revolution, the RS-485 port will reset to 9600 bps and no parity, but

the Ethernet port will remain unaffected. To restore

communications, broadcast another set data rate and parity

command (9600 and no parity) via MaxSSD.

© Sealevel Systems, Inc.

- 48 -

SeaI/O User Manual

Page 52

Digital I/O Tab

The “Digital IO” tab of MaxSSD is displayed when using SeaI/O devices featuring

discrete inputs and outputs. It displays the device’s current input and/or output status

in an intuitive and usable manner.

The “Digital IO” tab displays inputs and outputs in groupings (or banks) of eight.

Therefore, a SeaI/O device with 16 inputs and 8 outputs would show two banks of

inputs and one bank of outputs.

When displaying banks of inputs, the status LEDs update on each of the banks

automatically. This allows the user to dynamically monitor external signals.

With a bank of outputs, the output coils can be set using the buttons below each

output LED. As each coil is set, the SeaI/O module is read. The corresponding status

LED in the “Digital IO” window indicates the state of the coil.

© Sealevel Systems, Inc.

- 49 -

SeaI/O User Manual

Page 53

Programmable I/O Tab

The “Programmable IO” tab of MaxSSD is displayed when using SeaI/O devices

featuring programmable inputs or outputs. This tab allows for bank configuration,

input/output configuration, as well as bit-level presets.

Each bank of programmable I/O can be set as either an 8-bit group of inputs or

outputs. By selecting “Bank 1” from the drop-box, clicking the “Bank functions as

Input” radio button, and then clicking the “Set Programmable IO Options” button, the

first 8 PIO bits on the device will now function as inputs. For ease of configuration,

an “All Banks of IO” option is available to configure all of the I/O at one time.

Inputs have no preset mode; therefore, the preset options are disabled for any bank of

inputs. Outputs; however, have bit-addressable presets. These presets are used

whenever the device is powered up or the bank direction changes from input to

output.

NOTE:

The output presets, will not lock the outputs into a specified on or

off state. They only set the state of the outputs on a power on or

bank direction change.

© Sealevel Systems, Inc.

- 50 -

SeaI/O User Manual

Page 54

A/D Inputs Tab

The “A/D Inputs” tab displays the current state of the analog-to-digital channels for

devices that feature A/D inputs. Settings are provided for both device wide and perchannel configuration.

The “Device Configuration” selection drop-box adjusts the arrangement and function

of the A/D input channels. Input channels are displayed as banks (groups of eight).

Each channel is range configurable via the voltage range dropdown list. Both the

channel voltage range and device-wide configuration are set on a dropdown list.

There is no need to save your settings – they are automatically saved to the device as

you select the various configuration options.

“10x Hardware Gain Enabled” checkbox – Indicates whether or not the onboard

hardware gain jumper is currently set. This option is not user configurable – it only

reflects the status of the onboard hardware jumper settings. Set the hardware jumper

to enable this functionality, which allows smaller voltages to be measured more