impro technologies HMW701-0-0-NN-XX, HMW700-0-0-NN-XX Installation Manual

MODEL NUMBER:

HMW700-0-0-NN-XX HMW701-0-0-NN-XX

Wiegand Reader

Module

Impro (WRM) Wiegand Reader Module

INSTALLATION MANUAL

SPECIFICATIONS

The WRM is a Cluster Expansion Module that works in conjunction with an Impro

(CCM) Cluster Controller Module; offering a Wiegand Reader Interface solution that is

adaptable and scalable, while also accommodating legacy hardware and software

suites.

Working Environment

Plastic Housing ............................

(HMW700)

Designed to work in an indoor (dry)

environment similar to IP20. The Module is

not sealed against water.

PCB Card for IPS / 19” Rack .......

(HMW701)

Designed to work in an indoor (dry)

environment similar to IP20. The Card is not

sealed against water.

Power

Input Voltage ................................

12 V DC to 15 V DC, polarity protected.

Power Requirements

Current (mA)

Power (W)

12 V DC with no Readers

connected and relays off ........

37

0.44

12 V DC with both relays

activated and maximum

reader load .............................

503

6

Communication with the Cluster Controller Module

Direct Communications ..............

When the WRM is clustered (plugged side-by-

side) directly into the CCM, or into an existing

Cluster, or installed as a PCB Card in IPS

Housing.

Electrical Interface .................. Proprietary Cluster-Bus

Baud Rate ..............................

115 200

Encryption .............................. AES Encryption

S-Bus Device Port

Electrical Interface ..................

Proprietary S-Bus

Baud Rate .............................. 9600

Encryption ..............................

AES Encryption

NOTE: The Wiegand Reader Module (being a Twin Reader Interface) can make

use of TWO S-Bus Addresses; this must be borne in mind when connecting

these modules to their Cluster Controller Module via S-Bus. No more than

eight Addresses should share an S-Bus. See WRM Address Information

on page 17 for Address usage with one Reader connected.

Reader Options

Reader 1 Wiegand and Reader 2 Wiegand allow connection to the following hardware:

Impro (MDR) Multi-discipline Reader, Impro (XFM) Multi-mode Remotes, Wiegand

Readers, Impro (IR) Infrared Receiver or the Impro (QR) Quad Receiver. The function

is selectable via the DIP-switches (See Table 1).

Power Output ...............................

12 V DC and 5 V DC (selectable) at maximum

200 mA.

Modes Supported

........................

Tag + PIN-code or Reason Code.

Baud Rate .....................................

9 600.

Data Format ..................................

8 data bits, no parity, 1 stop bit.

Electrical Interface .......................

TTL Full Duplex.

Communications Protocol ..........

Impro Proprietary Protocol.

Relays

Relay Output ................................

2 Relays, Form C, each with NO, COM and

NC contacts.

Relay Contact Ratings

.................

10 A at 28 V DC,

5 A at 220 V AC,

10 A at 120 V AC.

Operations ....................................

100 000 Minimum.

HMW300-0-0-GB-00 October 2013 Page 2

Digital Inputs

General

Type .............................................

2 Dry-contact inputs with End-of-line (EOL)

Sensing and 2 Dry-contact inputs without End-

of-line (EOL) Sensing.

Detection Resistance Range ......

< 2 kOhm.

Protection Range .........................

+15 V continuous.

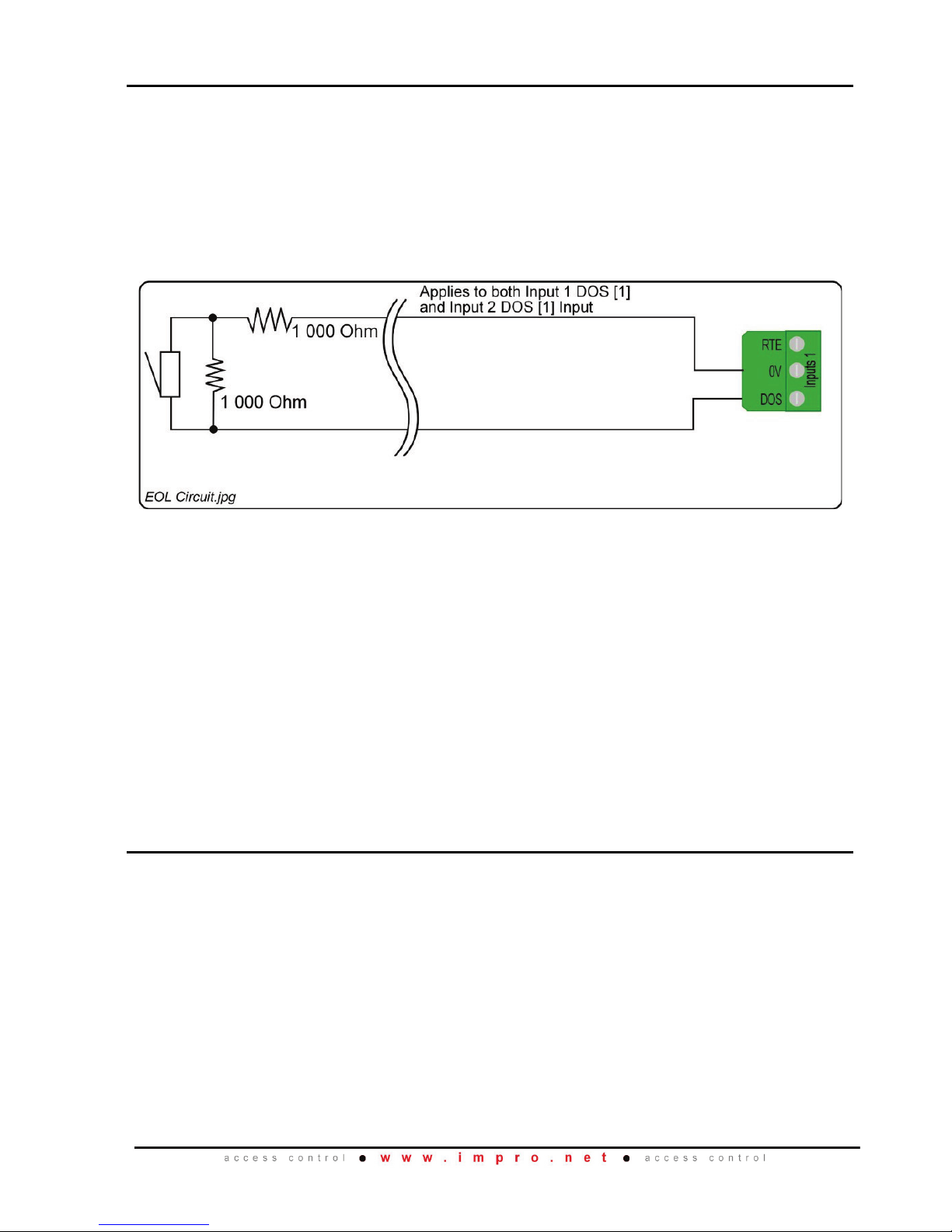

Figure 1: End-of-line (EOL) Sensing Circuit

NOTE: End-of-line (EOL) Sensing enables the WRM to raise an alarm when

somebody tampers with the circuit (cutting or shorting the wires) between

either Reader 1 Inputs [1] DOS or Reader 2 Inputs [2] DOS and GROUND

(GND). In other words the Module distinguishes between tampering on the

circuit, and the door being in an actual ‘Normally Open’ state.

By placing Resistors into the circuit between either Reader 1 Inputs DOS [1]

or Reader 2 Inputs DOS [1] and GROUND (GND), the Module’s Digital Input

monitors a constant resistance through the circuit. When the circuit is

tampered with, the Resistors are bypassed; the Module detects the

resistance change and raises an alarm.

LED Status and Diagnostic Indicators

Status LED (RED)

Supply Voltage Status ............

Off when supply voltage is too high, or too low

Upgrade Mode .......................

Flashing at a steady rate during upgrade

Communications Failure ........

Two brief flashes, repeating

Data LED (GREEN)

Flashing Green during communication

Digital Inputs (1-4) ......................

Continuous Green on detected contact closure

Relays (1 and 2) ...........................

Continuous Red on activation of the Relay

HMW300-0-0-GB-00 October 2013 Page 3

INSTALLATION INFORMATION

Accessories

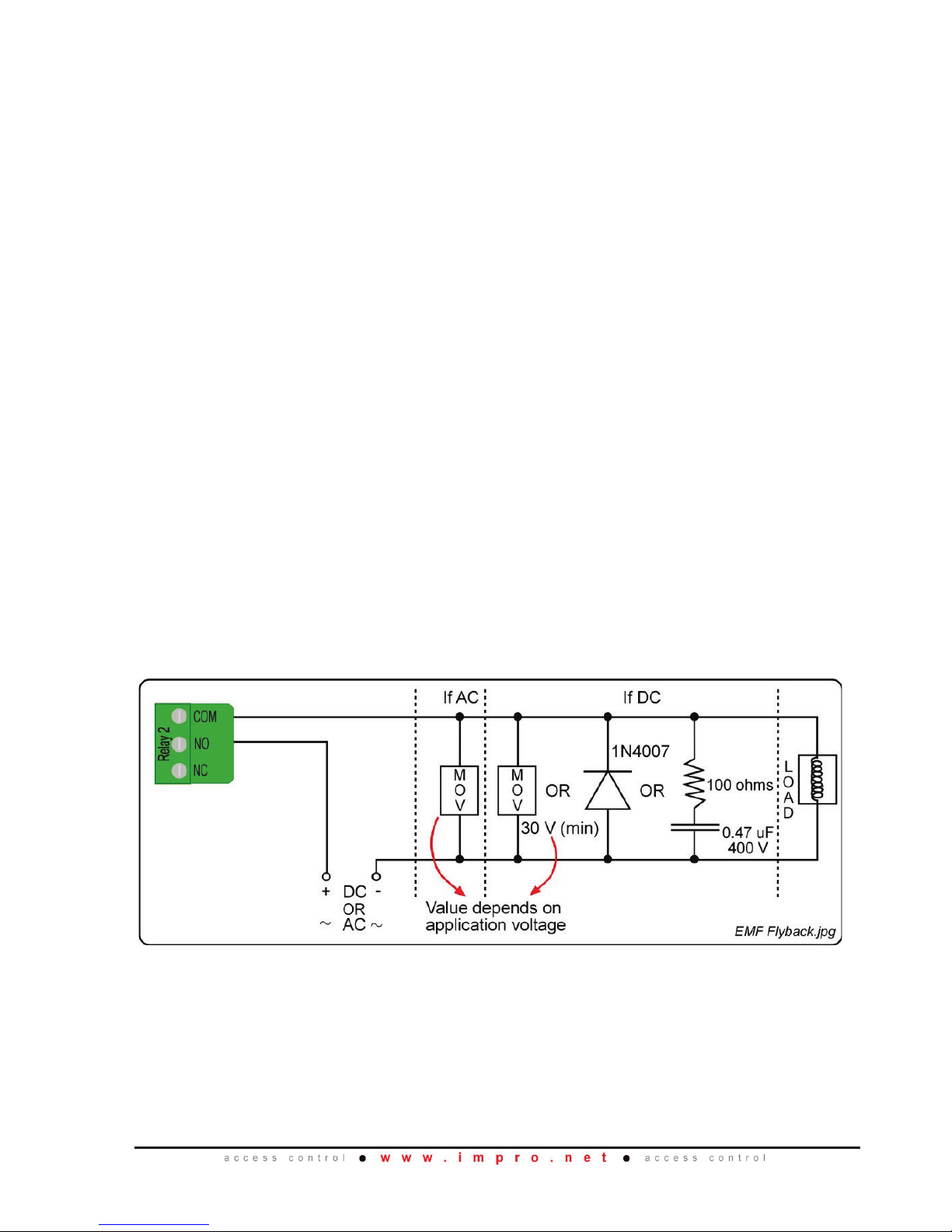

CAUTION: DO NOT use the Metal-oxide Varistors (25 Vrms, 500 A, 77 V max

clamping) with mains power applications.

Plastic Cluster Housing (HMW700)

Each Impro (WRM) Wiegand Reader Module is supplied in a Customisable Black, ABS

Plastic housing, with the following features / items:

• Housing, consisting of a Base, a Cover and a selection of Cable Entry Gland

Plates.

• The Housing Base has:

− Two slots to hold the User-Selectable Cable Entry Plates

− Six knock-out Cable Entry Points

− Four Drill-out Cable Entry Points

• The Housing Cover and Base are held together with two Allen Head Screws

(M4 x 10 mm) through the cover of the housing.

• Five Ziploc bags, containing the following:

− Four Stand-Offs (for spacing the WRM away from the mounting surface)

and two Cluster Connector Covers (for closing off the cluster connectors

when not in use.)

− Two Metal-Oxide Varistors 25 Vrms, 500 A, 77 V max clamping.

− A 2mm Allen Key and a spare Hex Head Screw

− Two extra gland plates

− An extra Fixed Address Label, for installation site mapping

NOTE: The installer needs to obtain fasteners (< 5 mm Diameter to fit through the

supplied Stand-Offs) that are suitable for securing the Module to the

mounting surface – these are NOT supplied in the kit.

PCB Card for IPS Housing (HMW710)

Included in the packaging is:

• Impro Wiegand Reader PCB Card on a Base Plate.

• An extra Fixed Address Label, for installation site mapping

HMW300-0-0-GB-00 October 2013 Page 4

General

Remember the following when installing the Wiegand Reader Module:

Clustering

Clustering allows for the easy addition or replacement of Modules, it saves on wiring

and requires only one DC Power Supply connection for the Cluster.

The following applies:

• The WRM may be plugged directly into its associated Cluster Controller, or

into an existing Cluster consisting of a Cluster Controller and other Expansion

Modules.

• No more than eight Expansion Modules can be clustered with their associated

Cluster Controller.

• The WRM is powered and controlled via its Cluster Connector.

• Clustering with the Cluster Controller is recommended where Offline

Validation is a high priority, as the WRM will have reliable access to the Tag

Buffer and Memory on board the Cluster Controller.

S-Bus

S-Bus is useful when it would be convenient to install a WRM some distance from its

Cluster Controller. The following applies:

• The maximum S-Bus Cable length from the Cluster Controller to the WRM is

150 m (490 ft.).

• A maximum total of 8 addresses may be connected to the S-Bus.

• The S-Bus cable should be dual core and at least 0.21 mm2 (AWG24).

Screened cable is recommended where interference rejection may be

necessary in electrically noisy sites – and to provide SOME MEASURE* of

resistance to damage from nearby lightning strikes.

• Remotely mounted WRMs will also require a suitable Isolated DC Power

supply, as they are no longer plugged into the Cluster Controller.

• In the event of the S-Bus cable breaking, the WRM will stop working.

NOTE: *NOTHING can survive a direct lightning strike. Impro Technologies does

NOT claim that its products are lightning proof.

A more detailed chapter on S-Bus is included in the Impro (CCM) Cluster

Controller Module Installation Manual: HCM320-0-0-GB-XX

HMW300-0-0-GB-00 October 2013 Page 5

Wiegand or Multi-Discipline Reader Distance

CAUTION: When implementing the 150 m (164 yd) cable distances with Impro

Wiegand Readers use the 12 V power output option. Note, however,

that the Multi-discipline Readers only connect using the 12 V power

output option.

For maximum, data communications distance, install the Readers no further than

150 m (164 yd) from the Terminal The cable individual conductor cross-sectional area

should not be less than 0.2 mm

2

(0.0003 in2).

Distance between the WRM and its Multi-mode Remote

The maximum cable distance between the Impro WRM and its Multi-mode Remote

MUST NOT exceed 10 m (33 ft). Achieve this by using good quality screened, twisted

pair cable.

Distance between Reader Units

To avoid mutual interference, install the Readers at least 500 mm (20 in) apart. (The

same rule applies between readers on opposite sides of the same wall.)

EARTH Connection

Connect the Impro WRM (“ETH” Terminal) to a good EARTH point. Mains EARTH can

be used, but electrical noise may exist.

Arc Suppression

Snubber devices are recommended for EMF Flyback and Arc Suppression when

driving an inductive load with the Relay, see Figure 2.

Figure 2: EMF Flyback and Arc Suppression

HMW300-0-0-GB-00 October 2013 Page 6

Loading...

Loading...