Page 1

NOTE:

Please read all instructions

carefully before using this

product

Table of Contents

Safety Notice

Hardware Pack

Assembly Instruction

Parts List

Resistance Chart

Warranty

Ordering Parts

MARCY MAGNUM V

HOME GYM

Model

MACH V

Retain This

Manual for

Reference

08-26-03

OWNER'S

MANUAL

IMPEX FITNESS PRODUCTS

14777 DON JULIAN RD., CITY OF INDUSTRY, CA 91746

Tel: (800) 999-8899 Fax: (626) 961-9966

www.impex-fitness.com

info@impex-fitness.com

Page 2

TABLE OF CONTENTS

BEFORE YOU BEGIN...................................................................................... 1

IMPORTANT SAFETY NOTICE...................................................................... 2

HARDWARE PACK…….......…....................................................................... 3

ASSEMBLY INSTRUCTIONS........................................................................... 7

PARTS LIST...................................................................................................... 25

RESISTANCE CHART…………......................................................................... 27

WARRANTY.................................................................................................… 28

ORDERING PARTS......................................................................................... 28

BEFORE YOU BEGIN

Thank you for selecting the MARCY MAGNUM V PERSONAL TRAINER

by IMPEX FITNESS PRODUCTS. For your safety and benefit, read this

manual carefully before using the machine. As a manufacturer, we are

committed to provide you complete customer satisfaction. If you have

any questions, or find there are missing or damaged parts, we

guarantee you complete satisfaction through direct assistance from our

factory. To avoid unnecessary delays, please call our TOLL-FREE

customer service number. Our Customer Service Agents will provide

immediate assistance to you.

Toll-Free Customer Service Number

1-800-999-8899

Mon. - Fri. 9 a.m. - 5 p.m. PST

www.impex-fitness.com

info@impex-fitness.com

1

Page 3

IMPORTANT SAFETY NOTICE

PRECAUTIONS

This exercise machine is built for optimum safety. However, certain precautions apply

whenever you operate a piece of exercise equipment. Be sure to read the entire

manual before you assemble or operate your machine. In particular, note the following

safety precautions:

1. Keep children and pets away from the machine at all times. DO NOT

leave children unattended in the same room with the machine.

2. Only one person at a time should use the machine.

3. If the user experiences dizziness, nausea, chest pain, or any other abnormal

symptoms, STOP the workout at once. CONSULT A PHYSICIAN IMMEDIATELY.

4. Position the machine on a clear, leveled surface. DO NOT use the machine

near water or outdoors.

5. Keep hands away from all moving parts.

6. Always wear appropriate workout clothing when exercising. DO NOT wear

robes or other clothing that could become caught in the machine. Running

or aerobic shoes are also required when using the machine.

7. Use the machine only for its intended use as described in this manual. DO

NOT use attachments not recommended by the manufacturer.

8. Do not place any sharp object around the machine.

9. Disabled person should not use the machine without a qualified person or

physician in attendance.

10. Before using the machine to exercise, always do stretching exercises to

properly warm up.

11. Never operate the machine if the machine is not functioning properly.

WARNING: BEFORE BEGINNING ANY EXERCISE PROGRAM, CONSULT YOUR

PHYSICIAN. THIS IS ESPECIALLY IMPORTANT FOR INDIVIDUALS OVER THE

AGE OF 35 OR PERSONS WITH PRE-EXISTING HEALTH PROBLEMS. READ ALL

INSTRUCTIONS BEFORE USING ANY FITNESS EQUIPMENT. IMPEX INC.

ASSUMES NO RESPONSIBILITY FOR PERSONAL INJURY OR PROPERTY

DAMAGE SUSTAINED BY OR THROUGH THE USE OF THIS PRODUCT.

SAVE THESE INSTRUCTIONS.

2

Page 4

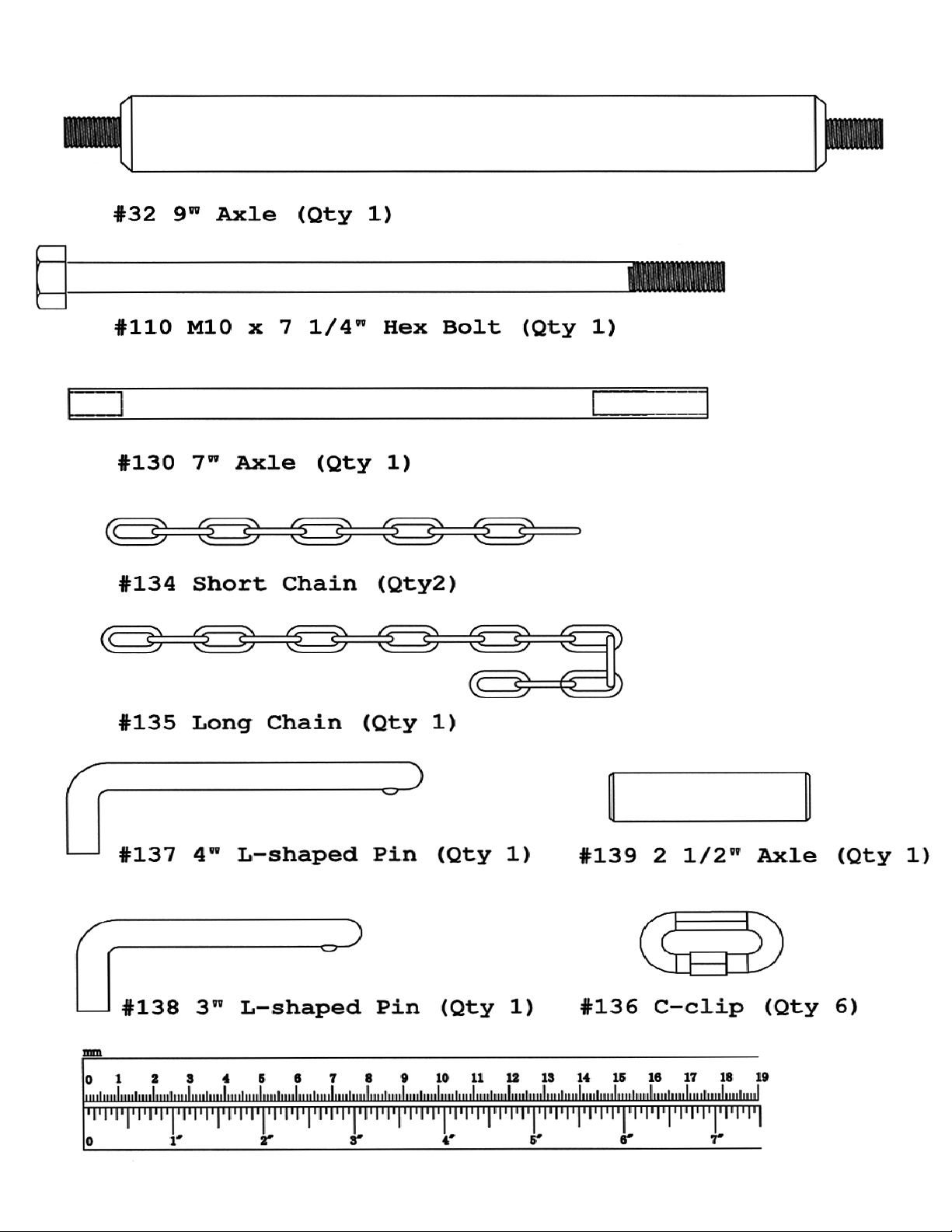

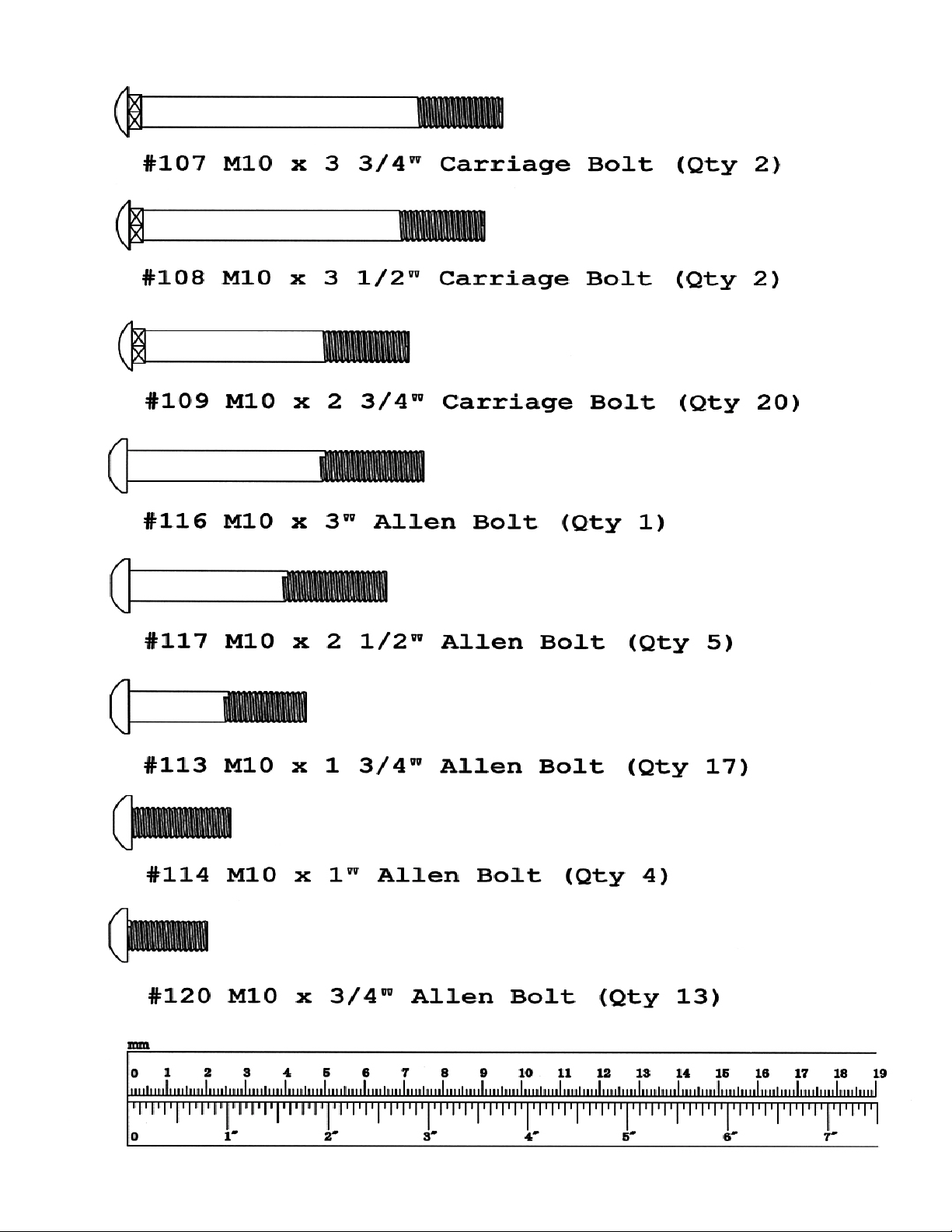

HARDWARE PACK

3

Page 5

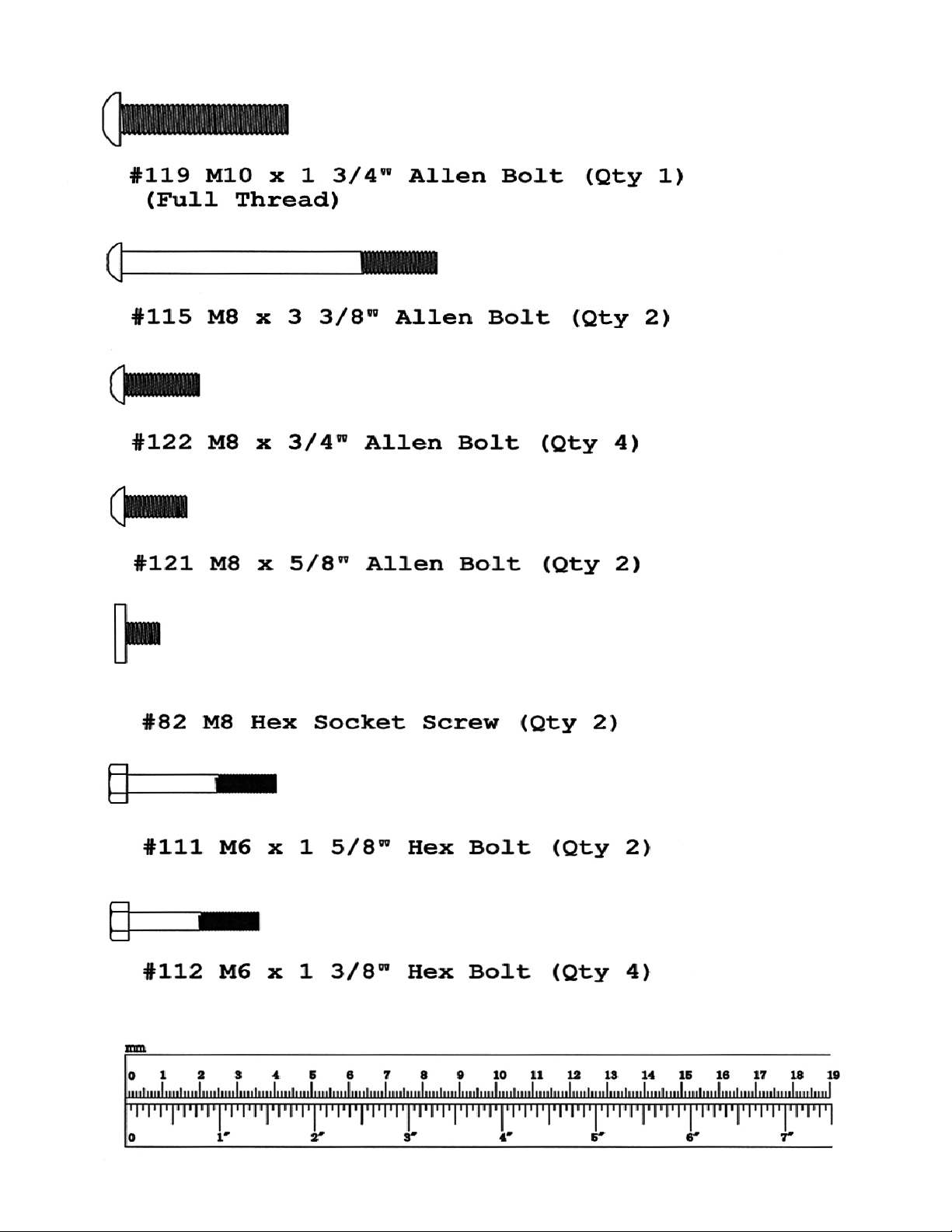

HARDWARE PACK

4

Page 6

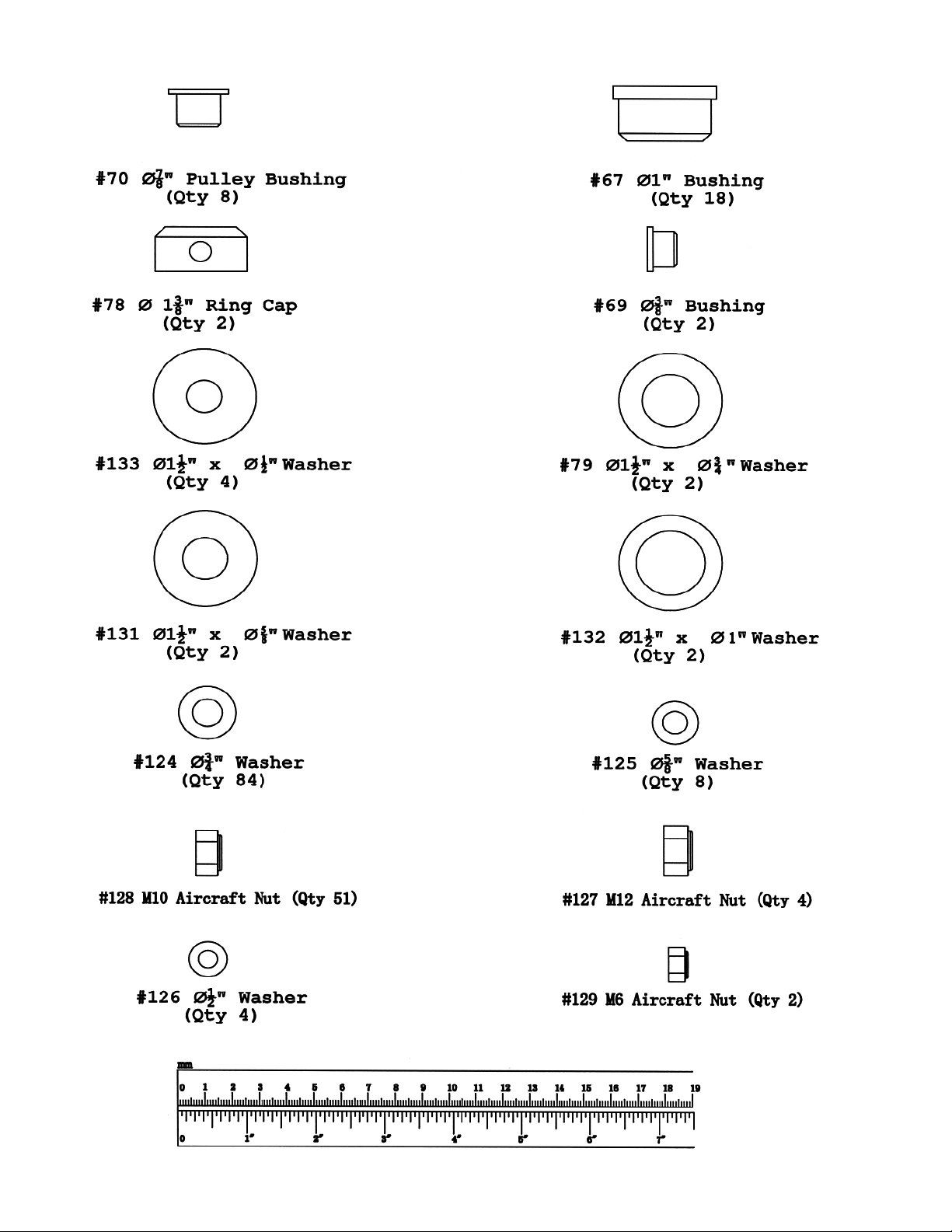

HARDWARE PACK

5

Page 7

HARDWARE PACK

6

Page 8

ASSEMBLY INSTRUCTION

Tools Required Assembling the Machine: Two Adjustable Wrenches and Allen

Wrenches

NOTE: It is strongly recommended this machine be assembled by two or more

people to avoid possible injury.

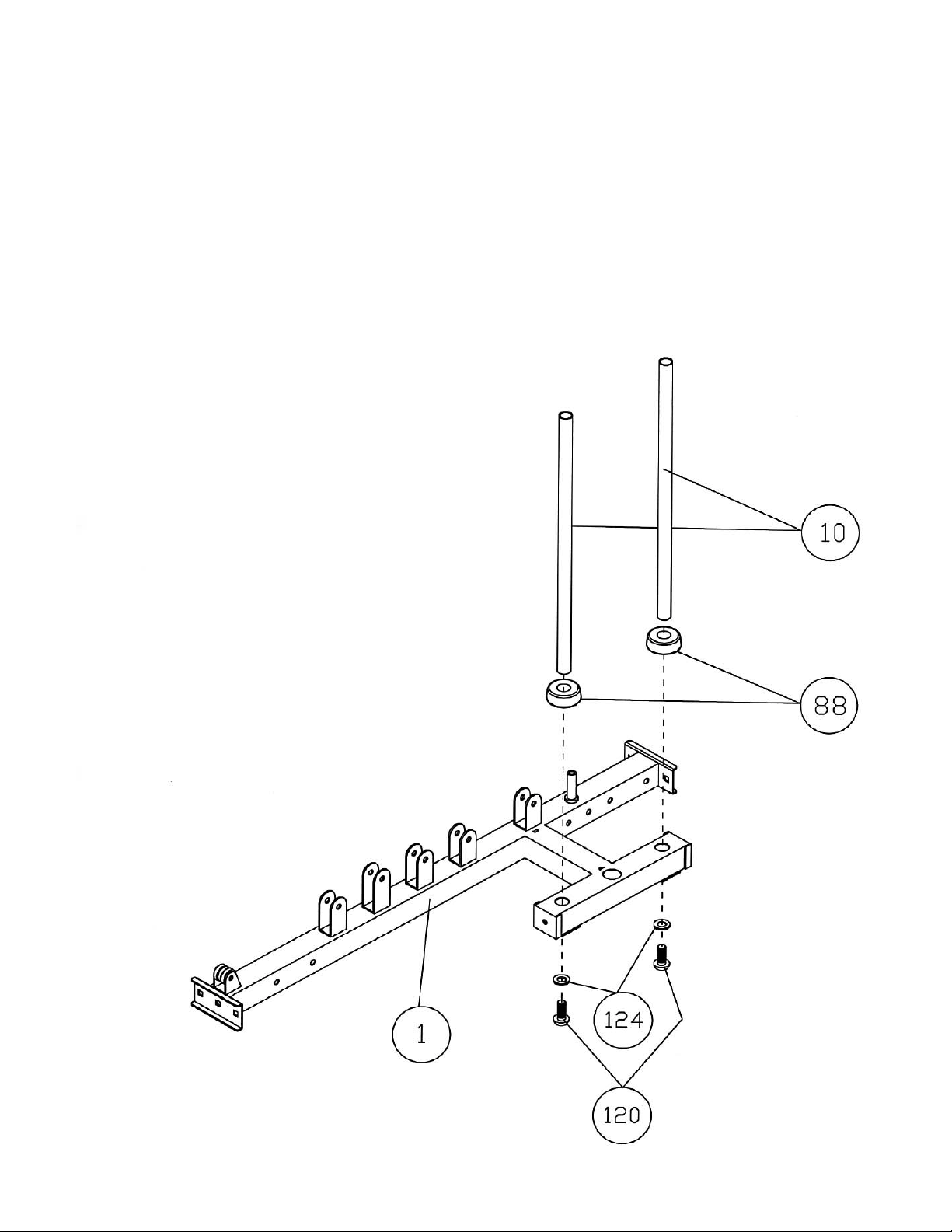

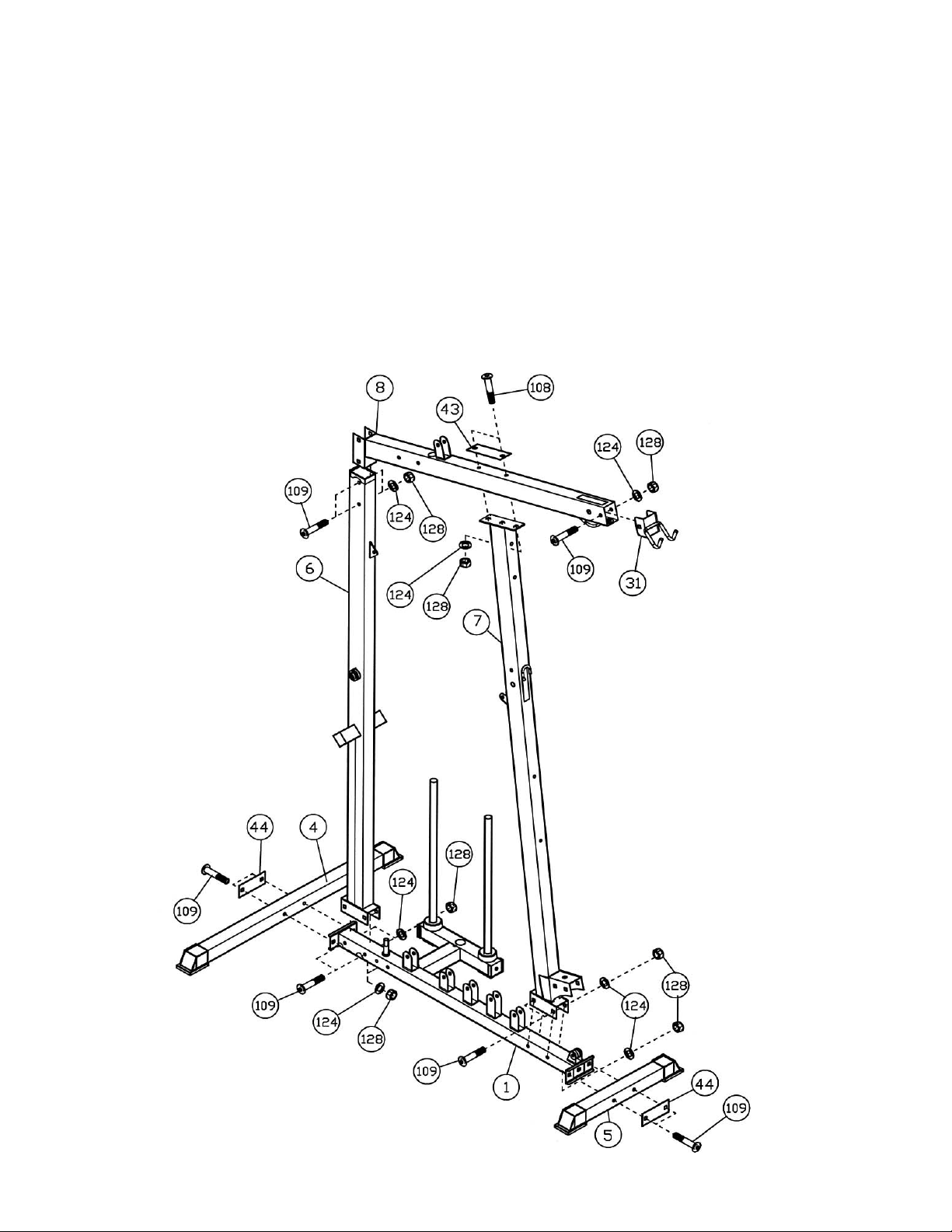

STEP 1 (See Diagram 1)

A.) Attach two Ø 2 ½” Rubber Bumpers (#88) to the holes on the Main Base Frame (#1).

B.) Align the holes and insert two Guide Rods (#10) into the holes. Secure the Guide

Rods from the Bottom of Main Base Frame with two M10 x ¾” Allen Bolts (#120) and

Ø ¾” Washers (#124).

DIAGRAM 1

7

Page 9

STEP 2 (See Diagram 2)

A.) Connect the Main Base Frame (#1) to both the Front & Rear Stabilizers (#5 & 4). Secure each end

with two M10 x 2 ¾” Carriage Bolts (#109), one 4 ¾” x 2” Bracket (#44), two ∅ ¾” Washers

(#124), and two M10 Aircraft Nuts (#128). DO NOT tighten all the nuts and bolts yet.

B.) Attach the Rear & Front Vertical Beams (#6 & 7) to the Main Base Frame (#1). Secure each Beam

with two M10 x 2 ¾” Carriage Bolts (#109), ∅¾” Washers (#124), and M10 Aircraft Nuts (#128).

C.) Place the Upper Frame (#8) onto the Front & Rear Vertical Beams. Secure the Upper Frame to

Rear Vertical Frame with two M10 x 2 ¾” Carriage Bolts (#109), ∅ ¾” Washers (#124), and M10

Aircraft Nuts (#128).

D.) Secure the Upper Frame to the Front Vertical Beam with two M10 x 3 ½” Carriage Bolts (#108),

one 6 ¼” x 2” Bracket (#43), two ∅ ¾” Washers (#124), and two M10 Aircraft Nuts (#128).

E.) Attach the Lat Bar Holder (#31) to the front of the Upper Frame (#8). Secure it with one M10 x 2

¾” Carriage Bolt (#109), ∅ ¾” Washer (#124), and M10 Aircraft Nut (#128).

F.) Securely tighten all Bolts and Nuts.

8

Page 10

STEP 3 (See Diagram 3)

A.) Place the Swivel Frame (#11) onto the axle on the Main Base Frame (#1). Secure it with one

M10 x ¾” Allen Bolt (#120) and Ø ¾” Washer (#124).

B.) Attach the Foot Support (#12) to the Main Base Frame. Attach the 4” x 2” Bracket (#42) to

the opposite side on the Main Base Frame. Secure them with one M10 x 2 ¾” Carriage Bolt

(#109), Ø ¾” Washer (#124), and M10 Aircraft Nut (#128) to the hole near the Rear

Stabilizer. Secure the other hole with a M10 x 2 ½” Allen Bolt (#117) and Ø ¾” Washer

(#124).

DIAGRAM 3

9

Page 11

STEP 4 (See Diagram 4)

A.) Attach the Butterfly Support Frame (#15) to the front of the Front Vertical Beam (#7). Attach the

Butterfly Pulley Support (#16) to the back of the Front Vertical Beam (#7). Align the holes and

secure them with two M10 x 3 ¾” Carriage Bolts (#107), ∅ ¾” Washers (#124), and M10 Aircraft

Nuts (#128).

B.) Attach a Pull Pin (#74) to the Left Butterfly Arm (#29). Repeat for the Right Butterfly Arm (#30).

C.) Slide a Butterfly Pulley Cam (#17) onto the axle on the Left Butterfly Arm (#29). Make sure the

Clip on the Cam is on the outside. Insert the axle into the hole on the Butterfly Support Frame

(#15) from the bottom up. Secure it with a ∅1 ½” x ∅ ¾” Washer (#79) and ∅ 1 3/8” Ring Cap

(#78). Secure the Ring Cap with one M6 x 1 5/8” Hex Bolt (#111) and M6 Aircraft Nut (#129).

D.) Repeat Step C above to install the Right Butterfly Arm (#30).

E.) Slide a ∅ 1 ½” x Ø 5/8” Washer (#131) onto the bottom axle on the Left Butterfly Arm (#29).

Attach a Butterfly Handle (#28) onto the axle. Secure it with one M10 x ¾” Allen Bolt (#120) and

Ø ¾” Washer (#124). Repeat the same procedure to install the other side.

10

Page 12

STEP 5 (See Diagram 5)

A.) Install 19 Weight Plates (#58). To install the plates, hold the plate at an angle and place between

the two Guide Rods (#10) then drop it down. Make sure the grooves on the plastic covers all

face up. The plates should all interlock with each other. It is strongly recommended to spray

lubricant such as WD-40 on the Guide Rods to minimize friction.

B.) Insert the Selector Rod (#62) into the center hole on the Weight Plates. Slide the Selector Stem

(#63) onto the Guide Rods from the top. Align the holes. Secure it to the Selector Rod with one

M10 x 1 ¾” Allen Bolt (#119).

C.) Insert the Weight Plate Selector Pin (#73) in between two plates to select the number of weight

plates for exercise and to secure the Selector Rod. Make sure the magnet on the Pin faces up.

D.) Attach the Top Socket Assembly (#9) to the Upper Frame and top of the Guide Rods. Secure it

to the Upper Frame with two M10 x 2 ¾” Carriage Bolts (#109), one 4 ¾” x 2 ¾” Bracket (#45),

two Ø ¾” Washers (#124), and two M10 Aircraft Nuts (#128).

E.) Secure the Top Socket Assembly (#9) to the Guide Rods (#10) with two M10 x ¾” Allen Bolts

(#120) and Ø ¾” Washers (#124).

11

Page 13

STEP6 (See Diagram 6)

A.) Attach the Bench Press Base (#14) to the opening on the Rear Vertical Beam (#6). Carefully

place two ∅1 ½” x Ø 1” Washers (#132) in between the Base and the Rear Vertical Beam. Align

the holes and insert a 9” Axle (#32). Secure both ends with two ∅1 ½ x ∅ ½”Washers (#133)

and M12 Aircraft Nuts (#127). Do not over tighten the Nuts. Make sure the Base is free to swivel

on the Axle. Close both ends with two Cone-shaped End Caps (#105).

B.) Attach four ∅1” Bushings (#67) to the openings on the Bench Press Frame (#13). Attach the

Bench Press Frame to the Bench Press Base (#14). Align the holes and insert a 13 ¾” Axle

(#33). Secure both ends with two ∅1 ½” x ∅ ½” Washers (#133) and M12 Aircraft Nuts (#127).

Close both ends with two Cone-shaped End Caps (#105).

C.) Lubricate the inside of the Foam Grips (#72) with water then slide them onto the Bench Press

Frame (#13).

D.) To adjust the Bench Press Arm, simply squeeze down the break handle on the right side of the

Press Arm.

DIAGRAM 6

12

Page 14

STEP 7 (See Diagram 7)

A.) Slide the Sliding Block (#37) onto the Main Seat Support (#2). Thread a Lock Knob (#87) into

the hole on the Sliding Block to hold it in position.

B.) Attach the rear end of Main Seat Support (#2) to the open bracket on the Front Vertical Beam

(#7). Secure it with three M10 x 2 ¾” Carriage Bolts (#109), Ø ¾” Washers (#124), and M10

Aircraft Nuts (#128).

C.) Place the Main Seat Support (#2) onto the Front Support Frame (#3). Secure it with two M10 x

2 ¾” Carriage Bolts (#109), Ø ¾” Washers (#124), and M10 Aircraft Nuts (#128).

D.) Attach the front bottom of Main Seat Support to the Front Support Frame. Secure it with one

M10 x 2 ¾” Carriage Bolt (#109), Ø ¾” Washer (#124), and M10 Aircraft Nut (#128).

E.) Attach the Seat Bracket (#18) to the pivot on the Main Seat Support (#2). Push two Ø 3/8”

Bushings (#69) through the holes on Seat Bracket into the pivot.

F.) Attach the Backrest Support (#25) to each end of the Backrest Incline Support (#22). Attach the

front holes on the Backrest Supports (#25) to the pivot. Align the holes and secure them with

one M10x7¼” Hex Bolt (#110), two Ø ¾” Washers (#124) and one M10 Aircraft Nut (#128).

G.) Attach the bottom of the Backrest Incline Support (#22) to the bracket on the Sliding Block

(#37). Secure it with one M10 x 3” Allen Bolt (#116), two Ø ¾” Washes (#124), and one M10

Aircraft Nut (#128).

H.) Attach the Leg Developer (#26) to the open bracket on the Main Seat Support (#2). Secure it

with a 2 ½” Axle (#139), two Ø ¾” Washers (#124), and two M10 x ¾” Allen Bolts (#120).

I.) Attach the Curl Bar Handle (#21) to the Leg Developer. Secure it with a 3” L-shaped Pin (#138).

13

Page 15

STEP 8 (See Diagram 8)

A.) Attach Backrest Board (#48) to the Front Vertical Beam (#7). Secure it with two M8 x 3 3/8”

Allen Bolts (#115) and Ø 5/8” Washers (#125).

B.) Attach the Adjustable Backrest Board (#49) to the Backrest Supports (#25). Secure it with four

M6 x 1 3/8” Hex Bolts (#112) and Ø ½” Washers (#126).

C.) Place the Seat (#50) onto the Seat Bracket (#18). Secure it to the two rear holes on the Seat

Bracket with two M8 x ¾” Allen Bolts (#122) and Ø 5/8” Washes (#125). Attach a Seat Incline

Adjustment (#19) to the two front holes and secure them with two M8 x ¾” Allen Bolts (#122)

and Ø 5/8” Washers (#125). Insert a 4” L-shaped Pin (#137) through the selected hole on the

Seat Incline Adjustment to hold the desired height.

D.) Insert one Foam Tube (#27) halfway through the hole on the Main Seat Support (#2). Insert two

Foam Tubes halfway through the holes on the Leg Developer (#26). Push six Foam Rolls (#71)

onto the Tubes from both ends. Plug six Foam Roll End Caps (#102) into the ends.

E.) Attach the Arm Curl Pad (#51) to the Arm Curl Stand (#20). Secure it with two M8 x 5/8” Allen

Bolts (#121) and Ø 5/8” Washers (#125). Insert the Arm Curl Stand into the opening on the

Main Seat Support. Use the Lock Knob to lock the desired Arm Curl exercise height. Remove

the Arm Curl Stand and Curl Bar Handle when doing Leg Developer exercises.

14

Page 16

STEP 9 (See Diagram 9)

A.) Attach the two Weight Stack Covers (#39) to the Top Socket Assembly (#9) and Main Base

Frame (#1). Secure each Cover with two M10 x ¾” Allen Bolts (#120) and Ø ¾” Washers

(#124).

DIAGRAM 9

15

Page 17

16

Page 18

STEP 10 (See Cable Loop Diagram & Diagram 10)

A.) Attach one end of the 143” Butterfly Cable (#56) to the Clip on the Butterfly Pulley Bracket (#17)

on the right side. Draw the Cable to the Butterfly Pulley Support (#16).

B.) Attach a Pulley (#66) to the open bracket. Secure it with one M10 x 1 ¾” Allen Bolt (#113), two

Ø ¾” Washers (#124), and one M10 Aircraft Nut (#128).

C.) Draw the Cable over the Pulley then pull downward. Repeat Step B above to install a Pulley to

the Single Floating Pulley Bracket (#35). Let the Pulley hanging for now.

D.) Draw the Cable around the Pulley then pull upward to the open bracket on the left side of the

Butterfly Pulley Support (#16). Repeat Step B to install another Pulley.

E.) Draw the Cable over the Pulley then to the left Butterfly Pulley Bracket. Secure the end of the

Cable to the Clip.

DIAGRAM 10

17

Page 19

STEP 11 (See Cable Loop Diagram & Diagram 11)

A.) Attach the 118” Upper Cable (#52) to the front opening on the Upper Frame (#8). Attach a

Pulley to the opening. Secure the Pulley with one M10 x 2 ½” Allen Bolt (#117), two Ø 7/8”

Pulley Bushings (#70), and one M10 Aircraft Nut (#128). Make sure the Ball Stopper of the

Cable is underneath the Frame.

B.) Draw the Cable over the Pulley and toward the back of the machine. Attach a Pulley to the

open bracket on the top of the Upper Frame. Secure the Pulley with one M10 x 1 ¾” Allen

Bolt (#113), one L-shaped Pulley Bracket (#46), two Ø ¾” Washers (#124), and one M10

Aircraft Nut (#128).

C.) Draw the Cable over the Pulley and pull downward. Attach a Pulley to an Angled Double

Floating Pulley Bracket (#34). Secure it with one M10 x 1 ¾” Allen Bolt (#113), two Ø ¾”

Washers (#124), and one M10 Aircraft Nut (#128). Draw the Cable around the Pulley then

pull upward to the opening on the Top Socket Assembly (#9). Let the Bracket hanging for

now.

D.) Repeat the Step A above to install a Pulley to the opening.

E.) Draw the Cable over the Pulley then to the open bracket on the top of the Top Socket

Assembly (#9). Repeat Step B above to install a Pulley.

F.) Draw the Cable around the Pulley then pull downward to the Selector Rod (#62). Screw

the Bolt on the end of Cable into the Selector Rod. Make sure to tighten down the nut on

the bolt against the Selector Rod.

G.) Connect a Short Chain (#134) to the end of the Cable with a C-clip (#136). Connect the

Lat Bar (#23) to the Short Chain with another C-clip. Adjust the length of Chain to adjust

the Lat Bar exercise height.

18

Page 20

DIAGRAM 11

19

Page 21

STEP 12 (See Cable Loop Diagram & Diagram 12)

A.) Attach the Ball-end of the 163” AB Cable (#55) to the opening on the Front Vertical

Beam (#7). Attach a Pulley to the opening. Secure it with one M10 x 2 ½” Allen Bolt

(#117), two Ø 7/8” Pulley Bushings (#70), and one M10 Aircraft Nut (#128). Use a C-clip

(#136) to connect the AB Strap (#59) to the end of the Cable.

B.) Draw the Cable over the Pulley then pull downward and over the Small Pulley Wheel

(#65) to the second open bracket on the Main Base Frame (#1). Attach a Pulley and Ushaped Pulley Bracket (#47) to the bracket.

C.) Secure the Pulley with one M10 x 1 ¾” Allen Bolt (#113), two Ø ¾” Washes (#124), and

one M10 Aircraft Nut (#128).

D.) Draw the Cable around the Pulley then Pull upward to the Angled Double Floating Pulley

Bracket (#34) previously installed in Step11-C. Repeat Step C above to install another

Pulley.

E.) Draw the Cable over the Pulley then pull downward. Attach the Cable to a Pulley.

Repeat Step C above to install the Pulley to a Double Floating Pulley Bracket (#36). Let

the Bracket hanging for now.

F.) Draw the Cable around the Pulley then pull the Cable upward. Use a C-clip (#136) to

connect the end of Cable to a Short Chain (#134). Secure the Short Chain to the Rear

Vertical Beam (#6) with one M10 x 1” Allen Bolt (#114), two Ø ¾” Washers (#124), and

one M10 Aircraft Nut (#128).

G.) After completing the entire cable installation, check the tightness of the Cable loop

system. Adjust the tension of Cables by adjusting the length of the Short Chain. If the

Cables are too loose, shorten the Chain.

20

Page 22

DIAGRAM 12

21

Page 23

STEP 13 (See Cable Loop Diagram & Diagram 13)

A.) Attach one end of the 78” Bench Press Cable (#54) to a Single Floating Pulley Bracket (#35).

Secure it with one M10 x 1” Allen Bolt (#114), two Ø ¾” Washers (#124), and one M10 Aircraft

Nut (#128). Let the Bracket hanging for now.

B.) Pull the Cable upward to the opening between the Bench Press Base (#14). Attach a Pulley to

the opening. Secure it with one 7” Axle (#130) and two M8 Hex Socket Screws (#82).

C.) Draw the Cable around the Pulley then pull downward to the third open bracket on the Main

Base Frame (#1). Attach a Pulley and a L-shaped Pulley Bracket (#46) to the bracket.

D.) Secure the Pulley with one M10 x 1 ¾” Allen Bolt (#113), two Ø ¾” Washers (#124), and one

M10 Aircraft Nut (#128).

E.) Draw the Cable underneath the Pulley and through the opening underneath the second Pulley

previously installed. Draw the Cable to the first open bracket on the Main Base Frame (#1).

Repeat Step D above to install another Pulley.

F.) Draw the Cable around the Pulley then pull upward to the Single Floating Pulley Bracket (#35)

previously installed in Step10-C. Secure the Cable with one M10 x 1” Allen Bolt (#114), two Ø

Washers (#124), and one M10 Aircraft Nut (#128).

22

Page 24

STEP 14 (See Cable Loop Diagram & Diagram 14)

A.) Attach the 163” Lower Cable (#53) to the Swivel Frame (#11).

B.) Install a Pulley to the bracket on the Swivel Frame with one M10 x 1 ¾” Allen Bolt

(#113), two Ø ¾” Washers (#124), one L-shaped Bracket (#46) and one M10 Aircraft

Nut (#128).

C.) Draw the Cable around the Pulley then pull upward to the Double Floating Pulley

Bracket (#36) previously installed in Step12-E. Install another Pulley.

D.) Draw the Cable around the Pulley then pull downward to the first open bracket on the

left. Repeat the Step B above to install a Pulley with a U-shaped Pulley Bracket (#47).

E.) Draw the Cable around the Pulley then pull upward to the Single Floating Pulley

Bracket (#35) previously installed in Step 13-A. Repeat Step B above to install a Pulley.

F.) Draw the Cable around the Pulley then pull downward to the open bracket on the Main

Base Frame. Repeat Step B above to install a Pulley with a L-shaped Pulley Bracket

(#46).

G.) Draw the Cable underneath the three Pulleys previously installed in Step 13 and

through the opening on the bottom of the Front Vertical Beam (#7). Continuously draw

the Cable underneath the Small Pulley Wheel (#65) on the Main Base Frame to the

opening on the Front Support Frame (#3). Attach a Pulley to the opening. Secure it with

one M10 x 2 ½” Allen Bolt (#117), two Ø 7/8” Pulley Bushings (#70), and one M10

Aircraft Nut (#128).

H.) Draw the Cable over the Pulley and to the open bracket on the Main Seat Support (#2).

Repeat Step B above to install a Pulley.

I.) Draw the Cable through the opening on the Main Seat Support to the open bracket on

the Leg Developer (#26). Secure the end of Cable with one M10 x 1” Allen Bolt (#114),

two Ø ¾” Washers (#124), and one M10 Aircraft Nut (#128).

J.) Use a C-clip (#136) to connect a Long Chain (#135) to the end of the Cable. Use

another C-clip to connect the Shiver Bar (#24), Single Handle (#61), or Ankle Strap

(#60) for various exercises.

23

24

Page 25

Page 26

PARTS LIST

KEY NO. DESCRIPTION Q’ty

1 Main Base Frame 1

2 Main Seat Support 1

3 Front Support Frame 1

4 Rear Stabilizer 1

5 Front Stabilizer 1

6 Rear Vertical Beam 1

7 Front Vertical Beam 1

8 Upper Frame 1

9 Top Socket Assembly 1

10 Guide Rod 2

11 Swivel Frame 1

12 Foot Support 1

13 Bench Press Frame 1

14 Bench Press Base 1

15 Butterfly Support Frame 1

16 Butterfly Pulley Support 1

17 Butterfly Pulley Cam 2

18 Seat Bracket 1

19 Seat Incline Adjustment 1

20 Arm Curl Stand 1

21 Curl Bar Handle 1

22 Backrest Incline Support 1

23 Lat Bar 1

24 Shiver Bar 1

25 Backrest Support 2

26 Leg Developer 1

27 Foam Tube 3

28 Butterfly Handle 2

29 Left Butterfly Arm 1

30 Right Butterfly Arm 1

31 Lat Bar Holder 1

32 9” Axle 1

33 13 ¾” Axle 1

34

35 Single Floating Pulley Bracket 2

36 Double Floating Pulley Bracket 1

37 Sliding Block 1

38 Curl Bar Handle Tube 1

39 Weight Stack Cover 2

40 Wire Control Handle 1

41 Shiver Bar Handle 1

42 4” x 2” Bracket 1

43 6 ¼” x 2” Bracket 1

44 4 ¾” x 2” Bracket 2

45 4 ¾” x 2 ¾” Bracket 1

46 L-shaped Bracket 6

47 U-shaped Bracket 2

48 Backrest Board 1

49 Adjustable Backrest Board 1

50 Seat 1

51 Arm Curl Pad 1

52 118” Upper Cable 1

53 163” Lower Cable 1

54 78” Bench Press Cable 1

55 163” AB Cable 1

Angled Double Floating Pulley Bracket

1

56 143” Butterfly Cable 1

57 Wire 1

58 Weight Plate 19

59 AB Strap 1

60 Ankle Strap 1

61 Single Handle 1

62 Selector Rod 1

63 Selector Stem 1

64 Foot Support Panel 1

65 Small Pulley Wheel 2

66 Pulley 22

67 Ø 1” Bushing 18

68 Ø 5/8” Bushing 6

69 Ø 3/8” Bushing 2

70 Ø 7/8” Pulley Bushing 8

71 Foam Roll 6

72 Foam Grip 2

73 Weight Plate Selector Pin 1

74 Pull Pin Set 2

75 Pull Pin Nut 1

76 Pull Pin Adjustment 1

77 Spring 1

78 Ø 1 3/8” Ring Cap 2

79 Ø 1 ½” x Ø ¾” Washer 2

80 1 ¼” Philips Screw 2

81 5/8” Philips Screw 2

82 M8 Hex Socket Screw 2

83 M5 x 3/8” Philips Screw 4

84 Wire Control Handle Grip 1

85 6” Handle Grip 4

86 Curl Bar Grip 2

87 Lock Knob 2

88 Ø 2 ½” Rubber Bumper 2

89 ∅ 1 ¾” Rubber Bumper 1

90 ∅ 1 5/8” Rubber Bumper 2

91 Lat Bar Grip 2

92 Ø 2 3/8” Washer 2

93 2 3/8” x 2” Sleeve 2

94 2” x 1 ¾” Sleeve 1

95 2” Square End Cap 1

96 2” Stabilizer End Cap 4

97 2 3/8” x 1 5/8” End Cap (Impex) 2

98 2 ¾” x 2” End Cap 1

99 2” Square End Cap (Impex) 8

100 1 ½” Square End Cap (Impex) 2

101 1” Square End Cap 2

102 Foam Roll End Cap 6

103 3 1/8” x 1 5/8” End Cap 2

104 Ø 1” x1” Bushing 4

105 Cone-shaped End Cap 4

106 Ø 5/8” x ¼” Bushing 2

107 M10 x 3 ¾” Carriage Bolt 2

108 M10 x 3 ½” Carriage Bolt 2

109 M10 x 2 ¾” Carriage Bolt 20

25

Page 27

110 M10 x 7 ¼” Hex Bolt 1 4

111 M6 x 1 5/8” Hex Bolt 2

112 M6 x 1 3/8” Hex Bolt 4

113 M10 x 1 ¾” Allen Bolt 17

114 M10 x 1” Allen Bolt 4

115 M8 x 3 3/8” Allen Bolt 2

116 M10 x 3” Allen Bolt 1

117 M10 x 2 ½” Allen Bolt 5

118 Ø ¾” Bushing 2

119 M10 x 1 ¾” Allen Bolt (Full Thread) 1

120 M10 x ¾” Allen Bolt 13

121 M8 x 5/8” Allen Bolt 2

122 M8 x ¾” Allen Bolt 4

123 M6 x 5/8” Allen Bolt 3

124 Ø ¾” Washer 84

125 Ø 5/8” Washer 8

126 Ø ½” Washer 4

127 M12 Aircraft Nut 4

128 M10 Aircraft Nut 51

129 M6 Aircraft Nut 2

130 7” Axle 1

131 Ø 1 ½” x Ø 5/8” Washer 2

132 Ø 1 ½” x Ø 1” Washer 2

133 Ø 1 ½” x Ø ½” Washer 4

134 Short Chain 2

135 Long Chain 1

136 C-clip 6

137 4” L-shaped Pin 1

138 3” L-shaped Pin 1

139 M10 x 2 ½” Axle 1

140 M6 x ¾” Adjustment Screw 2

141 M6 x ½” Adjustment Nut 2

142 1 ¾” Square End Cap 2

143 Ø 1 ½” End Cap 2

144 Ø 1” End Cap 2

145 Ø 1 ¼” End Cap 2

146 Ø 1 5/8” x 1 ½” Bushing 2

147 Ø 1 5/8” x 5/8” Bushing 1

26

Page 28

MACH IV WEIGHT RESISTANCE CHART

Plate Arm

Curl

0 40 30 20 20 30 60

1 50 40 30 23 40 70

2 60 50 40 26 50 80

3 70 60 50 29 60 90

4 80 70 60 32 70 100

5 90 80 70 35 80 110

6 100 90 80 38 90 120

7 110 100 90 41 100 130

8 120 110 100 44 110 140

9 130 120 110 47 120 150

10 140 130 120 50 130 160

11 150 140 130 53 140 170

12 160 150 140 56 150 180

13 170 160 150 59 160 190

14 180 170 160 62 170 200

15 190 180 170 65 180 210

16 200 190 180 68 190 220

17 210 200 190 71 200 230

18 220 210 200 74 210 240

19 230 220 210 77 220 250

Low

Pulley

High

Pulley

Butterfly AB

Station

Bench

Press

* Numbers are approximate. Actual weights may vary.

* Values for Butterfly are for each arm.

27

Page 29

IMPEX INC.

LIMITED WARRANTY

IMPEX Inc. ("IMPEX") warrants this pr oduct to be f ree fr om def ects in workm ans hip and m aterial,

under normal use and service c onditions , f or a per iod of two years on the Fr ame from the date of

purchase. This warranty extends only to the original purchaser. IMPEX's obligation under this

Warranty is limited to replacing or repairing, at IMPEX's option.

All returns must be pre-authorized by IMPEX. Pre-authorization may be obtained by calling

IMPEX Customer Service Department at 1-800-999-8899. All freights on products returned to

IMPEX must be prepaid by the customer. This warranty does not extend to any product or

damage to a product caused by or attributable to freight damage, abuse, misuse, improper or

abnormal usage or repairs not provided by an IMPEX authorized service center or for produc ts

used for commercial or rental purposes. No other warranty beyond that specifically set forth

above is authorized by IMPEX.

IMPEX is not responsible or liable for indirect, special or cons equential damages aris ing out of or

in connection with the use or performance of the pr oduct or other damages with respect to any

economic loss, loss of property, loss of revenues or profits, loss of enjoyments or use, cos ts of

removal, installation or other consequential damages or whatsoever natures. Some states do not

allow the exclusion or limitation of inc idental or consequential damages. Accordingly, the above

limitation may not apply to you.

The warranty extended hereunder is in lieu of any and all other warranties and any implied

warranties of merchantability or fitness for a particular purpose is lim ited in its sc ope and duration

to the terms set forth herein. Some states do not allow limitations on how long an implied

warranty lasts. Accordingly, the above limitation may not apply to you.

This warranty gives you specific legal right. You may also have other rights which vary from state

to state.

ORDERING REPLACEMENT PARTS

Replacement parts can be order ed by calling our Custom er Ser vice Department toll-free at 1-800-

999-8899 during our regular business hours: Monday through Friday, 9 am until 5 pm Pacific

standard time.

info@impex-fitness.com

When ordering replacement parts, always give the following information.

1. Model

2. Description of Parts

3. Part Number

4. Date of Purchase

Register on-line www.impex-fitness.com

IMPEX INC.

14777 Don Julian

City of Industry, CA 91746

28

Loading...

Loading...