Page 1

CHARGING OPTIONS: (continued)

Invert refrigerant tank (some tanks need not be inverted to dispense liquid

refrigerant). Open refrigerant tank supply valve and open the manifold’s red

“HI” side valve. After dispensing the proper amount of refrigerant, close the

manifold’s red “HI” side valve and close refrigerant tank supply valve.

Liquid Low Side Charging: To draw liquid from tank and charge into low

side. Turn the yellow “REF” valve fully clockwise to the “LOW SIDE LIQUID

CHARGE” position finger tight. Close the red “HI” side valve. Invert refrig erant tank (some tanks need not be inverted to dispense liquid refrigerant).

The compressor must be running. Open refrigerant tank supply valve and

open the manifold’s blue “LO” side valve. After dispensing the proper

amount of refrigerant, close the manifold’s blue “LO” side valve and close

refrigerant tank supply valve.

Vapor Low Side Charging: When drawing vapor from tank and charging

into system low side, turn the yellow “REF” valve fully counter-clockwise to

the “VACUUM, VAPOR, LIQUID HI SIDE” position, finger tight. Close the

red “HI” side valve. Compressor must be running. Open refrigerant tank

supply valve and open the manifold’s blue “LO” side valve. After dispensing

the proper amount of refrigerant close the manifold’s blue “LO” side valve

and close refrigerant tank supply valve.

4. When the system is operating properly, disconnect manifold by closing

both “HI & LO” valves - finger tight. Carefully remove the charging hoses

from the system.

REPLACEMENT PARTS LIST

Description: For P/N

Seal Kits (2) High & Low Valve 600R

Spring

Mylar Disc

Diaphragm

Actuator

Washer

Handles & Stem Kits High & Low Valve 602R

Handle (LO)

Handle (HI)

Stem (2) PIN 1000936

Control Valve Kit Ref. Control Valve 700CV

Handle (REF)

Stem Assy (Stem/Tip/O-ring)

Bonnet

Bonnet O-ring

*Filter Connector 1/4 SAE S

5/16 SAE S16003754

Boot Set 400RB

Red

Blue

*All port fittings equipped with

120 mesh filters. Filter connection

may be cleaned and rinsed in 91%

alcohol with O-ring removed.

PART NO. P0001613 Rev. B

30333 Emerald Valley Parkway • Glenwillow, Ohio 44139 USA

www.imperial-tools.com • info@stridetool.com © 2010 Stride Tool Inc.

10000800

This manifold should only be used by experienced professional service technicians in the refrigeration & air-conditioning field who are familiar with equipment

being serviced. Safety goggles should be worn at all times. Refrigerant and

lubricant vapor or mist may cause injury, frostbite, irritate eyes, nose and throat.

Avoid breathing or contact with skin. Always point hose away from you and

anybody near or around you. Remove hoses with care as they may be under

high refrigerant pressure. Improper procedures can cause refrigerant gas under

pressure to explode violently. Read all instructions before starting.

PROP 65 WARNING: This product contains chemicals, including lead,

WA RNING

known to the State of California to cause cancer, and birth defects or

other reproductive harm. Wash hands after use.

®

Kwik-Charger

Service Manifold Operating Instructions

2-VALVE SYSTEM ANALYZER WITH REFRIGERANT CONTROL VALVE

The Imperial Kwik-Charger manifold provides a safer, faster method

of charging CFC, HCFC, HFC, azeotropic and zeotropic blended

refrigerants into the low-pressure or suction side of a refrigerated

system. Zeotropic blended refrigerants (R-410A, R-404A, etc.) must

be charged as a liquid from the refrigerant cylinder. Great care must

be taken to avoid liquid slugging the compressor when charging into

the low side of a running system. The Kwik-Charger manifold

handles the process of charging liquid refrigerant into the system

low-pressure side with ease. Charge all refrigeration & airconditioning systems accor

To use the Kwik-Charger for liquid low side charging, turn the “REF”

valve clockwise, until finger tight, to the “LOW SIDE LIQUID

CHARGE” position. This engages an internal metering element that

reduces liquid flow to a level below capacity of the compressor

assuring a safe fast charge. The compressor must be running. For

vapor charging from the tank, liquid high side charging or

evacuating, turn the “REF” valve counter-clockwise, until finger

tight, to the “VACUUM, VAPOR, LIQUID HI SIDE” position. In this position,

the internal metering device is disengaged, and the Kwik-Charger

manifold performs as a conventional manifold.

Charging liquid into the low side of the system without engaging the internal

metering element may slug the compressor and damage the system.

Always turn the “REF” valve clockwise, finger tight, to the “LOW SIDE

LIQUID CHARGE” position for liquid low side charging. The compressor

CAUTION

must be running during this process.

ding to manufacturers specifications.

Page 2

It is unlawful to discharge or exhaust refrigerants into the atmosphere. Imperial strongly

recommends using recovery or recycling equipment for proper disposal of refrigerants.

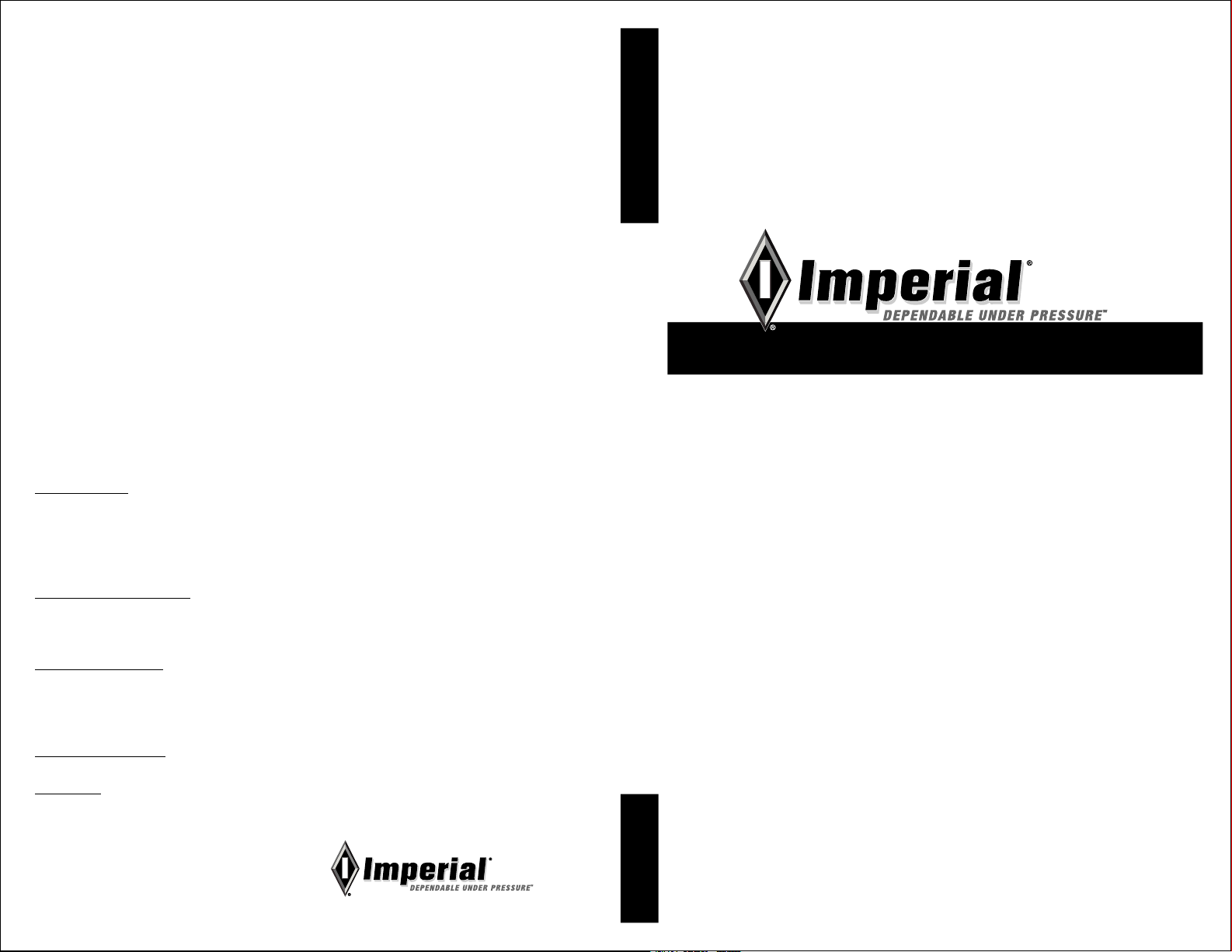

VAC.

PUMP

NOTE:

*Connection should be made to service valve or access fitting.

OBSERVE OPERATING PRESSURE:

1. Close red “HI” and blue “LO” side valves,

finger tight.

2. Connect blue low side hose to system’s

low side service port and the red high side

hose to the system’s high side service port.

3. Once the hoses have been connected, the

ystem pressure will be displayed on the gauge

s

face.

NOTE: A system that has service valves; the

valves should be cracked open after

connection. Hoses must be purged.

RECOVERING REFRIGERANT:

1. Turn yellow “REF” valve fully counter-clockwise,

finger tight, to the “VACUUM, VAPOR, LIQUID

HI SIDE” position.

2. Close the blue “LO” side valve and red “HI”

side valves, finger tight.

3 Connect blue low side hose to system’s low side

service port. Connect red high side hose to the

system’s high side service port.

4. Follow the instructions provided with the

recovery unit for proper recovery of refrigerant

from the system.

REF.

VACUUM

VAPOR CHARGE

LIQUID HI SIDE

BLUE HANDLE

(LOW SIDE)

YELLOW HOSE

FILTERED HOSE

CONNECTOR

3 PLACES

REFRIGERANT CONTROL VALVE

(YELLOW HANDLE)

BLUE HOSE

(LOW SIDE)

LOW SIDE

LIQUID CHARGE

RED HOSE

(HIGH SIDE)

RED HANDLE

(HIGH SIDE)

NOTE: Typically, the yellow hose is

connected to the inlet of the recovery unit.

EVACUATE (VACUUM):

1. Remove all refrigerant from system using a

refrigerant recovery system.

2. Turn yellow “REF” valve fully counter-clockwise,

finger tight, to the “VACUUM, VAPOR, LIQUID

HI SIDE” position.

3. Connect blue low side hose to system’s low

side service port. Connect red high side

hose to the system’s high side service port.

4. Connect the center hose (yellow) to the

vacuum pump.

5. Open red “HI” and blue “LO” side valves.

6. Start vacuum pump.

7. Evacuate system according to manufacturers

specifications then close red “HI” side and blue

“LO” side valves and turn off vacuum pump.

CHARGING:

1. Disconnect the yellow hose from vacuum pump

and connect to refrigerant tank.

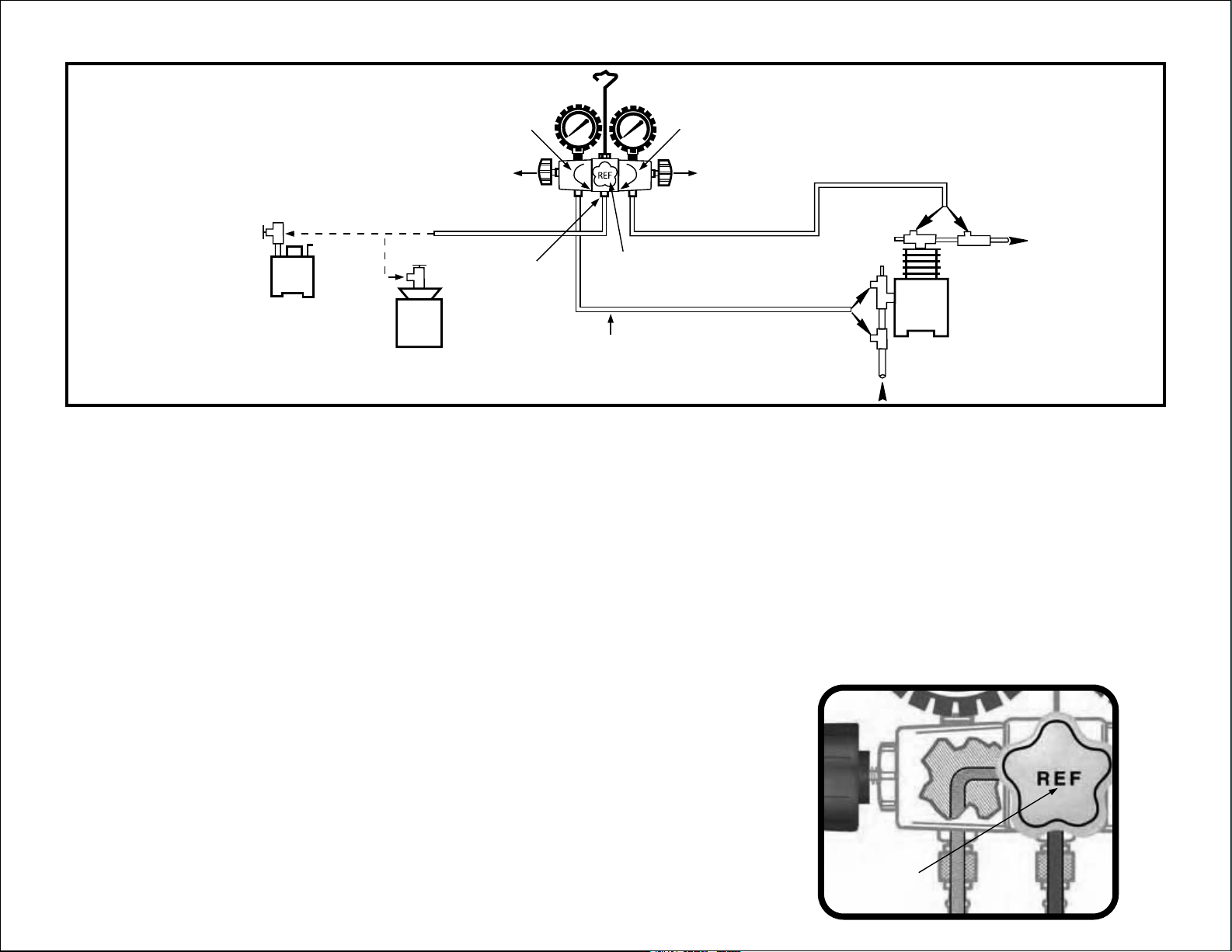

GAUGE RECALIBRATION:

Remove lens cover. Turn recalibrator

screw in the opposite direction to

desired movement of pointer until

gauge reads “0”. Replace lens.

No more than 1/2 Turn.

*

HIGH SIDE PORT

(DISCHARGE)

*

COMP.

LOW SIDE PORT

(SUCTION)

2. Slightly open the refrigerant supply valve on the

tank. Purge air from the yellow hose at the

manifold by loosening the yellow hose fitting

connection. When complete, tighten hose

connection and turn off refrigerant supply valve.

3 System can now be charged according to

the manufacturers specification.

CHARGING OPTIONS:

Liquid High Side Charging: To draw liquid from

tank and charge into system high side. Turn the

yellow “REF” valve fully counter-clockwise to the

“VACUUM, VAPOR, LIQUID HI SIDE” position - finger

tight. Close the blue “LO” side valve - finger tight.

continued on back page

Patented Metering

Device Engaged-

Converts Liquid to Vapor

Loading...

Loading...