RS-1600-X24 User Guide

Part No. 43061-01A

Issue 1-0

June 23, 2003

Notices

The information in this document is subject to change without notice.

While every effort has been made to ensure that all information in this document is accurate, the Authors

accept no liability for any errors that may arise.

No part of this document may be transmitted or copied in any form, or by any means, for any purpose,

without the written permission of the Authors.

Acknowledgments

Issue 1-0 June 23, 2003 Part No. 43061-01A

ii

RS-1600-X24 User Guide

Contents

iii

Contents

Preface .................................................................................................................................................. ix

International Standards .......................................................................................................................... ix

Potential for Radio Frequency Interference ........................................................................................... ix

European Regulations ............................................................. ..................................... ... ....................... x

Safety ...................................................................................................................................................... x

Battery Safety ....................................................................................................................................... xii

Laser Safety ..................... ..................................................................................................................... xii

Rack System Precautions ..................................................................................................................... xiii

ESD Precautions .................................................................................................................................. xiii

Data Security ....................................................................................................................................... xiv

Special Tools and Equipment .............................................................................................................. xiv

Related Documentation ....................................................................................................................... xiv

Conventions .......................................................................................................................................... xv

Revision History ................................................................................................................................... xvi

1 Introduction ..................................................................................................................................... 1

1.1 The RS-1600-X24 System ........................................... ... ..................................... ... .................... 1

1.2 The Enclosure Core Product ....................................................................................................... 2

1.2.1 Enclosure Chassis .............................................................................................................. 2

1.2.2 Tower Option ............................................... ... ... .................................... ............................. 3

1.3 The Plug-in Modules ................................................................................... ... ............................. 4

1.3.1 Power Supply/Cooling Module ........................................................................................... 4

1.3.2 Operators Panel ................................................................................................................. 5

1.3.3 Loop Resiliency Circuit Input/Output Module (FC-AL) ....................................................... 6

1.3.4 Drive Carrier Module .......................................................................................................... 9

1.3.5 Dummy Carrier Modules .................................................................................................. 10

1.4 Visible and Audible Alarms ........................................................................................................ 10

1.5 Installing your X24 Subsystem .................................................................................................. 11

1.6 RS-1600-X24 Technical Specification ....................................................................................... 11

1.6.1 Dimensions ....................................................................................................................... 11

1.6.2 Weight .............................................................................................................................. 11

1.6.3 AC Power (450W PSU) ...................................................................... ... ........................... 11

1.6.4 PSU Safety and EMC Compliance ................................................................................... 12

1.6.5 Power Cord ...................................................................................................................... 12

iv

RS-1600-X24 User Guide

1.6.6 Environment ..................................................................................................................... 12

1.6.7 Interfaces ......................................................................................................................... 13

1.6.8 Drive Carrier Module Specification ....................................... .. ......................................... 13

1.6.9 X24 FC-AL LRC I/O Module Specification ....................................................................... 14

1.6.10 RAID Card ........................................................................................................................ 14

1.6.11 Software Enclosure Services (SES) Support ................................................................... 14

2 Operation ....................................................................................................................................... 15

2.1 Before You Begin .............................. ... .................................... ... .............................................. 15

2.2 Power On ..................................................... ... .................................... ...................................... 15

2.2.1 Power Supply/Cooling Module LEDs .................................... .. ..................................... ... . 16

2.3 Ops Panel LEDs ........................................................................................................................ 16

2.4 Starting the Drives ..................................................................................................................... 18

2.4.1 Disk Drives LEDs ............................................................................................................. 18

2.5 Power Up/Down ........................................................................................... ............................. 18

3 X24 RAID Management ............................ .. ..................................... .................................... .......... 19

3.1 Managing Arrays and Partitions Using SAM ............................................................................. 19

3.2 Managing Arrays ....................................................................................................................... 20

3.3 Viewing Array and Drive Status Information ......................... ..................................... ... .. .......... 20

3.3.1 Viewing Array and Partition Statistics ............... ............................................................... 21

3.3.2 Verifying an Array ............................................................................................................ 22

3.3.3 Changing Array Ownership .............................................................................................. 23

3.3.4 Changing an Array Name ................................................................................................ 23

3.3.5 Trusting an Array ............................................................................................................. 23

3.3.6 Deleting an Array ......................................................... ... ................................................. 24

3.4 Managing Partitions .................................................................................................................. 25

3.4.1 Viewing Partition Status Information ................................................................. ... ............ 25

3.4.2 Changing a Partition Name .............................................................................................. 25

3.4.3 Changing a Partition LUN ............................................................................................... 26

3.4.4 Controlling Partition Access ............................................................................................. 27

3.4.5 Changing the Read-Ahead Cache Size ........................................................................... 30

3.4.6 Deleting a Partition ........................... ... .................................... ......................................... 31

4 System Status ............................................................................................................................... 33

4.1 Monitoring System Status Using SAM ...................................................................................... 33

4.2 Setting Up Remote Notification ................................................................................................. 33

4.2.1 Starting and Stopping Remote Notification ...................................................................... 34

4.2.2 Setting Up the Events to be Monitored ............................................................................ 34

4.2.3 Setting Up the E-mail Addresses ..................................................................................... 34

4.3 Saving Log Information to a File ............................................................................................... 35

4.4 Displaying Overall Statistics ...................................................................................................... 36

4.4.1 Resetting the All Statistics ...............................................................................................37

5 Configuring the X24 System ........................................................................................................ 39

5.1 Configuring the LAN-related Settings ........................................................................................ 40

5.1.1 Configuring the Telnet Timeout ........................................................................................ 40

5.1.2 Configuring the SNMP Settings ....................................................................................... 40

5.1.3 Configuring the System Information ................................................................................. 41

5.1.4 Setting Passwords ................................................................................................. .......... 41

5.1.5 Configuring the Security Options ..................................................................................... 42

Contents

v

5.2 Changing the Date and Time ............................................. ... .................................... ... ... .......... 43

5.3 Understanding LUNs and Viewing LUN Information ................................................................. 43

5.3.1 Viewing LUN Information .................................................................................................. 44

5.4 Changing Management LUNs ................................................................................................... 44

5.5 Changing the Alarm Mute Setting ............................................................................................. 44

5.6 Controlling Host Access to the X24’s Write-back Cache Setting .............................................. 45

5.7 Enabling and Disabling the Battery . ..........................................................................................46

5.8 Changing the Utility Priority ....................................................................................................... 46

5.9 Rescanning All Ports ................................................................................................................. 47

5.10 Pausing I/O ...... ... .. ...................................................................... ............................................... 47

5.11 Saving and Restoring a Configuration File ................................................................................ 48

5.11.1 Saving a Configuration File .............................................................................................. 48

5.11.2 Restoring a Configuration File .......................................................................................... 48

5.12 Viewing and Restoring Default Settings .................................................................................... 50

5.12.1 Viewing Default Settings ..................................................................................................50

5.12.2 Restoring Default Settings ................................................................................................50

5.13 Updating Software .................................................................................................................... 51

6 Managing Disk Drives & Enclosures ........................................................................................... 53

6.1 Managing Disk Drives ............................................................................................................... 53

6.1.1 Displaying Disk Drive Information .................................................................................... 53

6.1.2 Clearing Metadata from a Disk Drive ............................................................................... 54

6.1.3 Enabling and Disabling Write-back Cache ....................................................................... 55

6.1.4 Displaying Disk Drive Cache Status ................................................................................. 55

6.1.5 Enabling and Disabling SMART Changes ........................................................................ 55

6.1.6 Blinking a Drive LED ........................................................................................................ 56

6.1.7 Taking Down a Disk Drive ................................................................................................ 56

6.1.8 Testing a Disk Drive .......................................................... ... ..................................... ... .... 57

6.2 Managing Enclosures ................................................................................................................ 57

6.2.1 Setting the EMP LUN ........................................................ ... ..................................... ....... 57

6.2.2 Changing the Additional EMP Setting ............................................................................. 58

7 Troubleshooting and Problem Solving ....................................................................................... 59

7.1 Overview ................................................................................................................................... 59

7.1.1 Initial Start-up Problems ................................................................................................... 59

7.2 LEDs .......................................................................................................................................... 60

7.2.1 Power Supply/Cooling Module ......................................................................................... 60

7.2.2 Ops Panel ......................................................................................................................... 60

7.3 Audible Alarm ............................................................................................................................ 61

7.3.1 Audible Alarm Mute .......................................................................................................... 61

7.4 Troubleshooting ......................................................................................................................... 62

7.4.1 System Faults ................................................................................................................... 63

7.4.2 Power Supply/Cooling Faults ........................................................................................... 63

7.4.3 Thermal Control .................. ... .. ....................................................................... .................. 64

7.4.4 Thermal Alarm .......................................... ..................................... ................................... 65

7.5 Drive Carrier Module Faults ...................................................................................................... 65

7.5.1 Dummy Carrier Modules ................................................................................................. 65

7.5.2 Auto Start Failure .......................... .................................... ............................................... 66

7.6 Dealing with Hardware Faults ................................................................................................... 66

7.7 Continuous Operation During Replacement .............................................................................. 66

7.8 Problems Accessing the X24 Subsystem Using the Ethernet Port ........................................... 66

vi

RS-1600-X24 User Guide

7.9 Host Fibre Channel Problems ................................................................................................... 67

7.10 Array Problems ......................................................................................................................... 68

7.10.1 Changing the Backoff Percent Using SAM ...................................................................... 68

7.10.2 Changing the Backoff Percent Using the Disk Array Administrator ................................. 68

7.11 X24 Subsystem Problems ......................................................................................................... 69

7.12 Replacing a Module .................................................................................................................. 69

7.12.1 Power Supply/Cooling Modules ....................................................................................... 69

7.12.2 Ops Panel ........................................................................................................................ 72

7.12.3 Storage Manager Module ................................................................................................ 72

7.12.4 Insertion/Removal of SFP Modules ................................................................................. 74

7.12.5 Battery Replacement .......................................................................................................74

7.12.6 Drive Carrier Module ......................................... ... .................................... ........................ 75

7.13 Problems During Startup (When Using the Disk Array Administrator) ...................................... 75

7.14 Terminal Emulator and COM Port Problems ............................................................................. 76

7.15 Warning and Error Events ......................................................................................................... 77

7.15.1 Warnings .......................................................................................................................... 78

7.15.2 Errors ............................................................................................................................... 80

7.16 Setting Up and Viewing the Debug Log .................................................................................... 81

7.16.1 Summary of Debug Log Capabilities ............................................................................... 81

7.16.2 Collecting Debug Logs ................................................. ... ..................................... .. ..........81

7.16.3 Configuring Debug Logs .................................................................................................. 82

7.16.4 Using SAM to Set Up and View the Debug Log ............................................................... 83

7.16.5 Using the Disk Array Administrator to Set Up Debug Logging ......................................... 83

7.17 Using the Loader Diagnostics Menu ......................................................................................... 83

7.18 Using the Loader Utility Menu ................................................................................................... 84

7.19 Understanding Disk-related Errors ............................................................................................ 84

7.19.1 Disk Errors ....................................................................................................................... 84

7.19.2 Disk Channel Errors ......................................................................................................... 85

7.19.3 Voltage and Temperature Errors and Warnings .............................................................. 86

7.20 Slow Write Performance ........................................................................................................... 86

7.21 Spare Parts and Ancillary Items ............................................................................................... 87

7.22 Upgrading Your LRC I/O Modules ............................................................................................ 87

A Array Basics .................................................................................................................................. 89

A.1 Array Types ............................................................................................................................... 90

A.1.1 RAID 0 (Striped Disks) .....................................................................................................90

A.1.2 RAID 1, RAID 10 (Mirrored Disks) ................................................................................... 90

A.1.3 RAID 3 ............................................................................................................................. 90

A.1.4 RAID 4 ............................................................................................................................. 91

A.1.5 RAID 5 ............................................................................................................................. 91

A.1.6 RAID 50 ........................................................................................................................... 91

A.1.7 Volume Sets ..................................................................................................................... 91

A.2 Comparing RAID Levels ................................................ ............................................................ 92

A.3 Mixing Disks from Different Manufacturers or with Different Capacities ................................... 93

B Accessing Disk Array Administrator Software .......................................................................... 95

B.1 Accessing the Disk Array Administrator Using the RS-232 Serial Port ..................................... 96

B.2 Accessing the Disk Array Administrator Using the Ethernet Port .............................................. 98

B.2.1 Using the Ethernet Port for the First Time ....................................................................... 98

B.2.2 Accessing the Disk Array Software Using the Ethernet Port ........................................... 99

B.3 Navigating the Disk Array Administrator Software .................................................................. 101

Contents

vii

B.3.1 Changing the Screen Display ......................................................................................... 102

B.3.2 Disk Array Administrator Menu Tree .............................................................................. 103

C Creating and Managing Arrays & Partitions ............................................ ................................. 105

C.1 Creating Arrays .................................................................. ..................................... ................ 105

C.1.1 Creating a Single-Partition Array .................................................................................... 106

C.1.2 Creating a Multiple-Partition Array ................................................................................. 111

C.2 Managing Arrays ..................................................................................................................... 116

C.2.1 Viewing Array and Drive Status Information ................................................................... 117

C.2.2 Stopping the Array Initialization Process ........................................................................ 120

C.2.3 Adding a Partition .......................................................................... ................................. 121

C.2.4 Verifying an Array ........................................................................................................... 123

C.2.5 Reconstructing an Array ................................................................................................. 126

C.2.6 Expanding Array Capacity .............................................................................................. 126

C.2.7 Changing an Array Name ............................................................................................... 129

C.2.8 Changing Array Ownership ............................................................................................ 130

C.2.9 Trusting an Array ............................................................. .. ... ..................................... ..... 130

C.2.10 Deleting an Array ............................................................................................................ 131

C.3 Managing Partitions ................................................................................................................. 133

C.3.1 Understanding Partitions ................................................................................................ 133

C.3.2 Viewing Partition Status Information .............................................................................. 134

C.3.3 Expanding a Partition ..................................................................................................... 139

C.3.4 Changing a Partition Name ............................................................................................ 140

C.3.5 Changing a Partition LUN .............................................................................................. 141

C.3.6 Changing the Read-Ahead Cache Size ......................................................................... 142

C.3.7 Enabling or Disabling Write-back Cache ........................................................................ 143

C.3.8 Controlling Partition Access ........................................................................................... 144

C.3.9 Deleting a Partition ......................................................................................................... 151

D Monitoring System Status .......................................................................................................... 153

D.1 Introduction .............................................................................................................................. 153

D.2 Displaying the Event Log ......................................................................................................... 154

D.2.1 Viewing the Most Recent Event ..................................................................................... 154

D.2.2 Viewing One Event at a Time ......................................................................................... 155

D.2.3 Viewing a Whole Screen of Events ................................................................................ 156

D.2.4 Capturing the Event Log ................................................................................................ 157

D.3 Displaying Module Status Information ..................................................................................... 158

D.4 Displaying Hardware and Configuration Information ............................................................... 159

D.5 Capturing the Event Log, Hardware, and Configuration Information ....................................... 164

D.6 Displaying Drive Errors and Resetting Error Statistics ............................................................ 164

D.7 Displaying Overall Statistics .................................................................................................... 165

D.7.1 Resetting Overall Statistics ............................................................................................ 166

E Managing Spares ........................................................................................................................ 167

E.1 Managing Dedicated Spares ................................................................................................... 168

E.1.1 Adding a Dedicated Spare ............................................................ .. ............................... 168

E.1.2 Deleting a Dedicated Spare ........................................................................................... 168

E.2 Enabling Dynamic Spares ....................................................................................................... 169

E.3 Managing the Spare Pool ........................................................................................................ 170

E.3.1 Adding a Spare to the Spare Pool .................................................................................. 171

E.3.2 Deleting a Spare from the Spare Pool ............................................................................ 171

viii

RS-1600-X24 User Guide

E.3.3 Displaying the Spare Pool .............................................................................................. 171

F Managing Disk Drives and Enclosures ..................................................................................... 173

F.1 Managing Disk Drives ............................................................................................................. 173

F.1.1 Displaying Drive Information .......................................................................................... 173

F.1.2 Clearing Metadata from a Drive ..................................................................................... 177

F.1.3 Enabling and Disabling Write-back Cache ..................................................................... 177

F.1.4 Displaying Disk Cache Status ........................................................................................ 179

F.1.5 Ena bling and Disabling SMART Changes ..................................................................... 181

F.1.6 Blinking a Drive LED ....................................................... ... ............................................ 182

F.1.7 Taking Down a Drive ...................................................................................................... 182

F.1.8 Testing a Drive ............................................................................................................... 183

F.2 Managing Enclosures .............................................................................................................. 183

F.2.1 Setting the EMP LUN ............................................................................ ... ...................... 184

F.2.2 Changing the Additional EMP Setting ........................................................................... 187

G Configuring the X24 Subsystem ............................................................................................... 189

G.1 Shutting Down and Restarting the Storage Manager Module ................................................. 190

G.1.1 Shutting Down and Restarting the Current SM Module ................................................. 190

G.1.2 Shutting Down the Other SM Module ............................................................................ 191

G.1.3 Shutting Down Both SM Modules .................................................................................. 192

G.1.4 Other Controller Menu ................................................................................................... 192

G.2 Changing the Date and Time .................................................................................................. 192

G.3 Configuring the Host Channels ............................................................................................... 195

G.4 Understanding LUNs and Viewing LUN Information ............................................................... 196

G.4.1 Viewing LUN Information ................................................................. .............................. 197

G.5 Configuring the FC Disk Channels .......................................................................................... 198

G.6 Changing the Alarm Mute Setting ........................................................................................... 200

G.7 Locking the Cache Setting ...................................................................................................... 203

G.8 Enabling and Disabling the Battery ......................................................................................... 204

G.9 Changing the Utility Priority ..................................................................................................... 205

G.10Rescanning All Channels ........................................................................................................ 206

G.11Pausing I/O ............................................................................................................................. 207

G.12Restoring Default Settings ...................................................................................................... 208

G.13Updating Firmware .................................................................. ............................................... 209

G.13.1 Updating the SM, SM Loader and Memory Controller Firmware .................................. 209

G.13.2 Updating LAN Firmware .............................. ................................................................... 210

H LAN Configuration ...................................................................................................................... 213

H.1 Configuring the SM for TCP/IP ................................................................................................ 213

H.2 Configuring the LAN Settings .................................................................................................. 214

H.2.1 Configuring the IP Settings ............................................................................................ 214

H.2.2 Configuring the FTP Settings ......................................................................................... 215

H.2.3 Configuring the Telnet Settings ...................................................................................... 215

H.2.4 Configuring the SNMP Settings ..................................................................................... 216

H.2.5 Configuring the Contact Settings ................................................................................... 217

H.2.6 Configuring the HTTP Settings ...................................................................................... 218

H.2.7 Configuring the Security Options ................................................................................... 218

H.2.8 Resetting the LAN Subsystem ...................................................................................... 219

Glossary ............................................................................................................................................. 221

Contents

ix

Index .................................................................................................................................................. 229

x

RS-1600-X24 User Guide

Preface

ix

Preface

What is in this guide

This user guide gives you step-by-step instructions on how to install, configure and connect the RS-1600X24 storage Subsystem to your host computer system, and how to use and maintain the system.

Who should use this guide

This user guide assumes that you have a working knowledge of the Fibre Channel environment into

which you are installing the RS-1600-X24 system. If you do not have these skills, or are not confident with

the instructions in this guide, do not proceed with the installation.

International St andards

The RS-1600-X24 storage system complies with the requirements of the following agencie s and

standards:

• CE to IEC 950/EN60950

• UL 60950

•cUL

Potential for Radio Frequency

Interference

USA Federal Communications Commission (FCC)

Note This equipment has been tested and found to comply with the limits for a class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission

limits. The supplier is not responsible for any radio or television interference caused by using other than

recommended cables and connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to ope rate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Note FCC approval only applies when using the supplied screened Ethernet cable.

RS-1600-X24 User Guide

x

European Regulations

This equipment complies with European Regulations EN 55022 Class A: Limits and Methods of

Measurement of Radio Disturbance Characteristics of Information Technology Equipments and

EN50082-1: Generic Immunity.

Safety

All plug-in modules are part of the fire enclosure and must only be removed when a replacement can be

immediately added. The system must not be run without all units in place.

Permanently unplug the unit if you think that it has become damaged in any way and before you move it.

• An RS-1600-X24 enclosure can weigh up to 37kg (81lb). Do not try to lift it by yourself.

• Do not attempt to lift the enclosure by means of the extended LRC module or by the handles on the

PSU/Cooling module as they are not designed to support the weight of the populated enclosure.

• In order to comply with applicable safety, emission and thermal requirements no covers should be

removed and all bays must be fitted with plug-in modules.

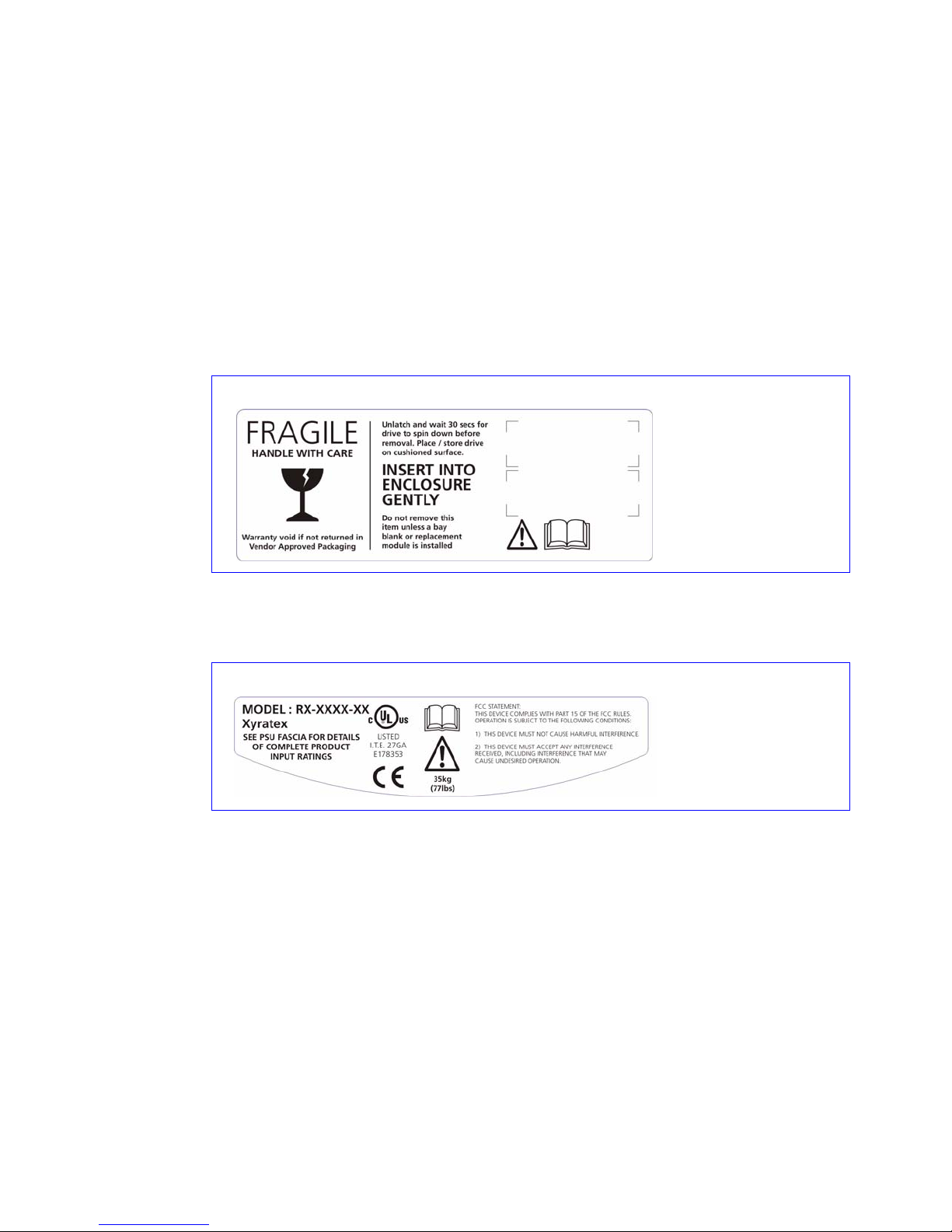

Drive Carrier Module

Caution Label:

• Do not operate with

modules missing

• Spin down time 30

seconds

Chassis Warning Label:

Weight Hazard

Preface

xi

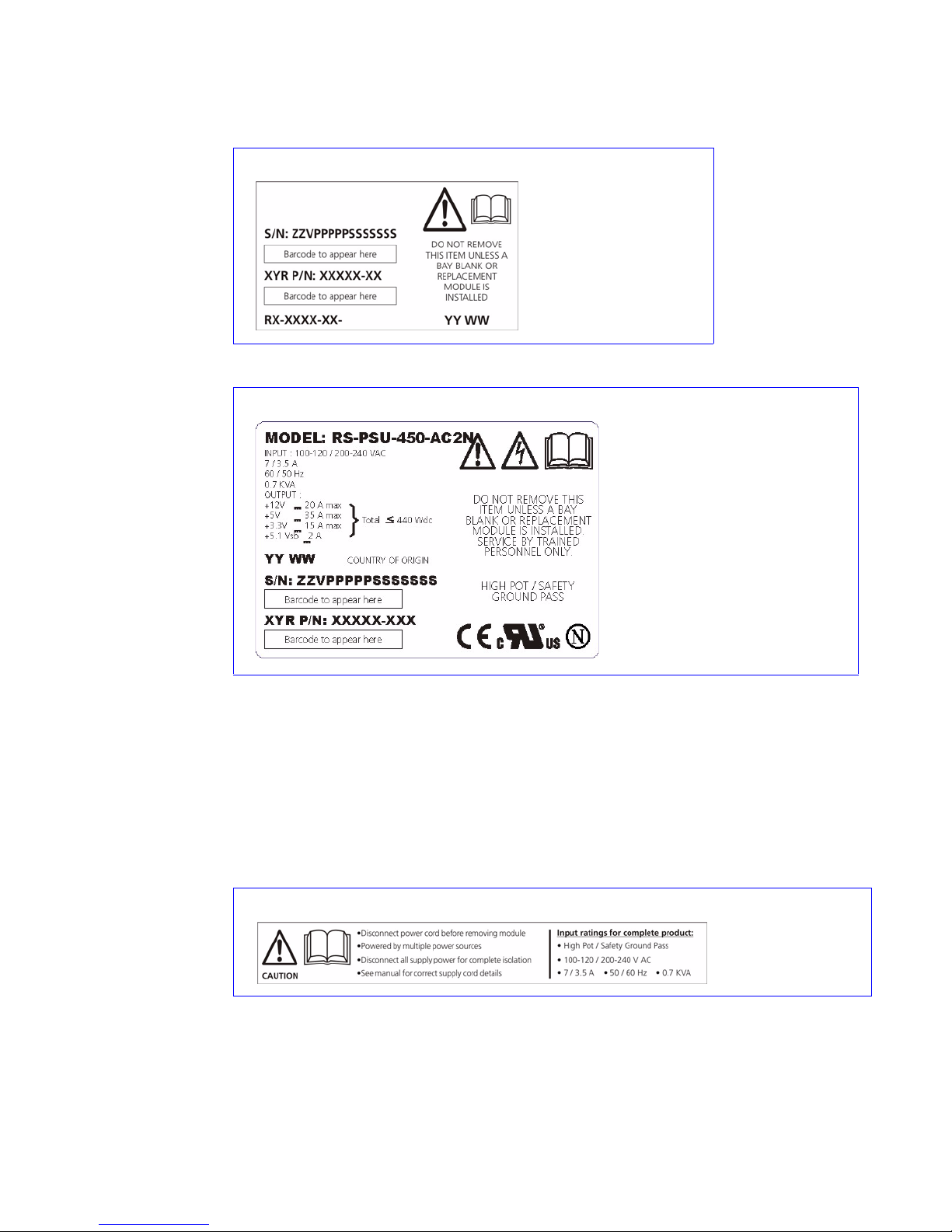

• The RS-1600-X24 unit must only be operated from a power supply input voltage range of 100 120VAC or 200-240 VAC.

• The plug on the power supply cord is used as the main disconnect device. Ensure that the socket

outlets are located near the equipment and are easily accessible.

• This equipment is intended to operate with two working PSUs.

• If powered by multiple AC sources, disconnect all supply power for complete isolation

• The power connection must always be disconnected prior to removal of the Power Supply/Cooling

module from the enclosure.

• A safe electrical earth connection must be provided to the power cord. Check the grounding of the

enclosure before applying power.

LRC Module Caution

Label:

Do not operate with

modules missing

PSU/Cooling Module Caution Label:

Do not operate with modules missing

PSU Warning Label:

Power Hazards

RS-1600-X24 User Guide

xii

• Provide a suitable power source with electrical overload protection to meet th e requirements laid

down in the technical specification.

• A faulty power supply/cooling module must be replaced with a fully operational module within 24

hours.

Warning Do not remove covers from the power supply unit. Danger of electric shock inside. Return the PSU

to your supplier for repair.

Caution Caution: If this equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

Battery Safety

The battery is user replaceable, please refer to the Battery Replacement Procedure.

Warning There is a danger of explosion if the battery is incorrectly replaced.

• Dispose of used batteries in accordance with the manufacturer’s instructions and National

regulations.

Laser Safety

Class 1 Laser Product

When the X24 Subsystem is supplied with optical modules they contain a laser that complies with Laser

Class 1, US 21 CFR (J) and EN 60825-1.

If optical modules are to be provided and fitted by the end user, lasers must comply with the standards

listed above.

PSU Safety Label:

Electric Shock Hazard Inside

Preface

xiii

Rack System Precautions

The following safety requirements must be considered when the unit is mounted in a rack.

• The rack design should incorporate stabilizing features suitable to prevent the rack from tipping or

being pushed over during installation or in normal use.

• When loading a rack with the units, fill the rack from the bottom up and empty from the top down.

• The rack should comply with the airflow requirements detailed in the technical specification.

• The rack design should take into consideration the maximum operating ambient temperature for the

unit, which is 40°C when dual cooling modules are fitted.

• The rack should have a safe electrical distribution system. it must provide overcurrent protection for

the unit and must not be overloaded by the total number of units installed in the rack. Consideration

of the electrical power consumption rating shown on the nameplate should be used when

addressing these concerns.

• The electrical distribution system must provide a reliable earth for each unit and the rack.

• Each power supply in each unit has an earth leakage current of 0.65mA. The design of the electrical

distribution system must take into consideration the total earth leakage current from all the power

supplies in all the units. The rack will require labelling with "HIGH LEAKAGE CURRENT. Earth

connection essential before connecting supply".

• The rack when configured with the units must meet the safety requirements of UL1950 and IEC

60950.

ESD Precautions

Caution It is recommended that you fit and check a suitable anti-static wrist or ankle strap and observe all

conventional ESD precautions when handling RS-1600-X24 plug-in modules and components. Avoid

contact with backplane components and module connectors, etc.

RS-1600-X24 User Guide

xiv

Data Security

• Power down your host computer and all attached peripheral devices before beginning installation.

• Each enclosure contains up to 16 removable disk drive modules. Disk units are fragile. Handle them

with care, and keep them away from strong magnetic fields.

• All the supplied plug-in modu les and blanking plates must be in place for the air to flow correctly

around the enclosure and also to complete the internal circuitry.

• If the Subsystem is used with modules or blanking plates missing for more than a few minutes, the

enclosure can overheat, causing power failure and data loss. Such use may also invalidate the

warranty.

• If you remove any drive module, you may lose data.

– If you remove a drive module, replace it immediately. If it is faulty, replace it with a drive module

of the same type and capacity

• Ensure that all disk drives are removed from the enclosure before attempting to manhandle or move

the rack installation.

• Do not abandon your backup routines. No system is completely foolproof.

Special Tools and Equipment

There are no special tools required but in order to complete the assembly of some configurations you may

need the following (not supplied):

• Security keys (one of these should be included with yo ur RS-1600-X24 enclosure for use with the

drive locks).

Related Documentation

• RS-1600-X24 Getting Started Manual (P/N 44521-01A), Issue 1.0

• RS-1600-X24 Quick Installation Guide (P/N 43062-01A), Issue 1.0

• RS-Salient Series Rack Installation Guide (P/N 43638-01A), Issue 1.0

Preface

xv

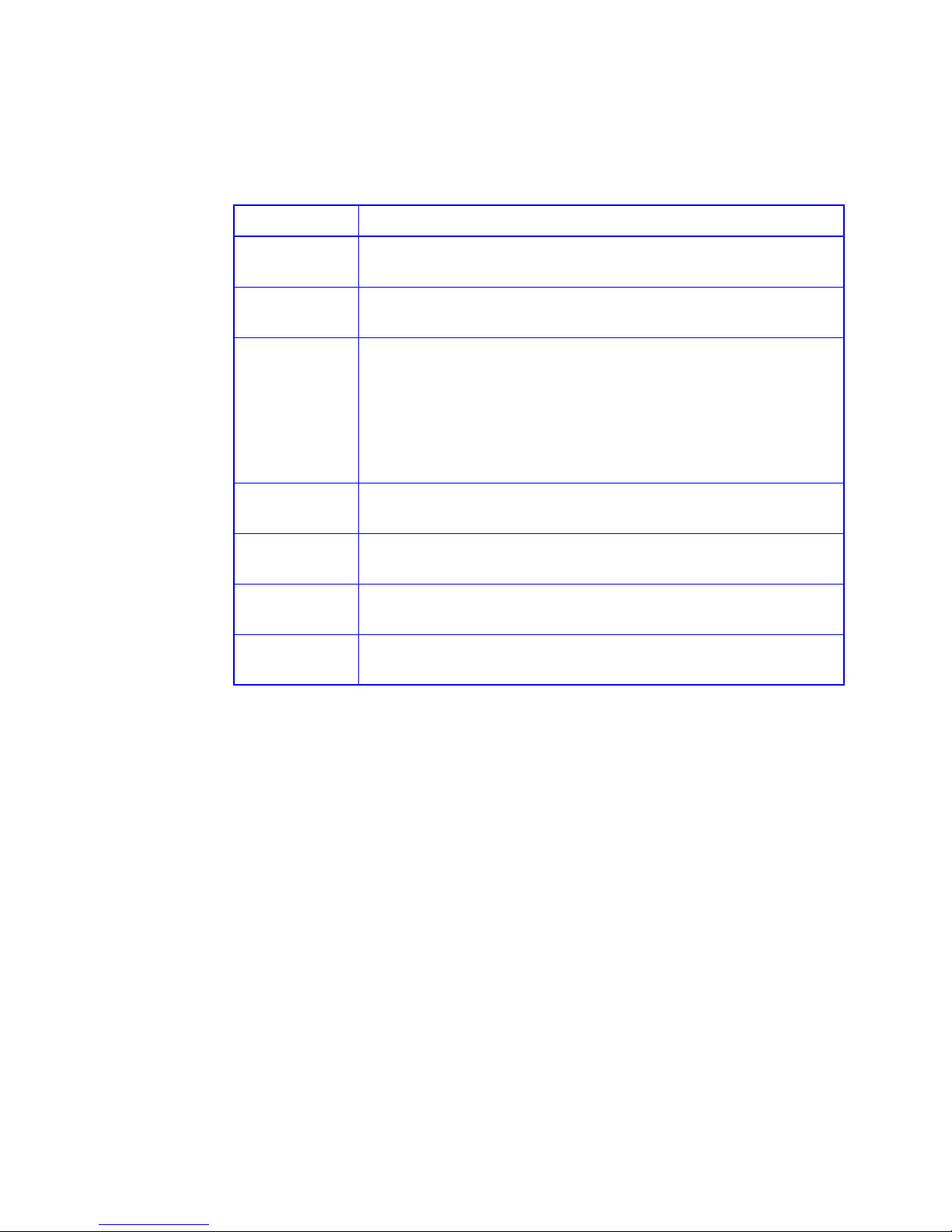

Conventions

This Getting Started guide uses several conventions to help explain how to use the X24.

Convention Definition

Bold Words in bold indicate items to select such as menu items or command

buttons.

CTRL-R Keys you press simultaneously. In this example, hold down the Ctrl key and

press the r key.

MB The abbreviation MB is used for megabytes in all situations. However, the

amount of data represented by MB differs as follows:

For disk drives, arrays, partitions, and data rate statistics, 1 MB equals

1,000,000 using the International System of Units (SI) standard.

For memory, 1 MB equals 1,048,576 using the memory industry standard.

Note Notes give you information that can help you improve the performance of your

system.

Important Important gives you important information that may affect how you decide to

set up your system.

Caution Cautions warn you about actions that may permanently delete data or cause

damage to your system.

Warning Warnings warn you about actions that may be hazardous to personnel,

resulting in injury or death

RS-1600-X24 User Guide

xvi

Revision History

Version Date Description of Change

Issue 1.0 June, 2003 Initial (Beta) Release

Introduction

1

Chapter 1

Introduction

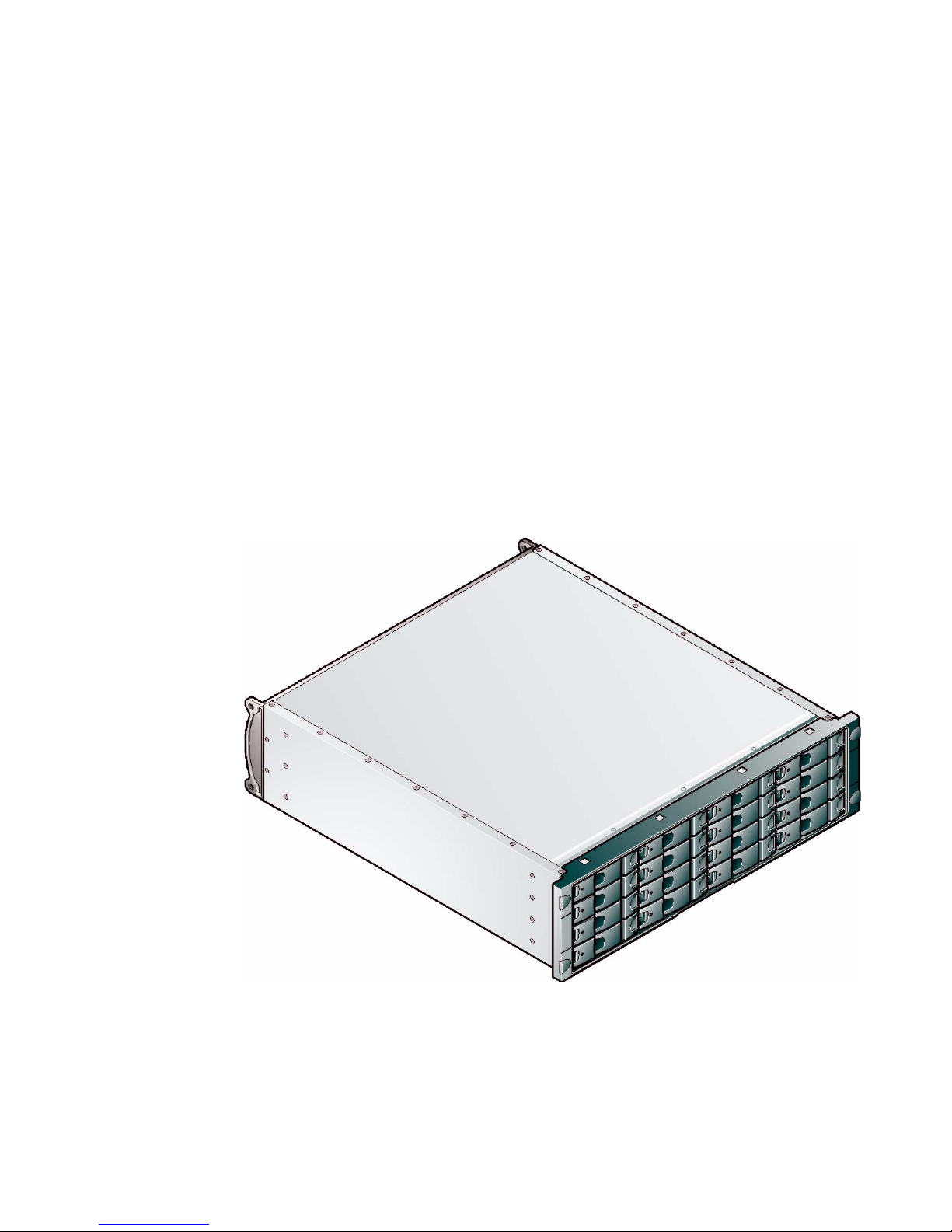

1.1 The RS-1600-X24 System

.

Figure 1–1 The RS-1600-X24 (FC-AL) System

RS-1600-X24 User Guide

2

1.2 The Enclosure Core Product

The RS-1600-X24 design concept is based on a Subsystem together with a set of plug-in modules. The

RS-1600-X24 Subsystem as supplied comprises:

• Chassis and Backplane with integral Operators Panel.

• Power Supply/Cooling plug-in modules, auto-ranging, 475W, AC (see Figure 1–5)

• FC-AL Drive Carrier Modules and associated dummy carrier modules (See Figure 1–10).

• FC-AL LRC 2Gb/s Input/Output Modules with integrated Xyratex X24 RAID controllers, known as

Storage Managers.(See Figure 1–8).

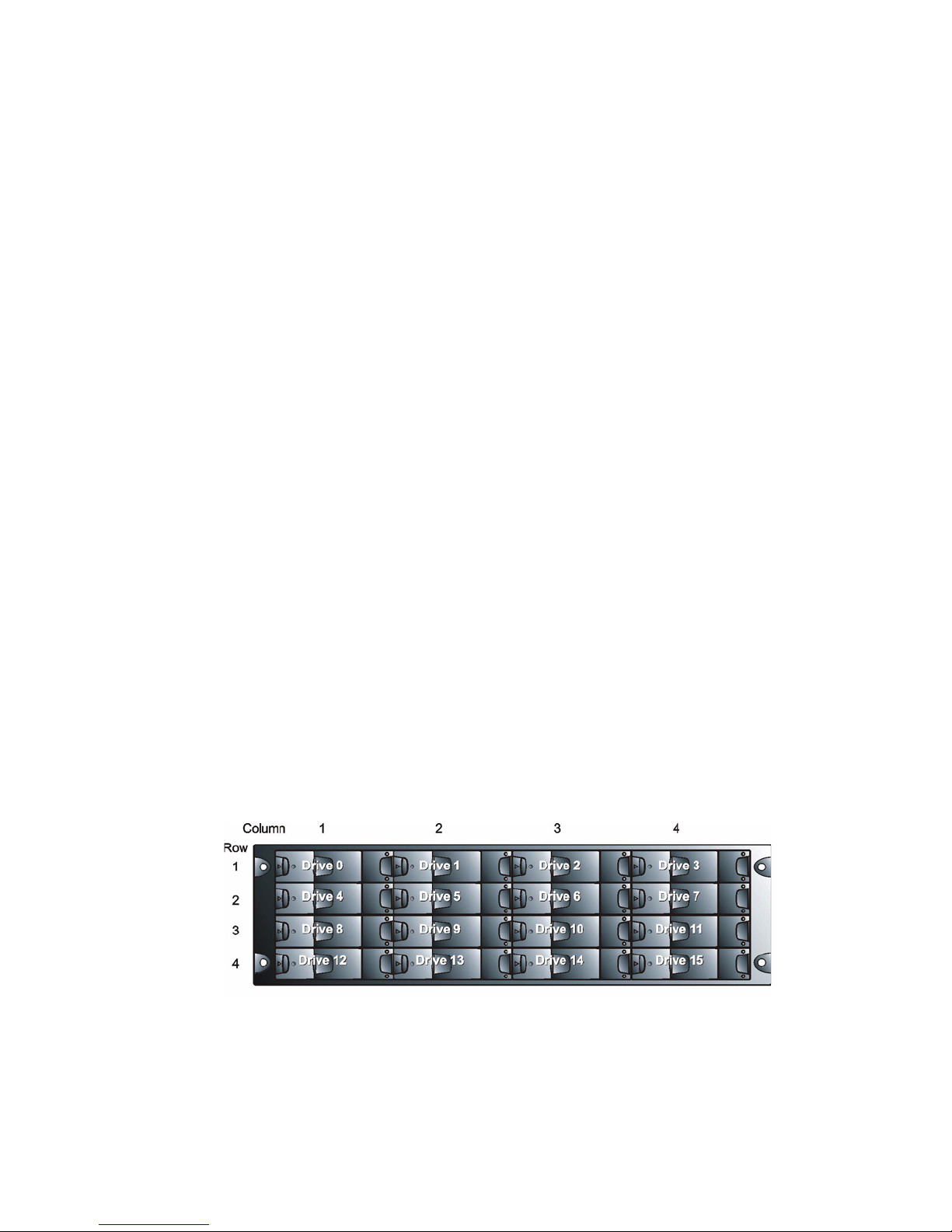

1.2.1 Enclosure Chassis

The chassis consists of a sheet metal enclosure assembly containing a Backplane PCB and module

runner system. This chassis assembly also includes an integral Operators (Ops) Panel mounted at the

rear.

The chassis assembly contains 16 drive bays at the front, each of which accommodates a plug-in drive

carrier module. The 16 drive bays are arranged in 4 rows of 4 drives. At the rear, the chassis assembly

contains 5 module bays to house two Power Supply/Cooling modules, two LRC I/O modules and the

integral Ops panel.

The Backplane PCB provides logic level signal and low voltage power distribution paths. Figure 1–2 and

Figure 1–3 show front and rear views of an RS-1600 chassis respectively.

The 4 x 4 chassis is fitted with 19 inch Rack mounting features which enables it to be fitted to standard

19 inch racks and uses 3EIA units of rack space.

• A Bay is defined as the space required to house a single 1.0" high 3.5 inch disk drive in its carrier

module. e.g. a 1 x 4 bay module would take the space of 1 drive width by 4 drive bays high (in rack

mount configuration).

.

Figure 1–2 X24 Enclosure Chassis (Front)

Introduction

3

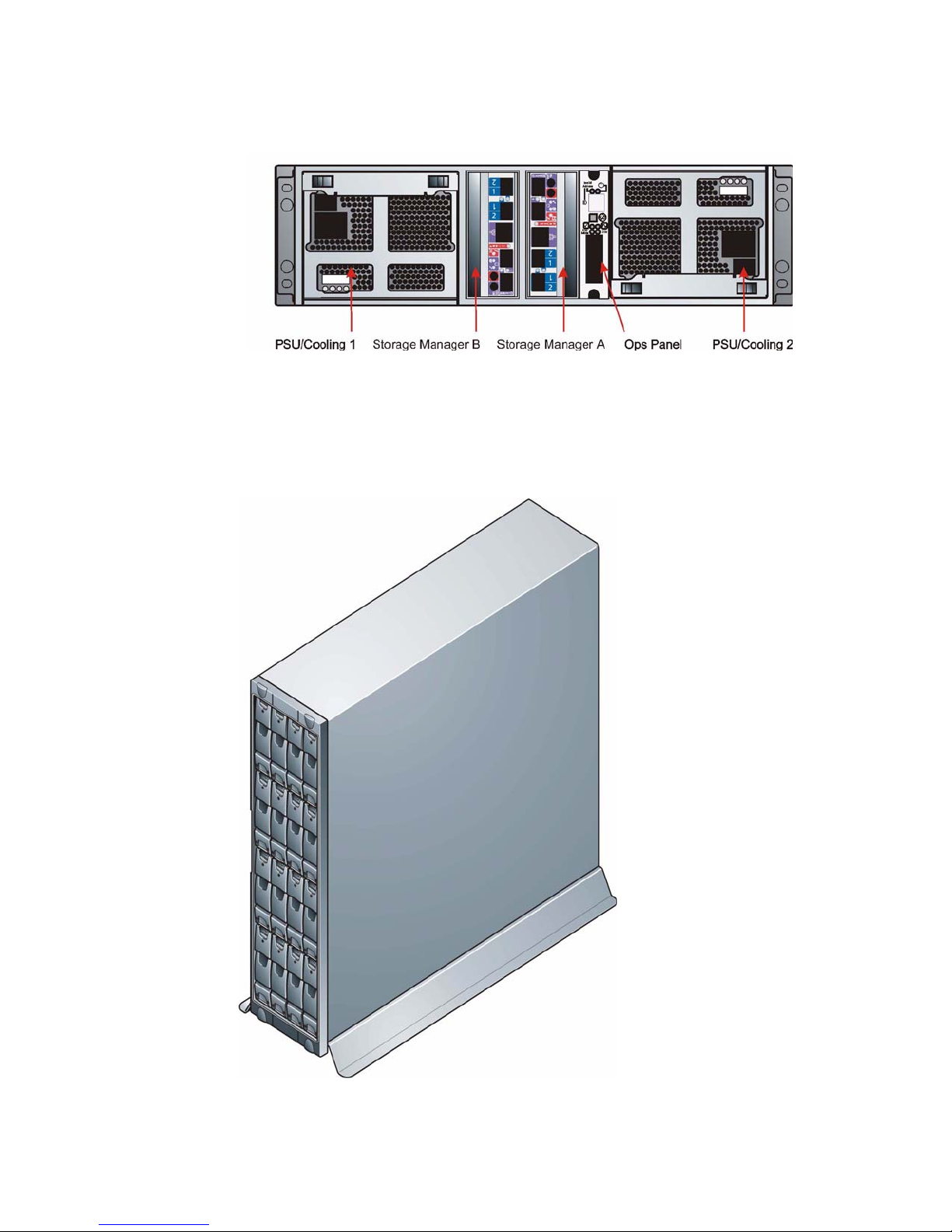

1.2.2 Tower Option

An optional tower kit is available, which can be fitted to the rack chassis described here.

.

Figure 1–3 X24 Enclosure Chassis (Rear)

Figure 1–4 RS-1600-X24 Tower Option

RS-1600-X24 User Guide

4

1.3 The Plug-in Modules

An RS-1600-X24 Enclosure requires one or more of the following modules for normal operation:

1.3.1 Power Supply/Cooling Module

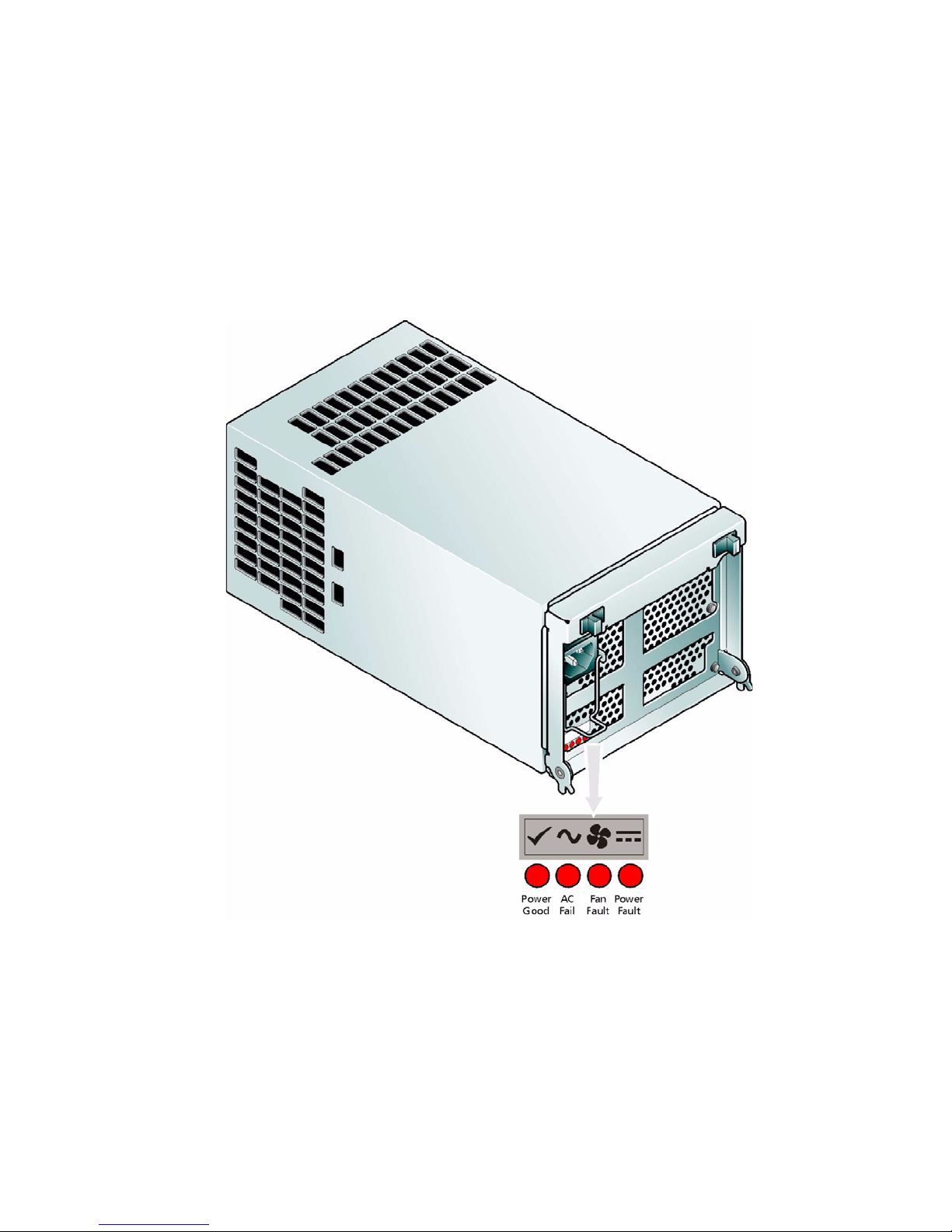

Two Power Supply/Cooling modules (Figure 1–5) are supplied mounted in the rear of the enclosure as

part of the Subsystem core product.

.

PSU voltage operating ranges are nominally 115V or 230V AC, selected automatically.

.

Four LEDs mounted on the front panel of the Power Supply/Cooling Module indicate the status of the PSU

and the fans.

Warning The Power Supply/Cooling module is not an operator removable part. It should only be remo ved

by a technician who has knowledge of the hazard s present within the module.

Figure 1–5 AC Power Supply/Cooling Module

Introduction

5

1.3.1.1 Multiple Power Supply/Cooling Modules

The RS-1600-X24 system must always be operated with two Power Supply/Cooling modules fitted. The

two Power Supply/Cooling modules operate together so that if one fails the other maintains the power

supply and cooling while you replace the faulty unit.

Module replacement should only take a few minutes to perform but must be completed within 5 minutes

from removal of the failed module.

1.3.2 Operators Panel

Supplied as an integral part of the Enclosure core product, a typical Operators (Ops) Panel is shown in

Figure 1–6.

The Ops Panel provides the enclosure with a micro controller which is used to monitor and control all

elements of the Enclosure.

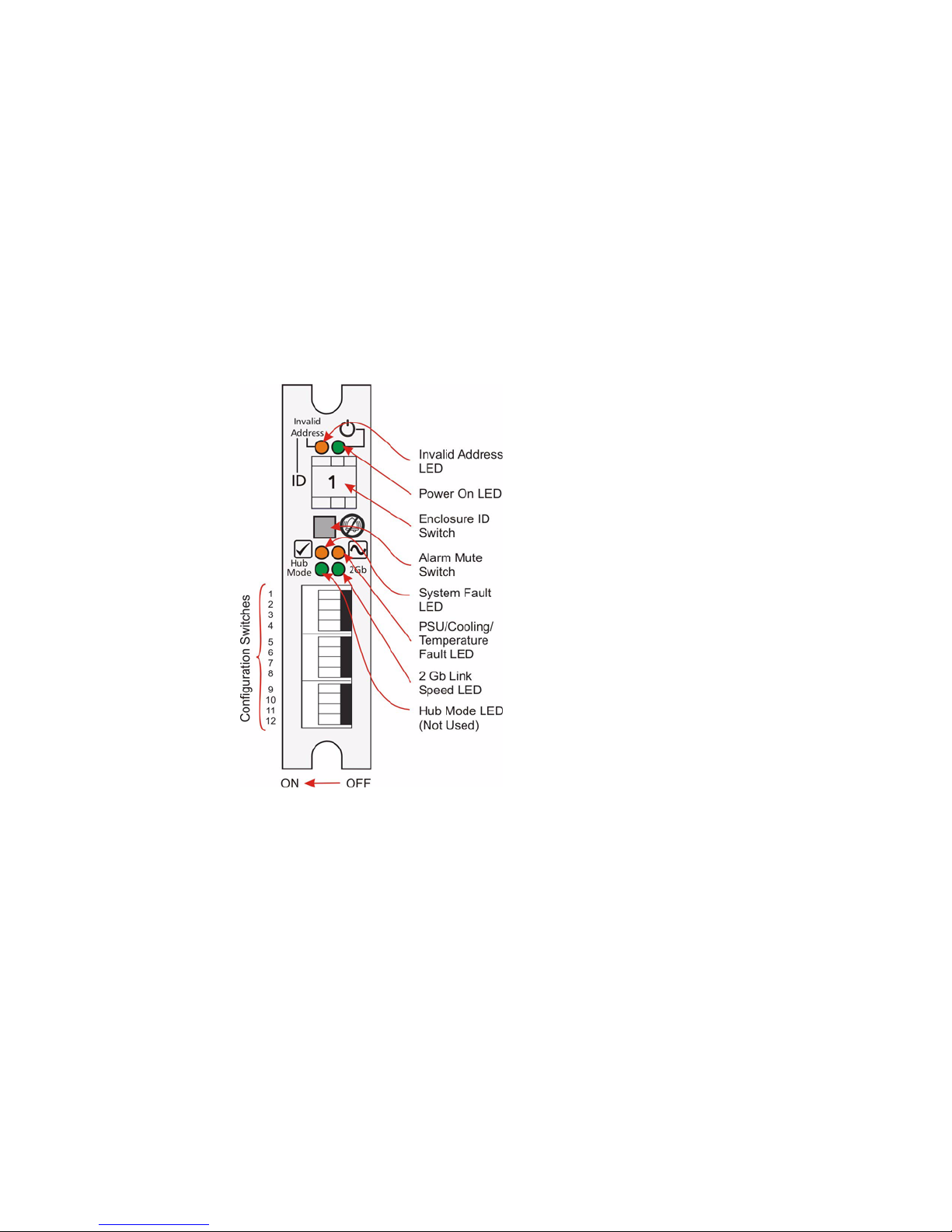

1.3.2.1 Ops Panel Indicators and Switches

The Ops Panel includes Light Emitting Diodes (LEDs) which show the status for all modules, an Audible

Alarm which indicates when a fault state is present, a push-button Alarm Mute switch and a thumb wheel

SEL_ID address Range selector switch.

The Ops Panel switch functions are shown in Table 1–1.

Important Switch settings are only read at Power On.

The X24 enclosure ID must always be set to select ID1.

Figure 1–6 Operators (Ops) Panel

RS-1600-X24 User Guide

6

Caution All mandatory settings must be observed in order for the RS-1600-X24 system to function correctly.

Note To set Host 1Gb use the Ethernet connected configurator.

1.3.3 Loop Resiliency Circuit Input/Output Module (FC-AL)

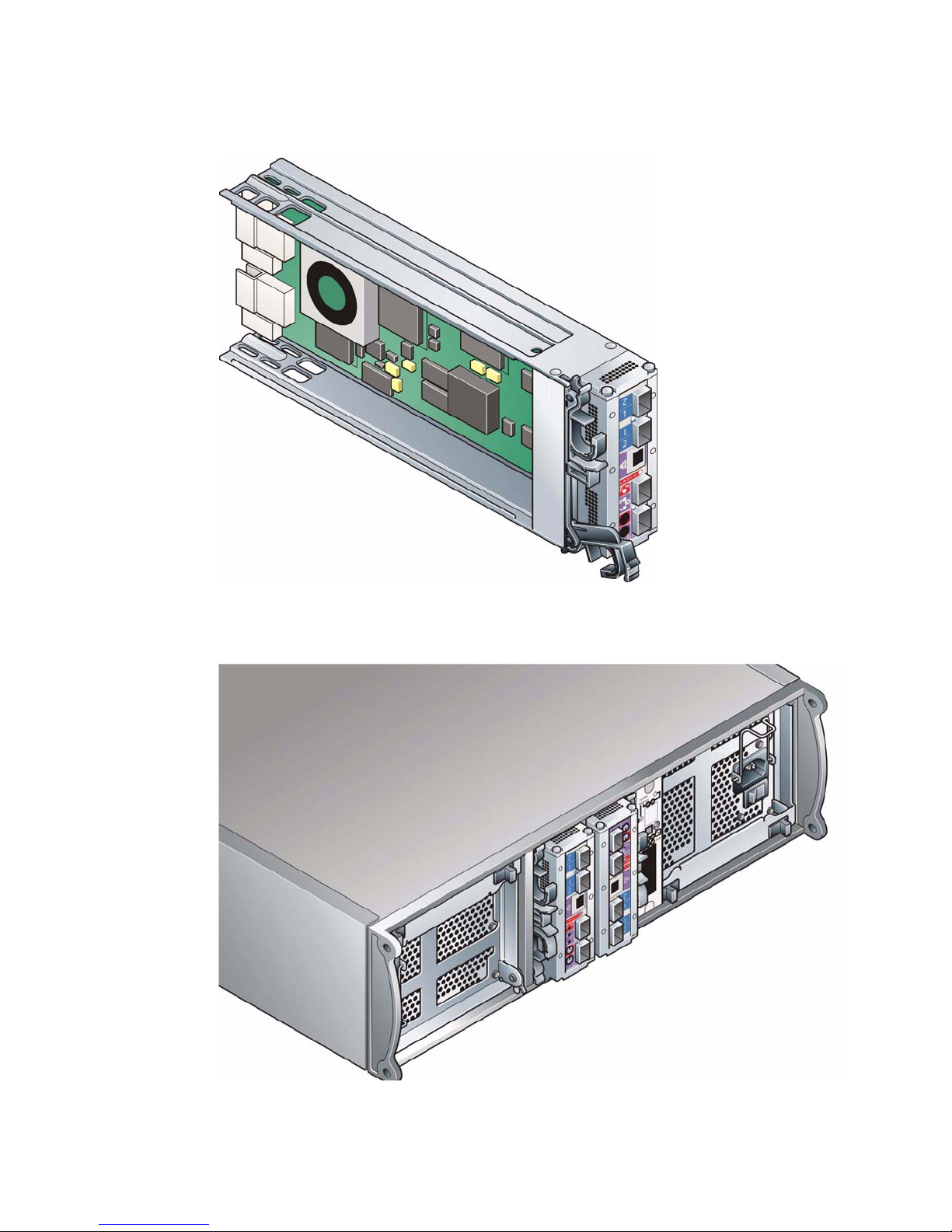

The RS-1600-X24 storage Subsystem includes an enclosure with rear facing bays which house two Loop

Resiliency Circuit (LRC) I/O modules with integrated Xyratex

X24 RAID controller, known as Storage

Managers (SM) modules. (see Figure 1–3)

The FC-AL Backplane incorporates two independent loops formed by Port Bypass Circuits within the LRC

I/O modules.

The plug-in SM modules have been designed for integration into a RS-1600-X24 storage Subsystem,

utilizing FCAL interfacing with the host computer system.

Processors housed on the LRC modules provide enclosure management and interface to devices on the

Backplane, PSU, LRC and Ops Panel, to monitor internal functions. These processors operate in a

master slave configuration to allow failover.

The module incorporates the following LED indicators, shown in Figure 1–7:

• Host Port 0 Signal Good (Green)

• Host Port 1 Signal Good (Green)

• Expansion Port 0 Rx Good (Green)

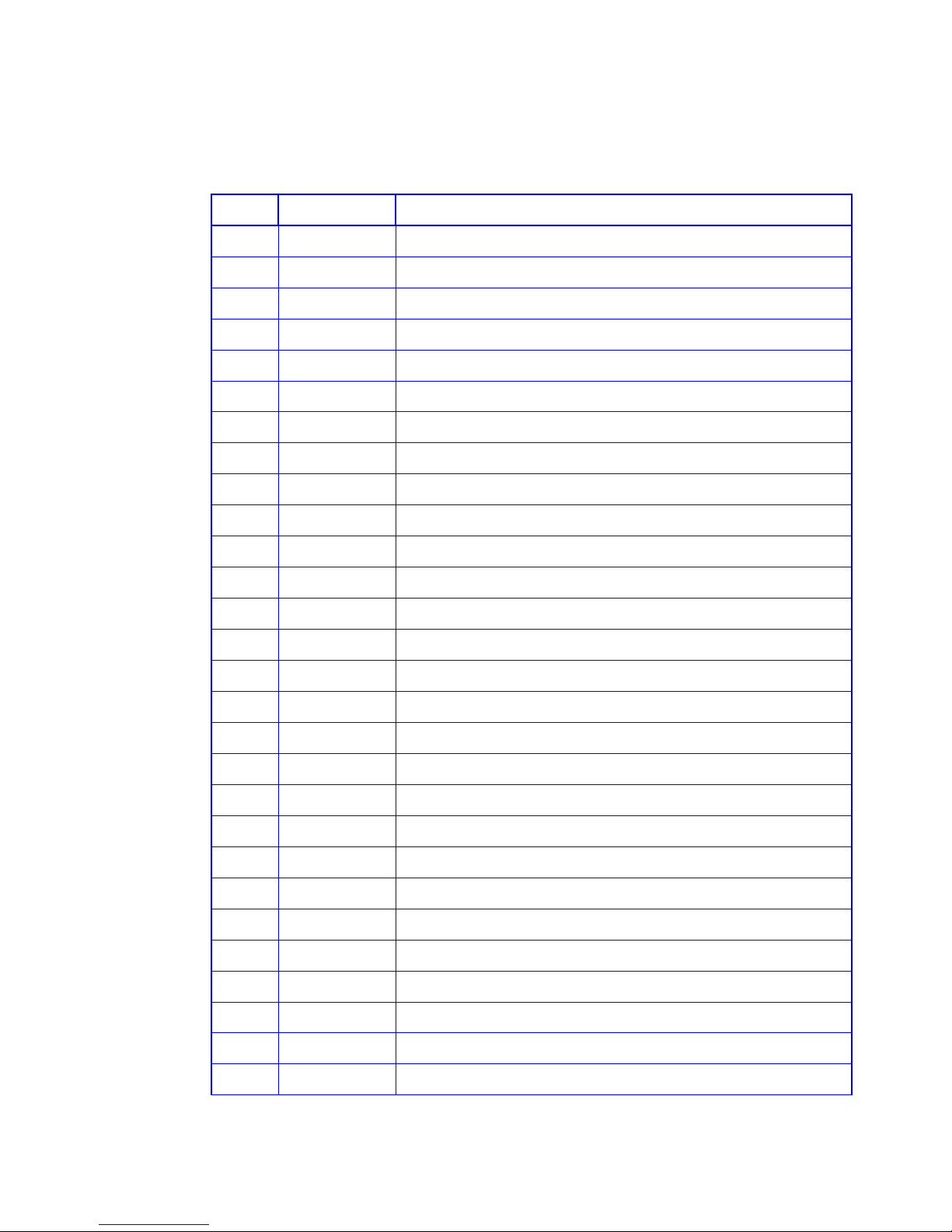

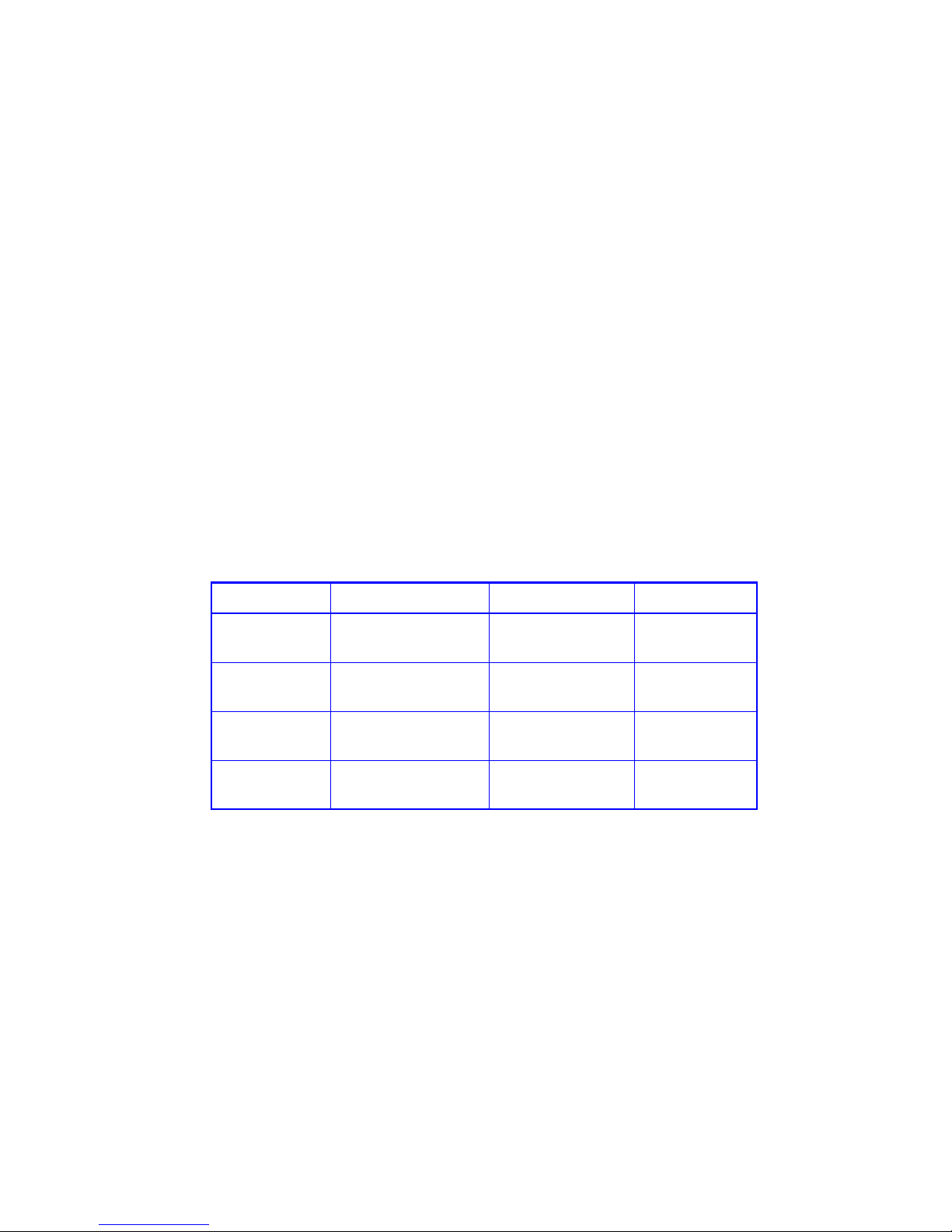

Table 1–1 Ops Panel Switch Functions (Default settings for RS-1600-X24 LRC usage at 2Gb/s)

Switch

Number

Function Recommended

Setting

Definition

1 Loop Select,

Dual (2x8)

Off LRC operates on two loops of 8 drives

Mandatory

2 Not Used Note: on RS-1600-FC2 enclosures this must be set On.

3 Not Used

4 Not Used

5 & 6 Not Used

7 & 8 Drive Loop Speed

Select

Sw7 Sw8

On Off Force 2Gb/s

Off Off Force 1Gb/s

9 & 10 Drive Addressing

Mode Selection

Sw9 Sw10

On Off Mode 2, 2x8 mode. Mandatory

11 SOFT SELECT On Select Functions using the hardware

switches

12 Not Used

Introduction

7

• Expansion Port 1 Rx Good (Green)

• ESI/LRC module fault LED (Amber)

• Cache Active (Green)

• RAID Controller Activity

– Ready (Green)

– Host Activity of either host channels (Flash off)

• Battery Fault (Amber)

Important Fitting of a RAID controller to the LRC module is a factory only operation.

Figure 1–7 LRC Panel Layout

RS-1600-X24 User Guide

8

Warning Do not attempt to lift the enclosure by means of the extended SM module

..

Figure 1–8 X24 LRC (Storage Manager) I/O Module

Figure 1–9 RS-1600-X24 Enclosure with Storage Manager Modules and PSUs Installed

Introduction

9

The Storage Manager module operates at 1 or 2 Gb.

• Two external ports for expansion to further enclosures are provided by SFP connectors

• Two external ports to the host controllers are provided from SM module all Form Factor (SFP) GBIC

modules, auto-bypass at the output ports is provided.

• An RJ45 10/100 Base T Ethernet controller management port is provided on the LRC board,

interfacing to the controller through 2 RS232 serial and GPIO lines.

Caution The RJ45 Ethernet connector on the LRC module must not be connecte d to telecommunications

networks.

• The SM module also incorporates a standby Li-ion ba ttery pack, 72 hours cache ho ld up time

(512Mb). The battery cell has thermal protection and is connected to the RAID con troller by flying

lead.

Note The RS-1600 product range is available in 1Gb, 2Gb, JBOD or RAID variants, by changing the LRC

modules. Please contact your supplier for details.

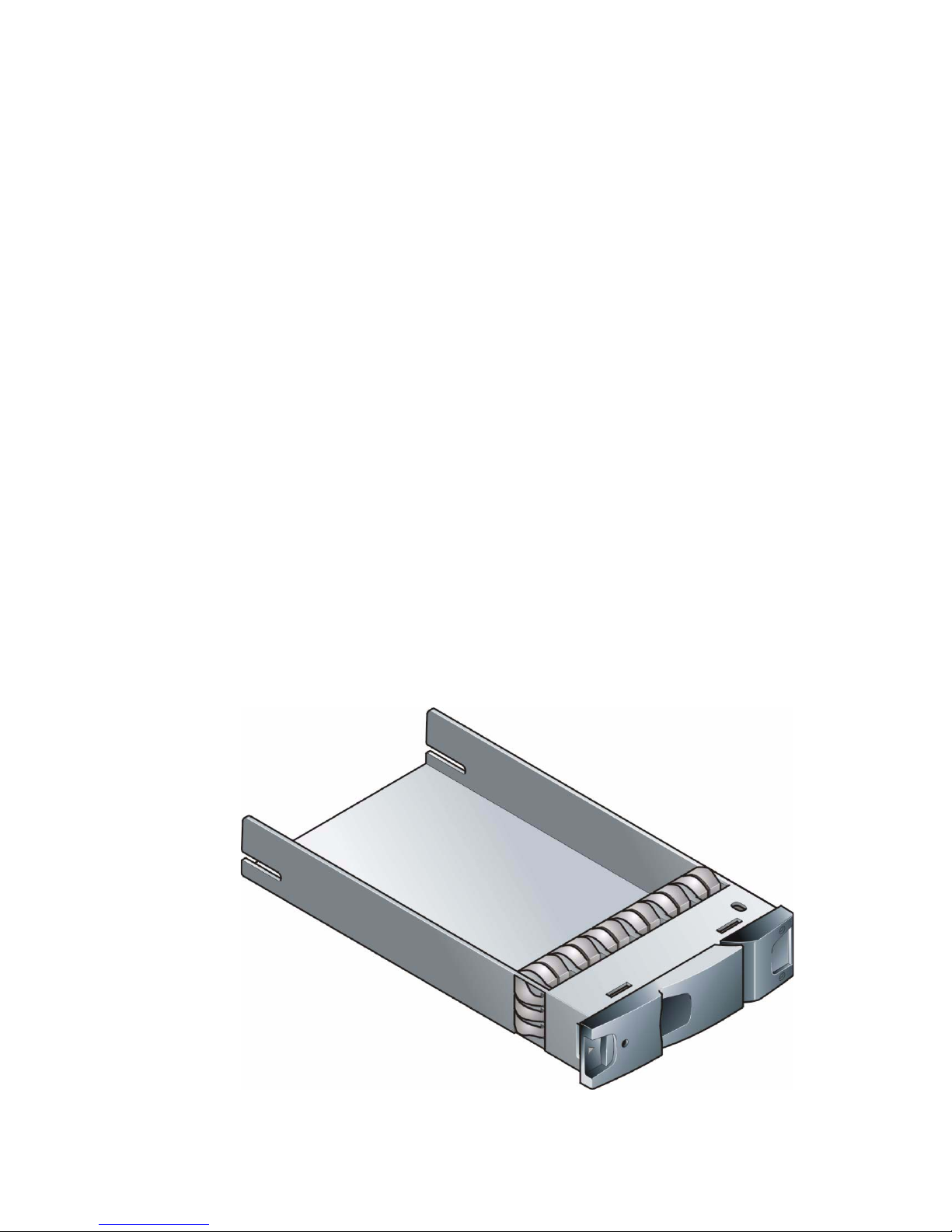

1.3.4 Drive Carrier Module

The Drive Carrier module comprises a hard disk mounted in a carrier. Each drive bay will house a single

1.0 inch high, 3.5 inch disk drive in its carrier.

Each disk drive is enclosed in a die-cast aluminum carrier which provides excellent thermal conduction,

radio frequency and electro-magnetic induction protection and affords the drive maximum physical

protection.

The front cap also supports an ergonomic handle which provides the following functions:

• Camming of carrier into and out of drive bays.

• Positive 'spring loading' of the drive/backplane connector.

• An anti-tamper lock operated by a torx socket type key.

Figure 1–10 Drive Carrier Module

RS-1600-X24 User Guide

10

1.3.4.1 Drive Status Indicators

Each drive carrier incorporates two indicators, an upper (Green) and lower (Amber). In normal operation

the green indicator will be ON and will flicker as the drive operates.

1.3.4.2 Anti-tamper Locks

Anti-tamper locks are fitted in the drive carrier handles (Figure 1–11) and are provided to disable the

normal ‘pinch' latch action of the carrier handle.

1.3.5 Dummy Carrier Modules

Dummy carrier modules are provided for fitting in all unused drive bays. They are designed as integral

drive module front caps with handles and must be fitted to all unused drive bays to maintain a balanced

airflow.

Warning Operation of the Enclosure with ANY modu les missing will disrupt th e airflow and th e drives will

not receive sufficient cooling. It is ESSENTIAL that all apertures are filled before operating the

unit. Dummy Carriers are available for this purpose.

1.4 Visible and Audible Alarms

The functional modules have associated status LEDs. The Ops Panel shows a consolidated status for all

modules.

LEDs show constant green for good or positive indication. Constant Amber LEDs indicate there is a fault

present within that module.

The Ops Panel also incorporates an Audible Alarm to indicate when a fault state is present and also an

Alarm Mute push-button.

Warning The Ops Panel is an integral part of the enclosure chassis assembly and can only be replaced by

trained personnel.

Figure 1–11 Anti-tamper Lock

Introduction

11

1.5 Installing your X24 Subsystem

Please refer to the RS-1600-X24 Getting Started Manual (P/N 44521-01A) for information on

how to install your RS-1600-X24 Enclosure and plug-in modules into an industry standard 19 inch rack

cabinet.

1.6 RS-1600-X24 Technical Specification

1.6.1 Dimensions

Rack Enclosure

Height 134mm, Width 446mm, Depth 511mm

Tower Enclosure

Height 501mm, Width 230mm (including mounting feet), Depth 511mm

Note It is recommended that a rack with a depth of no less than 700mm is used with this product.

1.6.2 Weight

1.6.3 AC Power (450W PSU)

Maximum Configuration Rack mount:

Tower:

37kg (81lb)

40kg (88lb)

Empty Enclosure (Rack) 9kg (19.8lb)

PSU/Cooling Module 4kg (8.8lb)

LRC I/O Module 1.5kg (3.11lb.)

Tower Conversion Kit 3kg (6.6lb)

Voltage Range 100-120 / 200-240 VAC Rated

Voltage Range Selection Automatic

Frequency 50/60 Hz

Inrush Current 50A @ 260VAC

Power Factor >0.98

Harmonics Meets EN61000-3-2

RS-1600-X24 User Guide

12

1.6.4 PSU Safety and EMC Compliance

1.6.5 Power Cord

(minimum requirements)

1.6.6 Environment

Safety Compliance

UL 60950

IEC 60950

EN 60950

EMC Compliance CFR47 Part 15B Class A

EN55022

EN55024

Cord Type SV 0r SVT, 18 AWG minimum, 3 conductor

Plug 250V, 10A

Socket IEC 320 C-14, 250V, 15A

Table 1–2 Ambient Temperature and Humidity

Temperature Range Relative Humidity Max. Wet Bulb

Operational 5°C to 40°C 20% to 80%

non-condensing

23°C

Non-Operational 0°C to +50°C 8% to 80%

non-condensing

27°C

Storage 1°C to +60°C 8% to 80%

non-condensing

29°C

Shipping -40°C to +60°C 5% to 100%

non-precipitating

29°C

Altitude, Operational 0 to 3047 m (0 to 10,000ft)

Altitude, Non-Operational -305 to 12,192m (-1000 to 40,000ft)

Shock, Operational Vertical axis 5g peak 1/2 sine, 10ms

Shock, Non-Operational 30g 10ms 1/2 sine

Vibration, Operational 0.21grms 5-500 Hz Random

Vibration, Non-Operational 1.04grms 2-200 Hz Random

Vibration, Relocation 0.3g 2-200 Hz sine

Introduction

13

1.6.7 Interfaces

1.6.8 Drive Carrier Module Specification

Please contact your supplier for details of approved drives.

Important Operating the RS-1600-X24 Subsystem with non-approved drives may invalidate the warranty.

Acoustics Less than 6.0 B LwA - operating at 20°C

Orientation & Mounting 19" Rack mount (3EIA Units)

• Rack Rails To fit 800mm depth Racks compliant with IEC 297

• Rack Characteristics Back pressure not exceeding 5 pascals (0.5mm water gauge)

Safety & Approvals CE, UL, cUL

• EMC EN55022 (CISPR - A), FCC A

Drive support See drive carrier specification

Attachment • 1 FC-X24 quad loop of 8 drives

Passive Backplane with 2 Loop Resiliency Circuit (LRC) I/O Module.

SFP HSSDC-2 cables Maximum external cable length: 10m

SFP optical cables Maximum daisy chain cable length:

see SFP manufacturer’s specification.

Expansion SFP Cable length: as above

Module Dimensions Height 29.1mm Width 106.55mm Depth 207mm

Weight 0.88kg (1.0” 36Gb drive)

Operating

Temperature

5° C to 40° C (when installed in an RS-1600 system enclosure with dual Power

Supply/Cooling Modules)

Power Dissipation 18.7 Watts maximum

RS-1600-X24 User Guide

14

1.6.9 X24 FC-AL LRC I/O Module Specification

1.6.10 RAID Card

1.6.11 Software Enclosure Services (SES) Support

The enclosure has a sophisticated self-monitoring and reporting function which conforms to ANSI SES

specifications.This reports on such topics as:

– Enclosure temperature

– Fan speed

– Drive condition

– Operator panel status

– RAID controller status: Not Ready, Partner Fail and Partner Present outputs

For more information on the implementation of this function please request a copy of the SES

specification from your supplier.

LRC-X24 Speed 2Gb

• Creates connections to 2 x 8 drive mode dual loop structures

• 2 external Expansion ports, SFP connectors

• 2 Host SFP ports

• 1 Ethernet port

Mounting Rear, single bays 3 and/or 4 (see Figure 1–3)

Connectors • 2 x SFP module LC optical, max. cable length 500m, or,

• 2 x Copper HSSDC-2 connector, max. cable length 6m.

• 1 x RJ42 Ethernet connector

• 1 x RS232, 6 pin Mini-DIN (factory use only)

Battery Backup Li-ion Battery, Hold up time for RAID cache:

– 512Mb: 72 hours (worse case)

LED Functions

• Host Port 0 Signal Good Green

• Host Port 1 Signal Good Green

• Expansion Port 0 Rx Good Green

• Expansion Port 1 Rx Good Green

• ESI/LRC module fault LED Amber

• Cache Active Green

• RAID Controller Ready Green

• Battery Fault Amber

Power Dissipation 5A @ 3.3V

7.4A @ 5V

RAID Integrated Fibre - Fibre controller

600k Hrs MTBF

LRC & ESI Function 1.2 MHz

Memory 512Mb - 1Gb (planned)

Operation

15

Chapter 2

Operation

2.1 Before You Begin

Before powering up your RS-1600-X24 enclosure please ensure that all the modules are firmly seated in

their correct bays.

2.2 Power On

Do not operate the Subsystem until the ambient temperature is within the specified operating range. If

the drives have been recently installed ensure they have had time to acclimatize before operating them.

Note Please refer to Section 2.3 for details of the Ops Panel LEDs and related fault conditions.

Follow the procedure below to po we r up the enclosure.

1 Apply AC Mains power to the enclosure. Turn the Power Supply/Cooling modules to ON.

2 On the Ops Panel, the Audible Alarm beeps once, all LEDs flash for 7 seconds then the Alarm double

beeps.

3 All LEDs on the Ops Panel should be lit (Green) when the enclosure power is activated (and the disk drive

motors should start).

Note All LEDs on the Ops Panel should be lit Green at power up to indicate that the system is functioning

correctly. If any show Amber then a problem exists and the procedure in Chapter 4 , ”System Status”, on

page 33 should be followed.

Important If mains power is lost for any reason, on restoration of power the enc lo sure will re-start

automatically.

RS-1600-X24 User Guide

16

2.2.1 Power Supply/Cooling Module LEDs

The Power Supply/Cooling module incorporates 4 LEDs, located below the On/Off switch and shown in

Table 2–1.

• Under Normal conditions the LEDs should all be illuminated constant GREEN

• If a problem is detected the color of the relevant LED will change to AMBER.

2.3 Ops Panel LEDs

The Ops Panel LEDs fault and status conditions are defined in Table 2–2 and shown in Figure 2–1.

Table 2–1 PSU LEDs

PSU Good Green

AC input Fail Amber

Fan Fault Amber

DC Output Fail Amber

Figure 2–1 Ops Panel LEDs and Switches

Operation

17

Please refer to Chapter 7, ”Troubleshooting and Problem Solving”, on page 59 for details of any fault

indication.

Table 2–2 Ops Panel LED States

Ops Panel LEDs Other Associated

LEDs or Alarm

State Description

Power

(Green)

PSU/

Cooling/

Temp

(Amber)

System

(Amber)

Address

Mode

Error

(Amber)

FC-X24

Loop

Speed

On Off Off Off Off 5V Aux present, overall power failed

On On On On On single beep, then

double beep

Ops Panel power On (5s) test state

On Off Off Off Power On, all functions good

On On Off PSU LEDs or Fan

LEDs

Any PSU fault or Fan fault

On On Flash Over or Under temperature

On Off On ESI LED on LRC ESI processor A Failed

On Off On ESI LED on LRC ESI processor B Failed

On Off On None • Unknown (invalid or mixed)

LRC module type installed, or

• I2C Bus Failure (inter ESI

processor), or

• Backplane autostart watchdog

failed.

On Flashing Flashing PSU Removed PSU removed and System power

redundancy check option set. No

indication if option not set.

On Off Flashing No SES Drives fitted

On Flashing On Intermittent

audible alarm

Ops to ESI Communications failed

On Flashing Invalid address mode setting

(change thumb wheel to valid

ranges)

On On 2Gb FC-X24 Drive loop speed

selected

On RAID ONLY

Host side

RS-1600-X24 User Guide

18

2.4 St arting the Drives

All drives in the enclosure should automatically start their motors. If this has not occurred there may be a

power problem (an alarm and power fault indication would normally be active). if there is only one Power

Supply/Cooling Module present, the drive motors will spin up in a delayed sequence.

2.4.1 Disk Drives LEDs

Each drive carrier incorporates two indicators, an upper (GREEN) and lower (AMBER). In normal

operation the Green LED will be ON and will flicker as the drive operates.

2.5 Power Up/Down

Power Up

Ensure all JBOD enclosures are powered up prior to powering on the X24 enclosure.

Power Down

Ensure the X24 enclosure is powered down prior to powering down the JBOD enclosures.

To power the Enclosure down,

either

• Switch off the Power Supply/Cooling modules installed in the Enclosure.

or

• Remove AC Mains at the power source

RAID Management

19

Chapter 3

X24 RAID Management

3.1 Managing Arrays and Partitions

Using SAM

Using SAM, you can manage arrays and partitions. You can perform the following array-related functions:

• Manage arrays (see page 20)

– View array and drive status (see page 20)

– View and reset array statistics (see page 21)

– Verify an array (see page 22)

– Change array owner (see page 23)

– Change the array name (see page 23)

– Trust an array (see page 23)

– Delete an array (see page 24)

• Manage partitions (see page 25)

– View partition status information (see page25)

– Change a partition name (see page 25)

– Change a partition LUN (see page 26)

– Control partition access (see page 27)

– Change a partition’s read-ahead cache size (see page 30)

– Delete a partition (see page 31)

• The X24 Subsystem Getting Started Guide describes the following array and partition functions:

•Arrays

– Creating an array

– Stopping the array initialization process

– Reconstructing an array

– Expanding array capacity

RS-1600-X24 User Guide

20

• Partitions

– Adding a partition

– Expanding a partition

• Managing spares

3.2 Managing Arrays

SAM lets you manage your arrays in a variety of ways. You can:

• View array and drive status (see page 20)

• View and reset array statistics (see page 21)

• Verify an array (see page 22)

• Change array owner (see page 23)

• Change the array name (see page 23)

• Trust an array (see page 23)

• Delete an array (see page 24)

3.3 Viewing Array and Drive Status

Information

Array status information is available from many pages in SAM. The top panel on all Disk Array Config and

LUN Management pages displays an icon for each array with information about the array below it.

In this top panel, critical arrays display a blinking, red, exclamation mark through the array. If a utility is

running on the array, the percent complete displays. If any array is critical for any reason other than

initializing or reconstructing, you should review the status information and take the appropriate action,

such as replacing a disk drive. For more information about the array icons, refer to the Understanding the

Array Icons section of the X24 Subsystem Getting Started Guide.

More detailed array and drive information is available from three pages (for information about the fields

on each page, click the Page Help icon):

• Monitor X24 Subsystem > Status > Storage Array Status—includes status information for the

selected array and its disk drives and partitions.

• Manage X24 Subsystem > Disk Array Config—includes array status information for the selected

array.

• Manage X24 Subsystem > Disk Array Config > Disk Drive Status—inclu des disk drive status

information for the selected array.

RAID Management

21

3.3.1 Viewing Array and Partition St atistics

You can view the current array and partition rate and cumulative statistics. The following statistics are

available:

• Rate statistics

– I/O operations per second (IOPS)

– Bandwidth (in millions of bytes per second)

• Cumulative statistics

– Number of read operations

– Number of write operations

– Number of sectors (512 bytes) read

– Number of sectors written

– Current command queue depth for each host port

– I/O size for each host port

– Host read/write histogram that shows how many host reads and writes fell into a particular size

range. The I/O ranges are based on powers of two.

Tip: This information may be helpful in interpreting performance based on individual system configuration

such as HBA, driver configuration, SAN configuration, and host operating system configuration. The

statistical information can be useful to profile applications and their usage of an array and partition, which

could be used to determine if additional arrays would increase performance and what RAID level is

applicable to your needs. You may want to analyze the performance of the same application using

different RAID levels to determine which level gives you the best performance. See Appendix A , ”Array

Basics”, on page 89 for more de tails on RAID levels.

Note The statistics are provided as general information for your use, however, they are not intended for

benchmarking purposes.

Similar statistics are also available on an aggregate basis for all arrays. For more information, see.

To view the rate statistics:

• From SAM, select Monitor X24 Subsystem > Statistics > Partition Rate Stats.

To view the cumulative statistics:

• From SAM, select Monitor X24 Subsystem > Statistics > Cumulative Part Stats.

3.3.1.1 Resetting All Statistics

You can reset the following array and partition statistics to zero:

• Read

•Write

•SecRd

•SecWt

• I/O Size

Note Resetting statistics here resets all statistics for the X24 Subsystem.

You may want to reset the statistics if you are monitoring performance. You may also want to reset

statistics when you change how you are using a partition.

RS-1600-X24 User Guide

22

Note You cannot reset the queue depth value. It always reflects the current I/O queue depth.

To reset all statistics:

1 From SAM, select Monitor X24 Subsystem > Statistics > Reset All Statistics.

The Reset All Statistics page displays.

2 Click Reset Statistics.

The system confirms that you want to make the change.

3.3.2 V erifying an Array

The Verify function allows you to verify the data on redundant arrays (RAID 1, RAID 3, RAID 4, RAID 5,

RAID 10, and RAID 50):

• RAID 3, RAID 4, RAID 5, and RAID 50: Verifies all parity blocks in the selected array and corrects

any bad parity.

• RAID 1 and RAID 10: Compares the primary an d secondary drives. If a mismatch occurs, the

primary is copied to the secondary.

You may want to verify an array when you suspect there is a problem.

To verify an array:

1 From SAM, select Manage X24 Subsystem > Disk Array Config > Verify Array.

The Verify Array page displays with a list of existing arrays.

2 Select the array you want.

3 Click Verify & Update Array Parity.

Verification begins and the percentage of verification completed displays. You can contin ue to use the

array during verification.

To check the progress of the verification, select Manage X24 Subsystem > Disk Array Config > Array

Utility Progress or any item from the Disk Array Config menu. The status of the verification displays in

the list of arrays.

3.3.2.1 Stopping the Array Verification Process

You can stop the array verification process.

Note If you stop the verification process, you cannot resume. You must restart from the beginning.

To stop the array verification process:

1 From SAM, select Manage X24 Subsystem > Disk Array Config > Abort an Array Utility.

The Abort an Array Utility page displays with a list of existing arrays.

2 Select the array you want.

RAID Management

23

3 Click Abort Array Verification.

3.3.3 Changing Array Ownership

You can change the ownership of any array between the SMs. When you create an array, SAM

automatically selects the owner and balances the number of arrays each SM owns. You can select the

array owner when you create an array by clicking Advanced Options from the third Create Array page.

In most situations, which SM owns the array does not matter. A single SM owns arrays and dedicated

spares. When a SM fails, the other SM assumes temporary ownership of its resources.

Note When you change the ownership of an array, the LUNs assigned to the array’s partitions become invalid.

After changing ownership, you must assign a new LUN to each array partition.

To change array ownership:

1 From SAM, select Manage X24 Subsystem > Disk Array Config > Change Array Owner.

The Change Array Owner page displays with a list of existing arrays.

2 Select the array you want.

The Change Array Owner drop-down list shows the current owner.

3 Select the other SM from the drop-down list.

4 Click Change Array Owner to Storage Manager X (where X is the other SM).

5 Assign a new LUN to each array partition.

See section 3.4.3 on page 26.

3.3.4 Changing an Array Name

You can change the name of an array. This does not affect the target ID or LUN values of the array. The

X24 Subsystem does not allow you to change an array name when a utility is running.

To change an array name:

1 From SAM, select Manage X24 Subsystem > Disk Array Config > Change Array Name.

The Change Array Name page displays with a list of existing arrays.

2 Select the array you want.

3 Enter a new name.

You can use up to 20 characters. You can use any character on your keyboard (any printable ASCII

character), except double quotes (").

4 Click Change Array Name.

3.3.5 Trusting an Array