Page 1

Owner's Manual

Split Type Wall-mounted Air Conditioner

Model:

Thank you for choosing our product.

For proper operation, please read and keep this manual carefully.

If you have lost the Owner’s Manual, please contact the local agent or

visit www.impecca.com for an electronic version.

ISMO-1821

v

. 1.1

Page 2

In line with the company

’s policy of continual product improvement, the aesthetic and dimensional

characteristics, technical data and accessories of this appliance may be changed without notice.

CONTENTS

Conformity And Range

The Instructions Before Use

Name of Parts

Technical Data

GENERAL

INFORMATION

Outdoor Unit Working Temperature Range

Electrical Connections

Installing The Outdoor Unit

Bleeding

Maintenance

Installation Dimension Diagram

INSTALLER

Check After Installation

GENERAL INFORMATION

1

2

3

4

4

5

8

6

7

7

8

The products in this manual may be different with the rea one, according to different models, l

some models have displayer and some models without displayer, the position and shape of

the displayer please refer to the real one.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Children should be supervised to ensure that they do not play with the appliance.

This marking indicates that this product should not be disposed with other

household wastes throughout the EU. To prevent possible harm to the

environment or human health from uncontrolled waste disposal, recycle

it responsibly to promote the sustainable reuse of material resources. To

return your used device, please use the return and collection systems or

contact the retailer where the product was purchased. They can take this

product for environmental safe recycling.

Page 3

Explanation of Symbols

Indicates a hazardous situation that, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation that, if not avoided, could result in death

or serious injury.

Indicates a hazardous situation that, if not avoided, may result in minor

or moderate injury.

Indicates important but not hazard-related information, used to indicate

risk of property damage.

Indicates a hazard that would be assigned a signal word

WARNING or CAUTION.

CONFORMITY AND RANGE

Please read this owner's manual carefully before operating the unit and keep it carefully for consultation.

Instructions for installation and use of this product are provided by the manufacturer.

Only use the air conditioner as instructed in this booklet. These instructions are not intended to

cover every possible condition and situation. As with any electrical household appliance, common sense

and caution are therefore always recommended for installation, operation and maintenance.

GENERAL INFORMATION

1

Page 4

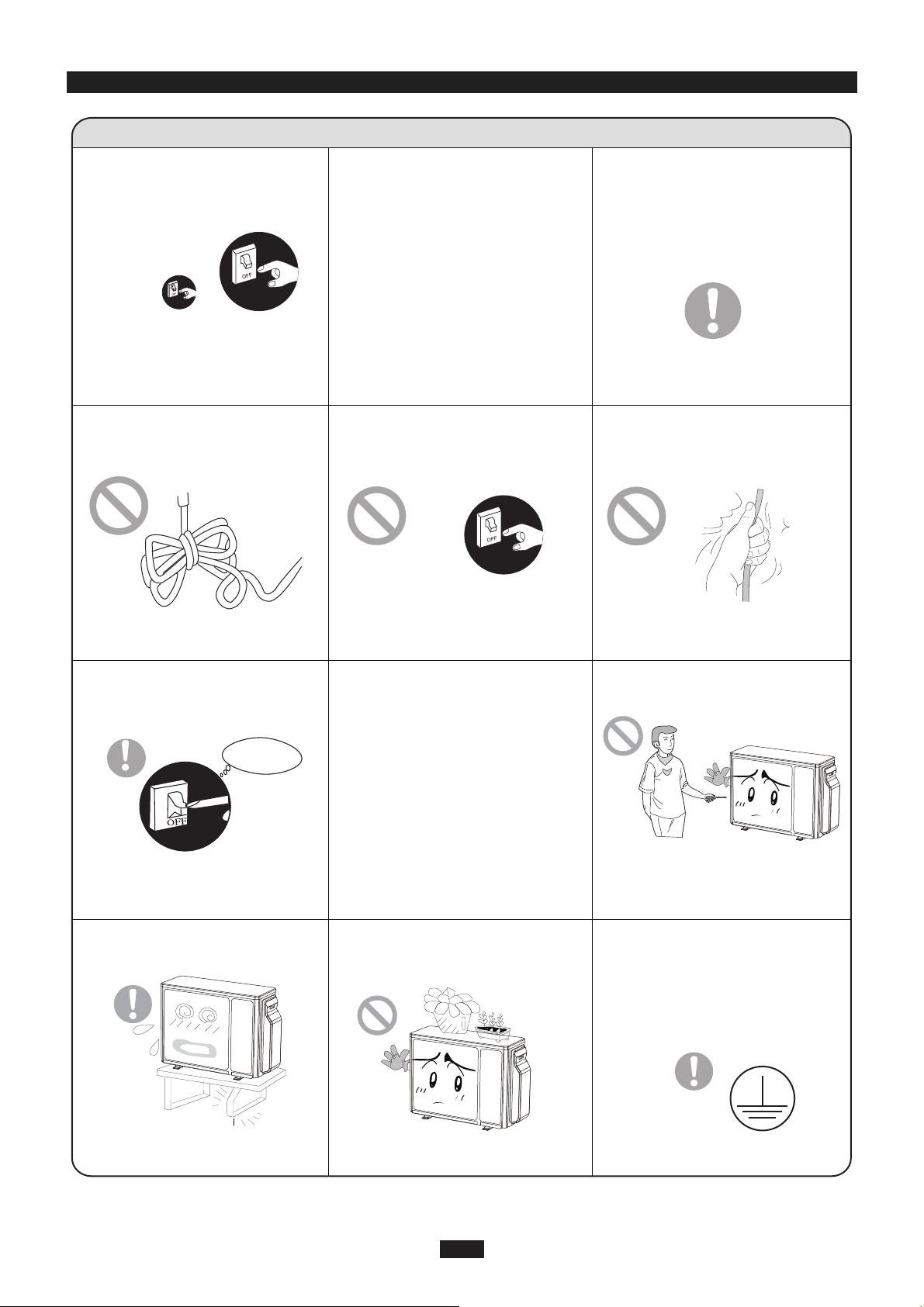

THE INSTRUCTIONS BEFORE USE GENERAL INFORMATION

WARNING

When having a burning smell or

★ ★

smoke,please turn off the power

supply and contact with the service center.

If the abnormity still exists,the unit

may be damaged,and may cause

electric shock or fire.

Power must adopts the special

★

circuit to prevent fire.

Otherwise, it can cause electric

shock or fire.

★ ★

Otherwise,the accumulated dusts

may cause overheating or fire.

The power supply must adopt the

special circuit that with air switch

protection and assure it has enough capacity.The unit will be turned

on or off according to your requirement automatically,please do not

turn on or turn off the unit frequently,otherwise disadvantage effect

may be caused to the unit.

Disconnect the power supply if

long putting the air conditioner

out of use.

Never cut off or damage power

★

cables and control wires. If the

power cable and signal control

wire were damaged, change

them by professional.

Never damage the electric wire

or use the electric wire which is

not appointed.

Otherwise,it will cause overheating

or fire.

When cleaning,it is necessary

★ ★

to stop driving and turn off the

power supply.

Cut off power supply

Otherwise,it may cause electric

shock or damage.

Please note whether the insta-

★ ★

lled stand is firm enough or not.

Rated voltage of this air conditioner 220-240V, 60Hz, The compressor will vibrate sharply if the

voltage is too low, resulting in

damage to refrigerating system.

Electrical component are easy to

damage if the voltage is too high.

Don't step on the top of the

outdoor unit or place something

on it.

Don't attempt to repair the air

★

conditioner by yourself.

The wrong repair will lead to an

electric shock or fire,so you should

contact the service center to repair.

Earthing: The unit must be reli-

★

ably earthed.The earthing cable

shall be connected to the special earthing device in the construction.

If it is damaged, it may lead to the

fall of the unit and cause the injury.

As falling off the outdoor unit can be

dangerous.

2

Page 5

NAME OF PARTS

GENERAL INFORMATION

WARNING

Be sure to cut off the power supply before cleaning the air conditioner; otherwise electric

shock might happen.

Wetting of air conditioner may cause the risk of electric shock. Make sure not to wash

your air conditioner in any case.

Volatile liquids such as thinner or gasoline will cause damage to the appearance of air

conditioner. (Only use soft dry cloth moist cloth clean the air conditioner cabinet).

This product must not be disposed together with the domestic waste.

This product has to be disposed at an authorized place for recycling of electrical and

electronic appliances.

The temperature of refrigerant circuit will be high,please keep the interconnection cable

away from the copper tube.

1

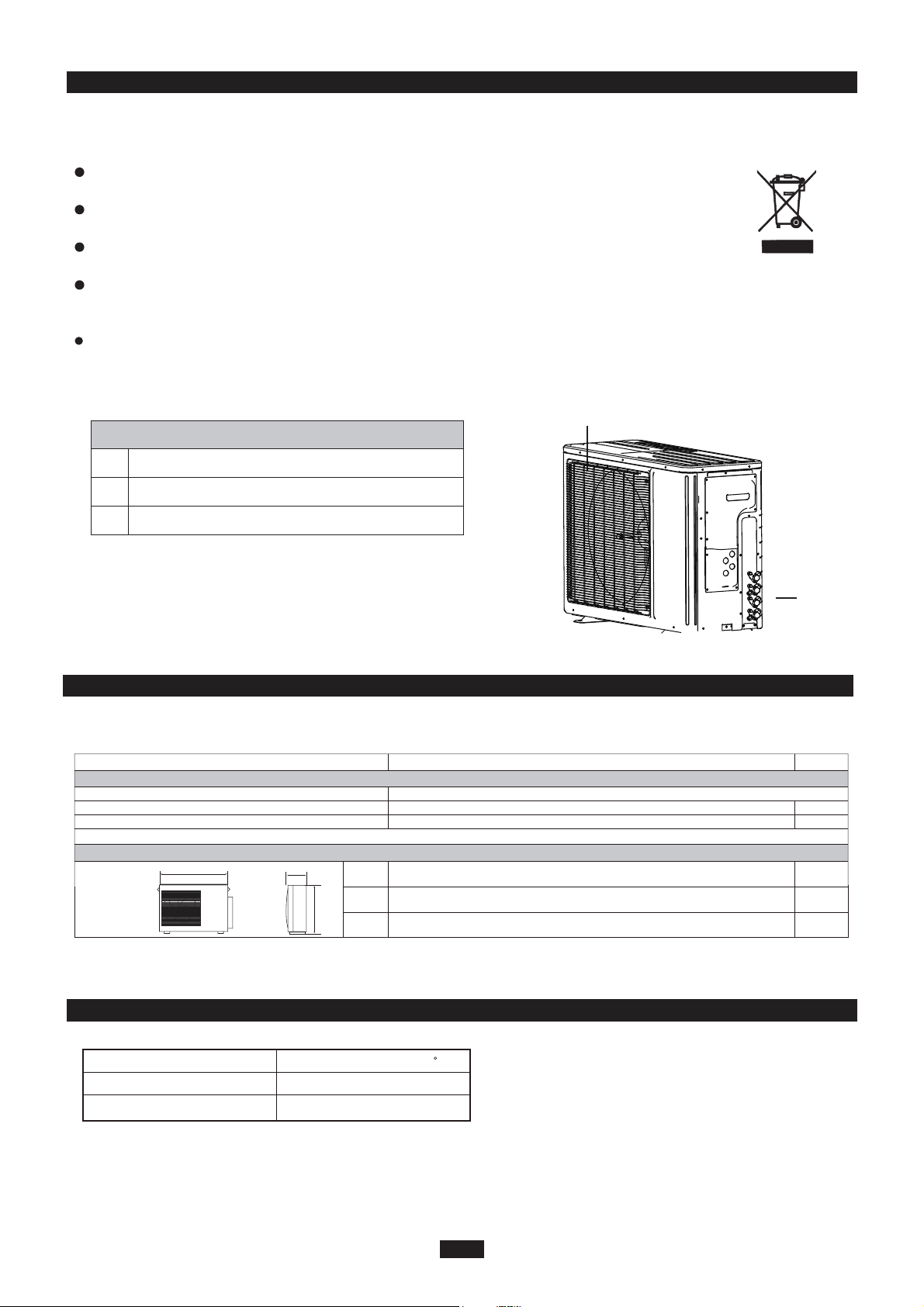

OUTDOOR UNIT

No. Description

1 Air outlet grille

2 Valve

Note: The above figures are only intended to a simple

diagram of the appliance and may not correspond to the

appearance of the units that have been purchased.

2

TECHNICAL DATA GENERAL INFORMATION

MODE

Electrical data

Electricity supply

Fuse or air switch

Minimum power cord section

Size and clearance

L

P

L

P

H

H

ISMO-1821

208/230V,60HZ

20

2.5

890

362

700

mm

mm

mm

mm

2

OUTDOOR UNIT WORKING TEMPERATURE RANGE GENERAL INFORMATION

OutdoorsideDB/WB(c)

Maximum cooling

Maximum heating

48/27/-

3

Page 6

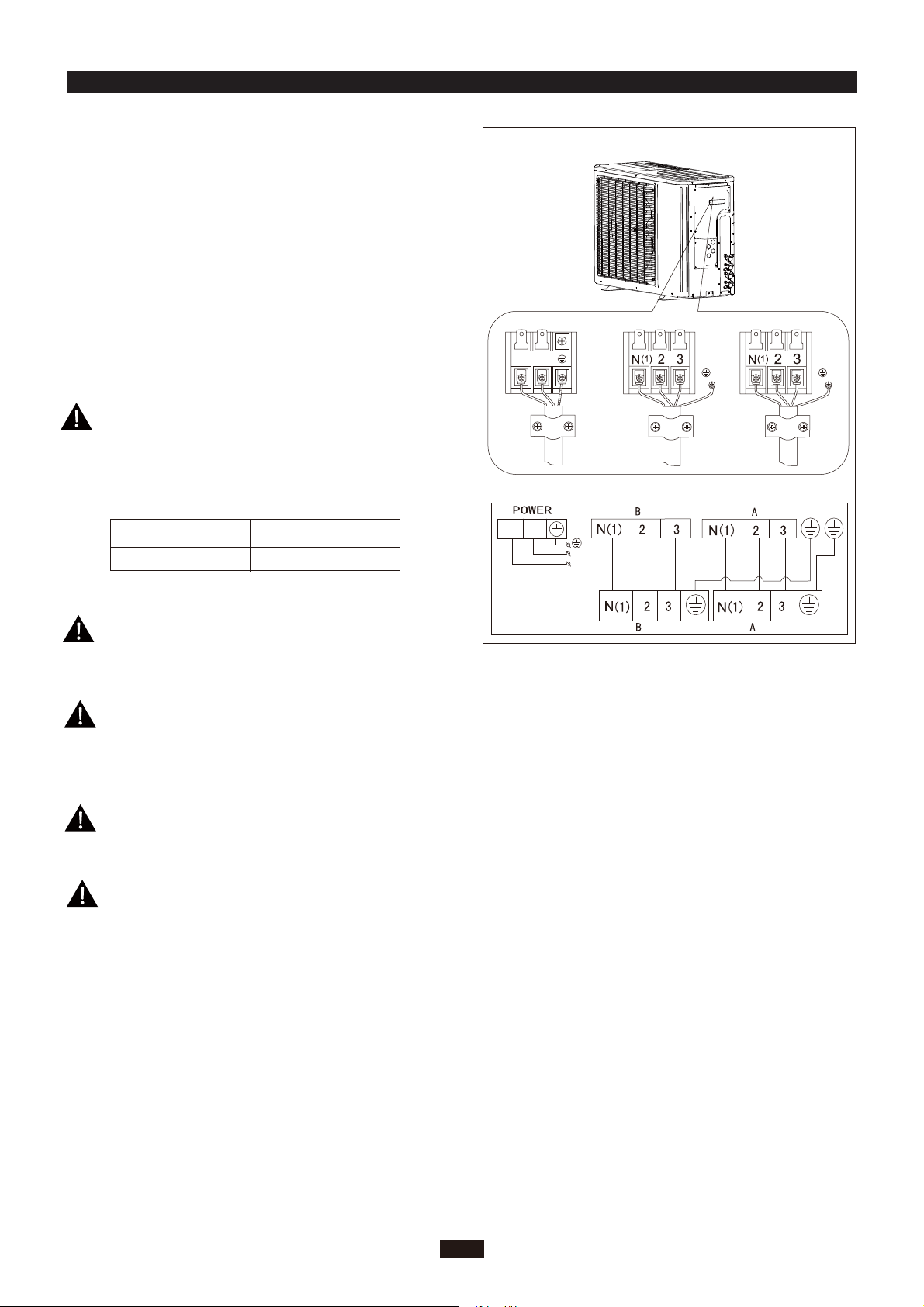

ELECTRICAL CONNECTIONS

1. Remove the handle at the right side plate of the outdoor

unit (one screw).

2. Remove the cable clamp, connect the power connection

cable with the terminal at the row of connection and fix

the connection. The fitting line distributing must be

consistent with the indoor unit. terminal of line bank.

Wiring should meet that of indoor unit.

3. Fix power connection wire by wire clamp.

4. Ensure wire has been fixed well.

To unit A

INSTALLER

To unit B

5. Install the handle.

Including an air switch with suitable capacity,

please note the following table. Air switch

should be included magnet buckle and heating

buckle function, it can protect the circuit-short

and overload. (Caution: please do not use the

fuse only for protect the circuit)

Air switch capacityAir-conditioner

ISMO-1821

25A

An all-pole disconnection switch having a contact

separation of at least 3mm in all pole should be

connected in fixed wiring.

Wrong wire connection may cause malfunction of

some electric components.After fixing cable, ensure

that leads between connection to fixed point have

some space.

L1

L1 L2

L2

Power cord

connecting

cable

L2

L1

connecting

cable

To the power supply

The connection pipes and the connectiong wirings

of the unit A and unit B must be corresponding to

each other respective.

The appliance shall be installed in accordance with

national wiring regulations.

Note: the above figures are only intended to be a simple

diagram of the appliance and may not correspond to the

appearance of the units that have been purchased.

4

Page 7

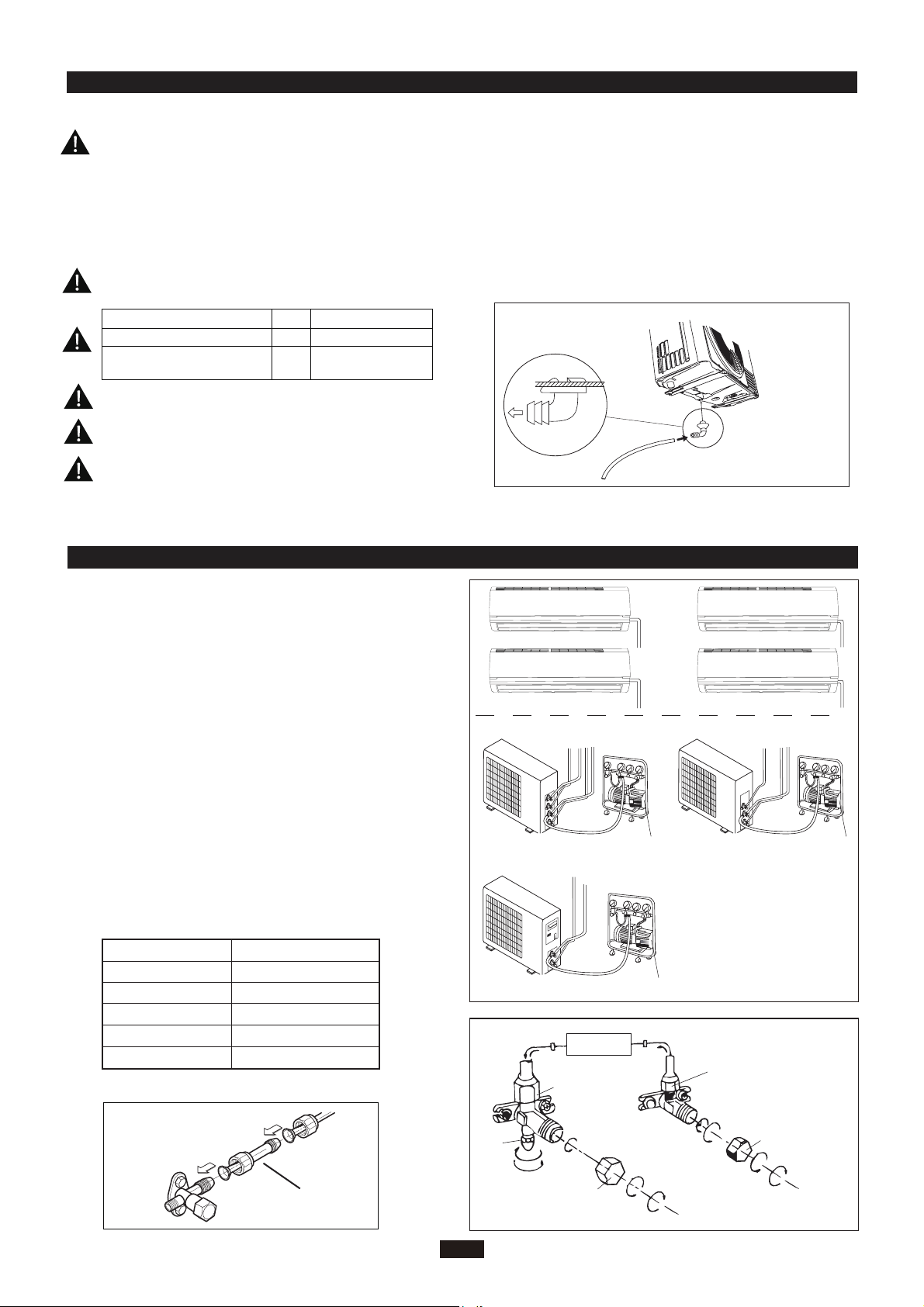

INSTALLING THE OUTDOOR UNIT INSTALLER

Location

Use bolts to secure the unit to a flat, solid floor.

When mounting the unit on a wall or the roof, make

sure the support is firmly secured so that it cannot

move in the event of intense vibrations or a strong

wind.

Do not install the outdoor unit in pits or air vents

●

Installing the pipes

Use suitable connecting pipes and equipment for

the refrigerant R410A.

Model(m) 1821x2

Max. connection pipe length

Max. connection pipe length

(Simple one indoor unit)

The refrigerant pipes must not exceed the maximum

heights 5m(1821K).

Wrap all the refrigerant pipes and joints.

Tighten the connections using two wrenches wor-

king in opposite directions.

Caution: Installation Must be Performed in Accordance

with the NEC/CEC by Authorized Personnel Only.

20

10

Install the drain fitting and the drain hose

(for model with heat pump only)

Condensation is produced and flows from the outdoor unit when the appliance is operating in the

heating mode. In order not to disturb neighbours

and to respect the environment,install a drain fitting

and a drain hose to channel the condensate water.

Install the drain fitting and rubber washer on the

outdoor unit chassis and connect a drain hose to it

as shown in the figure.

BLEEDING INSTALLER

Humid air left inside the refrigerant circuit can cause compressor malfunction. After having connected the indoor

and outdoor units, bleed the air and humidity from the

refrigerant circuit using a vacuum pump.

(1) Unscrew and remove the caps from the 2-way and 3-

way valves.

(2) Unscrew and remove the cap from the service valve.

(3) Connect the vacuum pump hose to the service valve.

(4) Operate the vacuum pump for 10-15 minutes until an

absolute vacuum of 10 mm Hg has been reached.

(5) With the vacuum pump still in operation, close the

low-pressure knob on the vacuum pump coupling.

Stop the vacuum pump.

(6) Open the 2-way valve by 1/4 turn and then close it

after 10 seconds. Check all the joints for leaks using

liquid soap or an electronic leak device.

(7) Turn the body of the 2-way and 3-way valves. Discon nect the vacuum pump hose.

(8) Replace and tighten all the caps on the valves.

Diameter (mm)

Φ9.52

Φ16

Φ12

Φ19

Twisting moment (N.m)

15-20Φ6

35-40

60-65

45-50

70-75

18K unit need to be installed the indoor unit

18K MODE:

conversion joint

Service

inlet

(2)Turn

(8) Secure

Refrigerant fluid di

3-way valve

Vacuum pump Vacuum pump

Vacuum pump

INDOOR

UNIT

rection of fiow

(7)Turn to open fully

Valve cap

(8) Secure

2-way valve

(6) Open by 1/4 turn

(7)Turn to open fully

(2)Turn

alve cap

V

(2)Turn

(8) Secure

Connect to the

indoor unit

5

Page 8

MAINTENANCE INSTALLER

Use suitable instruments for the refrigerant R410A.

Do not use any other refrigerant than R410A.

●

Do not use mineral oils to clean the unit.

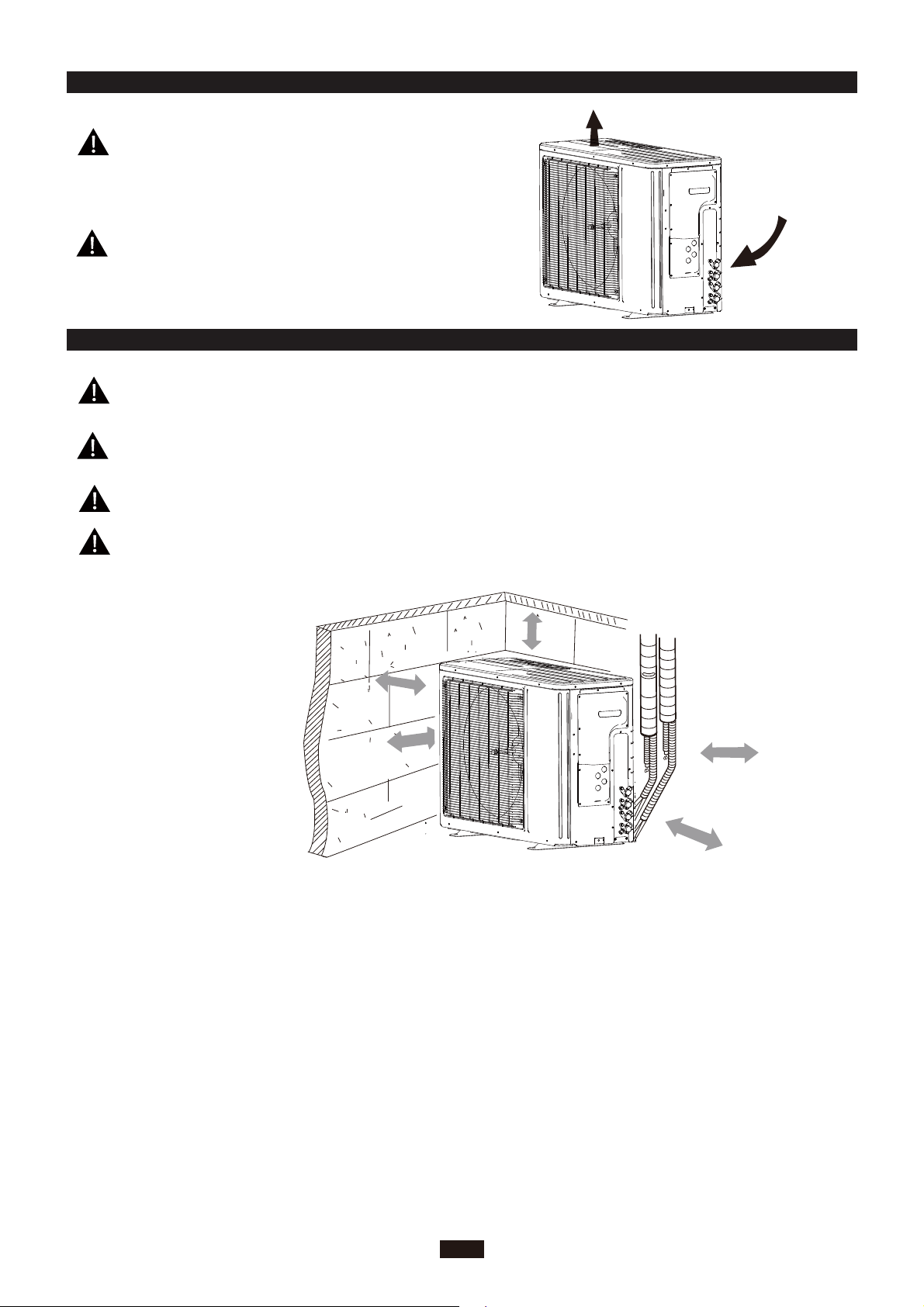

INSTALLATION DIMENSION DIAGRAM INSTALLER

The installation must be done by trained and qualified service personnel with reliability according to this

manual.

Contact service center before installation to avoid the malfunction due to unprofessional installation.

When picking up and moving the units, you must be guidedby trained and qualified person.

Ensure that the recommende dspace is left around the appliance.

50c

Space to the cover

or above

30cm

Space to the cover

or above

200cm

(Air outlet side)

m

or more

30cm

(Air inlet side)

50cm

Space to the wall

or above

or above

6

Page 9

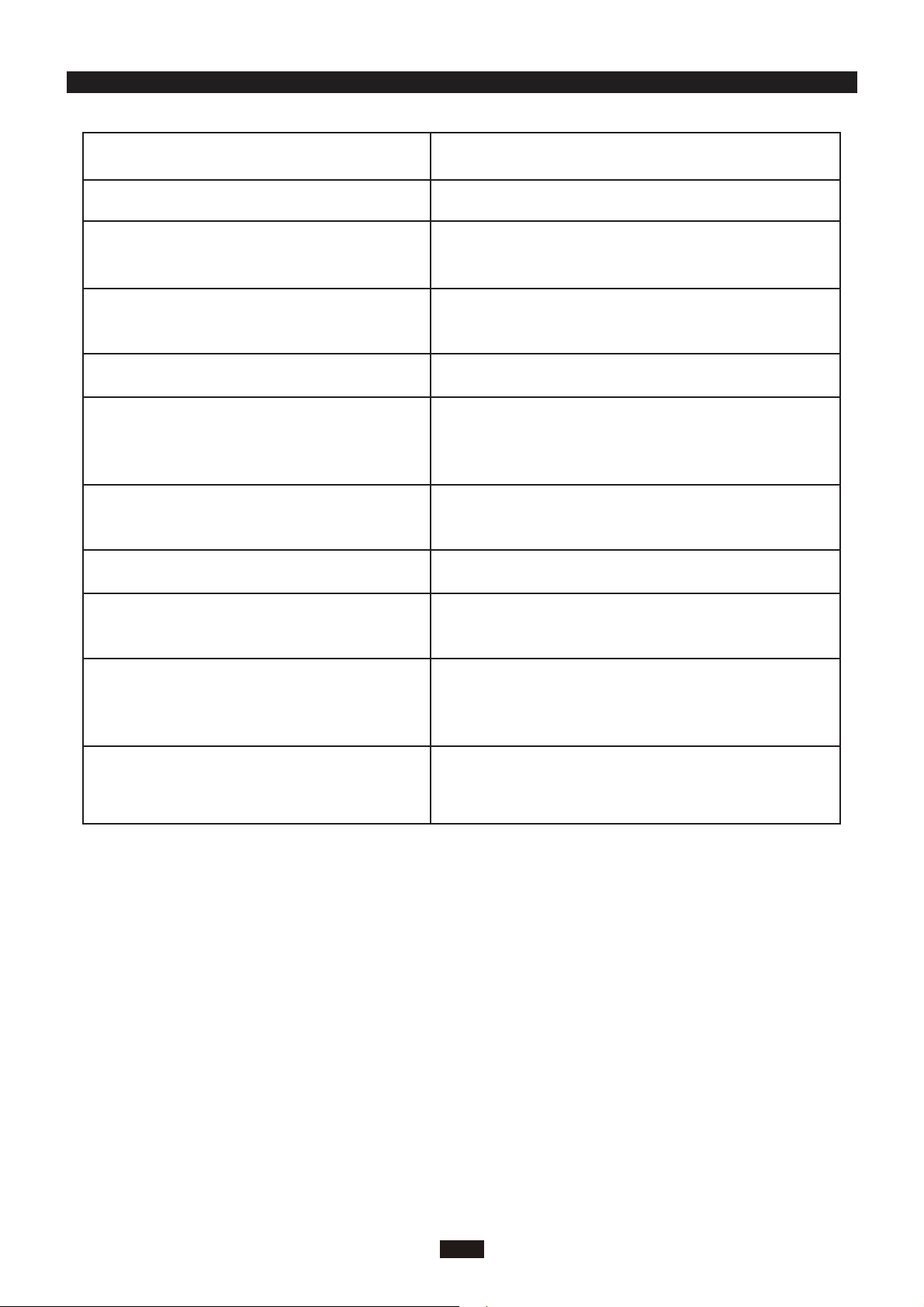

CHECK AFTER INSTALLATION INSTALLER

Check Items

Is the installation reliable?

Has the gas leakage been checked?

Is the thermal insulation of the unit

sufficient?

Is the drainage smooth?

Does the power supply voltage accord

with the rated voltage specified on the

nameplate?

Are the lines and pipelines correctly

installed?

Has the unit been safely grounded?

Problems Owing to Improper Installation

The unit may drop, vibrate or make noises

May cause unsatisfactory cooling (heating)

effect

May cause condensation and water dropping

May cause condensation and water dropping

The unit may bread down or the components

may be burned out

The unit may bread down or the components

may be burned out

Risk of electrical leakage

Are the models of lines in conformity

with requirements?

Are there any obstacles near the air

inlet and outlet of the indoor and outdoor units?

Have the length of refrigerating pipe

and refrigerant charge amount been

recorded?

The unit may bread down or the components

may be burned out

The unit may bread down or the components

may be burned out

It is not easy to decide the charge amount

of refrigerant.

7

Page 10

CUSTOMER S

Before contacting customer support, please see the troubleshooting guide above.

Visit our website to contact us, find answers to Frequently Asked Questions, and for other

resources which may include an updated version of this user's guide.

UPPORT

WWW.IMPECCA.COM

If you wish to contact us by phone, please be sure to have your model number and serial

number ready and call us between 9:00am and 6:00pm ET, at +1 866-954-4440.

Keep tabs on Impecca's newest innovations & enter contests via our social network feeds:

www.facebook.com/Impecca/

www.instagram.com/impecca/

@impeccausa

Page 11

Page 12

© 2016 Impecca, a division of LT Inc., Wilkes Barre, PA.

Page 13

Flex Series R410A GMV Multi VRF

Floor and Ceiling Type

Indoor Unit (For North America)

Owner's Manual

Commercial Air Conditioners

Models:

ISMI-FC18

ISMI-FC24

Thank you for choosing Commercial Air Conditioners, please read this

owner’s manual carefully before operation and retain it for future reference.

v 1.1

Page 14

User Notice

When installing, the entire capacity of the cooperating indoor unit should be not larger than

◆

150% of outdoor unit, otherwise, it will cause the shortage of cooling (heating) capacity.

The power supply of the entire unit must be the power supply of outdoor unit. And disconnect

◆

the main power of outdoor unit before cleaning.

In order to start up the unit successfully, the main power switch should be opened 8 hours

◆

before the operation.

After receiving the turn off signal, every indoor unit will continue to work for 20-70sec to

◆

make good use of the rest cool air or the rest heat air in the heat exchanger, which will prepare for

the next operation. And this is normal.

When the selected operating mode of the indoor unit is conflicted to the operating mode of

◆

the outdoor unit, 5 sec later, the malfunction hint will be shown on the indoor unit or wired controller,

then the indoor unit will stop. At this time, change the operating mode of the indoor unit to the one

that would not conflict with the outdoor operating mode to make the operation normal. The HEAT

mode conflicts with each of the COOL mode, DRY mode and FAN mode, while the COOL mode,

DRY mode and FAN mode are compatible between each other.

The appliance shall not be installed in the laundry. The appliance shall not be used by

◆

children without supervisor.

Power supply fluctuating range (+/-10%, +/-1Hz)

◆

Humidity range: 30%~95%.

◆

Main switch provided by end user: main switch handle should be black or gray, it can be

◆

locked in “OFF” position with padlock.

The main disconnection device should be installed at a height of 0.6~1.7m. Over current

◆

protection is required(UL 1995,CSA C22.2).

The cooling range of the unit is the outdoor ambient temp -5~48℃ DB, the heating range of

◆

the unit (only for the heat pump type unit) is the outdoor ambient temp. -15~27℃ DB.

This appliance is not intended for use by persons (including children) with reduced physical,

◆

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

This product must not be disposed together with the domestic waste. This product has

to be disposed at an authorized place for recycling of electrical and electronic appliances.

Thank you for selecting Impecca air conditioner. Before use, please read this

manual carefully and keep it properly for furthur reference.

Page 15

Contents

1 Safety Precautions .......................................................................................... 1

2 Installation Precautions and Location Choosing ............................................. 2

2.1 Installation Precautions ......................................................................................... 2

2.2 Location Choosing ................................................................................................ 2

2.3 Imappropriate Location ......................................................................................... 2

3 Installation of Floor and Ceiling Type Indoor Unit ............................................ 3

3.1 Space Dimension for Unit Installation ................................................................... 3

3.2 Important Notice .................................................................................................... 3

3.3 Installation Description .......................................................................................... 3

3.4 Electrical Wiring .................................................................................................... 6

3.5 Drainpipe Installation ............................................................................................ 7

3.6 Install the Connection Pipes ................................................................................. 8

4 Part Names of Floor and Ceiling Type Indoor Unit ........................................ 10

5 Working Temperature Range ......................................................................... 11

6 Maintenance Method ..................................................................................... 12

6.1 Cleaning the Air Filters ........................................................................................ 12

6.2 Cleaning the Unit ................................................................................................ 12

6.3 At the Start of the Season ................................................................................... 12

6.4 During the off Season ......................................................................................... 12

7 Operating Instructions ................................................................................... 13

8 Malfunction Analysis ...................................................................................... 15

8.1 Service Center ..................................................................................................... 15

8.2 After-sales Service ............................................................................................... 16

Page 16

Flex Series for North America

1 Safety Precautions

Please read this manual carefully before using this unit. Operate it correctly according to the

guide in this manual.

Please pay special attention to the indicating meaning of these two marks:

Warning! This mark means that the unit may cause property damage, personal injury or

loss of life if the operation is incorrect.

Caution! This mark means that the unit may cause minor or moderate property damage or

personal injury.

Warning!

The unit should be earthed reliably. Do not connect the earth line to the gas pipe, water pipe,

◆

drainage pipe or other unsafe places in potential.

Air conditioner must use special power supply circuit and switches for creepage protect and

◆

air with enough capacity should be installed in the circuit.

Ensure that the connecting of power cord is reliable, otherwise, electric shock or fire may

◆

happen.

Do not cut off the power supply when the unit is running, otherwise the lifetime of the unit will

◆

be shortened.

Do not damage wires or use the wires that are not recommended, otherwise, electric shock

◆

or fire may happen

Please don’t operate the unit with wet hands, or electric shock may happen.

◆

Do not put a finge , a rod or other objects into the air outlet or inlet to avoid of damage or

◆

injury.

Cut down the main power supply immediately if any abnormality happens (such as smell of

◆

fire etc.). Contact with the service center and consult the qualified technician

Do not repair or adjust the air conditioner by yourself. Please contact the service center or

◆

Impecca technicians for help.

Do not use the fuse with unsuitable capacity or iron thread instead of fuse, otherwise, it will

◆

cause malfunction or fire

Switch off the power supply of the unit before cleaning the air conditioner, otherwise, electric

◆

shock or damage may happen.

Please turn off the main power of the whole unit before cleaning the conditioner, otherwise

◆

electric shock or harm may be happened.

Chemical sprayer should be placed 1m or more away from the unit, otherwise fire or

◆

explosion may happen.

Do not block air inlets or outlets. Impaired air flow may result in insufficient performance or

◆

trouble.

1

Page 17

Flex Series for North America

2 Installation Precautions and Location Choosing

2.1 Installation Precautions

The installation of air conditioner must be conform to national and local safety

laws.

Installation quality will directly affect the normal use of air conditioner. Do not

attempt to install the air conditioner by yourself. Please contact your dealer after buying

this machine. Professional installation workers will provide installation and test services

according to installation manual.

Do not connect to power until all installation work is completed.

2.2 Location Choosing

Such a place where cool air can be distributed throughout the room.

*

Such a place where condensate water could be easily drained out.

*

Such a place that can handle the weight of indoor unit.

*

Such a place, which is easy for maintenance.

*

Such a place where is easy to get connected with the outdoor unit.

*

Such a place where is 1m or more away from other electric appliances such as television,

*

audio device, etc.

Avoid a location where there is heat source, high humidity or inflammable gas

*

Do not use the unit in the moist surroundings, such as a laundry, a bath, a shower or a

*

swimming pool.

Be sure that the installation conforms to the installation drawings.

*

2.3 Imappropriate Location

Where there is too much of oil.

*

Where it is acid base area.

*

Where there is irregular electrical supply.

*

2

Page 18

Flex Series for North America

3 Installation of Floor and Ceiling Type Indoor Unit

3.1 Space Dimension for Unit Installation

The space around the unit is adequate for ventilation. (Refer to Fig.1)

>1500

POWER

RUN

TIMER

>600

>300

>600

>1000

>600

>200

>600

>2300

>1500

>300

Fig.1

3.2 Important Notice

(1). The unit must be installed by the professional personnel according to this install instruction

to ensure the well use.

Please contact the local Impecca special nominated repair department before installation. Any

malfunction caused by the unit that is installed by the department that is not special nominated

by

Impecca would not deal with on time by the inconvenience of the business contact.

(2). It should be done by professional personnel when the air conditioner unit is moved to other

place.

3.3 Installation Description

Ceiling type

*

Floor type

*

These two types of units have similar installing procedure as follows:

(1). Determine the mounting position on ceiling or wall by using paper pattern to indicate indoor

frame. Mark the pattern and pull out the paper pattern.(Refer to Fig.2)

(2). Remove the return grill, the side panel and the hanger bracket from the indoor unit as per

procedure bellow.

Press the fixing knob of the air intake grills, the grilles will be opened wider and then pull

*

them out from the indoor.

Loosen the side panel fixing screw and remove the side panel. (Refer to Fig.3

*

Loosen two hanger bracket setting bolts (M8) on each side for less than 10mm. Remove two

*

hanger bracket fixing bolts (M6) on the rear side. Detach the hanger bracker by pulling it backward

3

Page 19

(Refer to Fig.5).

Flex Series for North America

Installation

paper plank

Fig.2 Fig.3

(3). Set the suspension bolt. (Use W3/8 or M10 size suspension bolts)

Adjust the distance from the unit to the ceiling slab beforehand. (Refer to Fig.4)

*

(4). Fix the hanger bracket to the suspension bolt.

Warning!

Make sure that extended suspension bolt from the ceiling stays inside the appointed

*

position. Readjust the hanger bracket when it is out of the appointed position. (Refer to Fig.6)

Suspension bolt is fixed in the cap of indoor unit. Never remove the cap

*

(5). Lift the unit and slide forward unit in place. (Refer to Fig.7)

(6). Screw tightly both hanger bracket-setting bolts (M8). (Refer to Fig.5)

(7). Screw tightly both hanger bracket-fixing bolts (M6) to prevent the displacement of the

indoor unit. (Refer to Fig.5)

(8). Adjust the height so that rear side of the drainpipe slightly inclines to improve drainage.

Caution!

Adjust the height by rotating the nut with a spanner.

*

Insert the spanner into the hanger bracket through the interspace. (Refer to Fig.8)

*

In case of hanging

It is possible to install hanger brackets by not removing the brackets from the indoor unit. (Refer

to Fig.9)

Only the specified accessories and parts for installation work could be used

Side panel fixing screw(M4)

4

Page 20

Flex Series for North America

40 or less

Hanger bracket

Celling

Suspension bolt

Fig.4

Celling slab

Hanger bracket

BOLT POSITION

INWARD

Hanger bracket

Hanger bracket

setting bolt(M8)

Hanger bracket

fixing bolt(M6)

Fig.5

Fig.6 Fig.7

Fig.9Fig.8

When installing the indoor unit, you can refer the paper pattern for installation. Make sure that

the drainage side must be 10mm lower than the other side in order to drain the condensate water

easily.

H

A

C

B

D

Unit:mm

5

Page 21

Flex Series for North America

Model A B H C D

ISMI-FC18

ISMI-FC24

1220 225 700 1158 280

3.4 Electrical Wiring

Caution:

The power of every indoor unit should be connected in outdoor unit.

①.

Open front panel.

②.

Remove the electrical box cover.

③.

Route the power connection cord from the back of the indoor unit and pull it toward the front

through the wiring hole upward.

④.

Put the 4-core cable through the hole of the chassis and the bottom of the appliance

upward, and then connect the power line and the communication line from the outdoor

unit to the corresponding terminals N(1), 2, 3 , and grounding terminal of the indoor unit.

Wiring shall be done properly as per the wiring diagram. (Note: Be sure the wring terminals

A/B/C/D and piping joints A/B/C/D of the indoor unit match with that of the outdoor unit

respectively).

⑤.

Reassemble the electrical box cover.

⑥.

Reinstall the front panel.

⑦.

Do not use copper tube at interconnection part as the temperature of refrigerant circuit is

high.

POWER

INDOOR UNIT D

INDOOR UNIT C

INDOOR UNIT B

INDOOR UNIT A

XT

XT XT2

OUTDOOR UNIT

6

L

N

Page 22

Flex Series for North America

INDOOR UNIT E

XT6

G

XT5

G

XT4

T CINDOOR UNIT D

OUTDOOR UNI

G

T

XT3

G

INDOOR UNIT AINDOOR UNIT BINDOOR UNI

XT2

G

L

XT1

POWER

N

Caution!

① .

The incorrect of wiring connection would lead malfunction of some of the electric parts.

② .

Be sure to leave some space between the connecting end and the clamp end after the

wiring is fixed

③ .

The installing operation should comform to national wiring regulations.

3.5 Drainpipe Installation

Make sure the drain ows out

(1). Drain piping.

7

Page 23

Flex Series for North America

Either the right rear or right side of the unit is suitable for fixing the drainpipe

*

The diameter of the drainpipe should be equal to or greater than that of the connecting pipe.

*

Take the drainpipe as short as possible and slope downward at a gradient of at least 1/100

*

to prevent air pockets.(Refer to Fig.10)

Use the attached drain hose ④and clamp⑤.

*

Insert the drain hose completely into the drain socket. Tighten the clamp within the range of

*

gray tape until the screw head is less than 4mm from the hose. (Refer to Fig.11,Fig.12)

Wrap the attached sealing pad

*

No folding of drain hose inside the indoor unit. (Refer to Fig.13)

*

(2). Confirm that smooth drainage is achieved after the piping work

Pour 600cc of water into the drain pan from the air outlet for confirming drainage.(Refer to

Fig.14)

(When drain hose is connected)

over the clamp and drain hose to insulate. (Refer to Fig.12)

11

Incling the drain hose

Not to be lifted

No foldings

Not to be

soaking in water

Taping area(Gray)

Clamp⑤

Drain hose④

Fig.10 Fig.11

Cramp⑤

(Accessory)

4mm or less

Large seeing pad⑤

(Accessory)

11

Fig.12 Fig.13 Fig.14

3.6 Install the Connection Pipes

Air outlet

Watering can

8

Page 24

Flex Series for North America

PipePipe Flare Nut

Spanner

Nut-Required Torque

Pipe Diameter (mm) Required Torque

φ6.35 15--30

φ9.52 35-40

φ12 45-50

φ15.9 60-65

(1). Align the flared end of the copper tube with the threaded connector, and then hand-tighten

the flared nut

(2). Further tighten the flared nut with a torque wrench until the t rque wrench sounds a “crack”.

(3). The bending of the pipe shall not be too small, otherwise the pipe may crack. A pipe bender

must be used when bending the pipe.

(4). Wrap the thermally untreated pipe and connectors with sponge and then tighten the sponge

with plastic tape.

Notes:

① .

During the piping, do not pull any connector forcefully to prevent the capillary and other

pipes from cracking, which then would result in leakage.

② .

The pipe should be properly supported in the way that its weight will not be borne by the

unit.

If the specification of the outdoor unit pipe joint does not conform to that of the indoor unit, then

the joint specification of the outlet pipe of the indoor unit takes precedence. A reducing nipple shall

be installed at the joint of the outdoor unit so as to make the joint of the outdoor unit compatible

with that of the indoor unit.

9

Page 25

Flex Series for North America

4 Part Names of Floor and Ceiling Type Indoor Unit

Air outlet

Guide louver

Front panel

Air filter, purifier

(in air inlet grille)

Air inlet

Note: Different models of air conditioners as shown above have the same appearances.

Connecting

pipe

10

Page 26

Flex Series for North America

5 Working Temperature Range

Working Temperature Range

Indoor side state

Dry bulb

temp.

℉(℃)

Rated. Cooling 80.0(26.7) 67.0(19.4) 95.0(35.0) 75.0(23.9)

Max. cooling 80.0(26.7) 67.0(19.4)

Min. cooling 67.0(19.4)

Rated. Heating

Max. heating 80.0(26.7) — 75.0(23.9)

Low Ambient heating

70

.0(21.1)

70

.0(21.1)

℉(℃)

Wet bulb

temp.

℉(℃)

57

.0(13.9) 67.0(19.4)

60

.0(15.6)

60

.0(15.6)

temp.

Outdoor side state

Dry bulb

℉(℃)

115

.0(46.1) 75.0(23.9)

47

.0(8.3)

5

.0(-15.0)

Wet bulb

temp.

57

43

65

3.2(-16.0

℉(℃)

℉(℃)

.0(13.9)

.0(6.1)

.0(18.3)

)

11

Page 27

Flex Series for North America

6 Maintenance Method

Warning!

① .

Turn off the unit and cut off the power supply when cleaning the air conditioner, otherwise,

electric shock may happen.

② .

Do not let the air conditioner get wet, or it will cause electric shock. Ensure that the air

conditioner will not be cleaned by water rinse under any circumstances.

③ .

Volatile liquid like thinner or gasoline would damage the appearance of air conditioner.

(Note: Only soft cloth and wet cloth that moistened by neutral cleaning fluid could be used to clean

the front panel of air conditioner.)

6.1 Cleaning the Air Filters

Warning!

Air lters should be cleaned by professionals with proper operation to ensure personal

safety.

Suggestion:

If the air filter is dirty, it will

influence normal airflow. As a result,

the unit will be overloaded and

consume 6% additional electric energy.

So regular cleaning is necessary.

6.2 Cleaning the Unit

Clean the air conditioner and the remote control with dry cloth or a vacuum cleaner. If damp

cloth is used, remove moisture by using dry cloth afterward.

Caution

① .

gasoline, thinners or polishing products for

cleaning.

② .

40

deformed.

6.3 At the Start of the Season

Check if there is blockage at inlet and outlet of the air conditioner.

*

Check if the batteries in wireless remote controller has been exchanged.

*

Check if the batteries in wireless remote controller had been exchanged.

*

Check if the air filter has been installed well by professionals

*

In order to start up the air conditioner smoothly after long period stop, switch on the main

*

power supply 8 hours before turning on the air conditioner.

Notice: All the operations above should be operated by professionals.

*

6.4 During the off Season

Switch off the main power supply.

*

Clean the air filters and other parts by professionals

*

Keep the fan running for 2-3 hours to dry out the inside of the unit.

*

Notice: All the operations above should be operated by professionals.

*

!

Do not use benzine solvent,

Do not wash with hot water (above

). Some parts of the unit may be

℃

12

Page 28

Flex Series for North America

7 Operating Instructions

The expected temperature should

*

be set at a moderate level to avoid of

unnecessary energy consumption.

Clean the air filter every week for

*

higher efficiency by professional.

Airflow direction will be changed by

*

adjusting the louvers and flaps as shown,

accordingly well air condition the room

temperature.

Close the window and door while operating

*

the unit for saving energy.

Cover windows with a blind or a curtain

*

to prevent heat source from sunlight when

the unit is cooling, which helps to reduce

energy consumption.

In case of ineffective ventilation,

*

open the window to ventilate room air

occasionally, meanwhile, close the window

timely for saving energy.

13

Page 29

Check electrical system (voltage and

*

frequency). Use the power supply indicated

on the nameplate of the unit to operate the

air conditioner and only fuses with specified

capacity should be done by technicians. Do

not use pieces of wire instead of fuse.

Do not insert objects into the air inlet or

*

outlet when the air conditioner is running

as it may cause damage or personal injury.

Also pay special attention when children

are around.

Flex Series for North America

If electric shock suddenly happens, turn

*

off the unit. If the unit is not to be used

for a long period, cut off the main power

supply.

Do not place any obstacles around

*

the indoor and outdoor unit to avoid of

inefficient performance or malfunction

*

Never expose infants, aged persons or

patients directly to the air flo .

Do not locate a heater or any other

*

heat source close to the unit. The heat

may deform plastic parts.

14

Page 30

Flex Series for North America

8 Malfunction Analysis

Warning!

Repairing work should be done by Impecca technicians. For saving your time and spending,

please check the following malfunction analysis before contacting customer service center.

Malfunction Phenomena Malfunction Analysis

After turning off the air

conditioner, the unit could not

restart immediately.

Odor gives out when the unit

just turns on.

Slight noise is heard when the

unit is running.

There is mist coming from air

outlet under cooling mode.

Creak sound is heard when the

unit is running or shut down.

The air conditioner could not

run.

The cooling (heating) effect of

the air conditioner is not good.

Wireless remote controller

doesn't work.

The overload protection switch of the unit needs 3 mins before

restarting.

When air conditioning, odor or smoke that was sucked in is

discharged again.

The refrigerant flows in the liquid pipe will make some noise.

Indoor temperature declines too fast.

When the ambient temperature changes, the panel and other

parts expand or shrink, which might cause some grating sound.

Whether the unit is powered off.

Whether the unit is disconnected with power supply.

Whether the circuit breaker trips off.

Whether the voltage is too high or too low.

Whether the TIMER has been s

controller.

Notice: All the operations above should be done by

Impecca

Wether the temperature is set properly.

Whether the inlet or outlet of the unit is blocked.

Whether the air filter is too dirty to cause blockage.

Whether the windows and doors are closed.

Whether the airflow volume is set at low speed.

Whether there is any heat source in the room.

If the wireless remote controller doesn't work with new

batteraries, remove the back cover and press ”ACL” button to

make it normal.

The air conditioner is under abnormal disturbance orchanging

function too frequently, to make wireless remote controller cannot

control. Cut off main power supply and re-electrify could resume

normal operation.

Whether the controller is within the signal receiving area;

Whether there is blockage;

Check if the batteries in wireless remote controller are worn out,

otherwise change the batteries.

technicians.

et in the wireless remote

8.1 Service Center

When the following phenomena appears, please stop operating immediately, cut off the power

supply and contact service center for help.

Harsh sound is heard when the unit is running.

*

When the fuse melts or the circuit breaker trips off frequently.

*

When some objects or water is sucked in the unit accidently.

*

15

Page 31

Flex Series for North America

When there is water leakage from indoor unit.

*

When the power cord is overheating.

*

Odor gives out when the unit is running.

*

8.2 After-sales Service

Please contact the dealer if the air conditioner has any quality problems.

8.3 CUSTOMER SUPPORT

Before contacting customer support, please see the troubleshoot

Visit our website to contact us, find answers to Frequently Asked Questions, and for other

resources which may include an updated version of this user's guide.

ing guide above.

WWW.IMPECCA.COM

If you wish to contact us by phone, please be sure to have your model number an

ready and call us between 9:00am and 6:00pm ET, at +1 866-954-4440.

Keep tabs on Impecca's newest innovations & enter contests via our social network feeds:

www.facebook.com/Impecca/

www.instagram.com/impecca/

@impeccausa

d serial number

16

Page 32

© 2016 Impecca, a division of LT Inc., Wilkes Barre, PA.

Page 33

Wired Controller

IS-TT850

User's Manual

Thank you for choosing Impecca Air Conditioners. Please read this

owner’s manual carefully before operation and retain it for future reference.

Page 34

User Notice

Please carefully read this manual before installation and use of this product

ƹ

(QVXUHthere is separate SRZHUVXSSO\IRUHDFKLQGRRUXQLW

ƹ

Never install wired controller in a

ƹ

Shielded twisted pair line must be substituted as signal line for wired controller if the unit is

installed in the place where there is electromagnetic interference.

ƹ

Make sure communication line is connected into correct port to avoid communication

malfunction.

ƹ

Never knock, throw or frequently disassemble the wired controller.

ƹ

Never operate the wired controller with wet hand.

wet place or under direct sunlight.

Page 35

Contents

1 Display Section................................................................................................ 1

1.1 Controller's LCD ........................................................................................1

1.2 Instruction to LCD ....................................................................................... 2

2 Buttons ............................................................................................................3

2.1 Layout of Buttons .......................................................................................3

2.2 Functions of Buttons ...................................................................................3

3 Operation Instructions .....................................................................................4

3.1 On/Off ......................................................................................................... 4

3.2 Mode Setting .............................................................................................. 4

3.3 Temperature Setting ...................................................................................4

3.4 Fan Setting ................................................................................................. 5

3.5 Timer Setting .............................................................................................. 5

3.6 Swing Setting .............................................................................................7

3.7 Sleep Setting .............................................................................................. 8

3.8 Turbo Setting .............................................................................................. 9

3.9 E-heater Setting .......................................................................................10

3.10 Blow Setting ........................................................................................... 11

3.11 Other Functions ......................................................................................12

4 Installation and Dismantlement .....................................................................12

4.1 Connection of the Signal Line of the Wired Controller ............................. 12

4.2 Installation of the Wired Controller ........................................................... 12

4.3 Dismantlement of the Wired Controller .................................................... 14

5 Errors Display ................................................................................................ 14

Page 36

1 Display Section

Wired Controller IS-TT850

Fig1.1.1 Diagram of wired controller

1.1 LCD Display of Wired Controller

Fig.1.1.2 LCD display

1

Page 37

Wired Controller IS-TT850

1.2 Instruction to LCD Display

Table 1.1

No. Symbols Description

1

2

3

4

5

6

7

8

9

10

11

12 SHIELD

13 Turbo Turbo function state

14 MEMORY

Swing function

Air exchange function (this function is yet unavailable for this unit).

Sleep function (Only sleep 1).

Each kind of running mode of indoor unit (auto mode)

Cooling mode

Dry mode

Fan mode

Heating mode

Defrosting function for the outdoor unit.

Gate-control function (this function is yet unavailable for this unit).

Lock function.

Shield functions (Button operation, temperature setting, On/Off operation,

Mode setting are disabled by the remote monitoring system.)

Memory function (The indoor unit resumes the original setting state after

power failure and then power recovery).

15

16

17

18 E-HEATER Electric auxiliary heating function.

19 BLOW Blow function.

20

21 QUIET

SAVE

It blinks under on state of the unit without operation of any button.

Energy-saving function (this function is yet unavailable for this unit).

Ambient/setting temperature value

Timing value.

Quiet function (two types: quiet and auto quiet)

(this function is yet unavailable for this unit).

2

Page 38

2 Buttons

2.1 Layout of Buttons

2.2 Functions of Buttons

Table 2.1

No. Name Function

Wired Controller IS-TT850

1 Enter/Cancel Function selection and cancellation.

2 Ÿ

6 ź

3 Fan

4 Mode Setting of the Cooling/Heating/Fan/Dry/Auto mode of the indoor unit.

5 Function Switchover among the functions of Turbo/Save/E-heater/Blow etc..

7 Timer Timer setting.

8 On/Off

4+2 Mode + Ÿ

3+6 )DQź

4+6

2+6 Ÿź

Mode ź

ķ

Running temperature setting of the indoor unit, range:

F(16°C-30°C).

Setting of the low/middle/high/auto fan speed.

Turn on/off the indoor unit.

With the A/C powered off, press these two buttons together for 5

seconds to toggle the Memory function. With Memory on, the unit will

return the the previous setting after resuming from a power failure.

With Memory toggled off, it will stay off

With the A/C powered off, press these two buttons together for 5 seconds

to determine if your unit is capable of just cooling or both cooling and

heating, indicated by the symbols shown.

With the A/C powered off, press these two buttons together for 5 seconds to

toggle between Fahrenheit and Celsius.

Press these two buttons together for 5 seconds to toggle the lock function.

ĸ

Timer setting, range:0.5(30 minutes) - 24 (hours).

61°F-86°

3

Page 39

Wired Controller IS-TT850

3 Operation Instructions

3.1 On/Off

Press On/Off button to toggle your A/C's power.

Note: The state shown in Fig.3.1.1 indicates the “Off” state of the unit after power has been restored

to the unit. The

3.2 Mode Setting

Under ON state of the unit, press the Mode to switch the operation modes as the

following sequence: Auto–Cooling–Dry–Fan–Heating.

screen shown in Fig.3.1.2 indicates the “On” state of the unit after power on.

Fig.3.1.1 “Off” State Fig.3.1.2 “On” State

3.3 Temperature Setting

3UHVVŸRUźWRLQFUHDVHGHFUHDVHWKHSUHVHWWHPSHUDWXUH,ISUHVVLQJHLWKHURIWKHP

continuously, the temperature will be increased or decreased by 1° every half a second,as

shown in Fig.3.3.1.

In the Cooling, Dry, Fan or Heating mode, the temperature setting range is 61°F-86°

F(16°C-30°C). In the Auto mode, the setting temperature not manually adjustable.

Fig.3.3.1 Fig.3.4.1

4

Page 40

Wired Controller IS-TT850

3.4 Fan Setting

While the unit is powered on, press

circularly as shown in Fig.3.4.1.

Fan

and then fan speed of the indoor unit will change

Low Middle

High

(Fig. 3.4.1)

3.5 Timer Settings

While the unit is powered on, pressing the Timer button allows you to

unit turns off. While the unit is powered off, pressing the Timer button allows you to set the dealy

until the unit turns on.

• 7LPHURQVHWWLQJ details

With the unit turned off, and no timer already programmed, press the Timer button. The

display will show "0.5" with "Hour on" blinking. PressŸorźbutton to adjust delay until unit

turns on and press Timer or Enter/Cancel to confirm.

• Timer off setting details:

With the unit turned on, and no timer already programmed, press the Timer button. The display

will show "0.5" with "Hour off" blinking.

• Timer off setting details:

With the unit turned on, and no timer already programmed, press the Timer button. The display will

show "0.5" with "Hour off" blinkingSUHVVŸRUźEXWWRQWRDGMXVWdelay until unit turns on and press

Timer or Enter/Cancel to confirm.

&DQFHOWLPHU

After setting of timer, if Timer button is pressed, LCD won’t display xx. Hour so that timer setting is

Timer off setting under the “On” state of the unit is shown as Fig.3.5.1.

canceled.

set the delay until the

Fig.3.5.1 Timer off Setting under the “On” State of the Unit

5

Page 41

Wired Controller IS-TT850

Timer on setting under the “Off” state of the unit is shown as Fig.3.5.2.

Fig.3.5.2 Timer on Setting under the “Off” State of the Unit

7LPHUUDQJHKU(YHU\SUHVVRIŸRUźZLOOPDNHWKHVHWWLPHLQFUHDVHGRUGHFUHDVHGE\

0.5hr. If either of them is pressed continuously, the set time will increase/ decrease by 0.5hr every

0.5s.

6

Page 42

Wired Controller IS-TT850

3.6 Swing Setting

Swing On: Press Function under on state of the unit to activate the swing function. In this case,

ZLOOEOLQN$IWHUWKDWSUHVV(QWHU&DQFHOWRPDNHDFRQ¿UPDWLRQ

Swing Off: When the Swing function is on, press Function to enter the Swing setting

interface,with

shown as Fig.3.6.1.

blinking. After that, press Enter/Cancel to cancel this function. Swing setting is

Fig.3.6.1 Swing Setting

Notes:

ķ

Sleep, Turbo or Blow setting is the same as the Swing setting.

ĸ

After the setting has been done, it has to press the key “Enter/Cancel” to back to the setting

VWDWXVRUTXLWDXWRPDWLFDOO\¿YHVHFRQGVODWHU

7

Page 43

Wired Controller IS-TT850

3.7 Sleep Setting

Sleep on: Press Function under the On state of the unit till the unit enters the Sleep setting

VWDWH$IWHUWKDWSUHVV(QWHU&DQFHOWRFRQ¿UPWKLVVHWWLQJ

Sleep off: When the Sleep function is activated, press Function to enter the Sleep setting

status. After that, press Enter/Cancel to cancel this function.

In the Cooling or Dry mode, the temperature will increase by 1°C after the unit runs under

Sleep1 for 1hr and 1°C after another 1hr.After that, the unit will run at this temperature.

In the Heating mode, the temperature will decrease by 1°C after the unit runs under Sleep 1 for

1hr and 1°C after another 1hr. After that, the unit will run at this temperature.

Sleep setting is shown as Fig.3.7.1.

Fig.3.7.1. Sleep Setting

8

Page 44

Wired Controller IS-TT850

3.8 Turbo Setting

Turbo function: The unit at the high fan speed can realize quick cooling or heating so that the

room temperature can quickly approach the setting value.

In the Cooling or Heating mode, press Function till the unit enters the Turbo setting status and

WKHQSUHVV(QWHU&DQFHOWRFRQ¿UPWKHVHWWLQJ

When the Turbo function is activated, press Function to enter the Turbo setting status and then

press Enter/Cancel to cancel this function.

Turbo function setting is as shown in Fig.3.8.1.

Fig.3.8.1 Turbo Setting

9

Page 45

Wired Controller IS-TT850

3.9 E-heater Setting

E-heater (auxiliary electric heating function): In the Heating mode, E-heater is allowed to be

WXUQHGRQIRULPSURYHPHQWRIHI¿FLHQF\

Once the wired controller or the remote controller enters the Heating mode, this function will be

turned on automatically.

Press Function in the Heating mode to enter the E-heater setting interface and then press

Enter/Cancel to cancel this function.

Press Function to enter the E-heater setting status, if the E-heater function is not activated,

and then press Enter/Cancel to activate it.

The setting of this function is shown as Fig.3.9.1 below:

Fig.3.9.1 E-heater Setting

10

Page 46

Wired Controller IS-TT850

3.10 Blow Setting

Blow function: After the unit is turned off, the water in evaporator of indoor unit will be

automatically evaporated to avoid mildew.

In the Cooling or Dry mode, press Function till the unit enters the Blow setting status and then

press Enter/Cancel to active this function.

When the Blow function is activated, press Function to the Blow setting status and then press

Enter/Cancel to cancel this function.

Blow function setting is as shown in Fig.3.10.1

Fig.3.10.1 Blow Setting

Notes:

ķ

When the Blow function is activated, if turning off the unit by pressing On/Off or by the

remote controller, the indoor fan will run at the low fan speed for 2 min, with “BLOW” displayed on

the LCD. While, if the Blow function is deactivated, the indoor fan will be turned off directly.

ĸ

Blow function is unavailable in the Fan or Heating mode.

11

Page 47

Wired Controller IS-TT850

3.11 Other Functions

a. Lock

8SRQVWDUWXS RI WKHXQLWZLWKRXWPDOIXQFWLRQ RUXQGHUWKH³2II´ VWDWHRIWKH XQLW SUHVVŸDQG ź at

the same time for 5s till the wired controller enters the Lock function. In this case, LCD displays

.

After that, repress these two buttons at the same time for 5s to quit this function.

Under the Lock state, any other button press won’t get any response.

b. Memory

0HPRU\VZLWFKRYHU 8QGHUWKH³2II´VWDWHRI WKHXQLWSUHVV 0RGHDQGŸDWWKH VDPHWLPHIRU

5s to switch memory states between memory on and memory off. When this function is activated,

Memory will be displayed. If this function is not set, the unit will be under the “Off” state after power

failure and then power recovery.

Memory recovery: If this function has been set for the wired controller, the wired controller after

power failure will resume its original running state upon power recovery. Memory contents: On/

Off,Mode, set temperature, set fan speed and Lock function.

4 Installation and Dismantlement

4.1 Connection of the Signal Line of the Wired Controller

Ɣ2SHQWKHFRYHURIWKHHOHFWULFFRQWUROER[RIWKHLQGRRUXQLW

Ɣ/HWWKHVLQJOHOLQHRIWKHZLUHGFRQWUROOHUWKURXJKWKHUXEEHUULQJ

Ɣ&RQQHFWWKHVLJQDOOLQHRIWKHZLUHGFRQWUROWRWKHSLQVRFNHWRIWKHLQGRRUXQLW3&%

Ɣ7LJKWHQWKHVLJQDOZLUHZLWKWLHV

Ɣ7KHFRPPXQLFDWLRQGLVWDQFHEHWZHHQWKHPDLQERDUGDQGWKHZLUHGFRQWUROOHUFDQEHXSWR

20 meters ( the standard distance is 8 meters)

4.2 Installation of the Wired Controller

PVC Pipe

1

3 4 52

Fig.4.1 Accessories for the Installation of the Wired Controller

Table 4.1

No.12345

Front Panel

of the Wired

Controller

Screw

ST 2.9X6*

Name

*Not included

Socket box

embedded

in the wall

*

Back-plate of

the Wired

Controller

Screw

M4X25

*

12

Page 48

Wired Controller IS-TT850

1

7

8 9

2

3 4

6

5

10

Fig.4.2

Fig.4.2 shows the installation steps of the wired controller, but there are some issues that need

your attention.

1) Prior to the installation, please firstly cut off the power supply of the wire buried in the

installation hole, that is, no operation is allowed with electricity during the whole installation.

2) Pull out the four-core twisted pair line from the installation holes and then let it go through

the rectangular hole behind the back-plate of the wired controller.

6WLFNWKHVROHSODWHRIWKH ZLUHGFRQWUROOHU WRWKH ZDOORYHU WKHLQVWDOODWLRQKROHDQGWKHQ¿[LW

with screws M4X25.

4) Insert the four-core twisted pair line into the slot of the wired controller and then buckle the

front panel and the back-plate of the wired controller together.

)LQDOO\¿[WKHIURQWSDQHODQGWKHVROHSODWHRIWKHZLUHGFRQWUROOHUWLJKWO\E\VFUHZV67;

CAUTION!

Please pay special attention to the followings during the connection to avoid the malfunction of

the air conditioning unit due to electromagnetic interference.

ķ

Separate the signal and communication lines of the wired controller from the power cord

13

Page 49

Wired Controller IS-TT850

and connection lines between the indoor and outdoor unit, with a minimum interval of 20cm,

otherwise the communication of the unit will probably work abnormally.

ĸ

If the air conditioning unit is installed where is vulnerable to electromagnetic

interference,then the signal and communication lines of the wired controller must be the shielding

twisted pair lines.

4.3 Dismantlement of the Wired Controller

1 3 42

5 Errors Display

If there is an error occurring during the operation of the system, the error code will be displayed

on the LCD, as show in Fig.5.1. If multi errors occur at the same time, their codes will be displayed

circularly.

Note: In event of any error, please turn off the unit and contact the professionally skilled

personnel.

Fig.5.1

14

Page 50

Wired Controller IS-TT850

Table 5.1 Meaning of Each Error

Error

Return air temperature sensor open/

short circuited

evaporator temperature sensor open/

short circuited

Indoor unit liquid valve temperature

sensor open/short circuited

Indoor gas valve temperature sensor

open/ short circuited

IPM temperature sensor open/short

circuited

Outdoor ambient temperature sensor

open/ short circuited

Outdoor unit condenser mid-tube

temperature sensor open/short circuited

Discharge temperature sensor open/

short circuited

Indoor and outdoor communication error E6 Compressor startup failure Lc

DC bus under-voltage protection PL High discharge temperature protection E4

DC bus over-voltage protection PH Overload protection E8

Compressor phase current sensing

circuit error

Compressor demagnetization protection HE Over phase current protection P5

PFC protection Hc Compressor desynchronizing H7

IPM Temperature Protection P8 IPM Current protection H5

Over-power protection L9

System charge shortage or blockage

protection

Capacitor charging error PU

High pressure protection E1

Low pressure protection E3

Compressor stalling LE

Over-speeding LF

Drive board temperature sensor error PF Indoor unit full water error E9

AC contactor protection P9 Anti-freezing protection E2

Temperature drift protection PE AC input voltage abnormal PP

Sensor connection protection Pd Whole unit current sensing circuit error U5

DC bus voltage drop error U3 4-way valve reversing error U7

Outdoor fan 1 error protection L3 Motor stalling H6

Outdoor fan 2 error protection LA PG motor zero-crossing protection U8

Error

Code

F1 Drive board communication error P6

F2 Compressor overheating protection H3

b5 Indoor and outdoor units unmatched LP

Communication line misconnected or

b7

expansion valve error

P7 5XQQLQJPRGHFRQÀLFW E7

F3 Pump-down Fo

F4 Jumper error C5

F5 Forced defrosting H1

U1 Whole unit over-current protection E5

Compressor phase loss/reversal

protection

Frequency restricted/reduced with whole

F0

unit current protection

Frequency restricted/reduced with IPM

current protection

Frequency restricted/reduced with high

discharge temperature

Frequency restricted/reduced with anti-

freezing protection

Frequency restricted/reduced with

overload protection

Frequency restricted/reduced with IPM

temperature protection

Error

Error

Code

dn

Ld

F8

En

F9

FH

F6

EU

15

Page 51

Technical Support

Before calling technical support, please see the troubleshooting guide above. You may also visit

our website at www.impecca.com for answers to Frequently Asked Questions and to contact us.

Email: support@impecca.com

Phone: +1 866–954–4440

Web: www.impecca.com

Loading...

Loading...