Page 1

Owner's Manual

Split Type Wall-mounted Air Conditioner

Model:

Thank you for choosing our product.

For proper operation, please read and keep this manual carefully.

If you have lost the Owner’s Manual, please contact the local agent or

visit www.impecca.com for an electronic version.

ISMO-1821

v

. 1.1

Page 2

In line with the company

’s policy of continual product improvement, the aesthetic and dimensional

characteristics, technical data and accessories of this appliance may be changed without notice.

CONTENTS

Conformity And Range

The Instructions Before Use

Name of Parts

Technical Data

GENERAL

INFORMATION

Outdoor Unit Working Temperature Range

Electrical Connections

Installing The Outdoor Unit

Bleeding

Maintenance

Installation Dimension Diagram

INSTALLER

Check After Installation

GENERAL INFORMATION

1

2

3

4

4

5

8

6

7

7

8

The products in this manual may be different with the rea one, according to different models, l

some models have displayer and some models without displayer, the position and shape of

the displayer please refer to the real one.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Children should be supervised to ensure that they do not play with the appliance.

This marking indicates that this product should not be disposed with other

household wastes throughout the EU. To prevent possible harm to the

environment or human health from uncontrolled waste disposal, recycle

it responsibly to promote the sustainable reuse of material resources. To

return your used device, please use the return and collection systems or

contact the retailer where the product was purchased. They can take this

product for environmental safe recycling.

Page 3

Explanation of Symbols

Indicates a hazardous situation that, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation that, if not avoided, could result in death

or serious injury.

Indicates a hazardous situation that, if not avoided, may result in minor

or moderate injury.

Indicates important but not hazard-related information, used to indicate

risk of property damage.

Indicates a hazard that would be assigned a signal word

WARNING or CAUTION.

CONFORMITY AND RANGE

Please read this owner's manual carefully before operating the unit and keep it carefully for consultation.

Instructions for installation and use of this product are provided by the manufacturer.

Only use the air conditioner as instructed in this booklet. These instructions are not intended to

cover every possible condition and situation. As with any electrical household appliance, common sense

and caution are therefore always recommended for installation, operation and maintenance.

GENERAL INFORMATION

1

Page 4

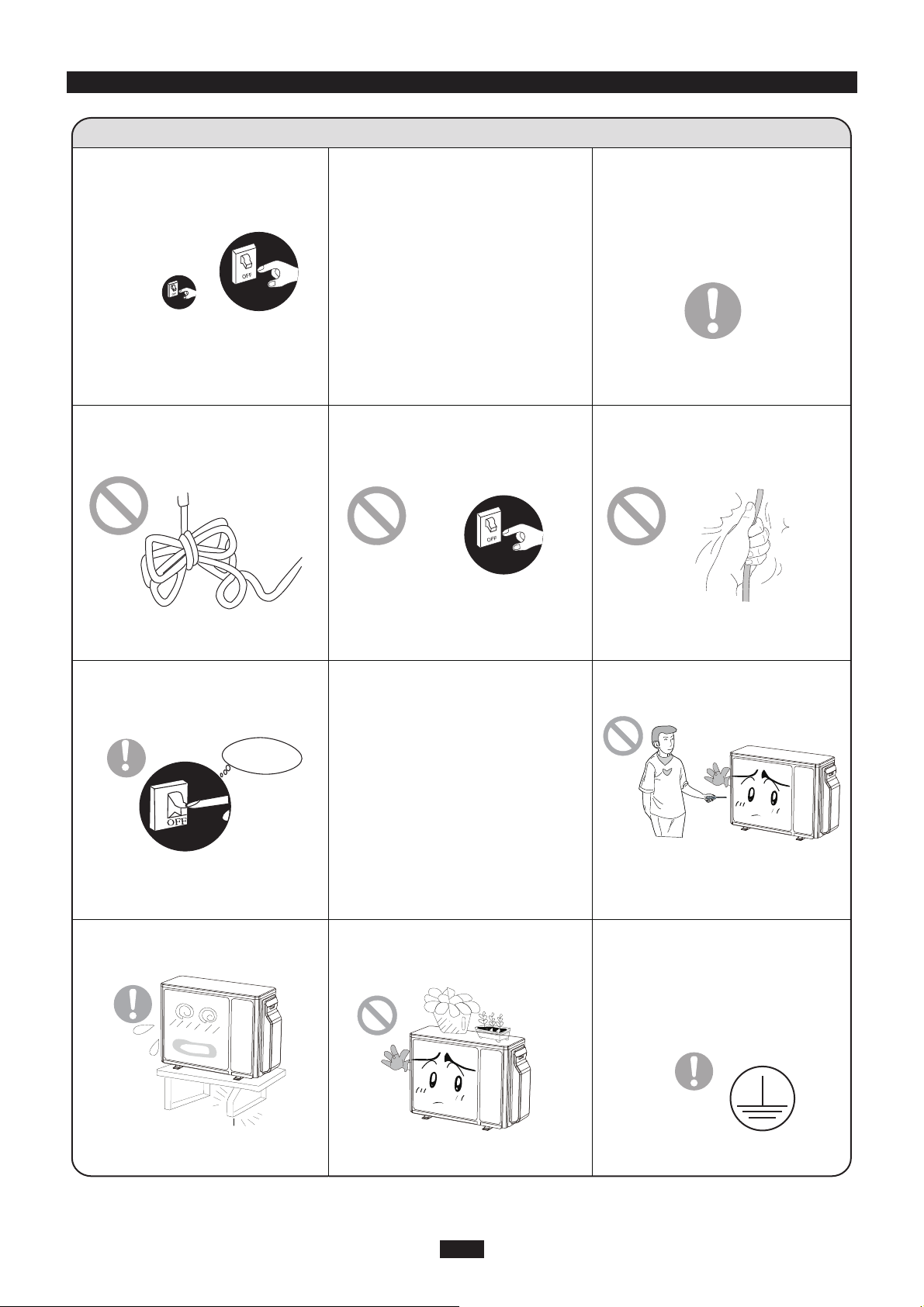

THE INSTRUCTIONS BEFORE USE GENERAL INFORMATION

WARNING

When having a burning smell or

★ ★

smoke,please turn off the power

supply and contact with the service center.

If the abnormity still exists,the unit

may be damaged,and may cause

electric shock or fire.

Power must adopts the special

★

circuit to prevent fire.

Otherwise, it can cause electric

shock or fire.

★ ★

Otherwise,the accumulated dusts

may cause overheating or fire.

The power supply must adopt the

special circuit that with air switch

protection and assure it has enough capacity.The unit will be turned

on or off according to your requirement automatically,please do not

turn on or turn off the unit frequently,otherwise disadvantage effect

may be caused to the unit.

Disconnect the power supply if

long putting the air conditioner

out of use.

Never cut off or damage power

★

cables and control wires. If the

power cable and signal control

wire were damaged, change

them by professional.

Never damage the electric wire

or use the electric wire which is

not appointed.

Otherwise,it will cause overheating

or fire.

When cleaning,it is necessary

★ ★

to stop driving and turn off the

power supply.

Cut off power supply

Otherwise,it may cause electric

shock or damage.

Please note whether the insta-

★ ★

lled stand is firm enough or not.

Rated voltage of this air conditioner 220-240V, 60Hz, The compressor will vibrate sharply if the

voltage is too low, resulting in

damage to refrigerating system.

Electrical component are easy to

damage if the voltage is too high.

Don't step on the top of the

outdoor unit or place something

on it.

Don't attempt to repair the air

★

conditioner by yourself.

The wrong repair will lead to an

electric shock or fire,so you should

contact the service center to repair.

Earthing: The unit must be reli-

★

ably earthed.The earthing cable

shall be connected to the special earthing device in the construction.

If it is damaged, it may lead to the

fall of the unit and cause the injury.

As falling off the outdoor unit can be

dangerous.

2

Page 5

NAME OF PARTS

GENERAL INFORMATION

WARNING

Be sure to cut off the power supply before cleaning the air conditioner; otherwise electric

shock might happen.

Wetting of air conditioner may cause the risk of electric shock. Make sure not to wash

your air conditioner in any case.

Volatile liquids such as thinner or gasoline will cause damage to the appearance of air

conditioner. (Only use soft dry cloth moist cloth clean the air conditioner cabinet).

This product must not be disposed together with the domestic waste.

This product has to be disposed at an authorized place for recycling of electrical and

electronic appliances.

The temperature of refrigerant circuit will be high,please keep the interconnection cable

away from the copper tube.

1

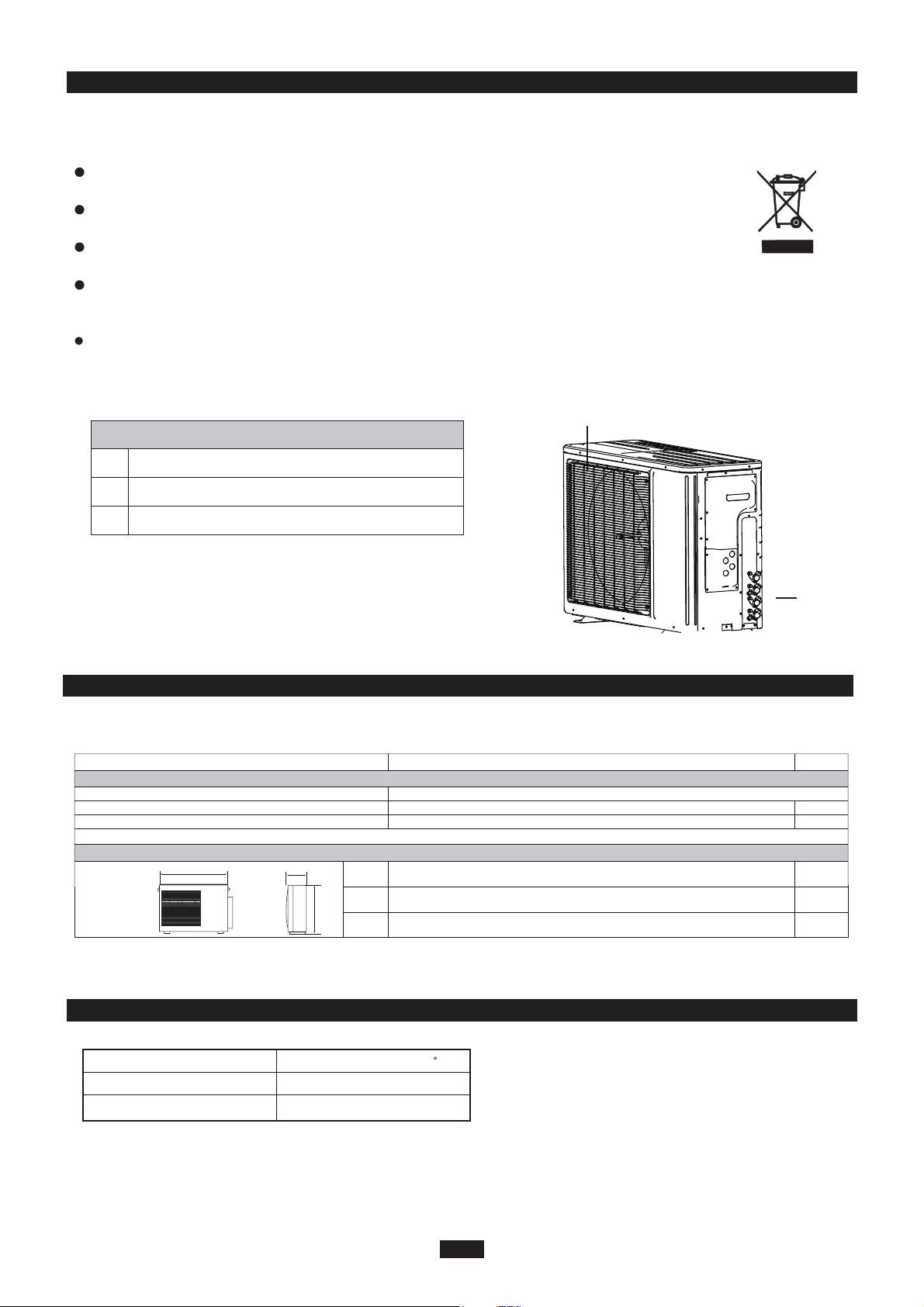

OUTDOOR UNIT

No. Description

1 Air outlet grille

2 Valve

Note: The above figures are only intended to a simple

diagram of the appliance and may not correspond to the

appearance of the units that have been purchased.

2

TECHNICAL DATA GENERAL INFORMATION

MODE

Electrical data

Electricity supply

Fuse or air switch

Minimum power cord section

Size and clearance

L

P

L

P

H

H

ISMO-1821

208/230V,60HZ

20

2.5

890

362

700

mm

mm

mm

mm

2

OUTDOOR UNIT WORKING TEMPERATURE RANGE GENERAL INFORMATION

OutdoorsideDB/WB(c)

Maximum cooling

Maximum heating

48/27/-

3

Page 6

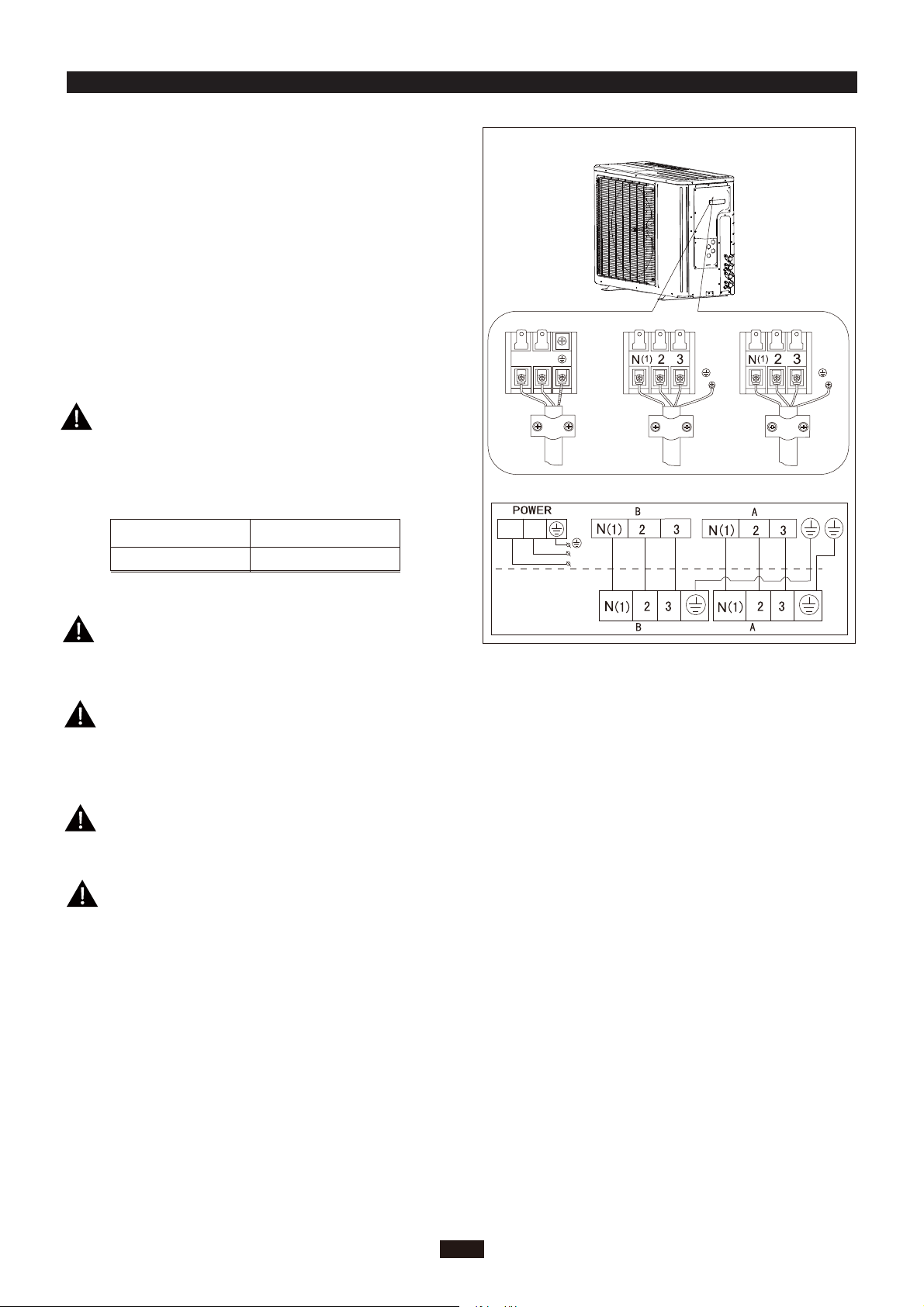

ELECTRICAL CONNECTIONS

1. Remove the handle at the right side plate of the outdoor

unit (one screw).

2. Remove the cable clamp, connect the power connection

cable with the terminal at the row of connection and fix

the connection. The fitting line distributing must be

consistent with the indoor unit. terminal of line bank.

Wiring should meet that of indoor unit.

3. Fix power connection wire by wire clamp.

4. Ensure wire has been fixed well.

To unit A

INSTALLER

To unit B

5. Install the handle.

Including an air switch with suitable capacity,

please note the following table. Air switch

should be included magnet buckle and heating

buckle function, it can protect the circuit-short

and overload. (Caution: please do not use the

fuse only for protect the circuit)

Air switch capacityAir-conditioner

ISMO-1821

25A

An all-pole disconnection switch having a contact

separation of at least 3mm in all pole should be

connected in fixed wiring.

Wrong wire connection may cause malfunction of

some electric components.After fixing cable, ensure

that leads between connection to fixed point have

some space.

L1

L1 L2

L2

Power cord

connecting

cable

L2

L1

connecting

cable

To the power supply

The connection pipes and the connectiong wirings

of the unit A and unit B must be corresponding to

each other respective.

The appliance shall be installed in accordance with

national wiring regulations.

Note: the above figures are only intended to be a simple

diagram of the appliance and may not correspond to the

appearance of the units that have been purchased.

4

Page 7

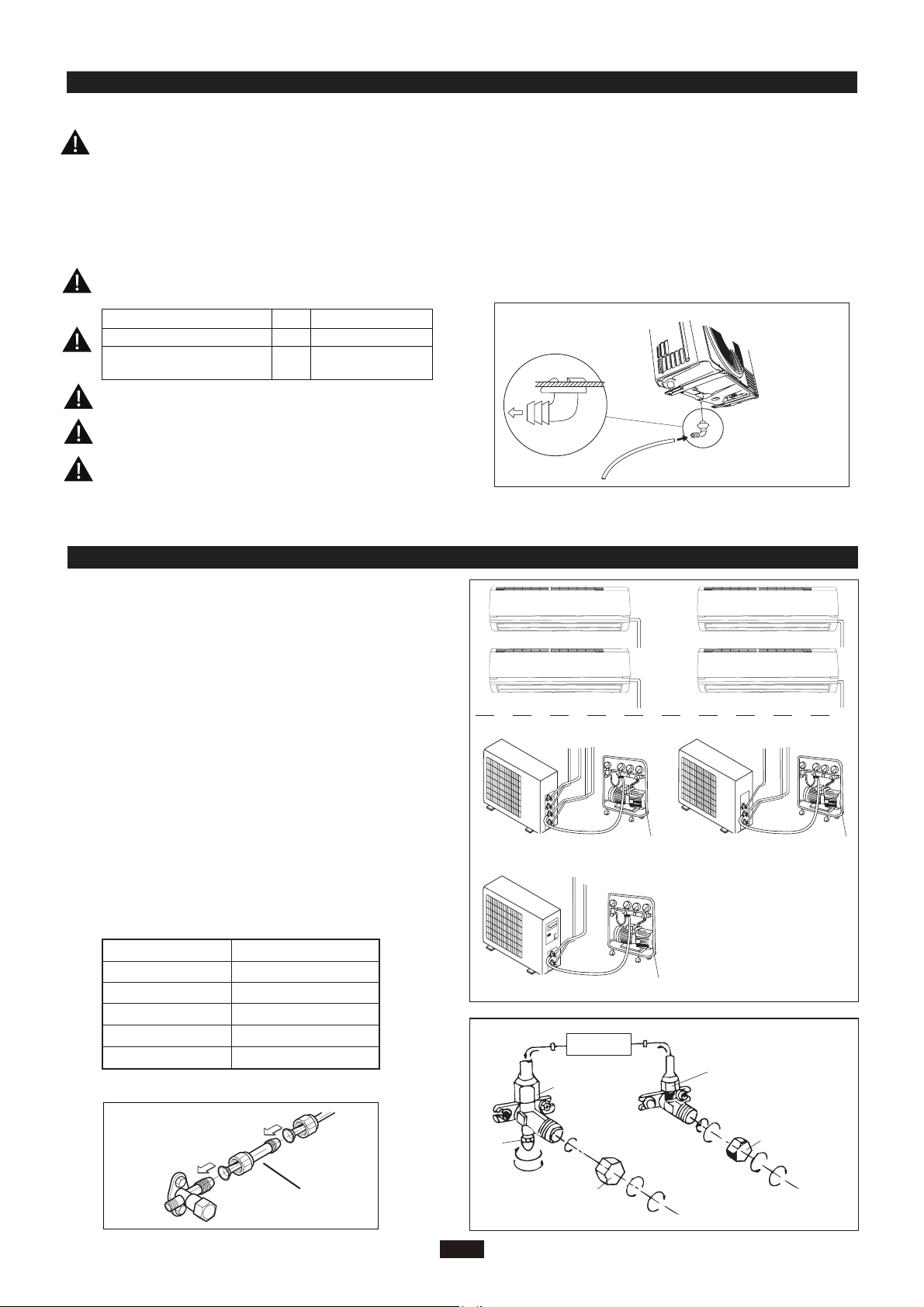

INSTALLING THE OUTDOOR UNIT INSTALLER

Location

Use bolts to secure the unit to a flat, solid floor.

When mounting the unit on a wall or the roof, make

sure the support is firmly secured so that it cannot

move in the event of intense vibrations or a strong

wind.

Do not install the outdoor unit in pits or air vents

●

Installing the pipes

Use suitable connecting pipes and equipment for

the refrigerant R410A.

Model(m) 1821x2

Max. connection pipe length

Max. connection pipe length

(Simple one indoor unit)

The refrigerant pipes must not exceed the maximum

heights 5m(1821K).

Wrap all the refrigerant pipes and joints.

Tighten the connections using two wrenches wor-

king in opposite directions.

Caution: Installation Must be Performed in Accordance

with the NEC/CEC by Authorized Personnel Only.

20

10

Install the drain fitting and the drain hose

(for model with heat pump only)

Condensation is produced and flows from the outdoor unit when the appliance is operating in the

heating mode. In order not to disturb neighbours

and to respect the environment,install a drain fitting

and a drain hose to channel the condensate water.

Install the drain fitting and rubber washer on the

outdoor unit chassis and connect a drain hose to it

as shown in the figure.

BLEEDING INSTALLER

Humid air left inside the refrigerant circuit can cause compressor malfunction. After having connected the indoor

and outdoor units, bleed the air and humidity from the

refrigerant circuit using a vacuum pump.

(1) Unscrew and remove the caps from the 2-way and 3-

way valves.

(2) Unscrew and remove the cap from the service valve.

(3) Connect the vacuum pump hose to the service valve.

(4) Operate the vacuum pump for 10-15 minutes until an

absolute vacuum of 10 mm Hg has been reached.

(5) With the vacuum pump still in operation, close the

low-pressure knob on the vacuum pump coupling.

Stop the vacuum pump.

(6) Open the 2-way valve by 1/4 turn and then close it

after 10 seconds. Check all the joints for leaks using

liquid soap or an electronic leak device.

(7) Turn the body of the 2-way and 3-way valves. Discon nect the vacuum pump hose.

(8) Replace and tighten all the caps on the valves.

Diameter (mm)

Φ9.52

Φ16

Φ12

Φ19

Twisting moment (N.m)

15-20Φ6

35-40

60-65

45-50

70-75

18K unit need to be installed the indoor unit

18K MODE:

conversion joint

Service

inlet

(2)Turn

(8) Secure

Refrigerant fluid di

3-way valve

Vacuum pump Vacuum pump

Vacuum pump

INDOOR

UNIT

rection of fiow

(7)Turn to open fully

Valve cap

(8) Secure

2-way valve

(6) Open by 1/4 turn

(7)Turn to open fully

(2)Turn

alve cap

V

(2)Turn

(8) Secure

Connect to the

indoor unit

5

Page 8

MAINTENANCE INSTALLER

Use suitable instruments for the refrigerant R410A.

Do not use any other refrigerant than R410A.

●

Do not use mineral oils to clean the unit.

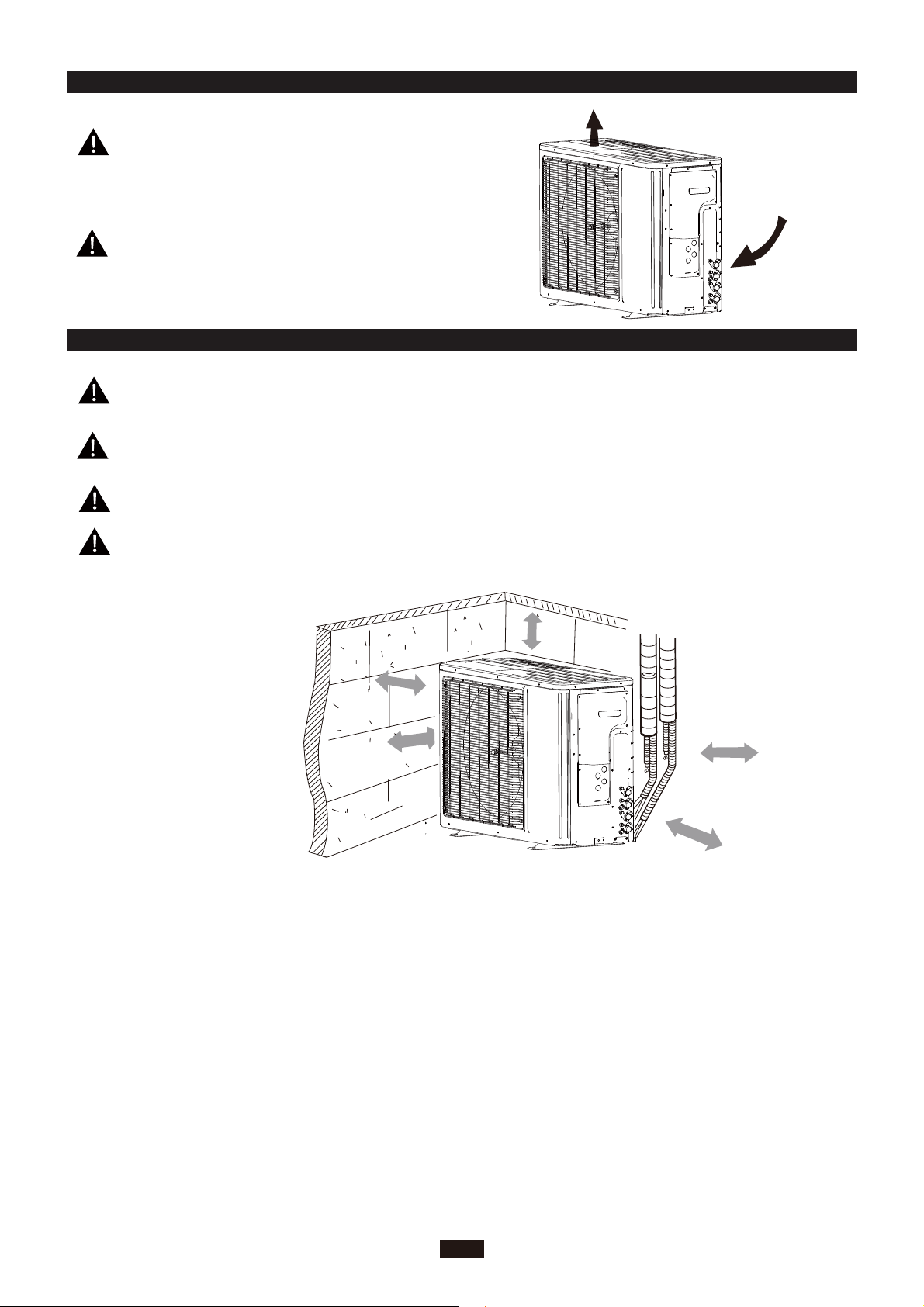

INSTALLATION DIMENSION DIAGRAM INSTALLER

The installation must be done by trained and qualified service personnel with reliability according to this

manual.

Contact service center before installation to avoid the malfunction due to unprofessional installation.

When picking up and moving the units, you must be guidedby trained and qualified person.

Ensure that the recommende dspace is left around the appliance.

50c

Space to the cover

or above

30cm

Space to the cover

or above

200cm

(Air outlet side)

m

or more

30cm

(Air inlet side)

50cm

Space to the wall

or above

or above

6

Page 9

CHECK AFTER INSTALLATION INSTALLER

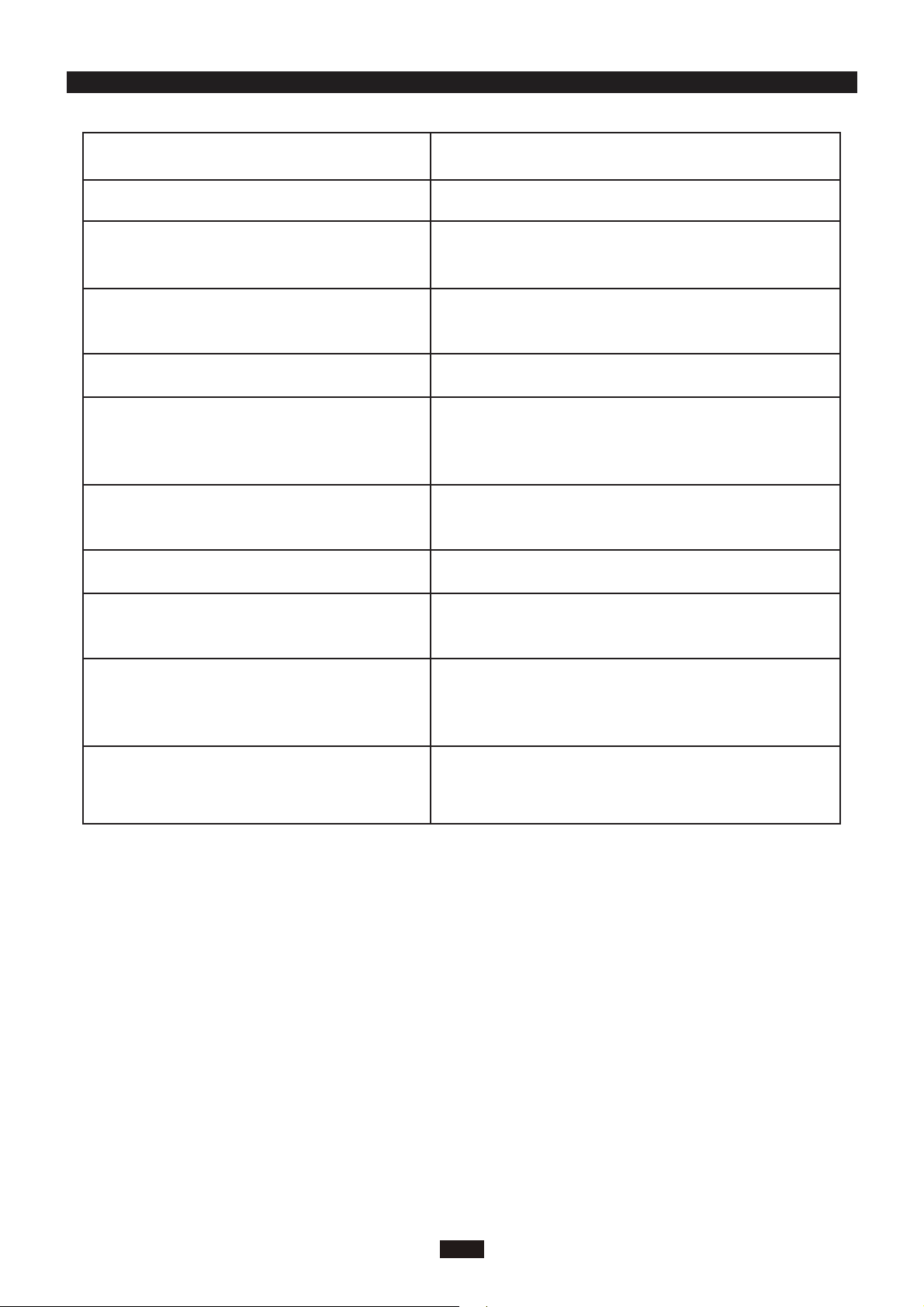

Check Items

Is the installation reliable?

Has the gas leakage been checked?

Is the thermal insulation of the unit

sufficient?

Is the drainage smooth?

Does the power supply voltage accord

with the rated voltage specified on the

nameplate?

Are the lines and pipelines correctly

installed?

Has the unit been safely grounded?

Problems Owing to Improper Installation

The unit may drop, vibrate or make noises

May cause unsatisfactory cooling (heating)

effect

May cause condensation and water dropping

May cause condensation and water dropping

The unit may bread down or the components

may be burned out

The unit may bread down or the components

may be burned out

Risk of electrical leakage

Are the models of lines in conformity

with requirements?

Are there any obstacles near the air

inlet and outlet of the indoor and outdoor units?

Have the length of refrigerating pipe

and refrigerant charge amount been

recorded?

The unit may bread down or the components

may be burned out

The unit may bread down or the components

may be burned out

It is not easy to decide the charge amount

of refrigerant.

7

Page 10

CUSTOMER S

Before contacting customer support, please see the troubleshooting guide above.

Visit our website to contact us, find answers to Frequently Asked Questions, and for other

resources which may include an updated version of this user's guide.

UPPORT

WWW.IMPECCA.COM

If you wish to contact us by phone, please be sure to have your model number and serial

number ready and call us between 9:00am and 6:00pm ET, at +1 866-954-4440.

Keep tabs on Impecca's newest innovations & enter contests via our social network feeds:

www.facebook.com/Impecca/

www.instagram.com/impecca/

@impeccausa

Page 11

Page 12

© 2016 Impecca, a division of LT Inc., Wilkes Barre, PA.

Page 13

Flex Series R410A GMV Multi

VFR System-Indoor Unit (For

North America) Compact Panel

Cassette Type Indoor Unit

Owner's Manual

Air Conditioners

Model:

ISMI-C15

Thank you for choosing Air Conditioners, please read this owner’s manual carefully before operation

and retain it for future reference. If you have lost the Owner’s Manual, please contact the local agent or

visit www.Impecca.com for an electronic version.

Impecca reserves the right to interpret this manual which will be subject to any change due to

product

improvement without further notice.

Impecca reserves the final right to interpret this manual.

v. 1.1

Page 14

User Notice

When operating, the entire capacity of the cooperating indoor unit should be not larger

◆

than 150% of outdoor unit. Otherwise, it will cause the shortage of cooling (heating) capacity.

A Breaker(or fuse) need to be installed in every indoor unit, and the capacity should

◆

in according with indoor unit’s electrical parameter; all the indoor units are required to be

centralized controlled by a total Switch, this Switch can cut off the electric power supply in

case of emergency. The Breaker(or fuse) on each indoor units have the function of short

circuit prevention and abnormal overload avoiding, it should be connected in normal situation.

The total switch controlling the power supply of all the indoor units. Before clearing and

maintenance job being carried out to the indoor units, it is very important to turn off the total

power supply switch.

In order to turn on the units successfully, the main power switch should be opened 8

◆

hours before the operation.

After receiving the turn off signal, every indoor unit will continue to work for 20-70sec to

◆

make use of the rest cool air or the rest heat air in the heat exchanger, while preparing for the

next operation. And this is normal.

When the selected operating mode of the indoor unit are clash with the operating

◆

mode of the outdoor unit, the malfunction light will blink after 5s on the indoor unit or remote

controller showing that the operation clash, then the indoor unit will stop. At this time, change

the operation mode of the indoor unit to the one that would not clash with the outdoor operating

mode to make the operation normal. The cooling mode is not clash with the dry mode, while

the fan mode is not clash with any mode.

The appliance shall not be installed in the laundry.

◆

An all-pole disconnection switch having a contact separation of at least 3mm in all poles

◆

should be connected in xed wiring.

Information regarding transport/storage temperature (-25-55°C) is missing.

◆

Main switch provided by end user: main switch handle should be black or gray, it can be

◆

locked in “OFF” position with padlock.

The main disconnection device should be explained in user manual and the height

◆

should be recommended at 0.6-1.7m. over current protection is required(UL 1995,CSA C22.2).

The cooling range of the unit is the outdoor environment temp.-5~48°C DB, the heating

◆

range of the unit( only for the heat pump type unit) is the outdoor environment temp. -15~27°C

WB.

This product must not be disposed together with the domestic waste. This product

has to be disposed at an authorized place for recycling of electrical and electronic

appliances.

Thank you for your selecting of Impecca air conditioner, please read this usage

and install instruction carefully and keep it well in order to use this unit correctly.

Page 15

Contents

1 Safety Information .....................................................................................1

2 Install of The Compact Panel Cassette Type Indoor Unit .......................... 2

2.1 Schematic diagram of installation spaces ......................................................... 2

2.2 Select install location of the indoor unit ............................................................. 2

2.3 Important notice ................................................................................................ 3

2.4 Dimension of ceiling opening and location of the hoisting screw (M10) ............ 3

2.5 Main body of hoisting air conditioner ................................................................. 3

2.6 Connection of the refrigerant pipe ..................................................................... 4

2.7 Drainage hose ................................................................................................... 5

2.8 Electrical wiring ................................................................................................. 7

2.9 Install the panel ................................................................................................. 8

3

Constitutes and Names of Parts of Compact Panel Cassette Type Indoor Unit

4 Working Temperature Range ................................................................... 11

5 Malfunction Debarring .............................................................................12

.. 10

5.1 Check the following items before contacting maintenance center .................. 12

5.2 Instruction ........................................................................................................ 13

5.3 The following circumstance are not malfunction ............................................. 13

5.4 After-sales Service .......................................................................................... 13

6 Maintenance Method ............................................................................... 14

6.1 Cleaning air lter ............................................................................................. 14

6.2 Clean air inlet grille .......................................................................................... 15

6.3 Install and change of air purier ...................................................................... 15

6.4 Clean Outlet vent and Surface Panel .............................................................. 16

6.5 Maintenance before or after usage season ..................................................... 16

Page 16

Safety Information

1 Safety Information

Please read this manual carefully before use this unit, and operate it correctly according to the

guide in this manual.

Please take specially note to the meaning of these two marks:

Warning!: This mark means that it may cause casualty or badly heart if the operation is

incorrect.

Note!: This mark means that it may cause casualty or property loss if the operation is

incorrect.

Warning:

Do not adopt fuse with unsuitable capacity or adopt iron thread instead of fuse, otherwise

◆

malfunction or re may happened.

Cut down the main power switch immediately if malfunction (such as smell the burning odor

◆

etc.) happened.

Maintain ventilation to prevent oxygen leakage in room.

◆

Don’t insert nger or stick like things into discharge vent or outlet grill.

◆

Please make sure that the unit is installed in the place that can bear the weight of it

◆

adequately. If the place is not strong enough, the air conditioner may drop and cause casualty event.

Don’t spray or smear any oil paint or insecticide on the surface of unit, otherwise, re may be

◆

leaded.

(1). Do not ret the conditioner. Please contact the agency or prefect ional personnel to repair or

move the conditioner.

An all-pole disconnection switch having a contact separation of at least 3mm in all poles

should be connected in xed wiring.

Note!:

Please check and make sure that the cord, drainage pipe and tubes are connected in the

◆

correct way to prevent leakage of water, refrigerant, electric shock or re.

The main power must connectable to the earth in order to assure the conditioner earthing

◆

effectively and to prevent electric shock. Please don’t connect the earthing line with the gas pipe,

water pipe, lightening rod or the connecting line of telephone.

The air conditioner should be turned off at least after 5 mins’ operation; otherwise it would

◆

affect the duration of the unit.

Don’t let the children operate the air conditioner.

◆

Please don’t operate the unit by wet hand.

◆

Please turn off the main power of the unit before cleaning the conditioner or change the lter.

◆

Please cut off the main power if the conditioner will be used for a long time.

◆

1

Page 17

Install of The Compact Panel Cassette Type Indoor Unit

2 Install of The Compact Panel Cassette Type Indoor Unit

2.1 Schematic diagram of installation spaces

Wall

surface

Wall

surface

≥1500

unit:mm

≥2500

Ground

surface

>20

Model

ISMI-C15

H

≥1500

H

260

Wall

surface

Fig.1

2.2 Select install location of the indoor unit

(1). Obstruct should put away from the intake or outlet vent of the indoor unit so that the airow

can be blown though all the room.

(2). Make sure that the installation had accord with the requirement of the schematic diagram of

installation spaces.

(3). Select the place where can stand 4 times of the weight of the indoor unit and would not

increase the operating noise and oscillate.

(4). The horizontally of the installation place should be guaranteed.

(5). Select the place where easy drain condensated coagulated water, and easy connect with

outdoor unit.

(6). Make sure that there are enough space for care and maintenance. Make sure that the

weight between the indoor unit and ground is above 2500mm.

(7). When installing the steeve bolt, check if the install place can stand the weight 4 times of the

unit’s. If not, reinforce before installation. (Refer to the install cardboard and nd where should be

reinforced)

Note!

There will be lots of lampblack and dust stick on the acentric, heat exchanger and water pump

in dining room and kitchen, which would reduce the capacity of heat exchanger, lead water leakage

and abnormal operation of the water pump. The following treatment should be taken under this

circumstance:

(8). Ensure that the smoke trap above cooker has enough capacity to obviate lampblack to

prevent the indraft of the lampblack by the air conditioner.

(9). Keep the air conditioner far from the kitchen so that the lampblack would not be indraft by

the air conditioner.

2

Page 18

Install of The Compact Panel Cassette Type Indoor Unit

2.3 Important notice

To guarantee the good performance, the unit must be installed by professional personnel

◆

according with this instruction.

◆ Please contact the local Impecca special

Any

malfunction caused by the unit that is installed by the department that is not special nominated

nominated repair department before installation.

by Impecca would not deal with on time by the inconvenience of the business contact.

2.4 Dimension of ceiling opening and location of the hoisting screw (M10)

650

570

400

570 604 650

Fig.2 Install dimension of mode

The drilling of holes in the ceiling must be done by the professional personnel.

◆

Installation stands for main body of the unit

Ceiling

(160)

Above 20

Fig.3

Notes: The dimension for the ceiling openings with * marks can be as large as 610mm. But the

overlapping sections of the ceiling and the decorated surface boards should be maintained at no

less than 20mm.

2.5 Main body of hoisting air conditioner

(1). The primary step for install the indoor unit.

When attach the hoisting stand on hoisting screw, do use nut and gasket individually at the

◆

upper and lower of the hoisting stand to x it. The use of gasket anchor board can prevent gasket

break off.

(2). Use install cardboard.

Please refer to the install cardboard about the dimension of ceiling opening.

◆

The central mark of the ceiling opening is marked on the install cardboard.

◆

3

Page 19

Install of The Compact Panel Cassette Type Indoor Unit

Install the install cardboard on the unit by bolt (3 piece), and x the angle of the drainage pipe

◆

at the outlet vent by bolt.

(3). Adjust the unit to the suitable install place. (Refer to the g.3)

(4). Check if the unit is horizontal.

Inner drainage pump and bobber switch are included in the indoor unit, check if 4 angle of

◆

every unit are horizontal by water lever. (If the unit is slant toward the opposite of the coagulate

water ow, there may be malfunction of the bobber switch and lead water drop.)

(5). Backout the gasket anchor board used to prevent gasket break off and tighten the nut on it.

(6). Backout the install cardboard.

Fig.4

Note!: Please do tighten the nuts and bolts to prevent air conditioner break off.

2.6 Connection of the refrigerant pipe

When connect the pipe to the unit or backout it from the unit, please do use both spanner and

◆

torque wrench. as shown in g.5.

When connect, smear both inside and outside of the are nut with freeze motor oil, screw it

◆

by hand and then tighten it with spanner.

Refer to form 1 to check if the wrench had been tightened (too tight would mangle the nut

◆

and lead leakage).

Examine the connection pipe to see if it had gas leakage, then take the treatment of heat

◆

insulation, as shown in the g.5.

Only use median sponge to entwine the wiring interface of the gas pipe and heat preservation

◆

sheath of the gas collection tube.

4

Page 20

Install of The Compact Panel Cassette Type Indoor Unit

Smear freeze motoroil

here

Median sponge (attachment)

(entwine the wiring interface

with seal mat)

Torque wrench

Spanner

Wiring interface

Flare nut

Thread fasten(x4)

Gas collection tube

Liquid inlet tube

Heat preservation

sheath of liquid inlet

tube (attachment) (for

liquid tube)

Heat preservation

sheath of gas collection

tube (attachment)(for

gas tube)

Fig.5

Form 1: The tightening torque needed for tightening nut

Diameter(Inch

φ1/4’’

φ3/8’’

φ1/2’’

φ5/8’’

φ3/4’’

)

Surface thickness(mm

0.5 15-30 (N·m)

≥

0.71 30-40 (N·m)

≥

1 45-50 (N··m)

≥

1 60-65 (N·m)

≥

1 70-75 (N··m)

≥

)

Tightening torque (N·m)

2.7 Drainage hose

(1). Install the drain hose

The diameter of the drain hose should be equal or bigger than the connection pipe’s. ( The

◆

diameter of polythene pipe: Outer diameter 25mm Surface thickness ≥1.5mm)

Drain hose should be short and drooping gradient should at less 1/100 to prevent the

◆

formation of air bubble.

If drain hose cannot has enough drooping gradient, drain raising pipe should be added.

◆

To prevent bent of the drain hose, the distance between hoisting stand should is 1 to 1.5m.

◆

Fig.6

Use the drain hose and clamp attached. Insert the drain hose to the drain vent, and then

◆

tighten the clamp.

Entwine the big sponge on the clamp of drain hose to insulate heat.

◆

Heat insulation should be done to indoor drain hose.

◆

5

Page 21

Install of The Compact Panel Cassette Type Indoor Unit

Sponge(attachment)

Drain hose

Clamp(attachment)

Below 4mm

Clamp

Sponge (gray)

Fig.7

Drain stepup pipe note

The install height of the drain raising pipe should less than 280mm.

◆

The drain raising pipe should form a right angle with the unit, and distance to unit should not

◆

beyond 300mm.

Fig.8

Instruction

The slant gradient of the attached drain hose should be within 75mm so that the drain hole

◆

doesn’t has to endure the unnecessary outside force.

Fig.9

Please install the drain hose according to the following process if several drain hoses join

◆

together.

Fig.10

(2). Check the smoothness of drain after installation.

Check the drain state by immitting 600cc water slowly from the outlet vent or test hole.

◆

Check the drain in the state of refrigerating after installation of the electric circuit.

◆

6

Page 22

Install of The Compact Panel Cassette Type Indoor Unit

Fig.11

2.8 Electrical wiring

Note:The power of the entire indoor unit must be connected in outdoor unit.

About the electrical wiring, please see the circuit diagram attached with the unit.

◆

All the installation of electrical wiring must be done by professional personnel.

◆

Please do take the earthing treatment.

◆

Wiring method of connection unit and controller

Connection wiring (communication):

◆

Open electric box cover, drag the wiring (communication)from the rubber plug A, and impact

①

them well individually by impact fastener.

Wiring according to the indoor side circuit diagram.

②

Fix the impact fastener after connection.

◆

Entwine the small sponge on the electric wire( do entwine it to prevent condensation).

◆

Impact tightly by impact fastener after connection and then t on the electric box.

◆

Connect the 3 cord rubber wire to the counter terminal of the 3 way terminal board.

◆

The power cord reference Power cord standard recommending table

Power cord standard recommending table

Power Supply

(V, Ph, Hz)

208~203V-1Ph-60Hz

Fig.12

Min. Sectional Area of

Earth Wire(AWG)

UL1015 AWG 18*1 UL1015 AWG 18*3

Min. Sectional Area of

Power Cord(AWG)

7

Page 23

Install of The Compact Panel Cassette Type Indoor Unit

2.9 Install the panel

(1). Set the panel to the indoor unit body by matching the position of the swing ap motor of the

panel to the piping position of the panel to the piping position of the indoor unit as shown by g.13.

(2). Install the panel

Install the panel on the indoor unit temporarily. When install, hang the latch on the hook

① .

that is located on the opposite side of the swing ap on the panel of the indoor unit. (2

positions)

Hang the remaining 2 latches to the hooks on the sides of the indoor unit.(Be careful not to

② .

let the swing motor lead wire get caught in the sealing material.)

Screw the 4 hexagon head screws under the latches in about 15mm. (The panel would

③ .

rise)

Adjust the panel by turning it toward the direction pointed by the arrow as shown in g.13,

④ .

so that the adjust board connect the ceiling well.

Tighten the screws until the thickness of the sealing material between panel and indoor

⑤ .

unit reduced to 5-8mm.

Fig.13

Notes:

Improper screwing of the screws may cause the troubles shown in g.14.

① .

8

Page 24

Install of The Compact Panel Cassette Type Indoor Unit

Air leak

Air leak from ceiling

Water condensatation, water drop

Fig.14

If gap still exist between ceiling and decoration panel after tightening the screws, readjust

② .

the height of the indoor unit. (As shown in g.15)

If the raising lever and drain hose are

not affect, can adjust the height of

indoor unit by the hole on the corner

of panel.

Gaps are not allowed

Fig.15

After xing, be sure no gap left between the ceiling and the panel.

※

Wiring of the decoration panel (Fig.16)

③ .

Connect the joints for swing ap motor lead wire (at 2 places) installed on the panel.

At body At pane

At body At pane

Fig.16

9

Page 25

Constitutes and Names of Parts of Compact Panel Cassette Type Indoor Unit

3 Constitutes and Names of Parts of Compact Panel Cassette Type

Indoor Unit

10

Page 26

Working Temperature Range

4 Working Temperature Range

Working Temperature Range

Indoor side state Outdoor side stae

Dry bulb

temp.

℃

Rated Cooling 27 19 35 24

Max. cooling 32 23 48 26

Wet bulb

temp.

Dry bulb

℃

temp.

℃

Wet bulb

temp.

℃

Min. cooling 21 15 18

Rated Heating 20 15 7 6

Max. heating 27

Min. heating

20 15 -

—

24 18

15

-

—

16

11

Page 27

Malfunction Debarring

5 Malfunction Debarring

Warning!

Cut down the main power switch immediately if malfunction (such as smell the burning odor

◆

etc.) happened, and then contact service center. If the abnormal state is maintained, the unit may be

damaged or electric shock or re may be happened.

Do not ret the conditioner. Please contact service center to repair or move the conditioner.

◆

5.1 Check the following items before contacting maintenance center

Phenomena Reason Remedial Measures

Blow of fuse or breaker Change fuse or close breaker

Air conditioner doesn’t

run at all

Air conditioner runs

but stops immediately

Abnormal cooling or

heating

Power cut

Don’t connect with power Connect power well

Low batteries of wireless remote

controller

Wireless remote controller exceed

remote control area

Blockage in inlet or outlet vent of

indoor or outdoor unit

Blockage in inlet or outlet vent of

indoor or outdoor unit

Improper of temp. setting

Low setting of fan speed

Incorrect of wind direction

Door or window opened Close

Direct sun burn

Too many people in room

Restart when there is power

supply

Change new batteries

Signal could be received within

8m

Clean out blockage

Clean out blockage

Adjust settings in wireless remote

controller

Adjust settings in wireless remote

controller

Adjust settings in wireless remote

controller

Hang curtain or jalousie before

windows

Too many heater in room

Filter blocked by dirt Clean lter

12

Page 28

Malfunction Debarring

5.2 Instruction

If problem still cannot found out after above checking, please contact service center and instruct

phenomena and model.

5.3 The following circumstance are not malfunction

“Malfunction” Reason

Air conditioner doesn’t

run

Mist is blown from air

conditioner

Noise is heard from

air conditioner

Dust be blown for air

conditioner

Odor gives out from

air conditioner

Start up unit immediately after

turned off

When opening power

When cooling

Slight click sound heard once

begin running

Hissing sound heard continuously

when cooling

Hissing sound heard when staring

or stopping

Slight hissing sound heard when

running or after running

Creak sound heard when running

or after running

Started up after long time’s doesn’t

runs

When running

The overload protects switch

makes it run after 3 minutes delay.

Run for about 1 minute without

other actions

The high humidity air in room is

cooled rapidly

Sound of initialization for electric

expand valve

The sound for gas refrigerant

owing in the unit

The sound for gas refrigerant

stops ow

Sound for running of drainage

system

The grating sound caused by

expands of panel and other parts

for the change of temperature

Dust in indoor unit be blown out

This is because when air

conditioning, odors or cigarette

smoke from the room that was

sucked in is discharged again.

5.4 After-sales Service

When having quality or other problems when purchasing air conditioner, please contact the local

service center.

13

Page 29

Maintenance Method

6 Maintenance Method

When air conditioner won’t be used for a long time, please cut off the main power supply

of air conditioner.

Warning!

Do turn off the unit and cut off the main power supply when cleaning the air conditioner,

◆

otherwise electric shock or harm may happen.

It is forbidden to wash air conditioner by water rinsing, otherwise electric shock may happen.

◆

6.1 Cleaning air lter

Air lters should be cleaned by professionals with proper operation to ensure personal safety.

When the usage environment has lots of dust, air lter should be cleaned more frequently (about

once 6 months).

(1). Open air inlet grille

Loosen two screws on the air inlet grille with a screwdriver. And

grille at the same time with the direction showed by arrow in g.17, pull down slowly. (Reverse when

closing)

(2). Disassembly air lter

As shown in fig.18, pull the handle behind air inlet grille, raise it and disassembly. Then

discharge the 3 purier xed on lter.

pull the 2 handle on air inlet

Fig.17 Fig.18

(3). Clean

Adopts cleaner or water to wash lter; if the lter is too dirty ( like oil stain on it ), adopts warm

water ( lower than 45℃) with neutral scourer to clean it, then dry it in the shade.

Note

Do not clean the filter by hot water whose temp. is higher than 45℃to prevent fade or

deformation.

Do not burn it on re or the lter would catches re or deformation.

(4). Install air lter

Fix the 3 puriers on lter, install lter on the several bulges on top of air inlet grille, pull the

handle behind air inlet grille toward inside to x lter. As shown in g.19.

!

14

purifier

Page 30

Maintenance Method

(5). Close air inlet grille (Refer to the 1st step)

Maintenance Method

Fig.19 Fig.20

6.2 Clean air inlet grille

(1). Open air inlet grille (the same with the 1st step of Clean Air Filter)

(2). Take out air lter (the same with the 2nd step of Clean Air Filter)

(3). Take out air inlet grille

Open air inlet grille for an angle of 45°, as shown in g.20, rise it.

(4). Clean

Clean it by pubescence brush, water and neutral cleaning, then throw water or dry it.

Note

!

Do not use water above 45℃ to wash the panel to prevent fade or deformation.

(5). Install air inlet grille (refer to 3rd step)

(6). Install air lter (refer to the 4th step of Clean Air Filter)

(7). Close air inlet grille (refer to the 1st step)

6.3 Install and change of air purier

(1). Open air inlet grille (the same the 1st step of Clean Air Filter)

(2). Disassembly purier

As shown in g.21, disassembly air lter, screw out xing bolts xed on purier on lter, then

purier could be disassembly.

(3). Take out the package sack of static ber net lter, then install the lter in stand of purier,

and x purier on air lter.

(4). Install air lter (the same with the 4th step of Clean Air Filter)

Air filter

Purifier filter

Stand for purifier

Fix bolt of

purifier

Fig.21

15

Page 31

Maintenance Method

Function and usage period for air purifying

Could adsorb CO, CO

◆

Could adsorb deleterious material that is smaller than 1μm in air, as dust, pollen, bacteria,

◆

and virus.

Usage period is 6 months to 1 year. If it is necessary to be changed, purchase new purier in

◆

the nearest Impecca special engaged maintenance

center. 6.4 Clean Outlet vent and Surface

Clean the surface panel by soft dry cloth or wet cloth with neutral scourer.

◆

Panel

It is forbidden to clean surface panel by gasoline, benzene, diluents, cleansing powder etc..

◆

If the guide louver is too dirty, it may be removed to be cleaned. (As narrated below)

◆

Disassembly and install of guide louver

(1). Disassembly guide louver

Screw bolts in both end of guide louver to loose.

Note

Do not wipe guide louver powerfully when cleaning, otherwise uff on surface would fall off.

(2). Install guide louver

Rotate guide louver slightly could install the protruding edge of both end into grooves on both

end of guide louver, and then tighten bolts.

!

, benzene, aldehydes and odor of gasoline etc..

2

6.5 Maintenance before or after usage season

Check before the usage season

Check if there is blockage in inlet or outlet vent of air conditioner.

◆

Check if the earthing wire had earthed reliably.

◆

Check if the air lter had been installed well.

◆

In order to start up the air conditioner smoothly after long time’s turned off, turn on the main

◆

power supply 8 hours before turning on the air conditioner.

Maintenance after usage season

Clean lter and body of air conditioner.

◆

Cut off the main power supply of air conditioner.

◆

The cooling or heating capacity and sound level are tested before leaving factory.

◆

If the parameter changed, refer to the data offered on nameplate.

◆

6.6 CUSTOMER SUPPORT

Before contacting customer support, please see the troubleshooting guide above.

Visit our website to contact us, find answers to Frequently Asked Questions, and for other resources which

may include an updated version of this user's guide.

WWW.IMPECCA.COM

If you wish to contact us by phone, please be sure to have your model number and serial number ready

and call us between 9:00am and 6:00pm ET, at +1 866-954-4440.

Keep tabs on Impecca's newest innovations & enter contests via our social network feeds:

www.facebook.com/Impecca/

www.instagram.com/impecca/

@impeccausa

16

Page 32

© 2016 Impecca, a division of LT Inc., Wilkes Barre, PA.

Page 33

Wired Controller

IS-TT850

User's Manual

Thank you for choosing Impecca Air Conditioners. Please read this

owner’s manual carefully before operation and retain it for future reference.

Page 34

User Notice

Please carefully read this manual before installation and use of this product

ƹ

(QVXUHthere is separate SRZHUVXSSO\IRUHDFKLQGRRUXQLW

ƹ

Never install wired controller in a

ƹ

Shielded twisted pair line must be substituted as signal line for wired controller if the unit is

installed in the place where there is electromagnetic interference.

ƹ

Make sure communication line is connected into correct port to avoid communication

malfunction.

ƹ

Never knock, throw or frequently disassemble the wired controller.

ƹ

Never operate the wired controller with wet hand.

wet place or under direct sunlight.

Page 35

Contents

1 Display Section................................................................................................ 1

1.1 Controller's LCD ........................................................................................1

1.2 Instruction to LCD ....................................................................................... 2

2 Buttons ............................................................................................................3

2.1 Layout of Buttons .......................................................................................3

2.2 Functions of Buttons ...................................................................................3

3 Operation Instructions .....................................................................................4

3.1 On/Off ......................................................................................................... 4

3.2 Mode Setting .............................................................................................. 4

3.3 Temperature Setting ...................................................................................4

3.4 Fan Setting ................................................................................................. 5

3.5 Timer Setting .............................................................................................. 5

3.6 Swing Setting .............................................................................................7

3.7 Sleep Setting .............................................................................................. 8

3.8 Turbo Setting .............................................................................................. 9

3.9 E-heater Setting .......................................................................................10

3.10 Blow Setting ........................................................................................... 11

3.11 Other Functions ......................................................................................12

4 Installation and Dismantlement .....................................................................12

4.1 Connection of the Signal Line of the Wired Controller ............................. 12

4.2 Installation of the Wired Controller ........................................................... 12

4.3 Dismantlement of the Wired Controller .................................................... 14

5 Errors Display ................................................................................................ 14

Page 36

1 Display Section

Wired Controller IS-TT850

Fig1.1.1 Diagram of wired controller

1.1 LCD Display of Wired Controller

Fig.1.1.2 LCD display

1

Page 37

Wired Controller IS-TT850

1.2 Instruction to LCD Display

Table 1.1

No. Symbols Description

1

2

3

4

5

6

7

8

9

10

11

12 SHIELD

13 Turbo Turbo function state

14 MEMORY

Swing function

Air exchange function (this function is yet unavailable for this unit).

Sleep function (Only sleep 1).

Each kind of running mode of indoor unit (auto mode)

Cooling mode

Dry mode

Fan mode

Heating mode

Defrosting function for the outdoor unit.

Gate-control function (this function is yet unavailable for this unit).

Lock function.

Shield functions (Button operation, temperature setting, On/Off operation,

Mode setting are disabled by the remote monitoring system.)

Memory function (The indoor unit resumes the original setting state after

power failure and then power recovery).

15

16

17

18 E-HEATER Electric auxiliary heating function.

19 BLOW Blow function.

20

21 QUIET

SAVE

It blinks under on state of the unit without operation of any button.

Energy-saving function (this function is yet unavailable for this unit).

Ambient/setting temperature value

Timing value.

Quiet function (two types: quiet and auto quiet)

(this function is yet unavailable for this unit).

2

Page 38

2 Buttons

2.1 Layout of Buttons

2.2 Functions of Buttons

Table 2.1

No. Name Function

Wired Controller IS-TT850

1 Enter/Cancel Function selection and cancellation.

2 Ÿ

6 ź

3 Fan

4 Mode Setting of the Cooling/Heating/Fan/Dry/Auto mode of the indoor unit.

5 Function Switchover among the functions of Turbo/Save/E-heater/Blow etc..

7 Timer Timer setting.

8 On/Off

4+2 Mode + Ÿ

3+6 )DQź

4+6

2+6 Ÿź

Mode ź

ķ

Running temperature setting of the indoor unit, range:

F(16°C-30°C).

Setting of the low/middle/high/auto fan speed.

Turn on/off the indoor unit.

With the A/C powered off, press these two buttons together for 5

seconds to toggle the Memory function. With Memory on, the unit will

return the the previous setting after resuming from a power failure.

With Memory toggled off, it will stay off

With the A/C powered off, press these two buttons together for 5 seconds

to determine if your unit is capable of just cooling or both cooling and

heating, indicated by the symbols shown.

With the A/C powered off, press these two buttons together for 5 seconds to

toggle between Fahrenheit and Celsius.

Press these two buttons together for 5 seconds to toggle the lock function.

ĸ

Timer setting, range:0.5(30 minutes) - 24 (hours).

61°F-86°

3

Page 39

Wired Controller IS-TT850

3 Operation Instructions

3.1 On/Off

Press On/Off button to toggle your A/C's power.

Note: The state shown in Fig.3.1.1 indicates the “Off” state of the unit after power has been restored

to the unit. The

3.2 Mode Setting

Under ON state of the unit, press the Mode to switch the operation modes as the

following sequence: Auto–Cooling–Dry–Fan–Heating.

screen shown in Fig.3.1.2 indicates the “On” state of the unit after power on.

Fig.3.1.1 “Off” State Fig.3.1.2 “On” State

3.3 Temperature Setting

3UHVVŸRUźWRLQFUHDVHGHFUHDVHWKHSUHVHWWHPSHUDWXUH,ISUHVVLQJHLWKHURIWKHP

continuously, the temperature will be increased or decreased by 1° every half a second,as

shown in Fig.3.3.1.

In the Cooling, Dry, Fan or Heating mode, the temperature setting range is 61°F-86°

F(16°C-30°C). In the Auto mode, the setting temperature not manually adjustable.

Fig.3.3.1 Fig.3.4.1

4

Page 40

Wired Controller IS-TT850

3.4 Fan Setting

While the unit is powered on, press

circularly as shown in Fig.3.4.1.

Fan

and then fan speed of the indoor unit will change

Low Middle

High

(Fig. 3.4.1)

3.5 Timer Settings

While the unit is powered on, pressing the Timer button allows you to

unit turns off. While the unit is powered off, pressing the Timer button allows you to set the dealy

until the unit turns on.

• 7LPHURQVHWWLQJ details

With the unit turned off, and no timer already programmed, press the Timer button. The

display will show "0.5" with "Hour on" blinking. PressŸorźbutton to adjust delay until unit

turns on and press Timer or Enter/Cancel to confirm.

• Timer off setting details:

With the unit turned on, and no timer already programmed, press the Timer button. The display

will show "0.5" with "Hour off" blinking.

• Timer off setting details:

With the unit turned on, and no timer already programmed, press the Timer button. The display will

show "0.5" with "Hour off" blinkingSUHVVŸRUźEXWWRQWRDGMXVWdelay until unit turns on and press

Timer or Enter/Cancel to confirm.

&DQFHOWLPHU

After setting of timer, if Timer button is pressed, LCD won’t display xx. Hour so that timer setting is

Timer off setting under the “On” state of the unit is shown as Fig.3.5.1.

canceled.

set the delay until the

Fig.3.5.1 Timer off Setting under the “On” State of the Unit

5

Page 41

Wired Controller IS-TT850

Timer on setting under the “Off” state of the unit is shown as Fig.3.5.2.

Fig.3.5.2 Timer on Setting under the “Off” State of the Unit

7LPHUUDQJHKU(YHU\SUHVVRIŸRUźZLOOPDNHWKHVHWWLPHLQFUHDVHGRUGHFUHDVHGE\

0.5hr. If either of them is pressed continuously, the set time will increase/ decrease by 0.5hr every

0.5s.

6

Page 42

Wired Controller IS-TT850

3.6 Swing Setting

Swing On: Press Function under on state of the unit to activate the swing function. In this case,

ZLOOEOLQN$IWHUWKDWSUHVV(QWHU&DQFHOWRPDNHDFRQ¿UPDWLRQ

Swing Off: When the Swing function is on, press Function to enter the Swing setting

interface,with

shown as Fig.3.6.1.

blinking. After that, press Enter/Cancel to cancel this function. Swing setting is

Fig.3.6.1 Swing Setting

Notes:

ķ

Sleep, Turbo or Blow setting is the same as the Swing setting.

ĸ

After the setting has been done, it has to press the key “Enter/Cancel” to back to the setting

VWDWXVRUTXLWDXWRPDWLFDOO\¿YHVHFRQGVODWHU

7

Page 43

Wired Controller IS-TT850

3.7 Sleep Setting

Sleep on: Press Function under the On state of the unit till the unit enters the Sleep setting

VWDWH$IWHUWKDWSUHVV(QWHU&DQFHOWRFRQ¿UPWKLVVHWWLQJ

Sleep off: When the Sleep function is activated, press Function to enter the Sleep setting

status. After that, press Enter/Cancel to cancel this function.

In the Cooling or Dry mode, the temperature will increase by 1°C after the unit runs under

Sleep1 for 1hr and 1°C after another 1hr.After that, the unit will run at this temperature.

In the Heating mode, the temperature will decrease by 1°C after the unit runs under Sleep 1 for

1hr and 1°C after another 1hr. After that, the unit will run at this temperature.

Sleep setting is shown as Fig.3.7.1.

Fig.3.7.1. Sleep Setting

8

Page 44

Wired Controller IS-TT850

3.8 Turbo Setting

Turbo function: The unit at the high fan speed can realize quick cooling or heating so that the

room temperature can quickly approach the setting value.

In the Cooling or Heating mode, press Function till the unit enters the Turbo setting status and

WKHQSUHVV(QWHU&DQFHOWRFRQ¿UPWKHVHWWLQJ

When the Turbo function is activated, press Function to enter the Turbo setting status and then

press Enter/Cancel to cancel this function.

Turbo function setting is as shown in Fig.3.8.1.

Fig.3.8.1 Turbo Setting

9

Page 45

Wired Controller IS-TT850

3.9 E-heater Setting

E-heater (auxiliary electric heating function): In the Heating mode, E-heater is allowed to be

WXUQHGRQIRULPSURYHPHQWRIHI¿FLHQF\

Once the wired controller or the remote controller enters the Heating mode, this function will be

turned on automatically.

Press Function in the Heating mode to enter the E-heater setting interface and then press

Enter/Cancel to cancel this function.

Press Function to enter the E-heater setting status, if the E-heater function is not activated,

and then press Enter/Cancel to activate it.

The setting of this function is shown as Fig.3.9.1 below:

Fig.3.9.1 E-heater Setting

10

Page 46

Wired Controller IS-TT850

3.10 Blow Setting

Blow function: After the unit is turned off, the water in evaporator of indoor unit will be

automatically evaporated to avoid mildew.

In the Cooling or Dry mode, press Function till the unit enters the Blow setting status and then

press Enter/Cancel to active this function.

When the Blow function is activated, press Function to the Blow setting status and then press

Enter/Cancel to cancel this function.

Blow function setting is as shown in Fig.3.10.1

Fig.3.10.1 Blow Setting

Notes:

ķ

When the Blow function is activated, if turning off the unit by pressing On/Off or by the

remote controller, the indoor fan will run at the low fan speed for 2 min, with “BLOW” displayed on

the LCD. While, if the Blow function is deactivated, the indoor fan will be turned off directly.

ĸ

Blow function is unavailable in the Fan or Heating mode.

11

Page 47

Wired Controller IS-TT850

3.11 Other Functions

a. Lock

8SRQVWDUWXS RI WKHXQLWZLWKRXWPDOIXQFWLRQ RUXQGHUWKH³2II´ VWDWHRIWKH XQLW SUHVVŸDQG ź at

the same time for 5s till the wired controller enters the Lock function. In this case, LCD displays

.

After that, repress these two buttons at the same time for 5s to quit this function.

Under the Lock state, any other button press won’t get any response.

b. Memory

0HPRU\VZLWFKRYHU 8QGHUWKH³2II´VWDWHRI WKHXQLWSUHVV 0RGHDQGŸDWWKH VDPHWLPHIRU

5s to switch memory states between memory on and memory off. When this function is activated,

Memory will be displayed. If this function is not set, the unit will be under the “Off” state after power

failure and then power recovery.

Memory recovery: If this function has been set for the wired controller, the wired controller after

power failure will resume its original running state upon power recovery. Memory contents: On/

Off,Mode, set temperature, set fan speed and Lock function.

4 Installation and Dismantlement

4.1 Connection of the Signal Line of the Wired Controller

Ɣ2SHQWKHFRYHURIWKHHOHFWULFFRQWUROER[RIWKHLQGRRUXQLW

Ɣ/HWWKHVLQJOHOLQHRIWKHZLUHGFRQWUROOHUWKURXJKWKHUXEEHUULQJ

Ɣ&RQQHFWWKHVLJQDOOLQHRIWKHZLUHGFRQWUROWRWKHSLQVRFNHWRIWKHLQGRRUXQLW3&%

Ɣ7LJKWHQWKHVLJQDOZLUHZLWKWLHV

Ɣ7KHFRPPXQLFDWLRQGLVWDQFHEHWZHHQWKHPDLQERDUGDQGWKHZLUHGFRQWUROOHUFDQEHXSWR

20 meters ( the standard distance is 8 meters)

4.2 Installation of the Wired Controller

PVC Pipe

1

3 4 52

Fig.4.1 Accessories for the Installation of the Wired Controller

Table 4.1

No.12345

Front Panel

of the Wired

Controller

Screw

ST 2.9X6*

Name

*Not included

Socket box

embedded

in the wall

*

Back-plate of

the Wired

Controller

Screw

M4X25

*

12

Page 48

Wired Controller IS-TT850

1

7

8 9

2

3 4

6

5

10

Fig.4.2

Fig.4.2 shows the installation steps of the wired controller, but there are some issues that need

your attention.

1) Prior to the installation, please firstly cut off the power supply of the wire buried in the

installation hole, that is, no operation is allowed with electricity during the whole installation.

2) Pull out the four-core twisted pair line from the installation holes and then let it go through

the rectangular hole behind the back-plate of the wired controller.

6WLFNWKHVROHSODWHRIWKH ZLUHGFRQWUROOHU WRWKH ZDOORYHU WKHLQVWDOODWLRQKROHDQGWKHQ¿[LW

with screws M4X25.

4) Insert the four-core twisted pair line into the slot of the wired controller and then buckle the

front panel and the back-plate of the wired controller together.

)LQDOO\¿[WKHIURQWSDQHODQGWKHVROHSODWHRIWKHZLUHGFRQWUROOHUWLJKWO\E\VFUHZV67;

CAUTION!

Please pay special attention to the followings during the connection to avoid the malfunction of

the air conditioning unit due to electromagnetic interference.

ķ

Separate the signal and communication lines of the wired controller from the power cord

13

Page 49

Wired Controller IS-TT850

and connection lines between the indoor and outdoor unit, with a minimum interval of 20cm,

otherwise the communication of the unit will probably work abnormally.

ĸ

If the air conditioning unit is installed where is vulnerable to electromagnetic

interference,then the signal and communication lines of the wired controller must be the shielding

twisted pair lines.

4.3 Dismantlement of the Wired Controller

1 3 42

5 Errors Display

If there is an error occurring during the operation of the system, the error code will be displayed

on the LCD, as show in Fig.5.1. If multi errors occur at the same time, their codes will be displayed

circularly.

Note: In event of any error, please turn off the unit and contact the professionally skilled

personnel.

Fig.5.1

14

Page 50

Wired Controller IS-TT850

Table 5.1 Meaning of Each Error

Error

Return air temperature sensor open/

short circuited

evaporator temperature sensor open/

short circuited

Indoor unit liquid valve temperature

sensor open/short circuited

Indoor gas valve temperature sensor

open/ short circuited

IPM temperature sensor open/short

circuited

Outdoor ambient temperature sensor

open/ short circuited

Outdoor unit condenser mid-tube

temperature sensor open/short circuited

Discharge temperature sensor open/

short circuited

Indoor and outdoor communication error E6 Compressor startup failure Lc

DC bus under-voltage protection PL High discharge temperature protection E4

DC bus over-voltage protection PH Overload protection E8

Compressor phase current sensing

circuit error

Compressor demagnetization protection HE Over phase current protection P5

PFC protection Hc Compressor desynchronizing H7

IPM Temperature Protection P8 IPM Current protection H5

Over-power protection L9

System charge shortage or blockage

protection

Capacitor charging error PU

High pressure protection E1

Low pressure protection E3

Compressor stalling LE

Over-speeding LF

Drive board temperature sensor error PF Indoor unit full water error E9

AC contactor protection P9 Anti-freezing protection E2

Temperature drift protection PE AC input voltage abnormal PP

Sensor connection protection Pd Whole unit current sensing circuit error U5

DC bus voltage drop error U3 4-way valve reversing error U7

Outdoor fan 1 error protection L3 Motor stalling H6

Outdoor fan 2 error protection LA PG motor zero-crossing protection U8

Error

Code

F1 Drive board communication error P6

F2 Compressor overheating protection H3

b5 Indoor and outdoor units unmatched LP

Communication line misconnected or

b7

expansion valve error

P7 5XQQLQJPRGHFRQÀLFW E7

F3 Pump-down Fo

F4 Jumper error C5

F5 Forced defrosting H1

U1 Whole unit over-current protection E5

Compressor phase loss/reversal

protection

Frequency restricted/reduced with whole

F0

unit current protection

Frequency restricted/reduced with IPM

current protection

Frequency restricted/reduced with high

discharge temperature

Frequency restricted/reduced with anti-

freezing protection

Frequency restricted/reduced with

overload protection

Frequency restricted/reduced with IPM

temperature protection

Error

Error

Code

dn

Ld

F8

En

F9

FH

F6

EU

15

Page 51

Technical Support

Before calling technical support, please see the troubleshooting guide above. You may also visit

our website at www.impecca.com for answers to Frequently Asked Questions and to contact us.

Email: support@impecca.com

Phone: +1 866–954–4440

Web: www.impecca.com

Loading...

Loading...