Page 1

Flex+ Series R410A

Systems―Outdoor Unit

Owner's Manual Impecca Air

Conditioners

ISMO-6021

Thank you for choosing Impecca air conditioners, please read this owner’s manual carefully

before operation and keep it for future reference.

Impecca reserves the right to interpret this manual which will be subject to any change due

to product improvement without further notice.

v. 1

.1

Page 2

Page 3

Preface

Flex + Series adopt the advanced manufacturing technology and takes the environmental-

friendly R410A as refrigerant, which is a green product in the 21st century. Please carefully read

the manual before installation and operation.

1

) Flex + Series systems conform to design standard ARI 210240-2008.

2) To ensure safety when operating this system, please strictly follow the instructions in this

manual.

3) Make sure that the manual is kept by the operators or serviceman.

4) The refrigerant pipes and accessories must be designed exclusively for R410A.

5) The total capacity of the indoor units which runs at the same time cannot exceed the capacity of

the outdoor units; otherwise, the cooling (heating) effect of each indoor unit would be lower

than the nominal capacity.

6) In case of malfunction, please examine the following items and contact our appointed service

centers as soon as possible.

Nameplate (model, cooling capacity, product code, ex-factory date).

Malfunction status (detail description of conditions before and after malfunction occurs).

7) It is a normal phenomenon that the fan of indoor unit will still run for 20~70 seconds after the

indoor unit receives the “stop” signal so as to make full use of the waste heat.

8) When the work mode of the indoors is conflict with the modes of outdoor units, it will be

indicated on the display of the wired controller in five seconds and then the indoor unit will

stop. In this case, please harmonize their work modes: the cooling mode is compatible with the

dry mode.

9) If the supply power fails when the unit is running, then the indoor unit will send the “start”

signal to the outdoor unit three minutes later after the power recovery.

10) The power cable and transmission line must not be twisted together, but instead of separated

with an interval of at least 2cm; otherwise it may be result in communication problem.

11) This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

12) All graphics and information in this manual are only for reference. Manufacturer reserves the

right for changes in terms of sales or production at any time and without prior notice.

This product must not be disposed together with the domestic waste. This product has

to be disposed at an appointed place for recycling of electrical and electronic appliances.

Thank you for purchasing Impecca air conditioners. Before using, please read

this manual carefully and keep it properly for further reference.

Page 4

Page 5

Contents

1 Safety Precautions ..................................................................................................................... 1

2 Attention for Installation ........................................................................................................... 3

2.1 Precautions for R410A .................................................................................................. 3

2.2 Precaution for Installation ............................................................................................. 3

2.3 Precaution for Operation Test........................................................................................ 3

2.4 Accessories .................................................................................................................... 3

3 Product Introduction ................................................................................................................. 4

3.1 Names of Main Parts ..................................................................................................... 4

3.2 Combinations for Outdoor and Indoor Units ................................................................ 4

3.3 Parts and Components of Unit ...................................................................................... 5

3.4 Working Temperature Range ......................................................................................... 5

4 Selection of Installation Location and Precautions ................................................................... 6

4.1 Selection of Installation Location ................................................................................. 6

4.2 Outline Dimension of Outdoor Unit .............................................................................. 7

4.3 Installation and Servicing Space ................................................................................... 7

5 Installation Instruction .............................................................................................................. 8

6 Installation of Refrigerant Pipes ............................................................................................... 9

6.1 Allowable Length and Drop Height of Connecting Pipe .............................................. 9

6.2 Dimension of Connecting Pipe ................................................................................... 10

6.3 Connection of Branch Pipe ......................................................................................... 10

6.4 Connection of Refrigerant Pipes ................................................................................. 11

6.5 Connec

6.6 Leak Test ..................................................................................................................... 13

6.7 Vacuum Operation ....................................................................................................... 13

6.8 Refrigerant Charging ................................................................................................... 14

7 Electrical Wiring Work ........................................................................................................... 17

7.1 Wiring Connection ...................................................................................................... 17

7.2 Requirements of Power Circuit and Cable .................................................................. 17

7.3 Ground Requirements ................................................................................................. 18

7.4 Precautions on the Electrical Wiring Work ................................................................. 18

7.5 Precaution of Laying Wires ......................................................................................... 19

7.6 Procedures for Electrical Wiring Work ....................................................................... 19

8 Design of Drainage Pipeline ................................................................................................... 20

8.1 Installation of Drain Hose ........................................................................................... 20

8.2 Design of Drainage Pipeline ....................................................................................... 20

9 Installation of Protective Layer ............................................................................................... 21

10 Test Operation ......................................................................................................................... 22

10.1 Check after Installation ............................................................................................... 22

10.2 Test Operation ............................................................................................................. 22

11 Testing Board Introduction ..................................................................................................... 23

11.1 Compose of the Testing Board .................................................................................... 23

11.2 Instruction of Function and Data Section .................................................................... 23

tion of Refrigerant Pipe ................................................................................... 12

I

Page 6

12 Troubleshooting ...................................................................................................................... 24

12.1 Check before Contacting Service Center .................................................................... 24

12.2 Problem Handling ....................................................................................................... 25

12.3 Error Description ......................................................................................................... 25

13 Maintenance ............................................................................................................................ 28

13.1 Outdoor Condenser ..................................................................................................... 28

13.2 Drain Pipe ................................................................................................................... 28

13.3 Check before the Seasonal Use ................................................................................... 28

13.4 Maintenance after Seasonal Use ................................................................................. 28

14 After-sales Service .................................................................................................................. 28

II

Page 7

1 Safety Precautions

Flex + Series

WARNING

CAUTION

NOTICE

This is t

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

This mark indicates procedures which, if improperly performed, might lead to the

death or serious injury of the user.

This mark indicates procedures which, if improperly performed, might possibly result

in personal harm to the user, or damage to property.

NOTICE is used to address practices not related to personal injury.

he safety alert symbol. It is used to alert you to potential personal injury

WARNING

1) Instructions for installation and use of this product are provided by the manufacturer.

2) Installation must be performed in accordance with the requirements of NEC and CEC by appointed

personnel only.

3) The installation should be left to the appointed service center and according to the instructions given in the

manual. Improper installation may cause fall down, water leakage, electric shock or fire etc.

4) For operating the air conditioner pleasantly, please install it as outlined in this installation manual.

5) The power supply must adopt the special circuit with air switch protection and assure it has enough capacity

6) Connect the indoor unit, BU module and outdoor unit with the room air conditioner piping and cord

available from our standard parts. This installation manual describes the correct connections using the

installation set available from our standard parts.

7) Before installation, check the parameter of power cord and make sure that it complies with the power

supply requirement on the nameplate. Make sure the power supply is safe.

8) This air conditioner must be properly grounded through the receptacle to avoid electric shock. The ground

wire shouldn’t be connected with gas pipe, water pipe, lightning arrester or telephone line.

9) If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in contact

with a flame, it produces toxic gas.

10) Do not power on until all installation work is complete.

11) During installation, make sure that the refrigerant pipe is attached firmly before you start up the compressor.

Do not operate the compressor under the condition of refrigerant piping not attached properly with valve

open. This may cause abnormal pressure in the refrigeration cycle that leads to breakage and even injury.

12) When installing and relocating the air conditioner, do not mix gases except the specified refrigerant

(R410A) to enter the refrigerant cycle. If air or other gas enters the refrigerant cycle, the pressure inside the

cycle will rise to an abnormally high value and cause breakage, injury, etc.

13) This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

14) Never cut off or damage power cables and transmission wires. If the power cable or transmission line were

damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to

avoid a hazard.

15) After the power cord is connected, please install the cover of electric box to avoid danger.

1

Page 8

Flex + Series

16) When installing or relocating the unit, please contact the appointed service center for the repair or

relocation. Meanwhile the specialized parts and accessories must be used. Otherwise, it may result in water

leakage, electric shock or fire hazard.

17) Diameter of power cord must be large enough. Damaged power cord or connecting wire must be replaced

by specialized electric cable.

18) The power wire and transmission line must be more than one meter away from televisions or radios which

can emit electromagnetic waves to prevent image interference or noise. Otherwise, the unit maybe not work

19) Nitrogen must be charged according to technical requirements.

20) For units with wired controllers, do not connect power supply until the wired controller is well installed.

Otherwise, the wired controller cannot be used.

21) When installation is finished, please check and make sure the drain pipe, pipeline and electric wire are all

well connected so as to avoid water leakage, refrigerant leakage, electric shock and fire hazard.

22) Never extend fingers or objects into air outlet or return air grille.

23) Please keep the room well-ventilated and it could avoid oxygen deficit.

24) Never start or stop the air conditioner by inserting or removing the power cord.

25) Before startup of the compressor, please turn on the main power switch of the unit for more than 8 hours

and it makes sure that the heater belt of the compressor has been energized for at least eight hours! Once the

compressor is started, it must be guaranteed that it works continuously for at least 30 minutes, otherwise it

would be damaged!

26) Never operate the unit with wet hands. Otherwise, it may cause electric shock.

27) Before cleaning and repairing, it is necessary to stop working and turn off the power supply. Otherwise, it

may cause electric shock or damage.

28) Do not spray water on the air conditioner or it will cause malfunction or electric shock.

29) The air conditioner is not support to install in the circumstances as the following that where there is full of

mist of oil, damp or corrosive gas, flammable gases, the acidic or alkaline vapor and the ocean.

30) Volatile liquid like thinner or gasoline will damage the appearance of air conditioner. (Please use soft dry

cloth and wet cloth with mild detergent to clean unit’s appearance.)

31) Never standing or place objects on outdoor unit. Person or objects falling from the unit may cause injury.

32) If abnormal condition occurs (e.g. unpleasant smell), please turn off the unit at once and disconnect power

supply. Then contact appointed service center. If the air conditioner continues to operate despite of

abnormal condition, it may be damaged and cause electric shock or fire hazard.

33) The drain pipe should be installed as instructed in the manual to guarantee the proper drainage; meanwhile

it should be insulated to prevent condensing; otherwise the improper installation would cause water leakage

and then wet the household wares in the room.

34) Don't attempt to repair the air conditioner by yourself. The improper repair will lead to electric shock or

fire, please contact the appointed service center and ask professional technicians to repair it.

35) Please take notice of the installation foundation of the unit after long use, if it is damaged, it may lead to the

fall of the unit and cause the injury.

36) Be sure to shut off the power supply when you do not use the air conditioner for a long time. Otherwise, the

dusts may accumulate in it, which may cause overheating or fire hazards.

37) Impecca is not responsible for any personal injury or property loss caused by improper installation,

improper debugging, unnecessary repair or not following the instruction

s of this manual.

2

Page 9

Flex + Series

2 Attention for Installation

2.1 Precautions for R410A

It is very strict that the refrigerant pipes should be clean and dry.

It does not support to let a lot of refrigerant go into the ambient atmosphere, because it will

2.2 Precaution for Installation

The unit is so heavy that it is more than 110kg, so more than two persons will be needed to

When remove the units, please place the hands on the corner and take care not to hurt the hands

It is very likely to dispose the waste to the garbage bin after the installation.

e R410A is a mixed refrigerant, when adding the refrigerant to the unit, it must be

Th

in its liquid state. If the refrigerant is in gas state, the composition has been changed and the

capability of the unit will decrease.

When the refrig

frostbite.

strengthen the green house effect. Otherwise, it will produce toxic gas when the refrigerant

contacts with the fire.

remove the unit. The package cannot bear it, so do not grasping it.

by the fins.

erant leaks out, please do not touch the leakage. Otherwise, it will result in

2.3 Precaution for Operation Test

In order to protect the compressor from vibrating during transportation and 2 metal gaskets are

used. They must be removed prior to commissioning and tied back the nut firmly; otherwise the unit

might not be operated well.

2.4 Accessories

For the accessories of the air conditioner, please look out the Packing List in the package.

3

Page 10

Flex + Series

3 Product Introduction

Impecca Flex + Series adopts inverter compressor technology. According to change

The

displacement of compressor, stepless capacity regulation within range of 10%~100% can be

realized. Various product lineups are provided with capacity range from 14kW to 16kW, which

can be widely used in residential house, business office, hotel and where especially applicable

to the place with variable load change. Impecca air conditioner is absolutely your best choice.

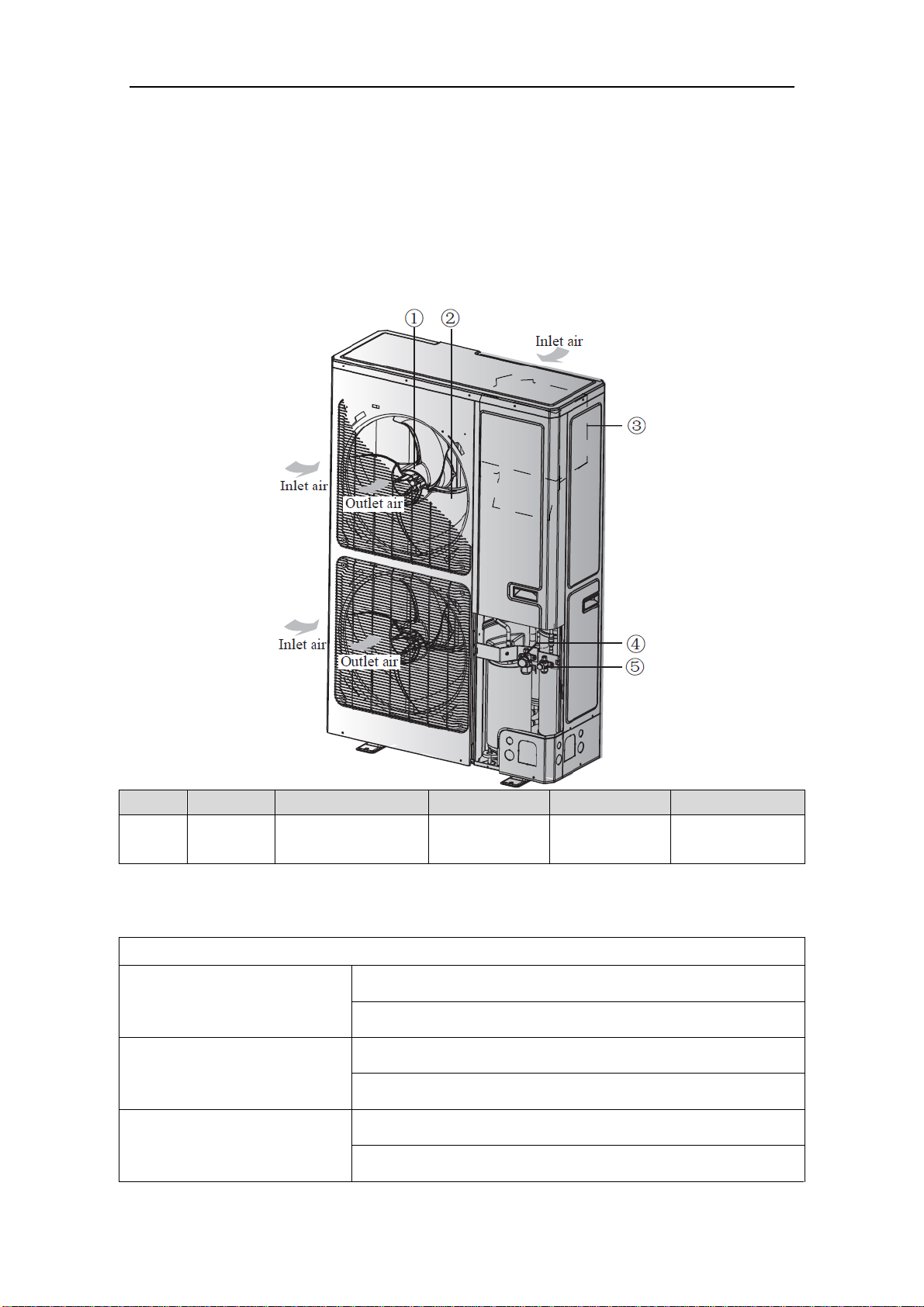

3.1 Names of Main Parts

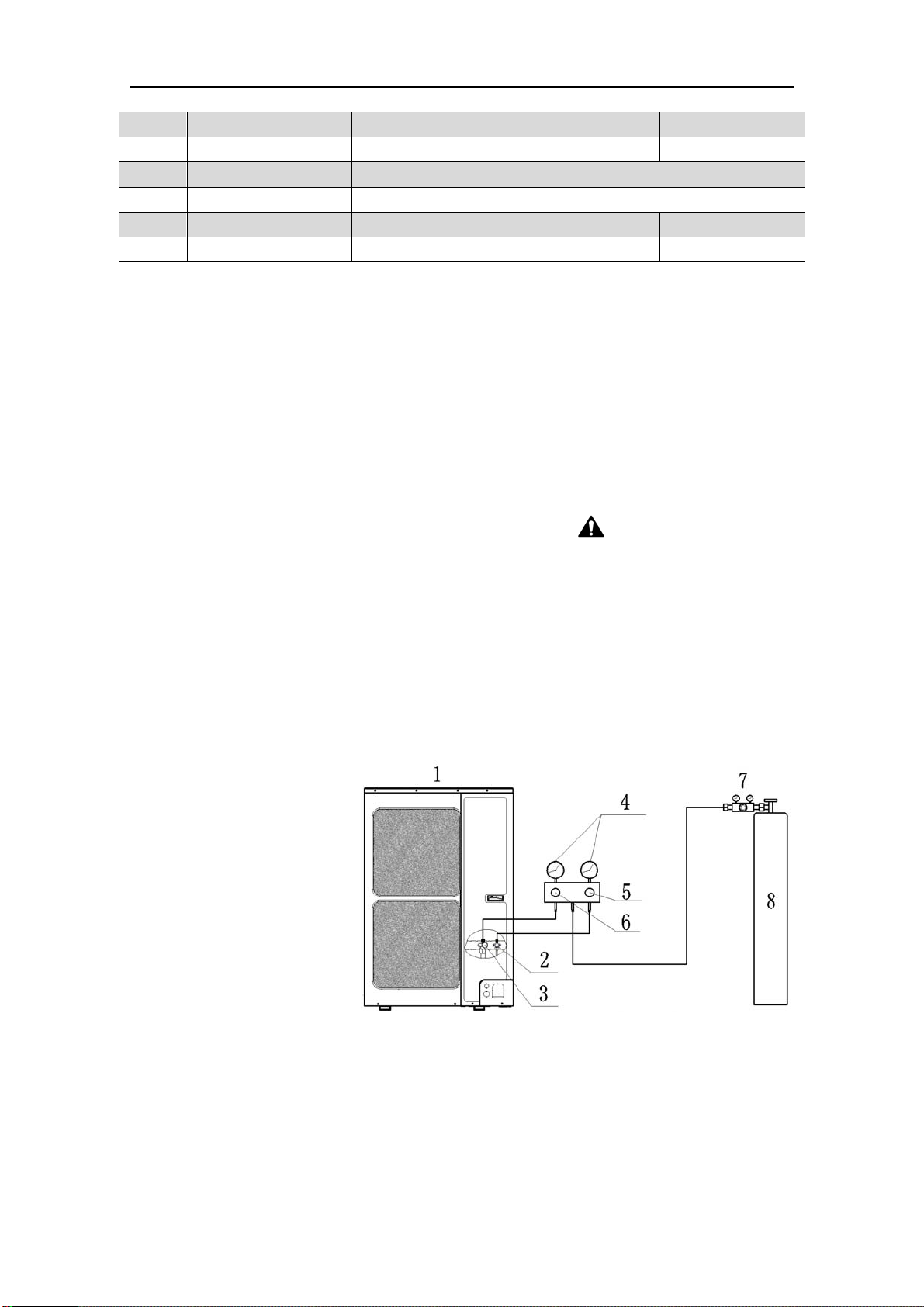

NO. ① ② ③ ④ ⑤

Name Fan motor Axial flow fan blade Electrical box

Fig. 1

Gas side stop

valve

Liquid side stop

3.2 Combinations for Outdoor and Indoor Units

Table 1

Sorts GWHD(56S)ND3CO

No. of indoor units to be

connected

No. of BU modules to be

connected

Total capacity of indoor units to

be connected(Btu/h)

Min 2

Max 9

Min 1

Max 3

Min 28000

Max 81000

valve

Page 11

Flex + Series

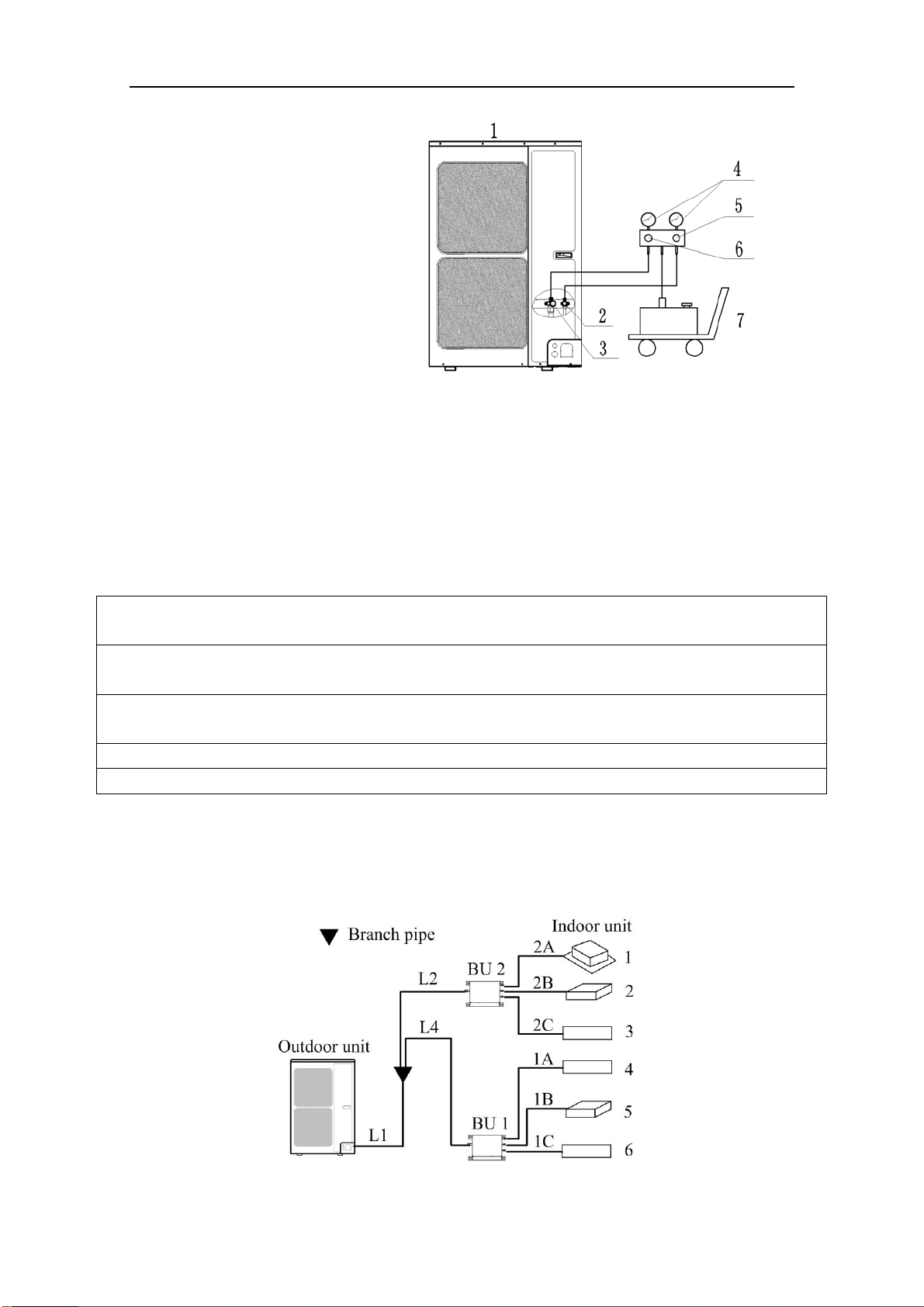

Parts and Components of Unit

3.3

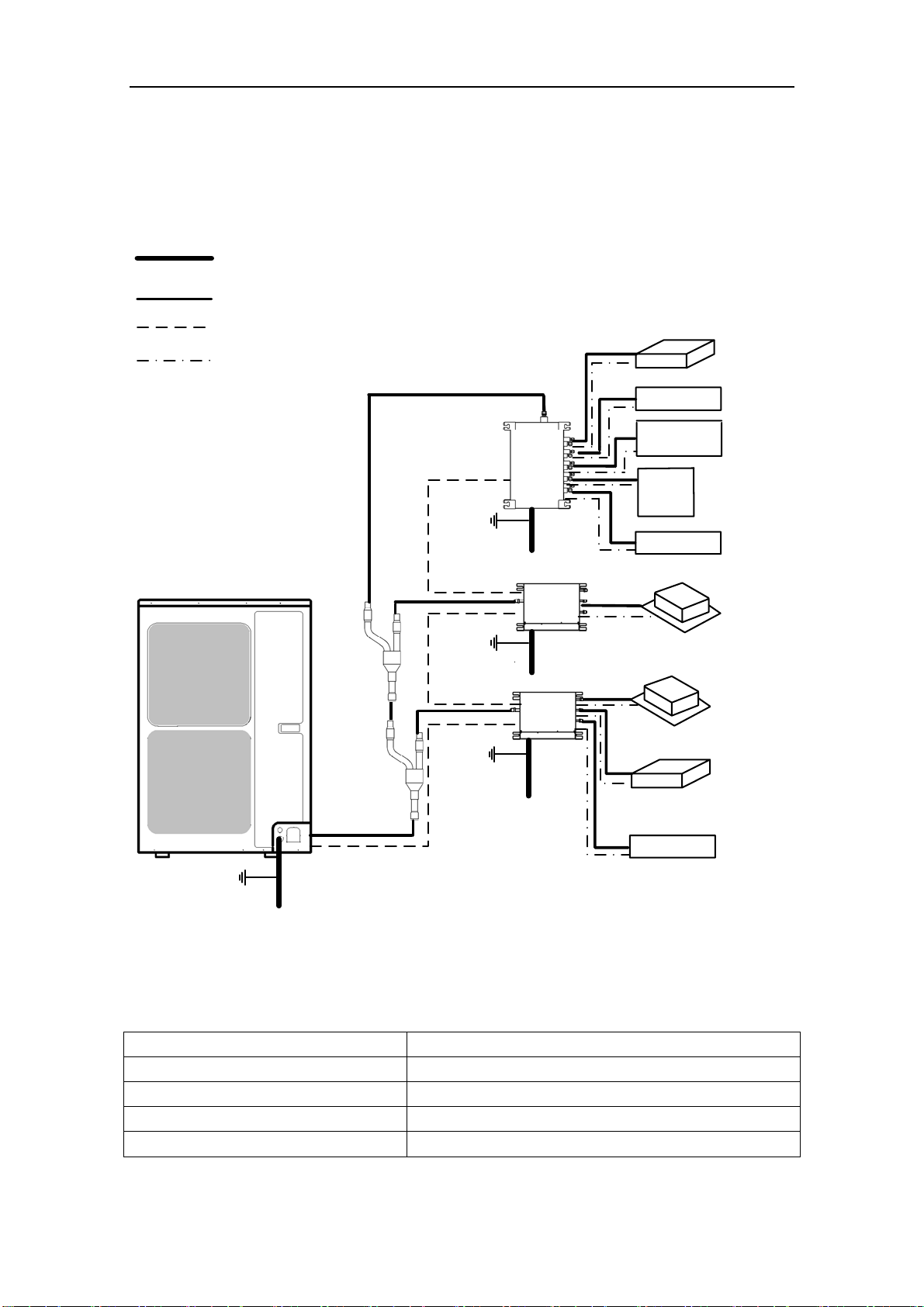

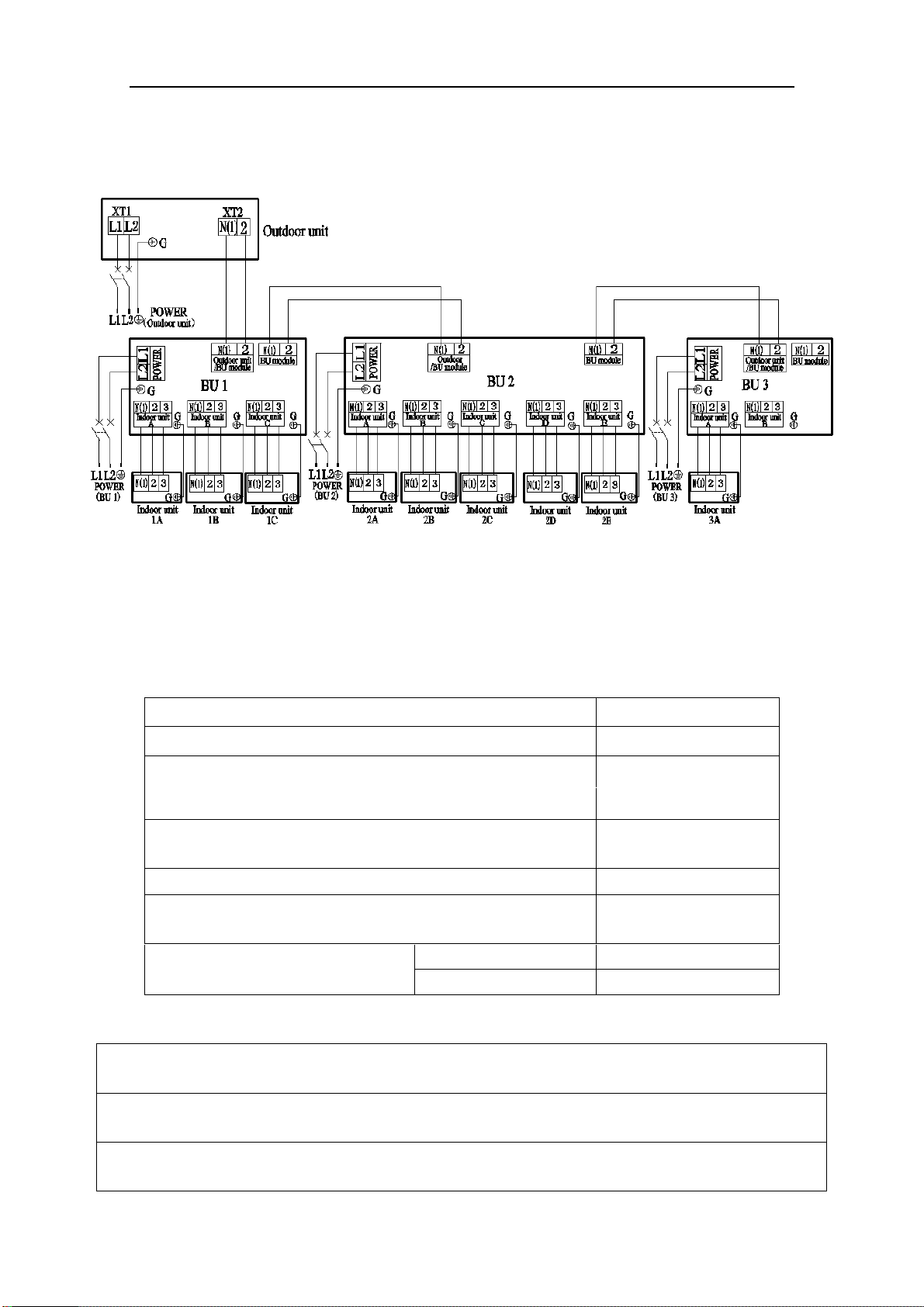

For the Flex + Series, one outdoor unit is able to drive up to three BU modules and nine

indoor units which include cassette type, duct type, wall mounted type, floor ceiling type and

console type. The outdoor unit will run as long as any one indoor unit receives the running

command, and all indoor units stop once the outdoor unit is turned off.

Power supply wire for outdoor

unit and BU module(3 wires)

Connection pipe

Transmission line(2 wires)

Power supply wire for

indoor unit(4 wires)

BU 3

Indoor unit

Duct type

Wall mounted

type

Floor ceiling

type

Console type

Outdoor unit

Ground

The 2nd

branch

The 1st

branch

Power

(60Hz, 208/230V)

Ground

Power

(60Hz, 208/230V)

BU 2

Ground

Power

(60Hz, 208/230V)

BU 1

Ground

Power

(60Hz, 208/230V)

Fig. 2

Wall mounted

type

Cassette type

Cassette type

Duct type

Wall mounted

type

3.4 Working Temperature Range

Maximum cooling 48℃(118℉)

Minimum cooling -18℃(0℉)

Maximum heating 24℃(75℉)

Minimum heating -20℃(-4℉)

Table 2

(BD :erutarepmet edistuO stroS ℃/℉)

5

Page 12

Flex + Series

4 Selection of Installation Location and Precautions

WARNING

1) The installation of the air conditioner must be in accordance with the national and local laws and

regulations.

2) The quality of the installation will affect the capability of air conditioner directly. The installation

should be left to the appointed service center. Please contact your dealer after purchasing this machine.

Professional installation workers will provide installation and test services according to the installation

manual.

3) The air conditioner should not install in this place where the small animals exist, because they may

cause malfunctions, smoke or fire. Please keep the area around the unit clean.

4.1 Selection of Installation Location

WARNING

1) The outdoor unit must be installed on a firm and solid support which can withstand the weight,

meanwhile the mounting surface must be horizontal plane. Otherwise, the unit would fall down and

cause injury or death.

2) The location must be out of children’s reach, please keep the unit away from children.

3) During installation, if the outdoor unit has to be exposed to strong wind, it must be fixed securely.

4) There is enough space for the installation and maintenance. Meanwhile, there is not any obstacle near

the air inlet and outlet of the indoor and outdoor units.

5) The place should be well-ventilated, so the machine can absorb and discharge sufficient air.

6) Avoid place the outdoor unit under the windows or between the constructions, hence to prevent normal

operating noise from entering the room.

7) When strong winds of 5 m/sec or more exist in the place of the installation, the outlet of the unit cannot

face the wind. If the wind blows against the outdoor unit's air outlet, it will cause deterioration of the

operational capacity and maybe break the fan.

8) Do not install in the place where there is heat source, flammable or explosive gas, a place subject to

severe dust, salty fog and polluted air.

9) Installation at the following places might lead to the air conditioner malfunction, such as where is full of

machine oil, saline-sodic soil near the sea, sulphide fog, high frequency facilities or special conditions.

If it is unavoidable, please contact the appointed service center.

NOTICE

1) It is better that do not install the unit where it will be exposed to direct sunlight. (If necessary, please

install a blind that does not interfere with the air flow.)

2) The unit should be free from getting dirty or getting wet by rain as much as possible

3) Outdoor unit shall be installed close to the indoor unit, hence to minimize the length and bends of

cooling pipe.

4) Do not place animals and plants in the path of the air inlet and outlet of the units.

5) Make sure that the unit will not cause any operating vibration or noise after installation.

6

Page 13

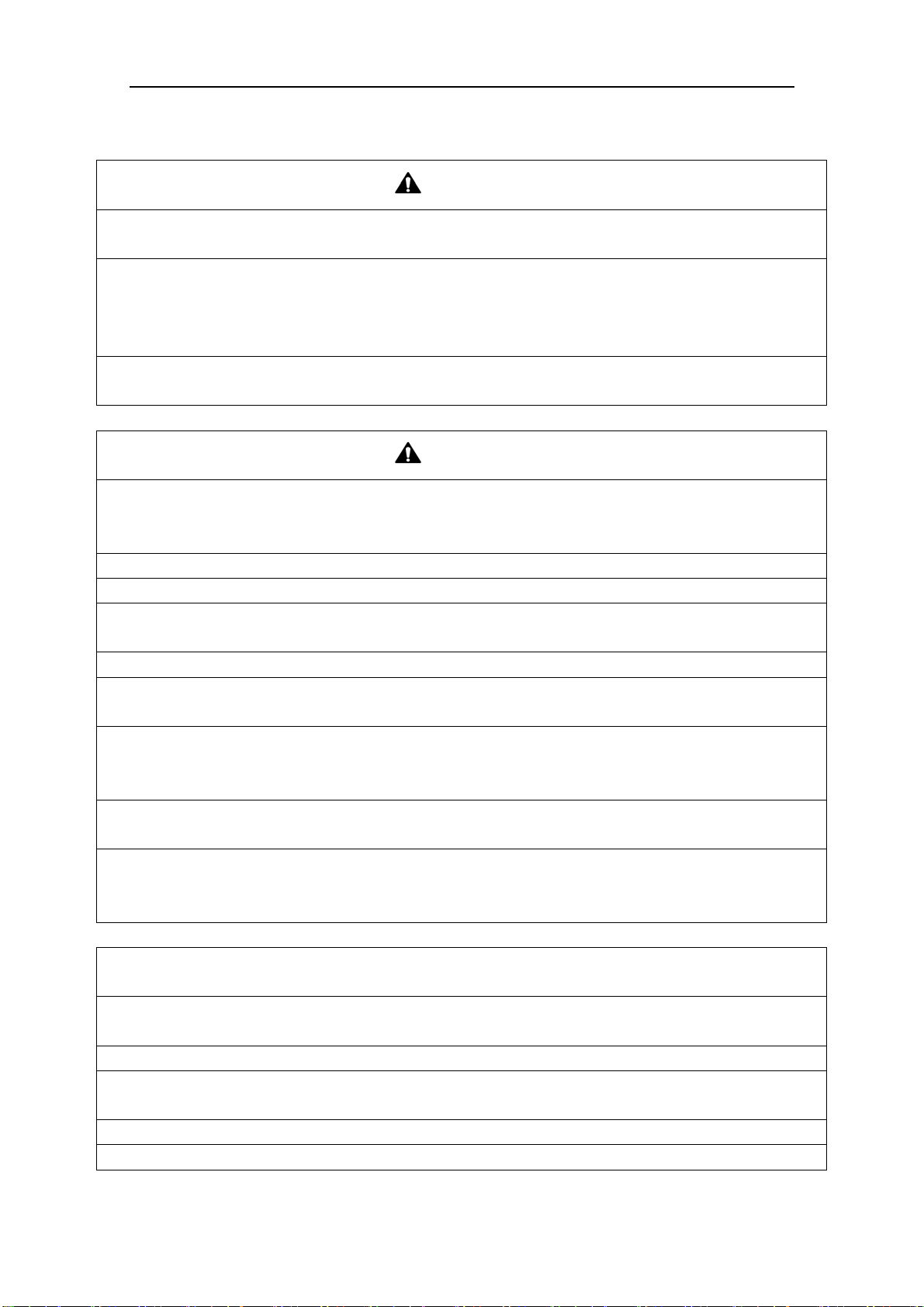

4.2 Outline Dimension of Outdoor Unit

Flex + Series

3 (unit: mm/inch)

Fig.

4.3 Installation and Servicing Space

1) In case of installing only one unit

In case obstacles exist around the unit, the required installation space is in the Fig. 4.

2) In case of installing multiple units(2 units or more)

In case multiple rows of series installation, the required installation space is in the Fig. 5.

Fig. 4 (unit: mm) Fig. 5 (unit: mm)

7

Page 14

Flex + Series

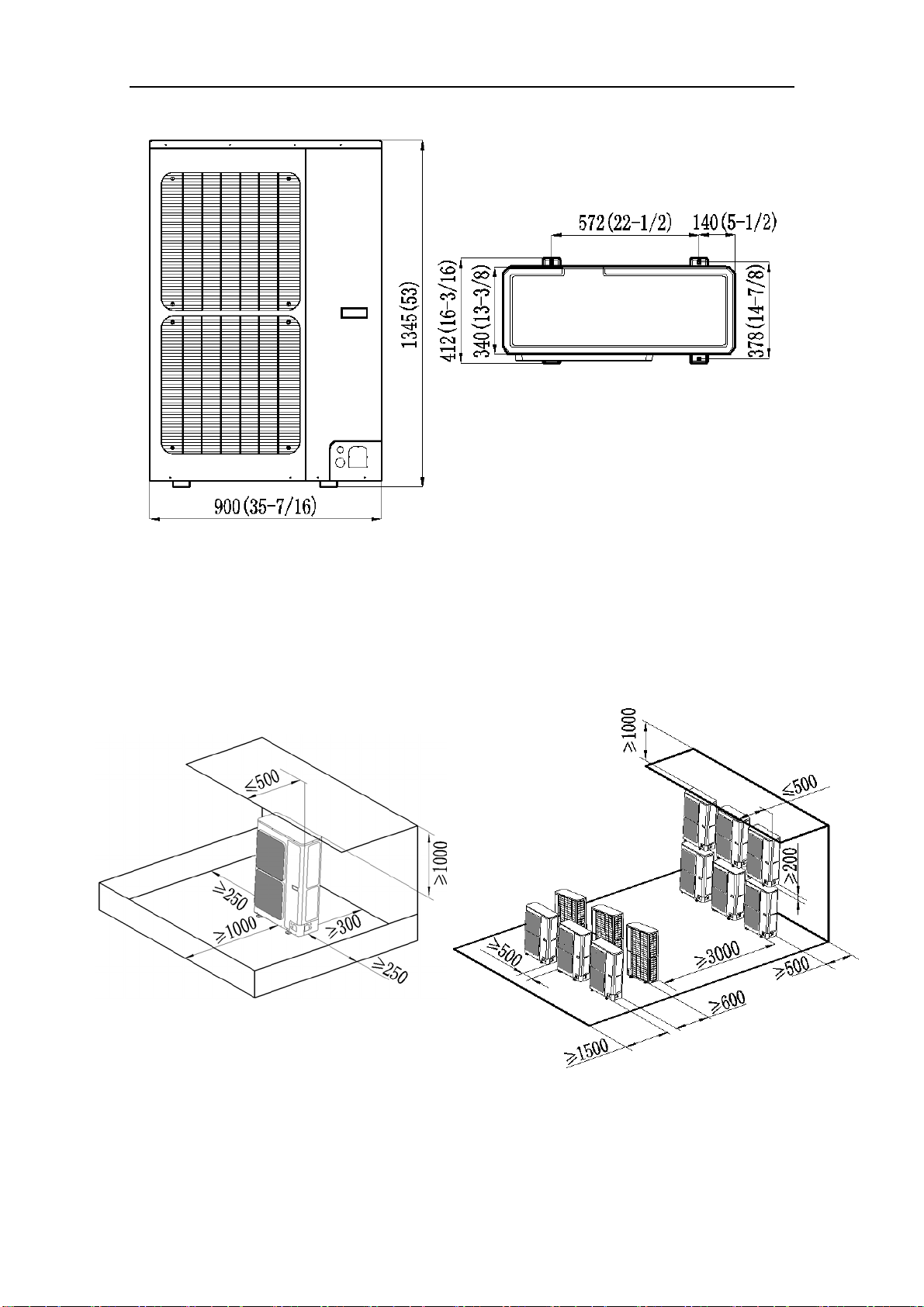

5 Installation Instruction

1) Check the installation location and ensure it is strength and level, so that the unit will not cause

any operating vibration or noise after installation.

2) In accordance with the foundation drawing in the following figure, please drill 4 holes in the

installation location.

A

: The outlet side B: Bottom view (mm) C: Drain hole

Fig. 6

3) Fix the unit securely with the foundation bolts. You can get the M10 or M12 foundation bolts,

nuts and washers from the market.

Fig. 7

4) Rub

5) Screw the foundation bolts into the ground and it is better that its length is less than 20mm

ber or spring shock absorbers should be used during the installation of the outdoor unit to

meet the noise and vibration requirements.

(4/5inch) from the foundation face.

8

Page 15

6 Installation of Refrigerant Pipes

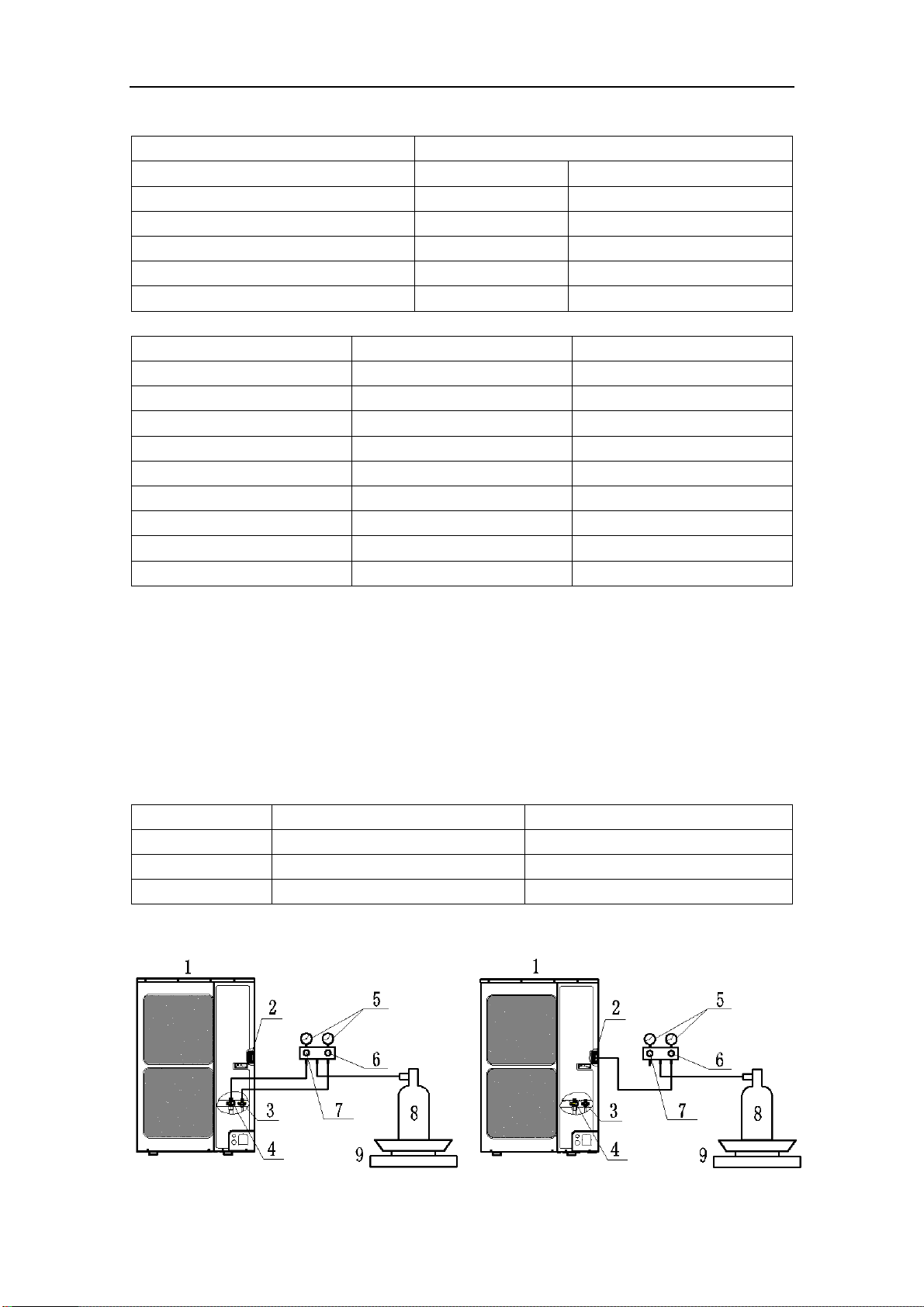

6.1 Allowable Length and Drop Height of Connecting Pipe

Flex + Series

Maximum

allowable

length

Maximum

allowable

length

Minimum

allowable

length

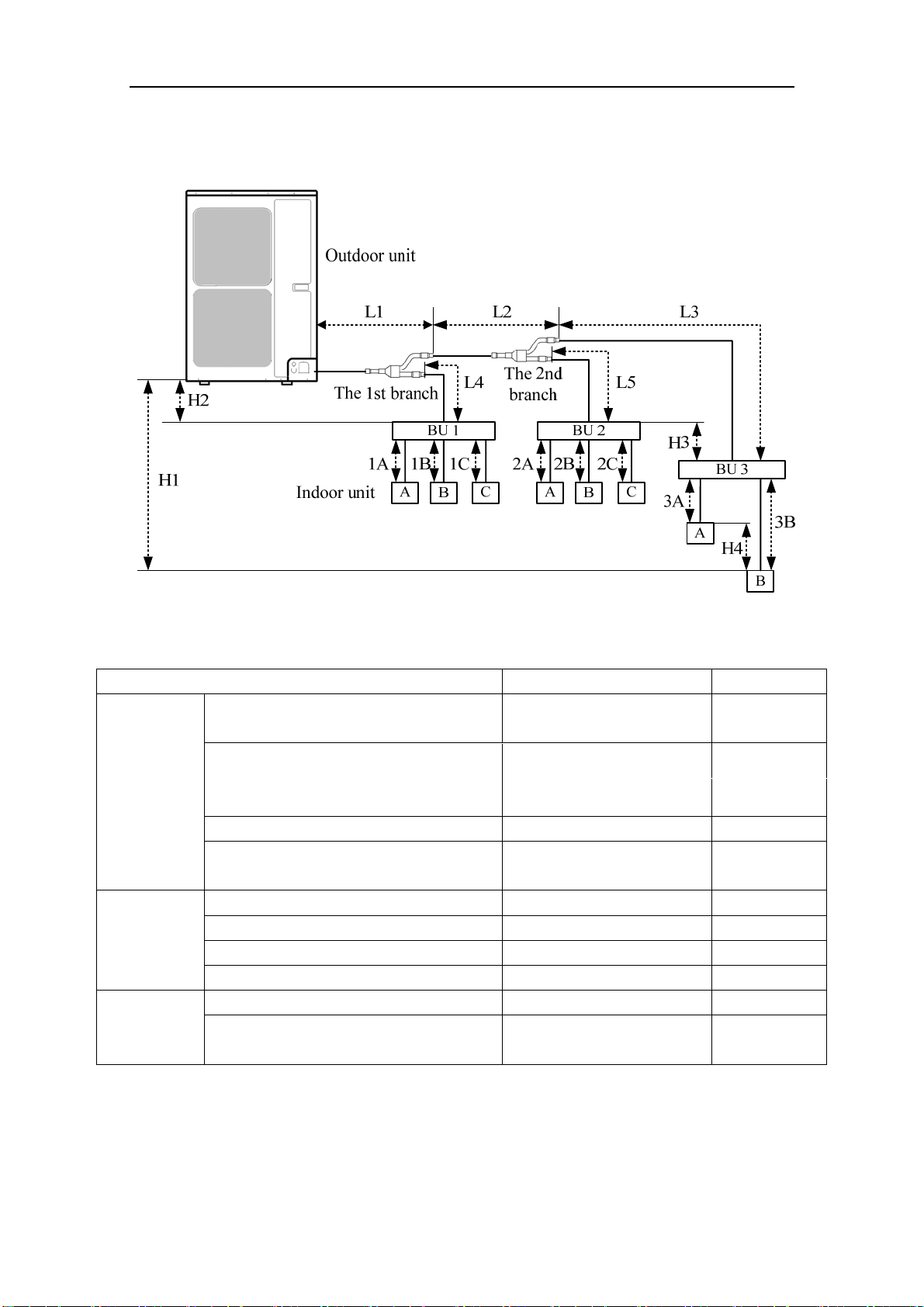

Fig. 8 (8 indoor units)

Table 3

The sorts The pipes Length(m/feet)

Total length between outdoor unit and BU

modules

Total length between indoor units and

BU

Between indoor unit and BU module 1A;1B;1C;2A;2B;2C;3A;3B ≤15(49)

Between indoor unit and the 1st branch

Between outdoor and indoor units H1 ≤30(99)

Between outdoor units and BU modules H2 ≤30(99)

Between BU and BU modules H3 ≤15(49)

Between indoor and indoor units H4 ≤15(49)

Between outdoor and the 1st branch L1 ≥5(16)

Between BU and the branch L3;L4;L5

L1+L2+L3+L4+L5 ≤55(181)

1A+1B+1C+2A+2B+2C+

3A+3B

L4+1B;L2+L5+2A;

L2+L3+3B

≤90(295)

≤40(131)

as possible as

short

NOTICE! BU module should be placed within the level between the outdoor unit and indoor

unit.

9

Page 16

Flex + Series

6.2 Dimension of Connecting Pipe

Sorts

Table 4

Gas Pipe

(mm/inch)

Liquid Pipe

(mm/inch)

Outdoor unit

Between outdoor unit and the

1st branch

Between the 1st and the 2nd

branch

ISMO-6021

The pipe L1 Φ19.05(3/4) Φ9.52(3/8)

The pipe L2 Φ15.9(5/8) Φ9.52(3/8)

Φ15.9(5/8) Φ9.52(3/8)

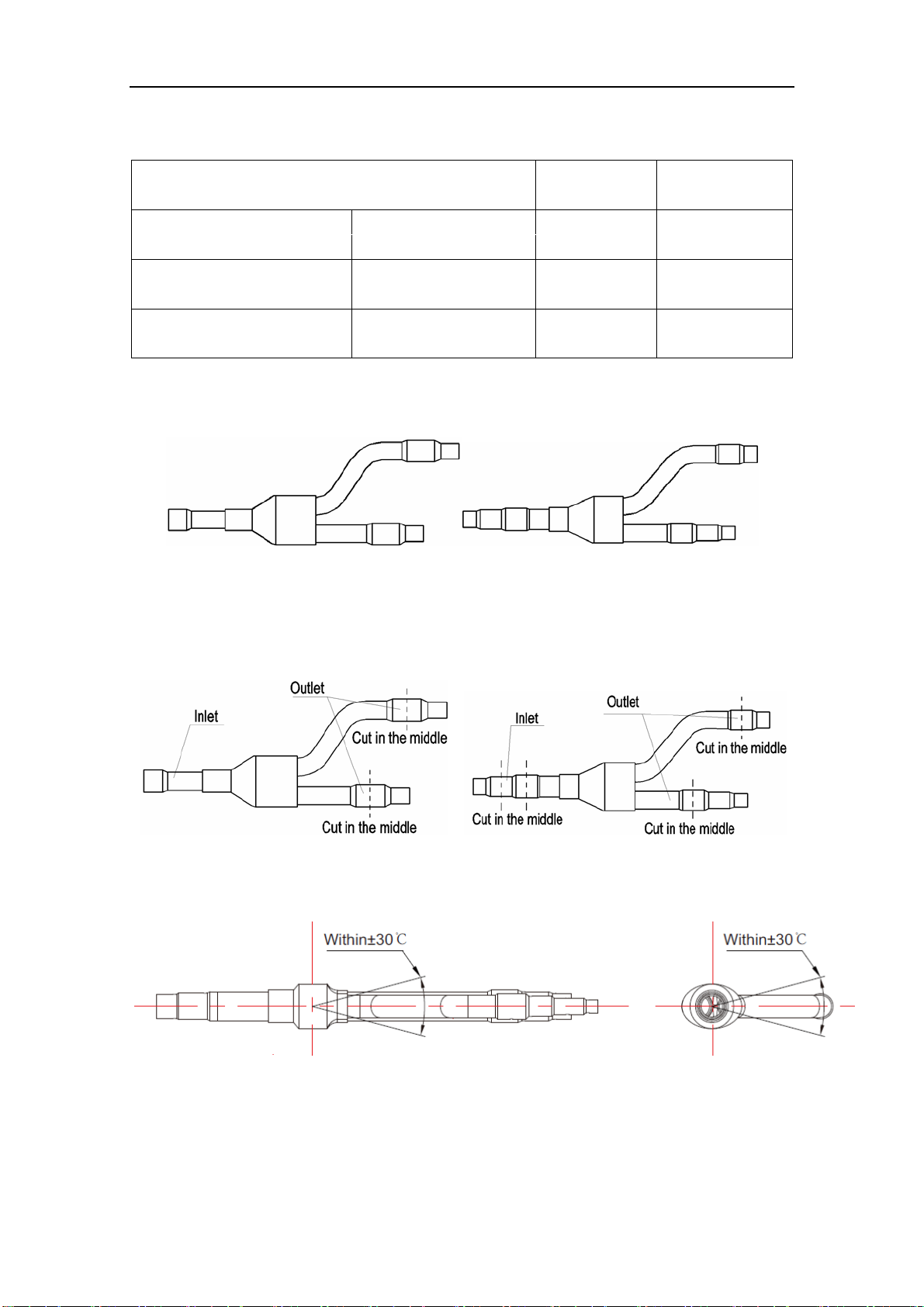

6.3 Connection of Branch Pipe

1) If two or three BU modules used, Y-type branch pipe of FQ01A/A will be chosen.

FQ01A/A (Liquid pipe) FQ01A/A (Gas pipe)

Fig. 9

2) Y-type branch pipe is equipped with auxiliary tubes to adjust the diameter of different pipes. If

the dimension of the pipe selected is different from the dimension of branch pipe joint, Cut the

copper tube in the middle with tube cutter and clear up burrs. Please do that as following figure.

Fig. 10

3) Y

-type branch pipe must be installed in vertical or horizontal direction. In the inlet of the branch

pipe, keep at least 500mm straight pipe.

Fig. 11

10

Page 17

Flex + Series

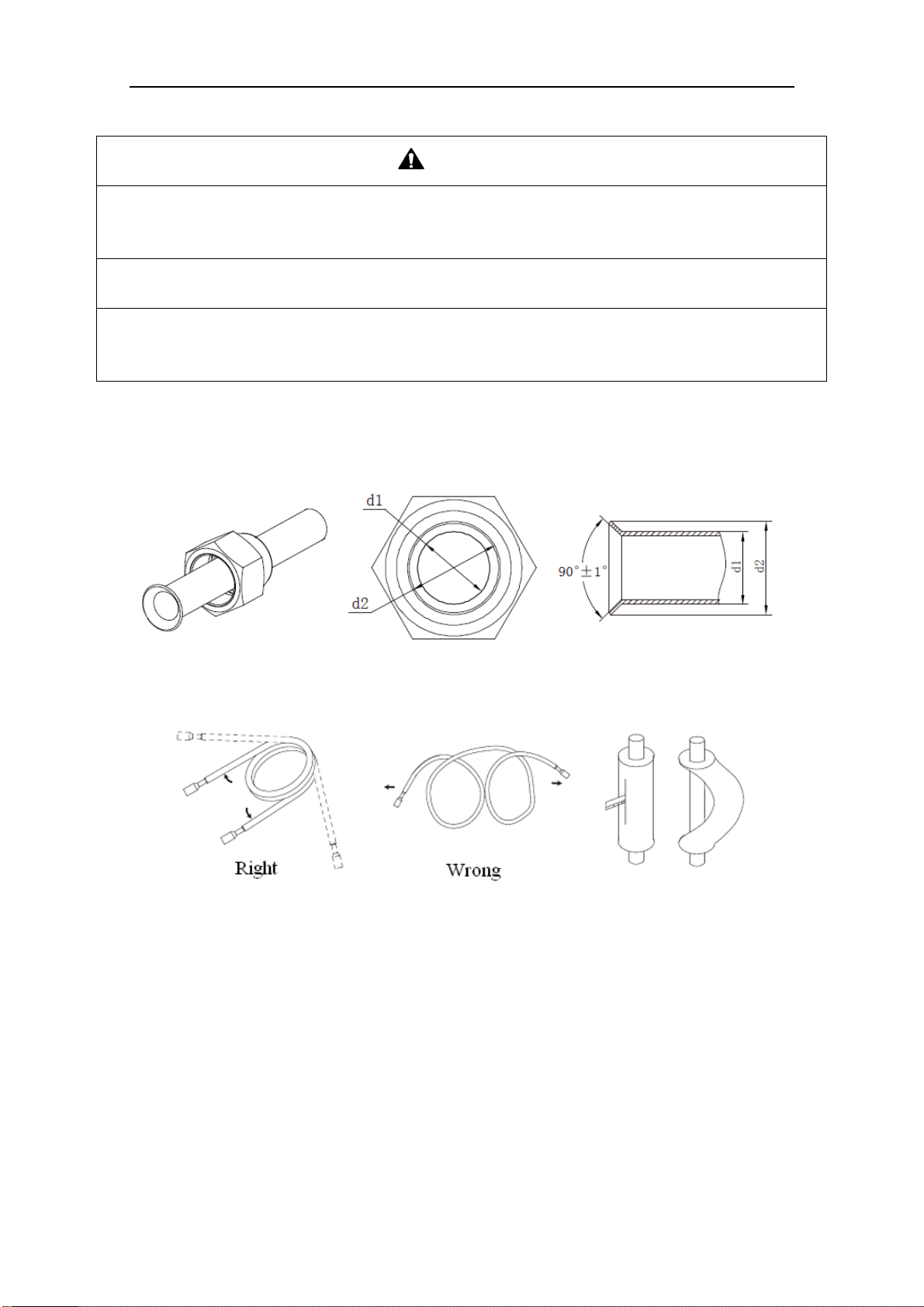

6.4 Connection of Refrigerant Pipes

CAUTION

1) Conform to the following principles during pipe connection: Outdoor unit shall be installed close to the

indoor unit, hence to minimize the length and bends of connection pipes; the height gap of outdoor unit

and indoor units should be as small as possible; the radius of curvature should be as large as possible.

2) The brazing operation must be strictly in accordance with the process requirements. Rosin joint or pin

hole is not allowed.

3) During the installation, do not damage the pipeline. The pipeline’s radius of bending must be over than

200mm(8inch). The pipes cannot repeatedly be bent or straightened. Otherwise it will get harden and

crack. Do not bend or straight the pipes for more than 3 times at the same position.

1) The process of flaring

① Using the tube cutter to cut the connecting pipe in the appropriate place and remove the burrs.

② Install the nut before the flaring operation.

③ Check the flared portion, whether there is fractured or not.

Fig. 12

2) Precaution for elbow operation

① The elbow operation could be done by hands. Be careful and do not damage the pipe.

Fig. 13

② If the thermal insulation of the refrigerant pipe is not removed, please do not bend the pipe.

Otherwise, it maybe leads the pipe to crack. It is better to make an incision with a knife in the

thermal insulation and removes it. After elbow operation is finished, recover the thermal

insulation with binding band.

3) The process of install refrigerant pipes

① Remove the screw caps from the pipes.

② Align the flared end of copper tube with the center of pipe joint. Tighten the nuts by hands. (If

the flared end of copper tube and the center of pipe joint are not in coaxial, it is hard to tighten

the nuts by hands, please do not tighten it with spanners, because the screw thread may be

broken by force).

③ Tighten the flaring nuts with torque wrench until you hear a “click”. (The spanner and torque

11

Page 18

Flex + Series

wrench should be perpendicular to the refrigerant pipeline).

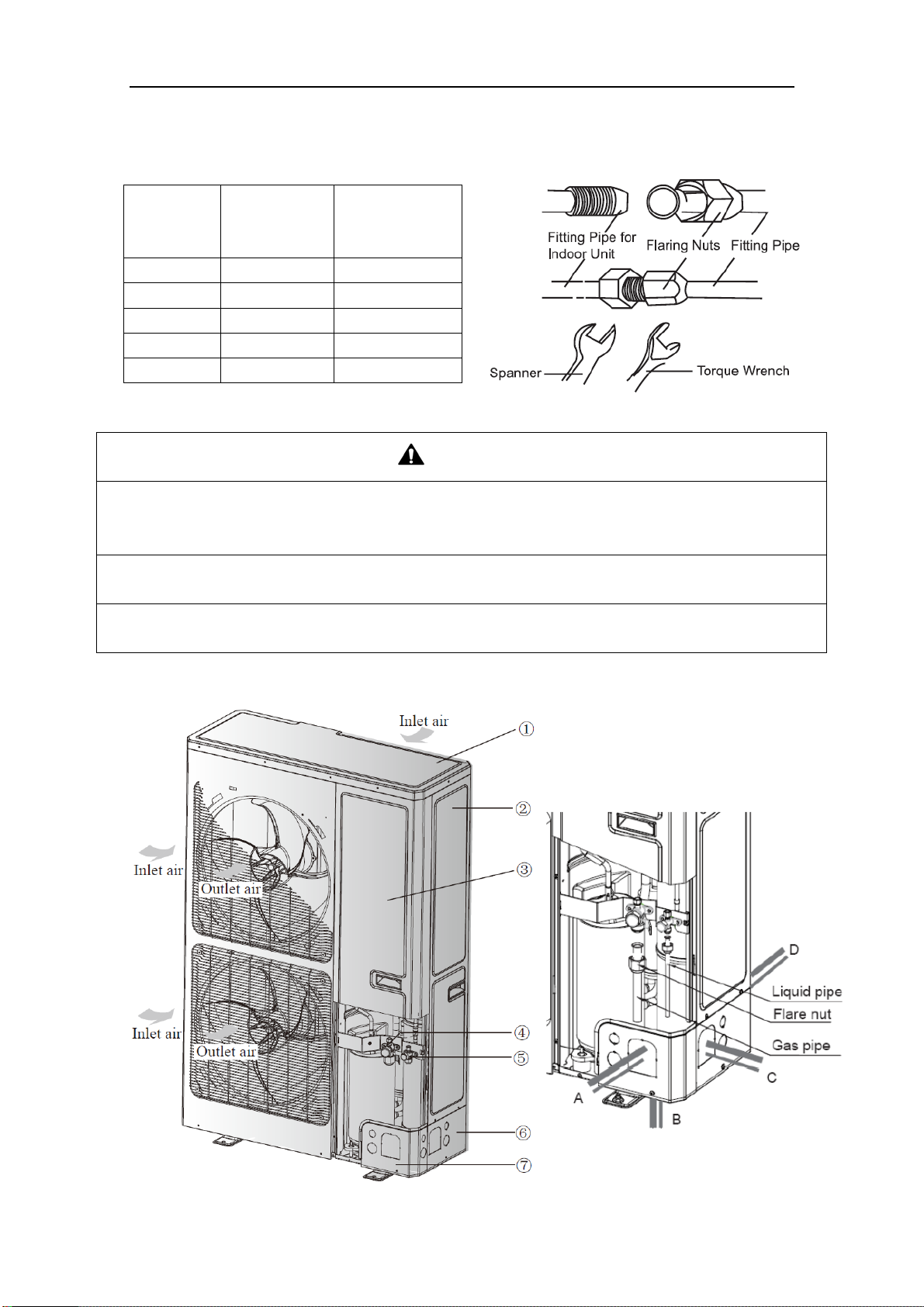

④ The following table for the torque required to tighten the nuts.

Table 5

Pipe

diameter

(mm/inch)

Φ6.35(1/4) ≥0.8(1/32) 15~30(11~22)

Φ9.52(3/8) ≥0.8(1/32) 35~40(26~29)

Φ12.7(1/2) ≥0.8(1/32) 45~50(33~37)

Φ15.9(5/8) ≥1.0(1/25) 60~65(44~48)

Φ19.05(3/4) ≥1.0(1/25) 70~75(52~55)

Thickness of

copper

tube(mm/inch)

Tightening

torque

(N·m/1bf·ft)

Fig. 14

CAUTION

1) During the connection of the indoor unit and BU module to the refrigerant pipe, never pull any joints of

the indoor unit and the BU module by force; otherwise the capillary pipe or other pipe may crack,

which then would result in leakage.

2) The refrigerant pipe should be supported by brackets, that is, don’t let the unit withstand the weight of

it.

3) For the Flex + Series, each pipe should be labeled to tell which system it belongs to avoid

mistaken inaccurate piping.

6.5 Connection of Refrigerant Pipe

12

Page 19

Flex + Series

NO. ① ② ③ ④

Name Coping plate Rear side plate Front side plate Gas side stop valve

NO. ⑤ ⑥ ⑦

Name Liquid side stop valve Right connection board Front connection board

NO. A B C D

Name Front connection Bottom connection Side connection Rear connection

Fig. 15

1) Unscrew the coping plate, front side plate, right connection board and front connection board.

2) The refrigerant pipes can be installed in four directions, please choose the proper direction.

3) Knock the holes in the plate of the chosen direction with the drill and hammer.

4) Connect the pipes to the stop valves.

5) Bend the pipes to go through the knockout holes.

6) Cover the through-holes with sealing materials to prevent the water, dust or small animals going

into the outdoor unit.

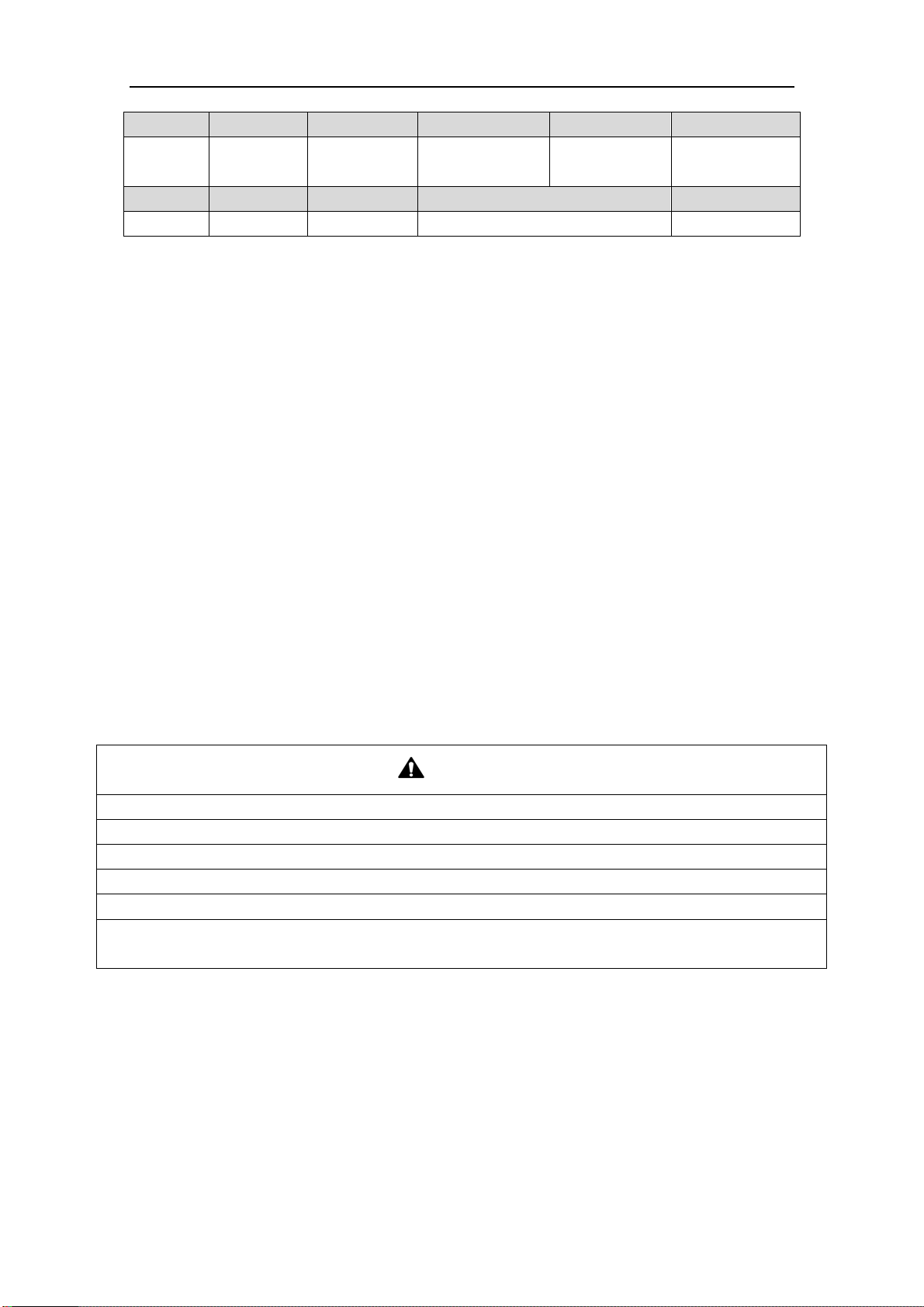

6.6 Leak Test

1) Please make sure that the stop valves of the outdoor unit are closed during the operation.

2) The leak test should be made by pressurizing nitrogen gas.

oxygen, C

3) Turn on the Hi-knob and Lo-knob.

at both the gas and liquid stop valves.

4) Open the pressure reducing valve, pressurize the connection pipes to 1.0 MPa (10 bar) slowly,

wait fifteen minutes, and make sure that the pressure will not drop.

5) Rise the pressure to 4.0 MPa (40 bar) slowly, wait 24 hours and make sure the pressure will not

drop

6) If the pressure does not decrease, the pipes have passed the test. Otherwise, look for where the

gas leaks from.

1: Outdoor unit

2: Liquid side stop valve

3: Gas side stop valve

4: Pressure-vacuum gauge

5: Hi-knob

6: Lo-knob

7: Pressure reducing valve

8: Nitrogen

or other dangerous gas into the refrigerant circuit.

2H2

NOTICE! The leak test should be done simultaneously

WARNING! Do not mix

Fig. 16

6.7 Vacuum Operation

1) Make sure the stop valves of the outdoor unit are closed fully during the operation.

2) As shown in the following figure, expel the gas from the refrigerant pipes by the vacuum pump.

3) Open the pump and turn on the knobs to evacuate the gas in the liquid and gas pipes.

The vacuuming should be done simultaneously at both the gas and liquid stop valves.

4) When the pressure of the system is less than -0.1Mpa (-1bar), keep the system for more than

13

NOTICE!

Page 20

Flex + Series

one hour under the condition.

1: Outdoor unit

2: Liquid side stop valve

3: Gas side stop valve

4: Pressure-vacuum gauge

5: Hi-knob

6: Lo-knob

7: Vacuum pump

Fig. 17

5) Turn off the knobs firstly and then the pump, and if the pressure of the pressure-vacuum gauge

does not rise within 2 hours, the system is under a vacuum. Otherwise, the system has leaked,

please look for where the gas leaks in.

6.8 Refrigerant Charging

The refrigerant has been charged into the outdoor unit before shipped from the manufacturer,

while additional refrigerant still need be charged into the refrigerant pipe in the field installation.

6.8.1 Calculation of the Additional Refrigerant Charging

et the refrigerant charge of the outdoor unit from the nameplate.

1) G

NOTICE

1) The refrigerant charge of the outdoor unit does not include the charged additionally in the indoor unit,

BU module and the refrigerant pipe.

2) For the length of the connecting pipe is decided on the field, the amount of additional refrigerant shall

be decided depending on the dimension and the length of the liquid pipe used on the field.

3) It does not need to add refrigerant if the total length of liquid pipe is within 30m (98-3/8feet).

4) Record the amount of additional refrigerant for convenience of future maintenance.

2) Calculating the Mass of Additional Refrigerant

Additional Refrigerant Charge (kg/oz) =

(0.020oz/inch)+

Σ the Liquid Pipe Length of Φ9.52×0.054kg/m (0.048oz/inch)-1.47kg(51.86oz)

NOTICE! If the additional refrigerant charge is negative, it does not need to add refrigerant.

3) Example: GWHD(56S)ND3CO

Σ the Liquid Pipe Length of Φ6.35 ×0.022kg/m

Fig. 18

14

Page 21

Flex + Series

Table 6

Serial No. Model

Indoor unit 1 Cassette type

Indoor unit 2 Duct type

Indoor unit 3 Wall mounted type

Indoor unit 4 Wall mounted type

Indoor unit 5 Duct type

Indoor unit 6 Wall mounted type

Table 7

Serial Diameter(mm/inch) Length(m/feet)

L1 Φ9.52(3/8) 20(65-5/8)

L2 Φ9.52(3/8) 10(32-3/4)

L4 Φ9.52(3/8) 10(32-3/4)

1A Φ6.35(1/4) 5(16-3/8)

1B Φ6.35(1/4) 5(16-3/8)

1C Φ6.35(1/4) 5(16-3/8)

2A Φ6.35(1/4) 5(16-3/8)

2B Φ6.35(1/4) 5(16-3/8)

2C Φ6.35(1/4) 5(16-3/8)

The total length of the liquid pipes: 20+10+10+5+5+5+5+5+5=70m (229-5/8feet).

Thus, the total length is over than 30m (98-3/8feet), so the air conditioner needs to add refrigerant.

Additional refrigerant charge

N/A

N/A

ISMI-C15

ISMI-W092

ISMI-W092

ISMI-W092

Σ the Liquid Pipe Length of Φ6.35×0.022kg/m +Σ the Liquid Pipe Length of Φ9.52×0.054kg/m

-1.47kg

=(5+5+5+5+5+5)(m)×0.022kg/m+(20+10+10)(m)×0.054kg/m-1.47kg

=1.35kg (47.63oz)

4) Additional refrigerant charge record for future maintenance

Table 8

Diameter(mm) Total length(m/feet) Additional refrigerant charge(kg/oz)

Φ6.35(1/4)

Φ9.52(3/8)

Total

6.8.2 Proced

ures for adding refrigerant

15

Page 22

Flex + Series

NO. 1 2 3 4 5

Name

NO. 6 7 8 9

Name Hi-knob Lo-knob R410A tank Scale

1) When the liquid and gas stop valves have not been opened, the system is under the vacuum:

① Refer to the left of the figure above; connect the R410A tank to the system.

② Turn on the R410A tank and the Hi-knob; charge the R410A refrigerant into the unit from the

liquid side stop valve. The Lo-knob should be closed completely.

③ Turn off the R410A tank and the Hi-knob immediately, when the adding refrigerant is enough.

④ Turn on the liquid and gas side stop valves in an anticlockwise direction slowly and completely.

2) If the pressure of the system is too high to charge refrigerant, you can do as follow.

① Turn on the liquid and gas side stop valves in an anticlockwise direction slowly and completely.

② Turn on the power of the air conditioner, and set cooling mode, running more than 0.5h when

outside temperature is higher than 15℃(59℉) DB.

a) Refer to the left of the figure above; connect the R410A tank to the system.

b) Turn on the R410A tank and the Lo-knob; charge the R410A refrigerant into the unit from

c) Turn off the R410A tank and the Lo-knob immediately, when adding refrigerant is enough.

③ Turn on the power of the air conditioner, and set heating mode, running more than 0.5h when

outside temperature is lower than 15℃(59℉) DB.

a) Refer to the right of the figure above; connect the R410A tank to the system.

b) Turn on the R410A tank and the Hi-knob; charge the R410A refrigerant into the unit from

c) Turn off the R410A tank and the Hi-knob immediately, when adding refrigerant is enough.

Outdoor

unit

the gas side stop valve. The Hi-knob should be closed completely.

the service port. The Lo-knob should be closed completely.

Service port

Liquid side stop

valve

Fig. 19

Gas side stop

valve

Pressure-vacuum

gauge

CAUTION

1) Make sure that the liquid and gas side stop valves are opened completely after the installation.

2) Make sure that the length of liquid pipe is exactly.

3) Additional refrigerant charge must be measured exactly.

4) Make sure that the refrigerant which charge into the unit is in liquid state.

5) Please prevent the refrigerant leakage away from your body when remove the charging hose.

6) Please heat the refrigerant tank with hot water or hot air when the outside temperature is too low.

However, it must be forbidden to heat with fire directly, otherwise it may lead to explosion.

16

Page 23

7 Electrical Wiring Work

7.1 Wiring Connection

Flex + Series

NOTICE! The “L1”, “3” terminals are connected to the live wire, the “L2”,”N(1)” terminals

are connected to the neutral wire and the ”2” terminal is connected to the transmission line.

Fig. 20

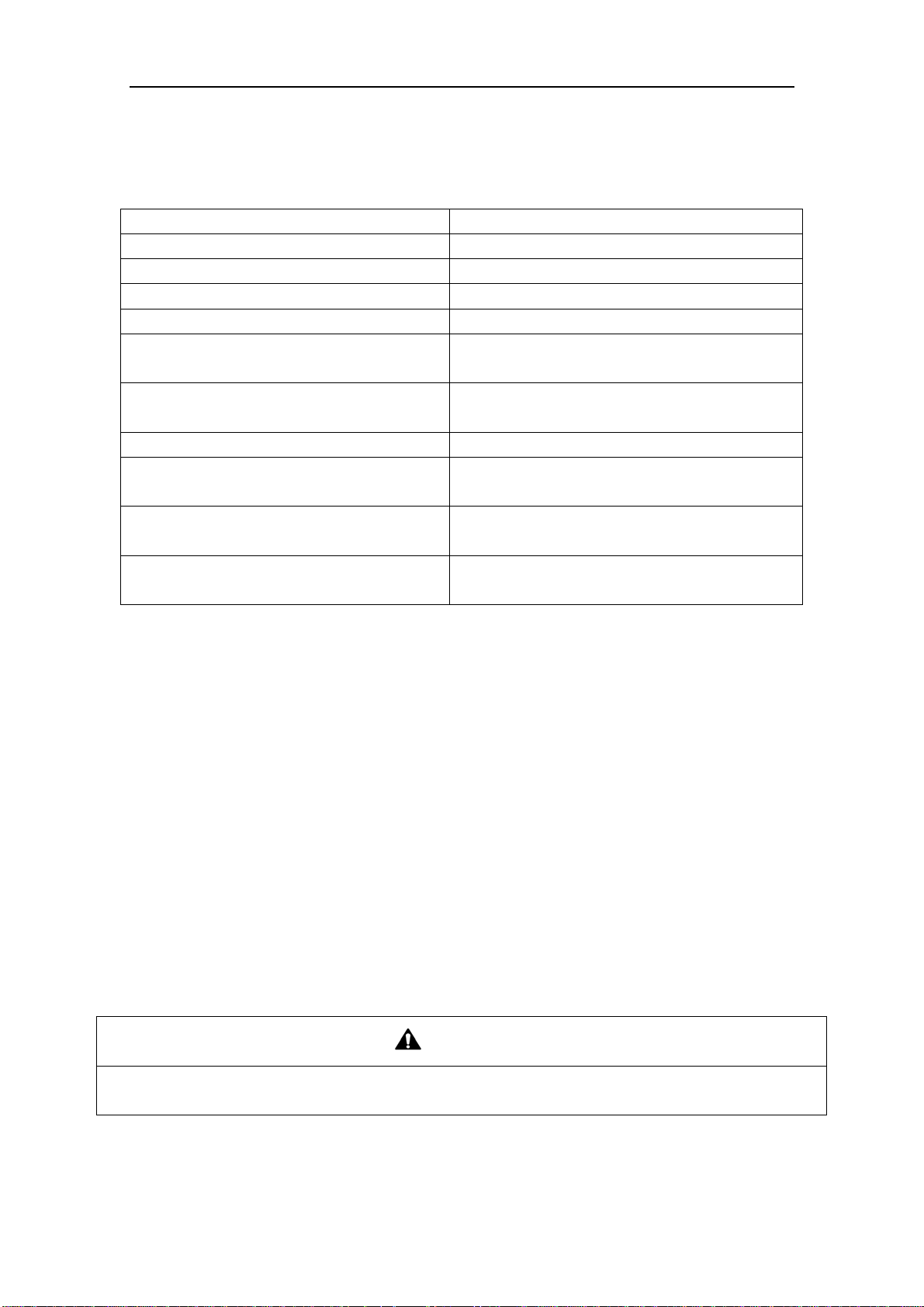

7.2 Requirements of Power Circuit and Cable

Table 9

Phase and frequency 1Ph,60Hz

Voltage 208/230V

40A

2

2

2

Recommended cable of outdoor unit (Pieces × Sectional area)

Recommended cable of BU module

(Pieces × Sectional area)

Transmission line (Pieces × Sectional area) 2×1.5 mm2

Recommended cable of indoor unit

(Pieces × Sectional area)

ISMO-6021

Capacity of the air switch

BU module 10A

3×6.0 mm

3×0.75 mm

4×0.75mm

NOTICE

1) The total length of the transmission line between the outdoor unit and the furthest BU module is not

more than 55m (180feet). Otherwise, the system cannot work possibility.

2) The specifications of the power cable and transmission line listed in the table above are determined

based on the maximum power (maximum amps) of the unit.

17

Page 24

Flex + Series

3) The specifications of the power cable listed in the table above are applied to the conduit-guarded

multi-wire copper cable (like, YJV copper cable, consisting of PE insulated wires and a PVC cable

jacket) used at 40℃(104℉) and resistible to 90℃(194℉), and shall be at least those of ordinary

polychloroprene sheathed cords. If the working condition changes, they should be modified according

to the related national standard.

4) The specifications of the air switch listed in the table above are applied to the breaker with the working

temperature at 40℃(104℉). If the working condition changes, they should be modified according to the

related national standard.

5) The length of the recommended power cable should be less than 15meters (49feet); otherwise, the

diameter of the power cable is not enough.

6) Mentioned power cable and transmission line length is just a reference value. It may be different

depending on the condition of installation, humidity or materials, etc.

7) An all-pole disconnection switch having a contact separation of at least 3mm in all poles should be

connected in fixed wiring.

7.3 Ground Requirements

WARNING

1) The air conditioner is classified into the Class I appliances, so its ground ways must be reliable.

2) The ground wire must be fixed on the screw hole with the sign as the right figure.

3) The yellow-green wire of the air conditioner is the ground wire and must be fixed by the tapping screw.

And it cannot be used for other purpose or cut off. Otherwise, it will cause the hazard of electric shock.

4) The reliable ground terminal should be provided and the ground wire cannot be connected to any of the

following places: a. Water pipe; b. Coal gas pipe; c. Sewage pipe; d. Lightning rod

e. Telephone line f. Other unreliable places considered by a professional.

7.4 Precautions on the Electrical Wiring Work

WARNING

1) The electrical installation should be carried out by the professional as instructed by the local laws,

regulations and also this manual.

2) The ground connection should be reliable and the ground wire should be connected to the dedicated

device of the building by the professional.

3) Before starting work, the power must not be supplied to the unit.

4) The air switch coupled with the leakage current protection switch must be equipped in the circuits,

which is of enough capacity and of both magnetic and thermal tripping functions in case of the short

circuit and overload.

5) The electrical work should use a cable length enough to cover the entire distance with no connection. If

it is unavoidable, please make sure the connection should be reliable, the external forces will not act on

the wires and the joint is not bared. Otherwise it will cause electrical shock or fire etc.

6) The power cable with the rated voltage and exclusive circuit for the air conditioner should be used.

7) Do not pull the power cable by force after it is installed.

8) The diameter of the power cable should be large enough and once it is damaged, it must be replaced by

the dedicated one.

9) The multi-wire copper cable should be used for the power cable and the transmission line.

18

Page 25

Flex + Series

7.5 Precaution of Laying Wires

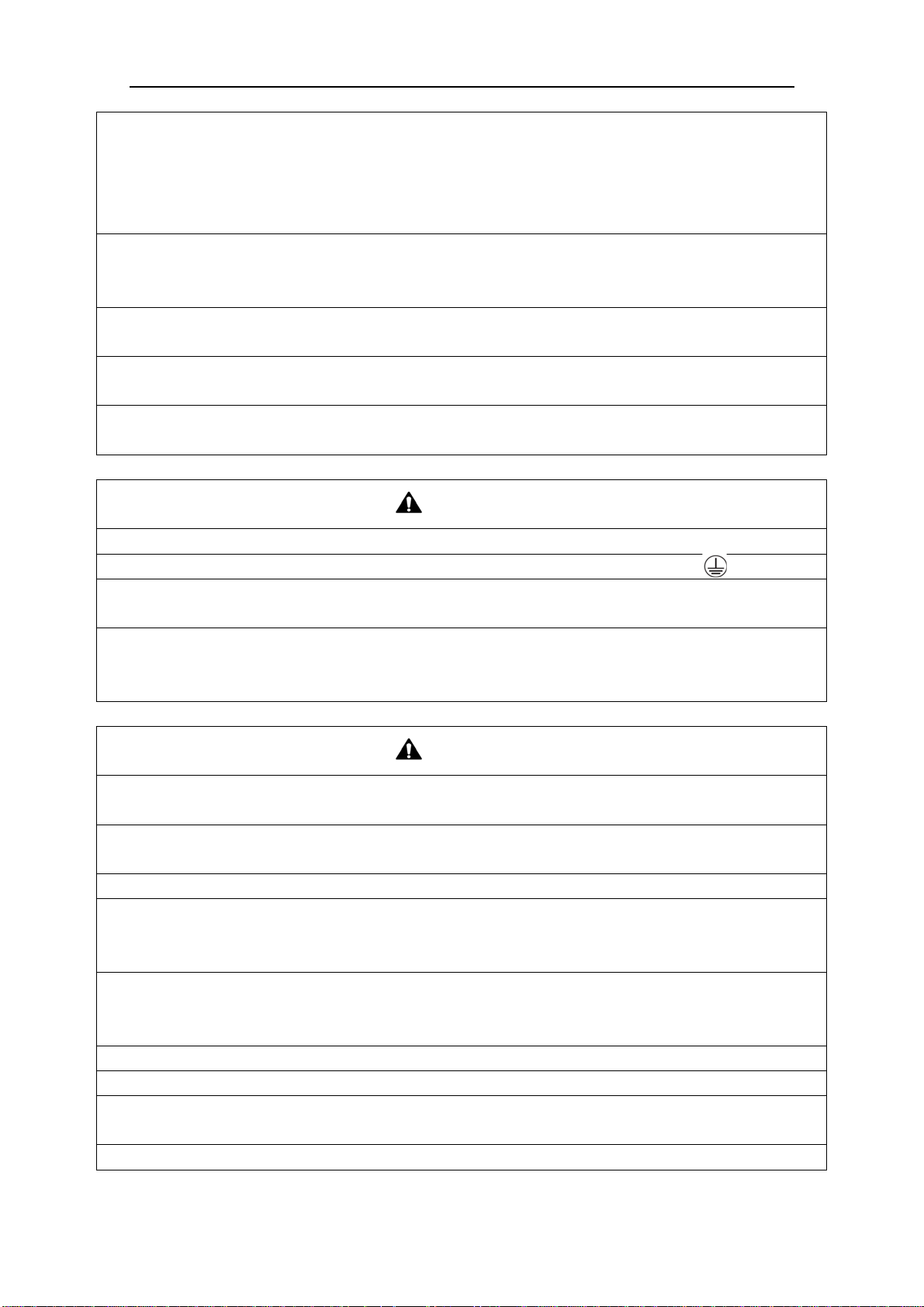

1) Use a wire stripper to strip off a length of the insulation layer at the end of the wires;

2) Loosen the screws on the terminal block of the air conditioner;

3) Press the ends of the cable tightly onto the round terminals corresponding to the size of the

screws.

4) Pass the screw through the round terminals and fix it onto the terminal block.

Fig. 21

7.6 Procedures for Electrical Wiring Work

1) Knock the holes in the plate of the chosen direction with the hammer.

2) Place the rubber ring on the knockout hole.

3) Let the power cable and transmission line go through the knockout hole.

4) Connect the power cable of the outdoor unit to the L1, L2 terminals with the sign of the XT1

and as well as the ground screw.

5) Connect the transmission line of the outdoor unit to the N(1), 2 terminals with the sign of the

XT2.

6) Fix the power cable and transmission line firmly by cable fixing clip. In order to protect the

power cable and transmission line from damage by the pipes or others, an interval of at least

2cm (3/4inch) away is essential.

7) Screw the coping plate, front side plate, right connection board, front connection board back.

8) Cover the through-holes with sealing materials to prevent the water, dust or small animals going

into the outdoor unit.

CAUTION

1) The transmission line and the power cable must be separated with an interval of at least 2cm (3/4inch);

otherwise it may be result in communication problem.

2) In order to protect the power cable and transmission line from damaging by the knockout hole, the

rubber ring must be placed on the hole. Otherwise, it may cause electrical shock or fire etc.

3) The power wire and transmission line must be more than 1 meter (3-1/4feet) away from televisions or

radios which can emit electromagnetic waves to prevent image interference or noise. Otherwise, the unit

maybe cannot work.

4) Confirm the each cable connected to the terminal screw is exactly and securely after finishing the

electric work.

5) Fix each ground wire separately with the ground screw.

6) If the connecting wire is connected to the terminal incorrectly, it may cause a fire.

19

Page 26

Flex + Series

8 Design of Drainage Pipeline

8.1 Installation of Drain Hose

1) Choose one drain hole in the bottom of the outdoor unit.

2) Connect the drain hose to the drain hole.

3) The drain hose should be kept at 5~10 degrees of gradient to facilitate discharge of the

condensing water. Take care that does not exert too much force on the hose.

4) Thermal insulation materials should be placed at the joints of the drain hose so as to prevent

from dew condensation. Fix the drain hose firmly by binding band.

Fig. 22

5) The

end of the drain hose should be inserted into the hole of drainage pipeline.

8.2 Design of Drainage Pipeline

1) The drainage pipeline should be kept at a certain gradient (1/50—1/100) so as to avoid bulges

of pipes where there might be water bends.

2) The drainage pipeline is form of the hard PVC pipes for common purposes which can be

purchased locally. The diameter of the PVC pipes is not less than 17mm (11/16inch) and the

pipeline should be fixed as close to the BU module as possible.

3) Insert the drain hose into the drain hole of drainage pipeline. Use binding band to fix it tightly.

It is not allowed to use adhesive glue to join the drain hose to the drainage hole.

4) When

the drainage pipeline is laid for a couple

should be approximately 100mm lower than the drainage hole of each module. In this case,

some special-purpose pipes with thicker walls will be used.

of units, the position of the shared pipeline

NOTICE! At intervals of about 1 meter (3-1/4feet), fix the drain pipes to the wall with

brackets, not floating in the air.

20

Page 27

Flex + Series

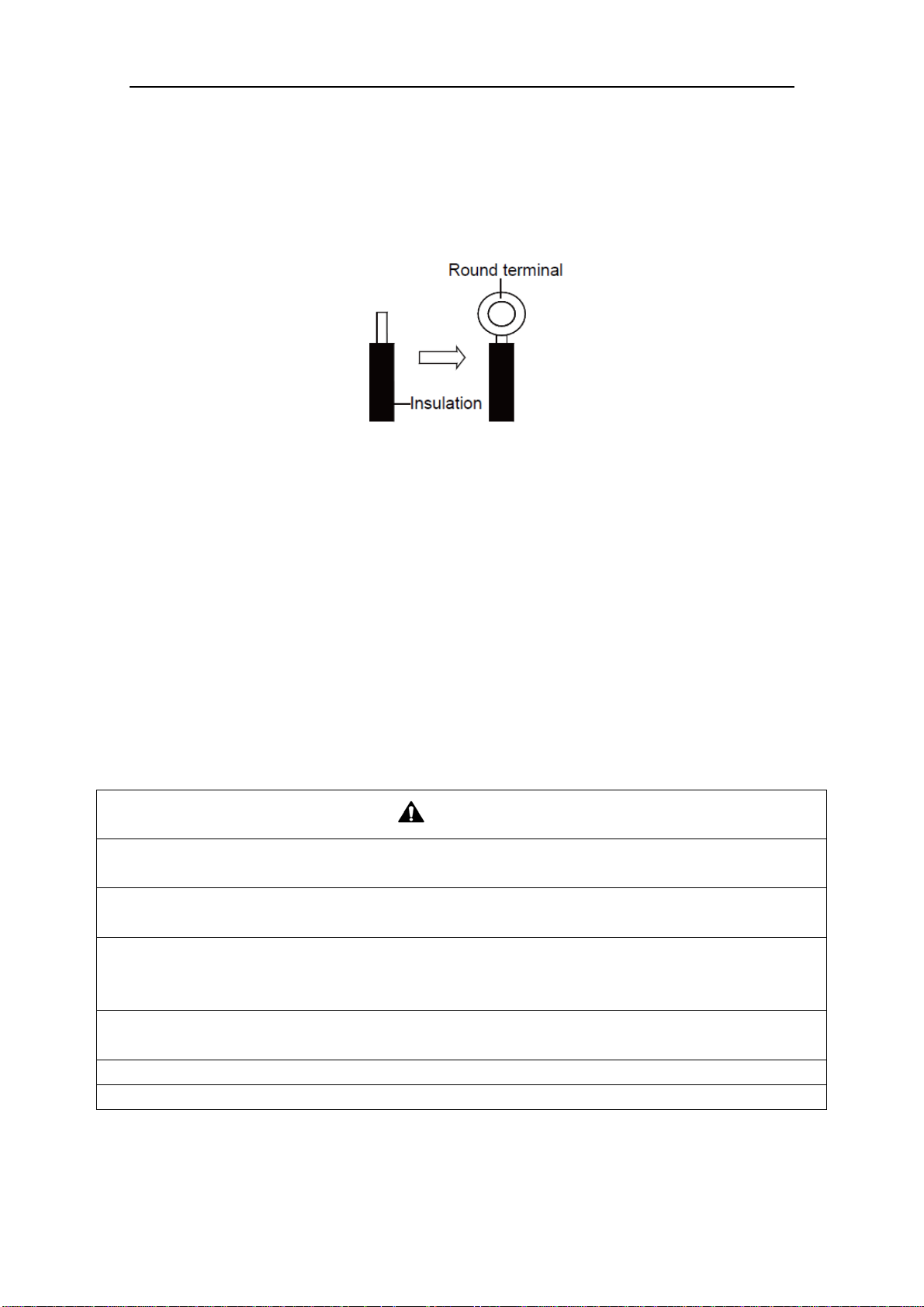

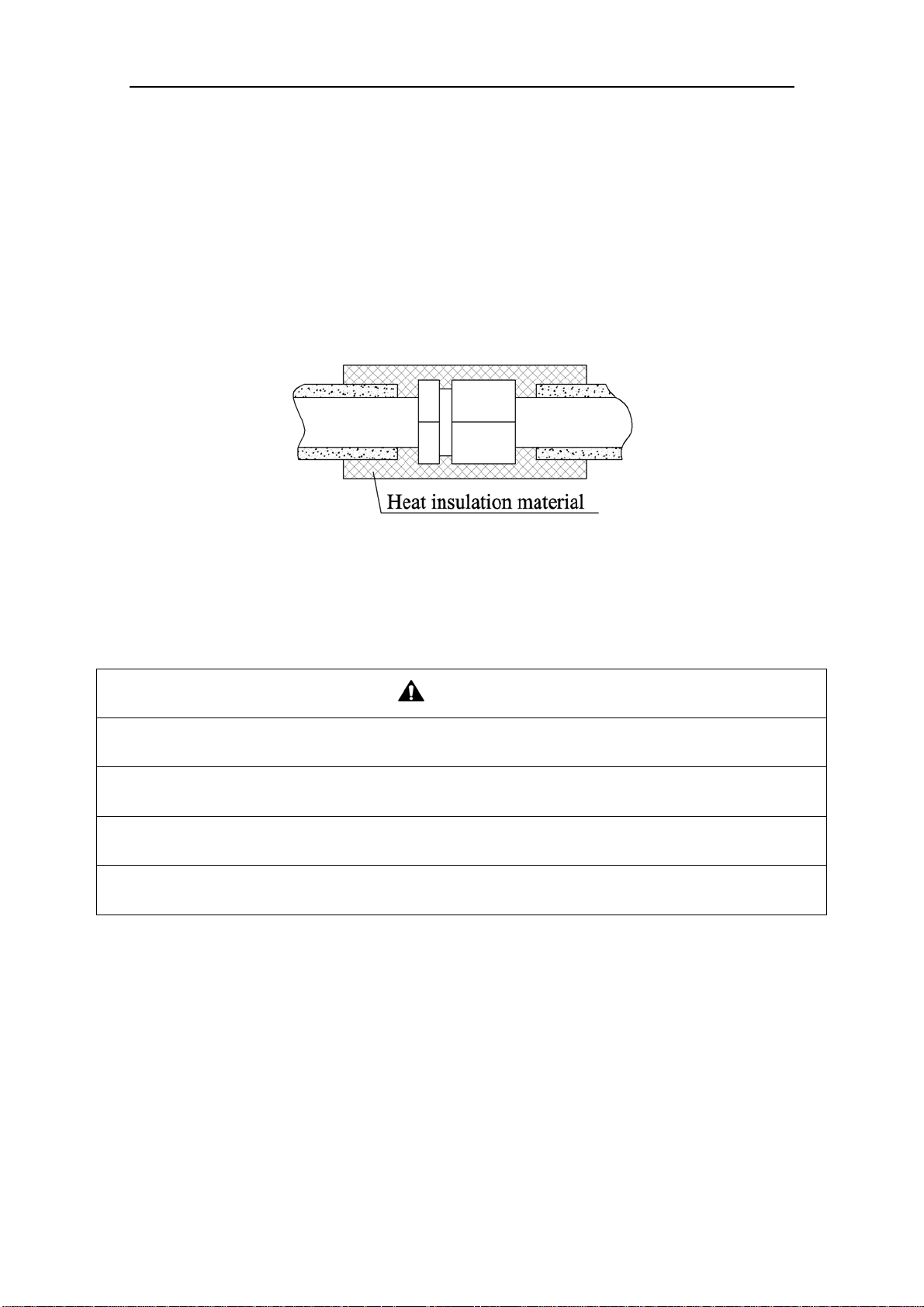

9 Installation of Protective Layer

1) The refrigerant pipes should be insulated by the heat insulation material and plastic tape in

order to prevent water condensation and leakage.

2) Do not use the foam on the branch pipe as the material for heat insulation, heat insulation

material of branches should be the same as that of the pipeline.

NOTICE! The heat resistance of heat insulation material should be over than 120℃(248℉)

and its thickness is more than 9mm(3/8inch).

3) The joints of the system should be wrapped with the heat insulation material and no gap is

allowed on the joint of the system, as shown in the following figure.

Fig. 23

4) Bun

5) Wrap the pipe from the bottom of the outdoor unit to the top of the pipe where it enters the wall.

dle the refrigerant pipe and transmission line together with tape, and separate them from the

drain pipe to prevent the condensate water overflowing.

During the wrapping, the later circle should cover half of the former one.

CAUTION

1) At intervals of about 1 meter (3-1/4feet), fix the refrigerant pipes to the wall with brackets, that is, don’t

let the unit withstand the weight of it or float it in the air.

2) After the pipe is protected well enough, never bend it to form a small angle(<90°), otherwise it would

crack or break.

3) Do not wrap the refrigerant pipes very tight, otherwise the insulation effect would be weakened.

Additionally, make sure the drain hose is separated from the refrigerant pipes.

4) After that, cover the hole on the wall with sealing materials to prevent wind and noise going into the

room.

21

Page 28

Flex + Series

10 Test Operation

10.1 Check after Installation

Table 10

Items to be checked Possible malfunction

Has it been fixed reliable? The unit may drop, vibrate or make noise.

Has the gas leakage been checked? It may cause insufficient cooling(heating) capacity.

Is the thermal insulation of the unit sufficient? It may cause condensation and dripping.

Is the drainage well? It may cause condensation and dripping.

Is the voltage in accordance with the rated

voltage marked on the nameplate?

Are the lines and pipelines correctly installed?

Has the unit been safely grounded? It may cause electrical leakage.

Are the models of lines in conformity with

requirements?

Are there any obstacles near the air inlet and

outlet of the indoor and outdoor units?

Have the length of connection pipes and

refrigerant charge amount been recorded?

It may cause electric malfunction or the

components may be burned out

It may cause electric malfunction or the

components may be burned out

It may cause electric malfunction or the

components may be burned out

It may cause insufficient cooling(heating) capacity.

It is not easy to decide the charge amount of

refrigerant.

10.2 Test Operation

1) Before test operation

The appearance of the unit and the refrigerant pipes cannot be damaged during the installation.

Do not switch on power before installation is finished completely.

Electrical wiring must be connected correctly and securely.

The stop valves of the outdoor unit should be opened fully.

All the impurities such as scraps and thrums must be cleared from the unit.

2) Test operation method

① The test operation should be carried out by the professionally skilled personnel on the premise

that all items listed above are in normal conditions.

② Set the status of the power supply switch as “ON” eight hours before the start of operation

③ Press mode button, to select the COOL, or HEAT. Whether the air conditioner is work

normally or not.

The fan motor of the indoor unit will run automatically in one minute.

The fan motor and compressor of the outdoor unit will run automatically in one minute.

④ Make sure that every combination of indoor units can work well.

WARNING

If the unit cannot work nor has any abnormal noise after the compressor is started, turn off the unit for an

immediate check.

22

Page 29

Flex + Series

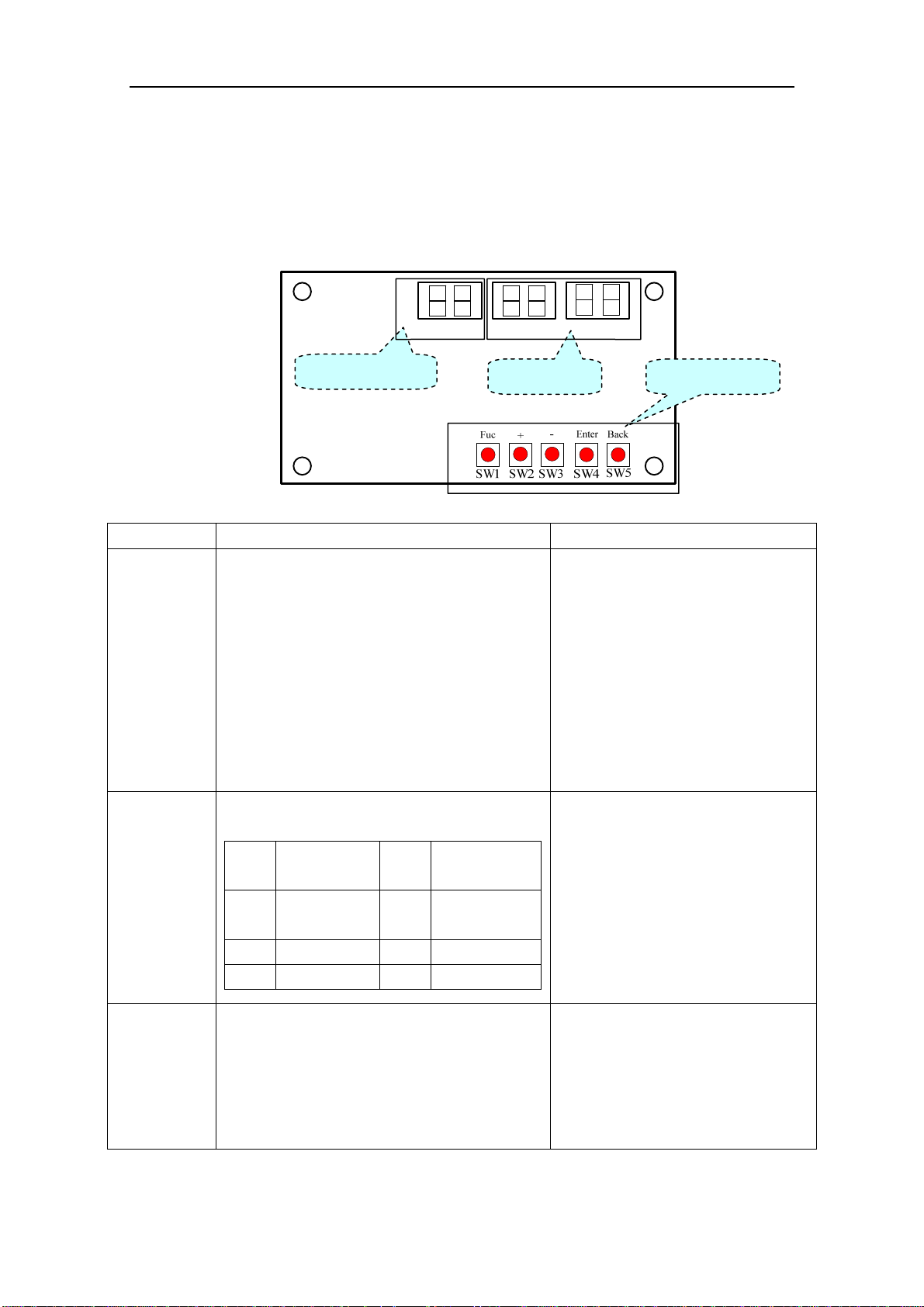

11 Testing Board Introduction

11.1 Compose of the Testing Board

The testing board is in front of electrical box and can be observed well. It has several following

advantages: detect indoor unit numbers and indoor unit address, displays real running function and

error code automatically. It is composed of the function section, data section and button section.

Function section

Data section Button section

11.2 Instruction of Function and Data Section

Running state The display of function section The display of data section

① If the function section displays the

numbers of the indoor units, the data

section will display the outside

temperature. For example, the “35” is

represented of 35℃.

② If the function section displays the

address of the indoor unit,the data

section will display the model of the

indoor unit, for example, the “35” is

represented of 35 model.

It displays the target gear of the

compressor. If the gear is zero, it will

display “0”. For example, the gear is

the fifteenth; it will display “15”. The

range of the gear is from 0 to 60.

Stop

Normal

① The section will display the numbers of the

indoor units which have established

communication with the outdoor unit. For

example, if there are seven established indoor

units, the section will display “7”.

② It will display the address of the indoor units

by turns. For example, the “1b” is represented

of the indoor unit 1B.

(BU module:1/2/3,Indoor unit: A/b/C/d/E)

The code of running state:

Code

UE

UP Pump down F7 Oil returning

UC Cooling H1 Defrosting

Running

state

Pressure

equalization

Code Running state

UH Heating

Malfunction

If the malfunction occurs in the system, the

section will display the error code. If there are

several malfunctions, it will display the error

codes by turns at intervals of 2 seconds.

23

① If the malfunction occurs in the

outdoor unit, the section displays

nothing;

② If the malfunction occurs in the

indoor units, the section displays the

address of the indoor unit.

Page 30

Flex + Series

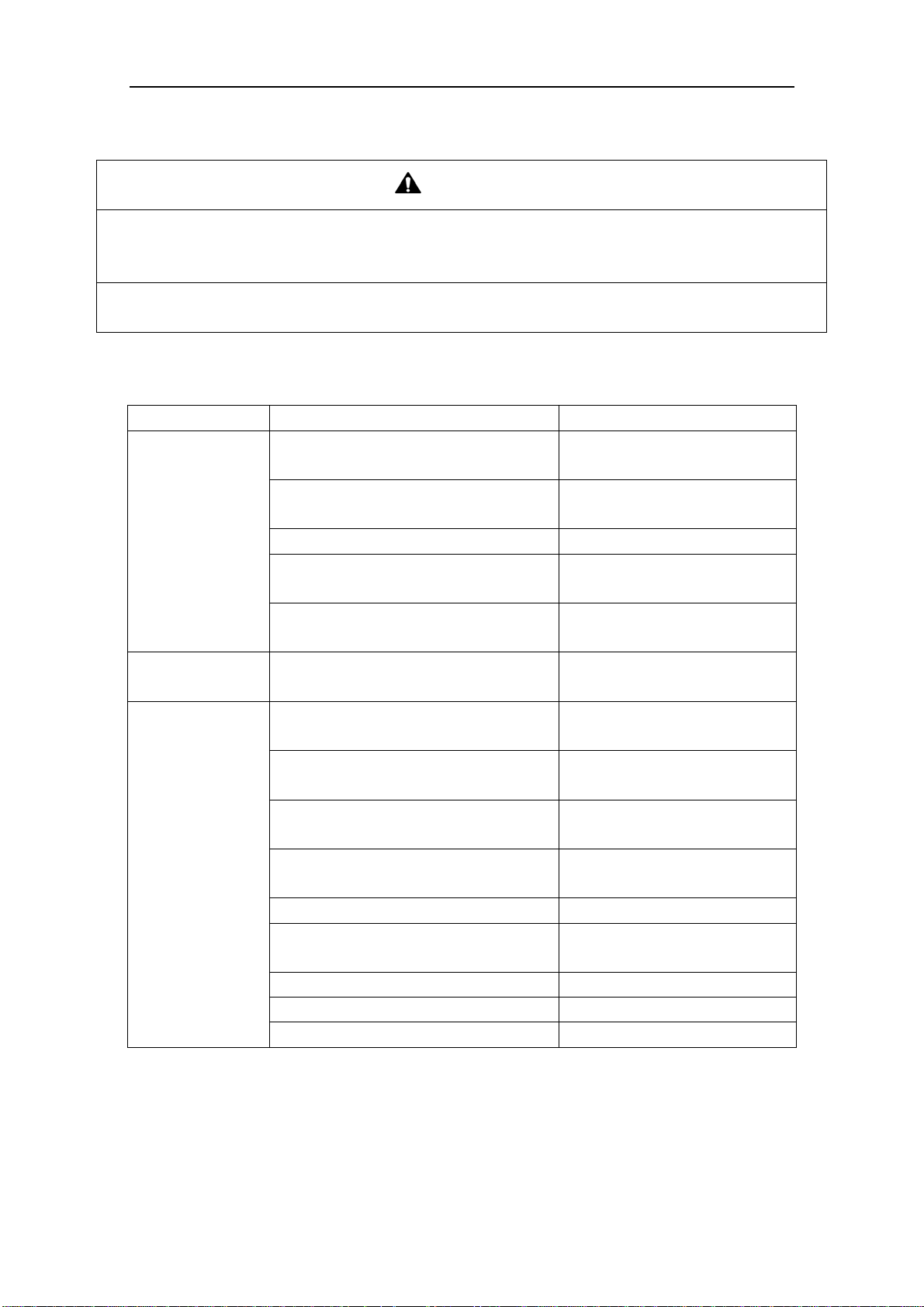

12 Troubleshooting

WARNING

1) In the event of abnormal conditions (like, stinky smell), please shut off the power supply immediately

and then contact the appointed service center; otherwise, the abnormal running would damage the air

conditioner and also would cause electric shock or fire hazard .

2) Do not repair the air conditioning personally but instead contact the professionally skilled personnel at

the appointed service center, as the incorrect repair would cause electric shock or fire hazard etc.

12.1 Check before Contacting Service Center

Please check the following items before contacting the maintenance serviceman.

Conditions Causes Corrective actions

Broken fuse or breaker is off

Power off

The unit does not

run at all

The unit stops

soon after it starts

Cooling or heating

is abnormal

Power supply plug is loose Plug the power supply properly

The batteries voltage of the remote

controller is insufficient

Remote controller is out of the control

scope

Air inlet or outlet of indoor unit or

outdoor unit is blocked

Air inlet or outlet of indoor unit or

outdoor unit is blocked

Temperature setting is improper

Air speed is set too low

Improper airflow direction

Door or window is open Close the door or window

Under direct sunshine

Too many people in the room

Too many heat sources indoors Reduce the heat sources

The filter screen is dirt or blocked Clean the filter screen

NOTICE! If the air conditioner still runs abnormally after the above check and handling,

please contact the local appointed service center and also give a description of the error

occurred as well as the model of the unit.

Replace the damaged fuse or

close the breaker

Restart the unit after power

supply resumes

Replace with new batteries

The distance shall be within 8m

Remove the obstacles

Remove the obstacles

Adjust the setting of remote

controller or wire controller

Adjust the setting of remote

controller or wire controller

Adjust the setting of remote

controller or wire controller

Hang curtain or blinders over the

window

24

Page 31

12.2 Problem Handling

The conditions listed below are not classified into errors.

Conditions Causes

When restart the unit soon after

The unit does

not run

The unit blows

out mist

The unit

generates noise

The unit blows

out dust

The unit emits

odors

it is stopped

As soon as power supply is on

When the cooling operation

starts

The unit “clatters” as soon as it

starts running

The unit “swishes” during the

cooling operation

The unit “swishes” when it is

started or stopped

The unit “swishes” when it is in

and after the running

The unit “squeaks” when it is in

and after the running

When the unit restarts after it is

not used for a long time

When the unit is running The odors absorbed in are blown out

Flex + Series

The overload protection switch of the unit let

the startup delayed for three minutes

The unit will stand by for approximate one

minute

The hi-humidity air indoor is cooled quickly

It is the sound generated during the

initialization of the electronic expansion

valve

It is the sound when the refrigerant gas runs

inside the unit

It is the sound when the refrigerant gas stops

running

It is the sound when the draining system is

operating

It is the sound of frication generated by the

skin plate etc which swells due to the

temperature change

The dust inside the unit is blown out again

12.3 Error Description

If some error occurs when the unit is running, the error code will be displayed and check for

more details about the meaning of each error.

Errors of definition

Main control display for outdoor unit

Yellow LED Red LED Green LED

The compressor is startup Flash 1 time

IPM current protection Flash 3 times

IPM temperature protection Flash 5 times

PFC current protection Flash 7 times

PFC temperature protection Flash 8 times

Low voltage protection Flash 9 times

High voltage protection Flash 10 times

Low pressure protection Flash 11 times

High pressure protection Flash 12 times

High pressure switch protection Flash 13 times

Capacitor charging error Flash 14 times

AC current protection Flash 15 times

Indoor

unit code

H5 H5

P8 P8

P8 P8

PL PL

PH PH

E5 E5

Testing

board code

HC

E3

E8

E1

PU

25

Page 32

Flex + Series

Memory card error Flash 16 times

Compressor demagnetizing

protection

Compressor desynchronizing Flash 18 times

Compressor phase lack Flash 19 times

Compressor phase circuit detection

error

Compressor power protection Flash 21 times

Compressor overload protection Flash 22 times

Compressor discharge temperature

protection

Lack of refrigerant or jam protection Flash 31 times

Normal operation Flash 1 time

Frequency limitation for AC current Flash 2 times

Oil returning Flash 3 times

Defrosting Flash 4 times

Frequency limitation for IPM

temperature

Frequency limitation for PFC

temperature

Frequency limitation for compressor

overload

Frequency limitation for compressor

discharge temperature

Frequency limitation for low pressure Flash 10 times

Frequency limitation for high

pressure

Discharge temperature sensor error Flash 12 times

Outdoor temperature sensor error Flash 13 times

Suction temperature sensor error Flash 15 times

Condenser temperature sensor error Flash 16 times

Sub-cool temperature sensor error Flash 17 times

Low pressure sensor error Flash 18 times

High pressure sensor error Flash 19 times

Fan motor error for indoor unit Flash 20 times

Driving board is connected Flash 1 time

Testing board is connected Flash 2 times

Computer is connected Flash 4 times

Indoor unit 1 is connected Flash 5 times

Indoor unit 2 is connected Flash 6 times

Indoor unit 3 is connected Flash 7 times

Indoor unit 4 is connected Flash 8 times

Indoor unit 5 is connected Flash 9 times

Flash 17 times

Flash 20 times

Flash 23 times

Flash 5 times

Flash 6 times

Flash 8 times

Flash 9 times

Flash 11 times

EE

HE HE

H7 H7

U2 U2

U1 U1

L9 L9

H3 H3

E4 E4

F0 F0

F8

F7

H1 H1

EU

EU

LU

F9

Pn

F6

F5 F5

F3 F3

dc

A7 A7

bC

dL

e1

H6 H6

26

Page 33

Flex + Series

Indoor unit 6 is connected Flash 10 times

Indoor unit 7 is connected Flash 11 times

Indoor unit 8 is connected Flash 12 times

Indoor unit 9 is connected Flash 13 times

Indoor unit anti-freeze protection

Indoor temperature sensor error

Indoor evaporator midway

temperature sensor error

Temperature sensor error for liquid

pipe of BU module

Temperature sensor error for gas pipe

of BU module

Running mode conflicts

Communication error

Communication error between the

main board and driving board

Communication error between the

main board and testing board

Gas sensor error of indoor unit

Humidity sensor error of indoor unit

Water full error of indoor unit

Jumper terminal error of indoor unit

Phase lack of power supply

Fan motor error of outdoor unit

Refrigerant recovery mode

E2 E2

F1 F1

F2 F2

b5 b5

b7 b7

E7 E7

E6

E6

unit address

CE

E9 E9

C5 C5

Fo Fo

Display mode of Red LED and Yellow LED: At intervals of half a second, flash for half a

second; if there are several malfunctions, it will display the error codes by turns at intervals of

one second.

Display mode of Green LED: At intervals of 1/4 second, flash for 1/4 second; and it displays

the running states by turns at intervals of half a second.

indoor

P6

Fn

L1

dJ

L3

27

Page 34

Flex + Series

13 Maintenance

Check, maintenance and care regularly should be performed by professional personnel, which

will prolong the unit service life.

13.1 Outdoor Condenser

Outdoor condenser is required to be cleaned every two months. Use vacuum cleaner with nylon

brush to clean up dust and sundries on the surface of condenser. Blow away dust by compressed air

if it is available. Never use water to wash the condenser.

13.2 Drain Pipe

In order to drain condensate smoothly, please check the drain pipe regularly is clogged or not.

13.3 Check before the Seasonal Use

Check the air inlet and outlet of the indoor and outdoor units to confirm there is no blockage.

Check the ground wire to confirm the grounding is reliable.

Check the batteries of the wireless remote controller to ensure that they have been replaced.

Check the filter screen that it has been set soundly.

If the air-conditioning unit shall be operated again after a long-term shut off, set the status of

the power supply switch as “ON” eight hours before the start of operation, so as to ensure the

successful startup of the air-conditioning unit.

Check the outdoor unit to ensure the installation of it is steady. Contact the appointed service

center if there is any abnormal condition.

13.4 Maintenance after Seasonal Use

Turn off the power supply of the air conditioning unit and set the status of the power supply

switch as “OFF”.

Clean the filter screen and the housing of the indoor and outdoor units.

Remove the dust and the foreign matters of the outdoor unit.

In the event of rusting, please use the anti-rust paint to stop spreading of rust.

Refer to the Insta

maintenance.

llation and Operation

Manual

each indoor unit respectively for detailed

of

14 After-sales Service

If the unit cannot work or has any problem, please contact the local after-sales service

agency designated by Impecca.

Warranty should meet the following requirements:

① The installation and test operation of the unit should be operated by professional personnel from

appointed service center.

② Only Impecca manufactured accessories

③ All the instructions listed in this manual should be followed.

④ Warranty will be automatically invalid if fails to obey any item mentioned above.

can be used on the machine.

Page 35

CUSTOMER SUPPORT

15

Before contacting customer support, please see the troubleshooting guide above.

V isit our website to contact us, find answers to Frequently Asked Questions, and for other resources

wh ich may include an updated version of this user's guide.

WWW.IMPECCA.COM

If you wish to contact us by phone, please be sure to have your model number and serial number ready

and call us between 9:00am and 6:00pm ET, at +1 866-954-4440.

Keep tabs on Impecca's newest innovations & enter contests via our social network feeds:

www.facebook.com/Impecca/

www.instagram.com/impecca/

@impeccausa

Page 36

© 2016 Impecca, a division of LT Inc., Wilkes Barre, PA.

Page 37

Flex+

R410A Systems—BU

module

IS-BU12

IS-BU13

IS-BU15

s:

Owner's Manual

Air Conditioners

Page 38

Preface

Flex+ Series adopt the advanced manufacturing technology and takes the environmental-

friendly R410A as refrigerant, which is a green produc

the manual before installation and operation.

1) Flex+ Series systems conform to design standard ARI 210240-2008.

2) To ensure safety when operating this system, please strictly follow the instructions in this

manual.

3) Make sure that the manual is kept by the operators or serviceman.

4) The refrigerant pipes and accessories must be designed exclusively for R410A.

5) The total capacity of the indoor units which runs at the same time cannot exceed the capacity of

the outdoor units; otherwise, the cooling (heating) effect of each indoor unit would be lower

than the nominal capacity.

6) In case of malfunction, please examine the following items and contact our appointed service

centers as soon as possible.

Nameplate (model, cooling capacity, product code, ex-factory date).

Malfunction status (detail description of conditions before and after malfunction occurs).

7) It is a normal phenomenon that the fan of indoor unit will still run for 20-70 seconds after the

indoor unit receives the “stop” signal so as to make full use of the waste heat.

8) When the work mode of the indoors is conflict with the modes of outdoor units, it will be

indicated on the display of the wired controller in five seconds and then the indoor unit will

stop. In this case, please harmonize their work modes: the cooling mode is compatible with the

dry mode.

9) If the supply power fails when the unit is running, then the indoor unit will send the “start”

signal to the outdoor unit three minutes later after the power recovery.

10) The power cable and transmission line must not be twisted together, but instead of separated

with an interval of at least 2cm; otherwise it may be result in communication problem.

11) This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

12) All graphics and information in this manual are only for reference. Manufacturer reserves the

right for changes in terms of sales or production at any time and without prior notice.

t in the 21st century. Please carefully read

This product must not be disposed together with the domestic waste. This product has

to be disposed at an authorized place for recycling of electrical and electronic appliances.

Thank you for purchasing Impecca air conditioners. Before using, please read

this manual carefully and keep it properly for further reference.

Page 39

Contents

1 Safety Precautions ......................................................................................................................... 1

2 Product Introduction ..................................................................................................................... 3

2.1 Names of Main Parts ......................................................................................................... 3

2.2 Combinations for Outdoor and Indoor Units .................................................................... 4

2.3 Parts and Components of Unit .......................................................................................... 4

2.4 Working Temperature Range ............................................................................................ 4

3 Selection of Installation Location and Precautions ....................................................................... 5

3.1 Selection of Installation Location ..................................................................................... 5

3.2

3.3

3.6

4 Installation Instruction ................................................................................................................ 11

5 Installation of Refrigerant Pipes ................................................................................................. 12

5.1 Allowable Length and Drop Height of Connecting Pipe ................................................ 12

5.2

5.4 Precaution for Connection .............................................................................................. 15

6 Electrical Wiring Work ............................................................................................................... 17

6.1 Wiring Connection .......................................................................................................... 17

6.2 Requirements of Power Circuit and Cable ...................................................................... 17

6.3 Ground Requirements ..................................................................................................... 18

6.4 Precautions on the Electrical Wiring Work ..................................................................... 18

6.5 Precaution of Laying Wires ............................................................................................. 19

6.6 Procedures for Electrical Wiring Work ........................................................................... 19

6.7 Instructions for DIP Switch ............................................................................................. 21

7 Design of Drainage Pipeline ....................................................................................................... 22

7.1 Installation of Drain Hose ............................................................................................... 22

7.2 Design of Drainage Pipeline ........................................................................................... 22

8 Test Operation ............................................................................................................................. 22

9 Troubleshooting .......................................................................................................................... 23

10 After-Sales Service ..................................................................................................................... 23

Outline Dimension and Servicing Space of IS-BU12 .................................................... 6

Outline Dimension and Servicing Space of IS-BU13 .................................................... 7

Outline

Installation of Piping Adapter (IS-BU12 IS-BU13 and IS-BU15) .................

Dimension and Servicing Space of IS-BU15 .................................................. 10

................. 12

Page 40

Page 41

1 Safety Precautions

BU Module

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert y

hazards. Obey all safety messages that follow this symbol to avoid possible injury or

death.

This mark indicates procedures which, if improperly performed, might lead to the

death or serious injury of the user.

This mark indicates procedures which, if improperly performed, might possibly result

in personal harm to the user, or damage to property.

NOTICE is used to address practices not related to personal injury.

ou to potential personal injury

WARNING

1) Instructions for installation and use of this product are provided by the manufacturer.

2) Installation must be performed in accordance with the requirements of NEC and CEC by appointed

personnel only.

3) The installation should be left to the appointed service center and according to the instructions given in the

manual. Improper installation may cause fall down, water leakage, electric shock or fire etc.

4) For operating the air conditioner pleasantly, please install it as outlined in this installation manual.

5) The power supply must adopt the special circuit with air switch protection and assure it has enough capacity

6) Connect the indoor unit, BU module and outdoor unit with the room air conditioner piping and cord

available from our standard parts. This installation manual describes the correct connections using the

installation set available from our standard parts.

7) Before installation, check the parameter of power cord and make sure that it complies with the power

supply requirement on the nameplate. Make sure the power supply is safe.

8) This air conditioner must be properly grounded through the receptacle to avoid electric shock. The ground

wire shouldn’t be connected with gas pipe, water pipe, lightning arrester or telephone line.

9) If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in contact

with a flame, it produces toxic gas.

10) Do not power on until all installation work is complete.

11) During installation, make sure that the refrigerant pipe is attached firmly before you start up the compressor.

Do not operate the compressor under the condition of refrigerant piping not attached properly with valve

open. This may cause abnormal pressure in the refrigeration cycle that leads to breakage and even injury.

12) When installing and relocating the air conditioner, do not mix gases except the specified refrigerant

(R410A) to enter the refrigerant cycle. If air or other gas enters the refrigerant cycle, the pressure inside the

cycle will rise to an abnormally high value and cause breakage, injury, etc.

13) This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

14) Never cut off or damage power cables and transmission wires. If the power cable or transmission line were

damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to

avoid a hazard.

15) After the power cord is connected, please install the cover of electric box to avoid danger.

1

Page 42

BU Module

16) When installing or relocating the unit, please contact the appointed service center for the repair or