Impco HHI Service Manual

2007-

2009

LPG

& Bi

2.0L

Service Manual

HHI

Emission Certified

-Fuel

System

Engine

Revision A/June, 2009

Table of Contents

General Information

................................

An overview

of this Service Manual

Maintenance

................................

General maintenance and maintenance interval information

LPG Fuel System

................................

An overview of the LPG fuel system and its components

LPG Fuel System Diagnosis

How to identify a general problem

LPG Symptom Diagnos

tics

How to correct a specific problem

Gasoline Fuel System

................................

An overview of the

Gasoline

Gasoline Fuel System Diagn

How to identify a general problem

Gasoline

Symptom Diagnostics

How to correct a specific problem

Electrical Section

................................

Diagnostic Scan Tool

................................

Using the DST for testing and trouble shooting

Wire Schematic

................................

Engine wiring schematic

Engine Wire Harness Repair

Repairing a wire harness on the vehicle

Diagnost

ic Trouble Codes (DTCs)

Application, schematic and DTC specific code information

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

fuel system (bi-fuel models only)

and its components

osis................................

................................

with the Gasoline fuel system bi-

fuel

................................

................................

with the Gasoline fuel system (bi-

fuel model

................................

................................

................................

...........................

................................

................................

................................

................................

................................

................................

.....5

............... 11

....... 19

..................... 29

....................... 39

55

.............. 63

models only)

............... 71

s only)

....... 85

87

..... 121

................ 125

...... 129

Servicing the Fuel System

Step by step instructions on how

Definitions

................................

Definitions of phrases and acronyms used throughout this Service Manual

Tool Kit & Accessories

................................

Definitions of phrases and acronyms used throughout this Service Manual

Appendix

................................

Altitude vs. Barometric Pressure

................................

................................

repair and/or replace fuel related c

omponents

................................

................................

................................

..............................

................................

................................

& Ignition System Specifications

........................ 457

.................. 475

481

.................... 483

4

5

General Information

GENERAL INFORMATION

6

INTRODUCTION

This service manual supplement has been

developed to provide the service technician

with the basic understanding of the IMPCO

certified fuel and emission systems for the

2.0L engine. This manual should be used in

conjunction with the base engine manual and

the OEM service manual when diagnosing

fuel or electrical problems.

HOW TO IDENTIFY THE ENGINE YEAR

The 2.0L engine blocks have been stamped

with a serial number. The number can be

found on the left side of the top edge of the

engine block near the exhaust manifold.

Engine Identification Number Table

SERVICING YOUR EMISSIONS

CERTIFIED ENGINE

Any maintenance and repair should be performed by trained and experienced service

technicians. Proper tools and equipment

should be used to prevent injury to the servic-

ing technician and damage to the vehicle or

components. Service repairs should always

be performed in a safe environment and the

technician should always wear protective

clothing to prevent injury.

For parts or labor to be reimbursed under the

IMPCO Technologies Inc. emission warranty,

only work performed by IMPCO or OEM

trained technicians using only IMPCO specified parts will qualify for reimbursement.

Refer to the IMPCO Labor Time Guide for additional information.

For parts or labor not reimbursed under warranty, a repair shop or person of the owner’s

choosing may maintain, replace, or repair

emission-control devices and systems. It is

highly recommended that any replacement

parts used for maintenance or for the repair of

emission control systems be new OEM replacement parts. The use of other than

genuine IMPCO replacement parts may impair the effectiveness of emission control

systems, therefore, the owner should assure

that such parts are warranted by their manufacturer to be equivalent to genuine IMPCO

OEM parts in performance and durability.

FUEL QUALITY

LPG

Note that LPG engines are designed to operate

on HD–5 or HD–10 specification LPG fuel. Fuel

other than HD–5 or HD–10 may cause harm to

the engine’s emission control system and a warranty claim may be denied on this basis if

operators can readily find the proper fuel*.

Use of any other fuel may result in your engine no

longer operating in compliance with CARB or

EPA emissions requirements.

*Not Applicable in the state of California.

GENERAL INFORMATION

7

Gasoline

IMPCO recommends the use of name brand

high detergent gasoline. Gasoline is a mixture

of many different hydrocarbons, including olefins, which are heavy, waxy compounds. Over

time, these deposits can build up and clog the

fuel injectors. The formation of these deposits

is a normal consequence of engine operation,

so detergents are added to high quality gasoline to help keep the injectors clean. The use

of low quality low detergent gasoline may

cause fuel injectors to fail. Fuel injector replacement or cleaning is expensive, and the

cleaning procedure requires special equipment that may not be practical in the industrial

lift truck market. Speak with your fuel supplier

to verify that the fuel you are supplied contains the necessary fuel additives to keep

your fuel system clean. IMPCO may deny

emissions related warranty claims due to the

use of low quality low detergent gasoline.

FUEL SYSTEM CAUTIONS

Do not smoke, carry lighted tobacco or

use a lighted flame of any type when

working on or near any fuel related

component. Highly flammable air-fuel

mixtures may be present and can be

ignited causing personal injury

Do not allow LPG to contact the skin.

LPG is stored in the fuel tank as a liquid. When LPG contacts the

atmosphere, it immediately expands

into a gas, resulting in a refrigeration

effect that can cause severe burns to

the skin.

Do not allow LPG to accumulate in

areas below ground level such as in a

service pit or underground ventilation

systems. LPG is heavier than air and

can displace oxygen, creating a dangerous condition

Do not make repairs to the LPG fuel

system if you are not familiar with or

trained to service LPG fuel system.

Contact the dealer who sold you the

vehicle to locate a repair facility with

trained technicians to repair your fuel

system

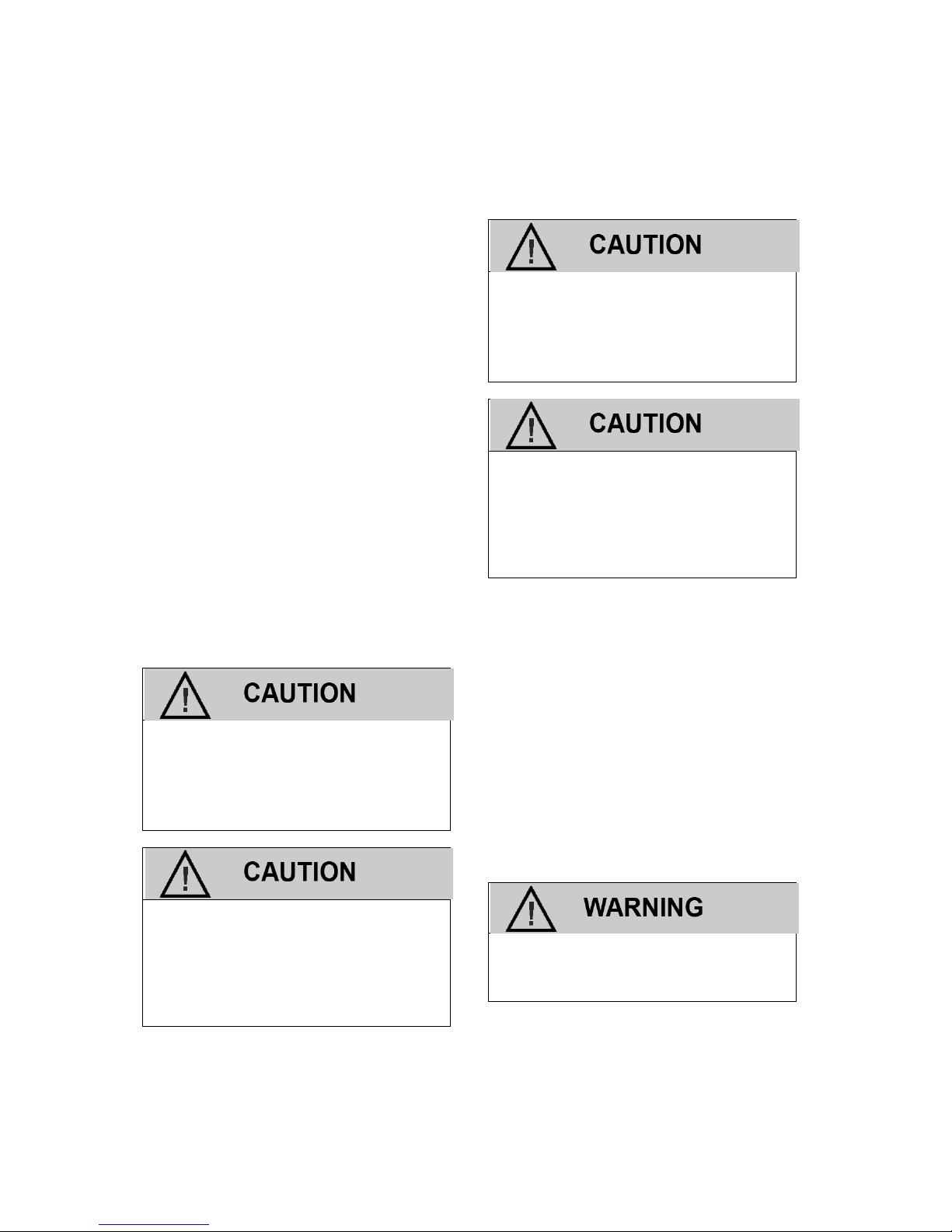

WARNINGS, CAUTIONS AND NOTES

This manual contains several different Warnings, Cautions, and Notes that must be

observed to prevent personal injury and or

damage to the vehicle, the fuel system or

personal property.

A “WARNING“ is an advisement that by performing a process or procedure listed in this

manual improperly may result in serious bodily injury, death and/or serious damage to the

vehicle or property.

Typical Warning Label:

Failure to heed instructions could result in death, injury, or property

damage.

A “CAUTION” label or statement is used when

it has been determine that by performing a

process or procedure defined in the manual

improperly a less severe result may occur. It

GENERAL INFORMATION

8

could however, result in serious bodily injury,

and or serious damage to the vehicle or property damage.

Less severe than WARNING but has the

potential to cause injury or damage.

Also used to notify of situations that

could lead to eventual failure, injury or

damage.

This caution label may also appear in area of

this manual that applies to service and repair

procedures which could render the fuel and

emissions control system non-compliant. In

addition it may also be used to indicate a failure to observe which may influence the terms

of the warranty.

An “IMPORTANT” statement generally denotes a situation that requires strict

adherence to the assembly, tightening, or

service procedure. Failure to observe this

procedure could result in an unsafe condition

or improper performance of the vehicle or a

component.

A “NOTE” statement applies to a specific item

or procedure that is to be followed during the

servicing of the vehicle or its components.

PROPER USE OF THIS SERVICE MANUAL,

TOOLS AND EQUIPMENT

To reduce the potential for injury to the technician or others and to reduce damage to the

vehicle during service repairs the technician

should observe the following steps:

The service procedures defined in this

manual, when followed, have been found

to be a safe and efficient process to repair

the fuel system. In some cases special

tools may be required to perform the necessary procedures to safely remove and

replace a failed component.

The installed IMPCO fuel system has

been certified with the Environmental Protection Agency (EPA) and the California

Air Resources Board (CARB) and complies with the regulation in effect at the

time of certification. When servicing the

fuel and emission control system you

should follow all the recommended service and repair procedures to insure the

fuel and emissions system is operating as

designed and certified. Purposely or knowingly defeating or disabling any part or

the fuel and emission system may be in

violation of the anti-tampering provision of

the EPA’s Clean Air Act.

Tools identified in this manual with the

prefix “J” or “BT” can be procured through

SPX in Warren, Michigan.

Tools identified in this manual with a prefix

“ITK” can be acquired through OEM Parts

Distribution.

IMPORTANT

It is important to remember that there may be

a combination of Metric and Imperial fasteners used in the installation of the IMPCO fuel

system. Check to insure proper fit when using

a socket or wrench on any fastener to prevent

damage to the component being removed or

injury from “slipping off” the fastener.

The IMPCO fuels system utilizes fuel lines

hoses with swivel connections which attach to

fixed mating connectors. You should always

use a wrench of the proper size on both the

swivel and fixed fitting to prevent turning of

the fixed fitting. Turning of the fixed fitting may

cause a “twisting” or “kinking” of the hose and

may result in a restriction of the fuel line or a

leak.

GENERAL INFORMATION

9

Always leak check any fuel system

connection after servicing! Use an

electronic leak detector and/or a liquid

leak detection solution. Failure to leak

check could result in serious bodily

injury, death, or serious property damage.

10

11

Maintenance

12

MAINTENANCE

The maintenance of an engine and related components are critical to its operating performance

and lifespan. Industrial engines operate in environments that often include hot and cold

temperatures and extreme dust. The recommended maintenance schedule is listed in this

section, however, environmental operating conditions and additional installed equipment may

require more frequent inspection and servicing.

The owner and/or service agent should review the

operating conditions of the equipment to determine the inspection and maintenance intervals.

When performing maintenance on the engine,

turn the ignition OFF and disconnect the battery negative cable to avoid injury or damage

to the engine.

The engine installed in this equipment uses a serpentine drive belt con

figuration that drives the

water pump, alternator and additional pumps or

devices. It is important to note that the drive belt

is an integral part of the cooling and charging system and should be inspected according to the

maintenance schedule in this section. When inspecting the belts check for:

Cracks

Chunking of the belt

Splits

Material hanging loose from the belt

Glazing, hardening

If any of these conditions exist the belt should be

replaced with the recommended OEM replacement belt.

Alcohol or Methanol based anti-freeze or plain

water are not recommended for use in the

cooling system at anytime.

SERPENTINE BELT SYSTEM

Serpentine belts utilize a spring-loaded tensioner

to keep the belt properly adjusted. Serpentine

belts should be checked according to the maintenance schedule in this section.

IMPORTANT:

The use of “belt dressing” or “anti-slipping

agents” on belts is not recommended.

COOLING SYSTEM

It is important that the cooling system of the engine be maintained properly to ensure proper

performance and longevity.

Do not remove the cooling system pressure

cap (radiator cap) when the engine is hot.

Allow the engine to cool and then remove the

cap slowly to allow pressure to vent. Hot

coolant under pressure may discharge violently.

Note that the LPG vaporizer is connected to the

cooling system and the fuel system may be adversely affected by low coolant levels and

restricted or plugged radiator cores. Therefore,

the cooling system must be maintained according

to the recommend maintenance schedule in this

section and also include:

The regular removal of dust, dirt and debris

from the radiator core and fan shroud.

Inspection of coolant hoses and components

for leaks, especially at the radiator hose connections. Tighten hose clamps if necessary.

Check radiator hoses for swelling, separation,

hardening, cracks or any type of deterioration.

If any of these conditions exist the hose

should be replaced with a recommended OEM

replacement part.

Inspect the radiator cap to ensure proper seal-

ing.

13

COOLANT

Check coolant level in coolant recovery tank and

add coolant as required. Add 50/50 mixture of

ethylene glycol antifreeze and distilled water or

coolant per engine manufacturer’s instructions.

Do not add plain water. Replace coolant per the

recommended schedule.

IMPORTANT:

The manufacturers of the engine and fuel system

do not recommend the use of “stop leak” additives

to repair leaks in the cooling system. If leaks are

present the radiator should be removed and repaired or replaced.

ENGINE ELECTRICAL SYSTEM MAINTNANCE

The engine’s electrical system incorporates computers to control various related components. The

electrical system connections and ground circuits

require good connections. Follow the recommended maintenance schedule in this section to

maintain optimum performance. When inspecting

the electrical system check the following:

Check Positive and Negative cables for corro-

sion, rubbing, chafing, burning and to ensure

tight connections at both ends.

Check battery for cracks or damage to the

case and replace if necessary.

Inspect engine wire harness for rubbing, chaf-

ing, pinching, burning, and cracks or breaks in

the wiring.

Verify that engine harness connectors are cor-

rectly locked in by pushing in and then pulling

the connector halves outward.

Inspect primary ignition coil wires for harden-

ing, cracking, arcing, chafing, burning,

separation, split boot covers.

Check spark plug wires for hardening, crack-

ing, chafing, arcing or burning, separation, and

split boot covers.

Replace spark plugs at the required intervals

per the recommended maintenance schedule.

Verify that all electrical components are se-

curely mounted to the engine or chassis.

Verify that any additional electrical services

installed by the owner are properly installed in

the system.

Verify that the MIL, charging, and oil pressure

lights illuminate momentarily during engine start.

ENGINE CRANKCASE OIL

OIL RECOMMENDATION

Select an engine oil that will best match the prevailing daytime temperature:

Motor oils meeting this spec receive the API

(American Petroleum Institute) starburst symbol:

The recommended API classification: Above SG.

The oil capacity for the 2.0L engine including a

new filter is 1.1 gallons (4.0L)

IMPORTANT:

Oils recommended by the engine manufacturer

already contain a balanced additive treatment.

Oils containing “solid” additives, non-detergent

oils, or low quality oils are not recommended by

the engine manufacturer. The supplemental additives added to the engine oil are not necessary

and may be harmful. The engine and fuel system

14

supplier do not review, approve or recommend

such products.

SYNTHETIC OILS

Synthetic oils have been available for use in industrial engines for a relatively long period of

time and may offer advantages in cold and hot

temperatures. However, it is not known if synthetic oils provide operational or economic

bene

fits over conventional petroleum-based oils

in industrial engines. Use of synthetic oils does

not permit the extension of oil change intervals.

CHECKING/FILLING ENGINE OIL LEVEL

IMPORTANT:

Care must be taken when checking engine oil level. Oil level must be maintained between the

“ADD” mark and the “FULL” mark on the dipstick.

To ensure that you are not getting a false reading,

make sure the following steps are taken before

checking the oil level.

1. Stop engine.

2. Allow approximately five minutes for the oil to

drain back into the oil pan.

3. Remove the dipstick. Wipe with a clean cloth

or paper towel and reinstall. Push the dipstick

all the way into the dipstick tube.

4. Remove the dipstick and note the amount of

oil on the dipstick. The oil level must be between the “FULL” and “ADD” marks.

Figure 2 Engine Oil Dip tick (Typical)

5. If the oil level is below the “ADD” mark reinstall

the dipstick into the dipstick tube and proceed

to Step 6.

6. Remove the oil

filler cap from the valve cover.

7. Add the required amount of oil to bring the

level up to, but not over, the “FULL” mark on

the dipstick Reinstall the oil

filler cap to the

valve rocker arm cover and wipe any excess

oil clean.

CHANGING THE ENGINE OIL

IMPORTANT:

When changing the oil, always change the oil

filter.

1. Start the engine and run until it reaches normal operating temperature.

An overfilled crankcase (oil level being too

high) can cause an oil leak, a fluctuation or

drop in oil pressure. When overfilled, the engine crankshafts splash and agitate the oil,

causing it to aerate or foam.

IMPORTANT:

Change oil when engine is warm and the old oil

flows more freely.

2. Stop engine

IMPORTANT:

Engine oil will be hot. Use protective gloves to

prevent burns. Engine oil contains chemicals

which may be harmful to your health. Avoid skin

contact.

3. Remove drain plug and allow the oil to drain.

4. Remove and discard oil

filter and its sealing

ring.

5. Coat sealing ring on the new

filter with clean

engine oil, wipe the sealing surface on the

filter mounting surface to remove any dust, dirt

or debris. Tighten filter securely (follow filter

manufacturer’s instructions). Do not over tigh-

ten.

6. Check sealing ring on drain plug for any damage, replace if necessary, wipe plug with clean

rag, wipe pan sealing surface with clean rag

and re-install plug into the pan. Tighten to

25.3-32.4 ft.lbs (34.3-44.1 Nm).

IMPORTANT:

Always use a new drain plug gasket when changing the oil.

7. Fill crankcase with oil.

8. Start engine and check for oil leaks.

15

9. Dispose of oil and filter in a safe manner.

FUEL SYSTEM INSPECTION AND

MAINTENANCE

LPG FUEL SYSTEM

The LPG fuel system installed on this industrial

engine has been designed to meet the emission

standard applicable for the 2007-2009 model

years. To ensure compliance to these standards,

follow the recommended maintenance schedule

contained in this section.

INSPECTION AND MAINTENANCE OF THE

FUEL STORAGE CYLINDER

The fuel storage cylinder should be inspected

daily or at the beginning of each operational shift

for any leaks, external damage, adequate fuel

supply and to ensure the manual service valve is

open. Fuel storage cylinders should always be

securely mounted, inspect the securing straps or

retaining devices for damage ensure that all locking devices are closed and locked. Check to

ensure that the fuel storage cylinder is positioned

with the locating pin in the tank collar on all horizontally mounted cylinders this will ensure the

proper function of the cylinder relief valve.

When refueling or exchanging the fuel cylinder,

check the quick

fill valve for thread damage. Also

verify O-ring is in place and inspect for cracks,

chunking or separation. If damage to the o-ring

is found, replace prior to

filling. Check the ser-

vice line quick coupler for any thread damage.

IMPORTANT:

When refueling the fuel cylinder, wipe both the

female and male connection with a clean rag prior

to

filling to prevent dust, dirt and debris from being

introduced to the fuel cylinder.

INSPECTION AND REPLACEMENT OF THE

LPG FUEL FILTER

The LPG system on this emission certified engine

utilizes an in-line replaceable fuel filter element.

This element should be replaced, at the intervals

speci

fied in the recommended maintenance sche-

dule. When inspecting the fuel

filter check the

following:

Check for leaks at the inlet and outlet fittings,

using a soapy solution or an electronic leak

detector and repair if necessary.

Check to make sure filter is securely mounted.

Check filter housing for external damage or

distortion. If damaged replace fuel filter.

REPLACING THE LPG FUEL FILTER:

1. Move the equipment to a well ventilated area

and verify that sparks, ignition and any heat

sources are not present.

2. Start the engine.

3. Close the LPG tank valve.

4. When the engine stalls when it runs out of

fuel, turn the ignition key to the OFF position

and disconnect the battery negative cable.

IMPORTANT:

A small amount of fuel may still be present in the

fuel line. Use gloves and proper eye protection

to prevent burns. If liquid fuel continues to

flow

from the connections when removed, make sure

the manual valve is fully closed.

5. Slowly loosen the inlet

fitting and disconnect.

6. Slowly loosen the outlet fitting and disconnect.

7. Remove the filter housing form the equipment.

8. Check for contamination.

9. Tap the opening of the

filter on a clean cloth.

10. Check for debris.

11. Check canister for proper mounting direction.

12. Reinstall the

filter housing to the equipment.

13. Tighten the inlet and outlet fittings to specifica-

tion.

14. Open the LPG tank valve.

IMPORTANT:

The fuel cylinder manual valve contains an

Excess Flow Check Valve. Open the valve slowly

to prevent activating the Excess Flow Check

Valve.

15. Check for leaks at the inlet and outlet

fittings,

and the filter housing end connection using a

soapy solution or an electronic leak detector, if

leaks are detected make repairs.

16

ELECTRONIC PRESSURE REGULATOR (EPR)

MAINTENANCE AND INSPECTION

IMPORTANT:

The Electronic Pressure Regulator (EPR) components have been speci

fically designed and

calibrated to meet the fuel system requirements

of the emission certi

fied engine.

If the EPR fails to operate or develops a leak, it

should be repaired or replaced with the OEM

recommended replacement parts. When inspecting the regulator check for the following items:

Check for any fuel leaks at the inlet and outlet

fittings.

Check for any fuel leaks in the regulator body.

Check the inlet and outlet fittings of the coo-

lant supply lines for water leaks.

Check the coolant supply lines for hardening,

cracking, chafing or splits. If any of these conditions exist replace coolant lines.

Check coolant supply hose clamp connec-

tions, ensure they are tight.

Check to ensure the EPR is securely mounted

and the mounting bolts are tight.

Check EPR for external damage.

Check EPR electrical connection to ensure the

connector is seated and locked.

CHECKING/DRAINING OIL BUILD-UP IN THE

ELECTRONIC PRESSURE REGULATOR

During the course of normal operation oil or

“heavy ends” may build inside the secondary

chamber of the Electronic Pressure Regulator

(EPR). These oil and heavy ends may be a result

of poor fuel quality, contamination of the fuel, or

regional variation of the fuel make up. A significant build up of oil can affect the performance of

the secondary diaphragm response. The Recommended Maintenance Schedule found in this

section recommends that the oil be drained periodically. This is the minimum requirement to

maintain the emission warranty. More frequent

draining of the EPR is recommended for special

situation where substandard fuel may be a problem. IMPCO recommends the EPR be drained at

every engine oil change if contaminated or substandard fuel is suspected or known to have been

used or in use with the emission complaint fuel

system. This is known as special maintenance,

and failure to follow this recommendation may be

used to deny a warranty claim.

IMPORTANT:

Draining the regulator when the engine is warm

will help the oils to

flow freely from the regulator.

To drain the EPR, follow the steps below:

1. Move the equipment to a well ventilated area

and ensure no external ignition sources are

present.

2. Start the engine.

3. With the engine running close the LPG tank

valve.

4. When the engine runs out of fuel turn OFF the

key when the engine stops and disconnect the

negative battery cable.

IMPORTANT:

A small amount of fuel may still be present in the

fuel line, use gloves to prevent burns, wear proper eye protection. If liquid fuels continues to

flow

from the connections when loosened check to

make sure the manual valve is fully closed.

5. Slowly loosen the inlet

fitting and disconnect.

6. Loosen the hose clamp at the outlet hose

fitting and remove the hose.

7. Remove the Retaining Pin in the LPG Temperature Sensor and remove from the EPR

8. Remove the EPR mounting bolts.

9. Place a small receptacle in the engine compartment.

10. Rotate the EPR to 90° so that the outlet

fitting

is pointing down into the receptacle and drain

the EPR.

11. Inspect the secondary chamber for any large

dried particles and remove.

12. Remove the receptacle and reinstall the EPR

with the two retaining bolts and tighten to

speci

fications.

13. Reinstall the outlet fitting and secure with the

previously removed Retaining pin.

14. Reconnect the electrical connector (push in

until it clicks and securely locks), then pull on

the connector to ensure it is locked.

15. Connect the vacuum line.

16. Reconnect the outlet hose and secure the

hose clamp.

17. Reinstall the fuel inlet line and tighten connection to speci

fication.

18. Slowly open the LPG tank valve.

17

IMPORTANT:

The fuel cylinder manual valve contains an

Excess Flow Check Valve. Open the manual

valve slowly to prevent activating the Excess

Flow Check Valve.

19. Check for leaks at the inlet and outlet

fittings

using a soapy solution or an electronic leak

detector. If leaks are detected make repairs.

Check coolant line connections to ensure no

leaks are present.

20. Start engine recheck for leaks at the regulator.

21. Dispose of any drained material in safe and

proper manner.

AIR FUEL MIXER/THROTTLE CONTROL

DEVICE MAINTENANCE AND INSPECTION

IMPORTANT:

The Air Fuel Mixer components have been

speci

fically designed and calibrated to meet the

fuel system requirements of the emission certi

fied

engine. The mixer should not be disassembled or

rebuilt. If the mixer fails to operate or develops a

leak the mixer should be replaced with the OEM

recommended replacement parts.

When inspecting the mixer check for the following

items:

Leaks at the inlet fitting.

Fuel inlet hose for cracking, splitting or chaff-

ing, replace if any of these condition exist.

Ensure the mixer is securely mounted.

Inspect air inlet hose connection and clamp.

Also inspect inlet hose for cracking, splitting or

chafing. Replace if any of these conditions exist.

Inspect Air cleaner element according to the

Recommended Maintenance Schedule found

in this section.

Check Fuel lines for cracking, splitting or chaf-

ing. Replace if any of these conditions exist.

Verify Throttle Body return action to ensure

throttle shaft is not sticking. Repair if necessary.

Check for leaks at the Throttle Body and in-

take manifold.

EXHAUST SYSTEM AND CATALYTIC

CONVERTER INSPECTION AND

MAINTENANCE

IMPORTANT:

The exhaust system on this emission certi

fied engine contains a Heated Exhaust Gas Oxygen

Sensor (HEGO) which provides feed back to the

ECM on the amount of oxygen present in the exhaust stream after combustion.

The measurement of oxygen in the exhaust

stream is measured in voltage and sent to the

ECM. The ECM then makes corrections to the

fuel air ratio to ensure the proper fuel charge and

optimum catalytic performance. Therefore, it is

important that the exhaust connections remain

secured and air tight.

IMPORTANT:

The HEGO sensor is sensitive to silicone based

products. Do not use silicone sprays or hoses

which are assembled using silicone lubricants.

Silicone contamination can cause severe damage

to the HEGO.

When inspecting the Exhaust system check the

following:

Exhaust manifold at the cylinder head for

leaks and that all retaining bolts and shields (if

used) are in place.

Manifold to exhaust pipe fasteners to ensure

they are tight and that there are no exhaust

leaks repair if necessary.

HEGO electrical connector to ensure connec-

tor is seated and locked, check wires to

ensure there is no cracking, splits chafing or

“burn through.” Repair if necessary.

Exhaust pipe extension connector for leaks

tighten if necessary

Visually inspect converter to ensure muffler is

securely mounted and tail pipe is properly

aimed.

Check for any leaks at the inlet and outlet of

the converter.

18

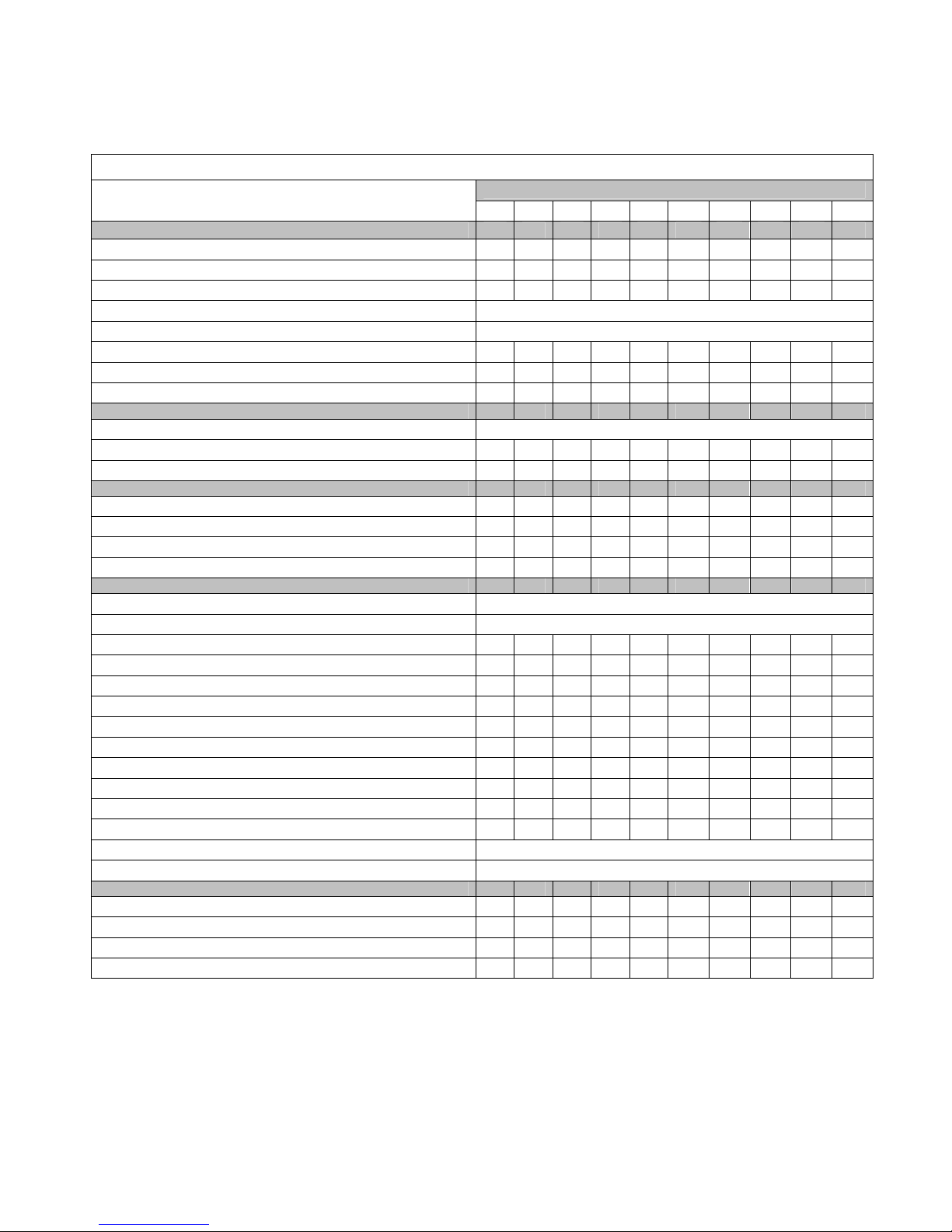

LPG

& BI

-

FUEL

CERTIFIED ENGINE MAINTENANCE REQUIREMENTS

Perform the following maintenance on the engine at the hours indicated and at equivalent hour intervals thereafter.

Interval Hours

Daily 1000 1500 2000 2500 3000 3500 4000 4500 5000

General Maintenance Section

Visual check for fluid leaks

X

Check engine oil level

X

Check coolant level

X

Change engine oil and filter

Every 100 hours or 60 days of operation

Check LPG

system for leaks Prior to any service or maintenance activity

Inspect accessory drive belts for cracks, breaks, splits or glazing

X X X X X

Inspect

electrical system wiring for cuts, abrasions or corrosion X X

Inspect all vacuum lines and fittings for cracks, breaks or harden

ing X X

Engine Coolant Section

Clean debris from radiator core

Every 100 hours or 60 days of operation

Change coolant

X X X X X

Inspect coolant hoses for cracks, swelling or deterioration

X X X X X

Engine Ignition System

Inspect Battery case for leaks or damage

X X X X X

Inspect battery cables for damage corrosion or contamination

X X X X X

Check all electrical connector retainer locks

X X X X X

Replace spark plugs

X X

Fuel System Maintenance

Inspect air cleaner

Every 200 hours, or every 100 hours in dusty environment

Replace filter element

Annually, or Bi-annually in dusty environments

Replace PCV Valve

X

Replace inline LPG fuel filter

X X X X X

Check LPG shut off solenoid valve function

X X

Replace fuel filter

(Bi-fuel only) X X X X X

Inspect

Shut-off Valve for leaks and closing X X

Leak check

fuel lines X X

Check air induction for leaks

X X

Check manifold for

vacuum leaks X X

Check fuel injector s& rail for leaks (Bi-fuel only) X X

Replace fuel injectors (Bi-fuel only) X

Inspect

EPR for coolant leaks

Annually or every 2000 hours

Drain

EPR oil build up

Every 2500 hrs

Engine

Exhaust System

Inspect exhaust manifold for leaks

X X

Inspect exhaust piping for leaks

X X

Check HEGO sensor connector and wires for burns, cuts or damage

X X

Inspect catalyst for mechanical damage

X X

This maintenance schedule represents the manufacturer’s recommended maintenance intervals to maintain proper engine/equipment function. Federal, State, or Local regulations may require additional or more frequent inspection or maintenance

intervals than those specified above. Check with the authority having jurisdiction for details. Note that LPG engines are designed to

operate on HD–5 or HD–10 specification LPG fuel. Fuel other than HD–5 or HD–10 may cause harm to the engine’s emission

control system and a warranty claim may be denied on this basis if operators can readily find the proper fuel*. Use of any other fuel

may result in your engine no longer operating in compliance with CARB or EPA emissions requirements.

*Not Applicable in the state of California.

19

LPG Fuel System

20

LPG FUEL SYSTEM OPERATION

21

DESCRIPTION AND OPERATION OF THE FUEL

SYSTEMS

LPG FUEL SYSTEM

The primary components of the LPG fuel system

are the Fuel Storage Tank, Electronic Pressure

Regulator (EPR), Fuel Mixer, Throttle Control Device, electric Shut-Off Valve, Engine Control

Module (ECM), Oxygen Sensor and a Catalytic

Converter. The system operates at pressures which

range from 355.60mm (14.0 inches) of water column up to 21.5 BAR (312 psi).

LPG FUEL TANK

LPG is stored in the fuel tank as a liquid. The approximate pressure of the fuel in the tank is 8.8 bar

(130 psi) when the tank is full at an ambient temperature of 27° C (81°F). The boiling point,

(temperature at which the liquid fuel becomes vapor) is approximately 40° C (-40° F). When the fuel

changes from liquid to vapor the fuel expands and

creates pressure inside the tank. When the tank

service valve is opened the pressure inside the

tank forces the liquid fuel out though the pickup

tube located near the bottom of the fuel cylinder.

Because the LPG is stored under pressure the tank

is equipped with a safety valves which are normally

set at 25.8 bar (375 psi) to prevent tank rupture due

to over-pressurization of the cylinder. The service

valve mounted in the end of the cylinder controls

the

flow of fuel from the tank. By turning the handle

to its “open” position, fuel flows out of the tank and

into the service line. The service valve is also

equipped with a safety feature called an excess

flow check valve. This feature reduces the flow

from the service valve in the event of a rupture of

the fuel line or any downstream.

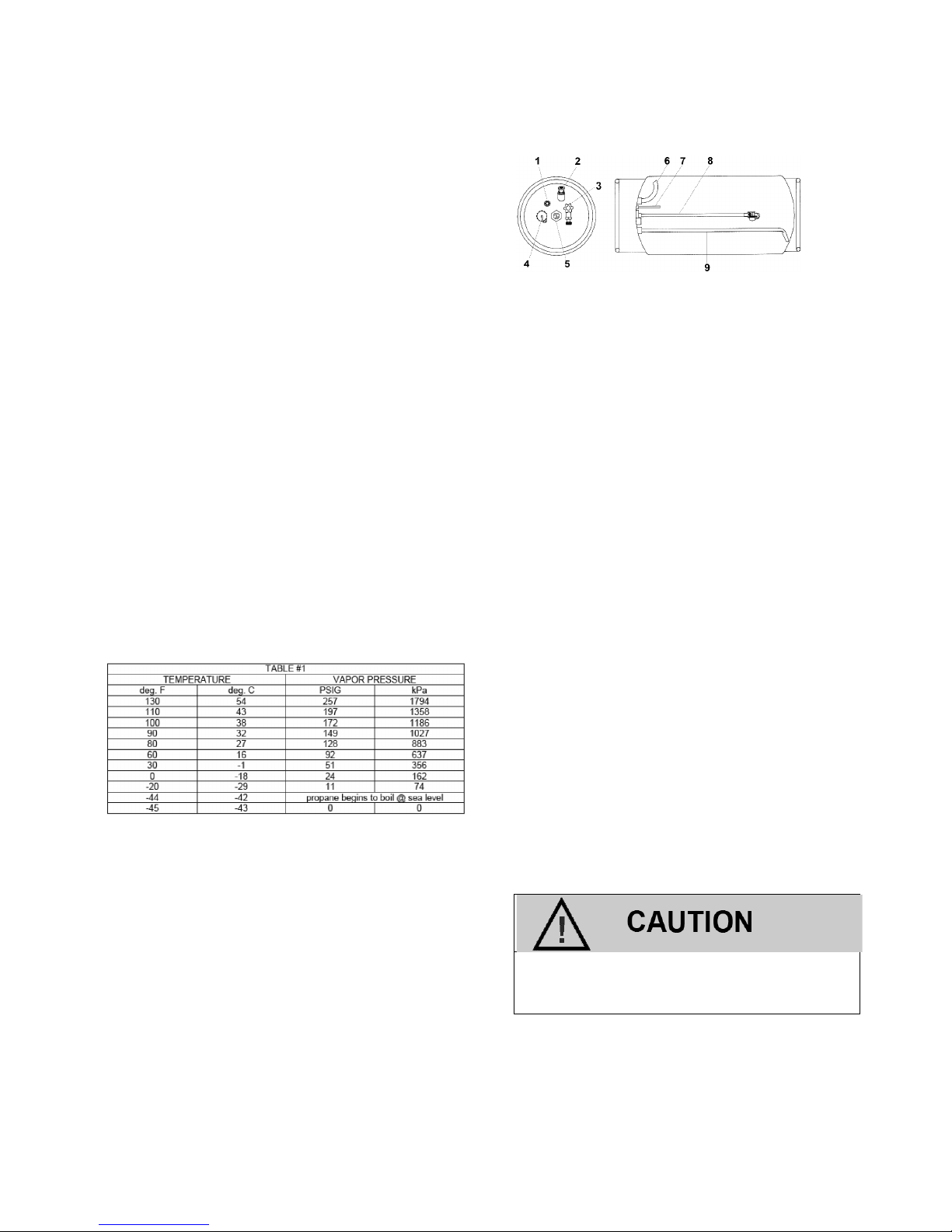

Typical LPG Cylinder

1. Liquid Outage Fill Check Valve

2. Pressure Relief Valve

3. Liquid Outage Valve w/quick disconnect coupling (also referred to as the manual shut-off

valve or MSV).

4. Filler Valve

5. Fuel Gauge

6. Vapor Withdrawal Tube (when applicable)

7. 80% Limiter Tube

8. Fuel Level Float

9. Liquid Withdrawal Tube

SERVICE LINE

LPG flows from the fuel tank to the electric LPG

Shut-Off Valve via the service line. The service

line is connected to the tank utilizing a quick

coupler. The other end of the service line is connected to a bulkhead connector mounted on the

equipment sheet metal. This bulkhead connector

allows for a safe means of passing through the

equipments engine compartment sheet metal and

into the engine compartment. If a bulkhead connector is used a pressure relief device is mounted

in the service line or the connector itself to prevent over pressurization. The service line is

made of high pressure hose with special material

or possibly tubing which is compatible with the

LPG fuel and should always be replaced with an

OEM supplied part.

The bulkhead assembly should never be

removed. Never run a service line through

the sheet metal.

22

FUEL FILTER

LPG, fuel like all other motor fuels is subject to

contamination from outside sources. Refueling of

the equipment tank and removal of the tank from

the equipment can inadvertently introduce dirt

and other foreign matter into the fuel system. It is

therefore necessary to

filter the fuel prior to entering the fuel system components downstream of

the tank. An inline fuel

filter has been installed in

the fuel system to remove the dirt and foreign

matter from the fuel, which is replaceable as a

unit only. Maintenance of the

filter is critical to

proper operation of the fuel system and should be

replaced according to the maintenance schedule

or more frequently under severe operating conditions.

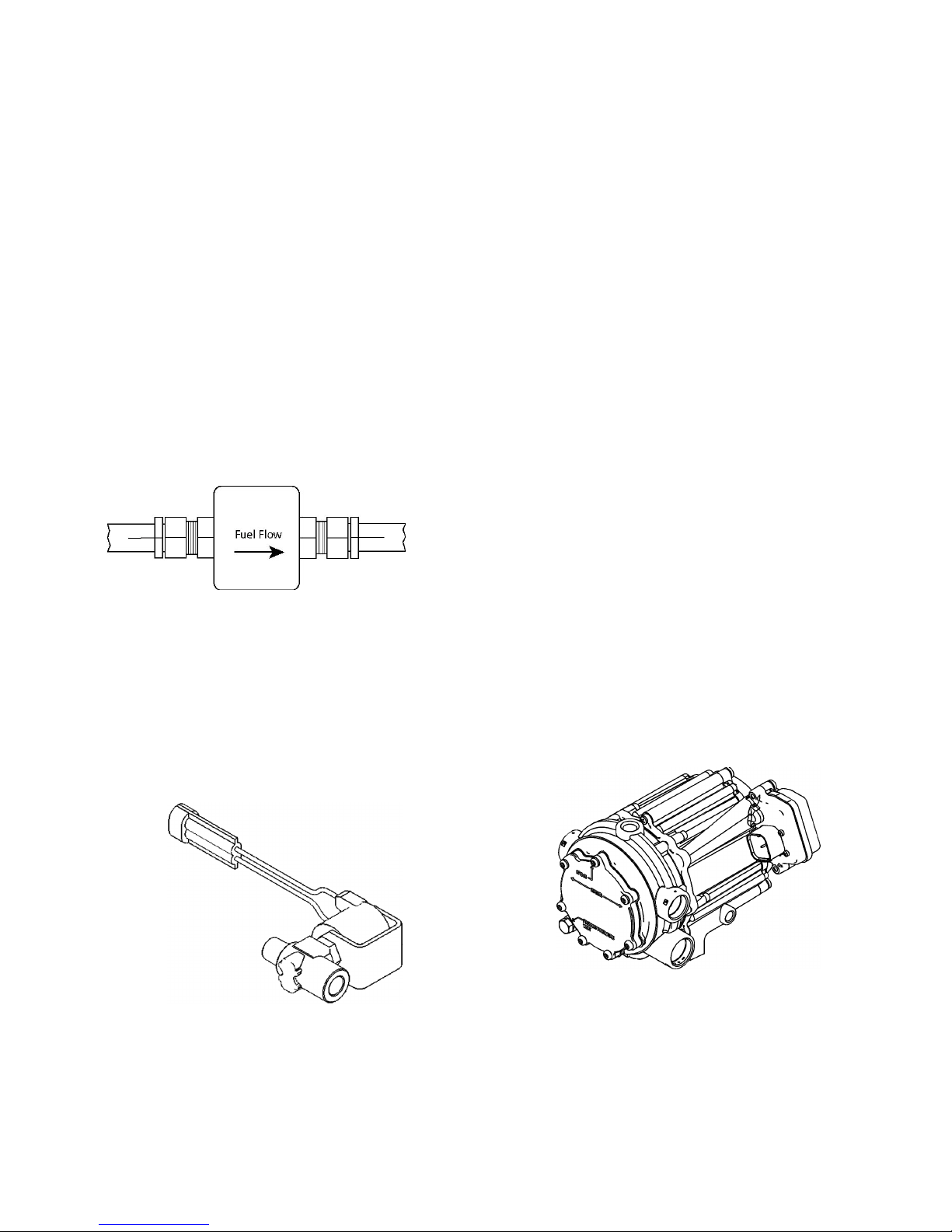

Inline Fuel Filter

LPG SHUT-OFF VALVE

The LPG Shut-Off Valve is an integrated assembly

consisting of a 12 volt solenoid and a normally

closed valve. When energized, the solenoid opens

the valve and allows the LPG fuel to

flow through

the device. The valve opens during cranking and

engine run cycles.

LPG Shut-Off Valve

Voltage to the LPG Shut-Off Valve is controlled by

the engine control module (ECM).

ELECTRONIC PRESSURE REGULATOR (EPR)

The EPR is a combination vaporizer and pressure

regulating device. The EPR functions as a negative pressure two stage regulator that is normally

closed with the ability to supply additional fuel by

command from the ECM. When the engine is

cranking or running, a partial vacuum is created

in the fuel line which connects the regulator to the

mixer. This partial vacuum opens the regulator

permitting fuel to

flow to the mixer.

LPG fuel enters the primary port of the EPR and

passes through the primary jet and into the primary/heat exchanger chamber and expands as it

heats up, creating pressure inside the chamber.

When the pressure increases above 10.34 kPa

(3.5 psi), sufficient pressure is exerted on the

primary diaphragm to cause the diaphragm plate

to pivot and press against the primary valve pin,

thus closing off the

flow of fuel. When the engine

is cranking, sufficient vacuum will be introduced

into the secondary chamber from the mixer drawing the secondary diaphragm down onto the

spring loaded lever and opening the secondary

valve. An increase in vacuum in the secondary

chamber increases the downward action on the

secondary lever, causing it to open wider and

permitting more fuel

flow to the mixer.

Electronic Pressure Regulator

23

The EPR is an emission control device

and should only be serviced by qualified

technicians.

AIR FUEL MIXER

The air valve mixer is a completely self-contained

air-fuel metering device. The mixer is an air valve

design, utilizing a relatively constant pressure drop

to draw fuel into the mixer from cranking to full load.

The mixer is mounted in the air stream ahead of the

throttle control device.

When the engine begins to crank it draws in air with

the air valve covering the inlet, and negative pressure begins to build. This negative pressure signal

is communicated to the top of the air valve chamber

through 4 vacuum ports in the air valve assembly.

A pressure/force imbalance begins to build across

the air valve diaphragm between the air valve vacuum chamber and the atmospheric pressure

below the diaphragm. The air valve vacuum spring

is calibrated to generate from 101.6 mm (4.0 inches) of water column at start to as high as 355.60

mm (14.0 inches) of water column at full throttle.

The vacuum being created is referred to as Air

Valve Vacuum (AVV). As the air valve vacuum

reaches 101.6mm (4.0 inches) of water column, the

air valve begins to lift against the air valve spring.

The amount of AVV generated is a direct result of

the throttle position. At low engine speed the air

valve vacuum and the air valve position is low thus

creating a small venturi for the fuel to

flow. As the

engine speed increases the AVV increases and the

air valve is lifted higher thus creating a much larger

venturi. This air valve vacuum is communicated

from the mixer venturi to the EPR secondary

chamber via the low pressure fuel supply hose. As

the AVV increases in the secondary chamber the

secondary diaphragm is drawn further down forcing

the secondary valve lever to open wider.

The mixer is equipped with a low speed mixture

adjustment retained in a tamper proof housing.

The mixer has been preset at the factory and

should not require adjustment. In the event that the

idle adjustment should need to be adjusted refer to

the Fuel System Repair section of this manual.

The air/fuel mixer is an emission control

device. Components inside the mixer are

specifically calibrated to meet the engine’s

emissions requirements and should never

be disassembled or rebuilt. If the mixer

fails to function correctly, replace with an

OEM replacement part.

THROTTLE CONTROL DEVICE—DRIVE BY

WIRE

Drive By Wire Engine speed control is maintained

by the amount of pressure applied to the foot

pedal located in the engine compartment. In a

Drive By Wire (DBW) application, there is no direct connection between the operator pedal and

the throttle shaft. Speed and load control are determined by the ECM. Defaults programmed into

the ECM software and throttle position sensors

allow the ECM to maintain safe operating control

over the engine. In a drive by wire application the

Electronic Throttle Control device or throttle body

assembly is connected to the intake manifold of

the engine. The electronic throttle control device

utilizes an electric motor connected to the throttle

shaft. In addition, a Foot Pedal Position sensor

(FPP) is located in the operator’s compartment.

When the engine is running electrical signals are

sent from the foot pedal position sensor to the

engine ECM when the operator depresses or release the foot pedal. The ECM then sends an

electrical signal to the motor on the electronic

throttle control to increase or decrease the angle

of the throttle blade thus increasing or decreasing

the air/fuel charge to the engine. The electronic

throttle control device incorporates two internal

Throttle Position Sensors (TPS) which provide

output signals to the ECM as to the location of the

throttle shaft and blade. The TPS information is

used by the ECM to correct for speed and load

control as well as emission.

24

CATALYTIC CONVERTER

The Catalytic Converter is a component of the

emissions system which is designed and calibrated to meet the emission standards in effect

for 2007-2009 model year.

The exhaust gases pass through the honeycomb

catalyst which is coated with a mixture of metals

(such as platinum, palladium, and rhodium) to

oxidize and reduce CO, HC and NOX emission

gases.

Catalytic Converter/Muffler

ENGINE CONTROL MODULE

To obtain maximum effect from the catalyst and

accurate control of the air fuel ratio, the emission

certi

fied engine is equipped with an onboard

computer or Engine Control Module (ECM). The

ECM is a 32 bit controller which receives input

data from sensors mounted to the engine and fuel

system and then outputs various signals to control engine operation.

Engine Control Module (ECM)

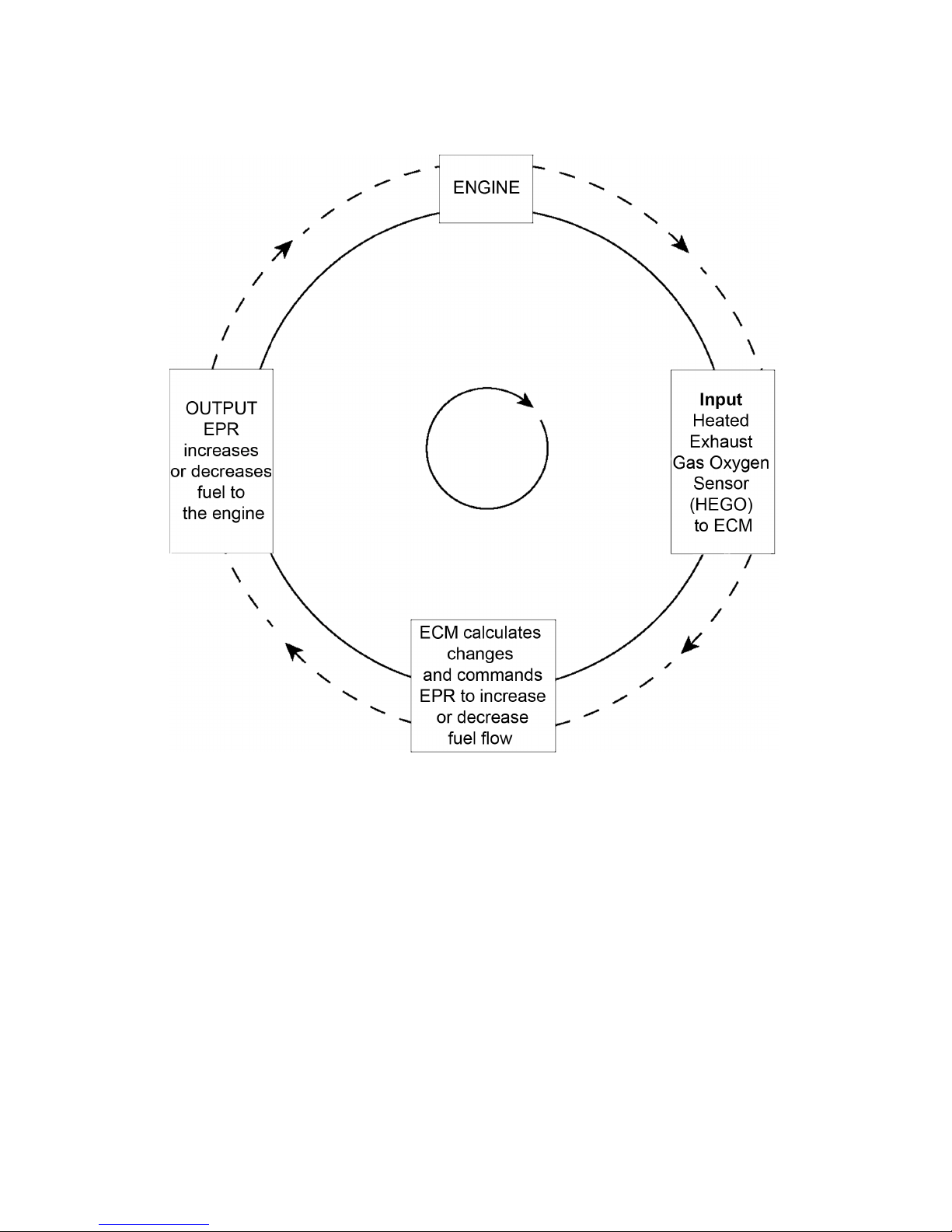

One specific function of the controller is to maintain a closed loop fuel control which is

accomplished by use of the Heated Exhaust Gas

Oxygen sensor (HEGO) mounted in the exhaust

system. The HEGO sensor sends a voltage signal to the controller which then outputs signals to

the EPR to change the amount of fuel being delivered from the regulator or mixer to the engine.

The controller also performs diagnostic functions

on the fuel system and noti

fies the operator of

engine malfunctions by turning on a Malfunction

Indicator Light (MIL) mounted in the dash. Malfunctions in the system are identi

fied by a

Diagnostic Trouble Code (DTC) number. In addition to notifying the operator of the malfunction in

the system, the controller also stores the information about the malfunction in its memory. A

technician can than utilize a computerized diagnostic scan tool to retrieve the stored diagnostic

code and by using the diagnostic charts in this

manual to determine the cause of the malfunction. In the event a technician does not have the

computerized diagnostic tool, the MIL light can be

used to identify the diagnostic code to activate

the “blink” feature and count the number of blinks

to determine the diagnostic code number to locate the fault in the system.

HEATED EXHAUST GAS OXYGEN SENSORS

The Heated Exhaust Gas Oxygen (HEGO) Sensors are mounted in the exhaust system, one

upstream and one downstream of the catalytic

converter. The HEGO sensors are used to

measure the amount of oxygen present in the exhaust stream to determine whether the fuel air

ratio is to rich or to lean. It then communicates

this measurement to the ECM. If the HEGO sensor signal indicates that the exhaust stream is too

rich, the ECM will decrease or lean the fuel mixture during engine operation. If the mixture is too

lean, the ECM will richen the mixture. If the ECM

determines that a rich or lean condition is present

for an extended period of time which cannot be

corrected, the ECM will set a diagnostic code and

turn on the MIL light in the dash.

By monitoring output from the sensor upstream

and the sensor downstream of the catalytic converter, the ECM can determine the performance

of the converter.

25

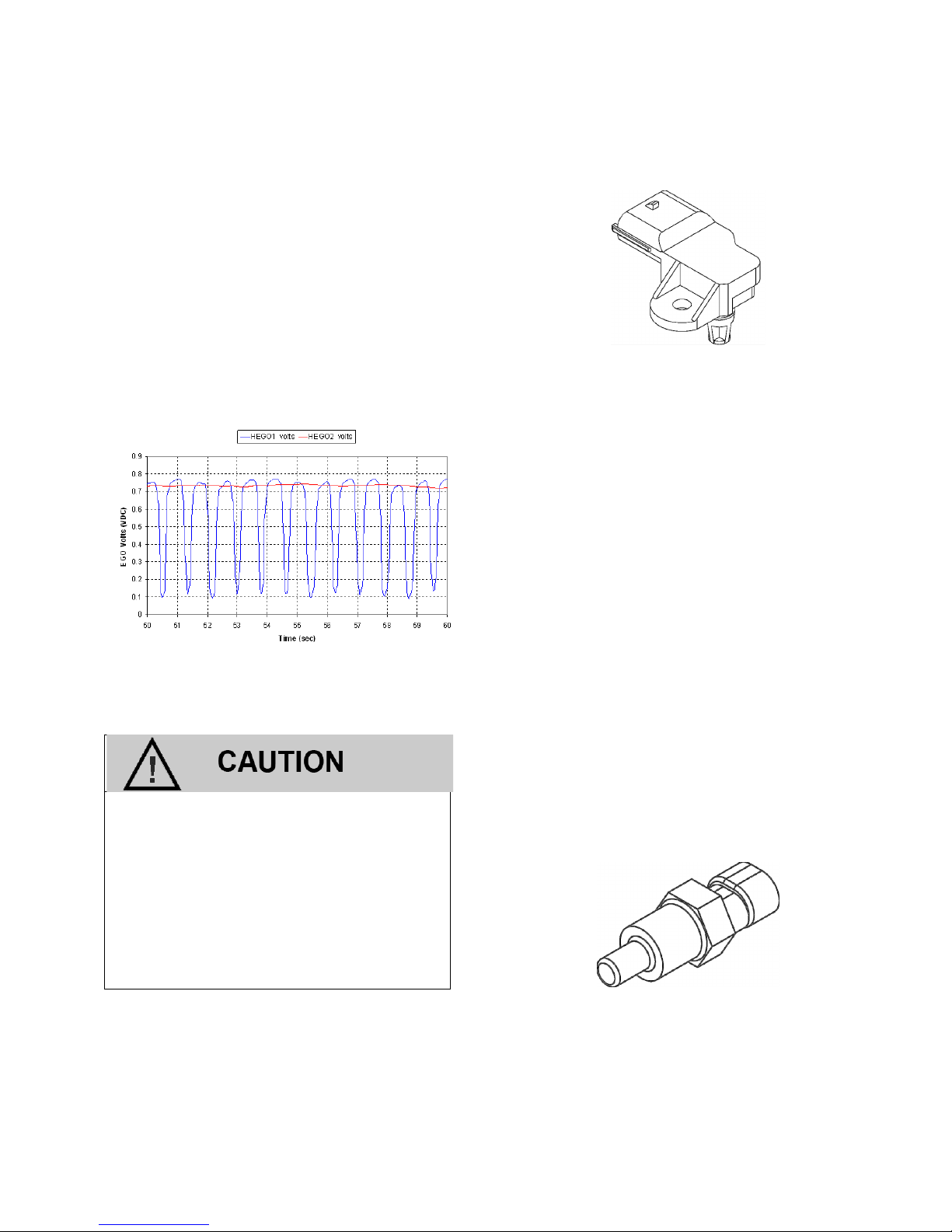

The Heat Exhaust Gas Oxygen (HEGO) Sensor

HEGO1 (upstream or before the catalytic converter) and HEGO2 (downstream) voltage

output.

The Heated Exhaust Gas Oxygen Sensor

(HEGO) is an emissions control component. In the event of a failure, the HEGO

should only be replaced with the recommended OEM replacement part. The

HEGO is sensitive to silicone based products and can become contaminated.

Avoid using silicone sealers or air or fuel

hoses treated with a silicone based lubricant.

TMAP SENSOR

T–MAP Sensor

The Air Temperature/Manifold Absolute Pressure

or TMAP sensor is a combination of two sensors:

1) A variable resistor used to monitor the differ-

ence in pressure between the intake manifold

and outside or atmospheric pressure. The

ECM monitors the resistance of the sensor to

determine engine load (the vacuum drops

when the engine is under load or at wide

open throttle). When the engine is under load,

the computer may alter the fuel mixture to improve performance and emissions.

2) The intake air temperature or IAT sensor is a

variable resistance thermistor located in the air

intake passage which measures the temperature of the incoming air. The ECM uses the

resistance value to monitor incoming air temperature and calculate the engine’s airflow

requirement. The ECM provides a voltage divider circuit so that when the air is cool, the

signal reads a higher voltage, and lower when

warm. On cold starts, the ECM richens the

fuel/air mixture.

COOLANT TEMPERATURE SENSOR

ECT

The Engine Coolant Temperature sensor or ECT

is a variable resistance thermistor that changes

resistance as the engine's coolant temperature

26

changes. The sensor's output is monitored by

the ECM to determine a cold start condition and

to regulate various fuel and emission control

functions via a closed loop emission system.

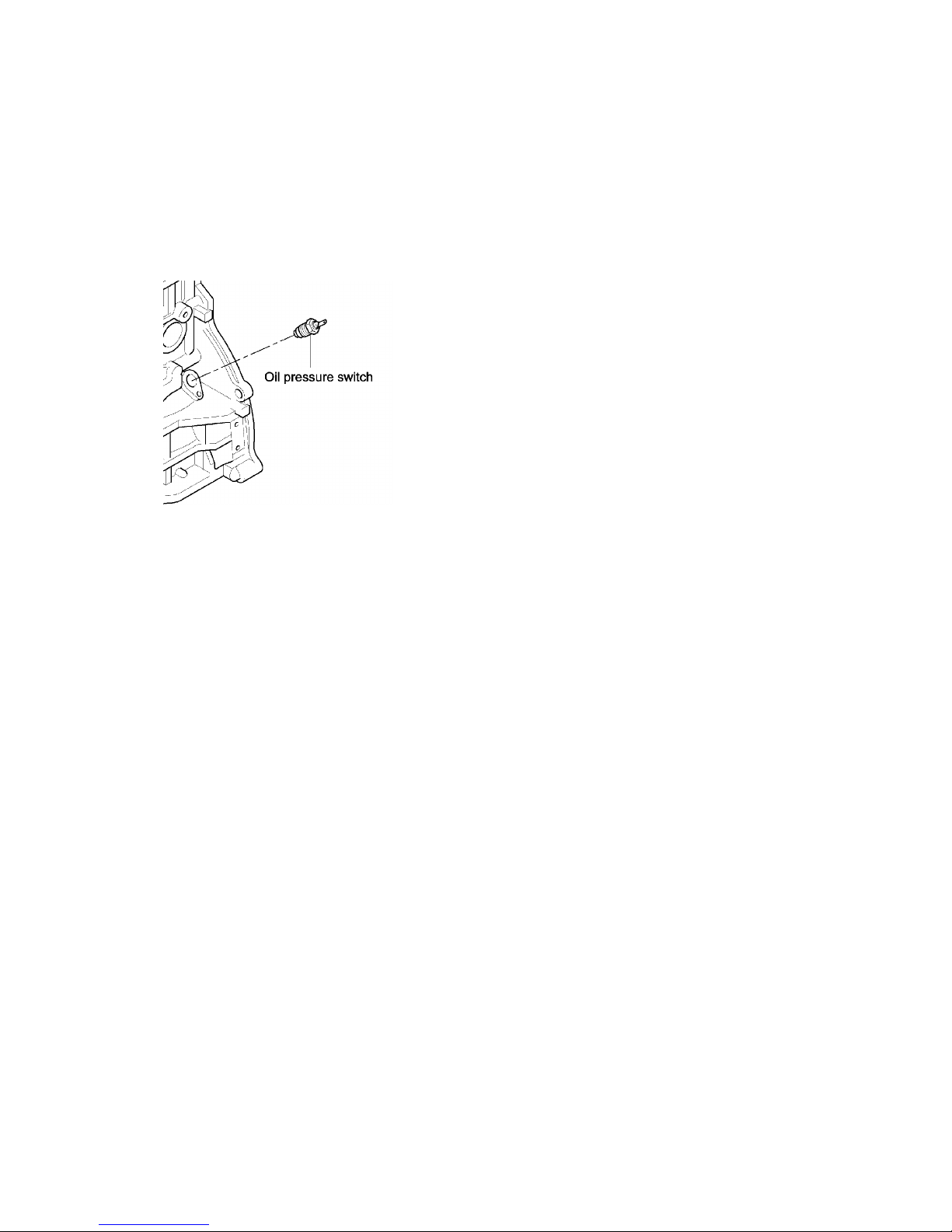

OIL PRESSURE SENDER/SWITCH

The Oil Pressure Switch is Mounted on the

side of the Engine Block

The Engine Oil Pressure switch or sender is designed to ensure adequate lubrication throughout

the engine. It provides a pressure value for the

oil pressure gauge and is monitored by the ECM.

If the pressure drops, an MIL will occur.

27

LPG Closed Loop Schematic

28

29

LPG System Diagnosis

30

LPG FUEL SYSTEM DIAGNOSIS

The Electronic Pressure Regulator Assembly (EPR), Shown with Port Fittings and Shut-off Valve.

FUEL SYSTEM DESCRIPTION

The Engine Control Module (ECM) receives information from various engine sensors in order

to control the operation of the Electronic Pressure Regulator (EPR) and Shut-Off Valve. The

Shut-Off Valve solenoid prevents fuel

flow un-

less the engine is cranking or running.

LPG is stored in the tank as a liquid and delivered under pressure of up to 21.5 BAR (312

psi). At Key ON, the EPR receives a two (2)

second prime pulse from the ECM, allowing

time for the LPG to

flow from the tank through

the fuel

filter and fuel lines to the EPR. Inside of

the EPR, fuel is vaporized and reduced in pressure in two stages. The

first stage reduces the

tank pressure to approximately 20.68 kilopascals (3.0 psi). The second stage then reduces

the pressure to approximately negative 38.1

mm (1.5” of water column) when vacuum from

the engine draws in fuel.

The fuel is then drawn in from the secondary

chamber of the EPR by the vacuum generated

by air

flowing through the Mixer. This vacuum

is also generates lift for the mixer air valve and

is commonly referred to as air valve vacuum.

Once in the mixer, the fuel is combined with air

and is drawn into the engine for combustion.

DIAGNOSTIC AIDS

This procedure is intended to diagnose a vehicle operating on LPG. If the vehicle will not

continue to run on LPG, refer to Hard Start for

preliminary checks. Before starting this proce-

dure, complete the following tasks to verify that

liquid fuel is being delivered to the EPR:

Inspect fuel tank to verify it has a sufficient

amount of fuel.

Verify manual shut off valve on the LPG

tank is fully opened.

Verify that the excess flow valve has not

been activated.

Inspect fuel tank to ensure it is properly

mounted and rotated to the correct position.

Inspect the hoses leading from the tank en-

suring they are properly connected and do

not have any kinks or damage.

Loading...

Loading...