2000

Supervisor’s

Guide

This manual is a comprehensive guide to the IMPAX 2000 Process Control System. It contains

all of the information from the IMPAX Operating Guide plus special instructions on

programming and troubleshooting, plus additional ideas and procedures for getting the best

performance from the system.

This User’s Guide should be read and kept for reference by managers and supervisors

responsible for the setup, operation, and repair of IMPAX monitoring systems. It is assumed

that the software in the IMPAX 2000 is versions 48 or 58.

If you are not sure not sure of the software version in your IMPAX 2000 unit please refer to

chapter 8 in the Supervisor’s Guide.

If you still have a question, problem, or an idea to make our system better, please let us know.

IMPAX Systems are manufactured and

distributed worldwide by:

Process Technologies Group, Inc.

30W106 Butterfield Road

Warrenville, IL 60555

Phone (630) 393-4777 Fax (630) 393-4680

Web: www.impaxptg.com E-Mail: impaxptg@aol.com

“IMPAX” is designed and manufactured by Process Technologies Group, Inc. And is

produced under the United States and Foreign Patent number 4,481,589. Any additional

patents are pending or applied for. “IMPAX” is a trademark owned by Process

Technologies Group, Inc. Copyright 1996.

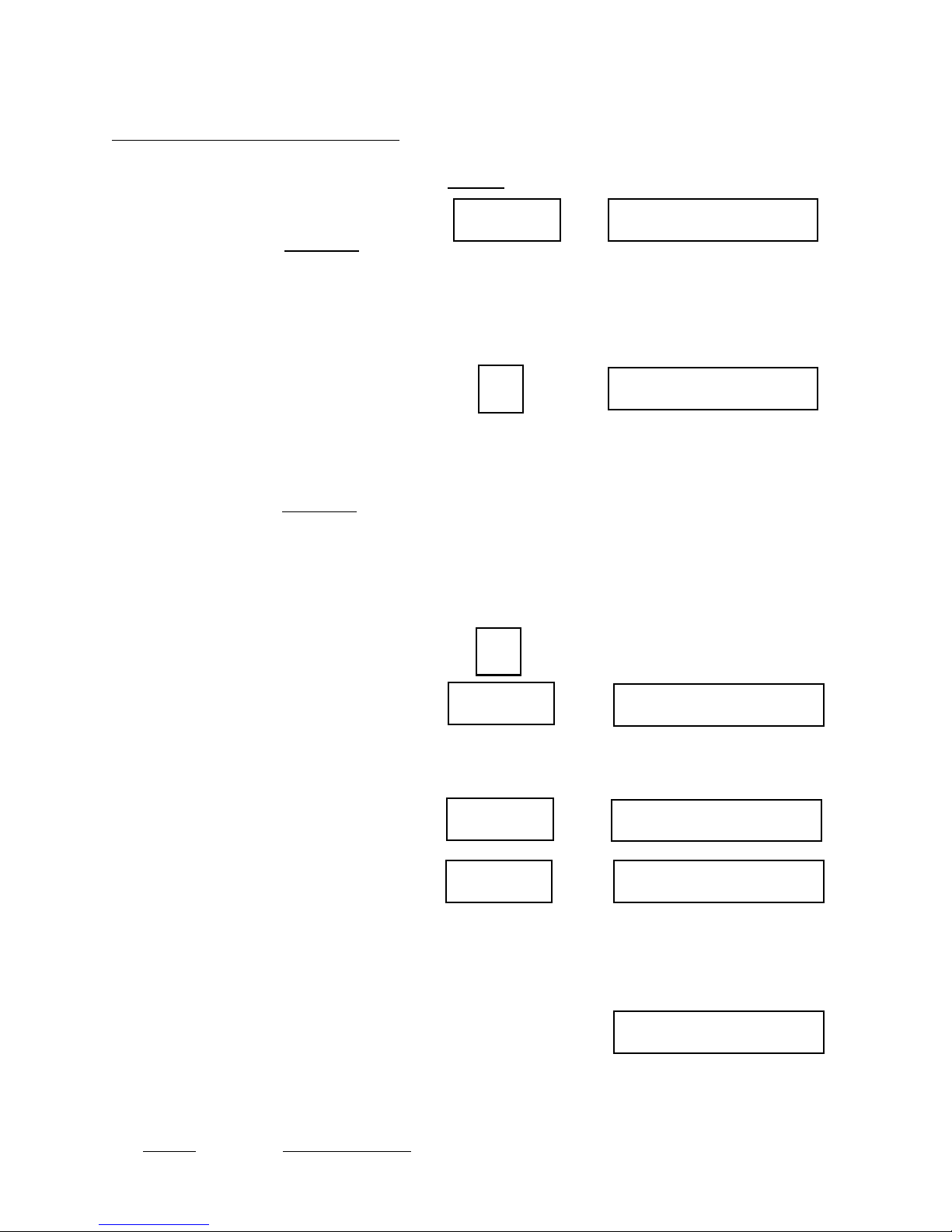

Table of Contents

Chapter Page

1. Introduction and Theory of Operation

2. Description of Controls

Control Console

3. Setup and Operation

Getting Started, Setting up new job

Clearing Counters

Clearing Tolerance/Errors

Starting a New Job

Tolerance Setup

Machine Operation

4. IMPAX Information Displays

Quantity Displays

Tolerance Displays

Error Displays

Force Displays

Backstroke/NoFeed Limilts

1

3

4

5

5

6

7

8

9

13

14

14

15

17

18

21

5. Tolerance Setting Guide

6. Troubleshooting and Service

Problems - cause/remedy

Simple Repairs

Initial Installation

Customer Service

7. Programming

System/Fault Procedures

Basic Information/Function #’s

Channel Definition

Machine/Relay Defintion

8. Diagnostics

9. Specifications and Drawings

22

24

24

25

27

30

31

32

33

33

39

45

49

Specifications

49

Back view of Control Console

Satellite Circuit

IMPAX Control Console

50

51

52

Chapter 1 - Introduction and Theory of Operation

INTRODUCTION

IMPAX can assist the operator of a forming, threadrolling or metal stamping machine by

counting parts produced, and monitoring stroke to stroke consistency. It is capable of stopping

the machine instantly when the job is completed or when it detects a problem.

IMPAX prevents smashups, scrap production, and overruns, thus making the forming operation

more productive and making the operator’s job easier. Because it is merely a tool, it cannot

replace skilled people, but it can help by reducing the drudgery of frequent inspections and

repairs.

Operation of the machine is not changed by the addition of IMPAX. IMPAX is ‘smart’ enough

to simply do its job, without interference or complication.

1

Although IMPAX operates mainly without attention, it does require the machine operator to

push a button once in a while. To get the best results from the system, you should become

familiar with its operation.

Operator attitude is very important when introducing and implementing IMPAX. Like any other

tool, its effectiveness depends on how well it is used. If machine operators perceive it as

unnecessary, complicated, an invasion of their routine, or a threat to their jobs, it will not work

even if it is technically perfect. It is vital that everyone understand that IMPAX can make

forming operations easier and more productive; that makes the whole company more

competitive, which in turn makes everyone’s job more secure.

THEORY OF OPERATION

The IMPAX monitoring system measures and remembers the forming force generated in each

forming station, for every machine stroke. The principle of operation is simply that when the

forming process changes (due to tool breakage, material variation, machine problems, etc.) The

forces required to form the part also change. IMPAX can be set up to detect a variety of changes

and stop the machine before further damage or waste occurs.

The heart of this system is the force measurement. Attached behind each forming station is a

piezoelectric force sensor. The piezoelectric element generates a voltage each time a part is

struck, twisted, deflected, etc. Another device, the machine position sensor, is turned on by a

timing cam when it is time for the part to be formed, at that time, the IMPAX monitor measures

the impulse from each force sensor. This measurement is converted to a number and stored in

memory. (The number is relative; it is not calibrated in any engineering units.) After a number

of new parts have been made, an average force level is determined and limits are set above and

below this average. Because some jobs run better than others, these limits are adjustable. When

the force of any stroke exceeds the limits, the process is stopped.

Stopping the machine is all the process monitor can do. It cannot fix the problem or restart the

machine. When a problem is detected a red light turns on to attract your attention and an error

message is displayed on the IMPAX unit’s display. The machine is stopped, and any accessories

are shut down in an orderly manner. A gate or diverter may also be used to trap the part which is

suspected to have caused the shutdown error.

Obviously, this system does not directly measure the quality of the parts; it indirectly measures

the consistency of the process. If a machine is running erratically or the raw material is

inconsistent, this monitor will not perform as well. Remember that IMPAX will not remedy any

problems with the manufacturing process, it can only detect them and shut the process down.

2

1. Ram Motion 6. Piezoelectric Sensor

2. Punch 7. Backplate

3. Finished Part 8. Machine Bed

4. Die 9. Kickout

5. Transmitted Force that will reach the sensor

Chapter 2 - Description of Controls

The IMPAX monitor is comprised of several components which are interconnected by wiring.

All components are mounted on the forming machine except for the IMPAX Control Console

which is isolated on its own pedestal.

The Control Console is the core of the system, housing the microcomputer and power supply.

Its front panel contains the Message Display Panel and the Keypad, through which you can

receive information and enter commands. It also contains the Locking Keyswitch which

accepts the Supervisor’s Key. This key allows the supervisor or operator to ‘program’ IMPAX.

The Satellite Box is the

junction for all the

controls and

components on the

machine. The Reset

Button is the only

operator control. The

red, yellow, and green

Status Lights indicate

the mode of operation

that the IMPAX unit is

in. The Bypass Key

Switch, operated by the

Supervisor’s Key,

disables the relay which

stops the machine and

its accessories, but has

no other effect on

operation. Note: There

is no machine

protection when the

IMPAX monitor is in Bypass mode.

Up to two Machine Position Sensors are used to sense the machine cycle and synchronize the

stop signal. Piezoelectric Sensors are installed in stressed locations near the forming stations;

on the back of the die-bolster or backing plate, on knockout rockers, in punch wedges, etc. A

recess is cut (about the size of a quarter), or a hole is drilled, and the sensor is installed using a

special epoxy adhesive. When the machine is reassembled, the sensors are out of sight, but

sensitive to the forming process.

Relays within the Satellite Box are also wired to the Machine Stop Circuit (if available), as

well as to the feed stop and other accessories, as required to stop the machine and the process.

The Control Console interfaces with the Satellite Box via a multi-conductor cable.

CONTROL CONSOLE

The IMPAX Control Console contains a message display panel, a data entry keyboard, and a

locking keyswitch. The display panel shows information which is requested, or supplies

prompts or questions during operation. The Keypad* is used to enter commands or information,

and the keyswitch enables authorized users to program the unit. The function buttons may

operate differently depending on the position of the key switch. If the key is removed, IMPAX

will only display information. If the key is inserted, the Keypad can be used for programming

and diagnostics.

There are three kinds of buttons on the keypad. Functions buttons let you command IMPAX to

display or change things, Control buttons are used to enter commands and Data buttons let you

enter in numbers and codes.

*Additional Keypad Reference on Page 52

5

Chapter 3 - Setup and Operation

Getting Started

To “Program” the IMPAX Controller, you must supply several basic types of information:

1. The total number of parts to be made on work order. (Up to 99,999,999)

2. The number of parts to be made prior to a predetermined inspection or tool change (this

feature may be omitted).

3. The force variation tolerance settings (scale of 1 to 9, automatic tolerance, or no tolerance)

for each forming process.

4. A “trend limit” which limits how much the force values can change as the machine heats

up or tools wear down (this feature may be omitted).

5. The desired number of exceptions, which let-by a small percentage of “bad” parts (this

feature may also be omitted).

Setting up the IMPAX unit for a new job may be done any time before beginning the job, by

anyone who has a Supervisor’s Key

Clearing the old job

Before setting up a new job you must Clear the existing functions which do not apply to the new

setup. When the old job is finished, insert the Supervisor’s Key and turn it to the right so it is in

a horizontal position.

Insert Key and turn to the right from the

Vertical position to the Horizontal position

Clearing Shift, Break, and Production Counters:

6

Press Clear . The display will show

“SELECT TO CLEAR”. This display

means that the IMPAX unit wants to

know what to erase.

Press Quantity. The display shows

“CLEAR SHIFT?” The IMPAX unit is

now asking whether or not you want to

erase the total number of parts made

during the shift. If not press Next/No.

(You may want to record this number

before erasing; to do so, see Chapter 4,

Information Displays.) If you wish to

erase this press Enter/Yes.

Now the shift total is erased and the

display shows “CLEAR BREAK?” The

IMPAX unit is now asking whether or

not you want to reset the counter which

makes the periodic stops for tooling

changes or inspection. If you do not

wish to do this, press Next/No. If you

desire to, press Enter/Yes.

Press

Quantity

Enter/Yes SHIFT CLEARED

Next/No CLEAR BREAK?

Enter/Yes BREAK CLEARED

Display Will Show

Clear SELECT TO CLEAR

CLEAR SHIFT?

IF YOUR ANSWER IS YES:

CLEAR BREAK?

IF YOUR ANSWER IS NO:

IF YOUR ANSWER IS YES:

Now the break counter is reset and the

display shows “CLEAR PROD?” The

IMPAX unit is now asking whether or

not you want to completely erase the

record of that preset production count.

This clears the total of parts made, as

well as the break counter. If you do not

wish to do this, press Next/No. If you

desire to, press Enter/Yes.

IF YOU HAVE AN IMPAX 2000, the

display will show “CLEAR

EXCEPTIONS”. If you wish to clear

this counter press Enter/Yes. If you do

not, press Next/No, and the display will

return to the default message display.

CLEAR PROD?

IF YOUR ANSWER IS NO:

Next/No CLEAR PROD?

IF YOUR ANSWER IS YES:

Enter/Yes PROD CLEARED

CLEAR EXPTS?

IF YOUR ANSWER IS NO:

Next/No EXPTS CLEARED?

Clearing The Tolerance and the Error Record:

7

The IMPAX monitor production

counters are now cleared. It is ready to

be set up for a new set of quantities. In

fact, it will not run (except in TEST

mode) until a new production quantity

is entered.

The Tolerance and the Error records can

be cleared by pressing Clear until the

“SELECT TO CLEAR” screen appears

and then pressing the respective button

on the Keypad. Remember these steps

can be avoided without harm to the unit

or the data for the next job.

The IMPAX monitor is now cleared and

is ready to be set up for a new job. In

fact, it will not run (except for short

setup runs) until new production

quantities and tolerance values have

been re-entered.

Press Display Will Show

TOLERANCE:

Clear SELECT TO CLEAR

Tolerance CLEAR TOLERNCE?

TOLERNCE CLEAREDEnter/Yes

ERROR:

Clear SELECT TO CLEAR

Error

CLEAR ERRORS?

The display will show “CLEAR

EXCEPTIONS?”. Press Enter/Yes to

clear the record of the Exceptions.

ERRORS CLEAREDEnter/Yes

In the IMPAX 2000, the display will now show:

CLEAR EXCPT?

Enter/Yes EXCPT CLEARED

Entering the Quantities Needed To Start a New Job:

8

Insert the Supervisor’s Key and turn it

to the right. Press the Quantity button

and the display will show “ENTER

QUANTITY”, which asks you to type

in the total number of pieces to be made

on this job.

Press the number buttons to show the

quantity you want to produce. If you

make a mistake, use the Back/Review

button to change the number. Check

the display to be sure you have typed in

the correct number. Press the Enter/Yes

button to enter the quantity.

The display will now ask for the

“BREAK QUANTITY” which is the

number of pieces to make before

stopping for inspection or tool change.

(This reminds you of periodic

adjustments, inspections, maintenance,

etc. that are based on machine or

production cycles). Press the number

buttons to show the quantity you wish

to make without interruption. Use the

Back/Review button if you make a

mistake. If you do not want any

interruptions due to the Break Quantity

counter, press the 0 button and the

IMPAX unit will skip this. When you

have typed in the correct Break

Quantity, press the Enter/Yes button.

Insert Key and turn to the right

Press

Quantity ENTER QUANTITY

(up to 99,999,999)

Enter/Yes BREAK QUANTITY

(up to 99,999,999)

Display Will Show

XX X XX

XX X XX

If the tolerances are

set and you are done:

COUNT SET Enter/Yes

If tolerance values have already been

entered into the IMPAX system, the

unit is ready to begin monitoring and

the display will read “COUNTS SET.”

If any tolerances need to be set, IMPAX

reminds you to continue by displaying

“CHANNEL 1 ?” If “COUNTS SET”

appears, you have completed the basic

program set up.

If the tolerances

need to be set :

CHANNEL 1 ?

Note: There is a way to change the piece counts

after the job has begun, or to begin a job with the

counters set to some number other than zero.

Setting Tolerances:

9

You will be asked to give a tolerance

number to each measuring channel.

This value controls how closely that

station is to be monitored. (Refer to

page 23 of this guide)

The display now shows “CHANNEL 1

?”, asking for a tolerance number for

the first station. Press a number from 1

to 9, 0, “*”,or “#”. (Remember that low

numbers give tight control and higher

numbers permit more variation; zero

means that the station has no tolerance

limits applied at all. “*” sets the

tolerance automatically). If fixed limits

are enabled in channel definition (see

Programming section of Supervisor’s

Guide for this procedure) then you can

press the # key to switch between fixed

and normal limits. These limits are

usually only used when the tolerance

needs to be tighter than a “9” will give

or looser than a “1” will give without

being zero.

Will Show

Z can be from 0 to 9,*, or #.

Z

NOTE: If Fixed limits are enabled in

#

IF FIXED LIMITS CHOSEN:

CHANNEL 1 ?

CHANNEL 1 Z

Programming, then press:

to toggle between normal and fixed.

If you enable this the screen by pressing

#, it will show “C1 LOW LIM 0”. It

is asking you what you want the lower

limit to be. Enter the lower limit and

press Enter. The next screen will say

“C1 HIGH LIM 0”. The monitor is

now asking for the upper limit of

tolerance. Enter the value and press

Enter. If you go to the Force screen,

you will see the limits you just entered.

For ideas on setting Normal tolerances,

see Section 5, Tolerance setting guide.

When you have entered the number,

press Enter/Yes.

The following options will only be

available if they are enabled in the

channel definition part of programming.

Press Display

X

X can be from 0 to 253 in both low and high limits.

X

Z

Display might show “ALL FACTORS

IF NORMAL LIMITS CHOSEN:

Z can be from 0 to 9,*, or #.

(Same as if fixed limits not enabled)

C1 LOW LIM 0

C1 HIGH LIM 0Enter/Yes

SET” or it might go on.

CHANNEL 1 Z

Setting Tolerances - cont.

10

Trend Setting

After the Tolerance has been set for the

first channel, press the Enter/Yes key.

If Trending is turned on in Channel

Definition, the next display will show

“C1 TREND 0%”. By entering a

number here from 1 to 99, you can limit

the amount that the force measurement

can drift due to gradual changes such as

tool wear. For example, pressing 50

displays “C1 TREND 50%”, which will

stop the machine after the force changes

(gradually) by 50%; you would then

clean or replace the tool. Set the Trend

Factor by pressing the Enter/Yes key.

Exception Setting

If Exceptions are turned on in Channel

Definition, the next display will show

either “C1 CUMU EX 0" or “C1

CONS EX 0." An exception is an

IMPAX detected error which you can

allow the monitor to ignore. This

feature is extremely useful if you have a

diverter installed on the machine. If a

diverter is installed, you can set one of

the relays to be an exception relay and it

will trip the diverter and divert the part

without stopping the machine.

Show

Enter/Yes C1 TREND 0%

(Trend can be set from 1% to 99%)

For Example:

5

These options will only be available if

turned on in Channel Definition in

programming.

To permit exceptions, backstrokes, and/or low

force readings: (All described below)

X

Enter/Yes

To not permit exceptions, backstrokes, and/or

Next/No

X can be from 1 to 9,999

low force readings:

or

C1 TREND 50%

(Next option or channel)

(Next option or channel)

“CUMU” stands for cumulative. This

means that IMPAX will allow a certain

number of errors out of 100 to be

ignored. For example, if I set the

number to 2, IMPAX would allow 2

parts out of 100 to exceed either the HI

or the LO limit without shutting down

the machine.

“CONS” stands for consecutive. This

means that IMPAX will allow a certain

number of errors in a row to be ignored.

Press Display Will

Enter/Yes (Next option or channel)

Once all tolerances, fixed limits, excpts, nofeeds,

and trend information is set:

ALL FACTORS SET

Setting Tolerances - cont.

For example, if I set the number to 2, IMPAX would allow 2 errors in a row but the 3rd error in a

row would cause the machine to stop. When tuning the IMPAX unit, it is often helpful to set a

large number of exceptions, say 10 or 15 and watch the force values in the Error/Exceptions

buffer. This can tell you what the values were for the exceptions and can give you information

needed to establish the proper settings for the tolerances.

11

Backstroke Exception Settings

Backstroke is only used for threadrolling applications. It is used to detect a part not being

properly ejected and remaining in the dies. It is always a high force error. If Backstroke Hi

Limit and Backstroke Exceptions are turned ON in Channel Definition, the display will show

“R1 BKSTR 00/100”. This function is always cumulative. You may put in a number between

1 and 99. Backstroke exceptions are rarely ever allowed but can be when there are problems

with a threadroller which causes nuisance shutdowns in the backstroke cycle, if all other causes

for backstroke noise have been eliminated.

No Feed Settings

No Feeds are cycles of the machines where no material is fed to the machine for processing.

Usually No Feeds are used with piece-fed machines like threadrollers, but under special

circumstances can be used with continuous or bar stock fed headers or other such applications.

No Feeds can be either Consecutive or Cumulative. If this feature is turned on in Channel

Definition, the display will show “R1 CONS NF 0000" or “R1 CUMU NF 0000." You can enter

a number between 1 and 9999. In a threadrolling application, this feature is extremely functional

since it will allow the machine to keep running even though the feed rail is not completely full or

does not feed a part every time

No Feed Exceptions

No Feed Exceptions is a special feature which will divert a certain number of parts immediately

after a No Feed condition. This may be used if, for example, there were several consecutive no

feeds and the dies cooled off. The first ten parts may not be as good quality as those produced

after the dies heated up. No Feed Exceptions could be set to eject these parts if they did not meet

the tolerance parameters. If this feature is activated in Channel Definition, the display will show

“R1 NOFEED EXCP.” You cannot enter anything on this display, it is just informing you that

No Feed Exceptions has been turned on. The next display is “ * 000 AFTER 000.” The number

entered here (0-999) is the number of “Fixed” cycles (when the Feed resumes) that the Special

Exceptions will be allowed. Enter a zero, 0, if you want the number of special exceptions to be

based on the amount of time the machine runs without feed. When the asterisk is in front of the

leftmost number, it means you can change that number. After you enter a number, press the

Enter/Yes key and the asterisk will move to in front of the rightmost number.

The number entered here (0-999) is the number of consecutive nofeeds which must be detected

before the Special Exceptions (for 15 cycles, in this case) will be allowed. Press Enter/Yes after

entering your number.

Setting Tolerances - cont.

The next display will be “PLUS 1/ 0000.” The number entered here (0-9999) will allow a

Special Exception for 1 machine cycle per each group of x cycles the machine runs without feed.

Example: If the number programmed here is 100, nd the machine runs 600 cycles without feed,

the forces will be allowed outside normal limits during the first 6 machine cycles during which

the feed is again detected.

Enter the proper number and press the Enter/Yes key. The next display will show “ALL

FACTORS SET.”

12

Chapter 4 - IMPAX Information Displays

Useful information is available from the IMPAX console simply by pressing buttons. This may

be done whether the machine is running or stopped. Unless otherwise instructed, the

Supervisor’s Key should be removed or turned to the vertical position while performing these

steps.

To inquire about Quantity settings or production totals, Tolerance settings, Error conditions

which have occurred, or Force measurements and limits, press the appropriate button.

Quantity Displays:

14

Press Quantity. The display will show

“MADE * 750” if 750 parts have been

produced on this job. If the machine is

running and the green light is on, the

number will be counting up.

Press Next/No again and the display

changes to “TO GO * 99250”, which is

the number of parts remaining to be

made. This number counts down when

the machine is running.

Press Next/No again and the display

changes to “SHIFT * 750”, which

means that 750 parts have been made

during the current shift.

Press Next again and IMPAX shows “B

MADE * 750”, which means that 750

parts have been made during the current

shift.

Press Display Will Show

Quantity MADE * 750

Pressing Enter will start Autoscroll, pressing Enter

again will stop it on the current screen. During

scroll, Next/No will not work.

Next/No

Next/No SHIFT * 750

Next/No

TO GO * 99250

B MADE * 750

Press Next/No again and the display

becomes “B TO GO * 4250”, meaning

that 4250 more pieces will be made

before the machine is stopped for an

inspection break. This also counts

down. If exceptions are turned on in

Channel Definition, then the next

display will show them.

Press Next/No and the display will

show “RPM 300” which is the speed

that the machine is running at.

Next/No

If exceptions are turned on:

Next/No

Next/No RPM 300

B TO GO * 4250

EXPTS

Quantity Displays - cont.

15

Press Next/No and the display will

show the date and the time.

Press Next/No again and the display

shows “TOTAL * 100000”, which tells

the total number of parts to be made on

that job. (Note that parts MADE plus

parts TO GO add up to the parts

TOTAL.)

Press Next/No again and the display

shows “BREAK * 5000”, which means

that the BREAK counter is set up to

stop after every 5000 parts.

Pressing Next/No again brings the

display back to “MADE * 750”, which

brings up the first display again;

continuing to press Next/No takes you

through all the choices again. At any

time, pressing Back moves backward to

the previous choice in the order listed

above. You may select which counter

you wish to be displayed while the

machine is running. To do so, display

the chosen counter as explained above,

then press Enter/Yes. The selected

counter will remain visible.

Press Display Will Show

Next/No

Next/No TOTAL * 100000

Next/No

Next/No

To display chosen counter:

Keep pressing

Next/No

until chosen counter appears.

Enter/Yes

(Date and Time)

BREAK * 5000

MADE * 750

Tolerance Displays:

(numbers are for example only)

Be sure the Supervisor’s Key is

removed or turned off (vertical).

Press Tolerance. The display will show

the tolerance setting for the first

channel. For instance, if it reads:

“CHANNEL 1 5(?)”, then the tolerance

setting for channel 1 is set to 5.

--You will know which tool the IMPAX

unit is referring to by the display: ex.

“STATION 1” or “BLOW 1”.

Make sure the Supervisor’s Key is turned off

(to the left)

Tolerance

X is the tolerance setting for channel Y

X can be from 0 to 9, or *.

CHANNEL Y X(?)

Tolerance Displays - cont:

16

--The number in parenthesis is the

variance IMPAX is detecting in the

forming process, also on a scale of 1 to

9. The tolerance can be set lower or

higher than the variance. When there is

a (?) in the variance, it means that

IMPAX is still learning.

--If the tolerance is set for automatic,

the “*” will appear after the channel

number and it may be accompanied by a

(number) which indicated the

equivalent tolerance level or a (?)

Which means no tolerance has been

computed yet.

--An “N” means that no tolerance has

been set; the setup is not complete and

the job may not be started.

Press Next/No. The display will show

the next channel, for instance,

“STATION 2 8(6)”, which would mean

that channel 2 is set for tolerance level 8

but should be set lower. IMPAX is

suggesting that it would run on a

tolerance of 6.

Press Next/No again, and the next

channel will be displayed. This may be

repeated until all the desired channels

have been displayed.

Press Display Will Show

Next/No

X is the tolerance setting for channel Y

X can be from 0 to 9, or *.

Next/No

until all channels have been displayed

CHANNEL Y X(?)

Press Back at any time to return to the

previous display.

If you wish to change a tolerance

setting you must insert the

Supervisor’s Key and proceed as

instructed in Chapter 5, Tolerance

Setting Guide.

Note: Roller tolerances are set the same

way as header tolerances, except that

“CHANNEL 1” will be replaced by

“ROLL” or whatever name is assigned.

Error Displays

17

(messages are for example only):

Press Error. If there have been no

problems since the job began (or since

the Error display was last cleared,) the

display will show “NO ERROR”. If an

error is recorded on a multi-station

header, the display might show

“CHANNEL 3 ERROR”. This would

mean that the problem was detected on

the station connected to channel 3. On

a threadroller the display might show

“BKSTR HI LIM”, meaning a problem

on the backstroke. Pressing Next will

show the Date and Time of the Error.

Press Next/No. The display will show

“ERROR 750”. This means that the

most recent error stopped the machine

when the 750th part was made.

Press Display Will Show

If there have been no errors since the errors were

last cleared

Error

If there have been errors since the errors were last

cleared

NOTE: These

displays will be

different if

exceptions are

turned on in Channel Definition. You can clear

the errors by pressing Enter when the “VIEW

ERRORS?” screen appears. Exceptions can be

cleared by pressing Next and then Enter.

Next/No

NO ERRORS

CHANNEL X ERROR

(Date and time of error)

ERROR XXXNext/No

Press Next/No. The display will show

“FORCE TOO HIGH or “FORCE TOO

LOW”, indicating which of the control

limits was breached.

Press Next/No. The display will now

show “SINGLE HIT”. This means that

the force change was severe enough to

warrant stopping after just one hit. It

may instead show “LO COUNT”,

“MED COUNT”, or “HI COUNT”;

these tell how many parts were run

before the force difference became

severe enough to stop. HI COUNT

means a small change in force was

detected over an average of many

blows. Generally, a single blow fault is

due to a smashup, double feed, or other

sudden, severe problem. An error

detected over a larger number of blows

is often due to a chipped tool, hard

material, or other small change.

XXX is the number of the part where

Next/No

Next/No

COULD BE

ANYONE

OF THESE:

(SINGLE HIT, LO

COUNT, MED

COUNT, OR HI

COUNT)

the most recent error occurred.

FORCE TOO HIGH

FORCE TOO LOW

SINGLE HIT

LO COUNT

MED COUNT

HI COUNT

Force Displays:

18

In certain cases, the above two

messages may be replaced by a special

message. “PEAK SATURATION”

would mean that the force input was

higher than IMPAX could measure; an

electronics adjustment may be required.

“TREND ERROR” means that the force

changed very slowly and reached a

previously set trend limit. This is

usually caused by tool wear or some

other slow change. “NOFEED

ERROR” means that too many strokes

have occurred without any forming

force being measured. “BKSTR HI

LIM” means that an excessive force

was measured on the backstroke of the

ram or slide.

Press Next/No. The display now shows

numbers, such as “101*157*150 6(3)”.

This shows the force measurement

which caused the IMPAX to stop the

machine. Note that the middle number

must always be either above the upper

limit or below the lower limit for an

error to occur in force. In this case it is

above the upper limit. The number 6 is

the current tolerance setting. The 3 is

the variance IMPAX is detecting in the

forming process.

Press Display Will Show

PEAK SATURATION

or

Only in special or

cases where

certain errors

have occurred!

or

numbers are for example only

Next/No

Next/No

TREND ERROR

NOFEED ERROR

BKSTR HI LIM

101*157*150 6(3)

CHANNEL 1 ERROR

Press Next/No. The display will show

“CHANNEL 1 ERROR”.This is

information about the fault which

occurred before the error at 750

(described above). Continuing to press

Next/No will display the faults which

have been recorded in reverse order.

At any time, you may press Back to

return to the beginning of that Error

message. Pressing Back again steps

backward to the beginning of the

previous Error message. Pressing Clear

returns the display to the selected

(default) screen. After the last Error is

displayed, pressing Next/No will

display “END OF ERRORS.” Refer to

page 10 to clear errors.

Next/No

Next/No END OF ERRORS

At any time during errors:

Clear

(All other errors in

reverse order)

(default screen)

(default screen)

Force Displays:

(numbers are for example only):

19

Press Force. The display will show “C1

098*120*142” which means that the

force measurement for channel 1 is 120

and the machine will be stopped if that

number falls to 98 or goes up to 142.

(Remember that the numbers are

relative; they do not represent pounds or

tons). The middle number may change

with every stroke; the other numbers

will change most when IMPAX first

‘learns.’ These numbers are devised by

IMPAX based on the average force

value and the tolerance number entered

for that channel.

Press Next/No. The display will now

show “C2 105*125*150” which is the

force measurement for the next channel,

channel 2. Pressing Next always

advances the display to the next

channel; pressing Back returns to the

previous channel.

Press 1. The display for the channel

being shown will change to “C2L

110*124*140”. The first digit shows

that it is still channel 2, and the force

measurement (middle number) remains

approximately the same. The “L”

means that the measurement now shown

is a “Low Count” sample, which is the

average of a few successive blows.

Note that the middle number does not

change as often or as greatly as before.

Therefore the upper and lower limits

can be closer.

Press 2. The display will change again

to “C2M 115*125*135”. This is the

“Medium Count” sample for channel 2

(shown by “C2M”) which is an average

of sixteen (16) blows. The limits are

closer yet, and the middle number

changes even less than before.

Press Display Will Show

Force

Next/No C2 105*125*150

Next/No (All other channels)

1

where X was the channel being displayed

2

where X was the channel being displayed

C1 098*120*142

CXL 110*124*140

CXM 115*125*135

Force Displays - cont.

20

Press 3. The display will now show

“C2H 118*125*132”. This is the “High

Count” sample for Channel 2 (“C2H”)

and it is an average of sixty four (64)

measurements. The middle number is

very steady so the limits can be very

close to it.

Press 4. The display will show “C2T

065*125*185”. This is the “Trend”

display for channel 2 (“C2T”) and it

shows how far the force can slowly

change before it is stopped.

If any of these limits have been disabled

by special programming, the display

will show the measurement without any

limits, for instance: “C1H *125*

”.

Press 9. The display will show “C1 M

120*128*136”. The upper and lower

limits show the highest high and the

lowest low in the last 64 strokes. This

is used to determine the correct

tolerance setting.

Press Display Will Show

3

4

any of these limits have been disabled, no

limits will be shown, only the measurement:

9

If

C2H 118*125*132

C2T 065*125*185

C1H *125*

C1 M 120*128*136

Each of these measurement levels is sensitive to certain kinds of problems. The single blow

limits can catch a smashup in one stroke, but may not be sensitive enough to notice a tool chip

because the force measurement varies too much. The High Count limits will not stop a smashup

quickly enough, but may notice a small chip and stop the machine after a few dozen have been

made. The Trend program can catch tool wear and other gradual changes. Remember that all of

these limits are working all the time; the force display only controls which one is being displayed

at that moment.

Another useful force function is the *. Typically IMPAX multiplies the force measurements by

a scale factor. If you wish to see the actual measurements instead of the scaled numbers, press

the * button while looking at the force display. The display will change to show actual sensor

measurements, on the scale from 0 to 65000. This is useful for comparing force displays to error

messages, which always show unscaled, actual measurements. To change the display back to

scaled numbers, press the * button again.

Note for roll-forming controllers: IMPAX controllers applied to rolling machine monitor forces

exactly as described above, except that there are only two channels, one for the forward rolling

stroke and one for the backstroke. Since no part should roll back through the die, there is never a

minimum limit on backstroke force.

Backstroke and Nofeed Limits:

Press Display Will Show

To see the Backstroke limit, press

Force then 9 (Minimum/Maximum

settings), then 9 again. This will

display “018*128*002”. The first

number, 018, is the Backstroke High

Limit, the middle number, 128, is the

Force, and the last number, 002, is the

Current Backstroke Force.

If you press 9 again and Nofeeds are

turned on in Channel Definition, then

this display will show: “C2 N

043*128*045”. The first number is the

NoFeed Threshold. This can be used to

check if Nofeeds are working correctly.

Just stop the feed and the Average

Force Value should go below the 043

Nofeed limit. The middle number is

once again the force and the last

number does not mean anything.

Note: For backstroke and nofeeds to

display, these features must be turned

on in Channel Definition.

(only for threadrolling applications)

(numbers are for example only)

Force

9

9

9

018: Backstroke High Limit

128: Force

002: Current Backstroke Force

043: NoFeed Threshold

128: Force

045: (meaningless)

C2 105*125*150

C2 M 120*128*136

C2 B 018*128*002

C2 N 043*128*045

21

22

Chapter 5 - Tolerance Setting Guide

tolerance limits are adjustable because every forming job is different. If a machine is running

well and making high quality, consistent parts, a low tolerance number can be used. If the job is

sloppy, or the material is inconsistent, or the quality of the part is not critical, a higher number

may be chosen. Tolerance selection is a compromise; there are several factors to consider. The

best compromise is a tolerance setting which is slightly wider than the normal force variation;

unnecessary stopping is minimized, but all real problems will be caught.

Consistency is important. IMPAX works best when the forming forces are unchanging.

Sometimes this may be improved by careful setup, tight tooling, and uniform material. This also

improves the quality of the finished part, which is an objective of any good manufacturing

operation.

Unnecessary Stops must be prevented. If the tolerance is set too tightly, productivity may

actually go down. When IMPAX stops a machine frequently for no reason, the tolerance setting

is too low (or the job is too sloppy; see paragraph above). When IMPAX catches every problem

but seldom stops when nothing is wrong, the tolerance is set properly.

IMPAX

MANUAL TOLERANCE

To set the tolerance on a new job, begin with a fairly high number such as 7, 8, or 9. Watch the

job and, if it runs well, set the tolerance lower after each few thousand parts are made. Look at

the force display to see how close the limits have been set. When the IMPAX begins to stop the

machine and no problem is found, ‘back off’ by raising the tolerance setting. Check the force

display occasionally to be sure the force limits are as close as they can be; adjust the tolerance as

needed. Also, check the tolerance display; it may indicate that a different tolerance setting may

be used. (The current variation may change slightly over a time.) These adjustments should be

made slowly, over a period of time.

AUTOMATIC TOLERANCE

This option may also be used to learn the settings for a new job. This is helpful if you are busy,

or if the machine has many stations. To use Auto-Tolerance, enter a * instead of a number when

setting up the tolerances for the job (see Chapter 3). IMPAX will automatically adjust the limits

on that station. The tolerance information display will then show the equivalent tolerance which

has been set, for instance; “CHANNEL 1 *(5)” would mean that, for Channel 1, Auto-Tolerance

has set a tolerance level equal to 5 on the scale from 1 to 9.

One problem with Auto-Tolerance is that if the forming process becomes inconsistent very

gradually, IMPAX may ‘track it’ and not catch the problem. You should set the tolerances

manually after the job is running well; the Auto-Tolerance numbers may be used as a guide.

Remember that the worst mistake is setting too loose a tolerance (high numbers) or no tolerance

at all (zero). IMPAX will count parts, but it will not catch important process changes.

The Supervisor’s Key is needed to set or change the tolerance settings. This helps to prevent

tampering by those who are not authorized to set tolerances.

23

Chapter 6 - Troubleshooting and Service

24

PROBLEM

CAUSE/REMEDY

IMPAX does not turn on. Not plugged in. Not turned on.

No display or lights. Check rear panel fuses.

Green light will not come on when Production quantity not set. Tolerances not set.

button is pushed. Job totals completed. Light burned out.

Yellow light will not go off although Force measurements are erratic. Check force

yellow and green have been on together display, check setup.

for hundreds of parts. (Learning mode)

After yellow and green are on together, Tolerance is too tight for the job. Job is not steady

yellow goes off but quickly changes to red. Enough for tolerance selected. Check setup, check

forces and tolerance.

IMPAX stops header repeatedly but Tolerance is too tight for job. Force measurements

no problem is found with parts made. Are changing. Check tooling, header, material

Uniformity. Run header; observe forces and parts

Produced. Check for loose tooling.

IMPAX fails to stop header when problems Tolerance is set too wide of set to zero. Enter

occur; smashups, breakage, dropped parts. lower tolerance number. Supervisor’s Key is in

Green light stays on. The bypass position.

Green light goes off, “RPM+” or “RPM-” Running speed of header is changing. Check

appears on the display. Header, check IMPAX machine position sensors.

Green light is on and header is running, but Check position senor, wires, and rear panel fuses.

IMPAX does not count.

IMPAX counts parts, but force Check force sensors and wires.

measurement numbers are zero for one

or more channels.

SIMPLE REPAIRS

Before performing any service, be sure power is off.

25

Fuse Replacement:

Primary circuit protection is provided by a circuit breaker built into the IMPAX power switch; if

this trips, merely turn on the switch to reset it. There are two fuses located on the back panel of

the IMPAX console. If the power is on but the displays do not light up, check the 3 amp fuse. If

the display comes up but the monitor won’t count or the force measurements do not come up,

check the 1 amp fuse.

To remove a fuse, press the cap in and turn it counter-clockwise. If the fuse appears blown,

replace it, but if it appears OK it should still be checked with a meter or test light. Replace only

with type 3AG slow-blow fuses of the correct current rating.

There is also a fuse located in the Satellite Box. If the lights on this box do not light, but the

IMPAX console is OK, remove the cover of the Satellite Box and inspect the fuse clipped on the

board. If bad, replace only with type 3AG slow-blow 1 amp fuse.

Lamp Replacement:

If a lamp on the Satellite Box will not light, unscrew just the colored lens which covers it. Do

not unscrew the ring which surrounds it. Be sure the power to the lamp is turned off, then

remove it by pressing the bulb in slightly and turning it one-sixth of a turn counter-clockwise. It

will then pull straight out. If it is burned out, replace only with a #1893 or other approved

equivalent. Many standard 12 volt bulbs will not be very bright.

Cable Inspection:

If there is reason to believe that a sensor cable has been damaged, it should be inspected for cuts,

abrasions, or undue crushing. Sensor cables may be repaired, but splicing of the damaged

section or complete replacement is recommended.

Damaged power cables are a safety hazard and should be repaired immediately according to

applicable electrical codes.

Plug and socket connectors should be inspected for damage, strain, or pulled-out wires. Unplug

the connection and inspect the mating contacts. Cables and connectors may be checked with a

meter or test light; defective assemblies should be spliced or replaced.

Program Memory (EPROM) Replacement:

To replace the program memory chips with a new program supplied by PTG/IMPAX, follow the

steps below. Before beginning, you may wish to display and write down any job or shift totals

which the IMPAX memory contains; these may be lost when the program is changed.

26

First, turn off the IMPAX console and pull the plug for safety. Using a Phillips screwdriver,

remove the screw which attach the front panel of the console. Gently tip the front panel

outwards. Disconnect the white power supply plug from the front panel circuit board by

pressing in the two latches on its sides and pulling it out. Lay the panel down flat on its face; be

careful not to stretch or break any of the other connections.

There are three circuit boards fastened to the front panel, the top one must be removed.

Disconnect the long gray plug along the side of the board by pressing the levers at each end

away from each other; the connector will be lifted up and out. Find and remove the screws

holding the board down, being careful not to damage any components on the board nearby.

Find the three sockets containing the program chips. They will have paper labels on top, and be

near the middle of the board. There will be a 0, 1, and a 2 chip. Also note that there is a small

notch or mark on the end of each chip which is toward one side of the board.

Remove one chip by inserting a small screwdriver or other prying tool under one end, between

the chip and the socket, and gently lifting the chip straight out. Try not to bend the pins.

Replace it with the new chip bearing the same digit, making sure that the mark at the end faces

the same way as the others. Line up the pins on one edge and gently enough to engage the pins

on the other side, then when every pin is lined up, press the chip home into the socket. Inspect to

be sure no pins are bent.

Repeat the procedure for the other 2 chips.

Replace the top circuit board. Re-insert the gray edge connector and the white power supply

connector until they click home. Insert the front panel back into the IMPAX console; being

careful that the cables and circuit boards are not pinched against the mounting surface. Replace

the front panel screws.

Turn on the unit and follow specified Startup/Initialization Procedures. Reprogram job totals as

necessary.

Force Sensor Replacement

:

If the force measurements become erratic, or fall to zero or a very low value, or the cable is cut,

the force sensor may need to be replaced. Unfortunately, the force sensor is very difficult to test

when installed, and may appear broken when the problem is actually somewhere else. Because

some of the force sensor types are usually difficult to replace, test everything else before

resorting to sensor replacement.

If the force sensor is to be replaced, disconnect its cable from the Satellite Box and disassemble

the machine as necessary. Note how the sensor is installed, then chip out the old sensor and

epoxy and clean the recess or mounting surface completely. Follow the instructions supplied

with the epoxy adhesive, and be sure to mix it thoroughly. Coat the mounting surface with it,

27

and install the sensor facing the same way as the old one - the brass plate down, the white part to

the top. Press the sensor through the epoxy to the bottom of the pocket. It is very important that

the white part, or the Piezoelectric crystal, does not short out to the pocket bottom or sides.

Check to make sure that the center wire is not above the surface of the block. Fill the sensor

pocket flush or slightly below the surface of the block with epoxy.

You can perform these tests with an ohmmeter - one lead of the meter to the center of the

conductor and the other lead to the block.

Reassemble the machine after the adhesive has set, and reconnect the cable.

Note: Pre-heating the block or wedge will significantly reduce the curing time of the epoxy.

Position Sensor Replacement or Adjustment:

If IMPAX will not count parts although the machine is running in green, the problem is related

to the position sensor. The simplest problem is that the cam or flag which passes in front of the

sensor to actuate it, may be damaged or missing. If this part does pass within 1/4" of the sensor

face for the 30mm proximity switch, then the sensor should be adjusted. If the proximity switch

is a 12mm one, it needs to be even closer. A voltmeter must be used to make sure that 10 volts is

applied to the red and black wires of the sensor, and that the white wire switches when metal is

placed in front of the sensor (these wires may be checked on the terminal strip of the circuit

board inside the Satellite Box).

If the sensor is bad, it should be replaced. Align and adjust the new sensor and actuator exactly

as the old one, or refer to the spacing and timing adjustment steps in “Initial Installation Position Sensor Installation” at the end of this Section. Even if the sensor is working

electrically, it may be wise to double check the timing adjustment.

INITIAL INSTALLATION

Before installing an IMPAX controller system on any manufacturing machine, IMPAX systems

may send a Field Service Engineer to evaluate the site, the machine, and any special customer

requirements. This includes sensor installation, programming preferences, and coordination with

in-plant personnel who may assist in installation.

The following guidelines may help you in preparing for future installations or modifying existing

ones. If in doubt, consult the IMPAX service department.

Of course, all mechanical and electrical work should conform to industry standards and

applicable safety codes.

28

General Guidelines - Electrical

Both low voltage (Class II) and high voltage (110v, Class I) are employed in each installation.

They should not be mixed within any conduit or enclosure unless properly partitioned apart. All

wiring should be conducted within suitable conduit and enclosures, and such should be oil proof

wherever oil is present. Wiring may be run inside or outside the machine, considering safety,

serviceability, appearance and convenience when deciding. In some cases, existing machine

wireways may be used (shared).

110 volt power for the IMPAX console should not be derived from the machine power, but

should be an isolated circuit known to be free of electrical interference, surges, and drops due to

motor loads.

The interconnection cables between the IMPAX console and the machine need not be encased in

conduit, but doing so may be desirable to enhance physical protection and appearance.

Termination and attachment of cables may be done by IMPAX service engineers at the time of

installation.

General Guidelines - Mechanical:

Because each machine and plant is different, mechanical attachment and arrangement of some

components may vary. Adaptation of these parts may require some ingenuity and fabrication. If

no reasonable solution to a problem can be found, the IMPAX installers can offer advice or

assistance. All work should be neat, solidly attached (shake proof), and should not interfere with

operation, maintenance, or repair practices.

:

Console Location:

The IMPAX console should be mounted near the machine it controls; ideally, visible from the

operating station. It is usually not advisable to attach it directly to a manufacturing machine, or

on any other place subject to sever vibration or heat. It may be hung from above, fastened to a

wall, pillar, shelf, or mounted on a pedestal. It should be convenient to reach, but not in a place

where it will obstruct traffic or be subject to damage. An isolated power line must be available

nearby.

Satellite Box location:

The small Satellite Box must be mounted on the manufacturing machine. It contains an

electronic board and serves as a junction point for all IMPAX wiring on the machine. Three

Status Lights may be mounted on this box, or in another place. The lights should be visible from

all directions. The IMPAX Reset Button is incorporated into the red light. On small machines,

the lights can be mounted on the box, in one location which meets all of these requirements.

Console to Satellite Box Cable:

A low-voltage, multi conductor cable must connect the Satellite Box to the IMPAX console.

This cable need not be encased in conduit.

29

Connection to Machine Electrical Cabinet:

In order to stop the machine, several wires must be run from the Satellite Box to the machine

electrical cabinet or control panel. These wires must be inside a conduit.

Sensor Connections:

Wires from the Position and Force sensors must be returned to the Satellite Box. Although it is

not strictly necessary that they be inside conduits, it is advisable to do so for the physical

protection of the delicate wires. Wiring should be spliced in such a way that troubleshooting or

replacement of sensors is not excessively difficult.

Installation of Force Sensors:

The sensor disk with attached wire is typically installed in a recess on a stressed location in the

forming machine, such as a die backing plate, punch wedge, ram, rocker, or other plate

depending on what force is to be measured. Consult Process Technologies Group if in doubt

about the best location. Once the location is chosen, cut the recess by milling, grinding or EDM,

as necessary. The dimensions of the milled pocket are available upon request from our

Technical Service Department. The groove for the wire should be cut so that the wire is safely

conducted away from the area into a conduit or under a cover; this is to protect it from damage.

Install the disk using the epoxy adhesive provided. The glue should be mixed thoroughly.

Apply a coating of adhesive to the recess, then press the sensor disk into place with the brass

side of the disk against the piece. The epoxy should set up in 1 to 2 hours. For best results allow

the epoxy to set overnight before running machine.

Installation of Position Sensors:

The Position Sensor, a proximity switch, is a non-contacting switch which is used to provide

timing information. Each time the machine makes a part, or strikes a blow, or reaches a certain

phase of its cycle, a position sensor can be adjusted to turn on or off to indicate it. Typically,

one sensor is used to count parts made (on and off once each time) and time the forming stroke

(on during the forming blow). Another sensor may be used on single and double die machines to

increase sensitivity. Observe the machine cycle to find a rotating or reciprocating member

which can be used to actuate the sensor. Attach a flag, cam, or sensor strip to the moving part

and position the sensor switch using appropriate brackets. The metal must move to within 1/4"

of the sensor for the 30mm prox. Switch to be “on”, and even closer for the 12mm prox. Switch.

When the flag or cam leaves that small space the switch will turn off until it passes close again.

Turn the machine through a full cycle to be sure that nothing touches or interferes. Verify that

the sensor is switched on and off at the intended times. It is important to note that on each

machine cycle of a single die, two blow header, two (2) blows occur. The proximity switch must

be timed off of the half speed shaft.

30

CUSTOMER SERVICE

If you have a problem which cannot be fixed by any of the procedures in this book, do not

hesitate to call IMPAX for service. Often, the problem can be fixed by simple instructions

over the telephone. Before calling, be sure you know all of the facts and symptoms of the

problem, information about the model and program revision numbers of the IMPAX unit,

and the make and the model of the header, roller, or other machine which it controls. This

makes it possible to quickly pinpoint and solve the problem.

Before calling, you should know:

IMPAX Serial number (on side of console): ___-___-___

Software Version: Version_________ (should be in the form of XXXXX-XX)

Definition Package P___TH___D___

*Note: Refer to Chapter 8 of the Supervisor’s Guide for instructions on

accessing the IMPAX software version and definition package.

Machine Make:__________________________

Machine Model:__________________________

Number of Stations:_______________________

31

Chapter 7 - Programming for the IMPAX 2000

Introduction

This section is provided as a guide to the IMPAX Version 58 software. It is not intended to replace

training, but rather to guide the user through changes they may choose to make in the options

available in the IMPAX Versions 58 Softw are. Every effort has been made to assure accuracy and

completeness.

This section makes a few assumptions. First and most important, is that the user has had some

IMPAX training. If you feel that your level of training is not what it should be, please contact

Process Technologies Group, Inc.

Since there are several combinations of selections, we m ust ha ve a starting point. In the interest of

simplicity, we assume that you have 8 channel software with the Standard Program initiated. A few

words about the Standard Program are in order.

The Standard Program is the set of options in the software program, as they were set when the

program was installed in the IMPAX unit at the factory. These options man have been customized

for your particular application when the IMPAX was tested or installed. If the prompts shown in

this guide differ from the prompts on your IMPAX unit, this may be due to changes made by the

installer at the time of installation. These changes were made for good reasons and may be

necessary for the proper operation of your IMPAX system. We suggest that you carefully consider

your changes before changing a "custom" setup, and that you document the changes, using the Setup

Sheet located in the back of this section, in case you need to change them back.

Before getting started, it would be good to review some things that are common to previous versions

of IMPAX software, such as using the alphanumeric keypad, and to cover some new material which

will be used later when we go through the program options step by step.

*Next can also be used to answer "No"

*Enter can also be used to answer "Yes"

*The Supervisor's Key is on when it is turned to the right, i.e. in the horizontal position.

*"ACCESS DENIED" is displayed when the wrong access code has been entered, or

when the new number has not been correctly entered (when changing the access code)

Generally, pressing Next will toggle such displays as "ON/OFF" or "ENABLE/DISABLE". Next

will also step through the displays offering choices such as Tag Names, Relay Names or Channel

Names.

32

SYSTEM/FAULT PROCEDURES

Whenever the power to the IMPAX CPU is interrupted, you will see a display “SYSTEM FAULT”.

This can happen whenever there is a power surge or if the IMPAX unit is taken apart and the front

panel is disconnected from the power supply.

If you know in advance that this is going to happen, it is recommended that the counts be recorded

so that they can be re-entered.

The sequence for recovery is as follows:

SYSTEM FAULT/CALL SUPERVISOR - ENTER

ACCESS X, X, X, X - ENTER

CALL PTG ENTER

CLEAR MEMORY?

ENTER COUNTS?

OLD TOTAL

OLD PARTS MADE

OLD SHIFT COUNT

OLD BREAK

OLD BREAK MADE

ENTER COUNTS?

If counts are known - ENTER

XXXXXXXX - ENTER

XXXXXXXX - ENTER

XXXXXXXX - ENTER

XXXXXXXX - ENTER

XXXXXXXX - ENTER

If counts are not known - ENTER

ENTER

BASIC INFORMATION/ FUNCTION #’s

You must understand the operation of the Function (#) Key before any programming can be

done. This key is used in combination with a numeric key to move to the appropriate selection.

Those selections are:

Function #3 will send you to the Channel Definition. This area will allow you to define

how the IMPAX will process the information from each sensor. For more information

see the section on Channel Definition.

Function #4 will send you to the Diagnostics. Please refer to Chapter 8 on Diagnostics

for more information.

Function #5 will send you to Relay Definition. In Version 58 Software, there is much

more than relays defined in this section. This section is actually the definition of how the

IMPAX interacts with the machine. See the section on Relay Definition for more details.

Function #6 will send you to the Timers Area. See the Section on Timers for more

information.

33

Function #7 will send you to the Downcode Area. See the Section on Downcodes for

more information.

Function #8 will send you to the Accumulated Downcodes Area. See the Section on

Accumulated Downcodes for more information.

Function #9 will send you to the Tag Entry Area. See the Section on Tag Entry for

more information.

Function #0, #1 and #2 have no meaning.

CHANNEL DEFINITION (FUNCTION #3)

To begin Channel Definition, press the Function (#) key and then the 3 key the display will show

“ACCESS”, which tells you that you must enter the four-digit access code for this unit before

you will be allowed to see and/or modify the Channel Definition. The default access code is 5 6

8 6.

Press the numbers of your access code; the display shows a “*” for each digit pressed. After you

have pressed the four digits, press Enter/Yes.

34

If the number you have entered does not match the IMPAX unit’s access code, the display will

show “ACCESS DENIED” for a few seconds, followed by the production counter. If the display

shows “LOAD STD PRGM?”, you have entered the correct access code, and you may now

check and/or modify the unit’s Channel Definition.

If you press Enter/Yes, the Default Channel Definition will be loaded for you to use as a starting

point in customization. Use caution however, because loading the Standard Program

permanently erases custom changes which were previously set into the IMPAX, and may be

difficult to reconstruct. If you press Next/No, the following steps will show you how the unit is

currently programmed.

The display will now say “DEFINE CHAN 1?”. If you wish to define Channel 1, press

Enter/Yes.

To operate on a different channel, press Back/Review or Next/No until that Channel Number is

displayed, then press Enter/Yes. There are sixteen channels, numbered 1 through 9 and A

through G.

These channels are software channels. All IMPAX monitors with Version 58 have sixteen

channels which means that you can define a sensor in more than one configuration. For

example, you can monitor the high limits on one channel and the low limits in a different

channel. There are many configurations which can be developed to make your IMPAX unit

better equipped to your particular machine and application.

When you have pressed Enter/Yes to select a channel, IMPAX will display “CHAN ENABLED”

or “CHAN DISABLED”. Press Next/No if you wish to change this, then press enter. If you

disable the channel, it will simply not exist in the operation. The channel definition program will

go on to the next channel number automatically.

If the channel is enabled, you must set up all of its operating parameters. The display will first

say “FORCE LINE - ”, asking which force sensor is to be assigned to that Channel. There may

be as many as 8 force sensors installed in the machine but only 1 can be selected for each

channel. Enter the number of the sensor you wish to select for this channel and the press

Enter/Yes.

The next display is “PEAK” or “INTEGRATE” ; this pertains to how the force measurement is

interpreted. When you select INTEGRATE, IMPAX will consider many observations during

each forming stroke. By considering all of the readings it establishes a number which represents

the total area under the curve. When you select PEAK, IMPAX will consider many observations

but will establish the number which represents the highest value in all of the readings. PEAK or

INTEGRATE may be selected by pressing Next/No, but should not be changed without good

reason. Press Enter/Yes to lock in your choice.

PTG/IMPAX recommends that INTEGRATE be used unless there are unusual circumstances

such as a very erratic reading from a sensor.

35

The next display is “P TARGET - ”, with a number from 0 through 255. This is the force

reading to which the IMPAX unit will try to calibrate its internal peak detection circuitry during

the automatic adjustment cycle. Enter a three-digit number from 0 to 255, then press Enter/Yes.

PTG/IMPAX recommends that this value be set to 96.

This display will now show “I TARGET - “ with a number from 0 through 255. This is similar

to the function above, except that it deals with the calibrated value for the integrated reading.

The recommended setting for this target is 128. Enter a three-digit number from 0 to 255, then

press Enter/Yes.

Next, the position sensor must be defined. The display will say “POSITION SENSE”; press

Enter/Yes.

It will then say “PROX SW. LINE --1", asking which proximity sensor is to be assigned to this

channel. There may be as many as 2 proximity sensors installed; press the number of the sensor

you wish to select and the press Enter/Yes.

The next display will either be “READ WHILE ON” or “READ WHILE OFF”; this determines

whether the force sensor is ‘looked at’ while the chosen proximity sensor is on or off its metal

cam or flag. Press Next/No if you wish to change the selection, then press Enter/Yes. If you

would like more information on this topic, please refer to the Timing Section of the IMPAX

Installation Guide.

The display will now show “BKST H LIM ON” or “BKST H LIM OFF”. BKST stands for

Backstroke, the return stroke of the moveable die on a flat-die threadroller. BKST H LIM, when

enabled, helps the IMPAX unit interact with a threadroller by allowing the IMPAX to detect a

part stuck to the die during the backstroke. If not detected by IMPAX, such a condition could

damage the tooling. Press Next/No to select between the two choices, then press Enter/Yes to

lock it in. If you select “BKST H LIM OFF”, the next three paragraphs are not applicable.

If you selected “BKST H LIM ON”, the next display will be “BKST HEAD RM -16”.

Backstroke Headroom is the value between the force seen during the backstroke and the HI

LIMIT for a backstroke error. Example: if the backstroke generates a force of * 002 *, and the

BKST HEAD RM IS 16, any backstroke force of * 018 * or above will generate a backstroke

error. Generally BKST HEAD RM should be left at 16 unless there is a problem with erroneous

backstroke errors.

The next display will be “BKST EXC ON” or “BKST EXC OFF”. This option will allow a

preset number of high force errors to occur without stopping the machine. Press Next/No to

select one choice or the other, then press Enter/Yes. Generally, this should be turned off.

The display will either show “NOFEED LIM OFF”, “NOFEED LIM CUMU”, or “NOFEED

LIM CONS”. NOFEEDS are cycles of the machine where no material is fed to the machine for

processing. Usually NOFEEDS are used with piece-fed machines like threadrollers, but under

36

special circumstances can be used with continuous or bar stock fed headers or other such

applications. NOFEEDs can be OFF, CONSecutuve, or CUMUlative. “CUMU” stands for

cumulative. This means that IMPAX will allow a certain number of errors out of 100 to be

ignored. For example, if I set the number to 2, IMPAX would allow 2 parts out of 100 to exceed

either the HI or the LO limit without shutting down the machine.

“CONS” stands for consecutive. This means that IMPAX will allow a certain number of errors

in a row to be ignored. For example, if I set the number to 2, IMPAX would allow 2 errors in a

row but the 3rd error in a row would cause the machine to stop. When tuning the IMPAX unit, it

is often helpful to set a large number of exceptions, say 10 or 15 and watch the force values in

the Error/Exceptions buffer. This can tell you what the values were for the exceptions and can

give you information needed to establish the proper settings for the tolerances. Press Next/No to

select one of the choices, then press Enter/Yes to lock it in.

The next display is "NOFEED EXC OFF" OR "NOFEED EXC ON." No Feed Exceptions is a

special feature which will divert a certain number of parts immediately after a No Feed

condition. This may be used if, for example, there were several consecutive no feeds and the

dies cooled off. The first ten parts may not be as good quality as those produced after the dies

heated up. No Feed Exceptions could be set to eject these parts if they did not meet the tolerance

parameters.

The next display is "IMMED LIM OFF" or "IMMED LIM ON." Immediate Limits enables the

fastest protection possible. This is useful because you may not want your machine to go

unprotected for 120 parts every time the machine stops and goes through another LEARN cycle.

IMMEDIATE LIMITS limits the LEARN cycle to only four parts. It takes the force values from

the last good part and stores them in memory. When the machine starts back up, it compares the

average force values of the first four parts to these stored values, and if the values are the same,

the machine will jump into run mode. If the first few parts during this “IMMEDIATE” cycle are

not consistent, the IMPAX monitor will shut the machine down again. Also, IMMEDIATE

limits cannot be used anytime the machine is cold or when there is a tool change. This is

because the force values in memory will not be the same as the ones when the machine is started

up and the IMPAX monitor will keep shutting down the process. Press Next to select your

choice, then press Enter/Yes.

The next display will be: “LO + HI LIMITS”, “LO LIMIT ONLY”, or “HI LIMIT ONLY”.

This option should normally left at LO + HI LIMITS and should only be changed for special

circumstances. One of the special circumstances is “Splitting the Channels” which will be

discussed in the Section on Advanced Operator Functions. Press Next/No to change this option

and then press Enter/Yes when you have found your choice.

The next display shows “LIMITS ON SLMH”. The SLMH indicates which of the limit tests are

activated for this channel. The IMPAX monitor performs four limit tests for every blow by

retaining in memory the learned force limits from the previous stroke. It then compares that

value in memory to the value of the current stroke and that is called the “Single Hit Limit.” The

IMPAX monitor can also compare the learned value of the last four (4) strokes and that limit is

37

called the “Low Count Limit”. The IMPAX monitor can further compare the learned value to

the average value of the last sixteen (16) strokes and that is called the “Medium Count Limit”.

Lastly, the IMPAX monitor can compare the learned value to the average value of the last sixtyfour (64) strokes and that is called the “High Count Limit”. It is possible to disable the limits for

this channel by blanking out the letters SLMH. The display shows which limits are enabled, for

example “LIMITS ON S ” would mean that only the Single Hit Limit is operating.

PTG/IMPAX recommends that all four tests remain active. The Single Hit Test is the critical

test but the others are valuable in detecting tool wear. To turn them on or off, press:

0 for Single Hit Limit

1 for Low Count Limit

2 for Medium Count Limit

3 for High Count Limit

Press Enter/Yes to lock in your selection once it is made.

The display now shows “FIXED ENABLED” or “FIXED DISABLED”. This feature disables

the automatic tuning built into IMPAX and allows the operator to establish their own upper and

lower limits. This feature is typically used if you want the limits wider than those supplied with

a tolerance setting of 9 or narrower than those supplied with a tolerance setting of 1.

PTG/IMPAX recommends FIXED DISABLED except under special circumstances. Press

Next/No to select one choice or the other, then press Enter/Yes.

The next display is “FAST LIMITS OFF” or “FAST LIMITS ON”. FAST limits ‘LEARNS’ just