Impact Test Equipment SL340 User Manual

User Guide

User Guide

Autologging Plate Load Tester

SL340

Impact Test Equipment Ltd

www.impact-test.co.uk & www.impact-test.com

Impact Test Equipment Ltd.

Building 21 Stevenston Ind. Est.

Stevenston

Ayrshire

KA20 3LR

T: 01294 602626

F: 01294 461168

E: sales@impact-test.co.uk

Test Equipment Web Site

www.impact-test.co.uk

Test Sieves & Accessories Web Site

www.impact-test.com

SL340

Auto-logging, Wireless

Plate Load Testing System

with GPS Positioning

OPERATION MANUAL

PLATEMAN English Manual V4.docx / 2015 / Page 2

TABLE OF CONTENTS

SECTION 1 INTRODUCTON

1.1 GENERAL DESCRIPTION OF THE SYSTEM

1.2 TEST METHOD

SECTION 2 SYSTEM & HARDWARE

2.1 PLATEMAN SYSTEM COMPONENTS

2.3 PLATEMAN OPERATING ENVIRONMENT

2.3 PLATEMAN SYSTEM SETTINGS

2.6 PLATEMAN PC SOFTWARE REQUIREMENTS AND

INSTALLATION

SECTION 3 CARRYING OUT A TEST

3.1 SETTING UP EQUIPMENT ON SITE

3.2 PERFORMING A PLATE LOAD TEST

SECTION 4 FILE OPERATIONS

4.1 REVIEWING DATA FILES

4.2 DELETING DATA FILES

4.3 TRANSFERING DATA TO A PC

SECTION 5 USING THE PLATEMAN PC SOFTWARE

5.1 OPENING DATA FILES

5.2 VIEW SETTINGS

5.3 PRINTING REPORT FILES

SECTION 6 CALIBRATION OF PLATEMAN AND TRANSDUCERS

SECTION 7 CARE AND MAINTENANCE OF THE PLATEMAN

PLATEMAN English Manual V4.docx / 2015 / Page 3

SECTION 1 : INTRODUCTON

1.1 GENERAL DESCRIPTION OF THE SYSTEM

Thank you for purchasing your PLATEMAN plate load testing system. The

PLATEMAN is brings the standard Plate Load Test up to date at last, with benefits for

both users and clients in terms of rapid testing, instant results and accurate

measurements. The PLATEMAN is a battery powered, wireless, auto logging test

system complete with reporting software.

Test results are viewed in real time as the test progresses and results can be viewed

instantly on site. The operator simply enters the required load, the number of

increments and cycles and presses the go button. The handheld rugged PDA then

prompts the operator when to increase the load and when to hold and release it.

Load and displacement measurements are recorded using wireless load cell and

digital displacement transducers and transmitted to the PDA in real time. The

operator never has to enter the potentially dangerous area below the reaction load to

take readings. After the test is completed, the data can be analysed and re-viewed

instantly on site, including calculation of estimated CBR.

The system includes a lightweight, modular, adjustable height, reference beam, that

the transducers and wireless connection module hang off. This is easily transportable

around site speeding up the testing process.

Data is downloaded to a PC using the PLATEMAN PC software, which analyses

data and produces detailed test reports, that can be printed out or transmitted

electronically to the client.

1.2 TEST METHOD

The Plate Load test is designed to determine the vertical deformation and

strength characteristics of soil by assessing the force and amount of

penetration with time when a rigid plate is made to penetrate the soil.

The method may be used to evaluate the ultimate bearing capacity, the shear

strength and deformation parameters of the soil beneath the plate without

entailing the effects of sample disturbance.

Testing may be carried out at the ground surface, in pits or in trenches in

accordance with BS1377: Part 9: 1990.

SECTION 2 : SYSTEM & HARDWARE

2.1 PLATEMAN SYSTEM COMPONENTS

Your PLATEMAN kit contains the following items :

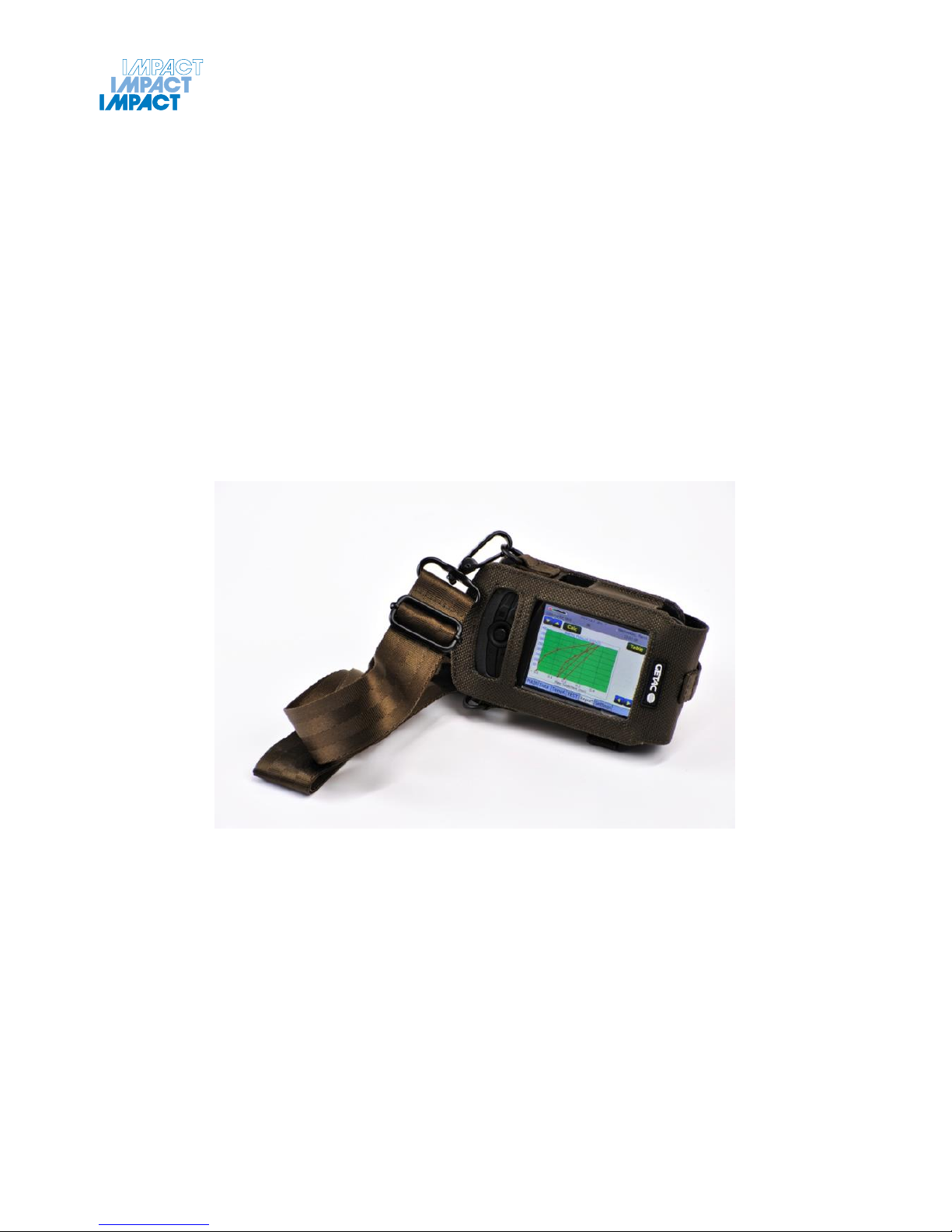

♦ PLATEMAN test unit (Getac 532F Rugged PDA)

♦ PLATEMAN bluetooth wireless transducer acquisition, power supply and

transmitter unit with calibration certificate

♦ AC & DC charger

♦ 250KN load cell with lead and calibration certificate

♦ 3No Displacement transducers with 50mm travel and calibration certificate. (Note

– 100mm travel displacement gauges are also available)

♦ PLATEMAN Lightweight 3m demountable reference beam with adjustable legs,

3No adjustable transducer clamps and carry case. (Note – 500mm short beam

extensions are also available)

♦ PLATEMAN Foam lined transport case

♦ PLATEMAN PDA carry pouch

♦ PLATEMAN Operation Manual

♦ PLATEMAN Software on datastick

The PLATEMAN is a lightweight portable plate load testing system, the main

components of which are described in detail below:

PLATEMAN TEST UNIT

The PLATEMAN test unit is based on a Steatite rugged 532F PDA unit, which is the

world’s smallest rugged PDA, with the following main features:

• MIL-STD 810G and IP65 Compliance

PLATEMAN English Manual V4.docx / 2015 / Page 5

• Microsoft Windows Mobile 6.5

• E-Compass and Altimeter

• 3M Pixels Auto-focus Camera

• VGA Display

• Transflective 3.5" TFT LCD

• Embedded High Sensitivity GPS Receiver

• Long Battery Life Provides All-day Power

A full technical spec is supplied on the GETAC datasheet in the appendix. The test

unit is supplied pre-loaded with the PLATEMAN software for foundation testing.

Power requirements and charging

AC adapter (10W, 100-240VAC; 50 / 60 Hz)

Li-lon smart battery (2400mAh) (up to 8 hours of battery life)

Charging time: Sleep mode, approx. 3.5 Hrs.

PLATEMAN TRANSDUCER ACQUISITION UNIT AND POWER SUPPLY

The PLATEMAN transducer unit is housed in a rugged aluminium and ABS plastic

casing, designed to withstand the rigours of site use. It has the following main

features:

• High Sensitivity accelerometer

• Bluetooth wireless data transfer

• On-board signal memory

• Battery charge indicator

• Long life re-chargeable Li-Ion battery

• IP65 Compliance

PLATEMAN English Manual V4.docx / 2015 / Page 6

Power requirements and charging

AC charger (8.4V DC Output, 10W, 100-240VAC Input)

Li-lon battery, 2200mAh. (One month typical daily usage on full charge)

Charging time: approx. 2 Hrs.

PLATEMAN lightweight reference beam

PLATEMAN displacement transducers

PLATEMAN load cell

Loading...

Loading...