Impact Subsea ISD4000 Installation & Operation Manual

www.impactsubsea.com

Innovative Underwater Products

ISD4000

Depth & Temperature Sensor

With Optional AHRS

Installation & Operation

Manual

Revision: 1.6

Date: 09/01/19

Impact Subsea Ltd

T. +44 (0) 1224 460 850

E. info@impactsubsea.co.uk

W. www.impactsubsea.com

Contents

1.0 Introduction.................................................................................................................................3

2.0 Specification................................................................................................................................4

2.1 Unit Overview .................................................................................................................4

2.2 Unit Dimensions..............................................................................................................4

2.3 Depth, Temperature & HMRU.........................................................................................5

2.4 Communications, Power & Physical...............................................................................5

3.0 Overview.....................................................................................................................................6

4.0 Installation .............................................................................................................................7

4.1 Location............................................................................................................................7

4.1.1 Pressure (For Depth Accuracy).............................................................................7

4.1.2 Magnetic Disturbers (For Heading Accuracy)......................................................7

4.1.3 Alignment with Vehicle (For Pitch/Roll Accuracy)...............................................8

4.1.4 Heat Sources (For Temperature Accuracy)...........................................................8

4.2 Mounting .........................................................................................................................9

4.3 Electrical .......................................................................................................................10

4.3.1 Connector Pin Out..............................................................................................10

4.3.2 Power..................................................................................................................11

4.3.3 Serial Interface....................................................................................................11

4.3.4 RS232 Wiring.....................................................................................................11

4.3.5 RS485 Wiring.....................................................................................................12

4.3.6 Establishing Communications............................................................................13

4.3.7 Connector Mating...............................................................................................13

4.3.8 Connector Cleaning............................................................................................13

5.0 Operation ..................................................................................................................................14

5.1 Use With The Impact Subsea Software..........................................................................14

5.2 Integration With Systems...............................................................................................15

5.3 Calibration......................................................................................................................15

5.4 Magnetic Calibration......................................................................................................17

6.0 ASCII Output Strings ...............................................................................................................22

6.1 Depth .............................................................................................................................22

6.2 AHRS...............................................................................................................................24

7.0 Servicing....................................................................................................................................27

8.0 Warranty....................................................................................................................................28

9.0 Technical Support .....................................................................................................................29

Every effort is made to ensure that information within this document is up to date. However, information within this

document is subject to change without notice, in-line with our commitment to continuous product development and

improvement.

www.impactsubsea.com

Innovative Underwater Products

1.0 Introduction

The ISD4000 sensor provides depth and temperature measurement with

exceptional accuracy and resolution. Optionally, the ISD4000 can also measure

Heading, Pitch & Roll.

Suitable for a large range of underwater applications, the ISD4000 can be used with

ROVs, AUVs, Hydro-graphic Survey, Construction, Positioning and any other task

where accurate depth and temperature is required underwater.

The ISD4000 utilises the latest in temperature compensated piezo-resistive depth

sensing technology, to provide an exceptional 0.01% full scale depth measurement

accuracy. A highly accurate RTD sensor is used to provide temperature to 0.01°C

accuracy.

Where fitted, the Heading, Pitch and Roll readings are provided from integrated

MEMs based Magnetometers, Accelerometers and Gyroscopes. The MEMs based

devices are fused together to provide highly accurate and stable Heading, Pitch and

Roll measurements.

Housed in a compact and lightweight titanium housing ensures that the ISD4000 is

not only at the forefront of sensor technology; but is built to withstand the most

extreme underwater environments.

ISD4000 Depth & Temperature Sensor

© Impact Subsea Ltd 3

www.impactsubsea.com

Innovative Underwater Products

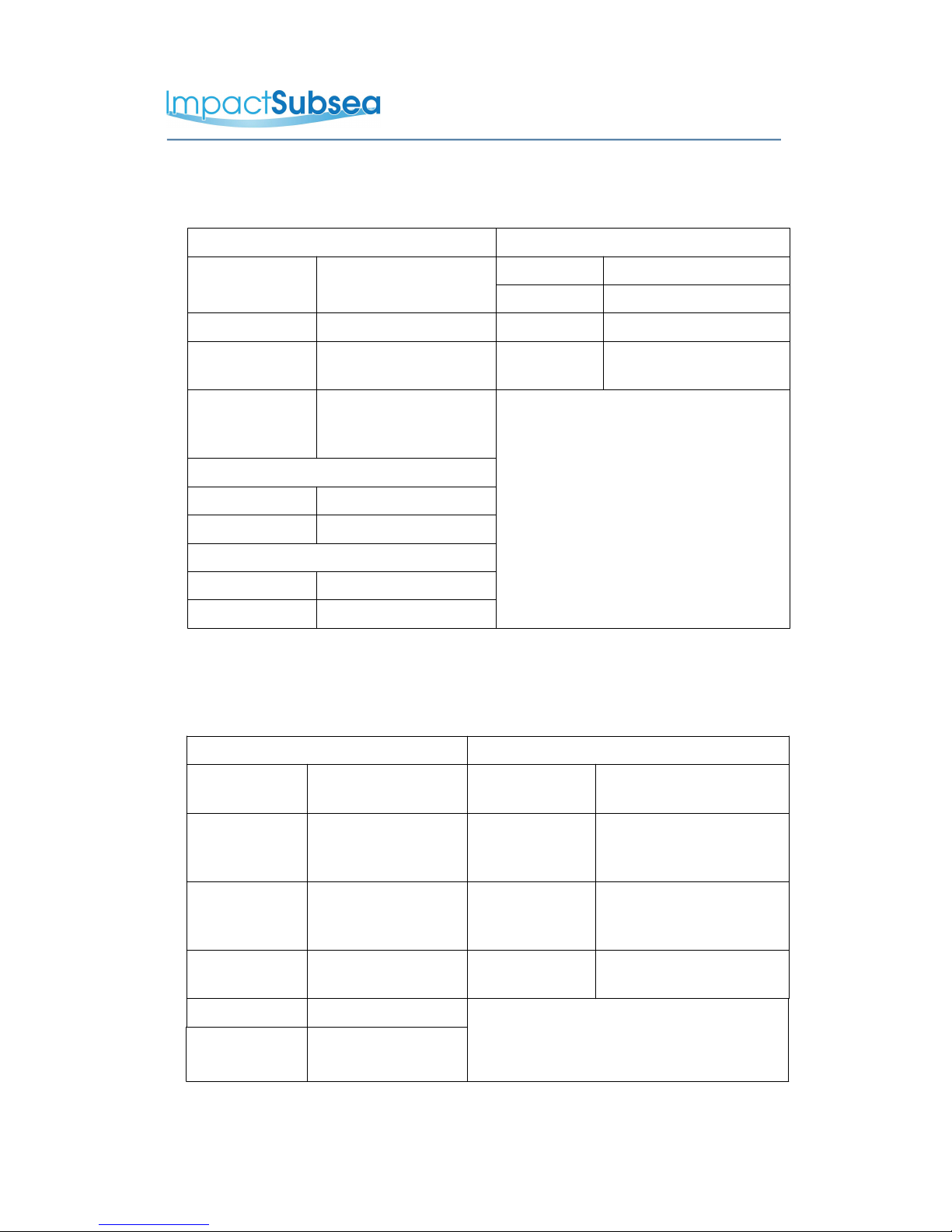

2.0 Specification

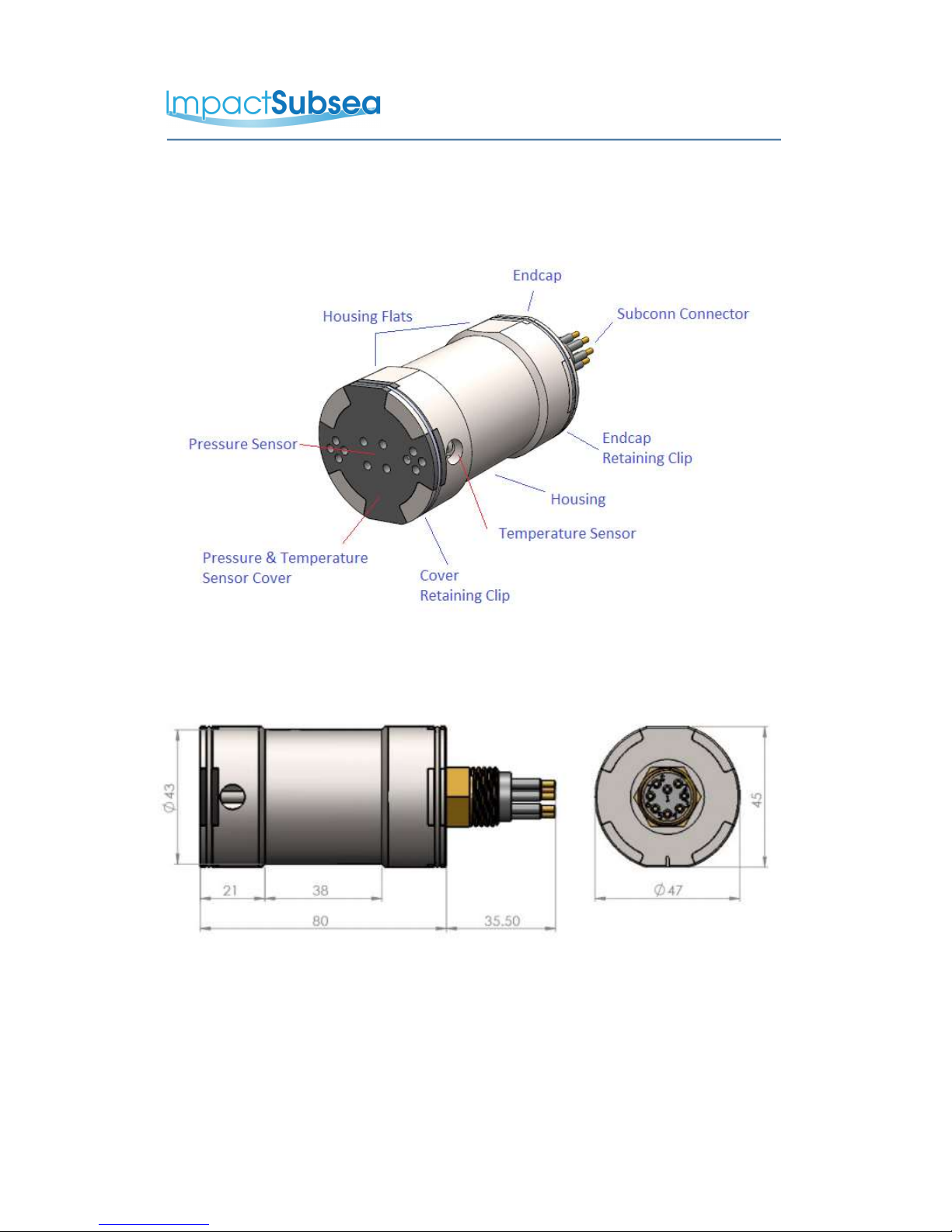

2.1 Unit Overview

2.2 Unit Dimensions

All dimensions are in mm.

© Impact Subsea Ltd 4

www.impactsubsea.com

Innovative Underwater Products

2.3 Depth, Temperature & HMRU

Depth Pitch & Roll*

Accuracy ± 0.01% Full Scale Pitch ± 90°

Roll ± 180°

Resolution 0.001% Full Scale Accuracy 0.2° RMS

Range 10, 30, 50, 100, 300,

400 or 600 Bar

Resolution 0.1°

Type Temperature

Compensated PiezoResistive

Temperature

Accuracy 0.01°C

Resolution 0.001°C

Heading*

Accuracy ± 0.5°

Resolution 0.1°

* Available as an option at time or order

2.4 Communications, Power & Physical

Communications & Power Physical

Digital RS232 & RS485 Weight

(Air/Water)

Titanium: 0.42 / 0.28kg

Delrin: 0.20 / 0.10kg

Protocol 300 to 115200

baud

Depth Rating Titanium: 6,000 meters

Delrin: 500 meters

Data Continuous or on

demand

Temperature Operating: -5 to 25°

Storage: -20 to 50°

Data Rate Up to 100Hz Connector Subconn MCBH8M-SS

fitted as standard

Input Voltage 7 to 32V DC

Power < 40mA @ 24V DC

© Impact Subsea Ltd 5

www.impactsubsea.com

Innovative Underwater Products

3.0 Overview

The ISD4000 is a pressure measurement device – making use of increasing pressure

in water to determine depth. It is important to note that the device is designed to

provide depth & temperature measurements in water, and will not provide accurate

readings when operated in air.

The Heading, Pitch and Roll readings are provided by a Micro-Electro-Mechanical

system (MEMS) based technology. MEMs based Gyros, Accelerometers and

Magnetometers are integrated within the unit.

The temperature reading is provided by a dedicated RTD sensor, located in a probe

next to the pressure sensor.

The ISD4000 can be configured using the supplied Impact Subsea software. The

software allows all settings to be configured (output strings, communications protocol,

baud rate, taring etc).

In addition to allowing the ISD4000 to be configured, the Impact Subsea software

also allows all outputs to be viewed in real time and logged.

© Impact Subsea Ltd 6

www.impactsubsea.com

Innovative Underwater Products

4.0 Installation

4.1 Location

When evaluating the installation location of the ISD4000, there are several

factors to consider to achieve optimum operation from each part of the

unit:

– Pressure (Depth Measurement)

– Magnetic Disturbers (Heading)

– Alignment with Vehicle (Pitch/Roll)

– Heat Sources (Temperature Measurement)

4.1.1 Pressure (For Depth Accuracy)

The ISD4000 pressure port must not be blocked or obstructed by any item.

Take care when mounting the unit not to block any of the holes on the

pressure port of the ISD4000.

The unit should be mounted to allow good water flow to the pressure sensor.

Ideally the ISD4000 should be mounted with the pressure sensor end

pointing downwards. This will help to minimise the build up of sediment

on the pressure sensor.

4.1.2 Magnetic Disturbers (For Heading Accuracy)

Where the heading output is to be used, the ISD4000 should be mounted as

far as possible from sources of magnetic interference.

Electrical items which can cause magnetic interference include motors,

transformers and valve packs. Ferrous metals, or any other

magnetically active materials will also have influence on the heading reading.

Thus, where possible, the unit should be installed as far as possible from

magnetically active materials.

© Impact Subsea Ltd 7

www.impactsubsea.com

Innovative Underwater Products

4.1.3 Alignment with Vehicle (For Pitch/Roll Accuracy)

When mounting vertically, the ISD4000 should be mounted with the

Pressure Sensor facing downwards (to the seabed) and the indentation in the

connector end cap pointing forwards, in the direction of forward vehicle

travel:

When mounting horizontally the ISD4000 should be installed with the

indentation in the connector end cap pointing upwards:

4.1.4 Heat Sources (For Temperature Accuracy)

In order for the ISD4000 to read the ambient temperature of the water, it

should not be installed in close proximity of any heat sources (such as

Hydraulic Power Packs).

© Impact Subsea Ltd 8

www.impactsubsea.com

Innovative Underwater Products

4.2 Mounting

The ISD4000 should be mounted using clamps around the mid section of the

body. The unit has a 38mm recess in the main body to enable a clamp to be

tightened securely around the unit:

Ideally a non-metallic clamp should be used, however in the event that this is

not possible, effort should be made to electrically isolate the clamp from the

ISD4000 housing. This can be achieved by using rubber or plastic strips

around the body of the ISD4000.

The ISD4000 has two flats, on either side of the body – these are to enable

the unit to sit tightly against another flat surface if available. These flats also

help prevent the unit moving when on the workbench for testing.

© Impact Subsea Ltd 9

Loading...

Loading...