Impact Products CN652 User Manual

Digital Concrete Test Hammer

CN652

Impact Test Equipment Ltd

www.impact-test.co.uk & www.impact-test.com

User Guide

User Guide

Impact Test Equipment Ltd.

Building 21 Stevenston Ind. Est.

Stevenston

Ayrshire

KA20 3LR

T: 01294 602626

F: 01294 461168

E: sales@impact-test.co.uk

Test Equipment Web Site

www.impact-test.co.uk

Test Sieves & Accessories Web Site

www.impact-test.com

- 2 -

1 Safety

General Information

Liability

Safety Regulations

Standards and Regulations Applied

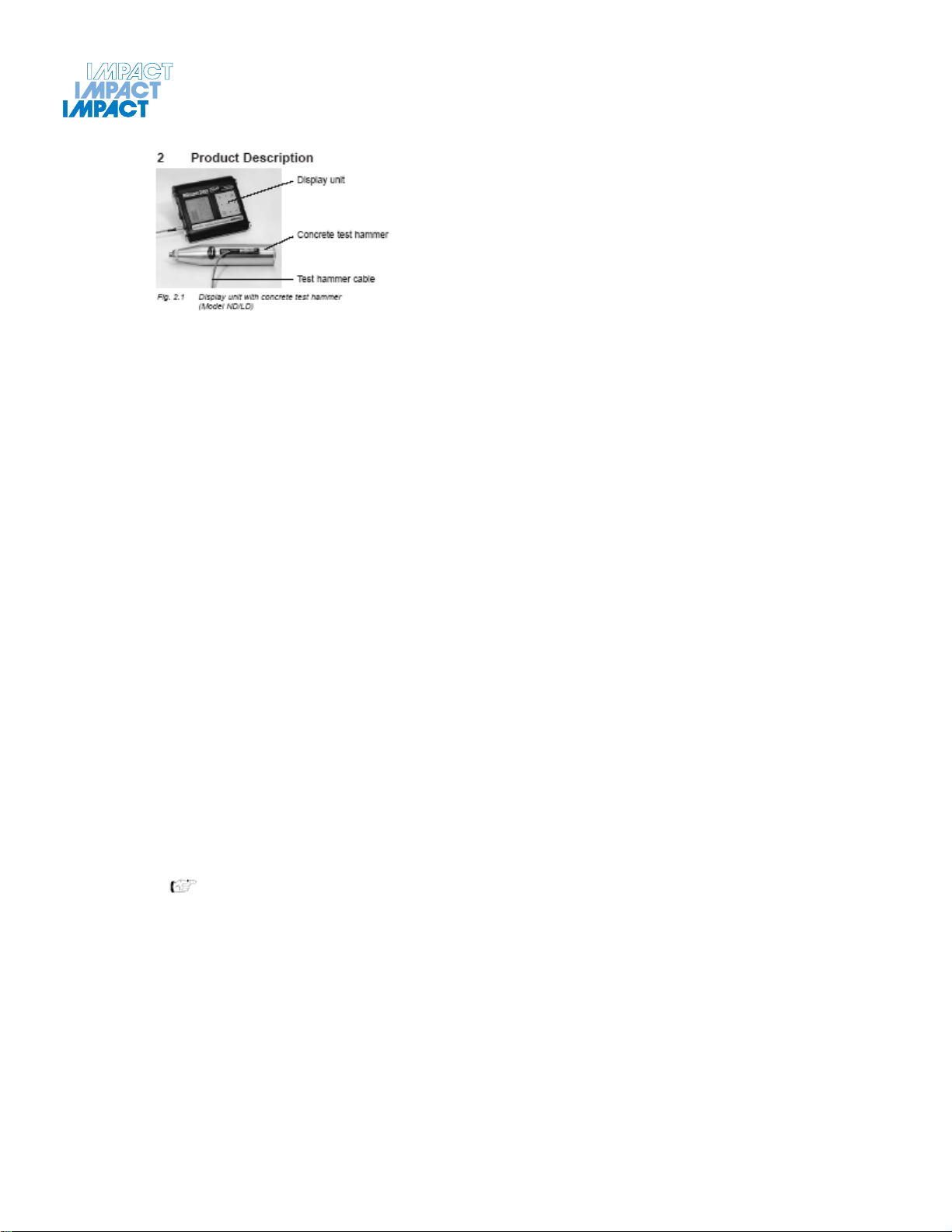

2 Product Description

3 Startup

Connecting the Components

Putting the Display Unit into Operation

4 Settings

Impact Direction

Mean Value

Measure Series Number

Conversion

Corrections

Display Range

Limit Values

Language

Date / Time

Data Output

5 Measuring Process

Measuring Procedure

Data Output

6 Maintenance and Care

Cleaning After Use

Performance Check

Storage

Maintenance

7 Data

Form of Delivery

Accessories / Spare Parts .

Technical Data

8 Appendix

Derivation of the PROCEQ Standard

Conversion Curves

Standard Conversion Curves, Creating New Conversion Curve

Determining Time Coefficient

Contents

- 1 -

1 Safety

1.1 General Information

1.1.1 Basic Information

The concrete test hammer is designed according to state-of-the-art technology

and the recognized safety regulations.

Please read through these operating instructions carefully before initial startup.

They contain important information about safety, use and maintenance of the

DIGISCHMIDT 2000 concrete test hammer.

1.1.2 Designated Use

The concrete test hammer is a mechanical device used for performing rapid,

non-destructive quality testing on materials in accordance with the customer's

specifications; in most cases, however, the material involved is concrete. The

device is to be used exclusively on the surfaces to be tested and on the testing

anvil.

1.2 Liability

Our ”General Terms and Conditions of Sale and Delivery” apply in all cases.

Warranty and liability claims arising from personal injury and damage to property

cannot be upheld if they are due to one or more of the following causes:

- Failure to use the concrete test hammer in accordance with its designated use -

Incorrect performance check, operation and maintenance of the concrete test

hammer

- Failure to adhere to the sections of the operating instructions dealing with the

performance check, operation and maintenance of the concrete test hammer

- Unauthorized structural modifications to the concrete test hammer

- Serious damage resulting from the effects of foreign bodies, accidents,

vandalism and force majeure

1.3 Safety Regulations

1.3.1 General Information

- Perform the prescribed maintenance work on schedule.

- Carry out a performance check once the maintenance work has been

completed.

- Handle and dispose of lubricants and cleaning agents responsibly.

1.3.2 Unauthorized Operators

The concrete test hammer is not allowed to be operated by children and anyone

under the influence of alcohol, drugs or pharmaceutical preparations.

Anyone who is not familiar with the operating instructions must be supervised

when using the concrete test hammer.

- 2 -

1.3.3 Safety Icons

The following icons are used in conjunction with all important safety notes in

these operating instructions.

Danger!

This note indicates a risk of serious or fatal injury in the event that certain

rules of

behavior are disregarded.

Warning!

This note warns you about the risk of material damage, financial loss and legal

penalties

(e.g. loss of warranty rights, liability cases, etc.)

This denotes important information.

1.4 Standards and Regulations Applied

- DIN 1048, part 2

- ASTM C 805

- B 15-225

- NEN 3880 A 607

- PN-74B 06262

- C 30-67 BDS 3816-72

- HS 201/1-72

- ISO/DIS 8045

- EN 12398

- ENV 206

- 3 -

The DIGI-SCHMIDT 2000 concrete test hammer comprises the actual concrete

test hammer and the display unit.

Both components belong together and are calibrated as one unit.

The impact bolt of the concrete test hammer strikes the surface of the concrete

with a defined force. After the impact, a metal body, the so-called hammer (see

pos. 14 in Fig. 6.2, page 16), rebounds. The rebound distance is measured by a

sensor and passed on to the display unit as an electrical signal. The signal

converted by the electronics is shown on the display unit as rebound value R

and, if necessary, displayed together with the corresponding compressive

strength of the concrete, fck.

There is a specific relationship between the rebound value R and the hardness

and strength of the concrete. The following factors must be taken into account

when ascertaining rebound values R:

- Impact direction: horizontal, vertically upwards or downwards

- Age of the concrete

- Size and shape of the comparison sample (cube, cylinder)

Model ND can be used for testing:

- Concrete items 100 mm or more in thickness

- Concrete with a maximum particle size < 32 mm

Model LD can be used for testing:

- Items with small dimensions (e.g. thin-walled items with a thickness from 50 to

100 mm)

With Model LD, it may be necessary to clamp the items to be tested

prior to measurement in order to prevent the material from deflecting.

- Items made from artificial stone which are sensitive to impacts

- 4 -

3 Startup

3.1 Connecting the Components

• Connect the Test hammer cable to the concrete test hammer and to the display

unit at input B.

• Connect the transfer cable for data transmission to the PC, and for transmission

to the printer, connect the printer cable to interface RS232.

3.2 Putting the Display Unit into Operation

• Press the ON/OFF key.

The following data are briefly displayed:

- Device model (Model ND or LD)

- Serial number of the concrete test hammer on the left and that of the display

unit on the right side

Check whether the serial number of the concrete test hammer on the display

corresponds to the number on the device.

- Installed software version

- Self-test performed: ”Test o.k.”

- Remaining battery life

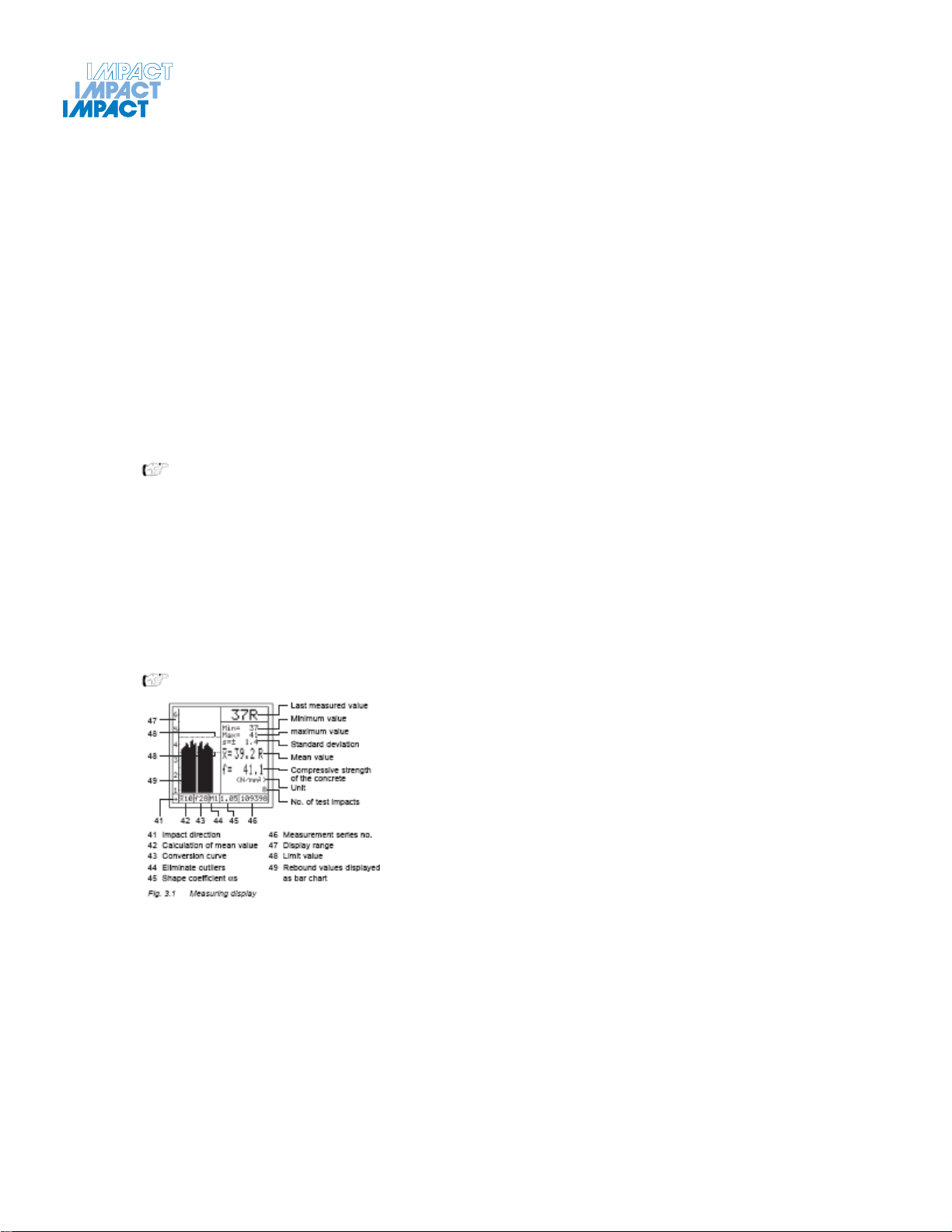

Then the measuring display of the previously measured object appears (see Fig.

3.1, but without values).

If no display appears, replace the batteries.

The symbols and values only appear if they have been set or if a measurement

series has been performed.

• Adopting the menu settings from the previous measurement:

Continue with ”Measuring Process”

• Making new settings:

Continue with ”Settings”

- 5 -

4 Settings

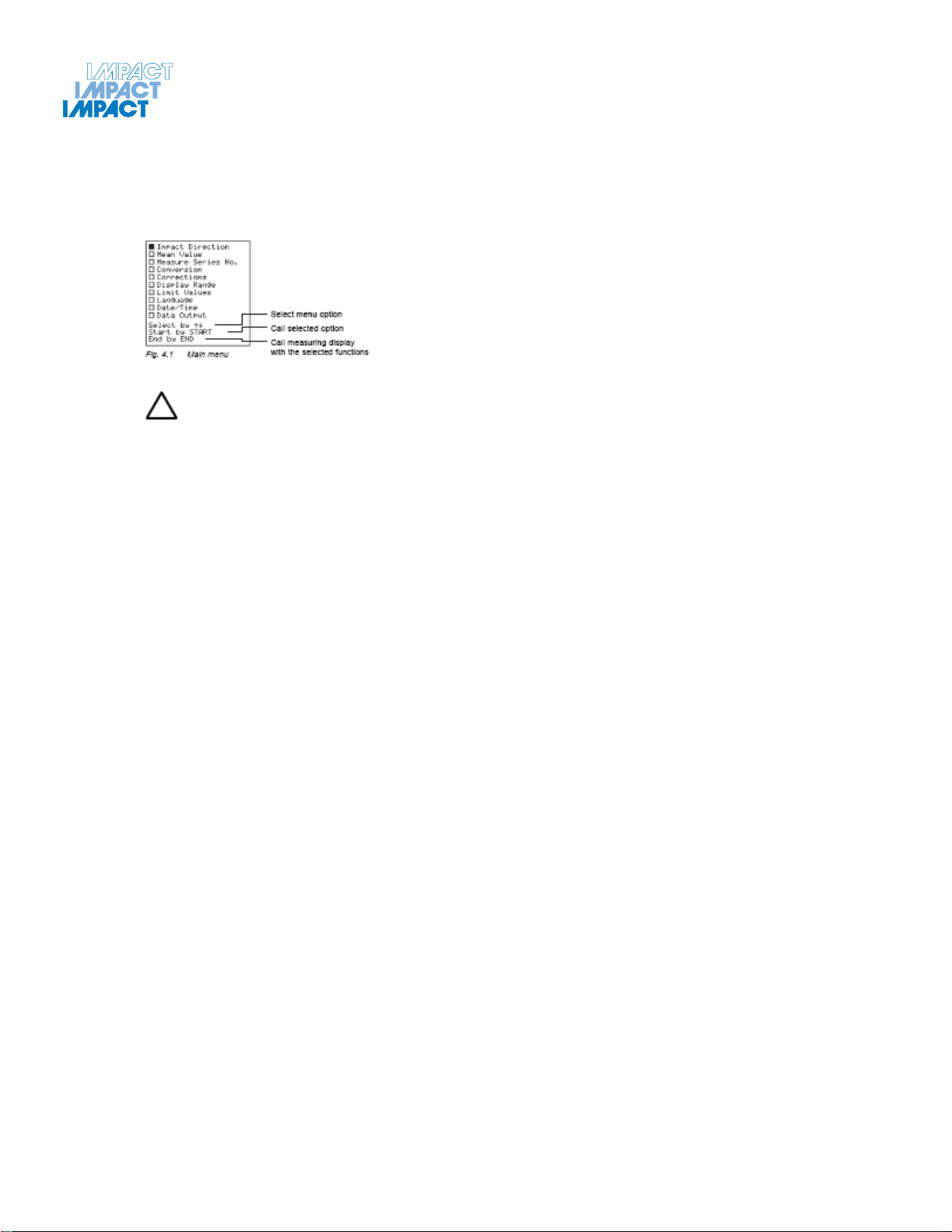

The display unit has a menu with user navigation. Please follow the instructions

in the respective display fields.

• Press the MENU key to display the main menu:

Warning!

Check the settings before performing a measurement! This applies in particular

for the impact direction and for the shape and time coefficient.

4.1 Impact Direction

• Select the symbol for the desired impact direction.

The rebound value is automatically corrected according to the preselected impact

direction.

4.2 Mean Value

The mean value is calculated from the number of test impacts n entered or after

a measurement series has been completed by pressing the END key.

• Where possible, enter at least n = 10 or n = 12 (see under “Mx”, example).

The actual mean value is displayed after every test impact.

4.3 Measure Series Number

• At the start of a measurement series, you can enter a number (max. 6 figures).

The number is automatically incremented by 1 after the first test impact of the

new measurement series.

4.3 Conversion

4.4.1 Unit

• Select the unit in which the compressive strength of the concrete is to be

displayed (N/mm2, MPa, psi, kg/cm2).

- 6 -

Loading...

Loading...