Page 1

Installation and Operating Manual

Slew Drives

WD-L, WD-H, SP-L, SP-I, SP-M, SP-H

IO SD 1.00

Read the operating manual prior to starting all work!

Page 2

© IMO Antriebseinheit GmbH & Co. KG

Gewerbepark 16

91350 Gremsdorf, Germany

Tel.: +49 9193 6395-20

Fax: +49 9193 6395-2140

email: slew.drives@goimo.com

Internet: www.goimo.com

Customer Service:

Tel.: +49 9193 6395-2200

email: service@goimo.com

This operating manual provides important instructions for working

with the component. The specified instructions must be precisely

followed, to protect yourself and others.

Inform yourself of the locally applicable accident prevention

regulations and the general safety regulations.

The operating manual must be carefully read prior to starting any

work! It is a component of the product and must be kept in the

immediate vicinity of the component. It must be accessible to

personnel at all times.

If this component is provided to a third party ensure that the

operating manual is provided with the component.

The illustrations in this manual are provided for the purpose of

better understanding. They are not necessarily true to scale and

can deviate from the actual design of the component.

2

Page 3

Slew Drives

Table of contents

1 Structure and function..................................................5

1.1 Brief description ........................................................ 5

1.2 Overview ..................................................................5

1.2.1

WD-L series (light series)............................. 5

1.2.2

WD-H series (heavy series).......................... 6

1.2.3

SP series.....................................................7

1.3 Intended use............................................................. 8

2 General .........................................................................9

2.1 Explanation of symbols .............................................. 9

2.2 Limitation of liability .................................................. 9

2.3 Copyright................................................................ 10

2.4 Original IMO parts ................................................... 10

2.5 Customer Service .................................................... 11

3 Safety..........................................................................12

3.1 Safety devices ......................................................... 12

3.2 Special dangers ....................................................... 12

3.3 Responsibility of the customer.................................. 13

3.4 Personnel requirements ........................................... 14

3.5 Personal protective equipment ................................. 14

4 Transport, packaging, and storage.............................16

4.1 Safety instructions for transport ............................... 16

4.2 Transport................................................................ 16

4.3 Transport inspection/incoming goods inspection........ 18

4.4 Packaging ............................................................... 19

4.5 Symbols on the packaging ....................................... 19

4.6 Storage................................................................... 20

5 Installation and commissioning .................................21

5.1 Safety..................................................................... 21

5.2 Preparation ............................................................. 22

5.2.1

Lubricating prior to commissioning ............. 22

5.2.2

Cleaning the slew drive and mounting

structure................................................... 22

5.2.3

Determination of flatness deviation, and

perpendicularity deviation and deformation

of the mounting structure .......................... 23

5.2.4

Selecting the mounting elements ............... 26

5.2.5

Tightening bolts with a torque wrench........ 27

5.2.6

Tightening bolts with a hydraulic bolt-

tensioning cylinder .................................... 28

5.3 Installing the slew drive ........................................... 30

5.3.1

Hardness gap............................................ 30

5.3.2

Positioning the slew drive .......................... 30

3

Page 4

Slew Drives

Table of contents

5.3.3

Bolting the slew drive ................................31

5.3.4

Determining the tilting clearance ................33

5.3.5

Determining the circumferential backlash ....34

5.4 Function test ...........................................................35

6 Maintenance ...............................................................36

6.1 Safety .....................................................................36

6.2 Cleaning..................................................................37

6.3 Maintenance schedule ..............................................37

6.4 Maintenance tasks ...................................................39

6.4.1

Inspecting the mounting bolts ....................39

6.4.2

Checking the tilting clearance .....................39

6.4.3

Checking the circumferential backlash.........40

6.4.4

Lubricating the slew drive ..........................41

6.4.5

Inspecting the seals ...................................42

6.5 Measures after successful maintenance.....................42

7 Dismantling.................................................................43

7.1 Safety .....................................................................43

7.2 Dismantling .............................................................44

7.3 Disposal ..................................................................44

8 Technical data – Type plate ........................................45

4

Page 5

Slew Drives

Structure and function

1 Structure and function

1.1 Brief description

Slew drives are used for concurrent transmission of axial and radial

forces, as well as transmission of tilting moments. Slew drives

consist of a ball or roller slewing ring, hydraulic or electric drives,

and a completely enclosing housing. Force is transmitted to the

mounting structure through bolts. For this purpose through holes

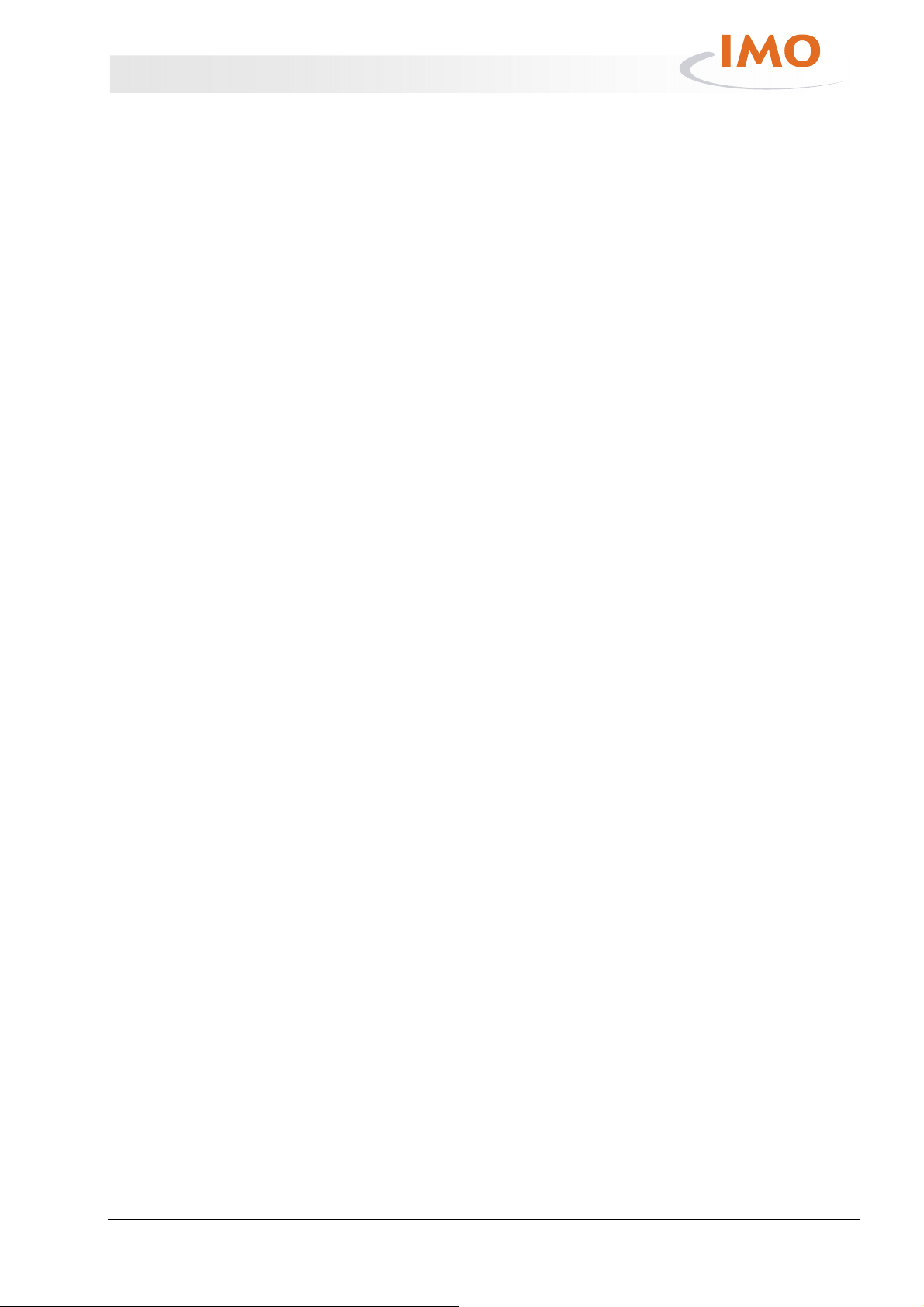

1.2 Overview

1.2.1 WD-L series (light series)

or threads are provided in the inner and outer ring.

Series WD slew drives are designed with worm gear. Series SP

slew drives are designed with spur gear and straight toothing.

The lighter series is designated as the WD-L series. The drive

motor (hydraulic/electric) is optional. Additional optional

components are potentiometers, permanent brake or front-end

brake.

Fig. 1: Slew drive WD-L

1 Connection for options: Potentiometer,

permanent brake or front-end brake

2 Worm shaft

3 Lubricating nipple

4 Ball slewing ring

5 Option: Drive motor

6 Bolted unions for the mounting structure

7 Housing

8 Lubricating nipple

5

Page 6

Slew Drives

Structure and function

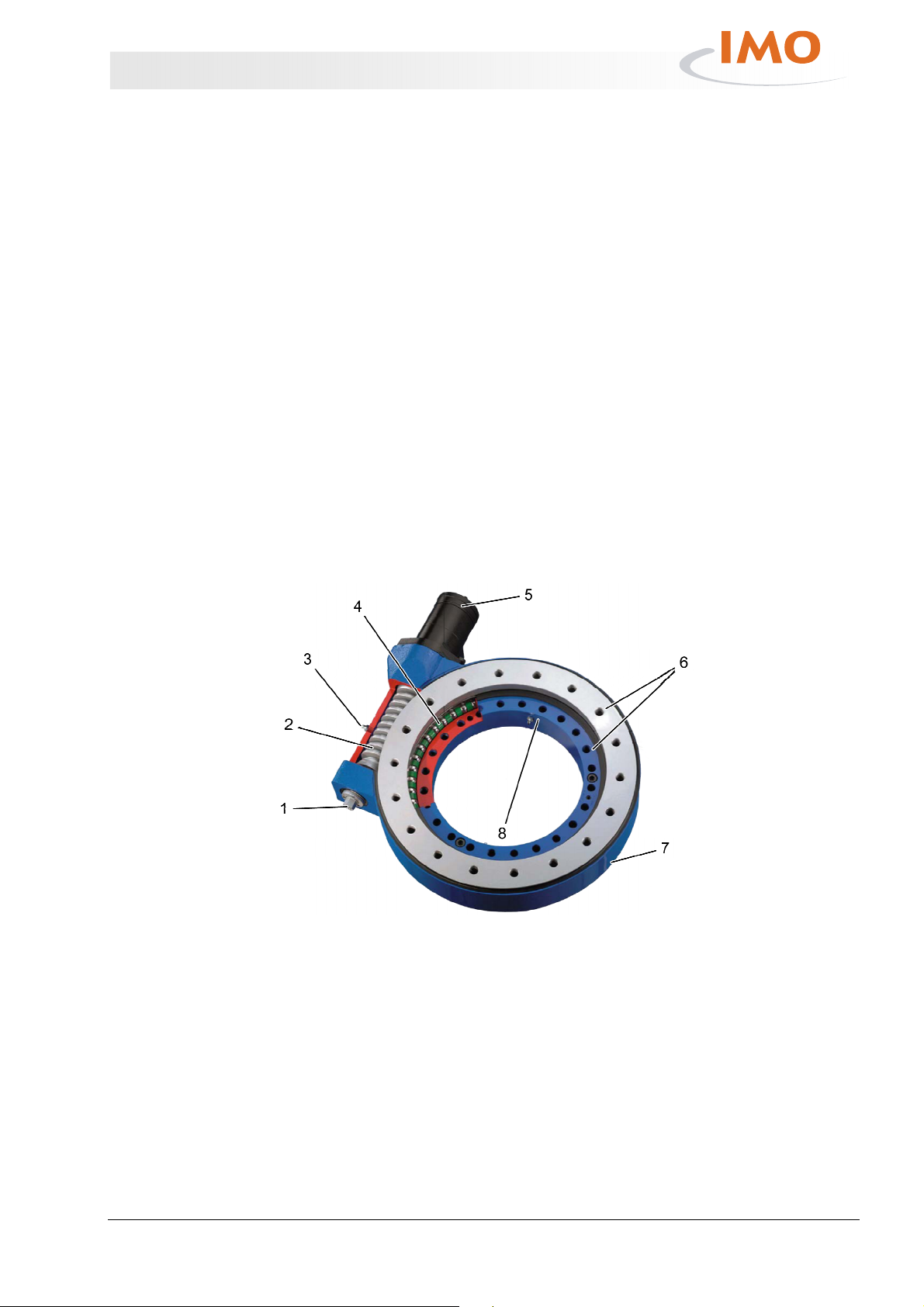

1.2.2 WD-H series (heavy series)

The heavy series is designated as the WD-H series. The drive

motors (hydraulic/electric) are optional. Additional optional

components are potentiometers, permanent brake or front-end

brake.

Fig. 2: Slew drive WD-H

1 Housing

2 Bolted unions for the mounting structure

3 Option: Drive motors

4 Lubricating nipple

5 Worm shaft

6 Roller slewing ring

7 Connection possibility for add-on parts

6

Page 7

Slew Drives

Structure and function

1.2.3 SP series

SP-L, light version

The SP slew drive is powered by a pinion gear unit. The drive

motor (hydraulic/electric) is optional.

Fig. 3: Slew drive SP-L, light version

1 Bolted unions for the mounting structure

2 Housing

3 Drive motors

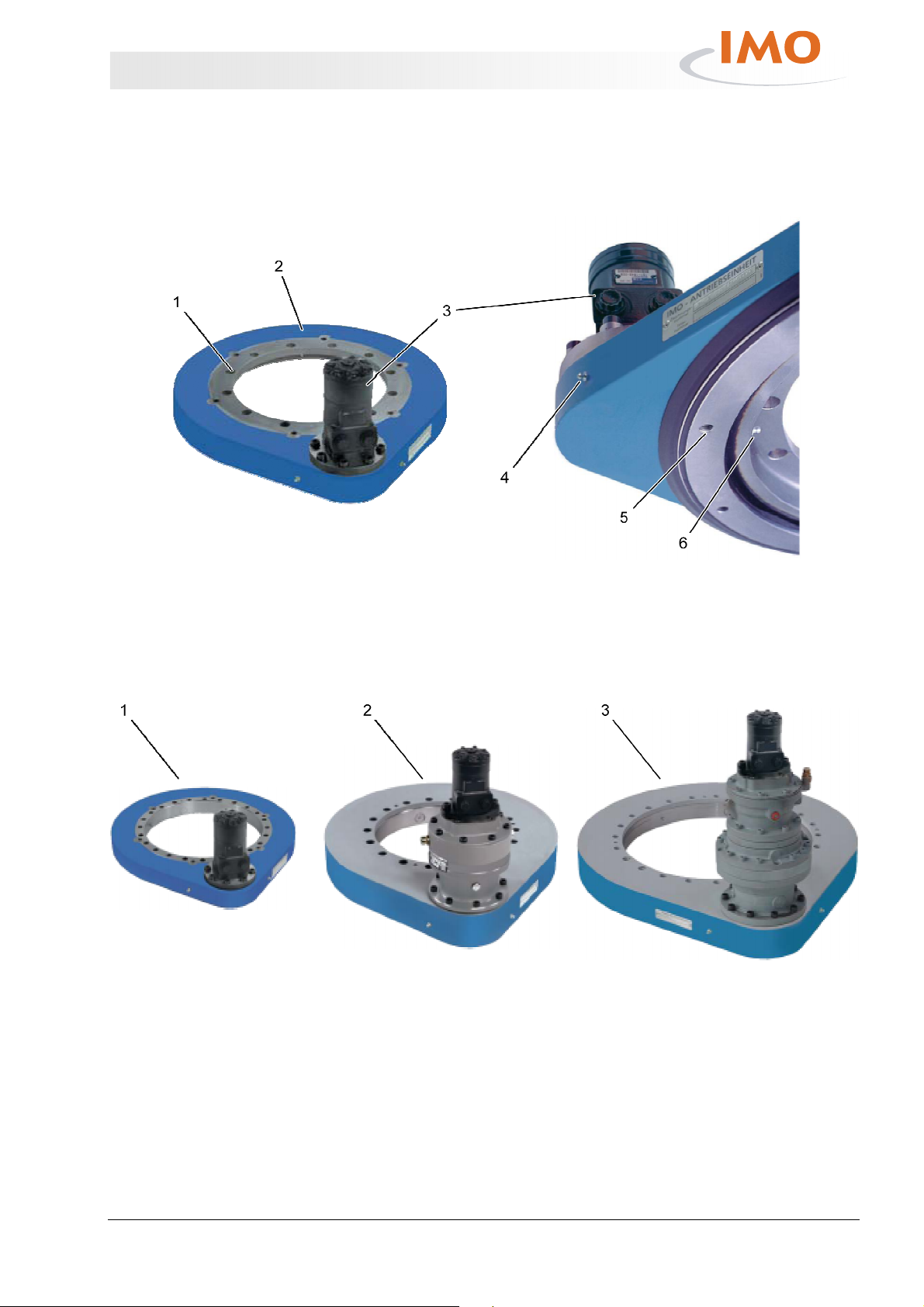

Additional versions

Fig. 4: Additional SP slew drives

1 SP-I, reinforced version

2 SP-M, medium version

3 SP-H, heavy version

4 Lubricating nipple for tooth mesh

5 Bolted unions for the mounting structure

6 Lubricating nipple for raceway

7

Page 8

Slew Drives

Structure and function

1.3 Intended use

WARNING

WARNING

WARNINGWARNING

The component is not designed for use in potentially

explosive atmospheres. Misuse of the component may

cause dangerous situations.

The component has been designed and manufactured exclusively

for the use according to this Installation and Operating Manual.

The slew drive is used

as a drive for generating a rotary movement as well as the

absorption of radial, axial forces and tilting moments. For

example it is used as steering gear for crane undercarriages,

manlift platforms, construction machines, mining and

tunneling.

Modification, retooling, or changing the construction or individual

parts of the equipment with the objective of changing the area of

application or usability of the component is not permitted, as this is

not considered intended use.

Claims of any type due to damage arising from improper use are

excluded.

The customer is solely liable for all damage in the case of improper

use.

8

Page 9

Slew Drives

General

2 General

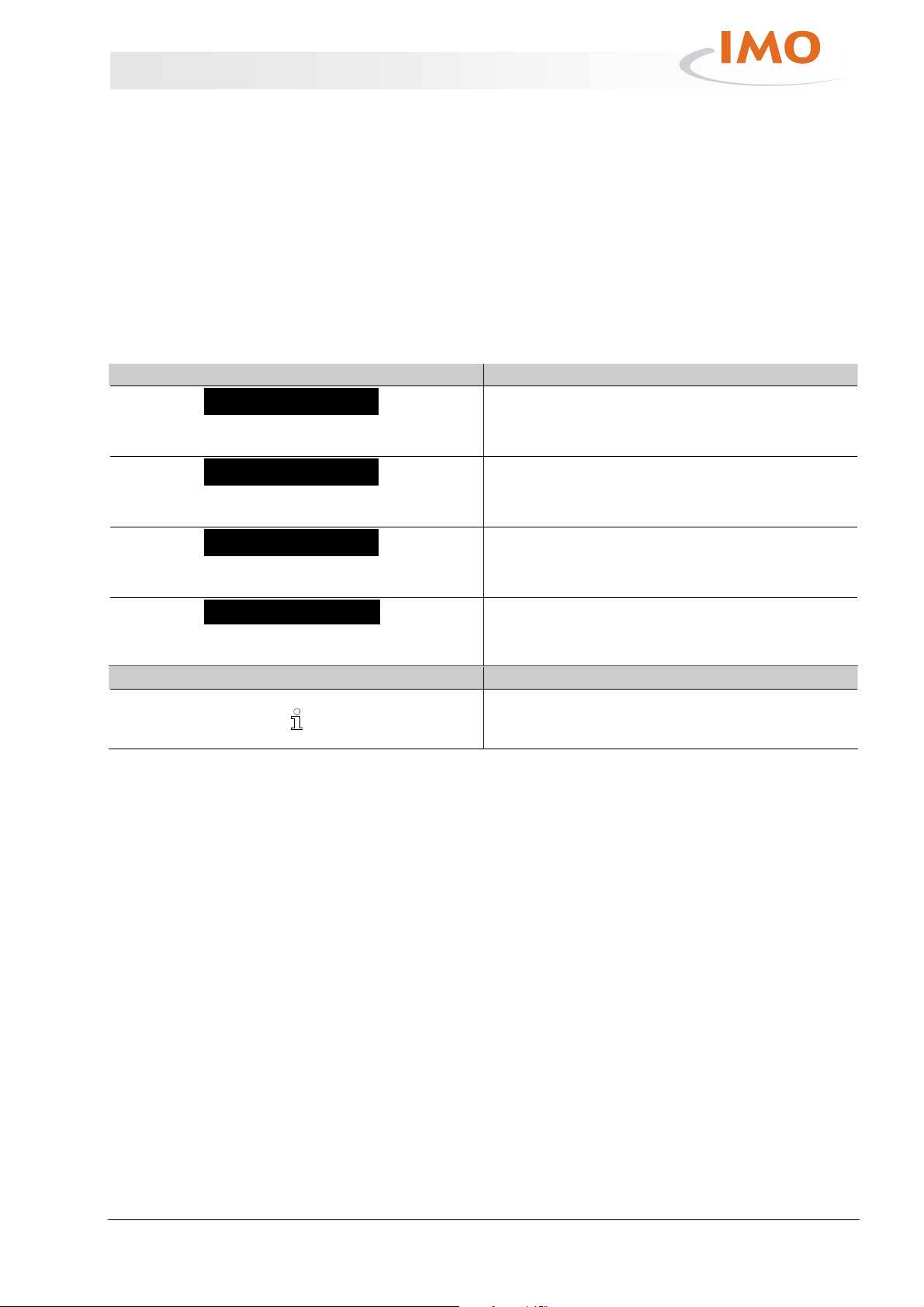

2.1 Explanation of symbols

Warnings

Warnings in this operating manual are indicated by a warning

symbol () and/or signal words. The scope of the hazard is

described by signal words.

The warnings must be strictly heeded; you must act prudently to

prevent accidents, personal injury, and material damage, as well

as life-threatening danger.

Warning symbol / signal word Explanation

DANGER

or

DANGER!

DANGER!

DANGER!DANGER!

WARNING

or

WARNING!

WARNING!

WARNING!WARNING!

CAUTION

or

CAUTION!

CAUTION!

CAUTION!CAUTION!

IMPORTANT

or

IMPORTANT!

IMPORTANT!

IMPORTANT!IMPORTANT!

Indicates an imminent dangerous situation that can

result in death or serious injury if it is not avoided.

Indicates a possible dangerous situation that can

result in death or serious injury if it is not avoided.

Indicates a possible dangerous situation that can

result in minor injury if it is not avoided.

Indicates a possible dangerous situation that can

result in material damage if it is not avoided.

Tips and recommendations Explanation

Indicates useful tips and recommendations as well

as information for efficient and trouble-free

operation.

2.2 Limitation of liability

All information and instructions in this operating manual have been

provided under due consideration of applicable guidelines, the

current state of technology, as well as our many years of

experience.

The manufacturer assumes no liability for damages due to:

Failure to follow the instructions in this manual

Non-intended use

Deployment of untrained personnel

Unauthorized conversions

Technical changes

Use of non-approved spare parts

The actual scope of delivery can vary from the explanations and

graphic representations provided in this manual in the case of

special versions, if supplemental order options are desired, or on

the basis of the latest technical changes.

9

Page 10

Slew Drives

General

2.3 Copyright

In all other respects the agreed obligations in the delivery contract,

the general terms and conditions, as well as delivery conditions of

the manufacturer, and the statutory regulations valid at the time

the contract was concluded, apply.

We reserve the right to make changes in the interest of

enhancements and improvement of the performance

characteristics.

© Copyright 2010, IMO Antriebseinheit GmbH & Co. KG

The information contained in this operating manual and/or in all

parts, sub-sections, or sections of this manual is the intellectual

property of IMO Antriebseinheit GmbH & Co. KG, and is subject to

German and international copyright legislation and other laws that

protect intellectual property.

The information contained in this manual is provided as in aid in

operating, maintaining, and eliminating faults of the units

described here.

2.4 Original IMO parts

WARN

WARNIIIING

WARNWARN

NG

NGNG

Duplication, reproduction, translation, microfilming, storing in

electronic or magnetic form, imitation, or forwarding of these

materials and/or the information contained without the previous

written consent of IMO Antriebseinheit GmbH & Co. KG, is strictly

prohibited.

All rights and legal remedies remain expressly reserved.

Actions to the contrary will be prosecuted.

IMO Antriebseinheit GmbH & Co. KG assumes no liability for

improper use of the information contained here by persons or legal

entities, regardless of the location.

IMO Antriebseinheit GmbH & Co. KG reserves the right at any time

and regardless of reason, to change or modify the information

contained here, as well change and modify the system itself, with

or without prior notice.

Only use original IMO parts! Use of non-authorized, wrong,

or defective spare parts may cause damage, and failures,

or may impair the safety of the device and thus cause

severe or fatal injuries.

Purchase original IMO parts from authorized dealers or direct from

the manufacturer ( page 2).

10

Page 11

Slew Drives

General

2.5 Customer Service

Our customer service is available for technical information

( page 2).

Our employees are always interested in new information and

experiences associated with the application, and which could prove

valuable in improving our products.

11

Page 12

Slew Drives

Safety

3 Safety

3.1 Safety devices

Integration in an emergency-stop

concept is required

3.2 Special dangers

This section provides an overview of all the important safety

aspects for optimal protection of personnel, as well as for safe and

trouble-free operation.

Significant hazards can occur if the handling instructions and

safety instructions in this manual are not complied with.

The component is designed for utilization within a system. It does

not have its own controller and does not have an autonomous

emergency-stop function.

Before the component is placed in service, emergency-stop devices

must be installed on the device and integrated in the safety chain

of the plant control system.

The emergency-stop devices must be connected in such a manner

that dangerous situations for persons and property are excluded in

the event of power supply interruption, or activation of the power

supply after an interruption.

The emergency-stop devices must always be freely accessible.

WARNI

WARNING

WARNIWARNI

Electrical current

Hydraulic system

VCI foil

NG

NGNG

Residual risks are cited in the following section.

Comply with the safety instructions listed here and the

warning instructions in the other chapters of this manual

to reduce health hazards and to avoid dangerous

situations.

DANGER!

DANGER! Only have qualified electricians perform work on

DANGER!DANGER!

electrical components of the system!

Improper installation of components, or improper handling of

electrical equipment may result in injuries and life-threatening

danger.

If insulation is damaged immediately switch off the power supply

and have the system repaired by a qualified electrician!

Keep moisture away from electrical components. Moisture can

cause short circuits.

DANGER!

DANGER! Only have trained, specialized personnel perform work

DANGER!DANGER!

on the hydraulic equipment. De-pressurize the hydraulic system

prior to starting work on the hydraulic system. Completely depressurize the pressure accumulator. Ensure that the system is depressurized. Do not change pressure settings to exceed the

maximum values. Hydraulically powered parts may move

unexpectedly.

Hydraulic energy may cause severe or fatal injuries.

DANGER! Keep out of reach of children and dispose of properly. If

used improperly there is danger of suffocation. Avoid skin and eye

contact with VCI foil. Repeated or longer skin contact may dissolve

skin fat and cause dermatitis.

12

Page 13

Slew Drives

Safety

Moving parts

WARNING! Do not reach into moving parts or handle moving

parts during operation. Do not open covers when the device is in

operation. Pay attention to overtravel time: Prior to opening the

cover ensure that all parts have come to a standstill. Wear tightfitting work clothing in the danger zone. Rotating components

and/or components with linear movements may cause serious

Falling materials

injury!

WARNING! Never enter the danger zones during operation. In

operation heavy material can fall uncontrolled or it may be

Fouling and loose objects

accelerated out of the device and cause severe injuries.

CAUTION! Always keep the work area clean. Remove objects that

are not being used. Mark stumbling hazards with a black/yellow

marking tape. Fouling and loose objects on the ground pose

slipping and stumbling hazards and may cause severe injuries.

3.3 Responsibility of the customer

Customer

The customer is the person or entity that operates the component

himself for commercial or economic purposes, or who transfers the

device to a third person for use/application, and who bears the

legal responsibility for protecting the users or third parties.

The component is used in commercial applications. Consequently

the owner of the component is subject to legal industrial safety

obligations.

In addition to the safety instructions in this manual, generally valid

safety and accident protection guidelines, and environmental

protection guidelines must be heeded and complied with for the

area of implementation of the component. In this regard:

The customer must inform himself of applicable industrial safety

regulations, and in a hazard analysis identify other hazards that

may exist at the installation site of the component due to the

special work conditions. Customer must convert this information

relative to hazards into operating instructions for operation of

the component.

The customer must ensure during the entire period of

component implementation that the operating instructions

created by the customer correspond to the current state of

legislation, and if necessary the customer must adapt these

operating instructions.

The customer must clearly regulate and specify responsibilities

for installation, operation, maintenance, and cleaning.

The customer must ensure that all employees who handle the

component have read and understood this manual.

In addition, customer must train personnel and inform

personnel of the hazards at regular intervals.

The customer must provide the required protective equipment

for personnel.

13

Page 14

Slew Drives

Safety

Moreover the customer is responsible for ensuring that the

component is always in faultless technical condition; consequently

the following applies:

The customer must ensure that the maintenance intervals

described in this operating manual are observed.

The customer must have all safety devices inspected regularly

for function and for completeness.

The seals in the slew drive are subject to a certain amount of

wear. From time to time it is necessary to check the seals for

trouble-free seat and function. However depending on system

runtime it may also be necessary to replace the seals. Thus the

system manufacturer must ensure that sufficient space and

accessibility for inspecting and replacing the seals are available on

the total circumference of the slew drive.

3.4 Personnel requirements

Unauthorized person

WARNING!

WARNING! Unauthorized persons should not enter the work

WARNING! WARNING!

area! Unauthorized persons may cause dangerous

Specialized personnel

situations.

Specialized personnel are personnel who thanks to their specialized

training, skills, and experience, as well as knowledge of the

applicable regulations are capable of executing the tasks assigned

Qualified electrician

to them and of recognizing possible hazards on their own.

...is a person who thanks to his specialized training, skills, and

experience, as well as knowledge of the applicable regulations is

capable of executing work on electrical equipment and of

recognizing possible hazards on his own. The qualified electrician is

especially trained for the work environment in which he is active

and knows all relevant standards and regulations.

In Germany the qualified electrician must meet the requirements

set forth in the accident prevention guideline BGV A3 (e.g. master

electrical contractor). Similar regulations apply in other countries.

3.5 Personal protective equipment

Wearing personal protective equipment is required to minimize the

health hazards when working with the device.

Always wear the protective equipment necessary for the

respective task when working with the device.

Always wear For all tasks always wear:

Follow the instructions that have been posted in the work area.

Protective work clothing

is tight-fitting work clothing with low resistance to tearing, with

tight sleeves, and without projecting parts. It is primarily used as a

protection against entanglement by moving machine parts.

Do not wear rings, chains, or other jewelry.

14

Page 15

Slew Drives

Safety

Safety footwear

for protection against heavy falling parts and slipping on slippery

substrates.

For special tasks wear

Protective gloves

to protect hands from friction, abrasion, puncture wounds, or

deeper injuries, as well as from contact with hot surfaces.

Special protective equipment is required when executing special

tasks. Separate reference is made to this equipment in the specific

sections. This special protective equipment is explained below:

Face protection

to protect the eyes and face from solvents.

Chemical-resistant protective gloves

to protect hands from aggressive substances.

Check protective gloves for leaks prior to use. Clean the gloves

before pulling them off, store them in a well-ventilated location.

15

Page 16

Slew Drives

Transport, packaging, and storage

4 Transport, packaging, and storage

4.1 Safety instructions for transport

WARNI

WARN

IMPORTANT

IMPORTANT

WARNING

WARNIWARNI

WARNIIIING

WARNWARN

4.2 Transport

NG

NGNG

NG

NGNG

Never position yourself under a suspended load! Swinging

or falling parts may cause injury or life-threatening

danger.

Carefully supervise the lifting processes and transport.

Only use the transport methods described here. A lifethreatening crushing hazard exists if the slew drive falls.

Proceed with caution when transporting objects! Comply

with instruction symbols on the packages and only use the

prescribed attachment points. Improper transport may

cause significant damage.

Avoid impact when transporting! Improper transport may

cause significant damage to the component.

Transport by specialized personnel only!

Transporting packages

Packages that are not attached to pallets can be transported with

a forklift or forklift truck under the following conditions:

The forklift or forklift truck must be configured appropriately for

the weight of the transport units.

The operator must be authorized to operate the forklift.

Attachment:

1. Place sufficiently long and wide extensions (e.g. of wood or

metal) between the forks and the package so that the weight

is distributed on the support surface.

2. Drive in the forks, with extensions if needed, far enough that

they protrude on the opposite side.

3. If there is an eccentric center of gravity, ensure that the

package cannot tip.

4. Lift the package and start the transport.

16

Page 17

Slew Drives

Transport, packaging, and storage

Transporting pallets with the

crane

Packages that are attached to pallets can be transported with a

crane under the following conditions:

Crane and hoist must be designed for the weight of the

packages.

The operator must be authorized to operate the crane.

Attachment:

1. Attach ropes, straps, or multi-point suspensions to the pallet as

shown in Fig. 5 and ensure that they cannot slip.

2. Ensure that the packages cannot be damaged by the lifting

tackle. Use other lifting tackle if necessary.

3. Start the transport.

Fig. 5 Transporting with the crane

Transporting pallets with the

forklift

Packages that are attached to pallets can be transported with a

forklift under the following conditions:

The forklift must be configured appropriately for the weight of

the transport units.

The operator must be authorized to operate the forklift.

Attachment:

1. Drive the forklift with the forks between or under the spars of

the pallet.

2. Drive in the forks until they protrude on the opposite side.

3. If there is an eccentric center of gravity, ensure that the pallet

cannot tip.

4. Lift the package and start the transport.

Fig. 6 Transporting with the forklift

Transporting unpacked slew drives

Fig. 7: Use suitable lifting gear/never transport product vertically

17

Page 18

Slew Drives

Transport, packaging, and storage

Unpacked slew drives can be transported with lifting gear when

using eye bolts under the following conditions

The lifting gear must be configured appropriately for the

weight of the transport units.

The ring bolts must be configured appropriately for the weight

of the transport unit.

The slew drive shall only be transported by itself, without

attached parts.

Maintain the insertion depth prescribed by the manufacturer.

If insertion depth is not prescribed, then a minimum insertion

depth of 1.5 x the bolt diameter must be selected.

Transport within the company shall only be executed

horizontally.

Attachment:

1. Screw the 3 eye bolts into the 3 threads that are distributed

uniformly on the circumference of the slew drive.

WARNING!

WARNING! Screw in the eye bolts to the full thread length!

WARNING!WARNING!

Improperly attached, unsuitable, or damaged eye bolts

may cause the slew drive to fall and cause life-threatening

injuries.

2. Attach lifting gear to the eye bolts.

3. Start the transport.

Fig. 8: Always use the full length of the

thread

4.3 Transport inspection/incoming goods inspection

Check delivery immediately upon receipt to ensure that delivery is

complete, and to identify any transport damage.

Proceed as follows if there is apparent external damage:

Do not accept the delivery, or only accept it with reservation.

Note the extent of transport damage on the transport

documents or on the transport company's delivery ticket.

Submit a complaint.

Report any defect within 2 days of delivery of goods. Claims for

damage compensation can only be enforced during this period

of notification.

18

Page 19

Slew Drives

Transport, packaging, and storage

4.4 Packaging

Packaging

The individual boxes are packaged according to the expected

transport conditions. Only environmentally-friendly materials have

been used for the packaging.

The packaging is designed to protect the individual components

against transport damage, corrosion, and other damage until

installation. Therefore do not damage the packaging; remove it

just before installation.

If parts are not installed within the agreed storage period, then

the customer must ensure that an appropriate preservation

agent is applied to these parts.

Unless otherwise agreed, it is assumed that the parts will be

Handling packaging materials

used within 8 weeks.

If a separate agreement regarding handling of the packaging has

not been concluded, then separate the materials according to type

and size, and keep them on hand for subsequent use, or recycle.

IMPORTANT!

environmentally responsible manner. Environmental

damage may be caused by improper disposal.

4.5 Symbols on the packaging

No user serviceable parts inside!

Unauthorized opening of the slew

drive voids the manufacturer's

warranty.

If packed in foil:

Danger!

Choking and asphyxiation hazard!

This bag is not a toy!

Keep away from children!

Dispose of packaging materials in an

19

Page 20

Slew Drives

Transport, packaging, and storage

4.6 Storage

Storage of packages

Fig. 9: Ensure protective storage

Fig. 10: Do not store vertically

Only store packages under the following conditions:

Do not store outdoors.

Store in a dry and dust-free location.

Do not expose to aggressive media.

If stacking, use stable intermediate layers.

Protect from direct sunlight.

Avoid mechanical vibration.

Storage temperature: >5° C (>41° F) to 40° C (104° F).

Relative humidity: < 65 %.

Do not store vertically.

For longer periods of storage (> 2 months) regularly check the

general status of the packages. Touch up or re-apply anticorrosion agents as needed.

The anti-corrosion protection period is 12 months, if the

aforementioned storage requirements are observed. We recommend

to re-apply the preservation after 12 months.

Please refer to tab. 1 below for anti-corrosion agents.

Recommended anti-corrosion agents

Manufacturer Product name

Cortec VpCITM -329 ≥ 12 months

Fuchs Europe

Schmierstoffe GmbH

Schramm Molecular Nato-Fluid-C634 ≥ 12 months

Pos: 5.35 /KN2006-SM/nL---------- Absc hnittsende ------- --- @ 8\mod_114 1997892953_0 .doc @ 75471

Tab. 1

Long-term preservation is possible for storages which are planned for

several years and can already be discussed during the technical

consultation. Re-application of anti-corrosion agents as well as initial

greasing can be performed by our customer service ( page 2) prior

to operation.

Greased slew drives shall not be stored for a longer period than 3

years. Greases can change their chemical-physical behaviour

during storage. Grease provisions can be diminished by a storage

period of more than 3 years. The storage of slew drives shall not

exceed 1 year if food lubricants are used.

Period of

anticorrosion

protection

Anticorit OHK-F ≥ 12 months

Under certain circumstances storage instructions are affixed to the

packages that go beyond the requirements cited here. Comply

with these instructions accordingly.

20

Page 21

Slew Drives

Installation and commissioning

5 Installation and commissioning

5.1 Safety

DANGER

WARN

WARNI

WARNI

IMPORTANT

IMPORTANT

IMPORTANT

DANGER

DANGERDANGER

WARNIIIING

WARNWARN

WARNING

WARNIWARNI

WARNING

WARNIWARNI

NG

NGNG

NG

NGNG

NG

NGNG

Prior to starting work switch off all energy supplies and

safeguard them from being switched on again. If the

power supply is switched on by unauthorized personnel, a

life-threatening danger exists for persons in the danger

zone.

Prior to starting work ensure that there is adequate free

space for installation. Handle open, sharp-edged

components carefully. Ensure order and cleanliness at the

installation location! Parts and tools that are lying loose or

on top of each other are accident hazards! Mount

components properly. Maintain the prescribed bolt torque

and fastening torque. Secure the components so that they

do not fall down or fall over. Improper installation and

commissioning may cause serious personal injury and/or

property damage.

Never position yourself under a suspended load! Swinging

or falling parts may cause injury or life-threatening

danger.

Carefully supervise the lifting processes and transport.

Only use the transport methods described here. A lifethreatening crushing hazard exists if the components fall.

Proceed with caution when transporting objects! Comply

with instruction symbols on the packages and only use the

prescribed attachment points. Improper transport may

cause significant damage.

Avoid impact when transporting! Improper transport may

cause significant damage.

Seals shall not be overpainted! Overpainting may cause

significant damage.

IMPORTANT

Prevent damage to coating and painting of slew drives.

Please refer to our customer service ( page 2), if the

coating is damaged.

Follow the instructions provided in the operating manuals for

the drive motors (hydraulic or electric), as well as the

instructions provided with the optional potentiometer or

Personnel

permanent brake.

Only trained, skilled personnel should perform installation and

commissioning work.

21

Page 22

Slew Drives

Installation and commissioning

Personal protective equipment

Wear the following protective equipment for all installation and

commissioning work:

Protective work clothing

Safety footwear

Protective gloves

The warnings in this chapter make special reference to

additional protective equipment that is required for certain

tasks.

5.2 Preparation

5.2.1 Lubricating prior to commissioning

Slew drives have been lubricated in the factory prior to delivery.

Nevertheless, prior to commissioning the slew drive must be

5.2.2 Cleaning the slew drive and mounting structure

lubricated ( section 6.4.4 "Lubricating the slew drive").

Wear the following additional protective equipment for cleaning

work:

Face protection

to protect the eyes and face from solvents.

Fig. 11: Do not let cleaning agents get

into the slew drive

Chemical-resistant protective gloves

to protect hands from aggressive substances.

Check protective gloves for leaks prior to use. Clean the gloves

before pulling them off, store them in a well-ventilated location.

Cleaning:

IMPORTANT!

Only use cold solvents (e.g. white spirit,

diesel oil, Kaltryl KEV) that do not corrode the sealing

material. Ensure that the cleaning agent does not get into

the slew drive. Do not use a high-pressure cleaner to clean

the slew drive. Unsuitable trichloroethylene-based or

perchloroethylene-based cleaning agents, or other

aggressive cleaners damage the seal and may cause

bearing damage.

22

Page 23

Slew Drives

Installation and commissioning

When using cleaning agents, ensure adequate ventilation.

Maintain a strict ban on smoking.

Remove old grease, dust, and fouling with lint-free cloths.

Remove foreign material from the support surface of the

mounting structure (including paint residue, welding beads,

burrs).

If necessary clean the support surface of the slew drive.

Strictly comply with industrial safety regulations.

Fig. 12: Cleaning

5.2.3 Determination of flatness deviation, and perpendicularity deviation and

deformation of the mounting structure

Determination of flatness deviation, and perpendicularity deviation of the mounting structure

IMPORTANT

If there are impermissibly high deviations in flatness and

perpendicularity in the mounting structure, then rotational

resistance of the slew drive may significantly increase and

damage the entire slew drive. In the worst case the slew

drive may block.

If the permissible values for flatness or perpendicularity

deviation are exceeded, the mounting structure of the

slew drive shall be replaced or reworked.

The mounting structure can be measured using a measuring plate

and dial gauges.

Laser processes and measuring with 3D systems have also proven

to be effective. These systems can be used without additional

auxiliary material, and they can document the actual gradient of

the mounting structure and process it accordingly.

Flatness deviation

Fig. 13: Flatness deviation

23

Page 24

Slew Drives

Installation and commissioning

δp = flatness deviation

max. δp = maximum flatness deviation

U = circumference

The maximum residual value for flatness deviation δp in

the circumferential direction should only be reached once

on half of the circumference. The gradient must look like a

sinus curve that slowly rises or falls.

Abb. 14: Permissible flatness deviation of

the mounting structure

Perpendicularity deviation

Fig. 15: Perpendicularity deviation

δw = perpendicularity deviation

B = flange width

The permissible perpendicular deviation δw (tilting) is based on

the actual flange width and should only be half of the values

from the tables below.

The size of the slew drive (WD-H) or of the running circle diameter

DL (WD-L/SP) is indicated in the drawing number at position (1)

and is shown in all documents and the type plate.

Fig. 16: Drawing number

For slew drives that are between the specified sizes, always

assume the smaller value. For slew drives that are larger than

the largest diameter, use the largest specified value.

The slew drive must be supported by the mounting structure up

24

to the diameter specified in the slew drive drawing.

Page 25

Slew Drives

Installation and commissioning

Permissible flatness and perpendicularity deviation for series WD-L and SP slew drives

Running circle diameter [mm] ≥100 ≥250 ≥500 ≥750 ≥1000 ≥1250

Permissible flatness deviation

including perpendicularity

deviation per support surface

Tab. 2

Permissible flatness and perpendicularity deviation for series WD-H slew drives

Size of the slew drive ≥146 ≥220 ≥300 ≥373 ≥490 ≥625

Permissible flatness deviation

including perpendicularity

deviation per support surface

Tab. 3

Determining the deformation of the mounting structure

[mm] 0.04 0.06 0.08 0.09 0.10 0.11

[in] 0.0016 0.0024 0.0032 0.0036 0.0040 0.0044

[mm] 0.06 0.06 0.07 0.07 0.08 0.09

[in] 0.0024 0.0024 0.0028 0.0028 0.0032 0.0036

Under maximum operating load an appropriate deformation of the

mounting structure occurs. The dimensions can be detected via

dial gauges, laser measurement processes, or 3D measuring

systems.

Because in some cases measurement in operation is difficult,

determination of deformation can also be executed

mathematically, e.g. with the finite element method.

Alternatively you can also reference comparable measurements on

test rigs.

For slew drives that are between the specified sizes, always

assume the smaller value. For slew drives that are larger than

the largest diameter, use the largest specified value.

The slew drive must be supported by the mounting structure up

to the diameter specified in the slew drive drawing. All the

installed dimensions as specified in the drawing must be

complied with.

Permissible deformation of the mounting structure, under maximum load for series WD-L and

SP slew drives

Running circle diameter [mm] ≥100 ≥250 ≥500 ≥750 ≥1000 ≥1250

Permissible deformation of the

[mm]

0.13 0.16 0.21 0.24 0.27 0.29

mounting structure per support

surface

[in] 0.0052 0.0063 0.0083 0.0095 0.0106 0.0114

Tab. 4

Permissible deformation of the mounting structure, under maximum load for series WD-H slew

drives

Size of the slew drive ≥146 ≥220 ≥300 ≥373 ≥490 ≥625

Permissible deformation of the

[mm] 0.10 0.11 0.12 0.13 0.15 0.16

mounting structure per support

surface

[in] 0.0040 0.0044 0.0048 0.0052 0.0059 0.0063

Tab. 5

25

Page 26

Slew Drives

Installation and commissioning

IMPORTANT

Axial deflection, tilting, radial extension (or radial

contraction) of the mounting structure under max. load

causes deformation of the mounting structure.

5.2.4 Selecting the mounting elements

CAUTION

CAUTION

CAUTIONCAUTION

Fig. 17: Do not use continuous thread

Only use mounting elements of the correct size, number

and quality. Do not reuse bolts, nuts, and washers. Using

unsuitable mounting elements may cause the bolted union

to fail and thus the entire construction to fail.

The function and service life, as well as the durability of the bolted

union are highly dependent on grip ratio, the type of bolt, and the

dimensions of the bolts. Consequently select the mounting

elements on the basis of the following:

Do not use any bolts with a fully threaded shaft.

Only use new, quality class 10.9 (metric) bolts or SAE Grade 8.

Maintain the grip ratio (grip length to the diameter of the bolt)

of at least ≥ 5 to maximum ≤ 10.

Select bolt length to ensure that the minimum insertion depth is

reached ( Tab. 6).

If the permissible interfacial pressure is exceeded use

appropriate washers ( Tab. 7).

If the specifications cannot be satisfied, please contact our

customer service ( page 2).

Minimum bolt insertion depth depending on fracture

strength of the mounting structure

Fracture strength Rm of the

mounting structure

in N/mm² in lbf/in²

Minimum insertion depth

(le)

Strength class

10.9 / Grade 8

500 to 700 72520 to 101525 le = 1.4*ds

700 to 900 101525 to 130535

le = 1.1*ds

over 900 over 130535 le = 0.9*ds

Tab. 6

Fig. 18: Mounting element

Mounting structures with fracture strength under 500 N/mm² or

72520 lbs/in² are prohibited.

ds = bolt diameter

lk = grip length

le = insertion depth

Permissible interfacial pressure for various materials

Material Max. surface pressure

in N/mm² in lbs/in²

St52/C45N/46Cr2N 600 87023

46Cr4V/42CrMo4V 800 116030

Tab. 7

26

Page 27

Slew Drives

Installation and commissioning

5.2.5 Tightening bolts with a torque wrench

Normally the mounting bolts are adequately secured through

WARNI

IMPORTANT

WARNING

WARNIWARNI

NG

NGNG

correct pretension.

Do not use impact screwdrivers. Using an impact

screwdriver may cause impermissible deviations between

the bolt tightening forces. Failure of the bolted union with

the mounting structure may cause severe personal injury

or material damage.

If there are shock loads or vibration additional screwlocking devices may be necessary. In this case use Loctite

or Nord-Lock® bolt lock washers.

Do not use split rings, spring washers, etc.

Do not reuse bolts, nuts, and washers, etc.

Only use hardened and tempered washers.

Adjust the limit torque in accordance with bolt size and quality.

Use a precisely indicating torque wrench.

Tightening torques and bolt tightening forces for metric

coarse-pitched thread in accordance with DIN 13 when

using a torque wrench:

Mounting

Tightening torque

bolt

dimensions

Strength class 10.9

MA 1)

in

Mounting pretension

force

FM 2)

Strength class 10.9

in

Nm ft-lbs kN lbs

M4 3.31 2.44 5.95 1338

M5 6.77 4.99 9.74 2190

M6 11.5 8.5 13.7 3080

M8 28.0 20.6 25.2 5665

M10 55.8 41.2 40.2 9037

M12 97.7 72.1 58.5 13151

M16 246 181 111 24954

M18 336 248 134 30124

M20 481 355 173 38892

M22 661 487 216 48559

M24 830 612 249 55977

M27 1230 907 328 73737

M30 1661 1225 398 89474

Tab. 8

1)

MA in accordance with VDI guideline 2230 (February 2003) for

µK=0.08 and µG=0.12

2)

FM in accordance with VDI guideline 2230 (February 2003) for

µG=0.12

27

Page 28

Slew Drives

Installation and commissioning

Tightening torques and bolt tightening forces for inch

thread in accordance with ANSI B1.1 when using a torque

wrench:

Mounting bolt

0.1900 – 24 UNC

0.2160 – 24 UNC

Tab. 9

1)

MA in accordance with VDI guideline 2230 (February 2003) for

µK=0.08 and µG=0.12

2)

FM in accordance with VDI guideline 2230 (February 2003) for

µG=0.12

dimensions

Tightening torque

MA 1)

Strength class

Grade 8

in

Mounting

pretension force

FM 2)

Strength class

Grade 8

in

Nm ft-lbs kN lbs

4.80 3.54 7.15 1607

7.69 5.67 10.1 2271

1/4 – 20 UNC 11.7 8.6 13.2 2967

5/16 – 18 UNC 24.4 18.0 22.1 4968

3/8 – 16 UNC 43.7 32.2 33.0 7419

7/16 – 14 UNC 70.1 51.7 45.4 10206

1/2 – 13 UNC 108 80 61.0 13713

9/16 –12 UNC 156 115 78.6 17670

5/8 – 11 UNC 216 159 97.8 21986

3/4 – 10 UNC 386 285 146 32822

7/8 – 9 UNC 625 461 202 45411

1 – 8 UNC 938 692 266 59799

1 1/8 – 7 UNC 1328 979 334 75086

1 1/4 – 7 UNC 1889 1393 428 96218

For mounting bolts from M30 or 1 1/8 - 7 UNC use a hydraulic

bolt-tensioning cylinder ( chapter 5.2.6 "Tightening bolts with

a hydraulic bolt-tensioning cylinder").

When using bolts with fine-pitched thread or other bolt sizes or

qualities, please contact our customer service ( page 2).

For further information about bolts, please refer to the IMO

main catalogues.

5.2.6 Tightening bolts with a hydraulic bolt-tensioning cylinder

Comply with the instructions provided in the operating manual

for the hydraulic fixture! The operating manual for the hydraulic

bolt-tensioning cylinder specifies how the hydraulic pressure is

converted to the pretension force.

28

Page 29

Slew Drives

Installation and commissioning

WARNI

IMPORTANT

WARNING

WARNIWARNI

NG

NGNG

The prescribed hydraulic pressure should not be exceeded

when pretensioning the bolts. Excess hydraulic pressure

may cause failure of the bolted union with the mounting

structure and may cause severe personal injury or material

damage.

When using other threaded bolts or other strength classes

you have to contact our customer service ( page 2).

Bolt tension forces when using a hydraulic bolt-tensioning

cylinder for metric coarse-pitched thread in accordance

with DIN 13:

Tab. 10

1)

FM for hydraulic bolt-tensioning cylinder pretensioned to 85% of

yield strength

Mounting bolt

dimensions

Mounting pretension force

FM 1)

Strength class 10.9

in

kN lbs

M24 282 63396

M27 367 82505

M30 448 100714

M33 554 124544

M36 653 146800

M42 896 201429

M45 1043 234476

M48 1177 264600

M52 1405 315857

M56 1622 364640

M60 1887 424215

M64 2138 480642

M68 2441 548759

Bolt tension forces when using a hydraulic bolt-tensioning

cylinder for inch thread in accordance with ANSI B1.1:

Mounting bolt

dimensions

Mounting pretension force

FM 1)

Strength class 10.9

in

kN lbs

1 – 8 UNC 301 67668

1 1/8 – 7 UNC 379 85203

1 1/4 – 7 UNC 481 108133

1 3/8 – 6 UNC 573 128816

1 1/2 – 6 UNC 697 156692

1 5/8 – 6 UNC 832 187041

1 3/4 – 5 UNC 942 211770

29

Page 30

Slew Drives

Installation and commissioning

Tab. 11

1)

FM for hydraulic bolt-tensioning cylinder pretensioned to 85% of

yield strength

5.3 Installing the slew drive

5.3.1 Hardness gap

The hardness gap occurs with the raceway hardening and is

located between the end and the beginning of the hardening.

For the WD-L series the hardness gap must be arranged with an

offset by 90° relative to the main load-carrying zone. The hardness

gap is marked by a filling plug or a stamped "S".

1 Main load-carrying zone

2 Filling plug or S-mark

2 – 4.5 UNC 1239 278538

2 1/4 – 4.5 UNC 1608 361493

2 1/2 – 4 UNC 1981 445347

2 3/4 – 4 UNC 2442 548984

Fig. 19: Hardness gap marking

5.3.2 Positioning the slew drive

Fig. 20: Main load-carrying zone

1 Hardness gap

2 Main slewing range

3 Main load-carrying zone

1. Determine the main load-carrying zone.

The main load-carrying zone is that area of the slewing ring

that is subject to the highest load, taking all aggressive forces

and torques, and all occurring load cases into account.

30

Page 31

Slew Drives

Installation and commissioning

2. Arrange the hardness gap ( section 5.3.1 "Hardness gap") of

CAUTION!

CAUTION! The hardness gap or the filling plug in a slewing

CAUTION!CAUTION!

ring constitute a zone of decreased load-carrying capacity.

The service-life of the slew drive will be reduced

significantly, if the hardness gap is in the main slewing

range. Fracture of bearing ring for example may cause

slew drive failure. Consequently place this marked point in

a reduced load zone if possible.

3. Use a feeler gauge to check whether the support surface of the

the bearing ring charged with point load so that it is offset by

90° relative to the main load-carrying zone. The main loadcarrying zone is in the main slewing range.

slew drive is completely supported by the mounting structure. If

this is not the case, the support surface of the mounting

structure must be reworked ( section 5.2.3 "Determining

flatness deviation, and perpendicularity deviation and

deformation").

Fig. 21: Check the support surface

5.3.3 Bolting the slew drive

WARNI

WARNING

WARNIWARNI

NG

NGNG

Do not use impact screwdrivers. Using an impact

screwdriver may cause impermissible deviations between

the bolt tightening forces. Failure of the bolted union with

the mounting structure may cause severe personal injury

or material damage.

Mount the slew drive in unstressed state.

Strictly comply with the procedure specified below to avoid

impermissible deviations between the bolt tightening forces:

First fasten the housing, then fasten the toothed bearing ring!

1. Lightly oil the bolt thread (not when using bolt locking devices

with adhesive).

2. Pretension the bolts, with washers if required, crosswise in 3

steps, 30%, 80%, and 100% of the tightening torque, or the

hydraulically applied pretension force.

3. In this process turn the unscrewed ring several times. Repeat

the procedure for the bearing ring that has not yet been bolted.

If using a hydraulic bolt-tensioning cylinder the tensioning forces

for the bolt pretension should not exceed 90% of yield strength

( Tab. 10 and 11).

Fig. 22: Tighten crosswise

31

Page 32

Slew Drives

Installation and commissioning

The end customer or the operating company must be instructed

Tightening torque MA in Nm with incremental tightening

Tab. 12

Tightening torque MA in Nm with incremental tightening

Tab. 13

which tightening process was used. The process must also be

used when servicing the unit to check the bolted union.

Mounting bolt

dimensions

Step 1

30%

Tightening torque MA in Nm

Step 2

80%

Step 3

100%

Strength class 10.9

M6 3.50 9.20 11.5

M8 8.40 22.4 28.0

M10 16.7 44.6 55.8

M12 29.3 78.2 97.7

M16 73.8 197 246

M20 144 385 481

M24 249 664 830

M30 498 1329 1661

Mounting bolt

dimensions

Step 1

30%

Tightening torque MA in Nm

Step 2

80%

Step 3

100%

Strength class SAE Grade 8

1/4 - 20 UNC 3.50 9.30 11.6

5/16 - 18 UNC 7.30 19.4 24.3

3/8 - 16 UNC 13.1 34.9 43.6

7/16 - 14 UNC 21.1 56.2 70.2

5/8 - 11 UNC 64.4 172 215

3/4 - 10 UNC 115 308 385

7/8 - 9 UNC 187 498 622

1 1/8 - 7 UNC 397 1060 1324

32

Page 33

Slew Drives

Installation and commissioning

5.3.4 Determining the tilting clearance

Tightening torque MA in ft-lbs with incremental tightening

Mounting bolt

dimensions

Tab. 14

Tightening torque MA in ft-lbs with incremental tightening

Mounting bolt

dimensions

1/4 - 20 UNC 2.60 6.90 8.60

5/16 - 18 UNC 5.40 14.4 18.0

3/8 - 16 UNC 9.70 25.8 32.3

7/16 - 14 UNC 15.6 41.6 52.0

5/8 - 11 UNC 47.7 127 159

3/4 - 10 UNC 85.5 228 285

7/8 - 9 UNC 138 369 461

1 1/8 - 7 UNC 294 785 981

Tab. 15

Step 1

30%

Step 2

80%

Step 3

100%

Tightening torque MA in ft-lbs

Strength class 10.9

M6 2.50 6.80 8.50

M8 6.20 16.5 20.7

M10 12.3 33.0 41.2

M12 21.6 57.6 72.0

M16 54.3 145 181

M20 107 284 355

M24 184 490 612

M30 368 980 1225

Step 1

30%

Step 2

80%

Step 3

100%

Tightening torque MA in ft-lbs

Strength class SAE Grade 8

Tilting clearance increases as raceway system wear increases. To

determine the increase in tilting clearance a basic measurement

must be executed in installed status and prior to first-time

operation. This is the only way to determine changes.

1 Upper mounting structure

2 Tilting direction

3 Main load-carrying zone

4 Lower mounting structure

Fig. 23: Determine tilting clearance

33

Page 34

Slew Drives

Installation and commissioning

1 Dial gauge

2 Upper mounting structure

3 Slew Drive

4 Lower mounting structure

Fig. 24: Measurement setup

Procedure: Tilting clearance measurement

1. Switch off the system and safeguard it from being turned on

again.

2. Permanently mark the measuring point in the main load

direction on the housing and on the bearing ring.

3. Attach the dial gauge as shown in Fig. 24.

4. Apply defined tilt torque, at least 50% of max. operating load,

in direction "A".

5. Set dial gauge to zero.

6. Apply defined tilt torque, at least 50% of max. operating load,

in direction "B".

The displayed measured value m1 corresponds to the existing

tilting clearance and serves as the base value that will be used

for comparison in later inspections.

7. Log and document all measured values.

All inspections at a later point in time must be executed on the

same measuring point, with the same loads, at the same

relative position of the bearing rings, and in the same

sequence.

At pure axial or radial load check the tilting clearance by

applying an additional tilting load.

5.3.5 Determining the circumferential backlash

Toothing wear causes increased circumferential backlash.

Consequently it is necessary to check circumferential backlash in

accordance with the maintenance intervals ( section 6.3

34

IMPORTANT

"Maintenance schedule").

Do not exceed the specified values for the circumferential

backlash angle of the worm shaft ( Tab. 18). Exceeding

the specified values may result in failure of the slew drive

and damage to the connecting components.

1. Switch off the system and safeguard it from being restarted.

2. Determine the measuring point in the main load-carrying zone,

both on the housing as well as on the worm gear or on the

toothed ring and permanently mark these points.

Page 35

Slew Drives

Installation and commissioning

3. Remove the drive with the goal of ensuring that the worm shaft

4. Determine the circumferential backlash angle of the worm shaft

The determined measured value serves as the comparison

can be freely and easily moved by hand.

If using a front-end brake (flanged-mounted between

motor and slew drive):

Remove front-end brake and motor ( Operating

manual for the front-end brake and motor).

If using a brake that is bolted to the slew drive opposite

side of the motor:

Vent brake ( Operating manual for the brake).

If using a permanent brake (series WD-L):

Remove brake ( Operating manual for the permanent

brake)

in the area in which the worm gear is meshed the majority of

the time.

value for subsequent checks.

5.4 Function test

Limit values, see section 6.4.3 "Checking the circumferential

backlash".

Log and document the measured values.

All measurements at a later point in time must be performed on

the same measuring point.

The slew drive must rotate uniformly. Deviations in the mounting

structure as well as the influence of exterior loads can significantly

affect the friction torque.

1. Turn the mounted slew drive several complete revolutions.

2. Check whether the slew drive turns uniformly and without

jerking.

3. Perform additional test runs under full load.

4. After the function test, check the tightening torque of the

mounting bolts.

35

Page 36

Slew Drives

Maintenance

6 Maintenance

6.1 Safety

DANGER

WARN

Personnel

Personal protective equipment

Environmental protection

DANGER

DANGERDANGER

WARNIIIING

WARNWARN

NG

NGNG

Follow the instructions provided in the operating manuals for

the drive motors (hydraulic or electric), as well as the

instructions provided for the optional potentiometer or

permanent brake.

Prior to starting work switch off all energy supplies and

safeguard them from being switched on again. When

performing maintenance tasks there is danger of the

energy supply being switched on without authorization.

This poses a life-threatening hazard for persons in the

danger zone.

Prior to starting work ensure that there is adequate free

space for installation. Ensure order and cleanliness at the

installation location! Parts and tools that are lying loose or

on top of each other are accident hazards! If components

have been removed, ensure that they are properly reinstalled, that all fastening elements are re-installed, and

that all threaded connections are tightened with the

specified torque. Improper maintenance may cause

serious injury or property damage.

Only qualified, specialized personnel shall perform maintenance

and inspection work.

Only qualified electricians should perform work on the electrical

equipment.

Wear the following personal protective equipment for all

maintenance work:

Protective work clothing

Protective gloves

Safety footwear

Comply with the following instructions for environmental protection

when performing maintenance work:

At all lubricating points where lubricant is applied by hand,

remove escaping, used, or excess grease, and dispose of it in

accordance with applicable local regulations.

Collect hydraulic fluids and oils in suitable containers and

dispose of these substances in accordance with applicable local

regulations.

36

Page 37

Slew Drives

Maintenance

6.2 Cleaning

IMPORTANT

Use cold solvent (e.g. white spirit, diesel oil, Kaltryl KEV)

that does not corrode the sealing material. Ensure that the

cleaning agent does not get into the slew drive. Do not use

a high-pressure cleaner to clean the slew drive. Unsuitable

trichloroethylene-based or perchloroethylene-based

cleaning agents, or other extremely aggressive cleaners

damage the seal and may cause bearing damage.

Wear the following additional protective equipment for cleaning

work:

Face protection

to protect the eyes and face from solvents.

6.3 Maintenance schedule

Chemical-resistant protective gloves

to protect hands from aggressive substances.

Check protective gloves for leaks prior to use. Clean the gloves

before pulling them off, store them in a well-ventilated location.

When using cleaning agents, ensure adequate ventilation.

Remove old grease, dust, and fouling with lint-free cloths.

Maintenance tasks are described in the sections below that are

required for optimal and trouble-free operation.

If increased wear is detected during regular inspections, then

reduce the required maintenance intervals according to the actual

indications of wear.

If you have questions concerning maintenance tasks and intervals,

please contact our customer service ( page 2).

37

Page 38

Slew Drives

Maintenance

wö

Interval Maintenance task To be executed by

weekly Check seal Specialist

after 100 operating

hours

after every additional

700 operating hours

or at least every 6

months

Tighten bolts Specialist

Check tilting clearance Specialist

Tighten bolts

Reduce the inspection interval if there is heavy wear

or continuous operation.

Check tilting clearance

Reduce the inspection interval to 200 operating

hours if the detected increase in tilting clearance is

approximately 75% of the permissible tilting

clearance increase.

After further increase reduce the interval between

inspections to 50 - 100 hours.

Check circumferential backlash

Reduce the inspection interval to 200 operating

hours if the detected increase in circumferential

backlash is approximately 75% of the permissible

circumferential backlash increase.

After further increase reduce the interval between

inspections to 50 - 100 hours.

Tab. 16

Lubrication General re-lubrication of slew drives:

After each cleaning

Before and after longer periods of standstill, e.g. for cranes and

IMPORTANT

construction machines during the winter months.

The main cause for slewing ring failure is inadequate

lubrication. The lubrication intervals essentially depend on

existing working and environmental conditions, as well as

the version of the slew drive. Precise lubrication intervals

can only be determined by tests under normal operating

conditions.

If comparable results are not available, the following table can be

used as a guide value:

Specialist

Specialist

Specialist

Work conditions Lubricating interval To be executed by

Dry and clean workshop hall (rotary

tables, robots, etc.)

Severe conditions on open terrain

(cranes, excavators, etc.)

Aggressive climatic conditions, (ocean,

desert, arctic climate, extremely

Approx. every 300 operating hours, at

least every 6 months

Approx. every 100 to 200 operating

hours, at least every 4 months

Every 50 operating hours, at least every

2 months

Specialist

Specialist

Specialist

polluted environment, ≥70 operating

hours per week

Extreme conditions (tunnel boring

machines, steel works, wind turbines)

Tab. 17

38

Continuous lubrication (through central

lubrication or grease cups)

Specialist

Page 39

Slew Drives

Maintenance

The specified values are valid for the following conditions:

Operating temperature on the slew drive < 70° C (158° F).

Circumferential speed < 0.5 m/s (1.64 ft/sec) for SP slew

drives.

Output speed < 5 rpm for WD slew drives.

Low to moderate load.

Comply with the instructions in the operating manual provided

by the manufacturer, for lubrication of optional intermediate

gear units, brakes, and motors.

If necessary re-lubricate permanent brakes. For this only use

the special grease SHELL RETINAX HDX2.

6.4 Maintenance tasks

6.4.1 Inspecting the mounting bolts

IMPORTANT

Fig. 25: Inspecting the mounting bolts

To compensate for settling, the bolts must be retightened

with the prescribed tightening torque. Retightening must

be executed without exerting additional external stress on

the bolted union.

1 Detached bolt

Execution only by a specialist.

Special tools required:

Torque wrench

Hydraulic clamping fixture

Replace loose and detached bolts or nuts and washers with

new bolts, nuts and washers.

Use the same bolt size and bolt quality.

If a hydraulic clamping fixture was used to tighten the bolts,

then a hydraulic clamping fixture must also be used to check

the bolt pretension. Always use the same tightening procedure

as specified for installation of the slew drive when checking the

bolted union.

6.4.2 Checking the tilting clearance

Wear in the raceway system results in an increase in tilting

clearance. Consequently it is necessary to check the tilting

clearance in accordance with the maintenance intervals ( section

6.3 "Maintenance schedule").

CAUTION!

CAUTION! If the maximum permissible tilting clearance

CAUTION!CAUTION!

increase is reached, then the system must be brought to a

standstill and the slew drive must be replaced

immediately, as safe operation can no longer be ensured.

39

Page 40

Slew Drives

Maintenance

Checking the tilting clearance increase dk directly on the

slew drive

The measured value m1 determined at installation serves as the

base value ( section 5.3.4 "Determination of tilting clearance").

Determine the value mx as described in the section 5.3.4

"Determining the tilting clearance".

Subtract the base value m1 from the value mx determined in

the inspection measurement:

dk = mx – m1 ≤ dkperm

dkperm = 0.45 mm

dkperm = 0.0177 in

Checking the tilting clearance increase dk but not directly

on the slew drive

Proportionally convert the tilting clearance increase each time a

measurement is taken (after the installation measurement ) and

compare with dkperm.

6.4.3 Checking the circumferential backlash

CA

CAUTION

CACA

UTION

UTIONUTION

Toothing wear causes increased circumferential backlash.

When the maximum permissible circumferential backlash

is reached, then the system must be brought to a standstill

and the slew drive must be replaced immediately, as safe

operation can no longer be ensured.

1. Determine the circumferential backlash in accordance with

5.3.5 "Determining the circumferential backlash".

2. Compare the determined value with the permissible values of

the table.

See the type plate for the module specification.

For a module that is between the specified values, use the

value for the smaller module.

Circumferential backlash angle limit values

Module of

the

toothing

circumferential

backlash angle

3 34° 6 28°

4 32°

4/2

convolution

4,5 31°

5 30° 8 27°

5/2

convolution

Tab. 18

Limit of

Module of

the

toothing

circumferential

backlash angle

6/2

convolution

16° 7 28°

7/2

convolution

15°

8/2

convolution

Limit of

14°

14°

13.5°

40

Page 41

Slew Drives

Maintenance

6.4.4 Lubricating the slew drive

IMPORTANT

IMPORTANT

Regularly lubricate the slew drives to prolong their service

life and ensure safe operation.

Always use the lubricants specified in the order drawing. If

using other lubricants pay attention to the relative

mixability of the substances. The standard lubricants used

are "r.tecc Norplex LKP2" from Rhenus, or the grease

"Optimol Longtime PD0" from Castrol. If in doubt, or if

there is no specification on the drawing, consult with our

customer service ( page 2). Using the wrong lubricant

may cause damage to the slew drives and reduce the

service life. In this case, any warranty shall be excluded.

Comply with the instructions provided by the lubricant

manufacturer!

If possible use a central lubrication system to lubricate the

raceway system. In this regard ensure that the hoses are filled

with grease at commissioning and that the storage tanks are

regularly topped up with grease.

An automatic re-lubricating system significantly facilitates re-

lubrication for the raceway system and the toothing. Functional

safety as well as wear behavior are improved.

Comply with the instructions in the operating manual provided

by the respective manufacturer for lubrication of optional

intermediate gear units, brakes, and motors.

If it is evident that moisture has penetrated into the slew drive,

or has been absorbed by the grease, you must re-lubricate

more intensively.

Fig. 26: Lubricating the slew drive

1 Fresh lubricant

2 Lubricating nipple, bearing ring

3 Lubricating ring housing

41

Page 42

Slew Drives

Maintenance

1. In succession, press grease into all lubricating nipples while

simultaneously turning the slew drive all the way through, until

a continuous collar of grease forms under at least one seal.

2. Ensure that old lubricant can escape without obstruction.

6.4.5 Inspecting the seals

IMPORTANT

Damaged seals must be replaced immediately. If there is

corrosion damage or functional impairment as a

consequence of damaged seals not being replaced at the

proper time, any warranty shall be excluded. Penetrating

moisture may quickly cause corrosion in the bearing ring

and impairs safe operation. Note that the factory-installed

seal only offers protection against dust and splashing

water.

If damage is detected on a seal, contact the customer service

organization without delay ( page 2).

6.5 Measures after successful maintenance

Execute the following steps after concluding maintenance work

and before switching the system on:

1. Check all previously loosened bolted unions for firm seat.

2. Ensure that all previously removed protective devices and

covers have been properly installed.

3. Ensure that all tools, materials, and other equipment have/has

been removed from the work area.

4. Clean the work area and remove any substances that may have

escaped, such as liquids, processing material, or similar items.

5. Ensure that all system safety devices are again functioning

properly!

42

Page 43

Slew Drives

Dismantling

7 Dismantling

7.1 Safety

DANGER

WARNI

WARNI

WARNI

IMPORTANT

IMPORTANT

Personnel

DANGER

DANGERDANGER

WARNING

WARNIWARNI

WARNING

WARNIWARNI

WARNING

WARNIWARNI

NG

NGNG

NG

NGNG

NG

NGNG

At the end of the component's service life the component must be

dismantled and disposed of in an environmentally responsible

manner.

Prior to starting work switch off all energy supplies and

safeguard them from being switched on again. When

performing maintenance tasks there is a danger of the

energy supply being switched on without authorization.

This poses a life-threatening hazard for persons in the

danger zone.

Prior to starting work ensure that there is adequate free

space. Handle open, sharp-edged components carefully.

Ensure order and cleanliness at the workstation! Parts and

tools that are lying loose or on top of each other are

accident hazards! Dismantle components properly. Pay

attention to the high dead weight of some of the

components. Use hoist equipment if necessary. Secure the

components so that they do not fall down or fall over.

There is an injury hazard if the device is not dismantled

properly. Consult with the manufacturer if there are

questions.

Never position yourself under a suspended load! Swinging

or falling parts may cause injury or life-threatening

danger.

Carefully supervise the lifting processes and transport.

Only use the transport methods described here. A lifethreatening crushing hazard exists if the components fall.

Proceed with caution when transporting objects! Comply

with instruction symbols on the packages and only use the

prescribed attachment points. Improper transport may

cause significant damage.

Avoid impact when transporting! Improper transport may

cause significant damage.

Only trained, specialized personnel should perform dismantling

work.

43

Page 44

Slew Drives

Dismantling

7.2 Dismantling

Prior to dismantling:

Switch off the system and safeguard it from being turned on

again.

Physically disconnect all energy supplies to the system,

discharge stored residual energy.

Remove fuels and auxiliary materials, as well as residual

processing materials and dispose of these items in an

environmentally responsible manner.

Then clean subassemblies and components properly and dismantle

them, taking applicable local occupational safety and

environmental protection guidelines into consideration.

1. Unscrew the fastening elements of the toothed bearing ring.

2. Remove the mounting structure.

3. Unscrew the mounting elements of the housing.

4. Remove the slew drive.

7.3 Disposal

IMPORTANT

Electrical scrap and electronic components, lubricants and

other auxiliary materials are subject to treatment as

special waste, and should only be disposed of by approved

specialist companies! Improper disposal may cause

environmental damage.

If a return or disposal agreement has not been concluded, then

recycle dismantled components:

Scrap metals.

Recycle plastic elements.

Sort and dispose of the remaining components in accordance

with material condition

Local municipal authorities or specialized disposal companies

provide information on environmentally responsible disposal.

44

Page 45

Slew Drives

Technical data – Type plate

8 Technical data – Type plate

The type plate is on the housing and contains the following

information:

Manufacturer

Drawing no./type

Identification code consisting of:

Order number, year of manufacture and consecutive number

Module

Web address

Fig. 27: Type plate

45

Page 46

www.goimo.com

IMO Antriebseinheit GmbH & Co. KG

Gewerbepark 16

91350 Gremsdorf

Germany

Tel. +49 9193 6395-20

Fax +49 9193 6395-2140

slew.drives@goimo.com