Page 1

INSTRUCTION MANUAL

Micro-computer based digital indicating controller TP40A

To prevent accidents arising from the misuse of this controller, please ensure the operator using it receives

this manual.

Caution

• This instrument should be used according to the specifications described in the manual.

If it is not used according to the specifications, it may malfunction or cause fire.

• Be sure to follow the warnings, cautions and notices. If not, it could cause serious injury or malfunction.

• Specifications of the TP40A and the contents of this instruction manual are subject to change

without notice.

• This instrument is designed to be installed in a control panel. If not, measures must be taken to ensure

that the operator cannot touch power terminals or other high voltage sections.

• Be sure to turn the power supplied to the instrument OFF before cleaning this instrument.

• Use a soft and dry cloth when cleaning the instrument.

(If paint thinner is used, it might deform or tarnish the unit.)

• As the display section is vulnerable, do not strike or scratch it with a hard object.

• Any unauthorized transfer or copying of this document, in part or in whole, is prohibited.

• IMO Precision Controls Limited is not liable for any damages or secondary damages incurred as a result

of using this product, including any indirect damages.

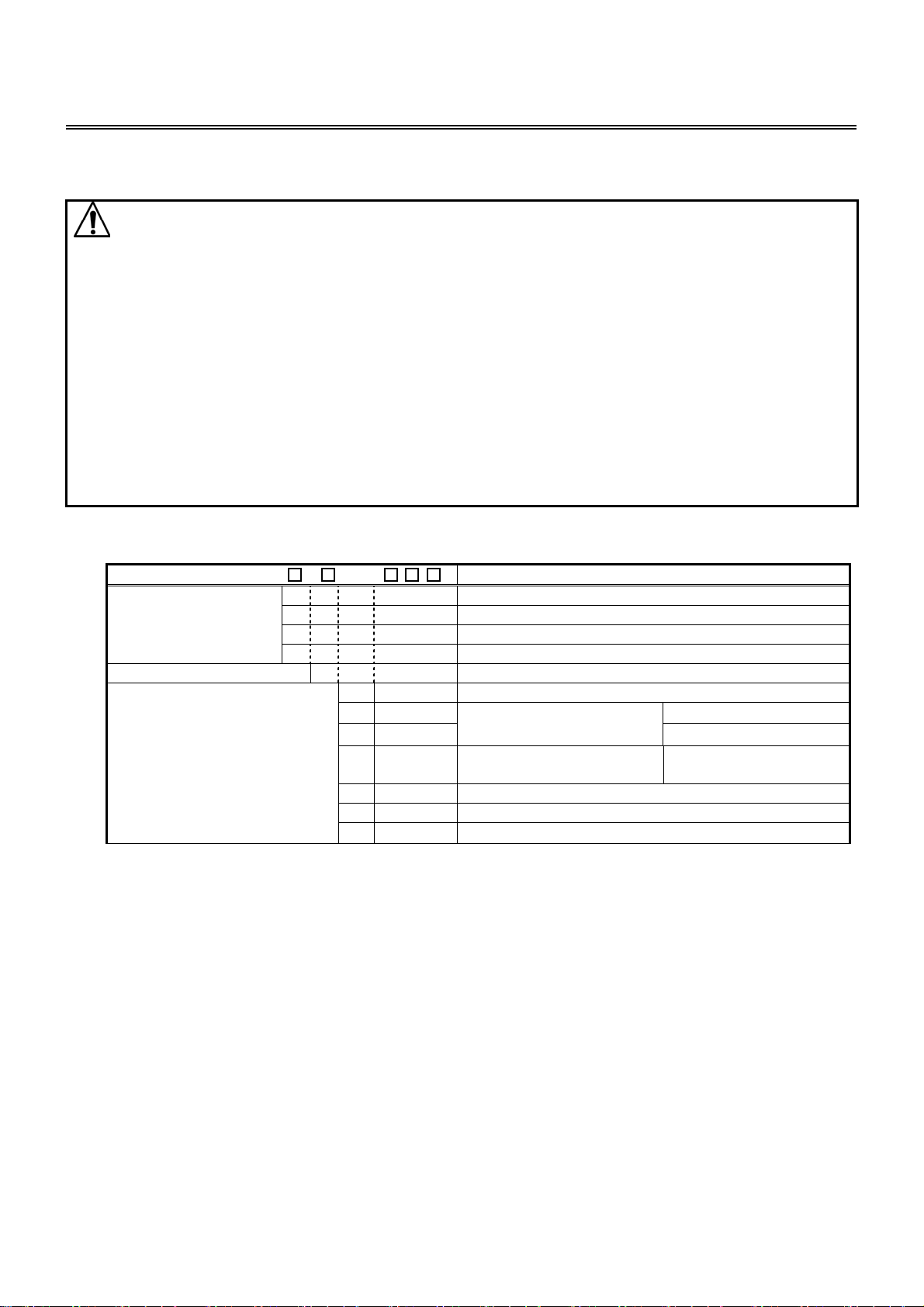

1. Name

1.1 Model name

TP40A , Series name: TP40A (W48 x H48 x D96.5mm)

R Relay contact: 1a

OUT1

Input M Multi-range *2

Option

*1: Alarm actions (9 types and No alarm action) and Energized/Deenergized can be selected by key

operation.

*2: Thermocouple, RTD, DC current, and DC voltage can be selected by key operation.

*3: 100 to 240V AC is standard specification for the supply voltage. However, when ordering please

specify 240AC for 100-240AC supply or 24DC for 24VAC/DC.

S Non-contact voltage (for SSR drive): 12

A DC current: 4 to 20mA DC

V DC voltage, 0 – 10 VDC

A2 Alarm 2 (A2) *1

W (5A) CT rated current: 5A

W (10A)

DT OUT2 (Heating/Cooling

C5 Serial communication (RS-485)

SM SV1/SV2 external selection

LA Loop break alarm

Heater burnout alarm

control output)

CT rated current: 10A

Non-contact relay

+2

0

V DC

1

Page 2

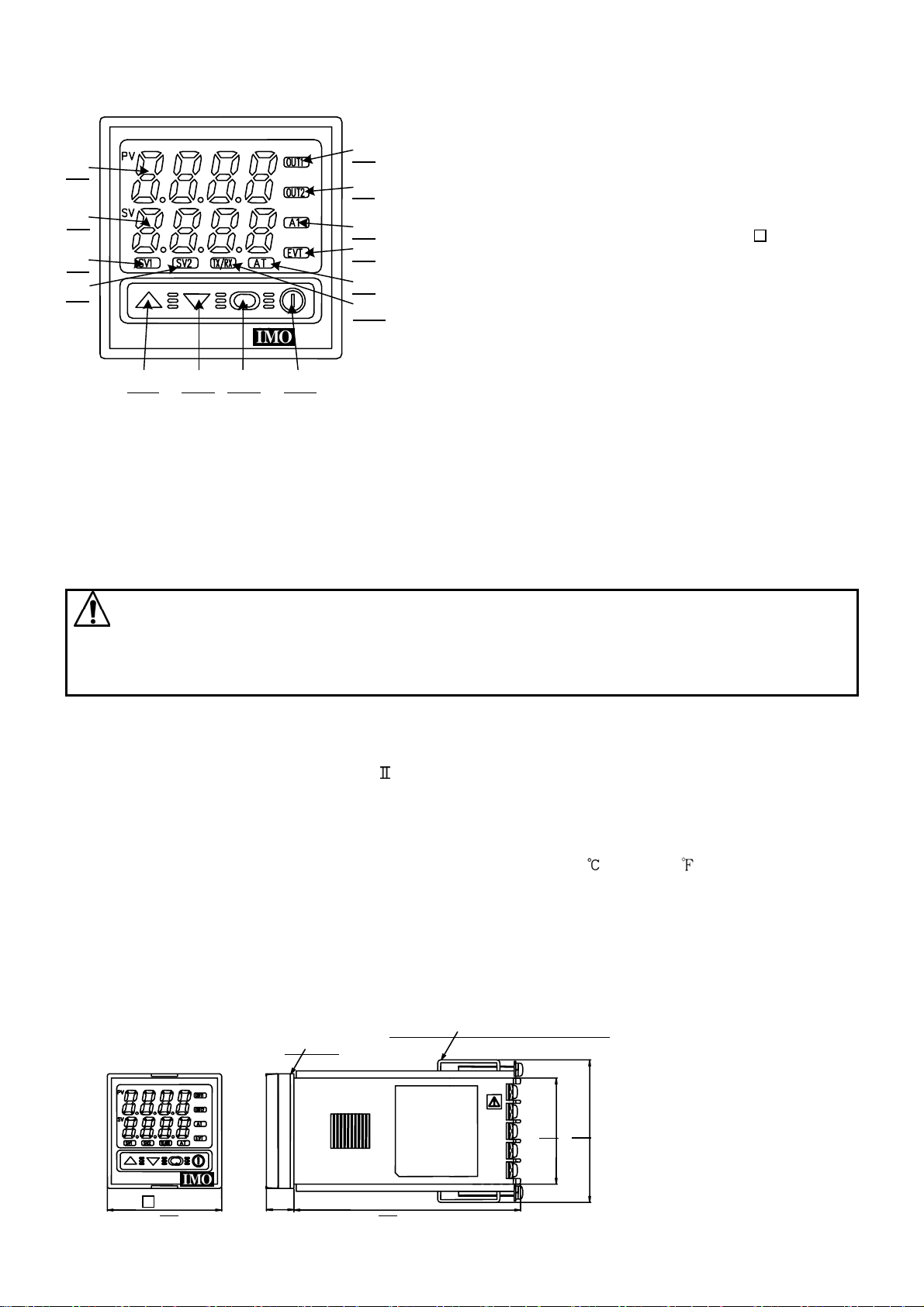

2. Name and functions of the sections

(1) PV display: Indicates the input value with a red LED.

(2) SV display: Indicates the setting value with a green LED.

(3) SV1 indicator: A green LED lights up when SV1 is indicated

on the SV display.

(1)

on the SV display.

(5) OUT1 indicator: When OUT1 or heating output is ON,

(2)

a green LED lights up. (For A/ type,

it blinks corresponding to the manipulated

(3)

variable in a 0.25 second cycle)

(4)

(6) OUT2 indicator: When OUT2 (option DT) is ON, a yellow

LED lights up.

TP40A

(7) A1 indicator : When A1 output is ON, a red LED lights up.

(8) EVT indicator: When Event output (option: A2, LA or W)

is ON, a red LED lights up.

(9) AT indicator : When auto-tuning or auto-reset is being

(Fig. 2-1) performed, a yellow LED blinks.

(10) TX/RX indicator: A yellow LED blinks during serial communication output (transmitting).

again for approx. 1 second.)

(11) (12) (13) (14)

(11) Increase key : Increases the numeric value.

(12) Decrease key : Decreases the numeric value.

(13) Mode key : Selects the setting mode or registers the setting value.

(By pressing the Mode key, the setting value or selected value can be registered)

(14) OUT/OFF key : The control output ON/OFF function or Auto/Manual control function can be

switched. (To cancel the control output ON/OFF function, press the OUT/OFF key

TP40A

(5)

(4) SV2 indicator: A yellow LED lights up when SV2 is indicated

(6)

(7)

(8)

(9)

(10)

Notice

When setting the specifications and functions of this controller, connect the terminals 1 and 2 for power

source first, then set them referring to “5. Setup” before performing “3. Mounting to control panel” and

“4. Wiring connection”.

3. Mounting to control panel

3.1 Site selection

This instrument is intended to be used under the following environmental conditions

(IEC61010-1): Overvoltage category

Mount the controller in a place with:

A minimum of dust, and an absence of corrosive gases

•

No flammable, explosive gasses

•

•

• No large capacity electromagnetic switches or cables through which large current is flowing

• No water, oil or chemicals or where the vapors of these substances can come into direct

Few mechanical vibrations or shocks

•

No exposure to direct sunlight, an ambient temperature of 0 to 50 (32 to 122 )

•

that does not change rapidly

An ambient non-condensing humidity of 35 to 85%RH

contact with the controller

3.2 External dimension

Gasket

, Pollution degree 2

Screw type mounting bracket

48

(Fig. 3.2-1)

95

2

44

59

Page 3

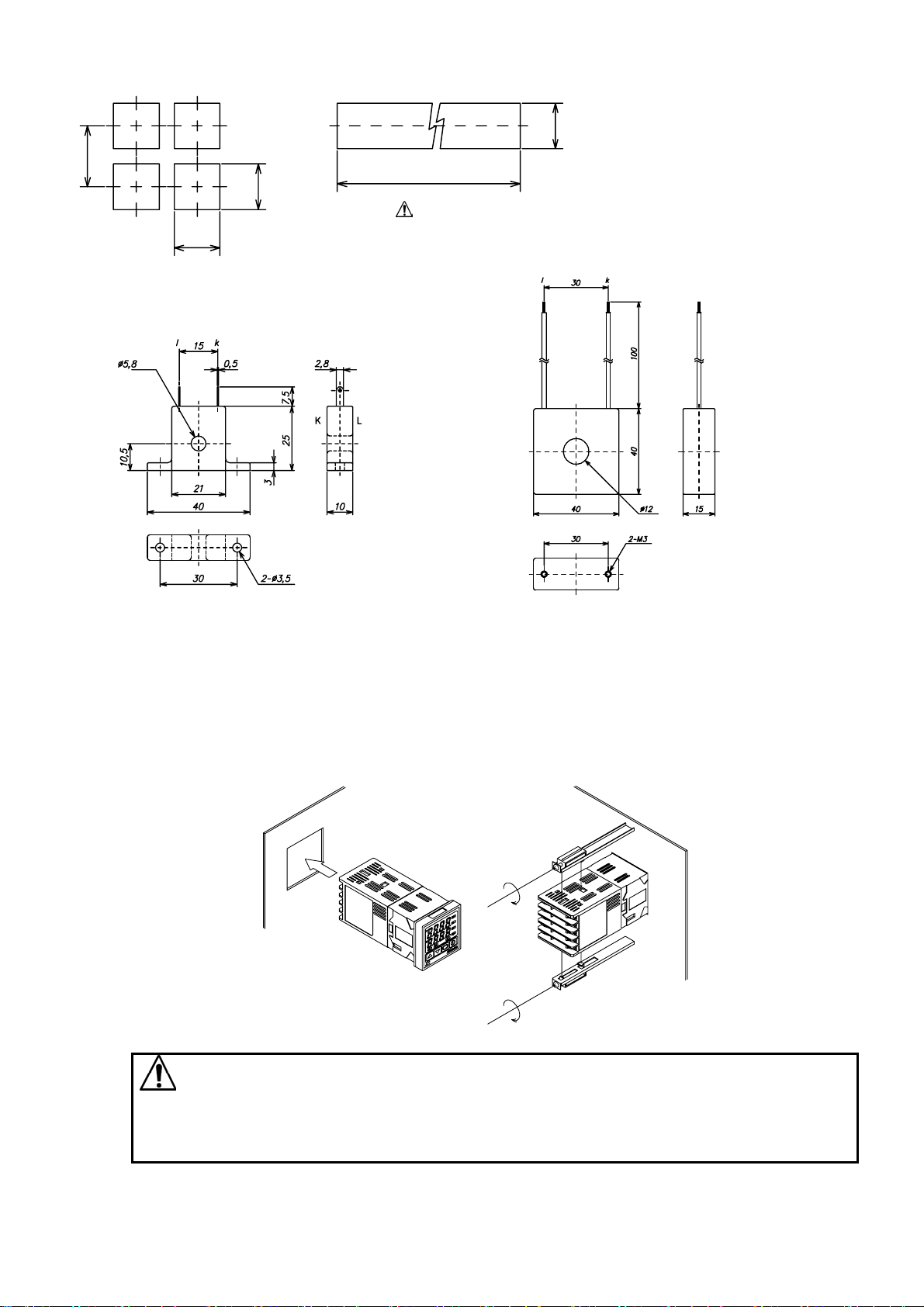

3.3 Panel cutout

75

controller, IP66 specification will not be fulfilled.

(Fig. 3.3-1)

3.4 CT (Current transformer) external dimension

45

0.5

+

0

0

+0.5

45

Lateral close mounting

+0.5

n: Number of units mounted

n x 48-3

0

Caution: If lateral close mounting is used for the

0

+0.5

45

CTL-6S (for 5A, 10A, 20A) CTL-12-S36-10L1 (for 50A)

(Fig. 3.4-1)

3.5 Mounting

Mount the controller vertically to fulfill the Dust-proof/Drip-proof specification (IP66).

Mountable panel thickness: Within 1 to 15mm

Insert the controller from the front side of the panel.

Attach the mounting brackets by the holes at the top and bottom of the case and secure the controller

in place with the screws.

(Fig.3.5-1)

Warning

As the case is made of resin, do not use excessive force while screwing in the

mounting bracket, or the case or screw type mounting bracket could be damaged.

The torque is approximately 0.12N•m.

3

Page 4

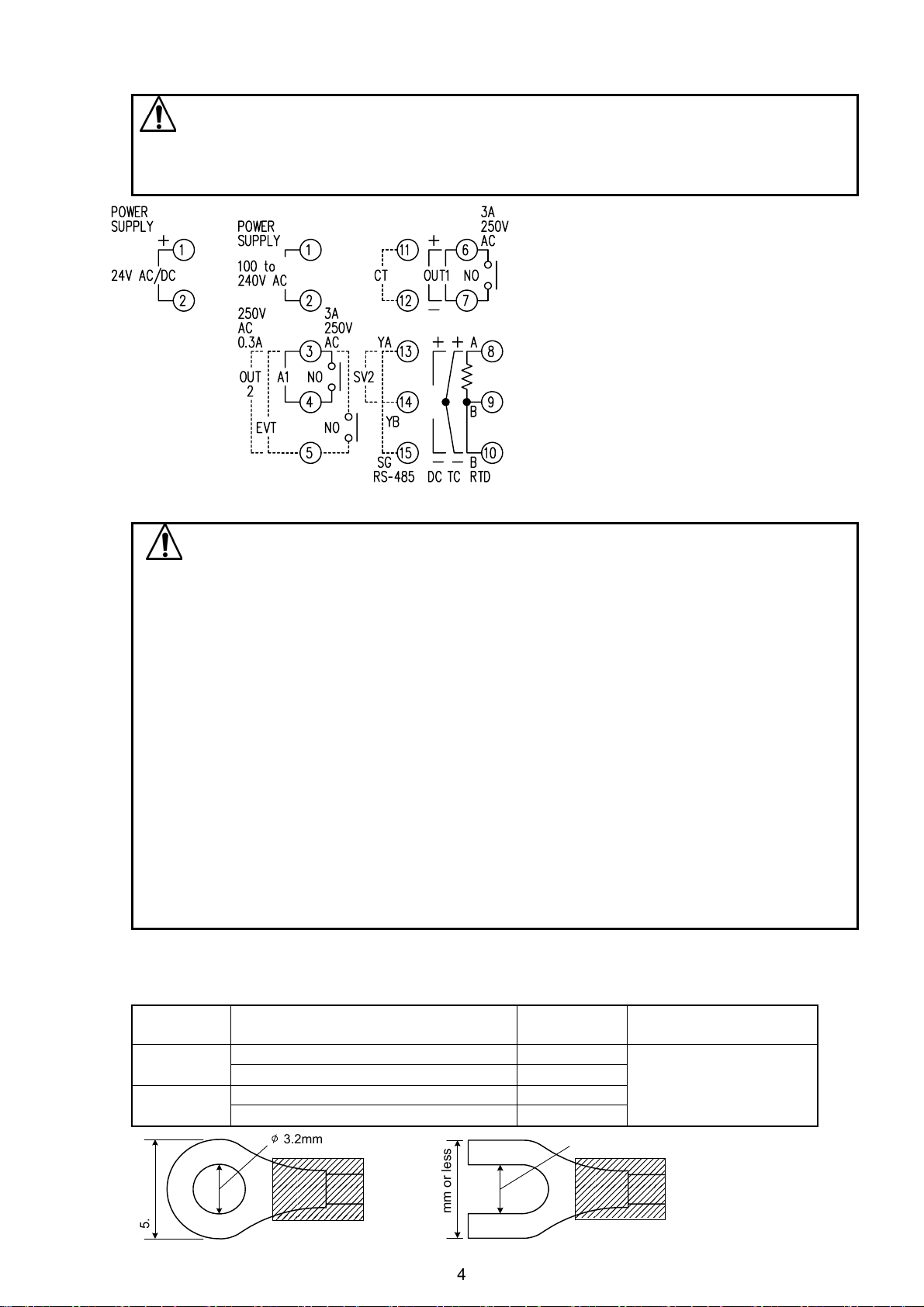

4. Wiring connection

Warning

Turn the power supply to the instrument off before wiring or checking it.

Working or touching the terminal with the power switched on may result in Electric

Shock causing severe injury or death.

• A1 : Alarm 1 output

• EVT : Event output (A2 output, Heater

burnout alarm output, Loop break

alarm output)

• CT : CT input

• TC : Thermocouple

• RTD : Resistance temperature detector

•

(Fig. 4-1)

OUT1 : Control output 1 (Heating output)

•

• OUT2 : Control output 2 (Cooling output)

• SV2 : Main setting 2 (SV2)

• RS-485 : Serial communication (RS-485)

DC : DC current, DC voltage

Notice

• The terminal block of the TP40A is designed to be wired from the left side.

The lead wire must be inserted from the left side of the terminal, and fastened by the

terminal screw.

• Dotted lines show options.

• Use a thermocouple and compensating lead wire according to the sensor input specification of

this controller.

• Use the 3-wire RTD which corresponds to the input specification of this controller.

• This controller does not have built-in power switch, circuit breaker or fuse. Therefore, it is

necessary to install them in the circuit near the external controller.

(Recommended fuse: Time-lag fuse, rated voltage 250V AC, rated current 2A)

• When using a 24V AC/DC for the power source, do not confuse the polarity when it is

DC.

• When using a relay contact output type, externally use a relay according to the capacity of

the load to protect the built-in relay contact.

• When wiring, keep input wires (thermocouple, RTD, etc.) away from AC sources or load

wires to avoid external interference.

• Do not apply a commercial power source to the sensor connected to the input terminal nor

allow the power source to come into contact with the sensor.

Lead wire solderless terminal

Use a solderless terminal with isolation sleeve that fits in the M3 screw as shown below.

The torque is approximately 0.6N•m to 1.0N•m.

Solderless

terminal

Y type

Round type

Nichifu Terminal Industries CO.,LTD.

Japan Solderless Terminal MFG CO.,LTD.

Nichifu Terminal Industries CO.,LTD.

Japan Solderless Terminal MFG CO.,LTD.

Manufacturer Model name Tightening torque

0.6N•m

Max. 1.0N•m

3.2mm

1.25Y-3

VD1.25-B3A

1.25-3

V1.25-3

3.2mm

5.8mm or less

5.8mm or less

(Fig. 4-2)

4

Page 5

Option: Heater burnout alarm

(1) This alarm is not available for detecting heater current

under phase control.

(2) Use the current transformer (CT) provided, and pass one

lead wire of the heater circuit into the hole of the CT.

CT

(11)

CT input Terminal

(12)

Power

supply

(3) When wiring, keep the CT wire away from AC sources

or load wires to avoid the external interference.

(Fig. 4-3)

Heater

5. Setup

Wire the power terminals only. After the power is turned on, the sensor input characters and temperature

unit are indicated on the PV display and the input range high limit value is indicated on the SV display for

approximately 3 seconds. (Table 5-1)

(If any other value is set during the scaling high limit setting, the set value is indicated on the SV display)

During this time, all outputs and the LED indicators are in OFF status.

Control will then start and the input value will be indicated on the PV display and main setting value (SV)

will be indicated on the SV display. (While control output OFF function is working,

the PV display.)

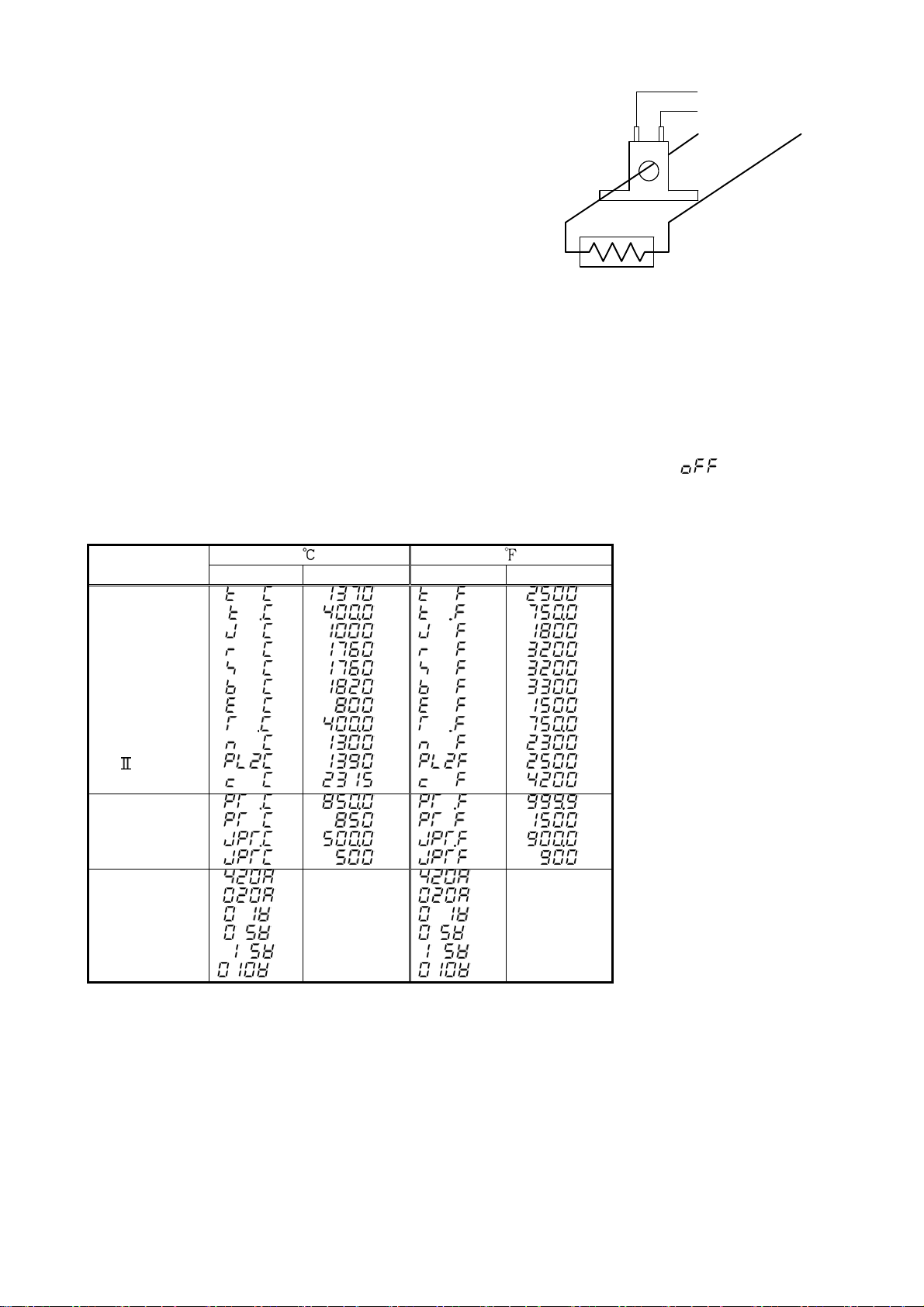

(Table 5-1)

Sensor input

K

J

R

S

B

E

T

N

PLC (W/Re5-26)

Pt100

JPt100

4 to 20mA DC

0 to 20mA DC

0 to 1V DC

0 to 5V DC

1 to 5V DC

0 to 10V DC

PV display SV display PV display SV display

Scaling high

limit value

Scaling high

limit value

is indicated on

5

Page 6

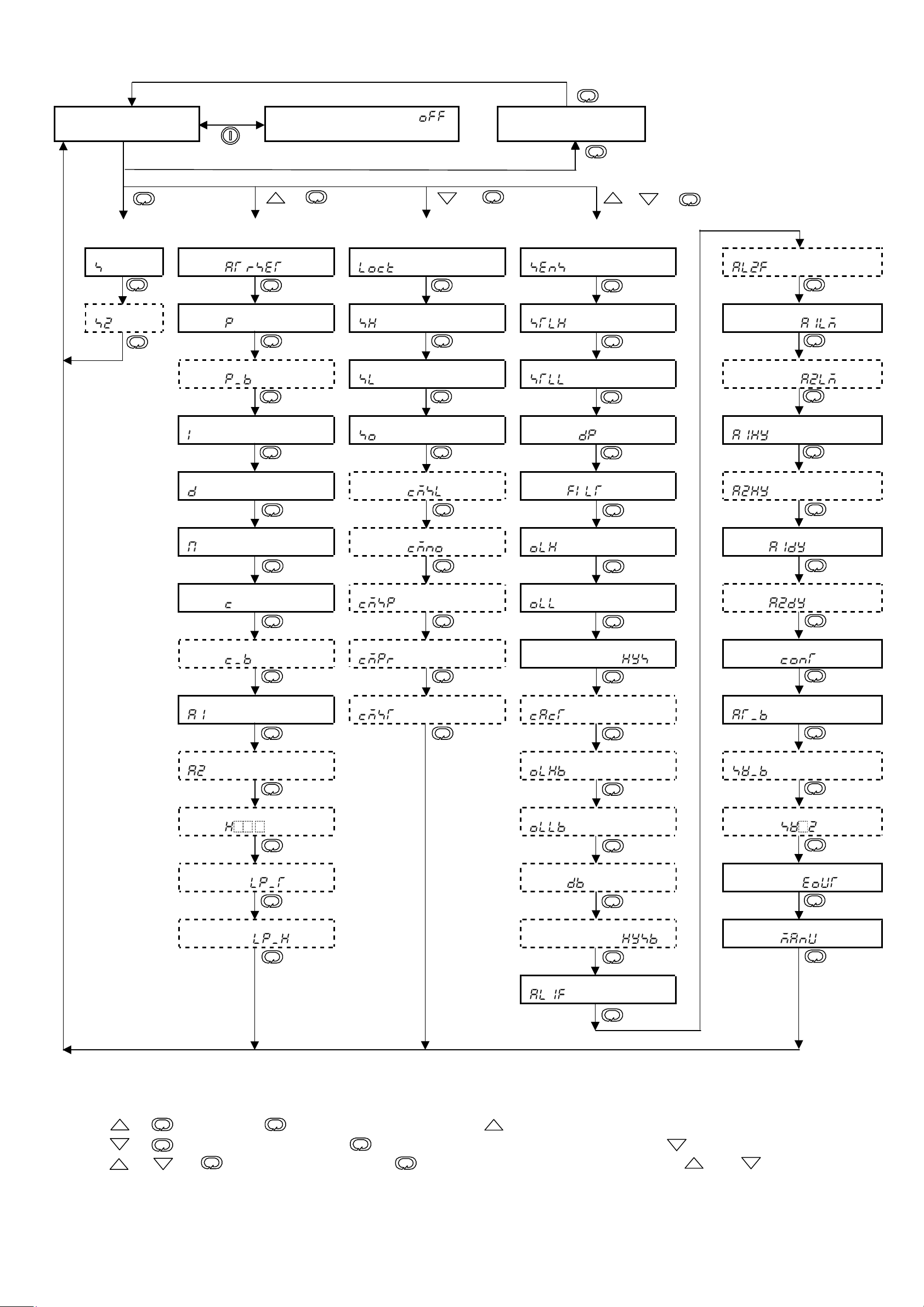

5.1 Setup flow chart

PV/SV display mode

(Approx. 3s)

(Approx. 3s) (Approx. 3s)

[Main setting mode] [Sub setting mode] [Auxiliary function [Auxiliary function

setting mode 1] setting mode 2]

SV1

]

[

SV2

]

[

OUT2 proportional cycle

A1 setting

A2 setting

Heater burnout alarm

Loop break alarm action

Loop break alarm action

AT setting/Auto-reset

OUT1 proportional band

OUT2 proportional band

Integral time setting

Derivative time setting

ARW setting

OUT1 proportional cycle

setting [ / ]

setting [ ]

setting [

]

[

]

[

]

[

setting [

setting [

[

[

setting [

time setting [

span setting [

]

]

]

Control output OFF function [

or Auto/Manual control function

]

]

. ]

]

+ + +

+

Setting value lock selection

[ ]

SV high limit setting

[ ]

SV low limit setting

[ ]

Sensor correction setting

[ ]

Communication protocol

selection [ ]

Instrument number

selection [ ]

Data transfer rate selection

[ ]

Parity selection

[ ]

Stop bit selection

[ ]

]

]

A1 action selection

Output manipulated

variable indication

Input type selection

[ ]

Scaling high limit setting

[ ]

Scaling low limit setting

[ ]

Decimal point place

selection [ ]

PV filter time constant

setting [ ]

OUT1 high limit setting

[ ]

OUT1 low limit setting

[ ]

OUT1 ON/OFF action

hysteresis setting [ ]

OUT2 action mode selection

[ ]

OUT2 high limit setting

[ ]

OUT2 low limit setting

[ ]

Overlap band/Dead band

setting [ ]

OUT2 ON/OFF action

hysteresis setting [ ]

[

]

A2 action selection

A1 action Energized/

A2 action Energized/

A1 hysteresis setting

A2 hysteresis setting

A1 action delayed timer

A2 action delayed timer

Direct/Reverse control action

AT bias setting

SVTC bias setting

SV2 setting mode indication

Output status selection when

[ ]

Deenergized [ ]

Deenergized [ ]

[ ]

[ ]

setting [ ]

setting [ ]

selection [ ]

[ ]

[ ]

selection [ ]

input burnout [ ]

OUT/OFF key function

selection [ ]

[Key operation]

• + : Press the key while holding down the key.

• + (Approx. 3s): Press the key for 3 seconds while holding down the key.

• + + (Approx. 3s): Press the for 3 seconds while holding down the and keys.

Dotted lines show options, which are indicated only when the options are applied.

6

Page 7

5.2 Main setting mode

Character Name, Function, Setting range Default value

SV1

• Sets SV1.

• Setting range: SV low limit to SV high limit

SV2

• Sets SV2.

• Available only when the option SM is applied.

• Setting range: SV low limit to SV high limit

5.3 Sub setting mode

Character Name, Function, Setting range Default value

AT setting/Auto-reset setting

• Designates auto-tuning Performance or auto-reset Performance.

• If the auto-tuning is cancelled during the process, P, I and D

• When auto-tuning has not finished after 4 hours, it is cancelled

• Auto-reset is cancelled in approximately 4 minutes.

OUT1 proportional band setting

• Sets the proportional band for OUT1.

• OUT1 becomes ON/OFF action when set to 0 or 0.0

•

OUT2 proportional band setting

• Sets the proportional band for OUT2.

• OUT2 becomes ON/OFF action when OUT1 proportional band

•

• 0.0 to 10.0 times (multiplying factor to OUT1 proportional band)

Integral time setting

• Sets integral time for OUT1.

• Setting the value to 0 disables the function.

• Not available when OUT1 is ON/OFF action.

• Auto-reset can be performed when PD action (I=0).

• Setting range: 0 to 1000 seconds

Derivative time setting

• Sets derivative time for OUT1.

• Setting the value to 0 disables the function.

• Not available when OUT1 is ON/OFF action.

• Setting range: 0 to 300 seconds

ARW setting

• Sets ARW for OUT1.

• Available only when PID is the control action.

• Setting range: 0 to 100%

OUT1 proportional cycle setting

• Sets proportional cycle for OUT1.

• Not available for DC current output type or when OUT1 is

• Setting range: 1 to 120 seconds

OUT2 proportional cycle setting

• Sets proportional cycle for OUT2.

• Not available if the option DT is not applied or when OUT2 is

• Setting range: 1 to 120 seconds

A1 setting

• Sets action point for A1 output.

• Not available if No alarm action is selected in A1 action selection

• Refer to (Table 5.3-1).

A2 setting

• Sets action point for A2 output.

• Not available if option A2 is not applied or if No alarm action is

selected in A2 action selection.

• Refer to (Table 5.3-1).

. ,

XX.X

indicated

in turn

Heater burnout alarm setting

• Sets the heater current value for Heater burnout alarm.

• Self-holding is not available for the alarm output.

• Available only when the option W is added.

• Rating 5A : 0.0 to 5.0A Rating 10A: 0.0 to 10.0A

values revert to the former value at which AT is performed.

automatically.

0 to 1000 (2000 ), 0.0 to 999.9 ( ) or 0.0 to 100.0%

is set to 0 or 0.0.

Not available if option DT is not added or if OUT1 is ON/OFF action.

ON/OFF action.

ON/OFF action.

Rating 20A: 0.0 to 20.0A Rating 50A: 0.0 to 50.0A

0

0

10

1.0 times

200 seconds

50 seconds

50%

30 seconds or

3 seconds

3 seconds

0

0

0.0A

7

Page 8

Loop break alarm action time setting

• Sets the time to assess the Loop break alarm.

• Available only when the option LA is applied.

• Setting range: 0 to 200 minutes

Loop break alarm action span setting

• Sets the temperature to assess the Loop break alarm.

• Available only when the option LA is applied.

• Setting range: 0 to 150

(Table 5.3-1)

Alarm action type Setting range

High limit alarm – (Input span) to input span ( ) *1

Low limit alarm – (Input span) to input span ( ) *1

High/Low limits alarm 0 to input span ( ) *1

High/Low limit range alarm 0 to input span ( ) *1

Process high alarm Input range low limit value to input range high limit value *2

Process low alarm Input range low limit value to input range high limit value *2

High limit alarm with standby – (Input span) to input span ( ) *1

Low limit alarm with standby – (Input span) to input span ( ) *1

High/Low limits alarm with standby 0 to input span ( ) *1

•

When input has a decimal point, the negative low limit value is –199.9, and the positive high limit

value is 999.9.

• All alarm actions except process alarms are

*1: For DC input, the input span is the same as the scaling span.

*2: For DC input, input range low (high) limit value is the same as scaling low (high) limit value.

5.4 Auxiliary function setting mode 1

Character Name, Function, Setting range Default value

Setting value lock selection

• Locks the setting values to prevent setting errors.

The setting item to be locked depends on the designation.

• When Lock 1 or Lock 2 is designated, PID Auto- tuning and

Auto-reset cannot be carried out.

•

setting items in the Auxiliary function setting mode 2. They return to their former

value after power is turned off because they are not saved in the non-volatile

memory. It is suitable to use in combination with our programmable controller

SV high limit setting

• Sets the SV high limit.

• Setting range: SV low limit to input range high limit value

SV low limit setting

• Sets the SV low limit.

• Setting range: Input range low limit value to SV high limit

Sensor correction setting

• Sets the correction value for the sensor.

• Setting range: –100.0 to 100.0

Communication protocol selection

• Selects communication protocol.

• Available only when the option C5 is applied.

• IMO protocol:

Modbus RTU mode:

Instrument number setting

• Sets the instrument number individually to each instrument when

communicating by connecting plural instruments in serial

communication.

• Available only when option C5 is added.

• Setting range: 0 to 95

Data transfer rate selection

• Selects a transfer rate to be equal to the rate of the host

computer.

• Available only when option [C5] is added.

• 2400bps:

(Unlock) : All setting values can be changed.

(Lock 1): None of the setting values can be changed.

(Lock 2): Only main setting value can be changed.

(Lock 3): All setting values can be changed. However, do not change the

(with SVTC) as this has no relation to memory life.

), 0.0 to 150.0

(

deviation setting to the main setting.

or SV low limit to scaling high limit value

or scaling low limit value to SV high limit

( ), or –1000 to 1000

,Modbus ASCII mode: ,

, 4800bps: , 9600bps: , 19200bps:

) or 0 to 1500

(

0 minutes

0

Unlock

Input range

high limit value

Input range

low limit value

0.0

IMO protocol

0

9600bps

8

Page 9

Parity selection

• Selects the parity.

• Not available when the option C5 is not added or when IMO

protocol is selected in the Communication protocol selection.

• No parity:

Stop bit selection

• Selects the stop bit.

• Not available when option C5 is not added or when IMO

protocol is selected in the Communication protocol selection.

• Setting range: 1, 2

5.5 Auxiliary function setting mode 2

Character Name, Function, Setting range Default value

Input type selection

• The input type can be selected from thermocouple (10 types),

RTD (2 types), DC current (2 types) and DC voltage (4 types),

and the unit

• When changing the input from DC voltage to other inputs,

remove the sensor connected to this controller first, then change

for the input. If the input is changed with the sensor connected,

the input circuit may be broken.

K –200 to 1370

–199.9 to 400.0

J –200 to 1000

R 0 to 1760

S 0 to 1760

B 0 to 1820

E –200 to 800

T –199.9 to 400.0

N –200 to 1300

0 to 1390 :

PLC (W/Re5-26) 0 to 2315

Pt100 –199.9 to 850.0

JPt100 –199.9 to 500.0 :

Pt100 –200 to 850

JPt100 –200 to 500

4 to 20mA –1999 to 9999:

0 to 20mA –1999 to 9999:

0 to 1V –1999 to 9999:

0 to 5V –1999 to 9999:

1 to 5V –1999 to 9999:

0 to 10V –1999 to 9999:

Scaling high limit setting

• Sets scaling high limit value.

• Available only for DC inputs

•

Setting range: Scaling low limit value to input range high limit value

Scaling low limit setting

• Sets scaling low limit value.

• Available only for DC inputs

•

Setting range: Input range low limit value to scaling high limit value

Decimal point place selection

• Selects decimal point place.

• Available only for DC inputs

•

No decimal point

2 digits after decimal point

PV filter time constant setting

• Sets PV filter time constant. (If the value is set too large, it

:

affects control result due to the delay of response)

• Setting range: 0.0 to 10.0 seconds

OUT1 high limit setting

• Sets the high limit value of OUT1.

• Not available when OUT1 is ON/OFF action

• Setting range: OUT1 low limit value to 105%

(Setting greater than 100% is effective to DC current output type)

, Even parity: , Odd parity:

/ can be selected as well.

:

:

:

:

:

:

:

:

:

:

:

K –320 to 2500

–199.9 to 750.0

J –320 to 1800

R 0 to 3200

S 0 to 3200

B 0 to 3300

E –320 to 1500

T –199.9 to 750.0

N –320 to 2300

0 to 2500 :

PL-

C (W/Re5-26) 0 to 4200

Pt100 –199.9 to 999.9

JPt100 –199.9 to 900.0

:

:

Pt100 –300 to 1500

JPt100 –300 to 900

1 digit after decimal point:

:

3 digits after decimal point

:

Even parity

1

K

(–200 to 1370 )

:

:

:

:

:

:

:

:

:

:

:

:

:

:

9999

–1999

No decimal

point

0.0 seconds

100%

9

Page 10

OUT1 low limit setting

• Sets the low limit value of OUT1.

0%

Not available when OUT1 is ON/OFF action.

• Setting range: –5% to OUT1 high limit value

(Setting less than 0% is effective to DC current output type)

OUT1 ON/OFF action hysteresis setting

• Sets ON/OFF action hysteresis for OUT1.

1.0

• Available only when OUT1 is ON/OFF action

• Setting range: 0.1 to 100.0

OUT2 action mode selection

• Selects OUT2 action from air, oil and water coolings.

( ), or 1 to 1000

Air cooling

• Not available when the option DT is not added or when OUT2 is

ON/OFF action

• Air cooling:

OUT2 high limit setting

• Sets the high limit value of OUT2.

, oil cooling: , water cooling:

100%

• Not available when the option DT is not added or when OUT2 is

ON/OFF action

• Setting range: OUT2 low limit value to 105%

(Setting greater than 100% is effective to DC current output type)

OUT2 low limit setting

• Sets the low limit value of OUT2.

0%

• Not available when the option DT is not added or when OUT2 is

ON/OFF action

• Setting range: –5% to OUT2 high limit value

(Setting less than 0% is effective to DC current output type)

Overlap band/Dead band setting

• Sets the overlap band or dead band for OUT1 and OUT2.

0

+ setting value: Dead band, – setting value: Overlap band

• Available only when the option DT is added

• Setting range: –100.0 to 100.0

OUT2 ON/OFF action hysteresis setting

• Sets ON/OFF action hysteresis for OUT2.

( ), or 1 to 1000

1.0

• Available only when the option DT is added

• Setting range: 0.1 to 100.0

A1 action selection

• Selects an action for A1.

No alarm action : Process high alarm :

High limit alarm :

Low limit alarm :

H/L limits alarm :

H/L limit range alarm:

A2 action selection

• Selects an action for A2.

( ), or 1 to 1000

Process low alarm :

High limit alarm w/standby :

Low limit alarm w/standby :

H/L limits alarm w/standby :

No alarm action

No alarm action

• Available only when alarm A2 is added

• Action selection and default value are the same as those of A1

action selection.

A1 action Energized/Deenergized selection

• Selects Energized/Deenergized for A1.

Energized

• Not available if No alarm action is selected in A1 action selection

• Energized:

A2 action Energized/Deenergized selection

• Selects Energized/Deenergized for A2.

Deenergized:

Energized

• Not available if alarm A2 is not added or if No alarm action is

selected in A2 action selection

• Action selection and default value are the same as those of A1

action Energized/Deenergized selection.

A1 hysteresis setting

• Sets hysteresis for A1.

1.0

• Not available if No alarm action is selected in A1 action selection

• Setting range: 0.1 to 100.0

A2 hysteresis setting

• Sets hysteresis for A2.

( ), or 1 to 1000

1.0

• Not available if alarm A2 is not added or if No alarm action is

selected in A2 action selection

• Setting range: 0.1 to 100.0

( ),or 1 to 1000

10

Page 11

A1 action delayed timer setting

• Sets action delayed timer for A1.

0 seconds

When setting time has passed after the input enters the alarm

output range, the alarm is activated.

• Not available if No alarm action is selected in A1 action selection

• Setting range: 0 to 9999 seconds

A2 action delayed timer setting

• Sets action delayed timer for A2.

0 seconds

When setting time has passed after the input enters the alarm

output range, the alarm is activated.

• Not available if alarm A2 is not added or if No alarm action is

selected in A2 action selection

• Setting range: 0 to 9999 seconds

Direct/ Reverse action selection

• Selects Reverse (Heating) or Direct (Cooling) action.

• Reverse (Heating):

AT bias setting

• Sets bias value during PID auto-tuning.

Direct (Cooling):

Reverse

(Heating) action

20

• Not available for DC inputs

• Setting range:

SVTC bias setting

• Control desired value adds SVTC bias value to the value

0 to 50 (0 to 100 ) or 0.0 to 50.0 (0.0 to100.0 )

0

received by the SVTC command.

• Available only when option C5 is added

• Converted value of

20% of the rated value or

20% of the scaling range

SV2 indication selection

• Selects whether SV2 setting item is indicated or not.

No indication

• Available only when the option SM is added.

•

Output status selection when input burnout

• Selects whether OUT1 is turned OFF or not when DC input is

(No indication), (Indication)

Output OFF

overscale or underscale.

• Available only for DC current output type with DC inputs

•

OUT/OFF key function selection

• Selects whether OUT/OFF key is used for control output

(Output OFF), (Output ON)

OUT/OFF

function

OUT/OFF function or for Auto/Manual control function.

•

(OUT/OFF function)

(Auto/Manual control function)

Sensor correction function

This corrects the input value from the sensor. When a sensor cannot be set at a location where

control is desired, the sensor measuring temperature may deviate from the temperature in the

controlled location. When controlling with plural controllers, sometimes the temperatures measured

(input value) do not concur with the same setting value due to difference in sensor accuracy or

dispersion of load capacities. In such a case, the control can be set at the desired temperature by

adjusting the input value of sensors.

Energized/Deenergized

When [alarm action energized] is selected, the alarm output (between terminals 3-4, or 3-5)

is conducted (ON) while the alarm output indicator is lit.

The alarm output is not conducted (OFF) while the alarm output indicator is not lit.

When [alarm action deenergized] is selected, the alarm output (between terminals 3-4, or 3-5) is not

conducted (OFF) while the alarm output indicator is lit.

The alarm output is conducted (ON) while the alarm output indicator is not lit.

High limit alarm (when Energized is set) High limit alarm (when Deenergized is set)

ON

A1 hysteresis

ON

A1 hysteresis

OFF

SV setting + A1 set point

OFF

SV setting

+ A1 set point

(Fig. 5.5-1) (Fig. 5.5-2)

11

Page 12

5.6 Auto/Manual control function

Name, Functions

Auto/Manual control function

• If Auto/Manual control function is selected in the OUT/OFF key function selection, Automatic or

Manual control function can be switched by pressing the key in the PV/SV display mode.

If control action is switched from automatic to manual or vice versa, balanceless-bumpless

function works to prevent sudden change of manipulated variable.

When automatic control is switched to manual control, the 1st dot from the right on the SV display

blinks, and the output manipulated variable (MV) can be increased or decreased by pressing

or key to perform the control.

By pressing the key again, the mode reverts to the PV/SV display mode (automatic control).

(Whenever the power to the controller is turned on, automatic control starts.)

5.7 Control output OFF function

Character Name, Functions

Control output OFF function

• A function to pause the control action or turn the control output of the unused

instrument of the plural units OFF even if the power to the instrument is supplied.

] is indicated on the PV display while the function is working.

[

• Once the control output OFF function is enabled, the function cannot be released

even if the power to the instrument is turned OFF and ON again.

To cancel the function, press the key again for approx. 1 second.

5.8 Output manipulated variable (MV) indication

Name and functions

Output manipulated variable indication

• In the PV/SV display mode, press the key for approx. 3 seconds.

Keep pressing the key until the output manipulated variable shows up, though the main

setting mode appears temporarily during the process.

(The SV display indicates output manipulated variable and the decimal point blinks at a cycle of

every 0.5 second). If the key is pressed again, the mode reverts to the PV/SV display.

6. Running

After the controller has been mounted to the control panel and wiring is completed, it can be started

in the following manner.

(1) Turn the power supply to the TP40A ON.

Turn the power supply to the TP40A ON.

• For approx. 3s after the power is switched ON, the sensor input character and the temperature unit

are indicated on the PV display and input range high limit value is indicated on the SV display. See

(Table 5-1). (If any other value has been set in the scaling high limit setting, the set value is indicated on

the SV display) During this time, all outputs and LED indicators are in OFF status.

•

After that, control starts indicating input value on the PV display, and main setting value on the SV display.

• While the Control output OFF function is working,

is indicated on the PV display.

(2) Input each setting value. Input each setting value, referring to “5. Setup”.

(3) Turn the load circuit power ON.

Starts the control action so as to keep the controlled object at the main setting value.

7. Action explanation

7.1 OUT1 action

Control

action

Relay contact

output

Non-contact

voltage output

DC current

output

Indication

(OUT1) Green

part : Acts ON or OFF.

Heating (Reverse) action Cooling (Direct) action

6

7

6

12V DC

7

6

7

Proportional band

SV setting

6

7

6

++

12/0V DC

7

6

7

6

7

6

0V DC

7

6

4mA DC

7

Unlit

Cycle action is performed according to deviation

++

+++

Changes continuously according to deviation

ON

OFF

Cycle action is performed according to deviation

+

Cycle action is performed according to deviation Cycle action is performed according to deviation

+

20mA DC 20 to 4mA DC

Changes continuously according to deviation

Lit Unlit

Proportional band

SV setting

6

7

6

0V DC 12V DC

7

6

4mA DC

7

6

7

6

0/12V DC

7

6

4 to 20mA DC

7

6

7

+

6

7

++

6

20mA DC

7

12

ON

OFF

Lit

Page 13

7.2 EVT (Heater burnout alarm) action

Alarm action

ON

OFF

7.3 OUT1 ON/OFF action

Heating (Reverse) action Cooling (Direct)action

Control

action

Relay contact

output

Non-contact

voltage output

DC current

output

Indication

(OUT1) Green

ON

OFF

6

7

+

6

7

++

6

20mA DC

7

Lit

part: Acts ON or OFF.

7.4 Temperature alarm action

High limit alarm

Alarm

action

Alarm

output

ON

OFF

A1 set point

+ side

side

High/Low limit range alarm

Alarm

action

Alarm

output

ON

OFF

A1 set point A1 set point

High limit alarm with standby

Alarm

action

Alarm

output

ON

OFF

A1 set point

+ side

side

A1 indicator lights up when output terminals between

3 and 4 is ON, and goes out when between them is OFF.

: Alarm output terminals between 3 and 4 is ON.

: Alarm output terminals between 3 and 4 is ON or OFF.

: Alarm output terminals between 3 and 4 is OFF.

: Standby functions in this section.

Setting

Load current

Hysteresis

SV setting

SV

setting

SV

setting

SV

setting

Output

Indication

LargeSmall

6

7

6

+

0V DC12V DC

7

6

4mA DC

7

Unlit

A1 hysteresis

+ A1 set point

A1 hysteresis A1 hysteresis A1 hysteresis

A1 set point

A1 hysteresis A1 hysteresis A1 hysteresis

+ A1 set point

6

7

+

6

0V DC 12V DC

7

6

+

4mA DC

7

A1 hysteresis

ON

OFF

A1 set point SV

+ side

side

ON

OFF

ON

OFF

A1 set point

+ side

side

3

5

Hysteresis

SV setting

Low limit alarm

setting

Process high alarm

A1 set point

SV

setting

6

7

+

6

7

6

+

20mA DC

7

+ A1 set point

ON

OFF

LitUnlit

3

5

UnlitLit

High/Low limits alarm

A1 hysteresis

ON

OFF

A1 set pointA1 set point

ON

OFF

High/Low limit alarm with standbyLow limit alarm with standby

ON

OFF

A1 set point SV

setting

Process low alarm

A1 set point

SV

setting

A1 set point

13

Page 14

7.5 OUT2 (Heating/Cooling control) action

Control

action

Relay contact

output (OUT1)

ON

Heaing

action

OFF

6

7

Cycle action is performed according to deviation.

Heating P-band (Cooling P-band)

SV setting

66

7

ON

(Cooling

action)

OFF

Non-contact

voltage output

(OUT1)

DC current

output (OUT1)

Non-contact

relay output

(OUT2)

Indication

(OUT1) Green

Indication

(OUT2) Yellow

12V DC 12/0V DC 0V DC

Cycle action is performed according to deviation.

20mA DC

Changes continuously according to deviation.

Lit

Unlit Lit

20 to 4mA DC

3

5

Cycle action is performed according to deviation.

4mA DC

Unlit

Page 15

7.7 OUT2 (Heating/Cooling control) action (When setting Overlap band)

r

r

Control action

ON

Heating

action

OFF

Relay contact

output (OUT1)

Cycle action is performed according to deviation.

Non-contact

relay output

(OUT2)

Indication

(OUT1) Green

Indication

(OUT2) Yellow

Lit

Unlit

Heating P-band

Cooling P-band

Overlap

band

(Cooling

action)

SV setting

6

7

3

5

Cycle action is performed according to deviation.

6

7

3

5

6

7

3

5

Unlit

ON

OFF

Lit

: Acts ON (lit) or OFF (unlit).

: Represents Heating control action.

: Represents Cooling control action.

8. PID auto-tuning of this controller

In order to set each value of P, I, D and ARW automatically, fluctuation is applied to the controlled object

to get an optimal value. One of 3 types of fluctuation below is automatically selected.

(1) When the difference between the setting value and processing temperature is large as the

temperature rises.

When AT bias is set to 20

Temperature 20

than the setting value

Setting value

(3) Controlled by the PID constant

(4)

( ), fluctuation is applied at the temperature 20 lower than the setting value.

( ) lowe

(1) Calculating PID constant

(2) PID constant calculated

set by auto-tuning.

Temperature

(4) AT bias value

(2) When the control is stable or when control temperature is within ±20

AT starting point

(1)

(2) (3)

Time

( ) of setting value.

Fluctuation is applied at the setting value.

Setting value

(1) Calculating PID constant

(2) PID constant calculated

(3) Controlled by the PID constant

Temperature

set by auto-tuning.

AT starting point

(1)

(2)

(3) When the control temperature is 20

Time

(3)

( ) or higher than the setting value.

When AT bias is set to 20 ( ), fluctuation is applied at the temperature 20 ( ) higher than the

setting value.

(1) Calculating PID constant

Temperature

Temperature 20 ( ) highe

than the setting value

(2) PID constant calculated

(3) Controlled by the PID constant

Setting value

set by auto-tuning.

(4)

(4) AT bias value

AT starting point

Time

(1)

(2)

(3)

15

Page 16

9. Specifications

9.1 Standard specifications

Mounting method : Flush

Setting method : Input system using membrane sheet key

Display PV display : Red LED 4 digits, character size 10.2 x 4.9 mm (H x W)

SV display : Green LED 4 digits, character size 8.8 x 4.9 mm (H x W)

Accuracy (Setting and Indication):

Thermocouple : Within

whichever is greater

However R, S inputs, 0 to 200

B input, 0 to 300

K, J, E, T, N inputs, less than 0

RTD : Within

within

DC current : Within

DC voltage : Within

Input sampling period : 0.25 seconds

Input Thermocouple : K, J, R, S, B, E, T, N, PL-

(However, B input: External resistance, 40

RTD : Pt100, JPt100, 3-wire system

Allowable input lead wire resistance (10

DC current : 0 to 20mA DC, 4 to 20mA DC

Input impedance: External shunt resistor 50

Allowable input current (50mA or less)

DC voltage : 0 to 1V DC Input impedance (1M

Allowable input voltage (5V or less)

Allowable signal source resistance (2k

: 0 to 5V DC, 1 to 5V DC, 0 to 10V DC Input impedance (100k

Allowable input voltage (15V or less)

Allowable signal source resistance (100

OUT1 output

Relay contact : 1a, Control capacity 3A 250V AC (resistive load)

1A 250V AC (inductive load cosø=0.4)

Electrical life, 100,000 times

Non-contact voltage (For SSR drive): 12

DC current : 4 to 20mA DC, Load resistance, maximum 550

A1 output

Action : ON/OFF action

Hysteresis : 0.1 to 100.0

Output : Relay contact 1a

Control capacity, 3A 250V AC (resistive load)

Electrical life, 100,000 times

Control action

PID action (with auto-tuning function)

PI action: When derivative time is set to 0

PD action (with auto reset function): When integral time is set to 0

P action (with auto reset function): When derivative and integral times are set to 0.

ON/OFF action: When proportional band is set to 0 or 0.0

OUT1 proportional band : 0 to 1000

(ON/OFF action when set to 0 or 0.0)

Integral time : 0 to 1000s (OFF when set to 0)

Derivative time : 0 to 300s (OFF when set to 0)

OUT1 proportional cycle : 1 to 120s (Not available for DC current output type)

ARW : 0 to 100%

OUT1 ON/OFF action hysteresis: 0.1 to 100.0

OUT1 high limit setting : 0 to 100% (DC current output type: –5 to 105%)

OUT1 low limit setting : 0 to 100% (DC current output type: –5 to 105%)

Circuit isolation configuration

1

Power

Power

supply

2

3

A1

4

5

EVT (A2, LA, W) or OUT2 (DT)

0.2% of each input span 1digit, or within 2 (4 ),

(400 ): Within 6 (12 )

(600 ): Accuracy is not guaranteed

(32 ): Within 0.4% of input span 1digit

0.1% of each input span 1digit, or

1 (2 ), whichever is greater

0.2% of each input span 1digit

0.2% of each input span 1digit

, C(W/Re5-26) External resistance, 100 or less

or less)

or less per wire)

or greater)

or less)

or less)

+2

V DC maximum 40mA (short circuit protected)

0

( ), or 1 to 1000

(2000 ), 0.0 to 999.9 ( ) or 0.0 to 100.0%

( ), or 1 to 1000

11

12

13

14

CT

input

SV2

Isolated

Commu-

nication

OUT1

13

14

CPU

15

Input

16

6

7

8

9

10

or greater)

Page 17

When OUT1 is non-contact voltage output or DC current output, between OUT1 and communication

and between OUT1 and SV2 are non-isolated and isolation test must not be carried out between them.

Isolation resistance : 10M

or greater at 500V DC

Dielectric strength : 1.5kV AC for 1minute between input terminal and power terminal

1.5kV AC for 1minute between output terminal and power terminal

Supply voltage : 100 to 240V AC 50/60Hz, 24V AC/DC 50/60Hz

Allowable voltage fluctuation 100 to 240V AC: 85 to 264V, AC 24V AC/DC: 20 to 28V AC/DC

Power consumption : Approx. 8VA

Ambient temperature

: 0 to 50 (32 to 122 )

Ambient humidity : 35 to 85%RH (no condensation)

Weight : Approx. 200g

External dimension : 48 x 48 x 95mm (W x H x D)

Material : Flame resistant resin (Case)

Color : Light gray (Case)

Attached functions : [Setting value lock], [Sensor correction], [Auto/manual control switching],

[Input burnout indication

]

Thermocouple and RTD inputs

If the input value exceeds the Indication range high limit value, the PV display blinks “

and if the input value exceeds the Indication range low limit value, the PV display blinks “

If the input value exceeds the Control range, OUT1 and OUT2 are turned off (for DC current

output type, OUT1 low limit value and OUT2 low limit value)

(However, for manual control, it outputs the preset manipulated variable

.

)

Input Input range Indication range Control range

KT

K

J

RS

B

E

N

PL-

C(W/Re5-26)

–199.9 to 400.0 –199.9 to 450.0 –205.0 to 450.0

–199.9 to 750.0

–199.9 to 850.0 –209.0 to 850.0

–200 to 1370 –250 to 1420 –250 to 1420

–320 to 2500

–370 to 2550 –370 to 2550

–200 to 1000 –250 to 1050 –250 to 1050

–320 to 1800

–370 to 1850 –370 to 1850

0 to 1760 –50 to 1810 –50 to 1810

0 to 3200

–50 to 3250 –50 to 3250

0 to 1820 –50 to 1870 –50 to 1870

0 to 3300

–50 to 3350 –50 to 3350

–200 to 800 –250 to 850 –250 to 850

–320 to 1500

–370 to 1550 –370 to 1550

–200 to 1300 –250 to 1350 –250 to 1350

–320 to 2300

–370 to 2350 –370 to 2350

0 to 1390 –50 to 1440 –50 to 1440

0 to 2500

–50 to 2550 –50 to 2550

0 to 2315 –50 to 2365 –50 to 2365

0 to 4200

–50 to 4250 –50 to 4250

–199.9 to 850.0 –199.9 to 900.0 –210.0 to 900.0

Pt100

–200 to 850 –210 to 900 –210 to 900

–199.9 to 999.9 –199.9 to 999.9 –211.0 to 1099.9

–300 to 1500

–318 to 1600 –318 to 1600

–199.9 to 500.0 –199.9 to 550.0 –206.0 to 550.0

JPt100

–200 to 500 –206 to 550 –206 to 550

–199.9 to 900.0 –199.9 to 999.9 –211.0 to 999.9

–300 to 900

–312 to 1000 –312 to 1000

DC current and voltage inputs (4 to 20mA DC, 0 to 20mA DC, 0 to 1V DC, 0 to 5V DC, 1 to 5V DC, 0 to 10V DC)

If input value exceeds Indication range high limit value, PV display blinks “

value exceeds the Indication low limit range, the PV display blinks “

”.

”, and if input

If input value exceeds the Control range, OUT1 and OUT2 are turned ON or OFF, depending on

which has been selected in the [Output status selection when input burnout] (for DC current output

type, OUT1 high or low limit value, OUT2 high or low limit value). However, for manual control, it

outputs the preset manipulated variable.

Indication range : [Scaling low limit value – Scaling span x 1%] to [Scaling high limit value

“

+Scaling span x 10%]

(If the input value exceeds the range –1999 to 9999, the PV display blinks

” or “ ”)

Control range : [Scaling low limit value – Scaling span x 1%] to [Scaling high limit value

+Scaling span x 10%]

DC input burnout: When DC input is burnt out, PV display blinks “

and 1 to 5V DC inputs, and “

” for 0 to 1V DC input.

” for 4 to 20mA DC

17

”,

”.

Page 18

For 0 to 20mA DC, 0 to 5V DC and 0 to 10V DC inputs, the PV display

indicates the corresponding value with which 0mA or 0V is inputted.

[Burnout]

output type, OUT1 low limit value, OUT2 low limit value) and PV display blinks “

[Self-diagnosis]

The CPU is monitored by a watchdog timer, and when any abnormal status is found on the

CPU, the controller is switched to warm-up status

[Automatic cold junction temperature compensation] (Only thermocouple input type

This detects the temperature at the connecting terminal between the thermocouple and the instrument

and always keeps it set to the same status as when the reference junction is located at 0

[Power failure countermeasure] The setting data is backed up in the non-volatile IC memory.

[Warm-up indication]

After the power supply to the instrument is turned on, the sensor input character and temperature

unit are indicated on the PV display and rated scale high limit value is indicated on the SV display

for 3 seconds

For DC current and voltage inputs, the scaling high limit value is indicated

Accessories included: Screw type mounting bracket 1 set, Instruction manual 1 copy

9.2 Optional specifications

Alarm 2 (A2) (Option code: A2

The output terminals will be common when the options [W] and [LA] are added togethe

Action : ON/OFF action

Hysteresis : 0.1 to 100.0

Output : Relay contact 1a

Loop break alarm (Option code: LA)

When MV (manipulated variable) is maximum or minimum and when the PV does not change as much

as the preset span within the Loop break alarm assessment time, the alarm is activated.

This also detects the breaking status on the loop such as heater burnout, sensor burnout or actuator

trouble.

The output terminals will be common if the options [W] and [A2] are applied together.

Setting range : Loop break alarm action time, 0 to 200minutes

Output : Relay contact 1a

Heater burnout alarm (including sensor burnout alarm) (Option code: W)

Monitors heater current with CT (current transformer), and detects burnout.

The output terminals will be common if the options [LA] and [A2] are applied with it.

This option cannot be applied to DC current output type.

Rating : 5A [W(5A)], 10A [W(10A)], 20A [W(20A)], 50A [W(50A)] (Must be specified)

Setting range : 5A [W(5A)], 0.0 to 5.0A (Off when set to 0.0)

Setting accuracy : Within

Action : ON/OFF action

Output : Relay contact 1a

Heating/Cooling control (Option code: DT)

The specification of Heating side is the same as that of OUT1.

OUT2 proportional band : 0.0 to 10.0 times OUT1 proportional band (ON/OFF action when set to 0.0)

OUT2 integral time : The same as that of OUT1.

OUT2 derivative time : The same as that of OUT1.

OUT2 proportional cycle : 1 to 120 seconds

Overlap band/Dead band setting range:

selection)

Output: Non-contact relay output 0.3A 250V AC

Cooling action mode selection function:

Serial communication (Option code: C5)

When this option is added, the option [SM] cannot be added with it.

The following operations can be carried out from the external computer.

Thermocouple, RTD inputs: –100.0 to 100.0

DC current, DC voltage inputs: –1000 to 1000 (The placement of the decimal point follows the

One cooling action can be selected from Air cooling (linear characteristic), Oil cooling (1.5th power o

the linear characteristic) and Water cooling (2nd power of the linear characteristic) by key operation

.

.

CT (Current transformer) CTL-6S 1 piece(for rating 5A, 10A, 20A)

CTL-12-S36-10L1 1 piece (for rating 50A)

)

( ), or 1 to 1000

Control capacity, 3A 250V AC (Resistive load)

Electrical life, 100,000 times

Loop break alarm action span, 0 to 150

Control capacity, 3A 250V AC (Resistive load)

Electrical life, 100,000 times

10A [W(10A)], 0.0 to 10.0A (Off when set to 0.0)

20A [W(20A)], 0.0 to 20.0A (Off when set to 0.0)

50A [W(50A)], 0.0 to 50.0A (Off when set to 0.0)

5% of the rated value

Control capacity, 3A 250V AC (resistive load)

Electrical life, 100,000 times

( )

18

( ), 0.0 to 150.0 ( ), 0 to 1500

.

”.

)

(32 ).

r.

t When the thermocouple or RTD input is burnt out, OUT1 and OUT2 are turned off (for DC curren

,

f

.

Page 19

(1) Reading and setting of the main setting value, PID values and each setting value

(2) Reading of the input value and action status

(3) Change of the functions

Communication interface : Based on EIA RS-485

Communication method : Half-duplex start stop synchronous

Data transfer rate : 2400, 4800, 9600, 19200bps (Selectable by key)

Parity : Even, Odd and No (Selectable by key)

Stop bit : 1 and 2 (Selectable by key)

Communication protocol : IMO protocol, Modbus RTU, Modbus ASCII (Key selectable)

Number of units connectable : Maximum 31 units to 1 host computer

Communication error detection: Double detection by parity and checksum

Digital external setting : The SV from the programmable controller (with the option SVTC) can be

When the data from the programmable controller exceeds the SV high

limit or low limit value, the TP40A ignores the value, and performs the

control with the former value.

The control desired value adds SVTC bias value to the value received

by the SVTC command.

SV1/SV2 external selection (Option code: SM)

SV1 or SV2 can be selected by the external contact.

When this option is added, the option [C5] cannot be added with it.

Contact open between 13-14: SV1, Contact closed between 13-14: SV2

Contact current: 6mA

digitally transmitted to the TP40A (with the option C5).

(The Setting value lock of the TP40A must be set to Lock 3)

10. Troubleshooting

If any malfunctions occur, refer to the following items after checking the power supply to the controller.

10.1 Indication

Problem

PV display is indicating [ ].

[ ] is blinking on the PV

display.

[ ] is blinking on the PV

display.

Presumed cause and solution

• Control output OFF function is working.

Press the key for approx. 1 second to release the function.

• Thermocouple, RTD or DC voltage (0 to 1V DC) is burnt out.

Change each sensor.

How to check sensor burnout

[Thermocouple]

If the input terminal of the instrument is shorted, and if nearby

room temperature is indicated, the instrument should be normal

and sensor may be burnt out.

[RTD]

If approx. 100

between A-B of the instrument and between B-B is shorted, then

if nearby 0

and sensor may be burnt out.

[DC voltage (0 to 1V DC)]

If the input terminal of the instrument is shorted, and if scaling low

limit value is indicated, the instrument should be normal

and the signal wire may be burnt out.

• Is the input terminal of thermocouple, RTD or DC voltage (0 to 1V

DC) securely mounted to the instrument input terminal?

Connect the sensor terminals to the instrument input terminals securely.

• Check if input signal source for DC voltage (1 to 5V DC) or DC

current (4 to 20mA DC) is normal.

How to check each signal wire

[DC voltage (1 to 5V DC)]

If the input to the input terminals of the instrument is 1V DC and

if scaling low limit value is indicated, the instrument should be

normal and the signal wire may be disconnected.

[DC current (4 to 20mA DC)]

If the input to the input terminals of the instrument is 4mA DC and

if scaling low limit value is indicated, the instrument should be

normal and the signal wire may be disconnected.

• Is input signal wire for DC voltage (1 to 5V DC) or DC current (4 to

20mA DC) securely connected to the instrument input terminals?

Connect the signal lead wire to the instrument input terminals securely.

• Is polarity of thermocouple or compensating lead wire correct?

Do codes (A, B, B) of RTD agree with the instrument terminals?

of resistance is connected to the input terminals

(32 ) is indicated, the instrument should be normal

19

Page 20

The PV display keeps indicating

the value which was set in the

Scaling low limit setting.

The indication of PV display is

abnormal or unstable.

The PV display is indicating

[

10.2 Key operation

• Unable to set the SV, P, I, D,

proportional cycle or alarm

setting

• The values do not change by

].

Problem

, key operation.

Wire them properly.

• Check if the input signal source for DC voltage (0 to 5V DC,

0 to 10V DC) and DC current (0 to 20mA DC) is normal.

How to check each signal wire

[DC voltage (0 to 5V DC, 0 to 10V DC)]

If the input to the input terminals of the instrument is 1V DC and

if the value corresponding to 1V DC is indicated, the instrument

should be normal and the signal wire may be disconnected.

[DC current (0 to 20mA DC)]

If the input to the input terminals of the instrument is 1mA DC and

if the value corresponding to 1mA DC is indicated, the instrument

should be normal and the signal wire may be disconnected.

• Are the input lead wire terminals for DC voltage (0 to 5V DC, 0 to

10V DC) or DC current (0 to 20mA DC) securely mounted to the

instrument input terminals?

Mount the sensor terminals to the instrument input terminals securely.

• Is sensor input or temperature unit ( or ) correct?

Select the proper sensor input and temperature unit (

• Sensor correcting value is unsuitable. Set the value suitably.

• Is the specification of the sensor correct?

Set the sensor to the proper specification.

• AC leaks into the sensor circuit. Use an ungrounded type sensor.

• There may be a piece of equipment producing inductive

interference or noise near the controller.

Keep the equipment producing inductive interference or noise

away from the controller.

• Internal memory is defective.

Contact our agency or us.

• Setting value lock (Lock 1 or Lock 2) is designated.

Release the lock designation.

• During PID auto-tuning or auto-reset.

In the case of PID auto-tuning, cancel the auto-tuning.

It takes approximately 4 minutes until auto-reset is finished.

Presumed cause and solution

or ).

The setting indication does not

change in the input range even if

the , keys are pressed,

and unable to set the value.

10.3 Control

Problem

Temperature does not rise. • Sensor is out of order. Replace the sensor.

The control output remains

ON status.

The control output remains

OFF status.

• If you have any inquiries, please consult our agency or the shop where you purchased the unit.

• SV high or low limit value in Auxiliary function setting mode 1 may

be set at the point the value does not change.

Set the proper value while in the Auxiliary function setting

mode 1.

Presumed cause and solution

• Sensor or control output terminals are not securely mounted to

the instrument input terminals.

Mount the sensor or control output terminals to the instrument

input terminals securely.

• The wiring of sensor or control output terminals is incorrect.

Connect it properly.

• OUT1 or OUT2 low limit value is set to 100% or greater

in Auxiliary function setting mode 2.

Set the value appropriately.

• OUT1 or OUT2 high limit value is set to 0% or less in

Auxiliary function setting mode 2.

Set the value appropriately.

20

Loading...

Loading...