Page 1

Screw pumps

ACG/UCG 7

This instruction is valid for all ACG/UCG pump models shown on page 2

Contents Page

List of components 2

Exploded view/Ordering code 3

Service intervals 4

Shaft seal/Service for ball bearing 4

Lubricating intervals/Useful tools 5

Inspection of rotors 5

Sectional view 6

Dismantling 7

Reassembly 9

Pressure relief valve 11

ACG1 ' IMO AB

ACG 0621GB

October 2002

A Member of the

COLFAX PUMP GROUP

Maintenance and Service

Instruction

Page 2

2 ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

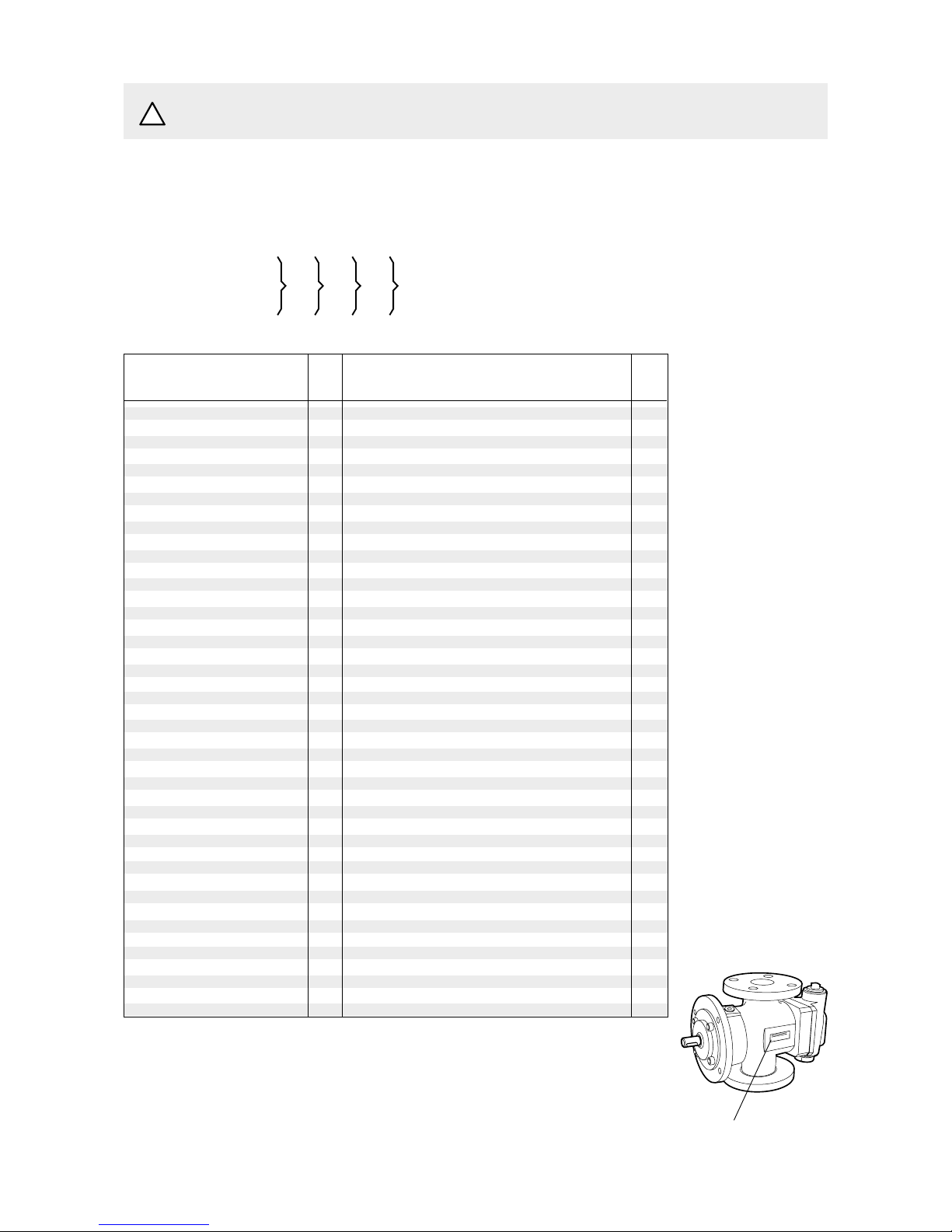

Qty Components included in Spare parts sets:

PosNo Denomination G011 G012 G050 G053 G054 G057 G070 Note

1010 Power rotor CCW-rot. 1 x (x)

1020 Power rotor CW-rot. 1 x x

106 Balancing piston 1 x x x 5

113 Shaft key 1 x x x

120 Distance sleeve 1

122 Ball bearing 1 x x

124 Retaining ring 1 x x x

124A Support ring 1 x x x

201 Idler rotor CCW-rot. 2 x (x)

202 Idler rotor CW-rot. 2 x x

359 Distance washer 1

359A Support ring 1 x x x

401 Pump body 1

424 Sleeve 1 4

424A Washer 1 4

429 Spindle 1 4

437 O-ring 1 4

440 Return valve 1

451 Screw 4/6

453 Screw 4

462 Plug 2 1

462A Sealing washer 2 x x x 1

473 Grease nipple 1

473A Grease nipple cover 1

480 Valve housing 1 2

5010 Front cover 1

502 Tension pin 1 6

502A Plug 1 6

506 Gasket 1 x x x

509 Shaft seal 1 x x x

514 Retaining ring 1 x x x

537 Plug 2

537A Sealing washer 2 x x x

551 Rear cover 1 3

556 Gasket 1 x x x

601 Valve cover 1 x 2,7

602 Sealing washer 1 x xxx2

605 O-ring 1 x xxx2

608 Valve spindle 1 x 2,7

608A Retaining ring 1 x xxx2

612 Set screw 1 x 2,7

614 Valve piston 1 x 2,7

615 Valve spring 1 x 2

Before commencing any work, read this instruction carefully! Failure to comply

with these instructions may cause damage and personal injury!

Valid for all pumps in sizes: ACG/UCG 045/052/060/070; Rotor diameter and generation: K7/N7

With version codes: Also valid for pump options: A101, A327, A385

Example of pump designations

std: ACG 045N7 NVBP; option ACG 070N7 NVBP A101

List of components

For more information about the pumps identification code, technical data and performance we refer to the

ACG/UCG Product description. Fore more information about the pumps installation, Start-up and trouble

shooting we refer to the IMO Installation and Start-up instruction for low pressure pumps.

Explanations:

G011: Rotor set

CCW-rotation option

G012: Rotor set

CW-rotation (std)

G050: Shaft seal

G053: Minor kit

(G050 + G057) + 122

G054: Major kit consisting

of: G053+G012 (G011)

G057: Joint kit

G070: Valve element

ACG Pump with DIN

flanges

UCG Pump with ANSI

flanges

A101: CCW

A327: With Tuning

A385: CCW and Tuning

Name plate of the pump

IMO AB

ACG2 ' IMO AB

N

T

VBF

E

P

G

!

Notes:

1) Excluded in xxxG

2) Excluded in xxxE

3) Valid for xxxE

4) Valid for pump option

A327

5) Included in item 1020

or 1010

6) Included in item 5010

7) Only sold as G070

Page 3

3

ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

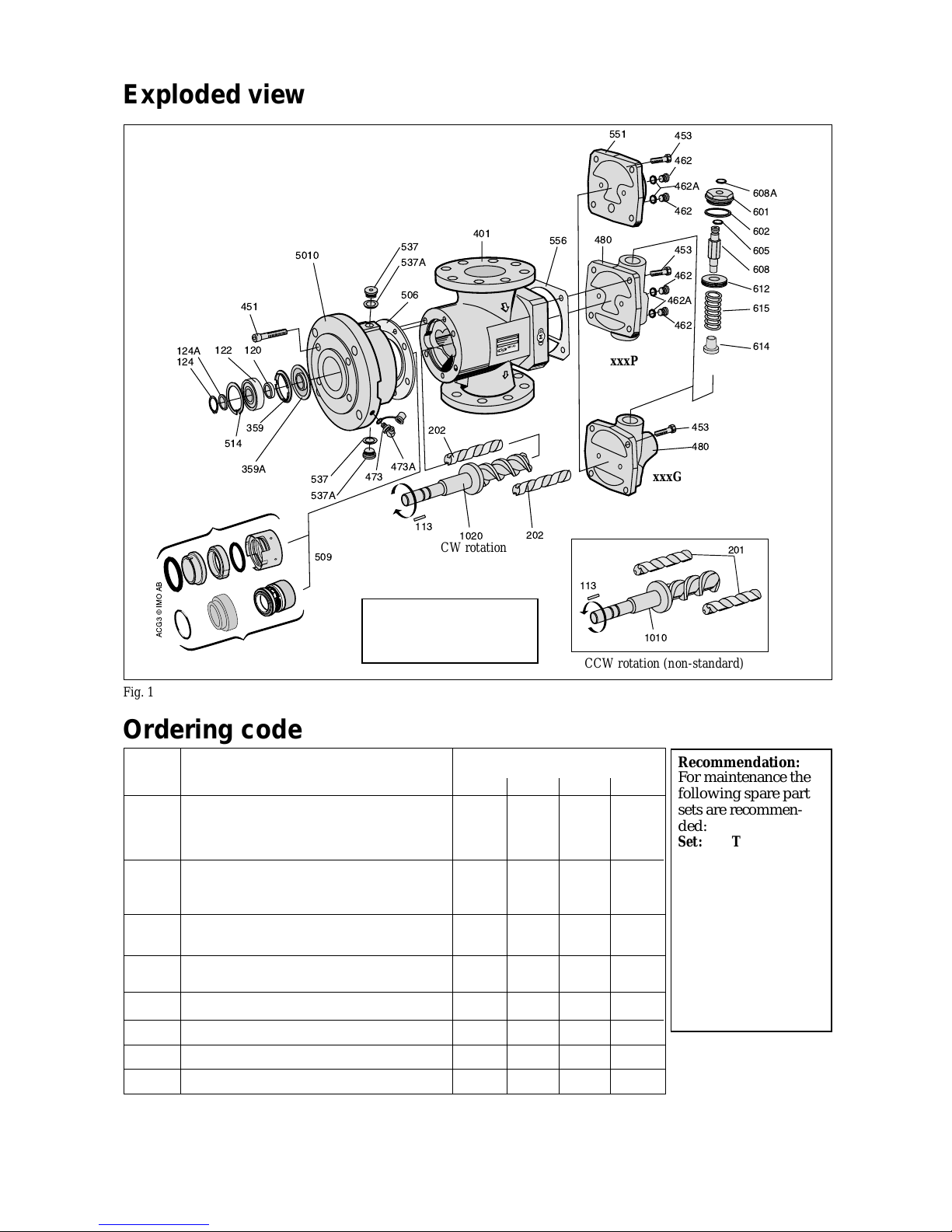

ACG3 © IMO AB

473

537

537A

506

401

556

480

551

453

462

462A

462

537

537A

473A

1010

201

608A

601

602

605

608

612

615

614

453

480

1020

202

113

113

509

359

359A

514

202

124A

124

122 120

451

5010

453

462

462A

462

Fig. 1

Exploded view

CCW rotation (non-standard)

xxxP

xxxG

CW rotation

Ordering code

Recommendation:

For maintenance the

following spare part

sets are recommended:

Set: To be used:

G057 Joint kit

For dismantling of

the pump

G053 Minor kit

For service

G054 Major kit

For repair after

damage or greater

wear.

Pos Spare parts sets Part numbers, sizes

No 045 052 060 070

Rotor set CW-rotation (std):

G012 Normal lead - pump version N7 178913 179507 179515 179523

" Low lead - pump version K7 187542 187559 187567 187575

Rotor set CCW-rotation (non-std):

G011 Normal lead - version N7 186478 186486 186494 186502

Low lead - version K7 189641 189642 189643 189644

G050 Complete shaft seal - version code xVxx 190335 190336 190338 190340

” ” - version code xTxx 174094 174102 174110 174128

G053 Minor kit - version code xVxx 191241 191243 191245 191247

” ” - version code xTxx 191242 191244 191246 191248

G054 Major kit=G012(G011)+G053 - - - G057 Joint kit 191237 191238 191239 191240

G070 Valve element - version code xxxP/G 191250 191250 191251 191251

122 Ballbearing 078576 077461 191181 191182

Details in pump option A327

See the sectional view p. 6

Fig. 2

Version xTxx

Ordering example:

For IMO-pump ACG 045N7

NVBP, serial number 456789

Shaft seal

pos G050 p/n 190335

Ballbearing

pos 122 p/n 078576

xxxE

ACG/UCG xxBE/BP/BG

Version xVxx

Page 4

4 ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

Service intervals

The intervals for inspection and replacement of wear

parts vary greatly with the properties of the pumped

liquid and can only be determined by experience.

All internal parts of the ACG-pump are lubricated

by the pumped liquid. Pumping liquid which

contains abrasive materials, or liquid that is corrosive, will significantly reduce service life

and call for shorter service intervals.

Wear in the pump may be indicated by:

• Vibration

• Noise

• Loss of capacity

• Reduction in flow/pressure

• Leakage

In installations where unplanned shut downs must

be avoided, it is advisable to have a complete pump

available for replacement, should any malfunction

occur. Furthermore we recommend planned inspection and overhaul at regular intervals, not exceeding

3 years.

It is recommended always to have the spares included in minor spare part kit available.

Service for ball bearing

The ACG-pump is fitted with an external grease

lubricated ball bearing.

When delivered from IMO AB, the ball bearings in

pump version xVxx are filled with grease of type B.

For version xTxx, type C is used.

Whenever the ball bearing is removed, it is recommended to exchange it for a new one.

Fit the new ball bearing properly greased and

regrease it after one hour of running, while the

pump is operating.

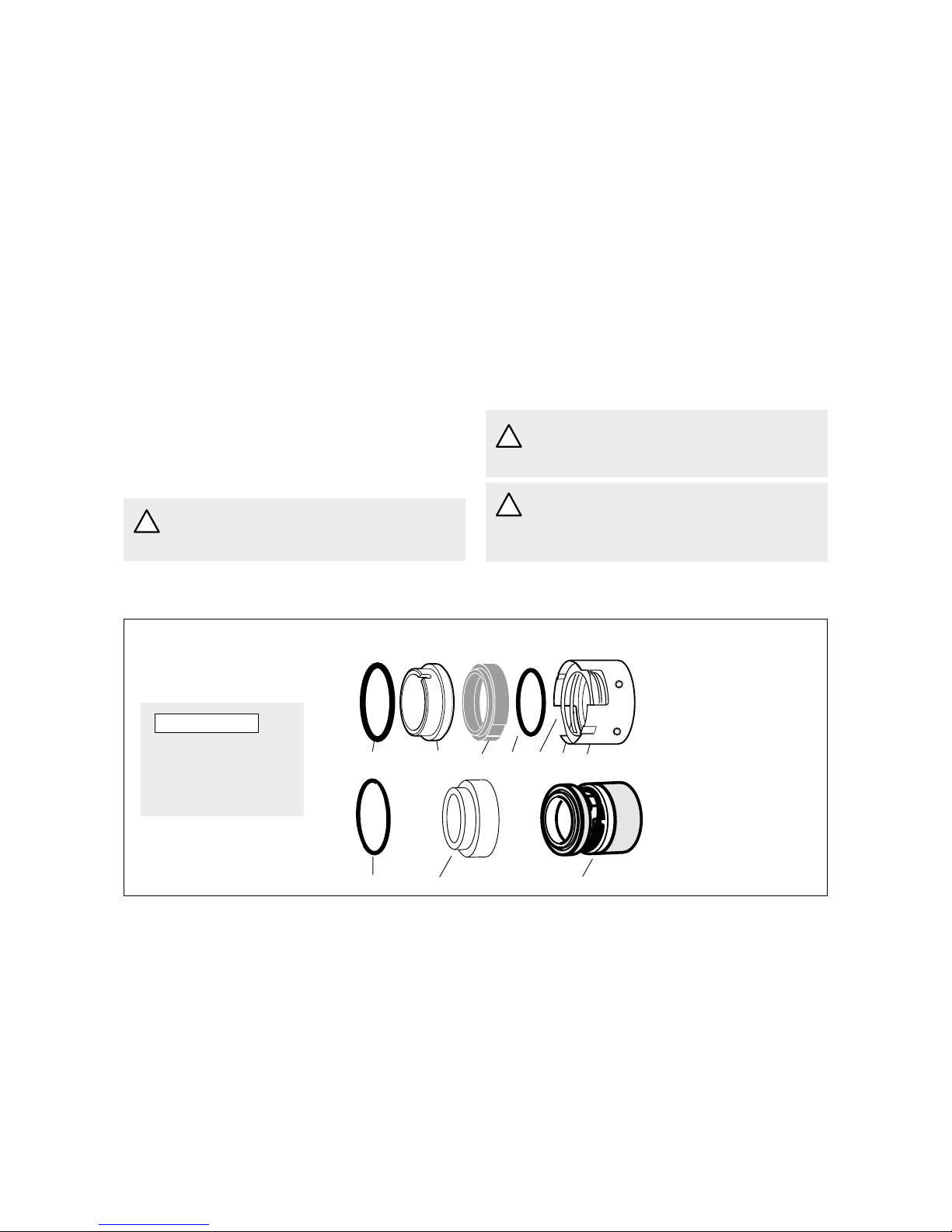

Inspection of shaft seal

As the seal faces of a mechanical shaft seal are

lubricated by the fluid a certain leakage will always

be present. Ten drops per hour can be considered as

acceptable.

An external visual inspection of the pump is advisable at least every two days to assure that the shaft

seal is not leaking too much.

Excessively leaking shaft seals should be changed

without delay, as the leakage normally will grow

worse and cause additional damage.

Follow the instructions in the dismantling/reassembly session.

When working with a shaft seal, cleanliness is of

utmost importance. Avoid touching the seal faces. If

necessary, the seal faces should be cleaned immediately prior to assembly, using a dustfree cloth and

clean solvent.

Never use grease on the seal faces.

Shaft seal-assembly drawing

Shaft seal G050 (pos 509)

Version code xVxx

Version code xTxx

S2 S1 S5

S2 S1 S4 S6 S9 S7 S5

S1 Seat

S2 O-ring

S4 Seal ring

S5 Seal ring carrier

S6 O-ring

S7 Spring

S9 Stop washer

S1 Seat

S2 O-ring

S5 Bellows unit

Fig. 3

ATTENTION

Be careful to mount

these parts in right

order and in right

direction.

If the pumps operating temperature exceeds

60°C let the pump cool off before any

service, maintenance or dismantling work is

commenced to avoid burn injury.

All work carried out on the pump has to be

performed in such a manner that risks for

personal injury are observed!

Use an appropriate type of grease, as per table and a

grease gun suitable for grease nipple (pos 473)

according to DIN 71 412 (ISO 6392).

On vertical mounted units the greasing intervals are

reduced to half.

Installed in dusty or dirty premises or in a corrosive

environment it should be lubricated at more frequent intervals.

If using others than these recommended greases

check if it is possible to mix them with each other,

otherwise clean before using a new grease.

Connecting and disconnecting of electric

cables must be done only by personnel

authorized to do such work.

ACG8 ' IMO AB

!

!

!

Page 5

5

ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

Useful tools

A

CG7 © IMO AB

Slide calliper

Puller

Mounting sleeve dimensions

Pump size D d L Part No

ACG/UCG 045 ø 25.0 ø 21.0 100 188887

ACG/UCG 052 ø 31.0 ø 26.0 100 188888

ACG/UCG 060 ø 35.0 ø 31.0 100 188889

ACG/UCG 070 ø 42.0 ø 36.0 100 188890

Fine

emery

Oil can Grease

Mounting

sleeve

2 pcs of

screw

driver

Plastic

mallet

Pair of

pliers

Fig. 4

Lubricating intervals in working hours

Temp Pump sizes 045 and 052 Pump sizes 060 and 070

max Grease Speed, r/min Speed, r/min

°C type 3500* 2900 1750 1450 1150 950 3500* 2900 1750 1450 1150 950

70 A 8500 10000 10000 10000 10000 10000 7500 8500 10000 10000 10000 10000

90 A 3350 3950 5350 5950 6350 7500 2950 3350 4750 5150 5950 6750

110 B 2650 3150 4250 4700 5000 5950 2350 2650 3750 4100 4700 5350

130 B 1050 1250 1650 1850 2000 2350 900 1050 1500 1600 1850 2100

155 C 650 750 1050 1150 1250 1500 600 650 950 1000 1150 1300

*) at rotation speed > 3 500 r/min special instructions are given by IMO AB.

Recommended greases (the availability of the greases can differ locally):

Type A: BP Energrease LS 3, Esso Beacon 2, Mobilgrease HP 222, Shell Alvania G3, Texaco Multifak EP2, SKF LGMT2,

Q8 REMBRANDT EP2, CASTROL APS2, ELF ROLEXA 3, TOTAL MULTIS TIR EP3, FINA MARSON L3.

Type B: BP Energrease LC2, CHEVRON SRI GREASE 2, Esso Unirex N3, Mobilith SHC220, SHELL RETINAX LX,

SHELL Albida LX, VAL-PLEX EP GREASE, Texaco Hytex EP2, SKF LGHQ 3, Q8 RUBENS, CASTROL LMX,

INDUSTRIAL GREASE HEAVY, TOTAL MULTIS THT2, FINA PLUTON L2.

Type C: Mobilith SHC 460

Before any maintenance work, ensure

that the driver is deenergized and the

pump hydraulically isolated.

!

!

!

Oil leakage may make the floor slippery

and cause personal injury.

When handling liquids that may harm

skin use gloves and/or protective clothing.

!

!

Pump size 045 052 060 070

Grease amount (g) 4 6 7 9

d

D

GREASE

L

Inspection of rotors

If an indication of a worn pump is noticed (see service

intervals above), a brief inspection of the idler rotors

is recommended.

A quick inspection of the idler rotors can be made

simply by removing the rear cover or valve cover.

Note that the driver must be deenergized and the

pump hydraulically isolated before the rear cover is

removed. Provisions to handle the fluid are to be

made. If a more thorough investigation is needed,

proceed as under ”Dismantling”.

Internal clearances in the pump, which are vital for its

proper function, may have been affected by wear.

Acceptable wear can be determined only by experience of the actual application. As a rule of thumb the

following max clearance values may apply:

• Between rotor and bores or bushings: 0.2 mm

• Between rotor flanks: 0.4 mm

For light duties (low pressure, medium viscosity)

even bigger clearances may be acceptable but for low

visc./high pressure duties the limit will be lower.

Also check if there are major scratches on these parts.

When handling liquids which may involve

fire hazards appropriate precautions to

avoid danger are to be taken.

In case of failure for a system with elevated

pressure, fluid jets may cause injury and/or

damage.

Allen

keys

d

D

L

Mounting kit (M8) Mounting sleeve

Page 6

6 ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

Sectional view

Fig. 5

Version xxxE

Version xxxG

Version xxBP

424A

424

437

429

Option A327

Page 7

7

ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

ACG14 ' IMO AB

Dismantling

• Note the axial position of the shaft coupling.

• Release the stop screw.

A. B.

C. D.

ACG11 ' IMO AB

• Remove the key

113.

• Remove the shaft

coupling.

F.E.

451

• Remove the screws 451.

124

124A

514

ACG12 ' IMO AB

ACG13 ' IMO AB

• Remove the retaining rings 124 and 514.

• Remove the support ring 124A.

Fig. 8 Fig. 9

Fig. 7Fig. 6

Fig. 11

Fig. 10

ACG10 © IMO AB

• Turn the

electricity OFF.

• Close the valves.

• Remove the pump

from the system.

ATTENTION

Use appropriate vessels to collect oil spill-

age when removing and opening the pump.

ACG9 © IMO AB

113

Page 8

8 ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

ACG17 © IMO AB

O AB

J–xTxx.

K.

Shaft seal

Version xTxx

Fig. 16

S4

S6

S5

Fig. 17

• Take out the

idler rotors.

• Clean all parts

that are going

to be used

again.

ACG20 © IMO AB

202

• Unscrew the

seal ring

carrier S5

screws and

take off the

seal ring

carrier S5

together with

the seal ring S4

and the o-ring

S6.

ACG18 © IMO AB

ACG15 © IMO AB

122

120

359

359A

Fig. 12

Fig. 13

G. H.

5010

• Push out the ball

bearing 122 together

with the distance

sleeve 120. If there is

tight fit use a mounting sleeve and a

mallet.

• Remove the distance

washer 359 and the

support ring 359A.

• Remove the

front cover

5010 with a

puller.

I.

J–xVxx.

Fig. 15

Fig. 14

• Turn the front cover 5010 upside down.

• Push out the seat from the front cover 5010.

• Remove the o-ring S2.

• Remove the gasket 506.

• Pull the power rotor 1020 out of the pump

body and place it into the jaws of a jaw vice

with soft jaws or a column drilling machine.

• Push with two drivers as shown on the

sketch, to remove the shaft seal.

S1

S2

506

5010

S5

S5

1020

No tools

from this

side

Shaft seal

Version xVxx

ACG16 ' IMO AB

5010

!

The sealing

surfaces of the

shaft seat

should not be

touched with

the fingers.

Mounting

sleeve

Page 9

9

ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

ACG22 ' IMO AB

S4

S5

Balance

piston

• Lubricate the

idler rotors and

fit them into the

pump.

Lubrication

groove turned

downwards.

202

A.

Fig. 18

Fig. 20

B–xTxx.

Version xTxx

Reassembly

• Open a package

with a new shaft

seal 509 version

xTxx.

• Place the seal ring

carrier S5 on the

shaft of the power

rotor 1020 flush

against the balance piston and

lock it with its

stop screws. Fit

the o-ring S6 and

the seal ring S4.

ACG21 © IMO AB

S6

ACG23 © IMO AB

• Carefully place the

power rotor 1020

into the jaw vice

with soft jaws.

• Lubricate all

surfaces of the

power rotor 1020.

• Open a package

with a new sealing

509, version xVxx.

• Place the bellows

unit S5 on the shaft

of the power rotor

and press it down

against the balance

piston (106) (See

fig. 5).

S5

B–xVxx.

Version xVxx

1020

Fig. 19

C.

Fig. 21

• Lubricate the Oring S2 and the

recess of the front

cover 5010.

• Clean the sealing

faces and fit the

seat S1 into the

front cover 5010.

Mind the position

of the retaining

pin if applicable.

S1

S2

ACG24 © IMO AB

5010

D.

• Lubricate the balance piston 106 with a thick oil (ISO VG 460).

• Fit the front cover onto the power rotor 1020 untill it rests on

the bellows unit S5.

• Fit the support ring 359A and the distance washer 359 into the

front cover. Mind the position of the distance washer 359.

• Fit the distance sleeve 120 into the front cover 5010.

• Fill the ball bearing with appropriate grease. See page 5 for

grease selection.

• Fit the ball bearing 122 onto the shaft.

359

359A

5010

Grease

120

1020

122

Mounting kit

106

Fig. 22

ATTENTION

The open side of the bearing towards the cover.

• Fit the mounting sleeve and push the bearing to

its final position in the front cover. To do this

some force is required. Use Your column drilling

machine or mounting kit (see fig 4).

!

Do not use a hammer etc. as this might

damage the shaft seal and ball bearing.

Page 10

10 ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

F.

• Fit the key back in position, see fig. 9.

• Fit the shaft coupling back into place (see fig. 7

and 8) with the same methode used when

fitting the ball bearing.

Fig. 24

!

Fig. 25

G.

• Remove the plug 537 and washer 537A.

• Hold the rotor unit horizontally with the

bore for 537 upwards. Carefully fill the

space completely with thin oil

(f. ex. ISO VG 46).

• When the oil is flooding, reassemble the

above parts in reverse order.

• Slowly turn the shaft a few turns to make

sure it moves freely (a certain resistance

from the shaft seal is normal but it must be

the same during the turns).

• Fit the support ring 124A and the retaining ring 124 on the shaft.

• Fit the retaining ring 514 back in place.

26 ' IMO AB

124

124A

514

E.

Fig. 23

5010

1020

537

537A

Do not use a hammer etc. as this might

damage the shaft seal and ball bearing.

Page 11

11

ACG 0621GB

October 2002

IMO AB, Telephone: + 46 8 50 622 800, Telefax: + 46 8 645 15 09

E-mail: info@imo.se

ACG29 ' IMO AB

H.

Fig. 26

Fig. 28

Pressure relief valve

Replacement of O-ring 605

• To avoid changing the setting of the valve, use an

Allen key to prevent spindle 608 to turn.

Unscrew cover 601 and pull up unit 601/608.

• Remove retaining ring 608A and pull the spindle

608 out of cover 601. Replace O-ring 605 and

assemble the unit 601/608 in reverse order.

Replace retaining ring 608A if necessary and

washer 602.

• Fit the unit 601/608 in the valve. Make sure the

608 enters the set screw 612 and use the Allen

key to prevent 608 to turn when cover 601 is

tightened.

Replacement of Valve Element G070

• Release the spring tension by turning the spindle

608 CCW with an Allen key. Use the Allen key to

prevent spindle 608 to turn and unscrew cover

601 but do not remove it yet.

• Remove the set screw 612 by turning the spindle

608 CCW. Pull out the valve piston/spring unit

614/615.

• Fit the valve element in reverse order with a new

washer 602. Turn the spindle 608 CW until the

set screw leave enough room for cover 601. Use

the Allen key to prevent 608 to turn further when

cover 601 is tightened.

• Adjust the valve setting according to the "Installation and Start-up Instruction for IMO Low

pressure pumps".

451

5010

1020

506

• Place the gasket 506 on the pump body 401.

• Lubricate the power rotor 1020 and fit the

front cover 5010 together with the rotor set

into the pump body. Mind the position of

the tension pin 545.

• Fit the screws 451 and tighten them crosswise.

Version G

Version P

ACG30 ' IMO AB

480

608A

601

602

605

608

612

615

614

453

480

453

462

462A

462

401

Fig. 27

I.

• Put the pump back into the system and

proceed according to instructions under

”Start-up” in the installation manual.

Page 12

IMO AB: P. O. Box 42090, SE 126 14 Stockholm, Sweden

Telephone: +46 8 50 622 800, Telefax: +46 8 645 1509

www.imo.se

Loading...

Loading...