Page 1

ACF5 0601.01 GB

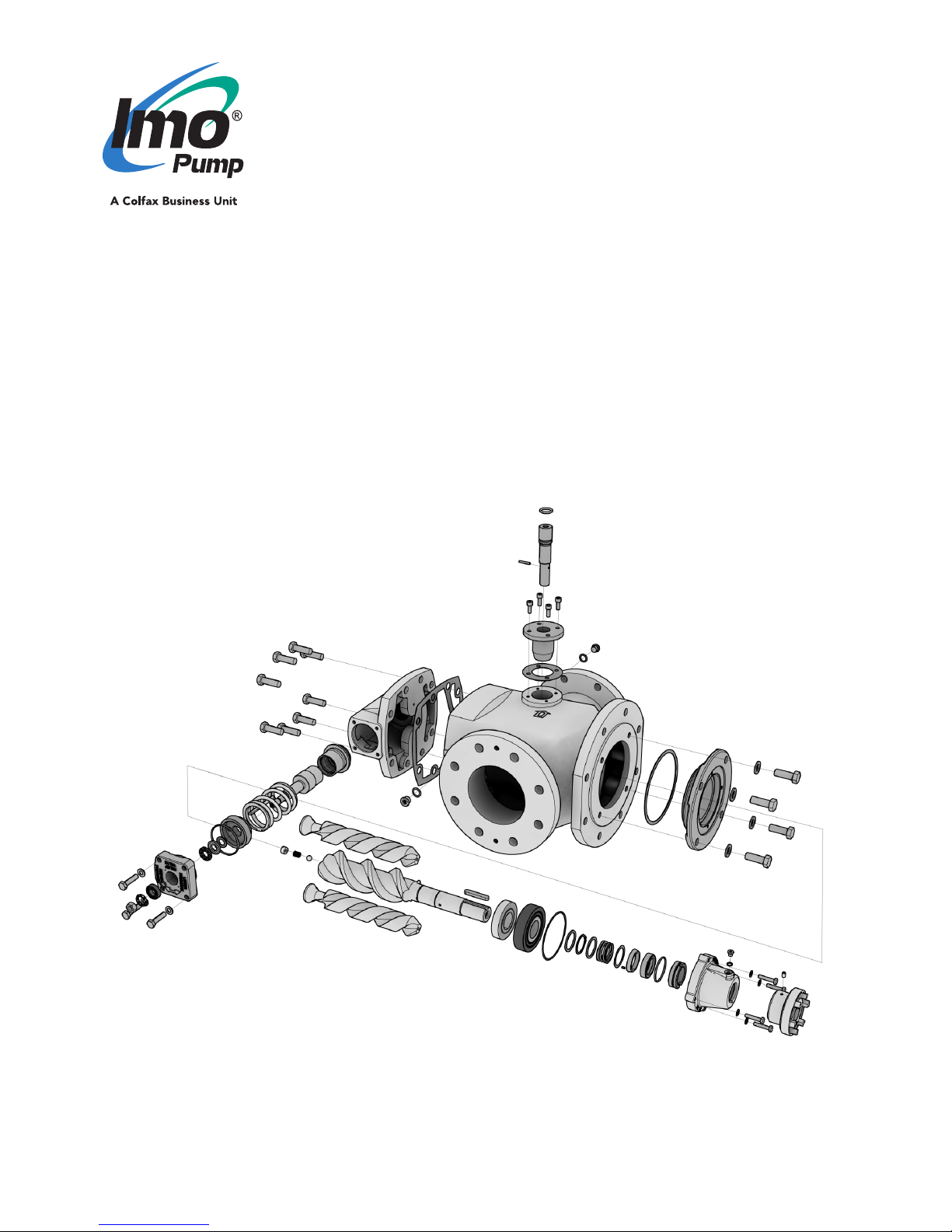

ACF5

Maintenance & Service Instruction

Screw pump

Page 2

ACF5 0601.01 GB

www.imo.se

2

Indentification of safety instructions

Non complience of safety instruc-

tions identied by the following

symbol could aect safety for

persons

Safety instructions where

electrical safety is invol-

ved are identied by:

Safety instructions which shall be considered

for reasons of safe operation of the pump

or pump unit and/or protection of the

pump or pump unit itself are marked

by the sign:

cm

;

Introduction

A screw pump from IMO is a quality product that is designed for a long problem free operation in tough environments. As all other mechanical products they do however requires a certain grade of maintenance and service in

order to guarantee a faultless and economic favourable operation.

A recommendation is to go through the pump each 5 year in order to replace wear details such as ball bearings,

the mechanical seal and certain gaskets and o-rings. A relatively small review of a screw pump from IMO means

that the pump in most of the cases will be in a condition “as new” and therefore give the operator another long and

problem free operation.

Page 3

ACF5 0601.01 GB

www.imo.se

3

Contents

Introduction .......................................................................................................................................................................... 2

List of components ............................................................................................................................................................... 4

Recommended Spare Parts Kits ......................................................................................................................................... 5

Service intervals ................................................................................................................................................................... 6

Inspection of rotors .............................................................................................................................................................. 6

Inspection of sha seal ........................................................................................................................................................ 6

Warranty maers ................................................................................................................................................................. 6

Precautions prior to starting maintenance on the pump .............................................................................................. 6

Dismantling and reassembling the pump 7

List of tools necessary for dismantling and reassembly ................................................................................................ 7

Sectional View ...................................................................................................................................................................... 7

Dismantling 8

Reassembly 1

2

Installation and Start-up Instruction 15

Installation 16

Transport and storage ....................................................................................................................................................... 16

Liing of pump .................................................................................................................................................................. 16

Allignment and sha couplings ...................................................................................................................................... 16

Strainer ................................................................................................................................................................................ 17

Pipe connections ................................................................................................................................................................ 18

Suction line ......................................................................................................................................................................... 18

Discharge line ..................................................................................................................................................................... 18

Deaeration ........................................................................................................................................................................... 18

Liquid trap .......................................................................................................................................................................... 18

Gauges ................................................................................................................................................................................. 19

Pressure relief valve .......................................................................................................................................................... 19

Start-up 20

Before starting: ................................................................................................................................................................... 20

Direction of rotation .......................................................................................................................................................... 20

Safety precautions before starting .................................................................................................................................. 20

Starting ................................................................................................................................................................................ 20

Seing the pressure relief valve ...................................................................................................................................... 21

Adjusting the tuning ......................................................................................................................................................... 21

Seing of tuning of the ACF: ............................................................................................................................................ 21

Trouble shooting 22

Page 4

ACF5 0601.01 GB

www.imo.se

4

Explanations:

ACF: Pump with

DIN anges

CW: Clockwise

rotation

CCW: Counter clock

-

wise rotation

G011: Rotor set CCW

rotation

G012: Rotorset CW

rotation

G050: Compl sha

seal

G053: Minor kit

(G050+G057)

G054: Major kit

G057: Joint kit

G070: Valve element

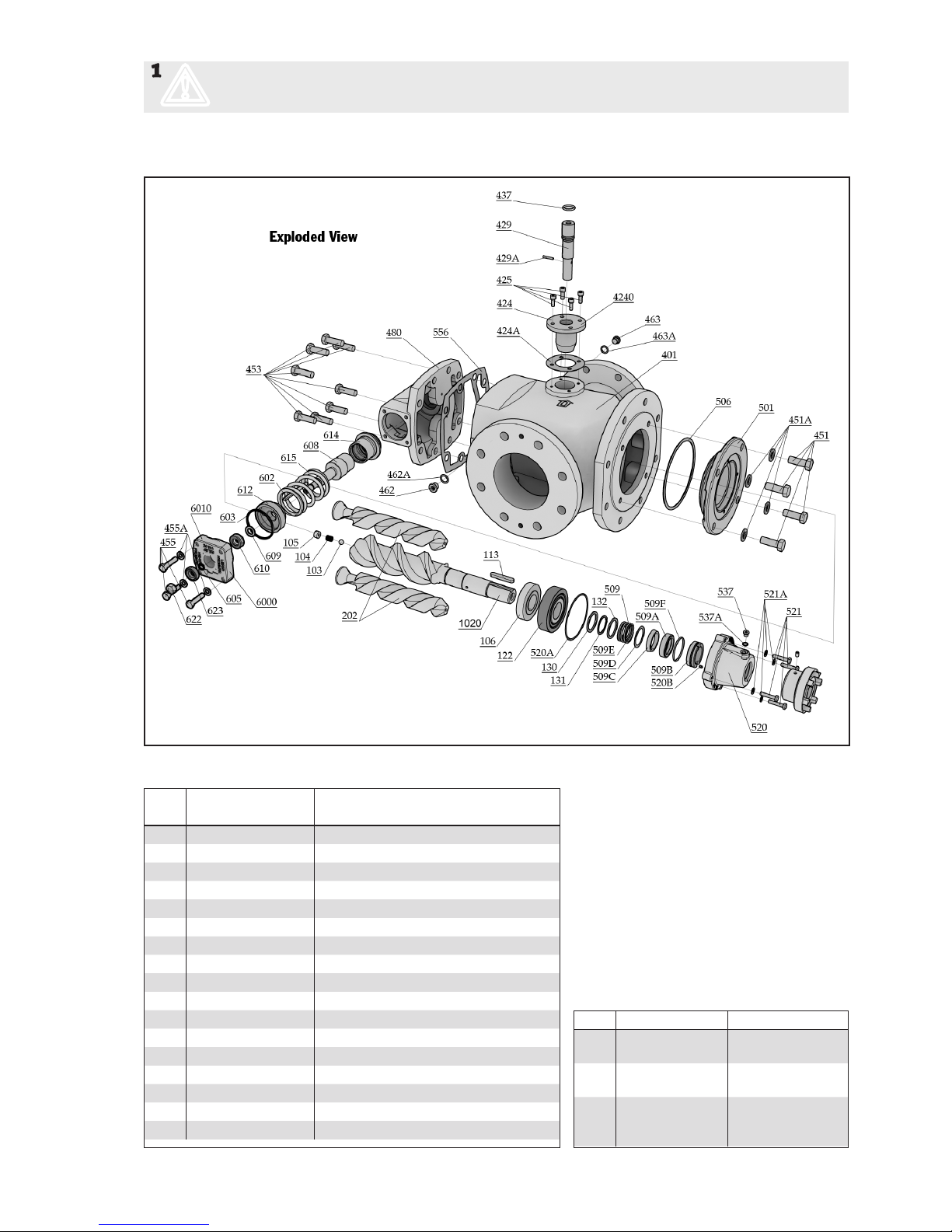

Included components in Spare part sets

Pos Part Denomination Qty G011 G012 G050 G053 G054 G057 G070

1010 Complete power rotor (CCW-rot.) 1 x x

1020 Complete power rotor (CW-rot.) 1 x x

(103) Ball 1 (x) (x) (x)

(104) Spring 1 (x) (x) (x)

(105) Hole screw 1 (x) (x) (x)

(106) Balancing piston 1 (x) (x) (x)

113 Key 1 x x x

122 Ball bearing 1 x x x

130 Support ring 1 x x x

131 Retaining ring 1 x x x

132 Support ring 1 x x x

201 Idler rotor (CCW-rotation) 2 x x

202 Idler rotor (CW-rotation) 2 x x

401 Pump body 1

4240 Tuning element 1

(424) Cover 1

(424A) Gasket 1 x x x

(425) Screw 4

(429) Guiding screw 1

(429A) Tenison pin 1

(430) Piston 1 (Valid for sizes 100-125) 1

(432) Tenison pin (Valid for sizes 100-125) 1

(437) O-ring 1 x x x

451 Screw 4

451A Washer 4

453 Screw 8

455 Screw 4

455A Washer 4

462 Plug 1

462A Washer 1 x x x

463 Plug 1

463A Washer 1 x x x

480 Valve housing 1

501 Front cover 1

506 O-ring 1 x x x

509 Mechnical seal 1 x x x

(509A) Rotating seal ring 1 (x) (x) (x)

(509B) Seat 1 (x) (x) (x)

(509C) Rubber ring 1 (x) (x) (x)

(509D) Washer 1 (x) (x) (x)

(509E) Spring 1 (x) (x) (x)

(509F) O-ring 1 (x) (x) (x) x

520 Compl. cover 1

520A O-ring 1 x x x

(520B) Tension pin 1

521 Screw 4

521A Washer 1

(537) Plug 1

(537A) Washer 1 x x x

556 Gasket 1 x (x) x

6000 Valve cartridge 1 x

(6010) Compl. valve cover 1 (x)

(602) Pin 1 (x)

(603) O-ring 1 x x x (x) (x)

(605) O-ring 1 x x x (x) (x)

(608) Valve spindle 1 (x)

(609) Washer 1 (x)

(610) Ball bearing 1 x x (x) (x)

(612) Regulating nut 1 (x)

(614) Valve piston 1 (x)

(615) Spring 1 (x)

(622) Nut 1 (x)

(623) Ball bearing 1 x x (x) (x)

List of components

Valid for all ACF Generation 5 pumps with leads and sizes: 080, 090, 100 K5/N5 & 110, 125 L5/N5.

With version codes: IVBP & NVBP. Also valid with options A020, A078, A101.

Page 5

ACF5 0601.01 GB

www.imo.se

5

1

m

Before commencing any work, read this instrucion carefully! Failure to comply with these instrutions

may cause damage and personal injury!

For more information about the pumps identication code, technical data and performance we refer to the ACF

Product description.

Pump size

Pos 080 090 100 110 125

G011 Rotor set N-lead 192966 192968 192970 192972 192974

CCW K-lead 192967 192969 192971

L-lead 192973 192975

G012 Rotor set N-lead 192785 192958 192960 192962 192964

CW CW K-lead 192786 192959 192961

L-lead 192963 192965

G050 Sha seal xVxx 192525 192525 192526 192526 192526

G053 Minor kit xVxx 192987 192987 192988 192988 192989

G057 Joint kit xVxx 192990 192990 192991 192991 192992

G070 Valve xxxP 192553 192553 192554 192554 192555

G099 Complete IEC 132 192993 192997

sha IEC 160 192994 192998 193002 193002 193002

coupling IEC 180 192995 192995 193003 193003 193003

IEC 200 192996 192996 193004 193004 193004

IEC 225 193001 193005 193005 193005

IEC 250 193006 193006 193006

IEC 280 193007 193007 193007

Kit Contents To be used for

G057 Gaskets, o-rings,

ball bearing, etc

Dismantling of

the pump

G053 G057 + Sha seal

G050

Normal scheduled inspection

G054 G053 + Complete

rotor set

Repair aer major

breakdown or

great wear

Recommended Spare Parts Kits

Every shutdown for service of a plant is

costly. The time for repair should therefore

be limited to a minimum which can be

accomplished by keeping a spare pump.

The changed pump can later be repaired at

a suitable place and can then be used as a

spare pump. For maintenance the following

spare parts kits are recommended:

Ordering Code

Page 6

ACF5 0601.01 GB

www.imo.se

6

Service intervals

The intervals for inspection and replacement of wear

parts vary greatly with the properties of the pumped

liquid and can only be determined by experience. All

internal parts of the ACF-pump are lubricated by the

pumped liquid.

Pumping liquid which contain abrasive materials, or

liquid that is corrosive, will signicantly reduce service

life and call for shorter service intervals.

Wear in the pump will normally show as:

• Vibration

• Noise

• Loss of capacity

• Reduction in ow/pressure

• Leakage

We recommend planned inspection and overhaul at

regular intervals, not exceeding 3 years.

It is recommended to always have the spares included

in minor spare part kit G053 available for a planned

inspection.

Inspection of rotors

To reach the idler rotors in a quicker way than described in the dismantling section, loosen the rear cover

(480) with valve. Screw out the idler rotors backwards.

Internal clearances in the pump, which are vital for its

proper function, may have been aected by wear. Acceptable wear can be determined only by experience of

the actual application. As a rule of thumb the following

max clearance values may apply: Between rotor and

bores: 0.2 mm, Between rotor anks: 0.4 mm For light

duties (low pressure, medium viscosity) even bigger

clearances may be acceptable but for low visc./high

pressure duties the limit will be lower. Also watch if

there are major scratches on these parts.

Inspection of shaft seal

As the seal faces of a mechanical sha seal are lubricated by the uid a certain leakage will always be present.

Ten drops per hour can be considered as acceptable. An

external visual inspection of the pump is advisable at

least every two days to assure that the sha seal is not

leaking too much.

Excessively leaking sha seals should be changed without delay, as the leakage normally will grove worse and

cause additional damage.

Follow the instructions in the dismantling/reassembly

session. When working with a sha seal, cleanliness is

of outmost importance. Avoid touching the seal faces.

If necessary, the seal faces should be cleaned immediately prior to assembly, using a dust free cloth and clean

solvent.

Warranty matters

IMO AB´s warranty obligations covers new pumps for 1

year aer the commissioning of the pump.

Parts that NOT are covered by the warranty are normal

wear details such as the mechanical sha seal, the ball

bearing or the exible coupling.

Precautions prior to starting maintenance on

the pump

2

m

If the pumps operating temperature

exceeds 60°C, let the pump cool o before

any service, maintenance or dismantling

work is commenced to avoid burn injury

3

m

All work carried out on the pump has to be

performed in such a manner that risks for

personal injury are observed!

4

m

When handling liquids that may harm skin,

use gloves and/or protecting clothing!

5

m

When handling liquids which may involve

re hazard appropriate precautions to

avoid danger are to be taken.

6

m

In case of failure for system with elevated

pressure, uid jets may cause injury and/

or damage.

7

m

Oil leakage may make the oor slippery

and cause personal injury.

8

m

Before any maintenance work, ensure that

the driver is deenergized and the pump

hydraulically isolated.

9

c

Connecting and disconnecting of electrical

cables must be done only by personnel

authorized to do such work.

Page 7

ACF5 0601.01 GB

www.imo.se

7

ACF 5 © IMO AB

d

D

GREASE

L

A B C D E F G H I

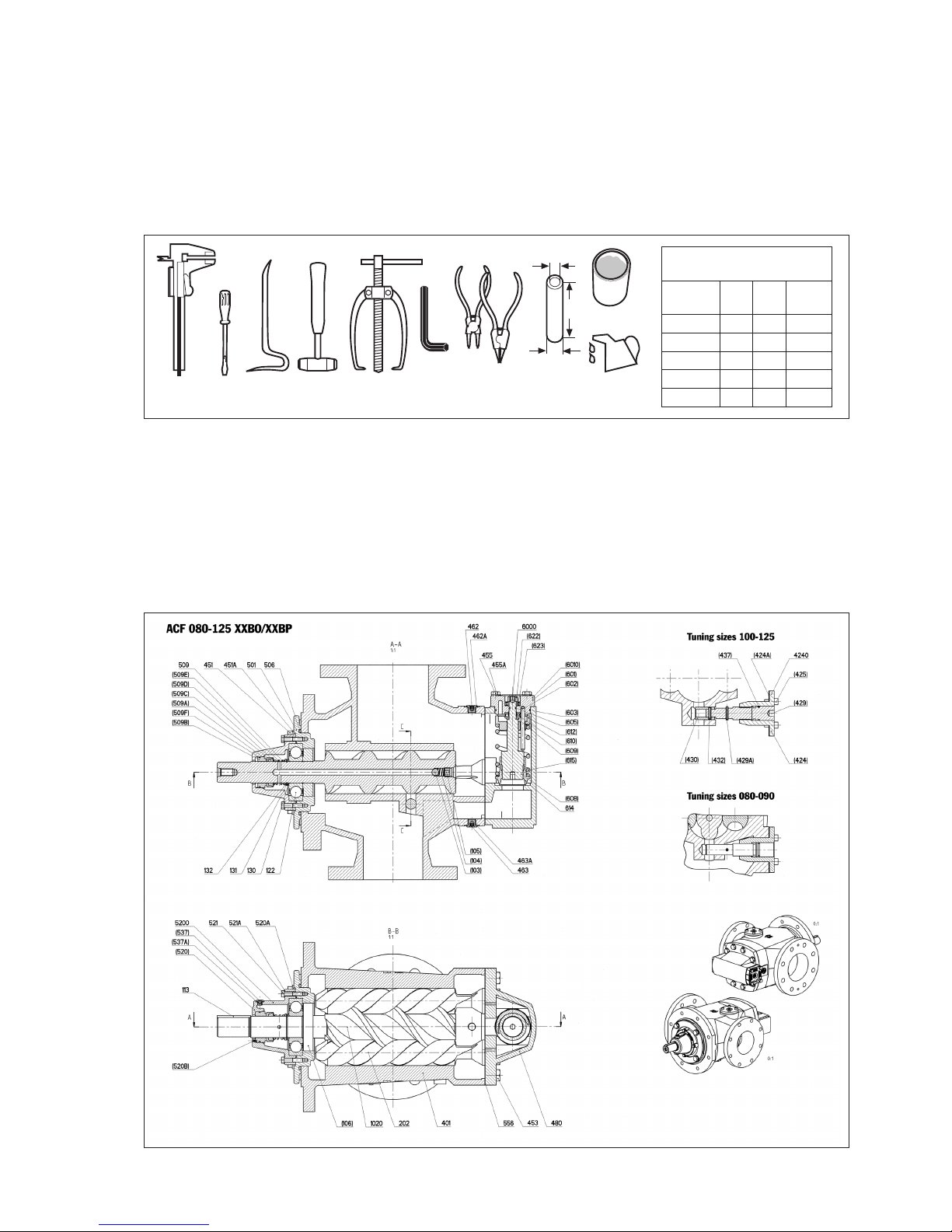

List of tools necessary for dismantling and reassembly

A = Slide calliper

B = Screw driver

D = Crow bar

E = Plastic mallet

F = Puller

G = Allen key

H = Pairs of pliers

I = Mounting sleeve

J = Oil can

Sectional View

Dismantling and reassembling the pump

Mounting sleeve

dimensions (mm)

Pump

size d L D

080 46 155 62 ±3

090 46 155 62 ±3

100 66 180 85 ±4

110 66 180 85 ±4

125 66 180 85 ±4

Page 8

ACF5 0601.01 GB

www.imo.se

8

ACF5 © IMO AB

ON

OFF

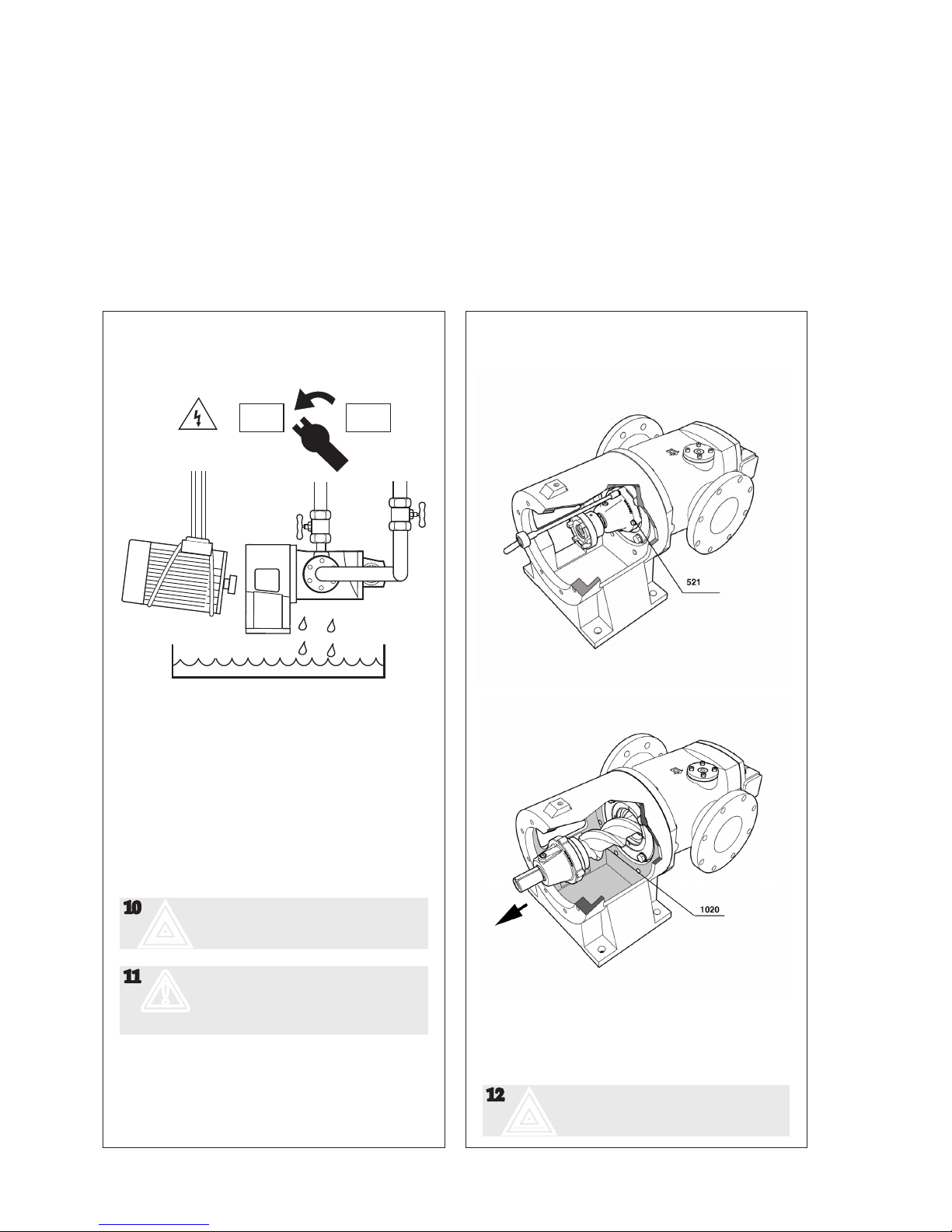

Dismantling

A.

For most installations repair can be done with the

pump in place by removing the motor.

• Turn the electricity OFF.

• Close the valves.

• Disconnect the electric motor.

• For horizontal installation drain the pump by

loosen screws 453 3-4 turns and loosen 480

valve housing.

10

;

Use appropriate vessels to collect oil

spillage when operating the pump

11

m

Pump and/or motor should be lied

with straps securely so that the

centre of gravity is located in order

to avoid tipping

B.

• Loosen and remove screws 521

• Pull out the power rotor 1020 with the help of

coupling half or an eye bolt ed in the power

rotor

12

;

Be careful when the threaded part of

the rotor passes the bore in the cover

Page 9

ACF5 0601.01 GB

www.imo.se

9

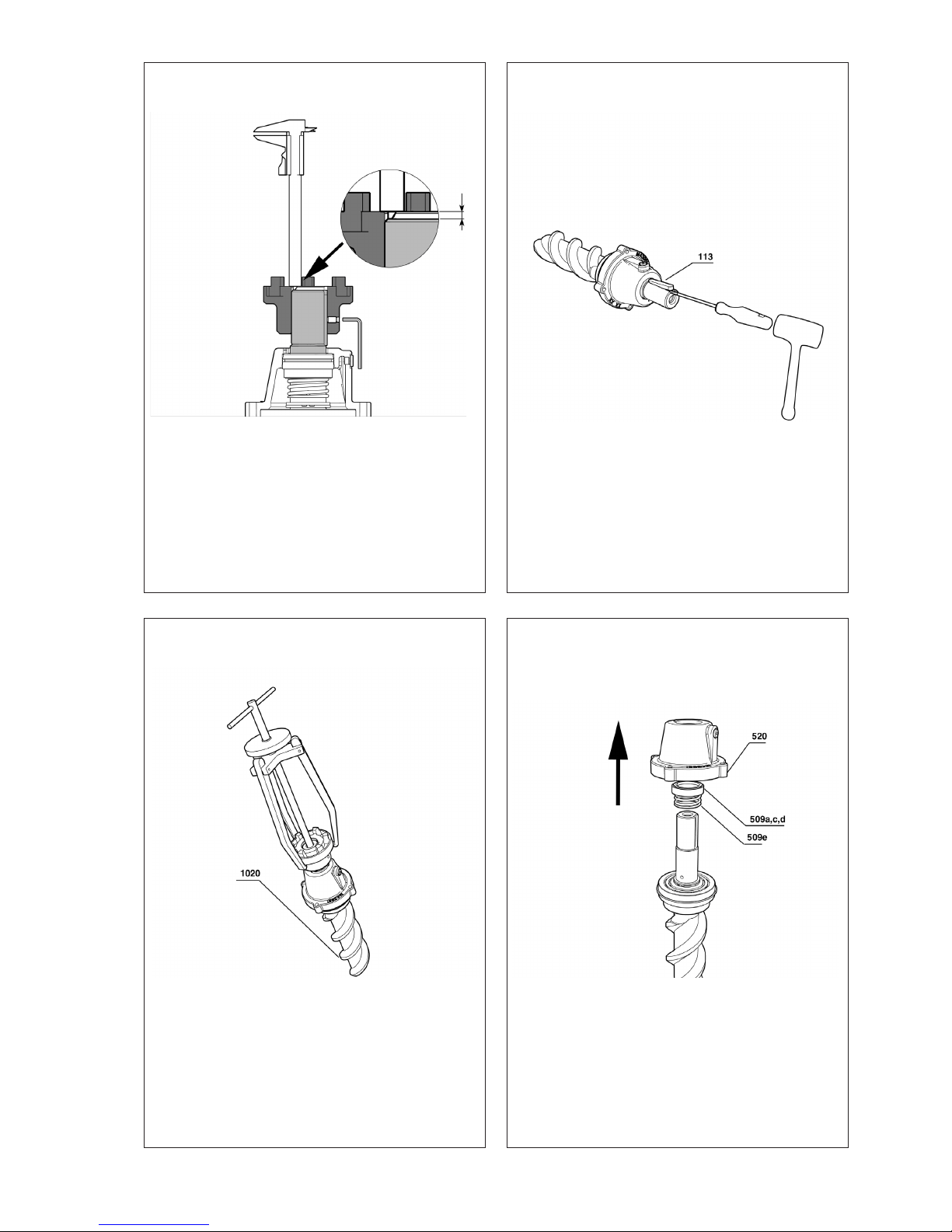

E.

• Remove the key 113

C.

• Note the axial posistion of the coupling half

• Release the stop screw

F.

• Pull the cover 520 upwards

• Carefully slide the rotary sha seal parts 509 a,

c, d, e upwards.

D.

• Remove the coupling half with a puller

Page 10

ACF5 0601.01 GB

www.imo.se

10

G.

• Remove the washer 132.

• Remove the circlip 131 with a plier.

• Remove the washer 130.

I.

• Press down the complete stationary part of the

sha seal 509b & 509f out the end cover 520 by

means of a Teon piece that ts smoothly.

NOTE: The other end of the Teon piece should

t on the opposite side of 509b and is used lager

on when 509b is pressed into the end cover 520

again.

J.

• Loosen the bolts 451 and remove the frontcover

504 with its o-ring 506 from the pump body

401.

H.

• Remove the ball bearing 122 from the rotor

1020 with a three legged puller.

Page 11

ACF5 0601.01 GB

www.imo.se

11

M.

• Remove the cylindrical spring loaded pin 429a

with a suitable puncher.

• Unscrew the tuning piston 429 counter-clock

-

wise from the cover 4420.

K.

• Carefully slide the idle rotors out of the Pump

body.

• Loosen the bolts 425 and pull the complete tun

-

ing device straight upwards.

N.

• Change o-ring 437 on the tuning piston 429

and mount it in 4240 in reverse order.

L.

• Loosen the 4 bolts 455 & 455a in order to pull

out the complete valve insert.

• Reassemble in opposite order.

• Loosen the 8 bolts 453 in order to remove the

back cover 480.

• Reassemble in opposite order.

Page 12

ACF5 0601.01 GB

www.imo.se

12

B.

• Mount the front cover 501 and its o-ring 506 on

the pump body 401 with the 4 screws.

• Lubricate the o-ring 506.

C.

• Mount the ball bearing 122 on the power rotor

1020 with the mounting tool by tightening the

nut.

NOTE: The measurement of this tool varies

depending on the pump size, a measurement

table can be found in the tool description on

page 7.

The tool can also be purchased from IMO AB.

A.

• Lubricate the idler rotors carefully and slide

them into the bores of the pump body.

NOTE: The position of the idler rotors should

be exactly as shown above as it otherwise will

be dicult to mount the power rotor.

Reassembly

Page 13

ACF5 0601.01 GB

www.imo.se

13

F.

• Slide on the rotating parts of the mechanical

sha seal on the power rotor as shown above,

grease the surface thoroughly on the power rotor as this prevents damage to the seals rubber

details when mounting it.

• Lubricate the seal face on the seat 509a with

grease. We recommend grease of ”Graphite”

or”Molybdendisulphite”type.

NOTE: It is verimportant that the mechanical seal

are handled with care and cleanliness is to be

considered as crucial.

D.

• Mount the washers 130 and 132 together with

the circlip 131.

E.

• Complete mechanical sha seal

Page 14

ACF5 0601.01 GB

www.imo.se

14

G.

• Mount the stationary sha seal part 509b with

its o-ring 509f into the end cover 520 by means of

a suitable Teon tool.

• The seal must be mounted so that the slot at the

boom of 509b corresponds with the guiding

pin 520b.

NOTE: The o-ring 509f must be thoroughly

greased as it otherwise easily could be damaged

during the mounting.

H.

• Mount the complete end cover 520 carefully on

the power rotor 1020.

• Remount the sha coupling with a suitable tool.

NOTE: Do NOT mount the coupling half with a

hammer as this will destroy the sha seal.

I.

• Lubricate and t the power rotor 1020 into the

pump by carefully guide it into the idler rotors

”openings”, see g A on page 12.

• Make sure that the de-aeration plug always is

pointing upwards and reconnect the de-aeration

extension pipe.

• Tight the screws 521 crosswise to help the rotor

to reach its nal position.

• Check that the pump sha moves freely.

• Fit the electric motor back to the pump.

• Check the correct seing of sha coupling ac

-

cording to ”Alignment and sha couplings” and

proceed according to instruction under ”Startup” in this manual.

Page 15

ACF5 0601.01 GB

www.imo.se

15

Installation and Start-up Instruction

Valid for ACF 080-125 Generation 5

BEFORE COMMENCING ANY WORK,

READ THIS INSTRUCTION CAREFULLY!

Indentification of safety instructions

Non complience of safety instruc-

tions identied by the following

symbol could aect safety for

persons

Safety instructions where

electrical safety is invol-

ved are identied by:

Safety instructions which shall be considered

for reasons of safe operation of the pump

or pump unit and/or protection of the

pump or pump unit itself are marked

by the sign:

cm

;

Page 16

ACF5 0601.01 GB

www.imo.se

16

max 90°

min 60°

max 90°

min 60°

Fig 1. Liing the pump

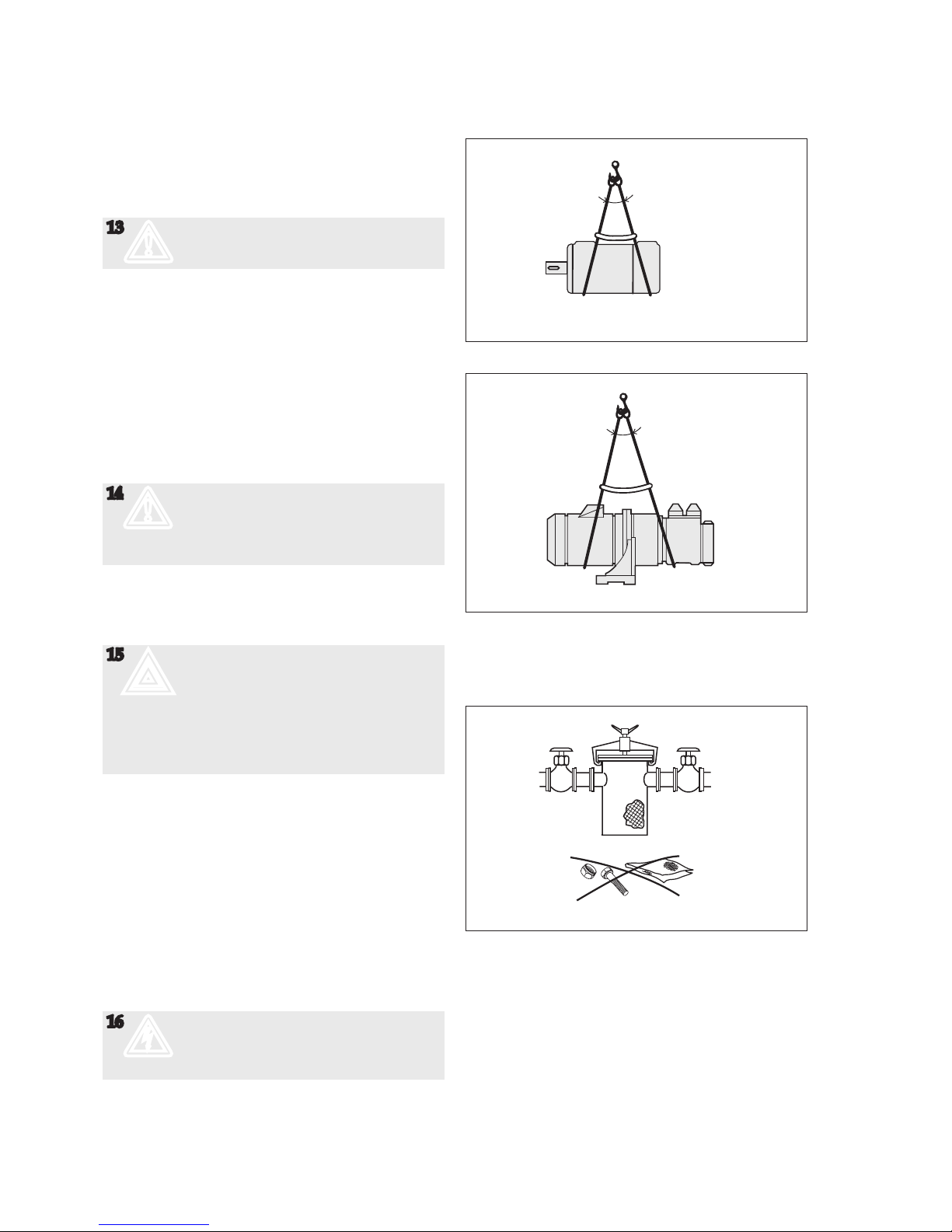

Design limitations and technical data for each pump

are found in the Product description. Installation of

IMO AB low pressure pumps does not require special

skills. However, these instructions presume that the

work is carried out by experienced ers!

13

m

Failure to comply with these instructions

may cause damage and personal injury

Transport and storage

Always protect the pump against ingress of water and

other impurities. Store the pump in a clean, dry and

warm environment. The pump is delivered with the

internals oiled and with protective covers over the

pipe connections and drain openings. These covers

should remain in place for as long as possible during

the mounting and installation procedure but must be

removed before start up.

Lifting of pump

14

m

All pumps should be lied with straps

securely aached to the pump or pump

unit, so that the center of gravity is located

between the straps in order to avoid

tipping of the pump.

Liing of the complete pump unit with the liing

device aached to the motor, should be avoided as the

motor’s liing provisions may not be able to carry the

combined weight of the pump and motor.

15

;

The installation must be designed

to minimize damage. Should an

operational or functional failure occur.

E.g. precautions should be considered to

collect oil spillage due to a broken pipe or

pump housing, to stop pump operation

if overheating should occur or if the oil

volume is below a minimum tank level.

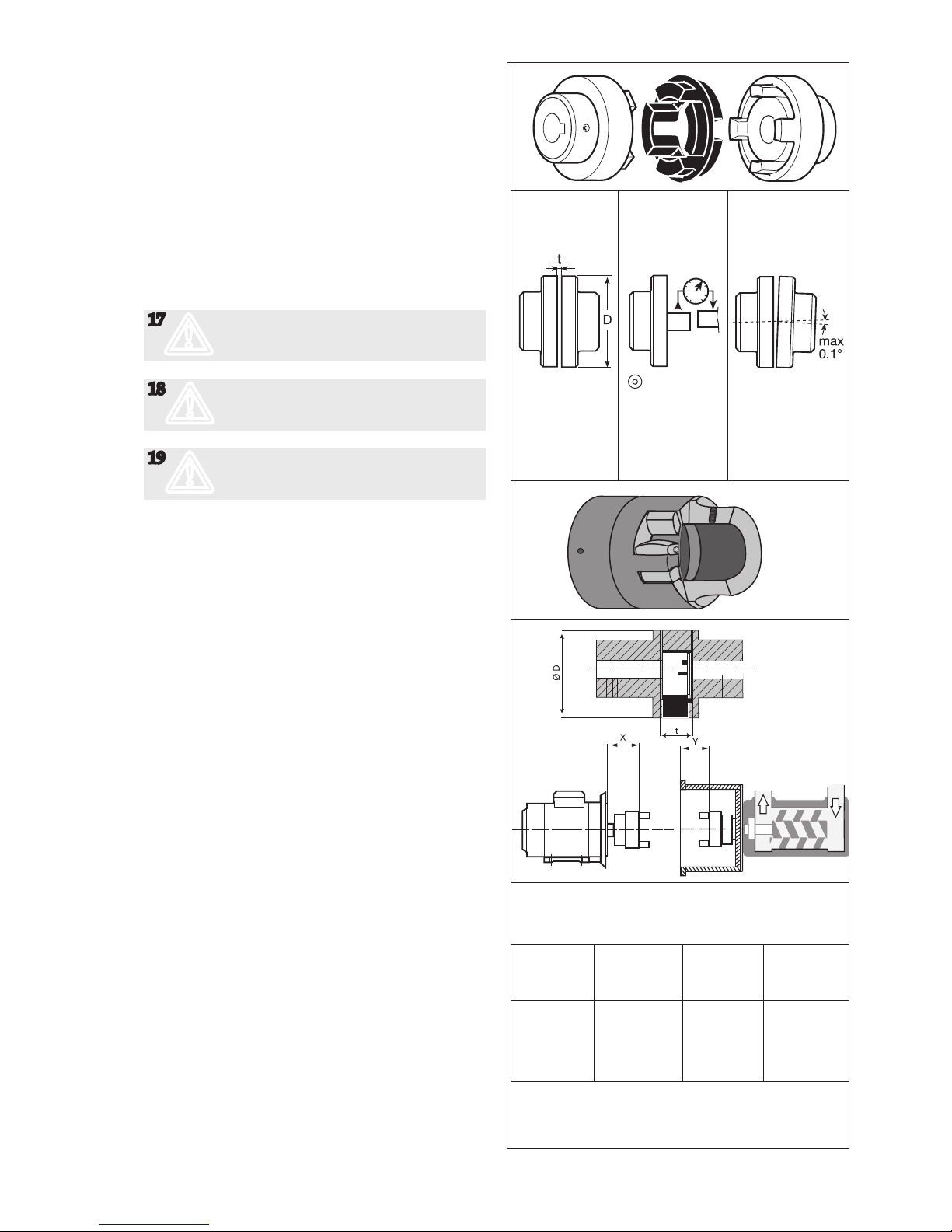

Allignment and shaft couplings

The pump shall be connected to its driver via a exible

sha coupling; they may also be driven via gears or

pulleys as specied in the Product Description, provided that the radial forces are kept within the specied

range. An angular misalignment of 0.1° corresponds to

approximately. 0.2 mm deviation/100 mm. The coupling

and alignment shall be selected not to transmit any axial or radial loads on the sha ends. IMO AB standard

couplings shall have a distance between the coupling

halves as per table, g 4. The coupling halves shall be

secured by lock screws. For other types of couplings,

please refer to respective maker’s manual.

16

c

When ing the sha coupling, do not use

a hammer or similar as this may damage

the ball bearing and sha seal.

Use some kind of press tool.

Fig. 2 Strainer

Installation

Page 17

ACF5 0601.01 GB

www.imo.se

17

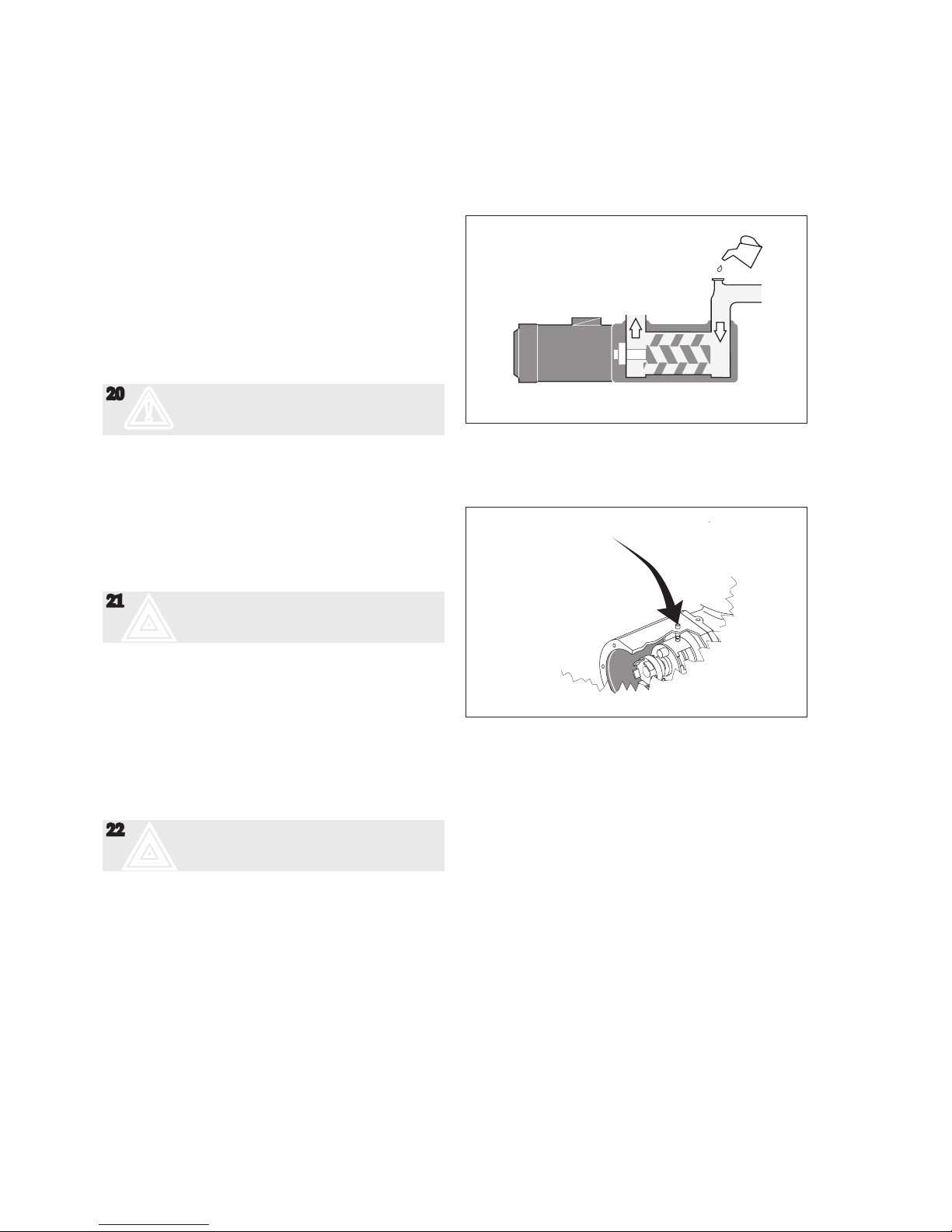

Strainer

The pump has to be protected from foreign maers

such as weld slag, pipe scale, etc., that could enter the

pump via the suction line. If the cleanliness of the system cannot be guaranteed, a strainer must be installed

in the inlet pipe near the pump. For practical reasons

a suction strainer with 0.8-2.0 mm mesh openings is

recommended.

The size of the strainer should be selected so that it is

large enough to allow adequate pressure at the pump

inlet. The pressure drop across the strainer should

preferably not exceed 0.1 bar at max. ow rate and normal operating viscosity. A vacuum gauge between the

strainer and the pump inlet is recommended to indicate

when the strainer needs cleaning.

17

m

Oil leakage may make the oor slippery

and cause personal injury

18

m

When handling liquids that may harm

skin, use gloves and/or protective clothing

19

m

When handling liquids which may involve

re hazard, appropriate precautions to

avoid danger are to be taken.

Fig. 4 Distance between coupling halves.

(IMO AB standard coupling)

Outer diameter

of coupling

(D mm)

Distance between

coupling halves

(t mm)

Outer diameter

of coupling

(D mm)

Distance between

coupling halves

(t mm)

A B A B

50 26 2.0 8 148 3.5

67 40 2.5 16 168 3.5

82 55 3.0 18 194 3.5

97 65 3.0 20 214 4.0

112 80 3.5 24 240 4.0

128 95 3.5 26

Fig. 3 Alignment of the IMO AB standard coupling

D4 ø max 0.3 mm

D6 ø max 0.4 mm

E4 ø max 0.4 mm

See table below

An angular

misalignment of

0.1° corresponds to

approx. 0.2 mm

deviation/100 mm.

Angular

alignment

Distance

between

coupling halves

Circular

run-out

A

x = y - t

B

Page 18

ACF5 0601.01 GB

www.imo.se

18

Fig. 7 Deaeration

Pipe connections

The pipe work shall be installed and supported so that

no pipe stresses are transferred to the pump body. The

pipe work should be tight in order to avoid leakage

and inltration of foreign particles and/or air. Shut o

valves should be installed in both suction and discharge pipes, so that the pump can be hydraulically

isolated.

Suction line

The suction pipe should be designed so that the total

pressure drop, measured at the pump inlet ange, does

not exceed the suction capability of the pump. Make a

proper calculation of the suction line including components such as valves, strainer, pipe bends etc. Generally, the pressure drop in the suction line should be as

low as possible, which is achieved if the suction pipe is

short, straight and has a suitable diameter. The velocity in the suction line should be kept in the range 0.5

- 1.2 m/s. For L.O. circulating systems, we recommend

to keep it as low as possible. The suction line must

be equipped with a port that allows lling the pump

before start.

Discharge line

The discharge line should be dimensioned to keep the

velocity in the range 1 - 3 m/s.

Deaeration

In installations with negative suction head, where the

pump might be started against a pressurized system, a

deaeration pipe with an orice (2-3 mm is recommended) has to be installed. The deaeration pipe should be

connected to the outlet pipe’s highest point. This must

also be installed when the pump is used as a stand-by

pump.

Shaft seal drain

The pump should be installed so that any leakage from

the sha seal does not become a hazard. As the sha

seal has to be lubricated a small amount of oil dripping

cannot be avoided. Provisions to collect the leakage

from the sha seal must be made. A drain pipe can

be connected to the drain connection on the pump.

However, when pumping heavy fuel oil or any other

liquid that is likely to become very viscous at ambient

temperature, we recommend that the liquid is allowed

to drop freely from the drain opening.

Liquid trap

In some mounting arrangements the pump may not

retain the liquid at stand still. In such installations the

suction pipe should be arranged so it forms a liquid

trap together with the pump, keeping the pump half

lled with liquid.

Fig. 5 Pipe connections

Fig. 6 Suction Line

Page 19

ACF5 0601.01 GB

www.imo.se

19

Gauges

Gauges for monitoring the pump’s working conditions

are recommended. These gauges should be placed

readable as close to the pumps in- and outlet anges as

possible. The ACF pump is equipped with convenient

connections for measuring the inlet and the outlet pressure by means of pressure gauges.

Pressure relief valve

All systems with screw pumps must be equipped with

a pressure relief valve installed immediately adjacent

to the pump. In the standard versions of IMO AB low

pressure pumps, this pressure relief valve is an integral

part of the pump to protect the system against excess

pressure. When liquid is circulated through the valve

it heats up in proportion to the set pressure level and

the percentage of by-passed liquid. 100% by-pass can

only be tolerated for less than about 3 minutes, 50%

by-pass generally for unlimited periods of time. If more

than 50% recirculation is anticipated, a value specic

to each application should be determined by closely

monitoring the pump body temperature. If the pump is

operating in line with a separate pressure control valve,

the seing of the relief valve should be high enough so

as not to interfere with the control valve. Likewise, if

two pumps are operating in parallel, the seing should

be such that interference between the two valves is

avoided.

Page 20

ACF5 0601.01 GB

www.imo.se

20

ACF

Deaeration plug

Before starting:

Aer installation and whenever it can be assumed

that the pump has been emptied, the pump must be

thoroughly lled with liquid. See g 8. The ACF type

pumps have been ed with a deaeration plug making venting of the sha seal compartment easy before

start-up.

In installations with positive suction pressure: Aer

opening the inlet and outlet valves, simply open the

deaeration plug a few turns until oil sips out. Tighten

the plug. In installation with negative suction pressure:

Aer opening the inlet and outlet valves, remove the

deaeration plug and ll the sha seal compartment

with oil. Fit and tighten the plug. See g. 9.

20

m

Make sure the prime mover is locked out

and can not be started accidentally.

Rotate the sha by hand while lling the pump, to

ensure that the rotor bores and the sha seal cavity is

lled.

On the ACF pumps, the pump can be turned using the

sha coupling. If the suction pipe cannot be completely

lled, it is important to ensure that the trapped air is

evacuated without any pressure build up. (See g. 9

Deaeration).

21

;

Starting a dry pump is likely to cause

damage, especially to the sha seal.

Direction of rotation

When the pump is ready to be started, switch the motor

briey on and o and check that the drive motor rotates

in the correct direction as indicated by the rotation arrow. The arrow is placed on dierent spots depending

on the conguration of the pump unit but can normally

be found on a steel plate that is riveted to the pump

close to the frame that connects the pump and the

electrical motor.

22

;

Don't mix up with arrow for inlet and

outlet!

Safety precautions before starting

If the fan cover on the electrical motor for some reason

should have been removed during the pump installation process do NOT forget to put it back as the rotating

fan can cause seriously personal injuries.

If the protecting cover steel net on the pumps frame

that connects the pump and the electrical motor to each

other has been removed do NOT forget to put it back

as the rotating coupling can cause seriously personal

injuries.

Fig. 8 Filling the pump

Fig. 9 Deaeration plug

Start-up

Page 21

ACF5 0601.01 GB

www.imo.se

21

Starting

Check that all valves necessary for the operation are

fully opened in both discharge and suction lines.

The rst time, the pump should be started with the adjusting spindle of the pressure relief valve tightened to

half of the available turns (the valve seing is increased

when the spindle is turned clockwise). By monitoring the pressure gauge it can be determined when the

suction line is primed and the pump begins to work.

Should the pump not operate normally soon aer start,

stop the pump within half a minute. Start again aer

about 3-5 minutes (the sha seal must have time to cool

o) and run for half a minute. This procedure may need

to be repeated a couple of times if the suction line is

extremely long. Should the pump still not work, it must

be assumed there is a problem in the system that needs

to be remedied. Check the suction line calculation or

see”Trouble shooting”, page 22.

Setting the pressure relief valve

The seing of the opening pressure is made as follows:

Tighten the valve spindle by rotating clockwise to the

maximum extent. The system pressure is regulated by

throling to required value. The pressure relief valve

is eased until the pressure is just beginning to decrease

by turning the spindle CCW. The valve is now preset

for desired opening pressure. Open the throling valve

entirely.

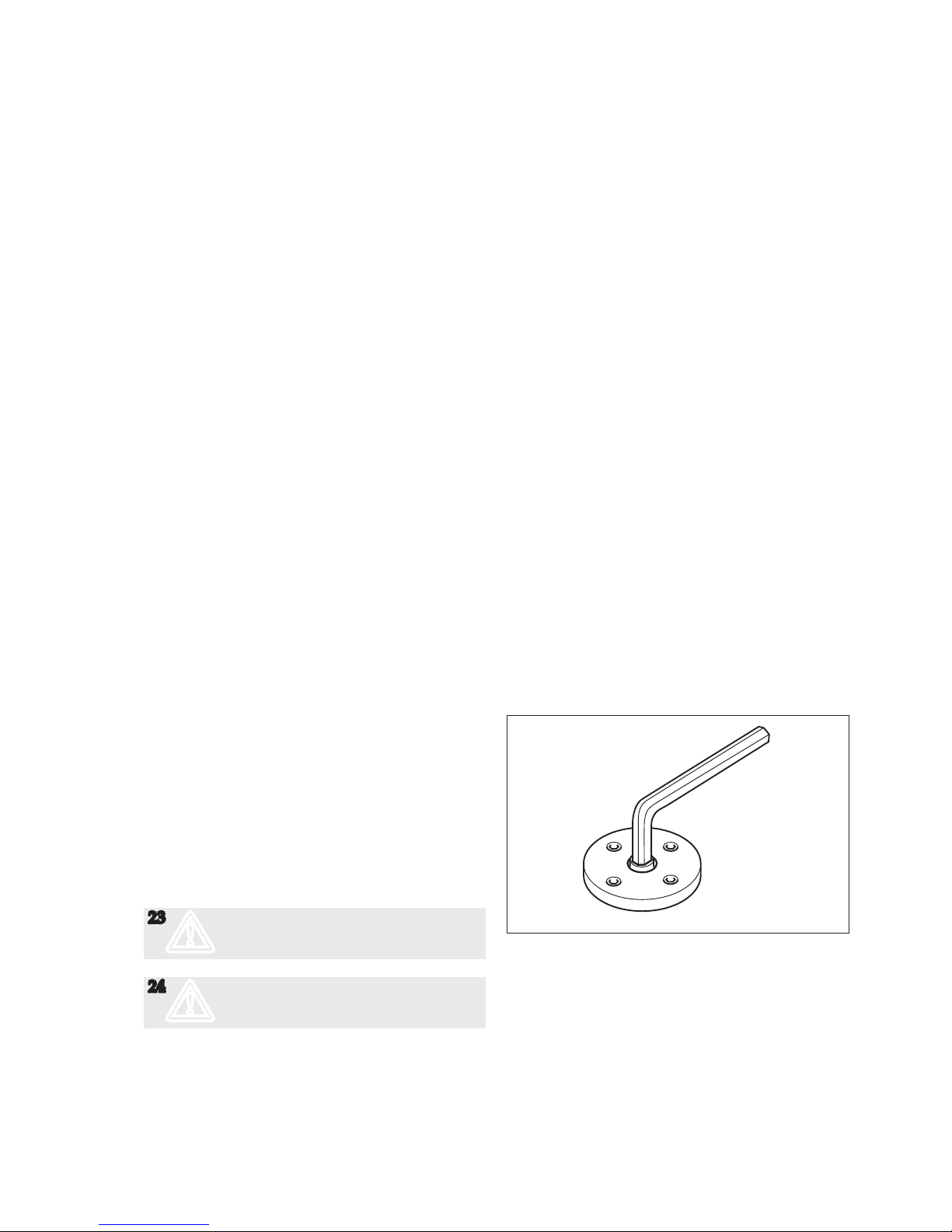

Adjusting the tuning

The tuning adjustment, which is a standard feature on

ACF pumps, is a device for minimizing the eects of

dissolved and free air in lube oil systems. The tuning

principle is described in the Product Description. The

tuning should be adjusted while the pump is working

under normal operating conditions. This is done by

turning the tuning spindle with an Allen key (size 12

mm for ACF) to a position where the noise level comes

to a minimum.

Setting of tuning of the ACF:

1. Before starting the seing, check that the seing

screw are closed.

2. Turn the screw CCW until the noise level becomes

the lowest (if turned too much the noise will increase

again).

Once set, the tuning needs no further adjustment, providing the operating conditions stay the same.

NOTE: It´ s not possible to accidentally turn the tuning

spindle too far as it is internally locked at the end of the

thread.

23

m

If operating temperature exceeds 60°C

(149°F), appropriate measures to avoid

skin contact shall be provided

24

m

Use hearing protection whenever high

noise can be expected from pump, motor

and/or environment.

Fig. 10 Tuning the ACF

Page 22

ACF5 0601.01 GB

www.imo.se

22

Problem Cause What to do

Wrong direction of rotation - Electric cables to motor wrongly

connected.

Reverse the terminal connection on

electric motor.

25

c

Connecting and disconnec-

ting of electric cables must

be done only by personnel

authorized to do such

work.

The pump cannot be

primed

- Wrong direction of rotation.

- Suction line is not open or pressure

drop in the suction line is too high.

- Major air leakage into the suction

line.

- The pump cannot evacuate the air

through the discharge line due to

excessive counter pressure.

See above.

Check all components in suction line.

The inlet condition should be checked

with a vacuum gauge at the pump inlet.

Check the suction line.

See the chapter on Deaeration

(see page 5).

No ow - The pump is not primed.

- The pressure relief valve is set be

-

low the counter pressure.

See above.

Readjust the pressure relief valve to a

value above counter pressure.

Flow too low - The pressure relief valve is set too

low (Discharge pressure also low).

- Something is restricting the ow in

the suction line. (This would usually

cause noise).

- The pumped liquid contains a sig

-

nicant amount of compressible gas,

such as free air. (This would usually

cause noise).

Readjust the pressure relief valve

Check all components in the suction

line (strainers, valves etc.).

See the chapter on Noise and Vibration.

( Page 11).

Pressure too low - The pressure relief valve is set too

low.

- Counter pressure in the discharge

line is too low due to a major leak-

age.

- The valve piston is stuck in open

position.

- Something is restricting the ow in

the suction line. (This would usually

cause noise).

- The pumped liquid contains a sig

-

nicant amount of compressible gas,

such as free air. (This would usually

cause noise).

- A too small pump has been chosen.

Readjust the pressure relief valve.

Check the components in the discharge

line inclusive the recipients.

Check the valve. See Maintenance

and Service instruction for respective

pump.

Check all components in the suction

line (strainers, valves etc.).

See the chapter on Noise and Vibration.

(Page 11).

Contact your IMO AB representative.

Trouble shooting

Page 23

ACF5 0601.01 GB

www.imo.se

23

Problem Cause What to do

Pressure too high - The pressure relief valve is set too

high.

- The oil is too cold (or has higher

viscosity than anticipated).

- Counter pressure in the discharge

line is too high.

Readjust the pressure relief valve.

Reduce the pressure seing until operational temperature has been reached.

Check the discharge line.

Drive motor dicult to

start or tends to stop by

tripping the motor overload

relay

- Counter pressure too high.

- Liquid too cold.

- Motor is undersized for the prevail

-

ing conditions.

- Electrical power supply faulty.

- Motor overload relay set too low or

is faulty.

- Incorrect seing of Y/D starter.

See above: Pressure too high.

Readjust the pressure relief valve to a

lower value. Thus the power consumption for the pumping is relieved and

overloading due to the high viscosity

may be avoided. When the liquid has

reached normal temperature and thus

ows easily, the relief valve is reset to

normal pressure.

Check the motor.

Check the motor and motor connection.

Readjust or replace the relay.

Readjust the seing of the starting

sequence. The time before the motor

overload relay is tripped should not

exceed 10-15 seconds.

Noise and vibration

26

m

Monitor the

pump function

and shut down

if any sign of

malfunction is

noticed

- The ow to the pump is insucient.

- Insucient support of pipe work.

- Bad alignment

- Air leakage into the suction line.

- Free air in the liquid or gas cavita

-

tion.

- Faulty electrical supply.

See chapter: The ow is too low.

Check for pipe vibrations in the pump

connections. Check that the pipes are

suciently clamped.

Check alignment, see page 4.

Check the suction line for air leakage.

For pumps with Tuning:

Adjust the Tuning. If this does not help

or for pumps without Tuning: Contact

your IMO representative or IMO service dept.

Check all three phases of the supply.

Page 24

ACF5 0601.01 GB

IMO AB: P.O. Box 42090, SE 126 14 Stockholm, Sweden

Telephone: +46 8 50 622 800, Telefax: +46 8 645 1509

www.imo.se

IMO AB: P.O. Box 42090, SE 126 14 Stockholm, Sweden

Telephone: +46 8 50 622 800, Telefax: +46 8 645 1509

Loading...

Loading...