Page 1

Zeus Maior 24 Instructions

Instruction Booklet

Wall Mounted, Room Sealed, Gas Fired

Combination Boiler with Unvented Hot Water

Storage

For technical assistance, spare parts or service call:

RVR Limited, Kenmare, Co. Kerry Tel: 064 41344, Fax: 064 89520

Read these instructions completely before using or installing the Immergas Zeus Maior 24

gas boiler

LEAVE THESE INSTRUCTIONS WITH THE USER

IMMERGAS ZEUS MAIOR 24

Page 2

Zeus Maior 24 Instructions

Introduction

Boiler Operating Instructions

The Immergas Zeus Maior 24 boiler is a wall mounted, fan assisted room-sealed combination boiler, incorporating a 60 litre unvented hot water storage cylinder. Heat output is controlled by a modulating gas valve,

with fully automatic direct burner ignition.

The boiler, providing both central heating and domestic hot water supply, is designed for use with a fully

pumped, sealed and pressurised heating system using Natural Gas or LPG. The boiler is supplied for use

with one of these gas types and must be converted before it can be used on another gas. A boiler

equipped for natural gas must not be used on LPG or vice versa.

The boiler is supplied with a pump, diverter valve, pressure relief valve, expansion vessel and pressure

gauge fully assembled and tested.

As supplied, the boiler will automatically modulate to provide central heating outputs between 10.5 and

27.9kW. The maximum output available for domestic hot water is 27.9 kW and provides hot water at temperatures of up to 60°C and flow rates of up to 17 litres/min (at a temperature rise of 60°C)

IMPORTANT

All gas appliances must be installed by a competent and qualified person, in accordance with relevant

clauses of applicable standards and recommendations. These include but may not be limited to the following:-

I.S. 813 Domestic Gas Installations

I.S, 820 Non-Domestic Gas Installations

All relevant Building Regulations.

Local Water Bye Laws

IEE Wiring Regulations

Health & Safety legislation

This appliance meets the requirements of IPX4D, ie degree of protection against moisture.

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of

safety to ensure that the law is complied with. Manufacturer's instructions must NOT be taken in anyway as

over-riding statutory obligations.

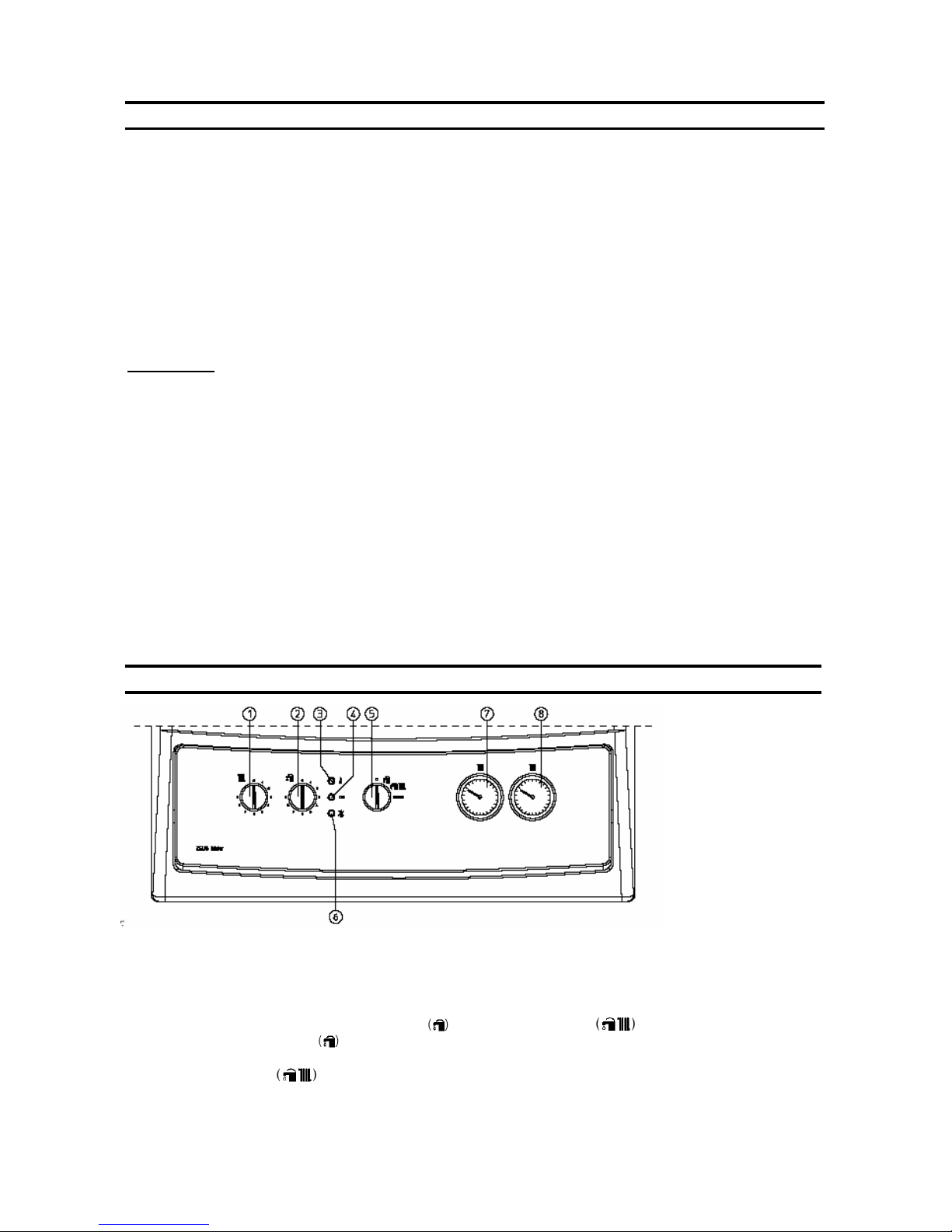

Key:

1 - Heating temperature selector

2 - Domestic hot water temperature

selector

3 - Boiler over temperature and flue

block red indicator

4 - Power On green indicator lamp

5 - Operating mode and Reset switch

6 - Lockout red indicator lamp

7 - Boiler thermometer

8 - Boiler manometer

Using the Boiler

Before lighting, make sure that the system is full of water and that the manometer (8) indicates a pressure

of 1 - 1.2 bar.

-Open the gas valve on the gas supply to the boiler.

-Turn Operating mode switch (5) to Hot Water or Hot Water/Heating.

N.B.: . With the switch set to the central Heating temperature setting (1) is not active, and the domestic

water temperature is controlled by selector (2).

With the switch set to the central heating temperature is set using selector (1) while selector (2) is

used for the domestic hot water. Turn the selectors clockwise to raise the temperature, anticlockwise to

lower it. Boiler operation is now automatic.

Page 3

Zeus Maior 24 Instructions

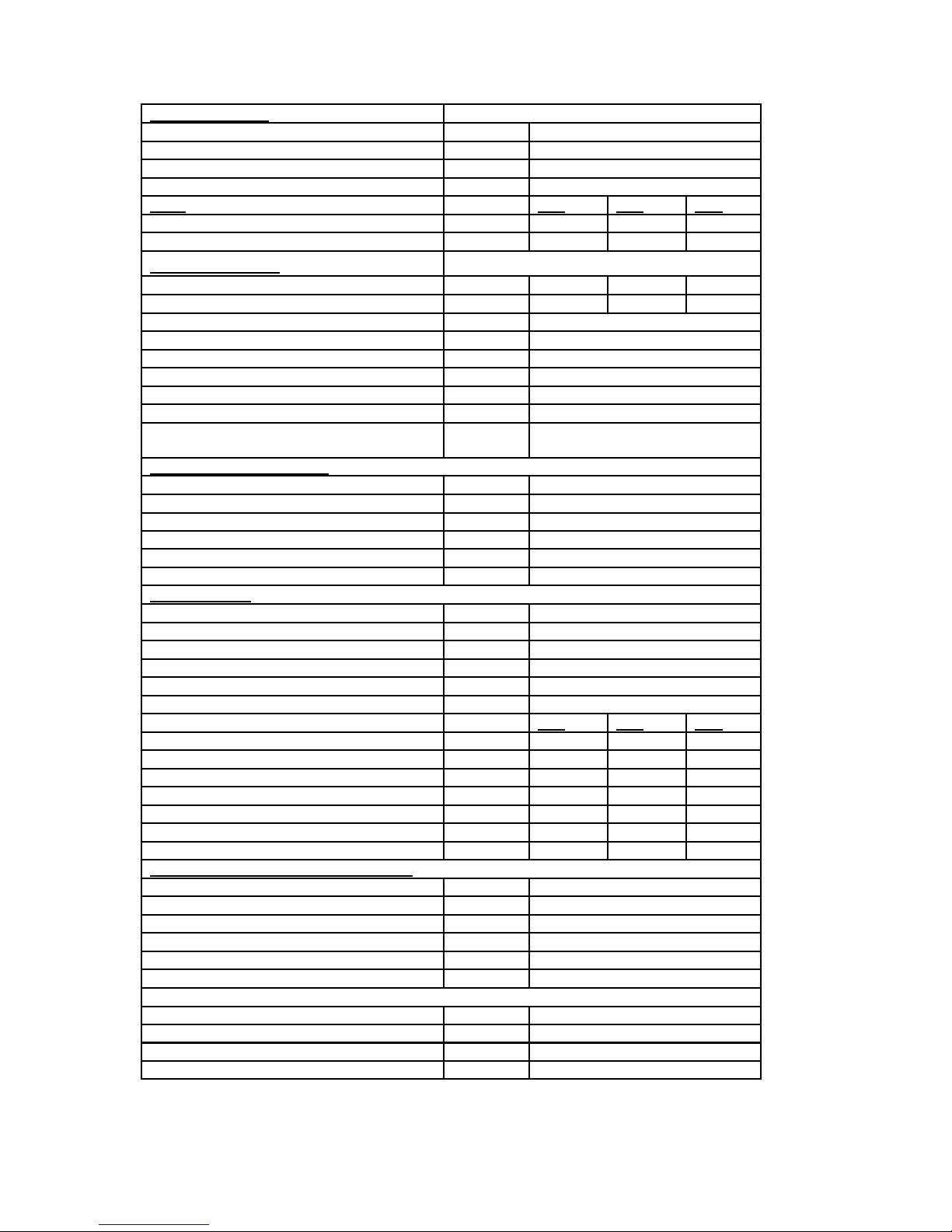

PERFORMANCE:

Nominal Heat Input kw 30.3 (26030)

Min. Heat Input kw 12.2 (10466)

Nominal Heat Output (useful) kw 27.9 (24000)

Min. Heat Output Kw 10.5 (9000)

GAS: G20 G30 G31

Nozzle diam. mm 1.3 0.75 0.75

Supply Pressure mbar 20 29 37

HEATING SYSTEM:

Burner Pressure (Nom Output) mbar 10.5 28.1 36.7

Gas Rate

m³/h/kg/h

3.2 2.39 2.35

Max working pressure heating circuit bar 3

Max working temp heating circuit

°C

90

Adjustable temp heating

°C

43-90

Expansion Tank Total Volume

L

8

Expansion Tank preload

bar

0.8

Water contained in boiler

L

4

Available head with flow rate 1000/l/h

kPa

(mH2O)

29.4 (3.0)

DOMESTIC HOT WATER:

Useful heat output hot water production

kw

27.9

Adjustable temp domestic hot water

°C

20-60

Hot water storage capacity

L

60

Continuous hot water flow rate@ ∆T =30oC

l/min

13.9

Boiler weight filled

kg

138

Boiler weight empty

kg

74

ELECTRICAL:

Electrical connection

v/hz

230/50

Nominal Absorption

A

0.76

Electrical power

W

155

Power absorbed by circulating pump

W

90

Power absorbed by fan

W

35

Equipment electrical system production

-

IP44

FLUE GASES:

G20 G30 G31

Flue gas production @ nom output

kg/h

67 69 71

Flue gas production @ min output

kg/h

71 79 79

CO2 at Q Nom/Min

%

6.5/2.3 7.2/2.4 7.0/2.4

CO at 0% O2 at Q Nom/Min

ppm

64/104 89/112 60/130

NOx at O% O2 at Q Nom/Min

ppm

150/83 240/108 201/102

Flue gas temperature at nominal output

°C

115 117 120

Flue gas at minimum output

°C

85 83 92

DIMENSIONS & INSTALLATION DATA:

Height

mm

900

Width

mm

600

Depth

mm

450

Gas Connection

3/4”

CH Connection

3/4”

DHW Connection

1/2”

Minimum clearances for servicing

Top

mm

200

Bottom

mm

150

Side

mm

10

Front

mm

600

Page 4

Zeus Maior 24 Instructions

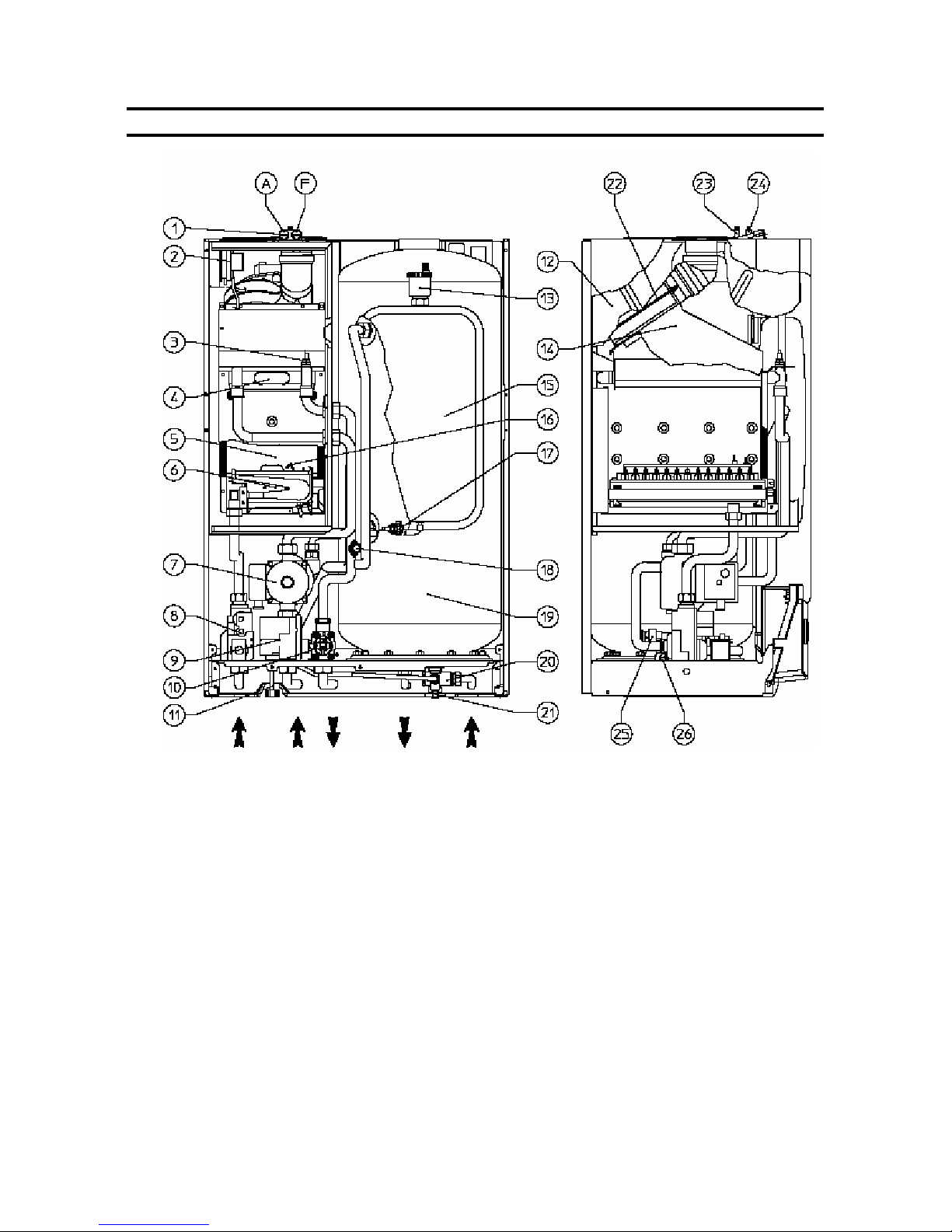

Main Boiler Components

Key:

1 Air (A) and Flue(F) connections 14 Flue Extractor Hood

2 Fan Safety Pressure Switch 15 Expansion Tank

3 Heating NTC limit and regulation sensor 16 Ignition/Detection Plugs

4 Primary Heat Exchanger 17 Domestic Circuit NTC sensor

5 Combustion Chamber 18 Over temperature Safety thermostat

6 Burner 19 Boiler 316L stainless steel

7 Circulating Pump 20 Domestic Circuit 8 Bar Safety Valve

8 Gas Valve 21 Boiler Drain Valve

9 Motor operated 3-way valve 22 Flue Extraction Fan

10 Circulating pump safety flow switch 23 Positive Signal pressure socket

11 System Filler Cock 24 Negative Signal pressure socket

12 Sealed Chamber 25 System 3 Bar Safety Valve

13 Air Vent Valve 26 System drain cock

Gas

CH

Return

CH

Flow

Hot Water

Out

Cold Water

In

Page 5

Zeus Maior 24 Instructions

Gas Supply

The meter and supply pipes must be sized to deliver the gas rate and pressure given on page 3. The

boiler requires at least a 22 mm (3/4”) gas supply pipe.

The complete installation, including the meter, must be tested for gas soundness and purged as described

in IS 813:2002.

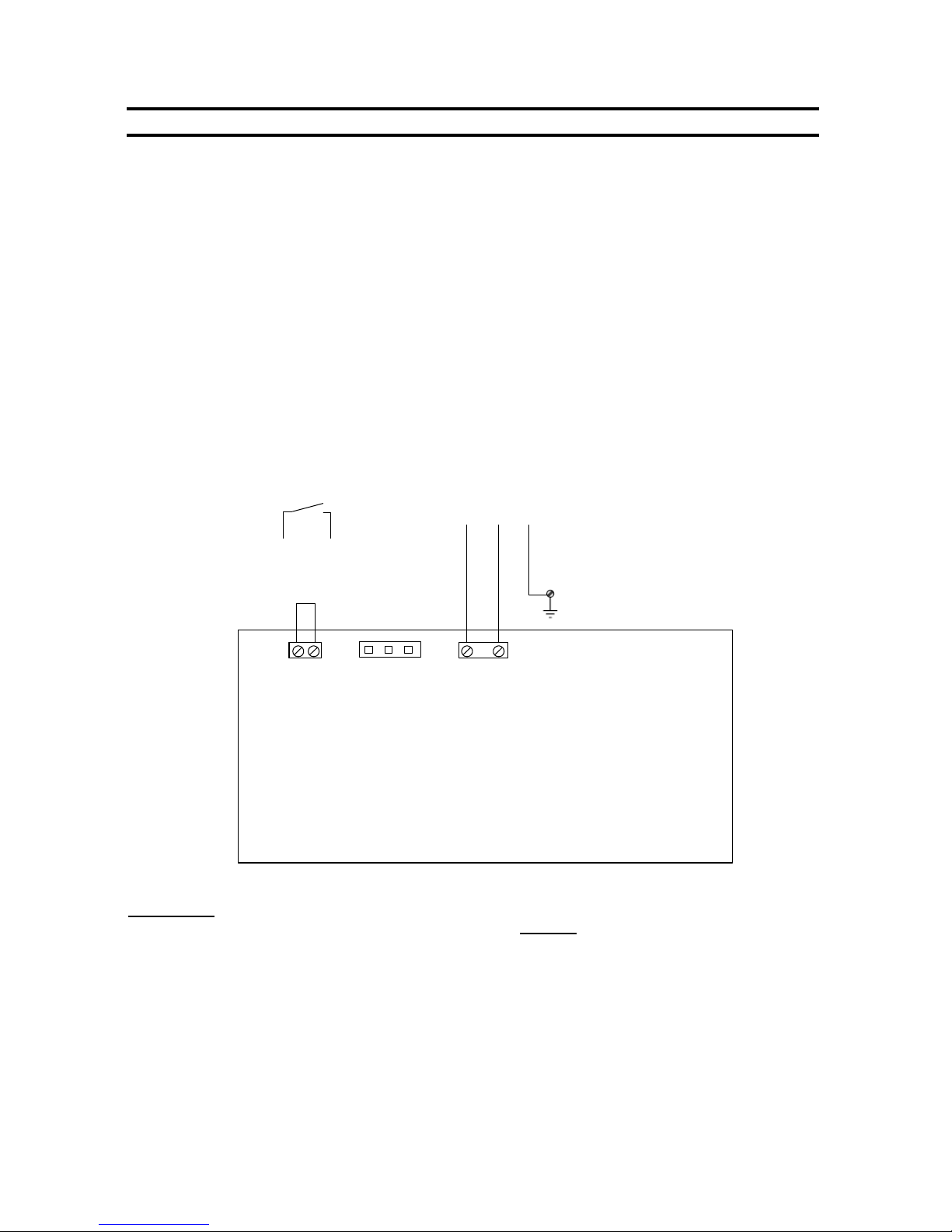

Electrical Installation

The boiler requires a 230V ~ 50 Hz mains supply, fused at 2 A. Polarity of the supply must not be reversed

or the boiler will not function properly. The boiler will not function properly and may be damaged when connected to a generator which does produce a true sine wave type output.

The boiler must be earthed.

There must only be one common isolator, providing complete electrical isolation, for the boiler and any external controls.

Using PVC insulated cable not less than 0.75 mm² (24 x 0.2 mm) to BS 6500 Table 16, the boiler should be

connected to a fused three pin plug and unswitched shuttered socket outlet (both complying with BS 1363),

or a fused double pole switch with a contact separation of at least 3 mm in both poles.

Wiring external to the boiler must be in accordance with the current IEE Wiring Regulations.

General Installation Information

Zeus Maior Control board

35 34 33 32

N L E

Brown

Blue

Green/Yellow

Replace link with

volt free contact from CH

controls

NB: Do not connect 220V !

Mains Lead

IMPORTANT:

External controls connected to the boiler must be of the volt free type and are connected to terminals 34 and 35 as shown above. Connection of a voltage to any boiler terminals other than the

mains lead will result in destruction of the boiler control panel.

Clearances and Air Supply

The boiler does not require any air vents for cooling in the room in which it is installed or when installed in a

cupboard or compartment. The minimum clearances for servicing must always be maintained. Please see

table on page 3.

Note: A cupboard or compartment used to enclose the boiler must be designed and constructed specifically

for the purpose.

Page 6

Zeus Maior 24 Instructions

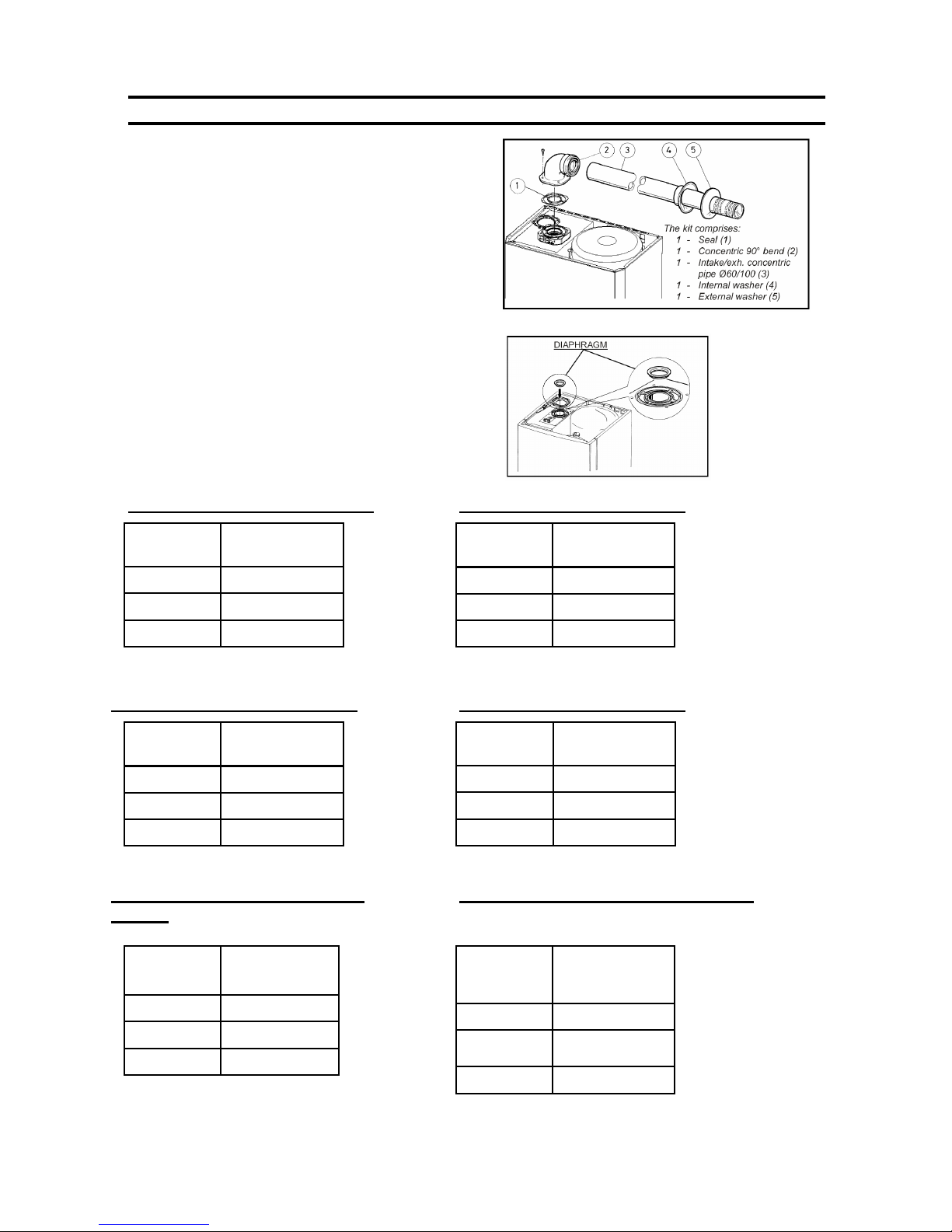

Note: a flue diaphragm is supplied with the boiler and

must be fitted depending on the flue arrangement.

Select the appropriate diaphragm from the tables below:

Diaphragm Flue length in

metres

Ø 44 0 - 0.5

Ø 47 0.5 - 1.5

None Over 1.5

Ø 60/100 Horizontal flue systems

Diaphragm Flue length in

metres

Ø 44 0 - 3

Ø 47 3 - 4

None Over 4

Ø 60/100 Vertical flue systems

Diaphragm Flue length in

metres

Ø 44 0 - 22

Ø 47 22 - 29

None Over 29

Diaphragm Flue length in

metres

Ø 44 0 - 0.5

Ø 47 0.5 - 3

None Over 3

Diaphragm Flue length in

metres

Ø 44 0 - 5

Ø 47 5 - 8

None Over 8

Diaphragm Flue length in

metres

Ø 44 0 - 17

Ø 47 17 - 24

None Over 24

Flue System

When the boiler is installed on an external wall, the

standard horizontal concentric 60/100 flue kit will be

used to flue the boiler. This is shown in the diagram.

A flue diaphragm with a 44mm diameter must be

fitted with this flue arrangement.

Please see the following information on the use of

flue diaphragms. Information on extended flue systems is given on the following pages.

Flue Systems

Flue diaphragms

Ø 80/125 Horizontal flue systems

Ø 80/80 separated Horizontal flue

systems

Ø 80/100 Vertical flue systems

Ø 80/80 separated Vertical flue systems

Page 7

Zeus Maior 24 Instructions

It is often necessary to install a longer flue system to cater for site

conditions. There are several different flue system sizes available

for the Zeus Maior 24 boiler.

Horizontal concentric kit 60 /100

The exhaust pipe (φ 60 mm) is fitted inside the air intake

pipe (φ 100 mm). Connection to the boiler is made using a 90°

bend (1) which can be turned in any direction and can be connected

to the terminal (2).

Max possible overall length after the first bend (1) is

3 straight and horizontal metres.

Horizontal concentric kit 80 /125

The exhaust pipe (φ 80 mm) is fitted inside the air intake

pipe (φ 125 mm). Connection to the boiler is made using a 90° bend

diameter 60/100 (1) which can be turned in any

direction and connected using the adapter 60/10080/125 (2) to the 80/125 terminal (3).

Max possible overall length beyond the first bend(1) is

7.3 straight and horizontal metres.

Vertical concentric kit 60 /100

The exhaust pipe (φ 60 mm) is fitted inside the

air intake pipe (φ 100 mm). Connection to the boiler is made using

a flange (1) which may be connected to the 60/100 vertical terminal.

Max possible overall length is 4.7 straight and

vertical metres.

Vertical concentric kit 80 /125

The exhaust pipe (φ 80 mm) is fitted inside the Air intake pipe (φ

125 mm). Connection to the boiler is made using a flange (1). The

adapter 60/100-80/125 (3) is used the connect the 80/125 terminal

(2). Max possible overall length is 12.2 straight and

vertical metres.

Separated 80/80 flue kit

Both pipes have a diameter of 80 mm. Connections to the boiler are

made using two special flanges for exhaust (1) from the centre pipe

and extraction (2) from one of the two side holes.

Max possible length (extraction + exhaust) is 33 straight horizontal

metres and 41 straight vertical metres.

To prevent condensation problems, the exhaust pipe should

not be more than 5 m long. Advice on prevention of condensation is available from RVR Limited. Please contact us when

designing longer flue systems.

Separated 80/80 insulated flue kit

Both pipes have a working diameter of 80 mm.

Connections to the boiler are made using two special

flanges for exhaust (1) from the centre pipe and

extraction (2) from one of the two side holes.

Insulation is obtained thanks to special seals (3)

whereby an air space can be created by means of a φ

125 mm external concentric pipe.

Max possible length (extraction + exhaust) is 33

straight metres.

To prevent condensation problems, the exhaust pipe

should not be more than 12 m long

Extended Flue Systems

Page 8

Zeus Maior 24 Instructions

Each component of the air inlet/flue system has a resistance factor . These are given in the following tables.

The resistance factor varies depending on whether the component in question conveys fresh inlet air or hot

combustion gases. All boilers have a maximum resistance factor of 100. The sum of all components in the

flue system must not exceed the maximum overall resistance factor of 100.

Flue calculations for more complex systems

Page 9

Zeus Maior 24 Instructions

Example:

Flue system consists of 9m of 80mm air intake pipe with 3 x 90 bends and 6m of exhaust pipe with 2 x 90

bends.

Component Resistances:

Component Resistance Quantity Total

80mm Intake pipe 2.3 9 20.7

90˚ air intake bend 5 3 15

80mm Flue pipe 3 6 18

90˚ Flue bend 6.5 3 19.5

73.2

Total Flue Resistance

In this case the total resistance of the

system is less than 100. The flue design is acceptable.

Care should be taken to insulate the

exhaust flue pipe to ensure that condensation is not possible.

Page 10

Zeus Maior 24 Instructions

Terminal Position Min. Distance

A Directly below an opening, air brick, windows, etc.

B Below gutters, soil pipes or drain pipes

C Below eaves

D Below balconies or car port roof

E From a vertical drain pipe of soil pipe

F From an internal or external corner

G Above ground, roof or balcony level

H From a surface facing the terminal

I From a terminal facing a terminal

J From an opening in the car port (door, window) into dwelling

K Vertically from a terminal on the same wall

L Horizontally from a terminal on the same wall

M Horizontally from an opening, air brick, window etc.

Below horizontally hinged windows where exhaust is directed upwards

Below horizontally hinged windows where exhaust is not directed upwards

300 mm

75mm

75mm

75mm

75mm

75mm

300mm

600mm

1200mm

1200mm

1500mm

300mm

300mm

3000mm

1000mm

The flue terminal must be exposed to the external air and the position must allow the free passage of air

across it at all times. In certain weather conditions the terminal may emit a plume of steam. Avoid positioning the terminal where this may cause a nuisance. If the terminal is fitted within 850 mm of a plastic or

painted gutter or 450 mm of painted eaves or 300 mm of a plastic car port roof, an aluminium shield at least

1 m long should be fitted to the underside of the gutter or painted surface. If the terminal is fitted less than 2

m above a surface to which people have access, the terminal must be protected by a terminal guard.

IMPORTANT— Failure to install flue systems correctly may lead to serious injury or death. Ensure

that:

• The flue slopes slightly towards the outlet by between 1 and 2 degrees to ensure any condensate

moves to the discharge point.

• The flue is adequately supported along it’s length so that it is straight.

• No chemicals, detergents or solvents of any kind are used in the assembly of the flue system. Clean

water may be used as to lubricate seals where necessary.

• The flue is thoroughly tested for leaks after installation.

Boiler Location

The boiler is not suitable for external installation.

The boiler must be installed on a flat vertical wall which is capable of supporting the weight of the boiler.

The boiler can be fitted to or adjacent to a wall comprising of a combustible material without the need for a

special thermal insulation barrier.

The boiler may be installed in any room or internal space, although particular attention is drawn to the requirements of the current IEE Wiring Regulations. Where a room sealed boiler is installed in a room containing a bath or shower, it must not be possible for a person using the bath or shower to touch any electrical switch or boiler control utilising mains electricity.

The boiler may be installed in a cupboard or compartment, provided it is correctly designed for that purpose.

NB: Adequate clearances are required to allow servicing of the boiler. Please see page 3.

Page 11

Zeus Maior 24 Instructions

The boiler is designed for use in a sealed central heating system. The system should be designed to operate with flow temperatures of up to 80°C. When designing the system, the pump head, expansion vessel

size, mean radiator temperature, etc. must be taken into account.

The pressure losses in the system must be compatible with the boiler circulation pump. See pump performance graph below.

Central Heating System

System volume - The 8 liter expansion vessel incorporated into the boiler is pre-charged to 1.0 bar and

is suitable for a sealed heating system with a maximum water content of 80 litres (18 gal). Above 80 litres, consideration should be given to fitting an additional expansion vessel fitted in the position shown

on the schematic below. To check correct operation of the expansion vessel(s) the system pressure

should not be more than 2.5 bar when the system is at maximum operating temperature.

The boiler is supplied with the following components built in:Central Heating Pressure relief valve - complying with BS 6759 and set to operate at 3 bar. The discharge pipe must be routed clear of the boiler to a drain, so that it can be seen, but cannot cause injury

to persons or property.

A Pressure gauge is included to indicate the pressure of the central heating system.

Important Note: In a central heating system where it is possible to shut off system circulation, such as a

system with zone valves or where all radiators are fitted with thermostatic radiator valves, an external bypass should be fitted. An optional automatic bypass is available as an accessory for the Zeus Maior 24

boiler. This may be fitted directly to the boiler central heating flow and return connections.

Pump performance curves

Page 12

Zeus Maior 24 Instructions

Filling the central heating system

The system design pressure (cold) should be set to 1.0 bar. This pressure is equivalent to a static head of

10.2 metres of water. Provision should be made to replace water lost from the system. This can be by

manual or automatic means.

Filling of the system must be carried out in a manner approved by the local authority. Where allowed, the

system may be filled via a temporary connection as shown below or by using the integrated filling valve in

the boiler. After filling, always disconnect the flexible hose of the filling loop if used and close the filling

valve in the boiler.

All fittings used in the system must be able to withstand pressures up to 3 bar. Drain taps (to BS 2879)

must be used to allow the system to be completely drained. The heating system should be thoroughly

flushed before the boiler is connected and again after the first heating. If it is necessary to add inhibitor to

Cold water

storage tank

Zeus

Maior

System

drain tap

Lockshield

valve

Radiator

valve

Automatic

Bypass

Non-Return

Valve

Pressure

Booster

Pump

To cold water outlets

To hot water outlets

The most important components of the system are shown in the diagram below.

• The cold water supply for the water heating side of the system may come from a booster pump or the

cold water mains where this is permitted by the local authority.

• A non-return valve must be installed on the cold feed to the boiler. This prevents expanding hot water back-feeding into the cold side of the system.

• An automatic bypass should be fitted in systems where central heating circulation can be shut off. (by

zone valves or thermostatic radiator valves).

Page 13

Zeus Maior 24 Instructions

Mains water pressurised unvented system are generally not permitted in Ireland. A cold water storage tank

and a pressure boosting pump will normally provide a pressurised cold water supply. The pressurisation

pump should provide a water pressure of between 1 and 3 bar. However, all taps and mixing valves used

with the hot water system must be suitable for operating at a pressure of up to 5.5 bar.

To ensure economic use, the pipe runs between the boiler and taps should be in 15 mm copper pipe and be

as short as possible. Where possible the pipe work should be insulated to reduce heat loss.

Before the cold water supply pipe is connected to the boiler, it should be thoroughly flushed out to avoid the

danger of dirt or foreign matter entering the boiler.

The stored water temperature is adjustable to a maximum of 55°C. In hard water areas this should avoid

possible scale build-up. However, if descaling is necessary contact RVR Limited for guidance.

Unvented Hot Water Storage System

The installation is subject to Building Regulations and the Water Bye Laws of the Local Authority.

The Immergas Zeus Maior 24 boiler is supplied with all the components required for a safe and efficient

unvented hot water system. An air cushion which is present at the top of the 60l storage vessel provides

sufficient expansion for the domestic hot water system. An optional additional DHW expansion kit is available for situations where the inlet pressure exceeds 3 bar or other situations where the expansion capacity

may not be adequate.

NOTE: In the Dublin City Council area the optional expansion vessel must be fitted to comply with

the approval requirements of the council. The council also requires that the minimum internal diameter of pipes connected to the boiler DHW connections should not be less that 13mm. As 1/2”

thermoplastic pipe does not provide the minimum diameter, the minimum suitable thermoplastic

pipe size is 3/4”

Discharge pipe - The discharge pipes from the expansion relief valves must be routed to a tundish in

1/2” (or 15 mm )pipe. The discharge pipe work from both relief valves may be joined together in the same

sized pipe, providing at least 3/4” (or 22 mm) pipe work is connected downstream of the tundish.

Tundish - The tundish must be positioned within 500 mm of the appliance, so that it is visible to the User

and away from electrical devices. The minimum size of the discharge pipe downstream of the tundish is

given in the following table.

Zeus Maior Boiler

Booster

pump

Cold

Water

Supply

Optional

Expansion

Vessel

Primary

expansion

valve

DHW

expansion

valve

Divertor

Valve

Expansion volume

Tundish

Check

Valve

Domestic Hot Water System

15mm (1/2”)

22mm (3/4”)

28mm (1”)

35mm (11/4”)

Page 14

Zeus Maior 24 Instructions

The discharge pipework from the tundish:-

1. Shall fall continuously through its length.

2. Shall be of a heat resistant material, e.g. metal.

3. Shall not be fitted with any valves or taps.

4. Shall discharge to a safe visible position, e.g. onto the surface of an external wall or into a gulley.

5. Shall have a minimum of 300 mm straight pipe work directly from the tundish.

Note: Where children may play or otherwise come into contact with discharges, a wire cage or similar

guard must be positioned to prevent contact whilst maintaining visibility.

Please see the diagrams below for suggested methods of terminating the discharge pipe safely. Where a

single pipe serves a number of discharges, such as in blocks of flats, the number served should be limited

to not more than 6 systems so that any installation can be traced reasonably easily. The single common

discharge pipe should be at least one pipe size larger than the largest individual discharge pipe to be connected. If the system is installed where discharges from safety devices may not be apparent, i.e. in dwellings occupied by blind, infirm or disabled people, consideration should be given to the installation of an

electronically operated device to warn when discharge takes place.

High Level Termination

At high level, discharge onto a roof is acceptable providing the roof is capable of withstanding high temperatures and there is a distance of 3 m from any

plastic guttering systems that would collect such discharge.

Example:-

The example below is for a G½ temperature relief valve with a

discharge pipe (D2) having four elbows and a length of 7 m from the

tundish to the point of discharge.

From Table :-

Maximum resistance allowed for a straight length of 22 mm copper discharge pipe (D2) from a G½ temperature relief valve is 9 m. Subtract the resistance for four 22 mm elbows of 0.8 m each = 3.2 m. Therefore the

maximum permitted length equates to 9 - 3.2 = 5.8 m

5.8 m is less than the actual length of 7 m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28 mm pipe (D2) from a G½ temperature relief valve

equates to 18 m.

Subtract the resistance for four 28 mm elbows at 1.0 m each = 4 m.

Therefore the maximum permitted length equates to 18 - 4 = 14 m

As the actual length is 7 m, a 28 mm (D2) copper pipe will be satisfactory

.

300mm Min

D1

D2

Type 'A' Air

Gap

End of pipe

clearly visible

Tundish installation

500mm

max

Metal Discharge

to Tundish (D1)

Tundish

Heat Resistant

discharge pipe

with continuous fall

300mm Min

Page 15

Zeus Maior 24 Instructions

An annual maintenance of the boiler and heating system is recommended. This ensures that the optimal

safety, performance and operation characteristics of the boiler remain unchanged over time.

Warnings

Never expose the wall-mounted boiler to direct vapours from a cooking surface. Use of the boiler by unskilled persons or children is strictly prohibited.

Never touch the flue extraction terminal (if fitted) due to the risk of burning caused by high temperatures;

For safety purposes, check that the concentric air intake/flue exhaust terminal (if fitted), is not blocked. If

temporary shutdown of the boiler is required, proceed as follows:

a) drain the heating system if anti-freeze is not used;

b) shut off all electrical, water and gas supplies.

When building or renovation work is carried out in the vicinity of the flue outlet, switch off the boiler and on

completion of work ensure that a qualified technician checks the safety of the installation. Never clean the

appliance or connected parts with flammable substances. Never leave containers or flammable substances

in the same environment as the appliance.

Electrical Safety

- never touch the appliance with wet hands or other parts of the body and never touch when barefoot.

- never pull electrical cables or leave the appliance exposed to atmospheric agents (rain, sunlight, etc.);

- the appliance power supply cable must never be replaced by the user;

- in the event of damage to the cable, switch off the appliance and contact a qualified service technician.

- in the event of prolonged periods when the boiler is not in use, turn off the main power switch.

Operation and Maintenance Instructions

Using the Boiler

Before lighting, make sure that the system is full of water and that the manometer (8) indicates a pressure

of 1 - 1.2 bar.

-Open the gas valve on the gas supply to the boiler.

-Turn main switch (5) to Hot Water or Hot Water/Heating.

N.B.: Once the main switch (5) is turned to the central Heating temperature setting (1) is not active,

and the domestic water temperature is controlled by selector (2). With the switch set to the central

heating temperature is set using selector (1) while selector (2) is used for the domestic hot water. Turn the

selectors clockwise to raise the temperature, anticlockwise to lower it. Boiler operation is now automatic.

Faults

Overheat lockout - Red indicator lamp (3)on. If during operation a fault causes the temperature to exceed

100°C.the boiler enters this condition. Turn the main switch (5) temporarily to the Reset position. If this condition occurs repeatedly, contact a qualified technician for assistance.

Flue blockage - Red indicator lamp (3) on. If there is a problem with the boiler flue then the boiler enters

‘flue blockage’ mode. Turn the main switch (5) temporarily to the Reset position. If this condition occurs

repeatedly, contact a qualified technician for assistance.

Ignition lockout - Red indicator lamp (6) on. Each time heating or hot water production is required the

boiler lights automatically. If the boiler does not light within 10 seconds, the boiler goes to “ignition lockout” (indicator lamp 6 on). Turn the main switch (5) temporarily to the Reset position. This condition may

occur repeatedly if the gas supply is interrupted or if the boiler has been out of service for some time. If this

condition occurs repeatedly, contact a qualified technician for assistance.

Boiler shutdown. Turn off the main switch (5) by turning it to “0” (yellow indicator lamp 4 off) and close the

gas supply valve upstream of the appliance. Never leave the boiler switched on if left unused for prolonged

periods.

1 Heating Temp Selector

2 Domestic Hot Water Selector

3 Boiler over temperature and flue

block red indicator

4 Power on green indicator lamp

5 0-Domestic—Domestic and Heating– Reset switch

6 Ignition lockout red indicator lamp

7 Boiler Thermometer

8 Boiler Manometer

Page 16

Zeus Maior 24 Instructions

Lack of water in boiler.

Periodically check the system water pressure. Make sure that the pressure in the system is between 1

and 1.2 bar. N.B. Close the filling valve on completion. If pressure valves reach around 3 bar the safety

valve may be activated. In this case contact a service technician for assistance. In the event of frequent

pressure drops, contact your plumber to eliminate system leakage.

System flow NTC sensor fault.

If a problem is detected with the system delivery NTC sensor, the boiler will not start; call a qualified technician.

Domestic circuit NTC sensor fault.

If the unit detects an problem in the domestic circuit NTC sensor, the boiler will not produce domestic hot

water; call a qualified technician.

No water circulating.

This occurs if there is overheating in the boiler due to insufficient water circulation through the boiler - check

that shutoff valves are not closed and that the system is free of air . Check that the circulating pump is running freely. If necessary, remove the pump cover screw and manually rotate the pump impellor using a flat

bladed screwdriver. If lockout occurs repeatedly, contact a qualified technician for assistance.

Draining the system.

To drain the boiler, use the special drain cock. Before draining, ensure that the filling valve is not connected.

Draining the DHW tank.

To drain the tank, use the special drain cock. N.B.: Before carrying out this operation, close the tank cold

water inlet cock and open any domestic circuit hot water cock to allow air to enter the tank.

Anti-freeze protection.

The boiler comes standard with an anti-freeze function that starts the pump and burner when the water temperature inside the boiler falls below 4°C and stops on exceeding 42°C. The anti-freeze function is operational if the boiler is in normal mode and not in “lockout” status, and is electrically connected with the main

switch is set to Summer or Winter. To avoid continued operation in the event of prolonged absence, the

system should be drained completely or anti-freeze should be added to the heating system water. In both

cases the boiler domestic water circuit must be drained. In appliances subject to frequent draining, the system must be refilled with suitably treated water. Do not use hard water to fill the system or there will be

scale formation in the boiler.

Casing Cleaning:

Use damp cloths and neutral

detergent to clean the boiler casing. Never use abrasive or powder

detergents.

Maintenance Operations

Page 17

Zeus Maior 24 Instructions

The following checks and maintenance should be performed at least once a year.

- Clean the flue side of the heat exchanger.

- Clean the main burner.

- Make a visual inspection of the flue extraction hood for wear or corrosion.

- Ensure correct ignition and operation.

- Ensure correct settings of the burner in domestic water and heating modes.

- Verify correct operation and adjustment of the boiler, in particular:

- operation of the electrical main switch on the boiler;

- operation of the system control thermostat;

- operation of the domestic water control thermostat.

- Ensure gas soundness of the gas intake circuit; insert a “U” or digital type pressure gauge in the pressure

test point upstream of the gas valve and then close the boiler shutoff valve. No pressure variation must

occur in the next five minutes on the gauge.

- Ensure activation of the device for protection against the ionisation flame control gas; activation time must

be less than ten seconds

- Visually inspect to check for leakage of water or oxidation of fittings.

- Check visually that the water safety valve outlets are not blocked and that the tundish is clear.

- Check that the charge of the expansion vessel after discharging system pressure to the zero setting

(check via boiler pressure gauge), is at 1,0 bar.

- Check that the system static pressure (in cold conditions and after system recharging via the filling valve )

is between 1 and 1.2 bar.

- Check visually that the safety and control devices have not been tampered with and/or shorted, in particular:

- temperature safety thermostat;

- air pressure switch.

- Check the integrity of boiler Magnesium Anode.

- Ensure correct maintenance and condition of the electrical installation with particular reference to:

electrical cables must be correctly routed

no traces of black marking or burns

Annual maintenance procedures

Page 18

Zeus Maior 24 Instructions

Zeus Maior 24 Series Variable Heat Output

Zeus Maior 24 Wiring Diagram

Loading...

Loading...