Page 1

*1.034468IE*

Instruction booklet and

warning

IE

ZEUS

24 - 28 kW

Page 2

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas

customer you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler.

Read the following pages carefully: you will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm

your satisfaction for the Immergas product.

Contact our area authorised aer-sales centre as soon as possible to request commissioning. Our technician will verify the correct functioning conditions;

he will perform the necessary calibrations and will demonstrate correct use of the generator.

For any interventions or routine maintenance contact Immergas Authorised Centres: these have original spare parts and boast of specic preparation

directly from the manufacturer.

All Immergas products are protected with packaging suitable for transport. e material must be stored in dry environments and protected from bad weather.

e instruction book is an integral and important part of the product and must be consigned to the user also in the case of transfer of ownership.

It must be kept well and consulted carefully, as all of the warnings supply important indications for safety in the installation, use and maintenance stages.

is instruction booklet contains technical information on how installing Immergas boilers. For other issues related to installation of boilers (i.e.: safety

in work sites, environment protection, injury prevention), comply with the laws in force and technical standards.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer and professionally qualied

sta, intending sta with specic technical skills in the plant sector.

Improper installation or assembly of Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to persons,

animals and objects. Read the provided product instructions carefully in order to install the product correctly. Maintenance must be carried out by skilled

technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use must be considered improper and therefore dangerous.

In the case of errors during installation, running and maintenance due tot he failure to comply with the technical laws in force, standards or the instructions

contained in this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for

any damages and the appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of gas heat generators, consult the Immergas site at the

following address: www.immergas.com

Dear Customer,

General recommendations

For the purpose and eect of the CE 90/396 Gas Directive, EMC CE 89/336 Directive, CE 92/42 Boiler Eciency Directives and CE 73/23 Low Voltage

Directive.

e Manufacturer: Immergas S.p.A. v. Cisa Ligure n° 95 42041 Brescello (RE)

DECLARES THAT: the Immergas boiler model: Zeus 24 -28 kW

comply with the above EC Directives

CE DECLARATION OF CONFORMITY

Mauro Guareschi

Research & Development Director

Signature:

INDEX

INSTALLATOR pag. MAINTENANCE pag.

1 Installation of the boiler ...........................3

1.1 Installation recommendation. .................3

1.2 Main dimensions. ......................................3

1.3 Attachments. .............................................. 4

1.4 Remote controls and room

chronothermostats (optional). ................5

1.5 External probe (optional). ........................5

1.6 Installation outside in a partially

protected place. ..........................................6

1.7 Installation indoors. ..................................7

1.8 Fume exhaust to ue/chimney...............12

1.9 Ducting of existing ues. ........................12

1.10 Flues, chimneys and chimney caps. ......12

1.11 System lling. ...........................................13

1.12 Gas system start-up. ................................13

1.13 Boiler start-up (lighting). .......................13

1.14 Domestic hot water boiler device..........13

1.15 Circulation pump. ...................................13

1.16 Kits available on request. ........................13

1.17 Zeus 24-28 kw boiler components. .......14

USER pag.

2 User and maintenance instructions ......15

2.1 Cleaning and maintenance. ...................15

2.2 General warnings. ...................................15

2.3 Control panel. .......................................... 15

2.4 Ignition of the boiler. ..............................16

2.5 Fault and anomaly signals. .....................16

2.6 Boiler shut-down. ....................................16

2.7 Restoring heating system pressure. ....... 17

2.8 Draining the system. ............................... 17

2.9 Anti-freeze protection. ...........................17

2.10 Case cleaning. ..........................................17

2.11 Decommissioning. ..................................17

3 Boiler commissioning (initial check) ...18

3.1 Plumbing layout. .....................................18

3.2 Wiring diagram. ......................................19

3.3 Troubleshooting. .....................................19

3.4 Converting the boiler to other

types of gas. ..............................................20

3.5 Checks following conversion to

another type of gas. .................................20

3.6 Possible adjustments of the gas valve. ..20

3.7 Programming the circuit board.............20

3.8 Automatic slow ignition function

with timed ramp delivery. ......................21

3.9 Chimney sweep “function”. .................... 21

3.10 Pump anti-block function. .....................22

3.11 ree-way anti-block system. ................22

3.12 Radiator anti-freeze function. ...............22

3.13 Electronic card periodical self-check. ..22

3.14 Casing removal. ....................................... 22

3.15 Yearly appliance check and

maintenance. ............................................22

3.16 Variable heat power ................................23

3.17 Combustion parameters. ........................24

3.18 Technical data. .........................................25

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

Page 3

INSTALLATION

1

OF THE BOILER

1.1 INSTALLATION

RECOMMENDATION.

e Zeus kW boiler has been designed for wall

mounted installation only; they must be used

to heat environments, to produce domestic hot

water and similar purposes.

e installation site and relative Immergas accessories must have suitable characteristics (both

technical and structural), in order to allow (always in safe, eciency and easiness conditions):

- installation (according to the legislation and

technical standards in force);

- maintenance operations (including those

scheduled, periodical, ordinary and special);

- removal (to the outdoors in a place suitable

for loading and transporting appliances and

components) as well as any replacement with

equivalent appliances and/or components.

e wall surface must be smooth, without any

protrusions or recesses enabling access to the

rear part. ey are NOT designed to be installed

on plinths or oors (Fig. 1-1).

By var ying the t ype of installation the

classication of the boiler also varies, precisely:

- B22 type boiler if installed using the relevant

terminal for air intake directly from the room

in which the boiler has been installed.

- C type boiler if installed using concentric pipes

or other types of pipes envisioned for the sealed

chamber boiler for intake of air and expulsion

of fumes.

Only professionally qualied heating/plumbing

technicians are authorised to install Immergas

gas appliances.

Installation must be carried out according to the

standards, current legislation and in compliance

with local technical regulations and the required

technical procedures.

Installation of the Zeus kW boiler when powered

by LPG must comply with the rules regarding

gases with a greater density than air (remember,

as an example, that it is prohibited to install plants

powered with the above-mentioned gas in rooms

where the oor is at a lower quota that the average

external country one).

Before installing the appliance, ensure that it

is delivered in perfect condition; if in doubt,

contact the supplier immediately. Packing

materials (staples, nails, plastic bags, polystyrene

foam, etc.) constitute a hazard and must be kept

out of the reach of children. If the appliance

is installed inside or between cabinets, ensure

sucient space for normal servicing; therefore

it is advisable to leave a clearance of at least 3

cm between the boiler casing and the vertical

sides of the cabinet.

Leave adequate space above the boiler for

possible water and fume removal connections.

At least 60 cm must be le below the boiler

in order to guarantee replacement of the

magnesium anode. Keep all ammable objects

away from the appliance (paper, rags, plastic,

polystyrene, etc.).

Do not place household appliances underneath

the boiler as they could be damaged if the safety

valve intervenes (if not conveyed away by a

discharge funnel), or if there are leaks from the

connections; on the contrary, the manufacturer

cannot be held responsible for any damage

caused to the household appliances.

In the event of malfunctions, faults or incorrect

operation, turn the appliance

o immediately and contact a qualied technician

(e.g. the Immergas Technical Assistance centre,

which has specically trained personnel and

original spare parts). Do not attempt to modify

or repair the appliance alone. Failure to comply

with the above implies personal responsibility

and invalidates the warranty.

• Installation regulations: this boiler can be

installed outside in a partially protected area.

A partially protected location is one in which

the appliance is not exposed to the direct action

of the weather (rain, snow, hail, etc..).

Important: Wall mounting of the boiler must

guarantee stable and ecient support for the

generator.

The plugs supplied are to be used only in

conjunction with the mounting brackets or xing

template to x the appliance to the wall; they only

ensure adequate support if inserted correctly

(according to technical standards) in walls made

of solid or semi-hollow brick or block. In the

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate support.

N.B.: the hex head screws supplied in the blister

pack are to be used exclusively to x the relative

mounting bracket to the wall.

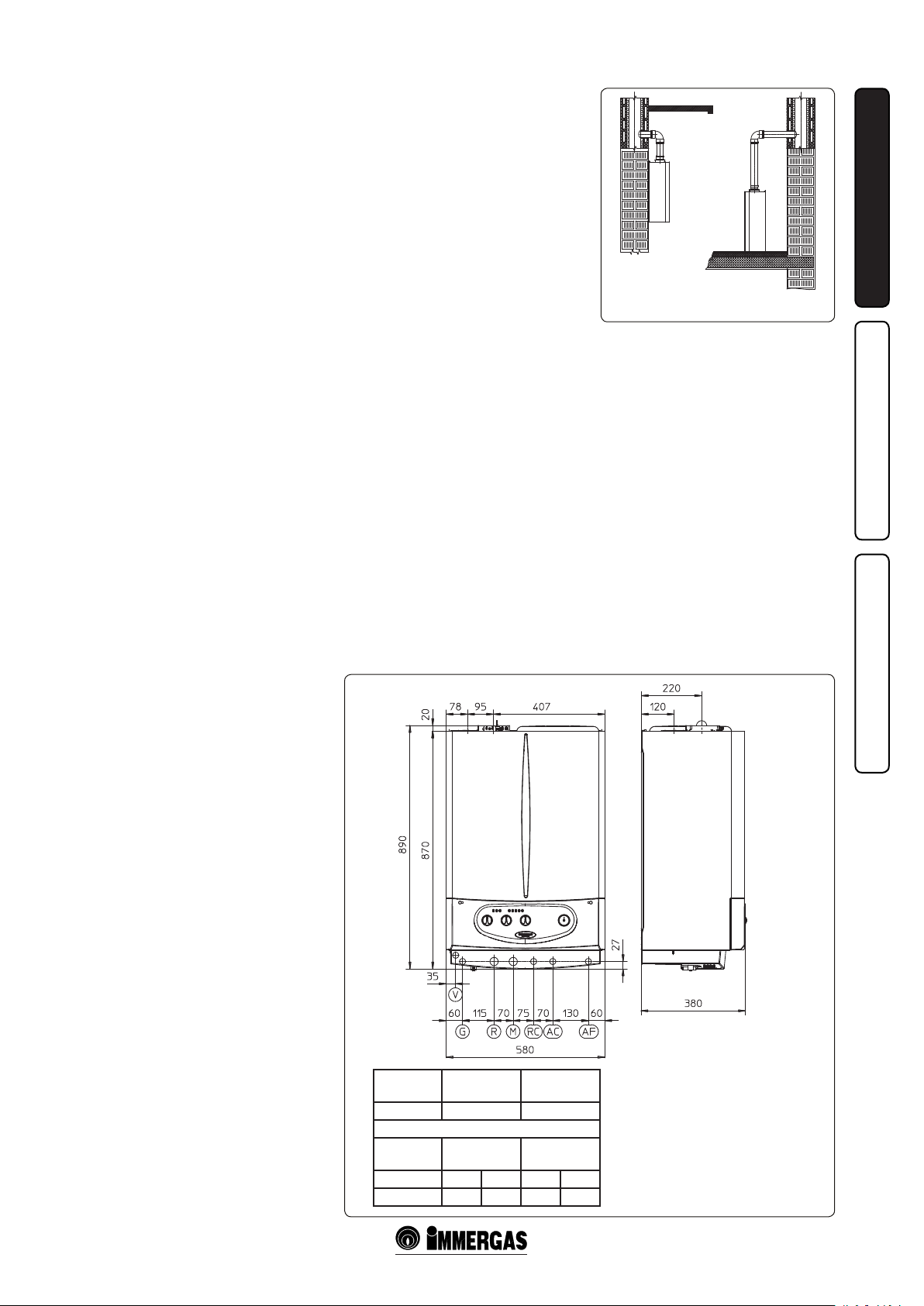

1.2 MAIN DIMENSIONS.

Height

(mm)

890 580 380

GAS PLANT

G R M AC AF

1/2” 3/4” 3/4” 1/2” 1/2”

Width

(mm)

ATTACHMENTS

Depth

(mm)

DOMESTIC

HOT WATER

INSTALLATORUSERMAINTENANCE

YES NO

1-1

ese boilers are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be connected to a heating system and

hot water circuit suited to their performance

and capacity.

Anti-Legionella thermal treatment of the Immergas storage tank (which can be activated

through the specic function present on the set

thermoregulation systems): during this phase,

the water temperature inside the storage tank exceeds 60 °C resulting in burns hazards. Keep this

DHW treatment under control (and inform the

users), to prevent unexpected damage to persons,

animals and objects. If required, a thermostatic

valve must be installed at the DHW outlet to

prevent burns.

1-2

Key:

G - Gas supply

R - System return

M - System delivery

RC - Domestic hot water re-circ.

AC - Domestic hot water outlet

AF - Domestic hot water inlet

V - Electric attachment

3 - IE

Page 4

1.3 ATTACHMENTS.

Gas attachment (II

Our boilers are designed to operate with methane

gas (G20) and LPG. Supply pipes must be the

same as or larger than the 1/2”G boiler tting.

Before connecting the gas line, carefully clean

inside all the fuel feed system pipes to remove any

residue that could impair boiler eciency. Also

make sure the gas corresponds to that for which

the boiler is prepared (see boiler data-plate).

If dierent, the appliance must be converted

INSTALLATORUSERMAINTENANCE

for operation with the other type of gas (see

converting appliance for other gas types). e

dynamic gas supply (methane or LPG) pressure

must also be checked according to the type used

in the boiler, as insucient levels can reduce

generator output and cause malfunctions.

Ensure correct gas cock connection. e gas

supply pipe must be suitably dimensioned

according to current regulations in order to

guarantee correct gas ow to the boiler even

in conditions of max. generator output and

to guarantee appliance efficiency (technical

specifications). The coupling system must

conform to standards.

Combustible gas quality. e appliance has been

designed to operate with gas free of impurities;

otherwise it is advisable to fit special filters

upstream from the appliance to restore the

purity of the gas.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

Hydraulic attachment.

Important: In order not to void the warranty

before making the boiler connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could compromise

correct boiler operation.

Water connections must be made in a rational way

using the couplings on the boiler template. e

boiler safety valve outlet must be connected to a

discharge funnel. Otherwise, the manufacturer

declines any responsibility in case of ooding if

the drain valve cuts in.

Important: to preserve the life and eciency of the

domestic hot water exchanger, it is recommended

to install the “polyphosphate proportioner” kit in

the presence of water whose characteristics can

give rise to scale deposits (in particular, and as

an example, the kit is recommended when water

hardness is higher than 25 French degrees).

category appliance).

2H3+

Electrical connection. e “Zeus kW” boiler

has an IPX4D protection rating for the entire

appliance. Electrical safety of the unit is reached

when it is correctly connected to an ecient

earthing system as specied by current safety

standards.

Imp ortant: Immergas S.p.A. declines any

responsibility for damage or physical injury

caused by failure to connect the boiler to an

ecient earth system or failure to comply with

the reference standards.

Also ensure that the electrical installation

corresponds to maximum absorbed power

specications as shown on the boiler data-plate.

Boilers are supplied complete with an “X” type

power cable without plug. e power supply

cable must be connected to a 230V ±10% / 50Hz

mains supply respecting L-N polarity and earth

connection; , this network must also have a

multi-pole circuit breaker with class III overvoltage category. When replacing the power

supply cable, contact a qualied technician (e.g.

the Immergas Aer-Sales Technical Assistance

Service).

e power cable must be laid as shown. In the

event of mains fuse replacement on the control

card, use a 3.15A quick-blow fuse.

For the main power supply to the appliance,

never use adapters, multiple sockets or extension

leads.

4 - IE

Page 5

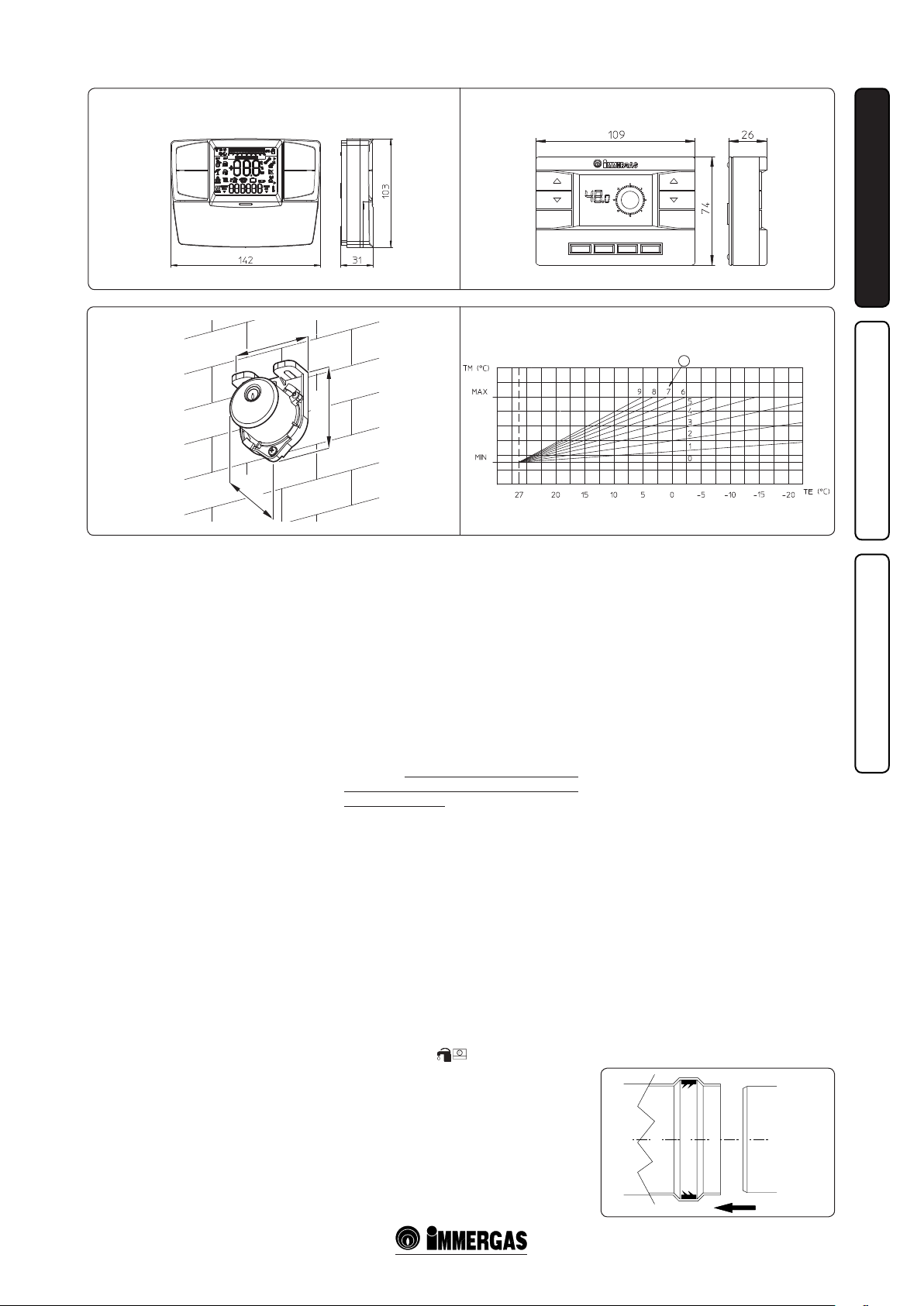

Remote Friend controlV2 (CARV2)

On/O digital timer thermostat.

45

58

31

Digital Remote Control

(CRD)

INSTALLATORUSERMAINTENANCE

1-3 1-4

*

1-5 1-6

1.4 REMOTE CONTROLS AND ROOM

CHRONOTHERMOSTATS

OPTIONAL.

e boiler is prepared for application of room

chronothermostats and external probe. ese

Immergas components are available as separate

kits to the boiler and are supplied on request.

All Immergas chronothermostats are connected

with 2 wires only. Carefully read the user and

assembly instructions contained in the accessory

kit.

• On/O ff d igita l chronothermost at. The

chronothermostat allows:

- to set two room temperature values: one for

day (comfort temperature) and one for night

(lower temperature);

- to set up to four on/o dierential weekly

programs;

- selecting the required function mode from

the various possible alternatives.

• permanent functioning in comfort temp.

• permanent operation in lower temp.

• permanent function in adjustable anti-freeze

temp.

e chronothermostat is powered by two 1.5V

LR 6 type alkaline batteries;

• ere are two types of Remote Friend ControlV2

(CARV2) (Fig. 1-3) and Digita l Rem ote

Control (CRD) (Fig. 1-4) both with room

chronothermostat functioning. In addition to

the functions described in the previous point,

the Remote Friend ControlV2 enables the

user to control all the important information

regarding operation of the appliance and the

heating system with the opportunity of easily

intervening on the previously set parameters

without having to go to the place where the

appliance is installed. The Remote Friend

ControlV2 panel is provided with self-diagnosis

to display any boiler functioning anomalies.

e climate chronothermostat incorporated in

the remote panel enables the system delivery

temperature to be adjusted to the actual needs

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving

in running costs. e chronothermostat is fed

directly by the boiler by means of the same 2

wires used for the transmission of data between

boiler and chronothermostat.

Important: If the system is subdivided into zones

using the relevant kit. the CARV2 must be used

with its climate thermostat function disabled, i.e.

it must be set to On/O mode. e CRD cannot

be used for plants divided into zones.

Electrical connection of the Remote Friend

Cont rolV2 or chronothermo stat On/Off

(Optional). e operations described below must

be performed aer having removed the voltage

from the appliance. The eventual thermostat

or On/Off room chronothermostat must be

connected to terminals 40 and 41 eliminating

jumper X40 (Fig. 3-2). Make sure that the On/

O thermostat contact is of the “clean” type, i.e.

independent of the mains supply, otherwise the

electronic adjustment card would be damaged.

The eventual Remote Friend ControlV2 must

be connected by means of terminals IN+ and

IN- to terminals 42 and 43, eliminating jumper

X40 on the terminal board (in the boiler)

respecting polarity (Fig. 3-2). Connection with

the wrong polarity prevents functioning, but

without damaging the Remote Friend ControlV2.

e boiler works with the parameters set on

the Remote Friend ControlV2 only if the boiler

main selector is turned to Domestic/Remote

Friend ControlV2 ( ). e boiler can only

be connected to one remote control.

Important: If the Remote Friend ControlV2,

Digital Remote Control or any other On/O

chronothermostat is used arrange two separate

lines in compliance with current regulations

regarding electrical systems. Boiler pipes must

never be used to earth the electric or telephone

lines. Ensure elimination of this risk before

making the boiler electrical connections.

1.5 EXTERNAL PROBE OPTIONAL.

• External temperature probe (Fig. 1-5). is

sensor can be connected directly to the boiler

electrical system and allows the max. system

delivery temperature to be automatically

decreased when the outside temperature

increases, in order to adjust the heat supplied

to the system according to the change in

external temperature. The external probe

always operates when connected, regardless of

the presence or type of room chronothermostat

used and can work in combination with the On/

O chronothermostat and the CARV2, (it cannot

be connected to the CRD). e correlation

between system delivery temperature and

outside temperature is determined by the

position of the knob on the boiler control

panel according to the curves shown in the

diagram (Fig. 1-6). e external probe electrical

connection must be made on clamps 38 and 39

on the boiler circuit board (Fig. 3-2).

* (Fig. 1-6) Position of the heating temperature

user adjustment.

1-7

5 - IE

Page 6

1.6 INSTALLATION OUTSIDE IN A

PARTIALLY PROTECTED PLACE.

N.B.: a partially protected location is one in which

the appliance is not exposed to the direct action of

the weather (rain, snow, hail, etc.).

• Conguration type B, open chamber and

forced draught.

The relevant terminal must be used for this

conguration (present in the intake kit for the

installation in question), which must be placed

on the central hole of the boiler (see following

INSTALLATORUSERMAINTENANCE

gure). Air intake takes place directly from the

environment in which the boiler is installed

and fumes are expelled in an individual ue or

directly to the outside.

e boiler in this conguration is classied as

type B22 according to the standards.

With this conguration:

- air intake takes place directly from the

environment in which the boiler is installed

and only functions in permanently ventilated

rooms

- the fumes pipe must be connected to its own

individual ue or channelled directly into the

external atmosphere.

The technical regulations in force must be

respected.

• Fitting the cover kit. (Fig. 1-10) Remove the

two plugs and the seals present from the two

holes to the laterally to the central one.

Install the Ø 80 outlet ange on the central

hole of the boiler, taking care to insert the seal

supplied with the kit and tighten by means

of the screws provided. Install the top cover,

xing it with the screws previously removed

from the lateral plugs. Engage the 90°, Ø 80

bend with the male end (smooth) in the female

end (with lip seal) of the Ø 80 ange until it

stops. Cut the seal in the relative groove at the

desired diameter (Ø 80), run it along the bend

and x it using the sheet steel plate. Insert the

exhaust pipe with the male end (smooth) into

the female side of the 90° bend, Ø 80, making

sure that the relative washer has already been

introduced. This will ensure tightness and

coupling of the elements making up the kit.

Max. length of exhaust ue. e ue pipe (vertical or horizontal) can be extended to a max.

length of 12 m straight route, using insulated

pipes (Fig. 1-28). To prevent problems of fume

condensate in the exhaust pipe Ø 80, due to fume

cooling through the wall, the length of the pipe

must be limited to just 5 m (Fig. 1-25).

• Coupling of extension pipes and elbows. To

install possible coupling extensions on other

fume extraction elements, proceed as follows::

Fit the male end (smooth) of the pipe or elbow

up to the stop on the female end (with lip seals)

of the previously installed element; this will

ensure correct seal and joining of the elements.

Example of installation with direct vertical

terminal in partially protected locatio. When

the vertical terminal for direct discharge of

combustion fumes is used, a minimum gap of

300 mm must be le between the terminal and

the balcony above. e distance A + B (always

with respect to the balcony above), must be equal

to or less than 2000 mm (Fig. 1-9).

• Conguration without cover kit in a partially

protected location (boiler type C).

By leaving the side plugs fitted it is possible

to install the appliance externally without the

cover kit. Installation is carried out using the

horizontal concentric Ø60/100, Ø80/125 and

Ø80/80 separator kits.

VERTICAL TERMINAL KIT

FOR DIRECT DISCHARGE

INTAKE

COVER KIT

1-8

e cover kit include:

N° 1 - Heat moulded cover

N° 1 - Gasket camping plate

N° 1 - Gasket

N° 1 - Gasket clamp

e terminal kit includes:

N° 1 - Seal

N° 1 - Exhaust ange Ø 80

N° 1 - 90° bend Ø 80

N° 1 - Exhaust pipe Ø 80

N° 1 - Ring

1-10 1-11

1-9

6 - IE

Page 7

1.7 INSTALLATION INDOORS.

• Type C conguration, sealed chamber and

forced draught.

Immergas supplies various solutions separately

from the boiler regarding the installation of air

intake terminals and ue extraction; fundamental for boiler operation.

Important: the boiler must only be installed

together with an origin Immergas air intake

and fume extraction system. is system can

be identied by a special distinctive marking

bearing the note: “not for condensing boilers”.

e fume exhaust pipes must not be in contact

with or near ammable materials and must not

cross building structures or walls made of ammable materials.

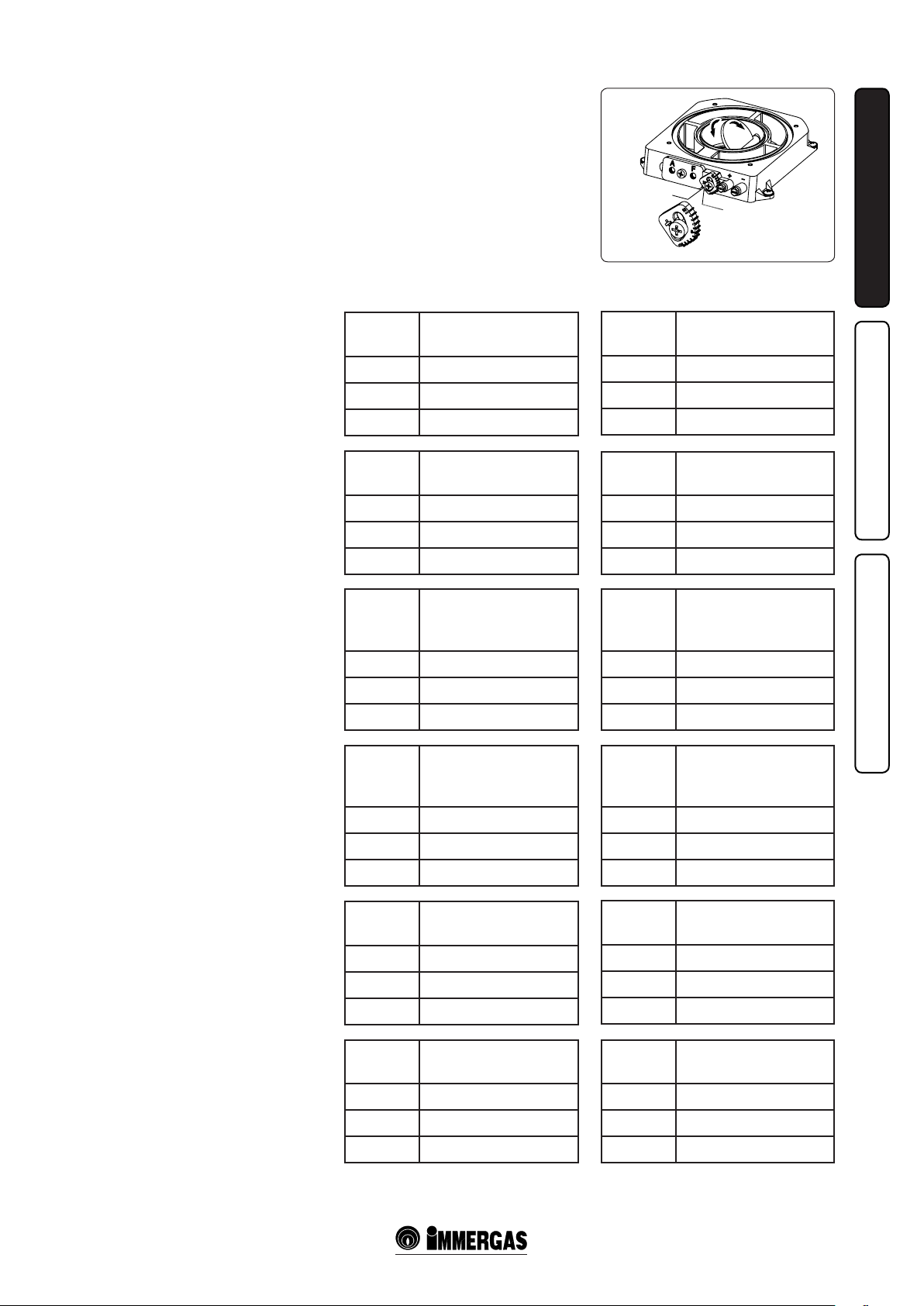

• Resistance factors and equivalent lengths.

Each flue extraction system component is

designed with a Resistance Factor based on

preliminary tests and specied in the table

below The resistance factor for individual

components does not depend either on the type

of boiler on which it is installed or the actual

dimensions. It is based on the temperature of

uids conveyed through the ducts and therefore

varies according to applications for air intake

or ue exhaust Each single component has a

resistance corresponding to a certain length

in metres of pipe of the same diameter; the

so-called equivalent length, obtained from the

ration between he relative Resistance Factors.

All boilers have an experimentally obtainable

maximum Resistance Factor equal to 100.

The maximum Resistance Factor allowed

corresponds to the resistance encountered with

the maximum allowed pipe length for each

type of Terminal Kit. is information enables

calculations to verify the possibility of various

congurations of ue extraction systems.

Positioning of double lip seals. For correct

positioning of lip seals on elbows and extensions,

follow the assembly direction given in the gure

(Fig. 1-7).

Fumes separ ator adjustment. For correct

functioning of the boiler the fumes separator

positioned on the air/fumes extraction well must

be adjusted (Fig. 1-12).

Adjustment is carried out by loosening the

front retainer screw and moving the indicator

to the correct position, aligning its value to the

horizontal reference (Fig. 1-12). Once adjustment

has been performed, tighten the screw to x the

separator. Appropriate adjustment takes place on

the basis of the type of pipe and its extension: this

calculation can be carried out using the fumes

separator adjustment tables.

Fumes separator adjustments

Zeus 24 kW.

Fumes

separator

3 From 0 to 0,5

5 From 0,5 to 2

10 From 2 to 3

Fumes

separator

3 From 0 to 2,2

5 From 2,2 to 3,7

10 From 3,7 to 4,7

Fumes

separator

3 From 0 to 4

5 From 4 to 26

6 From 26 to 35

Fumes

separator

3 Da 0 to 8

5 Da 8 to 30

6 Da 30 to 40

Fumes

separator

3 From 0 to 0,5

5 From 0,5 to 4,6

10 From 4,6 to 7,4

Duct length in metres

Ø 60/100 horizontal

Duct length in metres

Ø 60/100 vertical

*Duct length in metres

Ø 80 horizontal

With two bends

*Duct length in metres

Ø 80 vertical

without bends

Duct length in metres

Ø 80/125 horizontal

Fumes separator adjustments

Zeus 28 kW.

Fumes

separator

3 From 0 to 0,5

5 From 0,5 to 2

10 From 2 to 3

Fumes

separator

3 From 0 to 2,2

5 From 2,2 to 3,7

10 From 3,7 to 5,7

Fumes

separator

3 From 0 to 2

5 From 2 to 21

7 From 21 to 35

Fumes

separator

3 From 0 to 6

5 From 6 to 25

7 From 25 to 40

Fumes

separator

3 From 0 to 0,5

5 From 0,5 to 4,6

10 From 4,6 to 10,1

Duct length in metres

Ø 60/100 horizontal

Duct length in metres

Ø 60/100 vertical

*Duct length in metres

Ø 80 horizontal

with two bends

*Duct length in metres

Ø 80 vertical

without bends

Duct length in metres

Ø 80/125 horizontal

1-12

INSTALLATORUSERMAINTENANCE

Fumes

separator

3 From 0 to 5,4

5 From 5,4 to 9,5

10 From 9,5 to 12,2

* e values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

Duct length in metres

Ø 80/125 vertical

7 - IE

Fumes

separator

3 From 0 to 5,4

5 From 5,4 to 9,5

10 From 9,5 to 15,0

* e values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

Duct length in metres

Ø 80/125 vertical

Page 8

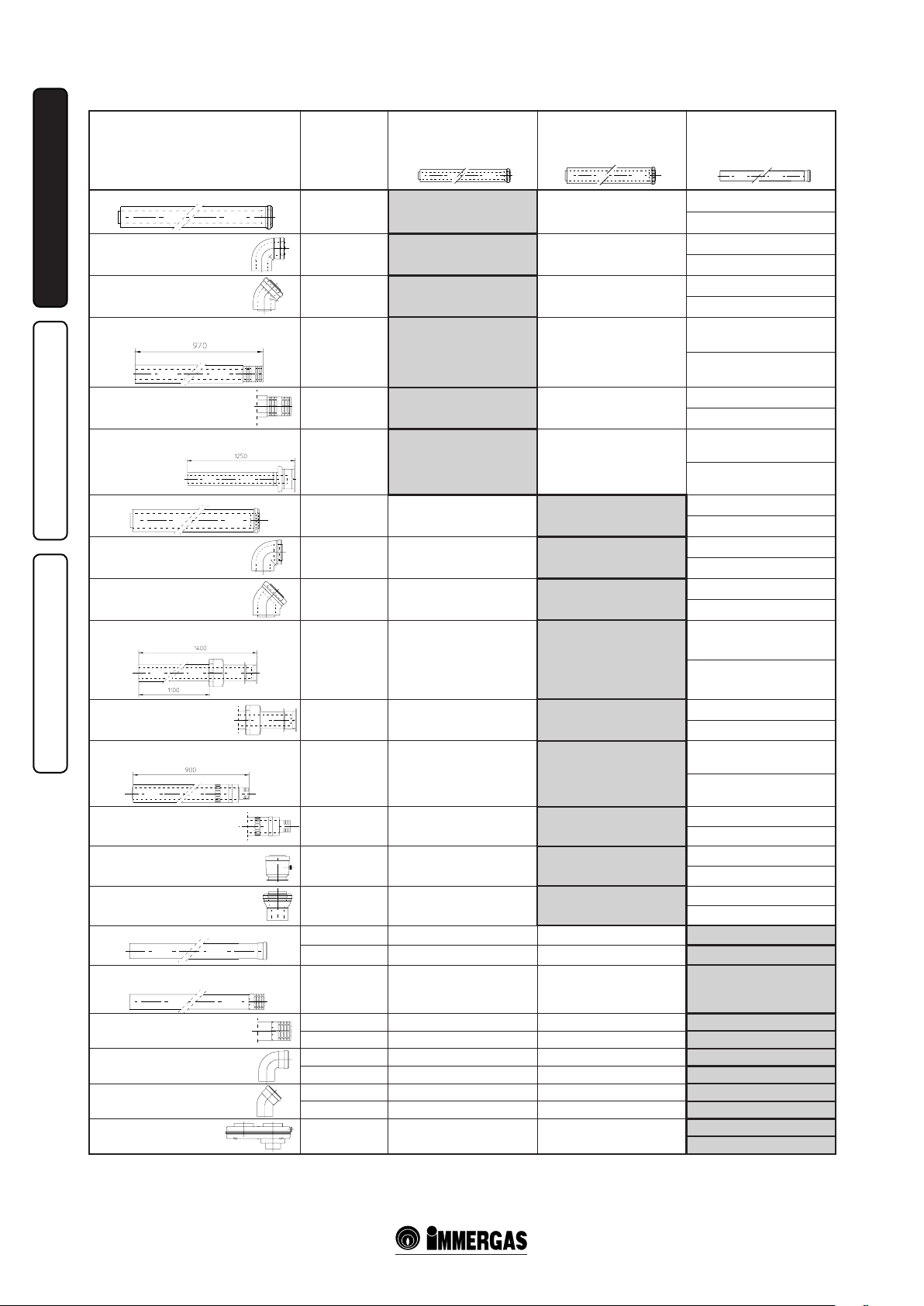

Resistance Factors and Equivalent Lengths Table

Resistance

DUCT TYPE

Factor

(R)

Equivalent length

in meter of concentric pipe

Ø 60/100

Equivalent length

in meter of concentric pipe

Ø 80/125

Equivalent length

in metres of pipe

Ø 80

Concentric pipe Ø 60/100 m 1

90° bend concentric Ø 60/100

INSTALLATORUSERMAINTENANCE

45° bend concentric Ø 60/100

Terminal complete with concentric

horizontal intake-exhaust Ø 60/100

Terminal complete with concentric

horizontal intake-exhaust Ø 60/100

Terminal complete with concentric

vertical intake-exhaust Ø 60/100

Concentric pipe Ø 80/125 m 1

90° bend concentric Ø 80/125

45 bend concentric Ø 80/125

Terminal complete with concentric horizontal intake-exhaust Ø 80/125

Terminal complete with concentric

horizontal intake-exhaust Ø 80/125

Terminal complete with concentric

horizontal intake-exhaust Ø 80/125

Terminal complete with concentric

horizontal intake-exhaust Ø 80/125

Concentric adapter from Ø 60/100

to Ø 80/125 with condensate collector

Concentric adapter from

Ø 60/100 to Ø 80/125

Pipe Ø 80, 1 m (with or without insulation)

Complete pipe terminal Ø 80, 1 m

(with or without insulation)

Intake and

Exhaust 16,5

Intake and

Exhaust 21

Intake and

Exhaust 16,5

Intake and

Exhaust 46

Intake and

Exhaust 32

Intake and

Exhaust 41,7

Intake and

Exhaust 6

Intake and

Exhaust 7,5

Intake and

Exhaust 6

Intake and

Exhaust 33

Intake and

Exhaust 26,5

Intake and

Exhaust 39

Intake and

Exhaust 34

Intake and

Exhaust 13

Intake and

Exhaust 2

Intake 2,3 m 0,1 m 0,4 Intake m 1,0

Exhaust 3 m 0,2 m 0,5 Exhaust m 1,0

Intake 5 m 0,3 m 0,8 Intake m 2,2

m 1 m 2,8

m 1,3 m 3,5

m 1 m 2,8

m 2,8 m 7,6

m 1,9 m 5,3

m 2,5 m 7

m 0,4 m 1,0

m 0,5 m 1,3

m 0,4 m 1,0

m 2,0 m 5,5

m 1,6 m 4,4

m 2,3 m 6,5

m 2,0 m 5,6

m 0,8 m 2,2

m 0,1 m 0,3

Intake m 7,1

Exhaust m 5,5

Intake m 9,1

Exhaust m 7,0

Intake m 7,1

Exhaust m 5,5

Intake m 20

Exhaust m 15

Intake m 14

Exhaust m 10,6

Intake m 18

Exhaust m 14

Intake m 2,6

Exhaust m 2,0

Intake m 3,3

Exhaust m 2,5

Intake m 2,6

Exhaust m 2,0

Intake m 14,3

Exhaust m 11,0

Intake m 11,5

Exhaust m 8,8

Intake m 16,9

Exhaust m 13

Intake m 14,8

Exhaust m 11,3

Intake m 5,6

Exhaust m 4,3

Intake m 0,8

Exhaust m 0,6

Intake terminal Ø 80

Exhaust terminal Ø 80

Bend 90° Ø 80

Bend 45° Ø 80

Split parallel Ø 80

from Ø 60/100 to Ø 80/80

Intake 3 m 0,2 m 0,5 Intake m 1,3

Exhaust 2,5 m 0,1 m 0,4 Exhaust m 0,8

Intake 5 m 0,3 m 0,8 Intake m 2,2

Exhaust 6,5 m 0,4 m 1,1 Exhaust m 2,1

Intake 3 m 0,2 m 0,5 Intake m 1,3

Exhaust 4 m 0,2 m 0,6 Exhaust m 1,3

Intake and

Exhaust 8,8

m 0,5 m 1,5

Intake m 3,8

Exhaust m 2,9

8 - IE

Page 9

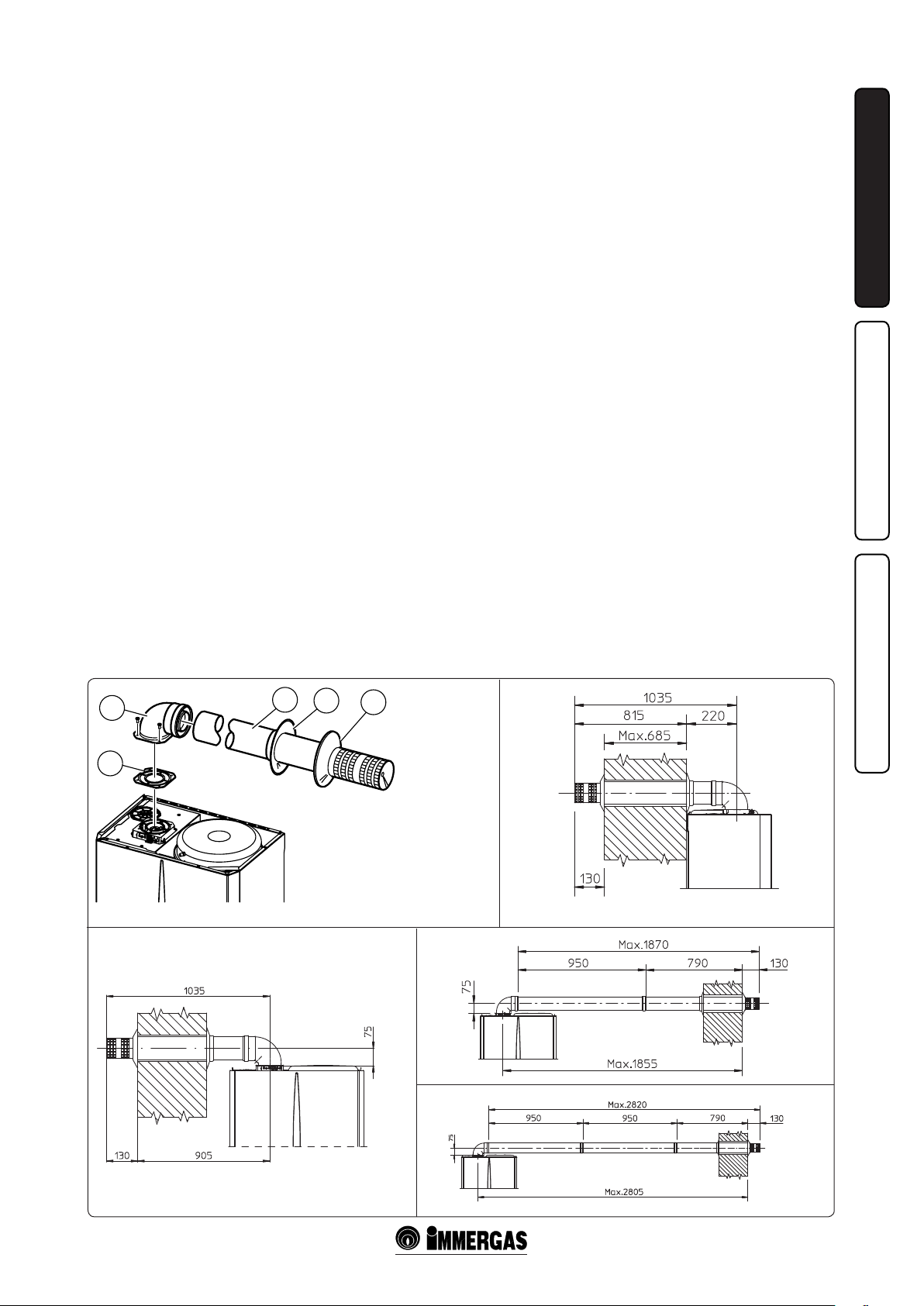

Horizontal intake kits - exhaust Ø60/100. Kit

assembly (Fig. 1-13): install the bend with ange

(2) on the central hole of the boiler inserting the

seal (1) and tighten using the screws present in

the kit. Engage the terminal pipe (3) with the

male side (smooth), into the female side (with lip

seal) of the curve (2) until it stops, making sure

the relevant internal and external rings are tted,

this will ensure hold and joining of the elements

making up the kit.

N.B.: when the boilers are installed in areas where

very rigid temperatures can be reached, a special

anti-freeze kit is available that can be installed as

an alternative to the standard kit.

• Coupling extension pipes and concentric elbows Ø 60/100 snap-t extensions with other

elements of the fume extraction elements

assembly, follows: t the concentric pipe or

elbow with the male on the female section

(with lip seal) to the end stop on the previously

installed element. to ensure sealing eciency

of the coupling.

e Ø 60/100 kit can be installed with the rear,

right side, le side and front outlet.

• Application with rear outlet (Fig. 1-14). e

970 mm pipe length enables routingthrough a

max. thickness 685 mm. Normally the terminal

must be shortened. Calculate the distance by

adding the following: part thickness+ internal

projection + external projection. e minimum

projectionvalues are given in the gure.

• Application with side outlet (Fig. 1-15); Using

the horizontal intake/exhaust kit, without the

special extensions, the maximum distance

between the vertical exhaust axis and the outside wall is 905 mm.

2

3

• Extensions for horizontal kit. e horizontal

intake/exhaust kit Ø 60/100 can be extended

up to a max. horizontal distance of 3000 mm

includingthe terminal with grille and excluding

the concentric bend leaving theboiler. is conguration corresponds to a resistance factor of

100. Inthese cases the special extensions must

be requested.

Connection with 1 extension (Fig. 1-16). Max.

distance between vertical boiler axis and external wall: mm 1855.

Connection with 2 extensions (Fig. 1-17).

Max. distance between vertical boiler axis and

external wall: mm 2805.

Horizontal intake/exhaust kits Ø 80/125. Kit

assembly (Fig. 1-18): install the bend with ange

(2) on the central hole of theboiler inserting the

seal (1) and tighten using the screws in the kit.

Fit the male end (smooth) of the adapter (3) up

to the stop on the female end of the bend (2)

(with lip seal). Fit the male end (smooth) of the

Ø 80/125 concentric terminal pipe (4) up to the

stop on the female end of the adapter (3) (with

lip seals),, making sure the relevant internal and

external rings are tted, this will ensure hold

and joining of the elements making up the kit.

• Coupling extension pipes and concentric

elbows Ø 80/125 snap-fit extensions with

other elements of the fume extraction elements

assembly, follows: t the concentric pipe or

elbow with the male on the female section

(with lip seal) to the end stop on the previously

installed element; this will ensure correct hold

and joining of the elements.

Important: if the exhaust terminal and/or

extension concentric pipe needs shortening,

consider that the internal duct must always

project by 5 mm with respect to the external duct.

4

5

C12

Normally the horizontal intake/exhaust kit Ø

80/125 is used if particularly long extensions

are required; the kit Ø 80/125 can be installed

with the rear, right side, le side or front outlet.

• Extensions for horizontal kit. e horizontal

intake/exhaust kit Ø 80/125 can be extended

up to a a maximum horizontal length of 7300,

including the terminal with grille and excluding

the concentric bend leaving the boiler and the

adapter Ø 60/100 in Ø 80/125 (Fig. 1-19). is

conguration corresponds to a resistance factor

of 100. In this case the special extensions must

be requested.

N.B.: When installing the ducts, a section

clamp with pin must be installed every 3

metres.

• External grill. N.B.: for safety purposes, do not

even temporarily obstruct the boiler intake/

exhaust terminal.

Vertical kit with aluminium tile Ø 80/125. Kit

assembly (Fig. 1-20): install the concentric ange

(2) on the central hole of the boiler inserting the

seal (1) and tighten using the screws in the kit. Fit

the male end (smooth) of the adapter (3) in the

female end of the concentric ange (2). Imitation

aluminium tile installation. replace the tile with

the aluminium sheet (5), shaping it to ensure that

rainwater runs o. Position the xed half-shell

(7) on the aluminium tile and insert the intake/

exhaust pipe (6). Fit the male end (smooth) of the

Ø 80/125 concentric terminal pipe (6) up to the

stop on the female end of the adapter (3) (with

lip seals), making sure that the ring is already

tted (4), this will ensure sealing and joining of

the elements making up the kit.

C12

INSTALLATORUSERMAINTENANCE

1-13

1

e kit includes:

N°1 - Seal (1)

N°1 - Concentric 90° curve (2)

N°1 - Intake/exhaust concentric pipe

Ø60/100 (3)

N°1 - Internal ring (4)

N°1 - External ring (5)

1-14

C12 C12

1-16

C12

1-171-15

9 - IE

Page 10

INSTALLATORUSERMAINTENANCE

1-18

3

2

4

5

6

C12

C12

1

e kit includes:

N°1 - Seal (1)

N°1 - Concentric bend Ø 60/100 (2)

N°1 - Adapter Ø 60/100 for Ø 80/125 (3)

N°1 - Concentric intake/exhaust

terminal Ø 80/125

N°1 - Internal ring (5)

N°1 - External ring (6)

1-19

• Coupling extension pipes and concentric elbows. To install possible coupling extensions

on other fume extraction elements, proceed

as follows: t the male end (smooth) of the

concentric pipe or concentric elbow up to the

stop on the female end (with lip seals) of the

previously installed element; this will ensure

correct hold and joining of the elements.

Caution: if the exhaust terminal and/or extension concentric pipe needs shortening, consider

that the internal duct must always protrude by 5

mm with respect to the external duct.

is specic terminal enables ue exhaust and

air intake in a vertical direction.

N.B.: the vertical kit Ø 80/125 with aluminium

tile enables installation on terraces and roofs with

maximum slope of 45% (24°). e height between

the terminal cap and half-shell (374 mm) must

always be respected.

e vertical kit with this conguration can be

extended up to a maximum of 12200 mm vertical

rectilinear, including the terminal (Fig. 1-21).

is conguration correspondsto a resistance

factor of 100. In this case specic extensions

must be requested.

The terminal Ø 60/100 can also be used for

vertical exhaust, in conjunction with concentric

ange code no. 3.011141 (sold separately). e

height between the terminal cap and half-shell

(374 mm) must always be respected (Fig. 1-21).

e vertical kit with this conguration can be

extended to a max. straight vertical length of 4700

mm, including the terminal (Fig. 1-21).

Separator kit Ø 80/80. e separator kit Ø 80/80,

enables separation of the exhaust ues and air

intake pipes according to the diagram shown in

the gure. (Fig. 1-22). Fumes are expelled from

duct (S). Air is taken in through duct (A) for

combustion. Intake duct (A) can be installed

either on the right or le hand side of the central

exhaust duct (S). Both ducts can be routed in

any direction.

• Assembly of separator kit Ø 80/80. Install the

ange (4) on the central hole of the boiler

inserting the seal (1) and tighten using the

hex and flathead screws supplied with the

kit. Remove the at ange in the lateral hole

with respect to the central one (depending on

installation requirements) and replace with

ange (3) inserting the seal (2) already tted

on the boiler and tighten using the self-tapping

screws supplied. Fit the male end (smooth) of

the bends (5) in the female end of the anges (3

and 4). Fit the male end (smooth) of the intake

terminal (6) up to the stop on the female end

of the bend (5), making sure that the relevant

internal and external rings are tted. Join the

exhaust pipe (9) with the male section (smooth)

in the female section of the bend (5) to the end

stop, ensuring that the internal washer is tted;

this will ensure the sealing eciency of the kit

components.

• Snap t extension pipe ttings and elbows. To

install snap-t extensions with other elements

of the fume extraction elements assembly,

proceed as follows: t the pipe or elbow with

the male section (smooth) in the female section

(with lip seal) to the end stop on the previously

installed element; in this way sealing eciency

of the couplings is assured.

• e gure (Fig. 1-24) shows the conguration

with vertical exhaust and horizontal intake.

• Installation clearances. e gure (Fig. 1-23)

gives the min. installation space dimensions

of the Ø 80/80 separator terminal kit al limit

condition.

• Extensions for separator kit Ø 80/80. e max.

vertical straight length (without bends) usable

for Ø 80 intake and exhaust pipes is 41 metres

of which 40 intake and 1 exhaust. is total

length corresponds to a resistance factor of 100.

e total usable length, obtained by adding the

length of the intake and exhaust pipes Ø 80,

must not exceed the maximum values given

in the following table. If mixed accessories or

components (are used (e.g. changing from a

C32

8

*

*

C32

5

e kit includes:

N°1 - Seal (1)

N°1 - Female concentric ange (2)

7

4

3

2

N°1 - Adapter Ø 60/100 for Ø 80/125 (3)

N°1 - Ring (4)

N°1 - Aluminium tile (5)

N°1 - Intake/Exhaust concentric pipe

6

Ø 80/125 (6)

N°1 - Fixed semi-shell (7)

N°1 - Mobile half-shell (8)

Max 12200 mm

Max 4700 mm

1

1-211-20

10 - IE

Page 11

separator Ø 80/80 to a concentric pipe), the

maximum extension can be calculated by

using a resistance factor for each component

or the the equivalent length. e sumof these

resistance factors must not exceed 100.

• Temperature loss in fume ducts (Fig. 1-25). To

prevent problems of fume condensate in the

exhaust pipe Ø 80, due to fume cooling through

the wall, the length of the pipe must be limited to

just 5 m. If longer distances must be covered,

use Ø 80 pipes with insulation (see insulated

separator kit Ø 80/80 chapter).

Insulated separator kit Ø 80/80. Kit assembly

(Fig. 1-26): install flange (4) on the central

hole of the boiler, tting seal (1), and tighten

with the at-tipped hex screws included in the

kit. Remove the at ange on the lateral hole

(depending on installation requirements) and

replace with ange (3) inserting seal (2) already

tted on the boiler and tighten using the selftapping screws supplied. Insert and slide cap

(6) onto bend (5) from the male side (smooth),

and join bends (5) with the male side (smooth)

in the female side of ange (3). Fit bend (11)

with the male side (smooth) in the female side

of ange (4). Fit the male end (smooth) of the

intake terminal (7) up to the stop on the female

end of the bend (5), making sure you have already

inserted the rings (8 and 9) that ensure correct

installation between pipe and wall, then x the

closing cap (6) on the terminal (7). Join the

exhaust pipe (10) with the male side (smooth) in

the female side of the bend (11) to the end stop,

ensuring that the washer (8) is already inserted

for correct installation between the pipe and ue.

• Coupling of extension pipes and elbows. To

install snap-t extensions with other elements

of the fume exhaust system, proceed as follows:

t the male end (smooth) of the concentric

pipe or concentric elbow up to the stop on the

INSTALLATORUSERMAINTENANCE

7

1-22

9

5

5

6

7

8

C82

C42

S

A

4

1

C52

3

e kit includes:

2

N°1 - Exhaust seal (1)

N°1 - Female intake ange (3)

N°1 - Flange seal (2)

N°1 - Female exhaust ange (4)

N°1 - 90° bend Ø 80 (5)

N°1 - Intake terminal Ø 80 (6)

N°1 - Internal rings (7)

N°1 - External ring (8)

N°1 - Exhaust pipe Ø 80 (9)

1-23

C82

1-24

Max. usable lengths (including intake terminal with grill and two 90° bends)

NON-INSULATED

PIPE

Exhaust (m) Intake (m) Exhaust (m) Intake (m)

1 36,0* 6 29,5*

2 34,5* 7 28,0*

3 33,0* 8 26,5*

4 32,0* 9 25,5*

5 30,5* 10 24,0*

* e air intake pipe can be increased to 2.5 metres if the exhaust bend is

eliminated, 2 metres if the air intake bend is eliminated, and 4.5 metres

eliminating both bends.

11 - IE

1-25

INSULATED

PIPE

11 22,5*

12 21,5*

Page 12

female end (with lip seals) of the previously

installed element; this will ensure correct hold

and joining of the elements.

• Insulation of separator terminal kit. In case

of problems of fume condensate in the

exhaust pipes or on the outside of intake

pipes, Immergas supplies insulated intake and

exhaust pipes on request. Insulation may be

necessary on the exhaust pipe due to excessive

temperature loss of fumes during conveyance.

Insulation may be necessary on the intake pipe

INSTALLATORUSERMAINTENANCE

as the air entering (if very cold) may cause the

outside of the pipe to fall below the dew point

of the environmental air. The figures (Fig.

1-27÷1-28) illustrate dierent applications of

insulated pipes.

Insulated pipes are formed of a Ø 80 internal

concentric pipe and a Ø 125 external pipe with

static air space. It is not technically possible

to start with both Ø 80 elbows insulated, as

clearances will not allow it. However starting

with an insulated elbow is possible by choosing

either the intake or exhaust pipe. When starting

with an insulated intake bend, it must be

inserted onto its ange up to the stop on the

fume exhaust ange, which will ensure that the

two intake and exhaust outlets are at the same

height.

• Temperature loss in insulated fume ducting.

To prevent problems of fume condensate in

the insulated exhaust pipe Ø 80, due to cooling

through the wall, the exhaust pipe length must

be limited to 12 metres. e gure (Fig. 1-28)

illustrates a typical insulation application in

which the intake pipe is short and the exhaust

pipe very long (over 5 m). e entire intake

pipe is insulated to prevent moist air in the

place where the boiler is installed, condensing

in contact with the pipe cooled by air entering

from the outside. The entire exhaust pipe,

except the elbow leaving the splitter, is insulated

to reduce heat loss from the pipe, thus

preventing the formation of fume condensate.

N.B.: When installing the insulated pipes, a

section clamp with pin must be installed every

2 metres.

• Conguration type B, open chamber and

forced draught.

By removing the lateral caps on the sealed

chamber and using the cover kit (optional) air

intake takes place directly from the environment

in which the boiler is installed and the fumes

are expelled in an individual ue or directly to

the outside.

The boiler in this configuration, following

the assembly instructions (Fig. 1-10÷1-11), is

classied as type B.

With this conguration:

- air intake takes place directly from the

environment in which the boiler is installed

and only functions in permanently ventilated

rooms;

- the fumes pipe must be connected to its own

individual ue or channelled directly into the

external atmosphere;

- type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the working of

wood, coal nes, cement, etc.), which may be

damaging for the components of the appliance

and jeopardise functioning.

When using type B installation conguration

indoors, it is compulsory to install the relative

upper cover kit along with the fumes discharge

kit.

The technical regulations in force must be

respected.

1.8 FUME EXHAUST TO FLUE/CHIMNEY.

Flue exhaust does not necessarily have to be connected

to a branched type traditional. Flue exhaust can be

connected to a special LAS type multiple flue.

Multiple and combine flues must be specially

designed according to the calculation method and

requirements of the standards, by professionally

qualied technical personnel. Chimney or ue

sections for connection of the exhaust pipe must

comply with standard requisites..

1.9 DUCTING OF EXISTING FLUES.

With a specic “ducting system” it is possible to reuse existing ues, chimneys and technical openings

to discharge the boiler fumes.. Ducting requires the

use of ducts declared to be suitable for the purpose

by the manufacturer, following the installation and

user instructions, provided by the manufacturer,

and the requirements of the standards.

1.10 FLUES, CHIMNEYS AND CHIMNEY

CAPS.

The flues, chimneys and chimney caps for the

evacuation of combustion products must be in

compliance with applicable standards.

Positioning the dra terminals. Dra terminals

must:

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum

distances specied in current technical standards.

Fume exhaust of forced draught appliances

in closed open-top environments. In spaces

closed on all sides with open tops (ventilation pits,

courtyards etc.), direct fume exhaust is allowed for

natural or forced draught gas appliances with a

heating power range from 4 to 35 kW, provided the

conditions as per the current technical standards

are respected.

8

10

11

6

5

5

S

4

1

e kit includes (Fig. 1-28):

N°1 - Exhaust seal (1)

N°1 - Flange seal (2)

N°1 - Female intake ange (3)

N°1 - Female exhaust ange (4)

N°1 - 90° bend Ø 80 (5)

N°1 - Pipe closure cap (6)

N°1 - Intake terminal Ø 80 insulated (7)

N°2 - Internal rings (8)

N°1 - External ring (9)

N°1 - Exhaust pipe Ø 80 insulated (10)

N°1 - Concentric 90° curve Ø 80/125 (11)

1-26

3

2

7

C82

8

9

C82

A

1-27

C82

1-28

12 - IE

Page 13

1.11 SYSTEM FILLING.

Once the boiler is connected, proceed with system

lling via the lling valve (Fig. 2-2).

Filling is performed at low speed to ensure release

of air bubbles in the water via the boiler and heating

system vents.

e boiler has a built-in automatic venting valve

on the circulator. Check if the cap is loose. Open the

radiator air vent valves.

Close vent valves only when water is delivered.

Close the lling valve when the boiler pressure gauge

indicates approx. 1.2 bar.

N.B.: During these operations, turn on the

circulating pump at intervals by means of the

main selector switch on the control pane. Vent the

circulation pump by loosening the front cap and

keeping the motor running.

Re-tighten the cap aerwards.

1.12 GAS SYSTEM STARTUP.

To start up the system proceed as follows:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specications.

1.13 BOILER STARTUP LIGHTING.

For issue of the Declaration of Conformity provided

for by Italian Law, the following must be performed

for boiler start-up:

- check that the internal system is properly sealed

according to specications;

- ensure that the type of gas used corresponds to

boiler settings;

- switch on the boiler and ensure correct ignition;

Total head available to the plant.

- make sure that the gas ow rate and relevant

pressure values comply withthose given in the

manual (Para. 3.16);

- ensure that the safety device is engaged in the event

of gas supply failureand check activation time;

- check activation of the main circuit-breaker

selector upstream from theboiler and on the unit;

- check that the concentric intake/exhaust terminal

(if tted) is not blocked.

e boiler must not be started up in the event of

failure to comply with any of the above.

N.B.: e boiler preliminary check must be carried

out by a qualied technician. e boiler warranty is

valid as of the date of testing. e test certicate and

warranty is issued to the user.

1.14 DOMESTIC HOT WATER BOILER

DEVICE.

e Zeus kW boiler is the accumulation type with

a capacity of 45 litres. It contains a large coiled

stainless steel heat exchanger pipe, which allows to

notably reduce hot water production times. ese

boilers built with stainless steel casing and bottoms,

guarantee long duration. e assembly concepts and

welding (T.I.G.) are implemented to the minimum

detail to ensure maximum reliability.

e lower inspection ange ensures practical control

of the boiler and the coiled heat exchanger and easy

internal cleaning. e domestic water attachments

are found on the ange cover (cold inlet and hot

outlet) and also the magnesium anode holder cap,

including the latter, supplied as standard for internal

protection of the boiler from possible corrosion.

N.B.: every year a skilled technician (e.g. Immergas

Authorised Aer-sales Service), must check the

eciency of the boiler’s Magnesium Anode. e

boiler is prepared for introduction of the domestic

water re-circulation connection.

1.15 CIRCULATION PUMP.

Zeus kW Range boilers are supplied with a built-in

circulation pump with 3-position electric speed

control. e boiler does not operate correctly with

the circulation pump on rst speed. To ensure optimal boiler operation, in the case of new systems

(single pipe and module) it is recommended to

use the circulation pump at maximum speed. e

circulation pump is already tted with a capacitor.

Pump release. If, aer a prolonged period of inactivity, the circulation pump is blocked, unscrew the

front cap and turn the motor sha using a screwdriver. Take great care during this operation to avoid

damage to the motor.

1.16 KITS AVAILABLE ON REQUEST.

• Kit of system shuto valves (on request). e

boiler is designed for installation of system shuto

valves to be placed on delivery and return pipes

of the connection assembly. is kit is particularly

useful for maintenance as it allows the boiler to be

drained separately without having to empty the

entire system.

• System zone Kit (on request). If the heating system

is to be divided into several zones (max. three), in

order to interlock them with separate adjustments

and to keep water ow rate high for each zone,

Immergas supplies zone system kits by request.

• Polyphosphate batching kit (on request). The

polyphosphate dispenser Reduces the formation

of lime-scale and preserves the original heat

exchange and domestic hot production water

conditions. e boiler is prepared for application

of the polyphosphate dispenser kit.

e above kits are supplied complete with instructions for assembly and use.

INSTALLATORUSERMAINTENANCE

Zeus 24 kW

A

Total head (kPa)

B

Capacity (l/h)

Zeus 28 kW

A

Total head (kPa)

B

Capacity (l/h)

A = Total head available to the plant on the third speed (screws tightened by 1.5 revs with

respect to the completely loose adjustment screws)

B = Total head available to the plant on the second speed (screws tightened by 1.5 revs

with respect to the completely loose adjustment screws).

O)

2

Total head (m H

O)

2

Total head (m H

1-29

13 - IE

Page 14

1.17 ZEUS 2428 KW BOILER COMPONENTS.

INSTALLATORUSERMAINTENANCE

Key:

1 - Negative signal pressure point

2 - Positive signal pressure point

3 - Intake points (air A) - (fumes F)

4 - Fumes pressure switch

5 - Fan

6 - Primary heat exchanger

7 - Air bleeding valve

8 - Boiler circulation pump

9 - Gas valve

10 - 3-way valve (motorised)

11 - System ller tap

12 - System expansion tank

13 - Domestic hot water probe

14 - Stainless Steel Boiler

15 - 3 bar safety valve

16 - System emptying tap

17 - 8 bar safety valve

18 - Boiler emptying tap

19 - Sealed chamber

20 - Flue extractor hood

21 - Delivery probe

22 - Combustion chamber

23 - Safety thermostat

24 - Burner

25 - Ignition and detection plugs

1- 30

14 - IE

Page 15

USER AND MAINTENANCE

2

INSTRUCTIONS

2.1 CLEANING AND MAINTENANCE.

Important: the heating plants must undergo

periodical maintenance (regarding this, see in

the section dedicated to the technician, the point

relative to “yearly control and maintenance of the

appliance”) and regular checks of energy eciency

in compliance with national, regional or local

provisions in force.

is ensures that the optimal safety, performance

and operation characteristics of the boiler remain

unchanged over time. We recommend stipulating

a yearly cleaning and maintenance contract with

your zone technician.

2.2 GENERAL WARNINGS.

Never expose the wall-mounted boiler to direct

vapours from a cooking surface.

Use of the boiler by unskilled persons or children

is strictly prohibited.

Do not touch the fumes exhaust terminal (if

present) due to the high temperature it reaches;

For safety purposes, check that the concentric

air intake/ue exhaust terminal (if tted), is not

blocked.

If temporary shutdown of the boiler is required,

proceed as follows:

a) drain the heating system if anti-freeze is not

used;

b) shut-o all electrical, water and gas supplies.

In the case of work or maintenance to structures

located in the vicinity of ducting or devices for

ue extraction and relative accessories, switch o

the appliance and on completion of operations

ensure that a qualied technician checks eciency

of the ducting or other devices. Never clean

the appliance or connected parts with easily

ammable substances. Never leave containers or

ammable substances in the same environment

as the appliance.

• Caution: the use of components involving use

of electrical power requires some fundamental

rules to be observed:

- do not touch the appliance with wet or moist

parts of the body; do not touch when barefoot.

- never pull electrical cables or leave the appliance

exposed to atmospheric agents (rain, sunlight,

etc.);

- the appliance power cable must not be replaced

by the user;

- in the event of damage to the cable, switch o

the appliance and contact exclusively qualied

personnel for replacement;

- if the appliance is not to be used for a certain

period, disconnect the main power switch..

INSTALLATORUSERMAINTENANCE

2.3 CONTROL PANEL.

2-1

Key:

1 - Flame presence LED

2 - Domestic hot water LED

3 - Heating function LED

4 - Temperature LED – Insucient

circulation anomaly

5 - Temperature LED – Delivery probe

anomaly

6 - Temperature LED – ignition block

7 - Temperature LED – Over-temperature

block

8 - Temperature LED – Fumes pressure

switch anomaly

9 - Stand-by-Domestic water / Remote

Control - Domestic water and HeatingReset Selector switch

10 - Domestic hot water temperature

selector switch

11 - Heating water temperature selector

switch

12 - Boiler manometer

15 - IE

Page 16

2.4 IGNITION OF THE BOILER.

Before ignition make sure the heating system is

lled with water and that the manometer (12)

indicates a pressure of 1 - 1.2 bar.

- Open the gas cock upstream from the boiler.

- Turn the master switch (9) taking it to the

Domestic/Remote Friend ControlV2 (CARV2) (

) or Domestic Hot Water ( ) position.

N.B.: once the main selector switch has been

placed (9) on one of these positions, the presence

of voltage is indicated by the switch-on with a

INSTALLATORUSERMAINTENANCE

xed light of one of the LEDS from 4 to 8, which

indicate the temperature of the output water from

the main heat exchanger.

Important: lashing of one of the LEDs from 4 to

8 indicates that there is an anomaly present, refer

to the successive paragraph.

Functioning of the boiler in domestic water mode

and in heating mode is indicated respectively by

the switch-on of LED 2 or LED 3 with a xed light

(in absence of remote controls).

• Operation with Remote Friend Cont rolV2

(Optional). With selector switch (9) in position

( ) Remote Control connected to the boiler

selector switches (10) and (11) excluded. e

boiler adjustment parameters are set from the

control panel of the Remote Friend ControlV2.

Connection tot he Remote Control is indicated

by the contemporary xed switch-on of LEDs 2

and 3 ( ). Also in the presence of Remote

Control the indications of the temperature and

any faults are maintained on the control panel.

• Operation without Remote Control. With the

selector switch (9) in position ( ) the

heating adjustment selector switch(4) is cut out,

the domestic hot water temperature is regulated

by selector switch (10). With the selector switch

in position ( ) the heating adjustment

selector switch (11) is used to regulate the

temperature of radiators, while selector (10)

continues to be used for domestic hot water. Turn

the selector switches in a clockwise direction

to increase the temperature and in an anticlockwise direction to decrease it.

Fr om this mome nt the b oil er fun ctio ns

automatically. With no demand for heat (heating

or domestic hot water production) the boiler goes

to “standby” function, equivalent to the boiler

being powered without presence of ame (LED

corresponding to the ignited boiler temperature).

Each time the boiler lights up, the relative ame

present symbol is displayed by the green LED

1 ( ).

N.B.: the boiler may start-up automatically if the

anti-freeze function is activated.

2.5 FAULT AND ANOMALY SIGNALS.

The Zeus kW boiler signals ant anomaly by

ashing of one of the LEDs from 4 to 8 or LEDs 1

and 2 coupled to LED 7. On any remote controls,

the error code will be displayed using a numerical

code preceeded or folowed by the letter E (e.g.

CARV2 = Exx, CRD = xxE)

Anomaly signalled

Boiling device probe

anomaly

Insucent

circulation

Delivery probe

anomaly

Ignition

block

Safety thermostat block

(over-temperature)

Fumes pressure switch

anomaly

Contacts resistance

block

Parasite ame block

Loss of remote control

communication

Flashing

LED

LED 2 (

LED 4 (

LED 5 (

LED 6 (

LED 7 (

LED 8 (

LEDs 2 (

and 7 ( )

contempora-

ry ashing

LEDs 1 (

and 7 ( )

contempo-

rary

ashing

LEDs 2 and

3 alterna-

ting ashing

(

)

)

) 05

)

)

) 11

)

)

)

Remote

display

12

27

01

02

04

20

31

Boiling device probe anomaly. If the card detects

an anomaly on the boiler NTC probe, the boiler

does not start-up in domestic water mode however,

functioning in heating mode; a skilled technician

must be called (e.g. Immergas Aer-sales Service).

Insucient water circulation. is occurs if there

is overheating in the boiler due to insucient water

circulating in the primary circuit; thecauses can be:

- low circulation; check that no shuto devices are

closed on the heating circuit and that the system

is free of air (deaerated);

- circulating pump blocked; free the circulating

pump.

If this phenomenon occurs frequently, contact a

qualied technician for assistance (e.g. Immergas

Technical Services Centre).

Delivery probe anomaly. If the board detects an

anomaly on the system NTC delivery probe (code

05) the boiler will not start; contact a qualied

technician for assistance (e.g. Immergas Technical

Services Centre).

Ignition block. e boiler lights up with each

demand for room heating or hot water production.

If this does not occur within 10 seconds, the

boiler remains in stand-by for 30 seconds, try

again and if the second attempt fails it goes into

“ignition block” (ashing LED 6). To eliminate

“ignition block” the main selector switch (9) must

be turned to the Rest position. e Anomaly can

be reset 5 times consecutively, aer which the

function in inhibited for at least one hour. One

attempt is gained every hour for a maximum of

5 attempts. By switching the appliance on and o

the 5 attempts are re-acquired. On commissioning

or aer extended inactivity it may be necessary to

eliminate the “ignition block”. If this phenomenon

occurs frequently, contact a qualied technician

for assistance (e.g. Immergas Aer-sales Service).

Safety thermostat block (over-temperature).

During operation, if a fault causes excessive

overheating internally, in the exhaust, or an

anomaly occurs in the flamecontrol section,

an over-temperature block is triggered in the

boiler (LED 7 ashing). To eliminate the “overtemperature block”, turn the main selector switch

(2)temporarily to the Reset position. If this

phenomenon occurs frequently, contact a qualied

technician for assistance (e.g. Immergas Technical

Services Centre).

Fume pressure switch fault. is occurs if the

intake or exhaust pipes are blocked or in case of

a fan fault. If normal conditions are restored the

boiler restarts without having to be reset. If this

anomaly persists, contact a qualied technician

for assistance (e.g. Immergas Aer-Sales Service).

Contacts resistance block. is occurs in the

case of faults to the safety thermostat overtemperature). The boiler does not start and a

technician must be called (e.g. Immergas AerSales Service).

Parasite ame block. is occurs in case of a leak

on the detection circuit or anomaly in the ame

control unit. e boiler does not start. A qualied

technician must be called (e.g. Immergas AerSales Service).

Loss of remote control communicaton. is

occurs if an incompatible remote control is

connected, or if communication between the

boiler and the CARV2 or CRD is lost. Try the

connection procedure again by turning the boiler

o and turning the selector switch (9) to position

( ). If the CARV2 is still not detected on restarting the boiler will switch to local operating

mode, i.e. using the controls on the boiler itself.

If this phenomenon occurs frequently, contact a

qualied technician for assistance (e.g. Immergas

Technical Services Centre).

Signalling and diagnostics - Display on Remote

Friend ControlV2 screen (optional). During

normal boiler operation the room temperature

value is displayed on the Remote Friend ControlV2

(CARV2 or CRD) screen; in case of malfunction or

anomaly, the temperature value is replaced by the

relative error code given in the table (Para. 2-5).

Important: if the boiler is set in stand-by “ ”

the “CON” connection error symbol will appear

on the CARV2 and error code “31E” on the CRD.

e remote controls are powered constantly so as

not to loose the memorised programs.

2.6 BOILER SHUTDOWN.

Disconnect the main selector switch (9) taking it to

position “ ” (LEDs from 1 to 8 o), disconnect

the external omni-polar switch to the boiler and

close the gas cock upstream from the appliance.

Never leave the boiler switched on if le unused

for prolonged periods.

16 - IE

Page 17

2.7 RESTORING HEATING SYSTEM

PRESSURE.

Periodically check the system water pressure.

e boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

If the pressure falls below 1 bar (with the circuit cool)

restore normal pressure via the valve located at the

bottom of the boiler (Fig. 2-2).

N.B.: close the valve aerwards.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case contact a professional technician for

assistance.

In the event of frequent pressure drops, contact

qualified staff for assistance to eliminate the

possible system leakage.

2.8 DRAINING THE SYSTEM.

To drain the boiler, use the special drain cock

(Fig. 2-2).

Before draining, ensure that the lling cock is

closed.

2.9 ANTIFREEZE PROTECTION.

The boiler comes standard with an antifreeze

function that activates the pump and burner when

the system water temperature in the boiler falls

below 4°C and stops once it exceeds 42°C. e

antifreeze function is guaranteed if the boiler is

fully operative and not in “block” status, and is

electrically powered. To avoid keeping the system

switched on in case of a prolonged absence, the

system must be drained completely or antifreeze

substances added to the heating system water.

In both cases the boiler domestic water circuit

must be drained. In systems that are drained

frequently, lling must be carried out with suitably

treated water to eliminate hardness that can cause

lime-scale.

N.B.: if the boiler is installed in places where the

temperature falls below 0°C the domestic water

and heating attachment pipes must be insulated.

INSTALLATORUSERMAINTENANCE

2.10 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.11 DECOMMISSIONING.

In the event of permanent shutdown of the boiler,

contact professional personnel for the procedures

and ensure that the electrical, water and gas supply

lines are shut o and disconnected.

5

4

BOTTOM VIEW

1 - Boiler drain cock

1

2 - Domestic water inlet cock

3 - Gas cock

4 - System drain cock

5 - System lling valve

23

2-2

17 - IE

Page 18

BOILER COMMISSIONING

3

INITIAL CHECK

To commission the boiler:

- ensure that the declaration of conformity of

installation is supplied with the appliance;

- ensure that the type of gas used corresponds to

boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

INSTALLATORUSERMAINTENANCE

- make sure the heating system is lled with

water and that the manometer indicates a

pressure of 1 - 1.2 bar;

- make sure the air valve cap is open and that the

system is well deaerated;

- switch the boiler on and ensure correct ignition;

- make sure the gas maximum, medium and

minimum flow rate and pressure values

correspond to those given in the handbook

(Para. 3.16);

3.1 PLUMBING LAYOUT.

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check activation of the master switch located

upstream from the boiler and in the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- check activation of the “no air” safety pressure

switch;

- ensure activation of all adjustment devices;

- seal the gas ow rate regulation devices (if

settings are modied);

- ensure production of hot domestic water;

- ensure sealing eciency of water circuits;

- check ventilation and/or aeration of the