Immergas VICTRIX ZEUS 20, VICTRIX ZEUS 27 Instruction Booklet

Page

Victrix Zeus 20/27 Instructions

Instruction Booklet

Eco-friendly wall-hung condensing boilers

with stainless steel storage tank

For Technical assistance, spare parts or service call:

RVR Limited, Kenmare, Co. Kerry Tel: 064 41344, Fax: 064 89520

Doc. Ref.: ALT112/171207

Read these instructions completely before using or installing the

Victrix Zeus 20/27 gas boilers

LEAVE THESE INSTRUCTIONS WITH THE USER

VICTRIX ZEUS 20/27

Page 2

Victrix Zeus 20/27 Instructions

The Victrix Zeus 20/27 boilers are condensing wall hung, room sealed combination boilers incorporating a

54 litre unvented hot water storage cylinder. This boiler has the highest efficiency possible for a gas boiler,

ie 4 stars (****) in conformity with European Directive 92/42 EEC.

The boiler, providing both central heating and domestic hot water supply, is designed for use with a fully

pumped, sealed and pressurised heating system using Natural Gas or LPG. The boiler is supplied for use

with one of these gas types and must be converted before it can be used on another gas. A boiler equipped

for natural gas must not be used on LPG or vice versa.

The boiler is supplied with a pump, diverter valve, automatic bypass, pressure relief valve, expansion vessel

and pressure gauge fully assembled and tested.

As supplied, the boiler will automatically modulate to provide central heating outputs between 4.7 and

23.5kW ( 6.2 to 31.4kW for Victrix Zeus 27 model). The maximum output available for domestic hot water is

23.5 kW (31.4kW for Victrix Zeus 27 model) and provides hot water at temperatures of up to 60°C.

IMPORTANT

All gas appliances must be installed by a competent and qualified person, in accordance with relevant

clauses of applicable standards and recommendations. These include but may not be limited to the the following:I.S. 813 Domestic Gas Installations

I.S, 820 Non-Domestic Gas Installations

All relevant Building Regulations.

Local Water Bye Laws

IEE Wiring Regulations

Health & Safety legislation

This appliance meets the requirements of IPX4D, ie degree of protection against moisture.

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of

safety to ensure that the law is complied with. Manufacturer's instructions must NOT be taken in anyway as

over-riding statutory obligations.

Introduction

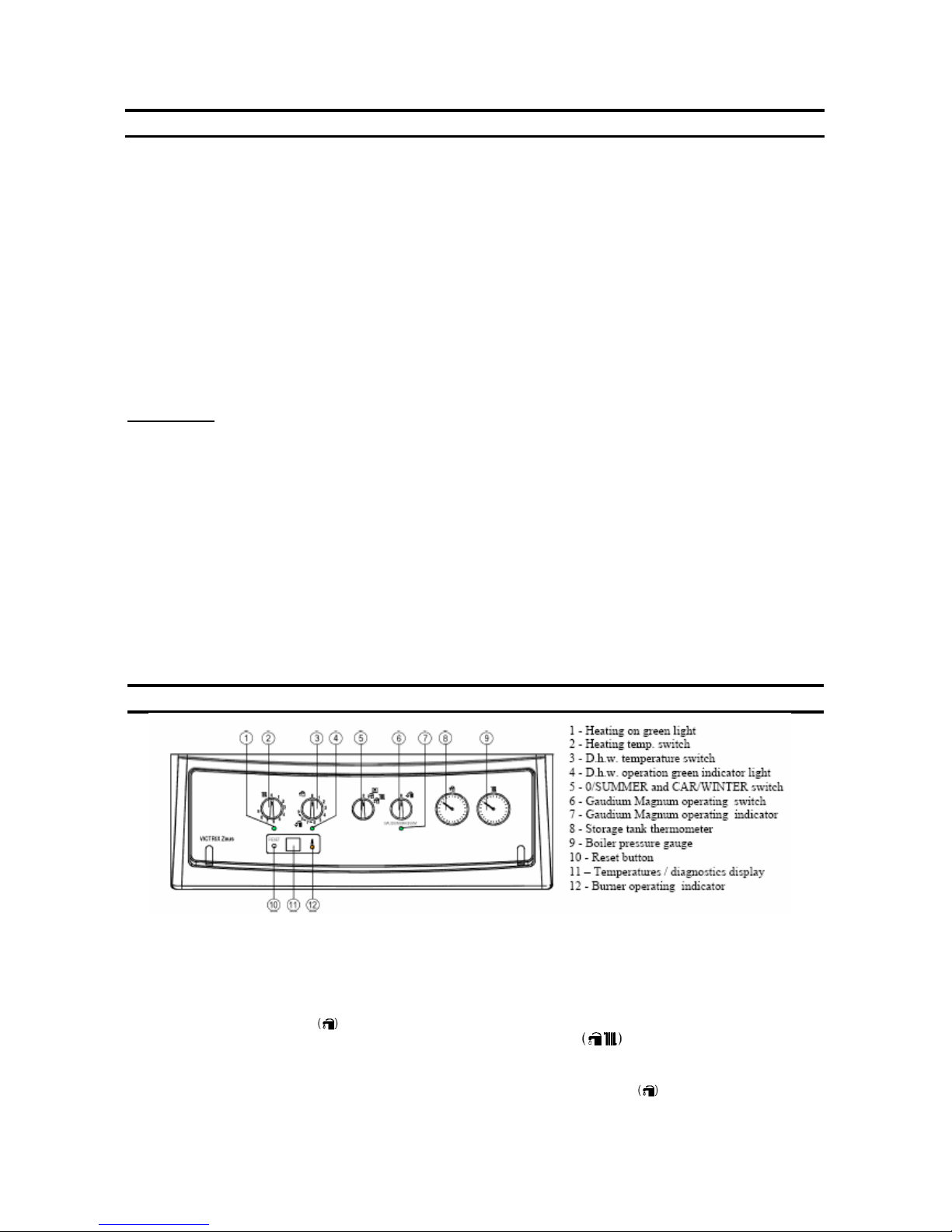

Boiler Operating Instructions

Using the Boiler

Before lighting, make sure that the system is full of water and that the manometer (9) indicates a pressure

of 1 - 1.2 bar.

-Open the gas valve on the gas supply to the boiler.

-Turn main switch (5) to Hot Water or Hot Water/Heating.

N.B.: With the switch set to the central Heating temperature setting is not active, and the domestic

water temperature is controlled by selector (3). With the switch set to the central heating temperature is set using selector (2) while selector (3) is used for the domestic hot water. Turn the selectors clockwise to raise the temperature, anticlockwise to lower it. Boiler operation is now automatic.

Gaudium Magnum System - When the Gaudium Magnum switch (6) is in the position, the flow rate

possible for domestic hot water is increased when the storage temperature is more than 50°C. If the temperature of the stored hot water drops below 41°C, the system is automatically disabled. Please see page

14 for further information on operating the boiler.

Page 3

Victrix Zeus 20/27 Instructions

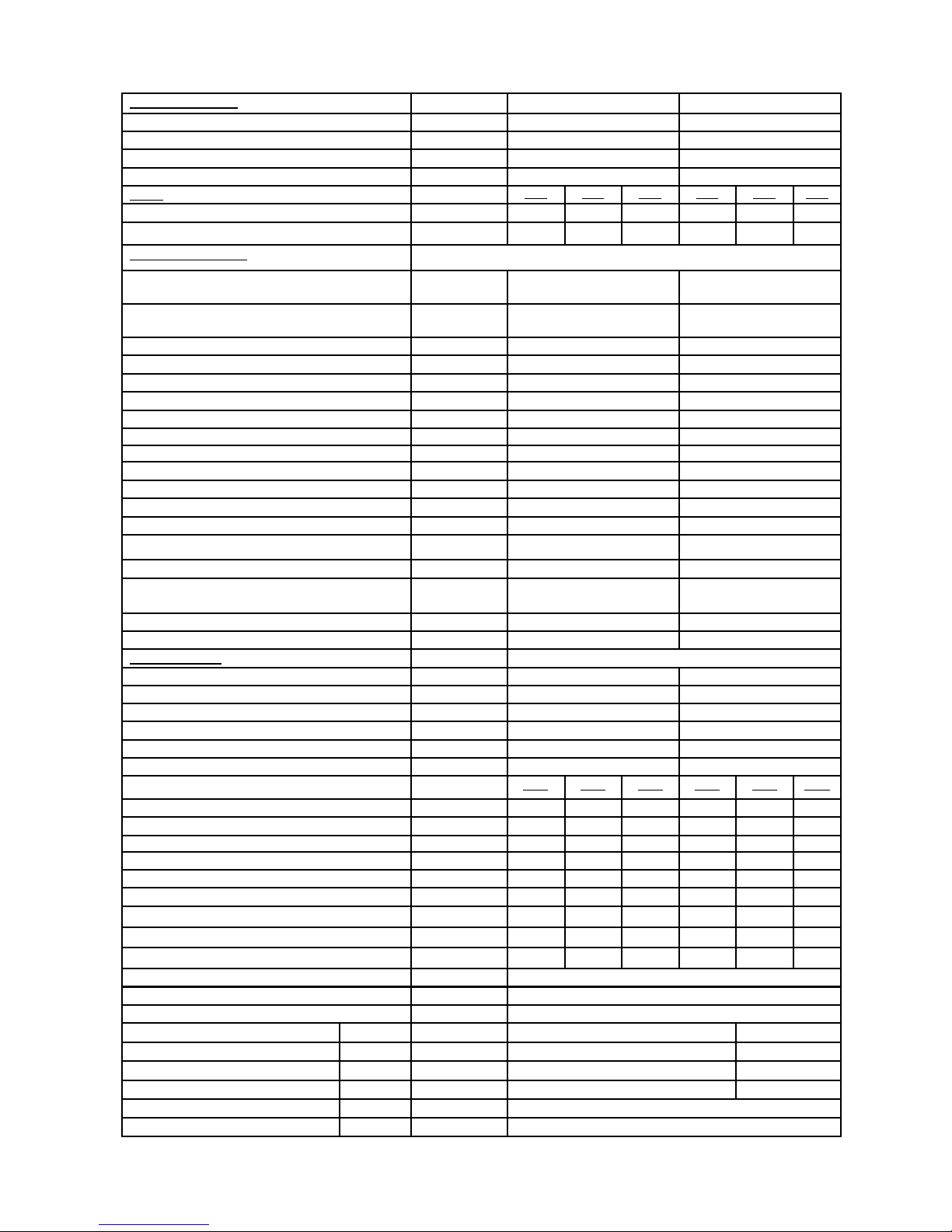

PERFORMANCE: Victrix 20 Victrix 27

Nominal Heat Input Kw 24.0 32.6

Min. Heat Input Kw 5.0 6.6

Nominal Heat Output (useful) Kw 23.5 32

Min. Heat Output Kw 4.7 6.3

GAS:

G20

G30

G31

G20

G30 G31

Nozzle diameter mm 5.0 3.8 3.8 7.0 5.0 5.0

Supply Pressure Mbar 20 29 37 20 29 37

HEATING SYSTEM:

Max Operating Pres. of Heating Unit bar 3

3

Max Operating Temp. of Heating Unit ºC 90

90

Adjustable Heat Temp (range 1) ºC 25 - 85 25-85

Adjustable Heat Temp (range 2) °C 25 - 45 25-45

Total Volume of expansion vessel l

10 10

Expansion Vessel preloading bar

1.0 1.0

Generator Water Content l 60

60

Available head capacity 1000 l/h kPa 14.7 35.28

Working Heat Output d.h.w production Kw 23.5 32.0

DHW adjustable temperature ºC 30-60 30-60

Flow Limiting Device l/min

8 12

DHW circuit minimum pressure bar

0.3 0.3

DHW circuit max operating pressure bar

8 8

Continuous service supply capacity with∆30ºC l/min

11.2 15.2

Capacity with ∆T 30ºC (10 mins) l/min 19.3

23.3

Minimum pressure for flow limiting device

rated capacity

bar

1.0 1.0

Full boiler Weight kg 129 128

Empty boiler weight kg 75 74

ELECTRICAL:

Power Connection v/hz 230/50 230/50

Rated Power Input A 0.59 0.90

Installed Electrical Power W 128 205

Power absorbed by circulator W 83 110

Power absorbed by fan W 20 43

Appliance electrical system callout - IPX4D IPX4D

FLUE GASES:

G20 G30 G31 G20 G30 G31

Rated power fume mass flow kg/h 39 33 33 51 46 53

Minimum power fume mass flow kg/h 8 7 9

11

10 11

CO2 at nominal output % 9.2 12.5 10.6 9.44 12.2 10.35

CO2 at minimum output % 9.0 11.9 9.7 8.9 11.5 10.0

CO at O% O2 at minimum output ppm 5 6 8 5 5 6

NOx at 0% of 02 at nominal output ppm 36 268 61 37 115 21

NOx at 0% of O2 at minimum output ppm 12 19 14 9 20 12

Temperature of fumes at rated output (50/30) ppm 43 47 45 53 65 54

Temperature of fumes at min. output (50/30) ppm 38 46 44 44 45 43

Boiler Dimensions:

Minimum Clearances for servicing:

Height 900mm Top 200mm

Depth 450mm Bottom 150mm

Width 600mm Side 20mm

Gas Connection ½” Front 600mm

CH Connection ¾”

DHW Connection ½”

Page 4

Victrix Zeus 20/27 Instructions

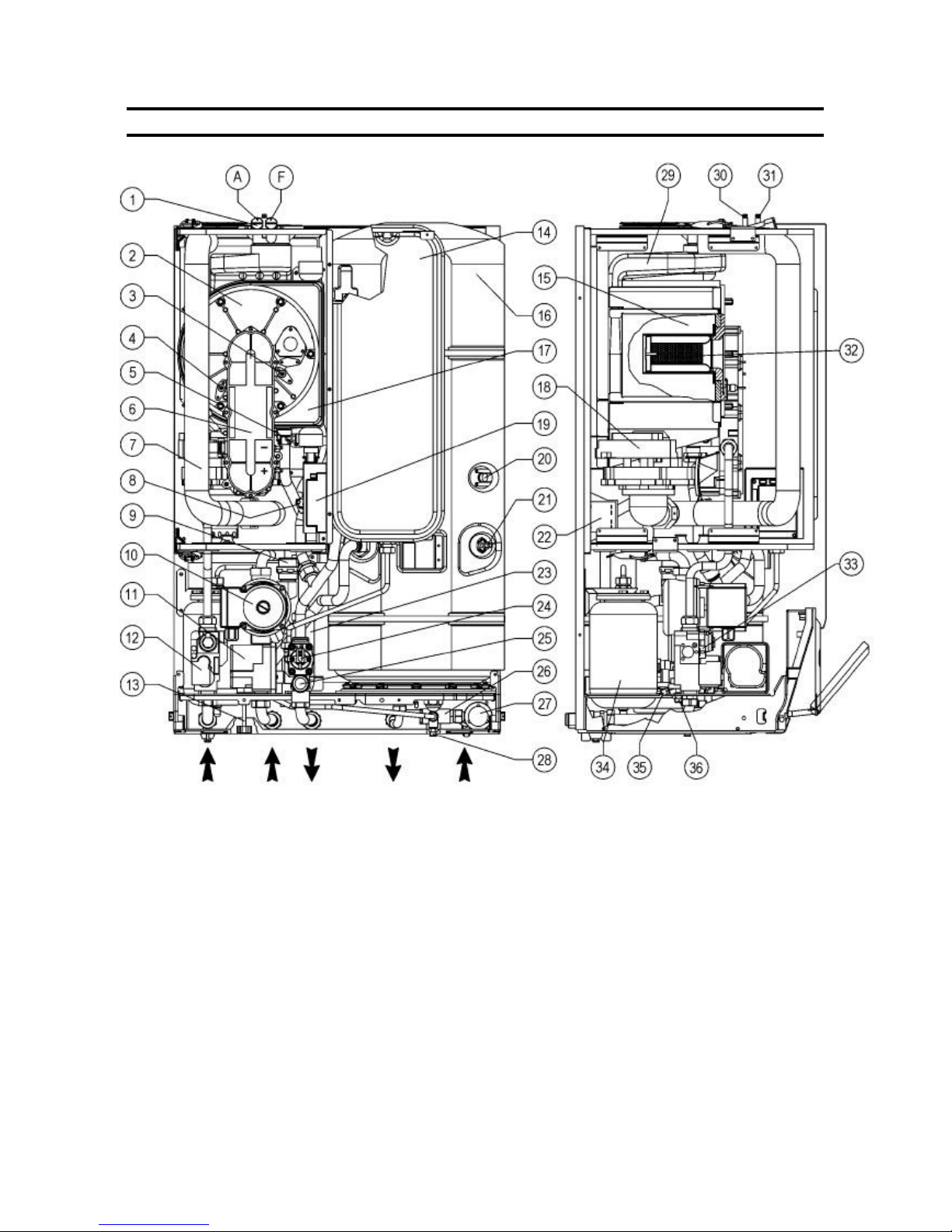

Main Boiler Components

Gas System

Return

System

Flow

DHW

Outlet

1.Intake sockets (A= air)

(F=fumes)

13. System filling cock 25.3-bar safety valve

2.Combustion chamber cover 14.Expansion vessel 26.8-bar safety valve

3.Ignition electrodes 15.Combustion chamber 27.Gaudium Magnum device

4.Detection electrode 16.SS storage tank 316L 28.Boiler emptying cock

5.Heating and limit NTC probe 17.Condensation module 29.Flue hood

6.Venturi duct 18.Fan 30.+ve signal pressure point

7.Air inlet pipe 19.Ignition & detection unit 31.-ve signal pressure point

8.Overheat safety thermostat 20.Max flow limit thermostat 32.Burner

9.Automatic air vent 21.DHW NTC probe 33.Gas valve outlet pres. test

10.Circulator 22.Voltage transformer 34.DHW expansion vessel

11.Motorised 3 way valve 23.Water trap (siphon) 35.System emptying cock

12.Gas Valve 24.No water safety flow switch 36.System adjustable bypass

Cold

DHW

Inlet

Page 5

Victrix Zeus 20/27 Instructions

Gas Supply

The meter and supply pipes must be sized to deliver the gas rate and pressure given on page 3. The

boiler requires at least a 22 mm (3/4”) gas supply pipe. The complete installation, including the meter, must

be tested for gas soundness and purged as described in IS 813:2002.

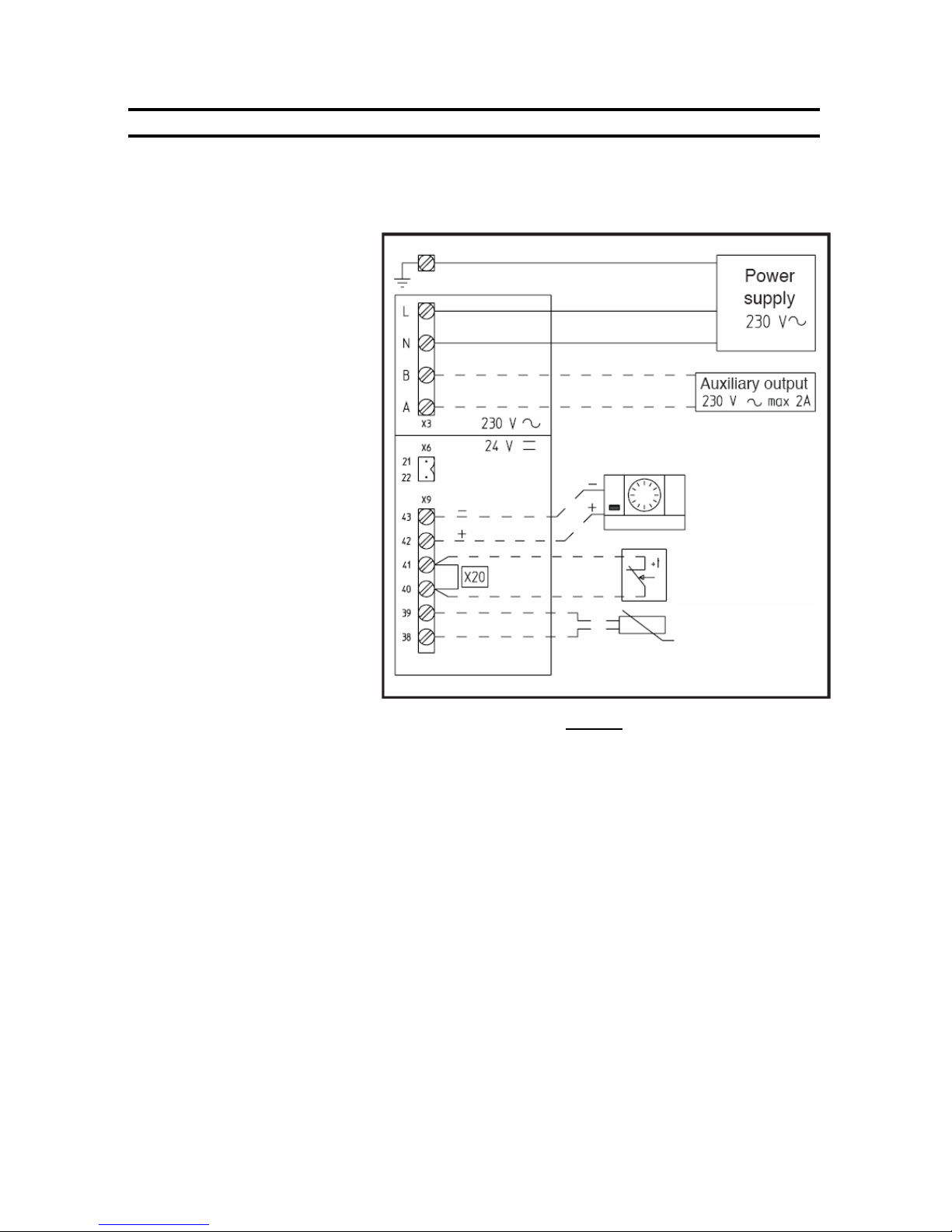

Electrical Installation

The boiler requires a 220/240 V ~ 50

Hz mains supply, fused at 3 A. The

boiler must be earthed. The polarity of the supply must be correct as

otherwise the boiler will not operate

properly.

There must only be one common isolator, providing complete electrical

isolation, for the boiler and any

external controls. Using PVC

insulated cable not less than 0.75

mm² (24 x 0.2 mm) to BS 6500

Table 16, the boiler should be

connected to a fused three pin plug

and unswitched shuttered socket outlet (both complying with BS 1363), or

a fused double pole

switch with a contact separation of

at least 3 mm in both poles.

Wiring external to the boiler must

be in accordance with the current IEE

Wiring Regulations.

Note: External controls connected to the boiler must be of the volt free type and are connected to

terminals 40 and 41 as shown above.

Weather Compensation

A temperature sensor for outdoors is available as an optional accessory for the boiler. This should be fitted

in an outdoor location which is not exposed to direct sunlight. A north facing wall is a good location.

If the optional weather compensation sensor is used, it should be connected to terminals 38 and 39 as

shown above using a two core cable. If this cable is routed in close proximity to cables carrying mains voltages, then screened cable should be used. Contact RVR for more information.

When the sensor is connected, the boiler adapts it’s flow temperature to suit the prevailing weather conditions. This results in lower energy usage and enhanced comfort.

WARNING ! - Connection of a voltage to any boiler terminals other than the mains

lead will result in destruction of the boiler control panel. The product warranty

does not cover this type of damage.

Clearances and Air Supply

The boiler does not require any air vents for cooling in the room in which it is installed or when installed in a

cupboard or compartment. The minimum clearances for servicing must always be maintained. Please see

table on page 3. Note: A cupboard or compartment used to enclose the boiler must be designed and constructed specifically for the purpose.

General Installation Information

Optional Immergas

Remote controller

(CAR)

Replace link with volt free

contact from CH controls.

Do not connect 220V!

External weather com-

pensation sensor

Page 6

Victrix Zeus 20/27 Instructions

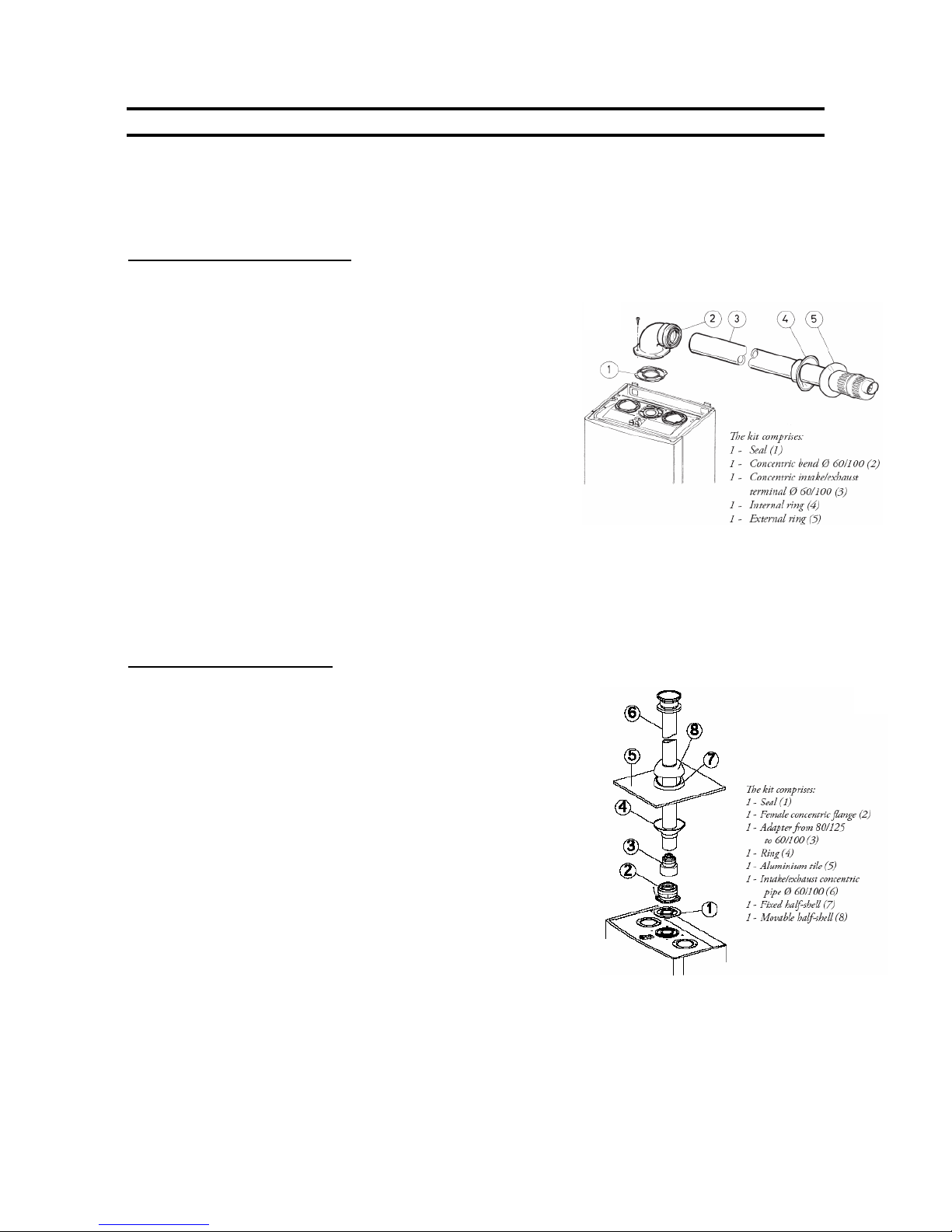

Flue Systems

When the boiler is installed on an external wall, the standard horizontal concentric 60/100 flue kit will normally

be used to flue the boiler. This is shown in the diagram.

It is often necessary to install a longer flue system to cater for site conditions. There are several different flue

system sizes available for the Victrix Zeus 20/27 boiler.

Horizontal concentric kit 60 /100

Install the bend with flange (2) on the central hole of the boiler inserting the seal (1) with the round protrusions facing downwards in

contact with boiler flange and tighten using the screws supplied

with the kit.

Fit the smooth male end of the 60/100 concentric terminal pipe (3)

until it reaches to the stop on the female end of the bend (2), making sure the internal and external sealing rings are fitted; this will

ensure the connection is properly sealed. Additional extensions

and bends may be installed if required using the same method.

Ensure that all seals are fitted and that the outer and inner pipes

are installed so that all joints are perfectly sealed. Ensure that the

terminal is installed the right way up.

A lubricant may assist in overcoming the friction of the seals. Oils

and conventional greases are not compatible with the EPDM seals

used and should never be used for this purpose. Silicone sprays

are compatible with EPDM and may be used. Please contact RVR

for more information.

A supporting clamp should be installed every three meters. The flue system should be slightly inclined so that

any condensate flows towards the boiler. This avoids any drips from the external flue terminal.

The maximum possible overall length after the first bend (2) is 12.9 straight and horizontal meters. See

the section on extended flue design for more information.

Vertical concentric kit 60 /100

Install the concentric flange (2) on the central hole of the boiler

inserting the seal (1) with the round protrusions facing downwards in contact with boiler flange and tighten using the screws

supplied with the kit.

Fit the male end (smooth) of the adapter (3) in the female end of

the concentric flange (2) until it reaches the stop on the female

end of the flange, making sure the internal and external sealing

rings are fitted; this will ensure the connection is properly sealed.

Additional extensions and bends may be installed if required using the same method.

Installing the flashing- Replace tiles with the aluminium sheet (5),

shaping it to ensure that the rainwater runs off. Position the fixed

half-shell (7) on the aluminium tile and insert the intake/exhaust

pipe (6). Fit the male end (6)(smooth) of the 60/100 concentric

terminal up to the stop on the female end of the adapter(3), making sure that the ring (4) is already fitted; this will ensure hold and

joining of the elements making up the kit.

Ensure that all seals are fitted and that the outer and inner pipes

are installed so that all joints are perfectly sealed. A lubricant may

assist in overcoming the friction of the seals. Oils and conventional greases are not compatible with the EPDM

seals used and should never be used for this purpose. Silicone sprays are compatible with EPDM and may be

used. Please contact RVR for more information.

A supporting clamp should be installed every three meters.

The maximum possible overall length including the terminal is 13.4 straight and horizontal meters.

NB: If the terminal or extension pipes need shortening ensure that the inner pipe protrudes by 5mm with

respect to the external pipe.

Page 7

Victrix Zeus 20/27 Instructions

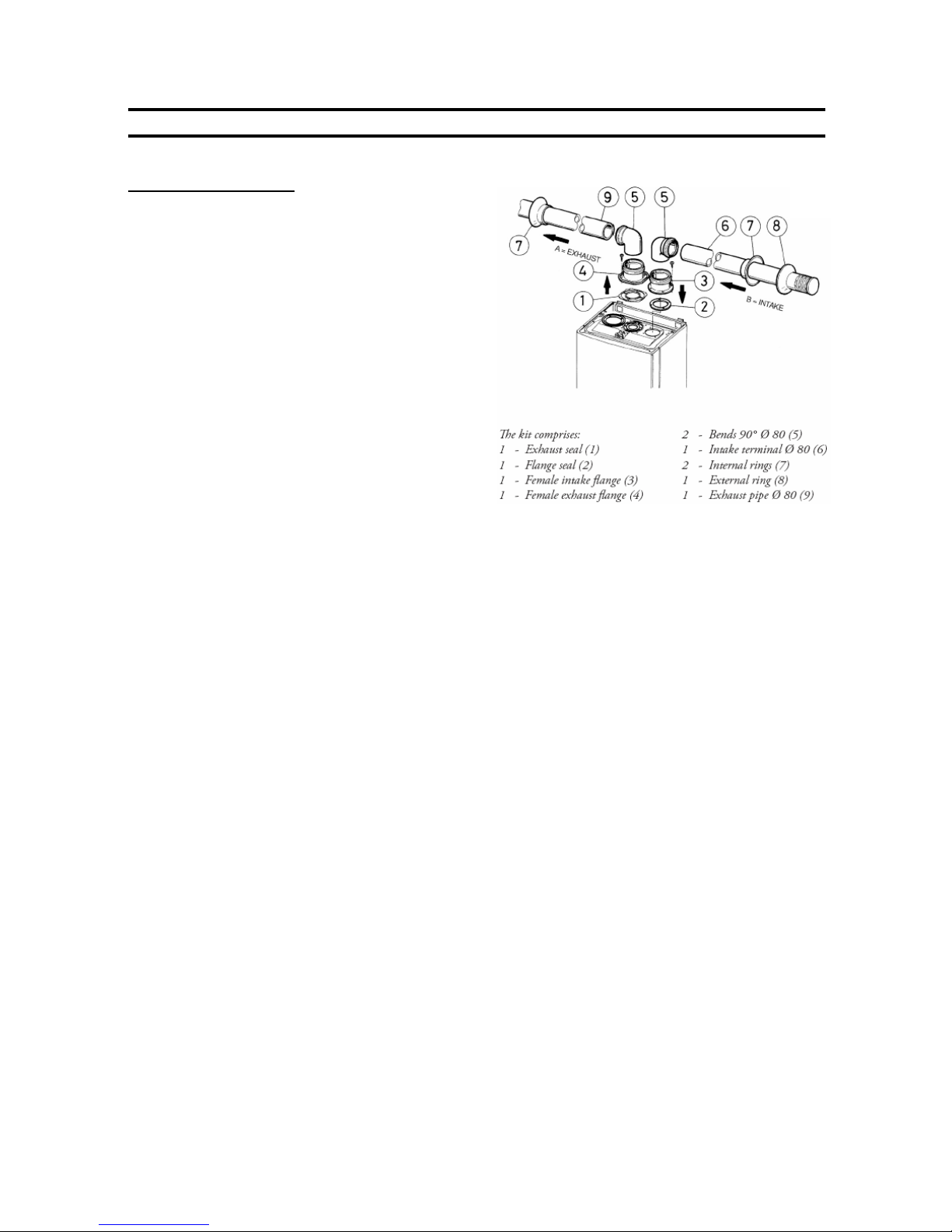

Separated 80/80 flue kit

This kit enables separation of the exhaust and air intake

pipes as shown in the figure.

Combustion products are expelled from pipe (A) (in

plastic material resistant to acidic condensates). Air is

taken in through pipe (B) (also in plastic material) for

combustion.

Intake pipe (B) can be installed either on the right or left

hand side of the central exhaust pipe (B). Both pipes

can be oriented in any direction.

Assembly:

Install the flange (4) on the central hole of the boiler inserting the seal (1), positioning it with the round protrusions downwards in contact with the boiler flange and

tighten using the screws supplied with the kit.

Remove the sealing plate from the air intake and replace it with flange (3)inserting seal (2) which is already

fitted on the boiler and tighten using the screws supplied.

Insert bends (5) with the male end (smooth) in the female end of the flanges (3&4). Fit the male end of the

intake terminal (6) up to the stop on the female end of

the bend (5), making sure that the relevant internal and

external sealing rings are fitted. Fit the male of the exhaust pipe up to the stop on the female end of the bend,

making sure that the internal sealing ring is fitted; this

will ensure a seal and joining of the elements making up

the kit.

Separated Flue Systems

A lubricant may assist in overcoming the friction of the seals. Oils and conventional greases are not compatible with the EPDM seals used and should never be used for this purpose. Silicone sprays are compatible with EPDM and may be used. Please contact RVR for more information.

A supporting clamp should be installed every three meters. The flue system should be slightly inclined so

that any condensate flows towards the boiler. This avoids any drips from the external flue terminal.

The maximum possible overall length without any bends is 36 straight, horizontal meters or 41

straight, vertical meters regardless of whether they are used in intake or exhaust. See the section

on extended flue design for more information.

Loading...

Loading...