Immergas VICTRIX X 12-24 2I Instruction And Warning Book

VICTRIX

X 12-24 2 I

IE

Instruction and

Warning book

*1.031274IE*

3 - IE

INSTALLERUSERTECHNICIAN

INDEX

USER page

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

INSTALLER page TECHNICIAN page

DECLARATION OF CONFORMITY

For the purpose and eect of the CE 2009/142 Gas Appliance Directive, EMC 2004/108/CE Directive, 92/42/CE Boiler Eciency Directives and

2006/95/CE Low Voltage Directive.

e Manufacturer: Immergas S.p.A. v. Cisa Ligure n° 95 42041 Brescello (RE)

DECLARES THAT: the Immergas boiler model:

Victrix X 12-24 2I

is in compliance with the same European Community Directives

Mauro Guareschi

Research & Development Director

Signature:

Dear Client,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully: you

will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction for the Immergas product.

Contact our area authorised aer-sales centre as soon as possible to request commissioning. Our technician will verify the correct functioning conditions; he

will perform the necessary calibrations and will demonstrate the correct use of the generator.

For any interventions or routine maintenance contact Immergas Authorised Centres: these have original spare parts and boast of specic preparation directly

from the manufacturer.

General recommendations

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be kept well and consulted carefully, as all of the warnings supply important indications for safety in the installation, use and maintenance stages.

In compliance with legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law. Installation

and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally qualied

sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Incorrect installation can cause injury to persons and animals and damage to objects, for which the manufacturer is not liable. Maintenance must be carried

out by skilled technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous. If errors occur during installation, running and maintenance, due to the non compliance of technical laws in force, standards or instructions

contained in this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any

damages and the appliance warranty is invalidated. For further information regarding legislative and statutory provisions relative to the installation of gas

heat generators, consult the Immergas site at the following address: www.immergas.com

1 Boiler installation ......................................4

1.1 Installation recommendations. ................4

1.2 Main dimensions. ......................................5

1.3 Main Dimensions Recess kit (optional). 5

1.4 Anti-freeze protection. .............................5

1.5 Connections. .............................................. 6

1.6 Remote controls and room chrono-

thermostats (Optional). ............................ 7

1.7 External probe (Optional). ......................7

1.8 Immergas ue systems. .............................8

1.9 Outdoor installation in partially protected

area. ............................................................. 8

1.10 Outdoor Installation using recess frame

(with direct air intake) ..............................8

1.11 Indoor installation. .................................11

1.12 Ducting of ue technical slots. ..............12

1.13 Flue exhaust to ue/chimney. ................ 13

1.14 Flues, chimneys and chimney caps. ......13

1.15 System lling. ...........................................13

1.16 Filling of the condensate trap. ...............13

1.17 Gas system start-up. ................................13

1.18 Boiler start up (ignition). .......................13

1.19 Circulation pump. ...................................14

1.20 Kits available on request. ........................15

1.21 Boiler components. ................................. 16

2 Instructions for use and maintenance. . 17

2.1 Cleaning and maintenance. ...................17

2.2 General warnings. ...................................17

2.3 Control panel. .......................................... 17

2.4 Using the boiler........................................17

2.5 Troubleshooting. .....................................18

2.6 Information menu. .................................. 19

2.7 Boiler shutdown ......................................20

2.8 Restore central heating system

pressure. ....................................................20

2.9 System Draining. ..................................... 20

2.10 Anti-freeze protection. ...........................20

2.11 Case cleaning. ..........................................20

2.12 Decommissioning. ..................................20

3 Boiler start-up (initial check). ...............21

3.1 Hydraulic diagram. ................................. 21

3.2 Wiring diagram. ...................................... 22

3.3 Troubleshooting. .....................................22

3.4 Converting the boiler to other

types of gas. ..............................................23

3.5 Calibration of number of fan revs. ........ 23

3.6 Adjustment of the air-gas ratio. .............23

3.7 Checks following conversion to another

type of gas. ................................................23

3.8 Programming the P.C.B. .........................24

3.9 Solar panels coupling function. .............26

3.10 "Chimney sweep" function. ...................26

3.11 Pump anti-block function. .....................26

3.12 three-way anti-block function. ..............26

3.13 Radiators anti-freeze function. ...............26

3.14 P.C.B. periodical self-check. ...................26

3.15 Automatic vent function. .......................26

3.16 System supervisor coupling function. .. 26

3.17 Yearly appliance check and

maintenance. ............................................26

3.18 Casing removal. ....................................... 27

3.19 Variable heat output. ...............................28

3.20 Combustion parameters. ........................29

3.21 Technical data. ......................................... 30

SI

NO

1-1

4 - IE

INSTALLERUSERTECHNICIAN

1

BOILER

INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

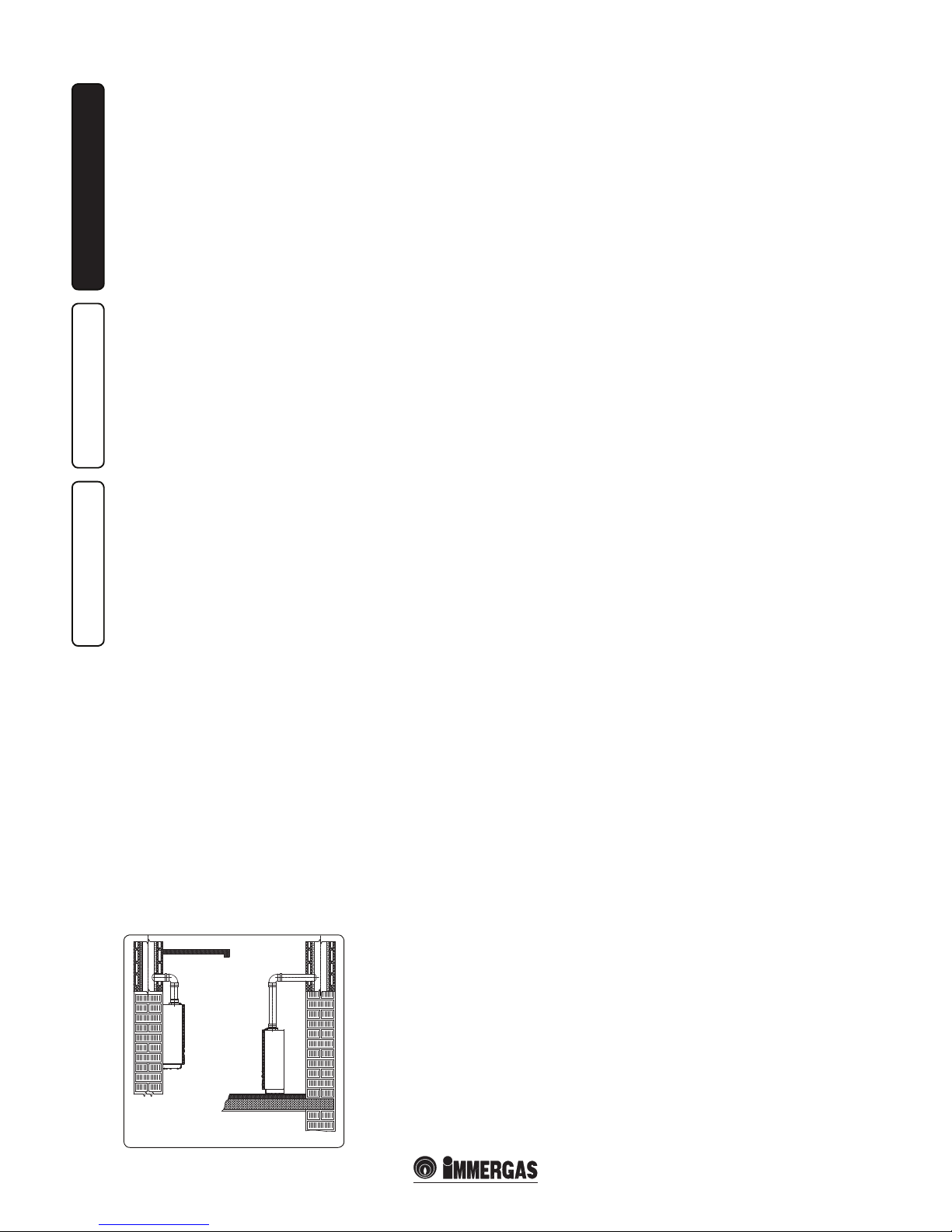

e Victrix X 12-24 2I boiler has been designed

only for wall mounted installation or installation

inside the wall using the recess frame provided;

they must be used to heat domestic environments

and similar purposes.

In the case of wall installation the wall surface

must be smooth, without any protrusions or

recesses enabling access to the rear part. ey

are NOT designed to be installed on plinths or

oors (Fig. 1-1).

By var yi ng t he typ e of i nst allat ion t he

classication of the boiler also varies, precisely:

- B23 type boiler

- if installed using the relevant terminal for air

intake directly from the room in which the

boiler has been installed.

- using the spacers under the side plugs of the

sealed chamber inside the recess frame kit

(optional).

- Type C boiler if installed using concentric

pipes or other types of pipes envisioned for

the sealed chamber boiler for intake of air and

expulsion of ue gases.

Only professionally enabled heating/plumbing

technicians are authorised to install Immergas

gas appliances.

Installation must be carried out according to the

standards, current legislation and in compliance

with local technical regulations and the required

technical procedures.

Before installing the appliance, ensure that it

is delivered in perfect condition; if in doubt,

contact the supplier immediately. Packing

materials (staples, nails, plastic bags, polystyrene

foam, etc.) constitute a hazard and must be kept

out of the reach of children. If the appliance

is installed inside or between cabinets, ensure

sucient space for normal servicing; therefore

it is advisable to leave clearance of at least 3

cm between the boiler casing and the vertical

sid es of the cabinet. Leave adequate space

above the boiler for possible water and flue

removal connections. Keep all ammable objects

away from the appliance (paper, rags, plastic,

polystyrene, etc.).

Do not place household appliances underneath

the boiler as they could be damaged if the safety

valve intervenes (if not conveyed away by a

draining funnel), or if there are leaks from the

connections; on the contrary, the manufacturer

cannot be held responsible for any damage

caused to the household appliances.

In the event of malfunctions, faults or incorrect

operation, turn the appliance o immediately

and contact a qualified technician (e.g. the

Immergas Technical Assistance centre, which

has specically trained sta and original spare

parts) Do not attempt to modify or repair the

appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

• Installation regulations:

- this boiler can be installed outdoors in a

partially protected area. A partially protected

area is one in which the appliance is not

exposed to the direct action of the weather

(rain, snow, hail, etc..).

- Installation in places with a fi re risk is

prohibited (for example: garages, box), gas

appliances and relative ue ducts, ue exhaust

pipes and combustion air intake pipes.

- Installation is prohibited on the vertical

projection of the cooking surface.

- Installation is also prohibited in places/

environments that constitute common parts

of oce condominiums such as stairs, cellars,

entrance halls, attics, los, escape routes,

etc. if they are not located inside technical

compartments under the responsibility of

each individual building and only accessible

to the user (for the features of the technical

compartments, see the Reference Standard).

Important: Wall mounting of the boiler on the

wall or inside the wall must guarantee stable

and efficient support for the generator. The

recessed frame kit (Optional) guarantees an

adequate support only if installed correctly (in

accordance with the code of practice) following

the instructions on the instruction leaet. e

recessed frame for the Victrix X 12-24 2I boiler is

not a supporting structure and must not replace

the wall removed. It is necessary to position the

boiler inside the wall. For safety reasons against

any leaks it is necessary to plaster the boiler

housing in the brick wall.

e plugs (standard supply) are to be used only in

conjunction with the mounting brackets or xing

template to x the appliance to the wall; they only

ensure adequate support if inserted correctly

(according to technical standards) in walls made

of solid or semi-hollow brick or block. In the

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate support.

N.B.: the hex head screws supplied in the blister

pack are to be used exclusively to x the relative

mounting bracket to the wall.

ese boilers are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be connected to a central heating

system and hot water circuit suited to their

performance and capacity.

YES NO

1-2

1-3

5 - IE

INSTALLERUSERTECHNICIAN

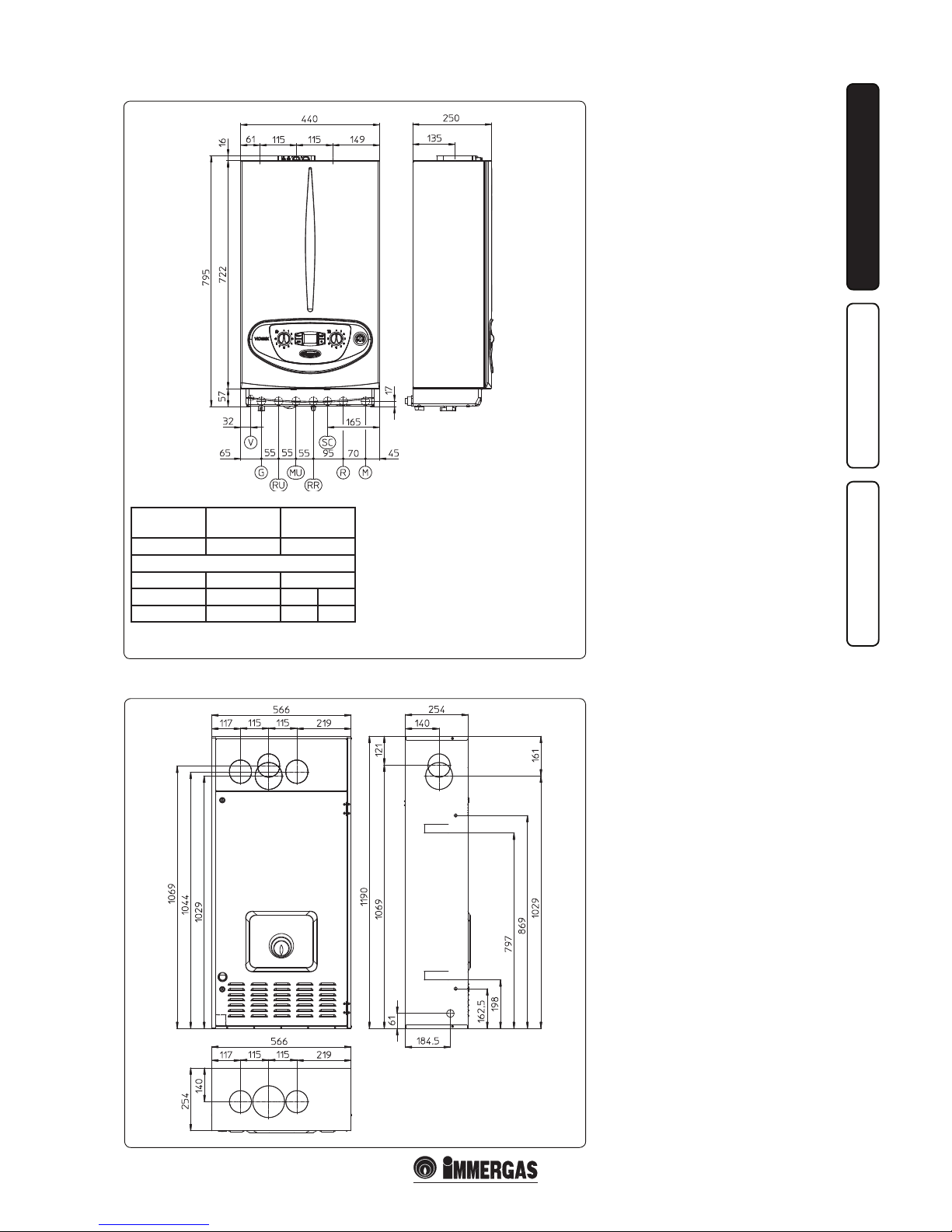

1.2 MAIN DIMENSIONS.

Key (Fig. 1-2):

V - Electrical connection

G - Gas supply

RU - Storage tank unit return (optional)

MU - Storage tank unit ow (optional)

RR - System lling

SC - Condensate drain (minimum

internal diameter Ø 13 mm)

R - System return

M - System ow

Height

(mm)

Width (mm) Depth (mm)

795 440 250

CONNECTIONS

GAS DOMESTIC SYSTEM

G RR R M

3/4” 1/2” 3/4” 3/4”

1.3 MAIN DIMENSIONS RECESS KIT OPTIONAL.

1.4 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e boiler comes

standard with an anti-fre ez e function that

activates the pump and burner when the system

water temperature in the boiler falls below 4°C.

e anti-freeze function is only guaranteed if:

- the boiler is correctly connected to gas and

electricity power supply circuits;

- the boiler is powered constantly;

- the boiler is not o ("o" mode);

- the boiler is not in no ignition block (Par. 2.6);

- the boiler essential components are not faulty.

In these conditions the boiler is protected against

freezing to an environmental temperature of -5°C.

Minimum temperature -15°C. If the boiler is

installed in a place where the temperature falls

below -5°C and in the event there is no gas (or

the boiler goes into ignition block), the appliance

can freeze.

To pre vent th e risk of fre ez ing follo w the

instructions below:

- protect the central heating circuit from freezing

by introducing a top quality anti-freeze liquid

into this circuit, which is not noxious to health.

e instructions of the manufacturer of this

liquid must be followed scrupulously regarding

the percentage necessary with respect to the

minimum temperature at which the system

must be kept. An aqueous solution must be

made with potential pollution class of water 2

on the basis of the Standards in force.

e materials used for the central heating circuit

of Immergas boilers resist ethylene and propylene

glycol based antifreeze liquids (if the mixtures are

prepared perfectly).

For duration and possible disposal, follow the

supplier's instructions.

- Protect the condensate drain trap and circuit

board against freezing by using an accessory

that is supplied on request (anti-freeze kit)

comprising two electric heating elements,

the relevant cables and a control thermostat

(carefully read the installation instructions

contained in the accessory kit pack).

Boiler anti-freeze protection is thus ensured only if:

- the boiler is correctly connected to gas and

electricity power supply circuits and powered;

- the anti-freezing kit components are ecient.

In these conditions the boiler is protected against

freezing to temperature of -15°C.

The warranty does not cover damage due to

interruption of the electrical power supply and

failure to comply with that stated above.

N.B.: if the boiler is installed in places where the

temperature falls below 0°C the domestic water

and heating attachment pipes must be insulated.

N.B.: connection group (optional)

1-5

CAVO ALIMENTAZIONE

1-6

Unità bollitore

Solo Plus e X

Termostato

ambiente

CAR

V2

Sonda

esterna

Sonda ingresso

sanitario

(NO Plus e X)

Segnale di stato

scheda a zone

1

2 3

5

4

6

6 - IE

INSTALLERUSERTECHNICIAN

1.5 ATTACHMENTS.

Gas connection (Appliance category II

2H3B/P

).

Our boilers are designed to operate with methane

gas (G20) and LPG. Supply pipes must be the

same as or larger than the 3/4”G boiler tting.

Before connecting the gas line, carefully clean

inside all the fuel feed system pipes to remove any

residue that could impair boiler eciency. Also

make sure the gas corresponds to that for which

the boiler is prepared (see boiler data-plate).

If dierent, the appliance must be converted

for operation with the other type of gas (see

converting appliance for other gas types). e

dynamic gas supply (methane or LPG) pressure

must also be checked according to the type used

in the boiler, as insucient levels can reduce

generator output and cause malfunctions.

Ensure correct gas cock connection. e gas

supply pipe must be suitably dimensione d

according to current regulations in order to

guarantee correct gas ow to the burner even

in conditions of maximum generator output

and to guarantee appliance eciency (technical

speci fications). The coupling system must

conform to standards.

Fue l ga s qual ity. The appliance has bee n

designed to operate with gas free of impurities;

other wise it is advisable to fit special filters

upstream from the appliance to restore the

purity of the gas.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

Hydraulic connection

Important: In order not to void the warranty

before making the boiler connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could compromise

correct boiler operation.

In compliance with Standards in force it is

mandatory to treat the water in the heating

system chemica lly, in compliance with the

indications of the decree, in order to protect the

system and appliance from deposits of lime scale.

Water connections must be made in a rational

way using the couplings on the boiler template.

e boiler safety valve outlet must be connected

to a draining funnel. Otherwise, the manufacturer

declines any responsibility in case of ooding if

the drain valve cuts in.

Important: to preserve the duration of appliance

eciency features, in the presence of water whose

features can lead to the deposit of lime scale,

installation of the “polyphosphate dispenser” kit

is recommended . On the basis of the Standards

in force, it is mandatory to treat the supply water

with temporary water hardness over or equal to 25

French degrees in the central heating circuit and

over than or equal to 15 French degrees for DHW,

using conditioning chemicals for powers ≤ 100 kW

or with soeners for powers > 100 kW

Condensate drain. To drain the condensate

produced by the appliance, it is nece ssar y

to connect to the drainage system by means

of acid condensate resistant pipes having an

internal diameter of at least 13 mm. e system

connecting the appliance to the drainage system

must be carried out in such a way as to prevent

freezing of the liquid contained in it. Before

appliance start-up, ensure that the condensate

can be correctly removed. Also, comply with

national and local regulations on discharging

waste waters.

Electrical connection: e "Victrix X 12-24 2I"

boiler has an IPX4D protection rating for the

entire appliance. Electrical safety of the appliance

is reached only when it is correctly connected

to an ecient earthing system as specied by

current safety standards.

Imp ortant: Immergas S.p.A . declines any

responsibility for damage or physical injury

caused by failure to connect the boiler to an

ecient earth system or failure to comply with

the reference standards.

Als o ensure that the ele ct ri cal installation

corresponds to maximum absorb ed power

specications as shown on the boiler data-plate.

Boilers are supplied complete with an “X” type

power cable without plug. e power supply

cable must be connected to a 230V ±10% /

50Hz mains supply respecting L-N polarity and

earth connection

. is network must also

have an omnipolar circuit breaker with class III

over-voltage category. When replacing the power

supply cable, contact a qualied technician (e.g.

the Immergas Aer-Sales Technical Assistance

Service). e power cable must be laid as shown

(Fig. 1-5).

In the event of mains fuse replacement on the

P.C.B., use a 3.15A quick-blow fuse. For the

main power supply to the appliance, never use

adapters, multiple sockets or extension leads.

Key:

1 - Only Plus and X storage

tank unit

2 - External probe

3 - DHW inlet probe (NO

Plus and X)

4 - Zones control unit status

signal

5 - Room thermostat

6 - Comando Amico Remoto

remote controlV2 (CARV2)

Jumper X40 must be eliminated whenever the room thermostat or CAR

V2

are connected. e resistance R8

(present only on Plus and X versions) must be eliminated whenever the Storage tank Unit is connected

POWER SUPPLY CABLE

1-8

1-7

1-9

1-10

45

31

58

1

2

7 - IE

INSTALLERUSERTECHNICIAN

1.6 REMOTE CONTROLS AND

ROOM CHRONOTHERMOSTATS

OPTIONAL.

e boiler is prepared for the application of room

chrono-thermostats or remote controls, which

are available as optional kits.

All Immergas chrono-thermostats are connected

with 2 wires only. Carefully read the user and

assembly instructions contained in the accessory

kit.

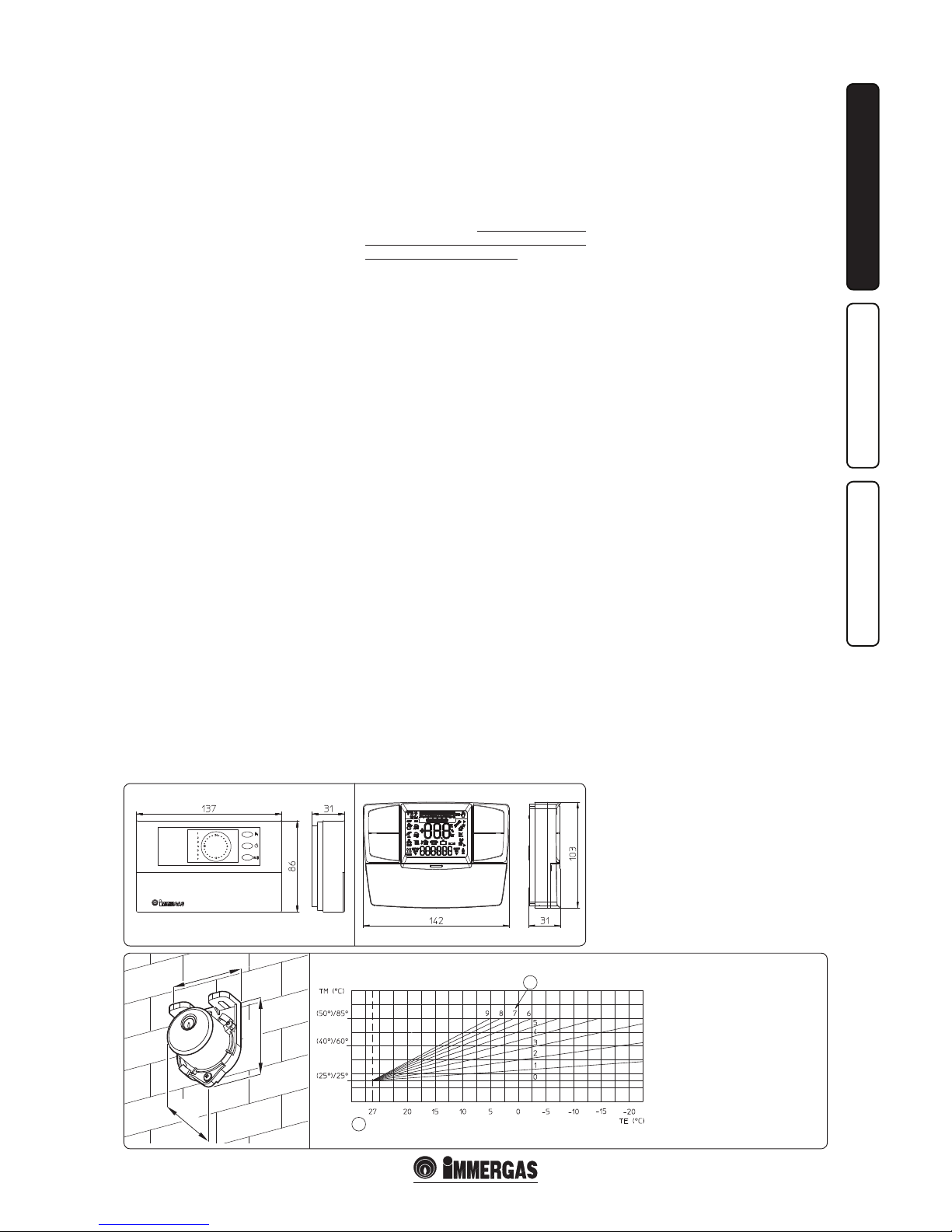

• On/O digital chrono-thermostat (Fig. 1-7).

e chrono-thermostat allows:

- to set two room temperature values: one for

day (comfort temperature) and one for night

(lower temperature);

- to set up to four on/o dierential weekly

programs;

- selecting the required function mode from

the various possible alternatives:

• permanent operation in comfort temp;

• permanent operation in lower temp;

• permanent operation in adjustable anti-freeze

temp.

e chrono-thermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• Comando Amico Remoto Remote Control

Device

V2

CARV2) (Fig. 1-8) with climate

chrono-thermostat function. In addition to

the functions described in the previous point,

the CARV2 panel enables the user to control all

the important information regarding operation

of the appliance and the heating system with

the opportunity of easily intervening on the

previously set parameters without having to

go to the place where the appliance is installed.

The Comando Amico Remoto V2 Remote

Control panel is provided with self-diagnosis

to display any boiler operating anomalies.

e climate chrono-thermostat incorporated

into the remote panel enables the system ow

temperature to be adjusted to the actual needs

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving

in running costs. It also allows to display the

eective room temperature and the external

temperature (if external probe is present).

e chrono-thermostat is fed directly by the

boiler by means of the same 2 wires used for

the transmission of data between boiler and

chrono-thermostat.

Important: if the system is divided into zones

using the relevant kit. the CAR V2 must be used

with its climate thermostat function disabled, i.e.

it must be set to On/O mode.

CARV2 or chrono-thermostat On/O electric

connection (Optional). e operations described

below must be performed aer having removed

the voltage from the appliance. The eventual

On/O environment chrono-thermostat must

be connected to clamps 40 and 41 eliminating

jumper X40 (Fig. 3-2). Make sure that the On/

O thermostat contact is of the “clean” type,

i.e. independent of the mains supply, otherwise

the P.C.B. would be damaged. Any CARV2 must

be connected by means of terminals + and - to

clamps 41 and 44 on the P.C.B. (in boiler),

eliminating jumper X40 and respecting polarity

(Fig. 3-2). Connection with the wrong polarity

prevents functioning, but without damaging the

CARV2 e boiler can only be connected to one

remote control.

Important: If the CARV2 remote control is used,

arrange two separate lines in compliance with

current regulations regarding electrical systems.

No boiler pipes must ever be used to earth

the electric system or telephone lines. Ensure

elimination of this risk before making the boiler

electrical connections.

Installation with system operating at direct

low temperature. e boiler can directly feed a

low temperature system by acting on parameters

“S5” and S6” (par. 3.8). In this situation it is good

practice to insert a relevant safety kit (optional)

made up from a thermostat (with adjustable

temperature). e thermostat must be positioned

on the system ow pipe.

1.7 EXTERNAL PROBE OPTIONAL.

e boiler is prepared for the application of the

external probe (Fig. 1-9), which is available as an

optional kit. Refer to the relative instruction sheet

for positioning of the external probe.

The probe can be connected directly to the

boiler electrical system and allows the max.

system ow temperature to be automatically

decrease d when the external tempe rature

increases, in order to adjust the heat supplied to

the system according to the change in external

temperature. e external probe always operates

when connected, regardless of the presence or

type of room chrono-thermostat used and can

work in combination with Immergas chronothermostats. e correlation between system

ow temperature and external temperature is

determined by the position of the central heating

selector switch on the boiler control panel (or

on the CARV2 control panel if connected to the

boiler) according to the curves shown in the

diagram (Fig. 1-10). e electric connection of

the external probe must be made on clamps 38

and 39 on the terminal board positioned under

the sealed chamber (Fig. 3-2).

Key:

1 - Position of the central heating

temperature user adjustment

2 - In brackets, temperature

value with 25°/50° range

TM - Flow Temperature (°C)

TE - External Temperature (°C)

(A)

(B)

1-121-11

8 - IE

INSTALLERUSERTECHNICIAN

1.8 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the boiler regarding the installation of air

intake terminals and ue exhaust; fundamental

for boiler operation.

Imp ortant: the b oiler must be instal led

exclusively with an original Immergas “Green

Range” air intake and flue gas extraction

system in plastic, as envisioned by Standards

in force.

e plastic pipes cannot be installed outdoors,

for tracts longer than 40 cm, without suitable

protection from UV rays and other atmospheric

agents.

This s ystem c an b e ident if ie d b y an

identification mark and special distinctive

marking bearing the note: “only for condensing

boilers”.

• Resistance factors and equivalent lengths.

Each ue extraction system component has

a Resistance Factor based on experimental

tests and specified in the table below. The

resistance factor for individual components is

independent from the type of boiler on which

it is installed or the actual dimensions. It is,

however, conditioned by the temperature of the

uids that pass through the pipe and therefore

varies according to applications for air intake

or ue exhaust. Each individual component has

a resistance corresponding to a certain length

in metres of pipe of the same diameter; the

so-called equivalent length, obtained from the

ratio between the relative Resistance Factors.

All boilers have an experimentally obtainable

maximum Resistance Factor equal to 100.

The maximu m Resistance Factor allowed

corresponds to the resistance encountered with

the maximum allowed pipe length for each

type of Terminal Kit. is information enables

calculations to verify the possibility of various

congurations of ue extraction systems.

Positioning of the gaskets (black) for “green

range” ue extraction systems. Position the

gasket correctly (for bends and extensions)

(Fig. 1-11):

- gasket (A) with notches, to use for bends;

- gas ket (B ) with out no tc hes , to us e for

extensions;

N.B.: if component lubrication (already carried

out by the manufacturer) is not sucient, remove

the residual lubricant using a dry cloth, then to

ease tting spread the elements with common

or industrial talc.

1.9 OUTDOOR INSTALLATION IN

PARTIALLY PROTECTED AREA.

N.B.: a partially protected area is one in which the

appliance is not exposed to the direct action of the

weather (rain, snow, hail, etc..)..

• Conguration type B, open chamber and

forced draught.

Using the relevant cover kit direct air intake is

possible (Fig. 1-12) and combustion products

are exhausted into a single ue or directly to the

outside. In this conguration it is possible to

install the boiler in a partially protected place.

In this conguration the boiler is classied as

type B23.

With this conguration:

- ai r intake ta kes pl ace direc tly from the

environment in which the appliance is installed

(external);

- the ue exhaust must be connected to its own

individual ue or channelled directly into the

external atmosphere.

The technical regulations in force must be

respected.

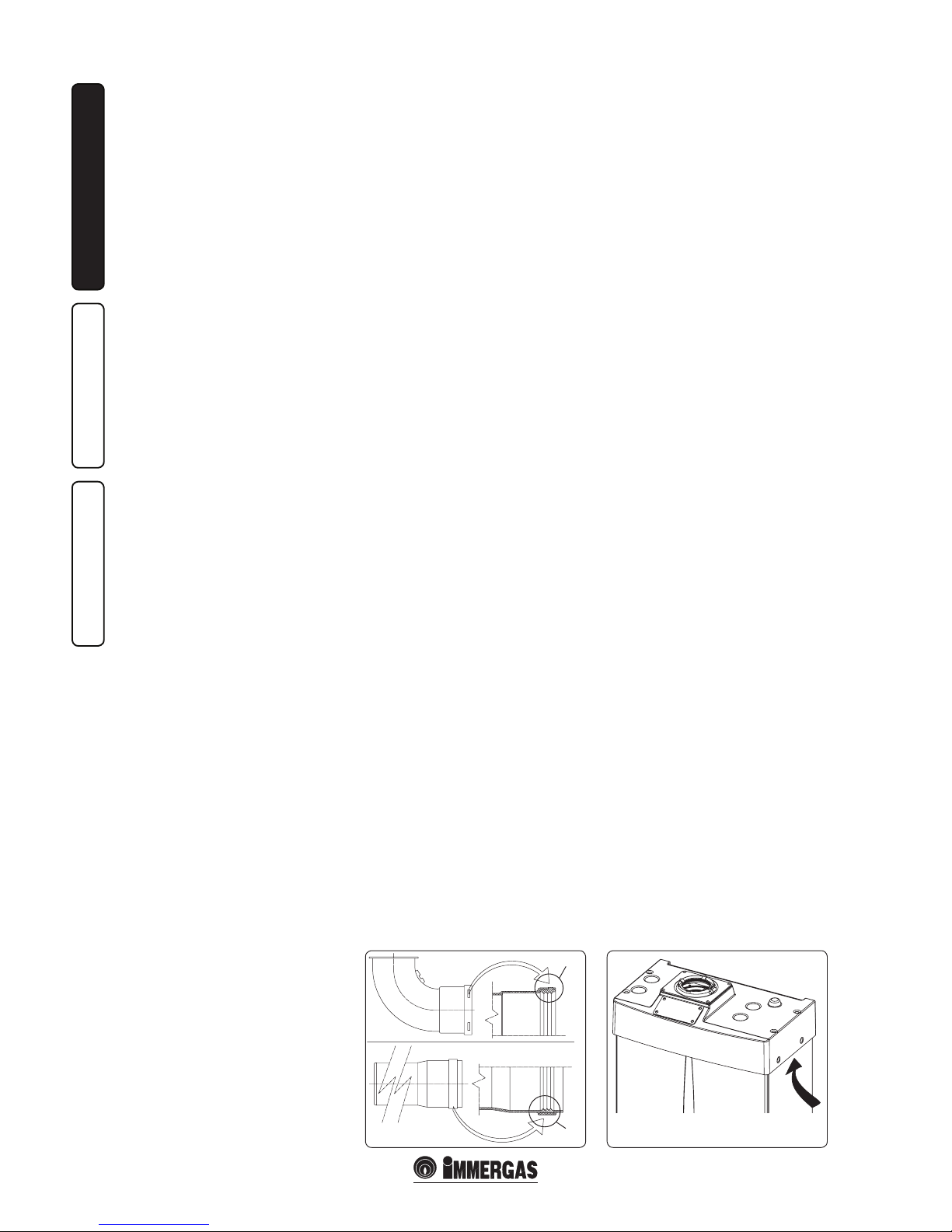

• Cover kit assembly (Fig. 1-13). Remove the

two plugs and the gaskets present from the

two lateral holes with respect to the central

one. Now cover the right intake hole using the

relevant plate, xing it onto the le side using

the two previously-removed screws. Install the

Ø 80 outlet ange on the central hole of the

boiler, taking care to insert the gasket supplied

with the kit and tighten by means of the screws

provided. Install the upper cover, xing it using

the 4 screws present in the kit, positioning the

relevant gaskets. Engage the 90° Ø 80 bend

with the male end (smooth) in the female end

(with lip seal) of the Ø 80 ange unit until it

stops. Introduce the gasket, making it run along

the bend. Fix it using the sheet steel plate and

tighten by means of the straps present in the

kit, making sure to block the 4 gasket aps. Fit

the male end (smooth) of the exhaust terminal

into the the female end of the bend 90° Ø 80,

making sure that the relevant wall sealing

plate is already tted; this will ensure hold and

joining of the elements making up the kit.

Max. length of exhaust duct. The flue pipe

(vertical or horizontal) can be extended to a max.

length of 30 straight metres.

• Coupling of extension pipes. To install push-

tting extensions with other elements of the

flue extraction elements assembly, proceed

as follows: Couple the pipe or elbow with the

male side (smooth) in the female side (with lip

seal) to the end stop on the previously installed

element. is will ensure sealing eciency of

the coupling.

Example of installation with direct vertical

terminal in partially protected location. When

the vertical terminal for direct discharge of

combustion products is used, a minimum gap

of 300 mm must be le between the terminal

and the balcony above. e height X+Y+Z+W

evaluated with respect to the balcony above,

must be equal to or more than 2000 mm. (Fig.

1-15). e term W must only be considered if the

balcony above has closed balustrade (W=0 if the

balustrade is open).

• Conguration without cover kit in a partially

protected location (type C boiler)

By leaving the side plugs fitted it is possible

to install the appliance externally without the

cover kit. Installation takes place using the

Ø60/100 concentric intake/ exhaust kits. Refer

to the paragraph relative to indoor installation.

In this conf ig uration th e uppe r cove r kit

guarantees additional protection for the boiler.

It is recommended but not compulsory.

1.10 OUTDOOR INSTALLATION USING

RECESS FRAME

WITH DIRECT AIR INTAKE

For this configuration, use the appropriate

spacers (included in the recess frame kit) and

place them under the side plugs of the sealed

chamber.

Air intake takes place directly from the external

envi ro nment (the rece ssed fra me is thus

ventilated) and ue exhaust in single ue or

directly outdoors.

The boiler in this configuration, following

mounting instructions stated below, is classed

as type B

In this configuration, the flue exhaust must

be connec ted to its own individua l flue or

channelled directly into the external atmosphere.

The technical regulations in force must be

respected.

Max. length of exhaust duct. The flue pipe

(vertical or horizontal) can be extended to a max.

length of 30 straight metres.

1-14

1-15

1-16 1-17

1-13

1

2

9 - IE

INSTALLERUSERTECHNICIAN

e cover kit includes:

N° 1 Heat moulded cover

N°1 Gasket clamping plate

N°1 Gasket

N°1 Gasket clamp

N°1 N°1 Intake hole covering plate

e terminal kit includes:

N° 1 Gasket

N° 1 Exhaust ange Ø 80

N° 1 Bend 90° Ø 80

N° 1 Exhaust pipe Ø 80

N° 1 Wall sealing plate

Spacer installation. For installation with direct

air intake, type B23, 4 spacers (present in the

recess frame kit) should be inserted between the

boiler and the two plugs of the sealed chamber

so that combustion agent air can reach the boiler

directly from the place of installation (Fig. 1-16

and 1-17).

• Coupling of extension pipes. To install push-

tting extensions with other elements of the

flue extraction elements assembly, proceed

as follows: Couple the pipe or elbow with the

male side (smooth) in the female side (with lip

seal) to the end stop on the previously installed

element. is will ensure sealing eciency of

the coupling.

Key:

1 - Vertical

terminal kit for

direct discharge

2 - Intake cover kit

10 - IE

INSTALLERUSERTECHNICIAN

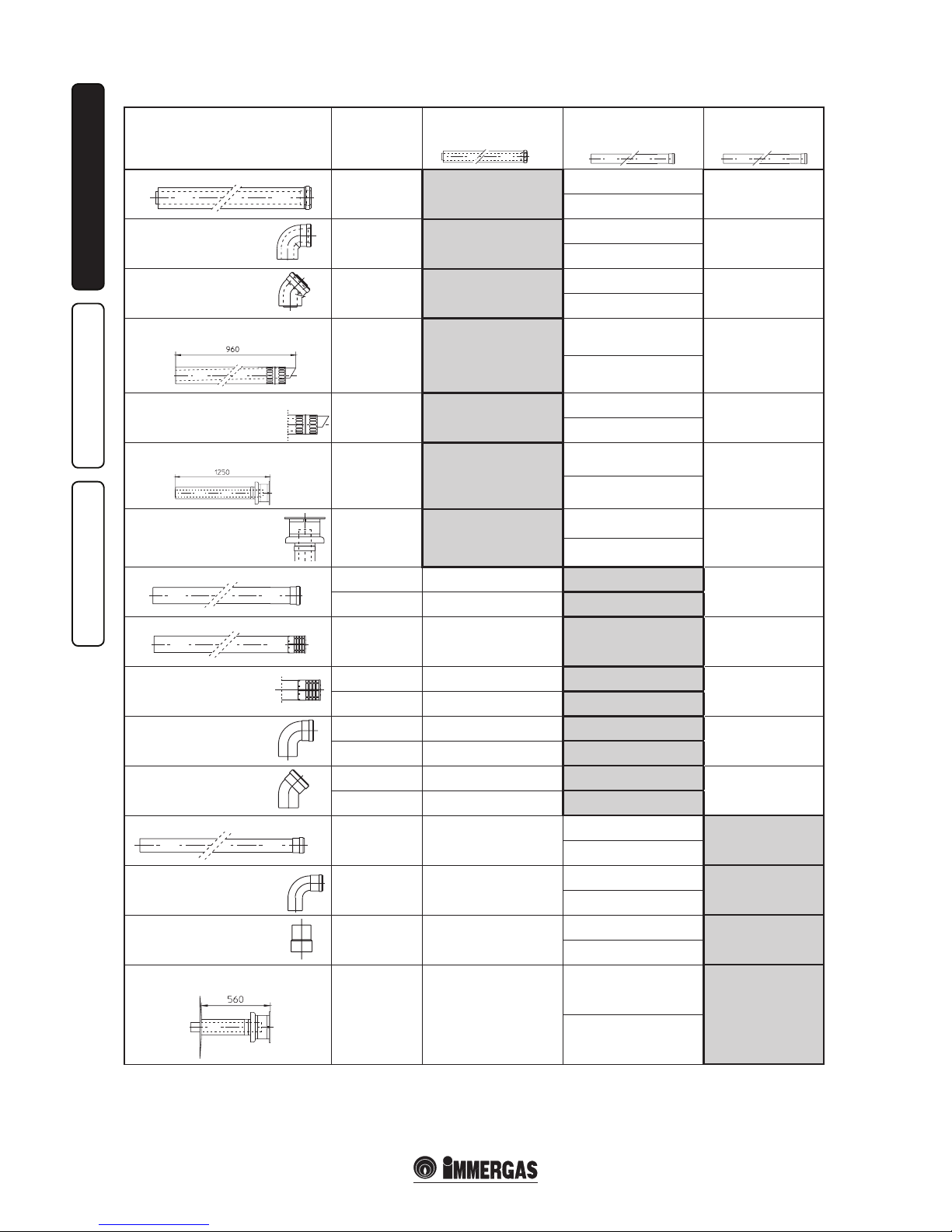

Tables of Resistance Factors and Equivalent Lengths.

DUCT TYPE

Resistance

Factor

(R)

Equivalent

length in m of concentric

pipe Ø 60/100

Equivalent

length in metres

of pipe Ø 80

Equivalent

length in metres

of pipe Ø 60

Concentric pipe Ø 60/100 m 1

Intake and

Exhaust 6.4

m 1

Intake m 7.3

Exhaust m 1.9

Exhaust m 5.3

Concentric bend 90° Ø 60/100

Intake and

Exhaust 8.2

m 1.3

Intake m 9.4

Exhaust m 2.5

Exhaust m 6.8

Concentric bend 45° Ø 60/100

Intake and

Exhaust 6.4

m 1

Intake m 7.3

Exhaust m 1.9

Exhaust m 5.3

Terminal complete with concentric

horizontal intake-exhaust Ø 60/100

Intake and

Exhaust 15

m 2.3

Intake m 17.2

Exhaust m 4.5

Exhaust m 12.5

Concentric horizontal intake- exhaust

terminal Ø 60/100

Intake and

Exhaust 10

m 1.5

Intake m 11.5

Exhaust m 3.0

Exhaust m 8.3

Terminal complete with concentric

vertical intake-exhaust Ø 60/100

Intake and

Exhaust 16.3

m 2.5

Intake m 18.7

Exhaust m 4.9

Exhaust m 13.6

Concentric vertical intakeexhaust terminal Ø 60/100

Intake and

Exhaust 9

m 1.4

Intake m 10.3

Exhaust m 2.7

Exhaust m 7.5

Pipe Ø 80, 1 m

Intake 0.87 m 0.1 Intake m 1.0

Exhaust m 0.4

Exhaust 1.2 m 0.2 Exhaust m 1.0

Complete intake terminal Ø 80, 1 m

Intake 3 m 0.5 Intake m 3.4 Exhaust m 0.9

Intake terminal Ø 80

Exhaust terminal Ø 80

Intake 2.2 m 0.35 Intake m 2.5

Exhaust m 0.6

Exhaust 1.9 m 0.3 Exhaust m 1.6

Bend 90° Ø 80

Intake 1.9 m 0.3 Intake m 2.2

Exhaust m 0.8

Exhaust 2.6 m 0.4 Exhaust m 2.1

Bend 45° Ø 80

Intake 1.2 m 0.2 Intake m 1.4

Exhaust m 0.5

Exhaust 1.6 m 0.25 Exhaust m 1.3

Pipe Ø60 m 1 for ducting

Exhaust 3.3 m 0.5

Intake 3.8

Exhaust m 1.0

Exhaust 2.7

Bend 90° Ø 60 for ducting

Exhaust 3.5 m 0.55

Intake 4.0

Exhaust m 1.1

Exhaust 2.9

Reduction Ø80/60

Intake and

Exhaust 2.6

m 0.4

Intake m 3.0

Exhaust m 0.8

Exhaust m 2.1

Terminal complete with exhaust

vertical Ø 60 for ducting

Exhaust 12.2 m 1.9

Intake m 14

Exhaust m 3.7

Exhaust m 10.1

Loading...

Loading...