Immergas Victrix Pro 80 2ErP, Victrix Pro 100 2ErP, Victrix Pro 120 2ErP Instruction And Warning Book

Instruction and

*1.041665ENG*

warning book

IE

VICTRIX PRO

80 - 100 - 120 2 ErP

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully: you

will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction for the Immergas product.

For assistance and scheduled maintenance contact Authorised Immergas Aer-Sales centres: they have original spare parts and are specically trained directly

by the manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry environments protected against bad weather.

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instructions manual provides technical information for installing Immergas boilers. As for the other issues related to boiler installation (e.g. safety in the work

site, environment protection, injury prevention), it is necessary to comply with the provisions specied in the regulations in force and principles of good practice.

In compliance with legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law. Installation

and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally qualied

sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to people, animals

and objects. Read the instructions provided with the product carefully to ensure a proper installation.

Maintenance must be carried out by skilled technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and

professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non compliance with technical laws in force, standards or instructions contained in this

book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and the

appliance warranty is invalidated.

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE), declares that the design, manufacturing and aer-sales

assistance processes comply with the requirements of standard UNI EN ISO 9001:2015.

For further details on the product CE marking, request a copy of the Declaration of Conformity from the manufacturer, specifying the appliance model

and the language of the country.

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without prior notice.

INDEX

USER page INSTALLER page MAINTENANCE TECHNICIAN page

1 Boiler installation .......................................5

1.1 Installation recommendations. ................. 5

1.2 Position of the appliances. ......................... 5

1.3 Aeration and Ventilation of the installation

rooms. ........................................................... 6

1.4 Outdoor installation. ..................................6

1.5 Anti-freeze protection. ...............................6

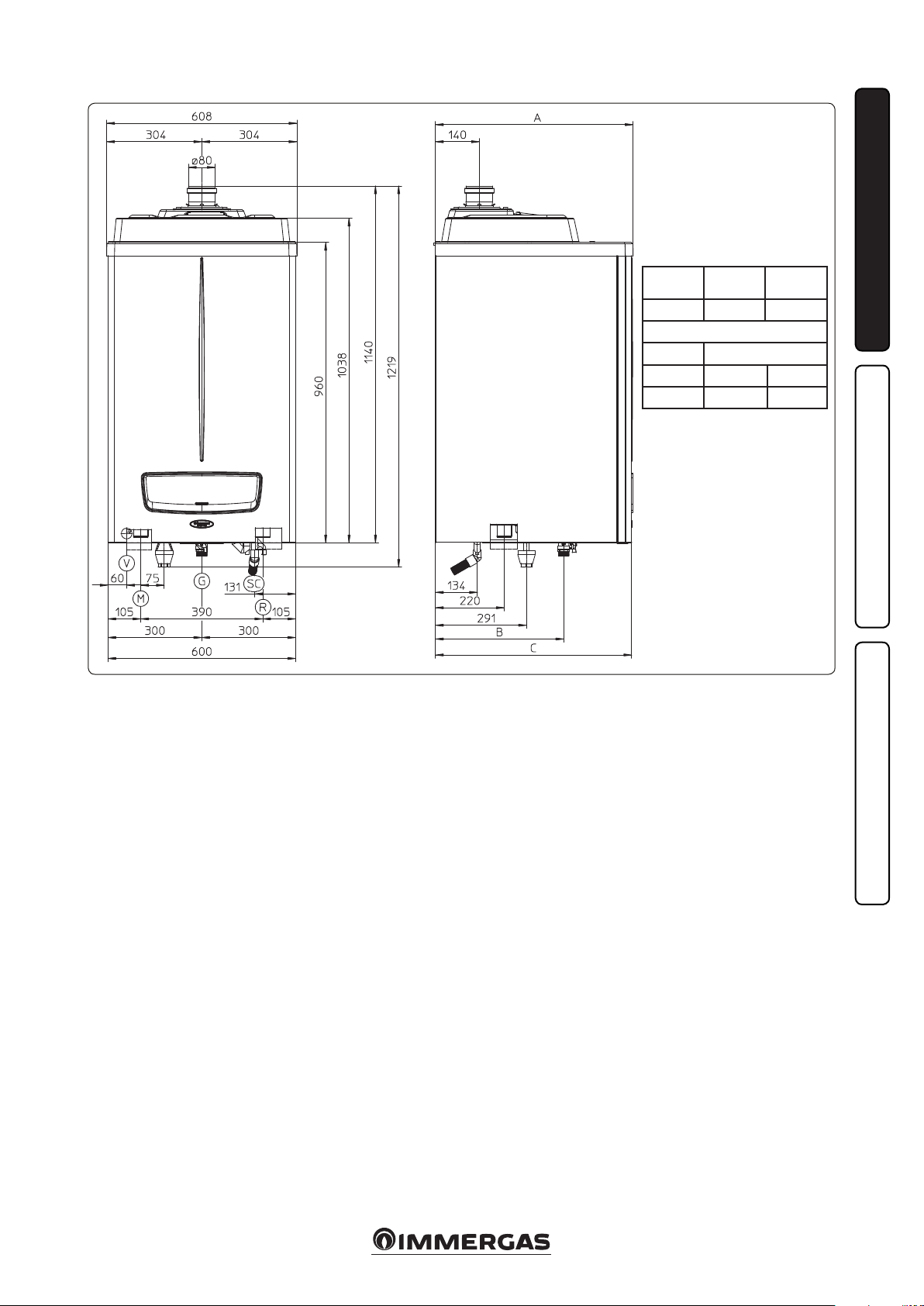

1.6 Main dimensions. ......................................7

1.7 Gas connection. ..........................................7

1.8 Hydraulic connection. ................................7

1.9 Electric connection. ....................................8

1.10 Optional boiler controllers. ......................9

1.11 External temperature probe. ..................... 9

1.12 Immergas ue systems. ............................10

1.13 Tables of equivalent length factors. ........11

1.14 Concentric horizontal kit installation. ... 12

1.15 Concentric Vertical kit installation. .......13

1.16 Installation of vertical terminals 80 ø. ...14

1.17 Installation of 80 ø horizontal terminals. 15

1.18 Flue duct systems for voids and

chimneys.

1.19 Flue exhaust with boilers in cascade. .....16

1.20 System lling. ............................................ 16

1.21 Condensate trap lling. ............................16

1.22 Gas system start-up. .................................16

1.23 Boiler start up (ignition). .........................16

1.24 Circulation pump......................................17

1.25 Kits available on request. .........................17

1.26 Boiler components. ...................................19

1.27 Hydraulic diagram with optional. ..........20

1.28 Installation examples of individual

boiler. ..........................................................21

................................................... 16

2 Use and maintenance instructions .........22

2.1 Cleaning and maintenance. .....................22

2.2 Aeration and Ventilation of the

installation rooms. ....................................22

2.3 General warnings. ..................................... 22

2.4 Control panel.............................................23

2.5 Using the boiler. ........................................23

2.6 Troubleshooting. .......................................25

2.7 Info menu. .................................................27

2.8 Boiler shutdown. ......................................27

2.9 Restoring central heating

system pressure. .......................................27

2.10 System drainage. ......................................27

2.11 Anti-freeze protection. .............................27

2.12 Case cleaning. ...........................................27

2.13 Decommissioning. ....................................27

3 Boiler commissioning .............................28

3.1 Hydraulic diagram. ...................................28

3.2 230 V circuit wiring diagram. .................29

3.3 very low voltage wiring diagram. ...........30

3.4 D.H.W. pump boiler and tank probe

wiring diagram. .........................................31

3.5 Common ow probe and 3-way boiler

wiring diagram. .........................................31

3.6 Simple cascade boiler with D.H.W. pump

and tank probe wiring diagram. .............31

3.7 Troubleshooting. .......................................32

3.9 Programming the boiler P.C.B. ............... 32

3.10 Converting the boiler to other types

of gas. ..........................................................35

3.11 Checks following conversion to another

type of gas. ................................................. 35

3.12 Adjustment of the air-gas ratio. ..............35

3.13 CH output adjustment. ............................35

3.14 Output adjustment during DHW (only

in combination with an optional external

storage tank).

3.15 "Chimney Sweep" function. .....................36

3.16 3-way pump anti-block function

(optional). ..................................................36

3.17 Radiators anti-freeze function. ...............36

3.18 Anti-humidity electrode function. ......... 36

3.19 Inlet 0 ÷ 10 V. ............................................36

3.20 Functioning with common ow probe. .36

3.21 Autodetection. ...........................................36

3.22 Simple cascade (max. 2 boilers) .............. 36

3.23 Yearly appliance check and

maintenance. .............................................37

3.24 Casing removal. ........................................38

3.25 Variable heat output. ................................40

3.26 Combustion parameters. .........................43

3.27 Technical data. ..........................................44

3.28 Key for Data plate. .................................... 45

3.29 Technical parameters for mixed boilers (in

compliance with Regulation 813/2013). 46

............................................. 35

BOILER

1

INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

Only professionally qualied heating/plumbing

technicians are authorised to install Immergas

gas appliances.

Individual and cascade installation Victrix Pro

2ErP boilers can be installed outdoors or in a

suitable plant room.

e installation must comply with all laws and

standards in force.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural) such to allow

(always in safety, efficiency and comfortable

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (to outdoors in the place for

loading and transporting the appliances

and components) as well as their eventual

replacement with appliances and/or equivalent

components.

Attention: these boilers must be used to heat

rooms and the like; they are for heating water

to a temperature lower that boiling point at

atmospheric pressure. erefore, they must be

connected to a heating system that is suitable for

their performance and their power.

Before installing the appliance, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately.

Packaging materials (staples, nails, plastic bags,

polystyrene foam, etc.) constitute a potential

hazard and must be kept out of the reach of

children.

Keep all flammable objects away from the

appliance (paper, rags, plastic, polystyrene, etc.).

In the event of malfunctions, faults or incorrect

operation, turn the appliance o and contact a

qualied company (e.g. the Immergas Technical

Aer-Sales Centre, which has specically trained

sta and original spare parts)

Do not attempt to modify or repair the appliance

alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

• Installation regulations: these boilers are not

in any way designed for installation on bases

or oors (Fig. 1-1), but exclusively for wall

installation. e wall surface must be smooth,

without any protrusions or recesses enabling

access to the rear part. Wall mounting of the

boiler must guarantee stable and efficient

support for the boiler. The plugs (standard

supply) are to be used only in conjunction

with the mounting brackets or xing template

to fix the appliance to the wall; they only

ensure adequate support if inserted correctly

(according to technical standards) in walls

made of solid or semi-hollow brick or block.

In the case of walls made from hollow brick or

block, partitions with limited static properties,

or in any case walls other than those indicated,

a static test must be carried out to ensure

adequate support. e boilers must be installed

in a way to prevent collisions and tampering.

N.B.: the hex head screws supplied in the

blister pack are to be used exclusively to x the

mounting bracket to the wall.

1.2 POSITION OF THE APPLIANCES.

e boilers can be installed:

- outdoors;

- in outdoor environments, also adjoining the

building served, located in uncovered space, as

long as structurally separated and without walls

in common, or situated on the at covering of

the building served, always without walls in

common;

- in building also destined for other use or in

places inserted in the volume of the building

served.

ese rooms must be intended exclusively to

house CH systems and must have characteristics

that comply with legislation in force.

Attention: the installation of appliances powered

with gas with a greater density than 0.8 (L.P.G.)

is only allowed in places out of the ground,

also communicating with places that are on the

ground. In both cases the walkway must not have

hollows or depressions such to create gas pockets

that determine dangerous conditions.

Height of the installation room.

Installation of individual appliance: the room

must have a minimum ceiling height of 2 m.

Installation of multiple appliances in cascade (2

÷ 5 Victrix Pro 2ErP): considering the size of the

boiler, the ue manifold (which must be installed

on a 3% gradient) and the hydraulic manifolds,

the room must have a minimum ceiling height

of 2.3 m.

e aforementioned heights allow for correct

installation of the appliances and observe the

technical regulations in force.

Position of the appliances in the room.

Individual appliance: the distances between

any external point of the boiler and the vertical

and horizontal walls of the room must allow

accessibility to the regulation, safety and control

elements for routine maintenance.

Multiple appliances, not interconnected, but

installed in the same room: the minimum distance

to maintain between several boilers installed

on the same wall must be 200 mm, in order to

allow accessibility to the regulation, safety and

control elements and routine maintenance of all

appliances installed.

Cascade installation (2 ÷ 5 Victrix Pro 2ErP):

e instructions for correct cascade installation

are provided in the respective documents or

on the www.immergas.com website in the high

power section.

INSTALLERUSER

MAINTENANCE TECHNICIAN

YES

NO

1-1

5

1.3 AERATION AND VENTILATION OF

THE INSTALLATION ROOMS.

e rooms must have one or more permanent

openings for aeration on external walls. The

openings used for aeration can be protected

using metal grills, meshes and/or rain-proof ns

as long as the net aeration surface is not reduced.

The aeration openings must be realised and

located in a way to prevent the formation

of pockets of gas, independently from the

conformation of the covering.

Aeration for installation in outdoor places. e

INSTALLERUSER

minimum free surfaces, in relation to the overall

heat input must not be below:

a) above-ground rooms (S ≥ Q x 10)

S > 755 cm2 for every Victrix Pro 80 2ErP

S > 925 cm2 for every Victrix Pro 100 2ErP

S > 1145 cm2 for every Victrix Pro 120 2ErP

(ex: to install 3 Victrix Pro 80 2ErP in cascade,

the minimum surface is 755 x 3 = 2265 cm2)

b) basements and underground rooms up to a

height of -5 m from the reference surface (S

≥ Q x 15).

S > 1130 cm2 for every Victrix Pro 80 2ErP

S > 1385 cm2 for every Victrix Pro 100 2ErP

S > 1712 cm2 for every Victrix Pro 120 2ErP

(ex: to install 3 Victrix Pro 80 2ErP in cascade,

the minimum surface is 1130 x 3 = 3390 cm2)

c) underground rooms at quota between -5 m

and -10 m from the reference surface (S ≥ Q

x 20 with a minimum of 5000 cm2).

S > 5000 cm2 for all congurations

In all cases each opening must not have a net

surface area less than 100 cm

2

.

Attention: in the case of installation of appliances

powered with gas with greater density than 0.8

(L.P.G.) in outdoor places, above-ground, at least

2/3 of the aeration surface must be ush with the

oor, with a minimum height of 0.2 m.

e aeration openings must be at least 2 m for

heating capacities not exceeding 116 kW and

4.5 m for higher heating capacities, cavities,

depressions or openings communicating with

rooms below the walkway surface or draining

ducts.

Aeration for installation in buildings also

destined for other use or in places inserted in

the volume of the building served. e aeration

surface must not be less than 3000 cm

MAINTENANCE TECHNICIAN

of natural gas and must not be less than 5000 cm

in the case of L.P.G..

The installation must comply with the

requirements of all relevant codes and standards.

2

in the case

1.4 OUTDOOR INSTALLATION.

The boiler has an IPX5D electric insulation

rating and can also be installed outdoors, without

additional protections.

Attention: all optional kits that can be potentially

connected to the boiler must be protected on the

basis of their electrical protection rating.

1.5 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e boiler comes

standard with an anti-freeze function that

activates the pump and burner when the system

water temperature in the boiler falls below 5°C.

e anti-freeze function is only guaranteed if:

- the boiler is correctly connected to gas and

electricity power supply circuits;

- the boiler is powered constantly;

- Main switch is inserted;

- the boiler is not in no ignition block (Par.

- the boiler essential components are not faulty.

In these conditions the boiler is protected against

freezing to an ambient temperature of -5°C.

Minimum temperature -15°C. If the boiler is

installed in a place where the temperature falls

below -5°C and in the event there is no gas (or

the boiler goes into failed ignition block), the

appliance can freeze.

To prevent the risk of freezing follow the

instructions below:

- Protect the central heating circuit from freezing

by inserting a good-quality antifreeze liquid

into this circuit, which is specially suited

for central heating systems and which is

manufacturer guaranteed not to cause damage

to the heat exchanger or other components of

the boiler.

e antifreeze liquid must not be harmful to

one’s health.

. e instructions of the manufacturer of this

liquid must be followed scrupulously regarding

the percentage necessary with respect to the

minimum temperature at which the system

must be kept. An aqueous solution must be

made with a potential water pollution class

of 2 (EN 1717).

e materials used for the central heating circuit

of Immergas boilers withstand ethylene and

propylene glycol based antifreeze liquids (if the

mixtures are prepared perfectly).

For life and possible disposal, follow the supplier’s

instructions.

2

- Protect the condensate drain trap and relative

drain against freezing by using an accessory

supplied on request (anti-freeze kit) comprising

two electric resistances, the relevant cables

and a control thermostat (carefully read the

installation instructions contained in the

accessory kit pack).

Boiler anti-freeze protection is thus ensured only if:

- the boiler is correctly connected to electricity

power supply circuits;

- Main switch is inserted;

- the anti-freeze kit components are ecient.

In these conditions the boiler is protected against

freezing to temperature of -15°C.

The warranty does not cover damage due to

interruption of the electrical power supply and

failure to comply with that stated on the previous

page.

6

1.6 MAIN DIMENSIONS.

Key:

V - Electrical connection

G - Gas supply

R - System return

M - System ow

SC - Condensate drain (minimum

internal diameter 13 mm Ø)

1.7 GAS CONNECTION.

Our boilers are designed to operate with with

natural gas (G20) and L.P.G. Supply pipes must be

the same as or larger than the 3/4” G boiler tting

Victrix Pro 80 2ErP, 1“ Victrix Pro 100-120 2ErP.

N.B.: the gas supply pipe must be suitably dimensioned according to current regulations in

order to guarantee correct gas ow to the burner

even in conditions of maximum generator output

and to guarantee appliance eciency (technical

specications). e connection to the gas supply

must conform to standards.

Before connecting the gas line, carefully clean

inside all the fuel feed system pipes to remove any

residue that could impair boiler eciency. Also

make sure the gas corresponds to that for which

the boiler is prepared (see boiler data-plate). If

dierent, the appliance must be converted for

operation with the other type of gas (see converting appliance for other gas types). e dynamic

gas supply (methane or L.P.G.) pressure must

also be checked according to the type used in

the boiler, which must comply with EN 437 and

relative attachments and with the local technical

regulations in force, as insucient levels can

reduce generator output and cause malfunctions.

Ensure correct gas cock connection.

Install a manual cut-o valve with quick closure

manoeuvre for 90° rotation and end run stops in

the all open or all closed positions on the gas supply pipe in a visible and easily reachable position

outside the room where the appliance is installed.

N.B.: the internal gas supply system must be

built in compliance with the provisions and

regulations and all legislation in force, and any

other reference on good technique.

Fuel gas quality. e appliance has been designed to operate with combustible gas free of

impurities; otherwise it is advisable to t special

lters upstream of the appliance to restore the

purity of the fuel.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance causing problems

with boiler operation.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

Height

(mm)

1038 600 A

GAS SYSTEM

G R M

* 1”1/2 1”1/2

A:

Victrix Pro 80 2ErP = 502 mm

Victrix Pro 100 - 120 2ErP = 632 mm

B:

Victrix Pro 80 2ErP = 265 mm

Victrix Pro 100 - 120 2ErP = 410 mm

C:

Victrix Pro 80 2ErP = 497 mm

Victrix Pro 100 - 120 2ErP = 627 mm

*:

Victrix Pro 80 2ErP = 3/4”

Victrix Pro 100 - 120 2ErP = 1”

1.8 HYDRAULIC CONNECTION.

Attention: in order not to void the condensation

module warranty, before making the boiler connections, carefully wash the CH system (pipes,

radiators, etc.) with special pickling or descaling

products to remove any deposits that could compromise correct boiler operation.

A chemical treatment of the thermal system water is required, in compliance with the technical

standards in force, in order to protect the system

and the appliance from deposits (e.g., lime scale),

sludge or other hazardous deposits.

It is recommended to prepare a filter in the

system to collect and separate any impurities

present in the system (slurry remover lter). In

order to avoid deposits, scaling and corrosion

in the central heating system, the provisions

set forth in the technical regulation in force on

water treatment in heating systems for civil use

must be respected.

Water connections must be made in a rational

way using the couplings on the boiler template.

e discharge of the boiler safety valve must

be connected to a tundish and then the waste

should be connected to the sewer. Otherwise, the

manufacturer declines any responsibility in case

of ooding if the drain valve cuts in.

Width

(mm)

Connections

Depth

(mm)

1-2

INSTALLERUSER

MAINTENANCE TECHNICIAN

7

Attention: Immergas declines all liability in the

event of damage caused by the inclusion of automatic lling that is not its own brand.

In order to meet the system requirements established by EN 1717 on the pollution of drinking

water and in observance of local technical

regulations in force, we recommend installing

an anti-backflow kit to be used upstream of

the cold water inlet connection of the boiler.

We also recommend using a category 1, 2 or

3 heat transfer uid (ex: water + glycol) in the

boiler’s primary circuit (CH circuit), as dened

INSTALLERUSER

in standard EN 1717.

Attention:to preserve the duration of appliance

eciency features, we recommend installation of

a suitable device for water treatment in presence of

water whose characteristics can lead to the deposit

of lime scale.

Condensate drain. To drain the condensate produced by the appliance, it is necessary to connect

to the drainage system by means of acid condensate resistant pipes, with an internal Ø of at least

13 mm. e system connecting the appliance to

the drainage system must be carried out in such a

way as to prevent freezing of the liquid contained

in it. Before appliance start-up, ensure that the

condensate can be correctly removed. Aer rst

ignition, check that the drain trap is lled with

condensation (paragraph. 1.21)

Also, comply with national and local regulations

on discharging waste waters.

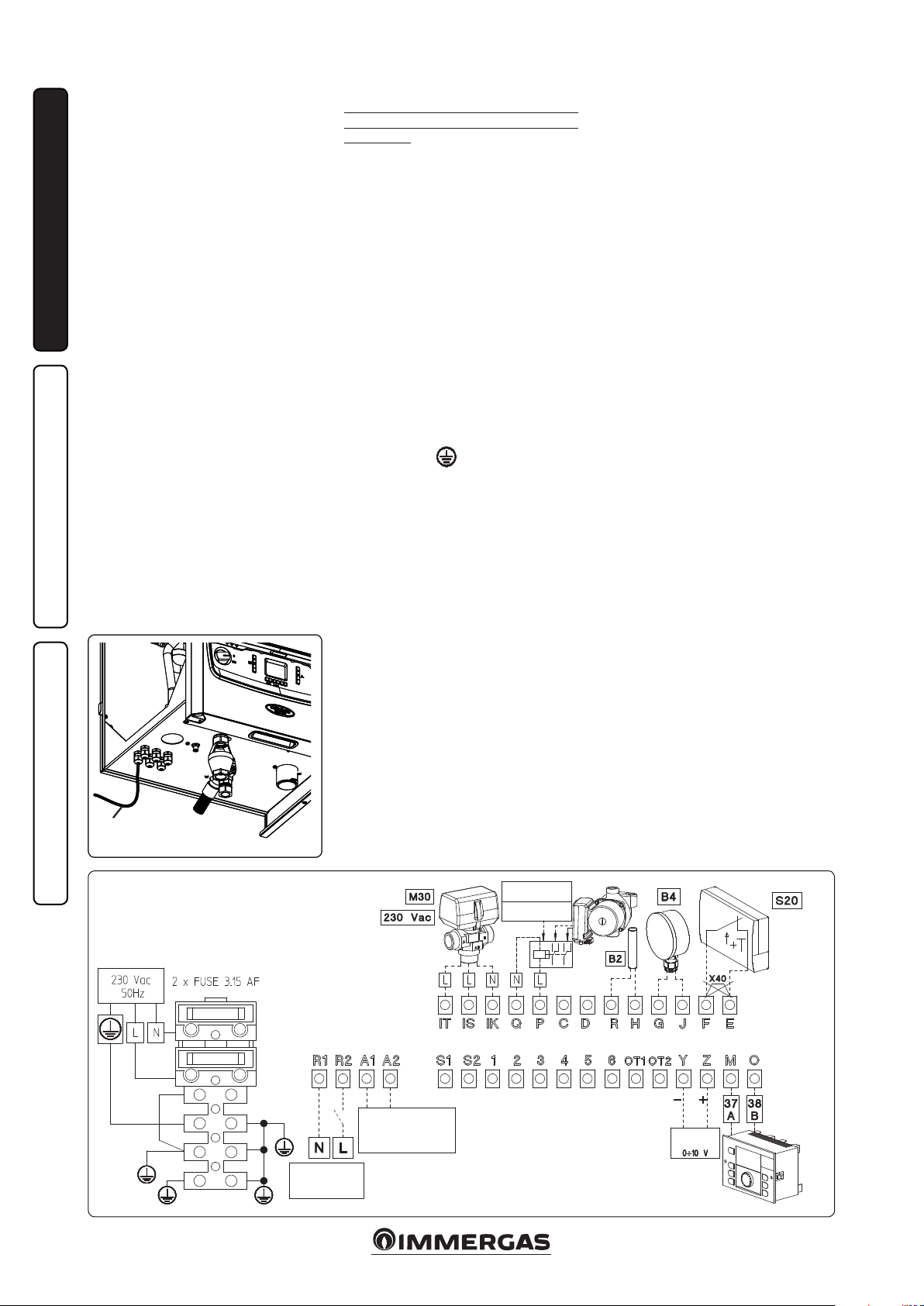

1.9 ELECTRIC CONNECTION.

e operations described below must be performed

aer having disconnecte d the electrical supply from

the appliance.

e electrical system must be built in compliance

with technical standards and all legislation in

force. e boiler has an IPX5D protection rating

for the entire appliance. Electrical safety of the

appliance is reached only when it is correctly

connected to an efficient earthing system as

specied by current safety standards.

Attention: Immergas S.p.A. declines any responsibility for damage or physical injury caused by

failure to connect the boiler to an ecient earth

system or failure to comply with the reference

standards.

Also ensure that the electrical installation corresponds to maximum absorbed power specications as shown on the boiler data-plate.

Boilers are supplied complete with an “X” type

power cable without plug. e power supply

cable must be connected to a 230V ±10% /

50Hz mains supply respecting L-N polarity and

earth connection;

, this network must also

have a multi-pole circuit breaker with class III

over-voltage category.

The main switch must be installed outside

the rooms in a position that is indicated and

accessible.

When replacing the power supply cable, contact a

qualied company (e.g. the Immergas Authorised

Aer-Sales Technical Assistance Service). e

power cable must be laid as shown (Fig. 1-3).

In the event of mains fuse replacement on the

connection terminal board, use a 3.15A fast fuse.

For the main power supply to the appliance,

never use adapters, multiple sockets or extension leads.

Important: if the Digital Remote Control is

used, arrange two separate lines in compliance

with current regulations regarding electrical systems. No boiler pipes must ever be used to earth

the electric system or telephone lines. Ensure

elimination of this risk before making the boiler

electrical connections.

•

Low temperature system installation. e

boiler can directly supply a low-temperature

system, limiting the value of the “P02” parameter, which denes the generator’s ow

temperature. In this situation it is good practice

to insert a safety device in series with the power

supply and boiler. is device is made up from

a thermostat with a temperature limit of 55

°C. e thermostat must be positioned on the

system ow pipe at a distance of over 2 metres

from the boiler.

MAINTENANCE TECHNICIAN

Supply

cable

1-3

1-3

External reset

230 Vac

ALARM

FREE CONTACTS

MAX. 230 Vac

EXTERNAL RELAY

(OPTIONAL)

230 vAC coil MAX 0.1 A

ANALOGUE

INPUT

1-4

1-4

8

1.10 OPTIONAL BOILER

CONTROLLERS.

e boiler is prepared for the application of a

cascade and zone regulator, zone manager and

external probe.

ese components are available as separate kits

to the boiler and are supplied on request.

Carefully read the user and assembly instructions

contained in the accessory kit.

• e cascade and area regulator (Fig. 1-5) is

connected to the boiler using only two wires,

powered at 230 V and allows to:

- manage a hydraulic circuit with 2 mixed

zones (mixing valve); 1 direct zone; 1 Storage

tank unit and relative pumps;

- self-diagnosis system to display any boiler

functioning anomalies;

- set two room temperature value: one for

daytime (comfort temperature) and one for

nighttime (lower temperature);

- to manage the temperature of the DHW (with

a storage tank unit);

- to manage the boiler ow temperature de-

pending on the external temperature;

- to select the desired operating mode from

the various possible alternatives for each

individual hydraulic circuit:

- permanent operation in comfort temp.;

- permanent operation in lower temp.;

- permanent operation in adjustable anti-freeze

temp.

• Zone manager (Fig. 1-6). In addition to the

functions described in the previous point, the

zone manager panel allows to control all the

important information regarding operation

of the appliance and the heating system with

the opportunity of easily intervening on the

previously set parameters without having

to go to the place where the appliance is

installed. The climate chrono-thermostat

incorporated into the zone manager enables

the system ow temperature to be adjusted to

the actual needs of the room being heated, in

order to obtain the desired room temperature

with extreme precision and therefore with

evident saving in running costs. It also allows

to display the eective room temperature and

the external temperature (if external probe

is present). e zone manager is powered

directly by the cascade heat adjuster via 2

wires.

ermoregulation electrical connection (Fig.

1-4).

ermoregulation electrical connections must

be carried out on the boiler terminal board

eliminating jumper X40.

- Thermostat or On/Off environment

chrono-thermostat: must be connected to

clamps “E” and “F”. Make sure that the On/O

thermostat contact is of the “clean” type, i.e.

independent of the mains voltage, otherwise the

P.C.B. would be damaged.

- Cascade and zone regulator: must be connected

through clamps 37 and 38 to clamps “M” and “O”

respecting polarity. e connection with incorrect

polarity will not damage the thermoregulator, but

will not allow it to operate.

Any thermostat or On/Off environment

chrono-thermostat must be connected to clamps

“E” and “F” eliminating jumper X40 (Fig. 1-4).

Make sure that the On/O thermostat contact

is of the “clean” type, i.e. independent of the

mains supply, otherwise the P.C.B. would be

damaged. Any cascade and zone regulator must

be connected by clamps 37 and 38 to clamps “M”

and “O” on the connecting terminal board in the

boiler, observing the poles and removing jumper

X40, (Fig. 1-4) connection with the wrong polarity

prevents the heat adjuster from working, although

it will not be damaged.

1.11 EXTERNAL TEMPERATURE PROBE.

e boiler is designed for the application of the

Room ermostat (Fig. 1-7) which is available as

an optional kit. Refer to the relative instruction

sheet for positioning of the external probe.

e probe can be connected directly to the boiler

electrical system and allows the max. system ow

temperature to be automatically decreased when

the external temperature increases, in order to

adjust the heat supplied to the system according

to the change in external temperature.

e electric connection of the external probe

must take place on clamps G and J on the connection in the boiler (Fig. 1-4).

By default, the external probe is not enabled. It is

necessary to set parameters “P14” and “P15” for

correct operation. e correlation between ow

temperature to the system and external temperature is determined by the curves represented in

the diagram (parameter “P14”) and by setting the

oset (parameter “P15”) (Fig. 1-8).

In case “P32” is bigger than “P15”, “P32” will be

the minimum limit for the set.

In case “P32” is lower than “P15”, “P32” will not

be considered.

N.B.: if the external probe is connected to the

cascade regulator, boiler parameter “P14” must

be set at “0”, and external probe control is delegated to the cascade regulator.

INSTALLERUSER

31

45

58

1-7

1-5 1-6

Note: this graph is prepared with the oset value (P15) at 30°C (default

value). By changing the oset value, the origin of the ow temperature

curve will also change accordingly and not the inclination.

Ex: with Oset = 40 the graph origin is 40 and not 30 °C and curve 5

with TE = -4°C, TM goes from 60°C to 70°C.

9

MAINTENANCE TECHNICIAN

1-8

1.12 IMMERGAS FLUE SYSTEMS.

Immergas can supply various solutions for ueing and air supply.

Attention: the boiler must be installed exclusively with an original Immergas “Green

Range” air intake device and fumes extraction

system, as required by the standard in force.

e plastic pipes cannot be installed outdoors,

for lengths longer than 40 cm, without suitable

protection from UV rays and other atmospheric agents.

INSTALLERUSER

is system can be identied by an identication mark and special distinctive marking

bearing the note: “only for condensing boilers”.

• Conguration type B, open chamber and fan

assisted. e boiler leaves the factory with type

“B23” conguration.

Air intake takes place directly from the envi-

ronment in which the boiler is installed via

relevant slots made in the back of the boiler

and ue exhaust in the individual ue or to the

outside. Boiler with this type of conguration

are classied as type B23 (in accordance with

standard EN 297 and relative standards in

force).

With this conguration:

- air intake takes place directly from the room

in which the appliance is installed;

- the ue exhaust must be connected to its own

individual ue or channelled directly into the

external atmosphere.

- Type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the working of wood,

coal nes, cement, etc.), which may be harmful for the components of the appliance and

jeopardise operation.

• Type C conguration, sealed chamber and

fan assisted. e boiler leaves the factory with

"B23" conguration, to change the conguration

of the boiler to type "C" (sealed chamber and

fan assisted), disassemble the 80 Ø adapter, the

bracket and the gasket present on the boiler

cover and install the designated ue.

• Coupling extension pipes and concentric

elbows. To install push-tting extensions with

other elements of the ue, proceed as follows:

Install the concentric pipe or elbow with the

male side (smooth) on the female section

(with lip seal) to the end stop on the previously

installed element in order to ensure sealing

eciency of the coupling.

Attention: if the exhaust terminal and/or

concentric extension pipe needs shortening,

consider that the internal duct must always

protrude by 5 mm with respect to the external

duct.

• N.B.: for safety purposes, do not obstruct the

boiler intake-exhaust terminal, even temporaril y.

• N.B.: when installing horizontal pipes, a minimum inclination of 3% must be maintained

and a section clamp with pin must be installed

every 3 metres.

• Maximum extension. Each individual component has a resistance corresponding to a certain

length in metres of pipe with the same diameter

(par. 1.13). With installations that involve using

various types of parts, deduct the length of

the added part from the maximum admissible

length of the kit.

Example: if you need to add a 90° bend to

a concentric system 125 Ø you will need to

deduct 1.9 m from the maximum admissible

length.

• Positioning of the gaskets (black) for “green

range” ue extraction systems. Position the

gasket correctly (for bends or extensions) (Fig.

1-9):

- gasket (A) with notches, to use for bends;

- gasket (B) without notches, to use for exten-

sions;

N.B.: if component lubrication (already carried

out by the manufacturer) is not sucient, remove the residual lubricant using a dry cloth,

then to ease tting coat the parts with talc,

supplied in the kit.

MAINTENANCE TECHNICIAN

10

10

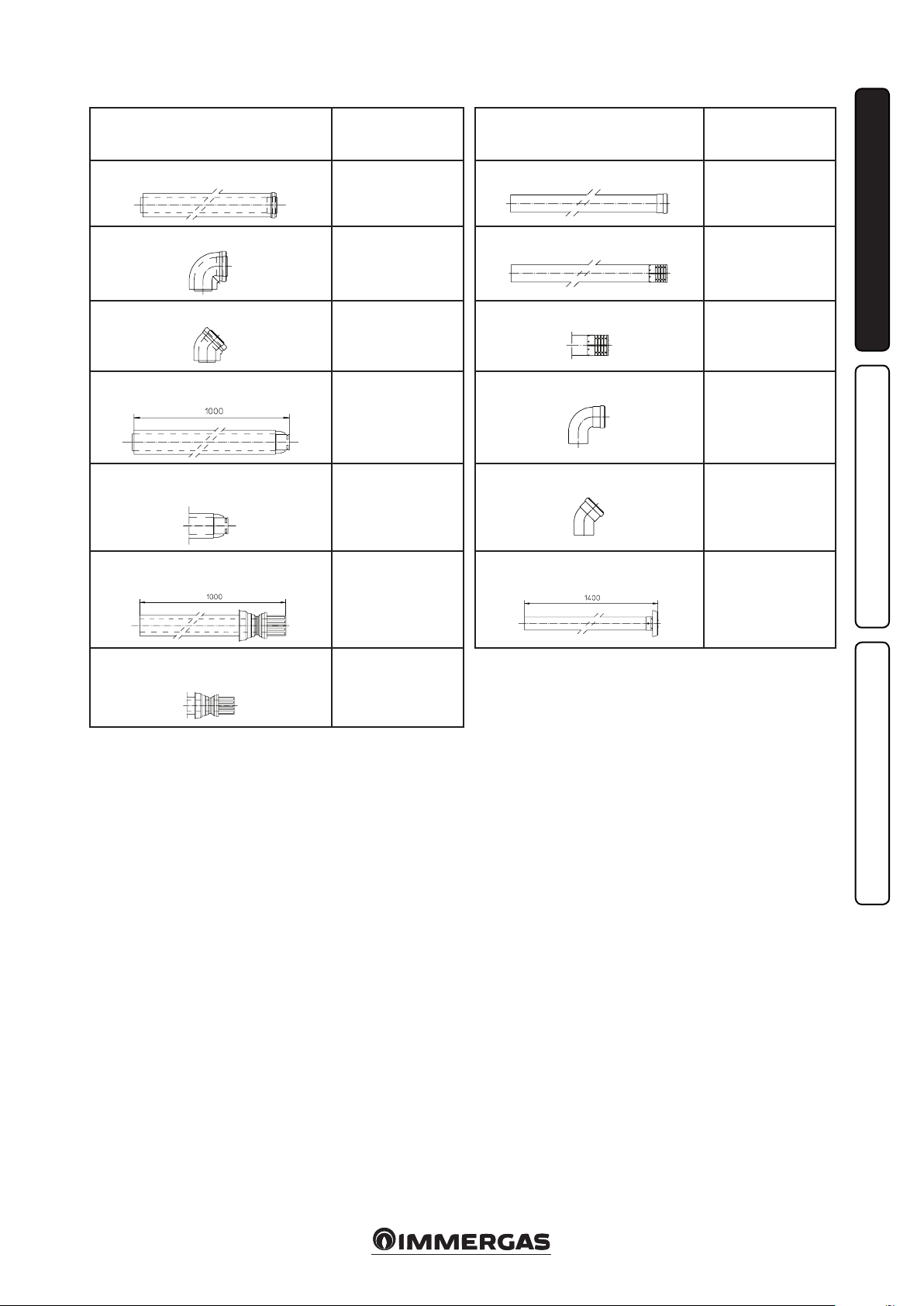

1.13 TABLES OF EQUIVALENT LENGTH FACTORS.

Equivalent length in

DUCT TYPE

Concentric pipe 80/125 Ø m 1

m of concentric pipe

80/125 Ø

1.0 m

DUCT TYPE

Pipe 80 Ø, 1 m

Equivalent length in

metres of pipe 80 Ø

Exhaust

1.0 m

Concentric bend 90° 80/125 Ø

Concentric bend 45° 80/125 Ø

Terminal complete with concentric

horizontal intake-exhaust 80/125 Ø

Concentric horizontal intake-exhaust

terminal 80/125 Ø

Terminal complete with concentric verti-

cal intake-exhaust 80/125 Ø

Concentric vertical intake-exhaust

terminal 80/125 Ø

1.9 m

1.4 m

5.5 m

4.7 m

3.4 m

2.7 m

Complete exhaust terminal 80 Ø, 1 m

Exhaust terminal 80 Ø

Bend 90° 80 Ø

Bend 45° 80 Ø

Terminal complete with vertical ex-

haust 80 Ø

Exhaust

2.6 m

Exhaust

1.6 m

Exhaust

2.1 m

Exhaust

1.3 m

Exhaust

m 3

INSTALLERUSER

11

11

MAINTENANCE TECHNICIAN

1.14 CONCENTRIC HORIZONTAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Installation of this terminal must comply with

the provisions set forth by all of the legislation

and regulations in force that may allow, in certain

cases, wall ue exhaust for low-NOx condensing

boilers.

e position of the terminal (in terms of distances from openings, overlooking buildings,

INSTALLERUSER

decking, etc.) must be set up in compliance with

regulations in force as well as the references of

good technique.

is terminal is connected directly to the outside

of the building for air intake and ue exhaust. e

horizontal kit can be installed with the rear, right

side, le side or front outlet. For installation with

frontal outlet, one must use the xing plate and

a concentric bend coupling in order to ensure

sucient space to carry out the tests required

by law upon commissioning.

• External grid. e intake/exhaust terminal,

if properly installed, is pleasant to look at on

the outside of the building. Make sure that

the external silicone sealing plate is properly

inserted in the wall.

Horizontal intake-exhaust kit Ø 80/125 Kit

assembly (Fig. 1-10): install the 80/125 Ø adapter

(1) on the central hole of the boiler fully home.

Slide the gasket (2) along the adapter (1) up to

the relevant groove, x it to the lid using the previously disassembled sheet steel plate (3) Engage

the bend (4) with the male side (smooth) until it

is fully home on the adapter (1). Fit the 80/125

Ø (5) concentric terminal pipe with the male

end (smooth) to the female end of the bend (4)

(with lip seals) up to the stop; making sure that

the internal (6) and external wall sealing plates

(7) have been tted, this will ensure sealing and

joining of the elements making up the kit.

• Maximum length (MAX L) (Fig. 1-11). e kit

with this conguration can be extended up to

a max. measurement of 11.0 m with Victrix Pro

80 2ErP, 8.0 m with Victrix Pro 100 2ErP and

5.0 m with Victrix Pro 120 2ErP, including the

grid-covered terminal and the concentric bend

on the boiler outlet.

MAINTENANCE TECHNICIAN

4

5

3

e kit includes:

2

1 - Adaptor 80/125 Ø (1)

1 - Gasket (2)

1

1 - Concentric bend 80/125 Ø at 87° (4)

1 - Int./exhaust concentric terminal

1 - Internal ring (6)

1 - External ring (7)

6

7

80/125 Ø (5)

C13

1-10

C13

1-11

12

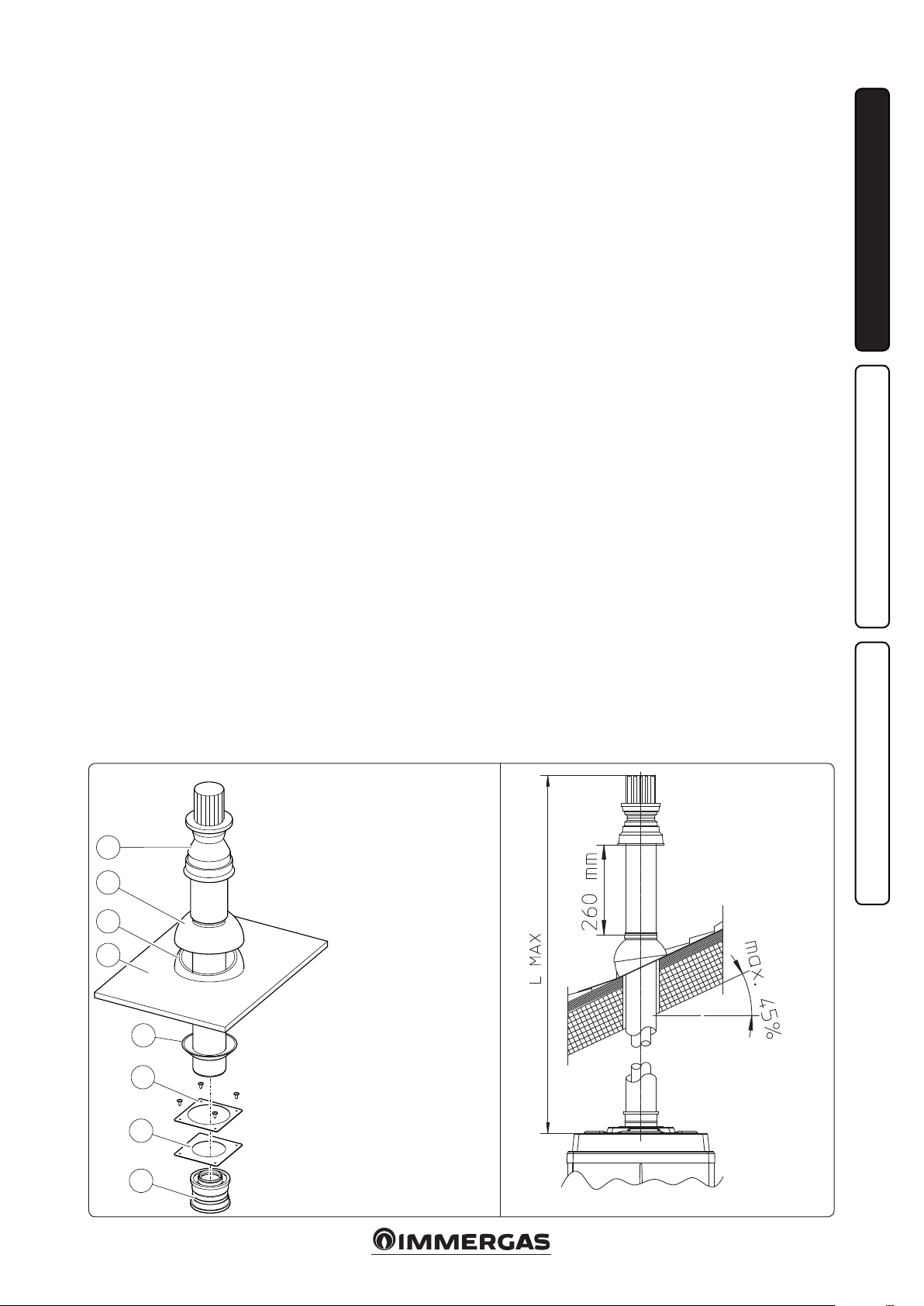

1.15 CONCENTRIC VERTICAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Concentric vertical intake and exhaust kit. is

vertical terminal is connected directly to the outside of the building for air intake and ue exhaust.

N.B.: the vertical kit with aluminium tile enables installation on terraces and roofs with a

maximum slope of 45% (approx. 25°) and the

height between the terminal cap and half-shell

(260 mm) must always be observed.

Vertical kit with aluminium tile 80/125 Ø.

Kit assembly (Fig. 1-13): Install the 80/125 Ø

adapter (1) on the central hole of the boiler fully

home. Slide the gasket (2) along the adapter (1)

up to the relevant groove, Fix it to the lid using

the previously disassembled sheet steel plate (3)

Installation of the fake aluminium tile: replace

the tiles with the aluminium sheet (5), shaping

it to ensure that rainwater runs o. Position the

xed half-shell (6) on the aluminium tile and

insert the intake-exhaust pipe (7). Fit the 80/125

Ø concentric terminal pipe with the male end

(6) (smooth) to the female end of the adapter

(1) (with lip gasket) up to the stop; making sure

that the wall sealing plate (4) has been tted, this

will ensure sealing and joining of the elements

making up the kit.

• Maximum length (MAX L) (Fig. 1-13). e kit

with this conguration can be extended up to

a max. measurement of 15.0 m with Victrix Pro

80 2ErP, 11.0 m with Victrix Pro 100 2ErP and

6.0 m with Victrix Pro 120 2ErP, including the

terminal.

INSTALLERUSER

C33C33

8

7

6

5

e kit includes:

1 - Adaptor 80/125 Ø (1)

4

3

1 - Gasket (2)

1 - Ring (4)

1 - Aluminium tile (5)

1 - Fixed half-shell (6)

1 - Int./exhaust concentric terminal

80/125 Ø (7)

1 - Mobile half-shell (8)

2

1

1-12 1-13

MAINTENANCE TECHNICIAN

13

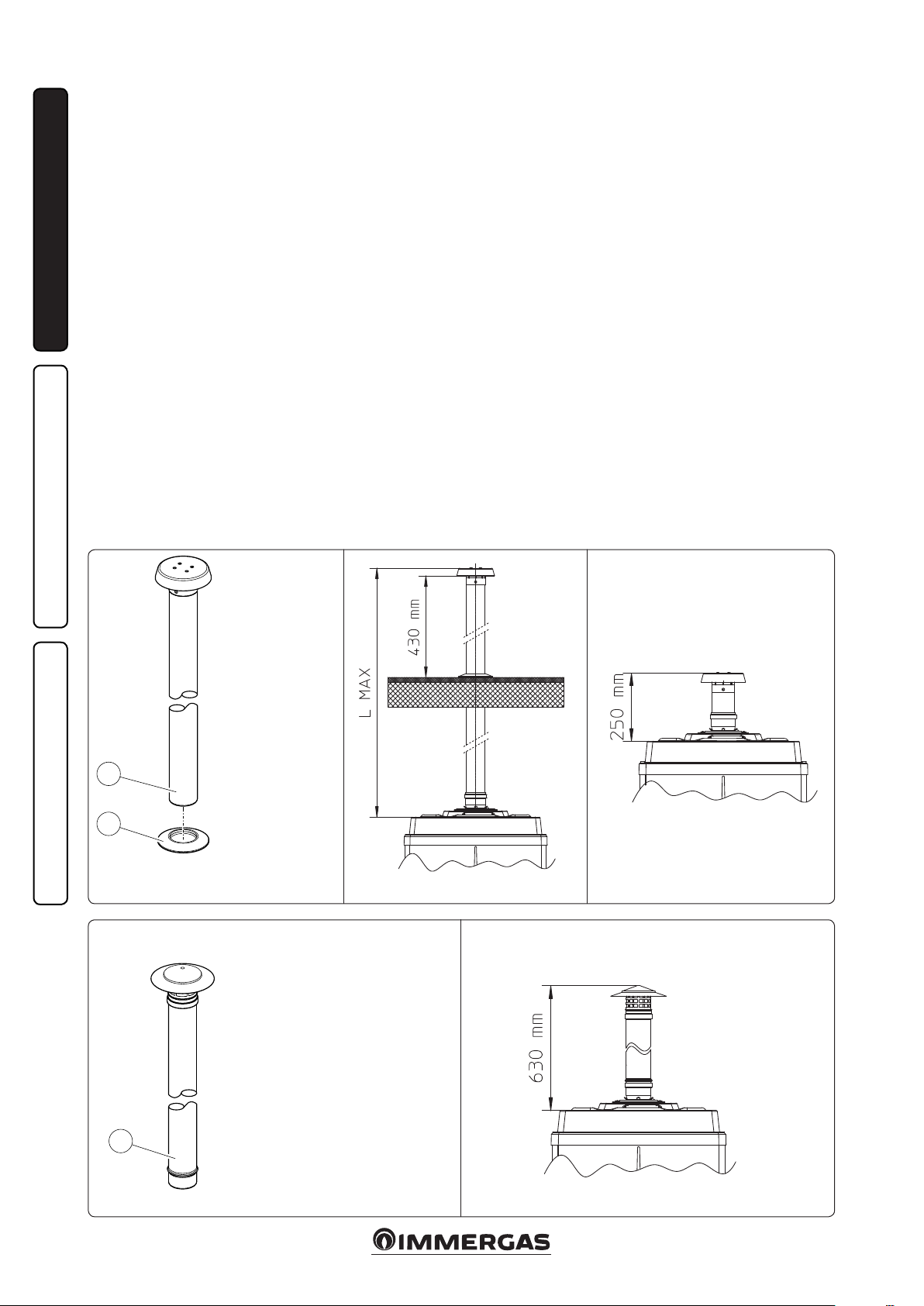

1.16 INSTALLATION OF VERTICAL

TERMINALS 80 Ø.

Configuration type B, open chamber and

forced draught.

80 Ø Vertical kit (plastic for indoor applications).

Kit assembly (Fig. 1-14): install the 80 Ø terminal

(2) on the central hole on the boiler up to stop,

making sure that the wall sealing plates (1) have

been tted. is will ensure the sealing eciency

of the kit components.

INSTALLERUSER

• Maximum length (MAX L) (Fig. 1-15). e kit

with this conguration can be extended up to

a max. measurement of 28.0 m with Victrix Pro

80 2ErP, 14.0 m with Victrix Pro 100 2ErP and

8.5 m with Victrix Pro 120 2ErP, including the

terminal.

Using the 80 Ø vertical terminal for direct discharge of the combustion products, the terminal

must be shortened (see quotas g. 1-16). e wall

sealing plate (1) must also be inserted in this case,

going up to stop on the boiler cover.

80 Ø Vertical kit (steel for outdoor applications).

Kit assembly (Fig. 1-17): install the 80 Ø terminal

(1) on the central hole on the boiler up to the

stop, ensuring the sealing eciency of the kit

components.

e 80 Ø steel terminal is used to install the boiler

outdoors with a direct exhaust. e terminal

cannot be shortened and once it is installed it

will extend out by 630 mm (Fig. 1-18).

MAINTENANCE TECHNICIAN

B23

e kit includes:

1 - Ring (1)

1 - 80 Ø exhaust

terminal (2)

B23

B23

2

1

1-14

B23

1-15

1-16

B23

e kit includes:

1 - Steel 80 Ø exhaust terminal (1)

1

1-17

1-18

14

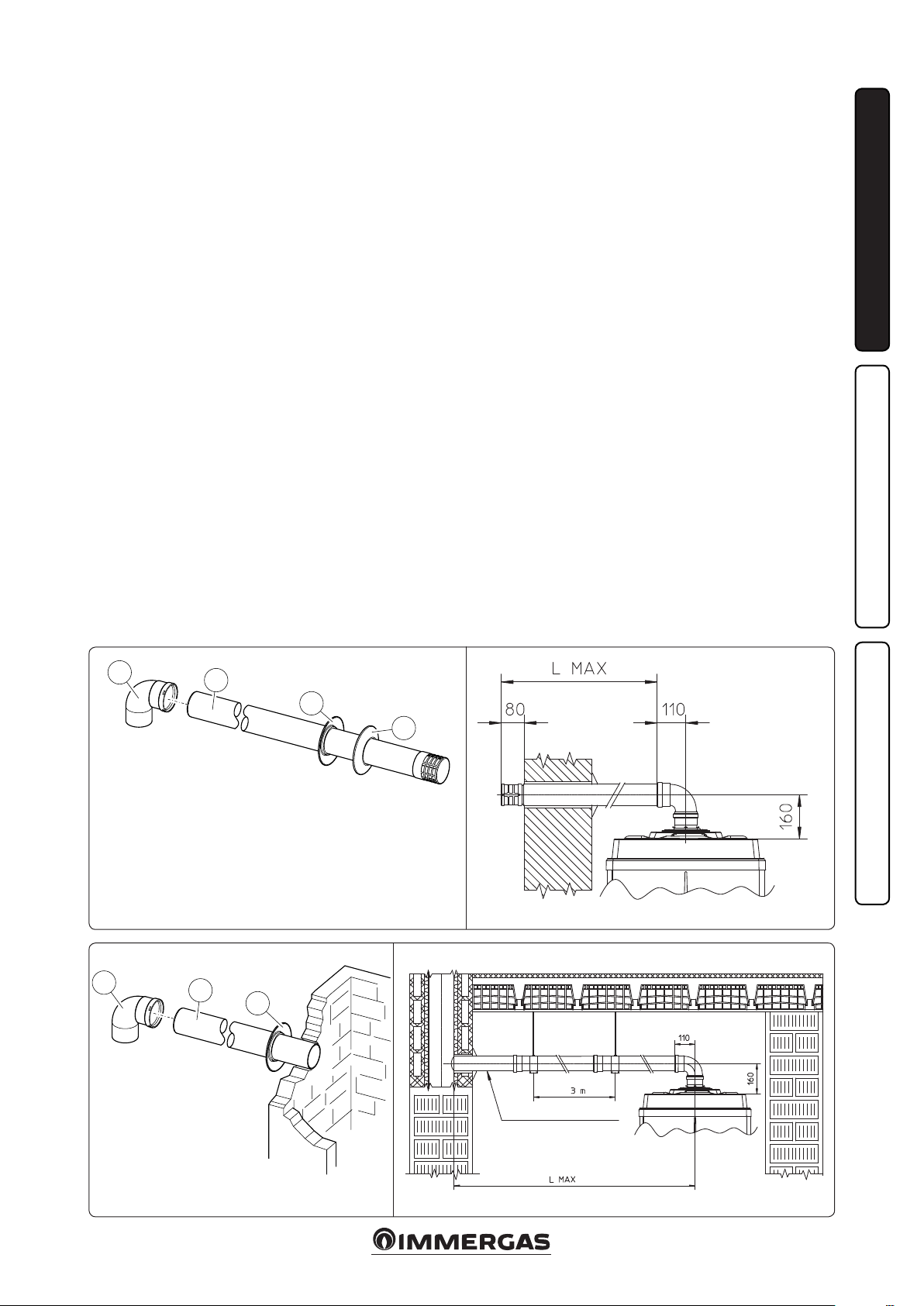

1.17 INSTALLATION OF 80 Ø

HORIZONTAL TERMINALS.

Configuration type B, open chamber and

forced draught.

80 Ø horizontal kit with wall ue exhaust.

Kit assembly (Fig. 1-19): install the 80 Ø bend (1)

with the male side (smooth) fully home on the

central hole of the boiler. Fit the exhaust terminal

(2) with the male end (smooth) to the female

end of the bend (1) up to the stop; making sure

that the internal (3) and external (4) wall sealing

plate has been tted. is will ensure sealing and

joining of the elements making up the kit.

Horizontal kit 80 Ø with exhaust in ue. Kit

assembly (Fig. 1-21): install the 80 Ø bend (1)

with the male side (smooth) fully home on the

central hole of the boiler. Fit the exhaust pipe (2)

with the male end (smooth) to the female end of

the bend (1) up to the stop; making sure that the

internal wall sealing plate (3) has been tted. is

will ensure sealing and joining of the elements

making up the kit.

• Maximum length (MAX L) (Fig. 1-20 and 22).

e kit with this conguration can be extended

up to a max. measurement of 28.0 m with Victrix

Pro 80 2ErP, 14.0 m with Victrix Pro 100 2ErP

and 8.5 m with Victrix Pro 120 2ErP, including

the terminal.

INSTALLERUSER

1

e kit includes:

1 - 90° 80 Ø bend (1)

1 - 80 Ø exhaust terminal (2)

1 - Internal ring (3)

1 - External ring (4)

1

e kit includes:

1 - 90° 80 Ø bend (1)

1 - 80 Ø drain pipe (2)

1 - Internal ring (3)

2

2

B23

B23

3

4

MAINTENANCE TECHNICIAN

1-19 1-20

B23 B23

3

Minimum slope 1.5 %

1-21

1-22

15

Loading...

Loading...