Immergas VICTRIX 50 User Manual

Wall mounted condensing boilers with low NOx

VICTRIX 50

1

1 SPECIFICATIONS

50 kW (43,000 kcal/h) wall-mounted premixed condensing boiler

with sealed or open chamber, forced draught, high efciency and

forced circulation.

Approved for installation in both heating plants and outside buildings. Can be used in two congurations:

Open chamber and forced draught (appliance type B23/ B

33

)

- Does not need any additional kit as it leaves the factory in this

conguration.

Sealed chamber and forced draught (appliance type C13/C33/C63)

- if installed using the vertical or horizontal concentric kits.

The generator consists of:

• combustion system of the total premixing type with cylindricel

multigas burner made of steel, complete with ignition electrodes

and ionizing monitoring probe;

• pneumatic type gas valve with double shutter;

• primary gas/water exchanger with coil made of AISI 316L stainless

steel;

• combustion chamber in stainless steel insulated on the inside with

ceramic panels;

• fumes extraction fan with electronically variable speed;

• condensation disposal circuit including syphon and exible drain

hose;

• hydraulics consisting of a delivery manifold, primary circuit

pressure switch, circulation pump including automatic air venting

valve;

• 4 bar system safety valve (ISPESL approved), pressure gauge for

the heating system;

• overtemperature safety thermostat;

• control panel equipped with electronic board with microprocessor

and innite ame modulation for the heating process plus P.I.D.

monitoring, modulation ranging from 10.0 to 50.0 kW (from 8,600

to 43,000 kcal/h);

• system delivery regulating probe;

• system return regulating probe;

• heating delivery temperature with 20 to 85°C factory setting;

• ignition delayer during the heating phase, antifreeze protection,

pump anti-blocking system, chinmey-sweep function;

• the boiler operating parameters can be entered and regulated by

means of keys while the status and operating modes are shown

on the 4-digit display;

• autodiagnosis system with digital display of the temperature,

the operating status and error codes on the permanently visible

display;

• IPX5D electrical insulation degree;

• pre-engineered for connection of the Series Regulator and external

probe;

• pre-engineered for connection of an external three-way valve for

use with a separate water heater in order to produce domestic hot

water;

• pre-engineered for operation in series (up to 3 generators);

• pre-engineered for installation of the ISPESL-approved safety

stub pipe;

• can be used with the Ø 80 mm hose pipe connecting system.

Supplied complete with traps for combustion analysis, bottom

protection grille and gas on-off cock.

Natural gas and L.P.G. fuelled Class II

2H3+

appliance. CE marking.

The following model is available:

• VICTRIX 50 code 3.015276

NOTE: to correctly install the boiler, use the "Green series" Immergas

air intake/fumes exhaust kit dedicated to the VICTRIX 50 boiler in

both the single and series (bank) congurations.

VICTRIX 50 is the new wall-mounted condensing boiler for

room heating alone. It is pre-engineered for operation both

independently and in series (up to 3 appliances connected),

with the advantage of providing a globally higher efciency at lower running costs. Condensing technology allows

particularly high efciency ratings to be achieved (4 stars,

as established by Directive 92/42/EEC). VICTRIX 50's high

power is ideal when it comes to heating domestic systems

that have to deal with large volumes (semi-detached houses,

small condominiums and apartment blocks) and for commercial and industrial uses. If a single boiler is installed, an

external three-way valve can be connected so as to use it

with a separate water heater and produce domestic hot water. A hydraulic manifold can also be connected to boost the

circulation in the system, thus making it versatile and quick

to install. When operation is in series, several distribution

manifolds can be connected by means of threaded mechanisms. The special environment-friendly burner guarantees

particularly low polluting emissions (the boiler belongs to the

most environment-friendly class established by the European

standards, i.e. class 5).

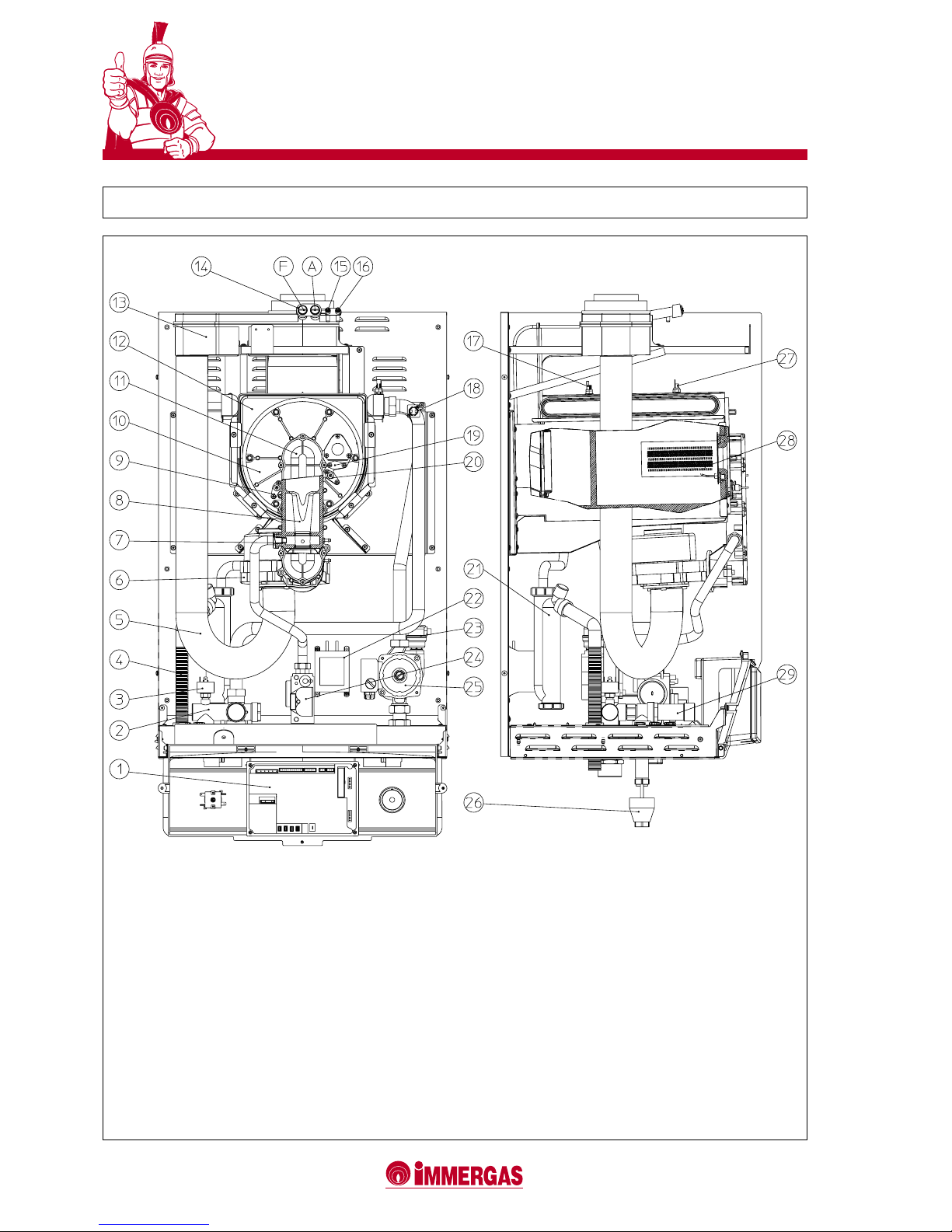

2

VICTRIX 50

3

VICTRIX 50

LEGEND:

1 - Electronic board

2 - Delivery manifold

3 - System pressure switch

4 - Condensation drain pipe

5 - Air intake pipe

6 - Air fan

7 - Gas nozzle

8 - Venturi

9 - Detection electrode

10 - Cover of condensing module

11 - Sleeve with Venturi housing

12 - Condensing module

13 - Draught diverter

14 - Intakes (air A) - (fumes F)

15 - Positive signal pressure point

16 - Negative signal pressure point

17 - System return regulating NTC probe

18 - Overtemperature safety thermostat

19 - Dummy electrode

20 - Ignition plug

21 - Condensate syphon

22 - Current transformer

23 - Air venting valve

24 - Gas valve

25 - Circolulation pump

26 - Drain funnel

27 - System delivery regulating NTC probe

28 - Burner

29 - 4-bar safety valve

2 MAIN COMPONENTS

3

VICTRIX 50

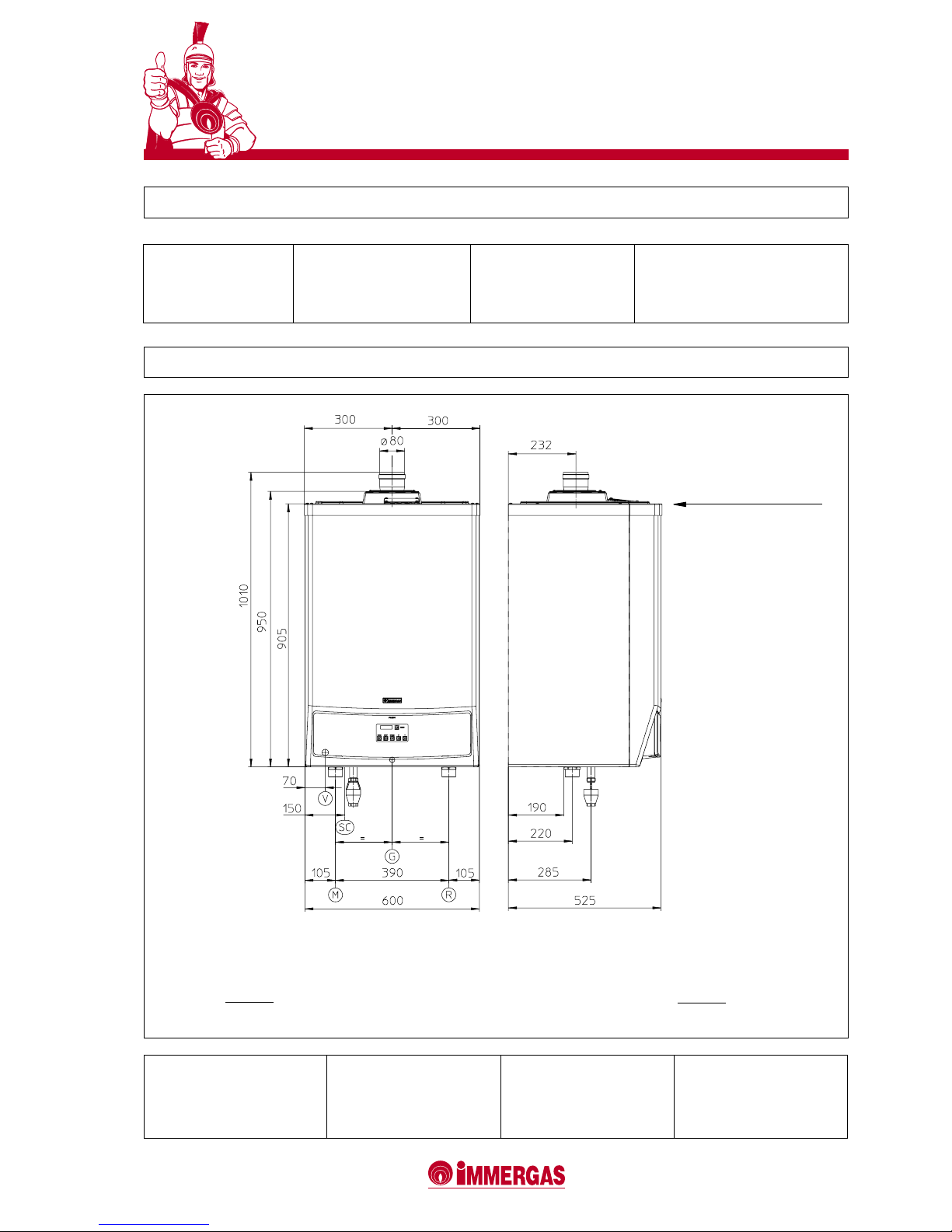

Upper casing line

3 MAIN DIMENSIONS

3.1 CONNECTIONS

SC = Condensation discharge

Distance between upper casing line and Ø 80 outlet

elbow: 170 mm

Distance between upper casing line and Ø 80/125

concentric inlet/outlet elbow: 200 mm

Model

VICTRIX 50

System delivery

M

1" 1/2

System return

R

1" 1/2

Gas supply

G

3/4"

Model

VICTRIX 50

Height mm

950

Width mm

600

Depth mm

525

4

VICTRIX 50

5

VICTRIX 50

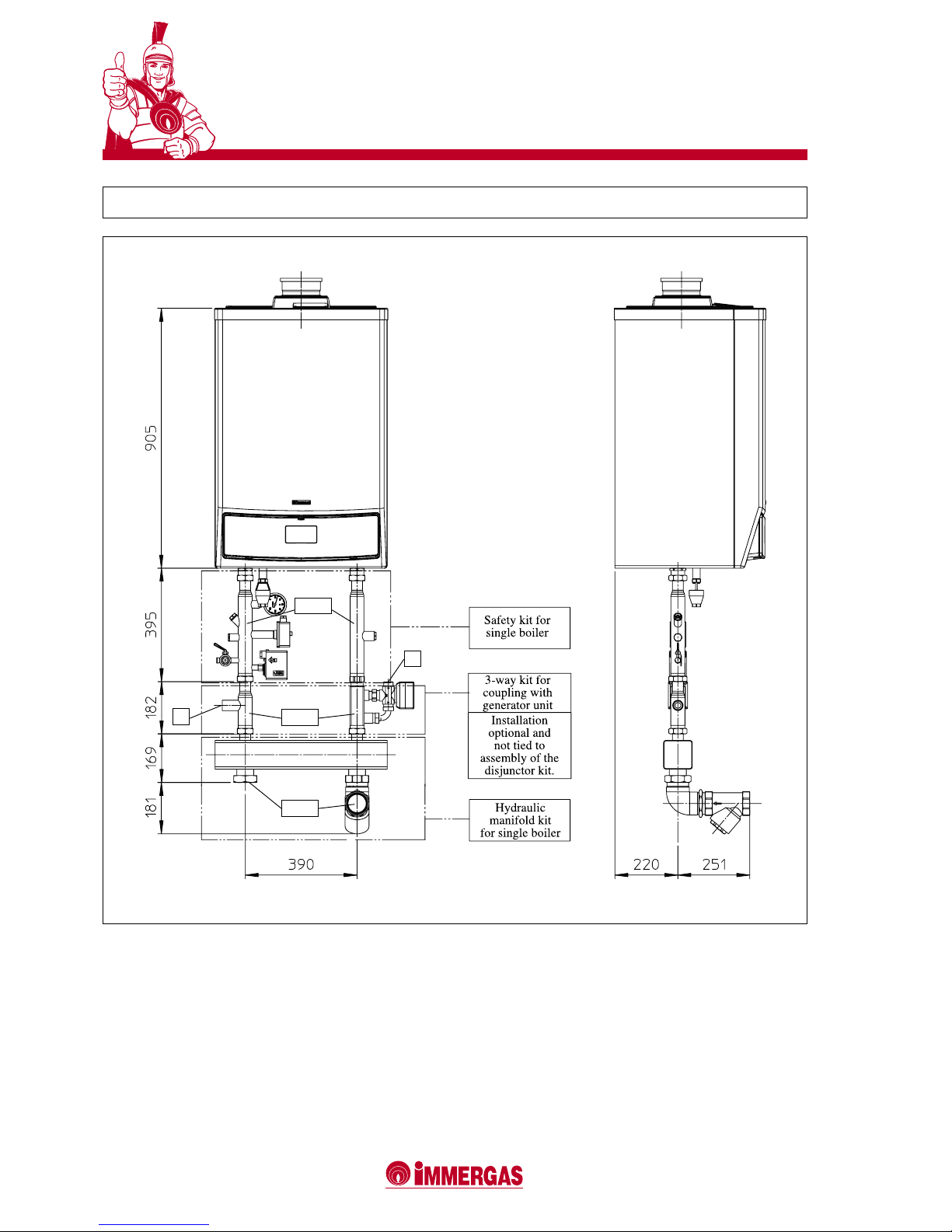

4 DIMENSIONS AND WET CONNECTIONS (OPTIONAL) WITH A SINGLE BOILER

NOTE: Unlike the appliance, the ISPESL safety kit and the

three-way valve kit (electric valve motor) have the IPX4D

electrical protection degree. If the appliance is installed outdoors, these safety devices and components must therefore

be adequately protected.

Immergas declines all liability if the installer fails to use the

genuine ISPESL-approved devices and kits manufactured by

Immergas, or uses them improperly.

The sensitive parts of the automatic thermal regulating and

blocking switches and those of the thermometer (not part of

the standard supply provided with the generator) must be

M

R

positioned as described in the installation instructions, in

compliance with the provisions given in the "R" le.

For ISPESL planning reasons, an ISPESL-approved pressure

gauge must be added when the Immergas safety kit is installed (as part of the standard supply, the boiler comes already

equipped with an ISPESL-approved 4-bar safety valve and

drain funnel).

The system return is pre-engineered with an expansion tank

connection.

1" 1/2

1" 1/2

1"

2" 1/2

1"

5

VICTRIX 50

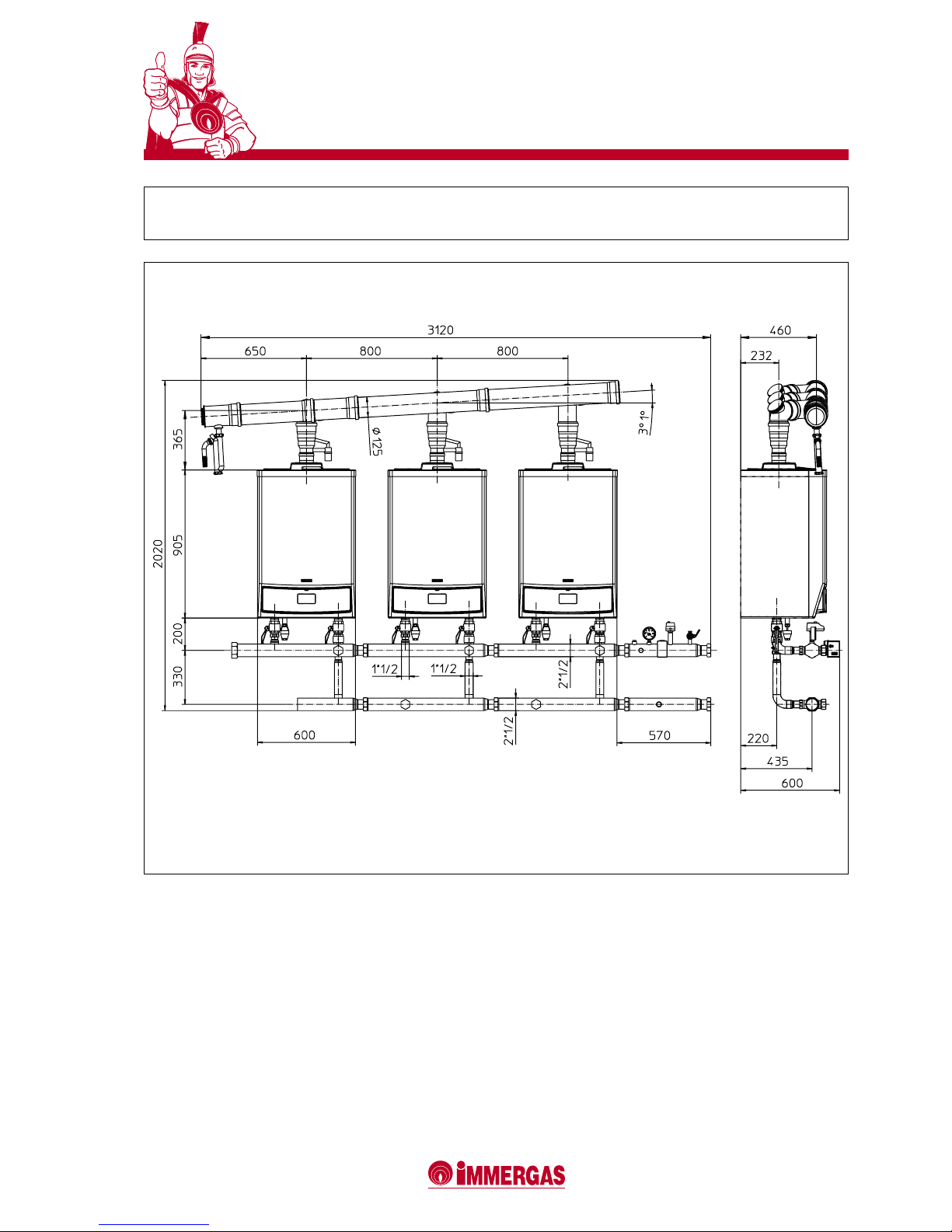

5 DIMENSIONS AND WET CONNECTIONS (OPTIONAL) WITH BOILERS IN SERIES

(UP TO THREE APPLIANCES)

NOTE: Unlike the appliance, the ISPESL safety kit has the

IPX4D electrical protection degree. If the appliance is installed

outdoors, these safety devices must therefore be adequately

protected.

Immergas declines all liability if the installer fails to use the

genuine ISPESL-approved devices and kits manufactured by

Immergas, or uses them improperly.

The sensitive parts of the automatic thermal regulating and

blocking switches and those of the thermometer (not part of

the standard supply provided with the generator) must be

positioned as described in the installation instructions, in

compliance with the provisions given in the "R" le.

For ISPESL planning reasons, an ISPESL-approved pressure

gauge must be added when the Immergas safety kit is instal-

led (as part of the standard supply, the boiler comes already

equipped with an ISPESL-approved 4-bar safety valve and

drain funnel).

The system return is pre-engineered with an expansion tank

connection.

The modular generators, or ones installed in the series

conguration (bank) with the genuine Immergas hydraulic

manifold kit, must be considered a single appliance which

will have the serial number (factory number) of the generator

nearest to the ISPESL safety device.

The hydraulic manifolds are equipped with a check valve

installed on the return pipe and system on-off cocks on the

delivery and return pipes of each generator.

R

M

6

VICTRIX 50

7

VICTRIX 50

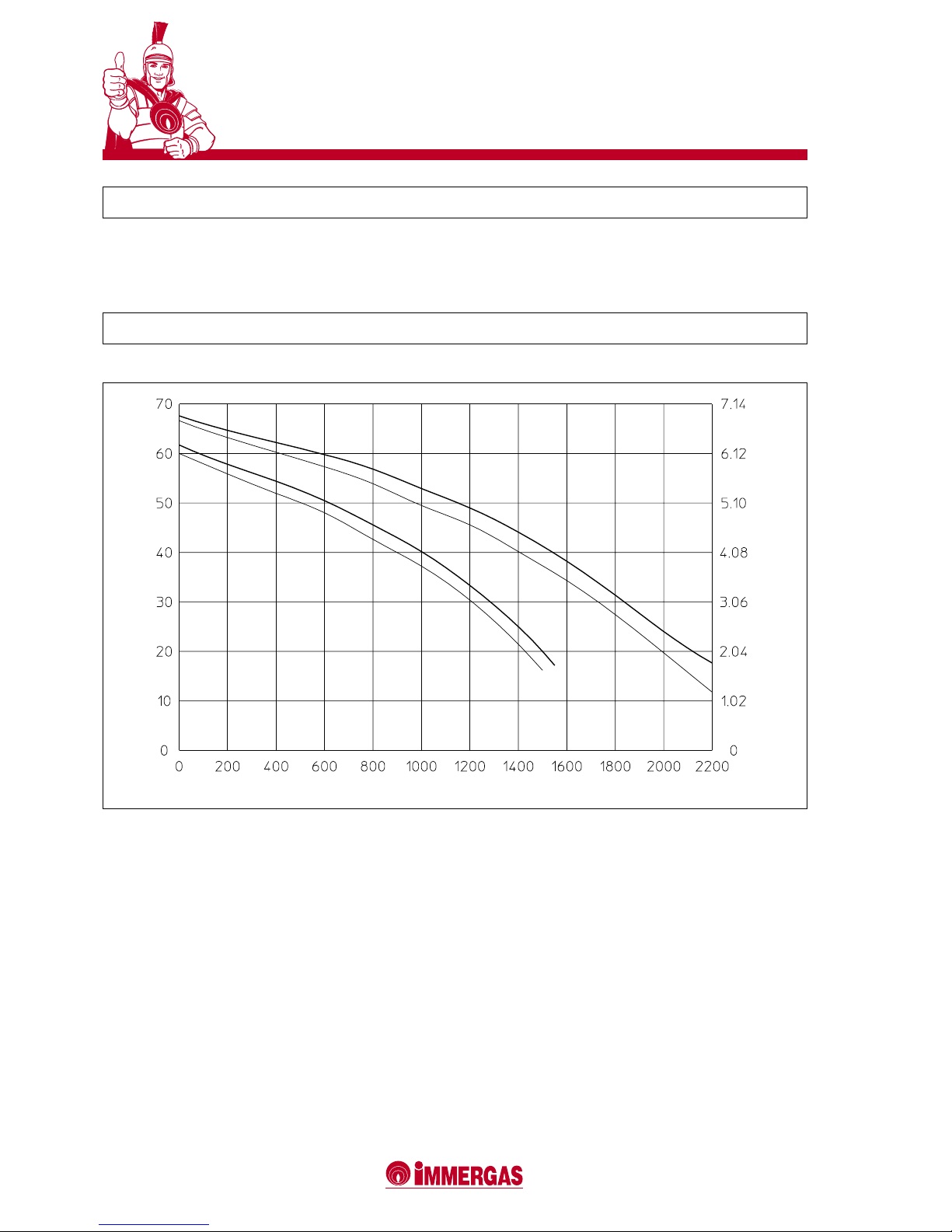

6 CIRCULATOR HEAD AND FLOW RATE GRAPH

VICTRIX 50 boilers are supplied with built-in circulator and

three-position electric speed governor.

The circulator is the single-phase type (230 V - 50 Hz) are co-

mes already equipped with condenser. In new systems (single

pipe and modules), it is advisable to use the circulator pump

at top speed to obtain optimum operation from the boiler.

A = Available head at top speed with single boiler

B = Available head at second speed with single boiler

C = Available head at top speed with check valve for boilers in series (bank)

D = Available head at second speed with check valve for boilers in series (bank)

DYL 63-15

Head (kPa)

A

Flow rate l/h

C

B

6.1 VICTRIX 50 CIRCULATOR

D

Head wc.)

7

VICTRIX 50

7 THERMOREGULATION SYSTEMS (OPTIONAL)

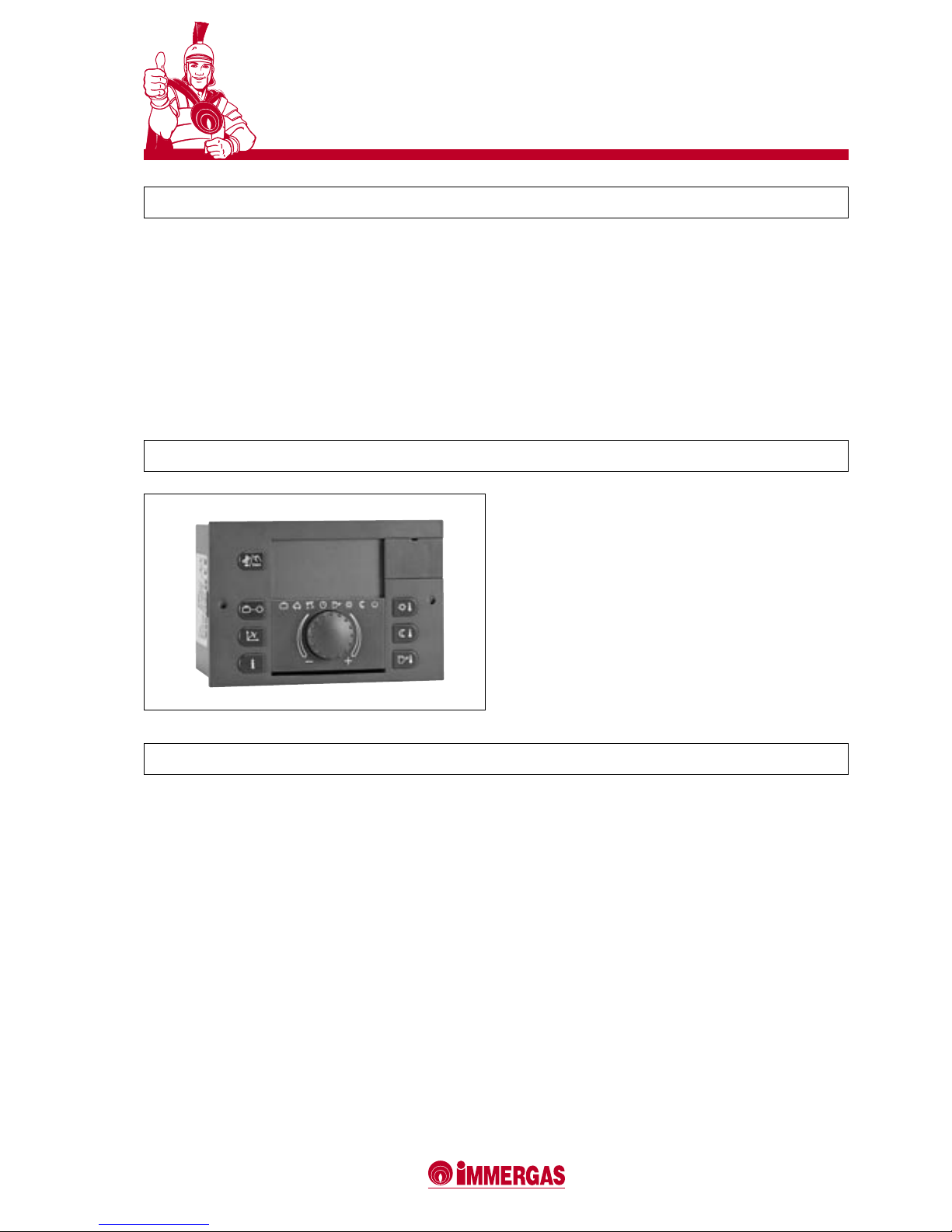

8 SERIES AND ZONE REGULATOR (CODE 3.015244)

Single modular generators or ones installed in series need an

adequate thermoregulation system able to dialogue with the

boiler in a simple way and meet the most varied operating

requirements.

This is why the VICTRIX 50 generator can be tted with a

series of accessories able to optimize the climatic adjustments

made to the entire system.

In short, VICTRIX 50 can be installed with two types of

system:

• In series (with the system divided into one or more zones),

using the series regulator with either the zone controller or

modulating ambient thermostat that regulates the heat in

the individual zones.

• Individually (with the system divided into zones) using the

series regulator with either the zone controller or modulating

ambient thermostat that regulates the heat in the individual

zones. A commercially available timer-thermostat can be

used if there is only one zone.

The Series and zone regulator allows the user to control, monitor and program the operating sequence of the generators

connected. The regulator can be set-up and programmed

using parameters that guarantee ideal temperature conditions at all times of the day and night and throughout every

day of the week for both the heating system and domestic

hot water system (when VICTRIX 50 is used in conjunction

with a water heater). The series regulator can be tted into a

support afxed to a wall.

8.1 SPECIFICATIONS

The electrical connections are made with 2 wires powered at

230V (1.5 mm2 ) in diameter.

2 BUS data cables up to 50 meters in length are used to

connect to the boiler, allowing the device to:

• control up to three zones (2 of which mixed if necessary)

and a separate water heater unit. Since up to 5 series regulators can be installed (of which only one, the so-called

Master, will be connected to the boiler board), systems with

up to a total 15 zones (of which 10 mixed if necessary) and

5 separate water heater units can be controlled;

• enter two ambient temperature values, one for the daytime

(comfort temp.) and one for the night (lower temp.);

• control the temperature of the domestic hot water (in

conjunction with a water heater Unit);

• select the operating mode for the heating and hot water

production functions of each individual hydraulic circuit:

- comfort temperature mode,

- low temperature mode,

- adjustable antifreeze temperature mode;

• control the boiler delivery temperature according to the outdoor temperature (in conjunction with the external probe),

with climatic curve settings;

• obtain information about the system:

- temperature of the system,

- operating mode,

- meter data,

- timer program,

- pump operating status,

- variable input values and operation;

• enter the operating parameters:

- operating times,

- operating mode,

- domestic hot water,

- direct, mixed 1, mixed 2 circuits,

- date and time;

• display operating faults with their relative error codes by

means of the check-control system;

• display the date, time, day of the week and temperature of

the generator.

8

VICTRIX 50

9

VICTRIX 50

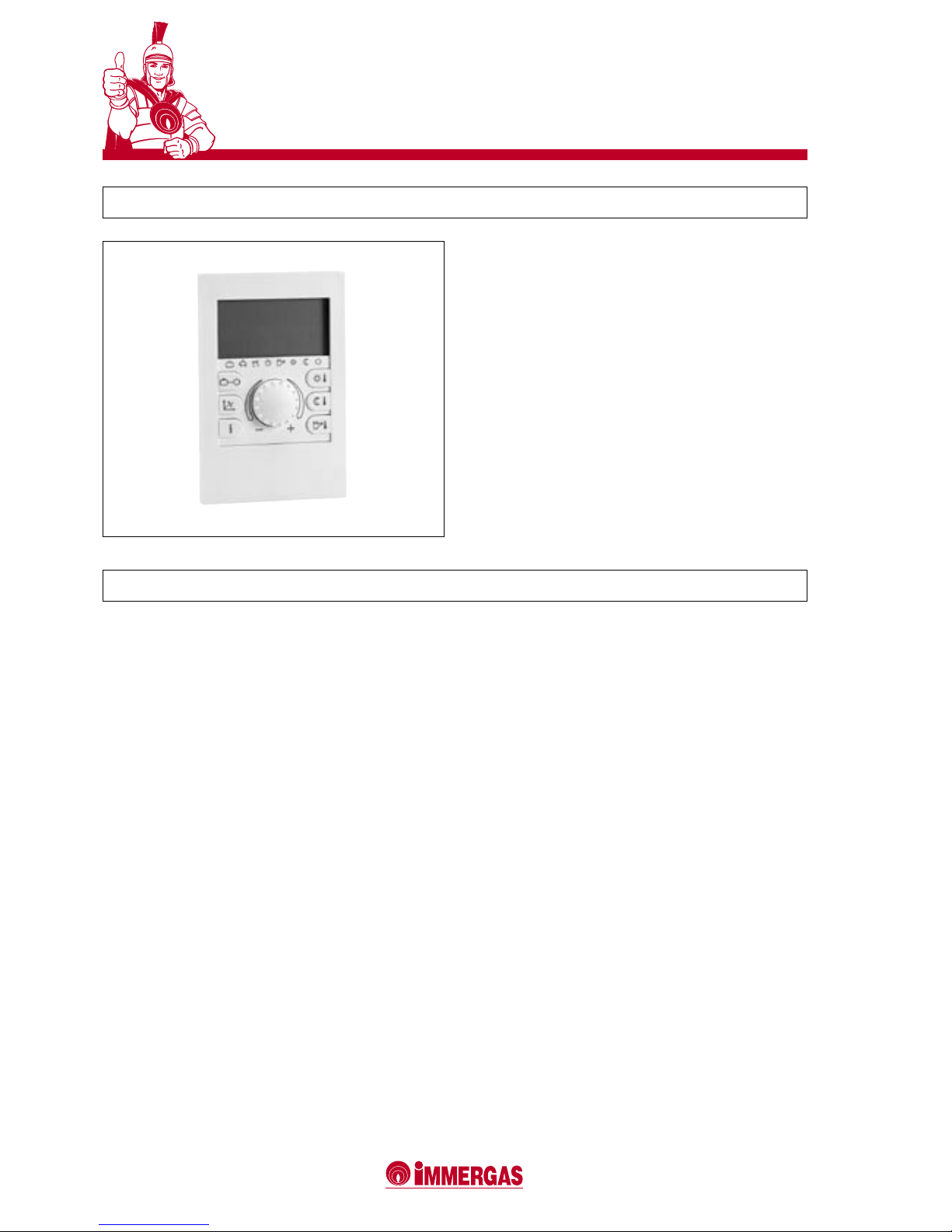

9 ZONE CONTROLLER (CE 3.015264)

The zone controller only operates in conjunction with the

series regulator. Besides the functions described for the series

thermoregulator, it allows the user to keep all the important

information concerning the operation of the appliance and

heating system under control and particularly ready to hand.

This means that the previously set parameters can be easily

modied without having go go to the place where the series

regulator is installed. the climatic timer-thermostat built

into the remote control panel allows the system's delivery

temperature to be adapted to the effective needs of the place

being heated so as to obtain the required ambient temperature

with the utmost precision and, thus, with evident savings in

running costs. The controller also allows the ambient temperature and effective outdoor temperature to be displayed (this

latter if the external probe is installed). The zone controller is

powered by the series thermoregulator by means of 2 BUS

data cables.

9.1 SPECIFICATIONS

2 BUS data cables up to 50 meters in length are used to

connect to the series and zone regulator, allowing the device

to:

• control up to one zone;

• enter two ambient temperature values, one for the daytime

(comfort temp.) and one for the night (lower temp.);

• control the temperature of the domestic hot water (in

conjunction with a water heater Unit);

• select the operating mode for the heating and hot water

production functions of each individual hydraulic circuit:

- comfort temperature mode,

- low temperature mode,

- adjustable antifreeze temperature mode;

• control the boiler delivery temperature according to the outdoor temperature (in conjunction with the external probe),

with climatic curve settings;

• obtain information about the system:

- temperature of the system,

- operating mode,

- meter data,

- timer program,

- pump operating status,

- variable input values and operation;

• enter the operating parameters:

- operating times,

- operating mode,

- domestic hot water,

- direct, mixed 1, mixed 2 circuits,

- date and time;

• display operating faults with their relative error codes by

means of the check-control system;

• display the date, time, day of the week and temperature of

the generator.

9

VICTRIX 50

11 EXTERNAL PROBE (CODE 3.015266)

The external probe allows the maximum temperature delivered to the system to be automatically lowered or raised as

the outdoor temperature rises or lowers, thus adapting the

heat supplied to the system to suit the outdoor temperature

variations.

The probe is connected straight to the boiler's terminal board

with two wires. Once connected, it always acts even without

the thermoregulation kit.

10 MODULATING AMBIENT THERMOSTAT (CODE 3.015245)

The modulating ambient thermostat (not a conventional

On/Off model) only operates in conjunction with the series

regulator and allows the user to regulate the ambient temperature of one of the zones into which the system is divided

(both in individual and series installations).

The regulation curve of the ambient temperature in the zone

can be modied by means of the series regulator itself.

The modulating ambient thermostat is powered by the series

thermoregulator via 2 BUS data cables.

10.1 SPECIFICATIONS

2 BUS data cables up to 50 meters in length are used to

connect to the series and zone regulator, allowing the device

to:

• control up to one zone;

• vary the ambient temperature of the zone;

• select the operating mode for the zone heating function:

- xed comfort temperature mode,

- xed low temperature mode,

- operation with the timer program.

10

VICTRIX 50

11

VICTRIX 50

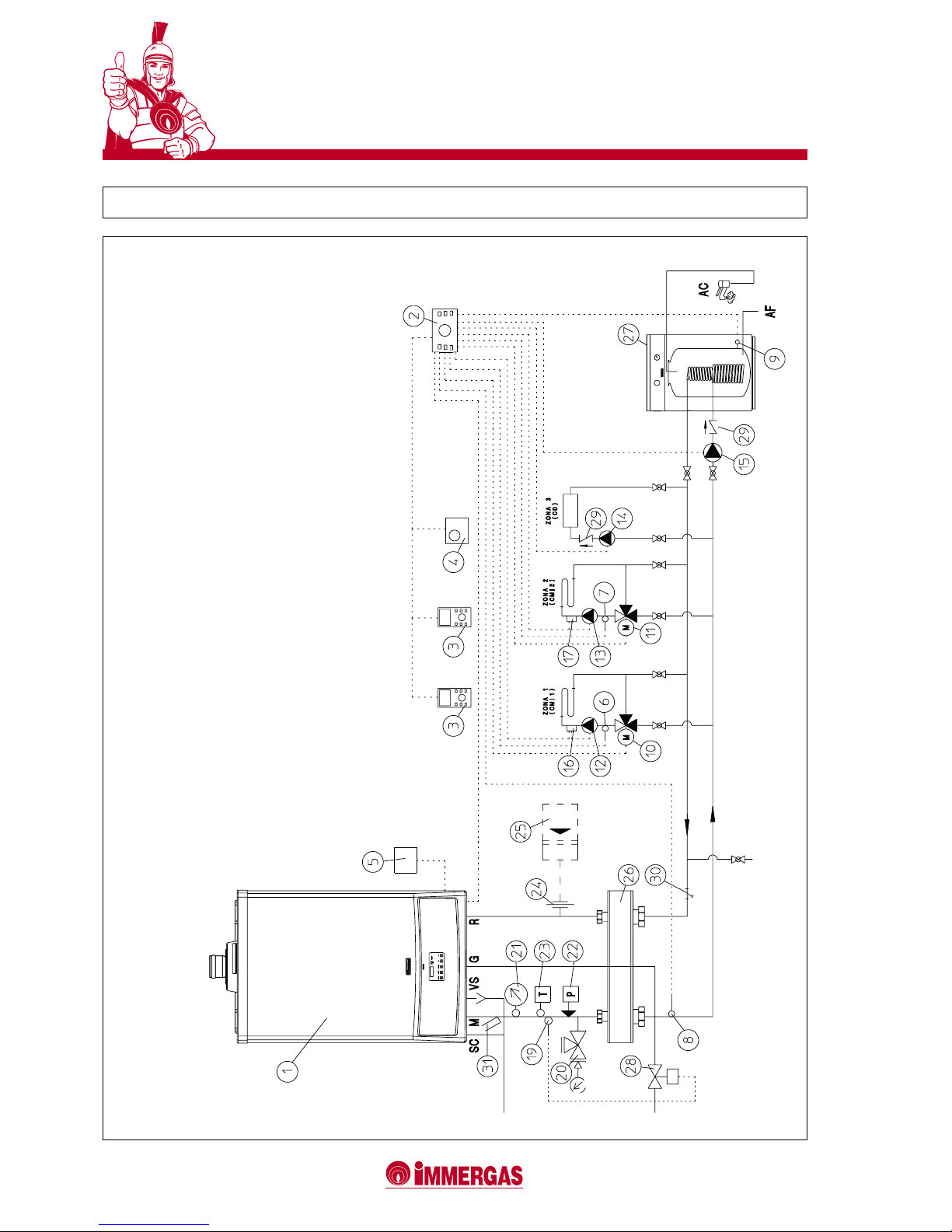

12 EXAMPLES OF VICTRIX 50 INSTALLATIONS WITH A SINGLE BOILER

LEGEND:

1 - VICTRIX 50 generator

2 - Series and zone regulator

3 - Zone controller

4 - Modulating ambient thermostat

5 - External probe

6 - Zone 1 temperature probe 1 (CMI-1)

7 - Zone 2 temperature probe 2 (CMI-2)

8 - Common delivery probe

9 - Temperature probe of Water heater unit

10 - Zone 1 mixer valve (CMI-1)

11 - Zone 2 mixer valve (CMI-1)

12 - Zone 1 heating circuit pump (CMI-1)

13 - Zone 2 heating circuit pump (CMI-2)

14 - Zone 3 direct circuit pump (CD)

15 - Water heater unit supply pump

16 - Zone 1 safety thermostat (CMI-1)

17 - Zone 2 safety thermostat (CMI-2)

19 - Fuel on-off valve bulb

20 - ISPESL approved pressure gauge cock

21 - ISPESL approved thermometer

22 - ISPESL approved manually reset pressure switch

23 - ISPESL approved manually reset thermostat

24 - Expansion tank connection

25 - Expansion tank

26 - Manifold/mixer

27 - External water heater unit

28 - Fuel on-off valve

29 - Check valve

30 - Sludge collecting system lter

31 - Thermometer trap

Loading...

Loading...