Page 1

GB

Instruction booklet

and warning

Installer

User

Technician

VICTRIX 20-27

Page 2

Dear Customer,

Congratulations for choosing a high quality Immergas product designed to ensure lasting comfort and safety. As an

Immergas customer you can always count on a qualied Authorized Assistance Service able to guarantee the constant

eciency of your boiler.

Read the following pages carefully as they contain important information on correct use of the boiler, enabling you to

make the most of the Immergas product.

Contact our local Authorized Assistance Centre as soon as possible to request the preliminary operation test. Our

technician will verify correct operating conditions, make the necessary adjustments and will show you how to use the

appliance correctly.

In the event of problems or ordinary maintenance requirements, contact Immergas Authorized Centres, which have the

availability of original parts as well as personnel specically trained by the manufacturer.

General instructions

e instruction booklet is an integral part of the product and must be consigned to the user with the appliance.

It must be kept in a safe place and read carefully as it contains important information to ensure safe installation use

and maintenance.

Installation and maintenance must be performed in compliance with current regulations, the manufacturer’s instructions

and by professionally qualied personnel having specic technical expertise in the sector of these systems.

Incorrect installation can cause damage to persons, animals or things, for which the manufacturer is not responsible.

Maintenance must be performed by qualied technical personnel; in this case, the Immergas Authorized Technical

Assistance Service represents a guarantee of qualication and professionalism.

e appliance must be used for the purpose for which it is expressly designed. Any other use is considered improper and

therefore hazardous.

In case of errors in installation, operation or maintenance, due to non-compliance with current technical regulations,

standards or the instructions contained in this booklet (or in any case supplied by the manufacturer) the manufacturer

is relieved of any contractual or non-contractual responsibility for possible damage and the relevant appliance warranty

is invalidated.

Page 3

INDEX

Immergas S.p.A. declines any responsibility for printing or transcription errors, and reserves the right to make any changes to

its technical and commercial lists without prior notice.

INSTALLER page

USER page

TECHNICIAN page

1 Boiler installation ...................................................................................................................................................... 3

1.1 Installation instructions.............................................................................................................................................3

1.2 Main dimensions. ..................................................................................................................................................... 3

1.3 Connections..............................................................................................................................................................4

1.4 Boiler installation - B23 type with open chamber and forced draught (optional)....................................................... 6

1.5 Air intake and fume exhaust terminal installation...................................................................................................... 7

1.6 Ducting existing ues.............................................................................................................................................. 12

1.7 Fume exhaust to ue/chimney................................................................................................................................. 13

1.8 Chimneys/ues. ......................................................................................................................................................13

1.9 Filling of system. ..................................................................................................................................................... 14

1.10 Condensate trap lling. ........................................................................................................................................... 14

1.11 Gas system start-up. ................................................................................................................................................14

1.12 Boiler start-up (lighting). ........................................................................................................................................ 14

1.13 Circulating pump.................................................................................................................................................... 14

1.14 Kits available by request. .........................................................................................................................................15

1.15 Boiler components - Victrix 20. ..............................................................................................................................16

1.16 Boiler components - Victrix 27. ..............................................................................................................................17

2 Use and maintenance instructions........................................................................................................................... 18

2.1 Cleaning and maintenance. ..................................................................................................................................... 18

2.2 General instructions. ...............................................................................................................................................18

2.3 Control panel.......................................................................................................................................................... 19

2.4 Restoring heating system pressure. ..........................................................................................................................20

2.5 Draining the system. ...............................................................................................................................................20

2.6 Anti-freeze protection. ............................................................................................................................................ 20

2.7 Casing cleaning. ......................................................................................................................................................20

2.8 Decommissioning. ..................................................................................................................................................20

3 Boiler start-up (preliminary check).......................................................................................................................... 21

3.1 Wiring diagram - Victrix 20.................................................................................................................................... 21

3.2 Wiring diagram - Victrix 27.................................................................................................................................... 22

3.3 Plumbing diagram - Victrix 20................................................................................................................................ 23

3.4 Plumbing diagram - Victrix 27................................................................................................................................ 24

3.5 Troubleshooting...................................................................................................................................................... 25

3.6 Converting the boiler to another type of gas............................................................................................................ 25

3.7 Checks following conversion to another type of gas. ............................................................................................... 25

3.8 Possible adjustments................................................................................................................................................ 25

3.9 Air/gas ratio adjustment Victrix 20 boiler................................................................................................................ 26

3.10 Air-gas ratio adjustment Victrix 27 boiler................................................................................................................ 26

3.11 Combustion parameters check. ...............................................................................................................................26

3.12 Adjustment of boiler rated heating power................................................................................................................ 26

3.13 Circulating pump operation.................................................................................................................................... 26

3.14 “Chimney Sweep” function..................................................................................................................................... 26

3.15 Pump antiblocking function. .................................................................................................................................. 26

3.16 Radiator antifreeze function. ................................................................................................................................... 27

3.17 System delivery temperature too high...................................................................................................................... 27

3.18 Casing removal. ...................................................................................................................................................... 30

3.19 Yearly appliance maintenance and check. ................................................................................................................ 31

3.20 Variable heat output - Victrix 20............................................................................................................................. 32

3.21 Variable heat output - Victrix 27............................................................................................................................. 32

3.22 Technical data - Victrix 20. ..................................................................................................................................... 33

3.23 Technical data - Victrix 27. ..................................................................................................................................... 34

Page 4

Key:

V - Electrical connection

G - Gas

U - Domestic hot water outlet

E - Domestic water inlet

R - System return

M - System delivery

S - Condensate drain (min. internal diameter Ø 13mm)

Important: wall mounting of the boiler must guarantee stable

and ecient support for the generator. e plugs supplied

standard with the appliance ensure adequate support only if

inserted correctly (according to technical standards) in walls

made of solid or cavity bricks. For walls made from bricks or

cavity blocks, partitions with limited static properties, or in

any case walls other than those indicated, a static test must

be carried out to ensure adequate support. ese boilers are

used to heat water to below boiling point at atmospheric

pressure. ey must be connected to a heating system and

domestic water circuit suitable for their performance and

output. Moreover, they must be installed in a place where

the temperature cannot fall below 0°C. ey must not be

exposed to atmospheric agents.

385 Victrix 27

350 Victrix 20

1

BOILER

INSTALLATION

1.1 Installation instructions.

Immergas gas appliances must be installed exclusively

by a professionally qualied and authorised technician.

Installation must be carried out according to the standards,

current legislation and in compliance with local technical

regulations and the required procedures. Before installing the

appliance, ensure that it is delivered in perfect condition; if

in doubt, contact the supplier immediately. Packing materials

(staples, nails, plastic bags, polystyrene foam, etc.) constitute

a hazard and must be kept out of the reach of children. If

the appliance is installed inside or between other cabinets or

furniture, ensure sucient space for normal maintenance; a

clearance of 2÷3 cm between the boiler casing and the sides

of the cabinet is recommended.

Keep all ammable objects (paper, rags, plastic, polystyrene,

etc.) away from the appliance. In case of anomalies, faults or

imperfect operation, the appliance must be deactivated; call a

qualied technician (e.g. the Immergas Technical Assistance

Centre, which has specic technical expertise and original

replacement parts). Never attempt to modify or repair the

appliance alone. Failure to observe the above implies personal

responsibility and invalidates the warranty.

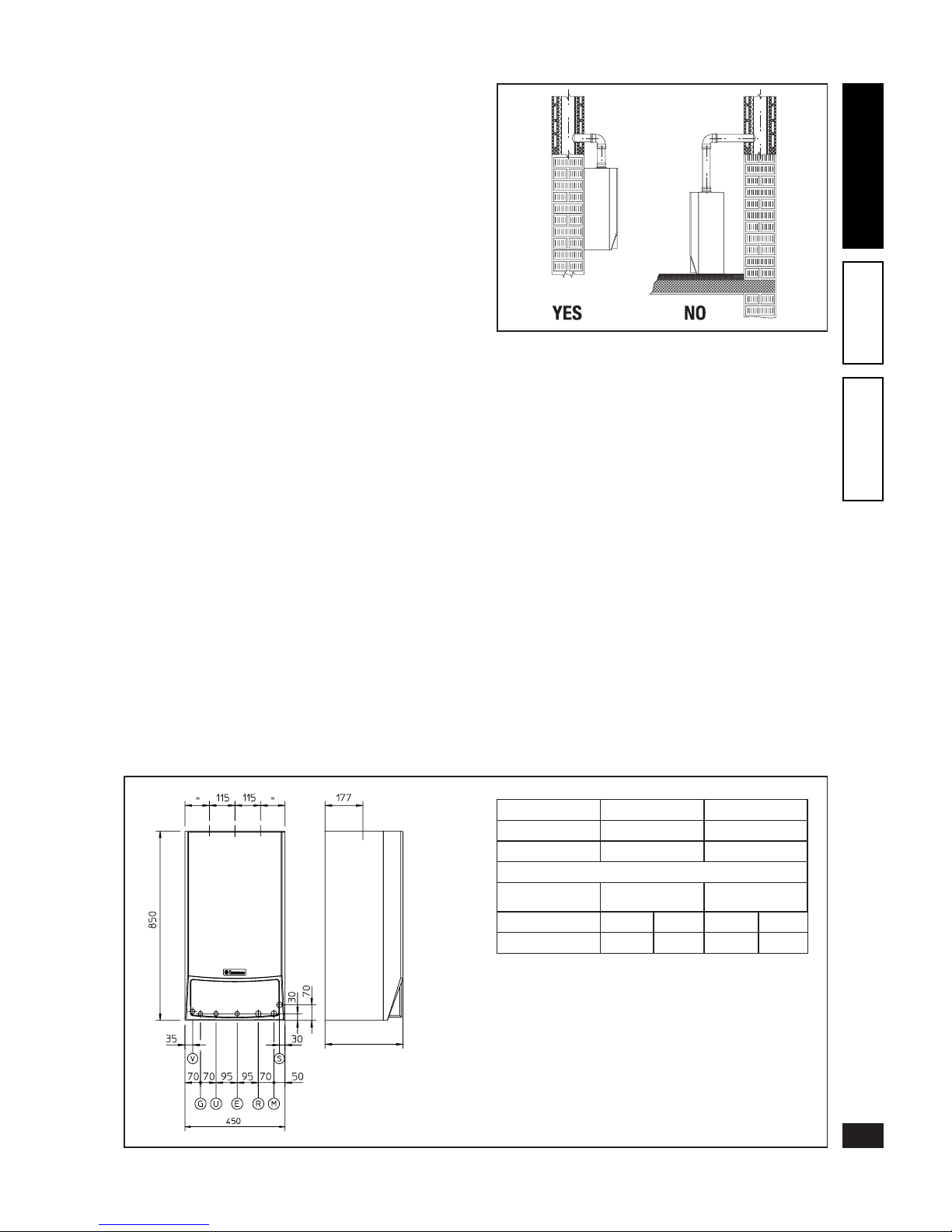

• Installation standards: these boilers are designed exclusively

for wall-mounted installation; they must be used for heating rooms and the production of domestic hot water and

similar uses. e wall surface must be smooth, without

any protrusions or cavities enabling access to the back

part. ey are NOT designed for installation on plinths

or oors (see g.).

1.2 Main dimensions.

Height (mm) Width (mm) Depth (mm)

850 450 350 - Victrix 20

385 - Victrix 27

CONNECTIONS

GAS

DOMESTIC

HOT WATER

SYSTEM

G U E R M

1/2” 1/2” 1/2” 3/4” 3/4”

3

INSTALLERUSERTECHNICIAN

Page 5

1.3 Connections.

Gas connection (Appliance category II

2H3+

).

Our boilers are built to operate on methane gas (G20) and

LPG. Supply pipes must be the same as or larger than the

1/2” G boiler tting. Before making the gas connection,

carefully clean the inside of all the gas supply piping in order

to remove any residue that could impair boiler eciency.

Also make sure the gas supply corresponds to that for which

the boiler is arranged (see boiler dataplate). Otherwise, the

appliance must be converted for operation with the other

type of gas (see converting appliances for another type of

gas). e dynamic gas supply pressure must also be checked

(natural or LPG) according to the type used in the boiler;

as insucient levels can reduce generator output and cause

malfunctions.

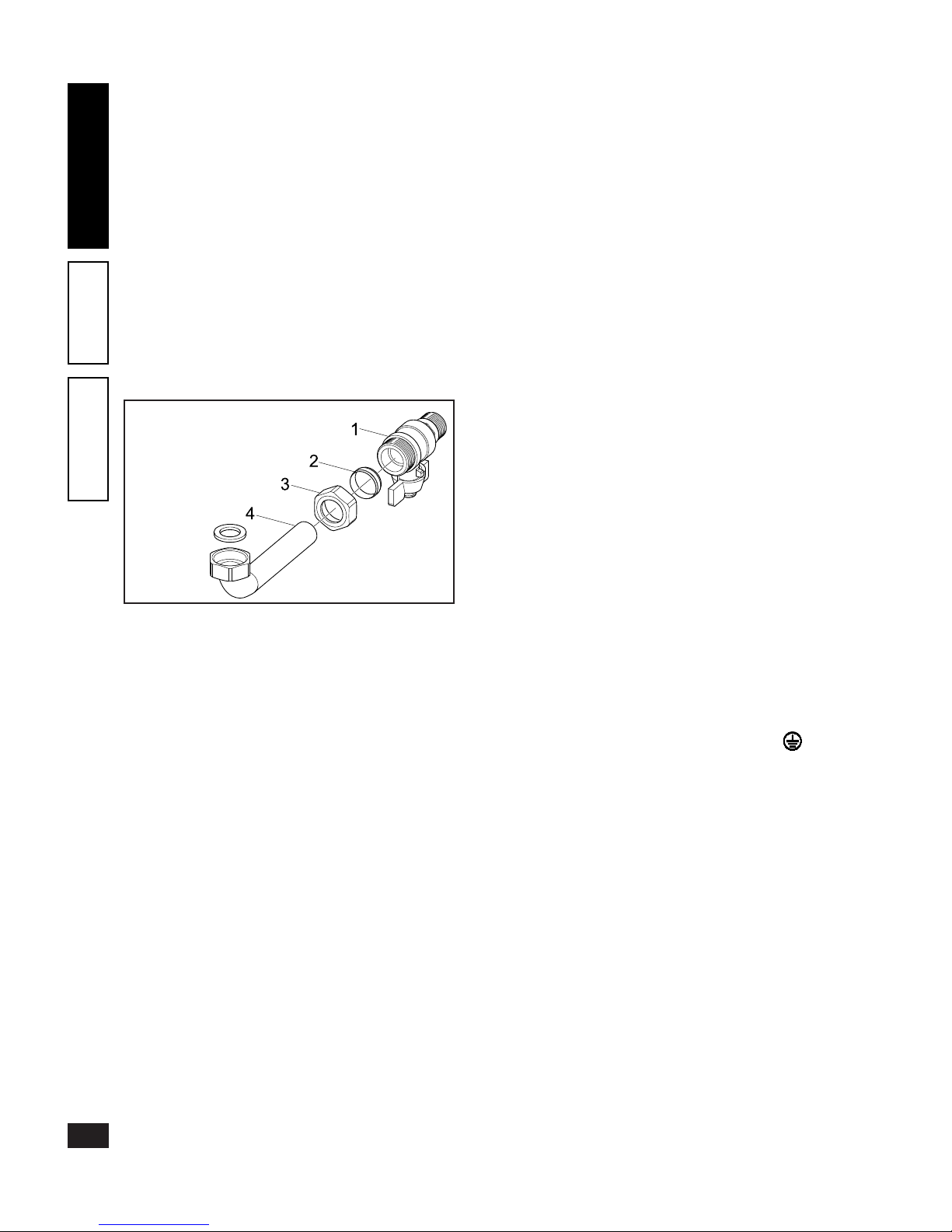

Ensure correct gas cock connection as shown in the assembly

sequence shown in the gure.

e gas supply pipe must be suitably dimensioned according

to current regulations in order to guarantee correct gas ow

to the boiler even in conditions of max. generator output

and to guarantee appliance eciency (technical data). e

coupling system must conform to standards.

Combustible gas quality. e appliance is designed to

operate on gas free of impurities; otherwise it is advisable

to t special lters ahead of the appliance for restoring the

purity of the gas.

Storage tanks (in case of supply from LPG depot).

- New LPG storage tanks may contain residuals of inert

gases (nitrogen) that impoverish the mixture delivered to

the appliance, causing anomalous operation.

- Due to the composition of the LPG mixture, layering

of the mixture components may occur during the period

of storage in the tanks. is can cause a variation in the

heating power of the mixture delivered to the appliance,

with subsequent change in its performance.

Water connection.

Important: before carrying out the boiler connections all the

system pipes must be carefully cleaned with special descaling

products for removing any deposits that could compromise

correct boiler operation.

In order to prevent scale forming in the heating system, the

provisions given in the regulations on water treatment in

heating systems for civil use must be respected.

Water connections must be made in a rational way using the

connections on the boiler template. e boiler safety valve

outlet must be connected to a discharge funnel. Otherwise,

the manufacturer declines any responsibility in case of ooding if the drain valve cuts in.

Important: to preserve the life and eciency of the domestic

circuit exchanger, it is advisable to install the “polyphosphate

dispenser” kit if the water has characteristics can give rise to the

forming of scale (in particular, the kit is recommended when the

water hardness is higher than 25 degrees French).

Condensate drain. To drain the condensate produced by

the appliance, it is necessary to connect to the drainage system by means of acid condensate resistant pipes having an

internal diameter of at least 13 mm. e appliance drainage

connection system must be executed in such a way as to

prevent freezing of the liquid contained in it. Before appliance start-up, ensure that the condensate can be correctly

removed. Also, comply with national and local regulations

on discharging waste waters.

Electrical connection. e entire “Victrix” boiler has IPX4D

protection rating. Electrical safety of the appliance is only

guaranteed when it is correctly connected to an ecient

earthing system according to current safety standards.

Important: Immergas S.p.A. declines any responsibility for

damage to persons or things caused by failure to connect

the boiler to an earthing system or non-compliance with

the reference standards

Also ensure that the electrical system is suitable for the

maximum power absorbed by the appliance, specied on

the boiler dataplate. Boilers are supplied complete with

an “X” type power cable without plug. e power cable

must be connected to a 230V ±10% / 50Hz mains supply

respecting the polarity L-N and earth connection ; the

mains power supply must also be equipped with a multi-pole

circuit breaker with contact opening gap of at least 3 mm.

When replacing the power supply cable, contact a qualied

technician (e.g. Immergas Authorized Technical Assistance

Service). e power cable must be laid as shown.

In the event of mains fuse replacement on the control card,

use a 3.15A quick-blow fuse. Never use adapters, multiple

sockets or extension leads for the main power supply to the

appliance.

If correct L-N polarity is not respected during connection,

the boiler will not detect the ame and inhibits start-up.

Important: also, whenever L-N polarity is not respected, if

the neutral is live with temporary residual voltage over 30V,

the boiler could operate just the same (but only temporarily).

Measure the voltage with suitable instruments; do not use a

phase tester screwdriver.

Key:

1 - Gas cock

2 - Biconical ring Ø 18

3 - Nut

4 - Gas pipe

4

INSTALLERUSERTECHNICIAN

5

INSTALLERUSERTECHNICIAN

Page 6

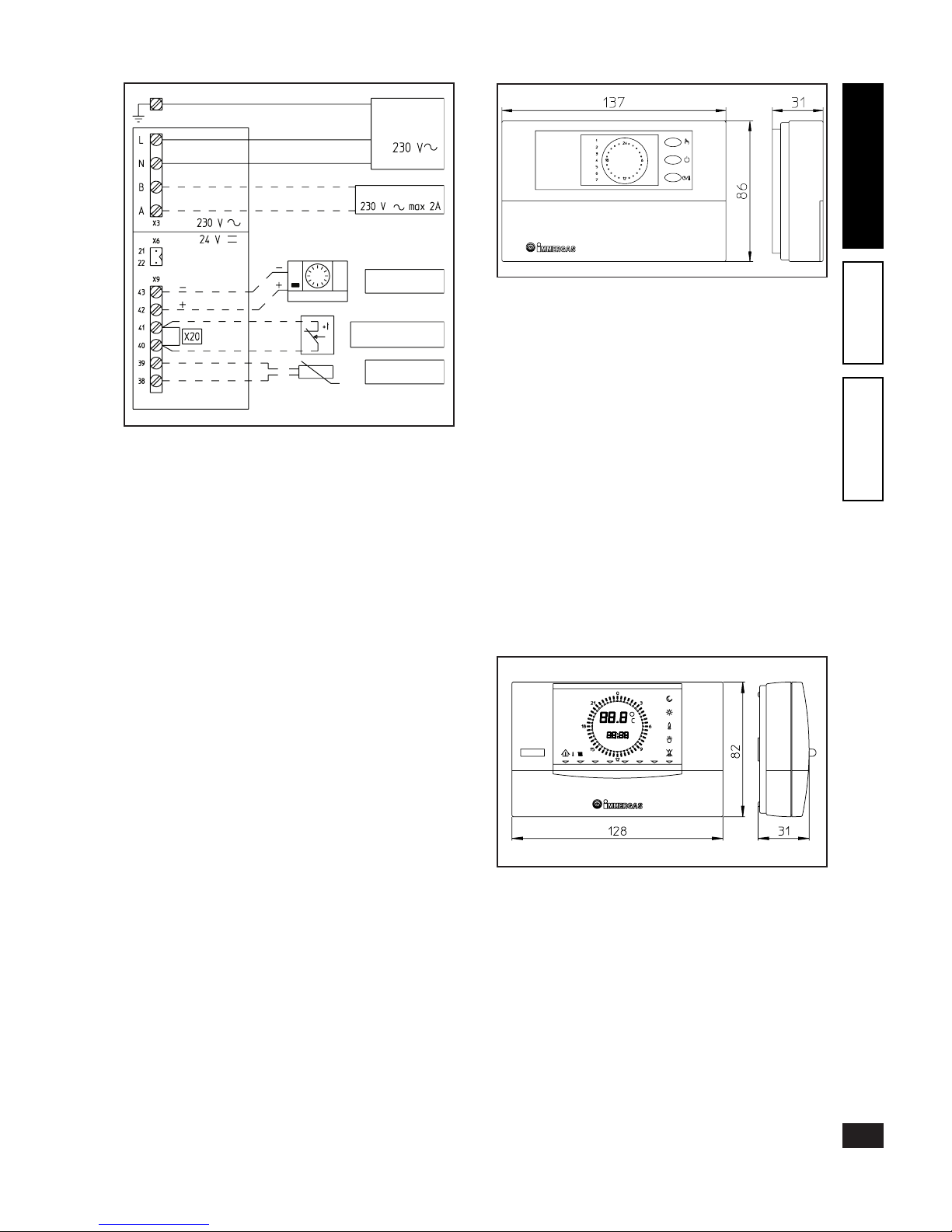

Room chronothermostats and external sensor (Optional).

e boiler is arranged for application of room chronothermostats and external sensor.

ese Immergas components are available as separate kits to

the boiler and are supplied by request.

All Immergas chronothermostats are connectable with 2

wires only. Carefully read the use and assembly instructions

contained in the accessory kit.

• On/O digital chronothermostat. e chronothermostat

enables:

- setting of two room temperature values: one for day

(comfort temperature) and one for night (lower

temperature);

- setting up to three on/o dierential weekly programs;

- selecting the required function mode from the various

possible alternatives:

• permanent operation in comfort temp;

• permanent operation in lower temp;

• permanent function in adjustable antifreeze temp.

e chronothermostat is powered by two 1.5V LR6 type

alkaline batteries.

• Remote Friend Contr ol Dev ice wi th climatic

chronothermostat function. In addition to the functions

described in the previous point, the Remote Friend

Control enables the user to have under control and at

hand all the important information regarding appliance

and heating system operation with the possibility of easily

changing the previously set parameters without having to

go to the place where the appliance is installed. e Remote

Friend Control panel is provided with self-diagnosis to

display any boiler operation anomalies. The climate

chronothermostat incorporated in the remote panel

enables the system delivery temperature to be adjusted

to the actual room heating needs, in order to obtain the

desired room temperature with extreme precision and

therefore with clear savings in running costs. It also enables

the room temperature and actual external temperature

(if the external sensor is present) to be displayed. e

chronothermostat is fed directly by the boiler by means of

the same 2 wires used for the transmission of data between

boiler and chronothermostat.

Power

supply

Auxiliary output

Remote control

(OPTIONAL)

On-Off Room Stat

(OPTIONAL)

External sensor

(OPTIONAL)

5

INSTALLERUSERTECHNICIAN

Page 7

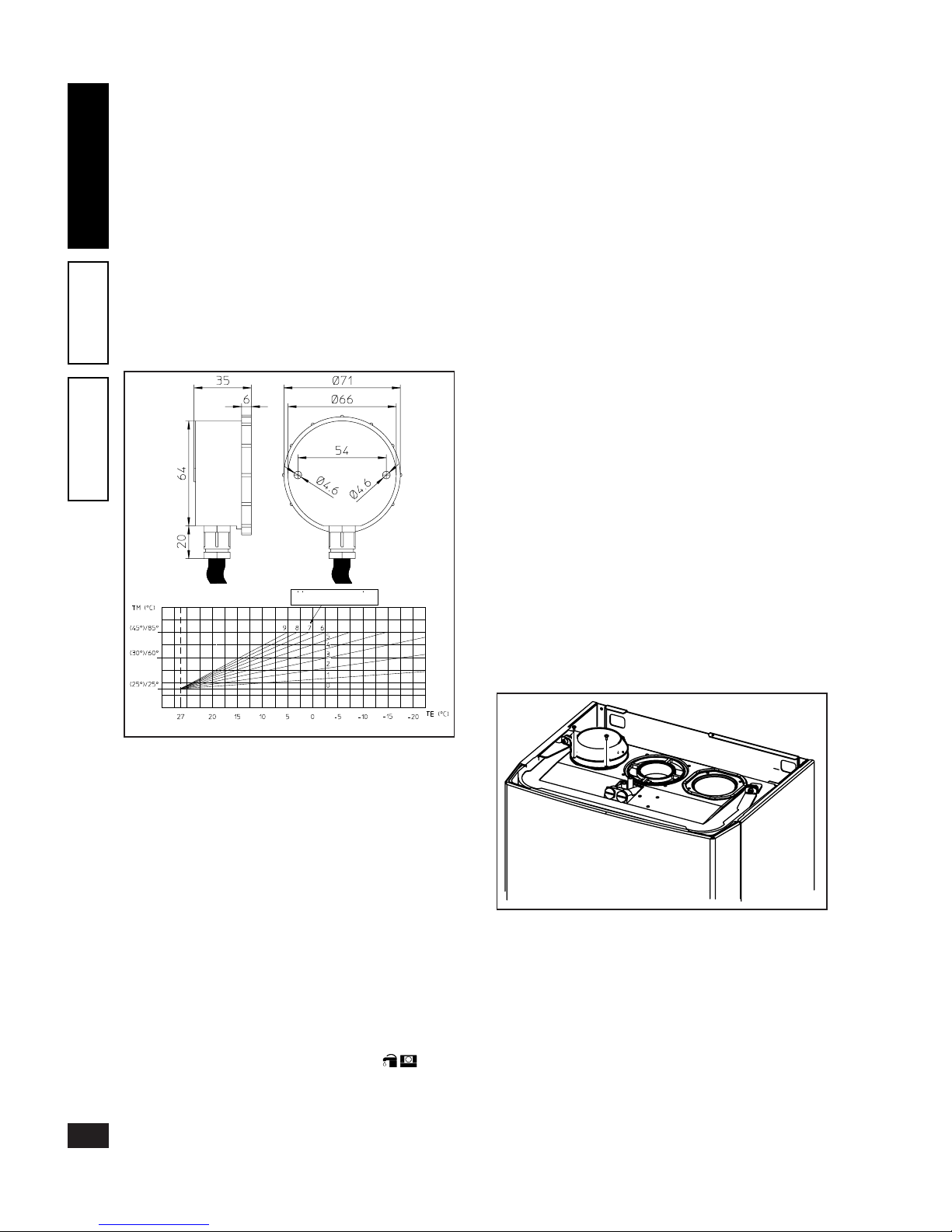

• External temperature sensor. is sensor can be connected

directly to the boiler electrical system and allows the max.

system delivery temperature to be automatically decreased

when the outside temperature increases, in order to adjust

the heat supplied to the system according to the change

in the outside temperature. e external sensor always

operates when connected, regardless of the presence or

type of room chronothermostat used, and can work in

combination with both Immergas chronothermostats.

e correlation between system delivery temperature and

outside temperature is determined by the position of the

knob on the boiler control panel according to the curves

shown in the diagram. e external sensor electrical connection must be made to terminals 38 and 39 on the boiler

electronic card (see g. page 5).

Electrical connection of the Remote Friend Control or

On/Off chronothermostat (Optional). The following

operations must be carried out after disconnecting the

electrical power supply; the possible thermostat or On/O

room chronothermostat must be connected to terminals 40

and 41 eliminating jumper X20 (see g. page 5). Make sure

the On/O thermostat contact is of the “clean” type, i.e.

separate from the mains supply, otherwise the electronic

adjustment card would be damaged. e possible Remote

Friend Control must be connected by means of terminals

IN+ and IN- to terminals 42 and 43 on the electronic card

(in the boiler) respecting the polarity, (see g. page 5);

connection with the wrong polarity inhibits its operation,

but without damaging the Remote Friend Control. After

connecting to the Remote Friend Control, jumper X20 must

be eliminated. e boiler works with the parameters set on

the Remote Friend Control only if the boiler main switch is

turned to Domestic/Remote Friend Control ( ).

Important: If the Remote Friend Control is used arrange

two separate lines in compliance with current regulations

regarding electrical systems. Boiler pipes must never be used

to earth the electrical or telephone system. Ensure this does

not occur, before making the boiler electrical connections.

Installation with system operating at low temperature.

e boiler can directly feed a low temperature system, by

operating on jumper (5) and setting the delivery temperature

range from 45°-25°C (as described on page 27). In this mode

it is advisable to include a safety in series with the boiler

circulating pump, formed of a thermostat having a limit

temperature of 55 °C. e thermostat must be positioned

on the system delivery pipe at more than 2 metres from the

boiler.

1.4 Boiler installation - B23 type with open chamber

and forced draught (optional).

In this conguration it is necessary to use the special terminal

(included in the special intake kit) to be tted on the intake

hole on the sealed chamber (see the following g.). Air is

drawn directly from the place where the boiler is installed,

and fumes are exhausted into a single ue or directly to the

outside. In this conguration, following the assembly instructions given on the relevant instruction sheet, the boiler

is classied as B

23

type.

With this conguration:

- air is drawn directly from the place where the appliance is

installed (which must only be in permanently ventilated

rooms).

- the fume exhaust must be connected to its own single ue

or ducted directly to the outside.

There fore the current technical standa rds must be

respected.

Max. length of exhaust ue. To avoid problems of fume

condensation due to cooling through the wall, the exhaust

duct can be extended up to a max. length of 30 m.

6

INSTALLERUSERTECHNICIAN

7

INSTALLERUSERTECHNICIAN

Page 8

1.5 Air intake and fume exhaust terminal installation.

Immergas supplies various solutions separately from the

boilers for the installation of air intake and fume exhaust

terminals necessary for boiler operation.

Important: the boiler must only be installed together with

an original Immergas “Green Range” air intake and fume

extraction system in plastic, as required by current regulations. is system is identiable by a special distinctive

marking giving the note: “for condensing boilers only”.

Important:

- for C1 type installation with doubled terminals, these must

be installed inside a 50 cm square perimeter;

- for C3 type installation the terminals must be installed

inside a 50 cm square perimeter and the distance between

the two levels of the openings must be less than 50 cm;

- for C5 type installation the two terminals must not be

installed on opposite walls of the building.

• Resistance factors and equivalent lengths. Each fume extraction system component has a resistance factor obtained

from preliminary tests and specied in the table below. e

resistance factor of the single component does not depend

on the type of boiler on which it is installed and is a dimensional value. It is based on the temperature of uids passing

through the ducts and therefore varies according to use in

air intake or fume exhaust. Each single component has a

resistance corresponding to a certain length in metres of

pipe of the same diameter: the so-called equivalent length.

All boilers have an experimentally obtainable maximum

Resistance Factor equal to 100. e maximum permissible

resistance factor corresponds to the resistance detected with

the maximum permissible pipe length with each type of

Terminal Kit. is information enables calculations for

verifying the possibility of executing a wide range of fume

extraction system congurations.

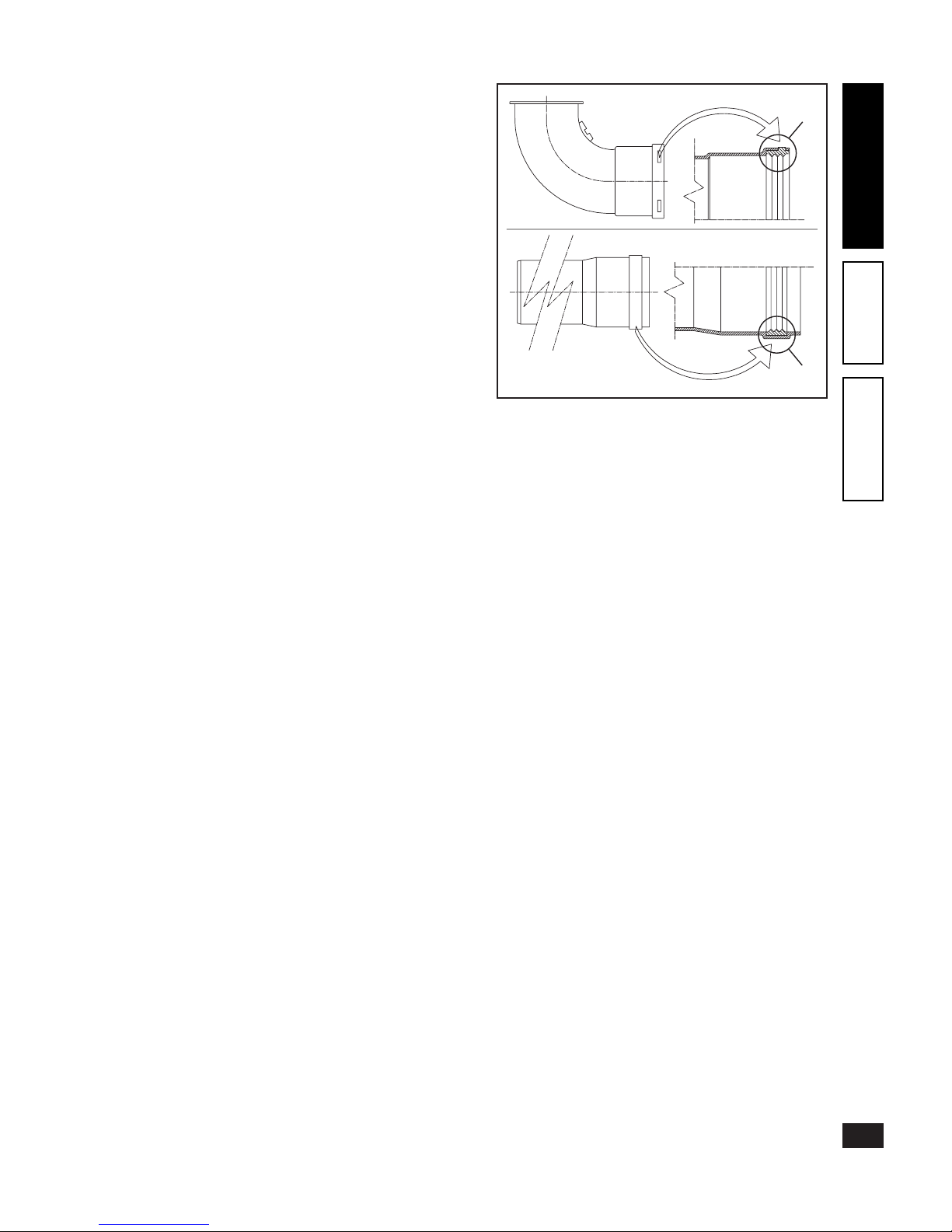

Positioning of seals (black) for “Green Range” fume extraction system. Make sure to correctly place the seal (for

bends or extensions) as shown in the gure:

- seal (A) with notches, to be used for bends;

- seal (B) without notches, to be used for extensions;

N.B.: if the lubrication of the components (already carried

out by the manufacturer) is insucient, remove the residual

lubricant using a dry rag, then cover the parts with normal

or industrial talc to facilitate coupling.

(A)

(B)

7

INSTALLERUSERTECHNICIAN

Page 9

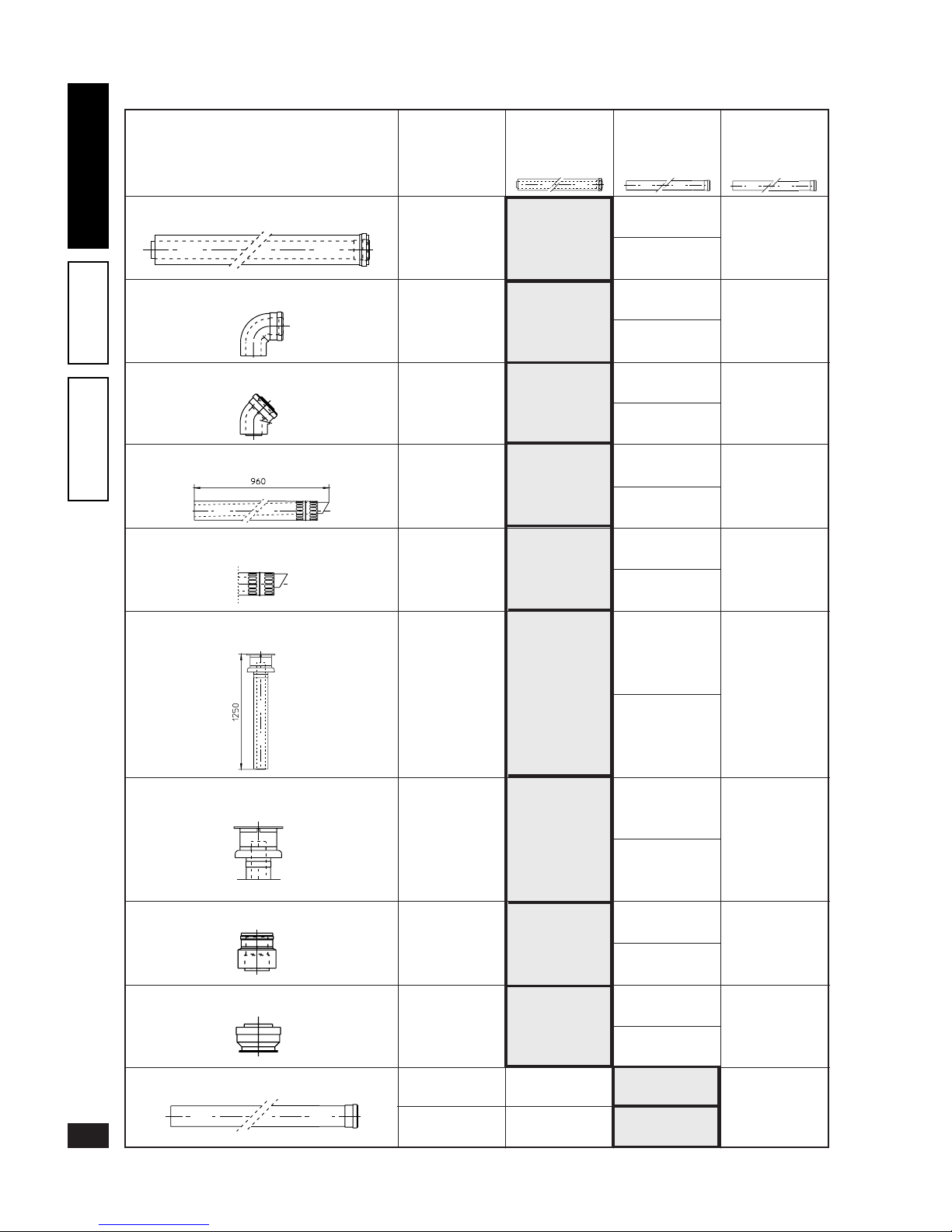

Resistance factor and equivalent length tables.

TYPE OF DUCT

Resistance

factor

(R)

Equivalent length

in metres of

concentric pipe

Ø 60/100

Equivalent

length in metres

of pipe

Ø 60

Concentric pipe Ø 60/100 length 1 m

90° bend concentric Ø 60/100

45° bend concentric Ø 60/100

Terminal complete with concentric

horizontal intake-exhaust Ø 60/100

Intake

and

exhaust

6.4

1 m

Intake

and

exhaust

8.2

1.3 m

Intake

and

exhaust

6.4

1 m

Intake

and

exhaust

15

2.3 m

Intake

and

exhaust

16.3

2.5 m

Exhaust

1.9 m

Exhaust

2.5 m

Exhaust

1.9 m

Exhaust

4.5 m

Exhaust

3.0 m

1.5 m

Intake

and

exhaust

10

Terminal complete with concentric

horizontal intake-exhaust Ø 60/100

Intake

and

exhaust

9

1.4 m

Intake

and

exhaust

5.2

0.8 m

Equivalent

length in metres

of pipe

Ø 80

Terminal complete with concentric

vertical intake-exhaust Ø 60/100

Concentric adapter from Ø 80/125 to 60/100

Terminal complete with concentric

vertical intake-exhaust Ø 60/100

Intake

7.3 m

Intake

9.4 m

Intake

7.3 m

Intake

17.2 m

Intake

18.7 m

Exhaust

5.3 m

Exhaust

6.8 m

Exhaust

5.3 m

Intake

11.5 m

Exhaust

12.5 m

Exhaust

8.3 m

Exhaust

13.6 m

Exhaust

1.6 m

Intake

6.0 m

Exhaust

4.3 m

Exhaust

4.9 m

Exhaust

2.7 m

Intake

10.3 m

Exhaust

7.5 m

Concentric ange Ø 80/125

Intake

and

exhaust

1.3

0.2 m

Exhaust

0.4 m

Intake

1.5 m

Exhaust

1.1 m

Pipe Ø 80 length 1 m

Intake

1.0 m

Exhaust

1.0 m

Exhaust

0.4 m

0.1 m

0.2 m

Intake

0.87

Exhaust

1.2

8

INSTALLERUSERTECHNICIAN

9

INSTALLERUSERTECHNICIAN

Page 10

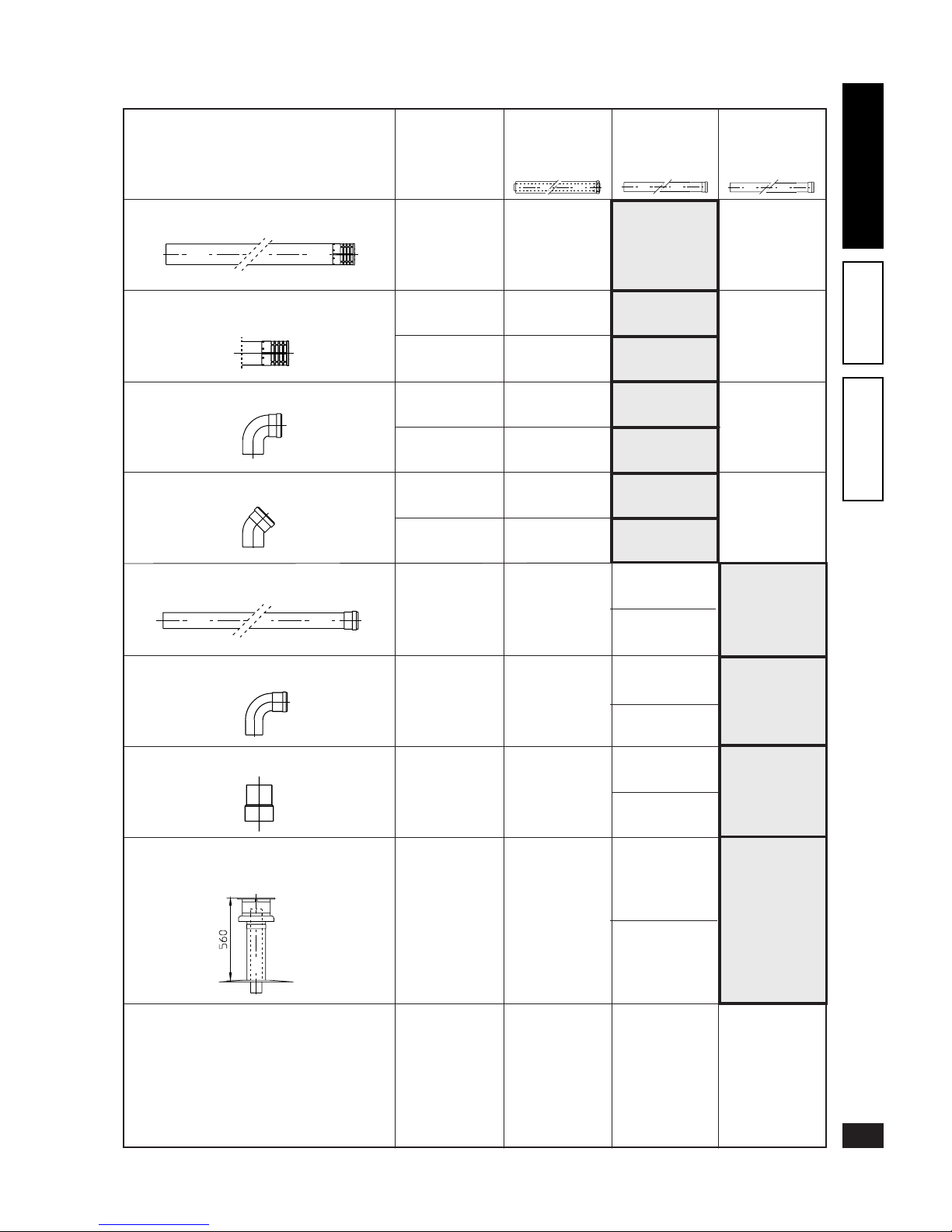

TYPE OF DUCT

Resistance

Factor

(R)

Exhaust

0.5 m

Exhaust

1.1 m

Exhaust

3.5

0.55 m

0.35 m

Exhaust

0.6 m

Exhaust

0.8 m

Exhaust

1.0 m

0.3 m

Resistance factor and equivalent length tables.

Exhaust

3.7 m

Exhaust

12.2

1.9 m

Intake terminal Ø 80

Exhaust terminal Ø 80

90° bend Ø 80

45° bend Ø 80

Pipe 1 m Ø 60 for ducting

90° bend Ø 60 for ducting

Equivalent

length in metres of

concentric pipe

Ø 60/100

Equivalent

length in metres

of pipe

Ø 60

Equivalent

length in metres

of pipe

Ø 80

Complete vertical exhaust

terminal Ø 60 for ducting

Intake

2.2

Exhaust

1.9

Intake

1.9

Exhaust

2.6

Intake

1.2

Exhaust

1.6

Exhaust

3.3

0.4 m

0.2 m

0.25 m

0.5 m

Intake

1.4 m

Exhaust

1.3 m

Intake

2.5 m

Exhaust

1.6 m

Intake

2.2 m

Exhaust

2.1 m

Intake

3.8 m

Exhaust

2.7 m

Intake

4.0 m

Exhaust

2.9 m

Intake

14 m

0.3 m

0.5 m

Complete intake terminal Ø 80 length 1 m

Intake

3

Exhaust

0.9 m

Intake

3.4 m

Exhaust

10.1 m

Intake

and

exhaust

2.6

0.4 m

Exhaust

0.8 m

Intake

3.0 m

Exhaust

2.1 m

Adapter Ø 80/60

9

INSTALLERUSERTECHNICIAN

Page 11

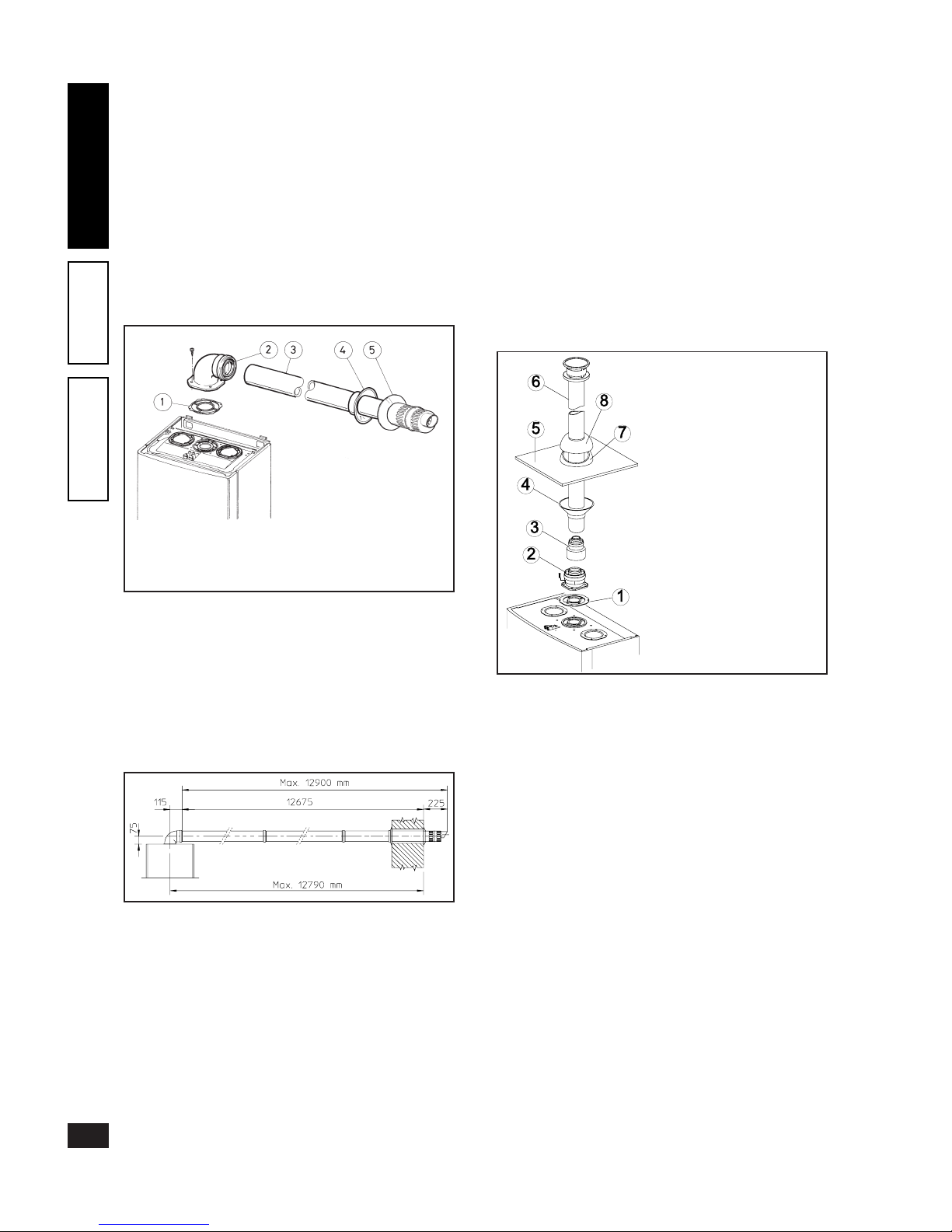

Horizontal intake kits - exhaust Ø 60/100.

Kit assembly: install the bend with ange (2) on the central

hole of the boiler inserting the seal (1) (which does not require

lubrication), positioning it with the round protrusions downwards in contact with the boiler ange and tighten using the

screws supplied with the kit. Fit the male end (smooth) of

the Ø 60/100 concentric terminal pipe (3) up to the stop

on the female end of the bend (2), making sure the relevant

internal and external rings are tted; this will ensure hold

and joining of the elements making up the kit.

N.B.: for correct operation of the system the terminal with

grill must be correctly installed, respecting the indication

“top” on the terminal.

• Coupling extension pipes and concentric elbows Ø 60/

100. To install possible coupling extensions on other fume

extraction elements, proceed as follows: t the male end

(smooth) of the concentric pipe or concentric elbow up to

the stop on the female end (with lip seals) of the previously

installed element; this will ensure correct hold and joining

of the elements.

e Ø 60/100 kit can be installed with the rear, right side,

left side and front outlet.

• Extensions for horizontal kit. e horizontal intake-ex-

haust kit Ø 60/100 can be extended up to a max. horizontal

length of 12.9 m, including the grill terminal and excluding

the concentric bend leaving the boiler. is conguration

corresponds to a resistance factor of 100. In this case special

extensions must be requested.

N.B.: when installing the ducts, a section clamp with pin

must be installed every 3 metres.

• External grill. N.B.: for safety purposes, do not even

temporarily obstruct the boiler intake/exhaust terminal.

Vertical kit with aluminium tile Ø 60/100.

Kit assembly: install the concentric ange (2) on the central

hole of the boiler inserting the seal (1) (not requiring lubrica-

tion), positioning it with the round protrusions downwards

in contact with the boiler ange and tighten using the screws

supplied with the kit. Fit the male end (smooth) of the

adapter (3) in the female end of the concentric ange (2).

Fake aluminium tile installation: replace the tiles with the

aluminium sheet (5), shaping it to ensure that rainwater runs

o. Position the xed half-shell (7) on the aluminium tile

and insert the intake/exhaust pipe (6). Fit the male end (6)

(smooth) of the Ø 60/100 concentric terminal up to the stop

on the female end of the adapter (3) (with lip seals), making

sure that the ring (4) is already tted; this will ensure hold

and joining of the elements making up the kit.

• Coupling extension pipes and concentric elbows. To install

possible coupling extensions on other fume extraction elements, proceed as follows: t the male end (smooth) of

the concentric pipe or concentric elbow up to the stop on

the female end (with lip seals) of the previously installed

element; this will ensure correct hold and joining of the

elements.

Important: if the exhaust terminal and/or extension concentric pipe needs shortening, consider that the internal

duct must always protrude by 5 mm with respect to the

external duct.

is specic terminal enables fume exhaust and air intake

necessary for combustion, in a vertical direction.

N.B.: the vertical kit Ø 60/100 with aluminium tile enables

installation on terraces and roofs with maximum slope of

45% (24°) and the height between the terminal cap and

half-shell (374 mm) must always be respected.

C13x

C13x

C33x

e kit comprises:

1 - Seal (1)

1 - Concentric bend Ø 60/100 (2)

1 - Concentric intake/exhaust

terminal Ø 60/100 (3)

1 - Internal ring (4)

1 - External ring (5)

e kit comprises:

1 - Seal (1)

1 - Female concentric ange (2)

1 - Adapter from 80/125

to 60/100 (3)

1 - Ring (4)

1 - Aluminium tile (5)

1 - Intake/exhaust concentric

pipe Ø 60/100 (6)

1 - Fixed half-shell (7)

1 - Movable half-shell (8)

10

INSTALLERUSERTECHNICIAN

11

INSTALLERUSERTECHNICIAN

Page 12

e vertical kit with this conguration can be extended to a

max. vertical length of 13.4 m, including the terminal. is

conguration corresponds to a resistance factor of 100. In

this case specic extensions must be requested.

Separator kit Ø 80/80. e separator kit Ø 80/80, enables

separation of the exhaust ues and air intake pipes according to the layout shown in the gure. Fumes are expelled

from duct (A) (strictly in plastic material resistant to acid

condensates). Air is taken in through duct (B) (also in plastic

material) for combustion. Intake duct (B) can be installed

either on the right or left hand side of the central exhaust

duct (B). Both ducts can be oriented in any direction.

• Assembly of separator kit Ø 80/80. Install the ange (4)

on the central hole of the boiler inserting the seal (1)

(which does not require lubrication), positioning it with the

round protrusions downwards in contact with the boiler

ange and tighten using the screws supplied with the kit.

Remove the at ange on the lateral hole (depending on

installation requirements) and replace it with ange (3)

inserting seal (2) already tted on the boiler and tighten

using the screws supplied. Insert bends (5) with the male

end (smooth) in the female end of the anges (3 and 4).

Fit the male end (smooth) of the intake terminal (6) up to

the stop on the female end of the bend (5), making sure

that the relevant internal and external rings are tted. Fit

the male end (smooth) of the exhaust pipe (9) up to the

stop on the female end of the bend (5), making sure that

the internal ring is tted; this will ensure hold and joining

of the elements making up the kit.

• Coupling of extension pipes and elbows. To install possible

coupling extensions on other fume extraction elements,

proceed as follows: t the male end (smooth) of the pipe

or elbow up to the stop on the female end (with lip seals)

of the previously installed element; this will ensure correct

hold and joining of the elements.

• Installation space. e previous gure gives the min.

installation space dimensions of the Ø 80/80 separator

terminal kit in several limit conditions.

• Extensions for separator kit Ø 80/80 e max. vertical

straight length (without bends) usable for Ø 80 intake

and exhaust pipes is 41 metres regardless of whether they

are used in intake or exhaust. e max. horizontal straight

length (with intake and exhaust bends) usable for Ø 80

intake and exhaust pipes is 36 metres regardless of whether

they are used in intake or exhaust.

N.B.: to favour the removal of possible condensate forming

in the exhaust pipe, incline the pipes towards the boilers

with a min. slope of 1.5% (see g.). When installing the Ø

80 ducts, a section clamp with pin must be installed every

3 metres.

e kit comprises:

1 - Exhaust seal (1)

1 - Flange seal (2)

1 - Female intake ange (3)

1 - Female exhaust ange (4)

2 - Bends 90° Ø 80 (5)

1 - Intake terminal Ø 80 (6)

2 - Internal rings (7)

1 - External ring (8)

1 - Exhaust pipe Ø 80 (9)

C33x

C83x

C43x

11

INSTALLERUSERTECHNICIAN

Page 13

Internal installation in B23 conguration.

The appliance can be installed inside buildings in B23

configuration; in this case, make sure to respect all

the technical standards and current national and local

regulations(see page 6).

1.6 Ducting existing ues.

Ducting is an operation through which, within the context

of restructuring a system and with the introduction of one or

more special ducts, a new system is executed for evacuating

the fumes of a gas appliance, starting from an existing ue

(or a chimney) or a technical hole. Ducting requires using

conduits declared suitable for the purpose by the manufacturer, following the installation and operation instructions

provided by the manufacturer, and the requirements of the

standard.

Immergas ducting system. “Green Range” Ø 60 mm rigid

and Ø80 exible ducting systems can only be used for domestic

use and with Immergas condensing boilers.

In any case, ducting operations must respect the provisions

contained in the standards and in current technical regulations; in particular, the declaration of conformity must be

compiled at the end of work and on commissioning of the

ducted system. e instructions in the project or technical

report must likewise be followed, in cases provided for by

the standard and current technical regulations. e system

or components of the system have a technical life complying

with current standards, provided that:

- it is used in average atmospheric and environmental conditions, according to current regulations (absence of fumes,

dusts or gases that can alter the normal thermophysical

or chemical conditions; existence of temperatures coming

within the standard range of daily variation, etc.).

C83x

C83x

12

INSTALLERUSERTECHNICIAN

13

INSTALLERUSERTECHNICIAN

Page 14

- Installation and maintenance are performed according

to the manufacturer’s instructions and the provisions of

current regulations.

- e max. possible length of the Ø 60 rigid ducting vertical section is 22 m is length is obtained considering

the complete Ø 80 intake terminal, 1m of Ø 80 pipe in

exhaust, two 90° Ø 80 bends at boiler outlet.

- e max. possible length of the Ø 80 exible ducting

vertical section is equal to 30 m. is length is obtained

considering the complete Ø 80 intake terminal, 1m of

Ø 80 pipe in exhaust, two 90° Ø 80 bends at boiler outlet

for connecting to the ducting system and two direction

changes of the flexible tube inside the flue/technical

hole.

1.7 Fume exhaust to ue/chimney.

e fume exhaust does not have to be connected to a conventional

type branched ue. e fume exhaust can be connected to a

special LAS type multiple ue. Multiple ues and combined

ues must also only be connected to type C appliances

and of the same category (condensing), having rated heat

outputs not diering by less than 30% with respect to the

max. connectable and fed by the same type of fuel. e

thermofluidodynamic characteristics (flowrate in mass

of fumes, % of CO2, % humidity, etc.) of the appliances

connected to the same multiple or combined ues must

not dier by more than 10% with respect to the average

boiler connected. Multiple and combine ues must be

specially designed according to the calculation method and

requirements of the standards, by professionally qualied

technical personnel. Chimney or ue sections for connection

of the exhaust pipe must comply with requirements of the

standards.

1.8 Chimneys/ues.

General details. A chimney/ue used to exhaust fumes

must:

- in case of wet operation, be made of materials suitable for

discharging the condensate in compliance with the provisions

of current standards and regulations;

- be fumetight, waterproof and insulated;

- be made from reproof materials ensuring lasting resistance

to normal mechanical stress, heat and the action of fumes

and their possible condensate;

- have a vertical path without any constrictions;

- be adequately separated, by means of a suitable air space

or insulation, from zones with combustible and/or easily

ammable materials;

- be suitably designed to prevent the possible freezing of

condensate inside the fume system and condensate discharge system (trap, passivator tank);

- comply with the current relevant national and local regulations, for discharge of the condensate produced by the

fume exhaust system;

- have a solid materials and possible condensate collection

unit below the opening of the rst ue at a height of at least

500mm, tted with an airtight metal door;

- have have a round, square or rectangular internal section

(in the latter two cases, with rounded angles and radius of

not less than 20 mm). Hydraulically equivalent sections

are also allowed;

- have a chimney-top in compliance with the specications

given below;

- be without mechanical extraction devices installed at the

top of the duct;

- in ues routed inside or against inhabited buildings, there

must be no risk of pressure surges.

Chimney-tops. A chimney-top is the device generally installed on top of single or multiple ues. is device facilitates

the dispersion of fumes also in adverse weather conditions

and prevents depositing of foreign matter. It must:

- have a useful outlet section not less than double that of

the ue/chimney on which it is installed;

- be suitably designed to prevent the entry of rain or snow

in the ue/chimney;

- be shaped in such as way that prevents the formation of

frost and ice at the free outlet sections;

- be designed to ensure constant exhaust of combustion

products with any wind direction or angle.

e outlet height, corresponding to the height of the top

of the ue/chimney, regardless of any chimney-tops, must

be outside the “backow zone”, to avoid the risk of counterpressures that prevent the free release of fumes into the

atmosphere. erefore always respect the minimum heights

given in the gures for standards, according to the pitch.

Positioning of draught terminals. Draught terminals must:

- be installed on external outer walls of the building;

- be positioned according to the minimum distances specied in current technical standards.

Fume exhaust of forced draught appliances in closed

open-top environments. In spaces closed on all sides

with open tops (ventilation pits, courtyards etc.), direct

fume exhaust is allowed for natural or forced draught gas

appliances with a heating power range from 4 to 35 kW,

provided the conditions as per the current technical standards

are respected.

13

INSTALLERUSERTECHNICIAN

Page 15

1.9 Filling of system.

After the boiler is connected, ll the system by means of

the ller cock (see g. page 16, 17 and 20). Filling must be

done slowly to ensure the release of air bubbles in the water

through the boiler and heating system relief valves.

e boiler has a built-in automatic air valve on the expansion

tank, located on the side of the sealed combustion chamber.

Check that the cap is loosened. Open the relief valves on the

radiators. Close the relief valves when only water comes out.

Close the ller cock when the boiler pressure gauge indicates

approx. 1.2 bar.

N.B.: During this operation, start the circulating pump at

intervals by means of the main switch on the control panel.

Vent the circulating pump by unscrewing the front cap and keeping the motor running. Tighten the cap on completion.

1.10 Condensate trap lling.

With the rst boiler lighting fumes may come out the

condensate drain; after a few minutes’ operation check that

fumes no longer come out. is means that the trap is lled

with condensate to the correct level thus preventing the

passage of fumes.

1.11 Gas system start-up.

To start up the system proceed as follows:

- open windows and doors;

- avoid the presence of sparks or naked ames;

- vent all air from pipelines;

- check gas supply tightness with the boiler gas ON/OFF

cock closed; no gas ow must be indicated on the meter

for 10 minutes.

1.12 Boiler start-up (lighting).

For issue of the Declaration of Conformity provided for by

Italian Law, the following must be done for boiler start-up:

- check gas supply circuit tightness with the 0n/O valve

closed and subsequently open with gas valve closed; no gas

ow must be read on the meter for 10 minutes;

- ensure that the type of gas used corresponds to that for

which the boiler is arranged;

- switch on the boiler and ensure correct ignition;

- make sure that the gas owrate and relevant pressure values

comply with those given in the manual (see page 32);

- ensure that the safety device activates in the event of no gas

and check activation time;

- check activation of the main switch generally located ahead

of the boiler and on the unit;

- check that the concentric intake/exhaust terminal (if tted)

is not blocked.

e boiler must not be started up in the event of negative

result of any of the above checks.

Preliminary boiler testing must be performed by a qualied technician. e boiler warranty is valid as of the date of testing.

e test and warranty certicate is issued to the user.

1.13 Circulating pump.

“Victrix” range boilers are supplied with a built-in circulating

pump with 3 or 4-position electric speed control (depending

on the circulating pump). e boiler does not operate

correctly with the circulating pump on rst and second

speed. To ensure optimal boiler operation, with new systems

(single pipe and modul) it is advisable to use the circulating

pump at maximum speed. e circulating pump is already

tted with a capacitor.

Pump release. If, after a prolonged period of inactivity, the

circulating pump is blocked, unscrew the front cap and turn

the motor shaft using a screwdriver. Take great care during

this operation, to avoid damaging the motor.

14

INSTALLERUSERTECHNICIAN

15

INSTALLERUSERTECHNICIAN

Page 16

1.14 Kits available by request.

• System on/o cock kit (by request). e boiler is arranged

for installation of system on/o cocks to be placed on the

delivery and return pipes of the connection assembly. is

kit is particularly useful for maintenance as it allows the

boiler to be drained separately without having to empty

the entire system.

Head available at system - Victrix 20.

A = Head available at system at max. speed with by-pass cut out (adjustment screw fully screwed down)

B = Head available at system at max. speed (screw tightened 4.5 turns with respect to the adjustment screw fully unscrewed)

C = Head available at system at max. speed with by-pass open (adjustment screw fully unscrewed)

Head (kPa)

A

Flowrate l/h

B

C

Head (m H

2

O)

• Polyphosphate dispenser kit (by request). e polyphosphate dispenser prevents the formation of scale and

preserves the original heat exchange and domestic hot

production water conditions. e boiler is arranged for

application of the polyphosphate dispenser kit.

e above kits are supplied complete with instructions for

assembly and use.

Head available at system - Victrix 27.

Flowrate (l/h)

A = Head available at system at max. speed with by-pass cut out (adjustment screw fully screwed down)

B = Head available at system at max. speed with by-pass cut out (screw tightened 4.5 turns with respect to adjustment screw the fully unscrewed)

C = Head available at system at max. speed with by-pass open (adjustment screw fully unscrewed)

Head (kPa)

A

B

C

Head (m H

2

O)

15

INSTALLERUSERTECHNICIAN

Page 17

1.15 Boiler components - Victrix 20.

Key:

1 - Gas valve

2 - Condensate trap

3 - Domestic circuit adjustment NTC sensor

4 - Sealed chamber back

5 - Igniter sensor

6 - Condensing module cover

7 - Intake points (air A) - (fumes F)

8 - NTC limit and heating control sensor

9 - Condensing module

10 - Igniters

11 - Air intake pipe

12 - Sleeve with seat for Venturi

13 - Electronic control unit

14 - Overtemperature safety thermostat

15 - Circulating pump

16 - Plate-type heat exchanger

17 - Pump safety pressure switch

18 - 3 bar safety valve

19 - 3-way valve monobloc

20 - Automatic by-pass

21 - System drain cock

22 - System ller cock

23 - Current transformer

24 - Air fan

25 - Expansion tank

26 - Air valve

27 - Fume extractor hood

28 - Positive signal pressure point

29 - Negative signal pressure point

30 - Burner

31 - Gas valve outlet pressure test

16

INSTALLERUSERTECHNICIAN

17

INSTALLERUSERTECHNICIAN

Page 18

1.16 Boiler components - Victrix 27.

Key:

1 - Gas valve

2 - Condensate trap

3 - Domestic circuit adjustment NTC sensor

4 - Sealed chamber back

5 - Igniter sensor

6 - Condensing module cover

7 - Intake points (air A) - (fumes F)

8 - NTC limit and heating control sensor

9 - Condensing module

10 - Igniters

11 - Air intake pipe

12 - Sleeve with seat for Venturi

13 - Electronic control unit

14 - Overtemperature safety thermostat

15 - Circulating pump

16 - Plate-type heat exchanger

17 - Pump safety pressure switch

18 - 3 bar safety valve

19 - 3-way valve monobloc

20 - Adjustable by-pass

21 - System drain cock

22 - System ller cock

23 - Current transformer

24 - Air fan

25 - Expansion tank

26 - Vent valve

27 - Fume extractor hood

28 - Positive signal pressure point

29 - Negative signal pressure point

30 - Burner

31 - Gas valve outlet pressure tester

32 - Aqua Celeris

33 - Aqua Celeris resistance

17

INSTALLERUSERTECHNICIAN

Page 19

2

USE AND MAINTENANCE

INSTRUCTIONS

2.1 Cleaning and maintenance.

Important:e user must have the heating system serviced

at least once a year and a combustion test (fume test) carried

out at least once every two years.

This ensures that the optimal safety, performance and

operation characteristics of the boiler remain unchanged

over time.

We recommend stipulating a yearly cleaning and maintenance

contract with your area technician.

2.2 General instructions.

Never expose the wall-mounted boiler to direct vapours

from cook-tops.

The boiler must not be used by unskilled persons or

children.

For safety purposes, ensure that the concentric air intake/

fume exhaust terminal (if tted) is not even temporarily

blocked.

If temporary shutdown of the boiler is required, proceed

as follows:

a)drain the water system if anti-freeze is not used;

b)shut-o all electrical, water and gas supplies.

In case of work or maintenance to structures located in the

vicinity of ducting or fume extraction devices and relevant

accessories, switch o the appliance and after completion

of work have qualied personnel check the eciency of the

ducting or devices.

Do not clean the appliance or its parts with easily ammable

substances.

Do not leave containers or ammable substances in the same

room as the appliance.

• Important: the use of any component that uses electricity

involves compliance with several fundamental rules:

- do not touch the appliance with wet or moist parts of

the body; do not touch when barefoot;

- do not pull electrical cables or leave the appliance exposed

to atmospheric agents (rain, sunlight, etc.);

- the appliance power cable must not be replaced by the

user;

- in the event of damage to the cable, switch o the appliance and contact exclusively qualied personnel for

replacement;

- if the appliance is not used for a certain period, disconnect the main power switch.

18

INSTALLERUSERTECHNICIAN

19

INSTALLERUSERTECHNICIAN

Page 20

Boiler ignition. Before lighting, make sure the system is full

of water and that the manometer (6) indicates a pressure of

1÷1.2 bar.

- Open the gas cock downstream of the boiler.

Turn main switch (5) to Domestic/Remote Friend Control

( ) or Domestic and Heating ( ).

• Operation with Remote Friend Control (Optional). With

the switch (5) set to ( ) and Remote Friend Control

connected the boiler sensors (2) and (3) are cut out; the

wording “CE” (External Commands) appears on the display. e boiler adjustment parameters are settable from

the Remote Friend Control panel.

• Operation without Remote Friend Control. With the

switch (5) set to ( ) the heating adjustment selector (2) is cut out, and the domestic water temperature

is adjusted by selector (3). With the switch set to ( )

the heating adjustment selector (2) is used to regulate the

temperature of radiators, whereas selector (3) is used for

the domestic water. Turn the selectors clockwise to increase

the temperature, and anticlockwise to decrease it.

Boiler operation is now automatic. Every boiler ignition is

signalled by means of the indicator (9) on the control panel.

When the selector (2) or (3) is turned, the temperature setting at that moment is shown on the display (8), and at the

same time indicator (1) or (4) ashes, depending on the

selector being used; after 5 seconds the current boiler delivery

temperature value appears on the display (8).

Signalling and diagnostics - Display (8). During normal

boiler operation the boiler delivery temperature value is displayed. With the boiler on Stand-by an illuminated horizontal segment appears on the display. In case of malfunction

or anomaly, the temperature is replaced by the relative error

code ashing.

1 = Ignition block

2 = Block due to the overtemperature safety thermostat

activation

5 = Delivery sensor fault

6 = Domestic circuit sensor fault

10 = Failed water ow switch activation

14 = Flame control unit fault

16 = Fan fault

17= Fan rpm incorrect

26= Water ow switch fault

31 = Remote Friend Control not compatible

e user can reset boiler blocks signalled by codes 1 and 2,

by pressing the boiler reset pushbutton (7) or the reset button

on the Remote Friend Control (if connected); if the block

persists request the intervention of a qualied technician (eg.

Immergas Technical Assistance Service).

Boiler block signalled by code 10 can be due to: lack of water

in the system, blocked or faulty circulating pump. In the rst

case check that the pressure gauge (6) indicates a value of

1÷1.2 bar; in the latter two, call a qualied technician (e.g.

Immergas Technical Assistance Service).

All the other signals (codes: 5-6-14-16-17-26-31) require

the intervention of a qualied technician (e.g. Immergas

Technical Assistance Service).

Boiler shutdown. Turn o the main switch (5), turning it

to “0”, and close the gas cock ahead of the appliance.

Never leave the boiler switched on if not used for prolonged

periods.

Key:

1 - Heating On indicator

2 - Heating temperature selector

3 - Domestic hot water temperature selector

4 - Domestic hot water On indicator

5 - 0-Domestic/Remote Control-Domestic and Heating switch

6 - Boiler manometer

7 - Reset

8 - Temperature and diagnostics display

9 - Burner On indicator

2.3 Control panel

19

INSTALLERUSERTECHNICIAN

Page 21

2.4 Restoring heating system pressure.

Periodically check the system water pressure.

e boiler pressure gauge must read a pressure of between

1 and 1.2 bar.

If the pressure falls below 1 bar (with the system cold) restore

normal pressure by means of the cock located at the bottom of

the boiler (see g.).

N.B.: close the cock on completion.

If pressure values reach around 3 bar the safety valve may

be activated.

In this case contact professionally qualied personnel for

assistance.

In the event of frequent pressure drops, contact professionally

qualied personnel for assistance to eliminate the possible

system leak.

2.5 Draining the system.

To drain the boiler, use the special system drain connection

(see detail 21 page 16-17).

Before draining, ensure that the system filler cock is

closed.

2.6 Anti-freeze protection.

e boiler is equipped with an antifreeze function that starts

the pump and the burner when the system water temperature

inside the boiler falls below 4°C. e anti-freeze function is

guaranteed if the boiler is fully operative and not in “block”

status, and is electrically fed with the main switch set to

Summer or Winter. To avoid keeping the system operating in

the event of prolonged absence, the system must be drained

completely or anti-freeze products added to the heating system water. In both cases the boiler domestic water circuit

must be drained. In a system subject to frequent draining,

the system must be relled with suitably treated water to

eliminate hardness that can cause the forming of scale.

2.7 Casing cleaning.

Use damp cloths and neutral soap to clean the boiler casing.

Never use abrasive or powder detergents.

2.8 Decommissioning.

In the event of boiler decommissioning, contact professionally qualied personnel for the relevant operations and

ensure that the electrical, water and gas supply lines are

disconnected.

20

INSTALLERUSERTECHNICIAN

Page 22

3

BOILER STARTUP

PRELIMINARY CHECK

To start up the boiler, proceed as follows:

- ensure that the declaration of conformity of installation is

supplied with the appliance;

- check the gas supply circuit tightness with the 0n/O valves

closed and subsequently open with gas valve closed; no gas

ow must be indicated on the meter for 10 minutes.

- check that the type of gas used corresponds to that for

which the boiler is arranged;

- check connection to a 230V-50Hz power supply, correct

L-N polarity and the earthing connection;

- switch on the boiler and check correct ignition;

- check the CO2 in the fumes at max. and min. output;

- check that the maximum, intermediate and minimum gas

owrate and relative pressure values comply with those

given in the handbook on page 32;

- check activation of the safety device in the event of no gas,

and the relevant intervention time;

- check activation of the main switch ahead of the boiler

and on the unit;

- check that the intake and/or exhaust terminals are not

blocked;

- check activation of the regulation devices;

- seal the gas ow regulation devices (if the settings are

modied);

- check the production of hot domestic water;

- check the tightness of water circuits;

- check ventilation and/or airing of the installation room

where provided.

If any safety checks give negative results, do not start the

boiler.

Remote Friend Control or Room ermostat:

e boiler is arranged for application of a Room thermostat or the

Remote Friend Control (C.A.R.). Connect the Room ermostat to

terminals 40 and 41 and remove jumper X20. e Remote Friend

3.1 Wiring diagram - Victrix 20.

Control must be connected to terminals 42 and 43 of the electronic

card, respecting the polarity and removing jumper X20.

M2 - Fan

PU1 - “Block” reset

S1 - Main rotary switch

S2 - Pump ow microswitch

S3 - Domestic circuit priority microswitch

T1 - Voltage transformer

TA - Room thermostat On/O (optional)

U1 - Rectier inside the gas valve connector (present on Honeywell and Dungs gas valves)

X20 - Room thermostat or Remote Friend Control inhibitor jumper

Y1 - Gas valve

white

black

black

black

black

black

white

white

white

white

white

red

red

red

red

red

red

pink

pink

purple

brown

brown

orange

brown

brown

purple

purple

pink

orange

grey

grey

grey

grey

orange

gey-green

red-black

red-black brown

red-black

white-blue

white-blue

red-black

blue

blue

blue

N.B.

The rectifier U1 is present on boilers equipped

with Honeywell and Dungs gas valv

e

N.B.

The connectors edged in black are

inserted on the ignition unit

Power supply

Zone station

(optional)

IGNITION/

DETECTION

UNIT

ADJUSTMENT

CARD

DISPLAY CARD

Auxiliary

output

Key:

B1 - Heating NTC sensor

B2 - Domestic circuit NTC sensor

B3 - External sensor (optional)

CAR - Remote Friend Control (optional)

DL1 - Heating mode LED

DL2 - Domestic mode LED

DL3 - Flame presence LED

E1-E2 - Igniters

E3 - Igniter sensor

E4 - Temperature safety thermostat

M1 - Circulating pump

21

INSTALLERUSERTECHNICIAN

Page 23

Remote Friend Control or Room ermostat:

the boiler is arranged for application of a Room ermostat

(TA) or Remote Friend Control (CAR). Connect the Room

ermostat to terminals 40 and 41 and remove jumper X20.

e Remote Friend Control must be connected to terminals

42 and 43 on the electronic card, respecting the polarity and

removing jumper X20.

3.2 Wiring diagram - Victrix 27.

Key:

B1 - Heating NTC sensor

B2 - Domestic circuit NTC sensor

B3 - External sensor (optional)

CAR - Remote Friend Control (optional)

DL1 - Heating On LED

DL2 - Domestic circuit On LED

DL3 - Flame presence LED

E1-E2 - Igniters

E3 - Detection plug

E4 - Temperature safety thermostat

M1 - Circulating pump

M2 - Fan

PU1 - “Block” reset

R2 - Domestic circuit thermal ywheel PTC

S1 - Main rotary switch

S2 - Pump ow switch microswitch

S3 - Domestic circuit priority microswitch

T1 - Voltage transformer

TA - Room thermostat On/O (optional)

U1 - Rectier inside gas valve connector (present on Honeywell and Dungs)

X20 - Room thermostat or Remote Friend Control inhibitor jumper

Y1 - Gas valve

white

white

white

white

red

gey-green

pink

pink

pink

purple

purple

purple

red

red

red

white

white

red

grey

grey

brown

orange

brown

brown

brown

white-blue

white-blue

brown

red-black brown

blue

black

black

black

red-black

red-black

red-black

black

black

grey

grey

red

orange

orange

orange

blue

blue

blue

blue

N.B.

The rectifier U1 is present on boilers equipped

with Honeywell and Dungs gas valve

N.B.

The connectors edged in black

are inserted on the ignition unit.

ADJUSTMENT

CARD

IGNITION/

DETECTION

UNIT

DISPLAY CARD

Zone unit

(optional)

Auxiliary

output

Power supply

22

INSTALLERUSERTECHNICIAN

23

INSTALLERUSERTECHNICIAN

Page 24

3.3 Plumbing diagram - Victrix 20.

Key:

1 - Minimum owrate valve

2 - Flow limiter

3 - 3-way hydraulic valve

4 - Gas valve

5 - Condensate trap

6 - Domestic water heat exchanger

7 - Domestic circuit adjustment NTC sensor

8 - Air fan

9 - Gas nozzle

10 - Igniter sensor

11 - Burner

12 - Condensing module cover

13 - Condensing module

14 - Fume extractor hood

15 - p gas pressure point

16 - NTC limit and heating control sensor

17 - Overtemperature safety thermostat

18 - Automatic air valve

19 - Igniters

20 - Expansion tank

21 - Air intake pipe

22 - Circulating pump

23 - Circulating pump pressure switch microswitch

24 - One-way valve

25 - Circulating pump pressure switch

26 - 3 bar safety valve

27 - Automatic by-pass

28 - Domestic circuit ow switch microswitch

29 - Filler cock

30 - Air analyzer chamber

31 - Fume analyzer chamber

32 - Venturi negative signal (P2)

33 - Venturi positive signal (P1)

34 - Gas valve outlet pressure point (P3)

35 - Air/gas Venturi manifold

G - Gas supply

S - Condensate drain

U - Hot domestic water outlet

E - Domestic water inlet

R - System return

M - System delivery

23

INSTALLERUSERTECHNICIAN

Page 25

3.4 Plumbing diagram - Victrix 27.

Key:

1 - Minimum ow valve

2 - Flow limiter

3 - 3-way hydraulic valve

4 - Condensate trap

5 - Gas valve

6 - Domestic water heat exchanger

7 - Gas valve outlet pressure point (P3)

8 - Domestic hot water adjustment NTC sensor

9 - Venturi positive signal (P1)

10 - Air fan

11 - Venturi negative signal (P2)

12 - Gas nozzle

13 - Air/gas Venturi manifold

14 - Igniter sensor

15 - Burner

16 - Condensing module cover

17 - Condensing module

18 - Fume extractor hood

19 - Air analyzer chamber

20 - p gas pressure point

21 - Fume analyzer chamber

22 - NTC limit and heating control sensor

23 - Overtemperature safety thermostat

24 - Automatic air valve

25 - Igniters

26 - Expansion tank

27 - Air intake pipe

28 - Aqua Celeris

29 - Circulating pump

30 - Aqua Celeris resistance (PTC)

31 - Circulating pump pressure switch microswitch

32 - One-way valve

33 - Circulating pump pressure switch

34 - 3 bar safety valve

35 - Adjustable by-pass

36 - Domestic circuit ow switch microswitch

37 - Filler cock

G - Gas supply

S - Condensate drain

U - Domestic hot water outlet

E - Domestic water inlet

R - System return

M - System delivery

24

INSTALLERUSERTECHNICIAN

25

INSTALLERUSERTECHNICIAN

Page 26

3.5 Troubleshooting.

N.B.: maintenance must be performed by a qualied techni-

cian (e.g. Immergas Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit pipes.

Check tightness of gas supply circuit.

- Repeated ignition blocks (error 1). is can be caused by:

incorrect electrical feed, check correct L and N polarity.

No gas, check pressure in mains and that the gas supply

cock is open. Incorrect gas valve adjustment, check correct

setting of gas valve.

- Irregular combustion or noisiness. is can be caused by:

dirty burner, incorrect combustion parameters, intakeexhaust terminal not correctly installed. Clean the above

components and check correct installation of the terminal,

check correct setting of the gas valve (O-Set setting) and

correct percentage of CO2 in fumes.

- Frequent activation of the overtemperature safety thermostat (error 2). is can be caused by lack of water in

the boiler, insucient water circulation in the system or

blocked circulating pump. Check on the pressure gauge

that values are within the xed limits. Check that radiator

valves are not all closed and that the circulating pump is

working correctly.

- Trap clogged (error 1). is can be caused by dirt or combustion products inside. By means of the condensate drain

plug check for any residuals of material possibly blocking

the ow of condensate.

- Exchanger blocked (error 1). is can be caused by the

trap being blocked. By means of the condensate drain plug

check for any residuals of material possibly blocking the

ow of condensate.

- Noise due to air in the system (error 10). Check opening of

the cap on the special air valve (see g. page 16-17). Check

that system pressure and the expansion tank precharge are

within the set limits. e expansion tank precharge value

must be 1.0 bar, and the system pressure between 1 and

1.2 bar.

3.6 Converting the boiler to another type of gas.

If the boiler has to be converted to a dierent gas type to that

specied on the dataplate, request the relative conversion kit

for quick conversion. Boiler conversion must be carried out

by a qualied technician (e.g. Immergas Technical Assistance

Service).

To convert to another type of gas the following operations

are required:

- replace the nozzle located between the gas pipe and gas/air

mixing sleeve (detail 9 page 23 or detail 12 page 24);

- adjust (if necessary) maximum boiler heat output;

- check the value of CO2 In the fumes with the boiler at

max. output with respect to the following table;

- check the value of CO2 in the fumes with boiler at min.

output with respect to the following table;

- seal the gas ow regulation devices (if the settings are

modied);

- after completing conversion, apply the sticker, included

in the conversion kit, near the dataplate. Using an indelible marker pen, cancel the data relative to the old type of

gas.

ese adjustments must be made with reference to the type

of gas used, following that given in the table on page 32.

3.7 Checks following conversion to another type of gas.

After ensuring conversion was carried out with a nozzle of

suitable diameter for the type of gas used and the settings

were made at the correct pressure, check that:

- the burner ame is not too high or low and is stable (does

not detach from burner);

- the pressure testers used for calibration are perfectly closed

and there are no leaks in the gas circuit.

N.B.: All boiler adjustment operations must be carried out by

a qualied technician (e.g. Immergas Assistance Service).

Burner adjustment must be carried out using a dierential

digital-type pressure gauge (with scale in tenths of mm or

Pascal), connected to the gas valve (P3 - P2) outlet pressure

point and on the pressure tester located above the sealed

chamber (detail 28 page 16-17), respecting the pressure value

given in the table on page 32 for the type of gas for which

the boiler is arranged.

3.8 Possible adjustments.

• Rated heat output check.

e boiler rated heat output is correlated to the length of

the air intake and fume exhaust pipes. It decreases slightly in

proportion to the increase in pipe length. e boiler leaves the

factory adjusted for minimum pipe length (1 m), therefore

in case of max. pipe extension, it is necessary to check the

“p” values at the ends of the Venturi and gas pressure at the

nozzle after at least 5 minutes of burner operation, when

the air intake and exhaust gas temperatures have stabilized.

e trimmer (9 page 28) inserted in the electronic adjustment card must be operated in order to adjust the rated heat

output according to the values given in the table on page 32.

Use dierential manometers connected to the “p” pressure

points on the Venturi and nozzle gas pressure as specied in

the chapter “Air/gas ratio adjustment”.

is adjustment is not necessary during the preliminary

check, as the boiler is factory-set with the correct air/gas

ratio.

However, it may be necessary during extraordinary maintenance, with replacement of air and gas circuit components.

After any adjustments:

- ensure that the pressure testers used for calibration are

perfectly closed and there are no leaks in the gas circuit;

- seal the gas ow regulation devices (if the settings are

modied).

25

INSTALLERUSERTECHNICIAN

Page 27

3.9 Air/gas ratio adjustment Victrix 20 boiler.

CO2 setting. Switch the boiler on and bring it to “chimney

sweep” phase, ensuring that the heating power trimmer