Immergas UB INOX 80 V2, UB INOX 120 V2, UB INOX 200 V2 Instruction And Recommendation Booklet

Page 1

Instruction and

*1.041260ENG*

recommendation booklet

IE

UB INOX

80-120-200 V2

Storage tank

Page 2

Page 3

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your storage tank.

Read the following pages carefully: you will be able to draw useful suggestions regarding the correct use of the storage unit, the respect of which, will conrm

your satisfaction for the Immergas product.

For any interventions or routine maintenance contact Authorised Centres: these have original spare parts and boast of specic preparation directly from the

manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry environments protected against bad weather.

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instructions manual provides technical information regarding installation of Immergas storage tank units. As for the other issues related to installation

of the said storage tank units (e.g. safety in the work site, environment protection, injury prevention), it is necessary to comply with the provisions specied in

the regulations in force and principles of good practice.

In compliance with legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law. Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer’s instructions and by an authorised

company, which has specic technical expertise in the system sector, as required by Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to people, animals

and objects. Read the instructions provided with the product carefully to ensure a proper installation.

Maintenance must be carried out by an authorised company. e Authorised Aer-sales Service represents a guarantee of qualication and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non compliance with technical laws in force, standards or instructions contained in this

book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and the

appliance warranty is invalidated.

e manufacturer declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

Page 4

INDEX

1 Storage tank unit installation ...................5

1.1 Installation recommendations. ................ 5

1.2 Main dimensions. ......................................5

1.3 Connection group. ....................................6

1.4 System lling. ............................................. 6

1.5 Domestic hot water storage tank unit. ... 6

1.6 Solar control unit installation.

(Optional for UB INOX 120-200 V2

models only). ............................................. 7

1.7 Hydraulic circuit resistance. .................... 8

1.8 Kits available on request. .......................... 8

1.9 Main components. ....................................9

USER pageINSTALLER page MAINTENANCE TECHNICIAN page

2 Instructions for use and maintenance. . 10

2.1 Cleaning and maintenance. ...................10

2.2 Emptying the storage tank unit. ............10

2.3 Case cleaning. .......................................... 10

2.4 Decommissioning. ..................................10

2.5 Control panel. ..........................................10

3 Control and maintenance ...................... 11

3.1 Hydraulic diagram. .................................11

3.2 Yearly appliance check

and maintenance. ....................................11

3.3 Casing removal. .......................................12

3.4 Replacing the anode. ...............................12

3.5 Technical data. ......................................... 12

3.6 Product data sheet (in compliance with

regulation 812/2013). ..............................13

Page 5

STORAGE TANK UNIT

1

INSTALLATION

1.1 INSTALLATION RECOMMENDATIONS.

Only professionally enabled companies are authorised to install Immergas appliances.

Installation must be carried out according to the

Standards, current legislation and in compliance

with local technical regulations and the required

technical procedures.

Before installing the appliance, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately. Packing materials

(staples, nails, plastic bags, polystyrene foam,

etc.) constitute a hazard and must be kept out of

the reach of children.

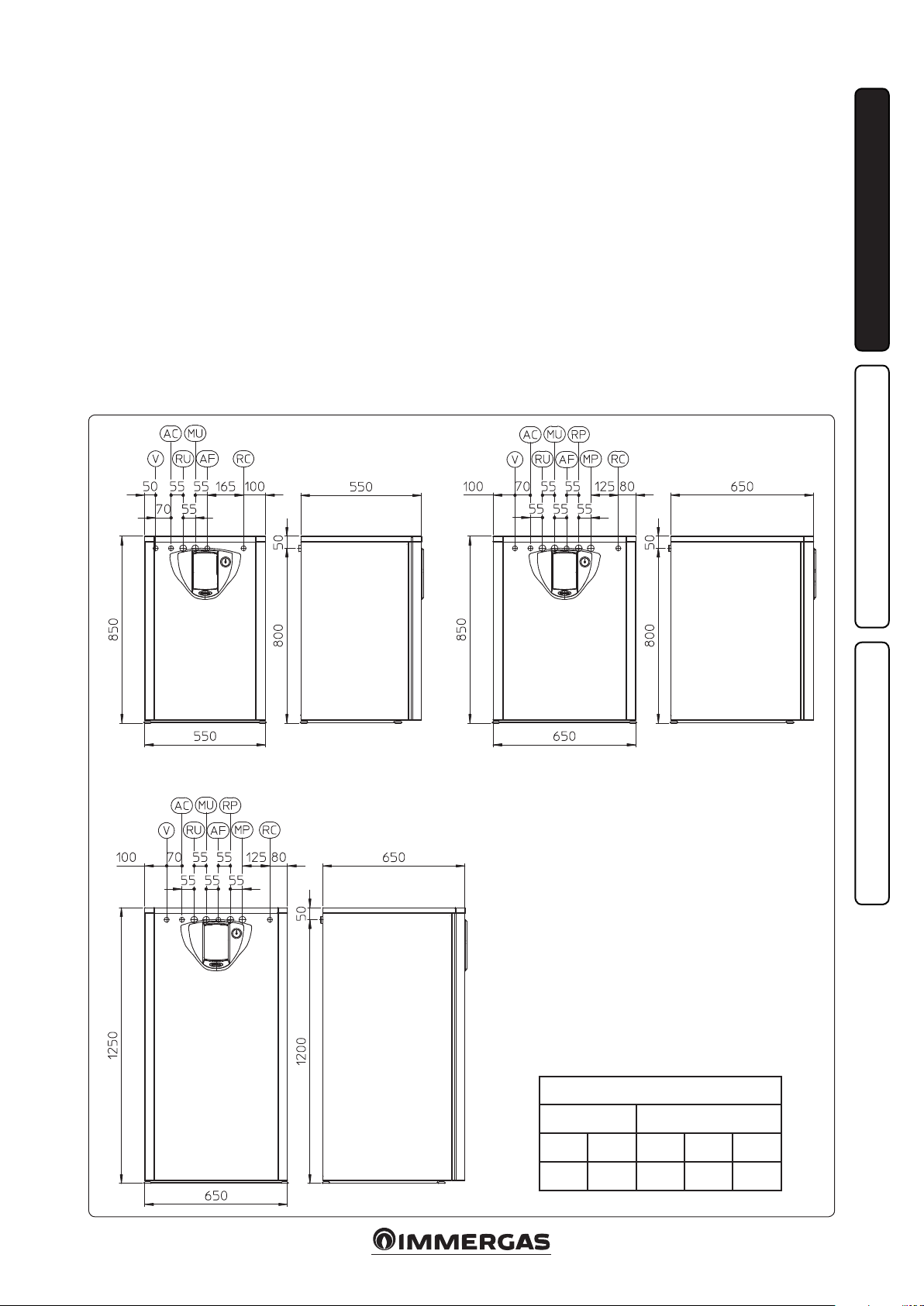

1.2 MAIN DIMENSIONS.

1-1

80 litre stainless steel storage tank unit

If the appliance is installed inside or between

cabinets, ensure sufficient space for normal

servicing; therefore it is advisable to leave a gap

of 2÷3 cm between the storage tank casing and

the sides of the cabinet.

In the event of a malfunction, fault or incorrect

-operation, disable the storage tank unit and

contact an authorised company (e.g. the

Authorised Technical Assistance centre, which

has specically trained sta and original spare

parts). Do not attempt to modify or repair the

appliance alone.

Failure to comply with the above implies personal

liability and invalidates the warranty.

• Installation Standards: These storage tanks

have been designed for oor installation; they

must be used for the storage of domestic hot

water and similar purposes. ey have not be

designed for wall-installation.

Important: these units are used to store water at

a temperature below boiling point at atmospheric

pressure. ey must be connected to a boiler and

to a DHW water distribution network. ey must

be installed in rooms where the temperature

cannot fall below 0°C and must not be exposed

to atmospheric agents.

INSTALLERUSER

120 litre stainless steel storage tank unit

200 litre stainless steel storage tank unit

5

Key:

V - Electrical connection

AC - Domestic hot water outlet

AF - Domestic hot water inlet

RU - Return from storage tank unit

MU - Flow to storage tank unit

RP - Return to solar panels (Optional)

MP - Flow from solar panels (Optional)

RC - Domestic hot water pump (Optional)

CONNECTIONS

SYSTEM DOMESTIC HOT WATER

MU-RU MP-RP AF AC RC

3/4” 3/4” 3/4” 3/4” 1/2”

MAINTENANCE TECHNICIAN

Page 6

1.3 CONNECTION GROUP.

MU

RU

V

INSTALLERUSER

Hydraulic connection. Before making the

connections, all of the system piping must be

washed thoroughly to remove any residues that

could compromise the good functioning of the

storage tank. Water connections must be made in

a rational way using the couplings on the storage

tank template. e storage tank safety valve outlet

must be connected to a draining funnel. If this

is not the case, the storage tank manufacturer

declines any liability in the event of ooding if

the drain valve cuts in.

AC

AF

RP

MP

RC

Key:

V - Electrical connection

AC - 3/4'' DHW outlet

RU - 3/4" return from storage tank

MU - 3/4" ow to storage tank

AF - 3/4'' DCW inlet

RP - 3/4" solar panels return (optional per UB INOX 120-200 V2)

MP - 3/4" solar panels ow (optional per UB INOX 120-200 V2)

RC - 1/2” recirculation (optional)

1-2

1.4 SYSTEM FILLING.

Once the storage tank has been connected, ll

the system via the boiler lling valve. Filling is

performed at low speed to ensure release of air

bubbles in the water via the boiler and central

heating system vents.

Close the lling valve when the boiler manometer

pointer indicates approx. 1.2 bar (see boiler

instruction book).

1.5 DOMESTIC HOT WATER STORAGE TANK UNIT.

e storage tank unit must be connected to a

boiler. It contains large coiled stainless steel heat

exchanger pipes, which allow to notably reduce

hot water production times. is storage tank

unit, manufactured with stainless steel casing and

MAINTENANCE TECHNICIAN

bottoms, guarantees long duration through time.

e assembly concepts and welding (T.I.G.) are

implemented to the minimum detail to ensure

maximum reliability.

e upper inspection ange ensures practical

control of the storage tank unit and the coil heat

exchanger pipe and easy internal cleaning.

e domestic hot water connections are placed

on the ange cover (cold inlet and hot outlet), the

Magnesium Anode cap inclusive of the same, is

provided as standard for the internal protection

of the storage tank from possible corrosion is

located on the side of the UB INOX 200 V2

storage tank, in the other models is placed on

the inspection ange.

N.B.: annually check (e.g. the Authorised

Technical Assistance centre) eciency of the

sacrificial anodes. The storage tank unit is

prepared for introduction of the domestic hot

water pump tting.

6

Page 7

INSTALLATION.

(Optional for UB INOX 120-200 V2

models only).

Using the solar control unit it is possible to couple

the UB INOX 120-200 V2 storage tank units to

a solar system.

Hole plug plaque removal (Fig. 1-3).

- Remove the casing as indicated in paragraph

3.3 of this book;

- Take the front casing (1) and remove the hole

plug plaque (2) unscrewing the 3 xing screws

(3).

Solar control unit xing (Fig. 1-4).

- Fix the screw (8) onto the support sheet steel

(9) paying attention to leave a couple of mm

between the head of the screw and the support

sheet steel;

- Remove the lid (6) from the solar control unit

(7) loosening the screw (5);

- Attach the upper part of the solar control unit

(7) to the screw (8);

- Block the solar control unit (7) in the lower

part using the screw (4);

- Make all electric connections as indicated in

the solar control unit instruction book;

- Re-mount the lid (6) from the solar control unit

(7) loosening the screw (5);

- Re-mount the storage tank unit casing.

Hole plug plaque removal.1.6 SOLAR CONTROL UNIT

223

223

INSTALLERUSER

222

221

Solar control unit xing.

226

227

229

228

1-3

MAINTENANCE TECHNICIAN

225

224

1-4

7

Page 8

1.7 HYDRAULIC CIRCUIT RESISTANCE.

In order to guarantee sucient DHW ow rate,

it is important to consider the resistance of the

storage tank hydraulic circuit to be coupled to

the boiler. (Fig. 1-5). For correct connection of

the storage tank unit to Immergas boilers, see t he

boiler instruction book.

1.8 KITS AVAILABLE ON REQUEST.

• Pump kit (on request). e storage tank unit

is prepared for application of the pump kit.

Immergas supplies a series of fittings and

INSTALLERUSER

attachments that allow connection between

the storage tank unit and domestic hot water

system. The pump kit attachment is also

envisioned on the template.

• Column attachment kit (on request for UB

INOX 200 V2) A vertical connection kit is

envisioned for the connection of the storage

tank unit to the column, which allows to

connect the storage tank unit directly to the

boiler without having to insert the connection

pipes into the wall.

Hydraulic circuit resistance.

• Solar collectors kit (on request for UB INOX

120-200 V2) On request Immergas supplies

complete packs for set-up, if solar collectors

are to be used for the production of domestic

hot water.

• Double storage tank kit in parallel (on request

for UB INOX 200 V2) A connection kit is

envisioned for the connection of two storage

tank units in parallel, which allows connection

of the two storage tank units directly to the

boiler without having to insert the connection

pipes into the wall.

• Solar panels kit in parallel (on request for

UB INOX 200 V2) For the connection of two

storage tank units to the solar panels without

having to insert the connection pipes into the

wall.

• Storage tanks pump kit in parallel (on request

for UB INOX 200 V2) For the connection of

two storage tank units to the recirculation

pump pipes without having to insert the

connection pipes into the wall.

• Electronic anode kit (on request).

(Not available for UB INOX 80 V2).

Direct current is made to circulate between the

device and the tank to be protected via a special

titanium anode.

Use the tting present on the storage tank upper

ange for installation of the anode (Free tting

for UB INOX 200 V2, or replacing the anode

present in the UB INOX 120 V2).

e above-mentioned kits are supplied complete

with instructions for assembly and use.

MAINTENANCE TECHNICIAN

UB INOX 80 V2

UB INOX 120 V2

UB INOX 200 V2

A

Flow rate (l/h)

Flow rate (l/h)

O)

2

O) Head (m H

2

A - Storage tank unit

A

hydraulic circuit resistance

O) Head (m H

2

Head (kPa) Head (kPa) Head (kPa)

Flow rate (l/h)

A

Head (m H

1-5

8

Page 9

1.9 MAIN COMPONENTS.

80 litre stainless steel storage tank unit

200 litre stainless steel storage tank unit

120 litre stainless steel storage tank unit

INSTALLERUSER

Key:

1 - Stainless steel coil for storage tank

2 - Domestic hot water probe

3 - Magnesium anode

4 - 8 bar safety valve

5 - Storage tank emptying cock

6 - ermometer probe

7 - DHW expansion vessel

8 - Coil that can be coupled to solar panels

9 - Solar panels probe (Optional)

MAINTENANCE TECHNICIAN

1-6

9

Page 10

INSTRUCTIONS FOR USE

2

AND MAINTENANCE.

2.1 CLEANING AND MAINTENANCE. Attention: to preserve integrity of the storage

tank unit and keep the safety features, performance and reliability, which distinguish it,

unchanged over time, you must at least execute

maintenance operations on a yearly basis in

compliance with what is stated in the relative

point at “annual check and maintenance of the

appliance”, in compliance with national, regional,

INSTALLERUSER

or local standards in force. Annual maintenance

is essential to validate the Immergas warranty.

We recommend stipulating a yearly cleaning

and maintenance contract with an authorised

local rm.

2.2 EMPTYING THE STORAGE TANK UNIT.

To drain the storage tank, use the special

valve in the lower part of the storage tank

(Part. 5 Fig. 1-6).

Before draining, ensure that the DHW inlet

valve is closed.

2.3 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the storage tank casing. Never use abrasive or

powder detergents.

2.4 DECOMMISSIONING.

In the event of permanent shutdown of the storage tank, contact an authorised company for the

relative operations, among other things making

sure that water supply is disconnected.

At the end of its service life the appliance must

not be disposed of like normal household waste

nor abandoned in the environment, but must

be removed by a professionally authorised

company. Contact the manufacturer for disposal

instructions.

2.5 CONTROL PANEL.

MAINTENANCE TECHNICIAN

Key:

1 - Hole plug plaque

2 - Storage tank unit thermometer

2-1

10

Page 11

CONTROL

3

AND MAINTENANCE

3.1 HYDRAULIC DIAGRAM.

200 L STAINLESS STEEL STORAGE TANK UNIT 120 L STAINLESS STEEL STORAGE TANK UNIT 80 L STAINLESS STEEL STORAGE TANK UNIT

INSTALLERUSER

Key:

1 - Storage tank unit draining valve

2 - 8 bar safety valve

3 - Magnesium anode

4 - Domestic hot water expansion vessel

5 - Stainless steel coil for storage tank

6 - One-way valve (OV 20)

3.2 YEARLY APPLIANCE CHECK AND MAINTENANCE.

e following checks and maintenance should

be performed at least once a year.

- Visually check for water leaks or oxidation

from/on connections;

- Check visually that the safety and control

devices have not been tampered with and in

particular, the DHW regulation NTC probe;

- Check the integrity of the storage tank

Magnesium anode;

- Check the state of the internal coil;

- Check the presence of any slurry deposits on

the bottom of the storage tank.

7 - Cold water inlet lter

8 - Cold water inlet cock

9 - Domestic hot water probe

10 - DHW inlet probe (Optional)

11 - Stainless steel coil that can be coupled

to solar panels

12 - System draining valve

13 - Solar panels probe (Optional)

AC - Domestic hot water outlet

RC - Pump (Optional)

AF - Domestic cold water inlet

MU - Flow to storage tank unit

RU - Return from storage tank unit

3-1

MAINTENANCE TECHNICIAN

11

Page 12

3.3 CASING REMOVAL.

To facilitate storage tank maintenance, the casing

can be completely removed as follows:

N.B.: the casing removal procedure is the same

for all storage tank unit models.

- remove the lid (1) pulling it upwards;

- loosen the screws (2) and pull the front panel

outwards (3);

- loosen the screws (4) of the side pieces (5)

positioned on the top and in the lower part

of the side pieces themselves. Aer having

INSTALLERUSER

released them from the screws, they can be

removed by pulling them forward and then

upwards.

3.4 REPLACING THE ANODE.

e magnesium anode (Part. 3 Fig. 1-6), present

in the storage tank, must be replaced every year

with another having the same features.

1

4

5

4

2

222

3

3.5 TECHNICAL DATA.

UB INOX 80 V2 UB INOX 120 V2 UB INOX 200 V2

Storage tank useful capacity l 83.9 128.8 199

Domestic hot water side maximum pressure bar 8 8 8

DHW side maximum temperature °C 99 99 99

Domestic hot water expansion vessel l 4.0 5.0 8.0

Dispersions kWh/24h 1.35 1.51 1.87

Psbsol W/K 1.25 1.39 1.73

Coil thickness mm 0.8 0.8 0.8

MAINTENANCE TECHNICIAN

Coil length mm 10350 - Lower coil length mm - 3850 6500

Upper coil length mm - 8400 10700

Coil exchange surface m

Lower coil exchange surface m

Upper coil exchange surface m

Coil capacity l 2.75 - Lower coil capacity l - 1.02 1.73

Upper coil capacity l - 2.23 2.84

Primary uid ow rate (coil) l/h 1030 1325 1390

Coil head loss at 1000 l/h kPa (m H2O) 13.2 (1.35) 7.1 (0.72) 8.3 (0.85)

Central heating side maximum pressure bar 6 6 6

Central heating side maximum temperature °C 90 90 90

Heat exchange maximum output kW 23.9 30.8 32.3

Reintegration heat output kW 15.7 18.8 20.2

Full weight kg 153.65 202.15 303.97

Empty weight kg 70.9 78.9 99.4

Total water content l 82.7 123.25 204.57

2

2

2

0.65 - -

- 0.24 0.41

- 0.53 0.67

4

5

3-2

12

Page 13

3.6 PRODUCT DATA SHEET IN COMPLIANCE WITH REGULATION 812/2013.

UB INOX 80 V2

+

A

A

B

C

D

E

F

UB INOX 80 V2

"! !

56 W

84 L

UB INOX 120 V2

UB INOX 120 V2

"! !

+

A

A

B

C

C

D

E

F

C

63 W

129 L

UB INOX 200 V2

+

A

A

B

C

D

E

F

UB INOX 200 V2

"! !

78 W

199 L

C

13

Page 14

14

Page 15

15

Page 16

Follow us

Immergas Italia

immergas.com

Immergas S.p.A.

42041 Brescello (RE) - Italy

Tel. 0522.689011

Fax 0522.680617

Certied company ISO 9001

is instruction booklet is made of ecological paper Cod. 1.041260ENG - rev. ST.003314/000 - 09/17 - Inglese per IRLANDA (IE)

Loading...

Loading...