Page 1

Instruction and

*1.041494ENG*

recommendation booklet

IE

RAPAX 100 V2

Page 2

Page 3

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to ensure well-being and safety for a long period of time. As an Immergas Customer,

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully:

you will be able to draw useful tips on the correct use of the device, compliance of which will conrm your satisfaction with the Immergas product.

For assistance and routine maintenance, contact Authorised Service Centres: they have original spare parts and are specically trained directly by the manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in a dry place protected from the weather.

e instruction booklet is an integral and essential part of the product and must be given to the new user in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instruction booklet provides technical information for installing Immergas boilers. As for the other issues related to boiler installation (e.g. safety in the

workplace, environmental protection, accident prevention), it is necessary to comply with the provisions specied in the regulations in force and with the

principles of good practice.

In compliance with the legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by an authorised

company, which has the specic technical skills in the system sector, as provided for by Law.

Improper installation or assembly of the Immergas device and/or components, accessories, kits and devices can cause unexpected problems for people, animals

and objects. Read the instructions provided with the product carefully to ensure proper installation.

Maintenance must be carried out by an authorised company. e Authorised Service Centre represents a guarantee of qualication and professionalism.

e device must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially dangerous.

If errors occur during installation, operation and maintenance, due to non-compliance with technical laws in force, standards or instructions contained in

this booklet (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages

and the device warranty is invalidated.

e manufacturer declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

Page 4

INDEX

1 Important recommendations. ........................... 5

1.1 Warnings. ............................................................. 5

1.2 installation. .......................................................... 5

1.3 Hydraulic connection. ........................................5

1.4 Wiring. .................................................................5

2 Introducing the product. ...................................6

2.1 Important advice. ................................................6

2.2 Technical specications......................................6

2.3 Dimensions and components. ...........................7

3 Installation. ..........................................................9

3.1 Choosing the place of installation. ................... 9

3.2 Product installation. .........................................11

3.3 Hydraulic connection. ......................................12

3.4 Air intake connection. ......................................12

3.5 Electrical connection. .......................................12

3.6 Water heater wiring diagram. ..........................14

3.7 Commissioning. ................................................14

4 Parameter settings / Use. .................................. 15

4.1 remote panel. .....................................................15

4.2 Description of the symbols. .............................15

4.3 Main menu. ........................................................15

4.4 System settings. .................................................16

4.5 Parameters to be adjusted upon installation. 16

4.6 Selecting the operating mode. ......................... 16

4.7 Display the information ...................................16

5 Recommendations - maintenance and

repairs. ................................................................17

5.1 Advice for the user. ........................................... 17

5.2 Household maintenance. ................................. 17

5.3 Maintenance by approved professionals. .......17

5.4 Troubleshooting support. ................................18

5.5 Work on the water heater. ................................19

5.6 Quick fault diagnosis for use carried out by a

professional technician.....................................20

5.7 Aer-sales service. ............................................ 20

5.8 Scope of application of the warranty. .............20

5.9 Declaration of conformity. ...............................20

6 Product che (in compliance with Regulation

812/2013). .......................................................... 21

7 Parameters for lling in the package che. ....22

Page 5

IMPORTANT

1

RECOMMENDATIONS.

1.1 WARNINGS.

is device may only be used by adult

users whose physical, sensory or mental abilities are not impaired.

Before using this device, this instruction booklet (User section) and/or the

operating instructions should be ready

by skilled technical sta.

Use by incompetent adult staff and

especially by children is forbidden

for safety reasons and due to issues of

correct device operation and warranty.

is device has been designed to serve

one residential housing unit only (and

similar) subject to assessment of the

energy requirement for domestic hot

water; it is not a heating system pursuant to the legislation in force.

1.2 INSTALLATION.

Warning: due to its weight (57 kg), this

device must be handled with care to

avoid injury to persons or damage to

property and to the product itself. Installation must therefore be performed

taking into account the following

instructions:

- Install the device in a frost-free room.

The warranty does not cover any

device breakdown caused by excessive pressure due to the safety valve

blocking because of ice.

- Ensure the wall on which the device

is to be installed is suitable to withstand the device's own weight and

that of the water content (100 litres

approximately). It is recommended

to perform a structural assessment

by the designer of the dwelling.

- If the storage tank is mounted on a

false ceiling, under the roof or above a

living area, it is mandatory to install a

drip tray to be connected to the drain.

- Suitably aerate the installation room

in the event the device is to be installed in a room and/or in a position

where the ambient temperature is

always higher than 35°C.

- is device is intended for use up to

a maximum height of 2000 m.

- Position the device in an accessible

area and at such a distance from the

wall to permit correct maintenance /

accessibility (Paragraph 3.1).

- Refer to the installation diagrams

(Paragraph 3.1).

Caution: failure to comply with recommended installation procedures,

especially a room volume below the 20

m3 minimum, may signicantly reduce

system performance.

- It is recommended to provide suitable shut-o valves on the hydraulic

connection to allow for any routine

and extraordinary maintenance operations which might require emptying/

lling the water heater.

- In order to prevent any stability and

safety issues, it is obligatory to secure

the water heater on the wall using the

fastening anchors supplied.

1.3 HYDRAULIC CONNECTION.

It is mandatory to install a safety device,

set to be triggered at 0.7 MPa (7 bars)

(not supplied with the water heater),

sized 3/4”, compliant with standard

EN1487 as amended and added, and

in any case compliant with local regulations in force, to be tted to the cold

water inlet of the water heater.

e safety device must be protected

from ice.

e safety unit must be tted with a

discharge device (overpressure) to

be operated regularly to remove any

limestone deposits.

It must also be checked regularly to

ensure it is not blocked.

e pressure reducer (not supplied as

standard) is required when the water

mains pressure exceeds 0.5 MPa (5

bars) and must be mounted on the

main water supply line.

e safety unit must also be connected

to an open drain pipe, in a frost-free

environment, with a permanent downward gradient, to remove any expansion water from the heating process, or

drainage water from the water heater.

To perform any discharge operations

of the water heater, strictly adhere to

the following sequence:

- Disconnect the device from the electrical supply voltage.

- Disconnect the device from the mains

water supply (cold water).

- Open the hot water tap.

- Actuate the discharge device of the

safety unit.

1.4 WIRING.

Before removing the cover of the water

heater, always ensure the power is dis-

connected, to prevent any risk of injury

due to electric shocks.

e following must be provided upstream of the electrical system:

- A circuit breaker or 16A multi-pole

fuse with contacts compliant with

regulations in force.

- A 30 mA dierential circuit breaker.

Should the power cable be found to

be damaged for any reason, it must be

replaced by the Aer-sales Support,

and/or in any case by skilled and qualied sta.

e water heater must be connected to

earth according to the methods set out

by the regulations in force.

A special terminal, suitably marked

is provided for the specic purpose.

is manual is supplied jointly with the

water heater; in the event of loss it may

also be obtained from the Authorised

area Support service or be downloaded

from the suitable website.

5

Page 6

INTRODUCING THE

2

PRODUCT.

2.1 IMPORTANT ADVICE.

Transport, handling and storage. e product

may be transported upright on a pallet, or rotated

by 90° on its side

The appropriate side is shown clearly on an

information label on the product packing box.

It is forbidden to transport the product lying on

its other sides as it could irreparably damage it.

Note: follow the transport and maintenance recommendations on the water heater’s packaging.

e product warranty is rendered null and void

if the above instructions are not complied with.

e manufacturer declines any liability for any

faults to the product resulting from transport or

handling not complying with the above recommendations.

Under no circumstances may this product be

stacked (Fig. 2-1).

Safety directives. The installation work and

commissioning of thermodynamic water heaters

can be hazardous due to high pressure and live

electrical parts.

ermodynamic water heaters must be installed,

commissioned and serviced by trained and

qualied sta only.

POSITIONS ALLOWED DURING TRANSPORT

2.2 TECHNICAL SPECIFICATIONS.

Dimensions

Empty weight

Tank capacity

Hot + cold water tting

Anti-corrosion protection

Maximum operating pressure

Electrical connection (voltage/frequency)

Max total power absorbed by the device

Max power absorbed by heat pump

Power absorbed by auxiliary electrical unit

Setting range of the water temperature of the heat pump

Temperature range for using the heat pump (air temperature)

Diameter of intake and exhaust ducts

Air ow rate without ducts

Load losses acceptable on ventilation circuit, without aecting performance

R134a refrigerant charge

Coolant

Coolant mass

Coolant volume

Amount of hot water at 40°: V40td in 8h (HC) / 14h (HC+6h)

Coecient of performance (COP)

Power absorbed at steady speed (Pes)

Heating time(th)

Reference temperature(Tref)

Air ow rate

Coecient of performance (COP)

Power absorbed at steady speed (Pes)

Heating time(th)

Reference temperature(Tref)

POSITIONS NOT ALLOWED DURING TRANSPORT

mm

kg

l

bar

W

W

W

°C

°C

mm

m3/h

Pa

kg

kg/l

Ton CO2 Eq.

l

-

W

h.min

°C

m3/h

-

W

h.min

°C

H 1234 x L 522 x D 538

57

100

3/4’’ M

Magnesium anode

8

230 V single-phase 50 Hz

1550

350

1200

from 50 to 62 (temperature factory setting 52°C)

from -5 to +43

125

160

25

0.6

R134a

0.006

0.86

151 / 289

2.47 - M

20

7 h 27

52.8

162.7

2.75 - M

18

6 h 25

52.5

2-1

6

Page 7

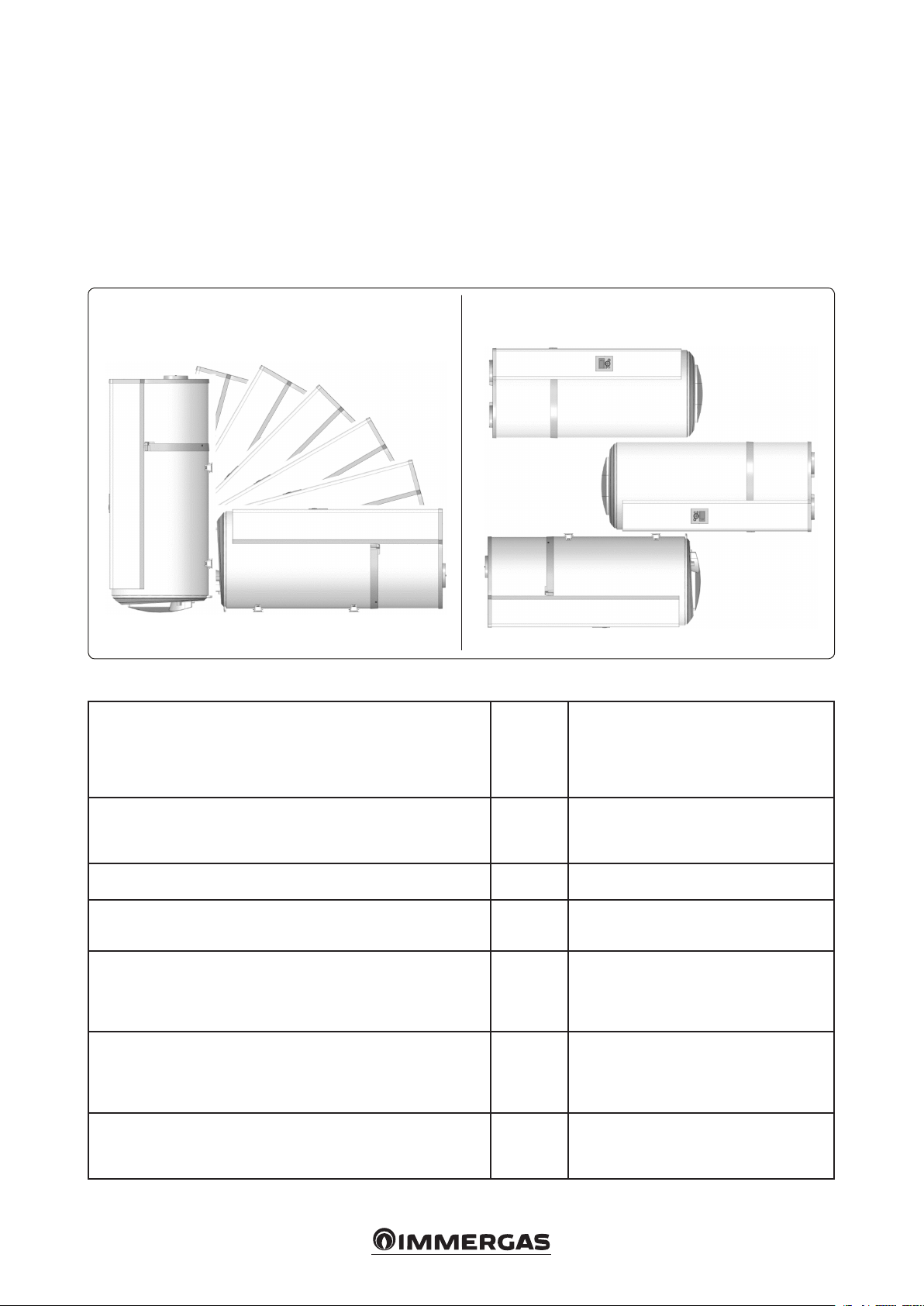

2.3 DIMENSIONS AND COMPONENTS.

Key:

AC - Domestic hot water outlet 3/4” M

AF - Domestic cold water inlet 3/4” M

SC - Condensate drain

2-2

7

Page 8

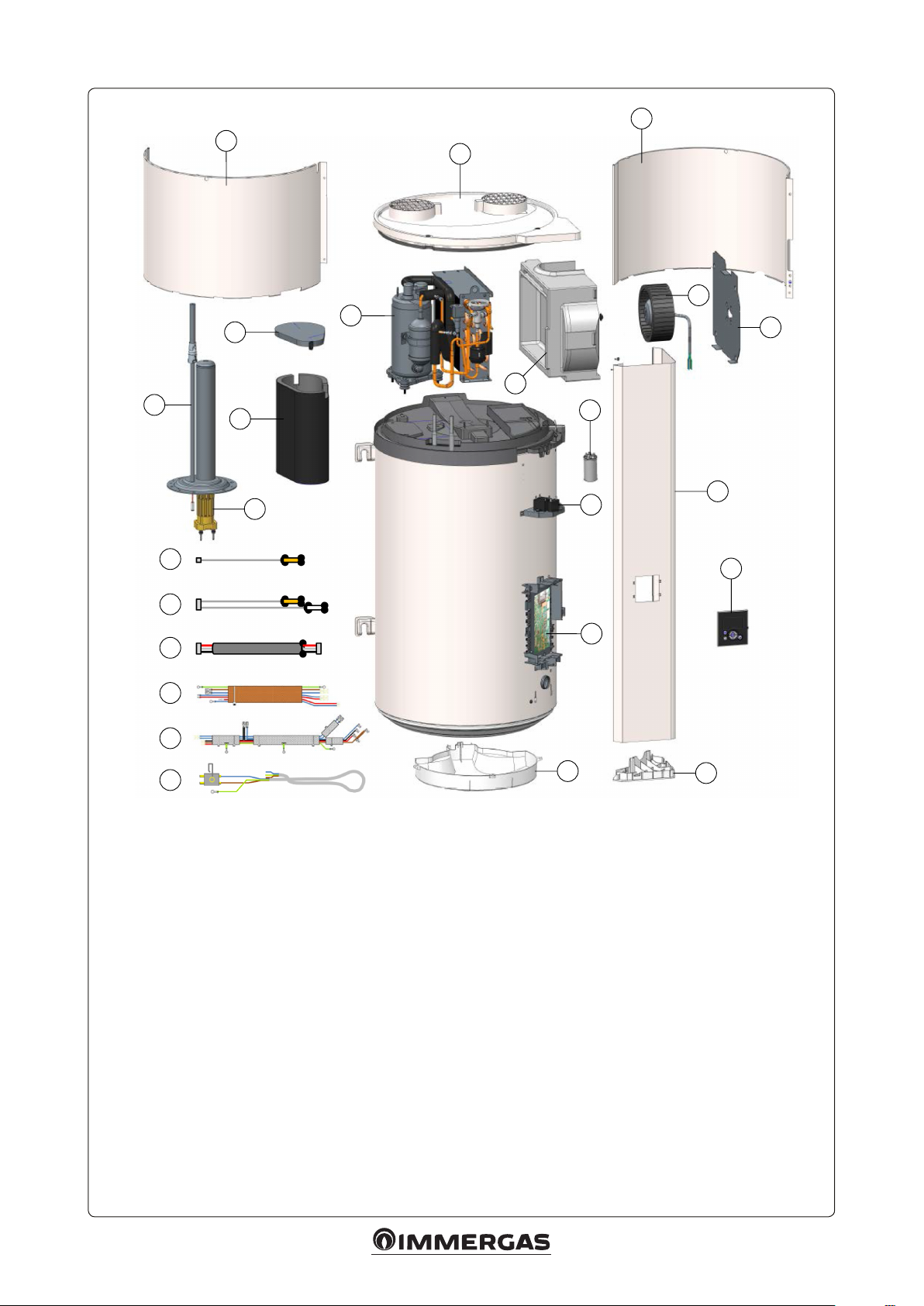

3

1

2

10

8

5

11

9

4

6

24

7

18

19

20

21

22

23

Key:

1 - Front cover

2 - Cover

3 - Rear cover

4 - Heating unit (Resistance + Anode)

5 - Casing cover

6 - Compressor casing

7 - Electrical resistance

8 - Compressor

9 - Fan casing

10 - Fan

11 - Fan support plate

12 - Front column

13 - Control unit

14 - Condenser 1.5-2.5-2.7F

15 - P.C.B.

16 - Cap

17 - Bottom part cap

18 - Water probe wiring 1

19 - PDC probe wiring 2

20 - Interface wiring

21 - Electrical integration

22 - Compressor wiring

23 - Fan wiring + terminal block

24 - Condenser 10F

Not shown: manual, dielectric connection, condensate draining pipe, safety unit.

16

14

12

13

15

17

2-3

8

Page 9

INSTALLATION.

3

3.1 CHOOSING THE PLACE OF

INSTALLATION.

Resistance of the wall • Withstands a load of at least 300 kg (water heater xing surface)

Note: only install a water storage tank under the water heater when this is positioned above in

residential buildings.

e installation area shall be suitable for protection index IPX1B, as set forth in IEC 64-8

Non-ducted or

semi-ducted conguration

Type of installation room

Room examples

Volume of room where air is extracted

Temperature of water heater installation

room

Air inlet temperature

• Unheated room, characterised by temperature

exceeding 5°C and preferably insulated from

the home's heated rooms.

• Recommended room = underground or basement, room where the temperature is higher

than 10°C all year round.

• garage, boiler room (with the exception of

rooms where type B generators are installed),

basement oor, ironing room, etc.

• Volume > 20 m

• from 5°C to 43°C.

• -5°C to 43°C.

3

• Room that is at least frost-free.

• Recommended room = living space (the heat

loss from the water heater is not wasted), close

to the outer walls.

• Do not install close to sleeping areas because of

the noise produced.

• laundry room, cellar, cupboard in entrance hall,

etc.

• /

• > 1°C.

• -5°C to 43°C.

Ducted conguration

Ceiling height

Surface area required

RECOMMENDED CONFIGURATIONS.

• 1st conguration: installation without duct in

unheated room (Volume > 20 m3) (Fig. 3-1).

INTERNAL/INTERNAL parameter (Para-

graph 4.5).

Examples of unheated rooms:

- Garage: Recovery of free calories released by

car engine when turned o aer running, or

other electrical appliances operating.

Min.

200 mm

• > 2.00 m.

• 2.10 m2.

• e wall must be perpendicular.

- Laundry room: dehumidifying the room

and recovery of waste calories from washing

machines and tumble-dryers.

- Room in basement: recovery of free calories

released by the oor and walls of the basement.

• > 2.00 m.

• 2.10 m2.

• e wall must be perpendicular.

Note: observe the minimum distance indicated

to prevent air recirculation.

Note: observe a space of 450 mm in front of the

electrical appliance, so that the water heater can

be accessed for maintenance work.

Min.

600 mm

Example of

installation without

ducts

Min. 400 mm

3

>20 m

Except for the volume of

bulky waste

Room temperature between 5 and

43°C, except for operation of the

water heater

522 mm

9

Min.

120

mm

3-1

Page 10

• 2nd conguration: installation in a heater or

unheated room, with ducts (Fig. 3-2).

EXTERNAL/EXTERNAL parameter (Par-

agraph 4.5).

Recommendations:

- Comply with maximum duct lengths (Para-

graph 3.4).

- Use rigid or semi-rigid pipes.

- Provide air inlet and outlet grids to avoid

ingress of foreign bodies. Note: manually

shuttered air inlet and outlet grids are forbidden.

3-2

Min.

100 mm

Note: observe a space of 450 mm in front of the

electrical appliance, so that the water heater can

be accessed for maintenance work.

CONFIGURATIONS IN CERTAIN CONDITIONS (subject to assessment).

• Installation in unheated room, with 1 duct

only (volume > 20 m3) (Fig. 3-3).

INTERNAL/EXTERNAL parameter (Para-

graph 4.5).

Possible consequence:

- In the event of installation with air intake in

the same room and expulsion through a duct,

the ventilation openings must be sized with

a minimum diameter of 125 mm.

Note: in winter, the inlet air will be colder than

that discharged by the water heater, which will

increase room cooling.

Note: observe a space of 450 mm in front of the

electrical appliance, so that the water heater can

be accessed for maintenance work.

3-3

Min.

670 mm

Min.

200 mm

Example of

installation with

ducts

Mandatory air

inlet

Ø 125 mm

Room at minimum

antifreeze

522 mm

Duct on air outlet

Min.

120

mm

Min.

670 mm

Example of

installation with 1

exhaust duct

Room temperature between 5 and

43°C, except for operation

of the water heater

Min.

522 mm

120

mm

10

Page 11

FORBIDDEN CONFIGURATIONS.

Forbidden installation congurations Associated risks

e water heater takes air from a room containing a

paid heat source used for heating this room.

Connection to a controlled mechanical ventilation

system (CMV).

Connection to an attic.

duct which intakes air from the outside, conveying

cold air inside.

Connection to a geo-thermal system.

Excessive system consumption: the water heater no longer uses free calories, but uses those

produced by other devices connected to other energy sources.

e air ow rates in the thermodynamic water heater are incompatible with those of a CMV.

Furthermore, the CMV ducts may convey greasy vapour and dust, potentially harmful for

the duration in service of your water heater.

In the presence of inadequate insulation between the building and the relative attics, this

type of installation may increase the thermal loss of the building.

In extreme cases, condensate might form on the ceilings of the rooms under the attic due

to its cooling.

ere is a greater risk from falling objects and dust ingress to the water heater in this

conguration, which could reduce its life expectancy.

Signicant loss of the coecient of performance (COP) and much greater cooling of the

room.

Excessive loss of load, and problems balancing the two fans in series.

High risk of clogging the evaporator.

Other prohibitions:

- Do not connect the device's fan to a tumble-dryer

- Avoid very dusty rooms

- Do not extract air containing solvents or explosive materials.

- Do not connect the device to a suction hood

used to extract greasy or polluted air.

- Do not install the water heater in a room exposed to frost

- Do not place any objects on the water heater

- In non-ducted or semi-ducted conguration,

do not place it in a room where an open chamber heat generator is installed (type B).

3-4 3-5

3.2 PRODUCT INSTALLATION.

1 - Take the water heater to the place of installa-

tion.

e device has various handholds to help

move it to the place of installation.

Use the bottom and top handholds to carry

the water heater to its place of installation.

2 - Open the packaging.

3 - Separate the boiler from the pallet and place

it next to the hydraulic connection.

e water heater must be installed on a

perpendicular wall (± 1°) or on smooth at

surface (± 1°).

4 - If the wall is load-bearing (concrete, stone,

bricks) (Fig. 3-4), anchor with Ø10 mm bolts

or drill holes for Ø10 mm MOLLY bolts.

5 - If the wall is not load-bearing (Fig. 3-5) it is

mandatory to put the water heater on a mount

(optional). Put the water heat on the mount

to trace the xing points. Drill the holes and

reposition the water heater. e top bracket

must be secured (using a Ø10 mm anchor

at least, depending on the wall) to prevent it

from tipping over.

11

Page 12

3.3 HYDRAULIC CONNECTION.

Connection to the cold water inlet.

Before connecting the water supply, it is essential

to clean the pipes thoroughly, to avert the risk of

any metal or other particles entering the water

heater tank.

It is mandatory to install a safety device, set to

be triggered at 0.7 MPa (7 bar) (not supplied

with the water heater), sized 3/4”, compliant with

standard EN1487 as amended, and in any case

compliant with local regulations in force, to be

tted to the cold water inlet of the water heater.

e safety device must be protected from ice.

Note: no hydraulic ttings (stop valve, pressure

reducer, etc.) must be placed between the safety

unit and the cold water inlet of the water heater,

except for a copper pipe.

Connect the safety unit to an open drain pipe,

in a frost-free environment, with a permanent

downward gradient, to remove any expansion

water generated by the heating process or drainage water coming from the water heater itself.

e pipes used must withstand a temperature of

100°C and a pressure of 1 MPa (10 bar).

When the inlet water pressure exceeds 0.5 MPa (5

bar), a pressure reducer is required (not supplied

as standard).

e pressure reducer must be installed at the

beginning of the main distribution network.

A pressure of 0.3 to 0.4 MPa (3 and 4 bar) is

recommended.

Connection to the hot water inlet.

Note: do not connect the hot water directly to

copper pipes, in order to avoid copper/iron galvanic coupling (risk of corrosion). It is therefore

obligatory to t a dielectric tting on the hot

water outlet (supplied with the device).

Any corrosion on the threads of the hot water

outlet tting, due to the tting supplied not

being used, shall void the product warranty.

In the event pipes in synthetic material have been

used (e.g.: PER), we strongly recommend installing a thermostatic control device water heater

outlets and set it according to the performance

of the material used.

Note: the use of D.H.W. recirculation is not feasible: this method causes water destratication

in the tank and makes the heat pump and the

electrical resistance work more.

Removing the condensate.

Note: cooling of the circulating air in contact

with the evaporator results in the water contained

in the air condensing. The condensed water

owing down the back of the heat pump must

be removed from it and conveyed into suitable

plastic pipes.

On the basis of air humidity, up to 0.25 l/h of

condensate may be formed. e condensate

run-o must not be conveyed into the drain,

since the ammonia fumes that ow back from

the drain could damage the heat exchanger ns

and parts of the heat pump.

It is therefore obligatory to t a siphon for the

discharge of waste water (do not use the pipe

supplied under any circumstances to make a

siphon).

3.4 AIR INTAKE CONNECTION.

When the volume of the room where the water

heater is installed is less than 20 m3, the device

may be connected to air ducts with 125 mm diameter. If these ducts are not insulated, condensate might form in them during device operation.

It is therefore essential to choose insulated

air ducts.

Poor-quality air ducts (crushed, too long, or

with too many bends, etc.) may cause a loss of

performance.

Therefore flexible ducts are definitely not

recommended.

Note: if there are connections to the ducts, adjust

fan settings accordingly.

Note: the overall head loss on ducts and ttings

for discharge and intake of air must be less

than 70 Pa. Calculate the pressure drop using

the table below, according to the proposed duct

accessories.

For installation without ducts, the direction of

the grids can be altered to direct the air ows.

To do this, unscrew the grids and screw them

back in one of the other 2 positions provided.

It is forbidden to direct the grids facing each

other (Fig. 3-6).

3.5 ELECTRICAL CONNECTION.

Note: the water heater can be electrically con-

nected only aer being lled with water.

Note: do not t a programming clock or timing

devices that may interrupt the device's supply

voltage upstream of the water heater’s electrical

connection.

e water heater can be connected and operated

only with single-phase 230V AC power supply.

Connect the water heater with a cable with

conductors having a cross-section of at least 1.5

mm². Installation shall consist of:

- A circuit breaker or 16A multi-pole fuse with

contacts compliant with regulations in force.

- A 30 mA dierential circuit breaker.

If the power cable is damaged, for safety reasons

it must be replaced by the manufacturer, the

aer-sales service or similarly qualied sta.

Note: earthing is obligatory.

Do not connect the supply voltage directly to the

electrical resistance.

e safety thermostat with which the electrical

integration is tted must not be tampered with; if

required, it may be repaired/serviced exclusively

by skilled and qualied sta, according to the

instructions provided by Immergas. Failure to

comply with this clause shall void the warranty.

e device must be installed in compliance with

the provisions of the regulations in force.

3-6

Number of bends

0 bends 10 m 21 m

1 90°

elbow tting

2 90°

elbow ttings

(*) semi-rigid ducts - (**) rigid ducts

Overall length of the ducts* with air outlet and

inlet mounted on the wall

8 m 17 m

6 m 13 m

Overall length of the ducts** with air outlet and

inlet mounted on the wall

12

Page 13

Photovoltaic self-consumption contact.

e water heater is equipped with a contact to

fully exploit the electricity produced by the PV

system, in order to accumulate thermal energy

within the storage tank (self-consumption).

Having an inverter/electronic device which

supplies a signal when PV production exceeds

a certain value, when this contact is closed the

water heater is triggered in heat pump mode to

heat the DHW up to 62°C.

When the photovoltaic contact opens, the system

returns to the previous settings.

Wiring diagram

e instructions for removing the front cover and

for accessing the terminal block can be found in

paragraph 5.5.

e photovoltaic station must be wired to the

appropriate connector provided (I1) (Fig. 3-10).

To pass the photovoltaic station’s connection

cable, a hole must be drilled in the bottom cap;

the point where the hole is to be drilled is marked

(Fig. 3-8).

3-8

Note: earth connection is mandatory.

Example of connection to a photovoltaic system

AC junction

box

Inverter

3-7

PV panel

230V~ - 50Hz signal

3-9

13

Page 14

3.6 WATER HEATER WIRING DIAGRAM.

3-10

Supply voltage

230 Vac

50Hz

Key:

1 - Water heater board

2 - Evaporator probe

3 - Air inlet probe

4 - Fan condenser - second speed

5 - Fan

6 - Fan engage condenser

7 - Safety thermostat

3.7 COMMISSIONING.

Filling the water heater.

- Open the hot water taps.

- Open the cold water tap on the safety device

(ensure the unit emptying valve is closed).

- Run the hot water from the taps then close

them: the water heater is now full.

- Check water tightness of the pipe ttings.

- Check correct operation of hydraulic devices by

opening the discharge valve of the safety device

to eliminate any residues from inside the relief

valve.

Θ>

8 - Immersion heater

9 - Domestic hot water sensor

10 - High pressure sensor

11 - Compressor protection thermostat

12 - Compressor engage condenser

13 - Compressor

14 - Hot gas valve

15 - Control panel

Commissioning.

Note: if the water heater has been tilted, wait at

least 1 hour prior to commissioning.

- Turn on the water heater.

- Check that the screen (4 Fig. 4-1) does not

display errors.

- During rst power-up, the adjustment instructions are displayed on the screen. Follow the

on-screen instructions carefully to set parameters (date and time, air ducts, installation, photovoltaic, operating time slots, anti-legionella

system).

- Setting the programming time slots:

In the “heating mode” menu, select the “HP 24

hours, programmable resistance” or the “programmable HP and resistance” option where

you have the choice of setting two time slots.

Colour codes key:

BK - Black

BL - Blue

BR - Brown

GY - Grey

YE - Yellow

GN - Green

G / Y - Yellow / Green

RD - Red

WH - White

e start time of the time slot and the duration

of the slot can be set with the arrow keys and ok

to conrm. e total minimum and maximum

heating periods between the two time slots are

respectively 12 and 20 total hours.

- Aer setting the parameters, check operation

of the water heater.

To return to the settings, refer to the "System

Settings" or "Setup Parameters" sections.

14

Page 15

MENU

Informazioni

Impostazioni

PARAMETER SETTINGS /

4

USE.

4.1 REMOTE PANEL.

Key:

1 - Main parameters key that

conrms and saves data when

pressed

2 - Key to open the settings

3 - Key to return to the previous

screen

4 - Display

5 - Key to temporarily increase hot

water production

6 - Up arrow: increases values/

browses through menus

7 - Down arrow: reduced values/

browses through menus

4

2

1

6

4.2 DESCRIPTION OF THE SYMBOLS.

Symbol Description

Forced start set

Absence set / in progress

Hot water set-point temper-

ature

Stand-by

Electrical integration in operation

Heat pump in operation

Anti-legionella cycle

Reception of a signal at the inlet

of the photovoltaic system

• BOOST function ( ).

Press the key (5 Fig. 4-1) to increase the production of hot water regularly.

Set the number of the BOOST operation days

(from 1 to 7). At the end of the chosen period,

the water heater resumes operation with the

initial settings. e BOOST can be interrupted

at any time:

BOOST pause

.

5

4.3 MAIN MENU.

Open the settings by pressing the “Access key”

( ) (2 Fig. 4-1) and follow the on-screen

instructions (4 Fig. 4-1). Browse through the

menu by pressing the “down arrow” (7 Fig. 4-1)

to reduce the values or the “up arrow” (6 Fig. 4-1)

to increase the values.

Press the main key in the centre (1 Fig. 4-1) to

conrm.

4-2

Modalità MANUALE

Modalità ASSENZA

• OPERATING mode ( ).

Choose the operating mode.

Select AUTO or MANUAL (see paragraph 4.6

"Operating modes").

• ABSENCE mode ( ).

Program an absence.

It allows you to indicate in the water heater:

- a permanent absence starting from the

current date;

- a programmed absence (set the start date of

the absence and the end date). On the eve of

your return, an anti-legionella cycle is activated. In this period, the water temperature

is kept above 15°C. e function can be in-

terrupted at any time:

Disable absence

3

7

4-1

• Information ( ).

- Display the energy savings.

It allows you to view the utilisation rate of

the heat pump and electrical integration

over the last 7 days, the last 12 months, from

commissioning.

- Display power consumption.

It allows you to view energy consumption in

kW/hour, in recent days, in recent months,

in recent years.

- Display the budget parameters.

It allows you to view all the settings recorded

in the water heater.

• Settings ( ).

- Set the time and date.

Set the day and then conrm. en set the

month, year, hour and minutes.

- Set the operating time slots

It lets you dene the time slots in which the

device is authorised to start.

- Set the language.

French, English, Dutch, Spanish, Portuguese, German, Italian and Polish.

- Connections.

It allows you to turn o the support of electrical integration.

.

15

Page 16

4.4 SYSTEM SETTINGS.

Access to the system settings: ( ) + Settings.

• Date and time.

Set the day and then conrm. Do the same for

the month, year, hour and minutes.

• Heating mode.

is parameter denes the operating time slots

of the heat pump and of the electrical integration according to the hot water requirements:

24/24 continuously

th e day.

Programming

riods.

• Setting the programming time slots.

In the “heating mode” menu, select the “HP

24 hours, programmable resistance” or the

“programmable HP and resistance” option

where you have the choice of setting two time

slots. e start time of the time slot and the

duration of the slot can be set with the arrow

keys and ok to conrm. e total minimum

and maximum heating periods between the

two time slots are respectively 12 and 20

total hours.

• Language.

Possible settings in French, English, Dutch,

Spanish, Portuguese, German, Italian and

Polish.

• Connections.

It allows you to activate or not the electrical

integration support. If it is o, the device will

never use the electrical integration; in case

of low temperatures, a shortage of hot water

is possible.

4.5 PARAMETERS TO BE ADJUSTED

UPON INSTALLATION.

(If not set at the time of commissioning)

e installation parameters can be accessed in

INSTALLER MODE.

Press “Menu” (2 Fig. 4-1) and “Up arrow” at the

same time for 5 seconds (6 Fig. 4-1).

To exit the installer mode, proceed in the same

way or wait for 3 minutes.

Start at any time of

Start in scheduled pe-

Access to the system settings: ( )

• Block

is mode enables continuous operation only

with the boost.

• Hot water.

- Heating mode

is parameter denes the operating time

slots of the heat pump and of the electrical

integration according to the hot water

requirements:

HP 24h / ELEC

24h

HP 24h /

ELEC Prog

HP Prog /

ELEC Prog

- Anti-legionella.

It allows you to turn on the water disinfection function several times a month. e

water temperature reaches 62°C 1-4 times

a month depending on the desired setting.

- PV Photovoltaic system.

is parameter is used to activate the device

coupled with a photovoltaic system. is

operating mode generates the forced start

of the heat pump when the water heater

receives a signal coming from the photovoltaic system. e setting automatically

returns to the previously selected mode

aer 30 minutes if the photovoltaic system

signal is lost. While receiving the signal the

set point temperature is automatically set at

62°C (not adjustable).

- Emergency mode.

Enabling this mode allows continuous operation only with the electrical integration.

- Additional Electricity BOOST (electrical

integration).

It allows you to activate or not the electrical

integration support. If it is o, the device

will never use the electrical integration; in

case of low temperatures, a shortage of hot

water is possible.

• Ducting (aeraulic operation).

is parameter denes the aeraulic connection

type realised:

Inside / Inside

Outside /

Outside

Inside /

Outside

Start at any time of

the day

Start the heat pump

at any time of the

day, start the electrical integration at the

programmed times

Start in programmed

periods.

Suction and return not

connected to air ducts

(ambient air)

Suction and return connected to air ducts (outside air)

Return connected to an air

duct (semi-ducted)

Settings

4.6 SELECTING THE OPERATING

.

MODE.

Press ( ) to access the

• In AUTO mode.

is operating mode automatically manages

the energy choice that allows maximum savings while guaranteeing an adequate comfort

in terms of hot water. e water heater analyses the consumption of the previous days to

adapt the production of hot water according

to needs. It reacts to unexpected events to

ensure hot water by switching the heat pump

on. erefore, the set point temperature is

automatically adjusted between 50 and 62°C

according to the consumption prole. e

Water heater operates preferably through the

heat pump. e electrical integration can be

automatically selected to ensure a sucient

volume of hot water.

• MANUAL mode.

is mode allows you to dene the desired

amount of hot water by choosing the set

point. is set point is also represented as an

equivalence of number of showers (about 50

litres of hot water).

If the ECO mode is not active, the water

heater favours operation of the heat pump

only. However, if the air temperature is low

or consumption is substantial, the electrical

integration can be authorised as a support at

the end of heating to reach the temperature

set. If the ECO mode is active, the water

heater works only with the heat pump with

an air temperature ranging from -5 to +43°C.

Therefore electrical integration is not authorised at the time of heating. is feature

optimises the savings, but can cause hot water

shortages. Regardless of the ECO adjustment,

if the air temperature exceeds the operating

time slots, the electrical integration will be

automatically selected to ensure a sucient

volume of hot water.

• BOOST mode.

This mode activates the heat pump and

electrical integration simultaneously at the

maximum set point of 62°C.

• ABSENCE mode.

is mode maintains the domestic hot water

temperature above 20°C using the heat pump.

Electrical integration can be activated if the

heat pump is not available.

4.7 DISPLAY THE INFORMATION

Open the “Info” menu to:

• Display the energy savings.

It allows you to view the utilisation rate of

the heat pump and electrical integration

over the last 7 days, the last 12 months, from

commissioning.

• Display the power consumption.

It allows you to view energy consumption

in kw/hour, in the last 7 days, in the last 12

months, from commissioning.

• Display the budget parameters.

It allows you to view all the settings recorded

in the water heater.

Mode

menu.

16

Page 17

RECOMMENDATIONS

5

MAINTENANCE AND

REPAIRS.

5.1 ADVICE FOR THE USER.

You must empty the water heater if the absence

mode cannot be used or when the device is not

on. Proceed in the following way:

• Stop the supply voltage.

• Close the cold water inlet tap.

• Open a hot water tap.

• Put the safety valve in the drain position.

Important note - End of the device’s ser vice life:

• At the end of its service life, the device must

be taken to a sorting centre for electrical and

electronic equipment for recovery of uids.

Do not dispose of the device with household

waste, but dispose of it in the collection centres provided, where it can be recycled. Check

your local collection service to nd out about

existing waste collection centres.

• It is forbidden by law to discharge the coolant

contained in the device into the atmosphere.

Degassing operations are strictly forbidden,

and may be hazardous.

Note: the GWP (Global Warming Potential) of

R134a is 1430.

5.2 HOUSEHOLD MAINTENANCE.

e user must perform some minor home maintenance operations on the water heater: act on the

safety valve once or twice a month to remove any

limestone deposits and ensure it is not blocked.

Regularly check that there are no alarms on the

display. If there are any alarms, contact the authorised local service centre to address the faults.

It is recommended to treat water with a soener

in the areas where there is a high amount of scale

(>20°F). Water hardness must remain above

15°F. e soener does not lead to warranty derogations, provided it is dosed in a workmanlike

manner and regularly maintained.

Water treatment must comply with the provisions

of UNI 8065.

5.3 MAINTENANCE BY APPROVED

PROFESSIONALS.

e device must be checked by a professional

once a year, in order to ensure its long-term

performance.

• Disconnect the device from the electricity

(circuit-breaker, fuses, etc.)

• Drain the tank:

- close the cold water inlet tap of the safety unit,

- open a hot water tap,

- put the safety valve in the drain position.

• Remove the bottom cover.

• Disconnect the wires from the thermostat

terminals.

• Dismantle the heating unit.

• Replace the magnesium anode. e magnesium

anode has to be changed every 2 years or as

soon as its diameter is less than 10mm.

• Remove the scale deposited as sludge or akes

in the bottom of the tank every two years,

and carefully clean the casings of the heating

elements and thermostat. Do not scratch or

remove the scale attached to the walls, as this

could aect the coating. Residues may be removed using a water and dust vacuum cleaner.

• Ret the heating unit with a new seal, carefully

and gradually tightening the nuts (cross-tightening).

• Fill the water heater by leaving a hot water tap

open, if the water ows it indicates that the

water heater is full.

• Check the water tightness of the seal and only

then replace the thermostat and its ttings, and

reconnect the supply voltage.

• e next day, check the water tightness of the

seal again and gently tighten the nuts again if

necessary.

• Check the electrical connections.

• Check that the temperature probe is properly

positioned in the sample point near to the

electrical integration (the probe must be at the

bottom of the sample point).

• Once a year check that the water heater is

connected to the ducts.

Check that the ducts are properly positioned

and are not obstructed.

• Once a year check that there are no loose wires

in the internal and external wiring and that all

connectors are in place.

• Once a year check that the electrical integration

works properly by measuring the output.

• Every 2 years check the heat exchange of the

heat pump.

• Every 2 years check that the fan works at two

speeds and the hot gas valve.

• Every 5 years check the coolant is charged.

Evaporator:

• e cleanliness of the evaporator and the fan

must be checked every 2 years. Clogging of

these components may reduce the performance

of the heat pump.

• Unscrew and remove the top cover to access

the evaporator. e front cover may also be

removed if necessary.

• If necessary, the evaporator and the fan are to

be cleaned with a so bristled brush. Brush

the evaporator very gently to avoid damaging

its ns. If the ns are folded, straighten them

using a suitable brush.

Note: always disconnect the device from the

power supply before starting any work.

Expansion valve:

• Only a refrigeration engineer is permitted to

access the expansion valve adjustment screw.

If the expansion valve is adjusted without

approval from the manufacturer, the product

warranty shall be voided.

• Generally speaking, it is not recommended to

change the expansion valve setting before all

other repair solutions have been exhausted.

Condensate draining pipe:

• Once a year check cleanliness of the condensate

draining pipe. Any pollution (dust) in the room

may in fact cause deposits in the condensate

recovery tank. ese deposits may block the

condensate draining pipe and cause excessive

accumulation of water in the tank, which could

lead to malfunctions.

17

Page 18

5.4 TROUBLESHOOTING SUPPORT.

Control panel alarm codes

Errors can be suspended or reactivated by

pressing “OK”.

is action also stops the buzzer.

Error

Code

W.03

W.07

Water temperature too

W.09

high (> 80°C)

W.15 Date and time not set

W.19 0V electrical connection Complete shut-down

W.21

W.22

W.25

W.28 Defrosting malfunction

W.301 Inecient HP heating

W.302 Inecient HP heating

W.303 Faulty pressure switch

W.304 HP deviation

W.305 Probes waste deviation

Cause Consequences System status / Solution

Defective water temperature probe (sample

point)

No water in the storage

tank or ACI connection

open

Faulty air inlet temperature probe.

Faulty evaporator temperature probes

Pressure switch alarm

(faulty high pressure)

No possible warming up

No warming up

Risk of mechanical safety device activation

No warming up

HP stoppage.

If PROG

HP stoppage.

Heating with electrical integration

HP stoppage.

Heating with electrical integration

HP stoppage.

Heating with electrical integration

HP stoppage.

Heating with electrical integration

HP stoppage.

ELEC heating.

HP stoppage.

ELEC heating.

HP stoppage.

ELEC heating.

HP stoppage.

ELEC heating.

HP stoppage.

ELEC heating.

Check the connections or replace the

probe (reference A1).

No water in the storage tank.

Check the thread connection (reference

AC), conductivity of the water.

Check the connections and the position

of the probe (reference A1).

Make sure the integration is not piloted

permanently

If necessary, reset the mechanical safety

device and contact the installer.

Enter date and time.

Check the electrical connection to the

mains.

e supply voltage must be permanent.

Check the connections or replace the

probe (reference A2).

Check the connections or replace the

evaporator probes (reference A2). Check

correct operation of the fan.

Ensure the air temperature has not exceeded 43°C.

If the mode key is pressed, the fault resets,

contact the installer.

Check the connections or replace the coil

(reference T2).

Check operation of the fan.

If the mode key is pressed, the fault resets,

contact the installer.

Check operation of the fan and ensure the

air ow is correct.

Check the coolant gas is charged.

Check operation of the fan and ensure the

air ow is correct.

Check the coolant gas is charged.

Check the coolant gas is charged.

If it is charged, replace the pressure switch.

Check the coolant gas is charged.

Check the connections (A2) and the

position of the air probe and the evaporator probe.

If necessary, replace the probe bundle.

18

Page 19

5.5 WORK ON THE WATER HEATER.

Accessing the electronic components.

Note: always disconnect the device from the

power supply before starting any work.

- Remove the four screws from the cover with

a screwdriver (Fig. 5-1).

- Pull the column to release it and then extract

it from the bottom cap (Fig. 5-2).

- Unscrew the 2 screws on the cover (Fig. 5-3).

5-1 5-2 5-3

Accessing the heat pump compartment.

Note: always disconnect the device from the

power supply before starting any work.

- Unscrew the 2 screws on the front cover (Fig.

5-4).

- Rotate the cover to the le to unlock it (Fig.

5-5).

- Li the cover to remove it (Fig. 5-6).

5-4 5-5 5-6

19

Page 20

5.6 QUICK FAULT DIAGNOSIS

FOR USE CARRIED OUT BY A

PROFESSIONAL TECHNICIAN.

Fault detected Possible cause Diagnosis and solution

Delivery temperature on a value that is too low.

Water not hot enough

Heating element or its wiring partially not working.

No warming up.

No hot water.

Poor ow of the hot water tap. Safety valve damaged or clogged. Replace the safety device.

Continued loss of water to the

level of the safety unit outside

the heating period.

The electrical integration does

not work.

Outow of condensates.

Presence of odours.

Emission of vapour during the

bleeding phase.

Loud boiling noise. Presence of scale in the storage tank. Descale it.

Another kind of malfunction.

Note: Do not connect the supply voltage directly

to the electrical resistance.

No storage tank supply voltage: fuses, wiring, etc.

Network pressure too high.

Faulty electrical thermostat. Replace the thermostat.

Faulty heating element. Replace the heating element.

e storage tank is not properly levelled.

Condensate ow obstructed.

ere is no siphon. Install a siphon.

ere is no water in the siphon. Fill the siphon.

Adjust the delivery temperature to a

higher value. Refer to the settings menu.

Check the resistance of the heating element on the connector of the electrical

bundle and the good conditions of the

bundle itself.

Check that the storage tank’s power cables

are live.

Make sure the outlet pressure of the

water meter does not exceed 0.5 MPa

(5 bar), otherwise install a pressure

reducer set at 0.3 MPa (3 bar) at the

beginning of the water mains.

Ensure that the storage tank is placed on

a at surface.

Clean (see the “maintenance carried

out by an authorised professional” paragraph).

Check there is no siphon on the drain

pipe.

Disconnect the supply voltage and

contact the installer.

Contact the aer-sales service for any

other kind of malfunction.

5.7 AFTERSALES SERVICE.

Only use original spare parts. Specify the exact

type of water heater and serial number for any

order.

Operations on electrical parts must be performed by skilled and qualied sta pursuant

to the legislation in force.

If the power cable is damaged, for safety reasons

it must be replaced by the aer-sales service or

similarly qualied sta.

Scope of application of the warranty.

5.8 SCOPE OF APPLICATION OF THE

WARRANTY.

The following faults are excluded from this

warranty:

• Abnormal environmental conditions:

- Various damages caused by impact or falling

during handling aer leaving the factory.

- Placement of the device in a location subject

to frost or bad weather (humidity, aggressive

or poorly ventilated rooms).

- Use of water with features that do not comply

with those set forth by the regulations in force

on the matter.

- Water pressure above 0.5 MPa (5 bar).

- Electrical power with significant voltage

peaks (mains, lightning, etc.).

- Damage from undetectable problems caused

by choice of location (places dicult to access) and that could have been avoided if the

device had been repaired immediately.

• System does not comply with regulations,

standards, professional rules, especially:

- Missing or incorrectly tted new safety unit,

modication of calibration, etc.

- Insulating sheath (cast iron, steel or insulating) missing on hot water connection pipes,

which could cause their corrosion.

- Faulty electrical connection: incorrect earthing, inadequate cable section, connection

of exible cables without metal terminals,

failure to comply with the wiring diagrams

provided by the Manufacturer.

- Switching on the device without rst lling

it (dry heating).

- Positioning the device without considering

the instructions in the manual.

- External corrosion caused by poor sealing on

pipes.

• Incorrect maintenance:

- Abnormal formation of scale on heating

elements or safety units.

- No maintenance of safety unit, leading to

excessive pressure.

- No maintenance on magnesium anode (magnesium anode diameter must be at least 10

mm).

- No cleaning of evaporator or condensate

evacuation.

- Modification of the original equipment,

without notifying the manufacturer, or use

of spare parts not recommended by the

manufacturer.

5.9 DECLARATION OF CONFORMITY.

If required, the declaration of conformity is

available at the manufacturer’s premises.

• is device has been designed to serve one

Residential Housing Unit only (and similar)

subject to assessment of the energy requirement for domestic hot water; it is not a heating

system pursuant to the legislation in force.

20

Page 21

6 PRODUCT FICHE IN COMPLIANCE WITH REGULATION 812/2013.

Rapax 100 V2

C

D

E

F

45

46

2017

A⁺

A

B

M

dB

dB

Rapax 100 V2

kWh/annum

553

475

430

A

+

812/2013

Parameter value

Energy eciency in average climate

conditions

Energy eciency in colder climate

conditions

Energy eciency in warmer climate

conditions

Annual energy consumption in average

climate conditions

Annual energy consumption in colder

climate conditions

Annual energy consumption in warmer

climate conditions

ermostat temperature 54 °C

Daily electrical power consumption

V40 127 L

For proper installation of the device, refer to

chapter 1 of this booklet (for the installer) and

current installation regulations. For proper

maintenance, refer to chapter 5 of this booklet

(for the maintenance technician) and adhere

to the frequencies and methods set out herein.

108 %

93 %

119 %

kW/h

kW/h

kW/h

2,260

kW/h

475

553

430

21

Page 22

7 PARAMETERS FOR FILLING

IN THE PACKAGE FICHE.

Should you wish to install a unit, starting from

the Rapax 100 V2 water heater with heat pump,

use the package che shown in g. 7-3.

To ll it in correctly, enter the gures shown

in table g. 7-2 (as shown in the package che

facsimile Fig. 7-1) .

e remaining values must be obtained from

the technical data sheets of the products used

to make up the assembly (e.g. solar devices, integration heat pumps, temperature controllers).

Facsimile for lling in the domestic hot water production system package che.

Use sheet g. 7-3 for “assemblies” related to the

domestic hot water function (e.g.: water heater +

solar thermal system).

Water heating energy efciency of the water heater

Stated load prole:

Solar contribution

From the board of the solar device

( 1,1 x ‘I’ - 10 % ) x ‘II’ - ‘III’ - ‘I’ =

Water heating energy efciency of the assembly in average climate conditions

Water heating energy efciency class of the assembly in average climate conditions

G F E D C B A A

M

L

XL

XXL

< 27 %

< 27 %

< 27 %

< 28 %

≥ 27 %

≥ 27 %

≥ 27 %

≥ 28 %

≥ 30 %

≥ 30 %

≥ 30 %

≥ 32 %

Auxiliary electricity

≥ 33 %

≥ 36 %

≥ 34 %

≥ 37 %

≥ 35 %

≥ 38 %

≥ 36 %

≥ 40 %

≥ 39 %

≥ 50 %

≥ 55 %

≥ 60 %

≥ 65 %

≥ 75 %

≥ 80 %

≥ 85 %

+

A

≥ 100 %

≥ 115 %

≥ 123 %

≥ 131 %

+

++

A

≥ 130 %

≥ 150 %

≥ 160 %

≥ 170 %

1

‘I’

2

3

+++

≥ 163 %

≥ 188 %

≥ 200 %

≥ 213 %

%

%

%

Water heating energy efciency class in colder and hotter climate conditions

3 2

Colder: - 0.2 x =

3 2

Hotter: + 0.4 x =

The energy efciency of the set of products indicated in this sheet may not reect the actual energy

efciency after installation since such efciency is affected by additional factors, such as the heat loss

in the distribution system and the size of the products compared to the size and features of the building.

%

%

22

Fig. 7-1

Page 23

Parameters for lling in the DHW package che.

Parameter Rapax 100 V2

‘I’ 108

‘II’ *

‘III’ *

* to be determined according to Regulation 812/2013 and transient calculation methods

as per Notice of the European Community no. 207/2014.

Domestic hot water production system package che.

Fig. 7-2

Water heating energy efciency of the water heater

Stated load prole:

Solar contribution

From the board of the solar device

( 1.1 x _____ - 10 % ) x _____ - ____ - ______ =

Water heating energy efciency of the assembly in average climate conditions

Water heating energy efciency class of the assembly in average climate conditions

G F E D C B A A

M

L

XL

XXL

< 27 %

< 27 %

< 27 %

< 28 %

≥ 27 %

≥ 27 %

≥ 27 %

≥ 28 %

≥ 30 %

≥ 30 %

≥ 30 %

≥ 32 %

Auxiliary electricity

≥ 33 %

≥ 36 %

≥ 34 %

≥ 37 %

≥ 35 %

≥ 38 %

≥ 36 %

≥ 40 %

≥ 39 %

≥ 50 %

≥ 55 %

≥ 60 %

≥ 65 %

≥ 75 %

≥ 80 %

≥ 85 %

+

A

≥ 100 %

≥ 115 %

≥ 123 %

≥ 131 %

+

++

A

≥ 130 %

≥ 150 %

≥ 160 %

≥ 170 %

≥ 163 %

≥ 188 %

≥ 200 %

≥ 213 %

1

_____

2

3

+++

%

%

%

Water heating energy efciency class in colder and hotter climate conditions

3 2

Colder: - 0.2 x =

3 2

Hotter: + 0.4 x =

The energy efciency of the set of products indicated in this sheet may not reect the actual energy

efciency after installation since such efciency is affected by additional factors, such as the heat loss

in the distribution system and the size of the products compared to the size and features of the building.

%

%

23

Fig. 7-3

Page 24

Follow us

Immergas Italia

immergas.com

Immergas S.p.A.

42041 Brescello (RE) - Italy

Tel. 0522.689011

Fax 0522.680617

Certied company ISO 9001

is instruction booklet is made of ecological paper Cod. 1.041494ENG - rev. ST.003494/000 - 04/18 - Inglese per IRLANDA (IE)

Loading...

Loading...