Immergas Maior Eolo 24 4E, Maior Eolo 32 4E, Maior Eolo 28 4E Installation Manual

143

GR

CZ

HU

ES

IE

PT

1

INSTALLER

BOILER

INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

e Maior Eolo boiler has been designed for wall

mounted installation; they must be used to heat

environments, to produce domestic hot water

and similar purposes. In the case of wall installation the wall surface must be smooth, without

any protrusions or recesses enabling access to the

rear part. ey are NOT designed to be installed

on plinths or oors (Fig. 1-1).

By varying the type of installation the classication of the boiler also varies, precisely:

- Boiler type B22 if installed without the 2 intake

caps and with the top cover kit.

- Type C boiler if installed using concentric pipes

or other types of pipes envisioned for the sealed

chamber boiler for intake of air and expulsion

of ue gas.

Only professionally qualied heating/plumbing

technicians are authorised to install Immergas

gas appliances. Installation must be carried out

according to the standards, current legislation

and in compliance with local technical regulations and the required technical procedures. Installation of the Maior Eolo boiler when powered

by LPG must comply with the rules regarding

gases with a greater density than air (remember,

as an example, that it is prohibited to install systems powered with the above-mentioned gas in

rooms where the oor is at a lower quota that the

average external country one). Before installing

the appliance, ensure that it is delivered in perfect condition; if in doubt, contact the supplier

immediately. Packing materials (staples, nails,

plastic bags, polystyrene foam, etc.) constitute

a hazard and must be kept out of the reach of

children. If the appliance is installed inside or

between cabinets, ensure sufficient space for

normal servicing; therefore it is advisable to

leave clearance of at least 3 cm between the boiler

casing and the vertical sides of the cabinet. Leave

adequate space above the boiler for possible water

and ue removal connections.

Keep all ammable objects away from the appliance (paper, rags, plastic, polystyrene, etc.).

Do not place household appliances underneath

the boiler as they could be damaged if the safety

valve intervenes (if not conveyed away by a

discharge funnel), or if there are leaks from the

connections; on the contrary, the manufacturer

cannot be held responsible for any damage caused to the household appliances.

In the event of malfunctions, faults or incorrect

operation, turn the appliance o immediately

and contact a qualified technician (e.g. the

Immergas Aer-Sales Assistance centre, which

has specically trained sta and original spare

parts). Do not attempt to modify or repair the

appliance alone. Failure to comply with the above

implies personal responsibility and invalidates

the warranty.

• Installation regulations:

- this boiler can be installed outdoors in a

partially protected area. A partially protected

location is one in which the appliance is not

exposed to the direct action of the weather

(rain, snow, hail, etc..).

- Installation in places with a fire risk is

prohibited (for example: garages, box), gas

appliances and relative ue ducts, ue exhaust

pipes and combustion air intake pipes.

- Installation is also prohibited in places/environments that constitute common parts of

oce condominiums such as stairs, cellars,

entrance halls, attics, los, escape routes,

etc. if they are not located inside technical

compartments under the responsibility of

each individual building and only accessible

to the user (technical compartments and the

appliances must be realised and installed in

compliance with re prevention Standards).

Important: Wall mounting of the boiler must

guarantee stable and ecient support for the

generator.

Fig. 1-1

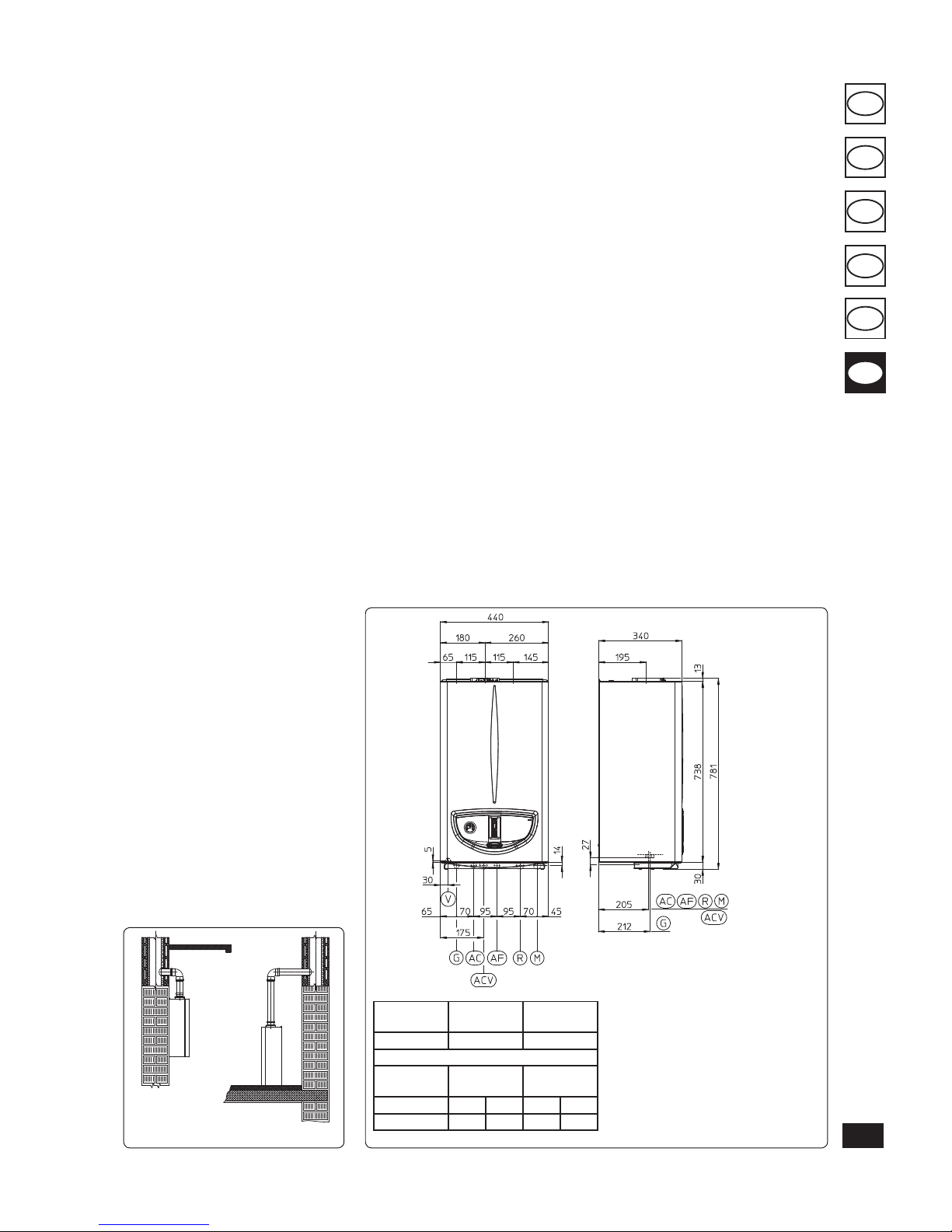

1.2 MAIN DIMENSIONS.

e plugs (standard supply) are to be used only in

conjunction with the mounting brackets or xing

template to x the appliance to the wall; they only

ensure adequate support if inserted correctly

(according to technical standards) in walls made

of solid or semi-hollow brick or block. In the

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate support.

N.B.: the hex head screws supplied in the blister

pack are to be used exclusively to x the relative

mounting bracket to the wall.

ese boilers are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be attached to a heating system suitable for their capacity and voltage.

Height

(mm)

Width

(mm)

Depth

(mm)

781 440 340

CONNECTIONS

GAS

DOMESTIC

HOT WATER

SYSTEM

G AC AF R M

3/4” 1/2” 1/2” 3/4” 3/4”

Fig. 1-2

Key:

G - Gas supply

AC - Domestic hot water outlet

ACV - Solar valve kit DHW inlet (Optional)

AF - Domestic cold water inlet

R - System return

M - System ow

V - Electrical connection

N.B.: connection group (optional)

YES

NO

144

GR

CZ

HU

ES

IE

PT

1.3 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e boiler is sup-

plied with an antifreeze function as standard that

activates the pump and burner when the system

water temperature in the boiler falls below 4°C.

e anti-freeze function is only guaranteed if:

- the boiler is correctly connected to gas and

electricity power supply circuits;

- the boiler is powered constantly;

- the boiler is not in “O” mode;

- the boiler is not in no ignition block (Par.2.5);

- the boiler essential components are not faulty.

In these conditions the boiler is protected against

freezing to an environmental temperature of -5°C.

Minimum temperature -15°C. If the boiler is

installed in a place where the temperature falls

below -5°C and in the event there is no gas or

the boiler goes into ignition block, the appliance

can freeze.

To prevent the risk of freezing follow the instructions below:

- protect the central heating circuit from freezing by introducing a good quality anti-freeze

liquid (specically for central heating systems),

carefully following the manufacturer’s instructions regarding the percentage necessary with

respect to the minimum temperature required

for preserving the system.

The materials the boilers are made from are

resistant to ethylene and propylene glycol-based

anti-freeze liquids.

For life and possible disposal, follow the supplier’s

instructions.

- Protect the domestic hot water circuit against

freezing by using an accessory that is supplied

on request (anti-freeze kit) comprising two

electric heating elements, the relevant cables

and a control thermostat (carefully read the

installation instructions contained in the accessory kit pack).

Boiler anti-freeze protection is thus ensured only if:

- the boiler is correctly connected to electricity

power supply circuits;

- main switch is inserted;

- the anti-freeze kit components are ecient.

In these conditions the boiler is protected against

freezing to temperature of -15°C.

e warranty does not cover damage due to interruption of the electrical power supply and failure

to comply with that stated on the previous page.

N.B.: if the boiler is installed in places where

the temperature falls below 0°C, the heating

attachment pipes must be insulated.

1.4 CONNECTIONS.

Gas connection (Appliance category II

2H3+

).

Our boilers are designed to operate with methane

gas (G20) and LPG. Supply pipes must be the

same as or larger than the 3/4”G boiler tting.

Before connecting the gas line, carefully clean

inside all the fuel feed system pipes to remove any

residue that could impair boiler eciency. Also

make sure the gas corresponds to that for which

the boiler is prepared (see boiler data-plate). If

dierent, the appliance must be converted for

operation with the other type of gas (see converting appliance for other gas types). e dynamic

gas supply (methane or LPG) pressure must also

be checked according to the type used in the

boiler, as insucient levels can reduce generator

output and cause malfunctions.

Ensure correct gas cock connection. e gas

supply pipe must be suitably dimensioned according to current regulations in order to guarantee

correct gas ow to the burner even in conditions

of maximum generator output and to guarantee

appliance eciency (technical specications).

e coupling system must conform to standards.

Fuel gas quality. e appliance has been designed to operate with gas free of impurities; otherwise it is advisable to t special lters upstream

from the appliance to restore the purity of the gas.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

Hydraulic connection.

Important: In order not to void the warranty

before making the boiler connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could compromise

correct boiler operation.

In compliance with Standards in force it is mandatory to treat the water in the heating system

chemically in order to protect the system and

appliance from deposits of lime scale.

Hydraulic connections must be made in a

rational way using the couplings on the boiler

template. e boiler safety valves outlet must be

connected to a draining funnel. Otherwise, the

manufacturer declines any responsibility in case

of ooding if the drain valve cuts in.

Important: to preserve the duration of appliance

eciency features, in the presence of water whose

features can lead to the deposit of lime scale,

installation of the “polyphosphate dispenser” kit

is recommended. On the basis of the Standards in

force, it is mandatory to treat the water with over

25 French degrees in the heating circuit and over

15 French degrees for DHW using conditioning

chemicals for powers < 100 kW or with soeners

for powers > 100 kW.

Electrical connection: e “Maior Eolo” boiler

has an IPX5D protection rating for the entire

appliance. Electrical safety of the unit is reached

when it is correctly connected to an ecient

earthing system as specied by current safety

standards.

Imp ortant: Immergas S.p.A. declines any

responsibility for damage or physical injur y

caused by failure to connect the boiler to an

ecient earth system or failure to comply with

the reference standards.

Also ensure that the electrical installation corresponds to maximum absorbed power specications

as shown on the boiler data-plate. Boilers are supplied complete with an “X” type power cable without

plug. e power supply cable must be connected to

a 230V ±10% / 50Hz mains supply respecting L-N

polarity and earth connection .

is network

must also have a multi-pole circuit breaker with

class III over-voltage category. When replacing the

power supply cable, contact a qualied technician

(e.g. the Immergas Aer-Sales Technical Assistance

Service). e power cable must be laid as shown.

In the event of mains fuses replacement on the

connection board, use a 3.15A quick-blow fuses.

For the main power supply to the appliance,

never use adapters, multiple sockets or extension leads.

145

GR

CZ

HU

ES

IE

PT

Important: if the system is subdivided into zones

using the relevant kit. the CARV2 must be used

with its climate thermostat function disabled, i.e.

it must be set to On/O mode.

Comando Amico Remoto remote controlV2or

On/Off chrono-thermostat electrical connections (Optional). e operations described

below must be performed aer having removed

the voltage from the appliance. Any thermostat

or On/O environment chrono-thermostat must

be connected to clamps 40 and 41 eliminating

jumper X40 (Fig. 3-2). Make sure that the On/

O thermostat contact is of the “clean” type, i.e.

independent of the mains supply, otherwise the

electronic adjustment card would be damaged.

Any Comando Amico Remoto remote controlV2

must be connected to clamps 40 and 41 eliminating jumper X40 on the circuit board, paying

attention not to invert the connections (Fig. 3-2).

Important: if the Comando Amico Remoto

remote controlV2 or any other On/O chronothermostat is used arrange two separate lines in

compliance with current regulations regarding

electrical systems. No boiler pipes must ever be

used to earth the electric system or telephone lines. Ensure elimination of this risk before making

the boiler electrical connections.

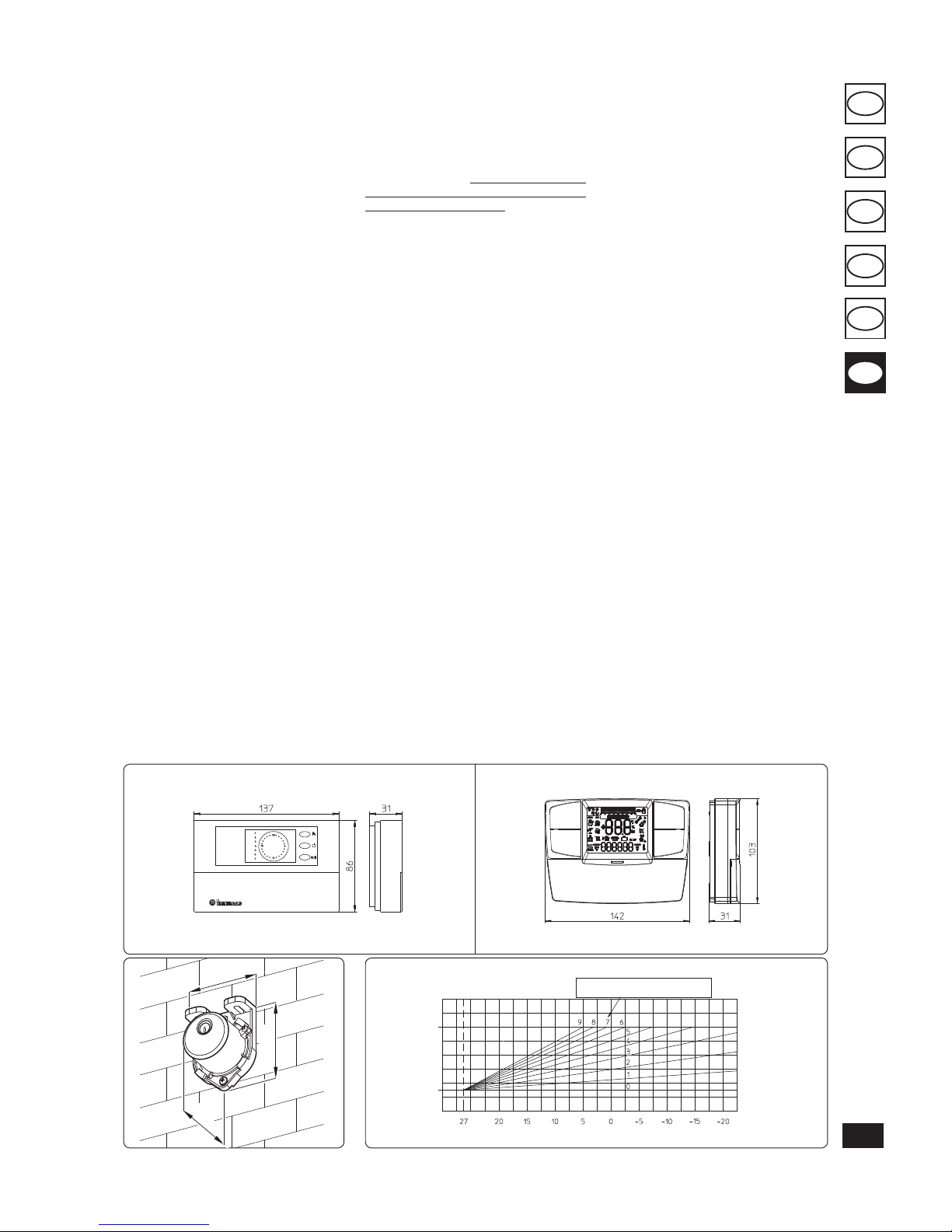

1.6 EXTERNAL PROBE OPTIONAL.

e boiler is prepared for the application of the

external probe (Fig. 1-7), which is available as

an optional kit.

e probe can be connected directly to the boiler

electrical system and allows the max. system

ow temperature to be automatically decreased

when the external temperature increases, in

order to adjust the heat supplied to the system

according to the change in external temperature.

e external probe always acts when connected

independently from the presence or type of room

thermostat used. e correlation between system

ow temperature and external temperature is determined by the position of the selector switch on

the boiler control panel according to the curves

shown in the diagram (Fig. 1-8). e electric connection of the external probe must be made on

clamps 38 and 39 on the boiler P.C.B. (Fig. 3-2).

1.5 REMOTE CONTROLS AND

ROOM CHRONOTHERMOSTATS

OPTIONAL.

e boiler is prepared for the application of room

chrono-thermostats or remote controls, which

are available as optional kits.

All Immergas chrono-thermostats are connected with 2 wires only. Carefully read the user

and assembly instructions contained in the

accessory kit.

• On/O digital chrono-thermostat (Fig. 1-5).

e chrono-thermostat allows:

- to set two room temperature values: one for

day (comfort temperature) and one for night

(lower temperature);

- to set up to four on/o dierential weekly

programs;

- to select the required operating mode from

the various possible alternatives:

• permanent functioning in comfort temp;

• permanent functioning in reduced temp;

• permanent functioning in adjustable anti-

freeze temp.

e chrono-thermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• Comando Amico Remoto Remote Control De-

viceV2 (CARV2) with climate chrono-thermostat

function. In addition to the functions described

in the previous point, the CAR panelV2 enables

the user to control all the important information regarding operation of the appliance

and the heating system with the opportunity

of easily intervening on the previously set

parameters without having to go to the place

where the appliance is installed. e panel is

provided with self-diagnosis to display any

boiler functioning anomalies. e climate chrono-thermostat incorporated into the remote

panel enables the system ow temperature to

be adjusted to the actual needs of the room

being heated, in order to obtain the desired

room temperature with extreme precision and

therefore with evident saving in running costs.

e chrono-thermostat is fed directly by the

boiler by means of the same 2wires used for

the transmission of data between boiler and

chrono-thermostat.

45

31

58

Fig. 1-8

Fig. 1-7

On/O digital chrono-thermostat.

Comando Amico Remoto remote controlV2 (CARV2)

Fig. 1-6

Fig. 1-5

POSITION OF THE CENTRAL HEATING

TEMPERATURE USER ADJUSTMENT

TM (°C)

TE (°C)

FLOW T.

TE (°C)

146

GR

CZ

HU

ES

IE

PT

1.7 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the boiler regarding the installation of air

intake terminals and ue extraction, which are

fundamental for boiler operation.

Important: e boiler must only be installed

together with an original Immergas air intake

and ue gas exhaust system. is system can be

identied by an identication mark and special

distinctive marking bearing the note: “not for

condensing boilers”.

e ue exhaust pipes must not be in contact with

or be near to ammable materials. Moreover,

they must not pass through buildings or walls

made of ammable material.

See following paragraphs for the detailed description of the kits available.

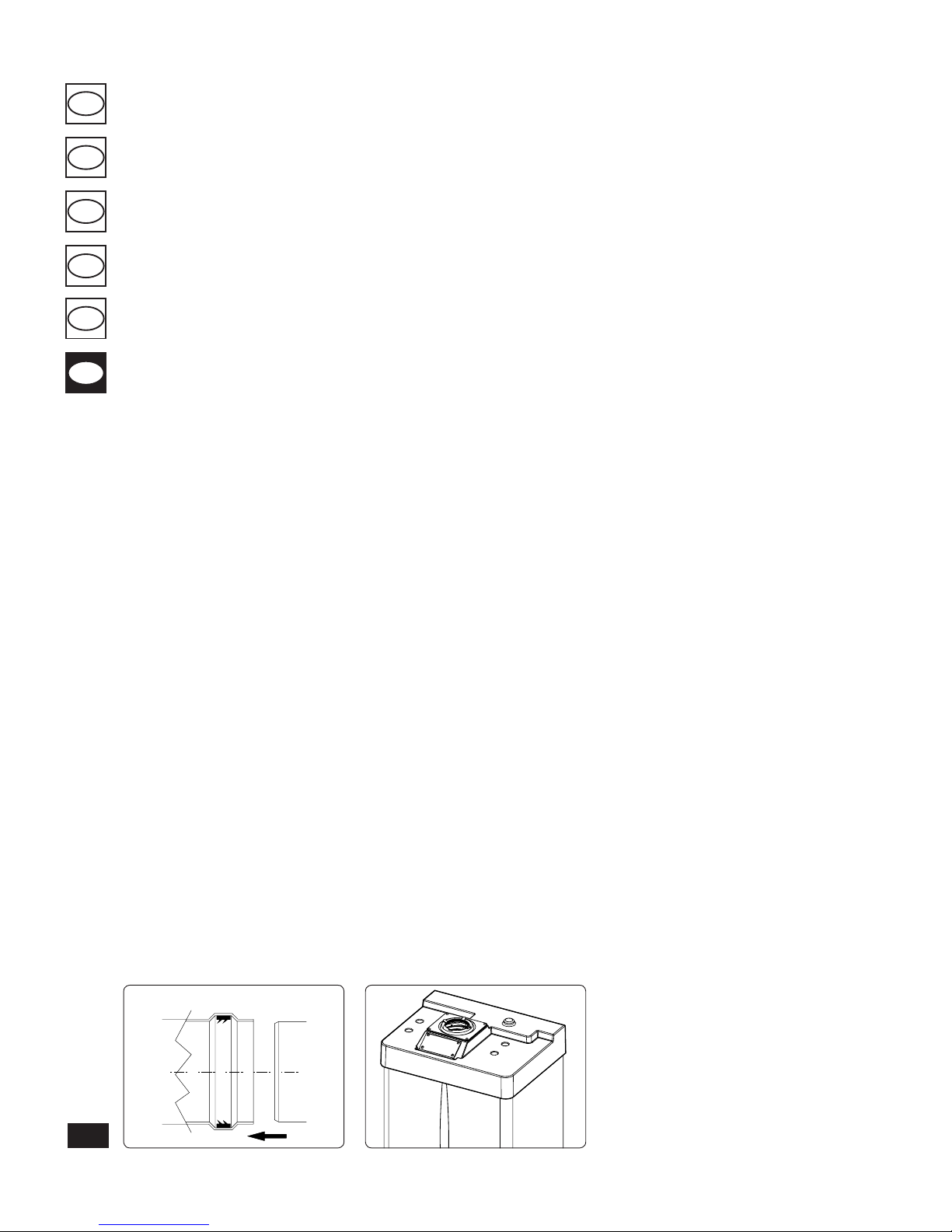

Positioning of double lip seals. For correct

positioning of lip seals on elbows and extensions,

follow the direction of assembly given in gure

(Fig. 1-9).

• Resistance factors and equivalent lengths. Each

ue extraction system component has a Resi-

stance Factor based on experimental tests and

specied in the table below. e resistance factor

for individual components is independent from

the type of boiler on which it is installed or the

actual dimensions. It is, however, conditioned

by the temperature of the uids that pass through the pipe and therefore varies according to

applications for air intake or ue exhaust. Each

single component has a resistance corresponding

to a certain length in metres of pipe of the same

diameter; the so-called equivalent length, obtained

from the ration between the relative Resistance

Factors. All boilers have an experimentally obtaina-

ble maximum Resistance Factor equal to 100. e

maximum Resistance Factor allowed corresponds

to the resistance encountered with the maximum

allowed pipe length for each type of Terminal

Kit. is information enables calculations to be

made in order to verify the possibility of various

congurations of ue extraction systems.

1.8 INSTALLAZIONE ALL’ESTERNO

IN LUOGO PARZIALMENTE

PROTETTO.

N.B.: a partially protected area is one in which the

appliance is not exposed to the direct action of the

weather (rain, snow, hail, etc..).

• Conguration type B, open chamber and fan

assisted.

The relevant terminal must be used for this

conguration (present in the intake kit for the

installation in question), which must be placed

on the central hole of the boiler (Fig. 1-12). Air

intake takes place directly from the environment

in which the boiler is installed and ue exhaust

in individual ue or to the outside.

In this conguration the boiler is classied as

type B22.

With this conguration:

- air intake takes place directly from the environ-

ment in which the boiler is installed and only

functions in permanently ventilated rooms;

- the ue exhaust must be connected to its own

individual ue or channelled directly into the

external atmosphere.

The technical regulations in force must be

respected.

Flue gas separator adjustment. For correct

functioning of the boiler in conguration with

direct intake it is necessary to regulate the ue

gas shutter according to that stated in the relative

tables (Fig. 1-14).

• Cover kit assembly (Fig. 1-11). Remove the

two plugs and the gaskets present from the two

lateral holes with respect to the central one. Now

cover the right intake hole using the relevant

plate, xing it onto the le side using the two

supplied screws. Install the Ø80 outlet ange on

the central hole of the boiler, taking care to insert

the gasket supplied with the kit and tighten by

means of the screws provided. Install the upper

cover, xing it using the 4 screws present in the

kit, positioning the relevant gaskets. Engage the

90° Ø80 bend with the male end (smooth) in

the female end (with lip seal) of the Ø80 ange

unit until it stops. Introduce the gasket, making

it run along the bend. Fix it using the sheet steel

plate and tighten by means of the straps present

in the kit, making sure to block the 4 gasket

aps. Fit the male end (smooth) of the exhaust

terminal into the female end of the bend 90°

Ø80, making sure that the relevant wall sealing

plate is already tted; this will ensure hold and

joining of the elements making up the kit.

• Coupling of extension pipes. To install pushtting extensions with other elements of the

ue extraction elements assembly, proceed as

follows: Install the pipe or elbow with the male

side (smooth) in the female section (with lip

seal) to the stop on the previously installed

element. is will ensure sealing eciency of

the coupling.

Max. length of exhaust duct. The flue pipe

(vertical or horizontal) can be extended to a

max. length of 12 m straight route, using insulated

pipes (Fig. 1-31). To prevent problems of ue gas

condensate in the exhaust pipe Ø 80, due to ue

gas cooling through the wall, the length of the

pipe (not insulated) must be limited to just 5 m.

Example of installation with direct vertical

terminal in partially protected location. When

the vertical terminal for direct discharge of combustion products is used, a minimum gap of 300

mm must be le between the terminal and the

balcony above. e height A + B (always with

respect to the balcony above), must be equal to

or greater than 2000 mm. (Fig. 1-13).

• Configuration without cover kit (boiler

typeC).

By leaving the side plugs tted, it is possible to

install the appliance externally, in partially covered places, without the cover kit. Installation

takes place using the Ø60/100 and Ø 80/125

concentric horizontal intake/ exhaust kits. Refer

to the paragraph relative to indoor installation.

In this conguration the top cover kit guarantees

additional protection for the boiler. It is recommended but not compulsory.

Fig. 1-9

Fig. 1-10

147

GR

CZ

HU

ES

IE

PT

Fig. 1-12

Fig. 1-13

Fig. 1-11

Fig. 1-14

Fig. 1-15

Flue gas separator adjustment. For correct functioning of the boiler it is necessary to regulate

the ue gas shutter positioned on the air/ue gas

sample points (Fig. 1-14).

Adjustment is carried out by loosening the

front retainer screw and moving the indicator

to the correct position, aligning its value to the

horizontal reference. Once adjustment has been

performed, tighten the screw to x the separator.

Appropriate adjustment takes place on the basis

of the type of pipe and its extension: this calculation can be carried out using the relevant tables.

Intake diaphragm installation. For correct boiler functioning with Ø80 separator kits and drain

measuring > 1 m a diaphragm must be installed

on the sealed chamber intake hole and before

the intake pipe (Fig. 1-15). e choice of suitable

diaphragm takes place on the basis of the type of

pipe and its maximum extension: this calculation

can be carried out using the following tables:

N.B.: the diaphragms are supplied together with

the boiler.

DIAPHRAGM

e cover kit includes:

N° 1 Heat moulded cover

N° 1 Gasket clamping plate

N° 1 Gasket

N° 1 Gasket clamp

N° 1 N°1 Intake hole covering

plate

e terminal kit includes:

N° 1 Gasket

N° 1 Exhaust ange Ø80

N° 1 Bend 90° Ø80

N° 1 Exhaust pipe Ø80

N° 1 Wall sealing plate

VERTICAL TERMINAL KIT FOR

DIRECT DRAINING

INTAKE COVER KIT

148

GR

CZ

HU

ES

IE

PT

Shutter regulation table

Maior Eolo 24 4E.

Shutter regulation table

Maior Eolo 28 4E.

Shutter regulation table

Maior Eolo 32 4E.

Flue gas shutter notch

Type of installation

(duct length in metres)

1 3 4 5 6 10

Ø60/100 horizontal concentric kit - - Da 0 a 0,5 Da 0,5 a 1,5 - Da 1,5 a 3,0

Ø60/100 vertical concentric kit - - Da 0 a 2,2 Da 2,2 a 3,7 - Da 3,7 a 4,7

Ø80/125 horizontal concentric kit - - Da 0 a 0,5 Da 0,5 a 4,6 - Da 4,6 a 7,4

Ø80/125 vertical concentric kit - - Da 0 a 5,4 Da 5,4 a 9,5 - Da 9,5 a 12,2

Ø80 vertical separator kit without bends *Da 0 a 20 *Da 20 a 40 **Da 0 a 22 - - **Da 22 a 32

Ø80 horizontal separator kit with two bend *Da 0 a 16 *Da 16 a 35 **Da 0 a 17 - - **Da 17 a 28

Direct intake kit and Ø80 drain in B22 conguration - - Da 0 a 1 - Da 1 a 12 -

* ese maximum extension values are considered intake with 1 metre drain pipe

** ese maximum extension values are considered in draining with 1 metre intake pipe and Ø44 diaphragm on the intake hole.

Type of installation

(duct length in metres)

2 4 7 10

Ø60/100 horizontal concentric kit - Da 0 a 0,5 Da 0,5 a 1,5 Da 1,5 a 3,0

Ø60/100 vertical concentric kit - Da 0 a 2,2 Da 2,2 a 3,7 Da 3,7 a 4,7

Ø80/125 horizontal concentric kit - Da 0 a 0,5 Da 0,5 a 4,6 Da 4,6 a 7,4

Ø80/125 vertical concentric kit - Da 0 a 5,4 Da 5,4 a 9,5 Da 9,5 a 12,2

Ø80 vertical separator kit without bends *Da 0 a 20 *Da 20 a 40 **Da 0 a 22 ** Da 22 a 32

Ø80 horizontal separator kit with two bend *Da 0 a 16 *Da 16 a 35 **Da 0 a 17 ** Da 17 a 28

Direct intake kit and Ø80 drain in B22 conguration Da 0 a 1 - Da 1 a 12 -

* ese maximum extension values are considered intake with 1 metre drain pipe

** ese maximum extension values are considered in draining with 1 metre intake pipe and Ø 50 diaphragm on the intake hole.

Type of installation

(duct length in metres)

3 4 5 6 10

Ø60/100 horizontal concentric kit - - Da 0 a 0,5 Da 0,5 a 1,5 Da 1,5 a 3,0

Ø60/100 vertical concentric kit - - Da 0 a 2,2 Da 2,2 a 3,7 Da 3,7 a 4,7

Ø80/125 horizontal concentric kit - - Da 0 a 0,5 Da 0,5 a 4,6 Da 4,6 a 7,4

Ø80/125 vertical concentric kit - - Da 0 a 5,4 Da 5,4 a 9,5 Da 9,5 a 12,2

Ø80 vertical separator kit without bends *Da 0 a 20 *Da 20 a 40 **Da 0 a 22 - **Da 22 a 32

Ø80 horizontal separator kit with two bend *Da 0 a 16 *Da 16 a 35 **Da 0 a 17 - **Da 17 a 28

Direct intake kit and Ø80 drain in B22 conguration - Da 0 a 1 - Da 1 a 12 -

* ese maximum extension values are considered intake with 1 metre drain pipe

** ese maximum extension values are considered in draining with 1 metre intake pipe and Ø 50 diaphragm on the intake hole.

149

GR

CZ

HU

ES

IE

PT

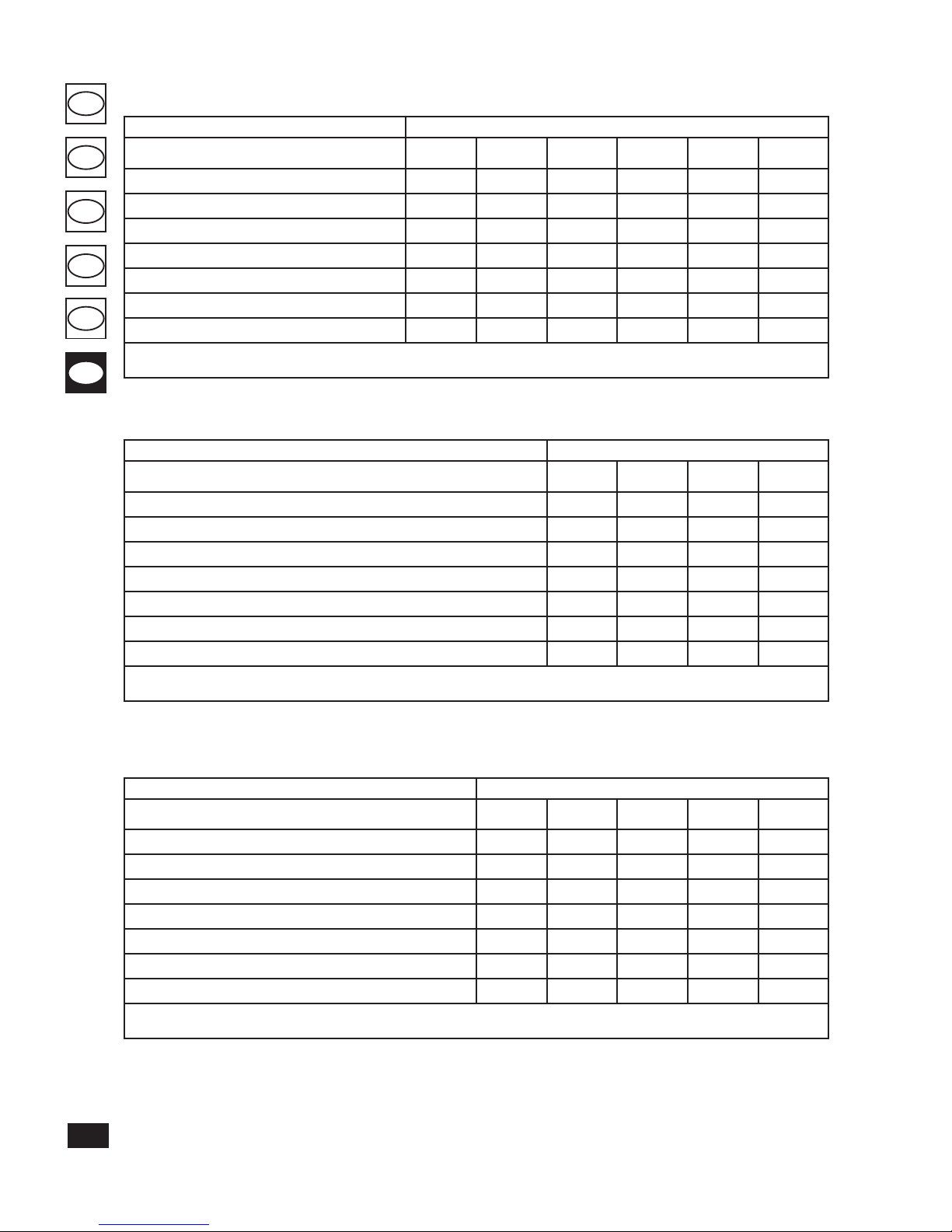

Tables of Resistance Factors and Equivalent Lengths.

DUCT TYPE

Resistance

Factor

(R)

Equivalent

length in m of

concentric pipe

Ø60/100

Equivalent

length in m of concentric

pipe

Ø80/125

Equivalent

length

in m of pipe

Ø80

Concentric pipe Ø60/100 m 1

Intake and

Exhaust 16,5

m 1 m 2,8

Intake m 7,1

Exhaust m 5,5

Concentric bend 90° Ø60/100

Intake and

Exhaust 21

m 1,3 m 3,5

Intake m 9,1

Exhaust m 7,0

Concentric bend 45° Ø60/100

Intake and

Exhaust 16,5

m 1 m 2,8

Intake m 7,1

Exhaust m 5,5

Terminal complete with concentric

horizontal intake-exhaust Ø60/100

Intake and

Exhaust 46

m 2,8 m 7,6

Intake m 20

Exhaust m 15

Terminal complete with horizontal

intake-exhaust Ø60/100

Intake and

Exhaust 32

m 1,9 m 5,3

Intake m 14

Exhaust m 10,6

Terminal complete with concentric vertical

intake-exhaust Ø60/100

Intake and

Exhaust 41,7

m 2,5 m 7

Intake m 18

Exhaust 14

Concentric pipe Ø80/125 m 1

Intake and

Exhaust 6

m 0,4 m 1,0

Intake m 2,6

Exhaust m 2,0

Concentric bend 90° Ø80/125

Intake and

Exhaust 7,5

m 0,5 m 1,3

Intake m 3,3

Exhaust m 2,5

Concentric bend 45° Ø80/125

Intake and

Exhaust 6

m 0,4 m 1,0

Intake m 2,6

Exhaust m 2,0

Terminal complete with intake-exhaust

vertical concentric Ø80/125

Intake and

Exhaust 33

m 2,0 m 5,5

Intake m 14,3

Exhaust m 11,0

Terminal complete with concentric vertical

intake-exhaust Ø80/125

Intake and

Exhaust 26,5

m 1,6 m 4,4

Intake m 11,5

Exhaust m 8,8

Terminal complete with concentric

horizontal intake-exhaust Ø80/125

Intake and

Exhaust 39

m 2,3 m 6,5

Intake m 16,9

Exhaust m 13

Terminal complete with horizontal

intake-exhaust Ø80/125

Intake and

Exhaust 34

m 2,0 m 5,6

Intake m 14,8

Exhaust m 11,3

Concentric adapter from Ø60/100

to Ø80/125 with condensate trap

Intake and

Exhaust 13

m 0,8 m 2,2

Intake m 5,6

Exhaust m 4,3

Concentric adapter from Ø60/100

to Ø80/125

Intake and

Exhaust 2

m 0,1 m 0,3

Intake m 0,8

Exhaust m 0,6

Pipe Ø80 m 1 (with and without insulation)

Intake 2,3 m 0,1 m 0,4 Intake m 1,0

Exhaust 3 m 0,2 m 0,5 Exhaust m 1,0

Complete air intake terminal Ø80

m 1

(with or without insulation)

Intake 5 m 0,3 m 0,8 Intake m 2,2

Intake terminal Ø80

Exhaust terminal Ø80

Intake 3 m 0,2 m 0,5 Intake m 1,3

Exhaust 2,5 m 0,1 m 0,4 Exhaust m 0,8

Bend 90° Ø80

Intake 5 m 0,3 m 0,8 Intake m 2,2

Exhaust 6,5 m 0,4 m 1,1 Exhaust m 2,1

Bend 45° Ø80

Intake 3 m 0,2 m 0,5 Intake m 1,3

Exhaust 4 m 0,2 m 0,6 Exhaust m 1,3

Parallel split Ø80 from

Ø60/100 to Ø80/80

Intake and

Exhaust 8,8

m 0,5 m 1,5

Intake m 3,8

Exhaust m 2,9

150

GR

CZ

HU

ES

IE

PT

C12

1.9 INDOOR INSTALLATION.

• Type C conguration, sealed chamber and

fan assisted.

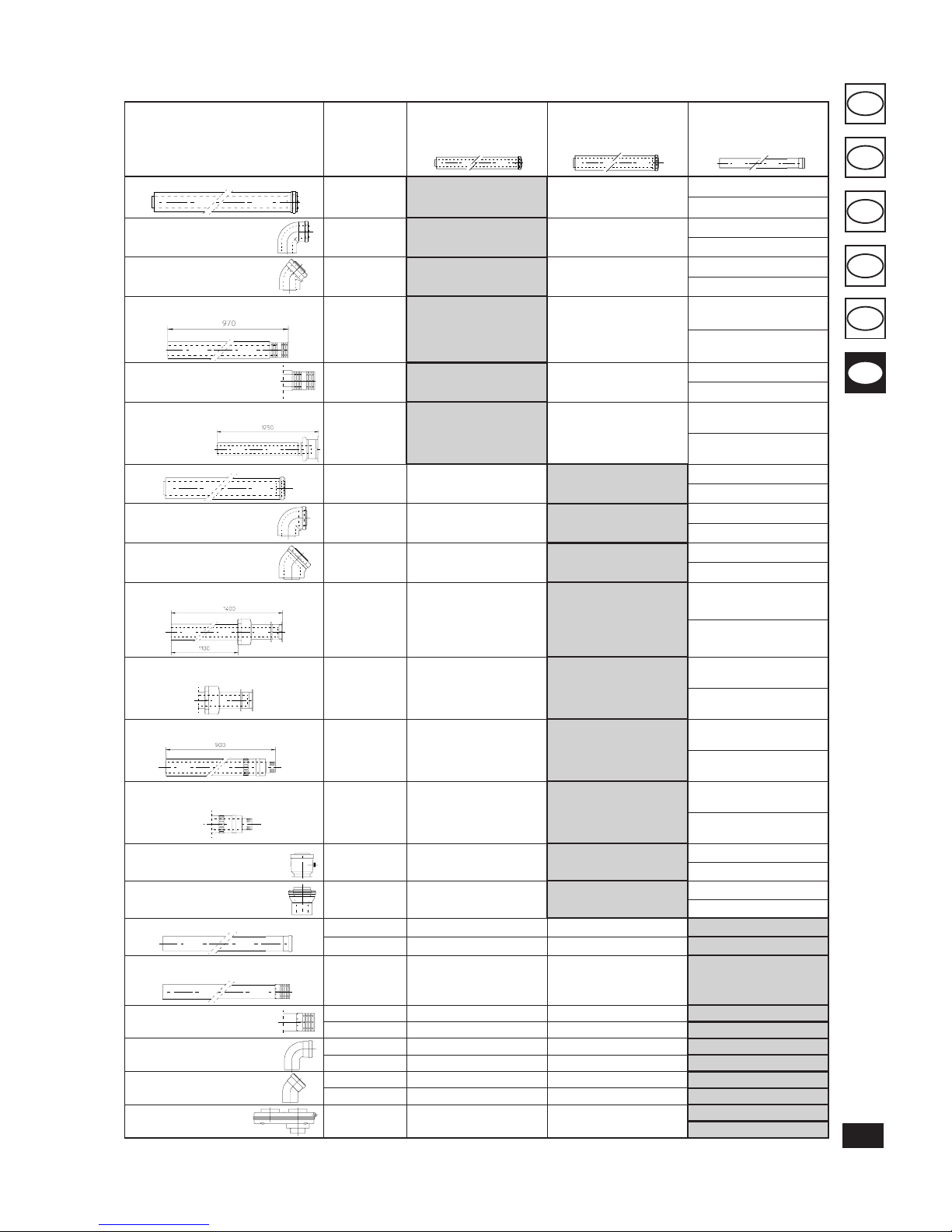

Horizontal intake - exhaust kit Ø60/100. Kit

assembly (Fig. 1-16): install the bend with ange

(2) onto the central hole of the boiler inserting

the gasket (1) and tighten using the screws in the

kit. Couple the terminal pipe (3) with the male

end (smooth) into the female end of the bend

(with lip seals) up to the stop; making sure that

the internal wall sealing plate and external wall

sealing plate have been tted, this will ensure

sealing and joining of the elements making up

the kit.

Note: when the boiler is installed in areas where

very rigid temperatures can be reached, a special

anti-freeze kit is available that can be installed as

an alternative to the standard kit.

• Coupling extension pipes and concentric

elbows Ø60/100. To snap-t extensions with

other elements of the ue extraction elements,

operate as follows engage the concentric pipe

or elbow with the male side (smooth) on the

female section (with lip seal) up to the stop

on the previously installed element. is will

ensure sealing and joining of the elements

correctly.

e Ø60/100 horizontal intake/exhaust kit can

be installed with the rear, right side, le side and

front outlet.

• Application with rear outlet (Fig. 1-17). e

970 mm pipe length enables routing through

a maximum thickness of 710 mm. Normally

the terminal must be shortened. Calculate

the distance by adding the following values:

Part thickness + internal projection + external projection. e minimum indispensable

projection values are given in the gure.

• Application with side outlet (Fig. 1-18); Using

the horizontal intake-exhaust kit, without the

special extensions, enables routing through

a wall thickness of 724 mm with the le side

outlet and 646 with the right side outlet.

• Extensions for horizontal kit. e horizontal

intake-exhaust kit Ø 60/100 can be extended

up to a max. horizontal distance of 3,000 mm

including the terminal with grid and excluding

the concentric bend leaving the boiler. is

conguration corresponds to a resistance factor

of 100. In these cases the special extensions

must be requested.

Connection with N°1 extension (Fig. 1-19).

Max. distance between vertical boiler axis and

external wall is 1855mm.

Connection with N°2 extensions (Fig. 1-20).

Max. distance between vertical boiler axis and

external wall is 2805mm.

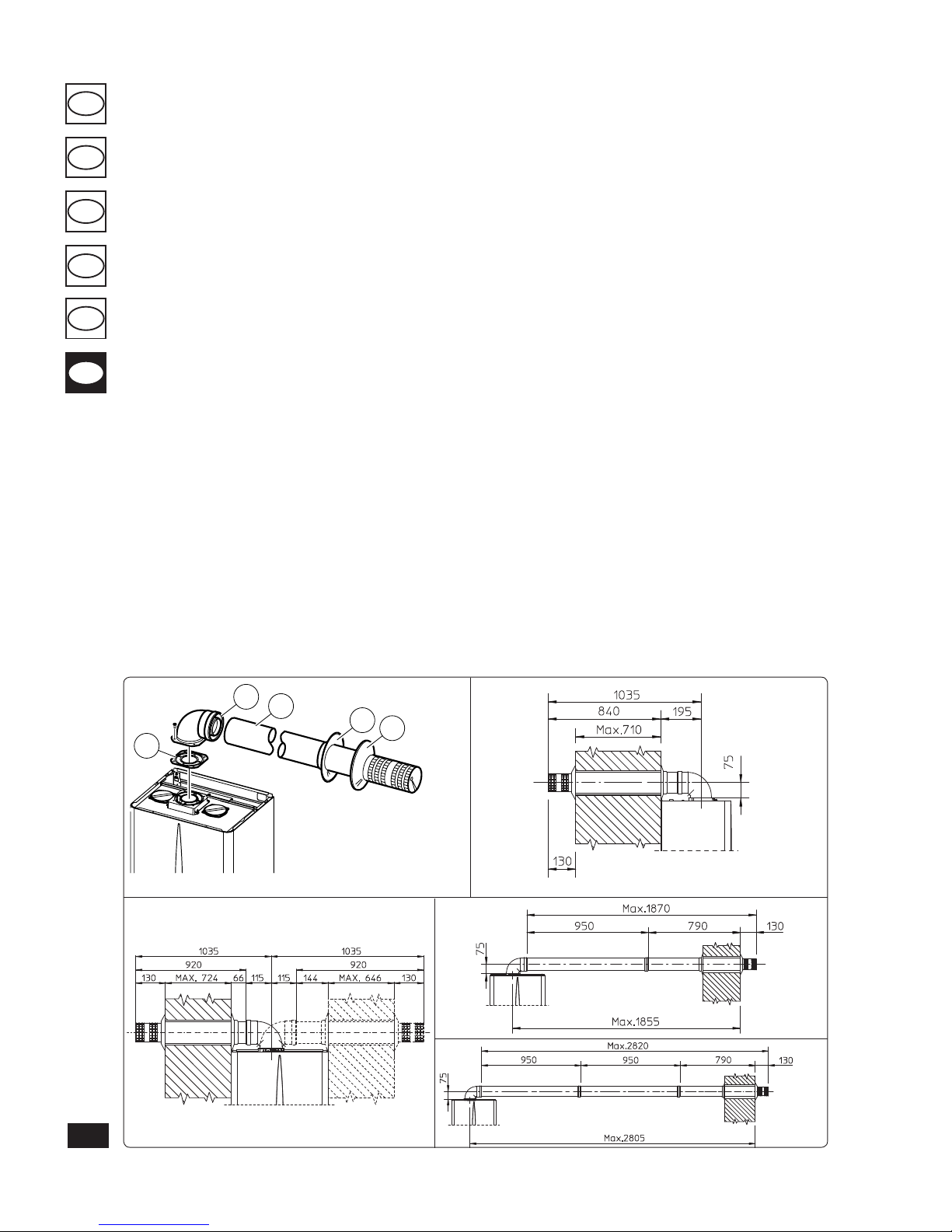

Horizontal intake-exhaust kit Ø80/125. Kit

assembly (Fig. 1-21): install the bend with ange

(2) onto the central hole of the boiler inserting

the gasket (1) and tighten using the screws in the

kit. Fit the male end (smooth) of the adapter (3)

up to the stop on the female end of the bend (2)

(with lip seal). Fit the Ø 80/125 (4) concentric

terminal pipe with the male end (smooth) to the

female end of the adapter (3) (with lip gasket) up

to the stop; making sure that the internal wall

sealing plate and external wall sealing plate have

been tted, this will ensure sealing and joining

of the elements making up the kit.

• Coupling extension pipes and concentric elbows

Ø80/125. To snap-t extensions with other elements of the ue extraction elements, operate as

follows engage the concentric pipe or elbow with

the male side (smooth) on the female section

(with lip seal) up to the stop on the previously

installed element. is will ensure sealing and

joining of the elements correctly.

Important: if the exhaust terminal and/or extension concentric pipe needs shortening, consider

that the internal pipe must always protrude by

5mm with respect to the external pipe.

Normally the Ø80/125 horizontal intake-exhaust

kit is used if particularly long extensions are required; the Ø80/125 kit can be installed with the

rear, right side, le side or front outlet.

• Extensions for horizontal kit. e Ø80/125

horizontal intake-exhaust kit can be extended

up to a max. horizontal distance of 7,300 mm

including the terminal with grid and excluding

the concentric bend leaving the boiler and the

adapter Ø60/100 in Ø80/125 (Fig. 1-22). is

conguration corresponds to a resistance factor

of 100. In these cases the special extensions

must be requested.

N.B.: when installing the ducts, a section clamp

with pin must be installed every 3 metres.

• External grill. N.B.: for safety purposes, do not

even temporarily obstruct the boiler intake/

exhaust terminal.

Fig. 1-16

C12

C12 C12

C12

Fig. 1-17

Fig. 1-19

Fig. 1-20

Fig. 1-18

1

3

2

4

5

e kit includes:

N°1 - Gasket (1)

N°1 - Concentric bend 90° (2)

N°1 - Intake-exhaust concentric pipe

Ø60/100 (3)

N°1 - Internal white wall sealing plate (4)

N°1 - External grey wall sealing plate (5)

151

GR

CZ

HU

ES

IE

PT

C32

Fig. 1-25Fig. 1-24

C32

Fig. 1-21

C12

Fig. 1-22

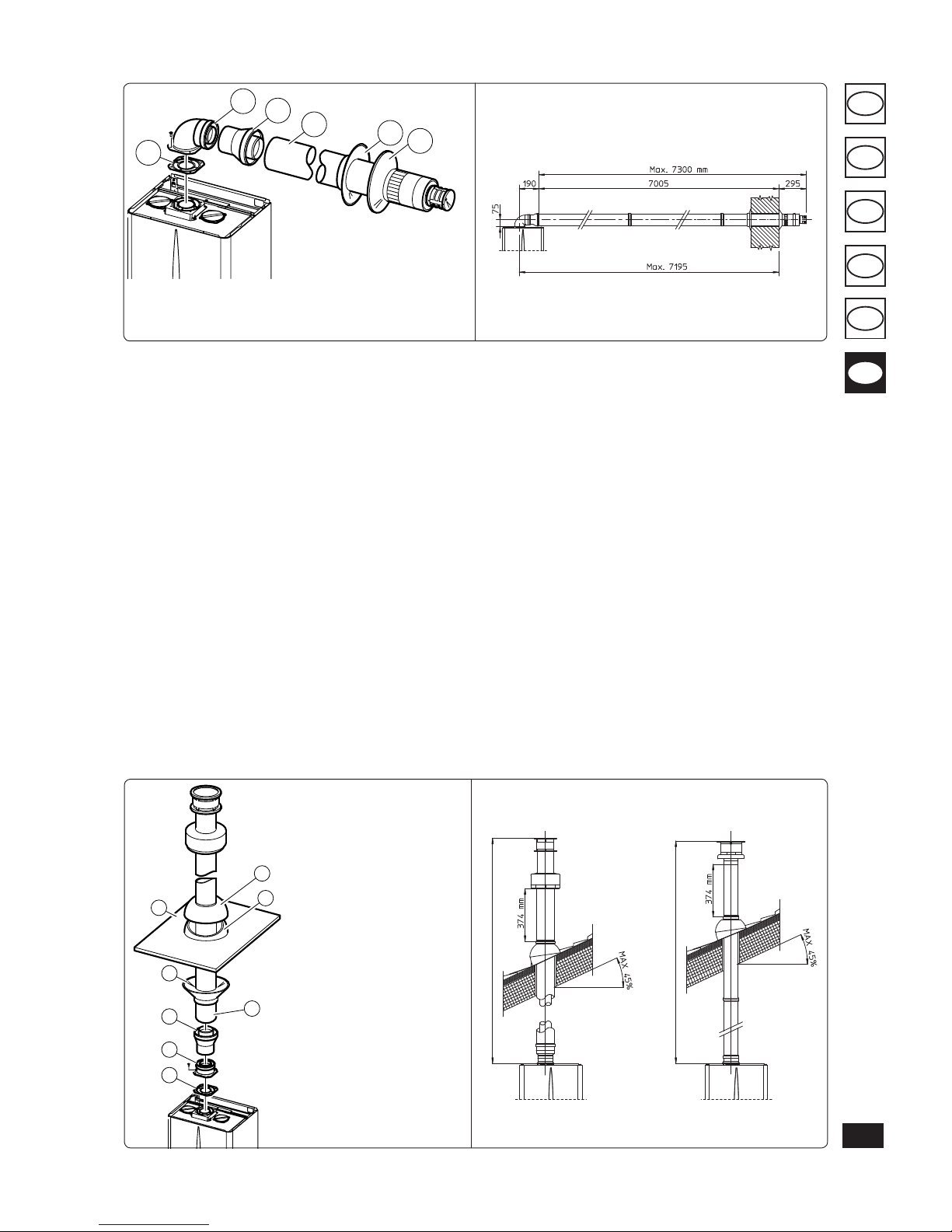

Vertical kit with aluminium tile Ø80/125. Kit

assembly (Fig. 1-24): install the concentric ange

(2) on the central hole of the boiler inserting the

gasket (1) and tighten using the screws in the

kit. Fit the male end (smooth) of the adapter (3)

into the female end of the concentric ange (2).

Imitation aluminium tile installation. Replace the

tile with the aluminium sheet (5), shaping it to

ensure that rainwater runs o. Position the xed

half-shell (7) and insert the intake-exhaust pipe

(6). Fit the Ø 80/125 concentric terminal pipe

with the male end (6) (smooth) to the female

end of the adapter (3) (with lip gasket) up to the

stop; making sure that the wall sealing plate has

been tted, this will ensure sealing and joining

of the elements making up the kit.

• Coupling extension pipes and concentric

elbows. To install push-fitting extensions

with other elements of the flue extraction

elements assembly, proceed as follows: engage

the concentric pipe or elbow with the male

side (smooth) on the female section (with lip

seal) up to the stop on the previously installed

element. is will ensure sealing and joining

of the elements correctly.

Important: if the exhaust terminal and/or extension concentric pipe needs shortening, consider

that the internal pipe must always protrude by

5mm with respect to the external pipe.

is specic terminal enables ue exhaust and

air intake, necessary for combustion, in a vertical

direction.

N.B.: e Ø80/125 vertical kit with aluminium

tile enables installation on terraces and roofs

with a maximum slope of 45% (25°) and the

height between the terminal cap and half-shell

(374mm) must always be respected.

e vertical kit with this conguration can be

extended up to a maximum of 12,200 mm vertical

rectilinear, with the terminal included (Fig. 1-25).

is conguration corresponds to a resistance

factor of 100. In this case the special extensions

must be requested.

The terminal Ø 60/100 can also be used for

vertical exhaust, in conjunction with concentric

flange code 3.011141 (sold separately). The

height between the terminal cap and half-shell

(374mm) must always be respected.

e vertical kit with this conguration can be

extended up to a maximum of 4,700 mm vertical

rectilinear, with the terminal included (Fig. 1-25).

Separator kit Ø80/80. e Ø80/80 separator kit,

allows separation of the exhaust ues and air intake

pipes according to the diagram shown in the gure .

Combustion products are expelled from pipe (S).

Air is taken in through pipe (A) for combustion.

e intake pipe (A) can be installed either on the

right or le hand side of the central exhaust pipe

(S). Both ducts can be routed in any direction.

• Kit assembly (Fig. 1-26): install ange (4) on the

central hole of the boiler, tting gasket (1) and

tighten with the at-tipped hex screws included

in the kit. Remove the at ange present in the

lateral hole with respect to the central one (according to needs) and replace it with the ange

(3), positioning the gasket (2) already present in

the boiler and tighten using the supplied selfthreading screws. Fit the male end (smooth) to

the bends (5) in the female end of the anges

(3 and 4). Fit the intake terminal (6) with the

male section (smooth) in the female section of

the bend (5) up to the stop, ensuring that the

internal and external wall sealing plates are

tted. Fit the exhaust pipe (9) with the male end

(smooth) to the female end of the bend (5) up

to the stop; making sure that the internal wall

sealing plate has been tted, this will ensure

sealing and joining of the elements making up

the kit.

e kit includes:

N°1 - Gasket (1)

N°1 - Female concentric ange

(2)

N°1 - Adapter Ø60/100

for Ø80/125 (3)

N°1 - Wall sealing plate (4)

N°1 - Aluminium tile (5)

N°1 - Concentric intake-

exhaust terminal

Ø80/125 (6)

N°1 - Fixed half-shell (7)

N°1 - Mobile half-shell (8)

1

3

2

5

6

4

1

2

3

4

6

5

7

8

e kit includes:

N°1 - Gasket (1)

N°1 - Concentric bend Ø60/100 (2)

N°1 - Adapter Ø60/100 for Ø80/125 (3)

N°1 - Int./exhaust concentric terminal

Ø80/125 (4)

N°1 - Internal white wall sealing plate (5)

N°1 - External grey wall sealing plate (6)

C12

MAXIMUM LENGTH 12200 mm

MAXIMUM LENGTH 4,700 mm

Loading...

Loading...