Immergas MAGIS PRO 5 ERP, MAGIS PRO ERP Series, MAGIS PRO 8 ERP, MAGIS PRO 10 ERP Instruction And Recommendation Booklet

Page 1

Instruction and

*1.039356ENG*

recommendation booklet

IE

MAGIS PRO ERP

Mono-phase hydronic module to

pair with an outdoor condensing

unit

Page 2

Page 3

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully: you

will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction for the Immergas product.

Contact our area authorised aer-sales centre as soon as possible to request commissioning. Our technician will verify the correct functioning conditions; he

will perform the necessary calibrations and will demonstrate the correct use of the generator.

For assistance and scheduled maintenance contact Authorised Immergas Aer-Sales centres: they have original spare parts and are specically trained directly

by the manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry environments protected from bad weather.

e instruction book is an integral and essential part of the product and must also be given to the new user in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instructions manual provides technical information for installing Immergas products. As for the other issues related to the installation of products (e.g.

safety at the workplace, environmental protection, accident prevention), it is necessary to comply with the provisions of the standards in force and the principles

of good practice.

In compliance with the legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally

qualied sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems for people, animals

and objects. Read the instructions provided with the product carefully to ensure proper installation.

Maintenance must be carried out by skilled technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and

professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non-compliance with technical laws in force, standards or instructions contained in

this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and

the appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of gas heat generators, consult the Immergas site at the

following web address: www.immergas.com

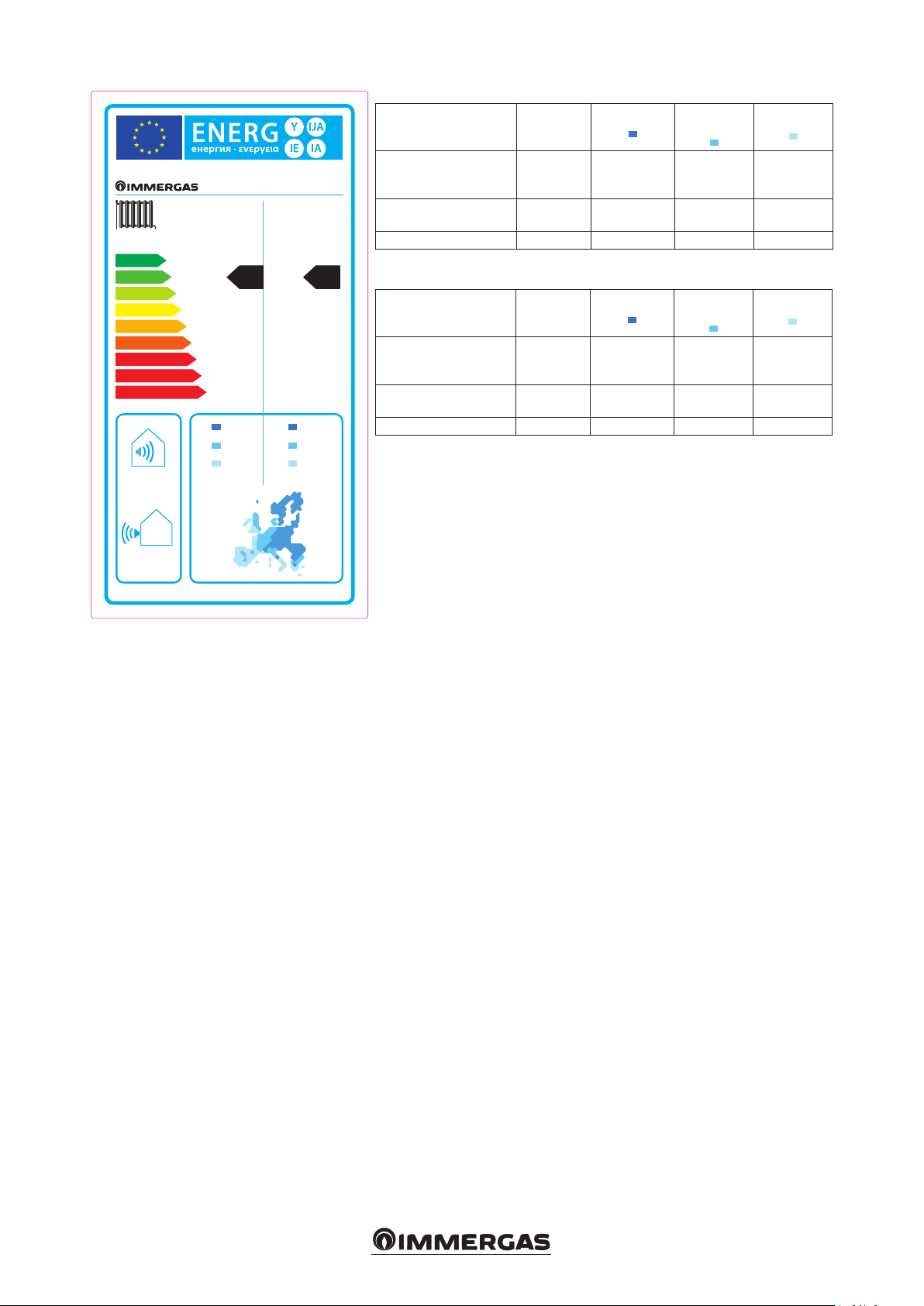

CE DECLARATION OF CONFORMITY

(according to ISO/IEC 17050-1)

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE), whose design, manufacturing and aer-sales assistance

processes comply with the requirements of standard UNI EN ISO 9001:2008,

MAGIS PRO ERP hydronic units comply with the following European Directives and European Commission Delegated Regulations:

“Eco-design” Directive 2009/125/EC, “Energy labelling” Directive 2010/30/EC, EU Regulation 811/2013, EU Regulation 813/2013, “Electromagnetic

Compatibility” Directive 2004/108/EC, “Eciency” Directive 92/42/EC and “Low-Voltage” Directive 2006/95/EC.

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without prior notice.

DECLARES that:

Mauro Guareschi

Research & Development Director

Signature:

Page 4

INDEX

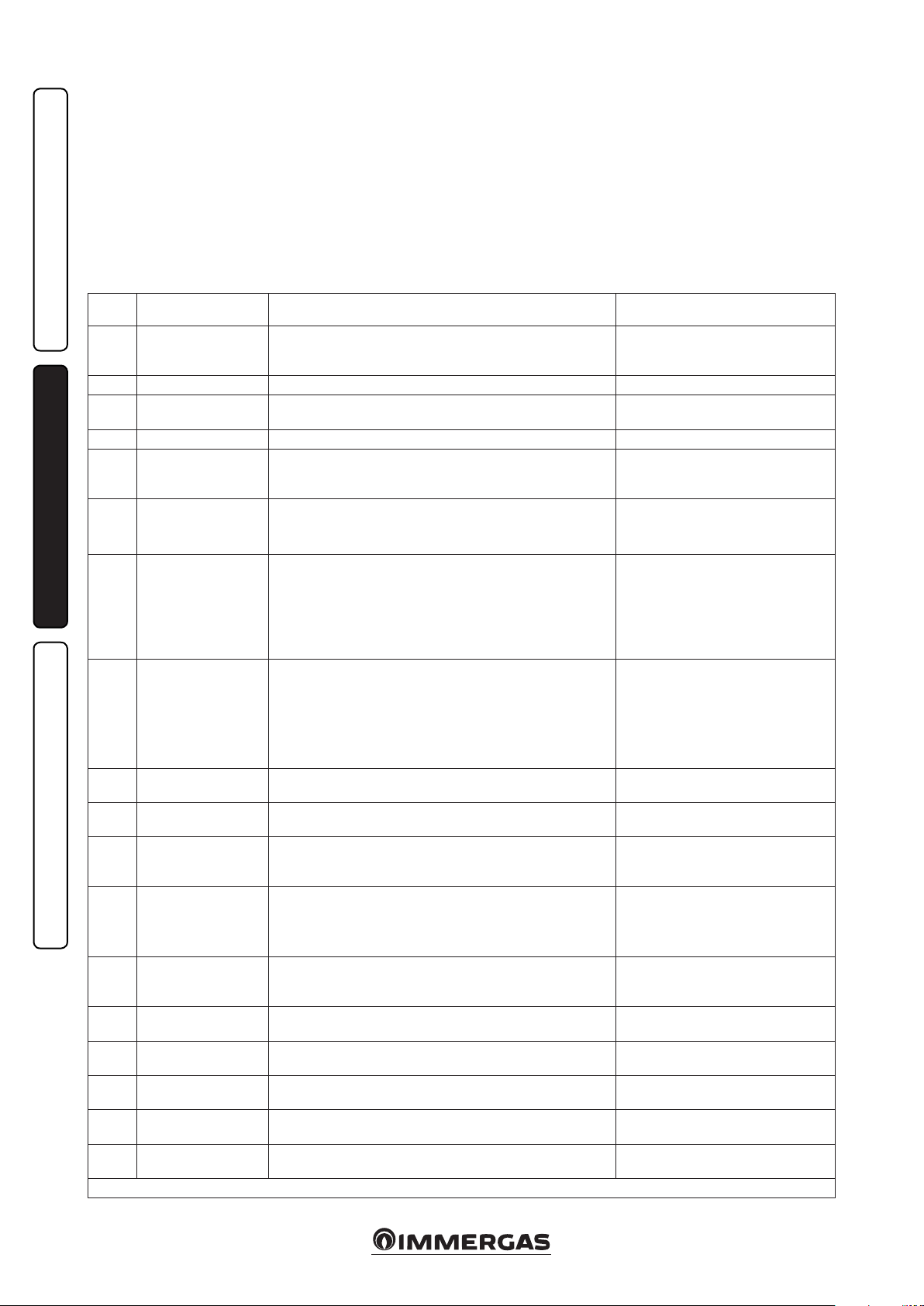

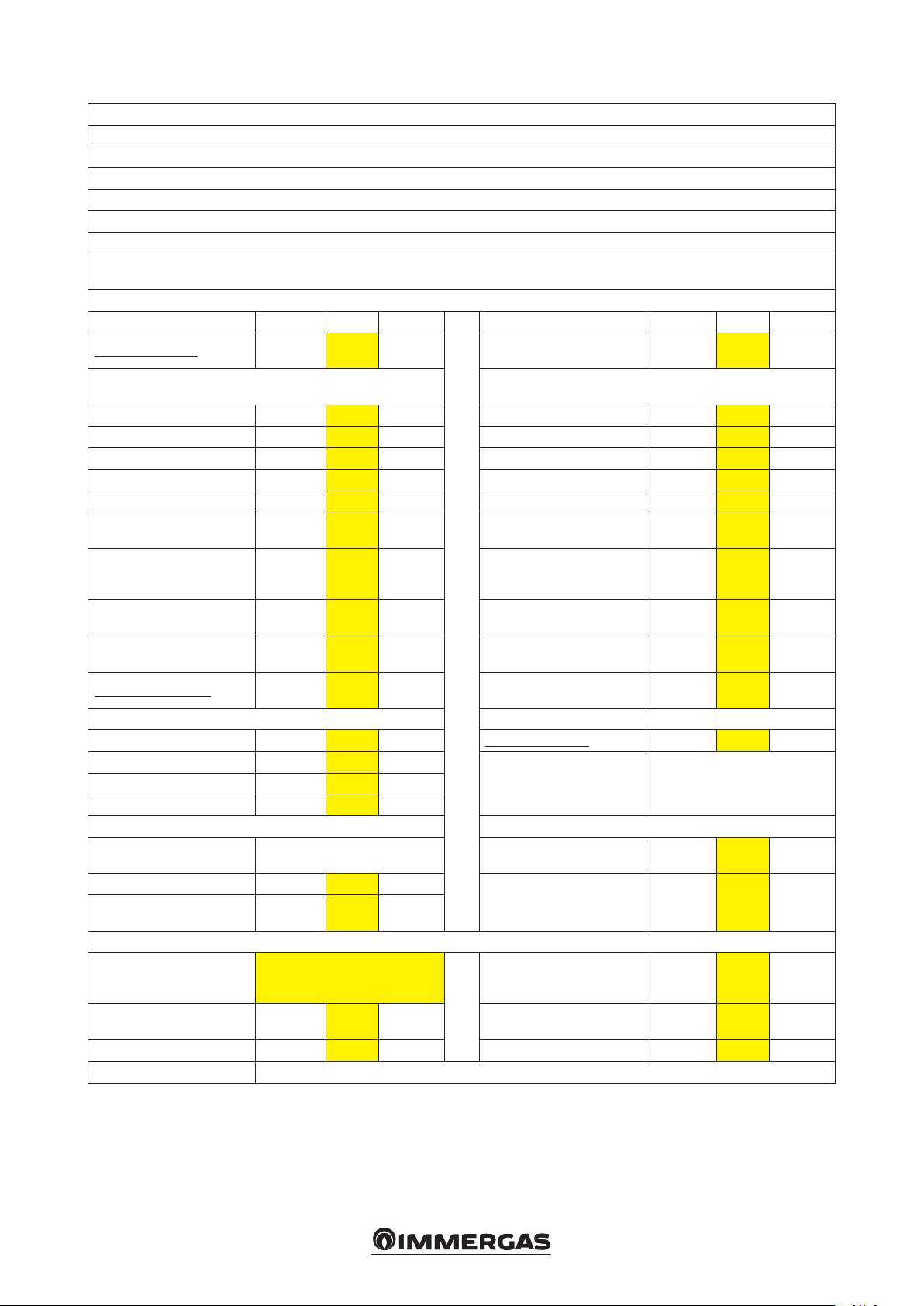

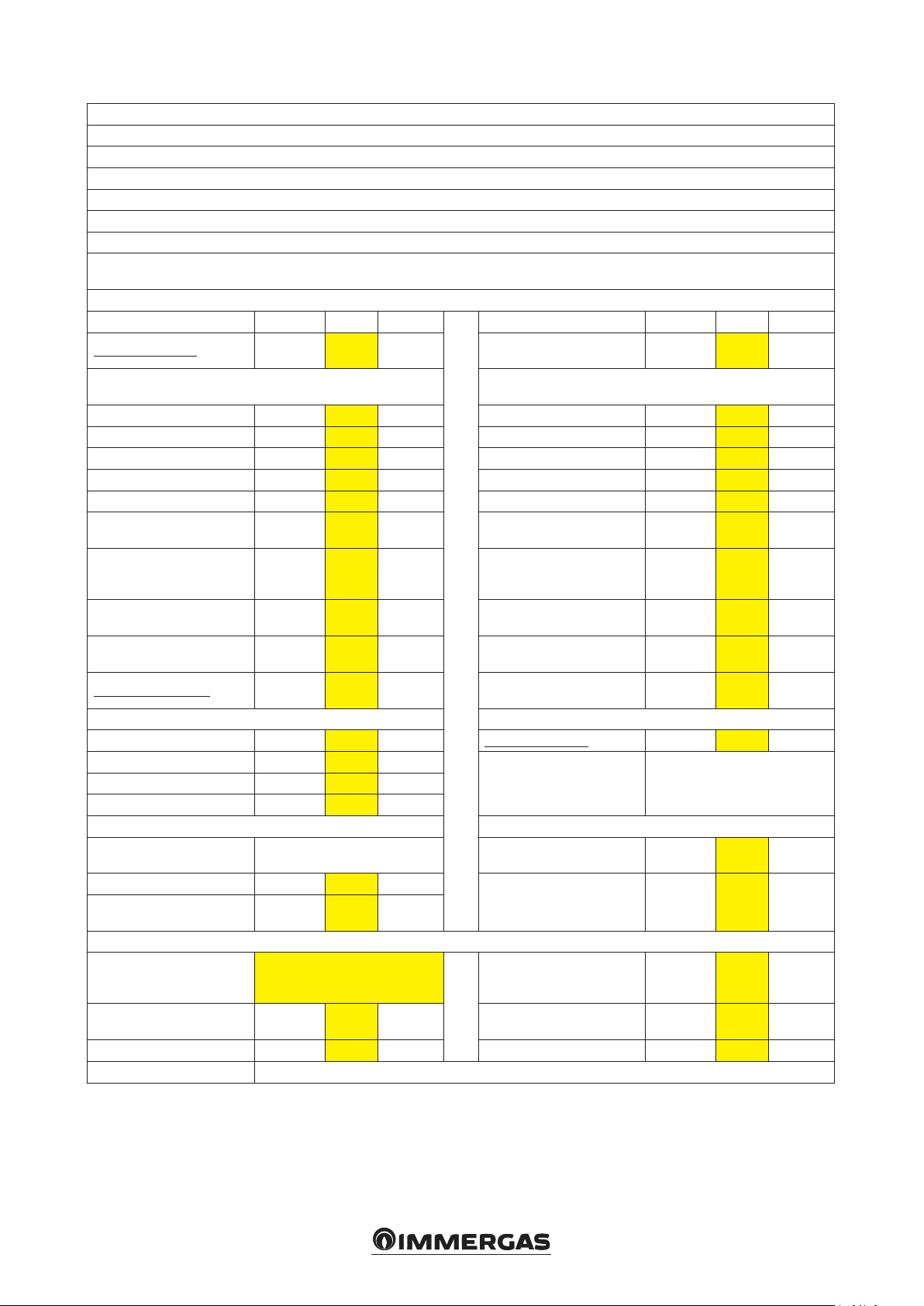

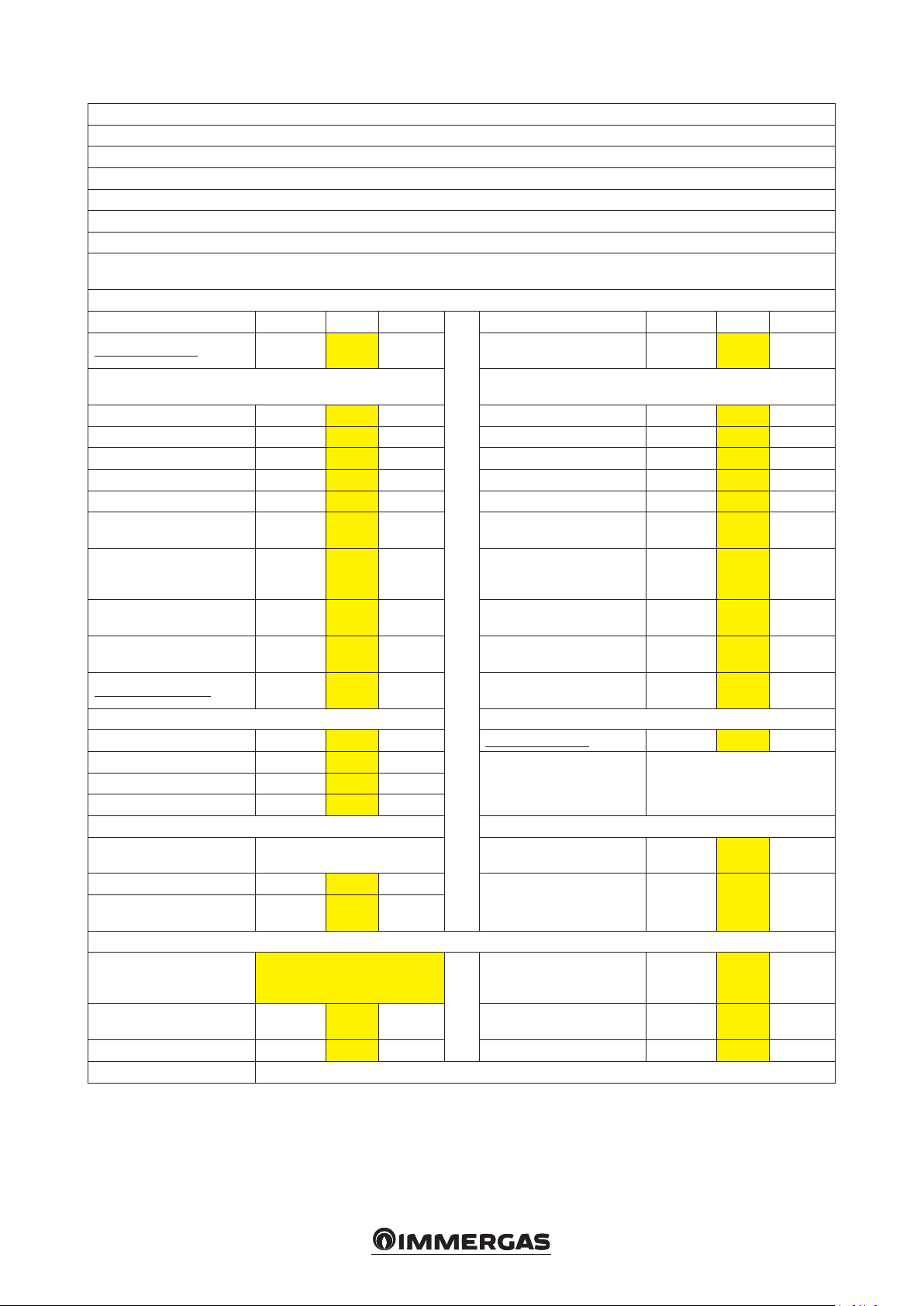

USER page INSTALLER page MAINTENANCE TECHNICIAN page

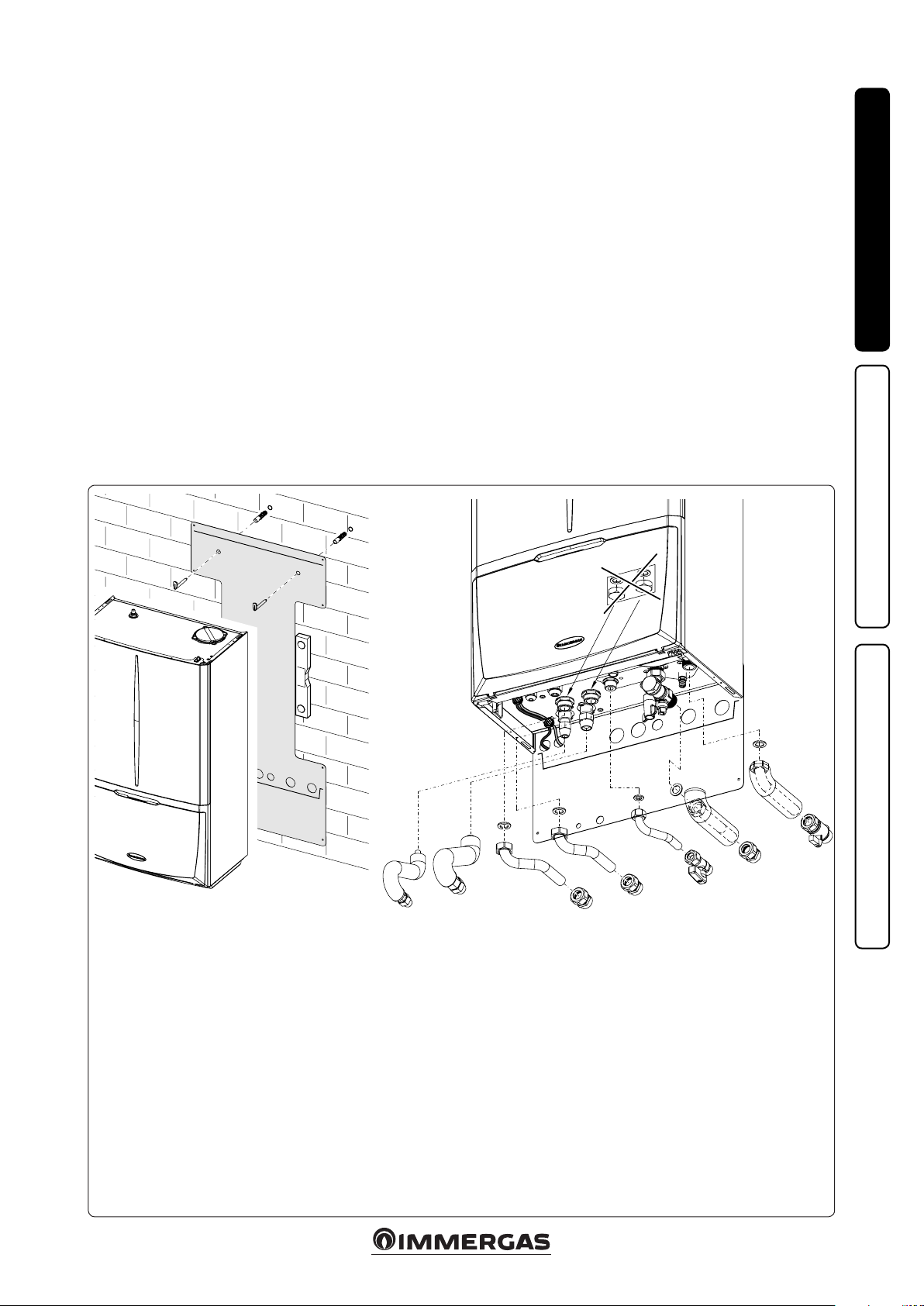

1 Hydronic module installation. ..........................5

1.1 Installation recommendations. ......................... 5

1.2 Main dimensions. ..............................................6

1.3 Antifreeze protection. ........................................6

1.4 Hydronic module connection unit. ..................7

1.5 Hydraulic connection. ........................................7

1.6 Connecting the chiller line. ............................... 7

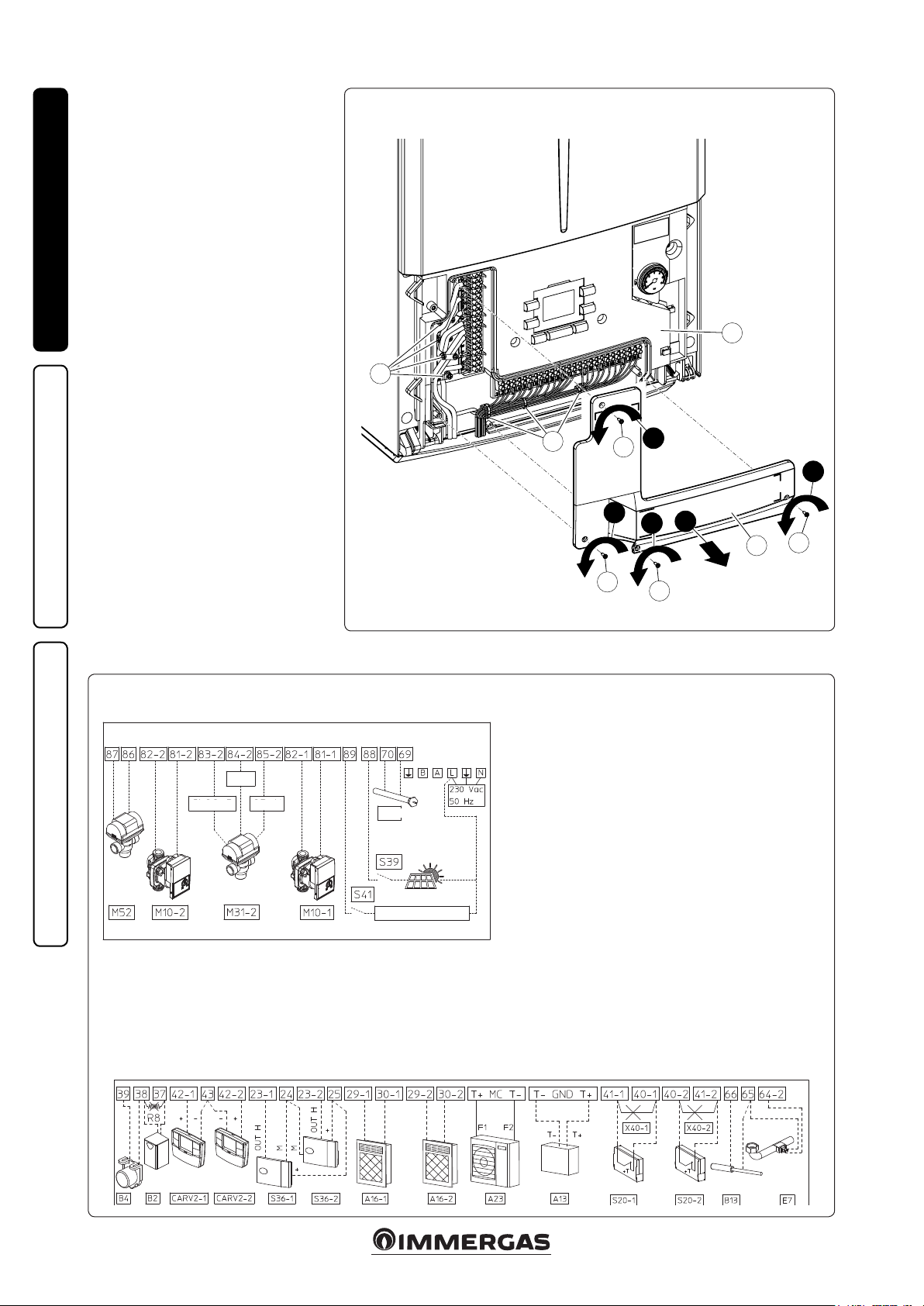

1.7 Electric connection. ........................................... 8

1.8 Remote controls and room chrono-thermostats

(Optional). ........................................................... 9

1.9 External temperature probe...............................9

1.10 Heat regulation setting. .................................... 10

1.11 Filling the system. ............................................. 11

1.12 Operating limits. ............................................... 11

1.13 Commissioning the hydronic module

(ignition). ...........................................................11

1.14 Circulation pump. .............................................12

1.15 Hydronic module components. ......................13

1.16 Kits available on request. .................................13

2 Use and maintenance instructions ................. 14

2.1 Cleaning and maintenance. .............................14

2.2 General warnings. ............................................. 14

2.3 Control panel. ....................................................14

2.4 System use. .........................................................15

2.5 Troubleshooting. ...............................................16

2.6 Parameters and information menu. ...............18

2.7 Switching o the hydronic module. ................. 19

2.8 Restoring central heating system pressure. ... 19

2.9 System draining................................................19

2.10 Anti-freeze protection. ..................................... 19

2.11 Case cleaning. .................................................... 19

2.12 Decommissioning. ............................................19

3 Commissioning the package (initial check) ..20

3.1 Hydronic module Hydraulic Diagram .............20

3.2 Wiring diagram. ................................................21

3.3 System lter. ........................................................ 23

3.4 Troubleshooting. ...............................................23

3.5 Programming the P.C.B....................................24

3.6 Pump anti-lock function ..................................28

3.7 3-way anti-lock function ..................................28

3.8 Radiator antifreeze function. ...........................28

3.9 Solar function. ................................................... 28

3.10 Outdoor unit disable function. ....................... 28

3.11 Diverter valve management (summer / winter).

...................................................................... 28

3.12 Anti-Legionalla function. ................................ 28

3.13 Automatic vent function. .................................28

3.14 Yearly appliance check and maintenance. .....28

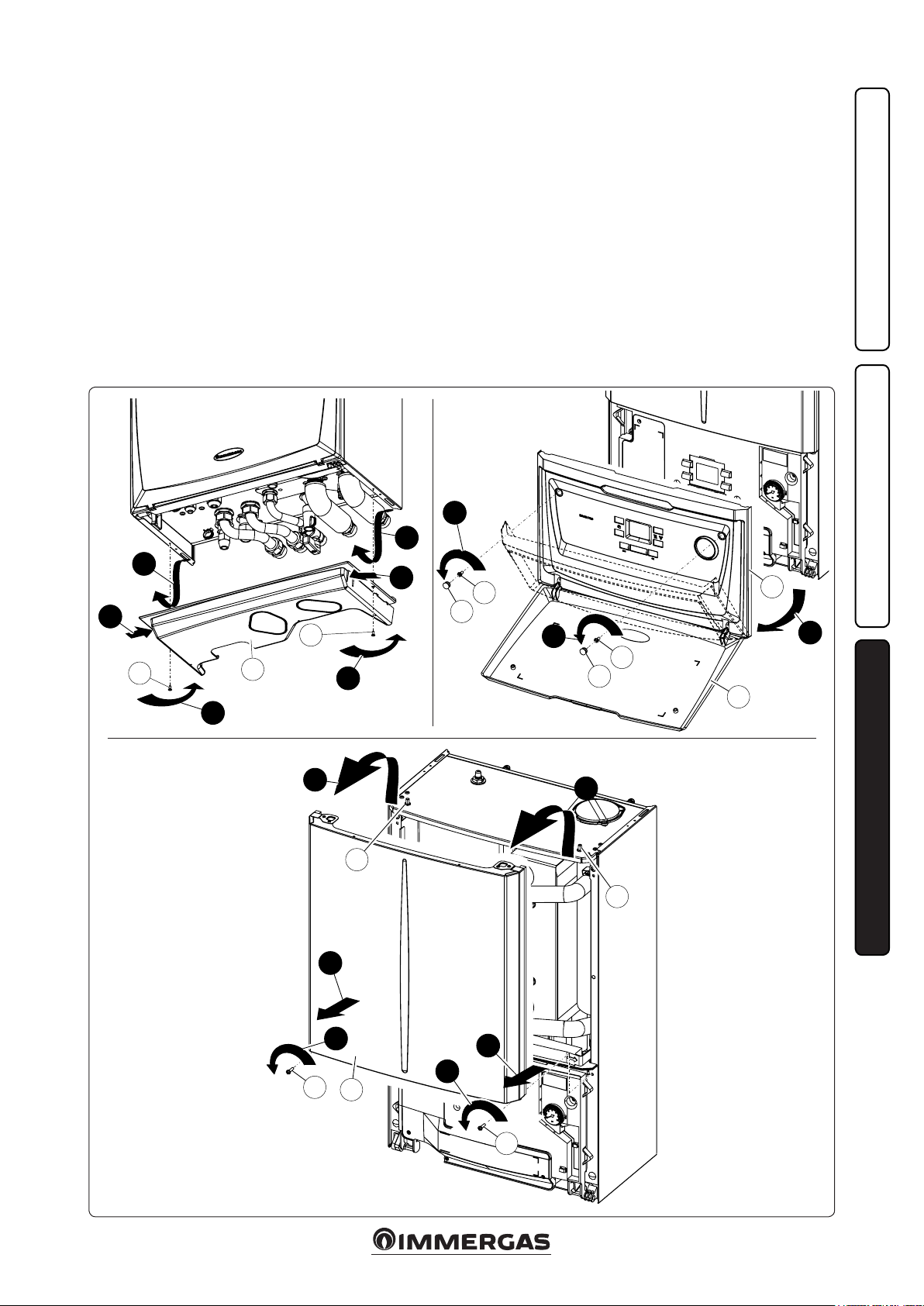

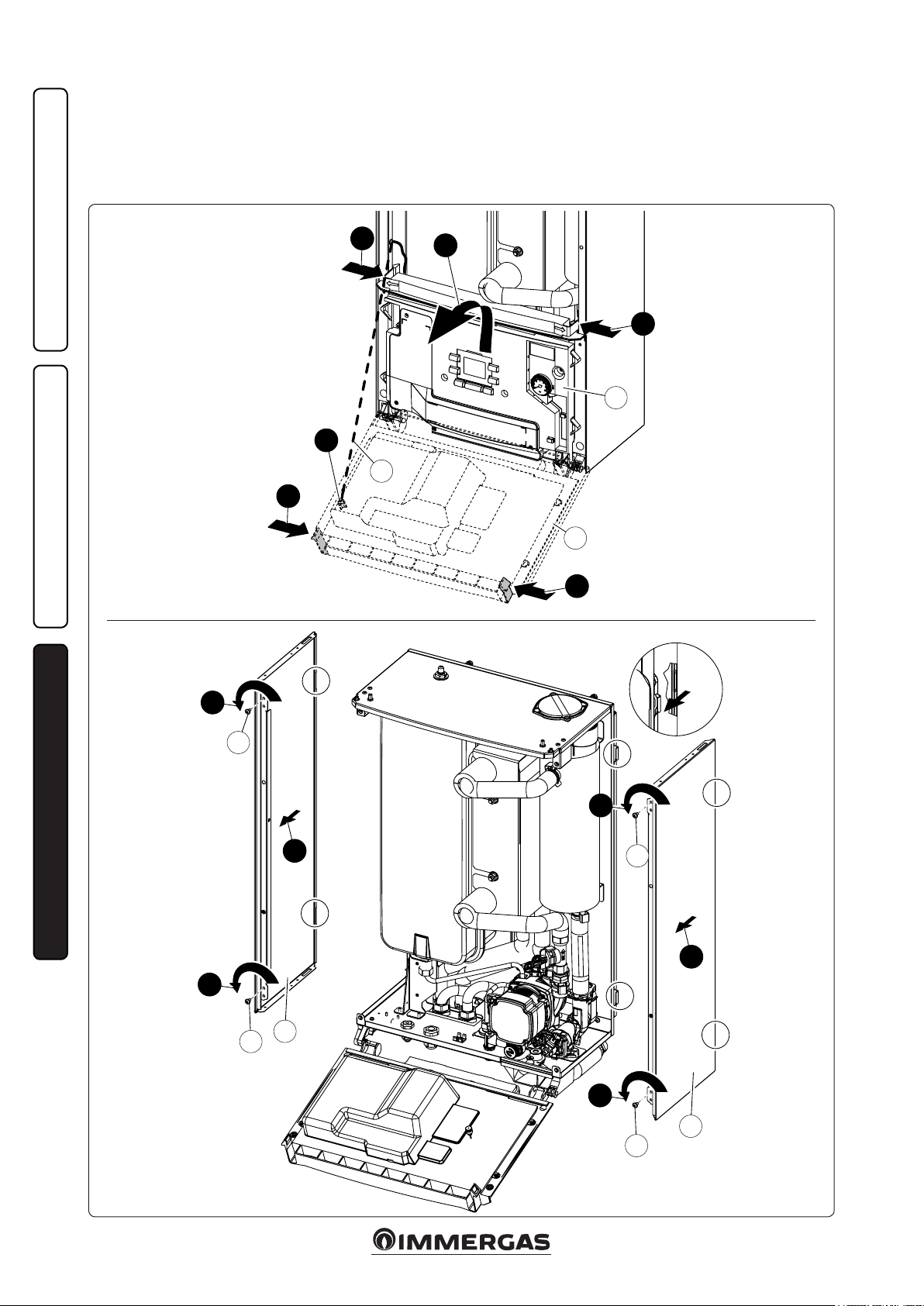

3.15 Casing removal. ................................................. 29

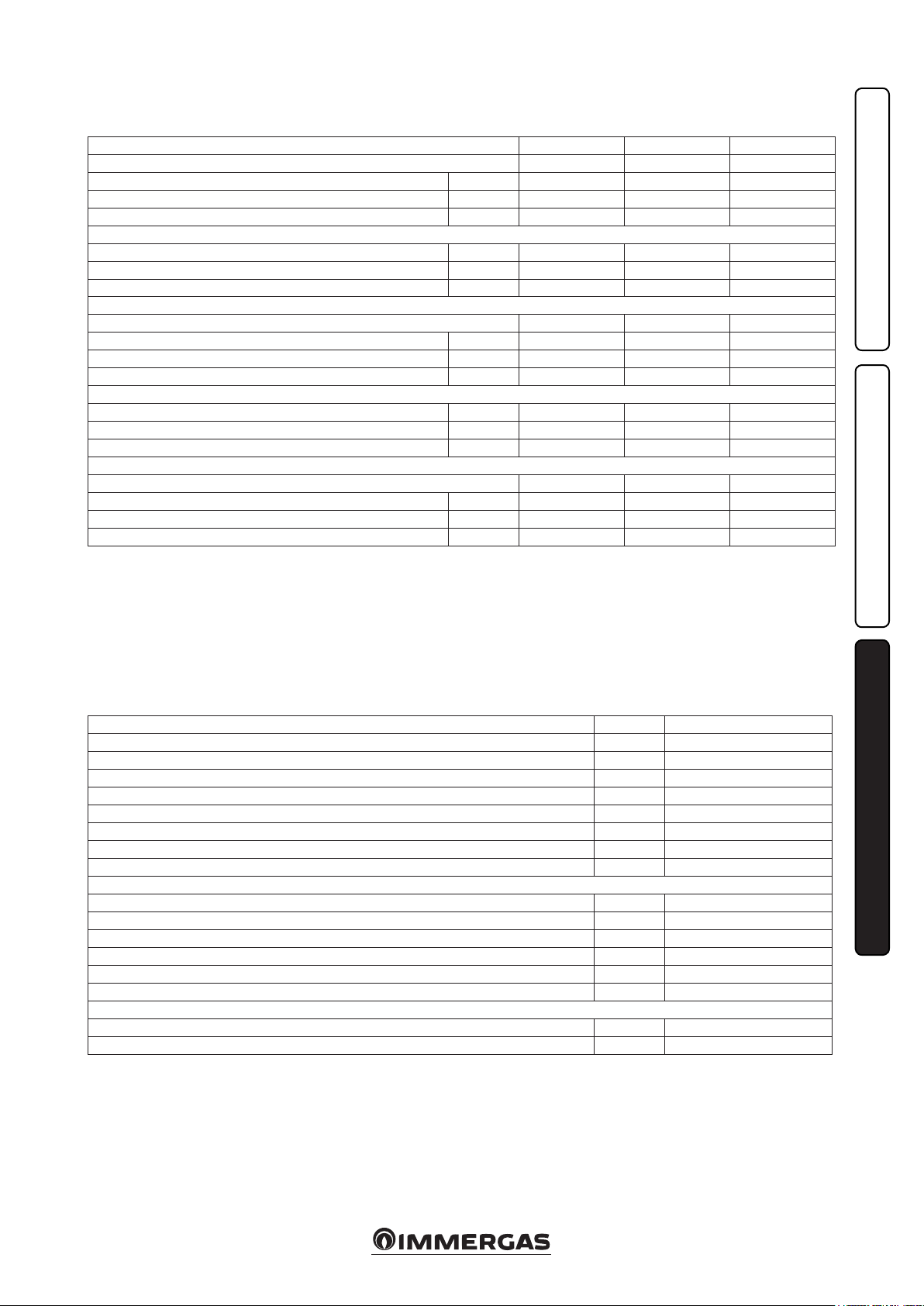

3.16 Technical data. ...................................................31

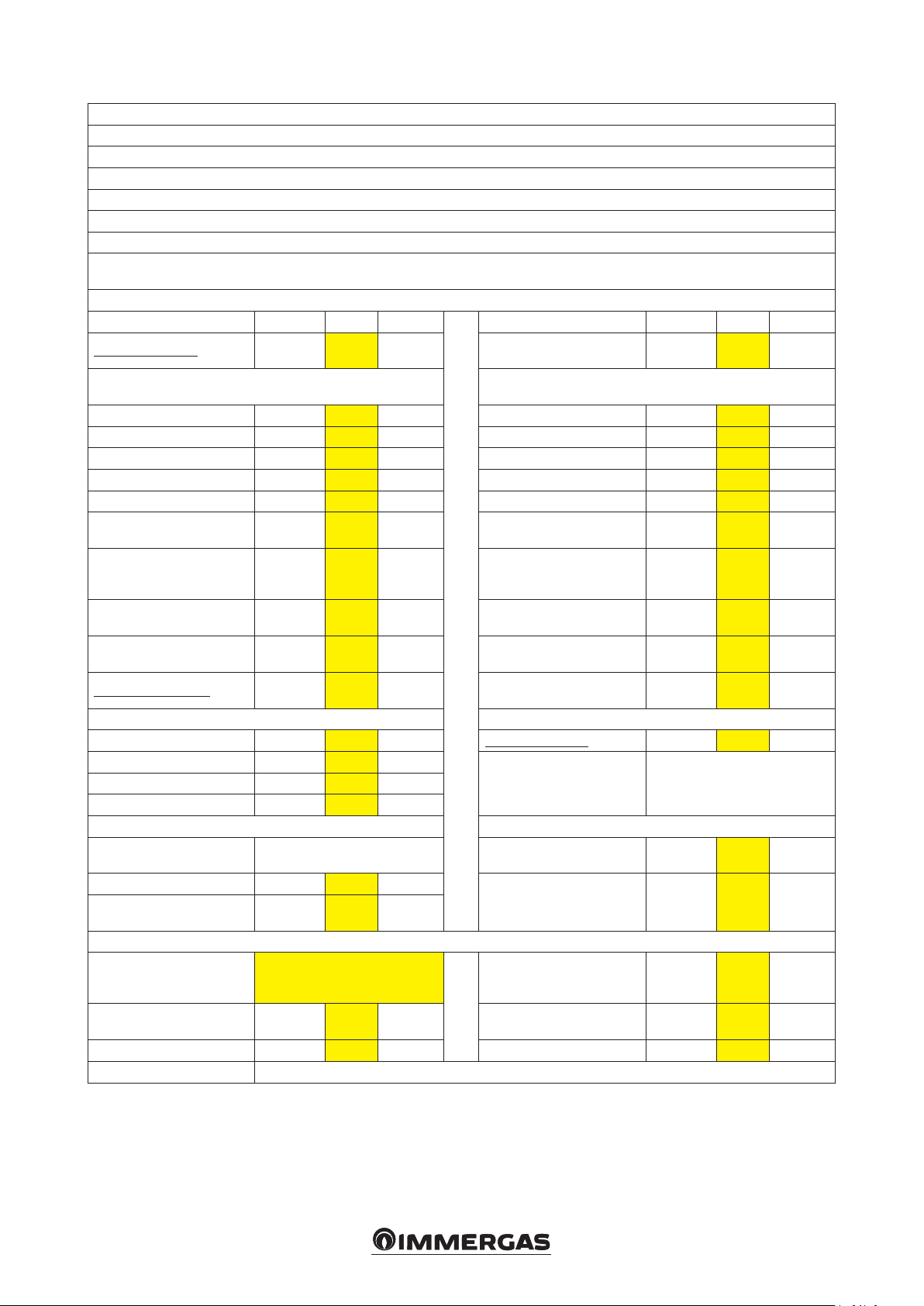

3.17 Product che (in compliance with regulation

811/2013). .......................................................... 32

3.18 Parameters for lling in the package che. ....53

Page 5

HYDRONIC MODULE IN

1

STALLATION.

1.1 INSTALLATION

RECOMMENDATIONS.

e Magis Pro ErP hydronic module was designed solely for wall mounted installation for

heating and air conditioning and to produce

domestic hot water for domestic use and similar

purposes.

In order to operate properly, it must be paired

with an Audax Pro condensing unit; as such, all

the provisions regarding the safety and use of

both appliances must be respected.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural), such as to allow for (always in safe, ecient and comfortable

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (to outdoors in the place for loading

and transporting the appliances and components) as well as their eventual replacement

with appliances and/or equivalent components.

e wall surface must be smooth, without any

protrusions or recesses enabling access to the

rear part. ey are not designed to be installed

on plinths or oors (Fig. 1-1).

Only professionally enabled companies are authorised to install Immergas appliances.

Installation must be carried out according to the

provisions of the laws in force and in compliance

with local technical regulations and the required

technical procedures.

Before installing the appliance, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately. Packing materials (staples, nails, plastic bags, polystyrene foam, etc.)

constitute a hazard and must be kept out of the

reach of children.

Should the appliance be contained inside or between pieces of furniture, there must be enough

space for routine maintenance; therefore, it is

recommendable to leave at least 3 cm between the

unit casing and the vertical walls of the furniture.

At least 25 cm of free space must be le above, in

order to be able to carry out maintenance and,

if necessary, install an additional resistance (optional). Leave space under the hydronic module

to allow the hydraulic connections to be serviced.

Keep all ammable objects away from the appliance (paper, rags, plastic, polystyrene, etc.).

Do not put household appliances under the hydronic module as they could be damaged if the

safety valve trips or if the hydraulic ttings leak.

Otherwise, the manufacturer cannot be held liable for any damage to the household appliances.

For the same reasons, it is also recommendable

not to put furnishings, furniture, etc. under the

hydronic module.

In the event of malfunctions, faults or incorrect

operation, turn the appliance o immediately

and contact an authorised company (e.g. the

Immergas Technical Assistance centre, which

has specically trained sta and original spare

parts). Do not attempt to modify or repair the

appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

• Installation regulations:

- this hydronic module can be installed outdoors in a partially protected area. By partially protected area, we mean one in which the

unit is not directly exposed to the elements

(rain, snow, hail, etc.).

- Installation is prohibited on the vertical

projection of cooking hobs.

- Installation is also prohibited in places/environments that constitute common parts of

oce condominiums such as stairs, cellars,

entrance halls, attics, los, escape routes,

etc. if they are not located inside technical

compartments under the responsibility of

each individual building and only accessible

to the user (for the features of the technical

compartments, see the technical standards in

force).

- Using specic kits, the hydronic module can

be paired with other Immergas products

and installed inside an outdoor wall using

the specic Solar Container recessed frame

or mounted on an indoor wall in the Domus

Container.

Attention: Installing the wall recessed frame

kit must guarantee the hydronic module stable, ecient support. e recessed frame kit

ensures appropriate support only if installed

correctly (according to the rules of good

practice), following the instructions on its

instructions leaet. e recessed frame for

the hydronic module is not a load-bearing

structure and cannot replace the removed

wall. erefore, correct positioning inside

the wall must be checked. For safety reasons

to prevent leaks, the compartment that will

house the hydronic module in the masonry

wall must be plastered.

Attention: installing the hydronic module

mounted on the wall must ensure the generator

itself stable, ecient support.

e dowels (standard supplied with the unit) must

only be used to secure the unit to the wall; they can

only ensure sucient support if inserted properly

(according to the rules of good practice) on walls

built with solid or semi-hollow bricks. In the

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate support.

ese hydronic units are used to heat water to below boiling temperature at atmospheric pressure.

ey must be connected to a central heating

system and domestic hot water circuit suited to

their performance and capacity.

Attention:e storage tank unit must also be

installed in an environment in which the temperature cannot fall below 0°C.

"Anti-Legionella" treatment of the Immergas

storage tank (function enabled when there is

an additional electrical resistance for domestic

hot water). During this phase, the temperature

of the water inside the tank exceeds 60°C with

the subsequent risk of burns. Keep this domestic water treatment under control (and inform

the users) to prevent unforeseeable damage

to people, animals, things. If required install a

thermostatic valve on the domestic hot water

outlet to prevent scalding.

INSTALLERUSERMAINTENANCE TECHNICIAN

YES NO

1-1

5

Page 6

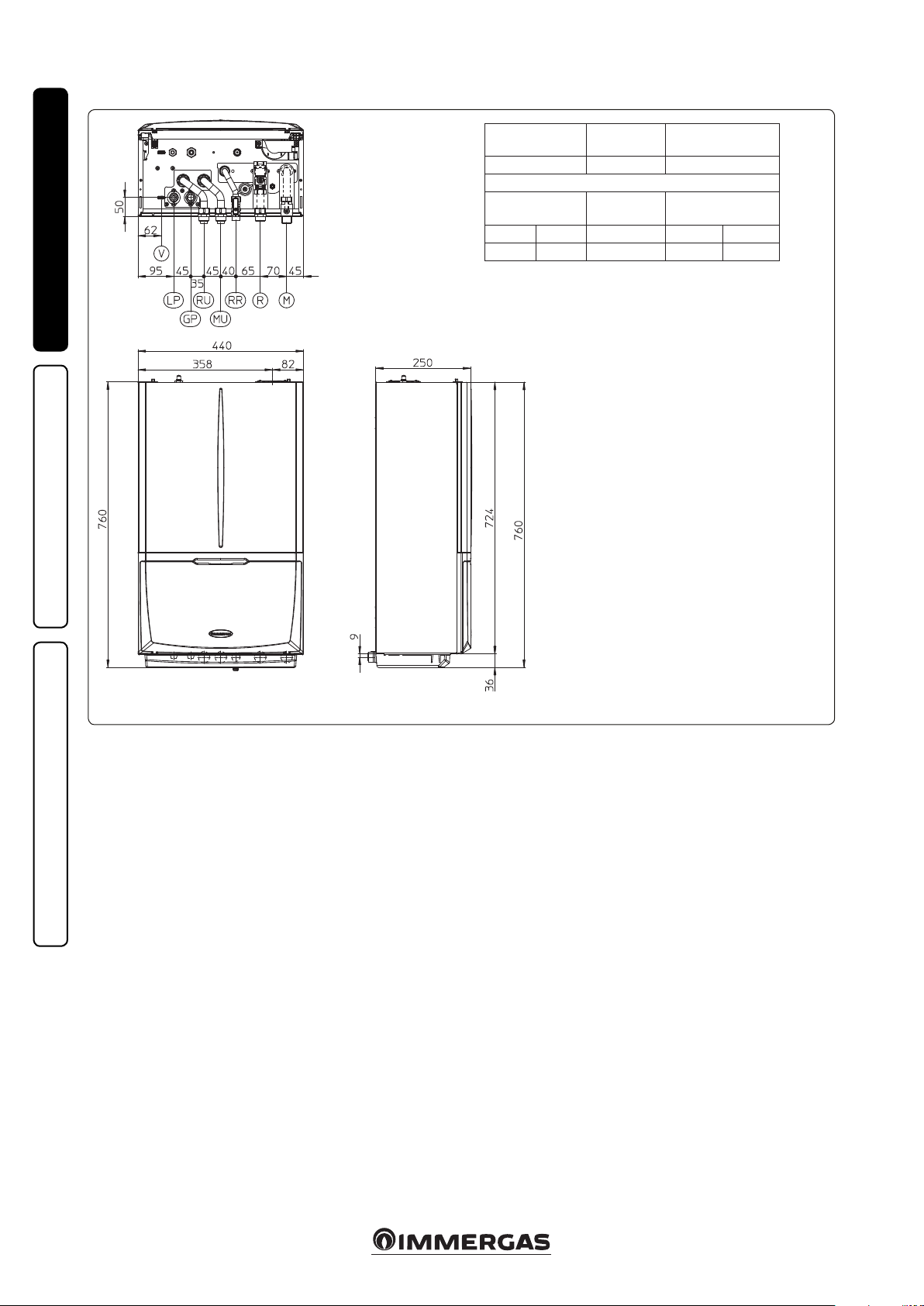

1.2 MAIN DIMENSIONS.

INSTALLERUSERMAINTENANCE TECHNICIAN

Height

(mm)

760 440 250

CHILLER LINE

LG GP RR R - M RU - MU

G 3/8” G 5/8” 1/2” 3/4” 3/4”

Width

(mm)

CONNECTIONS

DOMESTIC

HOT WATER

Key:

V - Electrical connection

RR - System lling

RU - Storage tank unit return

MU - Storage tank unit ow

R - System return

M - System ow

LP - Chiller line - liquid phase

GP - Chiller line - gaseous phase

Depth

(mm)

SYSTEM

1-2

1.3 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e hydronic unit

comes standard with an anti-freeze function that

activates the condensing unit when the temperature of the water inside of it falls below 4°C.

In these conditions, the hydronic unit is protected

against freezing up to an ambient temperature

of -5℃.

Minimum temperature -15°C. In the event the

hydronic unit is installed in a place where the

temperature falls below -5°C, it is possible for

the appliance to freeze.

To prevent the risk of freezing follow the instructions below:

- protect the central heating circuit from freezing

by inserting a good-quality antifreeze liquid

into this circuit, which is specially suited for

central heating systems and which is manufacturer guaranteed not to cause damage to

the heat exchanger or other components of

the hydronic module. e antifreeze liquid

must not be harmful to one's health. e instructions of the manufacturer of this liquid

must be followed scrupulously regarding

the percentage necessary with respect to the

minimum temperature at which the system

must be kept. An aqueous solution must be

made with potential pollution class of water 2

(EN 1717:2002).

e materials used for the hydraulic circuits of

Immergas hydronic units resist ethylene and

propylene glycol based antifreeze liquids (if the

mixtures are prepared perfectly).

For life and possible disposal, follow the sup-

plier's instructions.

- Protect the domestic hot water circuit against

freezing by using an accessory that is supplied

on request (antifreeze kit) comprising two

electric heating elements, the relevant cables

and a control thermostat (carefully read the

installation instructions contained in the accessory kit pack).

In these conditions, the hydronic unit is protected

against freezing up to a temperature of -15°C.

Hydronic unit anti-freeze protection (both -5°C

and -15°C) is only ensured if:

- e hydronic unit and the condensing unit are

properly connected to each other and to the

electrical supply voltage circuits;

- e units are continuously powered;

- e units are not in "o" mode.

- e units are not in anomaly (parag. 2.5);

- e unit and/or kit essential components are not

faulty.

e warranty does not cover damage due to interruption of the electrical power supply and failure

to comply with that stated on the previous page.

N.B.: if the hydronic unit is installed in places

where the temperature drops below 0°C, the

domestic hot water connection pipes must be

insulated.

6

Page 7

1.4 HYDRONIC MODULE

CONNECTION UNIT.

- e hydraulic connection unit is standard sup-

plied with Magis Pro ErP. Make the hydraulic

connection as shown below, making sure to

protect the system ow and return pipes with

their supplied insulating sheaths.

- The R410A circuit wall connection unit is

supplied as an extra kit. Connect the circuit,

following the instructions provided in the

condensing unit instructions booklet.

1.5 HYDRAULIC CONNECTION.

Attention: in order not to void the product war-

ranty, before making unit connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could jeopardise proper

hydronic module operation.

A chemical treatment of the heating system water

is required, in compliance with the technical

standards in force, in order to protect the system

and the appliance from deposits (e.g. scale),

slurry or other hazardous deposits.

Hydraulic connections must be made rationally,

using the couplings on the hydronic module

template.

Attention: Immergas declines all liability in the

event of damage caused by the inclusion of automatic lling that is not its own brand.

In order to meet the system requirements established by EN 1717 regarding the pollution

of drinking water, we recommend installing the

IMMERGAS anti-backow kit upstream of the

hydronic unit cold water inlet connection. We

also recommend using a category 1, 2 or 3 heat

transfer uid (ex: water + glycol) in the hydronic

unit primary circuit (CH circuit), as dened in

the EN 1717 standard.

Attention: to preserve appliance duration and

eciency features, we recommend installing a

suitable water treatment device if the water has

features that can lead to limescale deposits.

1.6 CONNECTING THE CHILLER LINE.

As far as connecting the chiller line is concerned,

all the instructions contained in the Audax Pro

condensing unit instructions booklet must be

followed.

Make the connections directly on the hydronic

module couplings, or use the rear outlet kit

(optional).

INSTALLERUSERMAINTENANCE TECHNICIAN

e hydraulic connection kit includes:

2 - adjustable expansion bolts

2 - hydronic module support hooks

1 - 3/4” storage tank unit return pipe (RU)

1 - 3/4” storage tank unit ow pipe (MU)

1 - 1/2” system lling pipe (RR)

1 - 1/2” ball valve (RR)

1 - 3/4” system return pipe (R)

1 - 3/4” system ow pipe (M)

1 - 3/4” ball valve (M)

2 - Insulating sheath for system pipes (R - M)

4 - 3/4” telescopic ttings (RU - MU - R)

Gaskets, screws and seal O-Ring

e R410A circuit wall connection kit (optional) includes:

1 - G 3/8” liquid phase chiller line pipe (LP)

1 - G 5/8” gaseous phase chiller line pipe (GP)

MU

RU

V

V

GP

LP

LP

GP

RU

MU

M

R

RR

M

R

RR

Key:

V - Electrical connection

RR - System lling

RU - Storage tank unit return

MU - Storage tank unit ow

R - System return

M - System ow

LP-Chiller line - liquid phase

GP-Chiller line - gaseous phase

Already installed on the module:

1 - System interception tap with 3/4” lter (R)

1-3

7

Page 8

1.7 ELECTRIC CONNECTION.

e appliance has an IPX4D degree of protection;

electrical safety of the appliance is achieved only

when it is properly connected to an ecient

earthing system, as specied by current safety

standards.

Attention: Immergas S.p.A. declines any responsibility for damage or physical injury caused by

failure to connect the hydronic module to an

ecient earthing system or failure to comply

with the reference standards.

INSTALLERUSERMAINTENANCE TECHNICIAN

- Connection cables must respect the prear-

ranged routes. Use 3 clips (c) (not supplied)

to group the individual cables (max. 1.5 mm2

into the lower terminal board. Use the specic

fairleads (d) on the le side, making sure to put

at most 2 multi-polar cables (max 3 x 1 mm2)

in each fairlead.

As an example, gure 1-5 shows cables in a

hypothetical connection. To make the connections based on your own requirements, see the

instructions below.

• Open the control panel connections compart-

ment (Fig. 1-5).

To carry out electrical connections, all you have

to do is open the connections compartment as

follows.

- Remove the front panel (Fig. 3-5b).

- Remove the cover (b g. 1-4).

1) Loosen the screws (a).

2) Remove the cover (b) from the control

panel (c).

- At this point, you can access the terminal board.

Also ensure that the electrical installation corresponds to the maximum absorbed power speci-

1-4

c

d

c

1

a

1

1

a

2

1

a

b

a

1-5

COM.

CLOSED OPEN

DHW

DIS. AUDAX PRO

Key:

86 /87 - Summer winter switch 3-way valve

81-2 / 82-2 - Zone 2 circulator

83-2 / 84-2 / 85-2 - Zone 2 mixing valve

82-1 / 81-1 - Zone 1 circulator

89 / L - Audax Pro disabling contact

88 / L - Solar inlet

69 / 70 - Domestic hot water integrated resistance control

38 / 39 - External Probe

37 / 38 - Domestic hot water probe (eliminate R8)

42-1 / 43 - Zone 1 CAR

42-2 / 43 - Zone 2 CARV2

23-1 / 24 - Zone 1 humidistat or humidity probe

23-2 / 24 - Zone 2 humidistat or humidity probe

25 - Humidity sensor supply voltage

29-1 / 30-1 - Zone 1 dehumidier

29-2 / 30-2 - Zone 2 dehumidier

T+ / T- (MC) - Audax Pro communication bus

T+ / T- (RS485) - Other Immergas appliance communication

bus

41-1 / 40-1 - Zone 1 room thermostat

41-2 / 40-2 - Zone 2 room thermostat

66 / 65 - Puer central heating probe

65 / 64-2 - Zone 2 ow probe

V2

8

Page 9

45

cations shown on the hydronic unit data plate.

e hydronic units are supplied complete with

a special “X”-type power cable without a plug.

e power supply cable must be connected to a

230V ±10% / 50Hz mains supply respecting L-N

polarity and earth connection; this network

must also have a multi-pole circuit breaker with

class III over-voltage category.

To protect from possible dispersions of DC voltage, it is necessary to provide a type A dierential

safety device.

When replacing the power supply cable, contact a

qualied company (e.g. the Immergas Authorised

Aer-Sales Technical Assistance Service). e

power cable must be laid as shown (Fig. 1-3).

If the fuses on the electronic boards must be

replaced, use:

- P.C.B.: a T 3.5 A fuse

- heat pump communication board: a T 5.0 A

fuse

For the main power supply to the appliance,

never use adapters, multiple sockets or extension leads.

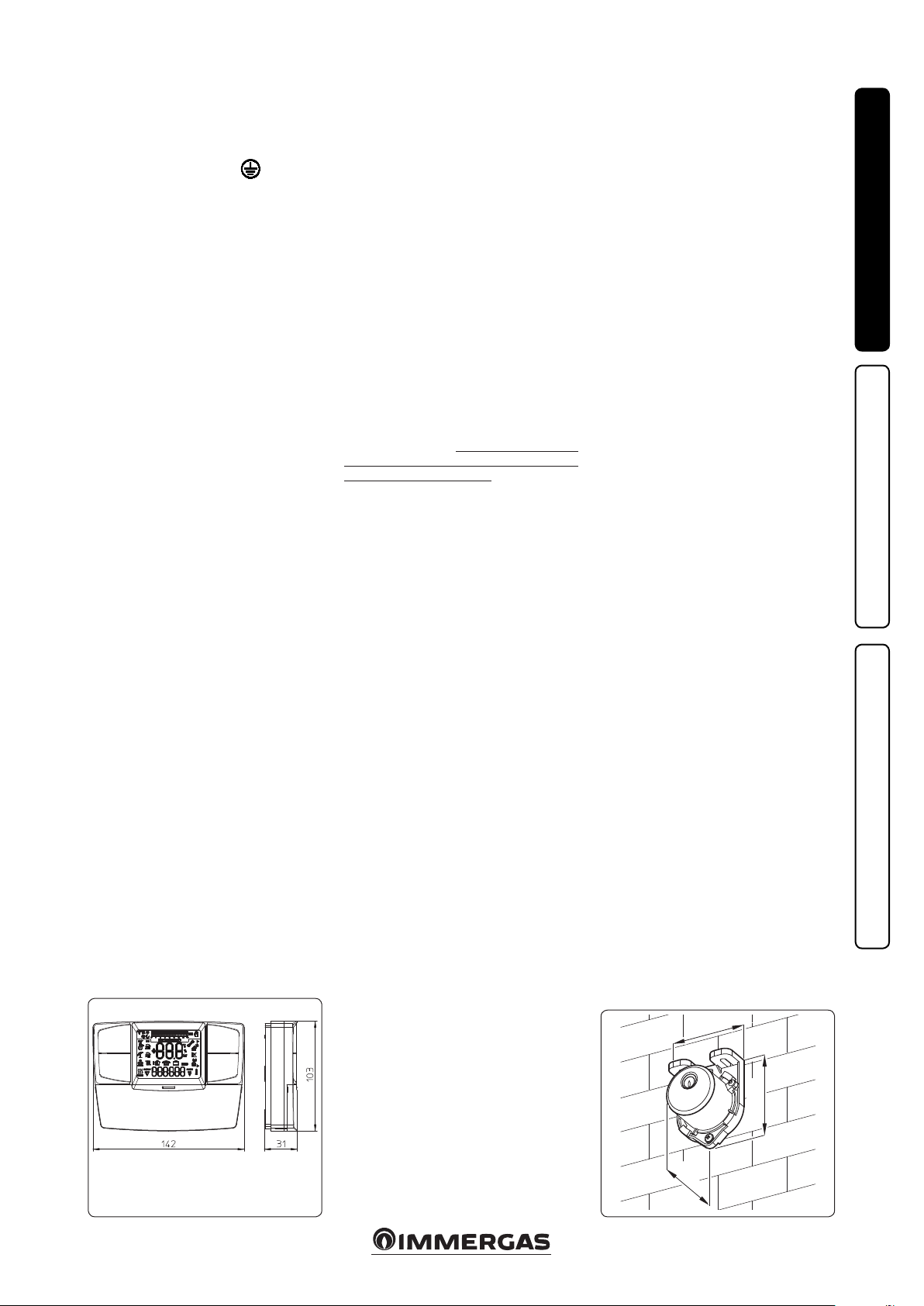

1.8 REMOTE CONTROLS AND

ROOM CHRONOTHERMOSTATS

OPTIONAL.

The hydronic module is set up for room

chrono-thermostats or remote controls, available as optional kits (Fig. 1-6). A maximum of

2 thermo-regulators can be applied directly to

the appliance.

All Immergas chrono-thermostats are connected

with 2 wires only. Carefully read the user and

assembly instructions contained in the accessory kit.

• On/O Immergas digital chrono-thermostat.

e chrono-thermostat allows:

- set two room temperature value: one for

daytime (comfort temperature) and one for

night-time (reduced temperature);

- set a weekly program with four daily switch

on and switch o times;

- select the required operating mode from the

various possible alternatives:

• manual operation (with adjustable tempera-

ture).

• automatic operation (with set programme).

• forced automatic operation (momentarily

changing the temperature of the automatic

programme).

e chrono-thermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• Comando Amico Remoto Remote Control

Device V2 (CARV2) with climate chrono-thermostat function. In addition to the functions

described in the previous point, the CARV2

panel enables the user to control all the important information regarding operation of

the appliance and the heating system with the

opportunity to easily intervene on the previously set parameters, without having to go

to where the appliance is installed. e panel

is equipped with self-diagnosis to show any

appliance operating anomalies on the display.

e climate chrono-thermostat incorporated

into the remote panel enables the system ow

temperature to be adjusted to the actual needs

of the room being heated or cooled, in order

to obtain the desired room temperature with

extreme precision and therefore with evident

savings in running costs. e CARV2 is powered

directly by the hydronic module by the same

2 wires used to transmit data between the

hydronic module and the device.

Important: the hydronic module is set up to be

able to work with two CARV2 used to control two

separate hydraulic zones.

Comando Amico Remoto Remote Control V2

or On/O chrono-thermostat electrical connections (Optional). e operations described

below must be performed aer having removed

the voltage from the appliance.

-On/O ambient thermostat or chrono-thermostat: must be connected to the 40-1 / 41-1

terminals, eliminating the X40-1 jumper for

zone 1 and 40-1 / 41-1 for zone 2. Make sure

that the On/O thermostat contact is of the

“clean” type, i.e. independent of the mains voltage, otherwise the P.C.B. would be damaged.

- V2 Comando Amico Remoto remote control

must be connected to terminals 42-1 / 43 for

zone 1 and 42-2 / 43 for zone 2, keeping the

X40-1 jumper for the CARV2 in zone 1 and adding another one for zone 2 on terminals 40-2

and 41-2, being careful not to invert polarity

in the connections.

e connections must be made on the terminal

board inside the appliance control panel as described in gure 1-5.

Important: if the Comando Amico Remoto Remote Control V2 or any other On/Off

chrono-thermostat is used, arrange two separate

lines in compliance with current regulations regarding electrical systems. e hydronic module

pipes must never be used to earth the electrical

or telephone system. Make sure this does not

happen before making the hydronic module

electrical connections.

1.9 EXTERNAL TEMPERATURE PROBE.

In general, Magis Pro ErP uses the probe standard supplied on the condensing unit to read the

outdoor temperature.

If the condensing unit is positioned in an area

that is not suitable for temperature reading, it

is advisable to use an additional external probe

(Fig. 1-7), which is available as an optional kit.

Refer to the relative instruction sheet to position

the optional external probe.

e probe can be connected directly to the hydronic module electrical system and allows the

system ow temperature to be set automatically

based on the outdoor temperature in order to

adapt the heat or cooling provided to the system.

e external probe always operates when connected, regardless of the presence or type of room

chrono-thermostat used and can work in combination with Immergas chrono-thermostats.

e correlation between system ow temperature

and outdoor temperature is managed dierently

based on whether the system is managed directly

by the hydronic module or by the CARV2; the

parameters set on the chrono-thermostat take

priority over those set on the hydronic module.

- Hydronic module: the system ow temperature

is determined by the setting on the "Heat regulation" menu and by the "User" menu for the

oset values based on the curves shown in the

diagram (Fig. 1-8).

- CARV2: the system ow temperature is determined by the setting on the central heating

selector (which can be adjusted from 0 to 9)

and by the "Oset" value on the "Regulat." menu

based on the curves shown in the corresponding instructions booklet.

N.B.: if the system is divided into two zones,

the ow temperature is calculated based on the

zone with the higher temperature in central

heating mode and with the lower temperature

in cooling mode.

e electric connection of the external probe

must be made on terminals 38 and 39 on the

terminal board on the hydronic module control

panel (Fig. 1-5).

INSTALLERUSERMAINTENANCE TECHNICIAN

1-6

58

31

1-7

9

Page 10

1.10 HEAT REGULATION SETTING.

By setting the parameters in the "Heat regulation"

menu, you can adjust how the system operates.

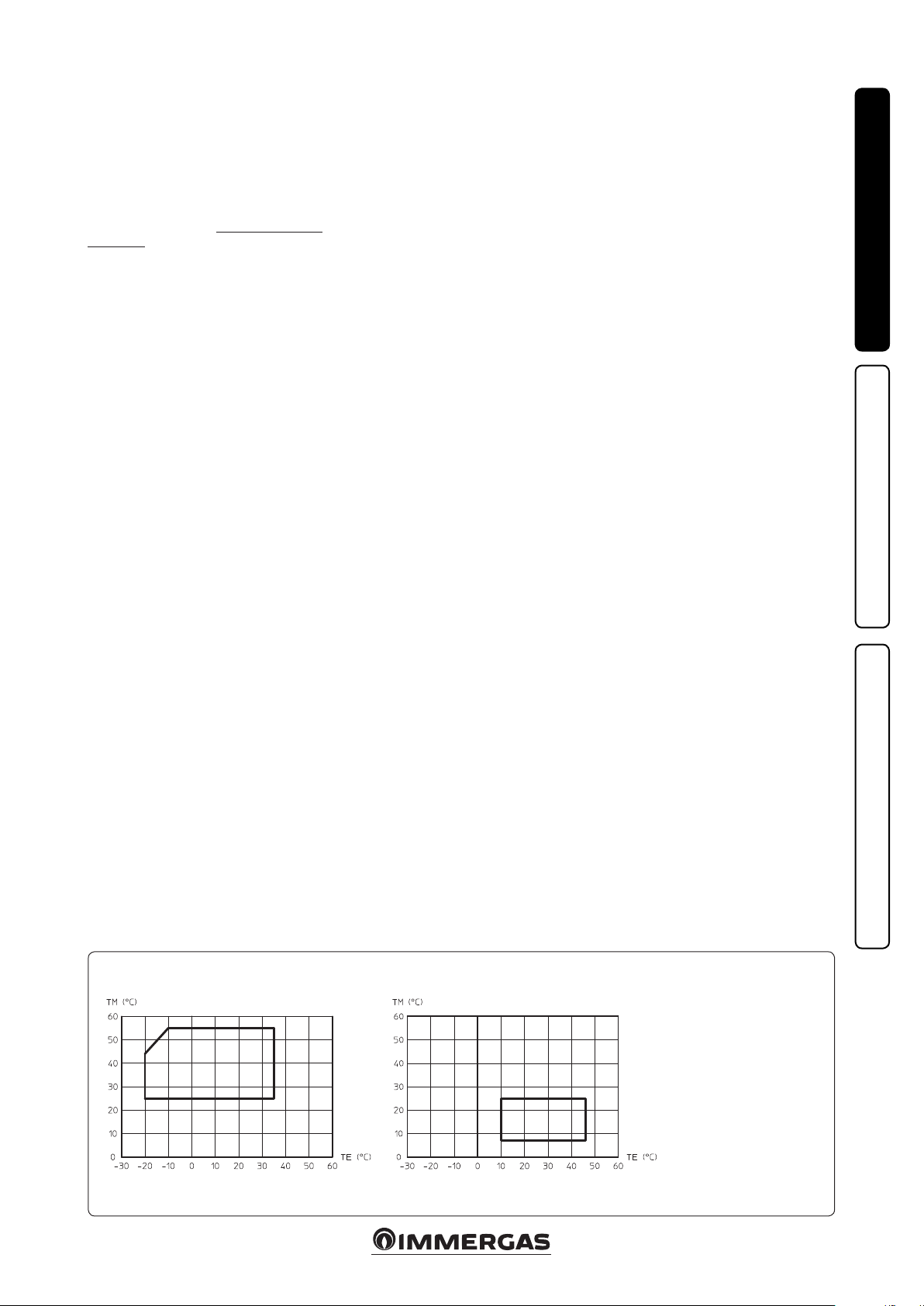

e curves (Fig. 1-8) show the default settings in

the various operating modes available both with

external probe and without.

INSTALLERUSERMAINTENANCE TECHNICIAN

Zone 1 ow temperature in central heating mode, with

R04

R05

R02 R03

Zone 1 ow temperature in cooling mode, with exter-

R13

R12

external probe

U03

nal probe

U05

Zone 2 mixed ow temperature in central heating

mode, with external probe

U04

R08

R09

R06 R07

Zone 2 mixed ow temperature in cooling mode, with

external probe

U06

R17

R16

R11 R10

Flow temperature in central heating mode without

Set Risc

U01

Key:

Rxx - "Heat regulation" menu parameter

TE - Outdoor temperature

TM - Flow temperature

U01 - Zone 2 ow temperature in "User" menu central

heating mode

1-8

external probe

Z1

Z2

R15 R14

Flow temperature in cooling mode without external

U02

Set Raresc

U02 - Zone 2 ow temperature in "User" menu cooling

mode

U03÷06 - Oset value compared to the curve set by the

external probe

Zx - Heating system zone

probe

Z2

Z1

10

Page 11

1.11 FILLING THE SYSTEM.

Once the hydronic module is connected, ll the

heating system using the lling cock (Fig. 1-33

and 1-4). Filling must be done slowly to allow

the air bubbles in the water to escape through

the vents in the hydronic module and the heating

and air conditioning system.

e hydronic module has one incorporated automatic

vent valve located on the circulator and another on

the central heating manifold. Make sure that the hoods

are loosened.

e lling cock must be closed when the hydronic module pressure gauge indicates approximately 1.2 bar.

N.B.: during these operations, enable the "Venting" functions by setting the "M01" parameter to

ON, which lasts about 18 hours (see the "P.C.B.

programming" paragraph).

System minimum water content.

Minimum water content is mainly important to

provide proper execution of defrosting cycles.

To this end, the minimum amount of water to

guarantee is 7 l/kW for any type of system.

N.B.: it is also important to check that the

dehumidier line has a minimum of 3 l/kW

(dehumidier hydraulic circuit connection).

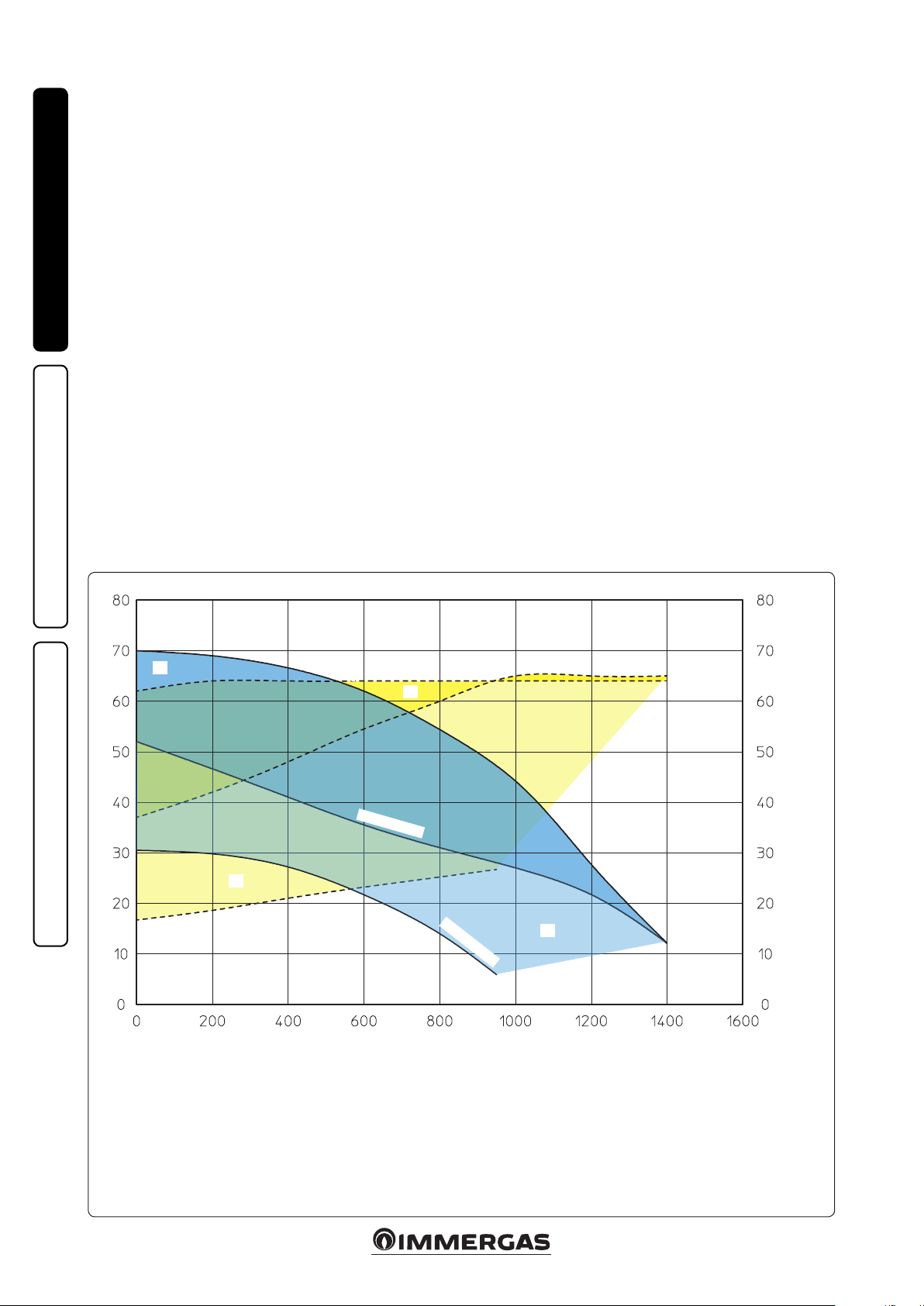

1.12 OPERATING LIMITS.

e system was designed to work in a specic

range of temperatures and at a specic maximum

ow temperature. e graphic (Fig. 1-9) shows

these limits.

1.13 COMMISSIONING THE HYDRONIC

MODULE IGNITION.

The following requirements must be met to

commission the hydronic module in order to

issue the Declaration of Conformity, if required

by the technical standards in force (the following

operations must be done only by professionally

qualied personnel and in the presence of professionals only):

- check that the internal system is properly sealed

according to the specications set forth by

technical regulations in force;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and earthing

connection;

- switch on the hydronic module and check for

proper ignition;

- check the operation of the main switch located

upstream of the hydronic module and on the

module itself;

Should even just one of these checks have a

negative outcome, the system must not be

commissioned.

INSTALLERUSERMAINTENANCE TECHNICIAN

Operating limits in central heating mode Operating limits in cooling mode

1-9

11

Key:

TE = Outdoor temperature.

TM = Flow temperature

Page 12

1.14 CIRCULATION PUMP.

e hydronic modules are supplied with a variable speed circulator, which operates at the speed

set in the "A04" parameter (which can be set

between 55% and 100%). e minimum speed

set on the "A03" parameter is used for special

functions (e.g. pump anti-locking function).

Attention: for proper system operation, make

sure that the minimum ow in operating conditions never drops below 500 l/h.

Pump release. If, aer a prolonged period of

INSTALLERUSERMAINTENANCE TECHNICIAN

inactivity, the circulation pump is blocked, turn

the motor sha using a screwdriver. Take great

care during this operation to avoid damage to

the motor.

By-pass Regulation (part. 17 Fig. 1-11). e

hydronic module comes out of the factory with

the by-pass closed.

If necessary, the by-pass can be regulated to

system requirements from minimum (by-pass

closed) to maximum (by-pass open). Adjust

using a at head screwdriver, turn clockwise

and open the by-pass, anticlockwise it is closed.

Total head available to the system.

A

Head (kPa)

D

Max. speed

Max. speed

C

Circulator pump absorbed power (W)

Min. speed

B

1-10

Flow rate (l/h)

A+B = Head available with by-pass closed

B = Head available with by-pass open

C+D = Power absorbed by the pump with by-pass open (dotted area)

D = Power absorbed by the pump with by-pass closed (dotted area)

12

Page 13

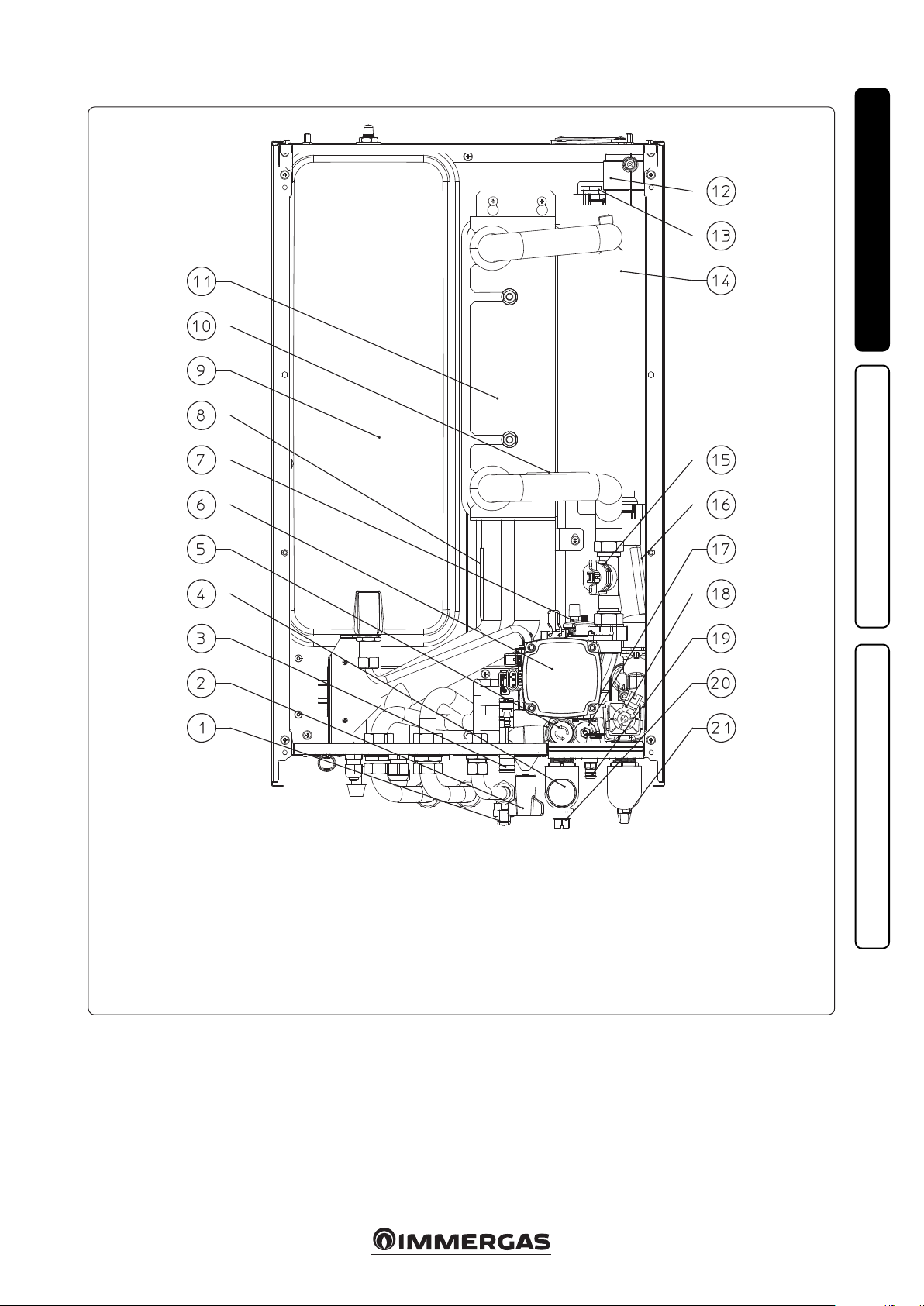

1.15 HYDRONIC MODULE COMPONENTS.

1-11

INSTALLERUSERMAINTENANCE TECHNICIAN

Key:

1 - Domestic hot water inlet valve

2 - System lling valve

3 - 3-bar safety valve drain tting

4 - Inspectable lter

5 - 3 bar safety valve

6 - Hydronic unit circulator

7 - Vent valve

8 - Liquid phase detection probe

1.16 KITS AVAILABLE ON REQUEST.

• 3 kW heating system integrated resistance

kit. Should it be necessary, you can install an

electrical resistance to supplement the central

heating system; this resistance can be installed

directly inside the hydronic module.

• 2 zone kit (1 direct and 1 mixed). Should it be

necessary, you can install the zone kit, which

allows you to divide the heating system into

two separate zones - one direct and one mixed.

• Congurable relay interface kit. e module

is set up for a relay board, which amplies the

9 - System expansion vessel

10 - Flow probe

11 - Plate heat exchanger

12 - Vent valve

13 - Central heating integrated electrical

resistance cap (optional)

14 - Central heating manifold

15 - System ow meter

16 - Return probe

17 - By-pass

appliance features and, thus, the operating

possibilities.

• 2 relay board kit. e hydronic module can

manage up to two dehumidiers. A 2 relay

board that manages dehumidier enabling is

available to pair the appliances.

• R410A circuit connection kit. For R410A

circuit wall connections, there is a kit with the

two pipes necessary to create the circuit.

13

18 - ree-way valve (motorised)

19 - System draining valve

20 - System cut-o tap

21 - System cut-o tap

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Page 14

USE AND MAINTENANCE

2

INSTRUCTIONS

2.1 CLEANING AND MAINTENANCE.

Attention: to preserve system integrity and keep

the distinguishing safety features, performance

and reliability unchanged over time, you must

execute maintenance operations at least on a

yearly basis in compliance with what is stated in

the point regarding “annual appliance check and

maintenance”. Annual maintenance is essential to

validate the conventional warranty of Immergas.

INSTALLERUSERMAINTENANCE TECHNICIAN

We recommend stipulating a yearly cleaning and

maintenance contract with your zone Immergas

Authorised Aer-sales Service.

2.2 GENERAL WARNINGS.

Do not expose the hydronic module to direct

steam from cooking surfaces.

Children and unskilled persons are not allowed

to use the hydronic module.

Should you decide to temporarily shut down the

hydronic module, you must:

a) drain the heating system if antifreeze is not

used;

b) shut o the electrical and water supply.

Never clean the appliance or connected parts

with easily ammable substances.

Never leave containers or ammable substances

in the same environment as the appliance.

• Attention: using any components that use

electrical power requires some fundamental

rules to be observed:

- do not touch the appliance with wet or moist

parts of the body; do not touch when barefoot;

- never pull electrical cables or leave the appliance exposed to weathering (rain, sunlight,

etc.);

- the appliance power cable must not be replaced by the user;

- in the event of damage to the cable, switch

off the appliance and contact exclusively

qualied sta for replacement;

- if the appliance is not to be used for a certain

period, disconnect the main power switch.

N.B.: the temperatures shown on the display

have a tolerance of +/- 3°C due to environmental conditions that cannot be attributed to the

hydronic module.

At the end of its service life, the appliance must

not be disposed of like normal household waste

nor abandoned in the environment, but must

be removed by a professionally authorised

company. Contact the manufacturer for disposal

instructions.

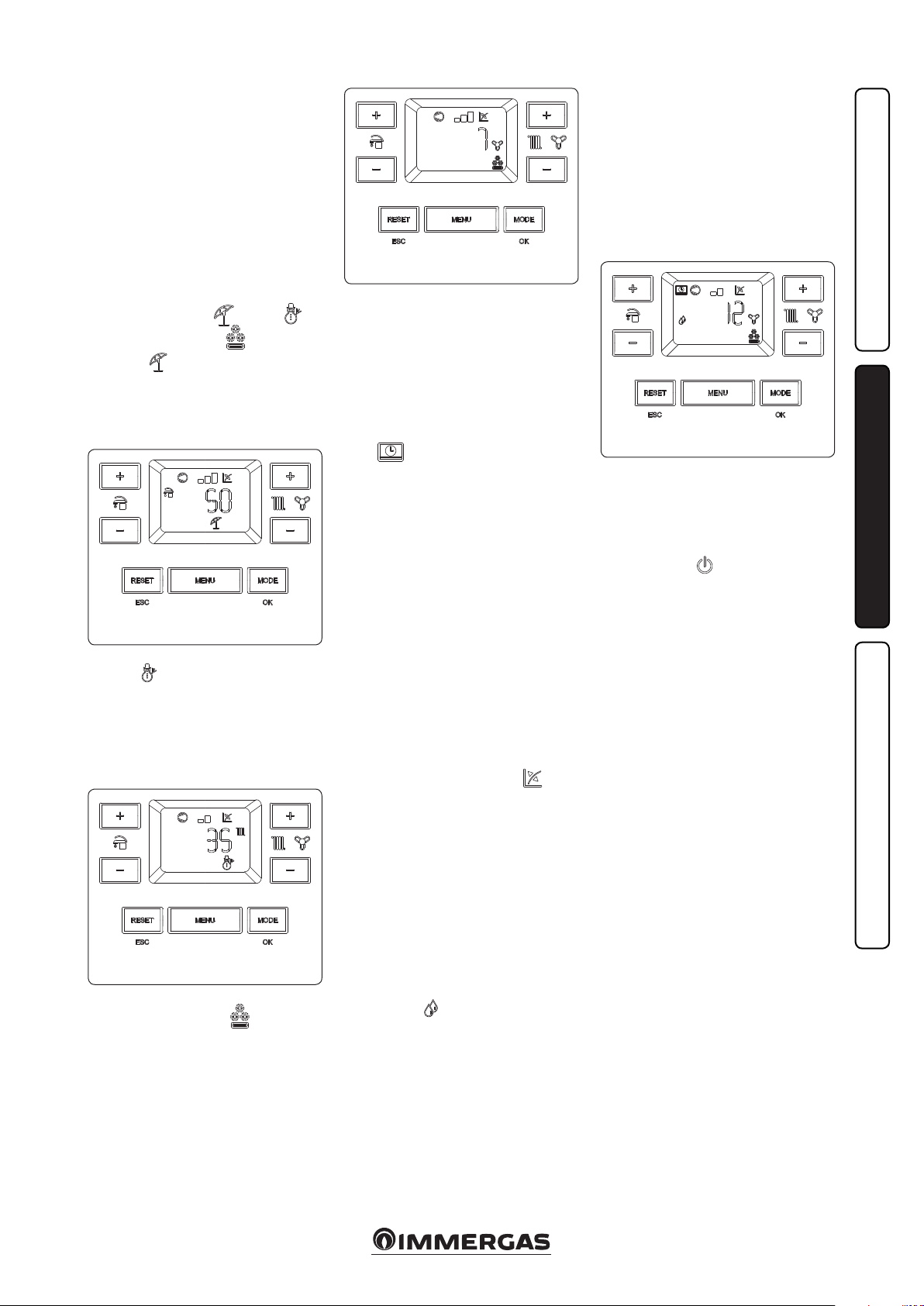

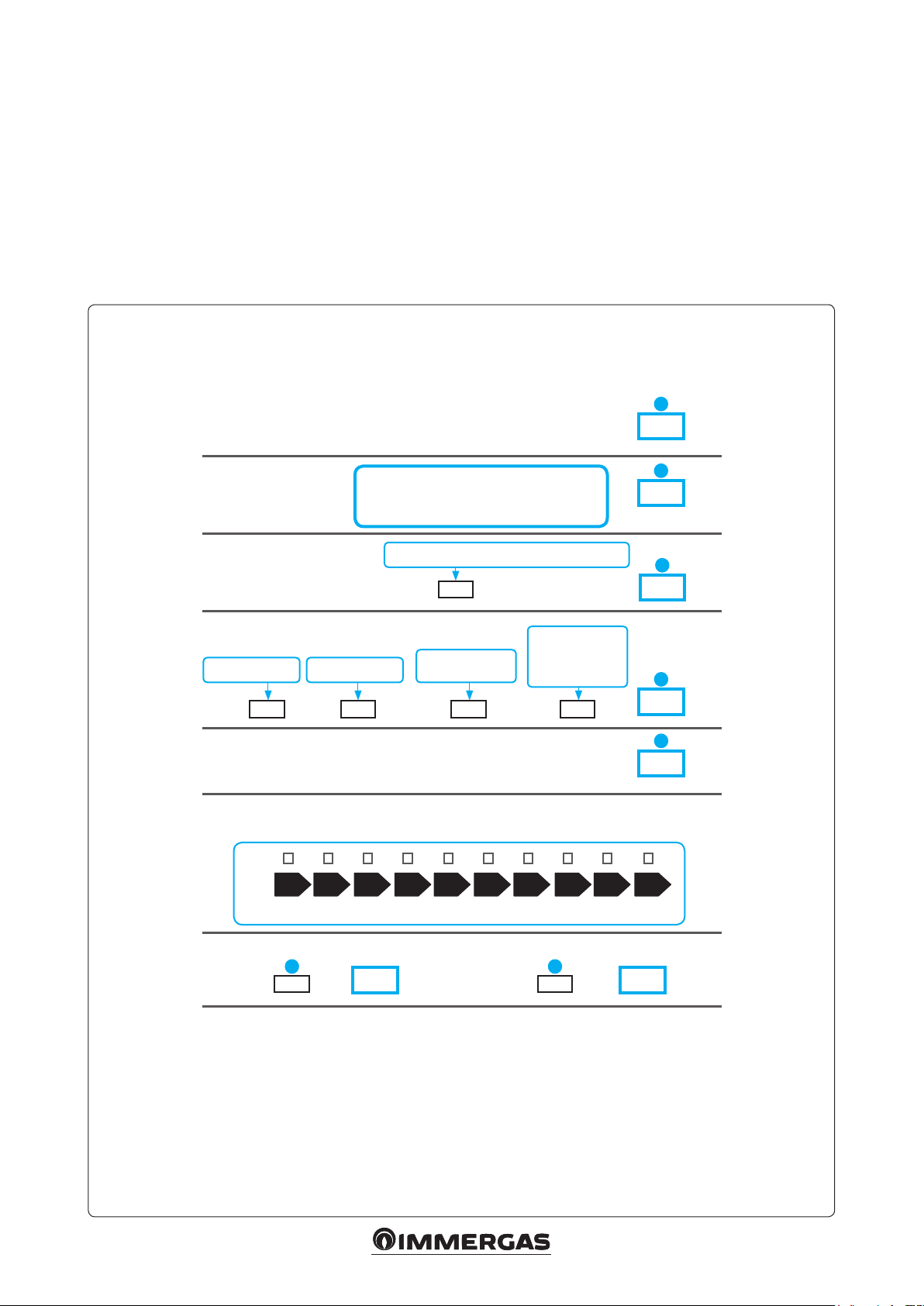

2.3 CONTROL PANEL.

2-1

ESC OK

Key:

1 - Operating mode (winter - heating/air

conditioning - summer - stand-by - o)

and parameter conrm button

2 - Menu selection button

3 - Reset and exit menu button

4 - Domestic hot water temperature selec-

tion buttons

5 - Heating system temperature selection

buttons

6 - Hydronic module pressure gauge

7 - Remote control connection (optional)

8 - Condensing unit operation in progress

bar

9 - Not used

10 - Dispensed output level

11 - Operation with external temperature

probe active (optional)

12 - Connection to other Immergas units

13 - Room central heating mode active

14 - Temperature indicator, hydronic module

info and error codes

15 - Room cooling mode operation active

16 - Operation in cooling mode

17 - Operation in winter mode

18 - Operation in summer mode

19 - Stand-by mode

20 - Not used

21 - Hydronic module locked, requiring

release by "RESET" button

22 - Operation in dehumidication mode

23 - DHW production phase operating mode

active

14

Page 15

2.4 SYSTEM USE.

Before ignition, make sure the system is full of

water, checking that the pressure gauge needle

(6) points to a value between 1 and 1.2 bar and

make sure that the chiller circuit has been lled

as described in the condensing unit instructions

booklet.

- Press the button (1) until the display switches

on. e system now goes back to the state prior

to switch-o.

- If the hydronic module is in stand-by, press the

button (1) again to activate it. Otherwise, go to

the next point.

- en press the button (1) in sequence and set

the system to summer ( ), winter ( ) or

heating/air conditioning ( ) position.

• Summer ( ): in this mode, the system only

works to produce domestic hot water, the

temperature is set using the buttons (4) and

the corresponding temperature is shown on

the display by the indicator (14).

Summer and DHW heating in

progress mode

• Winter ( ): in this mode, the system works

both to product domestic how water and room

central heating. e temperature of the DHW

is always regulated via buttons (4), the central

heating temperature is regulated via buttons

(5) and the relative temperature is shown on

the display by the indicator (14).

Winter and room central heating in

progress mode

• Heating/air conditioning ( ): in this mode,

the system works both to produce DHW and to

cool the room. e temperature of the DHW

is always regulated via buttons (4), the cooling

temperature is regulated via buttons (6) and the

relative temperature is shown on the display by

the indicator (14).

2-2

2-3

Heating/Air conditioning and room

cooling in progress mode

From here on, the system works automatically.

If there are no requests (room central heating,

DHW production or cooling), the system goes

into the "stand-by" function. Each time the

condensing unit ignites, the display shows the

corresponding symbol (8) with the corresponding power scale (10).

• Operation with Comando Amico RemotoV2

(CARV2) (Optional). If the CARV2 is connected,

the ( ) symbol will appear on the display.

e system regulation parameters can be set via

the CARV2 control panel and the reset button

(3) remains active on the hydronic module

control panel, along with the switch-o button

(1) (“o ” mode only) and the display showing

the functioning state.

e system is set up to manage two CARV2.

e CARV2 connected to the main zone (zone

2 or low temperature) is considered as the

hydronic module mount panel, while the

CARV2 connected to the secondary zone (zone

1 or high temperature) manages the requests

in the corresponding zone. Consequently, the

"secondary" CARV2 is not to be considered as

the hydronic module mount panel.

Attention: if the hydronic module is switched

“o” the CARV2 will display the connection

error symbol “ERR>CM”. e CARV2 is still

powered constantly so as not to lose the saved

programs.

•Operation with external probe ( ). e

system is set up to use the condensing unit

external probe or an optional external probe.

With the external probe connected, the system

ow temperature for room heating and air

conditioning is managed by the external probe

based on the outdoor temperature measured

(Parag. 1.9). You can change the ow temperature by choosing the oset value in the specic

user menu. If the CARV2 is connected, you can

change the operating curve using the controls

on it, selecting a value from "0 to 9" (See CARV2

instructions). In this case, any settings made

on the hydronic module will not aect system

operation.

• Dehumidify ( ). If the system is paired with

a humidistat (optional) or a humidity temperature sensor (optional), you can manage the

2-4

room humidity in summer air conditioning

mode.

- If paired with a humidistat, set the degree

of humidity on the humidistat itself (see the

instructions booklet).

- If paired with a humidity temperature sensor,

set the humidity percentage in the corresponding user menu or, if there is a CARV2,

you can set it on the remote control itself from

the "S UR %" parameter.

Heating/Air conditioning and

Dehumidication active mode

• In central heating or cooling request mode,

if the temperature of the water in the system

meets the request, the system can work simply

by activating the circulator.

• “Stand-by” mode. Press button (1) repeatedly

until the symbol ( ) appears. From then on,

the system remains inactive and the antifreeze

function, pump anti-block function and 3-way

and signalling of any anomalies is guaranteed.

N.B.: in these conditions the system must still

be considered powered.

• “O” mode. By holding the button (1) down

for 8 seconds, the display switches o and the

hydronic module is completely o. e safety

functions are not guaranteed in this mode.

N.B.: in these conditions, the hydronic module

must still be considered powered even if there

are no functions active.

• “Automatic vent” mode. Every time the

hydronic module is electrically powered, the

system automatic vent function is activated

(lasting 8 minutes). is function is displayed

via a countdown signalled by the indicator (14).

During this period the DHW and CH functions

are not active.

e “automatic vent” can be annulled by press-

ing the “reset” button (3).

• Display operation. e display lights up while

the control panel is being used; aer a set inactivity period, the brightness drops until only

the active symbols are displayed. e lighting

mode can be varied via parameter t8 in the

P.C.B. programming menu.

2-5

INSTALLERUSERMAINTENANCE TECHNICIAN

15

Page 16

2.5 TROUBLESHOOTING.

e hydronic module signals any anomalies by

ashing a code on the display (14) according to

the following table.

Hydronic module error codes are preceded by

the letter "E", while error codes referring to

the condensing unit are preceded by the letter

"A". For the latter, refer to the condensing unit

booklet for the complete list of all the anomalies.

e CARV2 displays error codes with only the

last two digits (e.g. E184 = ERR 84).

INSTALLERUSERMAINTENANCE TECHNICIAN

Error

Code

E 2

E 5 Flow probe anomaly e board detects an anomaly on the ow NTC probe. e system does not start (1).

E 12

E 23 Return probe anomaly e board detects an anomaly on the return NTC probe e system does not start (1).

E 24

E 26

E 27 Insucient circulation

E 31

E 32

E 37

46

E 50

E 54

E 129

E 130

E177

E178

E179

(1) If the block or anomaly persists, contact an authorised company (e.g. Immergas Technical Aer-Sales Service).

Anomaly signalled Cause Hydronic module status / Solution

Safety thermostat

block (over-temperature)

Storage tank probe

anomaly

Push button control

panel anomaly

System owmeter

anomaly

Loss of communication with the CARV2

(zone 1)

Low temperature zone 2

probe anomaly

Low power supply

voltage

Low temperature safety

thermostat (optional)

External probe missing

or faulty

Central heating storage

tank probe anomaly

(optional)

Zone 1 humidity probe

anomaly

Zone 2 humidity probe

anomaly

DHW maximum time

alarm

Anti-Legionella cycle

not successful

Liquid phase probe

anomaly

During normal operation, if a fault causes excessive overheating

internally, the boiler goes into overheating block.

e board detects an anomaly on the storage tank probe

e board detects an anomaly on the pushbutton panel.

e board detects an anomaly on the system owmeter.

Return pump (optional) always working.

is happens when the hydronic module overheats due to poor water

circulation in the primary circuit. e causes can be:

- low system circulation; check that no shut-o devices are closed on

the central heating circuit and that the system is free of air (deaerated);

- pump blocked; free the pump.

is happens when an incompatible remote control is connected or

when communication between the hydronic module and CARV2 is lost.

If the board detects an anomaly on the low temperature zone 2 probe,

the system cannot work in the aected area.

is occurs when the power supply voltage is lower than the allowed

limits for correct system operation.

During normal operation, if an anomaly causes excessive overheating

of the ow temperature in the low temperature zone, the unit indicates

the malfunction.

In the event the external probe is not connected or is faulty, the

anomaly is indicated.

e central heating storage tank has an out of range resistive value Puer mode is disabled. (1)

Anomaly on the zone 1 humidity probe (optional). Zone humidity

cannot be checked.

Anomaly on the zone 2 humidity probe (optional). Zone humidity

cannot be checked.

Domestic hot water production is not met within the pre-established time

e anti-Legionella cycle is run without success within the pre-established time

e board detects an anomaly on the liquid phase NTC probe. e system does not start (1).

Press the Reset button (1)

e hydronic module is unable to produce domestic hot water (1).

If normal conditions are restored, the

system restarts without having to be reset

(1).

e system does not start (1).

Make sure the return pump (optional) only

activates when requested.

Press the Reset button (1).

Cut power to the hydronic module then

power it back on. If the Remote Control is

still not detected at restart, the system will

switch to local operating mode, i.e. using

the controls on the control panel. In this

case the “Central Heating” (1) mode cannot

be activated.

(1)

If normal conditions are restored, the system restarts without having to be reset (1)

e unit does not meet the zone central

heating requirement. (1)

Check the external probe connection.

e system continues to operate with the

external probe integrated in the condensing

unit (1).

In addition to the humidity, the dew point

is not calculated for the zone (1) either

In addition to the humidity, the dew point

is not calculated for the zone (1) either

e system continues to operate with

non-optimal performance (1)

(1)

16

Page 17

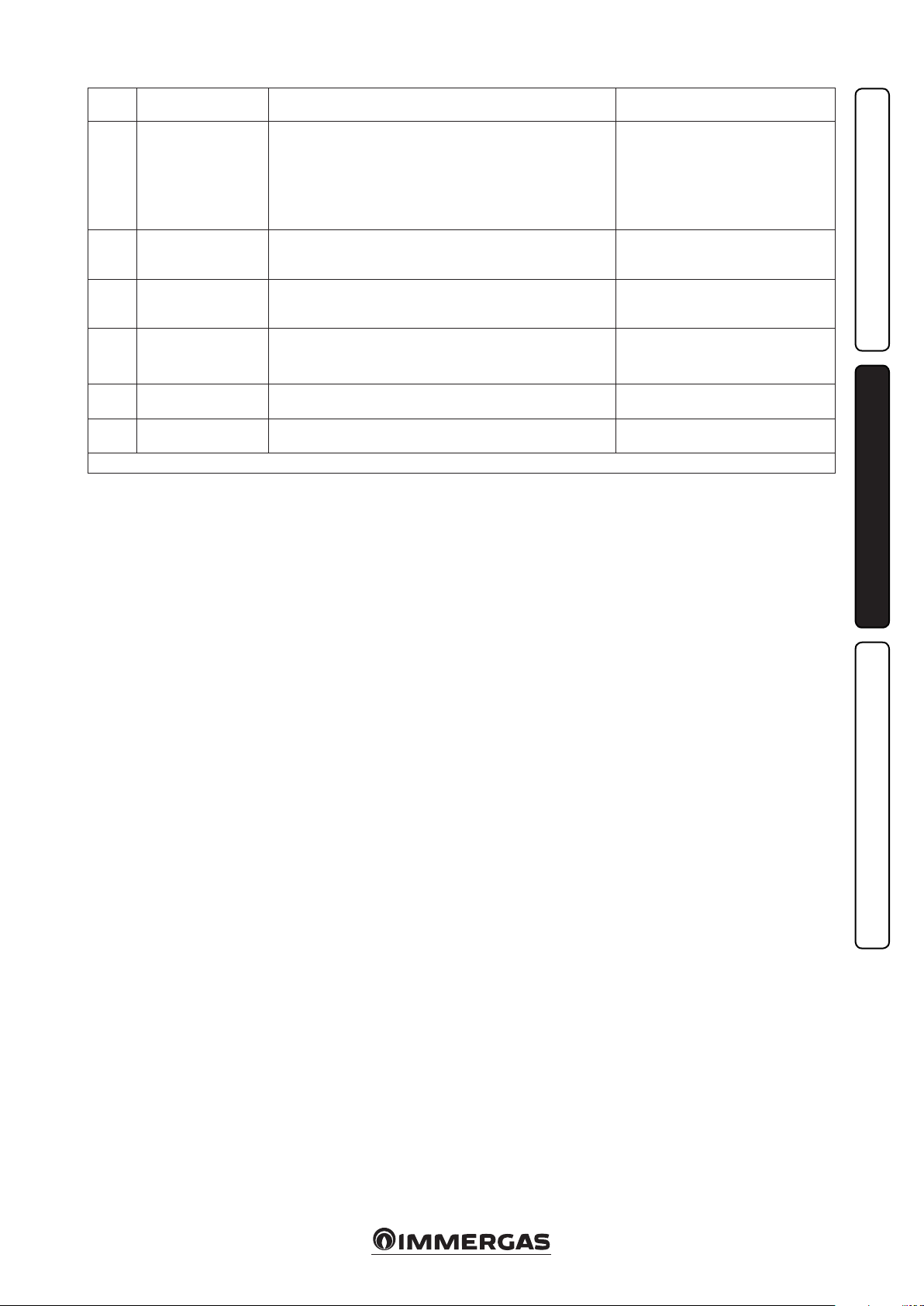

Error

Code

E181

E182 Condensing unit alarm An anomaly appears on the condensing unit

E183

E184

E188

E189

(1) If the block or anomaly persists, contact an authorised company (e.g. Immergas Technical Aer-Sales Service).

Anomaly signalled Cause Hydronic module status / Solution

Cut power to the hydronic module then

Loss of communication with the CARV2

(zone 2)

Condensing unit in test

mode

Communication error

with condensing unit

Request with temperature out of range

Time out alarm with

communication board

is happens when an incompatible remote control is connected

or when communication between the hydronic module and second

zone CARV2 is lost.

A signal noties that the condensing unit is in test mode

A signal noties an anomaly due to a communication problem

between the hydronic module and the condensing unit.

A request is made with the outdoor temperature exceeding the

operating limits (parag. 1.12)

If communication between the printed circuit boards is lost, an

anomaly is signalled.

power it back on. If the Remote Control is

still not detected at restart, the system will

switch to local operating mode, i.e. using

the controls on the control panel. In this

case the “Central Heating” (1) mode cannot

be activated.

e system does not work, see the

anomaly on the condensing unit and its

instructions booklet (1)

During this time, room heating/air conditioning and domestic hot water production requirements cannot be met

Have the electrical connection between

the units checked.

e system does not start (1).

e system does not start (1).

(1)

INSTALLERUSERMAINTENANCE TECHNICIAN

17

Page 18

2.6 PARAMETERS AND INFORMATION

MENU.

Pressing the "MENU" button (2), the display

cyclically shows the "Data" menu, "User" menu

and a menu protected by a "0000" access code

with the rst ashing digit reserved for a qualied

technician.

Data Menu.

To access an individual menu, once it appears,

press the "OK" button (1).

To scroll through the menu items and to edit the

values, use the DHW temperature regulation buttons (4). Pressing the "OK" button (1) conrms

the parameter, pressing the "ESC" button (3) goes

back to the previous menu or exits.

A minute aer the last operation, the system

automatically exits any of the menus.

INSTALLERUSERMAINTENANCE TECHNICIAN

Id

Parameter

D 03 Storage tank unit temperature 0 ÷ 99 °C

D 04 Value calculated for system setting 0 ÷ 99 °C

D 05 Value set for DHW setting 0 ÷ 99 °C

D 06

D 08 System return water temperature 0 ÷ 99 °C

D 09

D 10

D 14 Circulator ow rate

D 20 System ow temperature 0 ÷ 99 °C

D 22 DHW 3-way (DHW = domestic hot water, CH = central heating) DHW - CH

D 24 Chiller circuit liquid temperature - 20 ÷ 99 °C

D 25 Zone 2 ow temperature (if congured) 0 ÷ 99 °C

D 26 Probe for primary solar storage (puer) 0 ÷ 99 °C

D 28 System circulator instantaneous speed 0 ÷ 100 %

D 31 DHW integration function OFF - ON

D 32 System integration function OFF - ON

D 35 Solar system inlet OFF - ON

D 41 Zone 1 relative humidity 0 ÷ 99 %

D 42 Zone 2 relative humidity 0 ÷ 99 %

D 43 Zone 1 humidistat OFF - ON

D 44 Zone 2 humidistat OFF - ON

D 45 Dehumidier zone 1 OFF - ON

D 46 Dehumidier zone 2 OFF - ON

D 47 Zone 1 circulator pump OFF - ON

D 48 Zone 2 circulator pump OFF - ON

D 49 Central heating / cooling system separation 3-way (CL = cooling, HT = heating) CL - HT

D 51 Zone 1 remote control OFF - ON

D 52 Zone 2 remote control OFF - ON

D 53 System setting with remote connection in zone 1 0 ÷ 99 °C

D 54 System setting with remote connection in zone 2 0 ÷ 99 °C

D 55 Zone 1 thermostat OFF - ON

D 56 Zone 2 thermostat OFF - ON

D 61 Appliance model denition MP

D 62 Communication with outdoor condensing unit OFF - ON

D 63 Communication with other Immergas devices OFF - ON

D 71 Condensing unit operating frequency 0 ÷ 150 Hz

D 72 Condensing unit compressor temperature 0 ÷ 200 °C

D 73 Compressor outlet instantaneous temperature 0 ÷ 100 °C

D 74 Evaporator coil temperature 0 ÷ 100 °C

D 75 Condensing unit compressor absorption 0 ÷ 10 A

D 76 Condensing unit fan speed 0 ÷ 100 rpm

D 77 Electronic expansion valve position 0 ÷ 500

D 78 4-way side (CL = cooling, HT = heating) HT / CL

D 91 Soware version

Outdoor temperature (if the condensing unit external probe is connected or if the optional external probe is available)

List of the last ve anomalies.

(to scroll through the list, press the "OK" button (1))

Anomaly list reset. Once "D 10" is displayed, press the "OK" button. Deletion is conrmed via the "88" symbols

ashing for two seconds.

Description Range

- 20 ÷ 50 °C

D91 ÷ D95

0 ÷ 9999

(x 100 l/h)

-

18

Page 19

User Menu.

Id

Parameter

U 01 Zone 2 central heating setting 25 ÷ 55 °C 25

U 02 Zone 2 cooling setting 7 ÷ 25 °C 20

U 03 Zone 1 central heating oset

U 04 Zone 2 central heating oset - 15 ÷ + 15 °C 0

U 05 Zone 1 central heating oset

U 06 Zone 2 central heating oset - 15 ÷ + 15 °C 0

U 07 Zone 1 humidity setting

U 08 Zone 2 humidity setting 30 ÷ 70 °C 50

U 11 Night function

U 12 Night function enabling time 0 ÷ 23 0

U 13 Night function disabling time 0 ÷ 23 0

N.B.: the parameters referring to zone 2 can only be displayed if there is a zone 2 on the system and it is congured correctly.

2.7 SWITCHING OFF THE HYDRONIC

MODULE.

Switch o the hydronic module, putting it in

"o" mode. Switch o the omni-polar switch

outside the unit. Never leave the unit powered if

le unused for prolonged periods.

2.8 RESTORING CENTRAL HEATING

SYSTEM PRESSURE.

Periodically check the system water pressure.

e hydronic module pressure gauge must show

a value between 1 and 1.2 bar.

If the pressure is less than 1 bar (with the system

cold), you must restore it using the cock located at

the bottom of the unit (Fig. 1-3).

N.B.: close the cock aer the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case, remove water from an air vent valve

of a radiator until reaching pressure of 1 bar, or

ask for assistance from professionally qualied

personnel.

In the event of frequent pressure drops, contact

qualified staff for assistance to eliminate the

possible system leakage.

2.9 SYSTEM DRAINING.

To drain the hydronic mdule, use the special

drain tap (Fig. 1-3).

Before draining, ensure that the lling cock is

closed.

Description Range Default

You can edit the ow temperature with respect to the

external probe regulation curve in central heating

mode (Fig. 1-xx Oset value)

You can edit the ow temperature with respect to the

external probe regulation curve in cooling mode (Fig.

1-xx Oset value)

e humidity temperature sensor (optional) denes

room humidity in the corresponding area

is function can only be activated if CARV2 (optional)

is available

Activating the function allows you to disable condensing

unit operation during the time slot set in the U 12 and

U 13 parameters.

Make sure the additional power sources needed to meet

potential requirements that may present themselves

during active operation are available (e.g. additional

resistances)

2.10 ANTIFREEZE PROTECTION.

e hydronic module has an anti-freeze function

that automatically switches on the condensing

unit when the temperature drops below 4°C

(standard protection up to a minimum temperature of -5°C). All information relative to the

anti-freeze protection is stated in Par. 1.3. In

order to guarantee the integrity of the appliance

and the domestic hot water heating system in

areas where the temperature drops below zero,

we recommend protecting the central heating

system using anti-freeze liquid and installing the

Immergas Anti-freeze Kit in the hydronic module. In the case of prolonged inactivity (second

case), we also recommend that:

- disconnect the electric power supply;

- completely empty the central heating circuit

and the hydronic module domestic hot water

circuit. In systems that are drained frequently,

lling must be carried out with suitably treated

water to eliminate hardness that can cause limescale.

2.11 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the hydronic module casing. Never use abrasive

or powder detergents.

- 15 ÷ + 15 °C 0

- 15 ÷ + 15 °C 0

30 ÷ 70 °C 50

OFF - ON OFF

2.12 DECOMMISSIONING.

Should the system be shut down permanently,

have professional sta carry out the procedures,

making sure that the electrical and water supply

lines have been previously shut o.

Value

range

INSTALLERUSERMAINTENANCE TECHNICIAN

19

Page 20

COMMISSIONING THE

3

PACKAGE INITIAL

CHECK

To commission the package, you must:

- make sure that the declaration of conformity

for installation is supplied with the appliance;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the central heating system is lled

INSTALLERUSERMAINTENANCE TECHNICIAN

with water and the hydronic module pressure

gauge reads a pressure of 1÷1.2 bar;

- make sure the chiller circuit has been lled

3.1 HYDRONIC MODULE HYDRAULIC DIAGRAM

according to what is described in the Audax

Pro condensing unit instructions booklet;

- check the operation of the main switch located

upstream of and on the hydronic module.

- ensure activation of all adjustment devices;

- check the production of domestic hot water;

- check sealing eciency of water circuits;

Even if just one single safety check provides a

negative result, do not commission the system.

Key:

1 - System cut-o tap

2 - 3 bar safety valve

3 - Hydronic unit circulator

4 - Vent valve

5 - System draining valve

6 - Liquid phase detection probe

7 - System ow meter

8 - System expansion vessel

9 - Return probe

10 - Plate heat exchanger

11 - Vent valve

12 - Central heating integrated electric

resistance (optional)

13 - Central heating manifold

14 - Flow probe

15 - System lling cock

16 - ree-way valve (motorised)

17 - By-pass

18 - System with inspectable lter cut-o

tting

19 - System cut-o tap

3-1

LP - Chiller line - liquid phase

GP - Chiller line - gaseous phase

RU - Storage tank unit return

MU - Storage tank unit ow

RR - System lling

R - System return

M - System ow

20

Page 21

3.2 WIRING DIAGRAM.

INSTALLERUSERMAINTENANCE TECHNICIAN

CONDENSING UNIT

230 Vac

230 Vac

SOLAR

DHW

FUNCTION

INTEGRAT-

BLING

HEAT PUMP DISA-

TEMS FROM 3 KW

ANCE KIT FOR SYS-

INTEGRATED RESIST-

50 Hz

RIES

AUXILIA-

CONTROL

ED RESIST.

BUS

ING UNIT

CONDENS-

3-2A

21

Colour code key:

BK - Black

BL - Blue

BR - Brown

G - Green

GY - Grey

OR - Orange

P - Purple

PK - Pink

R - Red

W - White

Y - Yellow

agement (optional)

Key:

A3 - P.C.B.

A7 - Congurable relay board (optional)

A16-1 - Zone 1 dehumidier (optional)

A16-2 - Zone 2 dehumidier (optional)

A19 - Two relay board for dehumidier man-

A22 - Heat pump communication board

M1-2 - System circulator pump

M10-1 - Zone 1 circulator (optional)

M10-2 - Zone 2 circulator (optional)

M31-2 - Zone 2 mixing valve (optional)

M52 - Hot cold three-way (optional)

T1 - Transformer

Page 22

INSTALLERUSERMAINTENANCE TECHNICIAN

BL - Blue

BR - Brown

G - Green

GY - Grey

OR - Orange

P - Purple

PK - Pink

R - Red

W - White

Y - Yellow

is disconnected, the

V2

also be connected, put in a

V2

connecting the S20-1 room thermostat.

X40-1 jumper must be kept available

jumper between terminals 40-2 and 41-2

connect the congurable relay board.

relay board.

with other Immergas appliances.

R8 - Storage tank function unabling resistance

R14 - Conguration resistance

S20-1 - Zone 1 room thermostat (optional)

S20-2 - Zone 2 room thermostat (optional)

S36-1 - Zone 1 humidistat (optional)

S36-2 - Zone 2 humidistat (optional)

X40-1 - Zone 1 room thermostat jumper

Notes: - Eliminate the X40-1 jumper before

- When the CAR

- Should CAR

- e Y3 and Y5 connectors can be used to

- e Y6 connector is used to connect the 2

- T+ / T- (RS485): bus for communication

Colour code key:

BK - Black

remote control (optional)

remote control (optional)

(optional)

-1 - Zone 1 V2 Comando Amico Remoto

-2 - Zone 2 V2 Comando Amico Remoto

V2

V2

Key:

A3 - P.C.B.

A17-1 - Zone 1 humidity sensor (optional)

A17-2 - Zone 2 humidity sensor (optional)

A22 - Heat pump communication board

B1 - Flow probe

B2 - Domestic hot water probe (optional)

B3-2- Zone 2 ow probe (optional)

B4 - External probe (optional)

B5 - Return probe

B13 - Puer central heating probe (optional)

B25 - System ow meter

B27 - Liquid phase probe

CAR

CAR

E7 - Low temperature safety thermostat

M1-2 - System circulator pump

M50 - Priority 3-way valve

COMMUNICATION

OPTIONAL RS485

3-2B

22

Page 23

3.3 SYSTEM FILTER.

e hydronic module has a lter on the system

return tting to keep the system in good operating conditions.

Periodically and when necessary, the lter can be

cleaned as described below (Fig. 3-4).

Close the tap (4) and the tap (3) with a 12mm

spanner, drain the water contents in the hydronic

module using the drain tap (4).

Open the cap (1) and clean the lter (2).

P.C.B.

3.4 TROUBLESHOOTING.

N.B.: maintenance interventions must be carried

out by an authorised company (e.g. Immergas

Aer-Sales Technical Assistance Service).

- Noise due to air in the system. Check opening

of the special air vent valve cap (Part. 7 and 12

Fig. 1-11). Make sure the system pressure and

expansion vessel pre-charge values are within

the set limits; e factory-set pressure values of

the expansion vessel must be 1.0 bar, the value

of system pressure must be between 1 and 1.2

bar.

INSTALLERUSERMAINTENANCE TECHNICIAN

Communication P.C.B.

Key:

1 - T 3.5 A fuse

2 - T 5.0 A fuse

3-3

1

2

3

4

5

23

3-4

Page 24

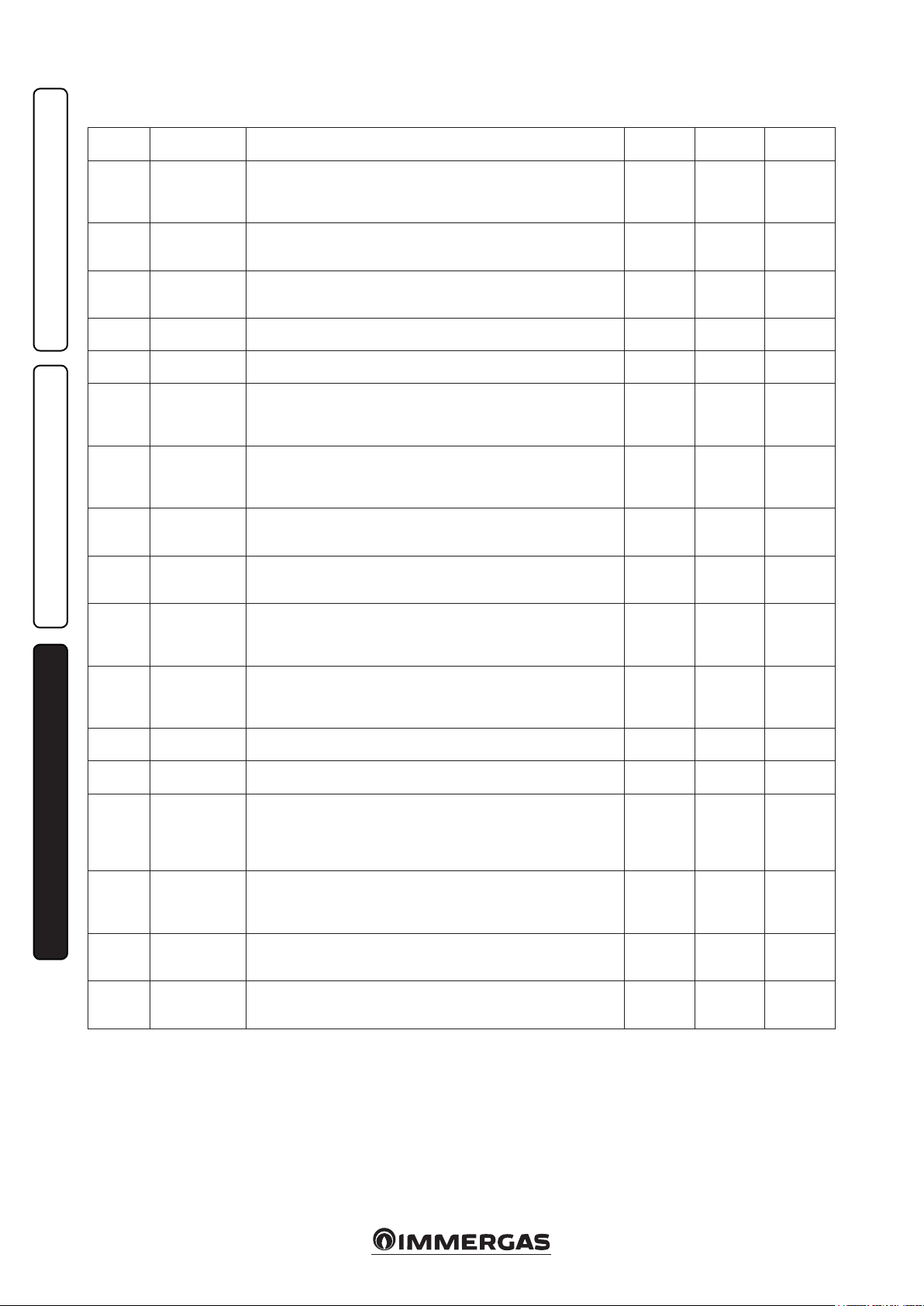

3.5 PROGRAMMING THE P.C.B.

The water heater is set up for possible programming of several operation parameters.

By modifying these parameters as described

below, the system can be adapted according to

specic needs.

To access the programming phase, press the

INSTALLERUSERMAINTENANCE TECHNICIAN

Id

Parameter

A 03

A 04

A 11

A 12 System vent

A 13

A 16

A 17

A 21

A 22

Parameter Description Range Default

Minimum

speed

Maximum

xed speed

Condensing

unit model

Number of

zones

Zone 1 humid-

ity sensor

Zone 2 humid-

ity sensor

BMS com-

munication

address

BMS com-

munication

setting

Denes the minimum operating speed of the system

circulator

Denes the maximum operating speed of the system

circulator

Establishes the condensing unit model paired with the

hydronic module.

If set to OFF, only the integrated generators are activated.

Enables the automatic vent function.

is function activates as soon as the unit is powered.

Denes the number of zones in the heating system 1 - 2 1

Humidity temperature sensor / Humidistat

Denes the type of control on zone 1 humidity

Humidity temperature sensor / Humidistat

Denes the type of control on zone 2 humidity

Denes the communication protocol between the hydronic module and the condensing unit

OFF = BMS communication protocol on 485; use if connected to optional Immergas devices.

485 = Do not use

UC = Do not use

"MENU" button (2) until the "Password" menu

appears. Enter the password, modify the numerical values using the "DHW regulation" buttons

(5) and conrm with the "OK" button (1).

Once you have accessed programming, you can

scroll through the parameters in the "System"

menu.

Using the "DHW regulation" button, select the

parameter and edit the value.

0 ÷ 99 % 100

0 ÷ 99 % 100

OFF - 5 - 8 - 10 8

OFF - ON ON

SE = Humidity temp. sensor

ST = Humidistat

SE = Humidity temp. sensor

ST = Humidistat

1 ÷ 247 11

OFF - 485 - UC OFF

To save the parameter change, press the "OK"

button.

Wait for 1 minute or press the "ESC" button (3)

to exit programming mode.

Customised

value

ST

ST

Id

Parameter

P 03

P 04

P 05

P 06

P07

Parameter Description Range Default

e hydronic module is set up to operate with a congurable relay

board (optional)

Relay 1

(optional)

Relay 2

(optional)

Relay 3

(optional)

Pump func-

tioning

External probe

correction

0 = O

1 = DHW recirculation

2 =General alarm

3 = Central heating / cooling phase active

4 = Puer mode active

e hydronic module is set up to operate with a congurable relay

board (optional)

0 = O

1 = DHW recirculation

2 =General alarm

3 = Central heating / cooling mode active

4 = Puer mode active

e hydronic module is set up to operate with a congurable relay

board (optional)

0 = O

1 = DHW recirculation

2 =General alarm

3 = Central heating / cooling mode active

4 = Puer mode active

e pump can function in two ways.

IN (intermittent): in "winter" mode, the circulator is managed by the

room thermostat or by the remote control

CO (continuous): in "winter" and "cooling" mode, the circulator is always

powered and is, therefore, always in operation

If the reading of the external probe is not correct it is possible to correct

it in order to compensate any environmental factors.

(Over the value of +9 the display shows “CE”, which enables an external

control function of the boiler for coupling of the same with a system

supervisor)

0 ÷ 4 0

0 ÷ 4 0

0 ÷ 4 0

IN - CO IN

-9 ÷ 9 K 0

Customised

value

24

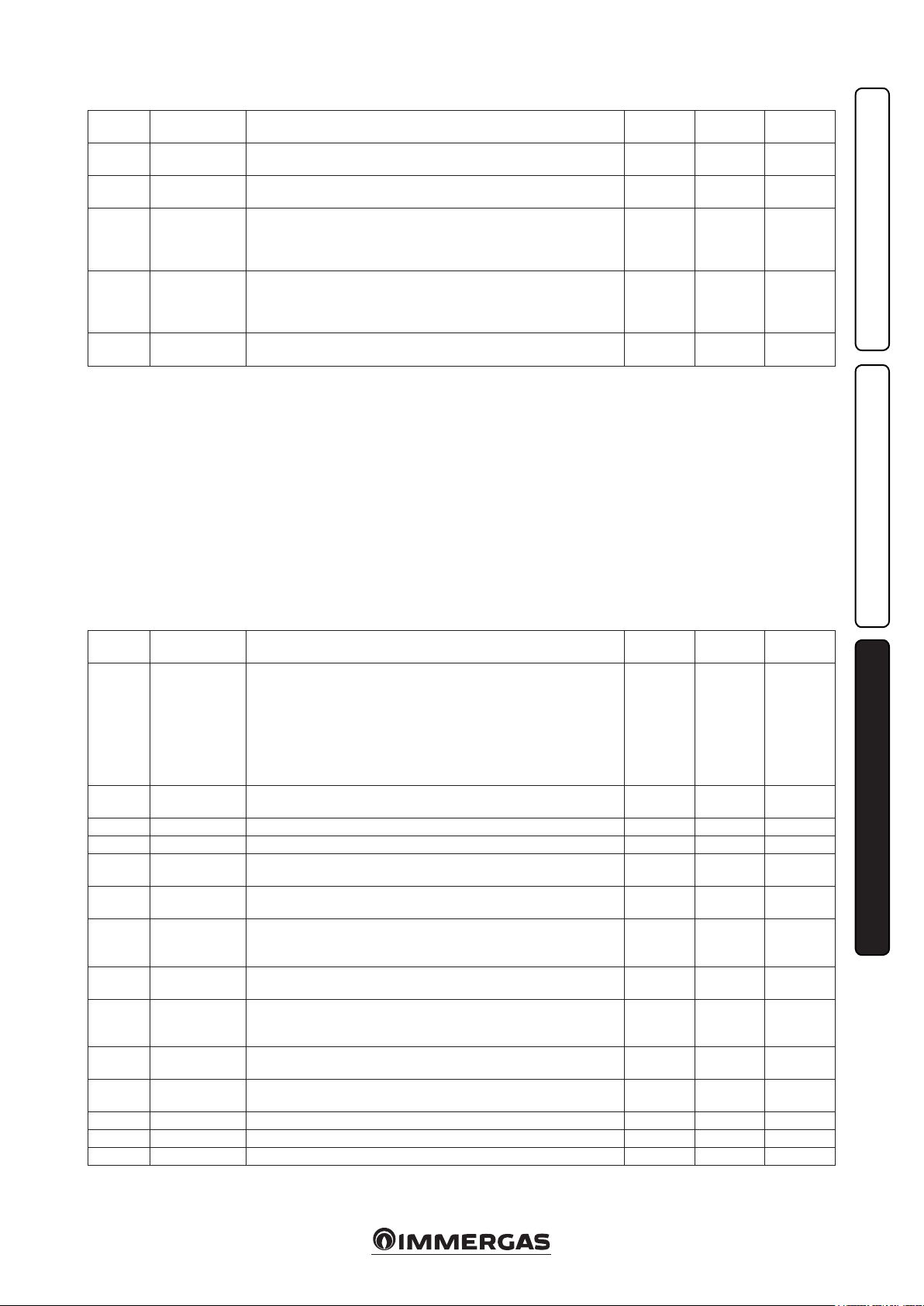

Page 25

Id

Parameter

T 02 DHW thermostat

T 05

T 07

T 08 Display lighting

T 09 Display

Parameter Description Range Default

Central heating

ignitions timer

Delay request

fr om TA

Establishes the unit ignition and switch-o mode in DHW mode.

It is enabled when the water in the storage tank goes below the DHW set

value and is disabled when the temperature exceeds the DHW set value.

e hydronic module has an electronic timer, which prevents the generator from igniting too oen in central heating mode

e system is set to switch on immediately aer a request for room heating/

air conditioning. For special systems (e.g. zone systems with motorised valves,

etc.), it may be necessary to delay ignition.

Establishes the display lighting mode.

AU: the display lights up during use and lowers aer 15 seconds of inactivity.

In the event of an anomaly, the display ashes.

OFF: the display lighting is always o.

ON: the display lighting is always on.

Establishes what the indicator displays 14 (Fig. 2-1).

"Summer" mode:

ON: circulator active, displays the ow temperature

pump o the indicator is o

OFF: the indicator is always o

"Winter" and "cooling" mode:

ON: circulator active, displays the ow temperature

circulator o, displays the value set on the central heating selector.

OFF: always displays the value set on the central heating selector

0 ÷ 20 °C 4

0 - 10 min-

utes

0 - 240

seconds

(step 10 sec)

AU - OFF

- ON

ON - OFF ON

Customised

value

3

0

INSTALLERUSERMAINTENANCE TECHNICIAN

AU

25

Page 26

Heat regulation menu.

INSTALLERUSERMAINTENANCE TECHNICIAN

Id

Parameter

R 01 External probe

R 02

R 03

R 04

R 05

R 06

R 07

R 08

R 09

R 10

R 11

R 12

R 13

R 14

R 15

R 16

R 17

Parameter Description Range Default

Outdoor temper-

ature for max CH

ow

Outdoor temperature for min CH

ow

Maximum cen-

tral heating

Minimum central

heating

Outdoor tem-

perature for low

temperature zone

max CH ow

Outdoor tem-

perature for low

temperature zone

min CH ow

Low temperature

zone maximum

central heating

Low temperature

zone minimum

central heating

Outdoor

temperature

for minimum

cooling ow

Outdoor

temperature

for maximum

cooling ow

Minimum

cooling

Maximum

cooling

Outdoor

temperature for

low temperature

zone minimum

cooling ow

Outdoor tem-

perature for low

temperature zone

max cooling ow

Low temperature

zone minimum

cooling

Low temperature

zone maximum

cooling

Denes if and which external probe is used to manage the system.

OFF = no external probe used

OU = external probe on the condensing unit

IU = optional external probe connected to the hydronic module

Establishes the outdoor temperature at which to have the maximum ow

temperature.

Establishes the outdoor temperature at which to have the minimum ow

temperature.

Denes the maximum ow temperature in room central heating mode 35 ÷ 55 45

Denes the minimum ow temperature in room central heating mode 25 ÷ 55 25

Establishes the outdoor temperature at which to have the maximum ow

temperature in the low temperature zone

Establishes the outdoor temperature at which to have the minimum ow

temperature in the low temperature zone

Denes the maximum ow temperature in room central heating mode in

the low temperature zone

Denes the minimum ow temperature in room central heating mode in

the low temperature zone

Establishes the maximum outdoor temperature at which to have the minimum ow temperature in cooling mode

Establishes the minimum outdoor temperature at which to have the maximum ow temperature in cooling mode