Immergas INTEC 30 System External, INTEC 12 System External, INTEC 30 COMBI EXTERNAL Installation Instructions Manual

Page 1

User Installation

Instruction Manual

AU

INTEC 12-30

SYSTEM

EXTERNAL

Wall mounted

heating only boiler

Page 2

Our compliments for having chosen a top-quality Hunt Heating/Immergas product, able to assure well-being and safety for a long period of time, you can also

count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully; you will be able

to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction for our product.

For any interventions or routine maintenance contact Hunt Heating for Authorised Service Personal.

Dear Client,

All Immergas products are protected with packaging suitable for transport.

e material must be stored in dry environments and protected from bad weather.

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instruction booklet contains technical information on how installing Immergas boilers. For other issues related to installation of boilers (i.e.: safety in work

sites, environment protection, injury prevention), comply with the laws in force and technical standards.

In compliance with legislation, the systems must be designed by qualied professionals, within the dimensional limits established by the Law. Installation and

maintenance must be performed in compliance with the regulations in force, according to the manufacturer’s instructions and by qualied professionals.

Improper installation or assembly of Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to persons, animals

and objects. Read the provided product instructions carefully in order to install the product correctly.

Maintenance must be carried out by Authorised Service Personal.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non compliance with technical laws in force, standards or instructions contained in this

book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and the

appliance warranty is invalidated.

e Immergas range of high eciency boilers are wall mounted, fan assisted, room-sealed boilers. e burner is lit electronically and the heat output is

controlled by a modulating gas valve.

e INTEC 12-30 SYSTEM EXTERNAL is a heating only boilers used for hydronic heating. Domestic hot water is an available option (Hunt Heating only)

used in conjunction with a stainless steel hot water storage tank, diverter valve and probe.

e boilers are supplied with a pump, pressure relief valve, expansion vessel and pressure gauge fully assembled and tested. ey are designed for use with

a fully sealed and pressurised central heating system using only Natural Gas and Universal LPG.

General recommendations

Introduction

IMPORTANT

It is the law that all gas appliances are authorised persons and registered technician in accordance with local laws and AS/NZS 5601 and AS/NZS 3500 A.

is appliance meets the requirements of IPX5D.

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of safety to ensure that the law is complied with.

Manufacturerís instructions must NOT be taken in anyway as over-riding statutory obligations.

WARNINGS

- Do not spray aerosols in the vicinity of this appliance while it is in operation;

- do not use or store ammable materials in or near this appliance;

- do not place articles on or against this appliance;

- do not modify this appliance.

NOTE

e Boilers MUST only be used with Immergas Condensing ue components.

THIS BOILER IS NOT SUITABLE FOR POOL OR SPA HEATER UNLESS CONNECTED TO A SUITABLE APPROVED HEAT EXCHANGER.

Hydronic System (Australia) Pty Ltd PO Box 294 Braeside VIC 3195.

On conformity to AS/NZS 5263.1.2 and AS 3498.

e manufacturer declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial documents without forewarning.

Page 3

INDEX

USER pageINSTALLER page MAINTENANCE TECHNICIAN page

1 Boiler installation ...................................... 4

1.1 Installation recommendations. ................4

1.2 Main dimensions. ......................................5

1.3 Anti-freeze protection. .............................5

1.4 connections. ............................................... 5

1.5

Remote control (CARv2) (Optional). .......6

1.6 External probe (Optional). ......................6

1.7 Immergas ue systems. .............................7

1.8 Installation of intake /

exhaust terminals. .....................................8

1.9 System lling. ............................................. 9

1.10 Gas system start-up. ..................................9

1.11 Boiler start up (ignition). ......................... 9

1.12 Circulation pump. .....................................9

1.13 Boiler components. .................................10

2 Instructions for use and maintenance. .11

2.1 Cleaning and maintenance. ...................11

2.2 General warnings. ................................... 11

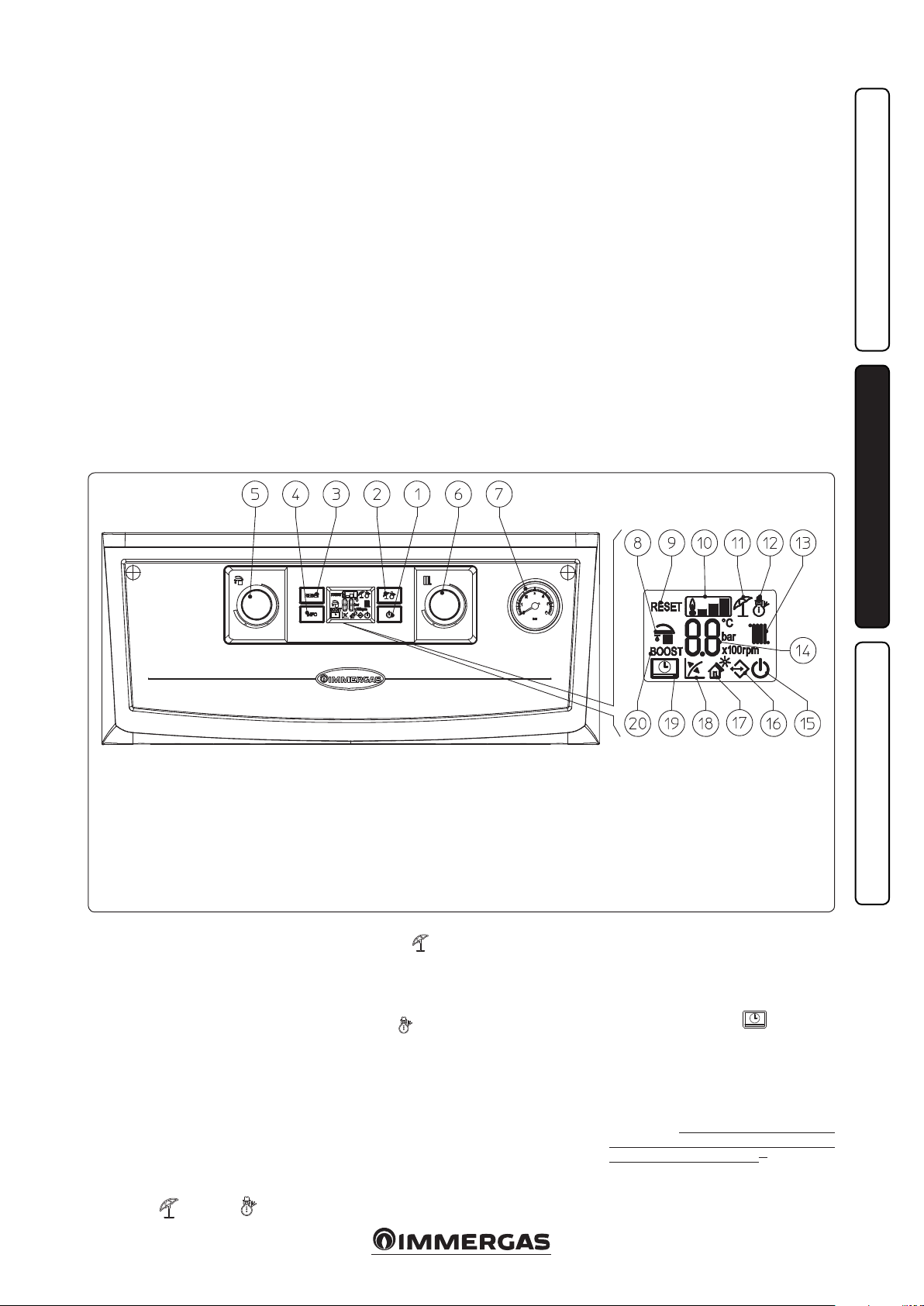

2.3 Control panel. ..........................................11

2.4 Using the boiler........................................ 11

2.5 Fault and anomaly signals. ..................... 12

2.6 Information menu. .................................. 14

2.7 Boiler shutdown ......................................14

2.8 Restoring central heating system

pressure. .................................................... 14

2.9 Draining the system. ...............................14

2.10 Anti-freeze protection. ...........................14

2.11 Case cleaning. .......................................... 14

2.12 Decommissioning. ..................................14

3 Boiler commissioning (initial check). ..15

3.1 Hydraulic Diagram. ................................15

3.2 Wiring diagram. ......................................16

3.3 Troubleshooting. .....................................17

3.4 Converting the boiler to other types of

gas. .............................................................17

3.5 Calibration of number of fan revs. ........ 17

3.6 Adjustment of the air-gas ratio. .............17

3.7 Checks following conversion to another

type of gas. ................................................17

3.8 Programming the P.C.B. .........................18

3.9 “Chimney sweep” function. ...................20

3.10 Pump anti-block function. .....................20

3.11 Radiators anti-freeze function. ..............20

3.12 P.C.B. periodical self-check. ................... 20

3.13 Automatic vent function. .......................20

3.14 Casing removal. .......................................21

3.15 Variable heat power. ................................ 22

3.16 Appliance check and maintenance. ......23

3.17 Combustion parameters. ........................23

3.18 Technical data. .........................................24

3.19 Exploded boiler diagram INTEC 12

System External. ......................................25

3.20 Spare part list INTEC 12 System

External. ................................................... 26

3.21 Exploded boiler diagram INTEC 30

System External. ......................................27

3.22 Spare part list INTEC 30 System

External. ................................................... 28

3.23 Boiler registration. ..................................29

3.24 Commissioning boiler check list. ..........30

3.25 Service records. ........................................31

Page 4

BOILER

1

INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

e INTEC 12-30 SYSTEM EXTERNAL boiler

has been designed uniquely for wall-installation,

for the heating of rooms for domestic use.

- installation (according to the legislation and

technical standards in force);

- maintenance operations (including those

scheduled, periodical, ordinary and special);

INSTALLERUSER

- removal (to the outdoors in a place suitable

for loading and transporting appliances and

components) as well as any replacement with

equivalent appliances and/or components.

e wall surface must be smooth, without any

protrusions or recesses enabling access to the

rear part. ey are not designed to be installed

on plinths or oors (Fig. 1-1).

By varying the type of installation the

classication of the boiler also varies, precisely:

- Type C boiler Uses concentric or Coaxial pipes

systems Hunt Heating supplies the correct ue

for this application.

Only professionally heating/plumbing

technicians are authorised to install Immergas

gas appliances.

Installation must be carried out according to

regulation standards AS/NZS 5601 or Local

Authority laws.

Installation of the INTEC 12-30 SYSTEM

EXTERNAL boiler when powered by Universal

LPG must also comply with the rules regarding

gases with a greater density and be installed

to meet all local and AS/NZS 5601 LAWS.

Before installing the appliance, ensure that it

is delivered in perfect condition; if in doubt,

contact the supplier immediately. Packing

materials (staples, nails, plastic bags, polystyrene

foam, etc.) constitute a hazard and must be kept

out of the reach of children. Leave adequate

space above the boiler for possible water and

ue removal connections. Keep all ammable

objects away from the appliance (paper, rags,

plastic, polystyrene, etc.). Do not place household

appliances underneath the boiler as they could

be damaged if the safety valve intervenes (if not

conveyed away by a draining funnel), or if there

are leaks from the connections; on the contrary,

the manufacturer cannot be held responsible for

any damage caused to the household appliances.

In the event of malfunctions, faults or incorrect

operation, turn the appliance o immediately and

contact a qualied technician (e.g. Hunt Heating

Service Dept which has specically trained sta

and original spare parts). Do not attempt to

modify or repair the appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

Installation Standards:

- Installations MUST comply with AS/NZS

5601 and Local laws. Use AS/NZS 5601 as

a guide for specic locations see below.

- Installation is prohibited on the vertical

projection of the cooking surface.

- Installation is also prohibited in places/

environments that constitute common parts

of oce condominiums such as stairs, cellars,

entrance halls, attics, los, escape routes,

etc. if they are not located inside technical

compartments under the responsibility of

each individual building and only accessible

to the user (for the features of the technical

compartments, see the technical standards in

force).

Attention: wall mounting of the boiler must

guarantee stable and ecient support for the

boiler.

Use the bracket supplied as standard, xing it

with proper plugs according to the wall type. e

installer is responsible for the choose of the correct

plugs, according to the technical standard. Place

the supplied bracket, following the indications

reported on drawing 1-3 preferring the holes

indicated in the before mentioned draw.

N.B.: to fix the bracket we suggest to use

hexagon screw or countersunk screw for plug.

ese boilers are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be attached to a heating system suitable for their capacity and voltage.

YES NO

1-1

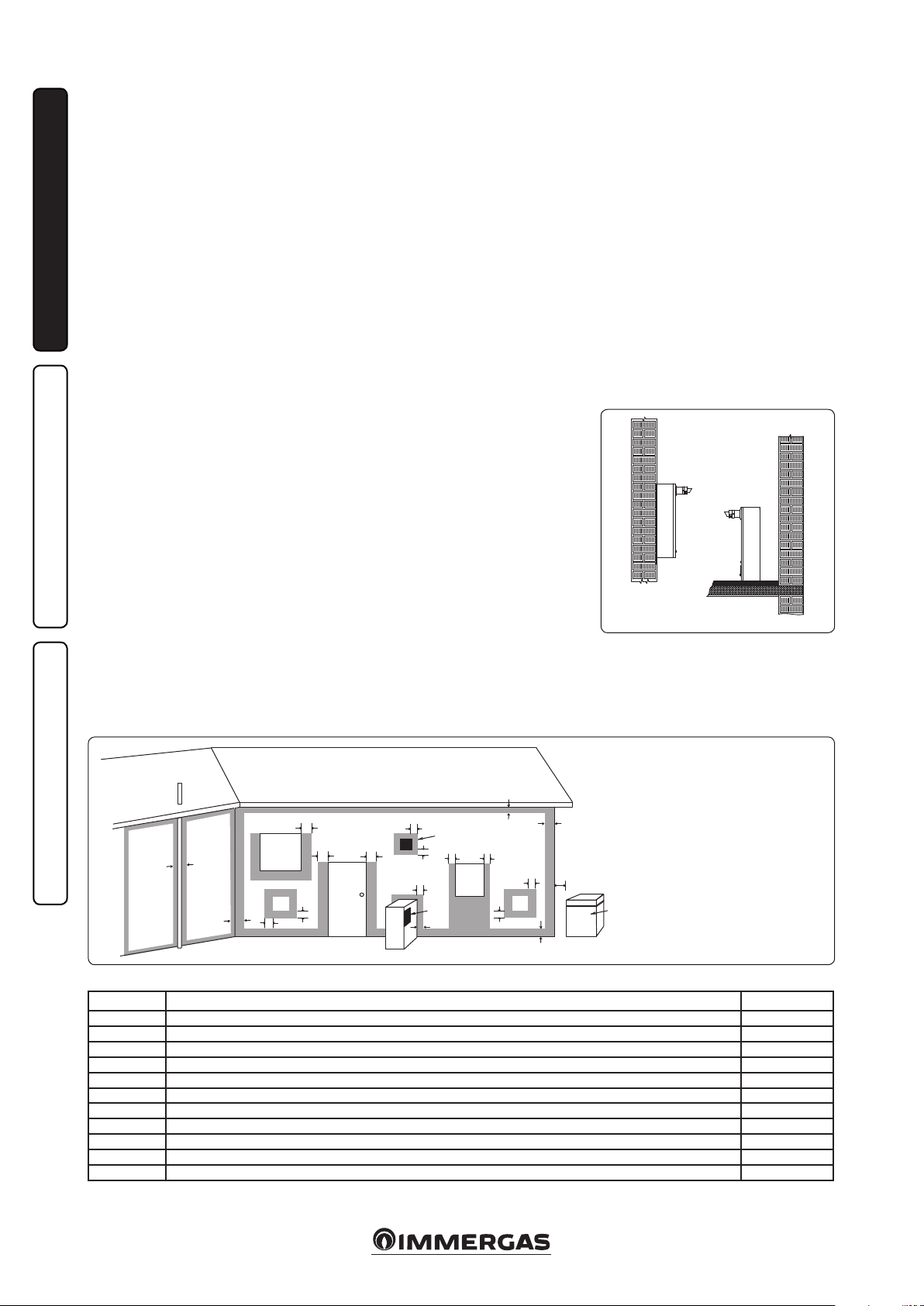

Flue terminal positions

Use as a guide only. Refer to AS/NZS 5601 or gas tting rules for specic location.

h

j

MAINTENANCE TECHNICIAN

j

W

f

c

k

j

D

I

k

Flue terminal positions. Shaded area indicates prohibited area

Ref. Item Min. Clearance mm

Below eaves, balconies and other projections (Appliances over 50MJ/h) 300

a

From the ground, above a balcony or other surface 300

b

From a return wall or external wall 300

c

From a gas meter 1000

d

From an electricity meter or fusebox/breaker panel 500

e

From a drain pipe or soil pipe 75

f

Horizontally from any building structure or obstruction facing a ue terminal 500

g

From any other ue terminal, cowl or combustion air intake 300

h

Horizontally from any opening window, door, non-mechanical air inlet or other opening into a building with the exception of sub-oor ventilation 300

j

From a mechanical air inlet including a spa blower 1000

k

Vertically below an opening window, non-mechanical air inlet or any other opening into a building with the exception of sub-oor ventilation 500

n

• e location of the ue terminal must comply with the clearances shown on this page.

If you are unsure about clearances not indicated here, in general

refer to AS/NZS 5601 or your local autority.

D - Door

a

T

e

h

h

T

g

e

P

c

d

g

M

k

b

T

I - Mechanical air inlet

M - Gas meter

T - Flue Terminal

W - Window

1-2

• All measurements are the minimum clearances required.

• Terminals must be positioned so to aviod combustion products

entering the building.

4

Page 5

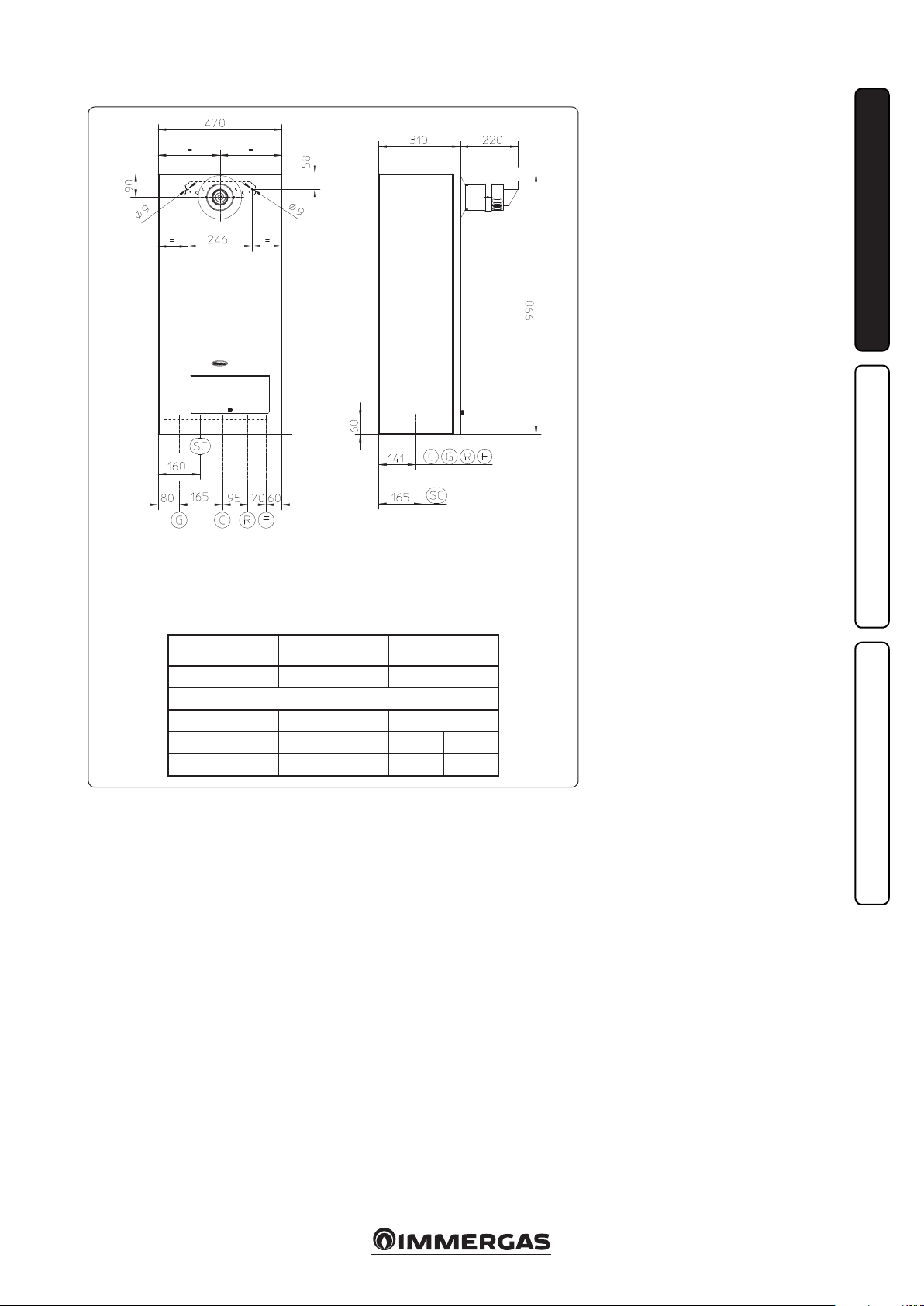

1.2 MAIN DIMENSIONS.

Height

(mm)

990 470 310

CONNECTIONS

CORD INLET GAS SYSTEM

C G R F

1/2” 3/4” 3/4” 3/4”

1.3 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e boiler comes

standard with an anti-freeze function that

activates the pump and burner when the system

water temperature in the boiler falls below 4°C.

e anti-freeze function is only guaranteed if:

- the boiler is correctly connected to gas and

electricity power supply circuits;

- the boiler is powered constantly;

- the boiler is not in no ignition block (Par. 2.5);

- the boiler essential components are not faulty.

In these conditions the boiler is protected against

freezing to an env ironmental temperature of -5°C.

Minimum temperature -15°C. If the boiler is

installed in a place where the temperature falls

below -5°C and in the event there is no gas, or

the boiler goes into ignition block, the appliance

may freeze.

To prevent the risk of freezing follow the

instructions below:

- Protect the central heating circuit from

freezing by introducing a good quality antifreeze liquid (specically for central heating

systems), (Fernox), carefully following the

manufacturer's instructions regarding the

percentage necessary with respect to the

Key:

G - Gas supply (not supplied as standard)

R - Return - CH

F - Flow - CH

SC - Condensate drain (supplied as standard)

(minimum internal diameter Ø13 mm)

C - Cold ll

Width

(mm)

Depth

(mm)

minimum temperature required for preserving

the system.

The boilers is made from materials that are

resistant to ethylene and propylene glycol-based

anti-freeze liquids.

For life and possible disposal, follow the

supplier's instructions.

- Protect the condensate drain trap and circuit

board against freezing by using an accessory

that is supplied on request (anti-freeze kit)

comprising two electric heating elements,

the relevant cables and a control thermostat

(carefully read the installation instructions

contained in the accessory kit pack).

Boiler anti-freeze protection is thus ensured only if:

- the boiler is correctly connected to gas and

electricity power supply circuits and powered;

- the anti-freezing kit components are ecient.

In these conditions the boiler is protected against

freezing to temperature of -15°C.

e warranty does not cover damage due to interruption of the electrical power supply and failure

to comply with that stated on the previous page.

N.B.: if the boiler is installed in places where the

temperature falls below 0°C the domestic water

and heating attachment pipes must be insulated.

1-3

1.4 CONNECTIONS.

Gas connection.

Our boilers are designed to operate with NG

and Universal LPG. Supply pipes must be sized

correctly to relevant gas codes.

Before connecting the gas line, carefully clean

inside all the supply pipes to remove any residue

that could impair boiler eciency. Also make

sure the gas corresponds to that for which

the boiler is prepared (see boiler data-plate).

If dierent, the appliance must be converted

for operation with the other type of gas (see

converting appliance for other gas types). e

dynamic gas supply (NG or Universal LPG)

pressure must also be checked according to

the type used in the boiler, which must be in

compliance, as insufficient levels can reduce

boiler output and cause malfunctions.

Ensure correct gas isolation valves connection.

e gas supply pipe must be suitably dimensioned

according to current regulations in order to

guarantee correct gas flow to the burner in

conditions of maximum boiler.

N.B.: there is a special adhesive label inside the

built-in frame displaying the layout of the boiler

connections.

Fuel gas quality. The appliance has been

designed to operate with gas free of impurities;

otherwise it is advisable to fit special filters

upstream from the appliance to restore the

purity of the gas.

Cold Water connection.

Attention: Filling the system, Hunt Heating

recommends the use of Auto fill valves sold

as an optional extra. Once satisfactory system

pressure is achieved, Auto ll valve MUST BE

TURNED OFF.

Attention: in order not to void the warranty

before making the boiler connections, carefully

clean the heating system on the primary heat

exchanger (pipes, radiators, etc.) with special

cleaning products (Fernox) to remove any

deposits that could compromise correct boiler

operation.

Chemical treatment of the heating system water

is required, in compliance with the technical

standards in force, in order to protect the system

and the appliance from deposits (e.g., lime scale),

slurry or other hazardous deposits. Products like

Fernox are suitable for this appliacation. Use

of backow devices are maditory when using

chemicals/water treatments or alternatively,

ensure physical air break.

Heating Water connections must be made using

approved valves this helps with maintenance and

servicing. Hunt Heating can provide valves as

optional extras.

e boiler safety valve outlet must be connected

to a Tun Dish or Directly to a suitable overow

outlet.

INSTALLERUSER

MAINTENANCE TECHNICIAN

5

Page 6

Condensate drain. To drain the condensate

produced by the appliance, it is necessary to

connect to the sewer system by means of acid

condensate resistant pipes i.e. p.v.c. having an

internal diameter of at least 13 mm. e system

connecting the appliance to the drainage system

must be carried out in such a way as to prevent

freezing of the liquid contained. Connections

must comply with national and local regulations

on discharging to waste waters, condensate must

not discharge to storm water. Pipes must be on

gradient to drain.

INSTALLERUSER

N.B.: ll the trap with water before operating

the boiler.

Electrical connection: The “INTEC 12-30

SYSTEM EXTERNAL” boiler has an IPX5D

protection rating for the entire appliance.

Electrical safety of the appliance is reached only

when it is correctly connected to an ecient

earthing system as specied by current safety

standards.

Attention: Immergas/Hunt Heating declines

any responsibility for damage or physical injury

caused by failure to connect the boiler to an

ecient earth system or failure to comply with

the reference standards.

Also ensure that the electrical installation

corresponds to maximum absorbed power

specifications as shown on the boiler dataplate. The boilers come complete with a 1.5

metre power cable that includes an Australian

electrowelded plug. The plug is of type I,

compliant with standard AS 3112. e power

cable must be connected to a 240V ±10% / 50Hz

mains respecting L-N polarity and the earth

connection

. When replacing the power

supply cable, contact a qualied technician (e.g.

Hunt Heating Service Dept) (Fig. 1-4).

In the event of mains fuses replacement on the

connection board, use 3.15A fast fuses. For the

main power supply to the appliance, never use

adapters, multiple sockets or extension leads.

Note: If the condensate cannot be on a gradient

and terminate to drain, then a suitable condensate

neutraliser must be used (available for purchase

from Hunt Heating).

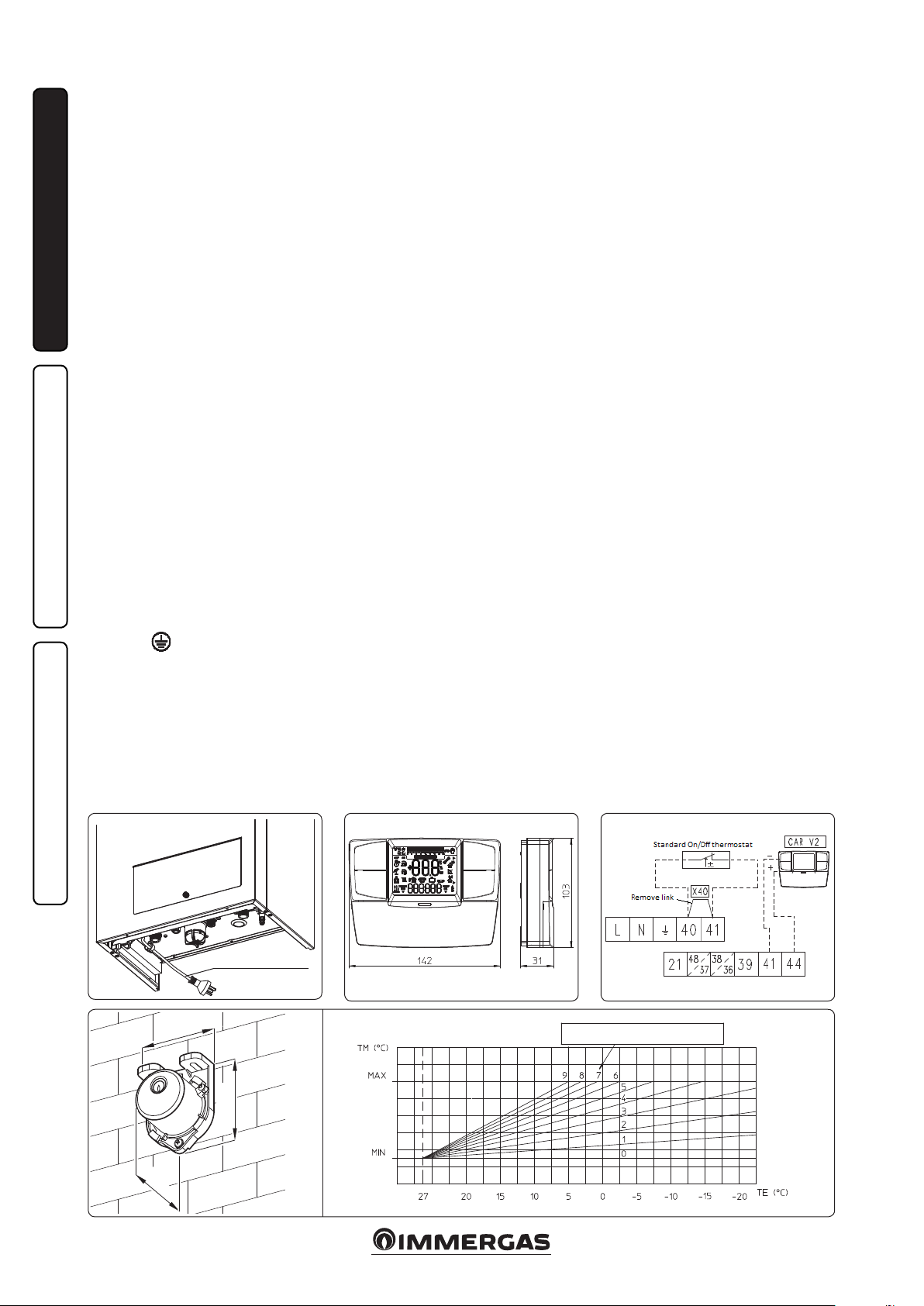

1.5

REMOTE CONTROL CARV2

OPTIONAL.

e boiler is prepared for the application remote

control CAR

(Fig. 1-5).

Immergas remote control CAR

V2

, which is available as optional kit.

V2

is connected

with 2 wires only. Carefully read the user and

assembly instructions contained in the accessory kit.

• In addition to the functions described in the

previous point, the CAR panel

V2

enables the

user to control all the important information

regarding operation of the appliance and the

heating system with the opportunity of easily

intervening on the previously set parameters

without having to go to the place where

the appliance is installed. e CAR

V2

panel

is equipped with self-diagnosis to display

any boiler functioning abnormalities. The

climate chrono-thermostat incorporated into

the remote panel enables the system flow

temperature to be adjusted to the actual needs

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving in

running costs. e chrono-thermostat is fed

directly by the boiler by means of the same 2

wires used for the transmission of data between

boiler and chrono-thermostat.

V2

CAR

(Optional). e operations described

below must be performed aer having removed

the voltage from the appliance. Any CARV2 must

be connected by means of terminals IN+ and

IN- (on the CAR

V2

terminal plate), respecting

polarity at boiler PCB, where IN+ connects to

terminal 44 and IN- connects to terminal 41

(See Fig. 1-6).

Attention: if the Comando Amico Remoto

V2

(CARV2) remote control is used, arrange two

separate lines in compliance with current

regulations regarding electrical systems. No

boiler pipes must ever be used to earth the

electric system or telephone lines.

Ensure elimination of this risk before making

the boiler electrical connections (ALL

ELECTRICAL CONNECTION MUST MEET

ALL LOCAL REGULATIONS).

1.6 EXTERNAL PROBE OPTIONAL.

e boiler is prepared for the application of the

external probe (Fig. 1-7), which is available as an

optional kit. Refer to the relative instruction sheet

for positioning of the external probe.

The probe can be connected directly to the

boiler electrical system and allows the max.

system ow temperature to be automatically

decreased when the external temperature

increases, in order to adjust the heat supplied to

the system according to the change in external

temperature. e external probe always operates

when connected, regardless of the presence or

type of room chrono-thermostat used and can

work in combination with Immergas chronothermostats. e correlation between system

flow temperature and external temperature

is determined by the position of the selector

switch on the boiler control panel according to

the curves shown in the diagram (Fig. 1-8). e

electric connection of the external probe must be

made on clamps 38 and 39 on the boiler P.C.B.

(Fig. 3-2).

NB: Thermostat connections if using own

after market thermostat, after removing

manufacturers link, connect to terminals 40

and 41 (Fig. 3-2).

MAINTENANCE TECHNICIAN

31

POWER SUPPLY CABLE

45

58

1-4

1-7

1-5 1-6

Position of the central heating temperature

user adjustment

1-8

6

Page 7

1.7 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the boilers regarding the installation of air

intake terminals and ue extraction, which are

fundamental for boiler operation.

Attention: the boiler must be installed

exclusively with an original Immergas “Green

Range” air intake and fume extraction system

in plastic, as envisioned by the Standards

in force. is system can be identied by an

identification mark and special distinctive

marking bearing the note: “only for condensing

b oi l er s ”.

• Resistance factors and equivalent lengths.

Each ue component has a Resistance Factor

based on experimental tests and specified

in the table below. e Resistance Factor for

individual components is independent from

the type of boiler on which it is installed

and has a dimensionless size. It is however,

conditioned by the temperature of the uids

that pass through the pipe and therefore,

varies according to applications for air intake

or ue exhaust. Each single component has a

resistance corresponding to a certain length

in metres of pipe of the same diameter; the

so-called equivalent length, obtained from the

ration between the relative Resistance Factors.

All boilers have an experimentally obtainable

maximum Resistance Factor equal to 100.

The maximum Resistance Factor allowed

corresponds to the resistance encountered with

the maximum allowed pipe length for each

type of Terminal Kit. is information allows

calculations to be made to verify the possibility

of setting up various ue congurations.

Positioning of the gaskets (black) for “green

range” ue extraction systems. Position the

gasket correctly (for bends and extensions) :

- gasket with notches, to use for bends;

- gasket without notches, to use for extensions.

N.B.: if component lubrication (already carried

out by the manufacturer) is not sucient, remove

the residual lubricant using a dry cloth, then to

ease tting spread the elements with common

or industrial talc.

With ue gaskets installed correctly, gently push

ue components together fully.

N.B.: considerations need to be made when

sighting/terminating ue extraction system as

an element of plumage will occur when boiler

is in operation.

N.B.: for safety purposes, do not obstruct the

boiler intake-exhaust terminal, even temporarily.

INSTALLERUSER

MAINTENANCE TECHNICIAN

7

Page 8

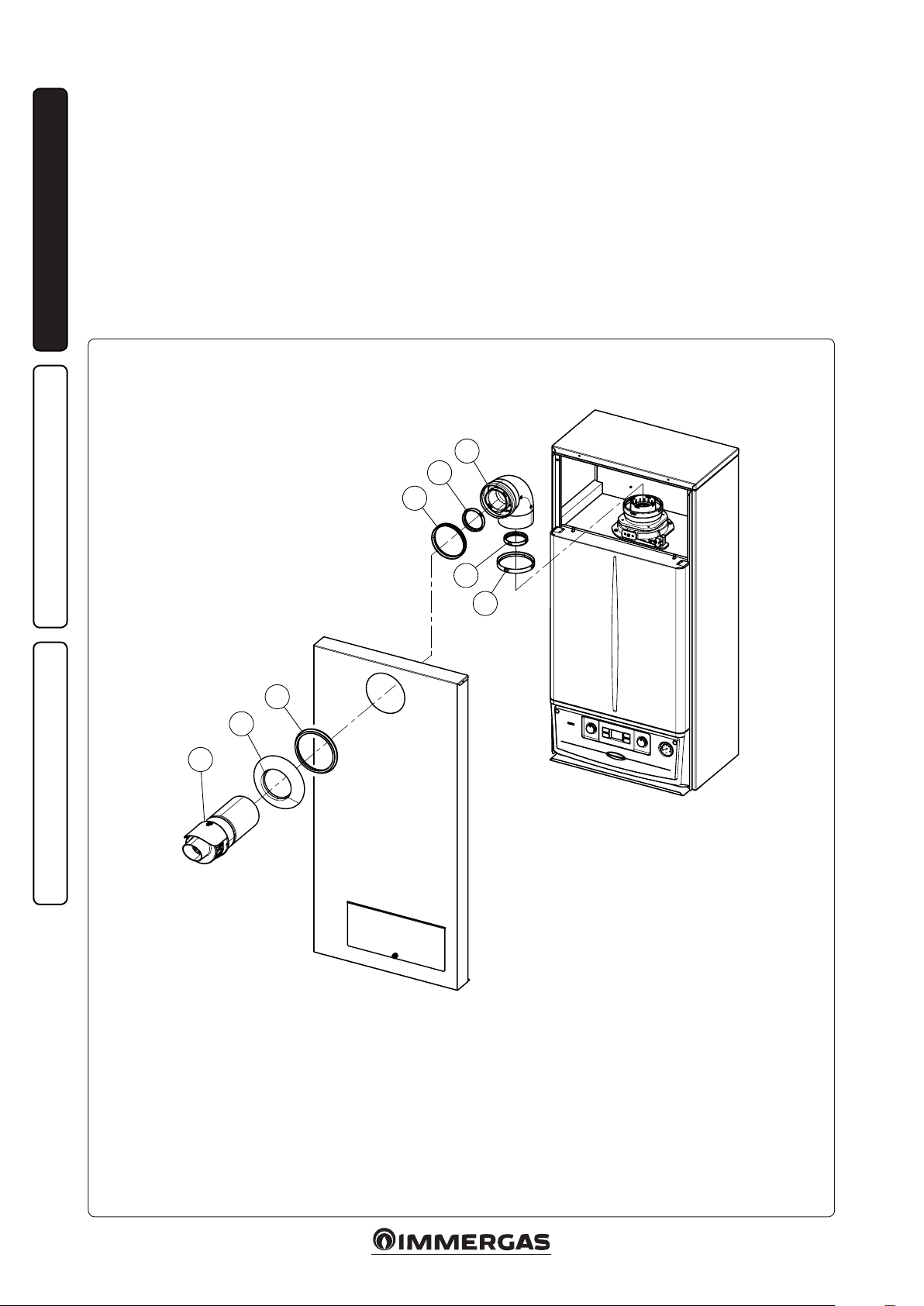

1.8 INSTALLATION OF INTAKE /

EXHAUST TERMINALS.

• Type C conguration, sealed chamber and

fan assisted.

Horizontal intake - exhaust terminal Ø60/100

(supplied as standard). Assembly (Fig. 1-9):

install the gaskets (1) and (2) in the concentric

ange (already installed).

Couple the bend (3) with the concentric ange up

to the stop aer having checked that the gaskets

are tted (4) and (5) in the female end.

Mount the casing front referring to Paragr. 3.14.

INSTALLERUSER

Couple the terminal pipe (8) with the male end

(smooth) into the female end (with lip seals) of

the bend (3) up to the stop, making sure that

the external wall sealing plate (7) has been tted

and checking it is on the casing front and gasket

(6); this will ensure proper sealing and joining

of the elements.

N.B.: Flue conguration supplied standard

with all INTEC external boilers.

6

7

8

C

12

3

4

5

2

1

MAINTENANCE TECHNICIAN

Components:

Concentric ange intake gasket (1)

Concentric ange exhaust gasket (2)

90° concentric bend (3)

90° concentric bend exhaust gasket (4)

90° concentric bend intake gasket (5)

Gasket (6)

External wall sealing plate (7)

Concentric intake/exhaust terminal Ø 60/100 (8)

Flue kit complete 60/100 Australia code: 3.026007

1-9

8

Page 9

1.9 SYSTEM FILLING.

Once the boiler is connected, proceed with

system lling through the arranged lling valve,

which can be connected to the return pipe system

and as close as possible to the boiler (Fig. 1-11),

or ideally via connection ‘C’.

Filling is performed at low speed to ensure release

of air bubbles in the water via the boiler and

heating system vents.

e boiler has a built-in automatic venting valve

on the circulator. Check if the cap is loose. Open

the radiator air vent valves.

Close radiator vent valves when only water

escapes from them.

Close the lling valve when the boiler manometer

indicates approx. 1.2 bar.

N.B.: during these operations, turn on the circulating pump at intervals by means of the main

selector switch on the control panel. Vent the

circulation pump by loosening the front cap and

keeping the motor running. Only open for a few

seconds at a time.

In presence of the automatic lling, the auto ll

valve must necessarily be isolated aer system

is pressurized.

1.10 GAS SYSTEM STARTUP.

To start up the system, make reference to the

Standard: is divides the systems and therefore

the start-up operations into three categories: new

systems, modied systems, re-activated systems.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specications.

1.11 BOILER START UP IGNITION.

For first ignition, the following must be

performed:

- check that the internal system is properly sealed

according to specications;

- ensure that the type of gas used corresponds

to boiler settings;

- switch the boiler on and ensure correct

ignition;

- make sure that the gas ow rate and relevant

pressure values comply with those given in the

manual;

- ensure that the safety device is engaged in the

event of gas supply failure and check activation

time;

- check activation of the master switch located

upstream from the boiler and in the boiler;

- check that the intake/exhaust concentric

terminal (if tted) is not blocked.

e boiler must not be started up even if only

one of the checks should be negative.

N.B.: the boiler preliminary check must be carried

out by a qualied technician. e conventional

boiler warranty is valid as of the date of testing if

not commissioned by a qualied technician.

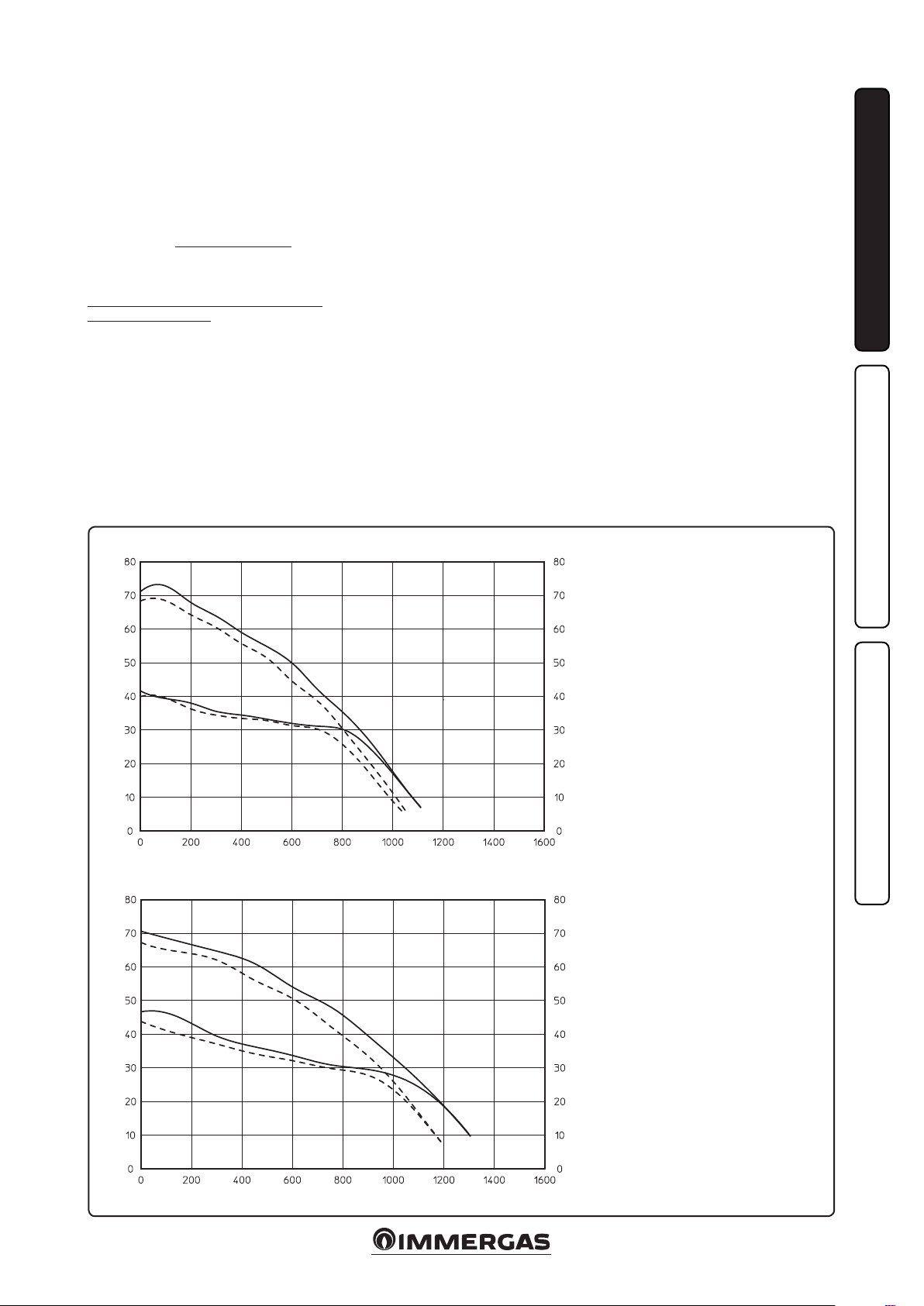

1.12 CIRCULATION PUMP.

e “INTEC 12-30 SYSTEM EXTERNAL” series

boilers are supplied with a built-in circulation

pump with 3-position electric speed control.

e boiler does not operate correctly with the

circulation pump on speed one. To ensure

optimal boiler operation, in the case of new

system it is recommended to use the pump at

maximum speed, position 3.

Pump release. If, aer a prolonged period of

inactivity, the circulation pump is blocked,

unscrew the front cap and turn the motor sha

using a screwdriver. Take great care during this

operation to avoid damage to the motor.

INSTALLERUSER

Head available to the system (INTEC 12).

C

Head (kPa)

Head available to the system (INTEC 30).

A

D

B

C

B

Flow rate (l/h)

A

O)

2

Head (m H

A = Head available to the system at maxi-

mum speed with by-pass closed.

B = Head available to the system at maxi-

mum speed with by-pass open.

C = Head available to the system at second

speed with by-pass closed.

D = Head available to the system at second

speed with by-pass open.

O)

2

1-10

MAINTENANCE TECHNICIAN

Head (kPa)

D

Flow rate (l/h)

Head (m H

9

Page 10

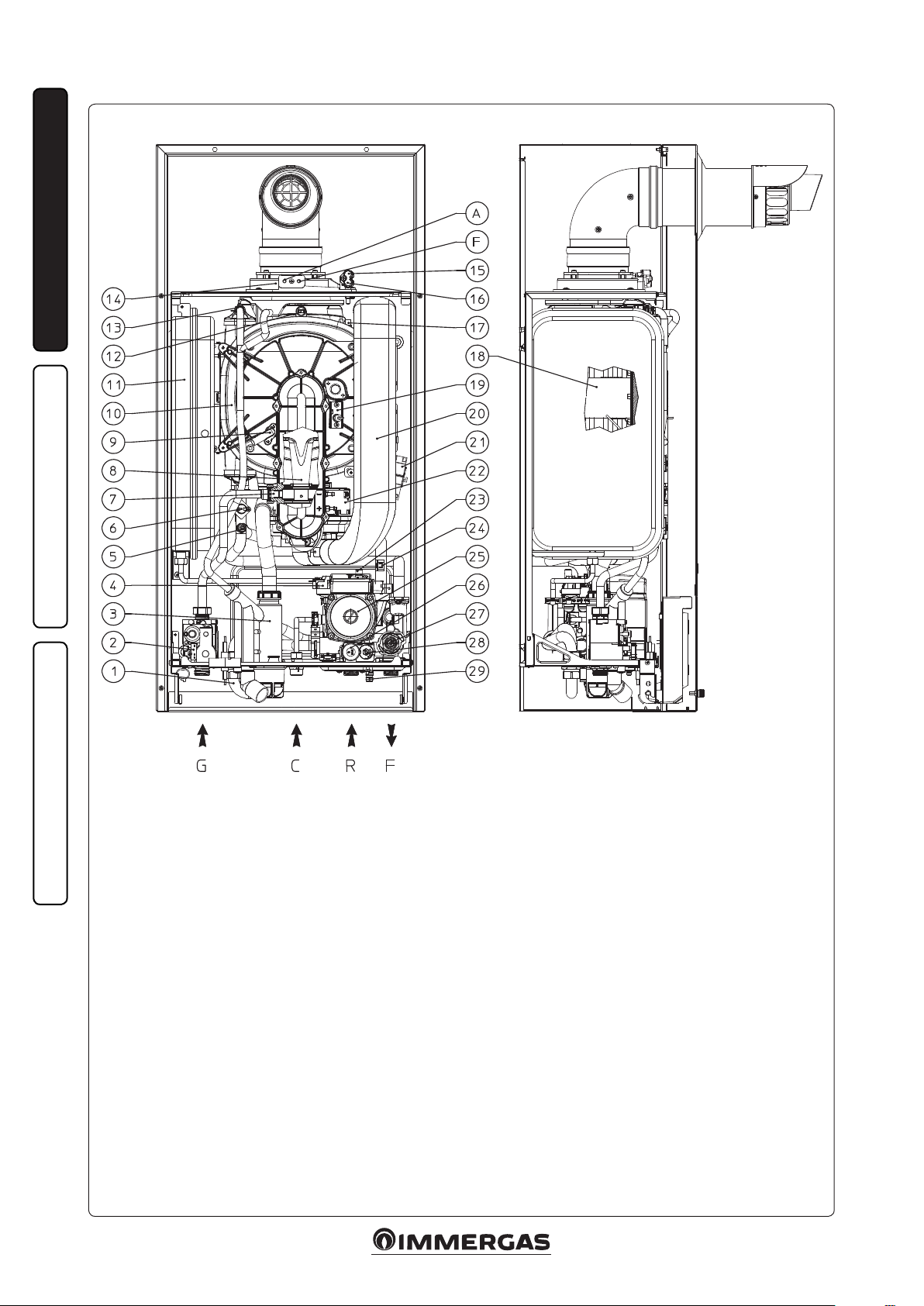

1.13 BOILER COMPONENTS.

INSTALLERUSER

MAINTENANCE TECHNICIAN

Key:

1 - Storage tank unit delivery return by-pass

2 - Gas valve

3 - Condensate drain trap

4 - System pressure switch

5 - Flow probe

6 - Safety thermostat

7 - Gas nozzle

8 - Venturi

9 - Detection electrode

10 - Condensation module

11 - System expansion vessel

12 - Flue probe

13 - Manual air vent valve

14 - Sample points (air A) - (ue gases F)

G - Gas supply

R - Return

F - Flow

C - Cold ll

15 - Negative signal pressure point

16 - Positive signal pressure point

17 - Heat exchanger safety thermofuse

18 - Burner

19 - Ignition electrode

20 - Air intake pipe

21 - Igniter

22 - Fan

23 - Air vent valve

24 - Return probe

25 - Boiler pump

26 - 3 bar safety valve

27 - 3-way valve (motorised)

28 - By-pass

29 - System draining valve

1-11

10

Page 11

INSTRUCTIONS FOR USE

2

AND MAINTENANCE.

2.1 CLEANING AND MAINTENANCE.

Attention: the boiler and heating systems must

undergo periodical maintenance, combustion

and energy eciency checks in compliance with

AS/NZS 5601, by a qualied licensed operative.

this insure that optimal safety performance

and operation of the boiler remains unchanged

over time.

We recommend your appliance is serviced every

24 months (see Par. 3.16).

2.2 GENERAL WARNINGS.

Use of the boiler by unskilled persons or children

is strictly prohibited.

If temporary shutdown of the boiler is required,

proceed as follows:

2.3 CONTROL PANEL.

2-1

a) drain the heating system if anti-freeze is not

used;

b) shut-o all electrical, water and gas supplies.

In the case of work or maintenance to structures

located in the vicinity of ducting or devices for

ue extraction and relative accessories, switch o

the appliance and on completion of operations

ensure that a qualied licensed operative checks

eciency of the ducting or other devices.

Never clean the appliance or connected parts

with easily ammable substances.

Never leave containers or ammable substances

in the same environment as the appliance.

• Attention: the use of components involving use

of electrical power requires some fundamental

rules to be observed:

- do not touch the appliance with wet or moist

parts of the body; do not touch it when

barefoot;

- the appliance power cable must not be replaced

by the user;

- in the event of damage to the cable, switch

off the appliance and contact a qualified

technician;

- if the appliance is not to be used for a certain

period, disconnect the main power switch.

INSTALLERUSER

Key:

1 - O/Stand-by/On Button

2 - Summer/Winter Button

3 - Reset button

4 - Information buttons

5 - Domestic hot water temperatureselector

switch

6 - Central heating water temperature selector

switch

7 - Boiler manometer

To access the control panel, remove the protection panel (6) from the casing front by unscrewing the bolt (7) and removing it as shown in

Fig. 3-4a.

2.4 USING THE BOILER.

Before ignition make sure the heating system

is lled with water and that the manometer (7)

indicates a pressure of 1 ÷ 1.2 bar (Fig. 2-1).

- Open the gas cock upstream from the boiler.

- Press the button (1) until the display switches

on. At this point, the boiler goes to the state

previous to switch-o.

- If the boiler is in stand-by, press the button (1)

again to activate it. If this is not the case, go to

the next point.

- Press button (2) in sequence and take the boiler

to summer (

) or winter ( ) position.

8 - DHW production phase functioning active

9 - Boiler in block does not require release via

“RESET” button

10 - Flame presence symbol and relative power

scale

11 - Functioning in summer mode

12 - Functioning in winter mode

13 - Room central heating active phase functio-

ning

• Summer (

functions only to produce the DHW, the

temperature is set via the selector (5) and the

relative temperature is shown on the display

via the indicator (14).

• Winter (

both for producing domestic hot water and

heating the environment. e temperature of

the DHW is always regulated via the selector

(5), the heating temperature is regulated via

selector (6) and the relative temperature is

shown on the display via the indicator (14).

From this moment the boiler functions

automatically. With no demand for heat (heating

or domestic hot water production) the boiler

goes to “standby” function, equivalent to the

boiler being powered without presence of ame.

): in this mode the boiler

): in this mode the boiler functions

14 - Temperature indicator, boiler info and

error codes

15 - Boiler in Stand-by mode

16 - Presence of external connected devices

17 - Solar function active

18 - Functioning with external temperature

probe active (optional)

19 - Boiler connected to remote control V2

(optional)

20 - Not used on this model

Each time the burner ignites, the relative ame

present symbol is displayed (10) with relative

power scale.

• Operation with Comando Amico Remoto

remote control

V2

is connected, the ( ) symbol will

CAR

appear on the display. e boiler regulation

parameters can be set via the CARV2 control

panel and the reset button (3) remains active

on the boiler control panel, along with the

switch-o button (1) (“o ” mode only) and the

display where the functioning state is shown

Important: if the boiler is put into “off ”

mode, the “ERR>CM” connection error

symbol will appear on the CAR

however powered constantly so as not to loose

memorised programs.

V2

(CARV2) (Optional). If the

V2

. e CAR V2is

MAINTENANCE TECHNICIAN

11

Page 12

• Solar functioning mode ( ). is function

is activated automatically if the boiler detects

a probe on the DHW inlet (optional) or if the

“Solar ignition delay” parameter is more than

0 seconds.

During a withdrawal, if the outlet water is

hot enough, the boiler does not switch on,

the DHW withdrawal symbol (

on the display along with the ashing solar

function symbol (

INSTALLERUSER

When the water supplied by the solar system

is at a temperature lower than that at which

the boiler is set, the boiler switches on. At this

point, the solar function symbol will stay on

without ashing.

• Functioning with optional external probe

(

). In the case of a system with optional

external probe, the boiler ow temperature

for room central heating is managed by the

external probe depending on the external

temperature measured (Par. 1.6). The flow

temperature can be modied by selecting the

functioning curve via the selector switch (6)

(or on the CARV2 control panel, if connected

to the boiler) selecting a value from “0 to 9”.

).

) appears

With external probe present, the relative

symbol (18) will appear on the display. In the

central heating phase, if the temperature of the

water contained in the system is sucient to

heat the radiators, the boiler can only function

with the activation of the pump.

• “Stand-by” mode. Press button (1) in

succession until the (

e boiler remains inactive from this moment

and the anti-freeze function, pump anti-block

function and 3-way and signalling of any

anomalies is guaranteed.

N.B.: in these conditions the boiler is

considered still powered.

• “O” mode. By holding the button (1) down

for 8 seconds, the display switches-o and the

boiler is o completely. e safety functions are

not guaranteed in this mode.

N.B.: in these conditions the boiler is considered

still live even if there are no functions active.

• “Automatic vent” mode. Every time power is

supplied to the boiler. the system automatic

vent function is activated (duration 8 minutes).

This function is displayed via countdown

signalled by the indicator (14). During this

period the DHW and CH functions are not

active.

The “automatic vent” can be annulled by

pressing the “reset” button (3).

) symbol appears.

• Display functioning. e display lights up

during the use of the control panel, aer 15

seconds inactivity, the brightness drops until

just the active symbols are displayed. The

lighting mode can be varied via parameter t3

in the circuit board customisation menu.

2.5 FAULT AND ANOMALY SIGNALS.

e INTEC 12-30 SYSTEM EXTERNAL boiler

signals any anomalies using a code shown on

the boiler display (14) according to the following table.

On the CAR

by means of the same numeric code represented

according to the following example (e.g. CARV2

= Exx).

V2

, the error code will be displayed

Error

Code

Anomaly signalled Cause Boiler status / Solution

In the event of request of room central heating or domestic hot water

01 No ignition block

Safety thermostat

02

block (overheating)

Flue safety thermo-

03

stat block

Contacts resistance

04

block

05 Flow probe anomaly e board detects an anomaly on the ow NTC probe. e boiler does not start (1).

Domestic hot water

06

probe anomaly

production, the boiler does not switch on within the preset time. Upon

appliance commissioning or aer extended downtime, it may be necessary to eliminate the block.

During normal operation, if a fault causes excessive overheating internally,

the boiler goes into overheating block.

During normal operation, if a fault causes excessive ue gas overheating,

the boiler blocks

e P.C.B. detects an anomaly on the gas valve supply. Check the connection. (the anomaly is detected and displayed only in the event of a request).

e board detects an anomaly on the domestic hot water NTC probe.

MAINTENANCE TECHNICIAN

Maximum N° of

08

reset

Insufficient system

10

pressure

15 Conguration error

16 Fan anomaly is occurs if the fan has a mechanical or electrical fault. Press the Reset button (1).

20 Parasite ame block

Return probe anom-

23

aly

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service).

Number of allowed resets that have already performed.

Water pressure inside the central heating circuit that is sucient to guarantee the correct operation of the boiler is not detected.

If the board detects an anomaly or incongruity on the electric wiring, the

boiler will not start.

is occurs in the event of a leak on the detection circuit or anomaly in

the ame control unit.

e board detects an anomaly on the return NTC probe e boiler does not start (1).

Press the Reset button (1).

Press the Reset button (1).

Press the Reset button (1).

e boiler does not start (1).

In this case the boiler continues to produce

domestic hot water but not with optimal

performance. Moreover, the antifreeze

function (1) is restrained.

Attention: the anomaly can be reset 5 times

consecutively, aer which the function in

inhibited for at least one hour. One attempt

is gained every hour for a maximum of 5

attempts. By switching the appliance on and

o the 5 attempts are re-acquired.

Check on the boiler pressure gauge (1) that

the system pressure is between 1÷1.2 bar

and restore the correct pressure if necessary.

If normal conditions are restored the boiler

restarts without having to be reset. Check

that the boiler is congured correctly (1).

Press the Reset button (1).

12

Page 13

Error

Code

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service).

Anomaly signalled Cause Boiler status / Solution

Push button control

24

panel anomaly

Block due to ue gas

25

temperature gradient intervention

Insucient circula-

27

tion

29 Flue probe anomaly

Loss of remote con-

31

trol communication

IMG Bus communi-

36

cation loss

Low power supply

37

voltage

38 Loss of ame signal

Block due to loss

43

of continue flame

signal

Block for exceeding

the maximum accu-

44

mulated time, close

gas valve opening

45 High T

Low temperature

46

safety thermostat

(optional)

Burner power limi-

47

tation

High temperature

49

block on return

probe

e board detects an anomaly on the pushbutton panel

If the board detects a rapid increase in ue gas temperature probably due

to a blocked circulating pump or lack of water in the heat exchanger, the

boiler shuts down due to the ue gas temperature gradient trip.

is occurs if there is overheating in the boiler due to insucient water

circulating in the primary circuit; the causes can be:

- low system circulation; check that no shut-o devices are closed on the

heating circuit and that the system is free of air (deaerated);

- pump blocked; free the pump.

If the board detects an anomaly on the ue gas probe the boiler will not

start

is occurs 1 minute aer communication is lost between the boiler and

the remote control.

Communication between the various components is interrupted due to

an anomaly on the boiler control unit, on the zone control unit or on

the IMG Bus.

is occurs when the power supply voltage is lower than the allowed limits

for the correct boiler operation.

is occurs when the boiler is ignited correctly and the burner ame

switches o unexpectedly; a new ignition attempt is performed and if

normal conditions are restored, the boiler does not need to be reset (this

fault can be checked in the list of errors in the “Information” menu only).

is occurs if the ''Flame signal loss'' error occurs many times in a row

within a preset period (38).

is occurs if the gas valve remains open for longer than required for

normal operation, without the boiler switching on.

If the board detects a sudden and unexpected rise in ΔT between the

system ow probe and return probe, the boiler limits the burner output

to prevent damaging the condensing module; when the correct ΔT has

been restored, the boiler returns to normal operation.

During normal operation, if an anomaly causes excessive overheating of

the ow temperature in low temperature conditions, the boiler blocks.

Should ue high temperature be detected, the boiler reduces power supplied so as not to damage it.

is occurs when the heat exchanger return circuit reaches too high of

a temperature.

If normal conditions are restored the boiler

restarts without having to be reset (1).

Press the Reset button (1).

Press the Reset button (1).

e boiler does not start (1).

Power cycle the boiler. If the Remote

Control is still not detected on re-starting

the boiler will switch to local operating

mode, i.e. using the controls on the control

panel (1).

e boiler does not satisfy the room heating

requests (1).

If normal conditions are restored the boiler

restarts without having to be reset (1).

If normal conditions are restored the boiler

restarts without having to be reset (1).

Press the Reset button, before restarting, the

boiler will run a post-ventilation cycle (1).

Press the Reset button (1).

Make sure there is water circulating in the

boiler, that the pump is congured according to system requirements and that the

return probe works properly (1).

In this case, aer suitable cooling, it is possible to reset the thermostat (see relative

instructions sheet) (1).

(1).

Make sure that water circulates properly

in the boiler and that the three-way valve

works properly. To eliminate it, the Reset

button (C) must be pressed (1).

INSTALLERUSER

MAINTENANCE TECHNICIAN

13

Page 14

2.6 INFORMATION MENU.

By pressing the “Info” button (4), the “Information

menu” is activated, which lists boiler functioning

information.

Press the “Info” button (4) to scroll the various

information.

To exit the menu, press the “Info” button (4) up

to the end of the list, or by pressing the “Reset”

button (3) or by waiting for 15 minutes.

With the menu active, the indicator (14) will

alternately show the indication of the parameter

via the letter “d” plus the number of the

parameter that is being displayed and the value

of the parameter itself.

Id

Parameter

d1 Displays the ame signal (uA x 10 approximate)

INSTALLERUSER

d2 Displays the primary exchanger output instant heating ow temperature

d3 Displays the instant output temperature from the DHW exchanger

d4 Displays the values set for central heating set

d5 Displays the values set for DHW set

Displays the external temperature (if external probe present)

d6

If the temperature is below zero, the value is displayed ashing.

d7 Display the temperature of the inlet DHW (with DHW inlet probe present)

d8 Display the temperature of the return probe.

Displays the list of the last ve anomalies.

d9

(to scroll the list, turn the CH temperature selector (6))

2.7 BOILER SHUTDOWN

Switch the boiler o by pressing the “

disconnect the power supply outside of the boiler

and close the gas cock upstream of the appliance.

Never leave the boiler switched on if le unused

for prolonged periods.

2.8 RESTORING CENTRAL HEATING

SYSTEM PRESSURE.

Periodically check the system water pressure.

e boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

If the pressure falls below 1 bar (with the circuit

cold) restore normal pressure via the ll valve.

N.B.: close the cock aer the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In the event of frequent pressure drops, contact

original installer or qualied licensed operative

for assistance to eliminate possible system

leakage.

” button,

Description

2.9 DRAINING THE SYSTEM.

To drain the boiler, use the special system

draining valve (Fig. 1-11, Part. 29).

Before draining, ensure that the system lling

valve is closed.

2.10 ANTIFREEZE PROTECTION.

The boiler has an anti-freeze function that

switches on automatically when the temperature

falls below 4°C (standard protection to minimum

temperature of -5°C). All information relative to

the anti-freeze protection is stated in Par. 1.3. In

order to guarantee the integrity of the appliance

and the domestic hot water heating system in

zones where the temperature falls below zero,

we recommend the central heating system is

protected using anti-freeze liquid and installation

of the Immergas Anti-freeze Kit in the boiler. In

the case of prolonged inactivity (second case),

we also recommend that:

- the electric power supply is disconnected;

- the heating circuit and boiler domestic water

circuit must be drained. In systems that are

drained frequently, filling must be carried

out with suitably treated water to eliminate

hardness that can cause lime-scale.

2.11 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.12 DECOMMISSIONING.

In the event of permanent shutdown of the

boiler, contact an authorised company for

the procedures and ensure that the electrical,

water and gas supply lines are shut off and

disconnected.

MAINTENANCE TECHNICIAN

14

Page 15

BOILER COMMISSIONING

3

INITIAL CHECK.

When commissioning the boiler, ensure the

appliance checklist, located at the rear of this

instruction booklet is completed.

To commission the boiler:

- ensure that the type of gas used corresponds to

boiler settings recorded on the appliance data

plate;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

3.1 HYDRAULIC DIAGRAM.

Key:

1 - Condensate drain trap

2 - 3 bar safety valve

3 - Gas valve

4 - Gas valve outlet pressure point (P3)

5 - Venturi positive sign (P1)

6 - Venturi negative sign (P2)

7 - Air/gas Venturi manifold

8 - Fan

9 - Gas nozzle

10 - Detection electrode

11 - Flue probe

12 - Air intake pipe

13 - Condensation module

14 - Manual air vent valve

15 - Heat exchanger safety thermofuse

16 - Air sample point

17 - ∆p gas pressure point

18 - Flue sample point

19 - Flue hood

20 - Safety thermostat

21 - Flow probe

22 - Ignition electrode

23 - Burner

24 - Condensation module cover

25 - Return probe

26 - System expansion vessel

27 - Air vent valve

28 - Boiler pump

29 - System draining valve

30 - System pressure switch

31 - 3-way valve

32 - By-pass

- switch the boiler on and ensure correct ignition;

- ensure the gas inlet working pressure is correct,

1.1 Kpa (Natural Gas), 2.75 Kpa (LPG);

- check and set expansion vessel air pressure to

1 bar;

- pre ll condense trap with clean water;

- ll and set system pressure to 1.2 bar;

- vent air from boiler and system, also allow

automatic vent function to run (Par. 3.13);

- check that the gas maximum and minimum

relative pressure values correspond to those

given in the handbook, Par. 3.15;

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check activation of the main switch located

upstream from the boiler and in the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- ensure activation of all adjustment devices;

- ensure sealing eciency of hydronic circuits;

- check ventilation and/or aeration of the

installation room where provided.

INSTALLERUSER

MAINTENANCE TECHNICIAN

G - Gas supply (not supplied as standard)

R - System return (not supplied as standard)

F - System delivery (not supplied as standard)

SC - Condensate drain (supplied as standard)

(minimum internal diameter Ø13 mm)

C - Cold ll

3-1

15

Page 16

3.2 WIRING DIAGRAM.

INSTALLERUSER

Key:

B1 - Flow probe

B2 - Domestic hot water probe (optional)

B4 - External probe (optional)

B5 - Return probe

B10 - Flue probe

CARV2 - Comando Amico Remoto Version 2

remote control (optional)

E1 - Ignition electrode

E2 - Detection electrode

E4 - Overheating safety thermostat

E13 - Exchanger safety thermofuse

G2 - Igniter

M1 - Boiler pump

M20 - Fan

R5 - Trimmer DHW set

R6 - Trimmer CH set

R8 - Storage tank inhibition resistor

S2 - Functioning knob

S3 - Reset button

S5 - System pressure switch

S20 - Room thermostat (optional)

S31 - On/Stand-by/O button

S33 - Info button

T2 - Voltage transformer

X40 - Room thermostat jumper

Y1 - Gas valve

MAINTENANCE TECHNICIAN

Storage tank unit: the boiler is prepared for the

connection to a storage tank unit, which must

be connected to clamps 36 - 37 of the terminal

board, eliminating resistance R8.

V2

CAR

: the boiler is prepared for the application

of the CARV2 (which must be connected to clamps

41 and 44 of the terminal board respecting the

polarity and eliminating jumper X40.

Room thermostat: the boiler is prepared for the

application of the room thermostat (S20), which

must be connected to clamps 40 and 41 of the

terminal board eliminating jumper X40.

3-2

e connector X5 is used for the connection to

the relay P.C.B..

e connector X6 is used for the connection to

the personal computer.

e connector X8 is used for soware updating

operations.

16

Page 17

3.3 TROUBLESHOOTING.

N.B.: maintenance interventions must be carried

out by a qualied licensed operative.

Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing eciency of gas intake

circuit.

- Repe ated ignition blocks. is may be caused by:

incorrect electric power supply, check respect of

L and N polarity. No gas, check the presence of

pressure in the network and that the gas intake

pipe is open. Incorrect adjustment of the gas

valve, check the correct calibration of the gas

valve. Also check that the heat exchanger or trap

are not clogged.

- Irregular combustion or noisiness. is may be

caused by: a dirty burner, incorrect combustion

parameters, intake-exhaust terminal not

correctly installed. Clean the above components

and ensure correct installation of the terminal,

check correct setting of the gas valve (O-Set

setting) and correct percentage of CO

gases.

in ue

2

- Frequent activation of the temperature

overload thermostat. It can depend on the lack

of water in the boiler, little water circulation

in the system or blocked pump. Check on the

manometer that the system pressure is within

established limits. Check that the radiator

valves are not closed and also the functionality

of the pump.

- Siphon blocked. is may be caused by dirt or

combustion products deposited inside. Check,

by means of the condensate drain cap, that

there are no residues of material blocking the

ow of condensate.

- Heat exchanger blocked. is may be caused by

the trap being blocked. Check, by means of the

condensate drain cap, that there are no residues

of material blocking the ow of condensate.

- Noise due to air in the system. Check opening

of the hood of the special air vent valve

(Fig. 1-11). Make sure the system pressure and

expansion vessel pre-charge values are within

the set limits; e factory-set pressure values of

the expansion vessel must be 1.0 bar, the value

of system pressure must be between 1 and 1.2

bar.

Boiler conversion must be carried out by a

qualied licensed operative.

To convert to another type of gas the following

operations are required:

- remove the voltage from the appliance;

- replace the nozzle located between the gas pipe

and gas/air mixing sleeve (Part. 7 Fig. 1-11),

taking care to remove the voltage from the

appliance during this operation;

- apply voltage to the appliance;

- calibrate the number of fan revs. (Par. 3.5):

- adjust the correct air/gas ratio (Par. 3.6);

- seal the gas ow rate devices (if adjusted);

- aer completing conversion, apply the sticker,

present in the conversion kit, near the dataplate. Using an indelible marker pen, cancel

the data relative to the old type of gas.

ese adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.15).

3.5 CALIBRATION OF NUMBER OF FAN

REVS.

Important: verification and calibration is

necessary, in the case of transformation to other

types of gas, in the extraordinary maintenance

phase with replacement of the circuit board,

air/gas circuit components or in the case of

installations with ue gas extraction systems,

with horizontal concentric pipe measuring more

than 1 metre.

The boiler heat output is correlated to the

length of the air intake and ue exhaust pipes.

is decreases with the increase of pipe length.

The boiler leaves the factory adjusted for

minimum pipe length (1m). It is therefore

necessary, especially in the case of maximum

pipe extension, to check the ∆p gas values aer at

least 5 minutes of burner functioning at nominal

heat output, when the temperatures of the intake

air and exhaust ue gases have stabilised. Adjust

the nominal and minimum heat output in the

domestic hot water and central heating modes

according to the values in the table (Par. 3.15)

using the dierential manometers connected to

the ∆p gas pressure point (15 and 16 Fig. 1-11).

Enter the congurations menu and regulate the

3.4 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a dierent gas

type to that specied on the data plate, request

the relative conversion kit for quick and easy

conversion.

following parameters (Par. 3.8):

- DHW minimum power output;

- DHW maximum power output;

- minimum heating output;

- maximum central heating output;

- ignition power.

Gas Valve 848 Key:

+

P1

+

12

P3

2

3

1

1 - Gas valve inlet pressure

point

2 - Gas valve outlet pressure

point

3 - O/Set adjustment screw

12 - Outlet gas ow rate

adjuster

3.6 ADJUSTMENT OF THE AIRGAS

RAT IO.

Important: the verication operations of the CO

must be carried out with the casing mounted,

while the gas valve calibration operations must

be carried out with the casing open and removing

the voltage from the boiler.

Calibration of the minimum CO

heating power).

(minimum

2

Enter the chimney sweep phase without

withdrawing domestic hot water and take the

selector switches to minimum (turn them in an

anti-clockwise direction until “0” is seen on the

display). to have an exact value of CO

gases the technician must insert the sampling

in the ue

2

probe to the bottom of the sample point, then

check that the CO2 value is that specied in the

table, otherwise adjust the screw (3 Fig. 3-3) (OSet adjuster). To increase the CO2 value, turn the

adjustment screw (3) in a clockwise direction and

vice versa to decrease it.

Calibration of the maximum CO

central heating power).

(nominal

2

On completion of the adjustment of the

minimum CO2 keeping the chimney sweep

function active, take the heating selector switch

to maximum (turn it in a clockwise direction

until “99” is seen on the display). To have an exact

value of CO2 in the ue gases the technician must

insert the sampling probe to the bottom of the

sample point, then check that the CO2 value is

that specied in the table, otherwise adjust the

screw (12 Fig. 3-3) (Gas ow adjuster).

To increase the CO2 value, turn the adjustment

screw (12) in a anticlockwise and vice versa to

decrease it.

At every adjustment variation on the screw 12 it

is necessary to wait for the boiler to stabilise itself

at the value set (about 30 sec.).

INTEC 12 SYSTEM EXTERNAL

NG

(G20)

LPG

(G31)

at nominal

CO

2

output

(central heating)

9,60% ± 0,2 8,90% ± 0,2

11,00% ± 0,2 10,30% ± 0,2

CO2 at minimum

output

(central heating)

INTEC 30 SYSTEM EXTERNAL

NG

(G20)

LPG

(G31)

at nominal

CO

2

output

(central heating)

9,45% ± 0,2 8,90% ± 0,2

10,60% ± 0,2 9,70% ± 0,2

CO2 at minimum

output

(central heating)

3.7 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

Aer making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that the burner ame is

not too high or low and is stable (does not detach

from burner);

N.B.:All boiler adjustment operations must be

carried out by a qualied licensed operative.

2

INSTALLERUSER

MAINTENANCE TECHNICIAN

17

3-3

Page 18

3.8 PROGRAMMING THE P.C.B.

e boiler is prepared for possible programming

of several operation parameters. By modifying

these parameters as described below, the boiler

can be adapted according to specic needs.

To access the programming phase, position the

DHW selector (5) (Fig. 2-1) on position “6”, the

CH selector (6) on position “9” and press the

“Reset” (3) and “Summer/Winter” buttons for

about 8 seconds (2).

Once the menu has been accessed, it is possible

INSTALLERUSER

to scroll through the three sub-menus present

(s, p, t) by pressing the “Summer/Winter” (2)

button for 1 second.

Use the “DHW regulator” selector (5), to select

the parameter (inside the same sub-menu) and

rotate the “CH regulator” selector (6) to modify

the value according to the range available.

Press the “Reset” button (3) for 1 second to

memorise the variation of the parameters.

Memorisation is represented via “88” on the

indicator (14) for 2 seconds.

Exit the programming mode by waiting for

15 minutes or by pressing the, “Reset” (3) and

“Summer/Winter” (2) buttons simultaneously.

MAINTENANCE TECHNICIAN

Id

Parameter

S0

S1

S2

S3

S4

S5

S6

S7

S8

Parameter Description Range Default

Minimum DHW

output

Maximum DHW

output

Minimum CH

output

Maximum CH

output

Power

block

Central heating

set point mini-

mum temperature

Central heating

set point maxi-

mum temperature

External probe

correction

Boiler power

e boiler also has electronic modulation that adapts the boiler potentiality to the ef

fective heating demand of the house. erefore the boiler works normally in a variable

gas pressure eld between minimum and maximum power depending on the system

heat load, setting fan speed (in rpm, hundreds of revs are represented on the display).

N.B.:the boiler is produced and calibrated in the central heating phase at nominal

output. Approximately 10 minutes are needed to reach the nominal heat output, which

can be changed using the parameter (S3).

N.B.: selection of parameters in the presence of requests, allows boiler functioning with

current equal to the respective value.

Denes the minimum ow temperature.

Denes the maximum ow temperature.

If the reading of the external probe is not correct it is possible to correct it in order to

compensate any environmental factors.

(Over the value of +9 the display shows “CE”, which enables an external control function

of the boiler for coupling of the same with a system supervisor)

Identies the boiler’s power

(only useful with a coupled storage tank and parameter P0=1).

900 ÷ 1500

-

3500 ÷ 6100

S0 ÷ S3

S2 ÷ S1

1500 ÷ 3500

20 ÷ 50 °C 25

(S5+5) ÷

85 °C

-9 ÷ 9 K 0

0 = 12 kW

1 = 26 kW

2 = 28 kW

3 = 32 kW

12 =1300 (NG/LPG)

30 =1300 (NG/LPG)

12 =4750 (NG/LPG)

30 =5100 (NG/LPG)

12 =1300 (NG/LPG)

30 =1300 (NG/LPG)

12 =4750 (NG/LPG)

30 =5100 (NG/LPG)

12 =2900 (NG/LPG)

30 =2900 (NG/LPG)

85

1

18

Page 19

Id

Parameter

P0 DHW thermostat

P1

P2

P3

P4

P5

Id

Parameter

t0

t1

t2

t3 Display lighting

t4 Display

Parameter Description Range Default

Solar delay

timing

Pump function-

ing

Relay 1

(optional)

Relay 2

(optional)

Relay 3

(optional)

Parameter Description Range Default

Central heating

ignitions timer

Central heating

ramp timer

CH ignition de-

lay from TA and

CR request

Establishes the boiler ignition and switch-o mode in DHW mode.

0 - Ignition occurs when the water contained in the storage tank drops by 7°C with

respect to the temperature set and switches o when the temperature is at -4°C with

respect to the value set (solar deactivated)

1 - Ignition occurs when the water contained in the storage tank drops by 2°C with

respect to the temperature set and switches o when the temperature is at +1°C with

respect to the value set (solar deactivated)

2 - Ignition occurs when the water contained in the storage tank drops by 10°C with

respect to the temperature set and switches o when the temperature is at the value

set (solar deactivated)

e boiler is set to switch-on immediately aer a request for DHW. In the case of

coupling with a solar storage tank positioned upstream from the boiler, it is possible to

compensate the distance between the storage tank and the boiler in order to allow the

water to reach the boiler. Set the time necessary to verify that the water is hot enough

(see par. Solar panels coupling)

e pump can function in two ways.

0 intermittent: In winter "mode" the pump is managed by the room thermostat or by the

remote control

1 continuous: In "winter" mode the pump is always powered and so functions continu-

ously

e boiler is set-up for functioning with the relay board (optional), which can be

congured

0 = O

1 = Main zone control

2 =General alarm

3 = CH phase active

4 = External gas valve power supply

5 = (Do not use on this boiler model)

e boiler is set-up for functioning with the relay board (optional), which can be

congured

0 = O

1 =General alarm

2 = CH phase active

3 = External gas valve power supply

4 = Secondary zone control (from TA on relay board contact

5 = Heat pump

e boiler is set-up for functioning with the relay board (optional), which can be

congured

0 = O

1 = Chiller remote activation

2 =General alarm

3 = CH phase active

4 = External gas valve power supply

5 = heat pump

6 = activation of storage tank pump

e boiler has electronic timing, which prevents the burner from igniting too oen in

central heating mode (with step of 10)

In the ignition phase, the boiler performs an ignition ramp in order to arrive at the

maximum power set (with step of 10)

e boiler is set to switch-on immediately aer a request. In the case of particular systems

(e.g. area systems with motorised thermostatic valves etc.) it could be necessary to delay

switch-on (with 10 step)

Establishes the display lighting mode.

0 Automatic: the display lights up during use and lowers aer 15 seconds of inactivity.

In the case of anomaly the display ashes.

1 Low: the display is always lit with low intensity

2 High: the display is always lit with high intensity.

Establishes what the indicator displays 14 (Fig. 2-1).

"Summer" mode:

0: the indicator is always o

1: pump active displays the ow temperature,

pump o the indicator is o

"Winter" mode:

0: always displays the value set on the CH selector

1: pump active displays the ow temperature,

pump o always displays the value set on the CH selector

0

On = -7°C

O = -4°C

1

On = -2°C

O = +1°C

2

On = -10°C

O = +0°C

0 - 30 seconds 0

0 - 1 0

0 - 5 1

0 - 5 0

0 - 6 0

0 - 600 sec-

onds

0 - 840

seconds

0 - 600 sec-

onds

0 - 2 0

0 - 1 1

2

INSTALLERUSER

18

18

0

MAINTENANCE TECHNICIAN

19

Page 20

3.9 “CHIMNEY SWEEP” FUNCTION.

When activated, this function forces the boiler

to variable output for 15 minutes.

In this state all adjustments are excluded and only

the safety thermostat and the limit thermostat

remain active. To activate the chimney sweep

function, press the “Reset” button (3) until

activation of the function in the absence of

DHW requests.

Its activation is signalled by simultaneous

ashing of the indicators (11 and 12 Fig. 2-1).

INSTALLERUSER

is function allows the technician to check the

combustion parameters.

Once the function is activated, it is possible to

select whether to make the check in CH status

or DHW status by opening any hot water cock

and regulating the power by turning the “CH

regulation” selector (6).

Functioning in CH or DHW mode is visualised

by the relative symbols

After the checks, deactivate the function

switching the boiler o and then on again.

3.10 PUMP ANTIBLOCK FUNCTION.

e boiler has a function that starts the pump at

least once every 24 hours for the duration of 30

seconds in order to reduce the risk of the pump

becoming blocked due to prolonged inactivity.

3.11 RADIATORS ANTIFREEZE

FUNCTION.

If the system return water is below 4°C, the boiler

starts up until reaching 42°C.

or .

3.12 P.C.B. PERIODICAL SELFCHECK.

During functioning in heating mode or with

boiler in standby, the function activates every 18

hours aer the last boiler check/power supply. In

case of functioning in domestic hot water mode

the self-check starts within 10 minutes aer the

end of the withdrawing in progress, for duration

of approx. 10 seconds.

N.B.:during self-check, the boiler remains o.

3.13 AUTOMATIC VENT FUNCTION.

In the case of new heating systems and in

particular mode for floor systems, it is very