Immergas HERCULES SOLAR 26 2 ErP, Hercules Condensing 26 3 ErP, Hercules Condensing 32 3 ErP Instruction And Recommendation Booklet

Page 1

Instruction and

*1.037974ENG*

recommendation booklet

IE

HERCULES

SOLAR 26 2 ErP

Page 2

Page 3

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully: you

will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction for the Immergas product.

Contact our area authorised aer-sales centre as soon as possible to request commissioning.

Our technician will verify the correct functioning conditions; he will perform the necessary calibrations and will demonstrate the correct use of the generator.

For assistance and scheduled maintenance contact Authorised Aer-Sales centres: they have original spare parts and are specically trained directly by the

manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry environments protected against bad weather.

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instructions manual provides technical information for installing Immergas boilers. As for the other issues related to boiler installation (e.g. safety in the work

site, environment protection, injury prevention), it is necessary to comply with the provisions specied in the regulations in force and principles of good practice.

In compliance with legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law. Installation

and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally qualied

sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to people, animals

and objects. Read the instructions provided with the product carefully to ensure a proper installation.

Maintenance must be carried out by skilled technical sta. e Authorised Aer-sales Service represents a guarantee of qualications and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non compliance with technical laws in force, standards or instructions contained in this

book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damages and the

appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of gas heat generators, consult the Immergas site at the

following address: www.immergas.com

CE DECLARATION OF CONFORMITY

(according to ISO/IEC 17050-1)

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE) whose design, manufacturing, and aer sale assistance

processes comply with the requirements of standard UNI EN ISO 9001:2008,

e boiler model Hercules Solar 26 2 ErP complies with European Directives and Delegated European Regulations listed below:

“Eco-design” Directive 2009/125/EC, “Energy labelling” Directive 2010/30/EC, EU Regulation 811/2013, EU Regulation 813/2013, “Gas Appliance” Directive 2009/142/EC, “Electromagnetic Compatibility” Directive 2004/108/EC, “Performance” Directive 92/42/EC and “Low Voltage” Directive 2006/95/EC.

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without prior notice.

DECLARES that:

Mauro Guareschi

Research & Development Director

Signature:

Page 4

INDEX

USER page INSTALLER page MAINTENANCE TECHNICIAN page

1 Boiler installation .......................................5

1.1 Installation recommendations. ................. 5

1.2 Main dimensions. ......................................6

1.3 Gas connection (Appliance

category II

1.4 Boiler hydraulic connection. .....................7

). ......................................... 7

2H3B/P

1.5 Solar circuit hydraulic connection. ..........7

1.6 Electrical connection. ................................8

1.7 Remote controls and room chrono-

thermostats (Optional). ............................. 8

1.8 External temperature

probe (Optional). ........................................9

1.9 Immergas ue systems. ...........................10

1.10 Tables of resistance factors

and equivalent lengths. ............................10

1.11 Installation of boiler type B with open

chamber and fan assisted (optional). ..... 12

1.12 Concentric horizontal kit installation. ...13

1.13 Concentric vertical kit installation. ........14

1.14 Separator kit installation. ......................... 15

1.15 Adaptor C9 kit installation. ....................16

1.16 Ducting of ues or technical slots. .........17

1.17 Conguration type B, open chamber

and fan assisted for indoors. ....................17

1.18 Flue gas exhaust to ue/chimney. ........... 17

1.19 Flues, chimneys, chimney

pots and terminals. ...................................18

1.20 Central heating circuit lling. .................18

1.21 Condensate trap lling. ............................18

1.22 Gas system start-up. ................................. 18

1.23 Solar circuit start-up. ................................ 18

1.24 Solar circuit lling. ...................................18

1.25 Boiler start up (ignition). .........................19

1.26 DHW mixing valve. ..................................19

1.27 Circulation pump......................................19

1.28 Solar circuit circulation pump. ...............21

1.29 Main circulation unit components. ........22

1.30 Domestic hot water storage tank unit. ...23

1.31 Kits available on request. .........................23

1.32 Boiler components. ...................................24

2 Use and maintenance instructions .........25

2.1 Cleaning and maintenance. .....................25

2.2 General warnings. ..................................... 25

2.3 Control panel.............................................25

2.4 Description of functioning states ..........26

2.5 Using the boiler. ........................................26

2.6 Troubleshooting. .......................................28

2.7 Parameters and information menu. .......30

2.8 Boiler shutdown. .......................................31

2.9 Restore central heating

system pressure.

........................................ 31

2.10 System drainage. ......................................31

2.11 Storage tank draining. ..............................31

2.12 Anti-freeze protection. .............................31

2.13 Case cleaning. ............................................ 31

2.14 Decommissioning. ....................................31

3 Boiler start-up (initial check) ..................32

3.1 Hydraulic diagram. ...................................32

3.2 Wiring diagram. ........................................33

3.3 Troubleshooting. .......................................33

3.4 Converting the boiler

to other types of gas. .................................34

3.5 Calibration of number of fan revs. ......... 34

3.6 Adjustment of the air-gas ratio. ..............34

3.7 Checks following conversion

to another type of gas. ..............................34

3.8 Programming the P.C.B. ............................35

3.9 "Chimney sweep function" ......................37

3.10 Pump anti-block function. ......................37

3.11 three-way anti-block function. ...............37

3.12 Radiators antifreeze function. ................37

3.13 Periodical P.C.B. self-check. .................... 37

3.14 Automatic vent function. .........................37

3.15 Yearly appliance check

and maintenance. ......................................38

3.16 Casing removal. ........................................39

3.17 Variable heat output. ................................43

3.18 Combustion parameters. .........................43

3.19 Technical data. ..........................................44

3.20 Key for Data nameplate. ..........................45

3.21 Technical parameters for mixed

boilers (in compliance

with Regulation 813/2013). .....................46

3.22 Product data sheet (in compliance

with Regulation 811/203). .......................46

3.23 Parameters for lling in the

assembly sheet. ..........................................47

Page 5

BOILER

1

INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

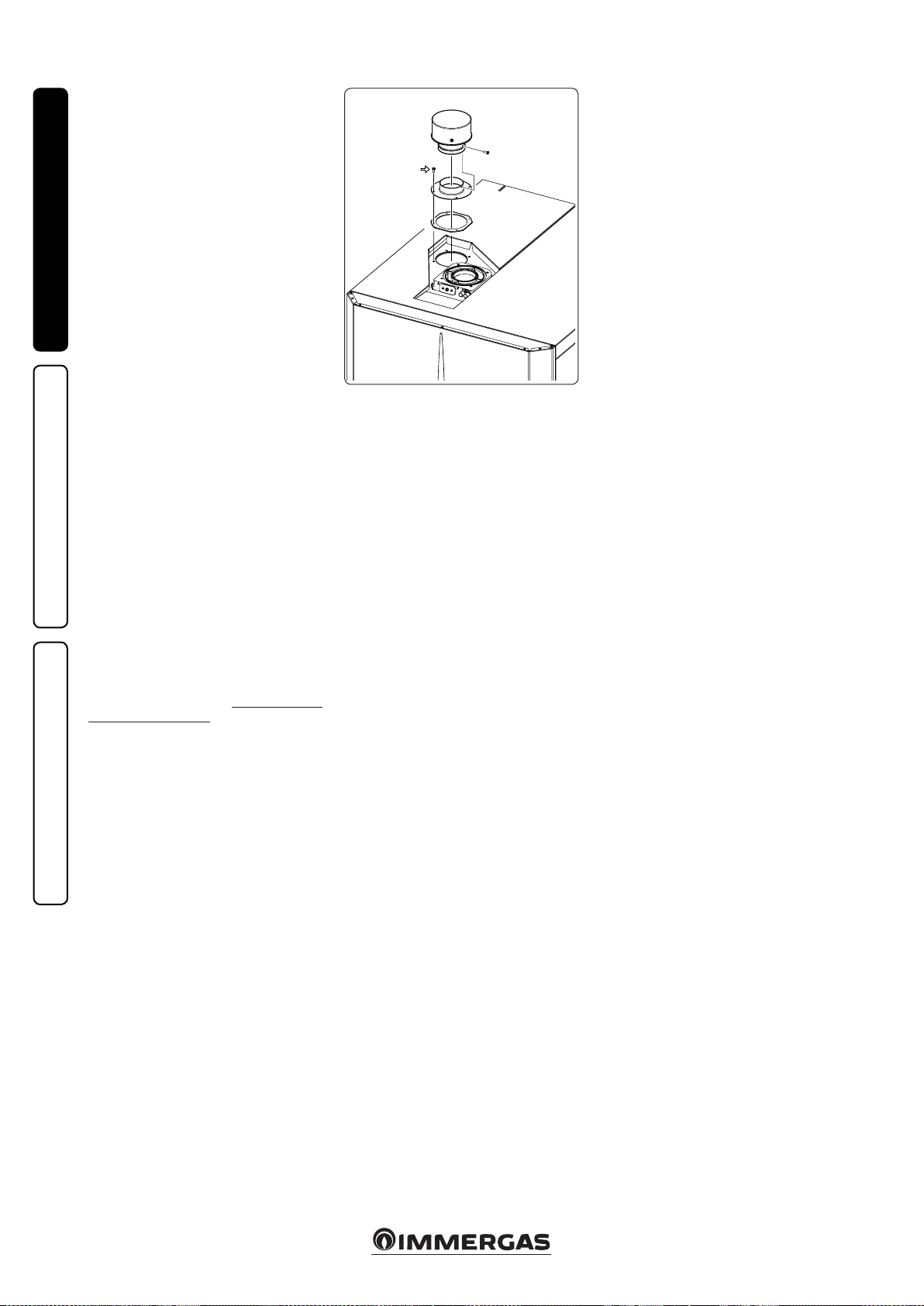

e Hercules Solar 26 2 ErP boiler has been designed uniquely for oor-installation, for heating

and production of DHW in domestic and similar

uses, with the possibility of coupling to a solar

panel system.

In the event the unit is installed in damp places,

one must provide an insulation system underneath it, to insulate it from the ground.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural) such to allow

(always in safety, efficiency and comfortable

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (to outdoors in the place for loading

and transporting the appliances and components) as well as their eventual replacement

with appliances and/or equivalent components.

By varying the type of installation the classication of the boiler also varies, precisely:

- Type B 23 or B53 boiler if installed using the

relevant terminal for air intake directly from

the room in which the boiler has been installed.

- Type C boiler if installed using concentric

pipes or other types of pipes envisioned for

sealed chamber boilers for air intake and expulsion of ue gas.

Note: appliance classication is provided in the

depictions of the various installation solutions

shown on the following pages.

Only professionally enabled companies are

authorised to install Immergas gas appliances.

Installation must be carried out according to

regulation standards, current legislation and in

compliance with local technical regulations and

the required technical procedures.

Before installing the appliance, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately. Packing materials (staples, nails, plastic bags, polystyrene foam, etc.)

constitute a hazard and must be kept out of the

reach of children. If the appliance is installed inside or between cabinets, ensure sucient space

for normal servicing; therefore it is advisable to

leave clearance of at least 40 cm on the right of

the boiler in order to open the lateral hatch and

a space of 3 cm between the remaining sides of

the boiler and the sides of the cabinet. Leave

adequate space above the boiler for possible

water and ue connections. Keep all ammable

objects away from the appliance (paper, rags,

plastic, polystyrene, etc.).

In the event of malfunctions, faults or incorrect

operation, turn the appliance o and contact an

authorised company (e.g. the Authorised Technical Assistance centre, which has specically

trained sta and original spare parts). Do not

attempt to modify or repair the appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

• Installation regulations:

- Installation in places with a re risk is prohibited (for example: garages, closed parking

stalls), gas appliances and relative ue ducts,

ue exhaust pipes and combustion air intake

pipes.

- Installation is also prohibited in places/environments that constitute common parts of

oce condominiums such as stairs, cellars,

entrance halls, attics, los, escape routes,

etc. if they are not located inside technical

compartments under the responsibility of

each individual building and only accessible

to the user (for the features of the technical

compartments, see the technical standards in

force).

Attention: these boilers are used to heat water

to below boiling temperature in atmospheric

pressure.

ey must be connected to a central heating

system and domestic hot water circuit suited to

their performance and capacity. ey must be

installed in rooms where the temperature cannot fall below 0°C and must not be exposed to

atmospheric agents.

"Anti-legionella" heat treatment of the Immergas

storage tank (activated by the specic function

present on the predisposed thermoregulatory

systems): during this stage, the temperature of

the water inside the storage tank exceeds 60°C

with a relative risk of burns. Keep this domestic

water treatment under control (and inform the

users) to prevent unforeseeable damage to people, animals, things.

N.B.: before starting the solar system, the solar

collector must be covered to protect the absorber from overheating and the operator from

scalding. e solar circuit must only be lled

when the hydraulic system has been completely

assembled and cannot be started before it has

been possible to eliminate the heat generated by

the solar collector.

Attention: to size the solar system, contact a

qualied heating engineer.

INSTALLERUSERMAINTENANCE TECHNICIAN

5

Page 6

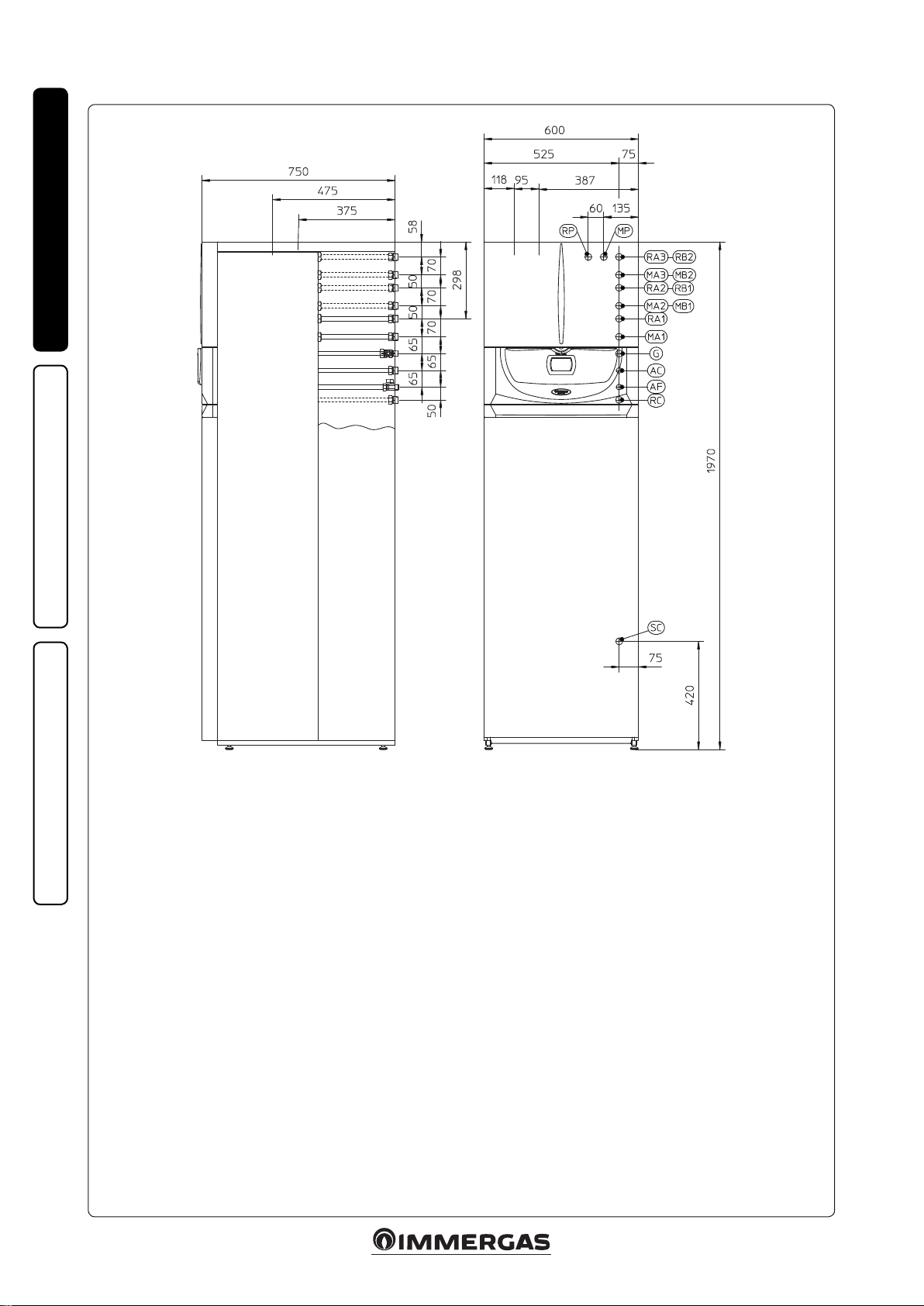

1.2 MAIN DIMENSIONS.

INSTALLERUSERMAINTENANCE TECHNICIAN

Key:

RP - Return to solar panels G 3/4”

MP - Flow from solar panels G 3/4”

RA3 - Zone 3 high temperature system return G 3/4” (optional)

MA3 - Zone 3 high temperature system ow G 3/4” (optional)

RA2 - Zone 2 high temperature system return G 3/4” (optional)

MA2 - Zone 2 high temperature system ow G 3/4” (optional)

RB2 - Zone 2 low temperature system return G 1” (optional)

MB2 - Zone 2 low temperature system ow G 1” (optional)

RB1 - Zone 1 low temperature system return G 1” (optional)

MB1 - Zone 1 low temperature system ow G 1” (optional)

RA1 - Zone 1 high temperature system return G 3/4”

MA1 - Zone 1 high temperature system ow G 3/4”

G - Gas supply G 1/2”

AC - DHW output G 3/4”

AF - DHW inlet G 3/4”

RC - Recirculation G 3/4” (optional)

SC - Condensate drain (min. internal diameter Ø 13 mm)

6

1-1

Page 7

1.3 GAS CONNECTION APPLIANCE

CATEGORY II

Our boilers are designed to operate with methane

gas (G20) and LPG. Supply pipes must be the

same as or larger than the 1/2”G boiler tting.

Before connecting the gas line, carefully clean

inside all the fuel feed system pipes to remove

any residue that could impair boiler eciency.

Also make sure the gas corresponds to that for

which the boiler is prepared (see boiler data

name plate). If different, the appliance must

be converted for operation with the other type

of gas (see converting appliance for other gas

types). e dynamic gas supply (methane or

LPG) pressure must also be checked according to the type used in the boiler, which must

comply with the technical standards in force, as

insucient levels can reduce generator output

and cause malfunctions. Ensure correct gas cock

connection. e gas supply pipe must be suitably

dimensioned according to current regulations

in order to guarantee correct gas ow rate to the

burner even in conditions of maximum generator output and to guarantee appliance eciency

(technical specications). e coupling system

must conform to technical standards in force.

Fuel gas quality. e appliance was designed

to operate with combustible gas free of impurities; otherwise it is advisable to t special lters

upstream of the appliance to restore the purity

of the fuel.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

2H3B/P

.

1.4 BOILER HYDRAULIC

CONNECTION.

Attention: in order not to void the condensa-

tion module warranty, before making the boiler

connections, carefully wash the heating system

(pipes, radiators, etc.) with special pickling or

descaling products to remove any deposits that

could compromise correct boiler operation.

A chemical treatment of the thermal system water is required, in compliance with the technical

standards in force, in order to protect the system

and the appliance from deposits (e.g., lime scale),

slurry or other hazardous deposits.

Water connections must be made in a rational

way using the couplings on the boiler template.

e boiler safety valves outlet must be connected

to a draining funnel. Otherwise, the manufacturer declines any responsibility in case of ooding

if the drain valve cuts in.

Attention: Immergas declines all liability in the

event of damage caused by the inclusion of automatic lling that is not its own brand.

In order to meet the system requirements established by the technical regulation in force in

relation to the pollution of drinking water, we

recommend installing the IMMERGAS antibackow kit to be used upstream of the cold

water inlet connection of the boiler. It is also

recommended that the heat transfer uid (e.g.

water + glycol) entered in the primary circuit

of the boiler (heating circuit), complies with the

local regulations in force.

Attention: to preserve the duration and the efciency features of the appliance, in the presence

of water whose features can lead to the deposit of

scale, installation of the “polyphosphate dispenser”

kit is recommended.

1.5 SOLAR CIRCUIT HYDRAULIC

CONNECTION.

Attention: when installing the solar circuit (pipes

and ttings), only use suitable materials that

withstand high temperatures.

e pump unit allows you to connect the storage

tank to the solar collector, making the water circulate according to the request of the control unit.

N.B.: the pipes for connection to the solar col-

lector must be ordered separately.

- Every time the solar system is emptied, the

system must be rinsed well with running water.

- e circulation unit is not designed for use in

direct contact with swimming pool water.

Condensate drain. To drain the condensate

produced by the appliance, it is necessary to

connect to the drainage system by means of acid

condensate resistant pipes, with an internal Ø of

at least 13 mm. e system connecting the appliance to the drainage system must be carried out

in such a way as to prevent freezing of the liquid

contained in it. Before appliance ignition, ensure

that the condensate can be correctly removed.

Aer rst ignition, check that the drain trap is

lled with condensate (para. 1.21). Also, comply

with national and local regulations on discharging waste waters.

INSTALLERUSERMAINTENANCE TECHNICIAN

7

Page 8

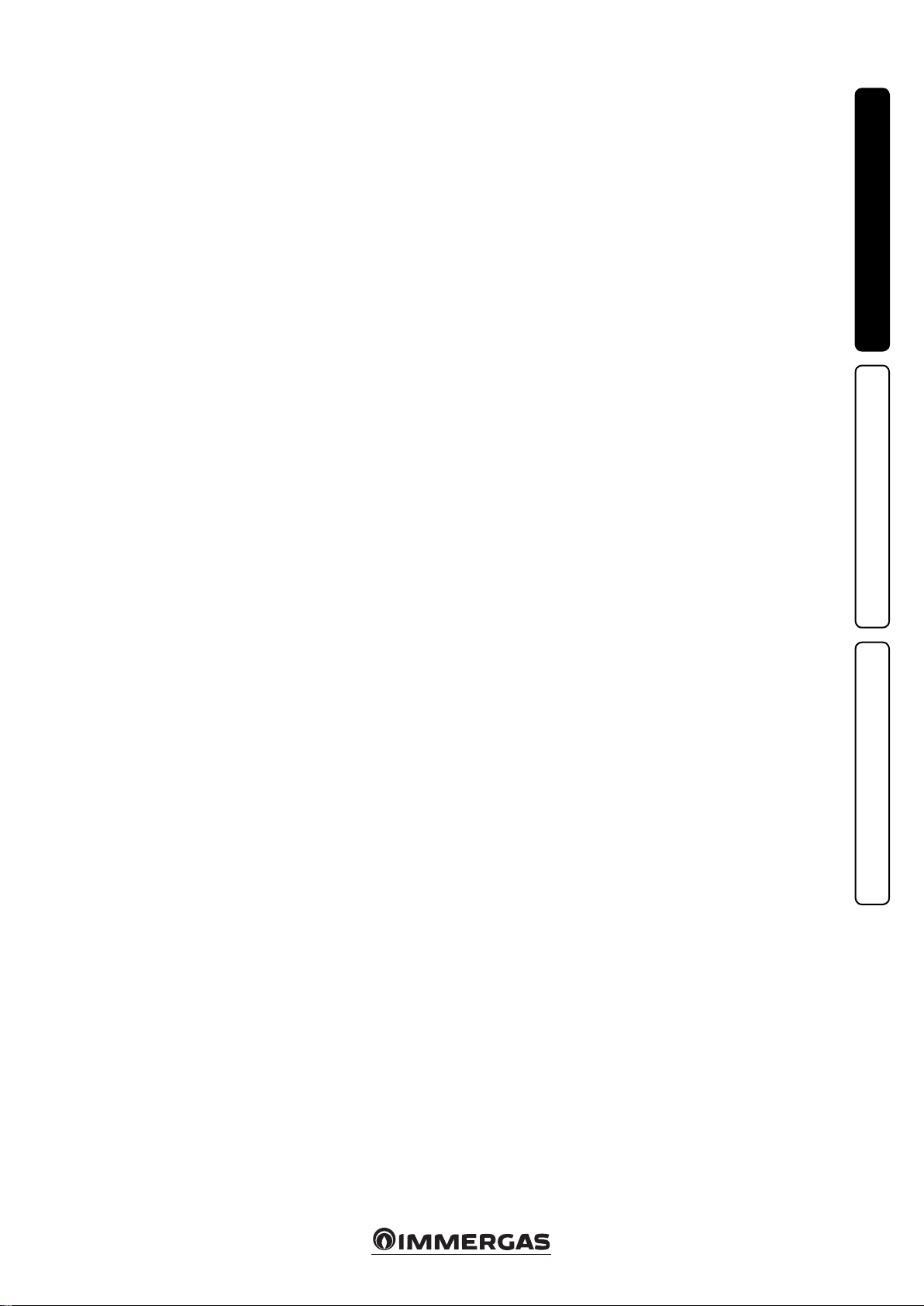

CAVO COMANDO REMOTO

1.6 ELECTRICAL CONNECTION.

e “Hercules Solar 26 2 ErP” boiler has an

IPX5D protection rating for the entire appliance.

Electrical safety of the appliance is reached only

when it is correctly connected to an ecient

earthing system as specied by current safety

standards.

Attention: Immergas S.p.A. disclaims any liability for damage or physical injury caused

by failure to connect the boiler to an ecient

earthing system or failure to comply with the

reference standards.

INSTALLERUSERMAINTENANCE TECHNICIAN

Also ensure that the electrical installation corresponds to maximum absorbed power specications as shown on the boiler data nameplate.

Boilers are supplied complete with an “X” type

power cable without plug.

e power supply cable must be connected to

a 230V ±10% / 50Hz mains supply respecting

L-N polarity and the earth connection

this network must also feature a multi-pole

circuit breaker of class III overvoltage category.

When replacing the power supply cable, contact

a qualied rm (e.g. the Authorised Aer-Sales

Technical Assistance Service).

e power cable must be laid as shown (Fig. 1-3).

In the event of mains fuse replacement on the

P.C.B., use a 3.15A quick-blow fuse. For the main

power supply to the appliance, never use adapters, multiple sockets or extension leads.

Relay (Optional)

DIM (Op-

tional)

Solar panels electrical connection. Only use an

appropriately sized cable to make the connections. Making them follow the same route as the

power supply cable (in the relevant pipe), make

the connections on the control panel on clamps

45 and 46, eliminating the resistance R15 (Fig.

1-2). Connect the supplied probe on the solar

panel and position it in the relevant seat.

Installation with system operating at direct

low temperature. e boiler can directly feed a

low temperature system by acting on parameter

“P66” (Par. 3.8) and setting the delivery temperature adjustment range “P66/A” and “P66/B”. In

this situation it is good practice to insert a safety

device in series with the power supply and boiler.

is device is made up from a thermostat with

a temperature limit of 60°C. e thermostat

must be positioned on the system ow pipe at

a distance of at least 2 metres from the boiler.

on

1.7 REMOTE CONTROLS AND ROOM

CHRONOTHERMOSTATS

OPTIONAL.

The boiler is prepared for the application of

room chrono-thermostats or remote controls,

which are available as optional kits. All Immergas

chrono-thermostats are connected with 2 wires

only. Carefully read the user and assembly instructions contained in the accessory kit.

• On/O digital Immergas chrono-thermostat

(Fig. 1-3). e chrono-thermostat allows:

Super CAR (Optional)

CAVO ALIMENTAZIONE

POWER SUPPLY CABLE

CAVO SONDA SOLARE

SOLAR PROBE CABLE

REMOTE CONTROL CABLE

- set two room temperature value: one for

daytime (comfort temperature) and one for

night-time (reduced temperature);

- set a weekly program with four daily switch

on and switch o times;

- select the required operating mode from the

various possible alternatives:

- manual mode (with adjustable temperature).

- automatic mode (with set program).

- forced automatic mode (momentarily

changing the temperature of the automatic

program).

e chrono-thermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• ere are two types of remote controls availa-

ble: Comando Amico Remoto remote controlV2

V2

) (Fig. 1-4) and Super Comando Amico

(CAR

Remoto remote control (Super CAR) (Fig. 1-5)

both with a climate chrono-thermostat operation. In addition to the functions described in

the previous point, the chrono-thermostat

panels enable the user to control all the important information regarding operation of

the appliance and the central heating system

with the opportunity of easily intervening on

the previously set parameters without having to

go to the place where the appliance is installed.

e panel is provided with self-diagnosis to

display any boiler functioning anomalies.

e climate chrono-thermostat incorporated

into the remote panel enables the system ow

temperature to be adjusted to the actual needs

1-2

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving in

running costs. e chrono-thermostat is fed

directly by the boiler by means of the same 2

wires used for transmitting data between boiler

and device.

Important: if the system is subdivided into areas

using the relevant kit, the CAR

CAR must be used with its climate thermostat

function disabled, i.e. it must be set to On/O

mode.

V2

CAR

, Super CAR or On/O chrono-ther-

mostat electrical connection (Optional). e

operations described below must be performed

aer having removed the voltage from the appli-

1-3

ance. Any On/O room chrono-thermostat must

be connected to clamps 40 and 41 eliminating

jumper X40 (Fig. 3-2). Make sure that the On/

O thermostat contact is of the “clean” type, i.e.

independent of the mains voltage, otherwise the

P.C.B. would be damaged. Any CAR V2 or Super

CAR must be connected by means of terminals

IN+ and IN- to terminals 42 and 43 on the

P.C.B. (in the boiler), eliminating jumper X40

and respecting polarity (Fig. 3-2). Connection

with the wrong polarity prevents functioning, but

without damaging the CARV2 e boiler can only

be connected to one remote control.

Important: if the Comando Amico Remoto

remote control

V2

is used, arrange two separate

lines in compliance with current regulations

regarding electrical systems. No boiler pipes

must ever be used to earth the electric system or

telephone lines. Ensure elimination of this risk

before making the boiler electrical connections.

V2

and the Super

8

Page 9

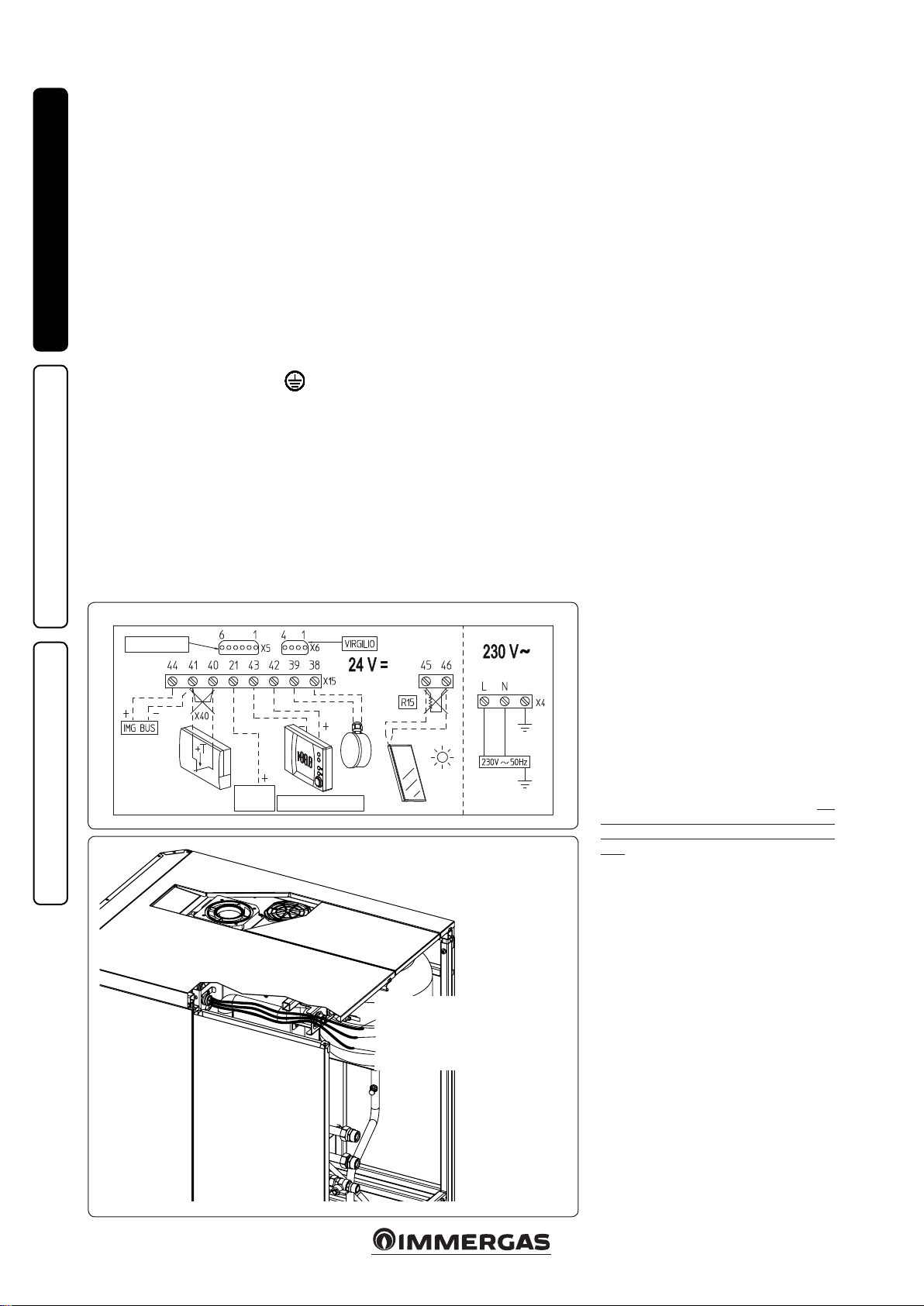

1.8 EXTERNAL TEMPERATURE PROBE

OPTIONAL.

e boiler is designed for the application of the

external temperature probe (Fig. 1-6), which is

available as an optional kit. Refer to the relative

instruction sheet to position the external probe.

e probe can be connected directly to the boiler

electrical system and allows the max. system

ow temperature to be automatically decreased

when the external temperature increases, in

order to adjust the heat supplied to the system

according to the change in external temperature. e external probe always operates when

connected, regardless of the presence or type of

room chrono-thermostat used and can work in

combination with Immergas timer thermostats.

e correlation between system ow temperature

and external temperature is determined by the

parameters set in menu “M5” under item “P66”

according to the curves represented in the diagram (Fig. 1-7). e electric connection of the

external probe must be made on clamps 38 and

39 on the boiler P.C.B. (Fig. 3-2).

INSTALLERUSERMAINTENANCE TECHNICIAN

Comando Amico Remoto remote control

On/O digital chrono-thermostat.

45

31

V2

(CARV2)

1-4 1-5

Super Comando Amico Remoto remote control

(Super CAR)

Correction law of the ow temperature depending on the external tem-

perature and user adjustment of the central heating temperature.

58

1-6

EXTERNAL PROBE

TM-MAX/MIN = Selected ow

temp. range.

TE = External temperature.

1-7

9

Page 10

1.9 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the boilers regarding the installation of

air intake terminals and ue exhaust, which are

fundamental for boiler operation.

Attention: the boiler must be installed exclusively with an original Immergas “Green

Range” inspectionable air intake device and

fumes extraction system made of plastic, as

required by the regulations in force.

e plastic pipes cannot be installed outdoors,

INSTALLERUSERMAINTENANCE TECHNICIAN

for tracts longer than 40 cm, without suitable

protection from UV rays and other atmospheric agents.

is system can be identied by an identication mark and special distinctive marking

bearing the note: “only for condensing boilers”.

• Resistance factors and equivalent lengths. Each

ue component has a Resistance Factor based

on experimental tests and specied in the table

below. e Resistance Factor for individual

components is independent from the type of

boiler on which it is installed and has a dimensionless size. It is however, conditioned by the

temperature of the uids that pass through the

pipe and therefore, varies according to applications for air intake or ue exhaust. Each single

component has a resistance corresponding to

a certain length in metres of pipe of the same

diameter; the so-called equivalent length,

can be obtained from the ratio between the

relative Resistance Factors. All boilers have an

experimentally obtainable maximum Resistance

Factor equal to 100. e maximum Resistance

Factor allowed corresponds to the resistance

encountered with the maximum allowed pipe

length for each type of Terminal Kit. This

information allows calculations to be made to

verify the possibility of setting up various ue

congurations.

• Positioning the gaskets (black) for “green

range” ue systems. Position the gasket correctly (for bends and extensions) (Fig. 1-8):

- gasket (A) with notches, to use for bends;

- gasket (B) without notches, to use for exten-

sions;

N.B.: if component lubrication (already car-

ried out by the manufacturer) is not sucient,

remove the residual lubricant using a dry cloth,

then to ease tting coat the parts with talc, supplied in the kit.

• Coupling extension pipes and concentric

elbows. To install push-tting extensions with

other elements of the ue, proceed as follows:

Install the concentric pipe or elbow with the

male side (smooth) on the female side (with lip

seal) to the end stop on the previously installed

element in order to ensure sealing eciency of

the coupling.

Attention: if the exhaust terminal and/or

concentric extension pipe needs shortening,

consider that the internal duct must always

protrude by 5 mm with respect to the external

duct.

• N.B.: for safety purposes, do not obstruct the

boiler intake/exhaust terminal, even temporaril y.

• N.B.: when installing horizontal pipes, a mini-

mum inclination of 3% must be maintained and

a section clip with pin must be installed every

3 metres.

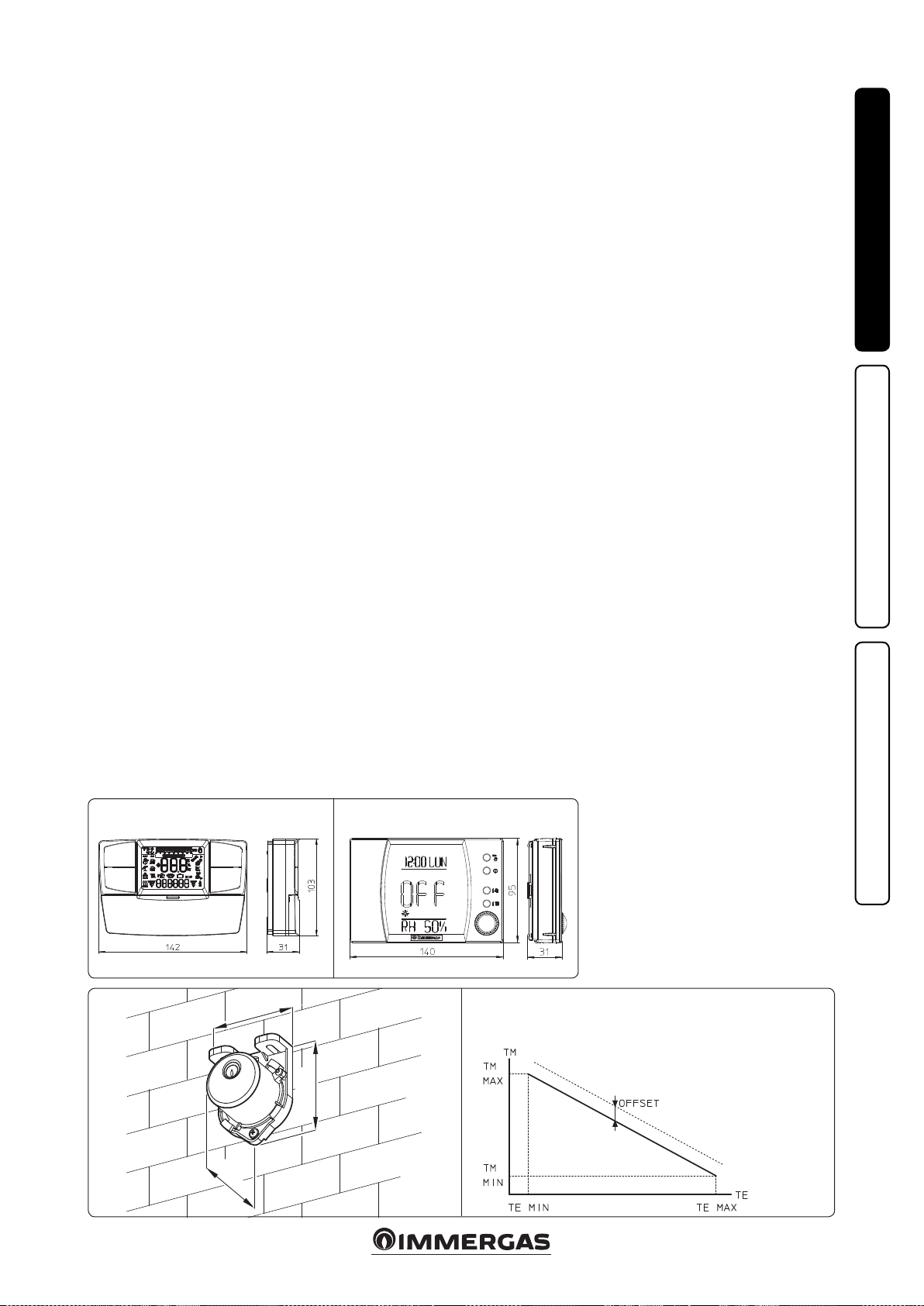

1.10 TABLES OF RESISTANCE FACTORS

AND EQUIVALENT LENGTHS.

TYPE OF DUCT

Concentric pipe Ø 80/125 m 1

Concentric bend 90° Ø 80/125

Concentric bend 45° Ø 80/125

Terminal complete with concentric

horizontal intake-exhaust Ø 80/125

1-8

Resistance

Factor

(R)

2.1

3.0

2.1

2.8

(A)

(B)

Equivalent length

in m of concentric

pipe Ø 80/125

1

1.4

1

1.3

Terminal complete with concentric

vertical intake-exhaust Ø 80/125

Concentric bend 90° Ø 80/125 with

inspection

Stub pipe with inspection Ø 80/125

10

3.6

3.4

3.4

1.7

1.6

1.6

Page 11

TYPE OF DUCT

Resistance

Factor

(R)

Equivalent length

in m of concentric

pipe Ø 60/100

Equivalent length

in metres of pipe

Ø 80

Equivalent length

in metres of pipe

Ø 60

Equivalent length

in m of concentric

pipe Ø 80/125

Concentric pipe Ø 60/100

m 1

Concentric bend 90° Ø

60/100

Concentric bend 45° Ø

60/100

Terminal complete with

concentric horizontal

intake-exhaust Ø 60/100

Concentric horizontal

intake- exhaust terminal

Ø 60/100

Terminal complete with

concentric vertical intakeexhaust Ø 60/100

Concentric vertical intakeexhaust terminal Ø 60/100

Pipe Ø 80 m 1

Complete intake terminal

Ø 80 m 1

Intake terminal Ø 80

Exhaust terminal Ø 80

Bend 90° Ø 80

Bend 45° Ø 80

Pipe Ø 60 m 1 for ducting

Bend 90° Ø 60 for ducting

Reduction Ø 80/60

Intake and

Exhaust 6.4

Intake and

Exhaust 8.2

Intake and

Exhaust 6.4

Intake and

Exhaust 15

Intake and

Exhaust 10

Intake and

Exhaust 16.3

Intake and

Exhaust 9

Intake 0.87 m 0.1 Intake m 1.0

Exhaust 1.2 m 0.2 Exhaust m 1.0

Intake 3 m 0.5 Intake m 3.4 Exhaust m 0.9 m 1.4

Intake 2.2 m 0.35 Intake m 2.5

Exhaust 1.9 m 0.3 Exhaust m 1.6

Intake 1.9 m 0.3 Intake m 2.2

Exhaust 2.6 m 0.4 Exhaust m 2.1

Intake 1.2 m 0.2 Intake m 1.4

Exhaust 1.6 m 0.25 Exhaust m 1.3

Exhaust 3.3 m 0.5

Exhaust 3.5 m 0.55

Intake and

Exhaust 2.6

m 1

m 1.3

m 1

m 2.3

m 1.5

m 2.5

m 1.4

m 0.4

Intake m 7.3

Exhaust m 5.3

Intake m 9.4

Exhaust m 6.8

Intake m 7.3

Exhaust m 5.3

Intake m 17.2

Exhaust m 12.5

Intake m 11.5

Exhaust m 8.3

Intake m 18.7

Exhaust m 13.6

Intake m 10.3

Exhaust m 7.5

Intake 3.8

Exhaust 2.7

Intake 4.0

Exhaust 2.9

Intake m 3.0

Exhaust m 2.1

Exhaust m 1.9 m 3.0

Exhaust m 2.5 m 3.9

Exhaust m 1.9 m 3.0

Exhaust m 4.5 m 7.1

Exhaust m 3.0 m 4.7

Exhaust m 4.9 m 7.7

Exhaust m 2.7 m 4.3

Exhaust m 0.4

Exhaust m 0.6

Exhaust m 0.8

Exhaust m 0.5

Exhaust m 1.0 m 1.5

Exhaust m 1.1 m 1.6

Exhaust m 0.8 m 1.2

INSTALLERUSERMAINTENANCE TECHNICIAN

m 0.4

m 0.5

m 1

m 0.9

m 0.9

m 1.2

m 0.5

0.7

Terminal complete with

exhaust

vertical Ø 60 for ducting

Exhaust 12.2 m 1.9

11

Intake m 14

Exhaust m 3.7 m 5.8

Exhaust m 10.1

Page 12

1.11 INSTALLATION OF BOILER TYPE B

WITH OPEN CHAMBER AND FAN

ASSISTED OPTIONAL.

In this conguration the relevant terminal must

be used (present in the intake kit for the installation in question) to be placed on the intake hole

above the sealed chamber (Fig. 1-8). Air intake

takes place directly from the environment and

ue exhaust in individual chimney or to the outside. e boiler in this conguration, following

the assembly instructions stated on the relative

instruction sheet, is classied as type B

INSTALLERUSERMAINTENANCE TECHNICIAN

(according to the applicable regulations).

With this conguration:

air intake takes place directly from the environ-

ment in which the boiler is installed and only

functions in permanently ventilated rooms

- the ue gas exhaust must be connected to its

own individual ue or ducted directly into the

external atmosphere;

- Type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the processing of

wood, coal dust, cement, etc.), which may be

harmful for the components of the appliance

and jeopardise operation;

- in B23 and B53 conguration, the boilers must

not be installed in bedrooms, bathrooms or in

studio ats;

- installation of appliances in B23 or B53 congura-

tion is recommended in non-residential premises and which are permanently ventilated.

The technical regulations in force must be

respected.

Max. length of exhaust duct. e ue pipe (both

vertical or horizontal) can be extended to a max.

length of 30 linear metres.

or B53

23

1-9

X4

12

Page 13

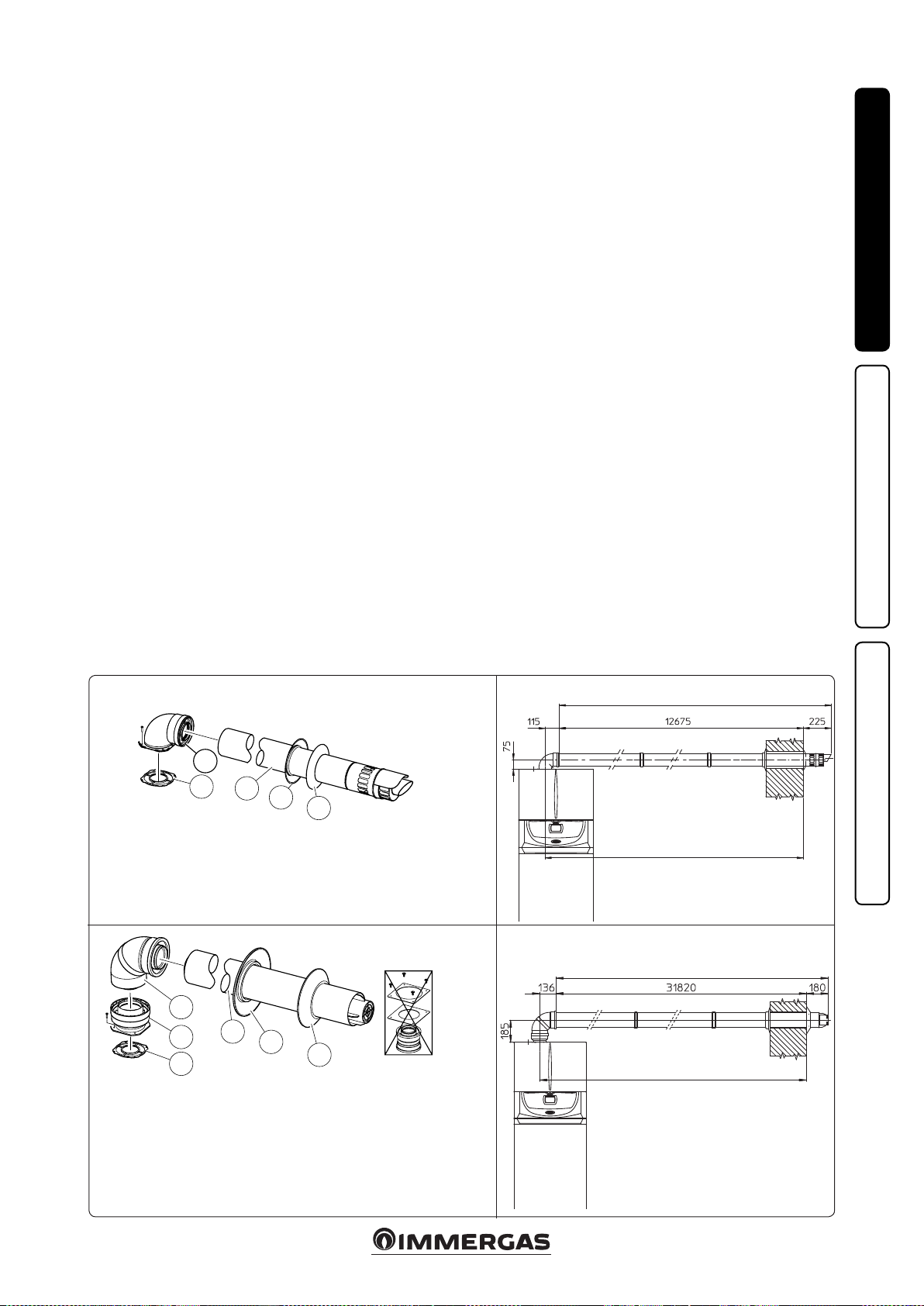

1.12 CONCENTRIC HORIZONTAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

e installation of this terminal is governed by

the applicable technical standards and subsequent amendments, that enables wall ue exhaust

for condensing boilers with low NOx in the cases

provided. e position of the terminal (in terms

of distances from openings, overlooking buildings, oor, etc.) must be in compliance with the

regulations in force.

is terminal is connected directly to the outside

of the building for air intake and ue exhaust. e

horizontal kit can be installed with the rear, right

side, le side or front outlet. For installation with

frontal outlet, one must use the xing plate and

a concentric bend coupling in order to ensure

sucient space to carry out the tests required

by law upon commissioning.

• External grid. Both the Ø 60/100 and Ø 80/125

intake/exhaust terminal, if properly installed, is

pleasant to look at on the outside of the building. Make sure that the external silicone wall

sealing plate is properly inserted in the wall.

N.B.: for proper system operation the terminal

with grid must be installed correctly ensuring

that, the "high" indication on the terminal is

observed during installation.

Horizontal intake-exhaust kit Ø 60/100 Kit

assembly (Fig. 1-10): install the bend with ange

(2) on the central hole of the boiler, positioning

gasket (1) with the circular projections downwards in contact with the boiler flange, and

tighten using the screws supplied with the kit. Fit

the Ø 60/100 (3) concentric terminal pipe with

the male side (smooth) to the female side of the

bend (2) up to the end stop; making sure that the

internal and external wall sealing plate have been

tted, this will ensure sealing and joining of the

elements making up the kit.

• Extensions for Ø 60/100 horizontal kit (Fig.

1-11). e kit with this conguration can be

extended up to a max. 12.9 horizontal m in-

cluding the terminal with grid and excluding

the concentric bend leaving the boiler. is

conguration corresponds to a resistance factor

of 100. In this case the special extensions must

be requested.

Immergas also provides a Ø 60/100 simplied

terminal, which in combination with its extension kits allows you to reach a maximum extension of 11.9 metres.

Horizontal intake-exhaust kit Ø 80/125 Kit

assembly (Fig. 1-12): to install the kit Ø 80/125

one must use the anged adapter kit in order

to install the ue system Ø 80/125. Install the

anged adaptor (2) on the central hole of the

boiler, positioning gasket (1) with the circular

projections downwards in contact with the boiler

ange and tighten using the screws supplied with

the kit. Engage the bend (3) with the male side

(smooth) to the end stop on the adapter (1). Fit

the Ø 80/125 (5) concentric terminal pipe with

the male side (smooth) to the female side of the

bend (4) (with lip seals) up to the end top; making

sure that the internal (6) and external wall sealing

plate (7) have been tted, this will ensure sealing

and joining of the elements making up the kit.

• Extensions for horizontal kit Ø 80/125 (Fig.

1-13). e kit with this conguration can be

extended up to a max. length of 32 m, including the terminal with grid and excluding the

concentric bend leaving the boiler. If additional components are assembled, the length

equivalent to the maximum allowed must be

subtracted. In this case the special extensions

must be requested.

INSTALLERUSERMAINTENANCE TECHNICIAN

2

1

3

4

e kit includes:

N° 1 - Gasket (1)

N° 1 - Concentric bend Ø 60/100 (2)

N° 1 - Int./exhaust concentric terminal Ø 60/100 (3)

N° 1 - Internal wall sealing plate (4)

N° 1 - External wall sealing plate (5)

5

3

2

1

e adaptor kit includes:

N° 1 - Gasket (1)

N° 1 - Adaptor Ø 80/125 (2)

1-12

4

5

6

e Kit Ø 80/125 includes:

N° 1 - Concentric bend Ø 80/125 a 87° (3)

N° 1 - Int./exhaust concentric terminal Ø

80/125 (4)

N° 1 - Internal wall sealing plate (5)

N° 1 - External wall sealing plate (6)

e remaining kit components must not be

used

C

13

C

13

Max 12900 mm

Max 12790 mm

Max 32000 mm

Max 31956 mm

C

13

1-111-10

C

13

1-13

13

Page 14

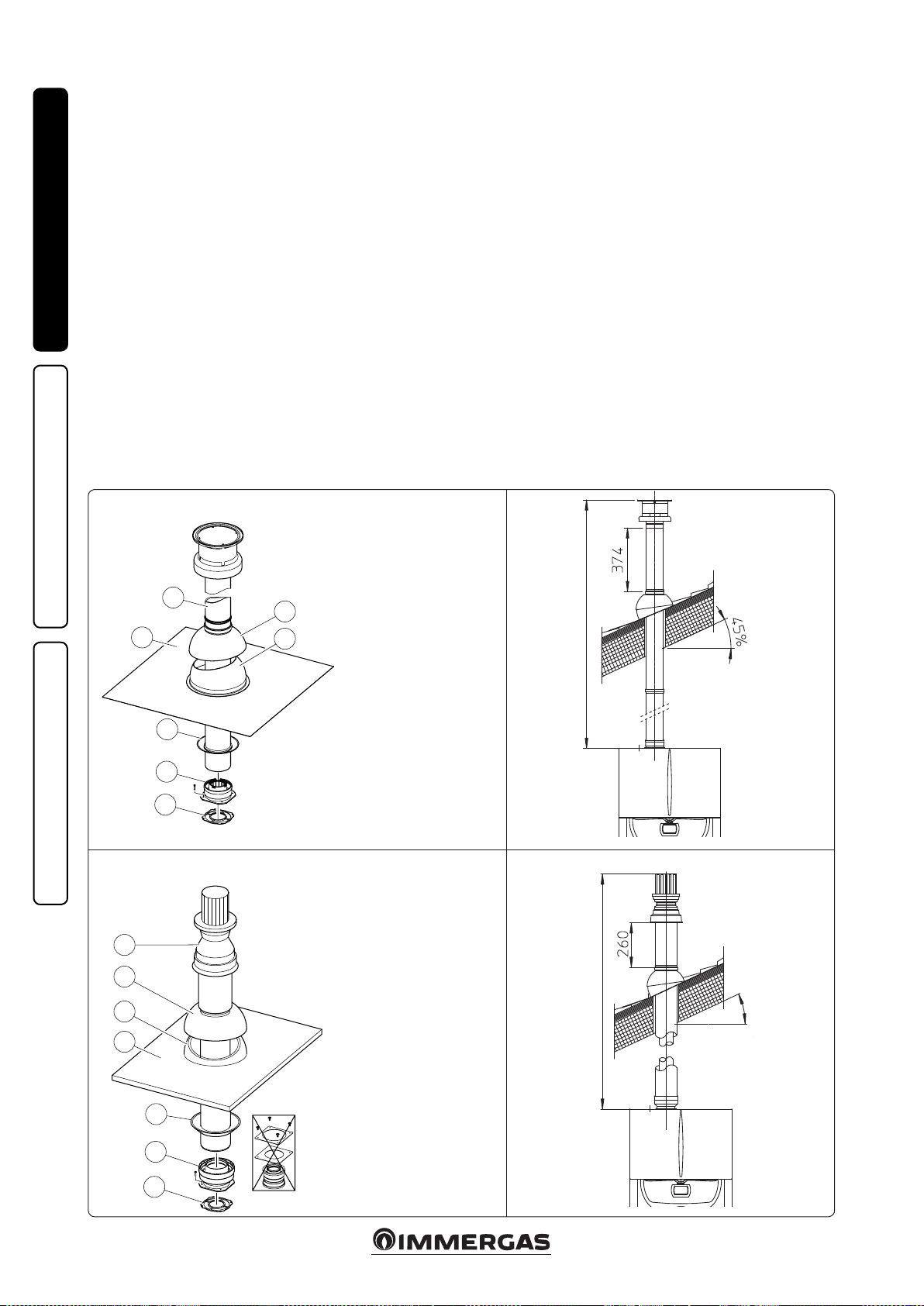

1.13 CONCENTRIC VERTICAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Concentric vertical intake and exhaust kit. is

vertical terminal is connected directly to the outside of the building for air intake and ue exhaust.

N.B.: the vertical kit with aluminium tile enables

installation on terraces and roofs with a maximum slope of 45% (approx 25°) and the height

between the terminal cap and half-shell (374 mm

INSTALLERUSERMAINTENANCE TECHNICIAN

for Ø 60/100 and 260 mm for Ø 80/125) must

always be observed.

Vertical kit with aluminium tile Ø 60/100.

Kit assembly (Fig. 1-14): install the concentric

ange (2) on the central hole of the boiler, positioning gasket (1) with the circular projections

downwards in contact with the boiler ange, and

tighten using the screws supplied with the kit.

Installation of the fake aluminium tile: replace

the tiles with the aluminium sheet (4), shaping

it to ensure that rainwater runs o. Position the

xed half-shell (6) on the aluminium tile and insert the intake-exhaust pipe (5). Fit the Ø 60/100

(3) concentric terminal pipe with the male end

(5) (smooth) into the ange (2) up to the stop;

making sure that the wall sealing plate has been

tted (3), this will ensure sealing and joining of

the elements making up the kit.

Note: when the boiler is installed in areas where

very rigid temperatures can be reached, a special

anti-freeze kit is available that can be installed as

an alternative to the standard kit.

• Extensions for vertical kit Ø 60/100 (Fig. 1-15).

e kit with this conguration can be extended

to a max. straight vertical length of 14.4 m,

including the terminal. This configuration

corresponds to a resistance factor of 100. In

this case specic extensions must be requested.

Vertical kit with aluminium tile Ø 80/125.

Kit assembly (Fig. 1-16): to install the kit Ø

80/125 one must use the anged adapter kit in

order to install the ue system Ø 80/125. Install

the anged adaptor (2) on the central hole of the

boiler, positioning gasket (1) with the circular

projections downwards in contact with the boiler

ange and tighten using the screws supplied

with the kit. Installation of the fake aluminium

tile: replace the tiles with the aluminium sheet

(4), shaping it to ensure that rainwater runs o.

Position the xed half-shell (5) on the aluminium

tile and insert the intake-exhaust pipe (7). Fit the

Ø 80/125 concentric terminal pipe with the male

side (smooth) to the female side of the adapter (1)

(with lip gaskets) up to the end stop; making sure

that the wall sealing plate (3) has been tted, this

will ensure sealing and joining of the elements

making up the kit.

• Extensions for vertical kit Ø 80/125 (Fig. 1-17).

e kit with this conguration can be extended

up to a max. length of 32 m including the terminal. If additional components are assembled,

the length equivalent to the maximum allowed

must be subtracted. In this case specic extensions must be requested.

1-14

1-16

C

5

4

3

2

1

7

6

e Kit includes:

N° 1 - Gasket (1)

N° 1 - Female concentric ange (2)

N° 1 - Wall sealing plate (3)

N° 1 - Aluminium tile (4)

N° 1 - Int./exhaust concentric pipe Ø

60/100 (5)

N° 1 - Fixed half-shell (6)

N° 1 - Mobile half-shell (7)

C

e adaptor kit includes:

7

6

5

4

3

N° 1 - Gasket (1)

N° 1 - Adaptor Ø 80/125 (2)

e Kit Ø 80/125 includes:

N° 1 - Wall sealing plate (3)

N° 1 - Aluminium tile (4)

N° 1 - Fixed half-shell (5)

N° 1 - Mobile half-shell (6)

N° 1 - Int./exhaust concentric

pipe Ø 80/125 (7)

e remaining kit components

must not be used

1-15

33

Max 14400 mm

1-17

33

Max 32000 mm

Max 45%

C

33

C

33

2

1

14

Page 15

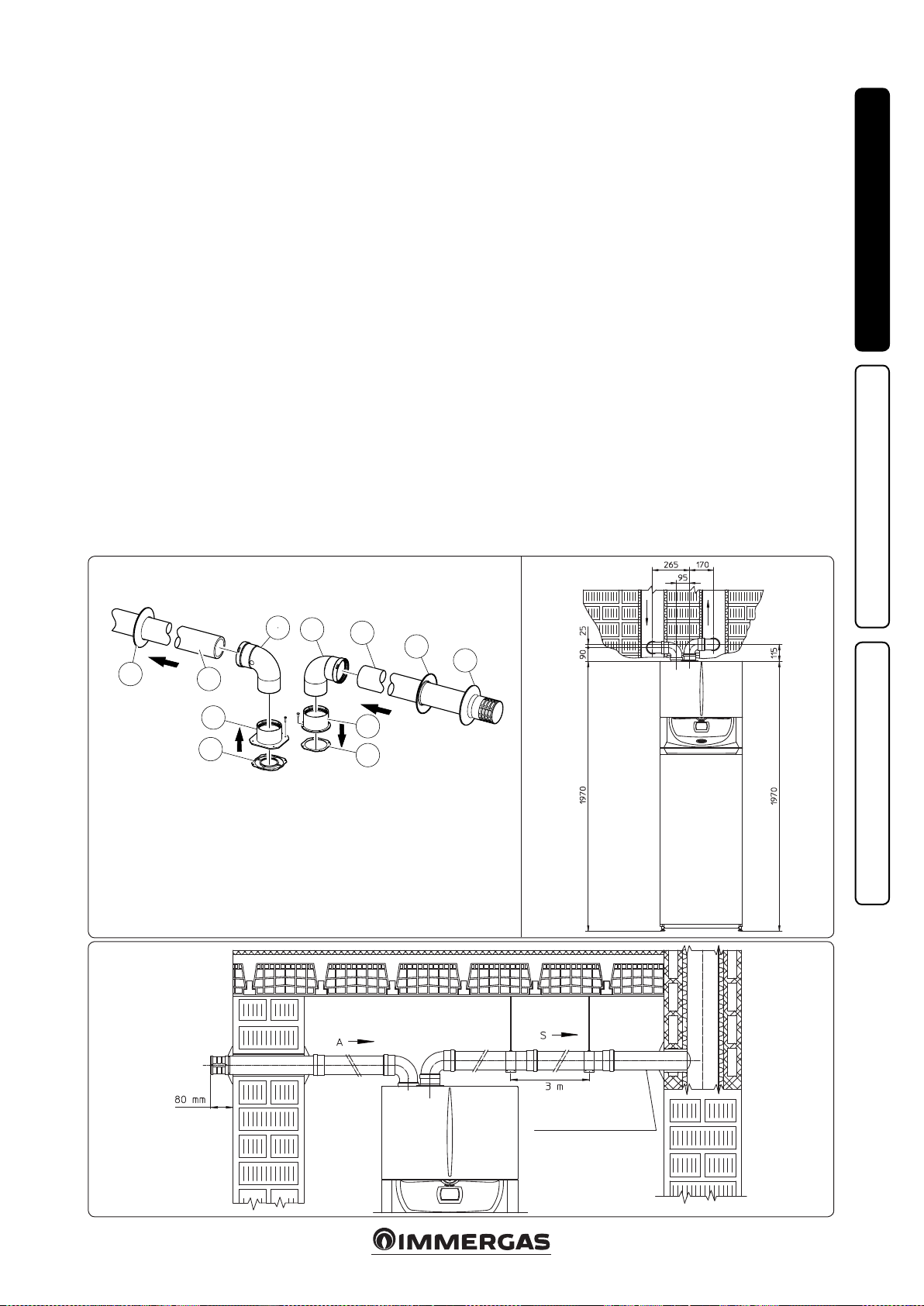

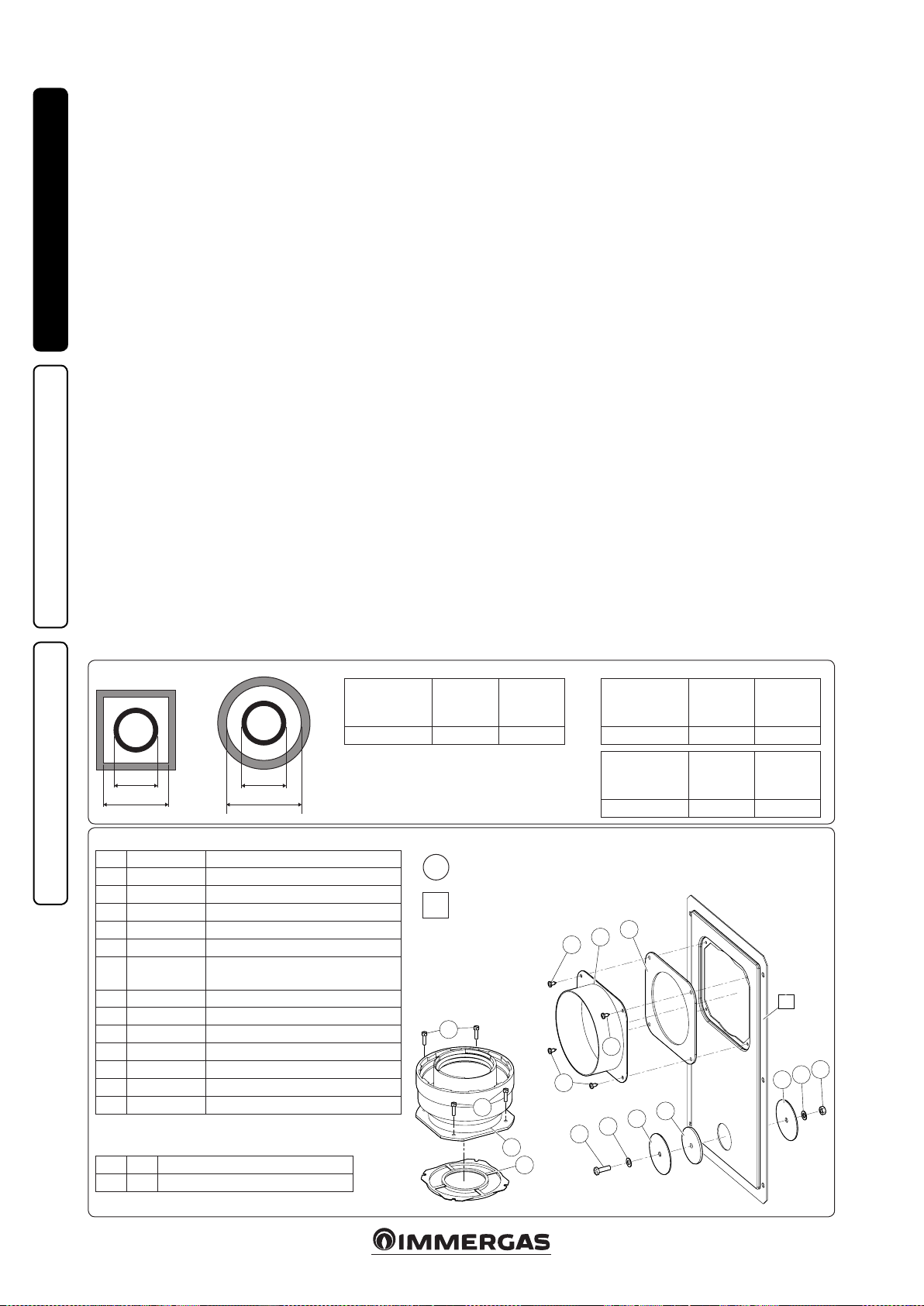

1.14 SEPARATOR KIT INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Separator kit Ø 80/80. is kit allows air to come

in from outside the building and the fumes to exit

from the chimney or ue through divided ue

exhaust and air intake pipes. Combustion products are expelled from pipe (S) (in plastic, so as

to resist acid condensate). Air is taken in through

duct (A) for combustion (this is also in plastic).

e intake pipe (A) can be installed either on the

right or le hand side of the central exhaust pipe

(S). Both ducts can be routed in any direction.

• Kit assembly (Fig. 1-18): install ange (4) on

the central hole of the boiler, positioning gasket

(1) with the circular projections downwards in

contact with the boiler ange, and tighten using

the hex screws with at tip supplied with the

kit. Remove the at ange present in the most

external hole and replace it with the ange (3),

positioning the gasket (2) already present in

the boiler and tighten using the supplied selfthreading screws. Fit the male side (smooth) to

the bends (5) in the female side of the anges

(3 and 4). Fit the intake terminal (6) with the

male side (smooth) in the female side of the

bend (5) up to the end stop, ensuring that the

internal and external wall sealing plates are

tted. Fit the exhaust pipe (9) with the male

side (smooth) to the female side of the bend

(5) up to the end stop; making sure that the

internal wall sealing plate has been tted, this

will ensure sealing and joining of the elements

making up the kit.

• Installation clearances (Fig. 1-19). e minimum installation clearance measurements of

the Ø 80/80 separator terminal kit have been

stated in some limit conditions.

• Extensions for separator kit Ø 80/80. The

maximum vertical straight length (without

bends) that can be used for Ø 80 intake and

exhaust pipes is 41 metres, regardless from

whether they are used for intake or exhaust.

e maximum horizontal straight length (with

bend in suction and in exhaust) that can be

used for Ø 80 intake and exhaust pipes is 36

metres, regardless from whether they are used

for intake or exhaust.

N.B.: to favour the removal of possible condensate forming in the exhaust pipe, tilt the pipes

towards the boiler with a minimum slope of

1.5% (Fig. 1-20).

INSTALLERUSERMAINTENANCE TECHNICIAN

1-18

5

5

6

C53* - C

7

nal.

S

9

4

1

N° 2 - Bend 90° Ø 80 (5)

N° 1 - Intake terminal Ø 80 (6)

N° 2 - Internal wall sealing plates (7)

N° 1 - External wall sealing plate (8)

N° 1 - Drain pipe Ø 80 (9)

A

3

2

7

e kit includes:

N° 1 - Exhaust gasket (1)

N° 1 - Flange seal gasket (2)

N° 1 - Female intake ange (3)

N° 1 - Female drain ange (4)

* to er complete C53 conguration also provide for a roof discharge termi-

1-19

83

C

43

8

C

83

15

Minimum slope 1.5 %

1-20

Page 16

1.15 ADAPTOR C9 KIT INSTALLATION.

is kit allows an Immergas boiler to be installed

in "C

" conguration, with combustion air intake

93

directly from the sha where the ue gas exhaust

is, obtained by means of a ducting system.

System composition.

e system must be combined with the following

components (sold separately) to be functional

and complete:

- kit C93 Ø 100 or Ø125 version

- ducting kit Ø 60 or Ø 80

INSTALLERUSERMAINTENANCE TECHNICIAN

- fumes exhaust kit Ø 60/100 or Ø 80/125 congured according to the installation and type

of boiler.

Kit Assembly.

- Mount the components of kit "C9" on the door

(A) of the ducting system (Fig. 1-22).

- (Version Ø 125 only) mount the anged adaptor (11) interposing the concentric gasket (10)

on the boiler, tting it with the screws (12).

- Mount the ducting system as described in the

relative instructions sheet.

- Calculate the distances between the boiler drain

and the bend of the ducting system.

- Prepare the boiler ue system, making sure that

the internal pipe of the concentric kit is tted

properly in the bend of the ducting system

(quota "X" g. 1-23), while the external pipe

must be tted on the adaptor until it stops (1).

N.B.: to encourage the removal of possible

condensate forming in the exhaust pipe, tilt

the pipes towards the boiler with a minimum

slope of 1.5%.

- Mount the cover (A) complete with adaptor (1)

and caps (6) on the wall and assemble the ue

system to the ducting system.

N.B.: (version Ø 125 only) before assembly

check the gaskets are in the right position. In

the event component lubrication (already carried out by the manufacturer) is not sucient,

remove the residual lubricant using a dry cloth,

then to ease tting coat the parts with common

or industrial talc.

Once all components have been assembled properly, the exhaust fumes will be expelled via the

ducting system; the combustion air for normal

boiler operation will be aspirated directly by the

sha (Fig. 1-23).

Technical data.

- e dimensions of the shas must ensure a

minimum gap between the outer wall of the

smoke duct and the inner wall of the sha: 30

mm for circular section shas and 20 mm in

the event of a square section sha (Fig. 1-21).

- Maximum 2 changes of direction are allowed

on the vertical section of the ue system with

a maximum clearance angle of 30° with respect

to the vertical.

- e maximum vertical extension using a Ø 60

ducting system is 13 m, the maximum extension includes 1 bend Ø 60/10 at 90°, 1 m of

horizontal pipe 60/100, 1 90° ducted bend Ø

60 and the roof terminal for ducting.

To determine the C93 ue system in congu-

rations other than that described (Fig. 1-23)

one must consider that 1 metre of ducted pipe

according to the indications described has a

resistance factor equal to 4.9.

- e maximum vertical extension using a Ø 80

ducting system is 28 m, the maximum extension includes 1 adapter 60/100 to 80/125, 1 87°

bend Ø 80/125, 1 m of horizontal pipe 80/125,

1 90° ducted bend Ø 80 and the roof terminal

for ducting.

To determine the C93 ue system in congura-

tions other than that described (Fig. 1-23) one

must consider the following pressure drops:

- 1 m of concentric pipe Ø 80/125 = 1 m of

ducted pipe;

- 1 87° bend = 1.4 m of ducted pipe;

Consequently one must subtract the equivalent

length of the part added to the 28 m available.

1-21

A

B

Kit composition:

Ref. Qty Description

1 1 Door adaptor Ø 100 or Ø 125

2 1 Door gasket made of neoprene

3 4 Screws 4.2 x 9 AF

4 1 Hex headed screw M6 x 20

5 1 Flat nylon washer M6

6 2 Door hole closure metal-sheet plate

plug

7 1 Plug gasket made of neoprene

8 1 Toothed washer M6

9 1 Nut M6

10 1 (kit 80/125) Concentric gasket Ø 60-100

11 1 (kit 80/125) Flanged adapter Ø 80-125)

12 4 (kit 80/125) Hex headed screws M4 x 16 slotted

- 1 (kit 80/125) Bag of lubricating talc

Supplied separately:

Ref. Qty Description

A 1 Ducting kit door

A

C

Rigid Ø 60

ducting (A)

mm

66 106 126

SHAFT

(B) mm

Installation drawings key:

Unique identication of the component in

1

the kit

Identication of the component not supplied

in this kit

A

12

12

SHAFT

(C) mm

11

10

Rigid Ø 80

ducting (A)

mm

86 126 146

Flexible Ø 80

ducting (A)

mm

90 130 150

2

1

3

3

3

6

5

4

SHAFT

(B) mm

SHAFT

(B) mm

7

SHAFT

(C) mm

SHAFT

(C) mm

A

6

8

1-22

9

16

Page 17

C

93

X

C

53

INSTALLERUSERMAINTENANCE TECHNICIAN

1.16 DUCTING OF FLUES OR

TECHNICAL SLOTS.

Ducting is an operation through which, via

the introduction of one or more relevant pipes,

one achieves a system for the evacuation of the

combustion products of a gas appliance, made up

from the coupling of an existing or new ducting

pipe with a chimney, ue or technical slot (also

in new buildings) (Fig. 1-24). Ducting requires

ducts declared to be suitable for the purpose by

the manufacturer, following the installation and

user instructions, provided by the manufacturer

and the requirements of the standards in force.

Immergas ducting system. e Ø 60 rigid and Ø

80 exible “Green Range” ducting systems must

only be used for domestic use and with Immergas

condensing boilers.

In any case, ducting operations must respect

the provisions contained in the standard and in

current technical regulations; in particular, the

declaration of conformity must be compiled at

the end of work and on commissioning of the

ducted system. e instructions in the project

or technical report must likewise be followed, in

cases provided for by the standard and current

technical regulations. e system or components

of the system have a technical life complying with

current standards, provided that:

- it is used in average atmospheric and environ-

mental conditions, according to current regulations (absence of fumes, dusts or gases that can

alter the normal thermophysical or chemical

conditions; existence of temperatures coming

within the standard range of daily variation,

etc.).

- Installation and maintenance must be per-

formed according to the indications supplied

by the manufacturer and in compliance with

the provisions in force.

- e max. possible length of the Ø 60 exible

ducting vertical section is equal to 22 m. is

length is obtained considering the complete

Ø 80 exhaust terminal, 1m of Ø 80 pipe in

exhaust, two 90° Ø 80 bends at boiler outlet.

1-23

- e max. possible length of the Ø 80 exible

ducting vertical section is equal to 30 m. is

length is obtained considering the complete

exhaust terminal, 1m of Ø 80 pipe in exhaust,

two 90° Ø 80 bends at boiler outlet for connecting to the ducting system and two direction

changes of the exible hose inside the chimney/

technical slot.

- e maximum possible length of the Ø 80 rigid

ducting vertical section is equal to 30 m. is

length is obtained considering the complete

Ø 80 exhaust terminal, 1m of Ø 80 pipe in exhaust, two 90° Ø 80 bends on the boiler outlet.

1.17 CONFIGURATION TYPE B, OPEN

CHAMBER AND FAN ASSISTED FOR

INDOORS.

e appliance can be installed inside buildings

in

or B53 mode; in this case, all technical rules

23

and national and local regulations in force, must

be complied with.

For installation the suitable kit must be used,

referred to in paragraph 1.11.

1-24

1.18 FLUE GAS EXHAUST TO FLUE/

CHIMNEY.

e ue exhaust does not necessarily have to be

connected to a branched type traditional ue.

e ue exhaust, for boiler clots installed in C

configuration, can be connected to a special

LAS type multiple ue. For B23 congurations,

exhaust is only allowed into individual chimney

or directly into the external atmosphere via a

relevant terminal. e multiple ues and the

combined ues must also only be connected to

type C appliances of the same type (condensing),

having nominal heat inputs that do not dier by

more than 30% less with respect to the maximum

that can be attached and powered by the same

fuel. e thermo-uid dynamic features (ue

ow rate, % of carbon dioxide, % humidity etc....)

of the appliances attached to the same multiple

ues or combined ues, must not dier by more

than 10% with respect to the average boiler attached. Multiple and combined ues must be

specially designed according to the calculation

method and requirements of the standards in

force, by professionally qualied technical sta.

Chimney or ue sections for connection of the

ue exhaust pipe must comply with requisites of

technical standards in force.

17

Page 18

1.19 FLUES, CHIMNEYS, CHIMNEY POTS

AND TERMINALS.

e ues, chimneys and chimney pots for the

evacuation of combustion products must be in

compliance with applicable technical standards.

Chimneys and roof-installed exhaust terminals

must comply with the outlet height and with the

distance from technical volumes set forth by the

technical standards in force.

Positioning the wall ue exhaust terminals. e

wall ue exhaust terminals must:

INSTALLERUSERMAINTENANCE TECHNICIAN

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum dis-

tances specied in current technical standards.

Combustion products exhaust of natural

draught or fan assisted appliances in open-top

closed environments. In spaces closed on all

sides with open tops (ventilation pits, courtyards etc.), direct combustion product exhaust

is allowed for natural draught or fan assisted gas

appliances with a heat input range from 4 to 35

kW, provided the conditions as per the current

technical standards are respected.

1.20 CENTRAL HEATING CIRCUIT

FILLING.

Once the boiler is connected, proceed with system lling via the lling cock (Fig. 2-8). Filling

is performed at low speed to ensure release of air

bubbles in the water via the boiler and central

heating system vents.

e pump may be noisy on start-up due to the

presence of air. is noise should stop aer a

few minutes of functioning and however aer

having correctly bled the air contained in the

hydraulic circuit.

e boiler incorporates an automatic vent valve

positioned on the boiler pump and one positioned on the hydraulic manifold. Make sure

that the hoods are loosened. Open the radiator

vent valves.

Close radiator vent valves when only water

escapes from them.

Close the lling cock when the boiler pressure

gauge indicates approx. 1.2 bar.

N.B.: during these operations, turn on the circulating pump at intervals using the main switch

on the control panel. Vent the circulation pump

by loosening the front cap and keeping the motor

running and assuring that the liquid that escapes

cannot cause injury/damage to persons/objects.

Tighten the cap aer the operation.

Attention: to carry out the lling procedure

correctly, activate the "automatic vent" function,

see paragraph 3.14.

1.21 CONDENSATE TRAP FILLING.

On rst lighting of the boiler, ue gas may come

out the condensate drain; aer a few minutes’

operation check that this no longer occurs. is

means that the drain trap is lled with condensate to the correct level preventing the passage

of ue gas.

1.22 GAS SYSTEM STARTUP.

To start up the system, refer to the technical

standard in force: is divides the systems and

therefore the start-up operations into three

categories: new systems, modied systems, reactivated systems.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or open ames;

- bleed all air from the pipelines;

- check that the internal system is properly sealed

according to the specications set forth by

technical regulations in force.

1.23 SOLAR CIRCUIT STARTUP.

Preliminary checks. Before lling the hydraulic

circuit and starting the system, carry out the

following checks:

- ensure that the declaration of conformity of

installation of the solar system is supplied with

the appliance;

- check the functionality of the safety devices,

particularly:

- safety valve (6 bar)

- expansion vessel

- thermostatic mixing valve

- make sure there are no leaks in the hydraulic

circuit;

- make sure there is an air vent valve positioned

in the highest point of the circuit above the

manifold and that it is operational.

If even only a single safety check oers a negative

result, do not commission the system.

Expansion vessel factory-set pressure of the

solar circuit hydraulic unit.

To compensate the high temperatures that

can be reached by the liquid in the circuit and

therefore its dilation, an expansion vessel has

been envisioned that has sucient capacity to

perform this task.

e expansion vessels are supplied pre-loaded

at 2.5 bar. It is therefore necessary to deate

them and reload them at the pressure required

for the circuit.

e expansion vessel must be charged to:

1.5 bar + 0.1 bar for every metre of the water

column.

“metre of the water column” means the vertical

distance that is present between the expansion

vessel and the solar manifold.

Example:

e circulation unit is found on the ground oor

and the solar manifold is found on the roof at a

hypothetical height of 6 m, the distance to be

calculated is:

6 m x 0.1 bar = 0.6 bar

therefore the expansion vessel must be charged

to:

1.5 + 0.6 = 2.1 bar

Hydraulic unit safety valve.

ere is a safety valve present on the hydraulic

unit that protects the system from an excessive

increase in pressure. is valve intervenes by

discharging the liquid contained in the circuit

when the pressure reaches 6 bar.

If the safety valve intervenes and therefore part of

the liquid contained in the circuit is lost, it must

be re-integrated.

1.24 SOLAR CIRCUIT FILLING.

N.B.: If errors occur during installation, opera-

tion and maintenance, due to non compliance

with the technical laws in force, standards or instructions contained in this manual (or however

supplied by the manufacturer), the manufacturer

accepts no contractual and extra-contractual

liability for any damages and the appliance warranty is invalidated.

e system can only be lled when:

- any operational residues have been eliminated

that may cause obstructions and deteriorate the

features of the glycol over time;

- any presence of water in the system has been

eliminated, which could otherwise cause damage to the system in winter;

- the absence of leaks has been veried by checks

using air;

- the storage tank unit has been lled;

- the expansion vessel has been charged according to system requirements.

e system must be lled only using the glycol

supplied by Immergas via an automatic pump.

e system must be lled with vent valve closed.

Proceed as follows to ll the system:

1 connect the ow pipe of the automatic pump

to the tting of the lling valve (9 Fig. 1-29)

located under the pump and open the valve.

2 connect the return pipe of the automatic pump

to the tting of the draining valve (8 Fig. 1-29)

and open the draining valve.

3 e ow-rate regulator screw (11 Fig. 1-29)

must be orientated horizontally to ensure the

closure of the integrated ball valve. Open the

ball valve with thermometer (2 Fig. 1-29) above

the pump.

4 ll the lling pump tank with the amount of

glycol necessary plus a minimum amount to

be le on the bottom of the tank in order to

prevent air circulating inside the circuit.

5 e lling stage must have a minimum dura-

tion of 20 ÷ 25 minutes. is time is required

to completely remove all air from the circuit.

Every now and again open the ow rate regulator adjustment screw in order to eliminate air

from inside (vertical position).

6 Eliminate any air in the solar circuit preferably

using the so-called "pressure shot" method,

which consists in raising the lling pressure of

the circuit followed by a quick opening of the

return valve (8 Fig. 1-29). is method allows

air to be expelled from the circuit.

7 Close the lling cock and switch the lling

pump o, open the regulator screw of the ow

rate regulator (notch in vertical position).

8 Leave the circuit pressurised. Any pressure

drop indicates a leak in the system.

9 Set the functioning pressure in the circuit

at 1.5 bar + 0.1 bar for every metre in the

distance between the solar manifold and the

expansion vessel (practically, set the same

pressure between expansion vessel and system).

N.B.: Do not exceed 2.5 bar.

18

Page 19

10 Switch the solar pump on at a maximum

speed and make it run for at least 15 minutes.

11 Disconnect the lling pump and close the

ttings using the relevant screw caps.

12 Open the ball valve above the pump com-

pletely.

Do not ll the system in conditions with strong

insolation and with the manifolds at high

temperatures.

Make sure that all air bubbles have been completely eliminated.

Solar circuit vent.

Any air present in the system must be bled:

- on start-up (aer lling);

- if necessary, e.g. in the case of breakdown.

Attention: danger of burns from the liquid

contained in the collectors.

1.25 BOILER START UP IGNITION.

In order to issue the Declaration of Conformity

required by the laws in force, one must full

the following requirements to commission the

boiler (the operations listed below must only

be performed by qualied personnel and in the

presence of professionals only):

- check that the internal system is properly sealed

according to the specications set forth by

technical regulations in force;

- make sure that the type of gas used corresponds

to boiler settings;

- Check that there are external factors that may

cause the formation of fuel pockets;

- switch the boiler on and check correct ignition;

- make sure that the gas ow rate and relevant

pressure values comply with those given in the

manual (Par. 3.17);

- ensure that the safety device intervenes in the

event of gas supply failure and check the relative

intervention time;

- check the intervention of the main switch

located upstream from the boiler and in the

boiler;

- check that the intake/exhaust concentric terminal (if tted) is not blocked.

e boiler must not be started up even if only

one of the checks should be negative.

N.B.: only upon completing commissioning by

an installer, may an authorised rm carry out an

initial inspection of the boiler, which is required to

activate the Immergas warranty. e test certicate

and warranty is issued to the user.

1.26 DHW MIXING VALVE.

e thermostatic mixing valve mixes the cold

water with the hot water and via an internal wax

element, sensitive to the temperature, automatically controls the temperature of the mixed water

set by the user.

N.B.: for excellent management of the temperatures, the mixing valve must be set by the installer

at a safety temperature required by the user. e

outlet temperature of the domestic hot water

can also depend on the value set on the boiler,

however, the upper limit temperature value of

the domestic hot water is always determined by

the position of the mixing valve: knob position 1

= 42°C, 2 = 48°C, 3 = 54°C, 4 = 60°C (standard)

(the values indicated refer to a storage tank with

water at 70°C).

Any release of the three-way mixing valve. If

aer a long period of inactivity the three-way

mixing valve is blocked, it is necessary to act

manually on the knob positioned on the top of

the same in a way to release the shutter of the

valve itself.

1.27 CIRCULATION PUMP.

Boilers in the “Hercules Condensing ErP” series

are supplied with 2 types of circulating pumps.

Set operation modes according to one's installation requirements.

• Boiler circulator pump. e circulating pump

is not equipped with speed selector. To change

operation mode, parameter “Pump sp.” in the

“Congurations” boiler menu must be changed.

Pump release. If the pump should be blocked

aer a long period of inactivity, it must be released. Loosen the front cap, making sure that

the liquid that escapes cannot cause injury/

damage to persons/objects and turn the motor sha very carefully using a screwdriver so

as not to damage the latter. Once the pump is

released, close the vent cap.

• Zone 1 circulator pump. e pump is ideal for

the requirements of each central heating system

in a domestic and residential environment.

In fact, the pump is equipped with electronic

control that allows to set advanced functions.

Adjustments. Turn the selector and set it on

the desired curve to adjust the circulator pump.

Program LED

P 1 lower (ΔP-V)

P 2 upper (ΔP-V)

C 3 lower (ΔP-C) - H=3 m

C 4 upper (ΔP-C) - H=4 m

Min - Max blue

Program P (1 lower 2 upper) (P-V) - Proportional curve (green LED). This allows

the pressure level (head) to be proportionally

reduced as the system heat demand decreases

(flow rate reduction). Thanks to this function, the electric power consumption of the

circulator pump is reduced further: the energy

(power) used by the pump decreases according

to the pressure level and ow rate. With this

setting, the pump guarantees optimal performance in most heating systems, thereby being

green

orange

particularly suitable in single-pipe and twopipe installations. Any noise of the water ow

in the pipes, valves and radiators is eliminated

by reducing the head. Optimal conditions for

thermal comfort and acoustic well-being.

Programs C (3 lower 4 upper) (P-C) - Constant curve (orange LED). The circulator

pump maintains the pressure level (head)

constant as the system heat demand decreases

(ow rate reduction). With these settings, the

circulator pump is suitable for all oor systems

where all the circuits must be balanced for the

same drop in head.

MIN-MAX Program (Blue LED). e pump

is distinguished by adjustable operating curves

by positioning the selector in any point between

the Min and Max positions, thereby satisfying

any installation requirement (from a simple

single-pipe to more modern and sophisticated

systems) and always guarantee optimum performance. e precise working point can be

selected in the entire eld of use by gradually

adjusting the speed.

Real time diagnostics: a lit LED (in various

colours) provides information regarding the

pump operating status, see g. 1-25

Possible pump release. e pump block is

indicated by a xed red LED switching on. Turn

the selector up to the MAX position, disconnect and reconnect the power to restart the

automatic release process. e pump will then

activate the procedure that will last a maximum

of 15 minutes and the LED will ash upon each

restart. It then turns blue for a few seconds and

goes back to red if the attempt to restart is not

successful. Once the process is complete, set

the selector back to the desired curve and if

the problem has not bee resolved, perform the

manual release procedure as described below.

- Disconnect the power to the boiler (the LED

switches o).

- Close the system ow and return and let the

pump cool down.

- Empty the system circuit via the relative cock.

- Remove the motor and clean the impeller.

- Once unblocked, remount the motor.

- Fill the primary circuit; restore boiler power

and set the desired curve.

Attention: there is a burns hazard due to high

uid temperature and pressure. Burns hazard

from coming in contact.

INSTALLERUSERMAINTENANCE TECHNICIAN

19

Page 20

Circulating pump

LED

LED steady on

Flashing white LED Noises during cir-

LED steady on Flow rate too high Reduce rotation speed

INSTALLERUSERMAINTENANCE TECHNICIAN

Head available to the direct zone system xed speed.

LED o

Red LED

Description Diagnostics Remedy

Pump

noisy

culation of the heat

transfer uid

e circulator does

not work

Insucient system pressure, circulating pump

in cavitation

Presence of foreign matter in the impeller Remove the motor and clean the impeller

Presence of air in the system Vent the system

Power outage

Faulty circulating pump Replace the circulating pump

Rotor seized Remove the motor and clean the impeller

Insucient power supply voltage Check boiler power supply voltage

Restore correct thermal circuit pressure

Ensure the boiler is correctly powered, ensure

the circulator is correctly powered

1-25

1-26A

MAX

A

Head (kPa)Head (kPa)

MIN

Flow rate (l/h)

Head available to the direct zone system proportional or constant speed.

C

D

E

H

G

Flow rate (l/h)

B

F

Key:

A = Available head

B = Power absorbed by the circulator

pump (dotted area)

Circulator pump absorbed power (W)Circulator pump absorbed power (W)

1-26B

Key:

C = Head available to the system with circula-

tor pump selector in position C4 (standard

setting)

D = Head available to the system with circula-

tor pump selector in position C3

E = Head available to the system with circula-

tor pump selector in position P2

F = Circulator pump power with selector in

position C4 (standard setting)

G = Circulator pump power with selector in

position C3

H = Circulator pump power with selector in

position P2

20

Page 21

1.28 SOLAR CIRCUIT CIRCULATION

PUMP.