Immergas EOLO Star 23 kW Technical Documentation Manual

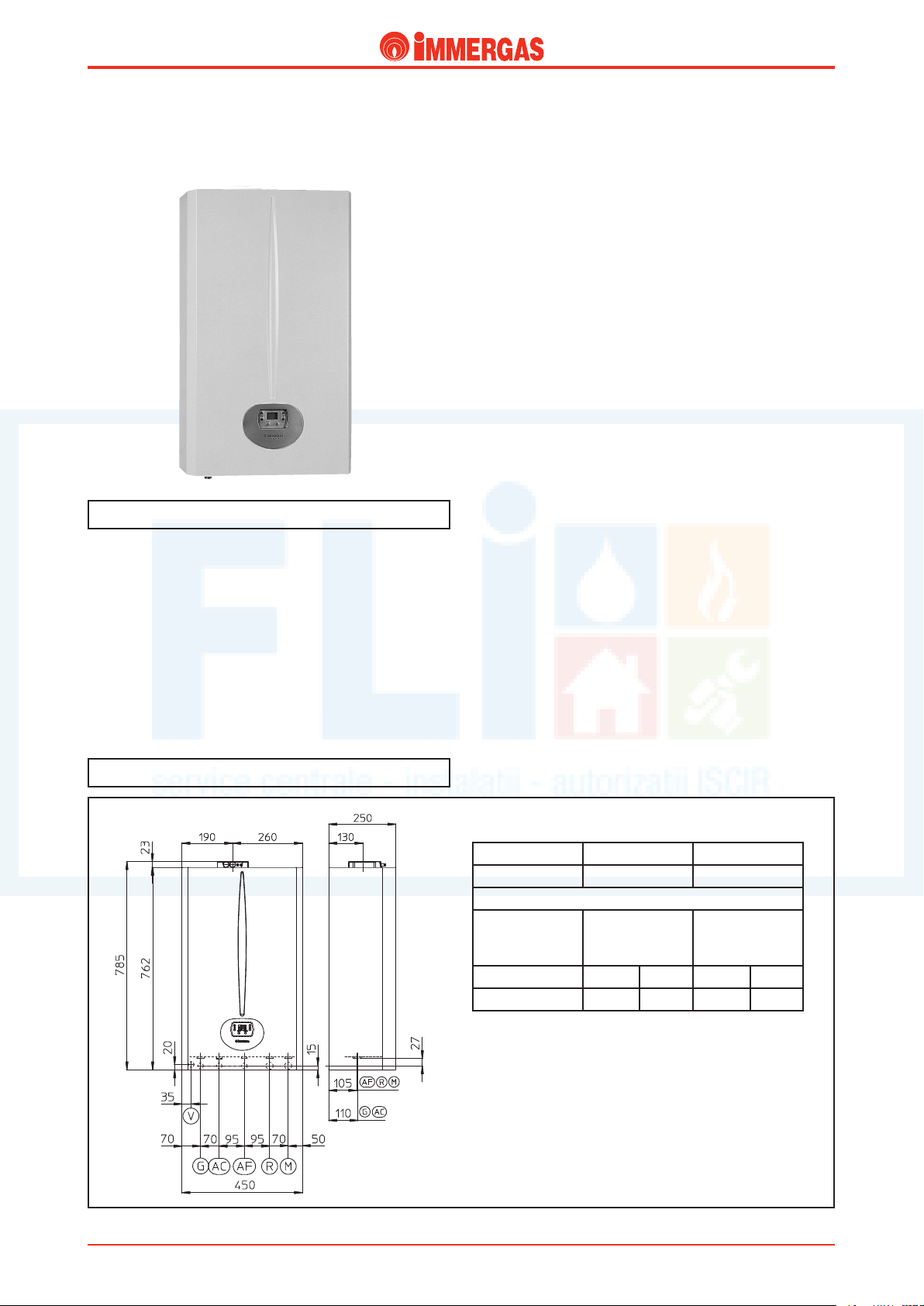

EOLO Star 23 kW

http://serviceimmergas.ro

Instantaneous wall-hung

with room-sealed boilers

EOLO Star 23 kW

S.C FUTURE LINE INSTAL S.R.L

str. Biharia nr.67-77, sector 1, Bucuresti, ROMANIA

serviceimmergas.ro

Dispecerat Non Stop

Tel. Fix : 021-201.11.14

http://serviceimmergas.ro

Technical Documentation

http://serviceimmergas.ro

EOLO Star 23 kW

Technical Documentation

Compact instantaneous wall-hung room-sealed

(type C) fan-assisted boiler.

EOLO Star 23 kW

General features.

EOLO Star 23 kW is a wall-hung, room-sealed fan-assisted

boiler for heating and production domestic hot water.

is very compact boiler (H=785 mm, W=450 mm, D=250

mm), has an output heat of 23.3 kW (20,000 kcal/h).

A microprocessor controlled electronic board adjusts and

controls the appliance (burner ignition, temperature adjust-

ment, flame modulation and diagnostics) and, by means of a

digital interface with display and push buttons, the operating

parameters can be displayed and set.

Main dimensions and main connections.

e hydraulic circuit is equipped with a copper bithermal type

water-gas exchanger for the production of hot water for central

heating and domestic use, an automatic by-pass on the system

and a flow switch for tapping the domestic hot water.

Combustion air intake inside the sealed chamber and the

expulsion of gases are ensured by a fan. A differential pressure

switch controls correct operation.

Height (mm) Width (mm) Depth (mm)

785 450 250

CONNECTIONS

DOMESTIC

GAS

G AC

3/4” 1/2” 1/2” 3/4” 3/4”

CIRCUIT

TER

WA

AF R M

SYSTEM

STESkW ed 05/06 EOLO Star 23 kW

Legend:

G - Gas supply

AC - Hot water outlet

AF - Cold water inlet

R - System return

M - System delivery

V - Electrical supply

1

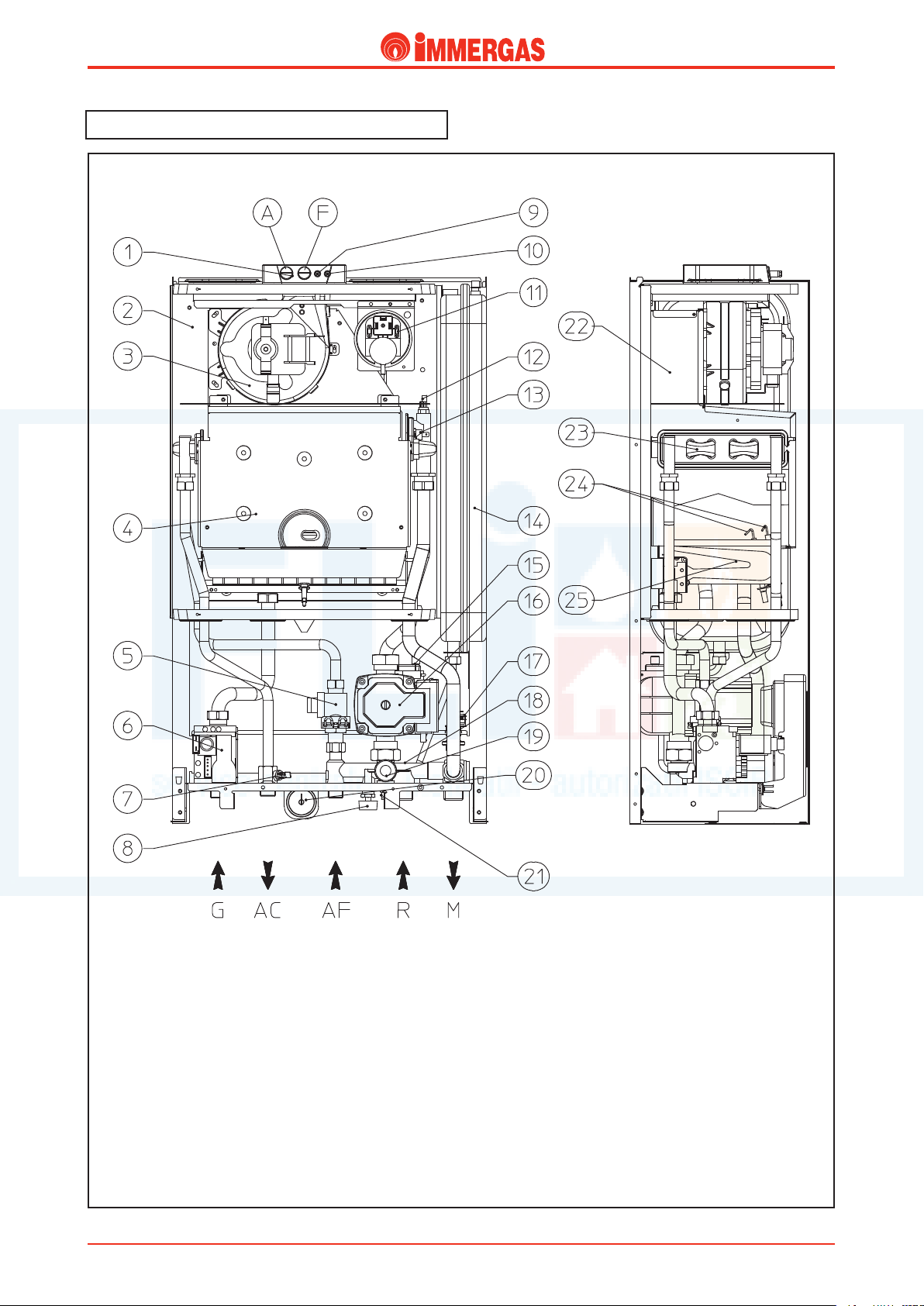

Main components.

http://serviceimmergas.ro

Technical DocumentationTechnical Documentation

Legend:

1 - Testing hole (A air) – (F flue)

2 - Sealed chamber

3 - Fan

4 - Combustion chamber

5 - D.h.w. flow switch

6 - Gas valve

7 - D.h.w. probe

8 - Filling valve

9 - Pressure point, positive signal

10 - Pressure point, negative signal

11 - Flue pressure switch

12 - Delivery probe

13 - Safety thermostat

14 - System expansion vessel

15 - Automatic air vent

STESkW ed 05/06 EOLO Star 23 kW

16 - Boiler circulator

17 - System pressure switch

18 - Manifold

19 - 3 bar safety valve

20 - Boiler pressure gauge

21 - System draining cock

22 - Draught diverter

23 - Rapid heat exchanger

24 - Ignition/detection electrodes

25 - Burner

2

Technical Documentation

http://serviceimmergas.ro

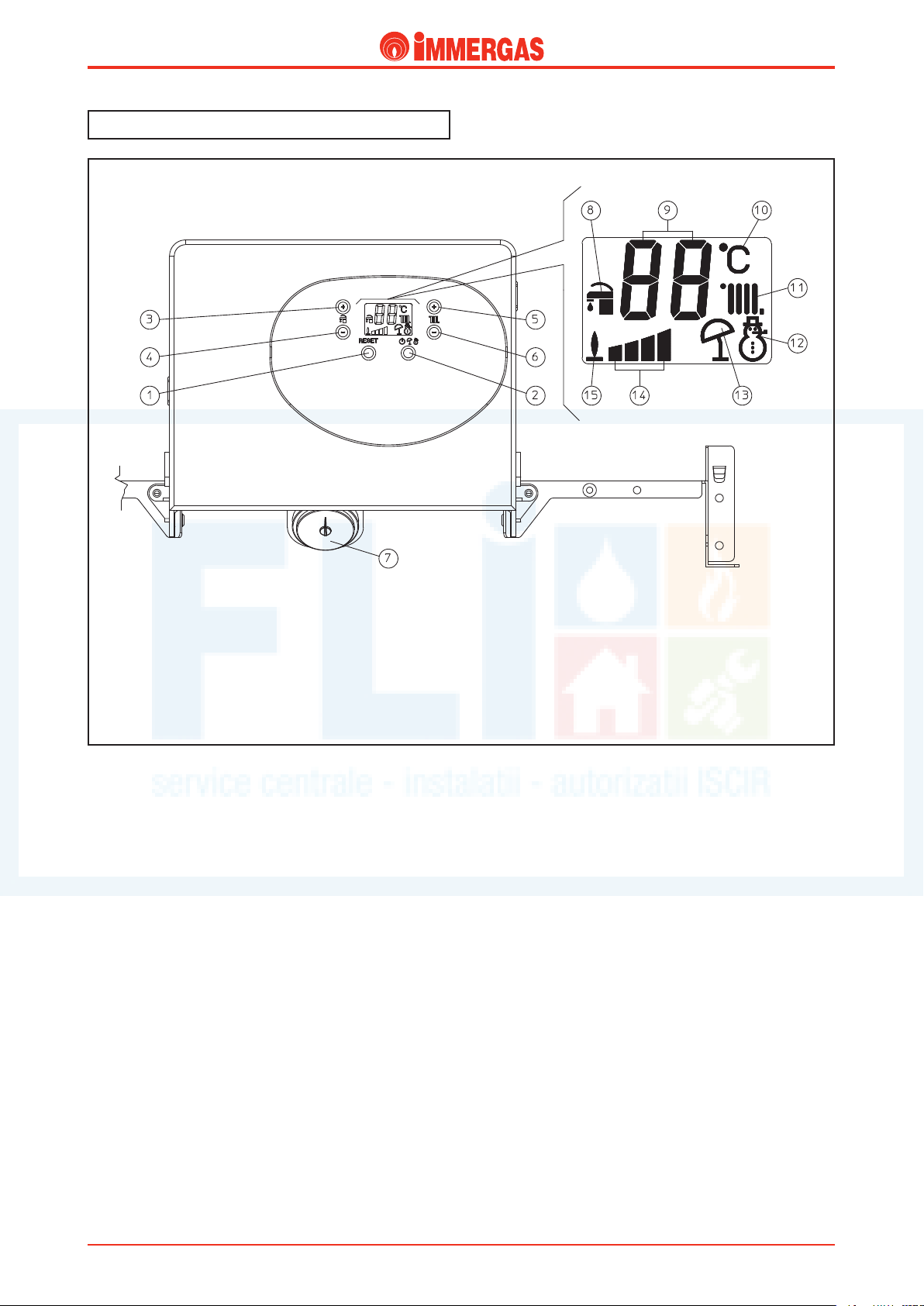

Control panel.

Technical Documentation

Legend:

1 - Reset Push Button

2 - Stand-by / Summer / Winter Push Button

3 - Push button (+) to increase d.h.w. temperature

4 - Push button (-) to reduce d.h.w. temperature

5 - Push button (+) to increase system water temperature

6 - Push button (-) to reduce system water temperature

7 - Boiler pressure gauge

8 - D.h.w. functioning mode

9 - Displays temperatures and error codes

10 - Unit of measure

11 - Central heating functioning mode

12 - Winter

13 - Summer

14 - Power supplied

15 - Burner operating

STESkW ed 05/06 EOLO Star 23 kW

3

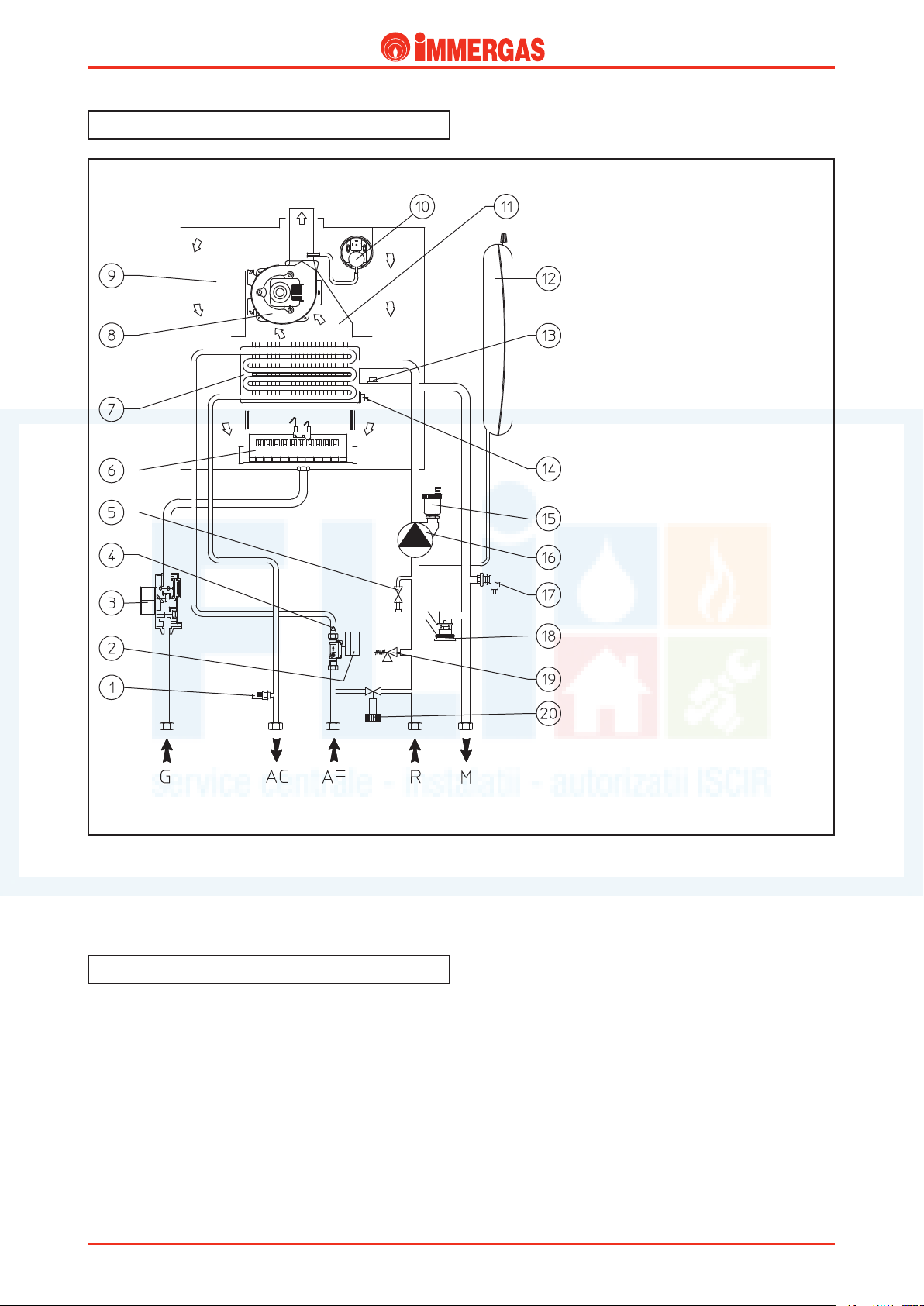

Hydraulic circuit.

http://serviceimmergas.ro

Technical DocumentationTechnical Documentation

Legend:

1 - D.h.w. probe

2 - D.h.w. flow switch

3 - Gas valve

4 - Flow limiter

5 - Draining cock

6 - Burner

7 - Rapid exchanger

8 - Fan

9 - Sealed chamber

10 - Flue pressure switch

11 - Draught diverter

12 - System expansion vessel

13 - Delivery probe

14 - Safety thermostat

15 - Automatic air vent

16 - Boiler circulator

17 - System pressure switch

18 - Automatic by-pass

19 - 3 bar safety valve

20 - Filling valve

Hot water for central heating and domestic use is produced

by two separate circuits that work as required.

Primary circuit (Boiler Circuit).

e central heating circuit, with relevant control and safety

devices, is operated every time a central heating request is

made.

G - Gas supply

AC - D.h.w. outlet

AF - Cold water inlet

R - System return

M - System delivery

ing system through the delivery (M) and return (R) pipes.

Operation.

e heat contained in the fumes produced by combustion

is absorbed by the copper blades of the water-gas exchanger

(7) which, in turn, transfers it to the water circulating inside

thanks to the boiler circulator (16).

e hot water is then transferred directly into the central heat-

STESkW ed 05/06 EOLO Star 23 kW

4

Technical Documentation

http://serviceimmergas.ro

Technical Documentation

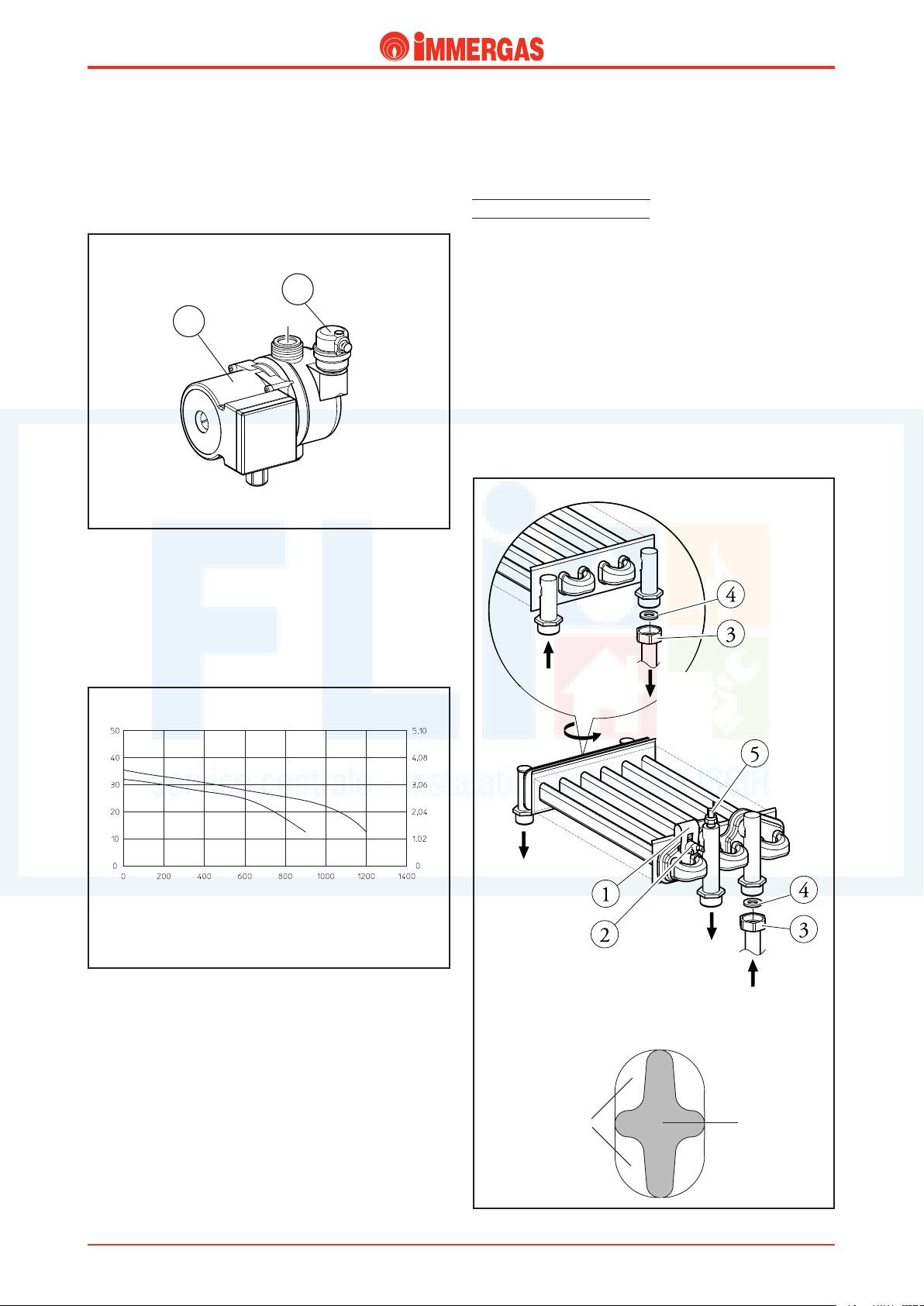

Boiler circulator (1).

e pump works on the primary circuit return and is located

on the brass manifold assembly.

It is connected to the enbloc and primary exchanger by means

of threaded fittings.

e automatic valve vent is housed on the body (2).

2

1

Primary exchanger.

is is a water-gas bithermal type blade exchanger with pipes

and fins in copper for the production of hot water for central

heating and domestic use.

(until serial number 3078554) number of fins = 79.

(from serial number 3078555) number of fins = 86.

It therefore works directly on both circuits to which it is connected by pipes with threaded fittings (3) with a flat gasket

seal (4).

e 6 oval pipes it consists of, inside which flows the water of

the central heating circuit, contain an equal number of “crossshaped” pipes for the direct transit of domestic hot water (see

illustration below).

ese pipes are plumbed in parallel in groups of three on the

central heating circuit and in series on the d.h.w. circuit.

e overheating safety thermostat (2) is fixed on the side of

the exchanger exit with a fork (1).

e relevant NTC delivery probe is screwed into place on the

central heating delivery pipe (5).

Head flow rate graph.

e available head the appliance is able to guarantee to the

system in the central heating mode depends on the flow rate

which is shown in the following graph where we can see the

characteristic curve with the pump working at second and

top speed.

O)

Head (kPa)

B

A = Head available to the system at third speed

B = Head available to the system at second speed

A

Flow rate (l/h)

Head (m H

Domestic

cold

water

inlet

2

Domestic

hot

water

outlet

Domestic

hot

water

outlet

System

deliv

ery

System

return

STESkW ed 05/06 EOLO Star 23 kW

Exchanger pipe section

System

central

heating circuit

5

D.h.w.

circuit

Safety devices and controls.

7

4

5

1

2

3

6

http://serviceimmergas.ro

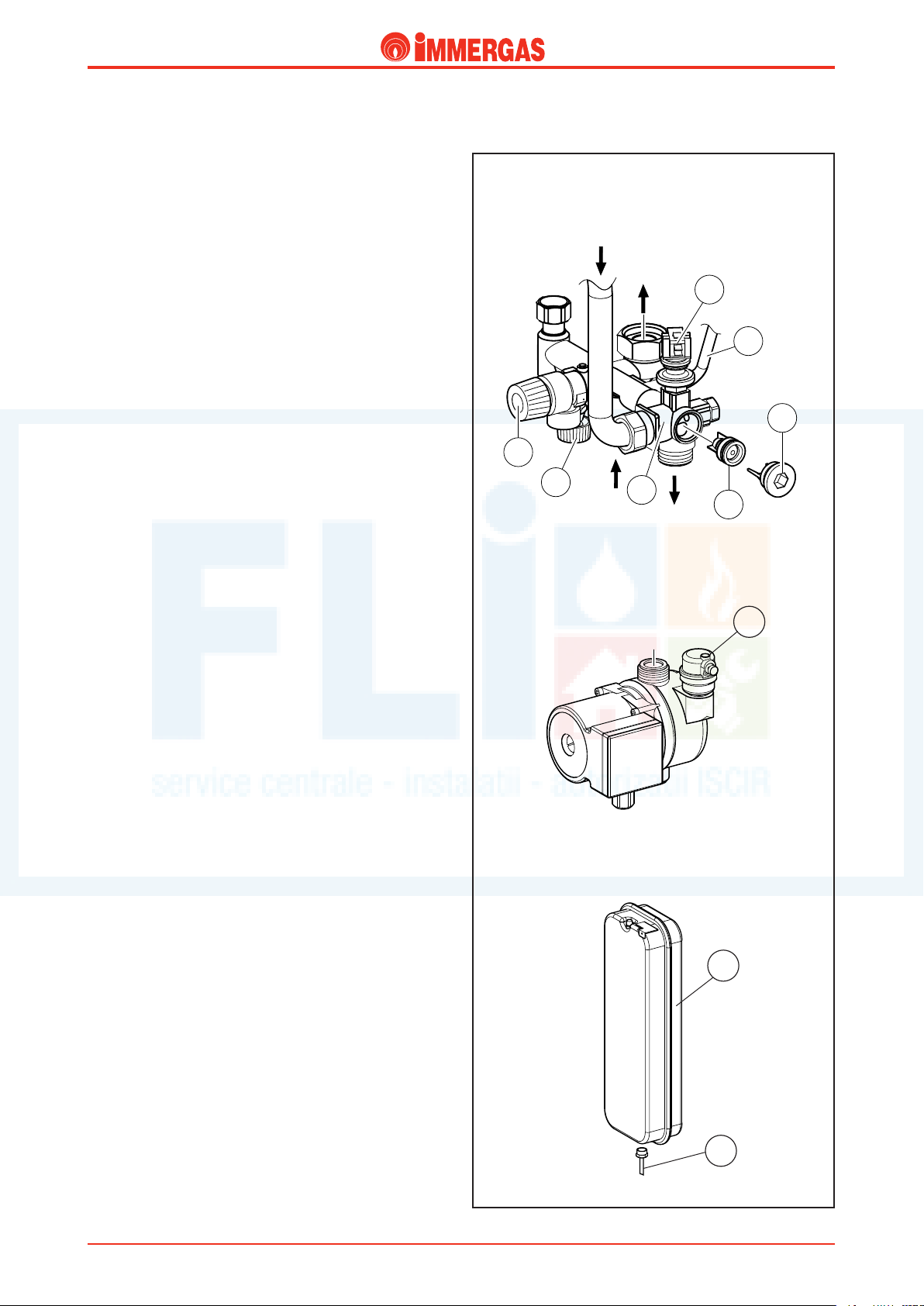

Automatic system by-pass (4).

is device ensures circulation in the central heating circuit

even when this is prevented by the system’s high resistance.

It works between the delivery and return of the central heating

circuit and is accessible after having unscrewed the cap (5) on

the brass manifold’s hook (1).

System water pressure switch (7).

is is an absolute pressure switch that reads the pressure inside

the central heating circuit.

It is housed in the manifold (1) and coupled to a microswitch

that prevents the boiler working when the pressure measured

is below 0.3 bar.

is prevents the bithermal exchanger from overheating.

Filling valve (3).

is valve is between the boiler circuit and the domestic cold

water inlet and permits pressurisation of the central heating

system.

It is located underneath the brass manifold (1) to which it is

screwed.

Technical DocumentationTechnical Documentation

Central

heating

exchanger

ery

deliv

System

return

Pump

return

System

delivery

3-bar safety valve (2).

is valve prevents the safety pressure being exceeded in the

circuit (3 bar).

It is on the front of the manifold (1), secured to it on the side

with an Allen screw.

When this valve triggers, water exits from the boiler return

pipe.

Automatic air vent (8).

It automatically expels any gaseous substances from the circuit.

It is mounted on the pump’s delivery side.

Expansion vessel (9).

It compensates for variations in volume as a result of heating

the water which also limits pressure variations.

It has a 6-litre capacity (3.95 useful litres) and a pre-load pres-

sure of 1.0 bar.

It is located on the right of the boiler alongside the sealed

chamber and is connected to the return manifold (1) by a

copper pipe (6) with threaded fittings.

8

9

STESkW ed 05/06 EOLO Star 23 kW

6

6

Technical Documentation

1

2

3

http://serviceimmergas.ro

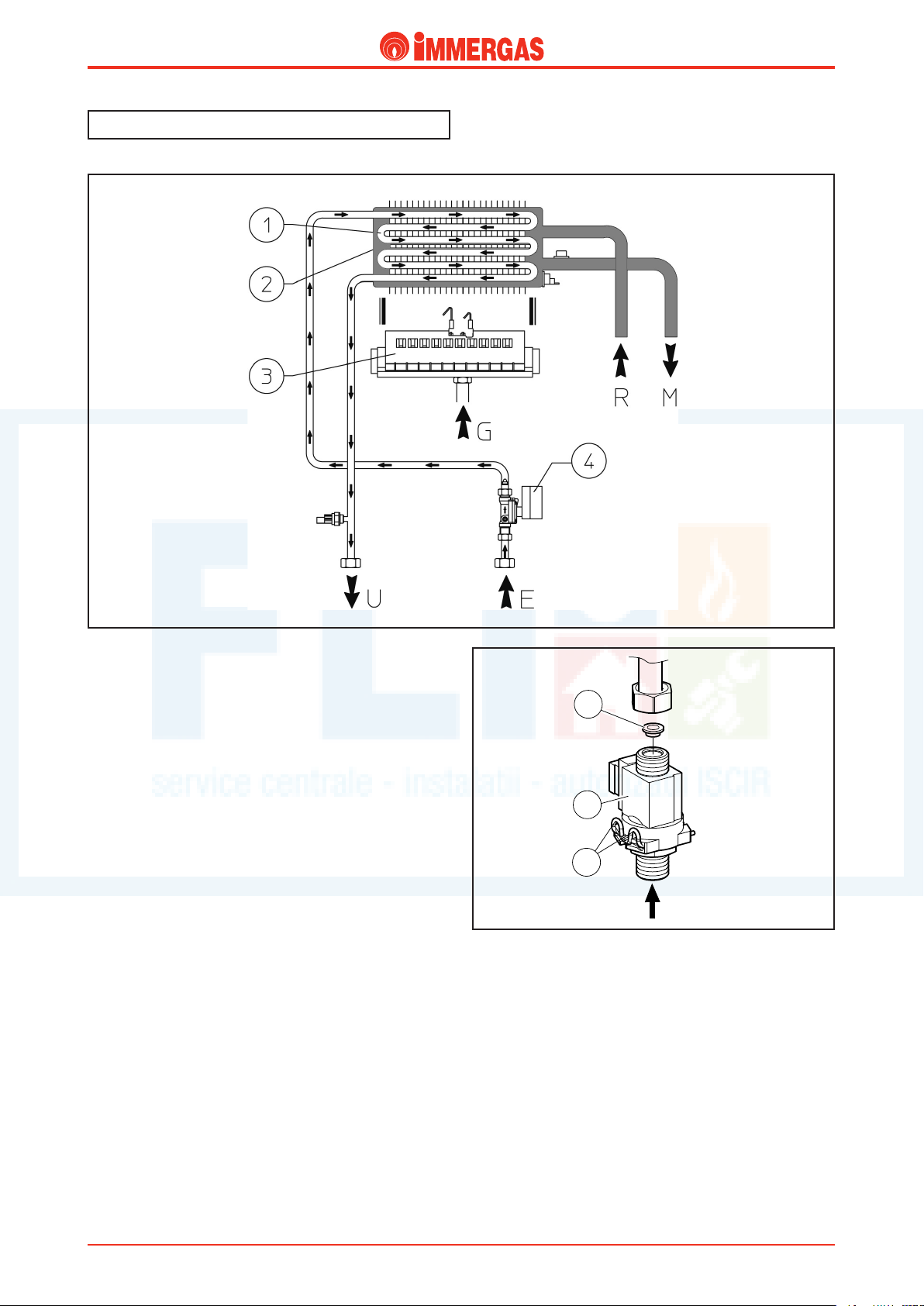

Secondary circuit (D.h.w. circuit).

Technical Documentation

Operation.

When domestic hot water is drawn, cold water flows inside

the flow switch (4) which closes the electrical contact coupled

to it (see the electrical circuit).

As a result, the adjustment circuit starts the d.h.w. priority

phase that ignites the burner (3) and, if there is an ongoing

central heating request, switches the boiler circulator off.

In this way, the heat in the fumes produced by combustion is

absorbed by the copper blades of the bithermal exchanger (2)

and transferred to the heating circuit water which, in turn,

transfers it to the domestic water circuit flowing through the

“cross-shaped” hot water circuit pipes (1).

D.h.w. flow switch.

Whenever hot water is drawn at a rate of at least 1.5 l/min and

with a dynamic pressure of 0.3 bar, the flow switch (2) enables

the boiler to operate in the d.h.w. mode.

is is done by means of a magnet that, by lifting when hit by

the flow of cold water, moves near to an electrical contact (reed

relay) causing it to move thanks to the effect of the magnet.

When the contact closes, which is located outside the pipe

through which the water flows, it enables the modulation board

to start the domestic hot water priority operating mode.

It consists of two blocks (one in brass and one in plastic) that

are coupled together and locked with a pin (3).

An 8.0 l/min (2 bar) flow limiter (1) is installed at the flow

switch exit.

Bithermal exchanger

(see the central heating circuit).

Note: to ensure long life and have an exchanger that is always

efficient, we recommend installing the “polyphosphates dispenser

kit” if the water is likely to lead to scale forming. For example,

this kit is recommended when the hardness of the water exceeds

25 French degrees.

Cold domestic

water inlet

STESkW ed 05/06 EOLO Star 23 kW

7

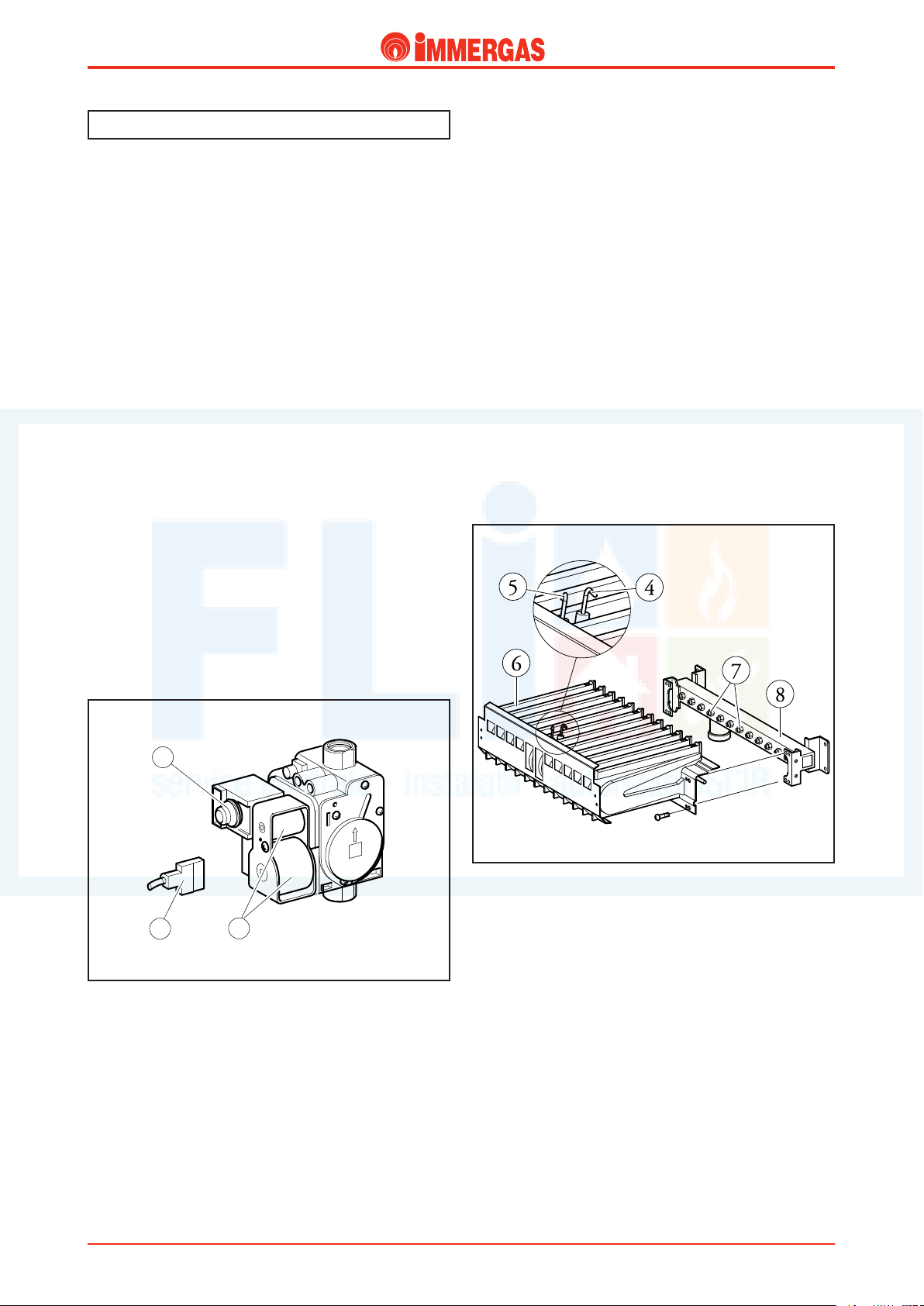

Gas circuit.

1

3

2

http://serviceimmergas.ro

Technical DocumentationTechnical Documentation

e circuit consists of an atmospheric burner and a modulating gas valve for gas combustion and flow adjustment

respectively.

Operation.

When the main coils are energised (3) both the inner valve

shutters open allowing gas to flow towards the burner.

e flow rate/outlet pressure is set by means of the gas valve

stabiliser and the modulation coil (1).

By mean of the burner nozzles (7) fuel is injected into the Venturi tubes (ramps) inside which the air-gas mixture is obtained

that is ignited by the spark from the ignition electrode (5).

Modulating gas valve.

e gas valve (SIT 845) features two main coils (3) and a

modulation coil (1) controlled by the integrated board.

e maximum and minimum outlet pressure can be set with

this valve (see gas settings).

Main electric coils (3).

ey are two ON-OFF type coils supplied (230 Vac) by the

integrated board when the burner has to be ignited.

ey are electrically connected in parallel and supplied by

mains power through a special connector (2).

Modulation coil (1).

is is a low voltage coil controlled by the integrated board.

It controls the gas valve stabiliser and permits changing of

the outlet pressure in a way proportionate to the DC running

through it.

Burner.

e burner consists of 12 horizontal Venturi tubes (6) inside

which the gas is injected by an equal number of nozzles (7)

mounted on the specific manifold (8) and whose diameter

varies according to the type of gas used (see technical data).

Ignition occurs by means of an integrated p.c.b. that controls

the ignition (5) and detection (4) electrodes.

Ignition electrode (5).

is is controlled by the integrated board that produces an

electrical charge between its end and the burner surface which

is responsible for igniting the air-gas mix.

is electrode is at the front of the burner in line with the

centre ramp.

Detection electrode (4).

is is controlled by the integrated board and detects burner

ignition.

It

is positioned at the front of the burner on the same ramp

as the ignition electrode.

STESkW ed 05/06 EOLO Star 23 kW

8

Loading...

Loading...