Page 1

CAR

V2

Modulating remote

control

0 3 6 9 12 15 18 21 24

Instructions for use

Page 2

2

Dear Client,

Our compliments for having chosen a top-quality

Immergas product, able to assure well-being and

safety for a long period of time.

As an Immergas customer you can also count on a

qualied after-sales service, prepared and updated to

guarantee constant eciency of your "Remote Control".

We would like to supply you with some important

indications, the respect of which will confirm your

satisfaction with the Immergas product:

• Read the following pages carefully: you will obtain

useful suggestions regarding the correct use of the

appliance.

• For any interventions or routine maintenance

contact "Immergas Authorised Centres": they

have original spare parts and specic preparation.

Page 3

3

INDEX

How to use the instruction book ................................................4

Foreword ...................................................................................... 4

General recommendations ..........................................................4

Case cleaning ................................................................................5

1. Installation .............................................................................. 6

1.1 Installation recommendations. .................................6

1.2 Installation operations. ...............................................6

2. Description of Controls ........................................................ 9

3. Description of display .........................................................10

4. Start-up .................................................................................12

4.1 Programming current day and time. ......................12

4.2 Selection of functioning mode ................................12

5. Summer mode functions ....................................................15

5.1 DHW temperature setting. ......................................15

5.2 DHW timer (for storage tank unit). .......................15

6. Winter mode functions.......................................................16

6.1 Manual functioning. ................................................. 16

6.2 Automatic functioning. ............................................ 17

6.3 Forced automatic functioning. ................................ 17

6.4 Boiler ow temperature. ...........................................18

6.5 Room anti-freeze function. ......................................18

6.6 Functioning in winter mode with external

temperature probe. ...................................................18

7. Cooling mode functions .....................................................19

7.1 Manual functioning. ................................................. 19

7.2 Automatic functioning. ............................................ 20

7.3 Forced automatic functioning. ................................ 20

8. Information .........................................................................21

9. Programming CAR V2 remote control. .............................22

9.1 Setting comfort and economy room

temperature. ...............................................................22

9.2 Programming functioning time. .............................23

10. Diagnostics and errors ........................................................25

10.1 Diagnostics.................................................................25

10.2 Reset errors. ...............................................................25

10.3 Reset CAR V2 remote control. ..................................25

11. Special functions .................................................................. 26

11.1 LANGUAGE (language selection). .........................26

11.2 REGULT (Management of regulation

parameter). .................................................................26

11.3 HOLIDY (holiday program). ................................... 27

11.4 LEGION (anti-legionella function ). ......................27

11.5 REMOTE (telephone control). ................................27

11.6 CODE. ........................................................................27

12. Functions protected by code (CODE). .............................28

12.1 AMB (room probe - On / O or modulating

functioning mode). ................................................... 28

12.2 REDUCT (functioning in reduced mode).............28

12.3 FRO PR (anti-freeze level). ......................................29

12.4 ZONE (function not present on this model).........29

12.5 SERVIC (programmed maintenance). ...................29

13. Disabling the chrono-thermostat. .....................................29

14. Technical characteristics ..................................................... 30

15. Factory setting .....................................................................31

Page

Page 4

4

HOW TO USE THE INSTRUCTION

BOOK

e instruction book has been divided into 3 main parts:

in the rst, for the installer, the assembly and connection

phases of the remote control with the boiler are described;

in the second, all functioning program customisation phases

are described;

in the third and last part, all operations for displaying and

keeping system functioning under control are described.

FOREWORD

e “Immergas” “CAR V2 modulating remote control has been

designed to guarantee ideal temperature conditions at any

time of the day and night for each individual day of the week.

Only a few minutes are required for installation: it is connected

to the boiler by just 2 cables, through which, it receives and

sends the adjustment and control commands and receives

the power supply. On completion of installation it is ready to

function thanks to the pre-set program inside. e customer

can modify the basic program according to requirements.

Programming of the "CAR V2" remote control is extremely easy

and a wide display allows constant control of all values set.

GENERAL RECOMMENDATIONS

is manual has been drawn-up for: the Installer and the

User.

• Carefully read the warnings contained in this document

as they are required to indicate the use of the CAR V2

remote control envisioned by the design hypothesis,

the technical features, the installation, assembly,

programming, adjustment and use instructions.

• e system must be in compliance with the IEC Standards

in force.

• e instruction manual must be considered a part of

the CAR V2 remote control and must be “kept for future

reference”.

• Aer having removed the packaging, check the integrity

of the CAR V2 remote control. If in doubt, do not use it

and contact the Dealer or Manufacturer.

• e CAR V2 remote control is destined only for the use

for which it has been expressly designed. Any other use

must be considered improper and therefore dangerous.

• Our products are realised in compliance with the Safety

Standards in force, it is therefore recommended to use all

those devices or attentions in a way that injury/damage

is not caused to persons or objects.

Page 5

5

• Do not remove parts of the CAR V2 remote control when

it is functioning.

• Do not use the CAR V2 remote control exposed to heat

sources or under the scorching sun.

• e manufacture is relieved from any liability in the

following cases:

a) Incorrect installation.

b) Boiler functioning defects to which the Remote

Control is applied.

c) Unauthorised modications or interventions.

d) Total or partial failure to comply with instructions.

e) Exceptional events etc.

CASE CLEANING

To clean the case of CAR V2 remote control use damp cloths.

Never use abrasive or powder detergents.

WARNING

Immergas reserves the right to make improvements and

modifications to details and accessories, excepting the

essential features of the model described and illustrated

herein.

Page 6

6

1. INSTALLATION

1.1 Installation recommendations.

e CAR V2 remote control, including the relative cables and

connections to the boiler, must be installed by specialised

sta. On the free initial check of the boiler, when the CAR

V2

remote control is inserted into the system, the Immergas

authorised aer-sales centre checks the connection to the

generator terminal board and adjusts functioning. e free

check just of the CAR V2 remote control is not envisioned

by the Immergas authorised aer-sales centre is requested

successively to the start phase of the boiler warranty.

Important: laying of the CAR V2 remote control cables is

excluded from the free boiler checks; it is the responsibility

of the installer company.

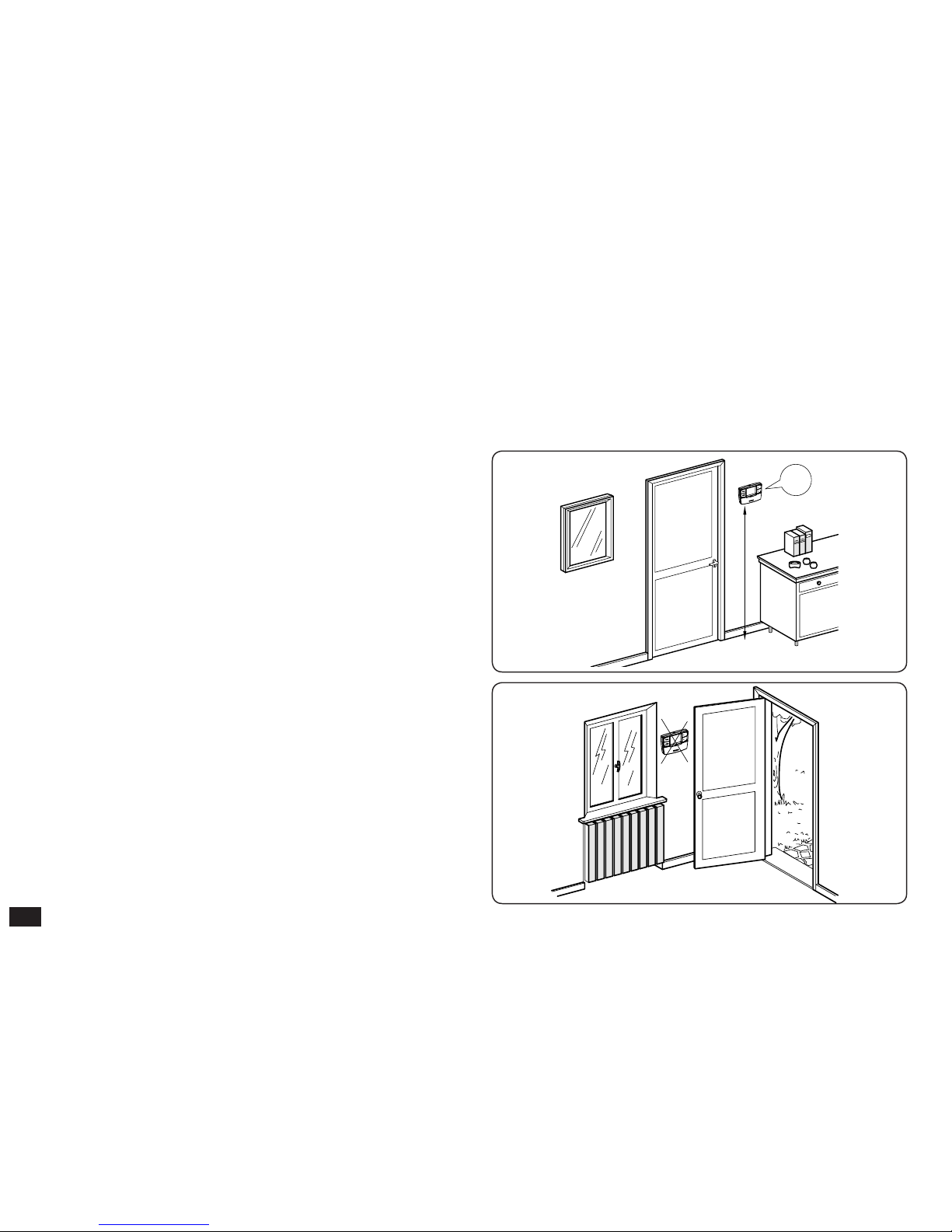

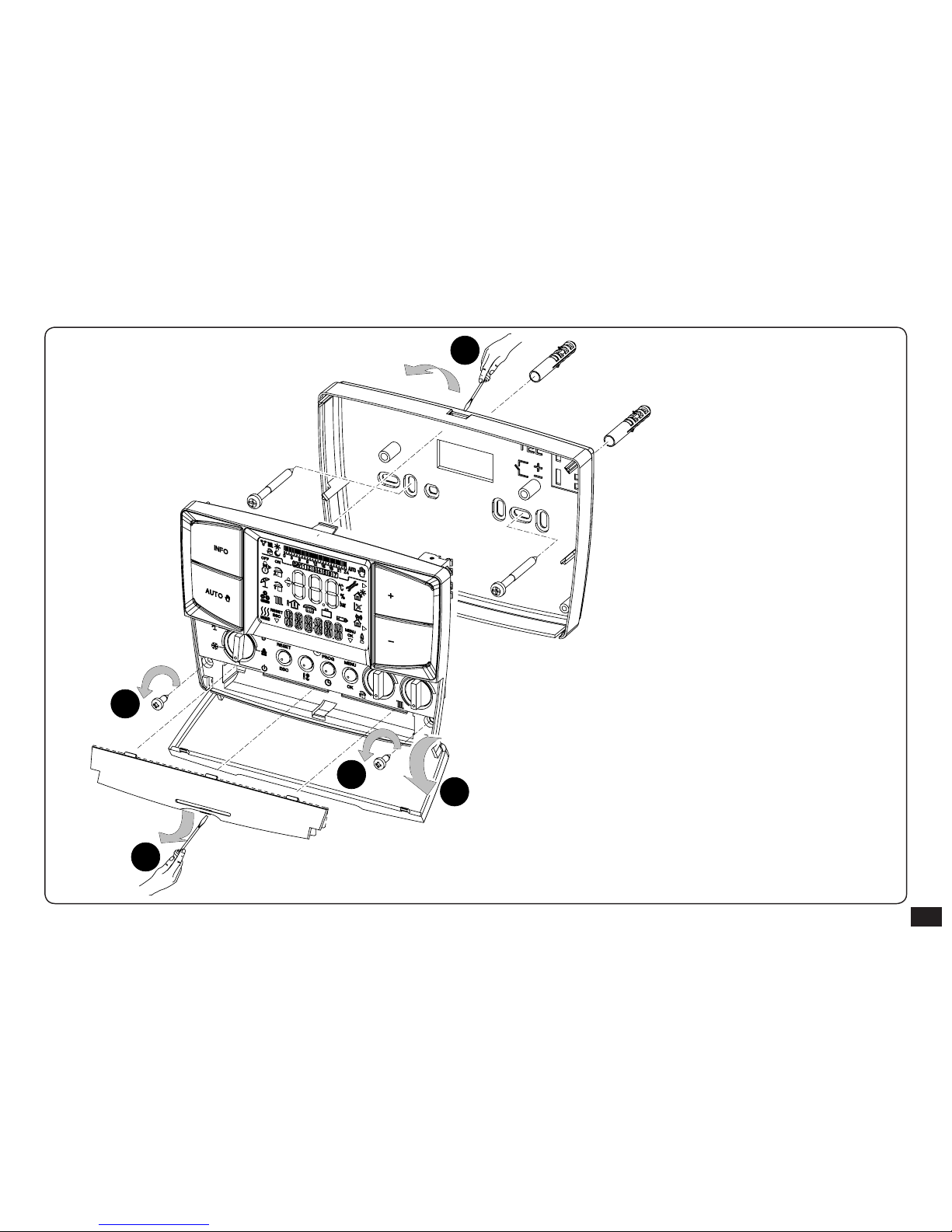

1.2 Installation operations.

1) Separate the xing template from the body of the CAR

V2

remote control using a screwdriver as a lever in the

relevant recess (Fig. 3). Install the CAR V2 remote control

away from heat sources and in a suitable position to detect

the room temperature correctly (Fig. 1 and 2).

Note:

the presence on the rear of the remote control of the

pipe for electric connection cables with the boiler could

recall air from outside the establishment and interfere with

the correct detection of the room temperature (e.g.: boiler

installed outside and use of the suction hood in the kitchen).

Have the job carried out by qualied sta.

2) Install the CAR V2 remote control using the holes made

in the rear of the same directly onto the wall (Fig. 4) or

on a recess box (Fig. 5) using the relative supplied screws.

Fig. 2

Fig. 1

OK

1,5m

NO

Page 7

7

Fig. 3

1

2

3

3

4

Important: the xing screws (action n° 3) on rst

installation are no present on the CAR V2 remote

control, but are supplied in a bag present in the

packaging box.

Once the template is xed to the wall, x the body of

the CAR V2 remote control using the 2 screws.

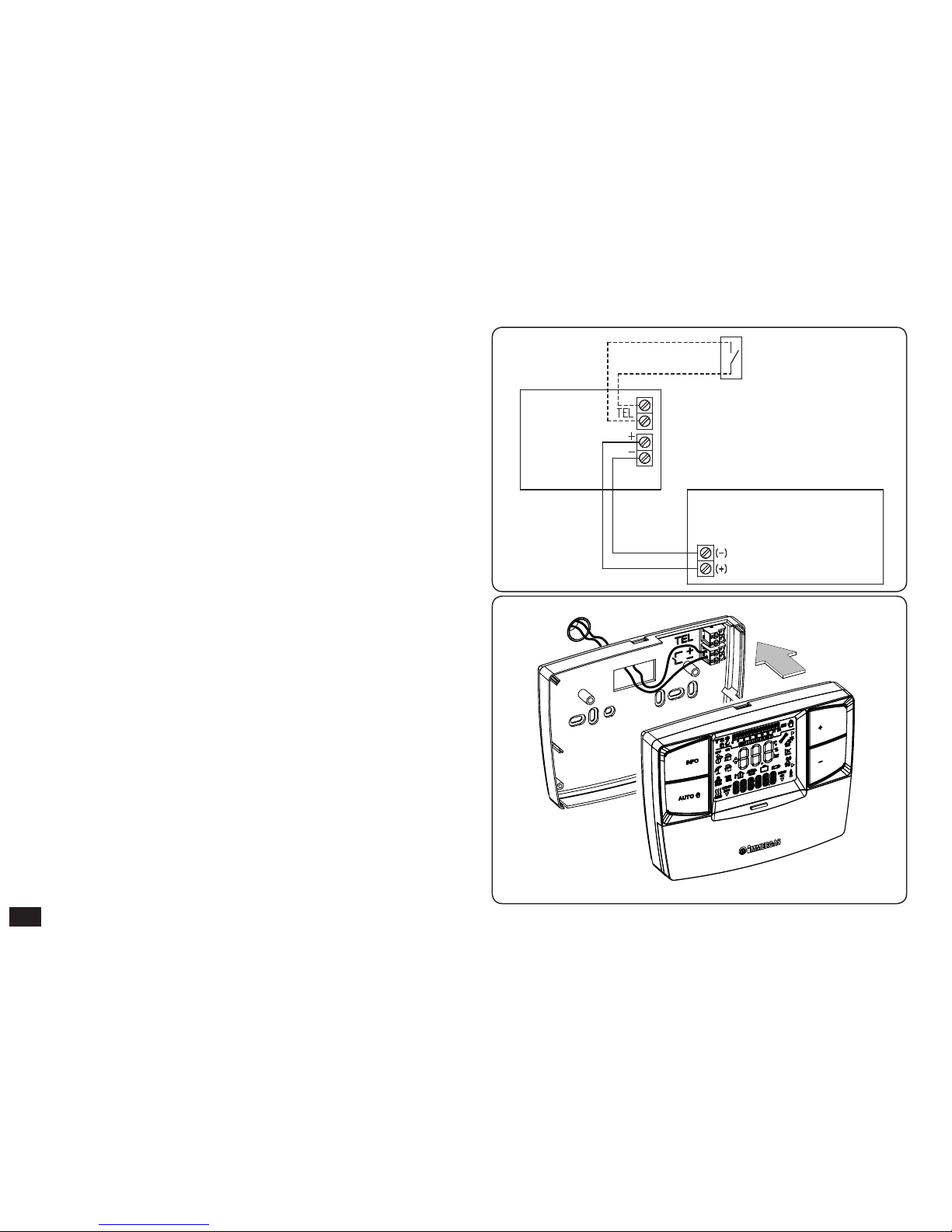

Page 8

8

Fig. 5

Fig. 4

3) To make the electrical connections (Fig. 4) do not operate

when the boiler is live. e connection must be made

respecting the polarity of the wires (+ and -). e jumper

on clamps 40 and 41 of the boiler P.C.B. (if present) must

also be eliminated.

Connect the CAR V2 remote control to the boiler clamps

envisioned at communication with the CAR remote control

or, if not present, to the clamps envisioned for the CRD.

Note: refer to the electrical connections stated in the boiler

instruction book.

e connection to the boiler is made using two wires (Fig.

5)with minimum section of 0.50 mm2 and maximum of 1.5

mm2 and with maximum length of 50 metres.

N.B: for correct installation prepare a dedicated line for the

connection of the CAR V2 remote control according to the

Standards in force regarding electrical systems. If this is not

possible interference due to other electric cables could cause

malfunctioning of the CAR V2 remote control itself.

4) Fix the body of the CAR V2 remote control to the support

template, engaging it with pressure and using the two screws

provided (Fig. 3).

5) Aer the boiler has been powered, wait about 30 seconds

before regulation in a way that the communication between

CAR V2 remote control and boiler has established.

Telephone control

(optional)

Boiler

CAR

V2

Page 9

9

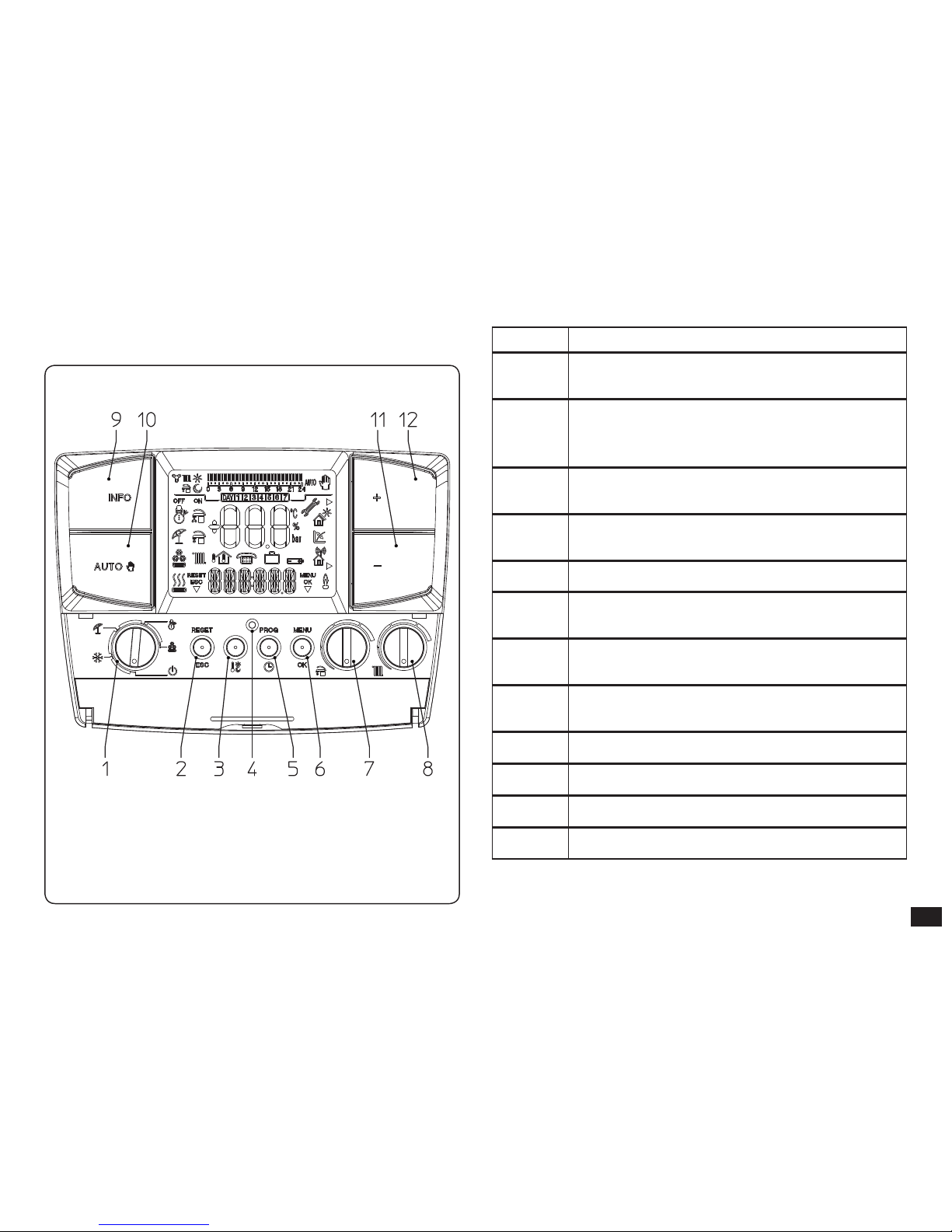

2. DESCRIPTION OF CONTROLS

Fig. 6

Ref. Description

1

Main selector: O, Stand-by/anti-freeze,

Summer, Winter, Cooling

2

“Reset” boiler anomalies/“Esc” escape

parameter or return to previous menu

button (programming mode)

3

Comfort and economy room temperature

setting button

4

Reset button for starting CAR V2 remote

control in event of anomaly of the same.

5 Access button to time, day and timer

6

Access button to the programming/conrm

parameters menu

7

Domestic hot water temperature selector

switch

8

Central heating water temperature selector

switch

9 Information buttons

10 Manual, automatic functioning button

11 Temperature decrease button

12 Temperature increase button

Page 10

10

3. DESCRIPTION OF DISPLAY

Symbol Description

winter - DHW heating and

room central heating buttons are

enabled

summer - only the DHW central

heating function is enabled

cooling - the cooling and DHW

central heating function is

enabled

request for room central heating

or cooling by CAR V2 remote

control

aqua celeris active/DHW

comfort in progress

request for DHW in progress

room central heating in progress

description of functioning of the

button (2 g. 6) - Reset, or esc

displays room temperature and

numerical data

Symbol Description

external temperature display

internal temperature display

function activation from remote

functioning with holiday timer

program

not used on this model

description of functioning state

in use

anomaly in boiler presence

symbol

indicates that it is possible to

modify a parameter via the two

buttons (11 and 12 g. 6)

functioning with solar system

active

functioning with external

temperature probe active

functioning in wireless mode

(not used on this model)

Page 11

11

Symbol Description

description of functioning of the

button (6 g. 6) - Menu or Ok

ame presence symbol (only

appears with the connection to

some boiler models)

symbols that identify the

functioning mode in the hourly

programming

time bar that identies the

functioning period at “comfort”

and “economy” temperature

on the basis of the type of

programming (cooling, central

heating, DHW)

functioning with automatic

program

functioning with manual

program

display of days of the week

N.B.: Some icons can assume dierent meanings according

to the context, see the successive paragraphs to identify the

functions activated by the presence of several icons at the

same time.

Page 12

12

4.2 Selection of functioning mode

According to the functioning mode selected, the CAR V2

remote control performs the requests of the user, displaying

the results on the display.

By turning the main selector (ref. 1 g. 6) the following

functions can be selected: Stand-by/Anti-freeze, Summer,

Winter, Cooling.

Note: the room anti-freeze function is active in the following

modes: antifreeze, summer, winter.

• Off mode. The room anti-freeze function is not

guaranteed in this mode (the boiler anti-freeze function

remains active). e CAR V2 remote control is o but

remains powered and therefore the times and programs

remain memorised.

4. STARTUP

4.1 Programming current day and time.

Switch the remote control on by turning the main selector

onto one of the functions available.

Press the button to enter time and current time

mode and press the button to modify the settings.

On entering the programming mode, the time starts to ash.

Modify the hour and minutes by pressing the + / - buttons

and the button to conrm. Select the day of the week

and conrm using the button.

Once regulation has been completed, press the button

to escape the regulation mode.

Fig. 7

Page 13

13

Fig. 8

Fig. 9

• Stand-by/anti-freeze mode ( ). In this mode, the boiler

can only function in the event of anti-freeze request.

In this state, the day, current time, any functioning

anomalies and the room temperature are displayed (g.

8).

• Summer mode ( ). In this mode the boiler is enabled

for producing domestic hot water excluding heating the

environment. e display shows the day and the current

time, the room temperature and hour bar with daily

programming of the DHW timer along with the relative

symbols (g. 9).

• Winter mode ( ). In winter mode the boiler is enabled

for producing domestic hot water and for central heating

the environment. In winter mode the CAR V2 remote

control can function in automatic or manual mode. For

the description of functioning see chapter 6. e display

shows the day and current time, the room temperature

and the hour bar with the daily programming of the

central heating timer along with the relative symbols (g.

10).

Fig. 10

Page 14

14

• Cooling mode ( ). In cooling mode the boiler is enabled

for the production of DHW and to control a chiller (only

for models set-up) for cooling rooms. In "cooling" mode

the CAR V2 remote control can function in automatic or

manual mode. For the description of functioning see

chapter 7. e display shows the day and current time,

the room temperature and the hour bar with the daily

programming of the cooling timer along with the relative

symbols (g. 11).

Fig. 11

Page 15

15

5. SUMMER MODE FUNCTIONS

With the CAR V2 remote control in summer mode ( ), only

the production of DHW is enabled.

The boiler produces hot water according to the DHW

temperature set on the CAR V2 remote control.

5.1 DHW temperature setting.

By turning the selector ( ) it is possible to set the

temperature of the DHW (see g. 12).

By turning in a clockwise direction the temperature

increases and in an anti-clockwise direction it decreases.

e temperature is memorised aer the selector remains

still for a few seconds.

Fig. 12

5.2 DHW timer (for storage tank unit).

If the temperature of the DHW contained in the DHW

storage tank on two distinct levels (comfort and minimum)

is to be regulated, this is possible using the “HW PRG”

function. Regarding this, see the activation mode in the

chapter relative to programming.

The “comfort” temperature corresponds to the value

regulated on the DHW selector. e “minimum” temperature

corresponds to the minimum DHW value envisioned for the

boiler to which the CAR V2 remote control is coupled.

N.B.: if the CAR V2 remote control is functioning at

minimum temperature level it is possible to force the DHW

temperature by acting on the DHW selector.

e CAR V2 remote control is factory set with the DHW

always activated on "comfort" temperature (ON1 00.00

OFF1 24.00).

Page 16

16

6. WINTER MODE FUNCTIONS

With the CAR V2 remote control in winter mode ( ),

the production of DHW and room central heating are

enabled. Two main functioning modes can be selected for

room central heating: automatic or manual. Plus a forced

automatic timed program.

- Manual ( ): the room temperature is kept constant

at the value set by the user every time, according to

requirements.

- Automatic ( ): the room temperature is regulated on

two levels (comfort and economy) during the day via a

program set by the user.

- Forced automatic ( ashing): the room temperature

is modified momentarily with respect to automatic

functioning until the successive passage between comfort

and energy mode of the automatic program set.

6.1 Manual functioning.

By pressing the button, pass alternately from

automatic to manual functioning.

Once manual functioning mode is set, the icon switcheson on the display (g. 13).

To set the desired room temperature, just press the + / buttons and the room temperature set will appear on the

display (g. 14). Just wait a few seconds to conrm the

new value.

In manual functioning mode it is possible to select any

room temperature from +10°C to +35°C, which will be kept

constant until new adjustments or selection of a dierent

functioning mode.

Fig. 14

Fig. 13

Page 17

17

6.2 Automatic functioning.

The CAR V2 allows automatic functioning, in which a

program manages the room temperature during the hours

of the day.

e desired room temperature can be adjusted onto two

independent levels: comfort ( ) and economy ( ) via the

button, whose distribution throughout the day or the

week is managed by hourly programming.

Press the button until the icon switches-on on

the display .

e CAR V2 is factory-set with a standard program stated in

the table that follows. If this should not satisfy requirements,

it is possible to modify it as described in the chapter relative

to programming.

Fig. 15

Note: the system is designed to function on comfort and

economy temperature levels depending on the hour program

set. erefore also during functioning on economy level,

if the room temperature measured is below that set, the

boiler can ignite.

6.3 Forced automatic functioning.

If in automatic functioning mode ( ) the room temperature

is modied by pressing the + / - buttons, the forced automatic

functioning mode is activated (displayed by the switch-on of

the ashing symbol). In this mode, the room temperature

will be regulated to the value set until the next switch-on or

switch-o phase of the automatic program set. e forced

automatic function can be interrupted by simply pressing

the button.

Days

16°C

20°C

Mon - Fri

(Day 1 - 5)

from 23 to 6

from 8 to 11

from 13 to 17

from 6 to 8

from 11 to 13

from 17 to 23

Sat - Sun

(Day 6 -7)

from 23 to 7 from 7 to 23

Fig. 16

Page 18

18

6.4 Boiler ow temperature.

From the winter function mode ( ) it is possible to regulate

the boiler flow temperature. Regulate by rotating the

selector ( ). Clockwise increases the ow temperature,

anti-clockwise decreases it.

N.B.: an excessively low boiler ow temperature adjustment

(below 60°C for traditional systems) may not allow to reach

the desired room temperature.

e boiler ow temperature during normal functioning

is however managed automatically of the CAR V2 remote

control on the basis of the room temperature set. erefore,

it is not certain that the boiler works at the temperature set

but functions at a lower ow temperature, but correct to

obtain the desired room temperature.

If the external temperature probe is present, the flow

temperature will be set according to that described in the

"Special functions" chapter.

6.5 Room anti-freeze function.

The anti-freeze function has maximum priority with

respect to other settings. When the room temperature

drops below 5°C (adjustable, see special functions chapter)

a central heating request is made at minimum of the power

programmed. is situation remains active until there is

a variation in room temperature of 0.6°C equal to 5.6°C

measured in the room where the CAR V2 remote control

is positioned.

6.6 Functioning in winter mode with external

temperature probe.

If an external temperature probe is present, it is possible to

set a ow temperature correction curve depending on the

external temperature. By turning the selector switch ( )

the curve can be regulated from 0 to 9 according to the

graphics g. 23. Regarding this, see the activation mode in

the chapter relative to the special functions.

Page 19

19

7. COOLING MODE FUNCTIONS

With the CAR V2 remote control in cooling mode ( ), the

of DHW heating and room cooling functions are enabled.

Important: this function can only be used with boilers that

an be coupled with a chiller.

Two main functioning modes can be selected: automatic or

manual. Plus a forced automatic timed program.

- Manual ( ): the room temperature is kept constant

at the value set by the user every time, according to

requirements.

- Automatic ( ): the room temperature is regulated on

two levels (comfort and economy) during the day via a

program set by the user.

- Forced automatic ( ashing): the room temperature is

modied momentarily with respect to automatic functioning

until the successive passage between comfort and energy

mode of the automatic program set.

7.1 Manual functioning.

By pressing the button, pass alternately from

automatic to manual functioning.

Once manual functioning mode is set, the icon switches

on on the display (g. 17).

To set the desired room temperature, just press the + / buttons and the room temperature set will appear on the

Fig. 18

Fig. 17

display (g. 18). Just wait a few seconds to conrm the

new value.

In manual functioning mode it is possible to select any

room temperature from +15°C to +40°C, which will be kept

constant until new adjustments or selection of a dierent

functioning mode.

Page 20

20

7.2 Automatic functioning.

The CAR V2 allows automatic functioning, in which a

program manages the room temperature during the hours

of the day.

e desired room temperature can be adjusted onto two

independent levels: comfort ( ) and economy ( ) via the

button, whose distribution throughout the day or the

week is managed by hourly programming.

Press the button until the icon switches-on on

the display .

e CAR V2 is factory-set with a standard program stated in

the table that follows. If this should not satisfy requirements,

it is possible to modify it as described in the chapter relative

to programming.

Note: the system is designed to function on comfort

and economy temperature levels depending on the hour

program set. erefore also during functioning in economy

temperature conditions, if the room temperature measured

is above that set, the chiller can switch-on.

7.3 Forced automatic functioning.

If in automatic functioning mode ( ) the room temperature

is modied by pressing the + / - buttons, the forced automatic

functioning mode is activated (displayed by the switch-on of

the ashing symbol). In this mode, the room temperature

will be regulated to the value set until the next switch-on or

switch-o phase of the automatic program set. e forced

automatic function can be interrupted by simply pressing

the button.

Days

40°C

25°C

Mon - Fri

(Day 1 - 5)

from 23 to 11

from 13 to 17

from 11 to 13

from 17 to 23

Sat - Sun

(Day 6 -7)

from 23 to 13 from 13 to 23

Fig. 20

Fig. 19

Page 21

21

8. INFORMATION

By pressing the button, access a menu that allows to

verify the functioning state of the CAR V2 remote control.

If a determined value is not present “--” will be displayed.

e display of the “info” is subject to the boiler model and

the method of connection of the CAR V2 remote control.

Press the button repeatedly to scroll the list .

To go back to normal functioning mode, press the

button or wait 60 seconds.

e parameters that can be displayed are listed below:

- EXT T: external temperature (the optional external

temperature probe if present).

- HF TMP: Central heating circuit ow temperature.

- HR TMP: central heating circuit return temperature.

- DWIN T: DHW input temperature.

- DHW T: DHW output temperature.

- PAN T: solar collector temperature.

- CH PRS: system pressure, central heating circuit.

- SERVIC: Days remaining before periodic maintenance.

- VER P “x”: “x” identies the type of communication

protocol with the boiler in use:

VER PC = CAR-Bus; VER PI = IMG-Bus.

e display shows the rmware version of the CAR

V2.

remote control

- ZONE: Not used on this model.

N.B.: the sizes displayed depend on the type of boiler to

which the CAR V2 remote control is connected.

Page 22

22

9. PROGRAMMING CAR V2 REMOTE

CONTROL.

Programming of the CAR V2 remote control allows to set/

modify the following parameters:

- comfort and economy temperature levels (dierent for

the “central heating” and “cooling” modes);

- daily/weekly functioning time program (dierent for the

“central heating” and “cooling” and "DHW" modes).

9.1 Setting comfort and economy room

temperature.

e two temperatures are dierent depending whether they

are in "winter" or "cooling" mode.

By pressing the button, the “comfort” (fig. 21) and

“economy” (g. 22) temperatures are displayed alternately.

To regulate both parameters, just press the + / - buttons to

regulate the temperature according to requirements.

To conrm the new temperature, press the button,

to exit without saving the modications, press the

button.

Fig. 21

Fig. 22

Page 23

23

9.2 Programming functioning time.

By pressing the button, it is possible to enter the

time periods programming window for programming the

room temperatures and DHW timer (as well as setting the

current time and day).

By pressing the + / - buttons, the items that can be set in the

menu are displayed alternately.

ere are, in fact, three types of program:

- CH PRG: room central heating program

- HW PRG: DHW heating program

e period in which the DHW temperature is in comfort

will be distinguished by the switch-on of the icon.

N.B.: the function must only be activated in the presence

of a cylinder. e DHW is always active as per standard.

- CHIPRG: room cooling program

By following the points described below, it is possible to

create or modify the time program selected.

1) Press the button, select the program to modify

by pressing the + / - buttons, aer which conrm by pressing

the button.

2) Select the day of group of days by pressing the + / - buttons

and conrm the selection by pressing the button:

- Monday, Tuesday, Wednesday... Sunday (individual day)

- Mon - Fri (from Monday to Friday)

- Sat - Sun (from Saturday to Sunday)

- Mon - Sat (from Monday to Saturday)

- Mon - Sun (from Monday to Sunday)

3) Set the functioning times with comfort and economy

temperature. Within the 24 hours it is possible to dene

a maximum of 4 time periods with Comfort temperature,

each of which is characterised by a switch-on time and a

switch-o time.

e minimum variation of the switch-on and switch-o

time is 30 minutes.

Set the rst functioning period with comfort temperature

(ON 1) indicated at the top and the switch-on time at the

bottom. Press the + / - buttons to modify the switch-on time

and press the button to memorise. At this point, pass

to the next functioning period with comfort temperature

(OFF) indicated at the top and the switch-o time at the

bottom. Press the + / - buttons to modify the switch-o

time and press the button to memorise. When the

Page 24

24

rst phase has been designed, pass automatically to the next

functioning phases at comfort and economy temperature in

order to program. is means repeating the points described

previously up to phase 4.

e sequences of the On and O states must always be

sequential. For example, it is not possible to set “OFF 2” at

13.30 and “ON 3” at 11.00.

Once the day or group of days have been programmed,

proceed in the same way for the remaining days and the

remaining programs.

N.B.: if only 3 switch-on times are used, set the fourth with

switch-on/o time at 24.

N.B. in automatic functioning conditions ( ) the

display will show the 24 hour bar indicating the dierent

time phases with Comfort or Economy temperature

. The presenc e of t h e

hyphen on the time bar corresponds to functioning in

Comfort mode.

Page 25

25

10. DIAGNOSTICS AND ERRORS

10.1 Diagnostics.

The CAR V2 remote control continually controls the

functioning status of the boiler and signals any anomalies,

stating the corresponding error code on the display.

e error codes have meaning depending on the boiler to

which the CAR V2 remote control is connected. erefore,

refer tot he boiler instruction book for a complete list of

error codes and their relative meaning.

In the case of a fault that cannot be reset, contact a qualied

technician (e.g. the Immergas After-Sales Technical

Assistance Service).

“ERR>XX” appears on the display in the event of an error,

where XX stands for the number that identies the error

code as well as the ashing symbol.

As well as the error codes referring to the functioning state

of the boiler, the CAR V2 remote control also checks its own

functioning state, indicating any malfunctions.

Code Description

ERR>CM

Communication error between CAR V2 remote

control and boiler or switch-over phase

between advanced type communication (e.g.

Superior kW) and a normal type

ERR>TP

Error in reading the room temperature or value

measured o scale (below 0°C or over 50°C)

10.2 Reset errors.

In the event of resettable boiler bock, the ashing

icon appears on the display. In this case, by acting on the

relevant button and holding it down for 5 seconds, it is

possible to send a release signal to the boiler that allows

to reset correct boiler functioning within a few seconds.

If normal functioning conditions are set, it goes back to

functioning as previously set.

It is possible to operate up to a maximum of 5 consecutive

reset attempts, aer which an hour must pass before another

5 attempts are available.

10.3 Reset CAR V2 remote control.

Acting on the hole for general rest (ref. 4 g. 6) the CAR V2

remote control hardware can be reset without loosing the

settings made by the user, such as time, date and time prog.

If the CAR V2 remote control original factory set conditions

are to be restored, act as follows.

Press and release the button in the “reset” hole (ref. 4 g. 6)

holding the button down (ref. 2 g. 6).

At this point CAR V2 remote control will be restored with all

factory set data, keeping current time and day.

Page 26

26

11. SPECIAL FUNCTIONS

By pressing the button, a list of options is accessed that

allows to customise functioning of the CAR V2 remote control,

according to the specic necessities.

To scroll the list, press the + / - buttons and press the

button to select the desired function.

11.1 LANGUAGE (language selection).

Allows to set the functioning language of the CAR V2 remote

control. It is possible to select from Italian (ITA as per standard)

and English (ENG).

11.2 REGULT (Management of regulation parameter).

Allows to customise the functioning parameters of the CAR

V2

remote control.

- CH MIN (central heating ow minimum temperature),

allows to regulate the central heating flow minimum

temperature value. Moreover, this value is used to calculate

the curves used for the external probe. Values that are too

high can cause ow temperatures that are too high on average

for room central heating.

- OFFSET (regulation constant), constant that can be regulated

from -15°C to +15°C and which in the presence of the

external probe (optional) modies the set ow temperature

(see g. 23)

set as per standard at 0°C.

TM-MAX/MIN = Selected ow temp. range.

Te = External temperature.

EXTERNAL PROBE

FLOW TEMPERATURE CORRECTION LAWS.

EXTERNAL TEMPERATURE FUNCTION AND THE POSITION OF

THE USER TEMP. ADJUSTMENT CENTRAL HEATING.

Fig. 23

N.B.: if the self-learning function is enabled, the Oset value

could be modied automatically.

- BUILD (dimension and building inertia), adjustable from

1 to 20, as per standard set on 10. It establishes the reaction

speed of the system depending on the type of system present.

For example:

Value System type

5 system with little heat inertia

10

system with normal dimensions with

radiators

Position of the central heating temperature

user adjustment central heating temp.

Page 27

27

20

system with a lot of heat inertia (e.g. oorstanding system)

- AUTO A (self-learning), defines the activation of selflearning, as per standard set at OFF. is function allows

the CAR V2 remote control to vary the oset, adapting it

to the room in which it is installed.

11.3 HOLIDY (holiday program).

From winter functioning mode it is possible to dene a number

of days (from 1 to 99) during which the system deactivates

both the hot water heating function and the room central

heating function.

e value is decreased every midnight in the day change. At the

end of the days set (the meter reaches 0) the previously active

functions are restored. e activation of the holiday function

is indicated by the ashing of the icon and the count of the

days remaining.

The holiday function can be deactivated by pressing the

button.

In the event of remote activation from telephone control, the

boiler is activated with the settings of the telephone control,

omitting the Holiday program.

N.B.: the room anti-freeze function is however guaranteed

also in holiday mode.

11.4 LEGION (anti-legionella function ).

Allows to activate the Anti-legionella function that takes

the temperature of the cylinder to maximum allowed for 20

minutes. It is possible to select between the once a day at 2 in

the night (ON 24H), every 7 days on Monday at 2 in the night

(ON 7 DAYS) or deactivate it (OFF standard function).

N.B.: the function must only be activated in presence of boiler

and eventually a thermostatic valve must be installed at the

DHW output to prevent burns.

11.5 REMOTE (telephone control).

Allows to set the functioning of the CAR V2 remote control

in a way that, in the event of remote activation, it functions

with the automatic time program if set at AUTO. Vice versa,

it functions at continuous comfort temperature (without time

program) if set at ON.

In the event of activation, it displays the ashing ( ) icon.

11.6 CODE.

To use this function, see the “Functions protected by code”

chapter.

Page 28

28

12. FUNCTIONS PROTECTED BY CODE

CODE.

They are advanced character settings (reserved for an

enabled technician), a four character code must be entered

in order to access them (code: 1122).

Press the button and scroll the options present

until “CODE” appears, press the button and insert the

code by selecting the characters using the + / - buttons and

conrming them by pressing the button.

Aer which it is possible to display and modify the following

functions.

12.1 AMB (room probe - On / O or modulating

functioning mode).

Allows to activate or deactivate the room probe present in

the CAR V2 remote control. On the basis of the parameter

setting, it will be possible to regulate the following options:

- AMB: ON (standard value); it is possible to select a cor-

rection factor of the room probe reading and change the

modulating function.

- AMB CR: room robe reading correction, the room

probe range reading can be corrected within a range

of + 3.0 - 3.0°C.

- MODUL (On / O or Modulating functioning):

allows setting functioning of the CAR V2 remote

control On/O or Modulating. Set at ON, the ow

temperature will be varied depending on the room

temperature set. Set at OFF, the ow temperature will

be kept constant until the desired room temperature

is reached. (Setting to be made on systems with zones

control unit).

N.B.: if an external temperature probe is present, the

ow temperature will be set depending on the relative

functioning curve.

- AMB: OFF, the system will not function, regulating

the room temperature but only depending on the time

program set. In this case the room anti-freeze function

is not assured.

12.2 REDUCT (functioning in reduced mode).

if activated with AMB parameter at “OFF”, it denes how the

ow temperature must be in Economy period.

- REDUCT OFF: in functioning periods in Economy mode,

the boiler is switched-o.

- REDUCT ON: in functioning periods in Economy mode,

it reduces the ow temperature by an amount equal to

that set (adjustable from -1°C to -40°C).

Page 29

29

12.3 FRO PR (anti-freeze level).

Allows to set the room temperature for activation of the

anti-freeze function. Can be regulated from 0°C to 10°C

and is set at 5°C as standard.

12.4 ZONE (function not present on this model).

12.5 SERVIC (programmed maintenance).

Sets the period for periodic maintenance (can be set from 6

to 24 months or “O ”). When the period has been set, the

telephone number that the user must contact to perform

periodic maintenance is set.

13. DISABLING

THE CHRONOTHERMOSTAT.

If CARV2 must be used as a boiler control only (simple remote

control function), proceed as follows:

- deactivate the room probe (para. 12.1):

- exclude the 4 time periods of the “PR RIS” in the “Mon

- Sun” group of days, setting the On and O of all 4 time

periods (on1, o1, on2, o2, on3, o3, on4, o4) to 24.00;

- press the AUTO button to set the automatic mode.

N.B.: for the boiler to work in heating mode, the room

thermostat contacts (40-41) on the boiler board must

be closed.

Page 30

30

14. TECHNICAL CHARACTERISTICS

• Dimensions (LxHxD): ..................................................................................................................................142 x 103 x 31 (mm)

• Power Supply: ................................................................................................ 24V nominal via twin-wire communication Bus

• CAR_BUS protocol power supply voltage: .............................................................................................................. 24 ÷ 35 Vdc.

• CAR_BUS protocol maximum input: ............................................................................................................. 10 mA - 350 mW.

• IMG_BUS protocol maximum power supply voltage: ....................................................................................................18 Vdc.

• IMG_BUS protocol maximum input: ............................................................................................................. 23 mA - 250 mW.

• Functioning room temperature: .................................................................................................................................... 0 - +40°C

• Warehouse temperature: ..............................................................................................................................................-10 - +50°C

• Protection rating according to EN 60730: .................................................................................................................................. II

• Protection rating according to EN 60529: ............................................................................................................................IP 20

• Connection technique: ........................................................................................................................................2 polarised wires

• Load reserve time: ......................................................................... 8 hours for hourly count (with at least 2 hours of charge)

• Connection cable max. length: .......................................50 m (with cable of 2x0.75mm2) (0.5 ÷mm2 min - 1.5 mm2 max)

• Precision indication room temp.: .....................................................................................................................+/- 0.5°C a 25°C*

• NTC room temp. sensor: ............................................................................................................................................50 k at 25°C

• Clock indication diversion ........................................................................................................................... +/- 15 minutes/year

* = the indication of the room temperature can be aected by the point of installation of the CAR V2 remote control (e.g.

hot wall, cold wall, height from the ground, etc.)

Page 31

31

15. FACTORY SETTING

• Functioning state ........................................................................................................................................................................O

• Functioning program ......................................................................................................................................................... Manual

• Central heating Comfort temperature ...............................................................................................................................20.0°C

• Central heating Economy temperature ..............................................................................................................................16.0°C

• Cooling Comfort temperature ............................................................................................................................................25.0°C

• Cooling Economy temperature ...........................................................................................................................................40.0°C

• Room temperature in manual .............................................................................................................................................20.0°C

• Anti-freeze ...............................................................................................................................................................................5.0°C

• Holiday Program..................................................................................................................................................HOLIDY = OFF

• Oset ....................................................................................................................................................................... OFFSET = 0°C

• Building inertia dimension ....................................................................................................................................... BUILD = 10

• Self-learning .........................................................................................................................................................AUTO A = OFF

• Room Probe ..................................................................................................................................................................AMB = ON

• Reading Correction ........................................................................................................................................... AMB CR = 0.0°C

• Reduction ............................................................................................................................................................. REDUCT = OFF

• Modulation .............................................................................................................................................................MODUL = ON

• Telephone control ................................................................................................................................................ REMOTE = ON

• Antilegionella: ......................................................................................................................................................LEGION = OFF

• Language: .................................................................................................................................................... LANG = ITA (Italian)

Page 32

Immergas S.p.A.

42041 Brescello (RE) Italy

Tel. 0522 689011

CUSTOMER SERVICE

Free Phone 800 - 306 306

immergas.com

Code 1.031170 - Rev. 15.033917/003 - 10/11

Loading...

Loading...