Page 1

Instructions and warnings

Installer

User

Maintenance technician

IE

CAESAR ECO 11-14

Wall-hung instantaneous water

heaters

with sealed chamber (type C) and

fan assisted

or

open chamber (type B) and

fan assisted

*1.042035ENG*

*1.042035ENG*

Page 2

Page 3

Dear Customer,

Congratulations for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas Customer,

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your water heater. Read the following pages

carefully: you will be able to draw useful tips on the proper use of the device, compliance with which will conrm your satisfaction with the Immergas product.

For assistance and scheduled maintenance contact Authorised Aer-Sales centres: they have original spare parts and are specically trained directly by the

manufacturer.

General warnings

All Immergas products are protected with suitable transport packaging.

e material must be stored in a dry place protected from the weather.

e instruction booklet is an integral and essential part of the product and must be given to the new user in the case of transfer or succession of ownership.

It must be stored with care and consulted carefully, as all of the warnings provide important safety indications for installation, use and maintenance stages.

is instructions manual provides technical information for installing Immergas water heaters. As for the other issues related to water heater installation (e.g.

safety in the work site, environment protection, injury prevention), it is necessary to comply with the provisions of the regulations in force and the principles

of good practice.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally

qualied sta, intended as sta with specic technical skills in the system sector, as envisioned by the Law.

Improper installation or assembly of the Immergas appliance and/or components, accessories, kits and devices can cause unexpected problems for people,

animals and objects. Read the instructions provided with the product carefully to ensure proper installation.

Maintenance must be carried out by skilled technical sta. e Authorised Aer-Sales Service represents a guarantee in terms of qualications and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous.

If errors occur during installation, operation and maintenance, due to non-compliance with technical laws in force, standards or instructions contained in

this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any damage and

the appliance warranty is invalidated.

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE), declares that the design, manufacturing and aer-sales

assistance processes comply with the requirements of standard UNI EN ISO 9001:2015.

For further details on the product CE marking, request a copy of the Declaration of Conformity from the manufacturer, specifying the appliance model

and the language of the country.

e manufacturer declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

Page 4

INDEX

USER page INSTALLER page MAINTENANCE TECHNICIAN page

1 Installation water heater. ............................5

1.1 Installation recommendations. ................. 5

1.2 Main dimensions. .......................................6

1.3 Antifreeze protection. ................................7

1.4 Gas connection. ..........................................7

1.5 Hydraulic connection. ................................7

1.6 Electrical connection. .................................7

1.7 Immergas ue systems. ..............................8

1.8 Tables of Resistance Factors and

Equivalent Lengths. .................................... 9

1.9 Concentric horizontal kit installation. ...10

1.10 Concentric vertical kit installation. ........10

1.11 Separator kit installation. .........................11

1.12 Ducting of ues or technical slots. .........12

1.13 Installation of boiler type B with open

chamber and fan assisted (optional). ..... 12

1.14 Flue exhaust to ue/chimney. ................. 12

1.15 Flues, chimneys and chimney pots. .......12

1.16 Gas system start-up. .................................12

1.17 Water heater start up (ignition). .............12

1.18 Procedure for rst ignition, preparation to

use the appliance. ......................................13

1.19 Kits available on request. ......................... 13

1.20 Water heater components. ....................... 14

2 Instructions for use and maintenance....15

2.1 Cleaning and maintenance. .....................15

2.2 General warnings. ..................................... 15

2.3 Quick appliance operation guide. ...........15

2.4 Control panel.............................................16

2.5 Faults and screen displays. .......................16

2.6 Emptying the water heater. ...................... 17

2.7 Anti-freeze protection (optional). ..........17

2.8 Cleaning the case. ..................................... 17

2.9 Decommissioning. ....................................17

2.10 Gas system not used for periods

over 12 months. .........................................17

3 Check and maintenance. ..........................18

3.1 Hydraulic diagram. ...................................18

3.2 Wiring diagram. ........................................19

3.3 Service Menu. ............................................20

3.4 Possible problems and their causes. .......21

3.5 Converting the water heater to other types

of gas. ..........................................................22

3.6 Solar panels coupling function. ..............23

3.7 Check the network pressure (minimum

power supply pressure - only with

appliances operating with methane). ..... 23

3.8 Yearly appliance check

and maintenance. ......................................23

3.9 Casing removal. ........................................24

3.10 Combustion parameters. .........................25

3.11 Technical data. ..........................................25

3.12 Product che (in compliance with

Regulation 812/2013). ..............................26

3.13 Parameters for lling in the

package che. ............................................27

Page 5

5 cm 5 cm

INSTALLATION

1

WATER HEATER.

1.1 INSTALLATION RECOMMENDATIONS.

e water heaters have been designed for wall

installation only, for the production of domestic

hot water in domestic and similar uses.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural), such as to allow for (always in safe, ecient and comfortable

conditions):

- installation (according to the provisions of

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (outdoors in the place for loading and

transporting the appliances and components)

as well as their eventual replacement with

appliances and/or equivalent components.

In the case of wall installation the wall surface

must be smooth, without any protrusions or

recesses enabling access to the rear part. ey

are not designed to be installed on plinths or

oors (Fig. 1).

By varying the type of installation the classication of the water heater also varies, precisely:

- Type B22 water heater if installed using the

relevant terminal for air intake directly from

the room in which the water heater has been

installed.

- Type C water heater if installed using concen-

tric pipes or other types of pipes envisioned for

the sealed chamber water heaters for intake of

air and expulsion of fumes.

Only professionally qualified companies are

authorised to install Immergas gas appliances.

Installation must be carried out according to

regulation standards, current legislation and in

compliance with local technical regulations and

the required technical procedures.

Attention: it is forbidden to install water heaters

removed from other systems. e manufacturer

declines all liability in the event of damage caused

by water heaters removed from other systems or

for any non-conformities with such equipment.

Attention: before commissioning the water

heater, if it is operated with LPG, make sure

parameters 2 and 13 on page 20 have been set

correctly.

Installation of the water heater when powered

by LPG must comply with the rules regarding

gases with a greater density than air (remember,

as an example, that it is prohibited to install systems powered with the above-mentioned gas in

rooms where the oor is at a lower quota that the

average external country one). Before installing

the appliance, ensure it has been delivered in

perfect condition; if in doubt, contact the supplier

immediately.

Packing materials (staples, nails, plastic bags,

polystyrene foam, etc.) constitute a hazard and

must be kept out of the reach of children. If the

appliance is installed inside or between cabinets,

ensure sufficient space for normal servicing;

therefore, leave clearance of at least 5 cm between

the water heater casing and the vertical sides of

the cabinet. Leave adequate space above and

below the water heater for possible water and

ue removal connections (Ref. Fig. 2).

Keep all ammable objects away from the appliance (paper, rags, plastic, polystyrene, etc.).

It is recommended not to position household

appliances under the water heater because they

could undergo damage in the case of leaks from

the hydraulic ttings. If this is not the case, the

manufacturer cannot be considered liable for

any damage caused to the household appliances.

For the aforementioned reasons, we recommend

not placing furnishings, furniture, etc. under the

water heater.

In the event of malfunctions, faults or incorrect

operation, turn the appliance o and contact an

authorised company (e.g. the Authorised Technical Assistance centre, which has specically

trained sta and original spare parts). Do not

attempt to modify or repair the appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

• Installation Standards:

- this water heater was designed and built for

installation inside buildings.

- Installation of gas appliances, ue exhaust

pipes and combustion air intake pipes is

forbidden in places with a re risk (for example: garages, closed parking stalls), and

in potentially dangerous places.

- Installation on the vertical projection of

cooking hobs is forbidden.

- Installation is forbidden in places/rooms

that constitute public areas of apartment

buildings, internal stairways or other escape

routes (e.g. oor landings, entrance halls,

etc.).

- Installation is also forbidden in places/rooms

that constitute public areas of apartment

buildings such as cellars, entrance halls, attics,

los, etc., unless otherwise provided for by

local regulations in force.

- It is forbidden to install the water heater

inside a closed recessed frame (e.g. Omni

Container).

- e appliance was designed to be installed in

indoor and protected places.

- It must also be installed in an environment

in which the temperature cannot fall below

0°C. It must not be exposed to atmospheric

agents.

If the water heater is installed in a place whose

temperature drops below 0°C, it is compulsory

to use the antifreeze accessory that provides for

adequate protection down to -15°C.

INSTALLERUSERMAINTENANCE TECHNICIAN

YES NO

1

- It is prohibited to obstruct the air intake

and aeration grids where the appliance is

installed.

Attention: wall mounting of the water heater

must guarantee stable and ecient support for

the generator.

e fastening plugs (standard supply) are only to

be used to x the water heater to the wall; they

only ensure adequate support if inserted correctly

(according to technical standards) in walls made

of solid or semi-hollow brick or block. In the

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate mount.

ese appliances are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be connected to a DHW distribution

network suited to their performance and power.

20 cm

2

5

Page 6

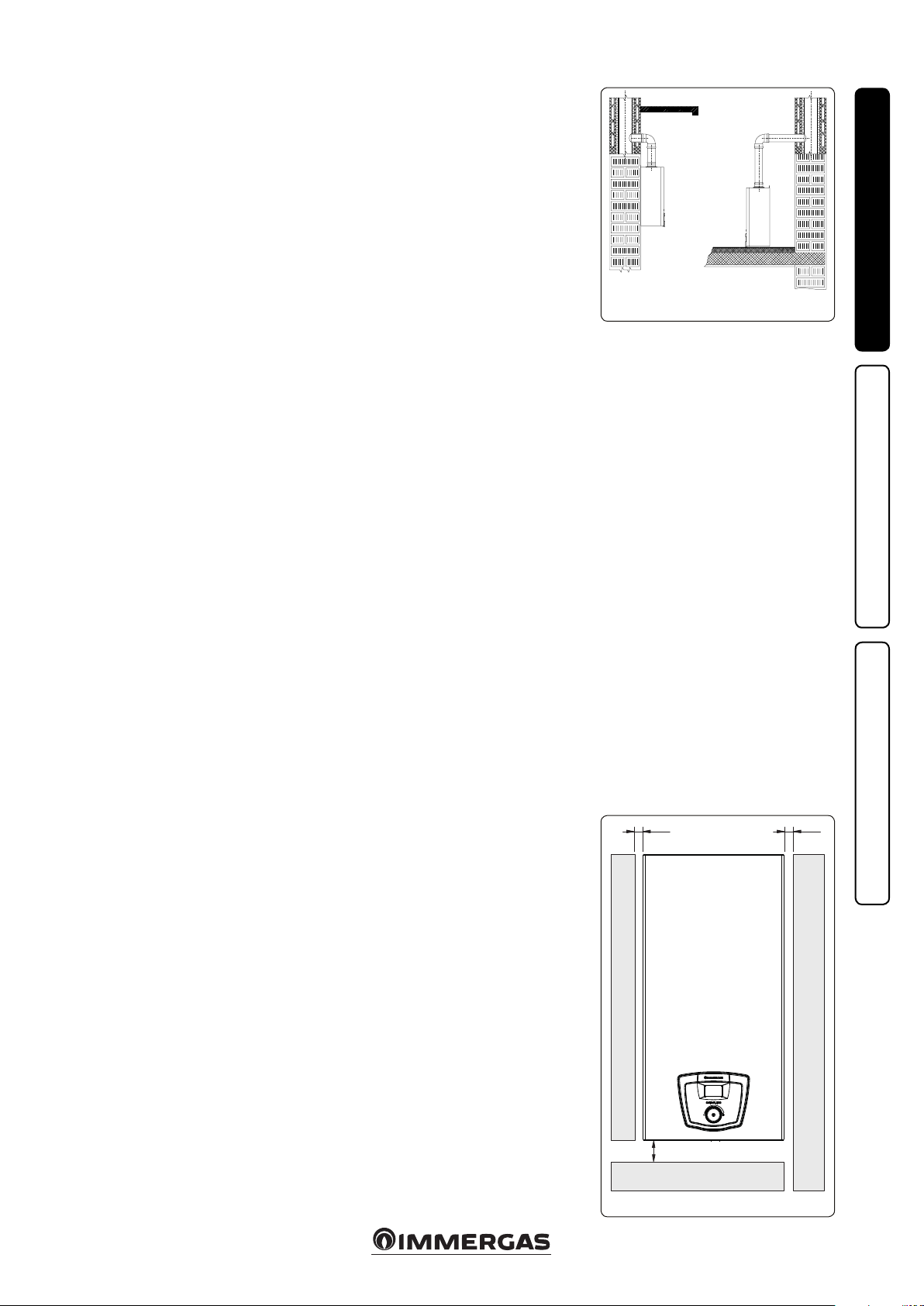

1.2 MAIN DIMENSIONS.

Caesar Eco 11

INSTALLERUSERMAINTENANCE TECHNICIAN

A

A/S

A/S

A

A

CONNECTIONS

A/S

GAS DOMESTIC HOT WATER

G AC AF

3/4” 1/2” 1/2”

Caesar Eco 14

Key:

A

A/S

A A/S

AC - Domestic hot water outlet

AF - Domestic hot water inlet

G - Gas supply

V - Electrical connection

A - Intake

S - Exhaust

A/S - Intake/Exhaust

A

A/S

3

6

Page 7

1.3 ANTIFREEZE PROTECTION. Minimum temperature. If the water heater

is installed in a place where the temperature

falls below 0°C, the connection pipes must be

insulated and, in the event there is no gas (or

the water heater goes into no ignition block), the

appliance can freeze.

To prevent the risk of freezing follow the instructions below:

- Protect the domestic hot water circuit against

freezing by using an accessory that is supplied

on request (anti-freeze kit) comprising two

electric heating elements, the relevant cables

and a control thermostat (carefully read and

follow the installation instructions contained

in the accessory kit pack).

Water heater anti-freeze protection is thus ensured

only if:

- the water heater is correctly connected to electricity power supply circuits;

- the main switch is on;

- the antifreeze kit is installed correctly;

- the connection pipes are insulated.

In these conditions the water heater is protected

against freezing to temperature of -15°C.

e warranty does not cover damage due to interruption of the electrical power supply and failure

to comply with that stated on the previous page.

1.4 GAS CONNECTION.

Our water heaters are designed to operate with

methane gas (G20) and LPG. Supply pipes must

be the same as or larger than the 3/4”G water

heater tting. Before connecting the gas line,

carefully clean inside all the fuel feed system

pipes to remove any residue that could impair

water heater eciency. Also make sure the gas

corresponds to that for which the water heater

is prepared (see water heater data-plate). If

dierent, the water heater must be converted

for operation with the other type of gas (see

converting appliance for other gas types). It is

also important to check the dynamic pressure

of the mains (methane or LPG) used to supply

the water heater, which must comply with EN

437 and its attachment, as insucient levels may

reduce generator output and cause discomfort

to the user.

Ensure correct gas cock connection. e gas supply pipe must be suitably dimensioned according

to current regulations in order to guarantee correct gas ow rate to the burner even in conditions

of maximum generator output and to guarantee

appliance eciency (technical specications).

e coupling system must conform to standards

in force (EN 1775).

Fuel gas quality. e appliance was designed to

operate with combustible gas free of impurities;

otherwise it is advisable to fit special filters

upstream of the appliance to restore the purity

of the fuel.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the caloric value of

the mixture delivered to the appliance, with

subsequent change in its performance.

1.5 HYDRAULIC CONNECTION. Attention: before connecting the water heater

and so as not to make the warranty null and void

on the DHW heat exchanger, wash the system

thoroughly (piping, etc.) in a way to remove

any residue that could compromise the good

functioning of the water heater.

Water connections must be made in a rational

way using the couplings on the water heater

template.

Attention: to preserve the duration and features

of appliance eciency, in the presence of water

whose features can lead to the deposit of lime

scale, it is necessary to install the “polyphosphate

dispenser” kit.

1.6 ELECTRICAL CONNECTION.

e “Caesar Eco” water heater has an IPX5D protection rating for the entire appliance. Electrical

safety of the appliance is reached only when it

is correctly connected to an ecient earthing

system as specied by current safety standards.

Attention: the manufacturer declines any

responsibility for damage or physical injury

caused by failure to connect the water heater to

an ecient earth system or failure to comply with

the technical reference standards.

Also ensure that the electrical installation corresponds to maximum absorbed power specications

as shown on the water heater data-plate. Water

heaters are supplied complete with an “X” type

power cable without plug. e power cable must be

connected to a 230V ±10% / 50Hz mains, respecting L-N polarity and the earthing connection ;

this network must have a multi-pole circuit breaker

with Class III overvoltage category. If the power

supply cable is damaged, it must be replaced by a

special cable or assembly, which are only available

from the manufacturer or its Aer-sales Service. It is

recommended to contact a qualied company (e.g.

the Authorised Aer-Sales Technical Assistance

Service) for replacement to avoid a hazard. e

power cable must be laid as shown (Fig. 4).

If the network fuse on the connection terminal

block needs replacing, this must also be done by

qualied personnel: use a 3.15 A fast fuse. For

the main power supply to the appliance, never

use adapters, multiple sockets or extension leads.

INSTALLERUSERMAINTENANCE TECHNICIAN

Power cable

N.B.: all water heater pipes must never be used

to earth the electric or telephone lines. Ensure

elimination of this risk before making the water

heater electrical connections.

4

7

Page 8

1.7 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the water heaters regarding the installation of

air intake terminals and ue extraction, which are

fundamental for water heater operation.

Attention: e water heater must only be installed

together with an original Immergas air intake and

ue gas exhaust system, in compliance with the

standards in force. is system can be identied

by an identication mark and special distinctive

marking bearing the note " not for condensing

boilers".

INSTALLERUSERMAINTENANCE TECHNICIAN

e ue exhaust pipes must not be in contact with

or be near to ammable materials. Moreover, they

must not pass through buildings or walls made of

ammable material.

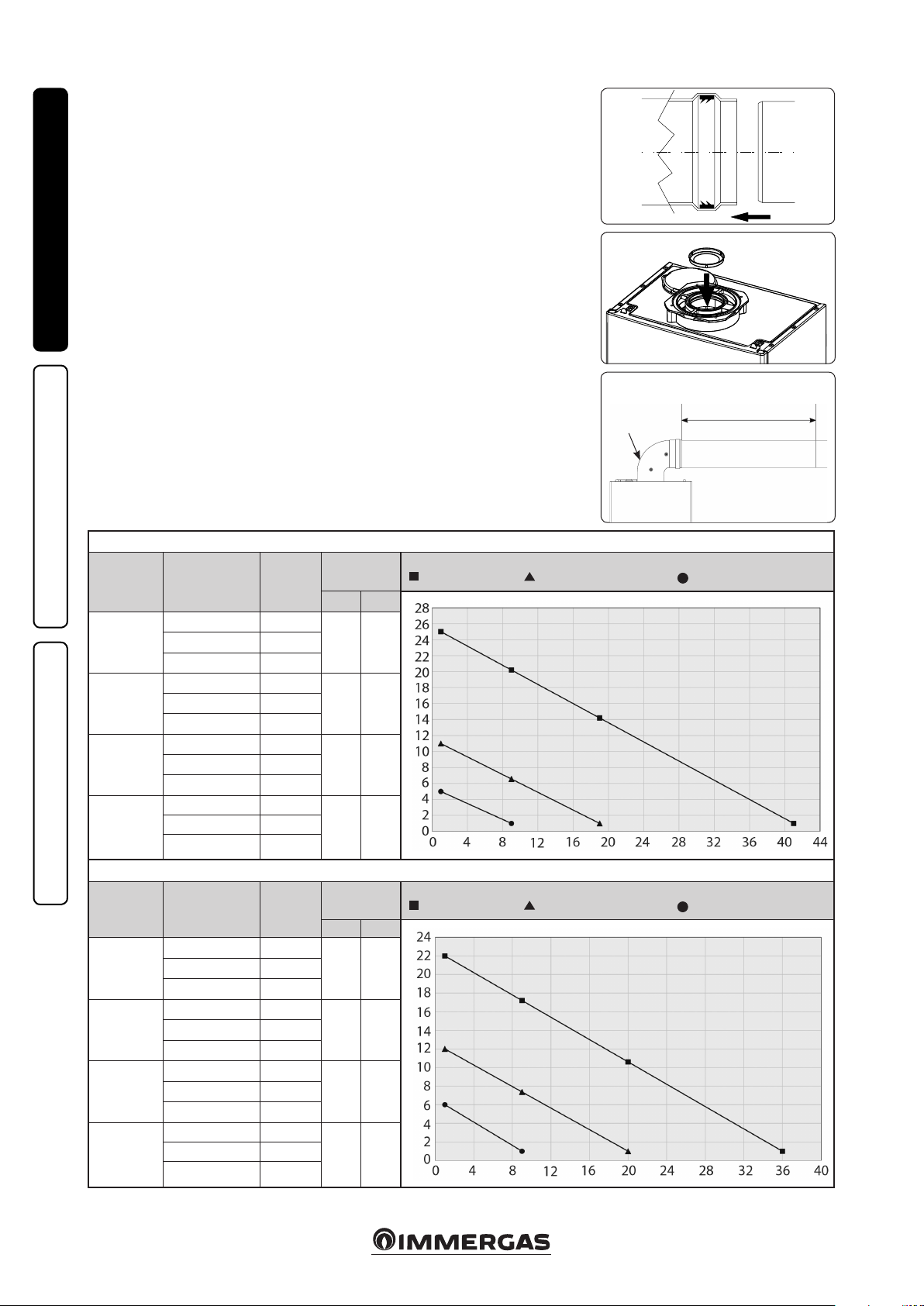

• Positioning of double lip seals. For correct posi-

tioning of lip seals on elbows and extensions, follow

the assembly direction (Fig. 5).

• Coupling extension pipes and concentric

elbows. To install snap-fit extensions with

other elements of the ue extraction elements

assembly, follows:

Fit the concentric pipe or elbow with the male

side (smooth) on the female section (with lip

seal) to the end stop on the previously installed

element. is will ensure sealing and joining of

the elements correctly.

Attention: if the exhaust terminal and/or

concentric extension pipe needs shortening,

consider that the internal duct must always

protrude by 5 mm with respect to the external

duct.

• N.B.: for safety purposes, do not obstruct the

water heater intake-exhaust terminal, even

temporarily.

• N.B.: when installing horizontal pipes, a min-

imum inclination towards the water either of

3% must be maintained and a section clamp

with plug must be installed every 3 metres.

• Diaphragm installation. For proper water

heater operation, a diaphragm must be installed

on the outlet of the sealed chamber and before

the exhaust pipe (Fig. 6).

N.B.: the diaphragm is supplied as per standard

with the water heater.

e head loss of the

90° bend coming

out from the appliance must NOT be

calculated

Duct length/metres

Maximum completed length

5

6

7

Caesar Eco 11

type of exhaust

B22

Type C

d.60/100

horizontal

Type C

d.60/100

vertical

Type C

d.80

duct length [m]

excluding the 90° outlet

bend from the appliance.

Ref. g. 7

diaphragm

[d. mm]

up to 5 43

from 10 to 23 none

up to 1 43

from 2.7 to 5.7 none

up to 2 43

from 3.7 to 6.7 none

4+4 43

from 4+4 to 8+8 45

from 8+8 to 16+16

ue gas

none

head loss of

every additional

bend

45° 90°

1.3 m 1.8 mfrom 5 to 10 45

1 m 1.4 mfrom 1 to 2.7 45

1 m 1.4 mfrom 2 to 3.7 45

1.3 m 1.8 m

without diaphragm - with a 45 diam. diaphragm - with a 43 diam. diaphragm

Length of ue exhaust pipe (m)

With separate ducts having dierent lengths

Air intake pipe length (m)

Caesar Eco 14

head loss of

every additional

bend

45° 90°

1.3 m 1.8 mfrom 4 to 10 47

1 m 1.4 mfrom 1 to 1.9 47

1 m 1.4 mfrom 2 to 2.9 47

1.3 m 1.8 m

without diaphragm - with a 45 diam. diaphragm - with a 43 diam. diaphragm

With separate ducts having dierent lengths

Length of ue exhaust pipe (m)

Air intake pipe length (m)

type of exhaust

duct length [m]

excluding the 90° outlet

bend from the appliance.

Ref. g. 7

ue gas

diaphragm

[d. mm]

up to 4 45

B22

from 10 to 20 none

Type C

up to 1 45

d.60/100

horizontal

Type C

from 1.9 to 3.7 none

up to 2 45

d.60/100

vertical

from 2.9 to 4.7 none

4+4 45

Type C

d.80

from 4+4 to 8+8 47

from 8+8 to 14+14

none

Attention: if installation requires signicant ue exhaust sections, it is necessary to consider the formation of condensate and thus use the “blue series”

insulated type of ue.

8

Page 9

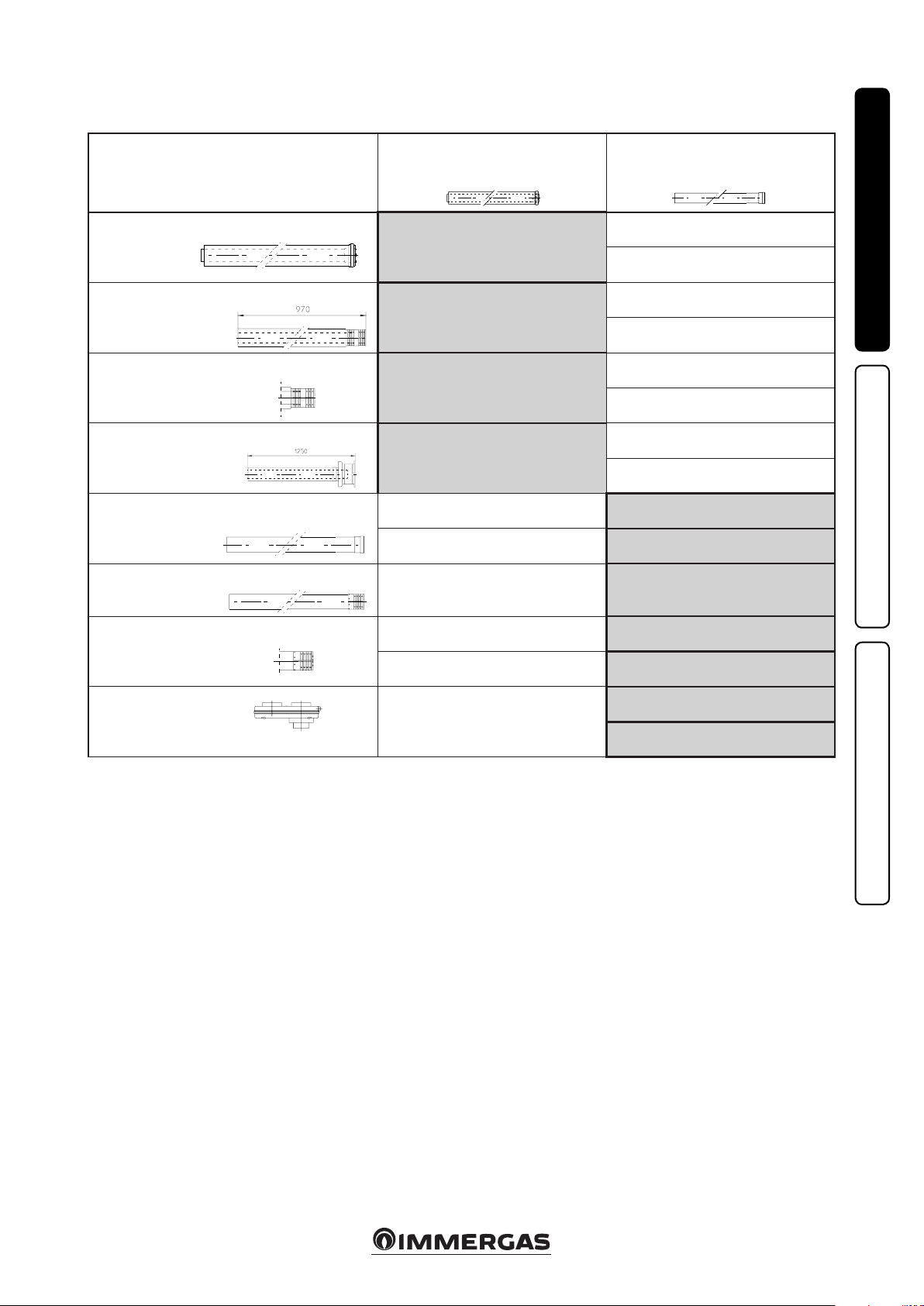

1.8 TABLES OF RESISTANCE FACTORS

AND EQUIVALENT LENGTHS.

TYPE OF DUCT

Concentric pipe Ø 60/100 m 1

Terminal complete with intake-exhaust

horizontal concentric Ø 60/100

Intake-exhaust terminal

horizontal concentric Ø 60/100

Intake-exhaust terminal

vertical concentric Ø 60/100

Pipe Ø 80 m 1 (with and without insulation)

Complete intake terminal Ø 80 m 1

(with or without insulation)

Length

in m of concentric pipe

Ø 60/100

m 1

m 2.8

m 1.9

m 2.5

m 0.1 Intake m 1.0

m 0.2 Exhaust m 1.0

m 0.3 Intake m 2.2

Length

in metres

of pipe

Ø 80

Intake m 7.1

Exhaust m 5.5

Intake m 20

Exhaust m 15

Intake m 14

Exhaust m 10.6

Intake m 18

Exhaust 14

INSTALLERUSERMAINTENANCE TECHNICIAN

Intake terminal Ø 80

Exhaust terminal Ø 80

Split parallel Ø 80

from Ø 60/100 to Ø 80/80

m 0.2 Intake m 1.3

m 0.1 Exhaust m 0.8

Intake m 3.8

m 0.5

Exhaust m 2.9

9

Page 10

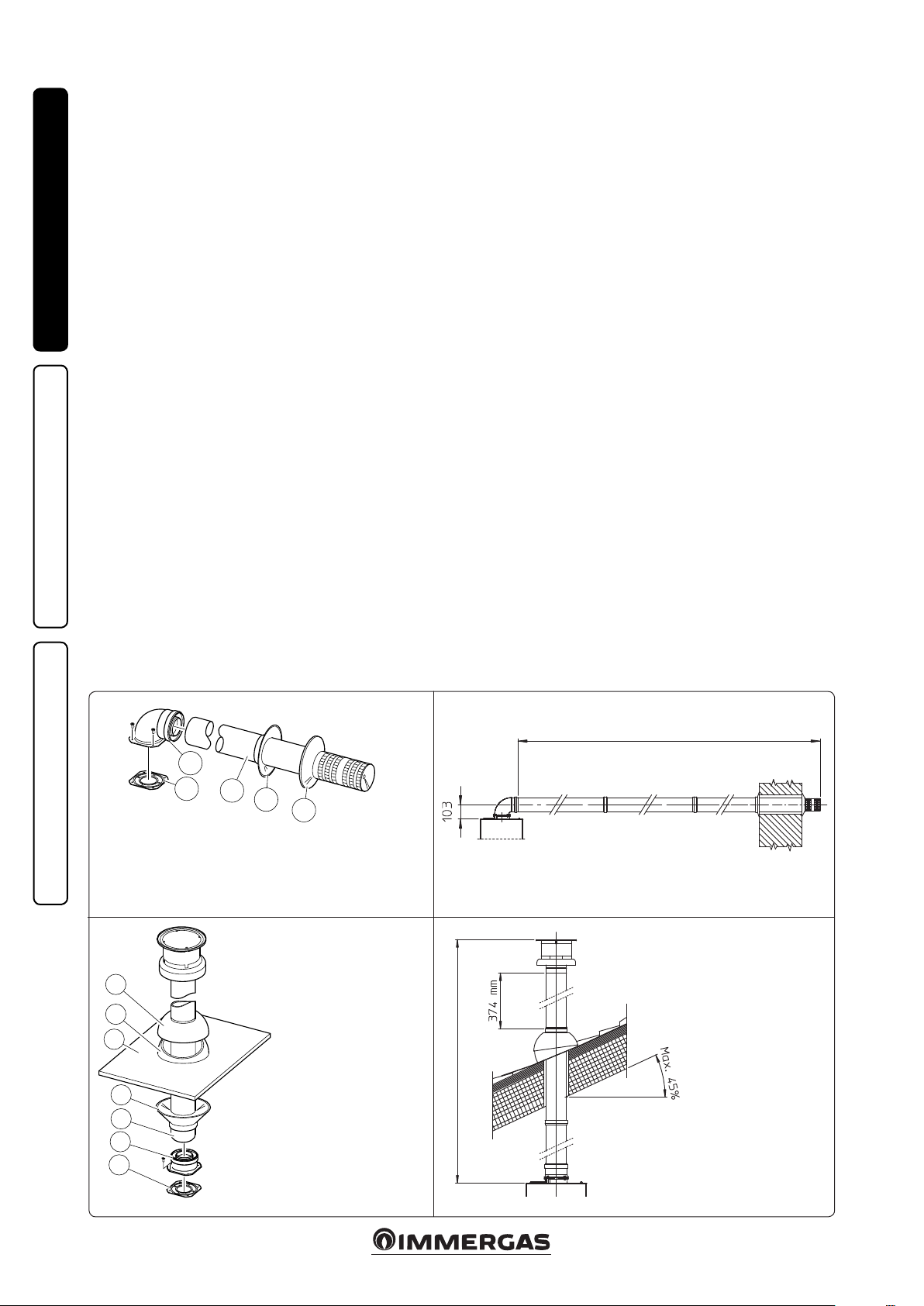

1.9 CONCENTRIC HORIZONTAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Installation of this terminal is governed by current technical regulations.

is terminal is connected directly to the outside

of the building for air intake and ue exhaust. e

horizontal kit can be installed with the rear, right

side, le side or front outlet.

• External grid. e Ø 60/100 intake/exhaust

INSTALLERUSERMAINTENANCE TECHNICIAN

terminal, if properly installed, is pleasant to

look at on the outside of the building. Make

sure that the external silicone wall sealing plate

is properly inserted in the wall.

Horizontal intake-exhaust kit Ø 60/100. Kit

assembly (Fig. 8): install the bend with ange

(2) onto the central hole of the water heater

inserting the gasket (1) and tighten using the

screws included in the kit. Couple the concentric

terminal pipe Ø 60/100 (3) with the male end

(smooth) into the female end (with lip seals)

of the bend (2) up to the stop, making sure that

the internal and external wall sealing plate have

been tted, this will ensure sealing and joining

of the kit elements.

• Extensions for Ø 60/100 horizontal kit

(Fig. 9). e kit with this conguration can be

extended up to a max. horizontal length of 5.7 m

(for Caesar Eco 11) and horizontal length of 3.7

m (for Caesar Eco 14), including the terminal

with grid and excluding the concentric bend

leaving the water heater. In this case the special

extensions must be requested.

1.10 CONCENTRIC VERTICAL KIT INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Concentric vertical intake and exhaust kit. is

vertical terminal is connected directly to the outside of the building for air intake and ue exhaust.

N.B.: the vertical kit with aluminium tile enables

installation on terraces and roofs with a maximum slope of 45% (approx 25°) and the height

between the terminal cap and half-shell (374

mm) must always be respected.

Vertical kit with aluminium tile Ø 60/100.

To use this kit one must use the xing plate kit

60/100 (sold separately).

Kit assembly (Fig. 10): install the concentric

ange (2) on the central hole of the water heater

inserting the gasket (1) and tighten using the

screws in the kit. Fit the male end (smooth) of the

adapter (3) into the female end of the concentric

ange (2). Imitation aluminium tile installation.

Replace the tile with the aluminium sheet (5),

shaping it to ensure that rainwater runs off.

Position the xed half-shell (7) and insert the intake-exhaust pipe (6). Fit the Ø 80/125 concentric

terminal pipe with the male end (6) (smooth) to

the female end of the adapter (3) (with lip gasket)

up to the stop; making sure that the wall sealing

plate (4) has been tted, this will ensure sealing

and joining of the elements making up the kit.

•Extensions for vertical kit Ø 60/100 (Fig. 11).

e kit with this conguration can be extended

up to maximum 6.7 vertical rectilinear metres

(for Caesar Eco 11) and 4.7 vertical rectilinear

metres (for Caesar Eco 14), including the

terminal. is conguration corresponds to

a resistance factor of 100. In this case specic

extensions must be requested.

2

1

3

4

e kit includes:

N° 1 - Gasket (1)

N° 1 - Concentric bend Ø 60/100 (2)

N° 1 - Int./exhaust concentric terminal Ø 60/100 (3)

N° 1 - Internal wall sealing plate (4)

N° 1 - External wall sealing plate (5)

7

6

5

4

3

2

1

5

e xing plate kit includes:

N° 1 - Gasket (1)

N° 1 - Female concentric

ange (2)

e Kit includes:

N° 1 - Concentric intake-

exhaust pipe

Ø 60/100 (3)

N° 1 - Wall sealing plate (4)

N° 1 - Aluminium tile (5)

N° 1 - Fixed half-shell (6)

N° 1 - Mobile half-shell (7)

C

12

MAXIMUM EQUIVALENT LENGTH 5700 (CAESAR ECO 11)

MAXIMUM EQUIVALENT LENGTH 3700 (CAESAR ECO 14)

N.B.: to calculate the equivalent lengths, refer to the table on page 8.

8 9

C

32

MAXIMUM EQUIVALENT LENGTH 6700 (CAESAR ECO 11)

MAXIMUM EQUIVALENT LENGTH 4700 (CAESAR ECO 14)

N.B.: to calculate the equivalent lengths,

refer to the table on page 8.

10

C

12

C

32

11

10

Page 11

1

7

9

5

5

6

3

2

S

A

4

7

8

1.11 SEPARATOR KIT INSTALLATION. Type C configuration, sealed chamber and fan assisted.

is kit allows air to come in from outside the

building and the fumes to exit from the chimney or ue through divided ue exhaust and air

intake pipes. Combustion products are expelled

from pipe (S). e required amount of air is taken

in through pipe (A) for combustion. Both ducts

can be routed in any direction.

Separator kit Ø 80/80. Kit assembly (Fig. 12):

install the ange (4) on the central hole of the

water heater, interposing the gasket (1) and

tighten with the at-tipped hex screws included

in the kit. Remove the at ange present in the

lateral hole with respect to the central one (according to needs) and replace it with the ange

(3), positioning the gasket (2) already present on

the water heater and tighten using the supplied

self-threading screws.

Fit the male side (smooth) to the bends (5) in

the female side of the anges (3 and 4). Fit the

intake terminal (6) with the male side (smooth)

in the female side of the bend (5) up to the end

stop, ensuring that the internal and external wall

sealing plates are tted. Fit the exhaust pipe (9)

with the male end (smooth) in the female end of

the bend (5) up to the stop, making sure that the

internal wall sealing plate has been tted, this will

ensure sealing and joining of the kit elements.

• Installation clearances (Fig. 13). e minimum

installation clearance measurements of the Ø

80/80 separator terminal kit have been stated

in one limit condition.

• e gure (Fig. 14) shows the conguration

with vertical exhaust and horizontal intake.

• Extensions for separator kit Ø 80/80. The

maximum vertical rectilinear length (without

bends) used for Ø80 intake and exhaust pipes

can be calculated by using the graphs for ducts

with dierent lengths on page 8.

INSTALLERUSERMAINTENANCE TECHNICIAN

C

82

e kit includes:

N°1 - Exhaust gasket (1)

12

14

N°1 - Flange gasket (2)

N°1 - Female intake ange (3)

N°1 - Female exhaust ange (4)

N°2 - 90° bend Ø 80 (5)

N°1 - Intake terminal Ø 80 (6)

N°2 - Internal wall sealing plates (7)

N°1 - External wall sealing plate (8)

C

52

N°1 - Exhaust pipe Ø 80 (9)

C

42

13

C

82

Attention: if the installation requires a signicant

development of the ue to the discharge, due

consideration must be given to the formation of

L Ø80 A

To calculate the intake “L Ø80 A” and exhaust “L Ø80 S” distance, refer to the graph on page

8 regarding separate ducts having dierent lengths.

condensate that could take place inside the pipe

and Immergas insulated “Blue Series” ue kits

must be used.

L Ø80 S

11

15

Page 12

1.12 DUCTING OF FLUES OR TECHNICAL SLOTS.

With a specic “ducting system” it is possible to

reuse existing ues, chimneys and existing or

new technical slots to discharge the water heater

fumes. Ducting requires ducts declared to be

suitable for the purpose by the manufacturer,

following the installation and user instructions,

provided by the manufacturer and the requirements of the regulations in force.

1.13 INSTALLATION OF BOILER TYPE B

INSTALLERUSERMAINTENANCE TECHNICIAN

WITH OPEN CHAMBER AND FAN

ASSISTED OPTIONAL.

This configuration requires use of a special

terminal (Ref. 1 Fig. 16) (present in the intake

kit for the installation in question) to be placed

on the intake hole above the sealed chamber

(Fig. 16). Air intake takes place directly from

the environment and ue exhaust in individual

chimney or to the outside.

With this conguration:

- air intake takes place directly from the envi-

ronment in which the appliance is installed

and only functions in permanently ventilated

rooms, according to the regulations in force;

- the ue exhaust must be connected to its own

individual flue or ducted directly into the

external atmosphere;

- type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours or

substances (e.g. acid vapours, glues, paints, solvents, combustibles, etc.), as well as dusts (e.g.

dust deriving from the working of wood, coal

nes, cement, etc.), which may be harmful for

the components of the appliance and jeopardise

operation.

- in conguration type B, the boilers must not be

installed in bedrooms, bathrooms or in bedsits.

The technical regulations in force must be

respected.

Max. length of exhaust pipe.

e exhaust pipe (both vertical or horizontal) can

be extended to the maximum length indicated in

the table on page 8.

1.14 FLUE EXHAUST TO FLUE/CHIMNEY.

e ue exhaust does not necessarily have to be

connected to a branched type traditional ue.

e discharge of ue gases, just for the water

heaters installed in configuration C, can be

connected to a particular LAS type collective

ue. For B22 congurations, discharge is only

allowed into individual ue or directly into the

outside atmosphere by the relevant terminal.

Multiple and combined ues must be specially

designed according to the calculation method

and requirements of the standards (such as EN

13384), by professionally qualied technical sta.

Chimney or ue sections for connection of the

ue exhaust pipe must comply with requisites of

technical standards in force.

1.15 FLUES, CHIMNEYS AND CHIMNEY POTS.

e ues, chimneys and chimney caps for the

evacuation of combustion products must be

in compliance with the applicable standards

in force.

Positioning the exhaust terminals. e exhaust

terminals must:

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum dis-

tances specied in current technical standards.

Combustion products exhaust of natural

draught or fan assisted appliances in open-top

closed environments. In spaces closed on all

sides with open tops (ventilation pits, courtyards etc.), direct combustion product exhaust

is allowed for natural draught or fan assisted gas

appliances with a heat input range from 4 to 35

kW, provided the conditions as per the current

technical standards are respected.

1.16 GAS SYSTEM STARTUP.

To start up the system, refer to the technical

standards in force. In particular, for new gas

systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from the pipelines;

- check that the internal system is properly sealed

according to the specications set forth by

technical regulations in force.

1.17 WATER HEATER START UP

IGNITION.

Attention: before commissioning the water heater,

if it is operated with LPG, make sure parameters 2

and 13 on page 20 have been set correctly.

To commission the water heater (the operations

listed below must only be performed by qualied

personnel and in the presence of sta only):

- check that the internal system is properly sealed

according to the specications set forth by

regulations in force;

- ensure that the type of gas used corresponds to

water heater settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

-check that there are no external factors that may

cause the formation of fuel pockets;

- switch the water heater on and ensure correct

ignition;

- ensure that the safety device intervenes in the

event of gas supply failure and check the relative

intervention time;

- check activation of the main switch located

upstream of the water heater;

- check that the concentric intake-exhaust terminal (if tted) is not blocked.

e water heater must not be started up even if

only one of the checks should be negative.

16

12

Page 13

1.18 PROCEDURE FOR FIRST IGNITION, PREPARATION TO USE THE APPLIANCE.

Starting the appliance

Aer checking everything, proceed as follows:

- power the water heater;

- open the gas cock installed upstream from the

water heater;

- open the water tap in the lower part of the water

heater;

Press the ignition button ( ). The screen

displays:

• e soware revision.

• e type of gas set up on the water heater (nG:

G20 - Bu: G30 - Pr: G31).

• LE indicating that it is a Low Emission product.

• Model of the water heater:

- 1E (Caesar Eco 11)

- 4E (Caesar Eco 14).

Aer the procedure, before ignition, the screen

displays the symbols ( ) (Fig. 17).

Press the button ( ) to start the water heater.

e screen displays the value of the set temperature, the symbol ( ) (in the event of hot water

ow rate in progress) and the symbol (in the

event of burner operation) ( ) (Fig. 18).

Regulation of the water temperature

e water temperature can be set within a range

of 37 and 60°C.

- Turn the ignition button clockwise to increase

the temperature and anticlockwise to decrease

it. e symbol ( ) ashes for 5 seconds and

the screen displays the new temperature set.

Appliance switch-o

- Press and hold the water heater switch-off

button ( ) for approximately 5 seconds;

- as soon as the symbols ( ) start ashing,

release the button;

- the appliance will go OFF and the screen will

display the xed symbols ( ) (Fig. 17).

From this point on, the appliance is inactive

(stand-by).

To restart the water heater again, press the ignition button ( ).

17

1.19 KITS AVAILABLE ON REQUEST.

• Polyphosphate dispenser kit. e polyphosphate dispenser reduces the formation of limescale and preserves the original heat exchange

and domestic hot water production conditions.

e water heater is prepared for application of

the polyphosphate dispenser kit.

• Anti freeze kit with resistance (on request). If

the water heater is installed in a place where the

temperature falls below 0°C and the appliance

can freeze. To prevent freezing of the domestic

hot water system, an anti freeze kit with an electrical resistance can be tted from the relative

cable and from a control thermostat.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

INSTALLERUSERMAINTENANCE TECHNICIAN

18

13

Page 14

1.20 WATER HEATER COMPONENTS.

5

INSTALLERUSERMAINTENANCE TECHNICIAN

6

4

7

3

8

2

1

9

12 11 10

Key:

1 - Gas valve

2 - Limit thermostat

3 - NTC probe (hot water outlet)

4 - Ignition/detection electrode

5 - Fan

6 - Heat exchanger

7 - Burner

8 - NTC probe (cold water intake)

9 - Flow meter

10 - Cold water inlet

11 - Gas

12 - Hot water outlet

19

14

Page 15

INSTRUCTIONS FOR USE

2

AND MAINTENANCE.

2.1 CLEANING AND MAINTENANCE. Attention: to preserve the water heater's integrity

and keep its safety features, performance and

reliability unchanged over time, maintenance

operations must be carried out on a yearly basis

in compliance with that stated in the “annual

check and maintenance of the appliance” section,

in compliance with national, regional, or local

standards in force.

2.2 GENERAL WARNINGS.

Never expose the wall-mounted water heater to

direct vapours from a cooking surface.

e device can be used by children at least 8

years old as well as by persons with reduced

physical, sensory or mental capabilities, or lack of

experience or required knowledge, provided that

they are under surveillance, or aer they have

been instructed relating to the safe use and have

understood the potential dangers. Children must

not play with the appliance. Cleaning and maintenance destined to be performed by the user

can not be carried out by unsupervised children.

Do not touch the ue gas exhaust terminal (if

present) due to the high temperatures it can

reach.

For safety purposes, check that the concentric

air intake/flue exhaust terminal (if fitted), is

not blocked.

Whenever temporary deactivation of the water

heater is decided, the electric, water and gas

supplies must be interrupted.

N.B.: you must leave the water heater powered

if the optional antifreeze kit is installed and the

room temperature can drop below 0°C.

In the case of work or maintenance to structures

located in the vicinity of ducting or devices for ue

extraction and relative accessories, switch o the

appliance and on completion of operations ensure

that a qualied technician checks eciency of the

ducting or other devices.

Never clean the appliance or connected parts

with easily ammable substances.

Never leave containers or ammable substances

in the same environment as the appliance

- It is prohibited to obstruct the air intake and

aeration grids where the appliance is installed.

- If there is a water leak, immediately close the

mains water supply and ask an authorised company for assistance (for example, Authorised

Aer-sales Service).

• Attention: using any components that use

electrical power requires some fundamental

rules to be observed:

- do not touch the appliance with wet or moist

parts of the body; do not touch it when barefoot;

- never pull electrical cables or leave the appliance exposed to atmospheric agents (rain,

sunlight, etc.);

- the appliance power cable must not be replaced

by the user;

- in the event of damage to the cable, switch o

the appliance and contact exclusively qualied

sta for replacement;

- if the appliance is not to be used for a certain

period, disconnect the main power switch.

N.B.: you must leave the water heater powered

if the optional antifreeze kit is installed and the

room temperature can drop below 0°C.

At the end of its service life, the appliance must

not be disposed of like normal household waste

nor abandoned in the environment, but must

be removed by a professionally authorised

company. C ontact the manufacturer for disposal

instructions.

2.3 QUICK APPLIANCE OPERATION GUIDE.

Ignition

Press the ignition button ( ).

Regulation of the water temperature

Turn the regulation knob to the right to increase

the temperature and to the le to decrease it

(temperature ranging between 37 and 60°C).

Switching o

Press and hold the switch-o button ( ). As

soon as the symbols ( ) start ashing, release

the button.

e appliance will go OFF and the screen will

display the xed symbols ( ).

Reset

Press and hold the reset button ( ). As soon as

the wording ( ) is displayed, release the button.

e appliance is ready for use.

Attention: if the appliance is switched o for long

periods, disconnect the external omnipolar water

heater switch and close the gas cock upstream of

the water heater.

Attention: if it is likely that the room temperature

where the water heater is installed can drop below

0° C, the water inside the water heater must be

emptied by closing the cold water inlet cock and

opening the hot water cock below the room’s main

water supply.

Ignition - switch-o - reset button/Water

temperature adjustment knob

20

INSTALLERUSERMAINTENANCE TECHNICIAN

15

Page 16

2.4 CONTROL PANEL.

INSTALLERUSERMAINTENANCE TECHNICIAN

EXTMENU

MEM

Key:

1 - Display

2 - On - O - RESET button/

Water adjustment knob

3 - Water ow rate in progress

4 - Value of the set temperature

Faults/Alarms

31

4 5

EXTMENU

MEM

78 62

5 - Remote control connection (accessory)

6 - Solar system connection

7 - Presence of faults

8 - Presence of ame (ame symbol)

Flame fault (crossed-out symbol)

21

2.5 FAULTS AND SCREEN DISPLAYS.

If the appliance blocks, the screen displays the

wording ( ) followed by a fault code to refer

to in order to release it.

Two types of stops can occur:

• Temporary stop (not permanent), the fault code

ashes, the stop is automatically removed when

its cause has been solved. If the fault persists, the

temporary stop switches to permanent.

Display Type of alarm Solutions

Flame control module block alarm.

Denite shutdown

Denite shutdown

Temporary stop

Temporary stop

Denite shutdown

Denite shutdown

Electronic ame control fault alarm.

Limit thermostat alarm.

IN-OUT DHW NTC fault alarm. (1)

Parasite ame alarm. (1)

Modulation coil cable disconnection alarm.

Alarm in the event of 5 consecutive resets.

• Denite stop (block), the fault code ashes. In

this case, the appliance does not restart automatically and must be released by the user or

operator by way of the release procedure only.

Below is a list of the types of alarms, their type of

display and the solutions to reset the appliance:

Press and hold the reset button ( ). As soon as the wording

( ) is displayed, release the button.

e appliance restarts automatically (1).

Press and hold the reset button ( ). As soon as the wording

( ) is displayed, release the button.

e appliance restarts automatically (1).

Press and hold the reset button ( ). As soon as the wording

( ) is displayed, release the button.

e appliance restarts automatically (1).

To reset the appliance, disconnect and connect it again.

Press and hold the reset button ( ). As soon as the wording

( ) is displayed, release the button.

e appliance restarts automatically (1).

22

Low Voltage alarm. Wait for the water heater to auto reset (1).

Temporary stop

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service)

16

Page 17

Display Type of alarm Solutions

Incorrect network frequency detection alarm. Wait for the water heater to auto reset (1).

Temporary stop

Flame loss alarm for more than 3 consecutive times. (1)

Denite shutdown

Temporary stop

Denite shutdown

Temporary stop

Denite shutdown

Denite shutdown

Denite shutdown

Denite shutdown

Temporary stop

Temporary stop

Button fault.

Valve calibration request. (1)

AL70 - Inlet temperature alarm >70°C

Displayed with a ashing bell only

Complete view is only displayed in the alarms log

Alarm regarding increased temperature not reached. (1)

Driver error alarm. (1)

Alarm caused by a problem with combustion during ignition.

Block caused by persistent bad combustion. (1)

Bad combustion alarm. (1)

AL84 - Bad combustion alarm

Displayed with a ashing ame only

Complete view is only displayed in the alarms log.

It is displayed when the button is held for over 30 seconds; once

released, the fault disappears.

(1)

Press and hold the reset button ( ). As soon as the wording

( ) is displayed, release the button.

e appliance restarts automatically (1).

(1)

INSTALLERUSERMAINTENANCE TECHNICIAN

Fan revs sensor alarm. (1)

Denite shutdown

High temperatures. (1)

Display

Soware, startup board error alarm. (1)

Denite shutdown

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service)

2.6 EMPTYING THE WATER HEATER.

To empty the water heater, close the cold water

inlet valve and open the hot water valve lower

down in the water network in the room.

2.7 ANTIFREEZE PROTECTION

OPTIONAL.

e water heater can be equipped with an optional antifreeze kit to protect it against freezing

down to outdoor temperatures of -15°C. To

install the kit correctly and, more importantly,

to ensure suitable operation, it is necessary to

follow the instructions supplied with the said kit.

2.8 CLEANING THE CASE.

Use damp cloths and neutral detergent to clean

the water heater casing. Never use abrasive or

powder detergents.

2.9 DECOMMISSIONING.

In the event of permanent shutdown of the water

heater, contact professional sta for the procedures and ensure that the electrical, water and

gas supply lines are shut o and disconnected.

2.10 GAS SYSTEM NOT USED FOR PERIODS OVER 12 MONTHS.

e current regulation provides that gas systems

not used for over 12 months must be checked

prior to being used again, as per regulations in

force, by professionally qualied sta.

If the inspection is successful, the water heater

can be recommissioned according to the instructions specied in Paragraph 1.17 herein.

17

Page 18

CHECK

3

AND MAINTENANCE.

3.1 HYDRAULIC DIAGRAM.

INSTALLERUSERMAINTENANCE TECHNICIAN

Key:

1 - Flue hood

2 - Domestic hot water heat exchanger

3 - Burner

4 - Valve/burner pipe

5 - NTC probe (cold water intake)

6 - Flow regulator

7 - Flow meter

8 - Gas valve

9 - NTC probe (hot water outlet)

10 - Nozzle manifold unit

11 - Limit thermostat

12 - Sealed chamber

13 - Fan

AC - Domestic hot water outlet

AF - Domestic cold water inlet

G - Gas supply

18

23

Page 19

P

3.2 WIRING DIAGRAM.

INSTALLERUSERMAINTENANCE TECHNICIAN

BL

BR

BL

BL

BR

BR

BKBKBRBRBR

P

BL

P

BKRGGW

Key:

EL - Ignition electrode

TR - Ignition transformer

F - Fan

FX - DHW ow meter

LT - Limit thermostat

SP - DHW probe (hot water output)

GV - Gas valve

YES - DHW probe (cold water input)

Colour code key:

BK - Black

BL - Blue

BR - Brown

G - Green

GY - Grey

R - Red

W - White

Y - Yellow

PK

Y

GR

BU

P - Purple

PK - Pink

BU - Light blue

24

19

Page 20

3.3 SERVICE MENU. “Service Menu” activation

It is possible to access the “SERVICE MENU”

in order to edit the operating parameters of the

appliance.

- With the water heater on, press the reset button

( ) (Fig. 23) for approximately 10 seconds. e

symbols on the display will start ashing and

rst ( ) will be displayed, followed by ( );

- release the reset button;

- enter the code ( ) by turning the knob and

conrm by pressing reset.

INSTALLERUSERMAINTENANCE TECHNICIAN

If the code is wrong, or if the time envisaged

for the operation should drop, the appliance

automatically goes back to the standby or operation status.

Upon accessing the “SERVICE MENU”, it is

possible to select the sub-menu concerned by

turning the knob:

• ( ) Parameters menu.

• ( ) Calibration menu.

• ( ) Alarms log menu.

• ( ) Info menu.

Once you have found the sub-menu you are

looking for, conrm by pressing reset ( ).

Attention: to exit from the “SERVICE MENU”,

press the reset button until the wording MENU

ashes, then release the button: the display goes

to the last sub-menu selected. Press the reset button again until the wording MENU ashes, then

release the button: the screen displays the value of

the set temperature.

Parameters menu ( )

On activating the menu, the index of the rst

parameter is displayed, followed by the set value:

- turn the knob to display the following parameters;

- having identied the parameter to edit, press

reset: the value that can be edited ashes and,

by turning the knob, it is possible to change it;

- save the value by pressing the reset button.

Attention: the menu is exited automatically aer

5 minutes of inactivity, or by pressing the reset

button for a while.

Calibration menu ( )

Attention: the pressure must only be adjusted by

an authorised technician.

Attention: the operations described below must

be carried out in sequence.

Attention: calibration is completed automatically

aer 15 minutes of inactivity or by pressing reset for

a long time, or in the event of overheating (67°C).

Before calibration, check the network pressure

by referring to the previous paragraph.

Two calibration methods are possible for the

gas valve:

- MANU. Enables a partial modication of the

values; it will be possible to deviate from the

set value by about +/- 1.5 mbar.

- AUTO. Enables to reset the values and perform

a complete calibration of the gas valve (e.g.:

aer replacing the valve, the board or following

a gas transformation).

e standard procedure is MANU.

e AUTO procedure can only be accessed by

the Authorised Assistance Technical Service (Ref.

Par. 3.5).

To access the MANU procedure, proceed as

follows:

- set the system’s electric switch O;

- remove the casing by loosening the fastening

screws situated in the lower part of the water

heater and release the casing from the upper

part;

- remove the cap that closes the service passage

(situated on the bracket - Fig. 35) and make it

pass through the hole of the silicone pipe of the

pressure gauge;

- loosen the pressure point screw downstream of

the gas valve by approximately two turns and

connect a pressure gauge;

- close the casing properly and set the system’s

switch On;

- access the calibration menu ( );

- open the hot water tap and wait for the burner

to ignite.

On activation of the menu, the wording Ma

25

will appear rst, followed by nu that makes up

the word Manu and ( ) to indicate that the

appliance is operating at its maximum.

- Turn the knob until the burner’s maximum

pressure value is displayed on the pressure

gauge (ref. technical data table);

- to save the value, press the reset button;

- press the reset button to select the next value

regarding minimum calibration ( );

- turn the knob until the burner’s minimum

pressure value is displayed on the pressure

gauge (ref. technical data table);

- to save the value, press the reset button;

- press the reset button until the word MENU

ashes, then release the button: the screen will

display ( );

- press the reset button again until the wording

MENU ashes, then release the button: the

screen displays the value of the set temperature;

- close the hot water cock.

Attention: the menu is exited automatically

aer 15 minutes of inactivity, or in the event of

overheating 67°C).

27

Alarms log menu ( )

is function enables you to view the last 10

errors triggered on the appliance.

On activating the menu, the following is displayed alternately: the wording ( ) (index of

the last error memorised), the error code and

wording ( ) (e.g.: ( ) => ( ) => ( ) ).

Turn the knob to scroll through the index of

errors; the displays run from the most recent to

the furthest in time.

If the user pauses, the screen displays the wording AL to indicate that they are in the errors

log menu.

Press the reset button until the wording MENU

ashes, then release the button, the screen displays ( ).

Attention: to exit the menu, press the reset but-

ton again until the wording MENU ashes, then

release the button: the screen displays the value of

the set temperature.

28

Info menu ( )

is function displays:

the soware revision.

e water temperature in real time.

e water ow rate in real time (l/min).

is function remains active when supplying

hot water.

Attention: the menu is exited automatically aer

15 minutes of inactivity, or by pressing the reset

button.

29

26

Below is a list of parameters that can be edited.

20

Page 21

No.

parameter

02

08

Description Range Default value

Gas type

0 = methane

1 = LPG

DHW mode o

0 = xed

1 = linked to the DHW setpoint

0-1

0-1 0

depending on the type of gas for which the boiler is

set in the factory

09

10 Ignition curve 0 - 3 1

13

17

18

26

27 Modulation coil reactivity 0 - 1 0

28

Attention: any other additional parameters with regard to the previous table must not be changed for any reason.

3.4 POSSIBLE PROBLEMS AND THEIR CAUSES.

N.B.: maintenance operations must be carried

out by an authorised company (e.g. Authorised

Aer-Sales Technical Assistance Service).

Refer to paragraph 2.5 for information regarding

faults and display signals.

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check tightness of gas intake circuit.

- Irregular combustion (red or yellow ame).

Can be caused by: dirty burner, clogged lamellar pack, intake - exhaust terminal not installed

properly. Clean the above components and

ensure correct installation of the terminal.

- Frequent trips of the overheating temperature

or safety thermostat. It can depend on an anomaly on the water heater P.C.B. or and anomaly

of the regulation NTC probe.

- Poor water flow: if, as a result of limescale

(calcium and magnesium), the domestic hot

water system does not work properly contact an

authorised company for descaling e.g. Authorised

Technical Assistance Service according to good

practice. To preserve integrity and eciency of

the heat exchanger, a non corrosive descaler must

be used. Cleaning must be carried out without the

use of tools which can damage the heat exchanger.

Ignition power 0...40 40

LPG gas type

1 = propane

2 = butane

Complete or partial calibration 0...100 0

DHW modulation with ow meter

0 = modulation without ow meter

1 = modulation with ow meter

Type of water heater

0 = Caesar Eco 11

1 = Caesar Eco 14

2 = not applicable to this model

3 = not applicable to this model

0 = standard water heater installation

from 1 to 20 = solar water heater, start-up delay (in

seconds) of the device upon request

1-2

0-1 1

0...3 depending on the model

0

from 1 to 20

depending on the type of gas for which the boiler is

INSTALLERUSERMAINTENANCE TECHNICIAN

set in the factory

0

21

Page 22

Fig. 18 aFig. 18 a

Fig. 18 d

3.5 CONVERTING THE WATER HEATER TO OTHER TYPES OF GAS.

e operation of appliance transformation from

a gas family to another can be easily carried out

even if the appliance is installed.

Instructions regarding the transformation and

adjustment of various types of gas are described

be low.

To transfer to LPG, place the plate on the manifold, as indicated in Fig. 30.

INSTALLERUSERMAINTENANCE TECHNICIAN

Attention: please note that transformation operations must be carried out by professionally

authorised and qualied sta, in compliance with

the technical regulations in force.

Switch o the device from the omnipolar switch

provided on the power supply line and close the

gas and water cocks.

- Remove the casing by referring to the specic

chapter;

- remove the wire spring placed on the cold water

pipe (Part. A Fig. 31);

- disconnect the gas pipe and remove it (Part.

B Fig. 31):

- loosen the three screws shown in Fig. 32 lower

the intermediate metal-sheet plate (Fig. 33);

- loosen the side fastening screws of the mani-

fold, remove the side brackets and extract the

gas manifold (Fig. 34);

- replace the manifold.

Attention: the manifold is already equipped

with injectors, it is therefore not necessary to

replace them.

- Reassemble the components proceeding in

reverse order;

- if there are seals, they must be restored.

Parameter change 02 (type of gas)

Start the appliance and access the Parameters

menu ( ), as follows:

- with the water heater on, press the reset button

( ) for approximately 10 seconds. e symbols on the display will start ashing and rst

( ) will be displayed, followed by ( );

- release the reset button;

- enter the code ( ) by turning the knob and

conrm by pressing reset;

- turn the knob to select ( ) (Parameters menu)

and conrm by pressing reset;

- on accessing the Menu, scroll through the list

with the knob until nding parameter 02 (gas

type), and press reset: the value that can be

reset will ash and it will be possible to select

the type of gas required by turning the knob:

0 (MTN) - 1 (LPG);

- if LPG gas is selected, propane gas is selected by

default. If you require butane gas, set parameter

13 to 2;

- save by pressing the reset button.

Aer the procedure, the appliance displays alarm

AL62, which indicates that you must calibrate

the gas valve.

Attention: the menu is exited automatically aer

5 minutes of inactivity, or by pressing the reset

button for a while.

Complete gas valve calibration

(Accessible ONLY by the Authorised Te chnical

Assistance Service).

To access the AUTO procedure, proceed as

follows:

- set the system’s electric switch O;

- remove the casing;

- remove the cap that closes the service passage

(located on the bracket Fig. 36) and make it

pass through the hole of the silicone pipe of

the pressure gauge;

- loosen the pressure point screw downstream of

the gas valve by approximately two turns (Fig.

36) and connect a pressure gauge;

- close the casing properly;

30

- set the system’s electric al switch to on and open

the hot water cock.

Access the Parameters menu ( ), as follows:

- with the water heater on, press the reset button

( ) for approximately 10 seconds. e symbols on the display will start ashing and rst

( ) will be displayed, followed by ( );

- release the reset button;

- enter the code ( ) by turning the knob and

conrm by pressing reset;

- turn the knob to select ( ) (Parameters menu)

and conrm by pressing reset;

- on accessing the Menu, scroll through the list

with the knob until nding parameter 17 (complete or partial calibration), and press reset: the

value that can be reset will ash and it will be

possible to select value 5 by turning the knob:

- save by pressing the reset button.

Attention: in case of a power failure the procedure

must be repeated.

Access the Calibration menu ( ) as follows:

- press the reset button ( ) until the ashing

MENU and ( ) appear on the display;

- turn the knob to select ( ) (C alibration menu)

and conrm by pressing reset;

- AUTO and ( ) appear on the display to

indicate that the device operates fully;

- Turn the knob until the burner’s maximum

pressure value is displayed on the pressure

gauge (Ref. Parag. 3.10);

- to save the value, press the reset button;

- press the reset button to select the next value

regarding minimum calibration ( );

- Turn the knob until the burner’s minimum

pressure value is displayed on the pressure

gauge (Ref. Parag. 3.10);

- press the reset key;

- Press the reset button ( ) until MENU ashes

on the display, then release the button, the

screen displays ( );

- press the reset button again until the wording

MENU ashes, then release the button: the

screen displays the value of the set temperature;

- close the hot water cock.

Attention: the menu is exited automatically aer

15 minutes of inactivity, or by pressing the reset

button for a while.

Attention: in case of a power failure the procedure

must be repeated.

Attention: write on the adhesive plate provided

the type of gas in which it was transformed, the

date when the transformation was carried out,

the name and signature of the operator who made

the transformation and then stick it close to the

existing plate.

A

B

31

32

33

34

22

Page 23

3.6 SOLAR PANELS COUPLING FUNCTION.

All Immergas models are supplied as standard

with the NTC probe applied to the DHW cold

water inlet pipe. e probe can be activated by

setting the parameter “P28”.

When parameter "P28" is equal to zero the

probe is disabled; when instead the parameter

is assigned a value between 1 and 20, the probe

is enabled and the function is activated with a

delay that can be set between 1 and 20 seconds.

e water heater is set up to receive pre-heated

water from a system of solar panels up to a maximum temperature of 65°C.

Attention: the manufacturer denies any liability for damage to persons or things caused by

exceeding this temperature.

In any case, it is always necessary to install a mixing valve on the hydraulic circuit upstream of the

boiler, on the cold water inlet. Set the temperature

on the mixing valve increased by 5°C with respect

to that set on the water heater, s o as to ensure that

the temperature at the water heater inlet does not

exceed the maximum value indicated.

If the temperature detected on the inlet probe

is lower than that set by the user with the knob,

the water heater switches on and goes into modulation until the desired temperature is reached.

On the other hand, if the temperature detected

on the inlet probe is close to or equal to that set

by the user, the water heater does not switch on.

3.7 CHECK THE NETWORK

PRESSURE MINIMUM POWER

SUPPLY PRESSURE ONLY WITH

APPLIANCES OPERATING WITH

METHANE.

- Disconnect power from the water heater

- remove the casing by loosening the fastening

screws situated in the lower part of the water

heater and release the casing from the upper

part (Fig. 36);

- remove the cap that closes the service passage

(situated on the bracket - Fig. 35) and make it

pass through the hole of the silicone pipe of the

pressure gauge;

- loosen the pressure point screw upstream of the

gas valve (Fig. 35) by approximately two turns

and connect the pressure gauge;

- close the casing properly;

- turn the water temperature adjustment knob

to maximum;

- connect power to the water heater;

- open a hot water tap to the maximum ow rate.

Check the gas pressure by referring to the values

indicated in the data table. If the pressure is above

15 mbar, proceed with calibrating the gas valve.

When measuring, a tolerance of +/- 0.5 mbar

is permitted.

- Close the hot water cock;

- disconnect the pressure gauge and secure the

pressure point screw upstream of the gas valve

again;

- if there are seals, they must be restored.

3.8 YEARLY APPLIANCE CHECK AND MAINTENANCE.

e following checks and maintenance should

be performed at least once a year.

- Clean the ue side of the heat exchanger.

- Clean the main burner.

- Visually check the ue hood for deterioration

or corrosion.

- Check correct lighting and functioning.

- Check correct burner calibration.

- Check correct operation of control and

adjustment devices of the appliance. and in

particular:

- the intervention of the functioning selector

positioned on the water heater control panel;

- domestic hot water control thermostat inter-

vention.

- Check that the internal system is properly

sealed according to the specications set forth

by technical regulations in force.

- Check the intervention of the device against no

gas ionisation ame control. Intervention time

must be less than 10 seconds.

- Check for water leaks or oxidation from/on the

ttings.

- Visually check that the safety and control

devices have not been tampered with and/or

shorted, in particular:

- temperature safety thermostat;

- Check the condition and integrity of the elec-

trical system and in particular:

- the power cables must be inside the cable

xings;

- there must be no traces of blackening or

burning.

INSTALLERUSERMAINTENANCE TECHNICIAN

Key:

1 - Pressure point downstream of the valve

2 - Pressure point upstream of the valve

3 - Service passage

3

1

2

35

23

Page 24

1

c

3.9 CASING REMOVAL.

To facilitate water heater maintenance, the casing

can be completely removed by following these

simple instructions (Fig. 36):

1) Loosen the lower screws (a) that secure the

casing (b).

2) Pull the casing towards you (b) in the lower

side.

3) Push the casing (b) upwards in a way to be

able to extract it from the upper hooks (c).

INSTALLERUSERMAINTENANCE TECHNICIAN

c

b

3

2

a

1

a

36

24

Page 25

3.10 COMBUSTION PARAMETERS. G20 G30 G31

Supply pressure mbar 20 28-30 37

Caesar Eco 11

Diameter of the main burner nozzle (No. of nozzles) (*) mm 0,86 (18) + 0,83 (4) 0,50 (18) + 0,48 (4) 0,50 (18) + 0,48 (4)

Nozzles (*) N.

P.C.I. (15° C 1013 mbar) MJ/m

WI (15° C 1013 mbar) MJ/m

Consumption

m3/h

kg/h - 1,70 1,67

3

3

22 22 22

34,02 116,09 88

45,67 80,58 70,69

2,28 - -

Max./min. burner pressure mbar 11,70 - 2,60 28,30 - 6,10 36,40 - 8,00

Min./max. flue flow rate at max heat output kg/h

39,308 - 60,035 42,465 - 57,527 43,379 - 49,379

Flue temperature at min./max. output °C 101 - 160 101 - 165 96 - 159

Emissions of nitrogen oxides (NOx) mg/kWh

Air ow rate Nm3/h

35,00 60,00 45,00

46,315 44,359 37,911

Caesar Eco 14

Diameter of the main burner nozzle (No. of nozzles) (*) mm 0,86 (24) + 0,83 (4) 0,50 (24) + 0,48 (4) 0,50 (24) + 0,48 (4)

Nozzles (*) N. 28 28 28

P.C.I. (15° C 1013 mbar) MJ/m

WI (15° C 1013 mbar) MJ/m

Consumption

m3/h

kg/h - 2,13 2,10

3

3

34,02 116,09 88

45,67 80,58 70,69

2,86 - -

Max./min. burner pressure mbar 12,40 - 2,00 28,20 - 4,40 36,00 - 5,60

Min./max. flue flow rate at max heat output kg/h 40,233 - 66,526 45,936 - 73,412 38,273 - 62,873

Flue temperature at min./max. output °C 90 - 177 95 - 177 91 - 174

Emissions of nitrogen oxides (NOx) mg/kWh 29,00 45,00 21,00

Air ow rate Nm3/h 51,262 56,620 48,280

INSTALLERUSERMAINTENANCE TECHNICIAN

(*): it is strictly forbidden to replace the nozzles individually. If necessary, replace the entire manifold.

3.11 TECHNICAL DATA.

Caesar Eco 11 Caesar Eco 14

Nominal heat input (Qn) kW (kcal/h) 21,5 (18490) 27,0 (23220)

Minimum heat input (Qm) kW (kcal/h) 9,5 (8170) 10,0 (8600)

Nominal heat output (useful) (Pn) kW (kcal/h) 19,3 (16600) 24,3 (20900)

Minimum heat output (useful) (Pm) kW (kcal/h) 8,6 (7400) 9,0 (7740)

Domestic hot water ow limiter l/min 8 10

Flow rate capacity in continuous duty (∆T 35°C) l/min 8 10

Minimum water ow rate ignition l/min 2 2

Domestic hot water adjustable temperature °C 37 - 60 37 - 60

Minimum water pressure bar 0,13 0,13

Maximum water pressure bar 10 10

Water heater weight kg 14 16

Fan residual head without pipes Pa 72 90

Electrical connection V/Hz 230/50 230/50

Installed electric power W 41 59

Equipment electrical system protection - IPX5D IPX5D

Type of appliance

B22 / B22P / B32 / C12 / C12x / C32 / C32x / C42 / C42x /

C52 / C52x / C62 / C62x / C82 / C82x

Category II2R3R

- e data relevant to domestic hot water performance refer to a dynamic inlet pressure of 2

bar and an inlet temperature of 15°C; the values

are measured directly at the water heater outlet

considering that to obtain the data declared

mixing with cold water is necessary.

25

Page 26

3.12 PRODUCT FICHE IN COMPLIANCE WITH REGULATION 812/2013.

Caesar Eco 11 Caesar Eco 14

2017

M

52 dB

CAESAR ECO 11

A

16 6

kWh/annum GJ/annum

812/2013

52 dB

2017

CAESAR ECO 14

L

A

20 12

kWh/annum GJ/annum

812/2013

Parameter value

Annual electricity consumption for the

domestic hot water function (AEC)

Annual fuel consumption for the domestic

hot water function (AFC)

Water heating energy eciency ( ηwh) 71 %

For proper installation of the appliance refer

to Chapter 1 of this booklet (for the installer)

and current installation regulations. For proper

maintenance, refer to Chapter 3 of this booklet

(for the maintenance technician) and adhere

to the frequencies and methods set out herein.

16 kWh

6 GJ

Parameter value

Annual electricity consumption for the

domestic hot water function (AEC)

Annual fuel consumption for the domestic

hot water function (AFC)

Water heating energy eciency ( ηwh) 77 %

20 kWh

12 GJ

26

Page 27

3.13 PARAMETERS FOR FILLING IN THE PACKAGE FICHE.

Should you wish to install an assembly, starting

from the Caesar Eco 11 or Caesar Eco 14 water

heater, use the package che in Fig. 39.

To complete it properly, ll the relevant spaces

(as shown in the assembly sheet facsimile Fig. 37)

with the values shown in tables Fig. 38.

Facsimile for lling in the domestic hot water production system package che.