Page 1

CAESAR 14 3 E

Super CAESAR 17 3 E

*1.032004IE*

Instruction booklet and

warning

IE

Page 2

Page 3

3 - IE

INSTALLATORUSERTECHNICIAN

Dear Client,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time.

As an Immergas customer you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your water heater.

Read the following pages carefully: you will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm

your satisfaction for the Immergas product.

For any interventions or routine maintenance contact Immergas Authorised Centres: these have original spare parts and boast of specic preparation directly

from the manufacturer.

General recommendations

e instruction book is an integral and essential part of the product and must be consigned to the new user also in the case of transfer or succession of owne rship.

It must be kept well and consulted carefully, as all of the warnings supply important indications for safety in the installation, use and maintenance stages.

Installation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer's instructions and by professionally

qualied sta, intending sta with specic technical skills in the plant sector, as envisioned by the Law.

Incorrect installation can cause injury to persons and animals and damage to objects, for which the manufacturer is not liable.

Maintenance must be carried out by skilled technical sta. e Immergas Authorised Aer-sales Service represents a guarantee of qualications and

professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use will be considered improper and therefore potentially

dangerous. If errors occur during installation, running and maintenance, due to the non compliance of technical laws in force, standards or instructions

contained in this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any

damages and the appliance warranty is invalidated.

For further information regarding legislative and statutory provisions relative to the installation of gas heat generators, consult the Immergas site at the

following address: www.immergas.com

DECLARATION OF CONFORMITY

For the purpose and eect of the 2009/142/CE Gas Appliance Directive, 2004/108/CE EMC Directive and 2006/95/CE Low Voltage Directive.

e Manufacturer: Immergas S.p.A. v. Cisa Ligure n° 95 42041 Brescello (RE)

DECLARES THAT: the Immergas water heaters model:

Caesar 14 3 E and Super Caesar 17 3 E

is in compliance with the same European Community Directives

Mauro Guareschi

Research & Development Director

Signature:

INDEX

USER page

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

INSTALLER page TECHNICIAN page

1 Water heater installation ..........................4

1.1 Installation recommendations. ................4

1.2 Main dimensions. .....................................4

1.3 Anti-freeze protection. .............................5

1.4 Connections. ..............................................5

1.5 Immergas ue systems. ............................6

1.6 Outdoor installation in partially protected

area. ............................................................. 6

1.7 Indoor installation. ...................................9

1.8 Flue exhaust to ue/chimney. ................ 12

1.9 Ducting of ues or technical

slots. ..........................................................12

1.10 Flues, chimneys and chimney caps. ...... 12

1.11 Gas system start-up. ................................12

1.12 Water heater start up (ignition). ............12

1.13 Kits available on request. ........................12

1.14 Water heater components. .....................13

2 Instructions for use and maintenance. . 14

2.1 Cleaning and maintenance. ...................14

2.2 General warnings. ...................................14

2.3 Control panel. .......................................... 14

2.4 Use of the water heater. ..........................15

2.5 Troubleshooting. .....................................15

2.6 Information menu. .................................. 15

2.7 Switch-o of the water heater. .............. 15

2.8 Emptying the water heater. ....................15

2.9 Anti-freeze protection (optional). .........15

2.10 Case cleaning. ..........................................15

2.11 Decommissioning. ..................................15

3 Controls and maintenance. ....................16

3.1 Hydraulic diagram. ................................. 16

3.2 Wiring diagram. ...................................... 17

3.3 Troubleshooting. .....................................17

3.4 Converting the water heater to other

types of gas. ..............................................17

3.5 Checks following conversion to another

type of gas. ................................................17

3.6 Possible adjustments ...............................18

3.7 Programming the P.C.B. .........................18

3.8 Automatic slow ignition function with

timed ramp delivery. ...............................18

3.9 Solar function. .........................................19

3.10 Solar panels coupling function. .............19

3.11 Yearly appliance check and maintenance.

19

3.12 Casing removal. .......................................20

3.13 Variable heat output. ............................... 21

3.14 Combustion parameters. ........................22

3.15 Technical data. .........................................23

Page 4

1-1

1-2

4 - IE

INSTALLATORUSERTECHNICIAN

1

WATER HEATER

INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

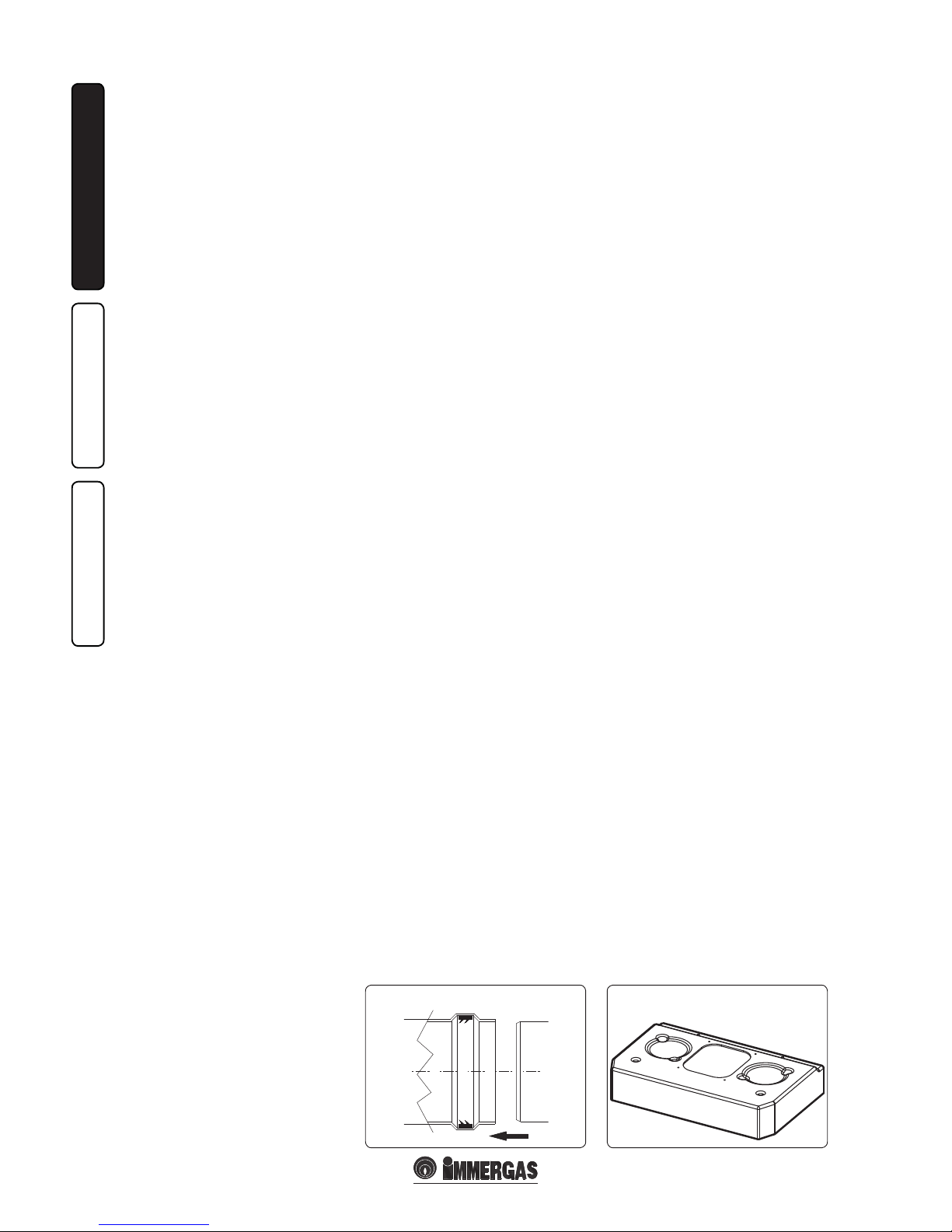

e water heaters have been designed for wall

installation only; they must be used for the

production of domestic hot water and similar

purposes. In the case of wall installation the wall

surface must be smooth, without any protrusions

or recesses enabling access to the rear part. ey

have NOT been designed to be installed on

plinths or oors (Fig. 1-1).

By varying the type of installation the

classification of the water heater also varies,

precisely:

- Water heater type B

22 if installed without the

2 intake caps and with the top cover kit

-

Type C water heater if installed using concentric

pipes or other types of pipes envisioned for the

sealed chamber water heaters for intake of air

and expulsion of ue gases.

Only professionally qualified heating/

plumbing technicians are authorised to install

Immergas gas appliances. Installation must

be carried out according to the standards,

current legislation and in compliance with local

technical regulations and the required technical

procedures. Installation of the water heater

when powered by LPG must comply with the

rules regarding gases with a greater density

than air (remember, as an example, that it is

prohibited to install systems powered with the

above-mentioned gas in rooms where the oor

is at a lower quota that the average external

country one). Before installing the appliance,

ensure that it is delivered in perfect condition;

if in doubt, contact the supplier immediately.

Packing materials (staples, nails, plastic bags,

polystyrene foam, etc.) constitute a hazard and

must be kept out of the reach of children. If the

appliance is installed inside or between cabinets,

ensure sufficient space for normal servicing;

therefore it is advisable to leave clearance of at

least 3 cm between the water heater casing and

the vertical sides of the cabinet. Leave adequate

space above the water heater for possible water

and ue removal connections.

Keep all flammable objects away from the

appliance (paper, rags, plastic, polystyrene, etc.).

It is recommended not to position household

appliances under the water heater because they

could undergo damage in the case of leaks from

the hydraulic ttings. If this is not the case, the

manufacturer cannot be considered liable for

any damage caused to the household appliances.

In the event of malfunctions, faults or incorrect

operation, turn the appliance o immediately

and contact a qualified technician (e.g. the

Immergas Technical Aer-Sales Centre, which

has specically trained sta and original spare

parts). Do not attempt to modify or repair the

appliance alone. Failure to comply with the above

implies personal responsibility and invalidates

the warranty.

• Installation regulations:

- this water heater can be installed outside in a

partially protected area. A partially protected

location is one in which the water heater

is not exposed to the direct action of the

weather (rain, snow, hail, etc..).

- Installation in places with a fire risk is

prohibited (for example: garages, box), gas

appliances and relative ue ducts, ue exhaust

pipes and combustion air intake pipes.

- Installation is prohibited on the vertical

projection of the cooking surface.

- Installation is also prohibited in places/

environments that constitute common parts

of oce condominiums such as stairs, cellars,

entrance halls, attics, los, escape routes,

etc. if they are not located inside technical

compartments under the responsibility of

each individual building and only accessible

to the user (for the features of the technical

compartments, see the Reference Standard).

Important: Wall mounting of the water heater

must guarantee stable and ecient support for

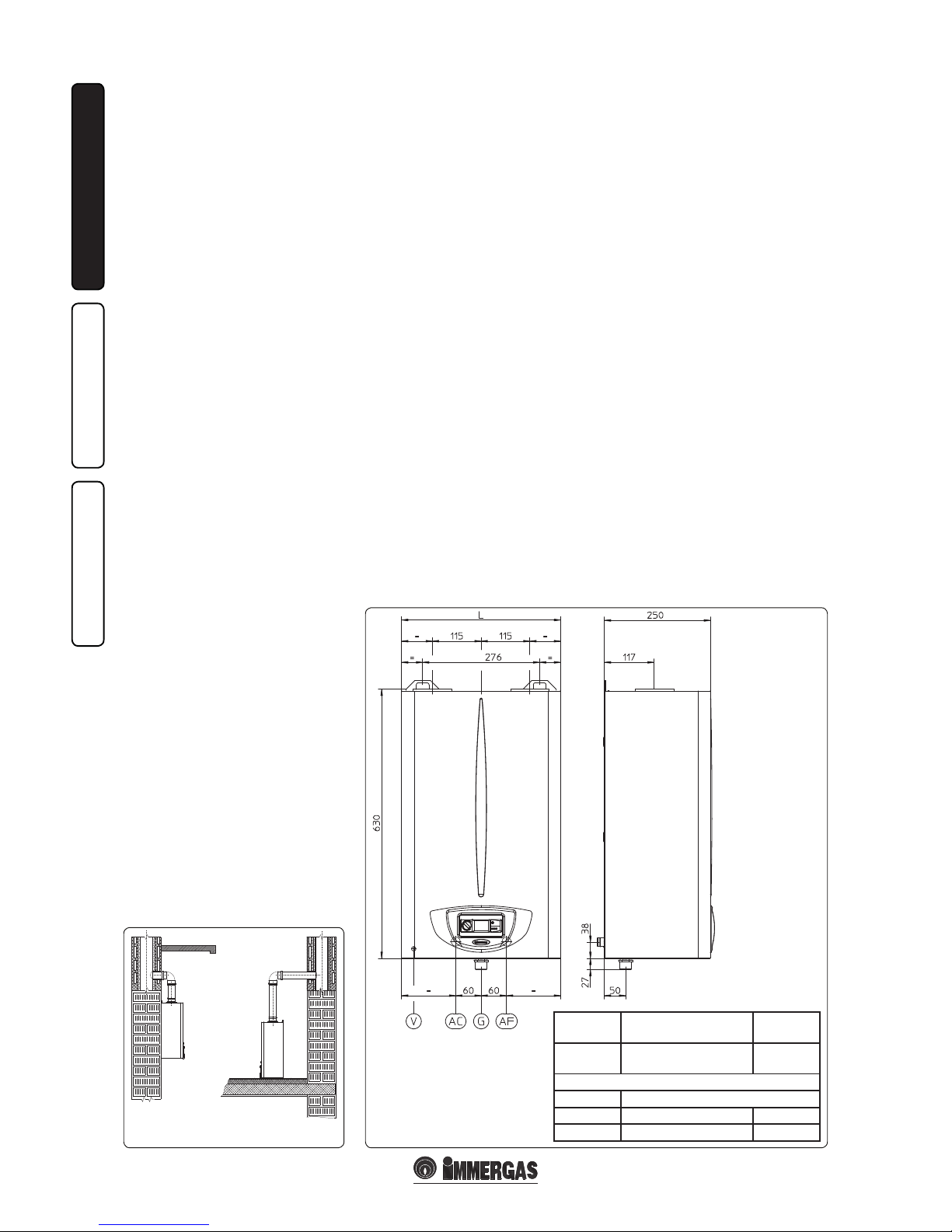

1.2 MAIN DIMENSIONS.

the generator.

e plugs (standard supply) are to be used only in

conjunction with the mounting brackets or xing

template to x the water heater to the wall; they

only ensure adequate support if inserted correctly

(according to technical standards) in walls made

of solid or semi-hollow brick or block. In the

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate support.

N.B.: the hex head screws supplied in the blister

pack are to be used exclusively to x the relative

mounting bracket to the wall.

ese appliances are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be connected to a DHW distribution

network suited to their performance and power.

Height

(mm)

Width (mm)

(L)

Depth

(mm)

630

Caesar 14 3 E = 375

Super Caesar 17 3 E = 420

250

CONNECTIONS

GAS DOMESTIC HOT WATER

GACAF

3/4” 1/2” 1/2”

Key:

AC - Domestic hot water outlet

AF - Domestic hot water inlet

G - Gas supply

V - Electrical connection

YES NO

Page 5

1-3

Cavo di alimentazione

5 - IE

INSTALLATORUSERTECHNICIAN

1.3 ANTIFREEZE PROTECTION.

Minimum temperature -15°C. If the water heater

is installed in a place where the temperature falls

below 0°C and in the event there is no gas (or

the water heater goes into ignition block), the

appliance can freeze.

To prevent the risk of freezing follow the instructions

below:

- Protect the condensate drain trap and circuit

board against freezing by using an accessory

that is supplied on request (anti-freeze kit)

comprising two electric heating elements,

the relevant cables and a control thermostat

(carefully read the installation instructions

contained in the accessory kit pack).

Water heater anti-freeze protection is thus ensured

only if:

- the water heater is correctly connected to

electricity power supply circuits;

- main switch is inserted;

- the anti-freeze kit components are ecient.

In these conditions the water heater is protected

against freezing to temperature of -15°C.

The warranty does not cover damage due to

interruption of the electrical power supply and

failure to comply with that stated on the previous

page.

N.B.: if the water heater is installed in places

where the temperature falls below 0°C, the

heating attachment pipes must be insulated.

1.4 ATTACHMENTS.

Gas connection (Appliance category II

2H3+

).

Our water heaters are designed to operate with

methane gas (G20) and LPG. Supply pipes must

be the same as or larger than the 3/4”G water

heater tting. Before connecting the gas line,

carefully clean inside all the fuel feed system

pipes to remove any residue that could impair

water heater eciency. Also make sure the gas

corresponds to that for which the water heater is

prepared (see water heater data-plate). If dierent,

the water heater must be converted for operation

with the other type of gas (see converting

appliance for other gas types). e dynamic gas

supply (methane or LPG) pressure must also be

checked according to the type used in the water

heater, as insucient levels can reduce generator

output and cause malfunctions.

Ensure correct gas cock connection. The gas

supply pipe must be suitably dimensioned

according to current regulations in order to

guarantee correct gas ow to the burner even

in conditions of maximum generator output

and to guarantee appliance eciency (technical

specifications). The coupling system must

conform to standards.

Fuel gas quality. e appliance has been designed

to operate with gas free of impurities; otherwise it

is advisable to t special lters upstream from the

appliance to restore the purity of the gas.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

Hydraulic connection

Important: before connecting the water heater

and so as not to make the warranty null and void

on the DHW heat exchanger, wash the system

thoroughly (piping, etc.) in a way to remove

any residues that could compromise the good

functioning of the water heater.

Water connections must be made in a rational

way using the couplings on the water heater

template.

Important: to preserve the duration of appliance

eciency features, in the presence of water whose

features can lead to the deposit of lime scale,

installation of the “polyphosphate dispenser” kit

is recommended . On the basis of the Standards

in force, it is mandatory to treat the supply water

with temporary water hardness over or equal to

25 French degrees in the heating circuit and over

than or equal to 15 French degrees for DHW, using

conditioning chemicals for powers ≤ 100 kW or

with soeners for powers > 100 kW

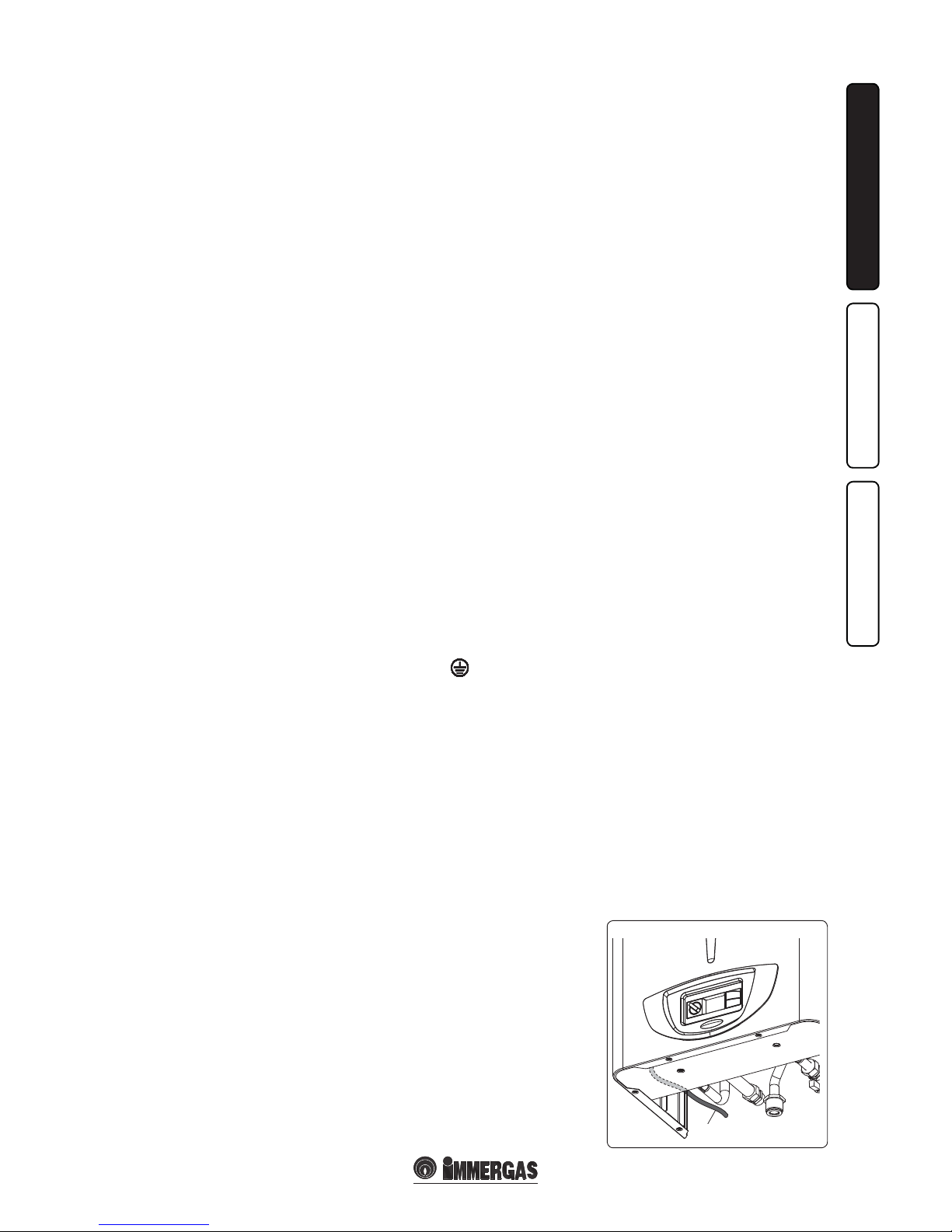

Electrical connection: e “Caesar” water heater

has an IPX5D protection rating for the entire

appliance. Electrical safety of the appliance is

reached only when it is correctly connected to an

ecient earthing system as specied by current

safety standards.

Important: Immergas S.p.A. declines any

responsibility for damage or physical injury

caused by failure to connect the water heater to

an ecient earth system or failure to comply with

the reference standards.

Also ensure that the electrical installation

corresponds to maximum absorbed power

specications as shown on the water heater dataplate. Water heaters are supplied complete with

an “X” type power cable without plug. e power

supply cable must be connected to a 230V ±10%

/ 50Hz mains supply respecting L-N polarity and

earth connection

is network must also

have an omnipolar circuit breaker with class III

over-voltage category. When replacing the power

supply cable, contact a qualied technician (e.g.

the Immergas Aer-Sales Technical Assistance

Service). e power cable must be laid as shown

(Fig. 1-3).

In the event of mains fuses replacement on the

connection board, use a 3.15A quick-blow fuses.

For the main power supply to the appliance,

never use adapters, multiple sockets or extension

leads.

N.B.: all water heater pipes must never be used

to earth the electric or telephone lines. Ensure

elimination of this risk before making the water

heater electrical connections.

Power supply cable

Page 6

1-4 1-5

6 - IE

INSTALLATORUSERTECHNICIAN

1.6 OUTDOOR INSTALLATION IN

PARTIALLY PROTECTED AREA.

N.B.: a partially protected area is one in which the

appliance is not exposed to the direct action of the

weather (rain, snow, hail, etc..)..

• Conguration type B, open chamber and

forced draught.

Using the relevant cover kit direct air intake is

possible (Fig. 1-7) and ue gases are exhausted

into a single ue or directly to the outside. In this

conguration it is possible to install the water

heater in a partially protected place.

In this conguration the water heater is classied

as type B

22

.

With this conguration:

- air intake takes place directly from the room

in which the appliance is installed (outdoor);

- the ue exhaust must be connected to its own

individual ue or channelled directly into the

external atmosphere.

The technical regulations in force must be

respected.

• Cover kit assembly (Fig. 1-6). Remove the

two plugs and the gaskets present from the two

lateral holes with respect to the central one.

Position the diaphragm on the discharge hole:

Caesar 14 3 E: Ø 45 present inn the water

heater.

Super Caesar 17 3 E: Ø 44 present in the

thermoformed kit.

Install the Ø 80 outlet ange on the central

hole of the water heater, taking care to insert

the gasket supplied with the kit and tighten

by means of the screws provided. Install the

upper cover, xing it using the screws and

relevant gaskets present in the kit. Fit the 90° Ø

80 curve with the male side (smooth) into the

female side (with lip seals) of the Ø 80 ange,

up to stop.Cut the gasket in the relevant groove

at the desired diameter (Ø 80), run it along the

curve and x it using the sheet steel plate. Fit

the male end (smooth) of the exhaust terminal

into the the female end of the bend 90° Ø 80,

making sure that the relevant wall sealing

plate is already tted; this will ensure hold and

joining of the elements making up the kit.

• Coupling of extension pipes. To install push-

tting extensions with other elements of the

flue extraction elements assembly, proceed

as follows: Couple the pipe or elbow with the

male side (smooth) in the female side (with lip

seal) to the end stop on the previously installed

element. is will ensure sealing eciency of

the coupling.

Max. length of exhaust duct. The flue pipe

(vertical or horizontal) can be extended to a max.

length of 12 straight metres (Fig. 1-21). To prevent

problems of ue gas condensate in the exhaust

pipe Ø 80, due to ue gas cooling through the

wall,the length of the pipe (not insulated) must

be limited to just 5 m.

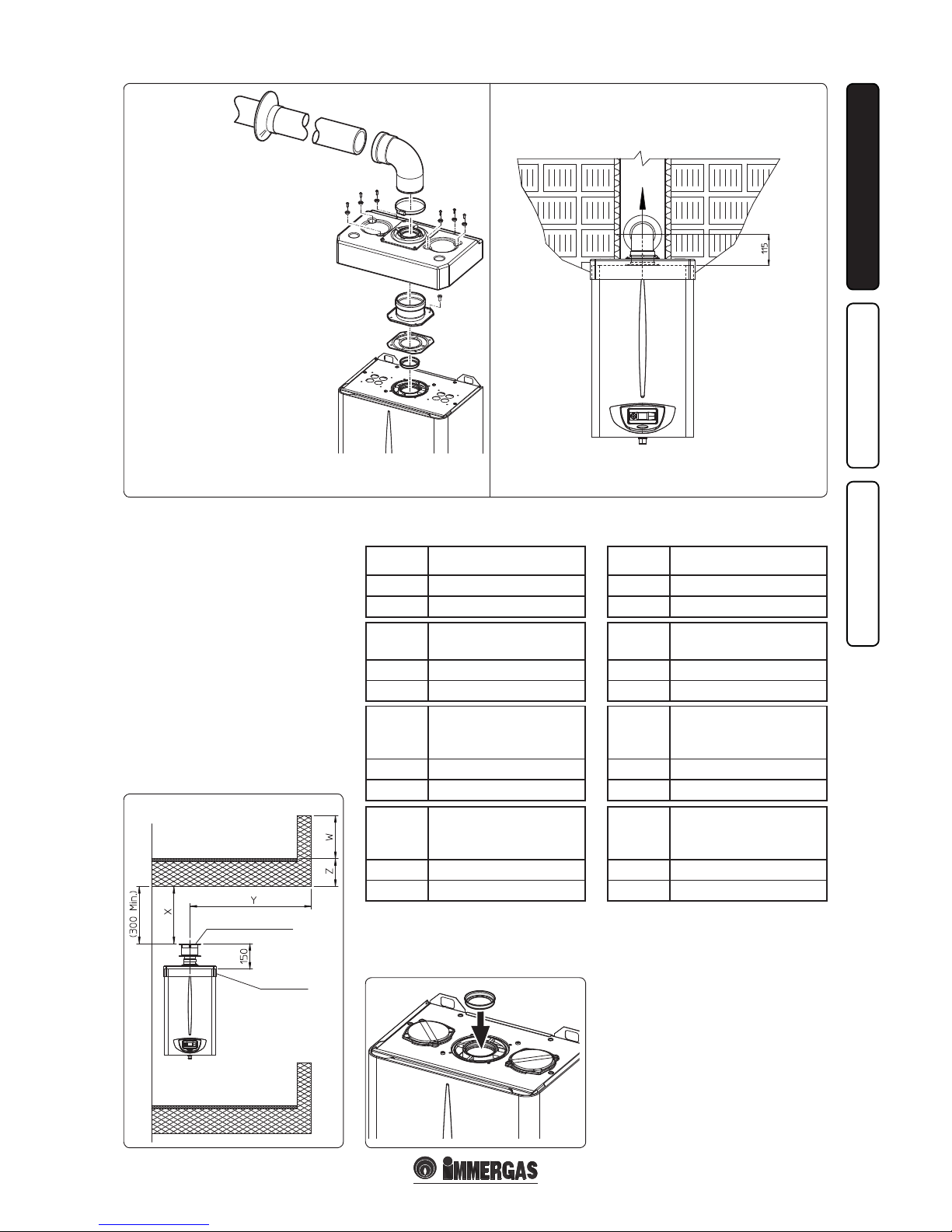

Example of installation with direct vertical

terminal in partially protected location. When

the vertical terminal for direct discharge of

combustion products is used, a minimum gap

of 300 mm must be le between the terminal

and the balcony above. e height X+Y+Z+W

evaluated with respect to the balcony above,

must be equal to or more than 2000 mm. (Fig.

1-8). e term W must only be considered if the

balcony above has closed balustrade (W=0 if the

balustrade is open).

• Conguration without cover kit (water heater

type C).

By leaving the side plugs tted, it is possible

to install the appliance externally, in partially

covered places, without the cover kit. Installation

takes place using the Ø60/100 and Ø80/125

concentric horizontal intake/ exhaust kits. Refer

to the paragraph relative to indoor installation. In

this conguration the upper cover kit guarantees

additional protection for the water heater. It is

recommended but not compulsory.

1.5 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the water heaters regarding the installation

of air intake terminals and ue extraction, which

are fundamental for water heater operation.

Important: the water heater must only be

installed together with an original Immergas

air intake and ue gas exhaust system. is

system can be identied by an identication

mark and special distinctive marking bearing

the note: “not for condensing boilers”.

e ue exhaust pipes must not be in contact with

or be near to ammable materials. Moreover,

they must not pass through buildings or walls

made of ammable material.

Positioning of double lip seals. For correct

positioning of lip seals on elbows and extensions,

follow the direction of assembly given in gure

(Fig. 1-4).

• Resistance factors and equivalent lengths.

Each ue extraction system component has

a Resistance Factor based on experimental

tests and specified in the table below. The

resistance factor for individual components is

independent from the type of water heater on

which it is installed or the actual dimensions.

It is, however, conditioned by the temperature

of the uids that pass through the pipe and

therefore varies according to applications for

air intake or flue exhaust. Each individual

component has a resistance corresponding to

a certain length in metres of pipe of the same

diameter; the so-called equivalent length,

obtained from the ratio between the relative

Resistance Factors. All water heaters have an

experimentally obtainable maximum Resistance

Factor equal to 100.e maximum Resistance

Factor allowed corresponds to the resistance

encountered with the maximum allowed pipe

length for each type of Terminal Kit. This

information enables calculations to verify the

possibility of various congurations of ue

extraction systems.

Diaphragm installation. For correct functioning

of the water heater, a Ø 45 diaphragm must be

installed on the outlet of the sealed chamber and

before the intake and exhaust pipe for the “Caesar

14 3 E” model and a diaphragm of Ø 46 for the

“Super Caesar 17 3 E” model (Fig. 1-9).

N.B.: the diaphragm is supplied as per standard

with the water heater.

Upper lid

Page 7

1-7

1-8

B22 B22

B22

1-6

1-9

7 - IE

INSTALLATORUSERTECHNICIAN

e terminal kit includes:

N° 1 - Gasket

N° 1 - Exhaust ange Ø 80

N° 1 - Bend 90° Ø 80

N° 1 - Exhaust pipe Ø 80

N° 1 - Wall sealing plate

e cover kit includes:

N° 1 - Heat moulded cover

N° 1 - Ø 44 discharge diaphragm

N°1 - Gasket clamping plate

N° 1 - Gasket

* e values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

* e values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

Diaphragm

Extension in meters

pipe Ø 60/100 horizontal

Ø 46 From 0 to 1

NONE Exceeding 1

Diaphragm

Extension in meters

pipe Ø 60/100 horizontal

Ø 45 From 0 to 1

NONE Exceeding 1

Diaphragm

Pipe extension in metres Ø

60/100 vertical

Ø 46 From 0 to 2.2

NONE Exceeding 2.2

Diaphragm

Pipe extension in metres Ø

60/100 vertical

Ø 45 From 0 to 2.7

NONE Exceeding 2.7

Diaphragm

*Extension in metres

vertical pipe Ø 80

without bends

Ø 46 From 0 to 22

NONE Exceeding 22

Diaphragm

*Extension in metres

vertical pipe Ø 80

without bends

Ø 45 From 0 to 25

NONE Exceeding 25

Diaphragm

*Extension in meters

horizontal pipe Ø 80 with

two bends

Ø 46 From 0 to 17

NONE Exceeding 17

Diaphragm

*Extension in meters

horizontal pipe Ø 80 with

two bends

Ø 45 From 0 to 20

NONE Exceeding 20

Caesar 14 3 E discharge diaphragm. Caesar 17 3 E Super discharge diaphragm.

INTAKE

COVER KIT

VERTICAL TERMINAL KIT

FOR DIRECT DRAINING

Page 8

8 - IE

INSTALLATORUSERTECHNICIAN

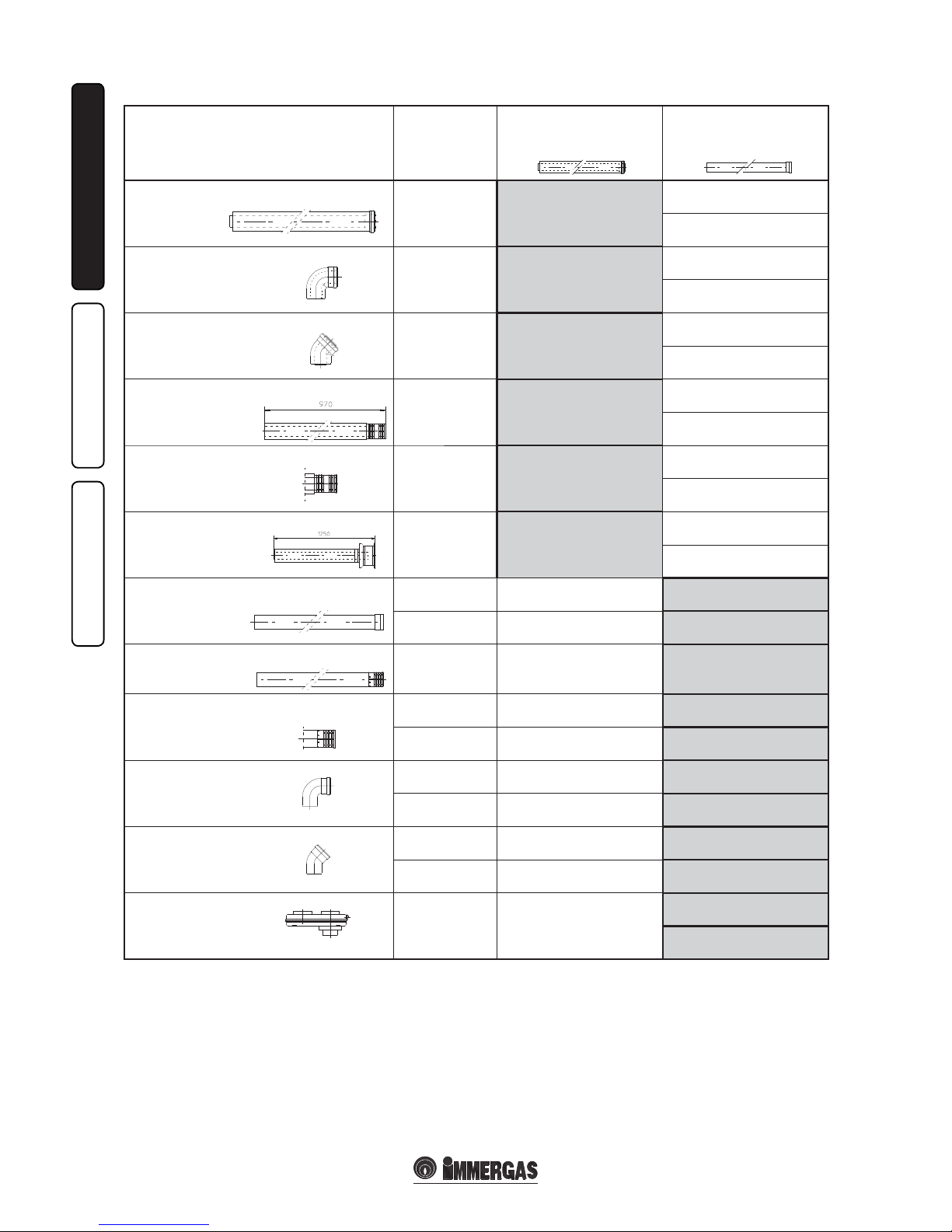

Tables of Resistance Factors and Equivalent Lengths.

DUCT TYPE

Resistance

Factor

(R)

Equivalent

length in m of concentric pipe

Ø 60/100

Equivalent

length

in m of pipe

Ø 80

Concentric pipe Ø 60/100 m 1

Intake and

Exhaust 16.5

m 1

Intake m 7.1

Exhaust m 5.5

Concentric bend 90° Ø 60/100

Intake and

Exhaust 21

m 1.3

Intake m 9..1

Exhaust m 7.0

Concentric bend 45° Ø 60/100

Intake and

Exhaust 16.5

m 1

Intake m 7.1

Exhaust m 5.5

Terminal complete with concentric horizontal

intake-exhaust Ø 60/100

Intake and

Exhaust 46

m 2.8

Intake m 20

Exhaust m 15

Concentric horizontal

intake- exhaust terminal Ø 60/100

Intake and

Exhaust 32

m 1.9

Intake m 14

Exhaust m 10.6

Concentric vertical

intake-exhaust terminal Ø 60/100

Intake and

Exhaust 41.7

m 2.5

Intake m 18

Exhaust 14

Pipe Ø 80 m 1 (with and without insulation)

Intake 2.3 m 0.1 Intake m 1.0

Exhaust 3 m 0.2 Exhaust m 1.0

Complete air intake terminal Ø 80 m 1

(with or without insulation)

Intake 5 m 0.3 Intake m 2.2

Intake terminal Ø 80

Exhaust terminal Ø 80

Intake 3 m 0.2 Intake m 1.3

Exhaust 2.5 m 0.1 Exhaust m 0.8

Bend 90° Ø 80

Intake 5 m 0.3 Intake m 2.2

Exhaust 6.5 m 0.4 Exhaust m 2.1

Bend 45° Ø 80

Intake 3 m 0.2 Intake m 1.3

Exhaust 4 m 0.2 Exhaust m 1.3

Split parallel Ø 80

from Ø 60/100 to Ø 80/80

Intake and

Exhaust 8.8

m 0.5

Intake m 3.8

Exhaust m 2.9

Page 9

C12

1-10

C12

C12

C12

C12

1-11

1-13

1-141-12

1

3

2

4

5

9 - IE

INSTALLATORUSERTECHNICIAN

1.7 INDOOR INSTALLATION.

• Type C conguration, sealed chamber and

fan assisted.

Horizontal intake - exhaust kit Ø60/100. Kit

assembly (Fig. 1-10): install the bend with ange

(2) onto the central hole of the water heater

inserting the gasket (1) and tighten using the

screws in the kit. Couple the terminal pipe (3)

with the male end (smooth) into the female

end of the bend (with lip seals) up to the stop;

making sure that the internal wall sealing plate

and external wall sealing plate have been tted,

this will ensure sealing and joining of the elements

making up the kit.

Note: when the water heater is installed in areas

where very rigid temperatures can be reached,

a special anti-freeze kit is available that can be

installed as an alternative to the standard kit.

• Coupling extension pipes and concentric elbows

Ø 60/100. To snap-t extensions with other

elements of the ue gas extraction elements,

operate as follows Install the concentric pipe

or elbow with the male side (smooth) on the

female section (with lip seal) to the end stop on

the previously installed element. is will ensure

the sealing and joining of the elements correctly.

e Ø 60/100 horizontal intake/exhaust kit can

be installed with the rear, right side, le side and

front outlet.

• Application with rear outlet (Fig. 1-11). e 788

mm pipe length enables routing through a wall

with maximum thickness of 788 mm. Normally

the terminal must be shortened. Calculate the

distance by adding the following values: Part

thickness + internal projection + external

projection. The minimum indispensable

projection values are given in the gure.

• Application with lateral output (Fig. 1-12); Only

using the horizontal intake-exhaust kit, without

the relevant extensions, permits to pass through

a wall with thickness of 715.5 mm with the

Caesar 14 3 E and of 705 mm with the Super

Caesar 17 3 E (height “X”), both with le and

right lateral output.

• Extensions for horizontal kit. e horizontal

intake-exhaust kit Ø 60/100 can be extended

up to a max. horizontal distance of 3000

mm including the terminal with grid and

excluding the concentric bend leaving the

water heater. is conguration corresponds

to a resistance factor of 100. In these cases the

special extensions must be requested.

Connection with N°1 extension (Fig. 1-13).

Max. distance between vertical water heater axis

and external wall is 1855mm.

Connection with N°2 extensions (Fig. 1-14).

Max. distance between vertical water heater axis

and external wall is 2805mm.

e kit includes:

N°1 - Gasket (1)

N°1 - Concentric bend 90° (2)

N°1 - Intake/exhaust concentric pipe

Ø60/100 (3)

N°1 - Internal white wall sealing plate (4)

N°1 - External grey wall sealing plate (5)

• External grill. N.B.: for safety purposes, do

not even temporarily obstruct the water heater

intake-exhaust terminal.

Page 10

C32

1-171-16

C32

1

2

3

4

5

7

6

10 - IE

INSTALLATORUSERTECHNICIAN

Vertical kit with aluminium tile Ø 60/100.

Kit assembly (Fig. 1-16): install the concentric

ange (2) on the central hole of the water heater

inserting the gasket (1) and tighten using the

screws in the kit. Imitation aluminium tile

installation. Replace the tile with the aluminium

sheet (4), shaping it to ensure that rainwater

runs o. Position the xed half-shell (6) and

insert the intake-exhaust pipe (5). Fit the Ø

60/100 concentric terminal pipe with the male

end (5) (smooth) to the female end of the ange

(2) (with lip gasket) up to the stop; making sure

that the wall sealing plate (3) has been tted, this

will ensure sealing and joining of the elements

making up the kit.

• Coupling extension pipes and concentric

elbows. To install push-fitting extensions

with other elements of the flue extraction

elements assembly, proceed as follows: Install

the concentric pipe or elbow with the male

side (smooth) on the female section (with lip

seal) to the end stop on the previously installed

element. is will ensure sealing and joining of

the elements correctly.

Important: if the exhaust terminal and/or

extension concentric pipe needs shortening,

consider that the internal duct must always

protrude by 5 mm with respect to the external

duct.

is specic terminal enables ue exhaust and

air intake, necessary for combustion, in a vertical

direction.

N.B.: the Ø 60/100 vertical kit with aluminium

tile enables installation on terraces and roofs with

a maximum slope of 45% (25°) and the height

between the terminal cap and half-shell (374

mm) must always be respected.

e vertical kit with this conguration can be

extended up to a maximum of 4700 mm vertical

rectilinear, with the terminal included (Fig. 1-17).

is conguration corresponds to a resistance

factor of 100. In this case the special extensions

must be requested.

Separator kit Ø 80/80. e Ø 80/80 separator

kit, allows separation of the exhaust ues and

air intake pipes according to the diagram shown

in the gure.

Combustion products are expelled from pipe (S).

Air is taken in through pipe (A) for combustion.

e intake pipe (A) can be installed either on the

right or le hand side of the central exhaust pipe

(S). Both ducts can be routed in any direction.

• Kit assembly (Fig. 1-18): install ange (4) on

the central hole of the water heater, tting

gasket (1) and tighten with the at-tipped hex

screws included in the kit. Remove the at

ange present in the lateral hole with respect

to the central one (according to needs) and

replace it with the ange (3), positioning the

gasket (2) already present in the water heater

and tighten using the supplied self-threading

screws. Fit the male end (smooth) to the bends

(5) in the female end of the anges (3 and 4).

Fit the intake terminal (6) with the male section

(smooth) in the female section of the bend (5)

up to the stop, ensuring that the internal and

external wall sealing plates are tted. Fit the

exhaust pipe (9) with the male end (smooth)

to the female end of the bend (5) up to the stop;

making sure that the internal wall sealing plate

has been tted, this will ensure sealing and

joining of the elements making up the kit.

• Coupling of extension pipes and elbows. To

install push-fitting extensions with other

elements of the flue extraction elements

assembly, proceed as follows: Install the pipe

or elbow with the male side (smooth) on the

female section (with lip seal) to the end stop

on the previously installed element. is will

ensure sealing and joining of the elements

correctly.

• Installation clearances. Figure 1-19 gives the

min. installation space dimensions of the

Ø 80/80 separator terminal kit in limited

conditions.

• Figure 1-20 shows the configuration with

vertical exhaust and horizontal intake.

• Extensions for the separator kit Ø 80/80.

The max. vertical straight length (without

bends) that can be used for Ø 80 intake and

exhaust pipes is 41 metres of which 40 intake

and 1 exhaust. e total length corresponds

to a resistance factor of 100. e total usable

length obtained by adding the length of the

intake and exhaust pipes Ø 80, must not

exceed the values stated in the following table.

If mixed accessories or components are used, t he

maximum extension can be calculated by using

a resistance factor for each component or its

equivalent length. e sum of these resistance

factors must not exceed 100.

e kit includes:

N°1 - Gasket (1)

N°1 - Female concentric

ange (2) (sold sepa-

rately)

N°1 - Wall sealing plate (3)

N°1 - Aluminium tile (4)

N°1 - Int./exhaust concentric

pipe Ø 60/100 (5)

N°1 - Fixed half-shell (6)

N°1 - Mobile half-shell (7)

MAXIMUM LENGTH 4700 mm

Page 11

C82

1-18

C42

C52

1-19

1-21

C82

A

S

7

6

8

3

2

5

1

4

4

9

1-20

11 - IE

INSTALLATORUSERTECHNICIAN

e kit includes:

N°1 - Exhaust gasket (1)

N°1 - Female intake ange (3)

N°1 - Flange gasket (2)

N°1 - Female exhaust ange (4)

N°2 - 90° bend Ø 80 (5)

N°1 - Intake terminal Ø 80 (6)

N°2 - Internal white wall sealing plates (7)

N°1 - External grey wall sealing plate (8)

N°1 - Exhaust pipe Ø 80 (9)

Important: if the installation requests a

development of the flue to the discharge

that exceeds the recommended 12 m, due

consideration must be given to the formation of

condensate that could take place inside the pipe

and Immergas insulated “Blue Series” ue kits

must be used.

• Conguration type B, open chamber and

forced draught.

When using type B installation conguration

indoors, it is compulsory to install the relative

upper cover kit along with the ue gas discharge

kit. e air intake comes directly from the area

where the water heater is installed and from the

ue exhaust in each single ue or directly from

outdoors.

e water heater in this conguration, following

the assembly instructions stated in the par. 1.6 is

classied as type B

22

.

With this conguration:

- air intake takes place directly from the

environment in which the boiler is installed and

only functions in permanently ventilated rooms;

- the ue exhaust must be connected to its own

individual ue or channelled directly into the

external atmosphere.

- type B open chamber water heaters must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts (e.g.

dust deriving from the working of wood, coal

nes, cement, etc.). ese may be damaging for

the components of the appliance and jeopardise

functioning.

- in type B

22

conguration, the water heaters must

not be installed in bedrooms or bathrooms.

On installation indoors in type B conguration

it is mandatory to install the relevant top cover

kit along with the ue gas exhaust kit.

The technical regulations in force must be

respected.

Maximum usable lengths

(including intake terminal with grill and two 90° bends)

NON-INSULATED PIPE INSULATED PIPE

Drain (metres) Intake (metres) Drain (metres) Intake (metres)

1 36.0* 6 29.5*

2 34.5* 7 28.0*

3 33.0* 8 26.5*

4 32.0* 9 25.5*

5 30.5* 10 24.0*

* e air intake pipe can be increased to 2.5 metres if the exhaust bend

is eliminated. 2 metres if the air intake bend is eliminated. 4.5 metres

eliminating both bends.

11 22.5*

12 21.5*

Page 12

12 - IE

INSTALLATORUSERTECHNICIAN

1.8 FLUE EXHAUST TO FLUE/CHIMNEY.

Flue exhaust does not necessarily have to be

connected to a branched type traditional ue.

e discharge of ue gases, just for the water

heaters installed in configuration C, can be

connected to a particular LAS type collective ue.

For B

22

congurations, discharge is only allowed

into individual ue or directly into the outside

atmosphere by the relevant terminal. Multiple

and combined ues must be specially designed

according to the calculation method and

requirements of the standards, by professionally

qualied technical sta. Chimney or ue sections

for connection of the exhaust pipe must comply

with requisites of technical standards in force.

1.9 DUCTING OF FLUES OR

TECHNICAL SLOTS.

With a specic “ducting system” it is possible to

reuse existing ues, chimneys and existing or

new technical slots to discharge the water heater

ue gases. Ducting requires the use of ducts

declared to be suitable for the purpose by the

manufacturer. Follow the installation and user

instructions provided by the manufacturer and

the requirements of standards.

1.10 FLUES, CHIMNEYS AND CHIMNEY

CAPS.

e ues, chimneys and chimney caps for the

evacuation of combustion products must be in

compliance with applicable standards.

Positioning the exhaust terminals. e exhaust

terminals must:

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum

distances specified in current technical

standards.

Combustion products exhaust of natural or

fan assisted appliances in open-top closed

environments. In spaces closed on all sides

with open tops (ventilation pits, courtyards etc.),

direct ue gas exhaust is allowed for natural or

forced draught gas appliances with a heating

power range from 4 to 35 kW, provided the

conditions as per the current technical standards

are respected.

1.11 GAS SYSTEM STARTUP.

To start up the system, make reference to the

Standard: is divides the systems and therefore

the start-up operations into three categories: new

systems, modied systems, re-activated systems.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specications.

1.12 WATER HEATER START UP

IGNITION.

For issue of the Declaration of Conformity

provided for by Italian Law, the following must

be performed for water heater start-up:

- check that the internal system is properly sealed

according to specications;

- ensure that the type of gas used corresponds to

water heater settings;

- switch the water heater on and ensure correct

ignition;

- make sure that the gas ow rate and relevant

pressure values comply with those given in the

manual (par. 3.13);

- ensure that the safety device is engaged in the

event of gas supply failure and check activation

time;

- check activation of the main switch located

upstream from the water heater;

- check that the concentric intake-exhaust

terminal (if tted) is not blocked.

e water heater must not be started up even if

only one of the checks should be negative.

N.B.: the water heater preliminary check must

be carried out by a qualified technician. The

conventional water heater warranty is valid as of

the date of testing.

e test certicate and warranty is issued to the

user.

1.13 KITS AVAILABLE ON REQUEST.

• Polyphosphate dispenser kit. e polyphosphate

dispenser reduces the formation of lime-scale

and preserves the original heat exchange and

domestic hot water production conditions. e

water heater is prepared for application of the

polyphosphate dispenser kit.

• Covering kit. For outdoor installations, in

partially protected areas and with direct air

intake, the top protection cover must be tted

for a correct functioning of the water heater

and to protect it from storms (Fig. 1-8). For

indoor installations, type B conguration, a

suitable top protection cover coupled with the

ue exhaust kit must be tted.

• Anti freeze kit with resistance (on request). If

the water heater is installed in a place where the

temperature falls below 0°C and the appliance

can freeze. To prevent freezing of the domestic

hot water system, an anti freeze kit with an

electrical resistance can be fitted from the

relative cable and from a control thermostat.

• Bracket kit for Omni Container. If necessary,

the water heater can be installed inside the

Omni Container. For assembly, use the relevant

support bracket contained in the kit.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Page 13

1- 22

13 - IE

INSTALLATORUSERTECHNICIAN

1.14 WATER HEATER COMPONENTS.

Key:

1 - Sealed chamber

2 - Fan

3 - DHW heat exchanger

4 - Ignition/detection electrode

5 - Gas valve

6 - Flue pressure switch

7 - Safety thermostat

8 - Flue hood

9 - DHW probe (hot water output)

10 - Combustion chamber

11 - Burner

12 - Gas manifold

13 - Flow limiter

14 - One-way valve

15 - Flow rate meter

16 - Domestic water inlet cock

17 - DHW probe (cold water input)

Page 14

2-1

14 - IE

INSTALLATORUSERTECHNICIAN

2

INSTRUCTIONS FOR USE

AND

MAINTENANCE.

2.1 CLEANING AND MAINTENANCE.

e appliance must be serviced every year.

is ensures that the optimal safety, performance

and operation characteristics of the water heater

remain unchanged over time.

2.2 GENERAL WARNINGS

Never expose the wall-mounted water heater to

direct vapours from a cooking surface.

Use of the water heater by unskilled persons or

children is strictly prohibited.

Do not touch the ue gas exhaust terminal (if

present) due to the high temperatures it can

reach;

For safety purposes, check that the concentric

air intake/flue exhaust terminal (if fitted), is

not blocked.

Whenever temporary deactivation of the water

heater is decided, the electric, water and gas

supplies must be interrupted.

In the case of work or maintenance to structures

located in the vicinity of ducting or devices

for flue extraction and relative accessories,

switch o the appliance and on completion of

operations ensure that a qualied technician

checks eciency of the ducting or other devices.

Never clean the appliance or connected parts

with easily ammable substances.

Never leave containers or ammable substances

in the same environment as the appliance.

• Important: the use of components involving

use of electrical power requires some

fundamental rules to be observed:

- do not touch the appliance with wet or moist

parts of the body; do not touch when barefoot;

- never pull electrical cables or leave the

appliance exposed to atmospheric agents (rain,

sunlight, etc.);

- the appliance power cable must not be replaced

by the user;

- in the event of damage to the cable, switch o

the appliance and contact exclusively qualied

sta for replacement;

- if the appliance is not to be used for a certain

period, disconnect the main power switch.

2.3 CONTROL PANEL.

Key:

1 - On/Stand-by/O Button

2 - Reset button

3 - Temperature selector

4 - Domestic hot water function

5 - Temperature and error code display

6 - Unit of measurement

7 - Not used on this model

8 - Not used on this model

9 - Not used on this model

10 - Output eciency

11 - Flame presence

Page 15

15 - IE

INSTALLATORUSERTECHNICIAN

2.4 USE OF THE WATER HEATER.

Ignition (Fig. 2-1). Before ignition, check that

the DHW inlet valve is open.

- Open the gas cock upstream from the water

heater.

- Press the button (1) until the display switches

on; pressing the button passes cyclically from

the “off ”, “stand-by” and “on” state of the

appliance.

- Regulate the DHW temperature according to

requirements by turning the selector (3).

Turning in a clockwise direction the

temperature increases and in an anti-clockwise

direction it decreases.

From this moment the water heater functions

automatically. If there is no request for DHW, it

goes to "Stand-by" which is equal to water heater

powered without ame presence. e display

shows the temperature of the water inside the

water heater (5). Each time the burner ignites,

the relative ame present symbol is displayed

(11) with relative power scale (10). Moreover, the

indication of the instant temperature supplied

by the water heater is supplied.

• “Stand-by” mode. Repeatedly press the

button (1) until the (

) symbol appears. e

water heater is inactive from this moment.

e indication of any anomalies is however

guaranteed.

N.B.: in these conditions the water heater is

considered still powered.

• “O” mode. Press button (1) repeatedly until

the display switches o. In this way the water

heater is o completely.

N.B.: in these conditions the water heater

is considered still live even if there are no

functions active.

2.5 FAULT AND ANOMALY SIGNALS.

The water heater signals out anomalies by

ashing on the display and relative error codes,

listed on the table, are displayed.

Anomaly signalled

code

displayed

(ashing)

No ignition block 01

Over-heating (safety) thermostat block

02

Domestic hot water probe

anomaly

06

Maximum N° of reset 08

Flue pressure switch failure 11

Domestic hot water inlet

probe anomaly

12

Parasite ame 20

Push button control panel

anomaly

24

Low power supply voltage 37

Ignition block. The water heater ignites

automatically with each demand for hot water

production. If this does not occur within 10

seconds, the water heater goes into ignition block

(code 01). To eliminate “ignition block” the Reset

button (2) must be pressed. On commissioning

or aer extended inactivity it may be necessary to

eliminate the “ignition block”. If this phenomenon

occurs frequently, contact a qualied technician

for assistance (e.g. Immergas Aer-Sales Technical

Assistance Service).

Overtemperature thermostat block. During

normal functioning, if a fault causes excessive

overheating internally, the water heater goes into

overtemperature block (code 02). Aer allowing

to cool, eliminate the "overtemperature block" by

pressing the Reset key (2). If this phenomenon

occurs frequently, contact a qualied technician

for assistance (e.g. Immergas Aer-Sales Technical

Assistance Service).

Domestic hot water probe anomaly. If the board

detects an anomaly on the delivery probe (code

06), the water heater will not start; contact a

qualied technician for assistance (e.g. Immergas

Aer-Sales Technical Assistance Service).

Maximum N° of reset. To eliminate any “anomaly”

the Reset button (2) must be pressed. e Anomaly

can be reset 5 times consecutively, aer which the

function in inhibited for at least one hour. One

attempt is gained every hour for a maximum of

5 attempts.

Flue gas pressure switch failure. is occurs if the

intake or exhaust pipes are blocked, in case of a fan

fault or a fault on the ue gas pressure switch (code

11). If normal conditions are restored the water

heater restarts without having to be reset. If this

anomaly persists, contact a qualied technician

for assistance (e.g. Immergas Aer-Sales Technical

Assistance Service).

Domestic hot water inlet probe anomaly. If the

board detects an anomaly on the domestic hot

water NTC probe, the water heater signals the

anomaly. In this case the water heater continues to

produce domestic hot water but not with optimal

performance. A qualified technician however

must be called (e.g. Immergas Aer-Sales Service).

Parasi te ame. is occ urs in case of a leak on the

detection circuit or anomaly in the ame control

unit.(code 20), try to reset the water heater. If the

anomaly continues contact a qualied technician

(e.g. Immergas Aer-Sales Technical Assistance

Service).

Push button control panel anomaly. is occurs

when the circuit board detects an anomaly on the

push button control panel. If normal conditions are

restored the water heater restarts without having

to be reset. If this anomaly persists, contact a

qualied technician for assistance (e.g. Immergas

Aer-Sales Technical Assistance Service).

Low power supply voltage is occurs when the

power supply voltage is lower than the allowed

limits for the correct functioning of the water

heater. If normal conditions are restored the

water heater restarts without having to be reset.

If this phenomenon occurs frequently, contact a

qualied technician for assistance (e.g. Immergas

Aer-Sales Technical Assistance Service).

2.6 INFORMATION MENU.

Pressing the button (2) for 8 seconds, the

“Information menu” is activated, which allows to

display some water heater functioning parameters.

To scroll the various parameters, press the button

(2), to exit the menu, press the button (1) or wait

for 15 minutes.

List of parameters.

N°

parameter

Description

d1

Displays the instant DHW ow

rate (l/min)

d2

Displays the temperature of the

inlet water on the water heater.

d3

Displays the temperature of

the outlet water from the water

heater.

d4

Displays the temperature set

on the water heater via the

temperature selector (3)

2.7 SWITCHOFF OF THE WATER

HEATER.

Press the button (1 Fig. 2-1) (

) until the

display is switched o completely.

N.B.: in these conditions the water heater is

considered still powered.

Disconnect the external omnipolar water heater

switch and close the gas cock upstream of the

appliance. Never leave the water heater switched

on if le unused for prolonged periods.

2.8 EMPTYING THE WATER HEATER.

To empty the water heater, close the cold water

inlet valve and open the hot water valve lower

down in the water network in the room.

2.9 ANTIFREEZE PROTECTION

OPTIONAL.

The water heater can be equipped with an

optional anti-freeze kit, which protects it from

freezing to outdoor temperatures of -15°C. For

correct installation of the kit and especially

to guarantee appropriate functioning, the

instructions supplied with the kit itself must

be followed.

2.10 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the water heater casing. Never use abrasive or

powder detergents.

2.11 DECOMMISSIONING.

In the event of permanent shutdown of the

water heater, contact professional staff for

the procedures and ensure that the electrical,

water and gas supply lines are shut off and

disconnected.

Page 16

3-1

16 - IE

INSTALLATORUSERTECHNICIAN

3

CONTROL AND MAINTENANCE

3.1 HYDRAULIC DIAGRAM.

Key:

1 - Fan

2 - Sealed chamber

3 - Safety thermostat

4 - Primary heat exchanger

5 - DHW probe (hot water output)

6 - Burner

7 - Gas valve

8 - Flue pressure switch

9 - Flue hood

10 - One-way valve

11 - Flow limiter

12 - Flow rate meter

13 - DHW probe (cold water input)

14 - Domestic hot water inlet valve

AC - Domestic hot water outlet

AF - Domestic cold water inlet

G - Gas supply

Page 17

3-2

17 - IE

INSTALLATORUSERTECHNICIAN

3.2 WIRING DIAGRAM.

3.3 TROUBLESHOOTING

N.B.: maintenance interventions must be carried

out by a qualified technician (e.g. Immergas

Aer-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing eciency of gas intake

circuit.

- e fan works but ignition discharge does not

occur on the burner ramp. e fan may start

but the safety air pressure switch does not

switch the contact over. Make sure:

1) 1) the intake-exhaust duct is not too long

(over allowed length).

2) 2) the intake-exhaust pipe is not partially

blocked (on the exhaust or intake side).

3) the diaphragm of the flue gas exhaust is

adequate for the length of the intake-exhaust

duct.

4) that the sealed chamber is kept in good

conditions.

5) the fan power supply voltage is not less than

196 V.

- Irregular combustion (red or yellow ame).

is may be caused by: dirty burner, incorrect

combustion parameters, intake - exhaust

terminal not correctly installed. Clean

the above components and ensure correct

installation of the terminal.

- Frequent activation of the overheating

temperature or safety thermostat. It can depend

on an anomaly on the water heater P.C.B. or and

anomaly of the regulation NTC probe.

- Ignition block see par. 2.6 and 1.4 (electric

connection).

- Low water ow: if, as a result of lime scale

(calcium and magnesium), the domestic hot

water system does not work properly contact a

qualied technician for descaling e.g. Immergas

Aer-Sales Technical Service according to good

practice. To preserve integrity and eciency

of the heat exchanger, a non corrosive descaler

must be used. Cleaning must be carried out

without the use of tools which can damage the

heat exchanger.

3.4 CONVERTING THE WATER HEATER

TO OTHER TYPES OF GAS.

If the boiler has to be converted to a dierent gas

type to that specied on the data plate, request

the relative conversion kit for quick and easy

conversion.

Boiler conversion must be carried out by a

qualied technician (e.g. Immergas Aer-Sales

Technical Assistance Service).

To convert to another type of gas the following

operations are required:

- remove the voltage from the appliance;

- replace the main burner injectors, making sure

to insert the special seal rings supplied in the

kit, between the gas manifold and the injectors;

- apply voltage to the appliance;

- Use the push button control panel to select the

gas parameter type (P2) and then select (nG)

in case of Methane supply or (LG) in the case

of LPG;

- adjust the water heater nominal heat output;

- adjust the water heater minimum heat output;

- seal the gas ow rate devices (if adjusted);

- aer completing conversion, apply the sticker,

present in the conversion kit, near the dataplate. Using an indelible marker pen, cancel

the data relative to the old type of gas.

ese adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.13).

3.5 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

Aer making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that:

- there is no ame in the combustion chamber

- the burner ame is not too high or low and that

it is stable (does not detach from burner)

- the pressure testers used for calibration are

perfectly closed and there are no leaks from

the gas circuit.

N.B.: all water heater adjustment operations

must be carried out by a qualied technician

(e.g. Immergas Aer-Sales Technical Assistance).

Burner adjustment must be carried out using a

dierential "U" or digital type pressure gauge,

connected to a Y-shaped pipes to be placed on

the small silicone pipe that goes from the gas

valve to the sealed chamber and to the gas valve

outlet pressure point (part. 4 g. 3-3), keeping

to the pressure value given in the table par. 3.13

according to the type of gas for which the water

heater is prepared.

Key:

B2 - Domestic hot water probe

B6 - Domestic hot water ow meter

B9 - DHW inlet probe

DS1 - Display

E3 - Ignition/detection electrodes

F1 - Phase fuse

F2 - Neutral fuse

M20 - Fan

R5 - Domestic hot water temperature selector

S2 - Stand-by - On Button

S3 - Reset button

S6 - Flue pressure switch

T2 - Ignition transformer

Y1 - Gas valve

Y2 - Gas valve modulator

230 Vac

50 Hz

Power supply

Blue

Blue

Blue

Brown

Brown

Brown

Black

Black

Black

Black

Black

Red

Condenser

Red

Red

White

Grey

Grey

White

White

White

Yellow/Green

THE X6 CONNECTOR IS

USED FOR AUTOMATIC

INSPECTION

N.B. THE USER INTERFACE

IS ON THE WELDING SIDE

OF THE BOILER BOARD

Page 18

3-3

18 - IE

INSTALLATORUSERTECHNICIAN

SIT 845 Gas Valve

Key:

1 - Coil

2 - Minimum power adjustment screws

3 - Maximum power adjustment screw

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

3.6 POSSIBLE ADJUSTMENTS

• Adjustment of nominal heat output (Fig. 3-3).

- Turn the hot water selector knob (3 Fig. 2-1)

to the maximum functioning position;

- Open the domestic hot water cock in order to

prevent modulation intervention.

- Adjust the water heater nominal power on the

brass nut (3), keeping to the maximum pressure

values stated in the tables (Par. 3.13) depending

on the type of gas.

- By turning in a clockwise direction the heating

potential increases and in an anti-clockwise

direction it decreases.

• Adjustment of minimum heat output (Fig. 3-3).

N.B.: only proceed aer having calibrated the

nominal pressure.

Adjustment of the minimum thermal input

is obtained by operating on the cross plastic

screws (2) on the gas valve maintaining the

brass nut blocked (3);

- disconnect the power supply to the modulating

coil (just disconnect a faston); By turning the

screw in a clockwise direction, the pressure

increases, in an anti-clockwise direction it

decreases. On completion of calibration, reapply the power supply to the modulating

coil. e pressure to which the water heater

minimum power must be adjusted, must not

be lower than that stated in the table (Par. 3.13)

depending on the type of gas.

N.B.: to adjust the gas valve, remove the plastic

cap (6); aer adjusting, ret the cap.

3.7 PROGRAMMING THE P.C.B.

The water heater is prepared for possible

programming of several operation parameters.

By modifying these parameters as described

below, the water heater can be adapted according

to specic needs.

To access the programming phase, proceed as

follows:

- press keys (1) and (2) at the same time for

approximately 10 seconds, keeping the selector

(3) at minimum;

- using key (2), select the parameter to be

changed indicated in the following table:

List of

param-

eters

Description

P1 Solar delay timing

P2 Gas type selection

P3 Ignition power value

P4 Display lighting

- adjust the corresponding value consulting the

following tables by turning the selector (3);

- conrm the value set by pressing the Reset

button (2) for about 3 seconds.

e value ashes when it is memorised.

N.B.: aer a period of time, without touching

any keys, the operation cancels automatically.

Solar delay timing.e water heater is set to

switch-on immediately aer a request for DHW

In the case of coupling with a solar storage tank

positioned upstream from the water heater, it

is possible to compensate the distance between

the storage tank and the water heater in order

to allow the water to reach the water heater. Set

the time necessary to verify that the water is hot

enough (see par. Solar panels coupling)

Solar delay timing

Range of values which can

be set

Parameter

From 0 to 60 sec. (0 Standard

setting)

P1

Gas type selection. e setting of this function

is used to adjust the water heater in order to

function with LPG gas or Methane gas.

Gas type selection

Range of values which can

be set

Parameter

G Town gas (rst family gas)

LG (LPG) or nG (Methane)

(nG Standard setting)

P2

Ignition power value. The water heater has

electronic modulation that adapts the ignition

power according to requirement.

Ignition power value

Range of values which can

be set

Parameter

from 0 % to 50 % (35 % Stand-

ard setting)

P3

Display lighting. Establishes the display lighting

mode.

0 O: the display is always o.

1 Automatic: the display lights up when the water

heater is used.

2 On: e display is always lit up.

Display lighting

Range of values which can

be set

Parameter

0 - 1 - 2 (1 Standard setting) P4

3.8 AUTOMATIC SLOW IGNITION

FUNCTION WITH TIMED RAMP

DELIVERY.

In the ignition phase, the burner ignites at the

"ignition power value" set (P3), aer which, on

the basis of the DHW withdrawal it carries out

a gas supply increasing ramp (with pressure

values that depend on the type of gas selected)

with a pre-dened duration. is prevents every

calibration or precision adjustment of the water

heater ignition phase in any conditions of use.

Page 19

19 - IE

INSTALLATORUSERTECHNICIAN

3.9 SOLAR FUNCTION.

e solar function is always active.

During a request for DHW, if the inlet

temperature is the same as or higher than -3°C

with respect to the value set, the water heater

does not switch-on.

Functioning is however shown on the display by

the ashing of the relevant signal (4).

3.10 SOLAR PANELS COUPLING

FUNCTION.

e water heater is set-up to receive pre-heated

water from a system of solar panels up to a

maximum temperature of 65°C. In all cases, it is

always necessary to install a mixing vale on the

hydraulic circuit upstream from the water heater

on the cold water inlet.

Note: for good functioning of the water heater;

the temperature selected on the mixing valve

must be 5 °C greater with respect to the

temperature selected on the water heater control

panel.

In this condition, parameter P1 (solar delay

timing) must be set at a temperature sucient

to receive water from a storage tank situated

upstream from the water heater. e greater the

distance from the storage tank, the longer the

stand-by time to be set. When these regulations

have been performed, when the water heater inlet

water is at the same or greater temperature with

respect to that set by the DHW selector switch,

the water heater does not switch on.

3.11 YEARLY APPLIANCE CHECK AND

MAINTENANCE.

e following checks and maintenance should

be performed at least once a year.

- Clean the ue side of the heat exchanger.

- Clean the main burner.

- Visually check the ue hood for deterioration

or corrosion.

- Check correct lighting and operation.

- Check correct burner calibration.

- Check correct operation of control and

adjustment devices and in particular:

- the intervention of the functioning selector

positioned on the water heater control panel;

- domestic hot water control thermostat

intervention.

- Check that the internal system is properly

sealed according to specications.

- Check the intervention of the device against no

gas ionisation ame control. Intervention time

must be less than 10 seconds.

- Visually check for water leaks or oxidation

from/on connections.

- Check visually that the safety and control

devices have not been tampered with and/or

shorted, in particular:

- temperature safety thermostat;

- air pressure switch

- Check the condition and integrity of the

electrical system and in particular:

- electrical power cables must be inside the

whipping;

- there must be no traces of blackening or

burning.

Page 20

3-5

c

4

4

d

d

2

a

3

1

a

a

1

1

1

b

20 - IE

INSTALLATORUSERTECHNICIAN

3.12 CASING REMOVAL.

To facilitate water heating maintenance the

casing can be completely removed as follows:

(Fig. 3-5):

1) Loosen the lower screws (a) that x the lower

protection grid (b) and the casing (c).

2) Widen the casing (c) pulling the sides slightly

outwards.

3) Pull the casing towards yourself in the lower

side.

4) Push the casing upwards in a way to be able

to extract it from the upper hooks (d).

Page 21

21 - IE

INSTALLATORUSERTECHNICIAN

3.13 VARIABLE HEAT POWER.

N.B.: the pressures indicated in the table

represent the dierence in existing pressures

between the gas valve outlet and the combustion

chamber. e adjustments should therefore,be

carried out using a differential manometer

(small "U"-shaped column or digital manometer)

with the probes inserted in the pressure test gas

valve outlet and on the sealed chamber positive

pressure test. e power data in the table has been

obtained with intake-exhaust pipe measuring 0.5

m in length. Gas ow rates refer to heating power

below a temperature of 15°C and at a pressure of

1013 mbar. Burner pressure values refer to use

of gas at 15°C.

Caesar 14 3 E.

METHANE (G20) BUTANE (G30) PROPANE (G31)

HEAT

OUTPUT

HEAT

OUTPUT

BURNER

GAS FLOW RATE

BURNER NOZZLES

PRESSURE

BURNER

GAS FLOW RATE

BURNER NOZZLES

PRESSURE

BURNER

GAS FLOW RATE

BURNER NOZZLES

PRESSURE

(kW) (kcal/h) (m3/h) (mbar) (mm H2O) (kg/h) (mbar) (mm H2O) (kg/h) (mbar) (mm H2O)

24.4 20984 2.92 13,20 134,6 2.18 28.70 292.7 2.14 36.40 371.2

24.0 20640 2.87 12,84 130,9 2.15 28.04 286.0 2.11 35.49 361.9

23.0 19780 2.77 11,96 122,0 2.06 26.42 269.4 2.03 33.26 339.1

22.0 18920 2.66 11,12 113,4 1.98 24.83 253.2 1.95 31.09 317.0

21.0 18060 2.55 10,30 105,0 1.90 23.28 237.4 1.87 28.98 295.5

20.0 17200 2.44 9,51 96,9 1.82 21.75 221.8 1.79 26.94 274.7

19.0 16340 2.33 8,74 89,1 1.74 20.24 206.4 1.71 24.95 254.4

18.0 15480 2.22 8,00 81,6 1.66 18.76 191.3 1.63 23.01 234.6

17.0 14620 2.11 7,29 74,3 1.58 17.31 176.5 1.55 21.13 215.5

16.0 13760 2.00 6,60 67,3 1.49 15.87 161.8 1.47 19.30 196.8

15.0 12900 1.89 5,94 60,5 1.41 14.46 147.4 1.39 17.52 178.6

14.0 12040 1.78 5,30 54,0 1.33 13.06 133.2 1.31 15.79 161.0

13.0 11180 1.67 4,68 47,7 1.24 11.68 119.1 1.22 14.11 143.9

12.0 10320 1.55 4,09 41,7 1.16 10.32 105.3 1.14 12.47 127.2

11.0 9460 1.44 3,52 35,9 1.07 8.98 91.5 1.05 10.89 111.0

10.0 8600 1.32 2,98 30,3 0.98 7.65 78.0 0.97 9.35 95.4

9.0 7740 1.20 2,46 25,1 0.89 6.33 64.5 0.88 7.86 80.2

8.0 6880 1.08 1,97 20,0 0.80 5.03 51.3 0.79 6.43 65.5

7.0 6020 0.95 1,50 15,3 0.71 3.74 38.1 0.70 5.04 51.4

Page 22

22 - IE

INSTALLATORUSERTECHNICIAN

3.14 COMBUSTION PARAMETERS.

Super Caesar 17 3 E.

METHANE (G20) BUTANE (G30) PROPANE (G31)

HEAT

OUTPUT

HEAT

OUTPUT

BURNER

GAS FLOW RATE

BURNER NOZZLES

PRESSURE

BURNER

GAS FLOW RATE

BURNER NOZZLES

PRESSURE

BURNER

GAS FLOW RATE

BURNER NOZZLES

PRESSURE

(kW) (kcal/h) (m3/h) (mbar) (mm H2O) (kg/h) (mbar) (mm H2O) (kg/h) (mbar) (mm H2O)

29.8 25628 3.56 12,50 127,5 2.66 28.50 290.6 2.62 36.60 373.2

29.0 24940 3.47 11,86 121,0 2.59 27.08 276.2 2.55 34.83 355.2

28.0 24080 3.36 11,10 113,2 2.50 25.37 258.7 2.46 32.70 333.4

27.0 23220 3.24 10,36 105,7 2.42 23.73 242.0 2.38 30.64 312.4

26.0 22360 3.13 9,66 98,5 2.33 22.15 225.9 2.30 28.66 292.3

25.0 21500 3.01 8,99 91,6 2.25 20.64 210.5 2.21 26.75 272.8

24.0 20640 2.90 8,34 85,0 2.17 19.19 195.7 2.13 24.92 254.1

23.0 19780 2.79 7,72 78,7 2.08 17.80 181.5 2.05 23.15 236.1

22.0 18920 2.68 7,13 72,7 2.00 16.46 167.8 1.97 21.45 218.7

21.0 18060 2.57 6,56 66,9 1.92 15.18 154.7 1.88 19.81 202.0

20.0 17200 2.46 6,02 61,4 1.83 13.95 142.2 1.80 18.23 185.9

19.0 16340 2.34 5,50 56,1 1.75 12.77 130.2 1.72 16.71 170.4

18.0 15480 2.23 5,01 51,1 1.67 11.64 118.7 1.64 15.24 155.4

17.0 14620 2.12 4,54 46,3 1.58 10.56 107.7 1.56 13.84 141.1

16.0 13760 2.01 4,10 41,8 1.50 9.54 97.2 1.47 12.49 127.3

15.0 12900 1.89 3,67 37,5 1.41 8.56 87.3 1.39 11.19 114.1

14.0 12040 1.78 3,27 33,4 1.33 7.63 77.8 1.31 9.95 101.5

13.0 11180 1.66 2,90 29,5 1.24 6.74 68.8 1.22 8.77 89.4

12.0 10320 1.55 2,54 25,9 1.15 5.91 60.3 1.14 7.63 77.8

11.0 9460 1.43 2,21 22,6 1.07 5.13 52.3 1.05 6.56 66.9

10.0 8600 1.31 1,91 19,5 0.98 4.39 44.8 0.96 5.53 56.4

9.0 7740 1.19 1,63 16,6 0.89 3.71 37.8 0.87 4.57 46.6

8.0 6880 1.07 1,37 14,0 0.80 3.08 31.4 0.78 3.66 37.3

7.7 6622 1.03 1,30 13,3 0.77 2.90 29.6 0.76 3.40 34.7

G20 G30 G31

Caesar 14 3 E

Gas nozzle diameter mm 1.35 0.81 0.81

Supply pressure mbar (mm H

2

O) 20 (204) 29 (296) 37 (377)

Flue ow rate at nominal heat output kg/h 55 57 59

Flue ow rate at min heat output kg/h 58 58 58

CO

2

at Nom Q./Min. % 7,20 / 2,10 8,10 / 2,42 7,64 / 2,40

CO with 0% O

2

at Nom Q /Min. ppm 70 / 145 78 / 174 40 / 172

NO

X

with 0% O2 at Nom Q /Min. mg/kWh 177 / 109 200 / 60 220 / 75

Flue temperature at nominal output °C 171 171 163

Flue temperature at minimum output °C 113 113 113

Super Caesar 17 3 E

Gas nozzle diameter mm 1.35 0.80 0.80

Supply pressure mbar (mm H

2

O) 20 (204) 29 (296) 37 (377)

Flue ow rate at nominal heat output kg/h 71 69 71

Flue ow rate at min heat output kg/h 76 72 79

CO

2

at Nom Q./Min. % 6,80 / 1,70 8,11 / 2,10 7,85 / 1,91

CO with 0% O

2

at Nom Q /Min. ppm 40 / 190 75 / 234 54 / 223

NO

X

with 0% O2 at Nom Q /Min. mg/kWh 135 / 107 210 / 65 230 / 90

Flue temperature at nominal output °C 157 164 161

Flue temperature at minimum output °C 92 97 90

Page 23

23 - IE

INSTALLATORUSERTECHNICIAN

- Flue temperature values refer to an air inlet

temperature of 15°C.

- The data relevant to domestic hot water

performance refer to a dynamic inlet pressure

of 2 bar and an inlet temperature of 15°C; the

values are measured directly at the water heater

outlet considering that, to obtain the data

declared, mixing with cold water is necessary.

- e max. sound level emitted during water

heater operation is < 55dBA. e sound level

value is referred to semianechoic chamber

tests with water heater operating at max. heat

output, with extension of flue gas exhaust

system according to product standards.

3.15 TECHNICAL DATA.

Caesar 14 3 E Super Caesar 17 3 E

Nominal heat input kW (kcal/h) 27.6 (23711) 33.7 (28958)

Minimum heat input kW (kcal/h) 9.0 (7748) 9.7 (8382)

Nominal heat output (useful) kW (kcal/h) 24.4 (20984) 29.8 (25628)

Minimum heat output (useful) kW (kcal/h) 7.0 (6020) 7.7 (6622)

Eciency at nominal heat output % 88.5 88.5

Heat loss at case with burner On % 2.0 2.4

Heat loss at ue with burner On % 9.5 9.1

Water content in generator l 1.0 1.0

Domestic hot water adjustable temperature °C 40 - 60 40 - 60

Domestic hot water circuit ow limiter at 2 bar l/min 9.5 10.0

Min. pressure (dynamic) burner ON (in ascent) bar 0.25 0.25

Min. pressure (dynamic) burner ON (in descent) bar 0.20 0.20

Min. ow rate (dynamic) burner ON (in ascent) l/min 2.5 2.5

Min. ow rate (dynamic) burner ON (in descent) l/min 2.0 2.0

Domestic hot water circuit max. working pressure bar 10.0 10.0

Withdrawal capacity in continuous service (ΔT 25 °C) in mixing mode l/min 14.0 17.0