Page 1

Instruction booklet and

*1.038455ENG*

warning

IE

AVIO 24 2 ERP

Installer

User

Maintenance Technician

Wall-hung boiler with storage

tank, open chamber (type B)

and natural draught

e European regulation 813/2013 provides that

this boiler can be installed only to replace similar

equipment connected to existing branched

multiple ues.

Page 2

Dear Customer,

Our compliments for having chosen a top-quality Immergas product, able to assure well-being and safety for a long period of time. As an Immergas customer

you can also count on a qualied aer-sales service, prepared and updated to guarantee constant eciency of your boiler. Read the following pages carefully: you

will be able to draw useful suggestions regarding the correct use of the appliance, the respect of which, will conrm your satisfaction for the Immergas product.

For any interventions or routine maintenance contact Authorised Centres: these have original spare parts and boast of specic preparation directly from the

manufacturer.

General recommendations

All Immergas products are protected with suitable transport packaging.

e material must be stored in dry premises and protected against weathering.

e instruction book is an integral and important part of the product and must be consigned to the user also in the case of transfer of ownership.

It must be kept well and consulted carefully, as all of the warnings supply important indications for safety in the installation, use and maintenance stages.

is instructions manual provides technical information for installing Immergas boilers. As for the other issues related to boiler installation (e.g. safety in the work

site, environment protection, injury prevention), it is necessary to comply with the provisions specied in the regulations in force and principles of good practice.

In compliance with legislation in force, the systems must be designed by qualied professionals, within the dimensional limits established by the Law. Instal-

lation and maintenance must be performed in compliance with the regulations in force, according to the manufacturer’s instructions and by an authorised

company, which has specic technical expertise in the system sector, as required by Law.

Improper installation or assembly of Immergas appliance and/or components, accessories, kit and devices can cause unexpected problems to persons, animals

and objects. Read the provided product instructions carefully in order to install the product correctly

Maintenance must be carried out by skilled technical sta. e Authorised Aer-sales Service represents a guarantee of qualications and professionalism.

e appliance must only be destined for the use for which it has been expressly declared. Any other use must be considered improper and therefore dangerous.

In the case of errors during installation, running and maintenance due to the failure to comply with the technical laws in force, standards or the instructions

contained in this book (or however supplied by the manufacturer), the manufacturer is excluded from any contractual and extra-contractual liability for any

damages and the appliance warranty is invalidated.

e company IMMERGAS S.p.A., with registered oce in via Cisa Ligure 95 42041 Brescello (RE), declares that the design, manufacturing and aer-sales

assistance processes comply with the requirements of standard UNI EN ISO 9001:2015.

For further details on the product CE marking, request a copy of the Declaration of Conformity from the manufacturer, specifying the appliance model

and the language of the country.

Immergas S.p.A. declines all liability due to printing or transcription errors, reserving the right to make any modications to its technical and commercial

documents without forewarning.

Page 3

INDEX

1 Installation of the boiler ...........................5

1.1 Installation recommendations. ................5

1.2 Main dimensions. ......................................5

1.5 Gas attachment. .........................................6

1.6 Hydraulic attachment. .............................. 6

1.7 Electrical connection. ............................... 6

1.3 Antifreeze protection. ...............................6

1.4 Boiler connection unit. ............................. 6

1.8 Remote controls and room

chronothermostats (optional). ................ 7

1.9 External probe (optional). ........................7

1.10 Ventilation of the rooms...........................8

1.11 Evacuation of combustion products:

ue duct and branched multiple ues ... 8

1.12 Flue exhaust control device. .....................8

1.13 System lling. ............................................. 8

1.14 Gas system start-up. ..................................8

1.15 Start-up of the boiler (ignition). ..............8

1.16 Domestic hot water boiler device............8

1.17 Circulation pump. .....................................9

1.18 Kits available on request. ........................ 10

1.19 Boiler components. .................................11

USER page INSTALLATOR page MAINTENANCE page

2 Instructions for use and maintenance ..12

2.1 Cleaning and maintenance. ...................12

2.2 Ventilation of the rooms.........................12

2.3 General warnings .................................... 12

2.4 Control panel. ..........................................12

2.5 Ignition of the boiler. ..............................13

2.6 Fault and anomaly signals. ..................... 13

2.7 Boiler shutdown. .....................................14

2.8 Restoring heating system pressure. .......14

2.9 Draining the system. ...............................14

2.10 Draining the boiler. .................................14

2.11 Anti-freeze protection. ...........................14

2.12 Case cleaning. .......................................... 14

2.13 Decomissioning. ......................................14

3 Boiler commissioning

(initial check) ...........................................15

3.1 Hydraulic layout. .....................................15

3.2 Wiring diagram. ......................................16

3.3 Troubleshooting. .....................................16

3.4 Converting the boiler to

other types of gas. ....................................17

3.5 Checks following conversion to

another type of gas. .................................17

3.6 Possible adjustments of the gas valve. ..17

3.7 Programming the circuit board.............17

3.8 Automatic slow ignition function with

timed ramp delivery. ............................... 18

3.9 “Chimney sweep” function. ...................18

3.10 Pump anti-block function. .....................19

3.11 ree-way anti-block system. ................19

3.12 Radiator anti-freeze function. ...............19

3.13 Electronic card periodical self-check. ..19

3.14 Yearly appliance check and

maintenance. ............................................19

3.15 Casing removal. .......................................19

3.16 Variable heat power. ................................20

3.17 Combustion parameters. ........................20

3.18 Technical data. .........................................21

3.19 Data plate key. ..........................................22

3.20 Technical parameters for combination

boilers (in compliance with

Regulation 813/2013). ............................23

3.21 Product che (in compliance with

Regulation 811/2013). ............................23

3.22 Parameters for lling in

the package che. ....................................24

Page 4

INSTALLATION OF THE

1

BOILER

1.1 INSTALLATION RECOMMENDATIONS.

e Avio 24 2 ErP boiler has been designed for

wall mounted installation only, for heating and

production of domestic hot water for domestic

use and similar purposes.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural) such to allow

(always in safety, efficiency and comfortable

INSTALLATORUSER

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (to outdoors in the place for loading

and transporting the appliances and components) as well as their possible replacement

with equivalent appliances and/or components.

e wall surface must be smooth, without any

protrusions or recesses enabling access to the

rear part. ey are NOT designed to be installed

on plinths or oors (Fig. 1-1).

Only professionally enabled companies are

authorised to install Immergas gas appliances.

Installation must be carried out according to

regulation standards, current legislation and in

compliance with local technical regulations and

the required technical procedures.

Attention: Immergas declines all liability for

damages caused by boilers removed from other

systems or for any non-conformities of such

equipment.

Before installing the appliance, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately.

Packing materials (staples, nails, plastic bags,

polystyrene foam, etc.) constitute a hazard and

must be kept out of the reach of children. If the

appliance is installed inside or between cabinets,

ensure sufficient space for normal servicing;

therefore it is advisable to leave a clearance of

at least 3 cm between the boiler casing and the

vertical sides of the cabinet.

Leave adequate space above the boiler for

possible water and fume removal connections.

At least 60 cm must be le below the boiler

in order to guarantee replacement of the

magnesium anode.

MAINTENANCE TECHNICIAN

It is just as important that the intake grids are

not obstructed.

Keep all flammable objects away from the

appliance(paper, rags, plastic, polystyrene, etc.).

Do not place household appliances underneath

the boiler as they could be damaged if the

safety valve intervenes (if not conveyed away

by a draining funnel), or if there are leaks from

the hydraulic connections; on the contrary, the

manufacturer cannot be held responsible for

any damage caused to the household appliances.

For the aforementioned reasons, we recommend

not placing furnishings, furniture, etc. under

the boiler.

In the event of a malfunction, fault or incorrect

operation, turn the appliance o and contact

an authorised company (e.g. the Authorised

Technical Assistance centre, which has

specically trained sta and original spare parts).

Do not attempt to modify or repair the appliance alone. Failure to comply with the above

implies personal responsibility and invalidates

the warranty.

• Installation regulations:

- installation of these boilers in bedrooms,

studio ats and bathrooms, or in premises

where there are wood red heaters (or by

solid fuels in general) and in premises next

to or connected to them, is subject to the

regulatory/legislative provisions in force in

the country.

- installation in places with a fire risk is

prohibited (for example: underground car

parks, garages), potentially dangerous places,

gas appliances and relative ue ducts.

- installation is prohibited on the vertical

projection of cooking hobs;

- installation is forbidden in places/rooms

that constitute public areas of apartment

buildings, internal stairways or other

escape routes (e.g. landings, entrance halls,

etc.) unless otherwise provided by local

regulations;

- install ation is also forbidden in places/rooms

that constitute public areas of apartment

buildings such as cellars, entrance halls, attics,

los, etc., unless otherwise provided for by

local regulations in force;

- Type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the working of wood,

coal nes, cement, etc.), which may be damaging for the components of the appliance and

jeopardise functioning.

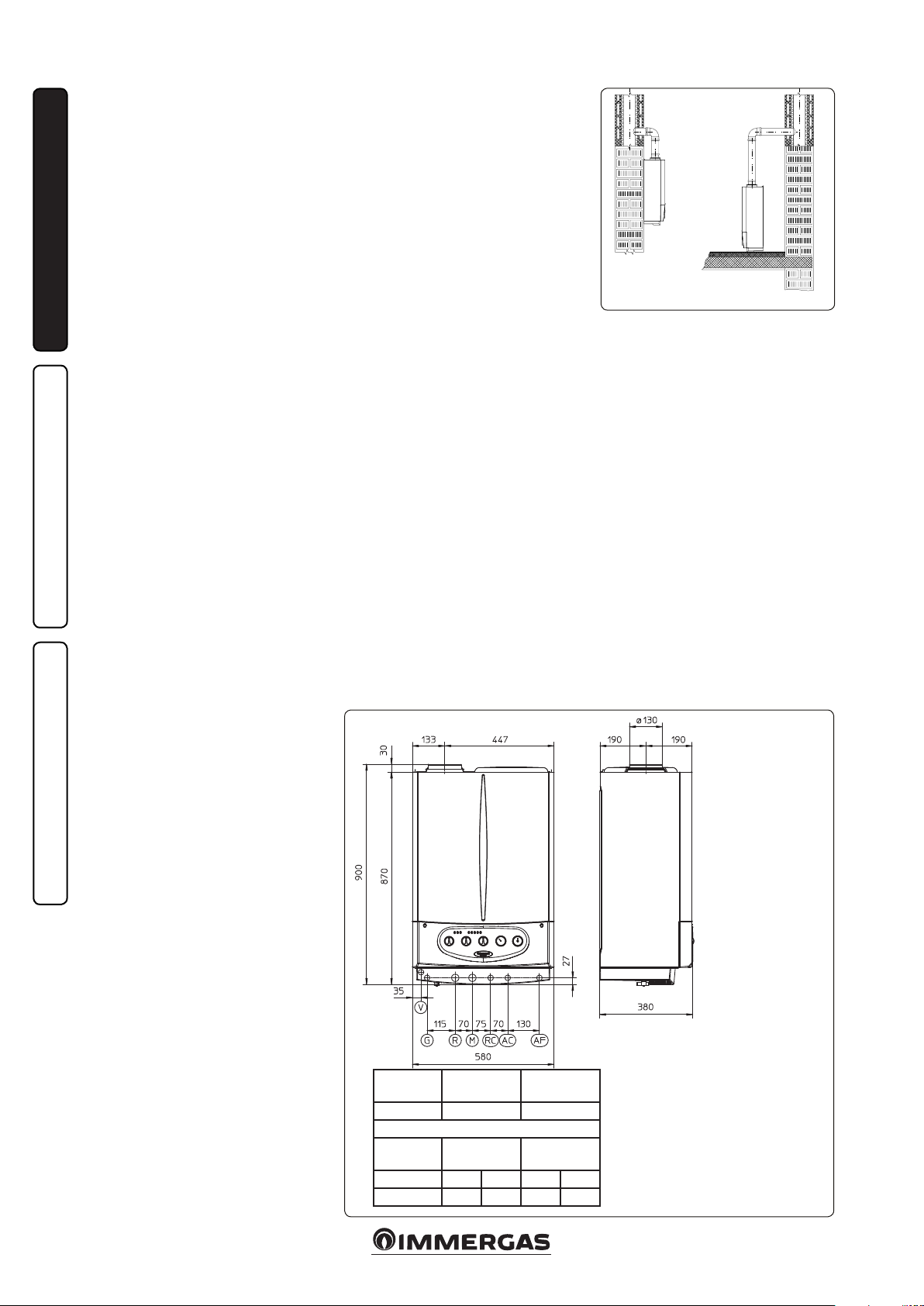

1.2 MAIN DIMENSIONS.

Height

(mm)

900 580 380

GAS PLANT

G R M AC AF

1/2” 3/4” 3/4” 1/2” 1/2”

Width

(mm)

ATTACHMENTS

Depth

(mm)

DOMESTIC

HOT WATER

YES NO

1-1

- ey must also be installed in an environment in which the temperature cannot fall

below 0°C. They must not be exposed to

atmospheric agents.

- is natural draught boiler can be connected

only to a multiple branched ue served by

a variety of users in existing buildings. e

boiler takes the combustion air directly from

the installation room and is equipped with

draught-breaker/anti-wind device. Due to

lower eciency, any other use of this boiler

must be avoided as it would lead to greater

consumption and higher operating costs.

Important: wall mounting of the boiler must

guarantee stable and ecient support for the

generator.

e plugs (standard supply) are to be used only in

conjunction with the mounting brackets or xing

template to x the appliance to the wall; they only

ensure adequate support if inserted correctly

(according to technical standards) in walls made

of solid or semi-hollow brick or block. In the

1-2

Key:

G - Gas supply

R - System return

M - System delivery

RC - Domestic hot water re-circ.

AC - Domestic hot water outlet

AF - Domestic cold water inlet

V - Electric attachment

4

Page 5

case of walls made from hollow brick or block,

partitions with limited static properties, or in any

case walls other than those indicated, a static test

must be carried out to ensure adequate support.

N.B.: the hex head screws supplied in the blister

pack are to be used exclusively to x the relative

mounting bracket to the wall.

These boilers are used to heat water to below

boiling temperature in atmospheric pressure.

ey must be connected to a heating system

and hot water circuit suited to their performance

and capacity.

Anti-Legionella thermal treatment of the Immergas storage tank (which can be activated

through the specic function present on the set

thermoregulation systems): during this phase,

the water temperature inside the storage tank exceeds 60 °C resulting in burns hazards. Keep this

DHW treatment under control (and inform the

users), to prevent unexpected damage to persons,

animals and objects. If required, a thermostatic

valve must be installed at the DHW outlet to

prevent burns.

1.3 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e boiler comes

standard with an anti-freeze function that activates the pump and burner when the system

water temperature in the boiler falls below 4°C.

e antifreeze function is only guaranteed if:

- the boiler is correctly connected to gas and

electricity power supply circuits;

- the boiler is powered constantly;

- the boiler is on and not in Stand-by;

- the boiler is not in ignition failure block (Par.

2.7);

- the boiler essential components are not faulty.

In these conditions the boiler is protected against

freezing to an ambient temperature of -5°C.

N.B.: if the boiler is installed in places where

the temperature falls below 0°C the domestic

hot water and central heating attachment pipes

must be insulated.

e water in the storage tank unit is not protected

against freezing when the boiler is switched o.

1.4 BOILER CONNECTION UNIT.

e connection unit consisting of all the necessary parts to perform the hydraulic and gas

system connections of the appliance comes as

standard with the boiler.

1.5 GAS ATTACHMENT.

Our boilers are designed to operate with methane

gas (G20) and LPG. Supply pipes must be the

same as or larger than the 1/2”G boiler tting.

Before connecting the gas line, carefully clean

inside all the fuel feed system pipes to remove

any residue that could impair boiler eciency.

Also make sure the gas corresponds to that

for which the boiler is prepared (see boiler

data-plate). If dierent, the appliance must be

converted for operation with the other type

of gas (see converting appliance for other gas

types). It is also important to check the dynamic

pressure of the mains (methane or LPG) used

to supply the boiler, which must comply with

the technical standards in force, as insucient

levels may reduce generator output and cause

discomfort to the user. Ensure correct gas cock

connection. e gas supply pipe must be suitably

dimensioned according to current regulations

in order to guarantee correct gas ow to the

boiler even in conditions of max. generator

output and to guarantee appliance efficiency

(technical specications). e coupling system

must conform to technical standards in force..

Combustible gas quality. e appliance has been

designed to operate with gas free of impurities;

otherwise it is advisable to fit special filters

upstream from the appliance to restore the

purity of the gas.

Storage tanks (in case of supply from LPG

depot).

- New LPG storage tanks may contain residual

inert gases (nitrogen) that degrade the mixture

delivered to the appliance casing functioning

anomalies.

- Due to the composition of the LPG mixture,

layering of the mixture components may occur

during the period of storage in the tanks. is

can cause a variation in the heating power of

the mixture delivered to the appliance, with

subsequent change in its performance.

1.6 HYDRAULIC ATTACHMENT.

Important: In order not to void the warranty

before making the boiler connections, carefully

clean the heating system (pipes, radiators, etc.)

with special pickling or de-scaling products to

remove any deposits that could compromise

correct boiler operation.

A treatment of the water of the heating and

water system is required, in compliance with the

technical standards in force, in order to protect

the system and the appliance from deposits (e.g.

limescale), slurry or other hazardous deposits.

Water connections must be made in a rational

way. The boiler safety valve outlet must be

connected to a discharge funnel. Otherwise, the

manufacturer declines any responsibility in case

of ooding if the drain valve cuts in.

Attention: Immergas declines all liability in

the event of damage caused by the inclusion of

automatic lling that is not of its own brand.

In order to meet the system requirements

established by the technical regulation in force

in relation to the pollution of drinking water,

we recommend installing the IMMERGAS

anti-backow kit to be used upstream of the

cold water inlet connection of the boiler. It is also

recommended that the heat transfer uid (e.g.

water + glycol) entered in the primary circuit

of the boiler (heating circuit), complies with the

local regulations in force.

Important: to preserve the life and eciency of the

domestic hot water exchanger it is recommended

to install the “polyphosphate proportioner” kit in

the presence of water whose characteristics can

give rise to scale deposits.

1.7 ELECTRICAL CONNECTION.

The “Avio 24 2 ErP” boiler has an IPX4D

protection rating for the entire appliance.

Electrical safety of the unit is reached when it

is correctly connected to an ecient earthing

system as specied by current safety standards.

Important: Immergas S.p.A. declines any

responsibility for damage or physical injury

caused by failure to connect the boiler to an

ecient earthing system or failure to comply

with the reference standards.

Also ensure that the electrical installation

corresponds to maximum absorbed power

specications as shown on the boiler data-plate

leads.

Boilers are supplied complete with an “X” type

power cable without plug.

e power supply cable must be connected to a

230V ±10% / 50Hz mains supply respecting L-N

polarity and earth connection; , this network

must also have a multi-pole circuit breaker with

class III over-voltage category. When replacing

the power supply cable, contact a qualified

rm (e.g. the Authorised Aer-Sales Technical

Assistance Service).

e power cable must be laid as shown.

In the event of mains fuse replacement on the

control card, use a 3.15A quick-blow fuse. For

the main power supply to the appliance, never

use adapters, multiple sockets or extension leads.

INSTALLATORUSER

MAINTENANCE TECHNICIAN

5

Page 6

INSTALLATORUSER

1-3 1-4

45

*

58

31

1-5 1-6

1.8 REMOTE CONTROLS AND

ROOM CHRONOTHERMOSTATS

OPTIONAL.

e boiler is prepared for application of room

chronothermostats and external probe. ese

Immergas components are available as separate

kits to the boiler and are supplied on request.

All Immergas chronothermostats are connected

with 2 wires only. Carefully read the user and

assembly instructions contained in the accessory

kit.

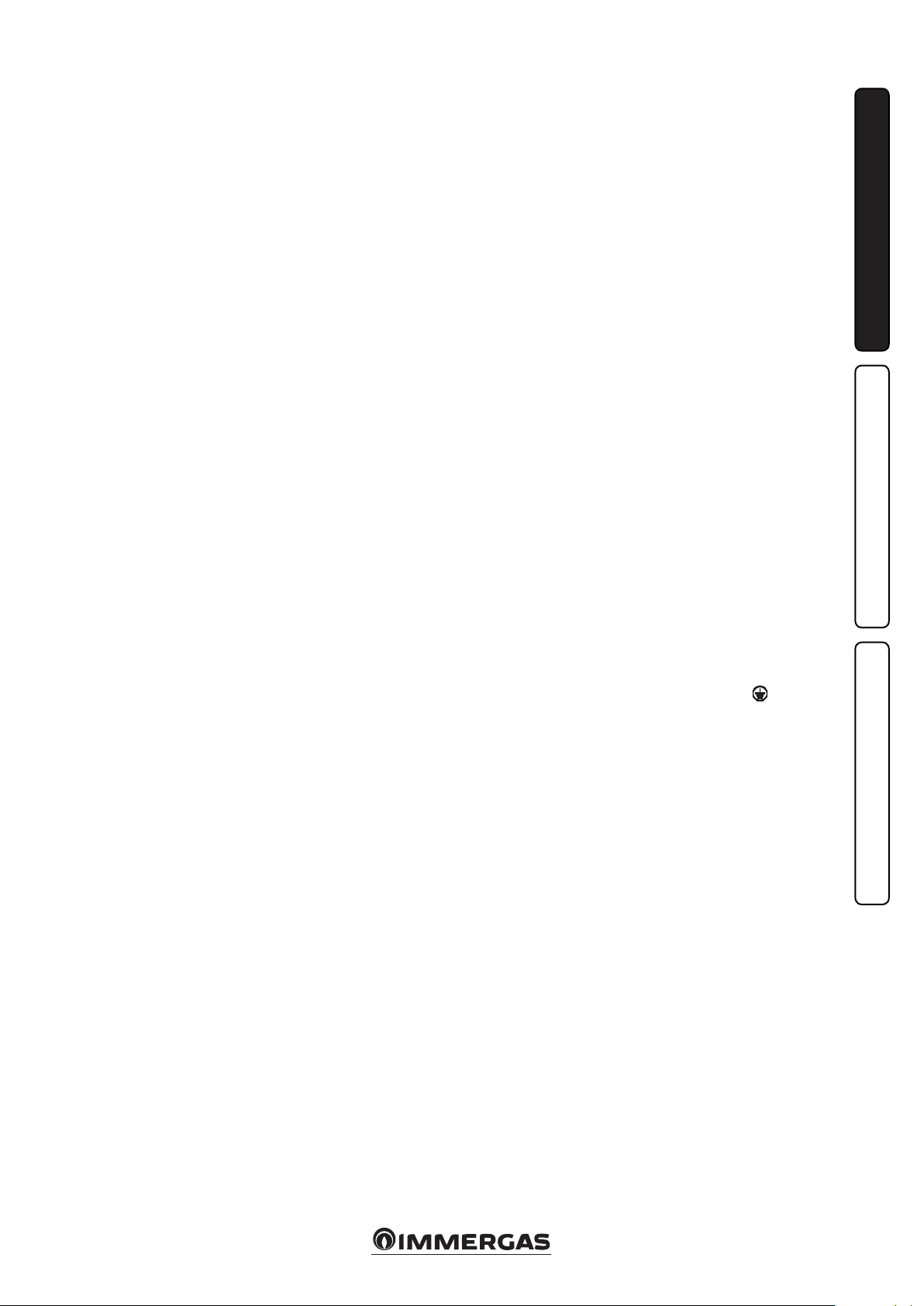

• On/O digital chrono-thermostat (Fig. 1-3).

e chrono-thermostat allows:

- set two room temperature value: one for

daytime (comfort temperature) and one for

night-time (reduced temperature);

- set a weekly program with four daily switch

on and switch o times;

- select the required operating mode from the

various possible alternatives:

- manual operation (with adjustable tempera-

MAINTENANCE TECHNICIAN

ture).

- automatic operation (with set programme).

- forced automatic operation (momentarily

changing the temperature of the automatic

programme).

e chronothermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• ere are two types of Remote Friend Con-

trolV2 (CARV2) (Fig. 1-3) and Mini Digital

Remote Control (Mini CRD) (Fig. 1-4) both

with room chronothermostat functioning.

In addition to the functions described in the

previous point, the control panel enables the

user to keep under control and within reach

all the important information regarding operation of the appliance and the heating system

with the ability to easily act on previously set

parameters, with no need to go to where the appliance is installed. e panel is provided with

self-diagnosis to display any boiler functioning

anomalies. The climate chrono-thermostat

incorporated into the remote panel enables the

system ow temperature to be adjusted to the

actual needs of the room being heated, in order

to obtain the desired room temperature with

extreme precision and therefore with evident

saving in running costs. e remote control is

fed directly by the boiler by means of the same 2

wires used for the transmission of data between

boiler and device.

Important: If the system is subdivided into zones

using the relevant kit. the CARV2 must be used

with its climate thermostat function disabled, i.e.

it must be set to On/O mode. e Mini CRD

cannot be used for plants divided into zones.

Electrical connection of the Remote Friend

ControlV2, chronothermostat On/O (Optional) or Mini . e operations described below

must be performed after having removed the

voltage from the appliance. e eventual ther-

mostat or On/O room chronothermostat must

be connected to terminals 40 and 41 eliminating

jumper X40 (Fig. 3-2). Make sure that the On/

O thermostat contact is of the “clean” type, i.e.

independent of the mains supply; otherwise the

electronic adjustment card would be damaged.

e eventual Remote Friend ControlV2 must be

connected by means of terminals IN+ and IN- to

terminals 42 and 43, eliminating jumper X40

on the terminal board (in the boiler) respecting

polarity (Fig. 3-2). Connection with the wrong

polarity prevents functioning, but without

damaging the Remote Friend ControlV2. Any

Digital Remote Control must be connected to

terminals 40 e 41 eliminating jumper X40 on

the P.C.B. (in the boiler), (Fig. 3-2). e boiler

works with the parameters set on the Remote

Friend ControlV2 only if the boiler main selector is turned to Domestic/Remote Control

( ). e boiler can only be connected to one

remote control.

Important: If the Remote Friend ControlV2,

Mini Digital Remote Control or any other On/O

chronothermostat is used arrange two separate

lines in compliance with current regulations

regarding electrical systems. Boiler pipes must

never be used to earth the electric or telephone

lines. Ensure elimination of this risk before making the boiler electrical connections.

1.9 EXTERNAL PROBE OPTIONAL.

• External temperature probe (Fig. 1-5).

Refer to the relevant instruction sheet for

positioning the external probe.

This sensor can be connected directly to

the boiler electrical system and allows the

max. system delivery temperature to be

automatically decreased when the outside

temperature increases, in order to adjust the

heat supplied to the system according to the

change in external temperature. e external

probe always operates when connected,

regardless of the presence or type of room

chronothermostat used. The correlation

between system delivery temperature and

outside temperature is determined by the

position of the knob on the boiler control

panel according to the curves shown in the

diagram (Fig. 1-6). e external probe electrical

connection must be made on clamps 38 and 39

on the boiler circuit board (Fig. 3-2).

* (Fig. 1-6) Position of the heating temperature

user adjustment.

6

Page 7

1.10 VENTILATION OF THE ROOMS.

In the room in which the boiler is installed it is

necessary that at least as much air ows as that

requested for by normal combustion of the gas

and ventilation of the room. Natural air ow must

take place directly through:

- permanent holes in the walls of the room to

ventilate that go towards the outside;

- ventilation pipes, individual or branched type.

e air used for ventilation must be withdrawn

directly from outside, in an area away from sources of pollution. Natural air ow is also allowed

indirectly by air intake from adjoining rooms. For

further information relative to ventilation of the

rooms follow that envisioned in the regulation.

Evacuation of foul air. In the rooms where the

gas appliances are installed it may also be necessary, as well as the intake of combustion agent air,

to evacuate foul air, with consequent intake of a

further equal amount of clean air. is must be

realised respecting the provisions of the technical

regulations in force.

1.11 EVACUATION OF COMBUSTION

PRODUCTS: FLUE DUCT AND

BRANCHED MULTIPLE FLUES

e European regulation 813/2013 provides that

this boiler can be installed only to replace similar equipment connected to existing branched

multiple ues.

Connection to branched multiple ues.

Fitting the appliances to a branched multiple ues

takes place by means of ue ducts.

In the event of ttings with pre-existing ues,

these must be in safe and ecient status and perfectly clean because the detachment of any waste

from the walls during functioning, could block

the passage of ue gases, thus causing extremely

dangerous situations for the user.

e ue ducts must be connected to the chimney

or ue in the same room in which the appliance

is installed or, at most, in the adjoining room and

must comply with the requirements indicated by

the current technical regulations.

1.12 FLUE EXHAUST CONTROL DEVICE.

Important: it is prohibited to put the fumes

exhaust control device out of order voluntarily.

Every piece of this device must be replaced using

original spare parts if they have deteriorated. In

the case of repeated interventions of the fumes

exhaust control device, check the fumes exhaust

ue and the ventilation of the room in which the

boiler is located.

1.13 SYSTEM FILLING.

Once the boiler is connected, proceed with system lling via the lling valve (Fig. 2-2).

Filling is performed at low speed to ensure

release of air bubbles in the water via the boiler

and heating system vents.

e boiler has a built-in automatic venting valve

on the circulator. Check if the cap is loose. Open

the radiator air vent valves.

Close vent valves only when water is delivered.

Close the lling valve when the boiler pressure

gauge indicates approx. 1.2 bar.

N.B.: During these operations, turn on the circulating pump at intervals by means of the main

selector switch on the control panel.

1.14 GAS SYSTEM STARTUP.

To start up the system, make reference to the

Standard.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specications.

1.15 STARTUP OF THE BOILER

IGNITION.

To commission the boiler (the operations listed

below must only be performed by a qualied rm

and without any unauthorised persons):

- check that the internal system is properly sealed

according to the specications set forth by

technical regulations in force;

- ensure that the type of gas used corresponds to

boiler settings;

- check that there are external factors that may

cause the formation of fuel pockets;

- switch on the boiler and ensure correct ignition;

- make sure that the gas ow rate and relevant

pressure values comply with those given in the

manual (Par. 3-16);

- check the correct ventilation of the rooms;

- check the existing draught during normal

functioning of the appliance, e.g. a draught

gauge positioned at the exit of the appliance

combustion products;

- check that there is no backow of combustion

products into the room, even during functioning of fans;

- ensure that the safety device is engaged in the

event of gas supply failure and check activation

time;

- check activation of the main circuit-breaker

selector upstream from the boiler and on the

unit.

e boiler must not be started up in the event of

failure to comply with any of the above.

1.16 DOMESTIC HOT WATER BOILER

DEVICE.

e Avio 24 2 ERP boiler is the accumulation

type with a capacity of 45 litres. It contains a large

coiled stainless steel heat exchanger pipe, which

allows to notably reduce hot water production

times. ese boilers built with stainless steel

casing and bottoms, guarantee long duration.

e assembly concepts and welding (T.I.G.) are

implemented to the minimum detail to ensure

maximum reliability.

e lower inspection ange ensures practical

control of the boiler and the coiled heat exchanger and easy internal cleaning.

e domestic water attachments are found on the

ange cover (cold inlet and hot outlet) and also

the magnesium anode holder cap, including the

latter, supplied as standard for internal protection

of the boiler from possible corrosion.

N.B.: every year a skilled technician (e.g. Authorised Aer-sales Service), must check the eciency

of the boiler’s Magnesium Anode. e boiler is

prepared for introduction of the domestic water

re-circulation connection.

INSTALLATORUSER

MAINTENANCE TECHNICIAN

7

Page 8

1.17 CIRCULATION PUMP.

e boiler is supplied with circulator tted with

speed regulator.

ese settings are suitable for most systems.

In fact, the pump is equipped with electronic

control to set advanced functions. For proper operation one must select the most suitable type of

operation for the system and select a speed in the

available range, with a focus on energy savings.

By-pass Regulation (part. 21 Fig. 1-10). e

boiler is supplied with by-pass closed by 1.5 turns

with respect to all open.

INSTALLATORUSER

If necessary, the by-pass can be regulated to

system requirements from minimum (by-pass

closed) to maximum (by-pass open). Adjust

using a at head screwdriver, turn clockwise to

open the by-pass; turn anti-clockwise to close it.

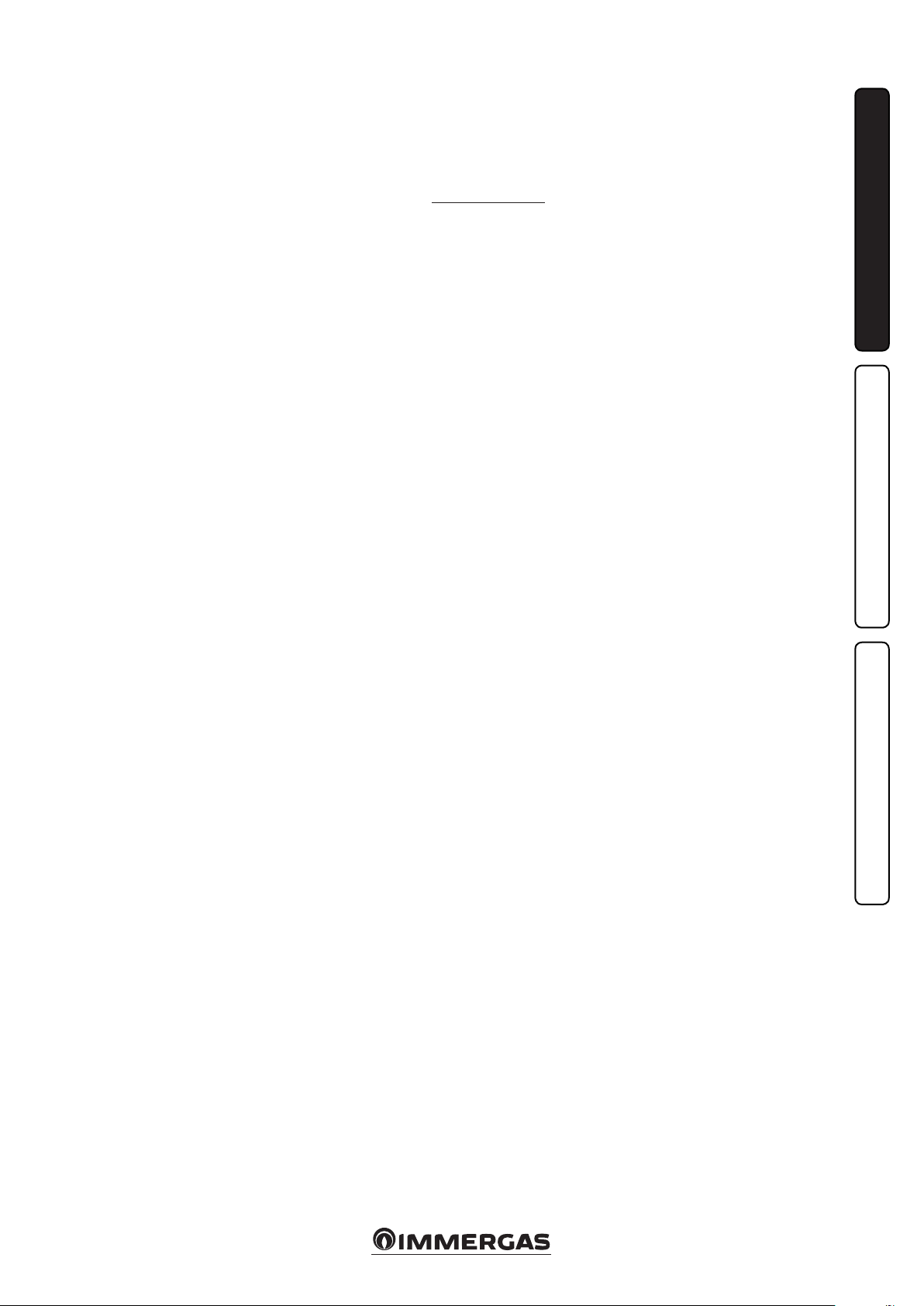

Display of operation status. During normal

operation the status LED (2) is on green, the four

yellow LEDs (3) indicate circulator absorption

according to the following table:

Circulating pump LED Absorption

G Y Y Y Y

On On O O O

G Y Y Y Y

On On On O O

G Y Y Y Y

On On On On O

0 ÷ 25 %

25 ÷ 50 %

50 ÷ 75 %

Circulating pump LED Description

G Y Y Y Y

On On On O O

G Y Y Y Y

On On On On O

G Y Y Y Y

On On On On On

G Y Y Y Y

On On On O On

Constant curve: the circulator operates maintaining constant speed.

Do not use

Constant curve

speed 2

Constant curve

speed 3 (default)

Constant curve

speed 4

1-7

Key:

1 - Function selection button

2 - Green (G) / red (R) LED

3 - 4 yellow LEDs (Y)

Selection button lock. e button has a feature

that locks its operation to prevent accidental

modications, to lock the control panel it is

necessary to press button (1) longer than 10

seconds (during which the current conguration

ashes), the active lock is signalled by all LEDs of

the control panel ashing. To unlock the button

press again longer than 10 seconds.

Real time diagnostics: in the event of malfunction the LEDs provide information on the

circulator operation status, see table (Fig. 1-8):

G Y Y Y Y

On On On On On

Selection of operating mode. To see the current

operation mode it is sucient to press button

(1) once.

To change operation mode press the button

for between 2 to 10 seconds until the current

conguration ashing, each time the button is

pressed all possible functions are scrolled cyclically. Aer a few seconds without doing any

operation the circulator memorises the selected

mode and goes back to operation display.

Attention: e circulator has various built-in

MAINTENANCE TECHNICIAN

operation modes, however the constant curve

operation mode must be selected according to

the following table.

75 ÷ 100 %

8

Page 9

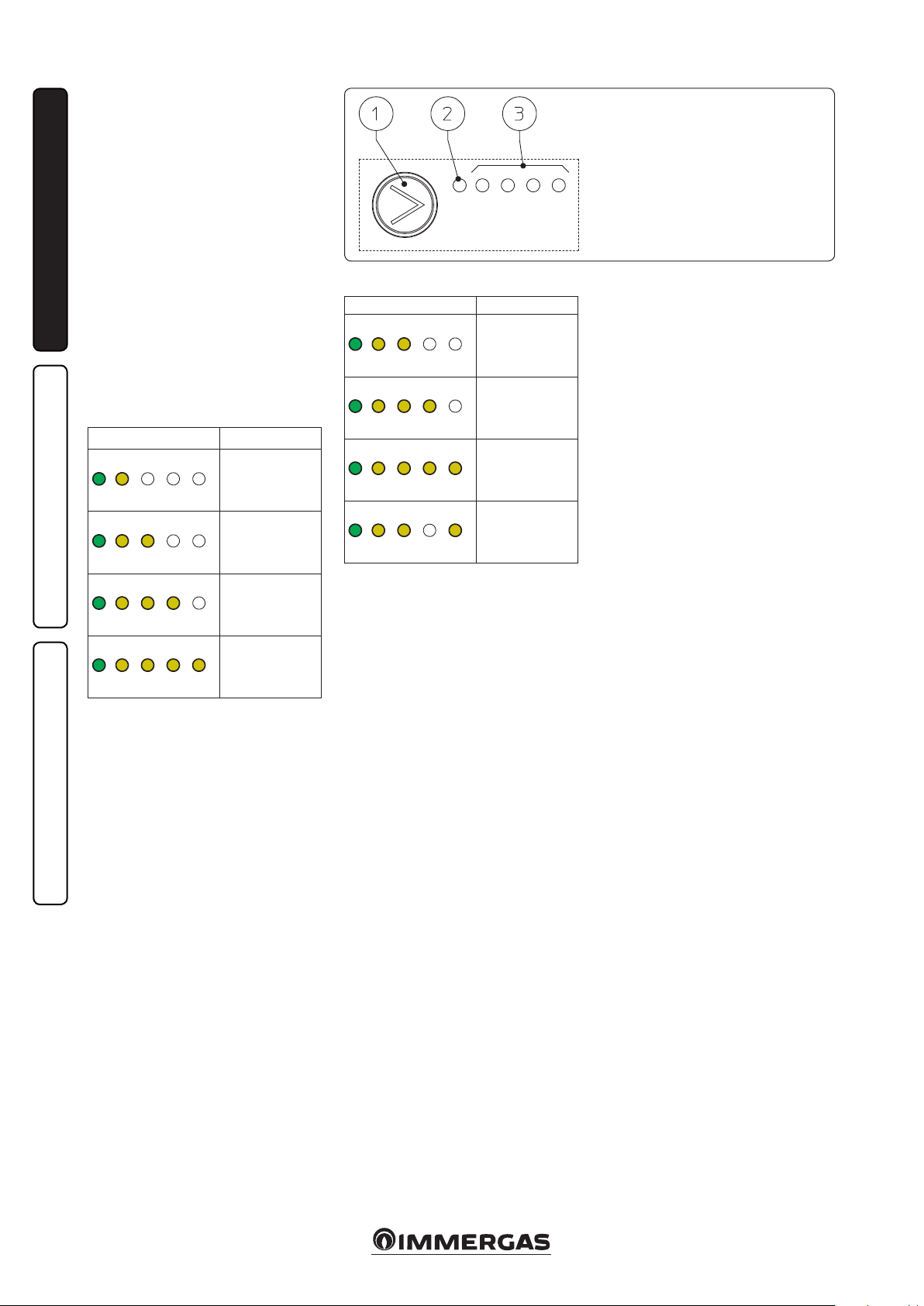

1-8

Circulating pump LED

(rst red LED)

R Y Y Y Y

On O O O On

R Y Y Y Y

On O O On O

Description Diagnostics Remedy

Circulator pump blocked

Abnormal situation (the circulator

continues operating).

low power supply voltage

Wait for the circulator to make auto-

The circulator pump cannot restart

automatically due to an anomaly

Voltage o range Check power supply

matic release attempts or manually

release the motor sha acting on the

screw in the centre of the head.

If the anomaly persists replace the

circulator.

INSTALLATORUSER

R Y Y Y Y

On O On O O

Total head available to the plant.

A2

Total head (kPa)

Electrical fault

(Circulator pump blocked)

Capacity (l/h)

e circulator is locked due to power

supply too low or serious malfunction

A4

A3

V4

V2 V3

Check the power supply, if the anomaly

persists replace the circulator

1-9

Key:

V2 = Total head available to the system with

pump at speed 2

V3 = Total head available to the system with

pump at speed 3

V4 = Total head available to the system with

pump at speed 4

A2 = Power absorbed by the pump at speed 2

A3 = Power absorbed by the pump at speed 3

A4 = Power absorbed by the pump at speed 4

Circulator pump absorbed power (W)

1.18 KITS AVAILABLE ON REQUEST.

• Kit of system shuto valves (on request). e

boiler is designed for installation of system

shuto valves to be placed on delivery and

return pipes of the connection assembly. is

kit is particularly useful for maintenance as

it allows the boiler to be drained separately

without having to empty the entire system.

• System zone Kit (on request). If the heating

system is to be divided into several zones (max.

three), in order to interlock them with separate

adjustments and to keep water ow rate high

for each zone, Immergas supplies zone system

kits by request.

• Polyphosphate batching kit (on request). e

polyphosphate dispenser Reduces the formation of lime-scale and preserves the original

heat exchange and domestic hot production

water conditions. e boiler is prepared for

application of the polyphosphate dispenser kit.

e above kits are supplied complete with instructions for assembly and use.

MAINTENANCE TECHNICIAN

9

Page 10

1.19 BOILER COMPONENTS.

INSTALLATORUSER

MAINTENANCE TECHNICIAN

Key:

1 - Fumes hood

2 - primary heat exchanger

3 - Air bleeding valve

4 - Boiler circulation pump

5 - Gas valve

6 - 3-way valve (motorised)

7 - System ller tap

8 - System expansion tank

9 - Domestic water probe

10 - Stainless steel boiler

11 - 3 bar safety valve

12 - System emptying tap

13 - 8 bar safety valve

14 - Boiler emptying cock

15 - Fumes thermostat

16 - Delivery probe

17 - Safety thermostat

18 - Combustion chamber

19 - Ignition and detection plugs

20 - Burner

21 - Adjustable by-pass

1- 10

10

Page 11

INSTRUCTIONS FOR USE

2

AND MAINTENANCE

2.1 CLEANING AND MAINTENANCE.

Attention: to preserve the boiler’s integrity

and keep the safety features, performance and

reliability, which distinguish it, unchanged over

time, you must at least execute maintenance

operations on a yearly basis in compliance with

what is stated in the relative point at “annual

check and maintenance of the appliance”, in

compliance with national, regional, or local

standards in force.

2.2 VENTILATION OF THE ROOMS.

In the room in which the boiler is installed it

is necessary that at least as much air ows as

that requested for by normal combustion of the

gas and ventilation of the room. e provisions

relative to ventilation, the flue ducts and

multiple ues are stated in Par. 1.10 ÷ 1.12. If in

doubt regarding correct ventilation, contact an

authorised company.

2.3 GENERAL WARNINGS

Never expose the suspended boiler to direct

vapours from a cooking surface.

Use of the boiler by unskilled persons or children

is strictly prohibited.

If temporary shutdown of the boiler is required,

proceed as follows:

a) drain the heating system if anti-freeze is not

used;

b) shut-o all electrical, water and gas supplies.

In the case of work or maintenance to structures

near ducting or devices for ue extraction and the

relative accessories, switch o the appliance and

on completion of the operations make sure that

an authorised company veries the eciency of

the ducting or the devices.

Never clean the appliance or connected parts

with easily ammable substances.

Never leave containers or ammable substances

in the same environment as the appliance.

It is prohibited ad dangerous to obstruct the air

intake, even partially, for the ventilation of the

room in which the boiler is installed.

Due to the danger, operation is also prohibited

in the same room as suction devices or the like,

at the same time as the boiler unless there are

additional openings dimensioned in a way to

satisfy the additional requirement for air. For the

dimensioning of these additional openings, refer

to an authorised company.

• Important: the use of components involving

use of electrical power requires some

fundamental rules to be observed such as:

- do not touch the appliance with wet or

moist parts of the body; do not touch when

barefoot;

- never pull electrical cables or leave the

appliance exposed to atmospheric agents

(rain, sunlight, etc.);

- the appliance power cable must not be

replaced by the user;

- if the cable is damaged, switch off the

appliance and solely contact an authorised

company to replace it;

- if the appliance is not to be used for a certain

period, disconnect the main power switch.

N.B.: the temperatures indicated by the display

have a tolerance of +/- 3°C due to environmental

conditions that cannot be blamed on the boiler.

At the end of its service life the appliance must

not be disposed of like normal household waste

nor discarded in the environment, but must be

removed by an authorised company. C ontact the

manufacturer for disposal instructions.

INSTALLATORUSER

2.4 CONTROL PANEL.

2-1

Key:

1 - Flame presence LED

2 - Domestic hot water LED

3 - Heating function LED

4 - Temperature LED – Insucient

circulation anomaly

5 - Temperature LED – Delivery probe

anomaly

6 - Temperature LED – ignition block

7 - Temperature LED – Over-temperature

block

8 - Temperature LED – Fumes thermostat

anomaly

9 - Stand-by-Domestic water / Remote

Control - Domestic water and HeatingReset Selector switch

MAINTENANCE TECHNICIAN

10 - Domestic hot water temperature

selector switch

11 - Heating water temperature selector

switch

12 - Boiler manometer

11

Page 12

2.5 IGNITION OF THE BOILER.

Before ignition make sure the heating system is

lled with water and that the manometer (12)

indicates a pressure of 1÷1,2 bar.

- Open the gas cock upstream from the boiler.

- Turn the master switch (9) taking it to

the Domestic/Remote Friend ControlV2

(CARV2) ( )or Domestic Hot Water

( )position.

N.B.: Once the main selector switch has been

placed (9) on one of these positions, the presence

of voltage is indicated by the switch-on with a

INSTALLATORUSER

xed light of one of the LEDS from 4 to 8, which

indicate the temperature of the output water from

the main heat exchanger.

Important: ashing of one of the LEDs from 4

to 8 indicates that there is an anomaly present,

refer to the successive paragraph.

Functioning of the boiler in domestic water mode

and in heating mode is indicated respectively by

the switch-on of LED 2 or LED 3 with a xed light

(in absence of remote controls).

• Operation with Remote Friend ControlV2

(Optional). With selector switch (9) in position

( ) and Remote Control connected to

the boiler selector switches (10) and (11)

excluded. e boiler adjustment parameters

are set from the control panel of the Remote

Friend ControlV2. Connection to the Remote

Control is indicated by the contemporary xed

switch-on of LEDs 2 and 3 ( ). Also in the

presence of Remote Control the indications of

the temperature and any faults are maintained

on the control panel.

• Operation without Remote Control. With the

selector switch (9) in position ( ) the

heating adjustment selector switch is cut out,

the domestic hot water temperature is regulated

by selector switch (10). With the selector switch

in position ( )the heating adjustment

selector switch (11) is used to regulate the

temperature of radiators, while selector (10)

continues to be used for domestic hot water.

Turn the selector switches in a clockwise

direction to increase the temperature and in

an anti-clockwise direction to decrease it.

From this moment the boiler functions

automatically. With no demand for heat (heating

or domestic hot water production) the boiler

goes to “standby” function, equivalent to the

boiler being powered without presence of

ame (LED corresponding to the ignited boiler

temperature). Each time the boiler lights up, the

relative ame present symbol is displayed by the

green LED 1 ( ).

N.B.: the boiler may start-up automatically if the

anti-freeze function is activated.

2.6 FAULT AND ANOMALY SIGNALS.

e Avio 24 2 ERP boiler signals ant anomaly by

ashing of one of the LEDs from 4 to 8 or LEDs 1

and 2 coupled to LED 7. On any remote controls,

the error code will be displayed using a numerical

code preceeded or followed by the letter E (e.g.

CARV2 = Exx, Mini CRD = xxE).

Flashing LED

Led 6 ( )

Led 7 ( )

MAINTENANCE TECHNICIAN

Led 8 ( )

Led 2 ( )

and 7 ( )

blinking

at the same time

Led 5 ( )

Led 2 ( )

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service).

(2) Error codes over 31 are not shown on the CARV2 display.

Error

Code

Anomaly signalled Cause Boiler status / Solution

01 No ignition block

Safety thermostat

02

block (over-temperature)

Flue safety thermo-

03

stat block

Contacts resistance

04

block

Flow probe

05

anomaly

Storage tank probe

12

anomaly

In the event of request of room central heating or domestic hot water production, the boiler does not switch on

within the preset time. If this does not occur within 10

seconds, the boiler remains in stand-by for 30 seconds, try

again and if the second attempt fails it goes into “ignition

block” (ashing LED 6).

During operation, if a fault causes excessive overheating

internally, in the exhaust, or an anomaly occurs in the ame

control section, an overheating block is triggered in the

boiler (LED 7 ashing).

The fume evacuation pipe does not function correctly

(code 03).

is occurs in the case of faults to the safety thermostat

over-temperature).

e board detects an anomaly on the ow probe. e boiler does not start (1).

If the board detects a fault on the storage tank probe.

To eliminate “no ignition block” the

main switch (9) must be temporarily

turned to the Reset position (1).

Warning: the fault may be reset up

to 5 times consecutively, aer which

the function in inhibited for at least

one hour. One attempt is gained every

hour for a maximum of 5 attempts. By

switching the appliance on and o the

5 attempts are re-acquired.

On commissioning or aer extended inactivity it may be necessary to eliminate

the “no ignition block”.

To eliminate the “overheating block” the

main switch (9) must be temporarily

turned to the Reset position (1).

e boiler goes into stand-by for 30

minutes, aer which, if normal working conditions are restored, it re-starts

without having to be reset. In the case

of 3 consecutive blocks, the boiler itself

blocks and it must be reset in order to

re-start (1).

e boiler does not start (1).

e boiler does not start in domestic

hot water mode however, it remains in

heating mode (1).

12

Page 13

Flashing LED

Led 1 ( )

and 7 ( )

blinking

at the same time

Led 4 ( )

Led 2 and 3

blinking

at the same time

( )

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service).

(2) Error codes over 31 are not shown on the CARV2 display.

Error

Code

20

27

31

Anomaly signalled Cause Boiler status / Solution

Parasite ame

block

Insucient

circulation

Loss of remote

control

communication

is occurs in the event of a leak on the detection circuit or

anomaly in the ame control unit.

is occurs if there is overheating in the boiler due to

insucient water circulating in the primary circuit; the

causes can be:

- low system circulation; check that no shut-o devices are

closed on the heating circuit and that the system is free of

air (deaerated);

- pump blocked; free the pump.

This occurs if an incompatible remote control is connected, or if communication between the boiler and the

Remote Comando AmicoV2 (CARV2) or digital remote

control (Mini CRD) is lost.

Press the Reset button (1).

Press the Reset button (1).

Try the connection procedure again

by turning the boiler off and turning

the switch (9) to position ( ). If

the CARV2 is still not detected on restarting, the boiler will switch to local

operating mode, i.e. using the controls

on the boiler itself (1) (2).

INSTALLATORUSER

2.7 BOILER SHUTDOWN.

Disconnect the main selector switch (9) taking

it to position “ ” (Leds from 1 to 8 off),

disconnect the external omni-polar switch to the

boiler and close the gas cock upstream from the

appliance. Never leave the boiler switched on if

le unused for prolonged periods.

2.8 RESTORING HEATING SYSTEM PRESSURE.

Periodically check the system water pressure.

e boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

If the pressure falls below 1 bar (with the circuit

cool) restore normal pressure via the valve located

at the bottom of the boiler (Fig. 2-2).

N.B.: close the valve aerwards.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case, remove water from an air vent valve

of a radiator until 1 bar is reached or ask for

assistance from an authorised company.

In the event of frequent pressure drops, contact

a qualied rm for assistance to remove any

system leakage.

2.9 DRAINING THE SYSTEM.

To drain the boiler, use the special drain cock

(Fig. 2-2).

Before draining, ensure that the lling cock is

closed.

2.10 DRAINING THE BOILER.

To drain the boiler, use the special drain cock

(Fig. 2-2).

N.B.: before performing this operation close the

boiler cold water inlet cock and open hot water

cock in the domestic water system in order to

allow water to enter the boiler.

2.11 ANTIFREEZE PROTECTION.

e boiler comes standard with an antifreeze

function that activates the pump and burner

when the system water temperature in the boiler

falls below 4°C.

e antifreeze function is guaranteed if the boiler

is fully operative and not in “block” status, and

is electrically powered with the general switch

positioned on Summer or Winter. To avoid

keeping the system switched on in case of a

prolonged absence, the system must be drained

completely or antifreeze substances added to

the heating system water. In both cases the

boiler domestic water circuit must be drained.

In systems that are drained frequently, lling

must be carried out with suitably treated water

to eliminate hardness that can cause lime-scale.

2.12 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.13 DECOMISSIONING.

In the event of permanent shutdown of the

boiler, contact an authorised rm for the relevant

procedures and also ensure the electrical,

water and fuel supply lines are shut off and

disconnected.

MAINTENANCE TECHNICIAN

BOTTOM VIEW

1 - Boiler drain cock

5

1

2 - Domestic water inlet cock

3 - Gas cock

4 - System drain cock

5 - System lling valve

4

23

2-2

13

Page 14

BOILER COMMISSIONING

3

INITIAL CHECK

To commission the boiler:

- ensure that the type of gas used corresponds to

boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the heating system is lled with

water and that the manometer indicates a

pressure of 1 - 1.2 bar;

INSTALLATORUSER

- make sure the air valve cap is open and that the

system is well deaerated;

- switch the boiler on and ensure correct ignition;

3.1 HYDRAULIC LAYOUT.

- make sure the gas maximum, medium and

minimum flow rate and pressure values

correspond to those given in the handbook

(Par. 3.16);

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check activation of the master switch located

upstream from the boiler and in the boiler;

- check the existing draught during normal

functioning of the appliance, e.g. a draught

gauge positioned at the exit of the appliance

combustion products;

- check that there is no backow of combustion

products into the room, even during

functioning of fans;

- ensure activation of all adjustment devices;

- seal the gas ow rate regulation devices (if

settings are modied);

- ensure production of hot domestic water;

- ensure sealing eciency of water circuits;

- check ventilation and/or aeration of the

installation room where provided.

If any checks/inspection give negative results, do

not start the boiler.

MAINTENANCE TECHNICIAN

Key:

1 - Gas valve

2 - Stainless steel coil for boiler

3 - Magnesium anode

4 - Stainless steel boiler

5 - Air bleeding valve

6 - Burner

7 - Combustion chamber

8 - Primary heat exchanger

9 - Fumes hood

10 - Flue safety thermostat

11 - Delivery probe

12 - Safety thermostat

13 - System expansion tank

14 - Boiler circulating pump

15 - Adjustable by-pass

16 - System drain cock

17 - 3-way valve (motorised)

18 - Domestic water probe

19 - 3 bar safety valve

20 - System lling cock

21 - 8 bar safety valve

22 - Cold water inlet non-return valve

23 - Boiler drain cock

G - Gas supply

AC - Domestic hot water outlet

AF - Domestic cold water inlet

R - System return

M - System delivery

14

3-1

Page 15

3.2 WIRING DIAGRAM.

6

7

3 4

1

2

Key:

A5 - CARV2 interface card

B1 - Delivery probe

B2 - Domestic water probe

B4 - External probe (Optional)

CARV2 - Remote Friend Control

V2

(Optional)

Mini CRD - Mini Digital Remote Control

(Optional)

E1 - Ignition plugs

5

E2 - Igniter sensor

E4 - Safety thermostat

E6 - Fumes thermostat

F1 - Neutral fuse

F2 - Line fuse

M1 - Boiler circulating pump

M30 - 3-way valve

R5 - Domestic water temp. trimmer

R6 - Heating temp. trimmer

INSTALLATORUSER

R10 - Main selector switch

S8 - Gas type selector

S20 - Environment thermostat

T2 - Switch-on transformer

X40 - Environment thermostat jumper

Y1 - Gas valve

Y2 - Gas valve modulator

1 - Primary

2 - Secondary

3 - 230 Vac 50Hz Power supply

4 - 230 Vac 50Hz max 2°aux. output

5 - Area card (Optional)

6 - Heating

7 - Domestic water

Colour code key:

BK - Black

BL - Blue

BR - Brown

G - Green

GY - Grey

G/Y - Yellow/Greene

R - Red

W - White

3-2

Remote controls: the boiler is designed to use

the Remote Friend ControlV2 (CARV2), or as an

alternative to the Mini Digital Remote Control

(Mini CRD) which must be connected to clamps

42 and 43 of connector X9 for the CARV2 (respecting polarity) and clamps 40 and41 of connector

X9 for the Mini CRD on the circuit board and in

both cases eliminating X40.

Environment thermostat (alternative to the Mini

CRD): the boiler is designed to use the Room

ermostat (S20). Connect it to clamps 40 –41

eliminating jumper X40.

Connector X12 is used for automatic inspection

for connection to the personal computer.

3.3 TROUBLESHOOTING. N.B.: maintenance operations must be carried

out by an authorised company (e.g. Authorised

Aer-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing eciency of gas intake

circuit.

- Irregular combustion (red or yellow ame).

This may be caused by: a dirty burner, or

blocked boiler lamellar pack.

- Frequent activation of the temperature

overload thermostat. is may be caused by

lack of water in the boiler, insucient water

circulation in the circuit, a blocked circulator

or an anomaly of the boiler adjustment card.

Check via the pressure gauge that values are

within admissible limits. Check that radiator

valves are not all closed.

- e boiler produces condensate. is can be

caused by obstructions of the chimney or ues

with height or section not proportioned to the

boiler. It can also be determined by functioning

at boiler temperatures that are excessively low.

In this case, make the boiler run at higher

temperatures.

- Frequent interventions of the chimney safety

thermostat. is can be caused by obstructions

in the fumes circuit. Check the ue. e ue

may be obstructed or by height or section

not suitable for the boiler. Ventilation may be

insucient (see room ventilation point).

- Presence of air in the system. Check opening

of the special air bleeding cap (Fig. 1-8). Make

sure the system pressure and expansion tank

pre-charge values are within the set limits; the

pre-charge value for the expansion tank must

be 1.0 bar, and system pressure between 1 and

1.2 bar.

- Ignition block and Flue block (Par. 2.6).

- Domestic water probe broken. e boiler does

not have to be emptied in order to replace the

domestic water probe as the probe is not in

direct contact with the domestic hot water

present in the boiler.

MAINTENANCE TECHNICIAN

15

Page 16

SIT 845 gas valve

Key:

1 - Coil

2 - Minimum power adjustment screws

INSTALLATORUSER

3 - Maximum power adjustment nut

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

Circuit board

10 - Line fuse 3.15AF

11 - Neutral fuse 3.15AF

12 - Main selector switch

13 - Domestic water temperature trimmer

14 - RS232 computer interface

15 - Heating temperature trimmer

16 - METHANE L.P.G. gas type selector

3.4 CONVERTING THE BOILER TO OTHER TYPES OF GAS.

If the boiler has to be converted to a dierent gas

type to that specied on the data-plate, request

the relative conversion kit for quick and easy

conversion.

e gas conversion operation must be carried

out by an authorised company (e.g. Authorised

Technical Aer-Sales Service).

To convert to another type of gas the following

operations are required:

- remove the voltage from the appliance;

- replace the main burner injectors, making sure

to insert the special seal rings supplied in the

kit, between the gas manifold and the injectors;

- move jumper 16 (Fig. 3-4) into the correct

position for the type of gas in use (Methane or

L.P.G.);

MAINTENANCE TECHNICIAN

- to access adjustments on the circuit board the

cover must be removed from the dashboard by

loosening the rear screw fasteners;

- apply voltage to the appliance;

- adjust the boiler maximum heat power;

- adjust the boiler minimum heat power;

- adjust (eventually) the heating power;

- seal the gas ow rate devices (if adjusted);

- aer completing conversion, apply the sticker,

present in the conversion kit, near the dataplate. Using an indelible marker pen, cancel

the data relative to the old type of gas.

ese adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.16).

4

1

5

3.5 CHECKS FOLLOWING CONVERSION TO ANOTHER TYPE OF GAS.

Aer making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that:

- there is no ame in the combustion chamber

- the burner ame is not too high or low and that

it is stable (does no detatch from burner)

- the pressure testers used for calibration are

perfectly closed and there are no leaks from

the gas circuit.

N.B.: all boiler adjustment operations must be

carried out by a qualied company (e.g. Authorised Aer-sales Service). Burner calibration

must be carried out using a “U” or digital type

dierential pressure gauge, connected to the gas

valve pressure outlet (part. 4 Fig. 3-3), keeping

to the pressure value given in the tables (Par.

3.16) according to the type of gas for which the

boiler is prepared.

3.6 POSSIBLE ADJUSTMENTS OF THE GAS VALVE.

• Adjustment of boiler nominal heat output (Fig.

3-3).

- Turn the domestic hot water selector knob (10

Fig. 2-1) to the maximum functioning position;

- open the domestic hot water cock in order to

prevent modulation intervention;

- adjust the boiler nominal power on the brass

nut (3), keeping to the maximum pressure

values stated in the tables (Par. 3.16) dep ending

on the type of gas;

- by turning in a clockwise direction the heating

potential increases and in an anti-clockwise

direction it decreases.

• Adjust the boiler minimum thermal input (Fig.

3-3).

N.B.: only proceed aer having calibrated the

nominal pressure.

Adjustment of the minimum thermal input is

obtained by operating on the cross plastic screws

3

2

6

(2) on the gas valve maintaining the brass nut

blocked (3);

- disconnect the power supply to the modulating

reel (just disconnect a faston); By turning

the screw in a clockwise direction, the

pressure increases, in an anti-clockwise

direction it decreases. On completion of

calibration, re-apply the power supply to the

modulating reel. e pressure to which the

boiler minimum power must be adjusted,

3-3

must not be lower than that stated in the

tables (Par. 3.16) depending on the type of gas.

N.B.: to adjust the gas valve, remove the plastic

cap (6); aer adjusting, ret the cap and screw.

3.7 PROGRAMMING THE CIRCUIT

BOARD.

e Avio 24 2 ERP boiler is prepared for possible

programming of several operation parameters. By

modifying these parameters as described below, the

boiler can be adapted according to specic needs.

To access the programming phase, proceed as

follows: position the main selector switch on Reset

for a period of time between 15 and 20 seconds

(aer about 10 sec. LEDs 2 and 3 will start to ash at

3-4

the same time. Wait for this to end and re-position

the main selector switch on domestic water and

heating). At his point, re-position the main selector

switch on domestic water-heating.( ).

When the programming phase has been

activated, enter the rst level where it is possible

to choose the parameter to be set.

e latter is indicated by the fast ashing of one

of the LEDs between 1 and 8 (Fig. 2-1).

Selection is made by turning the domestic hot

water temperature selector switch (10). For

association of the LED to the parameter, see the

following table:

List of parameters

Minimum heating power Led 1

Maximum heating power Led 2

Heating switch-on timer Led 3

Heating power output ramp Led 4

Heating switch-on delay on request

from Environmental ermostat,

Mini Digital Remote Control or

Remote Friend Control

Domestic water thermostat/Boiler

hysteresis

Circulating pump functioning Led 7

Functioning gas Led 8

Boiler mode Led 1 and 8

V2

Flashing

LED (fast)

Led 5

Led 6

Once the parameter to be modied has been

selected, conrm by turning the main selector

switch to Reset momentarily until the LED

relative to the parameter switches-off, then

release.

Given the OK for selection, pass to the second

level where it is possible to set the value of the

16

Page 17

parameter selected. e value is indicated by the

slow ashing of one of the LEDs between 1 and

8. e value is selected by rotating the heating

temperature selector switch (11).

Once the value of the parameter to be modied

has been selected, confirm the selection by

momentarily turning the main selector switch

onto Reset momentarily until the LED relative to

the parameter switches o, then release.

Programming mode is exited if no operation is

carried out for 30 seconds or if the main selector

switch is positioned at OFF from the “parameter

setting” level.

For association of the LED to the relative value,

see the following tables:

Heating power. The boiler is produced and

calibrated in the heating phase at nominal power.

It also has electronic modulation that adapts

the boiler potentiality to the eective heating

demand of the house. en the boiler works

normally in a variable gas pressure eld between

the minimum heating power and the maximum

heating power depending on the plants heating.

N.B: the selection of the “Minimum heating

power” and “Maximum heating power”

parameters, in the presence of a heating demand

, allows switch-on of the boiler and power supply

of the modulator with current equal to the value

of the respective selected parameter.

Minimum heating power

(continuous variation)

0% Imax. (Standard setting) Led 1

7% Imax. Led 2

14% Imax.

21% Imax. Led 4

28% Imax. Led 5

35% Imax. Led 6

42% Imax. Led 7

63% Imax. Led 8

Maximum heating power

(continuous variation)

0% Imax. Led 1

11% Imax. Led 2

22% Imax.

33% Imax. Led 4

44% Imax. Led 5

55% Imax. Led 6

88% Imax.

100% Imx. (Standard setting) Led 8

Permanent reduction of the timer. e boiler

has an electronic timing device that prevents the

burner from igniting too oen in the heating

phase. e boiler has a standard supply of a timer

adjusted at 180 seconds.

Flash-

ing LED

(slow)

Led 3

Flash-

ing LED

(slow)

Led 3

Led 7

Heating switch-on timer

(continuous variation)

30 seconds Led 1

55 seconds Led 2

80 seconds Led 3

105 seconds Led 4

130 seconds Led 5

155 seconds Led 6

180 seconds (Standard setting) Led 7

255 seconds Led 8

Heating ramp timing. e boiler distributes he

maximum power set in the previous parameter.

e boiler performs an ignition ramp of about

650 seconds to arrive from minimum power to

nominal heating power.

Heating ramp timer (continuous variation)

65 seconds Led 1

130 seconds Led 2

195 seconds Led 3

390 seconds

455 seconds Led 5

520 seconds Led 6

585 seconds Led 7

650 seconds (Standard setting) Led 8

Heating switch-on delay request from Room

thermostat and Remote Friend ControlV2. e

boiler is set to switch-on immediately aer a

request. In the case of particular plants (e.g. area

plants with motorised thermostatic valves etc.) it

could be necessary to delay switch-on.

Heating switch-on delay request from Room thermostat

and Remote Friend ControlV2

(continuous variation).

0 seconds (Standard setting)

54 seconds Led 2

131 seconds Led 3

180 seconds Led 4

206 seconds Led 5

355 seconds Led 6

400 seconds Led 7

510 seconds Led 8

Domestic water thermostat/Boiler hysterisis.

With the setting of hysteresis 1 the boiler switches

on with a boiling device temperature equal to a

set point at -3°C. With the setting of hysteresis

2 the boiler switches on with a boiling device

temperature equal to a set point at -10°C.

Flash-

ing LED

(slow)

Flash-

ing LED

(slow)

Led 4

Flash-

ing LED

(slow)

Led 1

Domestic water thermostat/

Boiler hysterisis

Hysteresis 1 (Standard setting) Led 1

Hysteresis 1 Led 8

Circulating pump function. Two circulating

pump operational modes

can be selected in heating phase.

In “intermittent” mode it is activated from the

environmental thermostat or from the remote

control, in “continual” mode the circulation

pump functions constantly when the main selector switch (12) is on heating mode.

Circulating pump function

Intermittent (Standard setting) Led 1

Continuous Led 8

Town Gas G110 - Industrial gas. e setting

of this function is used to ad just the boiler in

order to function with gases from the rst family.

Town Gas G110 - Industrial

gas (rst family gas)

O (Standard setting) Led 1

On Led 8

Boiler mode. Establishes if the boiler functions

in instantaneous mode or with boiler (standard

supply).

Boiler mode

Instantaneous (Cannot be

used)

With boiler (Standard setting) Led 8

3.8 AUTOMATIC SLOW IGNITION

FUNCTION WITH TIMED RAMP

DELIVERY.

In the switch-on phase the electronic card carries out an increasing gas delivery ramp (with

pressure values that depend on the type of gas

selected) of preset duration. is avoids every

boiler lighting phase calibration or preparation

operation in any conditions of use.

3.9 “CHIMNEY SWEEP” FUNCTION.

When activated, this function forces the boiler

at max. output for 15 minutes.

IIn this mode all the adjustments are cut out and

only the temperature safety thermostat and the

limit thermostat remain active. To activate the

“Chimney-Sweep” function, press the Reset key

for 8 to 15 seconds in absence of domestic water

and heating requests. Its activation is indicated

by the simultaneous ashing of LEDS (2) and

(3).is function allows the technician to check

the combustion parameters. Aer the checks

deactivate the function, switching the boiler o

and then on again.

Flash-

ing LED

(slow)

Flash-

ing LED

(slow)

Flash-

ing LED

(slow)

Flash-

ing LED

(slow)

Led 1

INSTALLATORUSER

MAINTENANCE TECHNICIAN

17

Page 18

3.10 PUMP ANTIBLOCK FUNCTION.

e boiler has a function that starts the pump

once every 24 hours for the duration of 30

seconds in order to reduce the risk of the pump

becoming blocked due to prolonged inactivity.

3.11 THREEWAY ANTIBLOCK SYSTEM.

Both in “domestic” and in “domestic-heating”

phase the boiler is equipped with a function that

starts the three-way motorized group 24 hours

aer it was last in operation, running it for a

full cycle so as to reduce the risk of the threeway group becoming blocked due to prolonged

INSTALLATORUSER

inactivity.

3.12 RADIATOR ANTIFREEZE

FUNCTION.

If the system return water is below 4°C, the boiler

starts up until reaching 42°C.

3.13 ELECTRONIC CARD PERIODICAL

SELFCHECK.

During operation in heating mode or with boiler

in standby, the function activates every 18 hours

aer the last boiler check/power supply. In case

of operation in domestic circuit mode the selfcheck starts within 10 minutes aer the end of

the drawing in progress, for a length of approx.

10 seconds.

N.B.: During self-check, the boiler remains o,

including signalling.

- fumes pressure switch.

- Check integrity of the boiler Magnesium anode.

- Check the condition and integrity of the

electrical system and in particular:

- electrical power cables must be inside the

whipping;

- there must be no traces of blackening or

burning.

N.B.: in addition to yearly maintenance, the thermal system must also be checked, with frequency

and procedures that comply with the provisions

of the technical regulations in force.

3.15 CASING REMOVAL.

To facilitate boiler maintenance the casing can be

completely removed as follows (Fig. 3-5):

- Disassemble the lower cover by removing the

two relevant screws (1).

- Unscrew the two screw fasteners on the

dashboard and open it making it pivot.

- Unscrew the 2 xing screws (2) on the casing.

- Unhook the lower part of the casing as

described in the gure.

- Pull the casing (4) forwards and up at the same

time (see gure) to detach it from the upper

hooks.

3.14 YEARLY APPLIANCE CHECK AND MAINTENANCE.

e following checks and maintenance should

be performed at least once a year.

- Clean the ue side of the heat exchanger.

- Clean the main burner.

- Visually check the fume hood for deterioration

or corrosion.

- Check correct lighting and operation.

- Ensure correct calibration of the burner in

domestic water and heating phases.

- Check correct operation of control and

adjustment devices and in particular:

- intervention of electrical main electrical

switch on boiler;

- system control thermostat intervention;;

- domestic water control thermostat

intervention

- Check that the internal system is properly

MAINTENANCE TECHNICIAN

sealed according to specications.

- Check intervention of the device against no gas

ionization ame control:

- Intervention time must be less than 10 seconds.

- Visually check for water leaks or oxidation

from/on connections.

- Visually check that the water safety drain valve

is not blocked.

- Check that, aer discharging system pressure

and bringing it to zero (read on boiler pressure

gauge), the expansion tank charge is at 1.0 bar.

- Check that the system static pressure (with

system cold and aer relling the system by

means of the ller cock) is between 1 and 1.2

bar.

- Check visually that the safety and control

devices have not been tampered with and/or

shorted, in particular

- temperature safety thermostat;

1

2

3-5

18

Page 19

3.16 VARIABLE HEAT POWER.

N.B.: Gas flow rates refer to heating power

below a temperature of15°C and at a pressure

of 1013 mbar.

Burner pressure values refer to use of gas at 15°C.

MAX.

MIN CEN.