Immergas AUDAX TOP ErP, AUDAX TOP 6 ErP, AUDAX TOP 8 ErP, AUDAX TOP 12 ErP, AUDAX TOP 18 ErP Series Manual

...

HEAT PUMPS

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

AND INTEGRATED

SYSTEMS

with reversible inverter mono-

phase and three-phase air-

water Heat Pumps

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

INDEX

MAIN INDEX

1 AUDAX TOP ErP DESCRIPTION .........................................................................................................................................................4

2 AUDAX TOP 6 8 12 ErP FEATURES MONOPHASE ..................................................................................................................5

3 AUDAX TOP 16 18 21 ErP FEATURES THREEPHASE ..............................................................................................................6

4 INTEGRATED SYSTEM FOR AIR CONDITIONING AND D.H.W. PRODUCTION .................................................................. 7

5 HEAT ADJUSTMENT WITH AUDAX TOP ERP CONTROL PANEL IN STANDALONE APPLICATIONS (SETTING AND

OPERATING LOGIC) .............................................................................................................................................................................. 9

6 AUDAX TOP ErP DIMENSIONS AND CONNECTIONS ................................................................................................................21

7 AUDAX TOP ErP MINIMUM INSTALLATION DISTANCES ......................................................................................................... 23

8 AUDAX TOP ErP HYDRAULIC CIRCUIT COMPONENTS ...........................................................................................................25

9 AUDAX TOP ErP OPERATING LIMITS AND ANTIFREEZE FUNCTION ................................................................................... 28

10 AUDAX TOP 6 ErP TECHNICAL DATA .............................................................................................................................................30

11 PRODUCT FICHE REGULATION 811/2013 AUDAX TOP 6 ErP .................................................................................................31

12 AUDAX TOP 6 ERP “POWER” AND “COP” CENTRAL HEATING / “EER” COOLING ............................................................. 32

13 GRAPH OF AUDAX TOP 6 ErP PUMP FLOW RATE/HEAD ...........................................................................................................34

14 AUDAX TOP 8 ErP TECHNICAL DATA ............................................................................................................................................. 35

15 PRODUCT FICHE REGULATION 811/2013 AUDAX TOP 8 ErP.................................................................................................36

16 AUDAX TOP 8 ERP “POWER” AND “COP” CENTRAL HEATING / “EER” COOLING ............................................................. 37

17 GRAPH OF AUDAX TOP 8 ErP PUMP FLOW RATE/HEAD ...........................................................................................................39

18 AUDAX TOP 12 ERP TECHNICAL DATA .......................................................................................................................................... 40

19 PRODUCT FICHE REGULATION 811/2013 AUDAX TOP 12 ErP ...............................................................................................41

20 AUDAX TOP 12 ERP “POWER” AND “COP” CENTRAL HEATING / “EER” COOLING ........................................................... 42

21 GRAPH OF AUDAX TOP 12 ErP PUMP FLOW RATE/HEAD .........................................................................................................44

22 AUDAX TOP 16 ErP TECHNICAL DATA ...........................................................................................................................................45

23 PRODUCT FICHE REGULATION 811/2013 AUDAX TOP 16 ErP ...............................................................................................46

24 AUDAX TOP 16 ERP “POWER” AND “COP” CENTRAL HEATING / “EER” COOLING ........................................................... 47

25 GRAPH OF AUDAX TOP 16 ErP PUMP FLOW RATE/HEAD .........................................................................................................49

26 AUDAX TOP 18 ErP TECHNICAL DATA ...........................................................................................................................................50

27 PRODUCT FICHE REGULATION 811/2013 AUDAX TOP 18 ErP ...............................................................................................51

28 AUDAX TOP 18 ERP “POWER” AND “COP” CENTRAL HEATING / “EER” COOLING ........................................................... 52

29 GRAPH OF AUDAX TOP 18 ErP PUMP FLOW RATE/HEAD .........................................................................................................54

30 AUDAX TOP 21 ErP TECHNICAL DATA ...........................................................................................................................................55

31 PRODUCT FICHE REGULATION 811/2013 AUDAX TOP 21 ErP ...............................................................................................56

32 AUDAX TOP 21 ERP “POWER” AND “COP” CENTRAL HEATING / “EER” COOLING ........................................................... 57

33 GRAPH OF AUDAX TOP 21 ErP PUMP FLOW RATE/HEAD .........................................................................................................59

34 AUDAX TOP 6 8 12 16 ErP P.C.B. .................................................................................................................................................. 60

35 AUDAX TOP 6 8 12 16 ErP CONTROL DIAGRAM .................................................................................................................... 63

36 AUDAX TOP 6 8 12 16 ErP TERMINAL BLOCK ELECTRICAL CONNECTIONS ................................................................ 64

37 AUDAX TOP 18 21 ErP P.C.B. ............................................................................................................................................................65

38 AUDAX TOP 18 21 ErP CONTROL DIAGRAM ..............................................................................................................................66

39 AUDAX TOP 18 21 ErP TERMINAL BLOCK ELECTRICAL CONNECTIONS ...........................................................................67

40 ELECTRIC CONNECTION CABLES FEATURES ............................................................................................................................ 68

41 SYSTEM MANAGER ............................................................................................................................................................................. 69

42 ZONE REMOTE CONTROL ............................................................................................................................................................... 76

43 ROOM TEMPERATURE/HUMIDITY SENSOR ................................................................................................................................ 76

44 EXPANSION BOARD FOR ZONE MANAGEMENT ........................................................................................................................76

45 SYSTEM DISTRIBUTION KIT ............................................................................................................................................................ 77

46 DEHUMIDIFIER ................................................................................................................................................................................... 81

47 INTRODUCTION WITH COMMENTARY TO INTEGRATED SYSTEMS: MAIN APPLICATIONS ...........................................85

48

DIAGRAM AUDAX TOP ERP AND 2 LOW TEMPERATURE ZONES+ SOLAR HEATING FOR D.H.W. PRODUCTION + MANAGER

49 DIAGRAM AUDAX TOP ErP + CONTROL PANEL TO CONTROL THE ROOM + SOLAR PACK ............................................ 90

50 DIAGRAM AUDAX TOP ErP AIR CONDITIONING ONLY + BOILER PLUS + 2 LOW TEMPERATURE ZONES AND

1 DIRECT ZONE + SOLAR HEATING FOR D.H.W. PRODUCTION + SYSTEM MANAGER ...................................................92

51 DIAGRAM AUDAX TOP ErP + BOILER WITH 1 HIGH TEMPERATURE ZONE + 2 LOW TEMPERATURE ZONES

+ SOLAR HEATING FOR DHW + SYSTEM MANAGER ..................................................................................................................94

52 DIAGRAM AUDAX TOP ErP + PLUS BOILER AND 2 LOW TEMPERATURE ZONES + STORAGE TANK UNIT FOR D.H.W.

PRODUCTION + SYSTEM MANAGER.............................................................................................................................................. 96

53

DIAGRAM AUDAX TOP ERP AIR CONDITIONING ONLY + BOILER WITH INTEGRATED STORAGE TANK UNIT + SOLAR

HEATING FOR D.H.W. PRODUCTION, SEPARATE CENTRAL HEATING/COOLING SYSTEM + SYSTEM MANAGER

54 DIAGRAM AUDAX TOP ErP IN CASCADE AIR CONDITIONING ONLY + HIGH POWER BOILER + THERMAL

FLYWHEEL AND MIXED ZONE + SOLAR HEATING FOR D.H.W. PRODUCTION + SYSTEM MANAGER ...................... 100

55 DIAGRAM AUDAX TOP ErP + BOILER AND 2 LOW TEMPERATURE ZONES + SOLAR HEATING FOR D.H.W.

PRODUCTION AND CENTRAL HEATING + SYSTEM MANAGER ........................................................................................... 102

56 OPTIONAL WHICH CAN BE COUPLED .......................................................................................................................................104

57 MAIN INERTIAL STORAGE TANK TECHNICAL FEATURES ..................................................................................................... 107

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

...88

voltar.com.ua

.......................98

voltar.com.ua

voltar.com.ua

3

voltar.com.ua

voltar.com.ua

1 AUDAX TOP ErP DESCRIPTION

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

A range of air/water reversible heat pumps with inverter technology. e mono-phase versions are available with AUDAX

TOP 6 ErP, AUDAX TOP 8 ErP and AUDAX TOP 12 ErP

models to full central heating and cooling requirements for

homes, oces, shops, etc...; while the three-phase versions are

available with AUDAX TOP 16 ErP, AUDAX TOP 18 ErP and

AUDAX TOP 21 ErP models to full central heating and cooling

requirements for large domestic systems (newly built large homes

such as duplexes, three-unit houses, condominiums), as well as

oces, shops, artisan activities, etc..

ese appliances are distinguished for their high energy eciency

and contained sound levels. ey can be used as a single generator to assist the system, but also inside an integrated system

(for example, with a heat pump - boiler - solar heating). ey

are engineering solutions that can be perfectly integrated with

each other, which allow to attain maximum benet from the

various energy production systems on the basis of the respective

eciency parameters.

For the entire system to operate correctly, Immergas oers an

“intelligent” system Manager capable of identifying the most

economical energy source at a given time and therefore choose

voltar.com.ua

voltar.com.ua

the right appliance to activate.

All AUDAX TOP ErP series models are equipped with a system

side plate heat exchanger and low energy consumption circulation pump, which facilitate installation. e maximum ow

temperature set-point with central heating is 60 °C (57 °C for

AUDAX TOP 21 ErP), which enables use of radiator systems

as well as fan coil or radiant systems.

e entire range complies with the requirements of ErP Directive

(2009/125/EC) and ELD (2010/30/EC). Various hydraulic,

electric and electronic kits are available, which enable exible

use in all circumstances.

voltar.com.ua

voltar.com.ua

voltar.com.ua

4

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

2 AUDAX TOP 6 8 12 ErP FEATURES MONOPHASE

voltar.com.ua

6 kW, 8 kW and 12 kW mono-phase inverter air/water heat

pumps for winter and summer air conditioning. e galvanised

steel structure makes the machines particularly suitable for

outdoor installation.

Main components:

• Control Panel - standard supply - which enables you to pro-

gram the machine and also functions as a room temperature/

humidity sensor. It also displays the error codes in the event

of malfunctions;

• R410A refrigerant gas (pre-loaded in the machine);

• Twin Rotary compressor with hybrid inverter activation in

direct current with PAM (Pulse Amplitude Modulation) and

PWM (Pulse Width Modulation) logic to oer improved

reliability, low energy consumption and vibration-free operation in all operating conditions and acoustic insulation with

sound-absorbing materials.

• cooling circuit including a compressor and air/gas refrigerant

nned coil, two-way electronic throttle valve, refrigerant gas/

water insulated stainless steel plate heat exchanger, 4-way

reversing valve (reversible heat pump cycle or cooling cycle

operation);

• variable speed fan with a 3-blade impeller characterised by an

innovative prole designed to guarantee better distribution of

air and contained sound levels (AUDAX TOP 6 - 8 ErP);

• double variable speed fan with a 3-blade impeller characterised

by an innovative prole designed to guarantee better distribution of air and contained sound levels (AUDAX TOP 12 ErP);

• system low energy consumption pump and ow switch to

ensure there is sucient water circulation to guarantee correct

operation of the hydronic and cooling circuits;

• 2 litre internal expansion vessel (AUDAX TOP 6 - 8 ErP);

• 3 litre internal expansion vessel (AUDAX TOP 12 ErP);

• 3 bar system safety valve;

• included and standard supply are the water Y lter 1”, vibra-

tion-dampening devices, condensate drain ttings and cable

clamp to pass electric cables;

• ow and return 1” M hydraulic connections situated at the

rear;

• electronic management system equipped with various sensors

situated in key positions of the cooling circuit to electronically

detect the system's operating status. e system's ow water

temperature is detected by means of a probe;

• option to pilot a 3-way diverter valve directly from AUDAX

TOP ErP for D.H.W. production heating and an external

booster pump on the system;

• maximum system water ow temperature up to 60 °C;

• operation up to outdoor air temperature of -20°C in winter

and +46°C in summer;

• protection against freezing up to -10°C as a result of periodic

activation of the pump and AUDAX TOP ErP cooling circuit

(with power supply voltage);

• IPX4 electrical insulation rating.

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

System solutions:

• Standalone system with AUDAX TOP ErP and integrative

resistance;

• can be coupled to a separate storage tank for DHW;

• can be coupled to a boiler via the System manager;

• can be coupled to a boiler and the solar heating system via the

voltar.com.ua

System manager.

• can be installed as a set conguration with the System manager.

Is available in the model:

• AUDAX TOP 6 ErP code 3.025557

• AUDAX TOP 8 ErP code 3.025558

• AUDAX TOP 12 ErP code 3.025560

EC Declaration Of Conformity.

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

5

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

3 AUDAX TOP 16 18 21 ErP FEATURES THREEPHASE

voltar.com.ua

16 kW, 18 kW and 21 kW three-phase inverter air/water heat

pump for winter and summer air conditioning. e galvanised

steel structure makes the machines particularly suitable for

outdoor installation.

Main components:

• Control Panel - standard supply - which enables you to program the machine and also functions as a room temperature/

humidity sensor. It also displays the error codes in the event

of malfunctions;

• R410A refrigerant gas (pre-loaded in the machine);

• twin Rotary compressor with hybrid inverter activation in

direct current with PAM (Pulse Amplitude Modulation) and

PWM (Pulse Width Modulation) logic to oer improved

reliability, low energy consumption and vibration-free operation in all operating conditions and acoustic insulation with

sound-absorbing materials.

• cooling circuit including a compressor and air/gas refrigerant

nned coil, two-way electronic throttle valve (2 in the 21 kW

version), refrigerant gas/water insulated stainless steel plate

heat exchanger, 4-way reversing valve (reversible heat pump

cycle or cooling cycle operation);

• double fan variable speed with a 3-blade impeller characterised

by an innovative prole designed to guarantee better distribution of air and contained sound levels;

• modulating system low energy consumption pump and ow

switch to ensure there is sucient water circulation to guarantee correct operation of the hydronic and cooling circuits;

• 3 litre internal expansion vessel (16 kW);

• 8 litre internal expansion vessel (18 - 21 kW);

• 3 bar system safety valve;

• included and standard supply are the water Y lter 1”, vibration-dampening devices, condensate drain ttings and cable

clamp to pass electric cables;

• ow and return 1” M hydraulic connections situated at the

rear;

• electronic management system equipped with various sensors

situated in key positions of the cooling circuit to electronically

detect the system's operating status. e system's ow water

temperature is detected by means of a probe;

• option to pilot a 3-way diverter valve directly from AUDAX

TOP ErP for D.H.W. production heating and an external

booster pump on the system;

• maximum system water ow temperature up to 60 °C (57 °C

for AUDAX TOP 21 ErP);

• operation up to outdoor air temperature of -20°C in winter

and +46°C in summer;

• for AUDAX TOP 16 ErP protection against freezing up to -10°C

(with power supply voltage) as a result of periodic activation of the

pump and AUDAX TOP ErP cooling circuit;

• for AUDAX TOP 18-21 ErP protection against freezing up to -10°C

(with power supply voltage) as a result of periodic activation of the

pump and electric resistances;

• IPX4 electrical insulation rating.

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

System solutions:

• standalone system with AUDAX TOP ErP and integrative

resistance;

• can be coupled to a separate storage tank for DHW;

• can be coupled to a boiler via the System manager;

• can be coupled to a boiler and the solar heating system via the

voltar.com.ua

System manager.

• can be installed as a set conguration with the System manager.

Is available in the model:

• AUDAX TOP 16 ErP code 3.025562

• AUDAX TOP 18 ErP code 3.025563

• AUDAX TOP 21 ErP code 3.026940

EC Declaration Of Conformity.

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

6

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP and Integrated System

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

4 INTEGRATED SYSTEM FOR AIR CONDITIONING AND D.H.W. PRODUCTION

Comprised of a boiler – solar heating – heat pump and possibly

photovoltaic – etc, they are the natural evolution of air-conditioning systems: with very high seasonal eciency, low energy

consumption and reduced polluting emissions.

ey are engineering solutions that can be perfectly integrated

with each other, which allow to attain maximum benet from the

various energy production systems on the basis of the respective

eciency parameters.

For the entire system to operate correctly, Immergas oers a

System Manager, able to:

- always make use of the most convenient heat source;

- keep the system performance high in every circumstance;

- control and command the entire system with a unique "brain"

(i.e. the System Manager);

- promote heat pump activation with a system that generates

electricity from renewable sources.

Basically, the System Manager is a supervisor that can control

the entire system).

Amongst other things, the following main operations are necessary:

voltar.com.ua

- acquire outdoor temperature (from the external probe, inserted

- set central heating side and cooling side (if provided) climatic

- congure the fuel cost (e.g. methane);

- congure the electric energy cost;

- set the AUDAX TOP ErP minimum integration (cut o) T.

e point of economic balance between the gas boiler and the

heat pump is a COP value between 2.4 and 2.6 approximately

(approximate value referred to methane); this value changes

based on the cost of electrical power and gas, in the location

voltar.com.ua

where the system is installed.

With sucient Toutdoor to full minCOP economical convenience, or Toutdoor is higher than Tminimum integration (cut o), the

heat pump starts and the performance eciency conditions are

constantly monitored. On the contrary, if the environmental

conditions are such that the AUDAX TOP ErP coecient of

performance tends towards lower values than COPmin for economical convenience, or outdoor T is less than minimum integration

(cut o) T, the system Manager starts the boiler (or integrative

resistance).

voltar.com.ua

as per standard on the heat pump);

curve operation to determine the system's ow temperature;

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

7

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP and Integrated System

voltar.com.ua

Each time AUDAX TOP ErP is operating, the Manager enables

an additional control, which checks the time it takes the system

to reach full operation: when a maximum time is exceeded (can

be set dierently between C.H. and D.H.W.) for the heat pump

to reach the owT, the boiler or integrative electrical resistance

is started.

It is also possible to choose the integration operation method

(boiler/resistance) between simultaneous or alternative Heat

Pump.

In all cases where radiant panels are also included for summer

cooling, alongside dehumidiers (see previous picture), the

System Manager will also monitor the dew point through the

installation of room probes (Immergas). anks to this intelligent

function the System Manager can increase the ow temperature

to the radiant panels by about 1°C (up to a maxT of 18°C - maximum limit of the cooling heat pump), avoiding the phenomenon

of condensation on the surface of the structure. is function can

only be activated with an Immergas accessory kit that controls

humidity. In some cases, for example, the System Manager can

turn the heat pump o if the ow temperature to the radiant

panels is not suciently corrected.

voltar.com.ua

voltar.com.ua

If on the other hand, there is a high temperature zone in the

system, in addition to the low temperature one, it will be served

exclusively by the boiler through an accordingly congured

dedicated expansion connected to the System Manager.

D.H.W: operation: amongst the possible congurations with

integrated systems is the option to connect the boiler and

AUDAX TOP ErP parallel with the same coil, and use a storage

tank probe with one DHW set for the entire storage tank, and set

voltar.com.ua

it in the system's Manager. If the system Manager is connected

to the boiler on external probe clamps (pre-set models), if the

set DHW temperature is < 50°C, the heat pump starts (always

checking the aforesaid convenience); however, if it is > 50°C,

AUDAX TOP ErP heats up to 50°C, then the boiler starts; if

there is no boiler but there is storage tank integrative electrical

resistance, the water is brought to 50°C via the heat pump and

AUDAX TOP ErP is then disabled, leaving the resistance to

integrate to the pre-set value.

In systems where there is a boiler or an integrative electrical

resistance on the storage tank, in addition to the heat pump, it

is also possible to enable the anti-legionella function.

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

8

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

5 HEAT ADJUSTMENT WITH AUDAX TOP ErP CONTROL PANEL IN

STANDALONE APPLICATIONS (SETTING AND LOGIC OPERATION)

e Control Panel (standard supply with AUDAX TOP ErP)

enables programming of several operating options and relative

voltar.com.ua

voltar.com.ua

temperature/humidity control of the system.

voltar.com.ua

For example, the Control Panel acquires data regarding outdoor

temperature (from the external probe), system ow temperature

(regarding the pre-set climatic curve), and also the room's humidity percentage.

e standard Control Panel supplied is connected to a specic

terminal block on AUDAX TOP ErP, which enables you to

program the machine and also functions as a room temperature/

humidity sensor. It also displays the error codes in the event of

malfunctions.

e room sensor function can be disabled in order to use it only

to display the heat pump statuses and leave AUDAX TOP ErP

external control management on/o.

e user interface is composed of an LCD display, keys and an

encoder central knob.

voltar.com.ua

N.B.: With system Manager applications, the Control Panel

(standard) can also function as a room temperature/humidity

probe of a system's zone.

voltar.com.ua

voltar.com.ua

voltar.com.ua

Factory set device class: "VI"

Ref. European Commission Notice 2014/C 207/02

5.1 TECHNICAL FEATURES

e Control Panel (standard) with Standalone conguration,

enables:

• Operation with variable ow temperature according to outdoor

temperature (through the standard AUDAX TOP ErP external

probe supplied);

• Machine time band operation (C.H and cooling) in Comfort

or Economy mode;

• Any operation anomalies with error codes via system self-diagnosis displayed on the screen.

e Control Panel also manages the following data:

• External temperature (via external probe as per standard with

AUDAX TOP ErP);

• System ow temperature settings (C.H and cooling);

• Instant outlet temperature from the machine;

• Dew temperature;

• No. of machine operating hours.

Please note that AUDAX TOP ErP can:

• Directly pilot one/two 3-way diverter valves for D.H.W.

production, and can manage activation of an external booster

pump on the system;

• Manage activation of an auxiliary heat source (e.g. electrical

resistance);

voltar.com.ua

voltar.com.ua

voltar.com.ua

• Manage and an external alarm that forces machine shutdown;

• Limit the machine's frequency (to reduce noise).

NOTE: With Standalone applications to manage any dehumidiers, you can opt for On/O room thermostats + On/

O humidistats (connected parallel with AUDAX TOP ErP),

with a relay to split the humidistat request and also take it to

the dehumidiers.

TECHNICAL DATA

• Dimensions: 100 x 129 x 37 mm (H x L x D);

• Supply voltage: 15 Vdc (directly from the Heat Pump terminal

block);

• Maximum input: 2 VA;

voltar.com.ua

• 4-pole cable connection (type H03VV-F 5 x 0.75 mm2 ), max

length 50 m. Use wires having minimum sections of 0.5 mm2

and maximum 1.5 mm2;

• Casing protection rating: IP20.

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

9

voltar.com.ua

voltar.com.ua

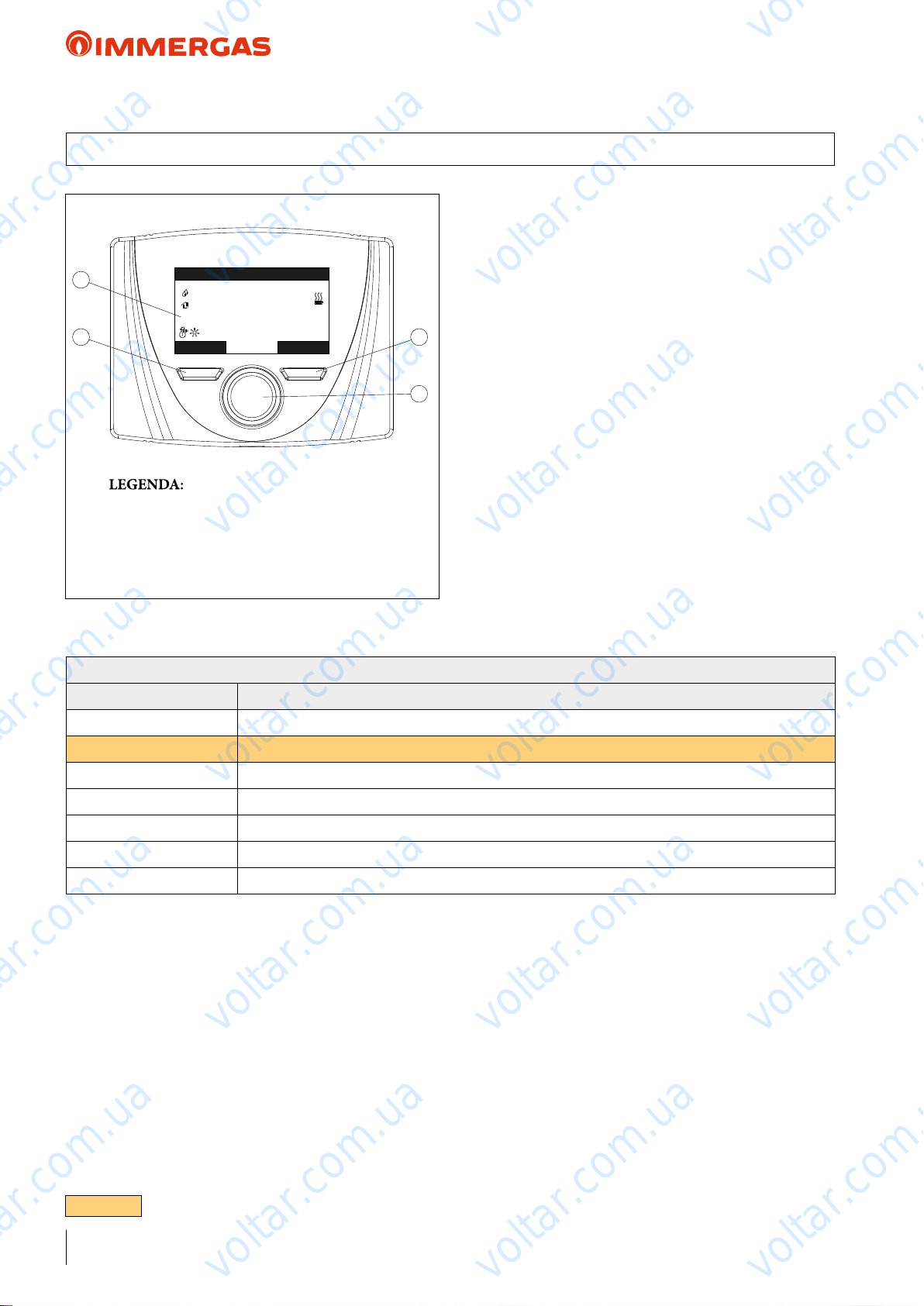

5.2 PROGRAMMING MENU

4

2

1 - Main parameters switch with button to

2 - Left context button

3 - Right context button

4 - Display

12:34 Fr 3 Jan 2014

voltar.com.ua

67%

20.6

13°C

Room set 21.0°C

Mode Menu

conrm and save data

voltar.com.ua

°C

3

1

voltar.com.ua

Once the device is powered, it goes into the status prior to switcho. Press the “Modo” (Mode) (2) button to cyclically select the

desired mode amongst those available.

Depending on the system's conguration, the main screen displays various information regarding the system.

voltar.com.ua

Press the “Menu” (3) button to access a list of variables that

enable you to customise use of the system.

To browse the menus, which can be accessed by pressing the

relative “RH” or “LH” context buttons, scroll through the

sub-menus displayed by turning the main switch (1).

Press the said main switch (1) to select the one highlighted.

erefore, by pressing repeatedly, you can scroll down the menu

levels and go back to a previous level by pressing the “Indietro”

(Back) context button. To exit the menu completely, press the

“Esci” (Exit) button, which will take you back to the initial page

of normal operation.

To conrm the parameter change, press the main switch (1).

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

voltar.com.ua

voltar.com.ua

MAIN MENU

Menu item Description

Set Point Zone Denes the operating parameters to manage the zone

Set Point DHW Denes the operation parameters in domestic circuit mode

Time and Program Denes the date/time and time operating ranges

Information Display system operating data

Historical alarm code Displays the list of the last 10 anomalies

Service Password protected menu dedicated to a qualied technician

Language Denes the control panel operation language

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

10

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

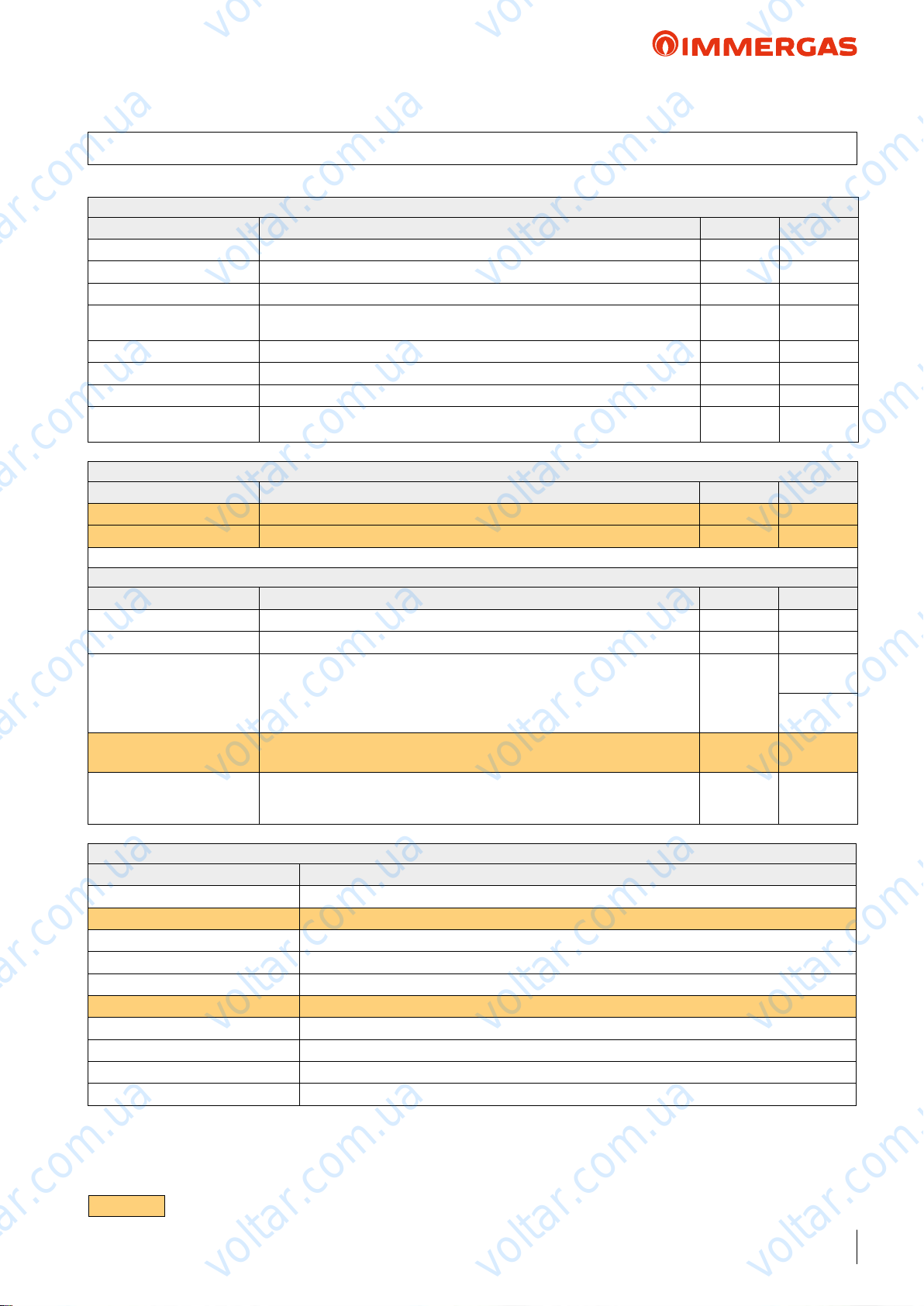

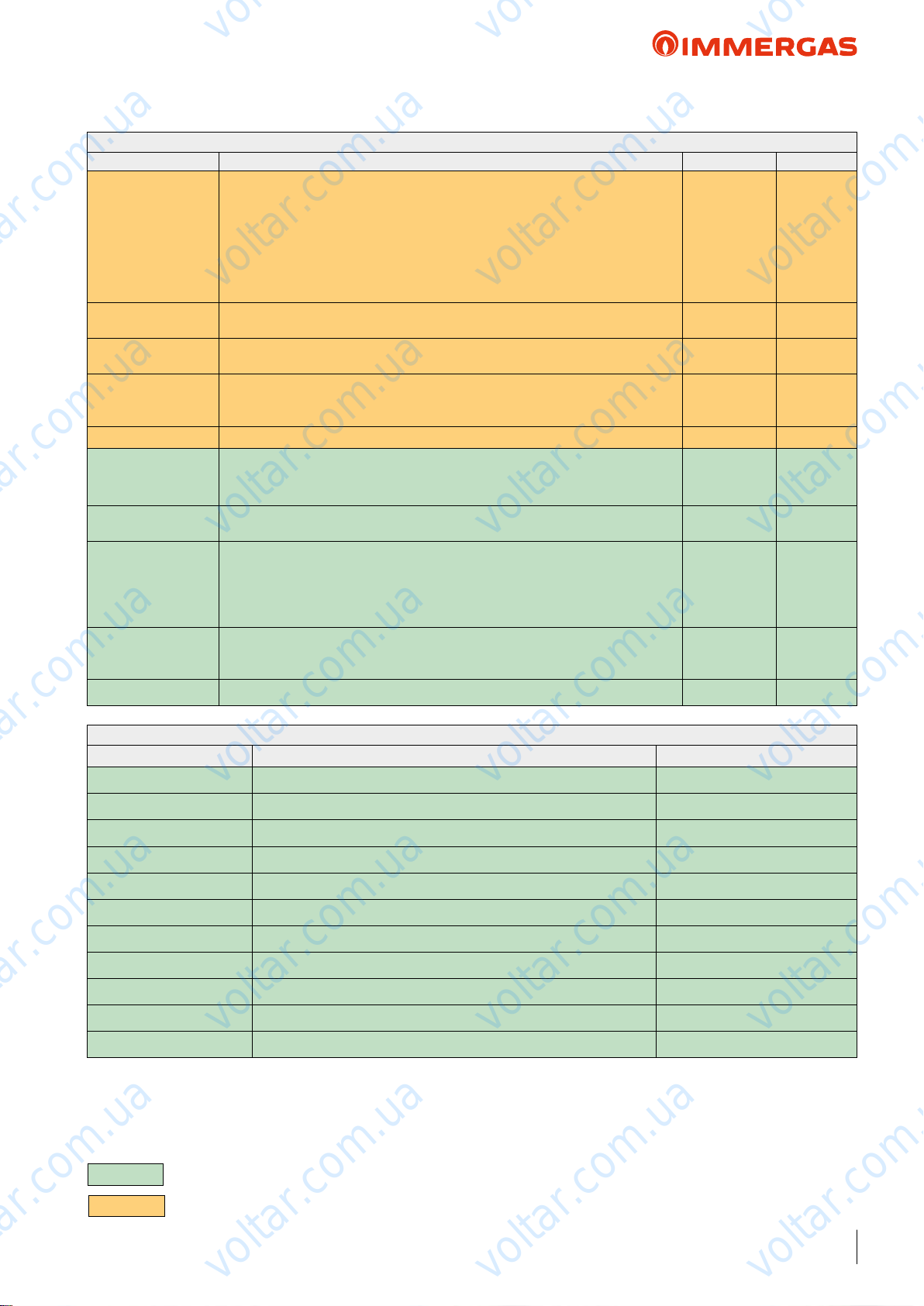

5.3 USER PROGRAMMING MENU

Menu Set Point Zone

Menu item Description Range Default

Set comfort heat. Room temperature in central heating zone Comfort mode 15 ÷ 35 °C 20

Set economy heat. Room temperature in central heating zone Economy mode 5 ÷ 25 °C 17

Set ow heat. Flow temperature in room zone central heating mode 20 ÷ 60°C 40

Oset ow heat. Oset temperature for central heating zone

Set comfort cool. Room temperature in cooling zone Comfort mode 15 ÷ 35 °C 25

Set economy cool. Room temperature in cooling zone Economy mode 15 ÷ 35 °C 28

Set ow cool. Flow temperature in room zone cooling mode 4 ÷ 25 °C 8

Oset ow cool. Oset temperature for cooling zone

Menu item Description Range Default

Set comfort DHW storage temperature in Comfort phase 30 ÷ 60 °C 50

Set economy DHW storage temperature in Economy phase 30 ÷ 45 °C 30

voltar.com.ua

Menu Set point DHW

voltar.com.ua

voltar.com.ua

- 15 ÷ + 15

°C

-15 ÷ + 15

°C

voltar.com.ua

voltar.com.ua

voltar.com.ua

0

0

voltar.com.ua

Menu Time and Programs

Menu item Description Range Default

Date and time Current date and time setting

Time slots Denes the time range for operation in Comfort and Economy mode

Program Zone Time programming for controlled zone

Program DHW DHW operation time programming

Denes the period during which the system disables both hot water heating and

voltar.com.ua

Program Holiday

Menu item Description

Flow temperature Instant outlet temperature from the system

Return temperature Instant inlet temperature to the system

External temperature External temperature detected by the external probe

Flow temp. system calc. Flow temperature requested by the generators

Dew point Dew temperature

Temp DHW Storage water temperature

Firmware board version Heat pump control board software revision

Firmware display version Display software revision installed on the control panel

H.P. hours of operation Number of operating hours of the heat pump

Mode of operation H.P. Describes the heat pump operation mode.

room central heating and/or cooling functions.

At the end of the set days, the previously active functions will be reset.

Menu Information

voltar.com.ua

voltar.com.ua

voltar.com.ua

Mon - Sun

voltar.com.ua

voltar.com.ua

Mon - Fri

Cal 1

Sat - Sun

Cal 3

Cal 1

Disabled

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

11

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

Menu Historical alarm code

Description

Displays the history log of the last 10 anomalies

Menu Service

Menu item Description Range Default

Password protected menu dedicated to a qualied technician

voltar.com.ua

Menu Language

Menu item Description Range Default

Language Denes the control panel operation language ITA - ENG ITA

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

12

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

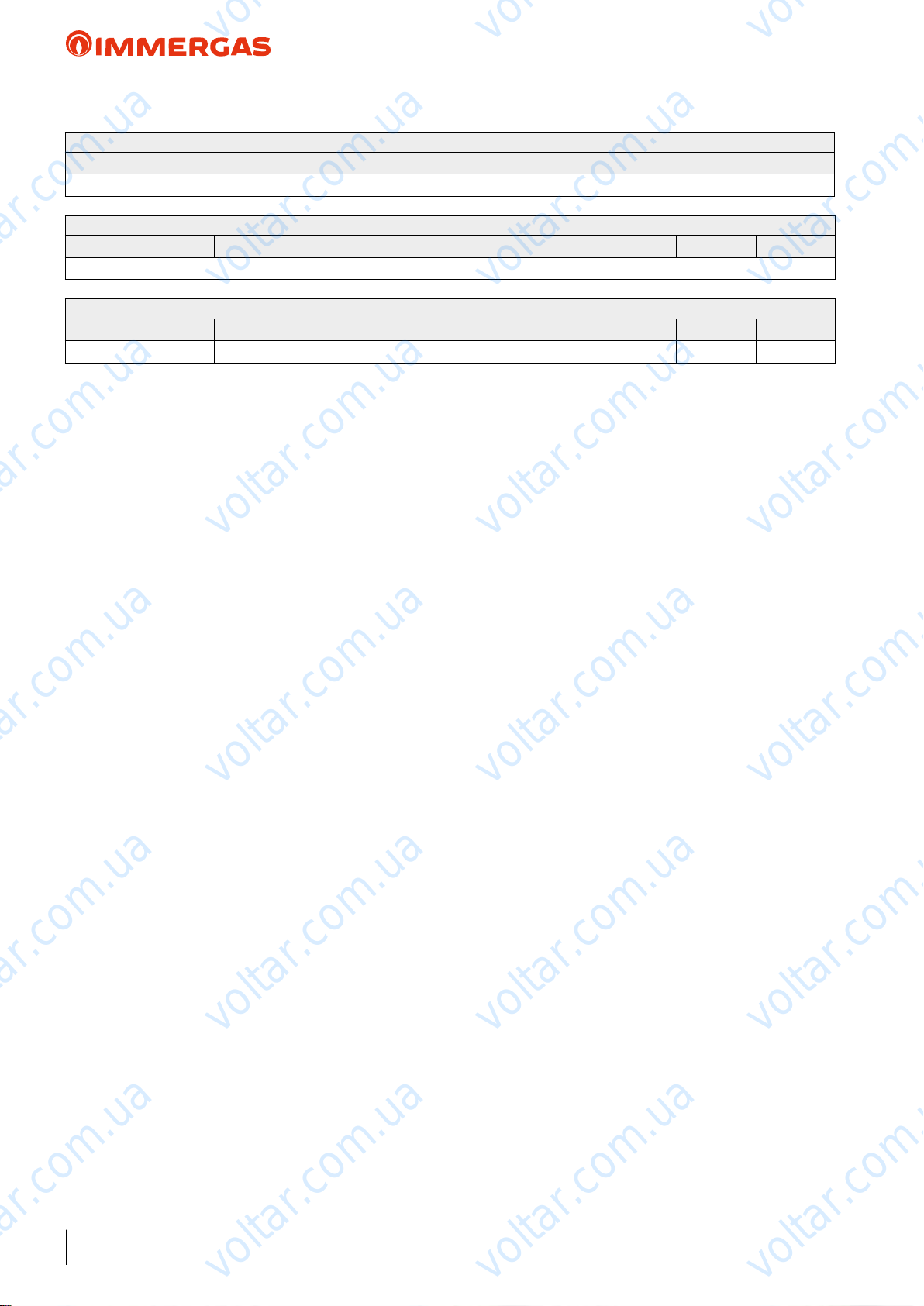

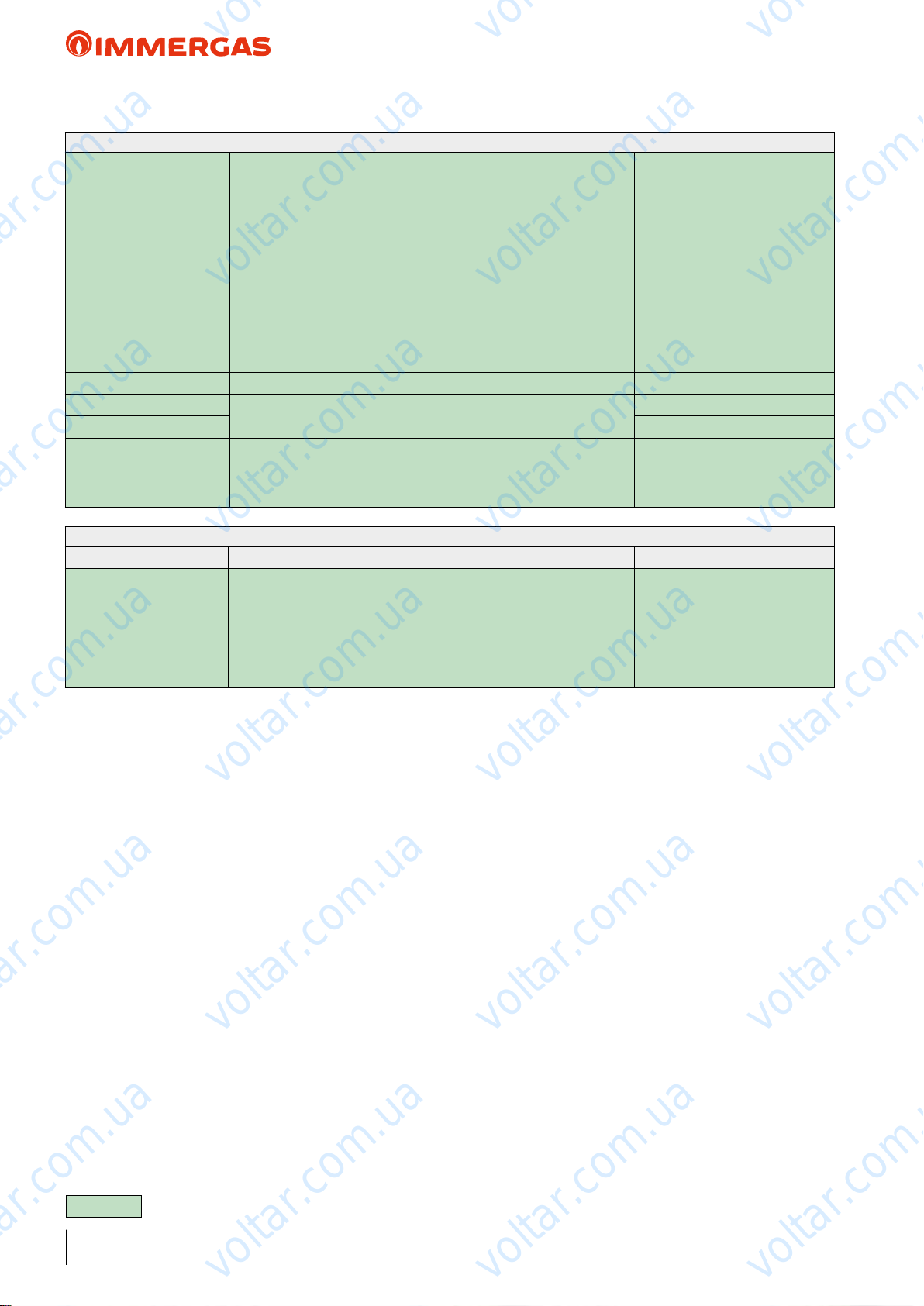

5.4 MAINTENANCE TECHNICIAN PROGRAMMING MENU

Menu Service

Menu item Description Range

Denition of zone Zone system sub-menu settings -

Dening plant Sub-menu to dene the devices connected to the system -

Device conguration Sub-menu to set the device's conguration -

ermoreg. heat. Central heating thermoregulation setting sub-menu -

ermoreg. cool Cooling thermoregulation setting sub-menu -

ermoreg. parameters Parameters thermoregulation setting sub-menu -

Integration System integration setting sub-menu -

Heat pump Heat pump operating parameters sub-menu -

Manual Manual operating parameters sub-menu -

Factory settings Default settings restore sub-menu Yes / No

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

Menu Service -> Denition of Zone

Menu item Description Range Default

Mode Display the operating mode

Room control inter-

face

Enable Remote

Control

Enable thermostat

Enable dew point Enable operation with a humidity probe in the control panel. Yes / No No

Menu item Description Range Default

External probe Enables operation with the external probe.

Enable DHW Operation in domestic circuit

Reduction function

Power Power percentage in reduction mode. 50% ÷ 100% 75%

Circulator control

Speed Min Value of minimum speed used in modulating operation. 19% ÷ 50% 50%

Speed Max Value of maximum speed used in modulating operation. 50% ÷ 100% 100%

Delta T Temperature delta to be maintained with modulating operation. 2 ÷ 20 5

voltar.com.ua

Enable operation of the supplied control panel if set on “R. Panel”.

If “TA” set, the central heating and cooling requests will be made based on the

request of an external thermostat.

Enable operation of the supplied control panel.

If “No” is set, the control panel only displays the heat pump statuses.

N.B.: setting “No”, it is compulsory to enable the room thermostat (refer to the

next item), otherwise the machine will display an anomaly.

Enable operation of a room thermostat to check the heat pump

PdC is controlled by contacts in the said P.C.B.

voltar.com.ua

Enable PdC operation frequency reduction, which is controlled by the said terminal

board.

Enable the pump operation with speed set “Max.speeed” or the modulating mode

with tracking of the “Modulating” temperature dierential.

Menu Service -> Dening Plant

voltar.com.ua

voltar.com.ua

- Heat + Cool

Remote Pan-

el/T.A.

Yes / No Ye s

Yes / No No

voltar.com.ua

No / PdC

Yes / No

Yes / No No

Max.speed/

Modulating

voltar.com.ua

voltar.com.ua

R.Panel

voltar.com.ua

Modulating

voltar.com.ua

-

No

No

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 6 - 8 - 12 - 16 ErP

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

13

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

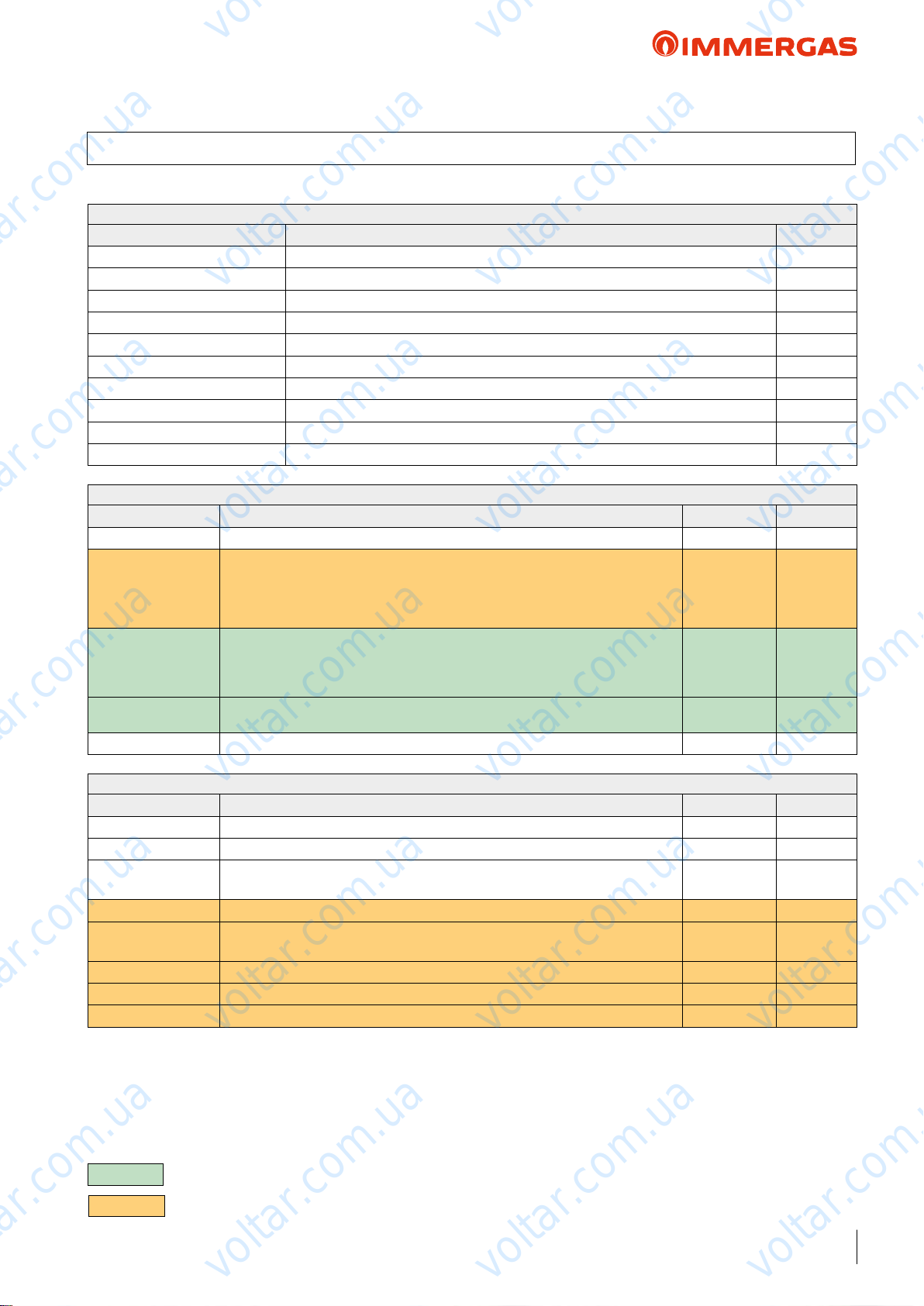

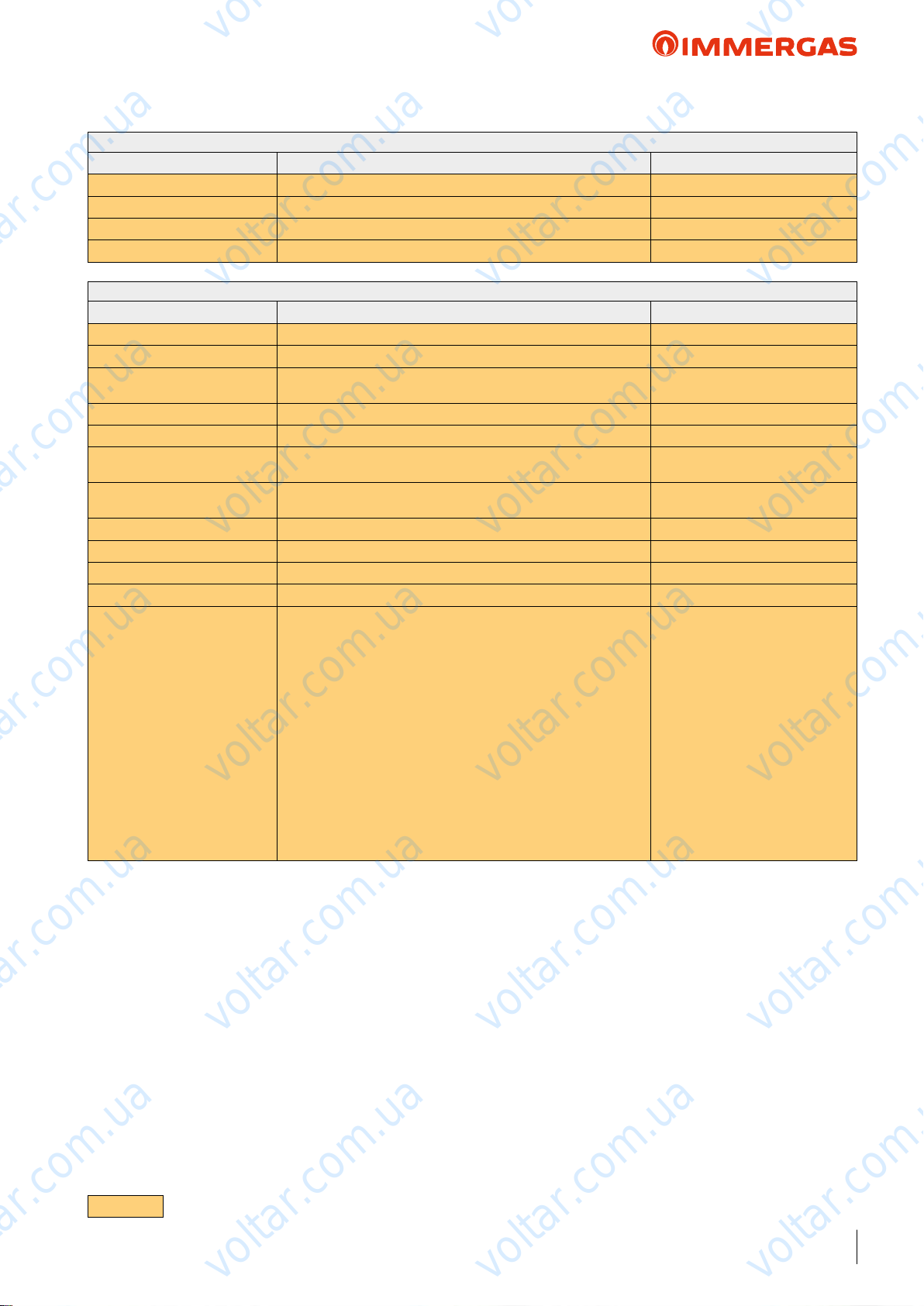

Menu Service -> Device conguration

Menu item Description Range Default

Setting “Yes”, the default control panel supplied manages the heat pump.

Setting “No”, the control panel does not control the heat pump and must be cou-

H.P. control

Slave address

Menu item Description Range Default

Discharge Set min

Discharge Set max

External Temp. min

External Temp. max

pled with other Immergas systems (for example, TRIO, MAGIS HERCULES, Or

System manager). If “No” is set, it displays another item “slave address”.

N.B.: if it is erroneously set to “No”, it is still possible to change the selection.

Address to congure according to the zone where the device is installed (e.g.: zone 1

= 41, zone 2 = 42, zone 3 = 43, etc...).

voltar.com.ua

Menu Service -> ermoreg. Heat

Without the external probe it denes the minimum ow temperature that can be

set by the user. With the external probe present it denes the minimum ow temperature corresponding to operation with maximum external temperature

Without the external probe it denes the maximum ow temperature that can be

set by the user. With the external probe present it denes the maximum ow temperature corresponding to operation with minimum external temperature

With the external probe present it denes at what minimum external temperature

the system must operate at the maximum ow temperature

With the external probe present it denes at what maximum external temperature

the system must operate at the minimum ow temperature

voltar.com.ua

voltar.com.ua

voltar.com.ua

Yes / No Ye s

1 ÷ 247 -

20 ÷ 45 °C 30°C

35 ÷ 60 °C 50 °C

-25 ÷ +15 °C -5 °C

-5 ÷ +45 °C 20°C

voltar.com.ua

voltar.com.ua

voltar.com.ua

Menu Service -> ermoreg. Cool

Menu item Description Range Default

Without the external probe it denes the minimum ow that can be set by the user.

Discharge Set min

Discharge Set max

External Temp. min

External Temp. max

Menu item Description Range

Room probe modul.

System inertia

Antifreeze enable Enables the room antifreeze function Yes / No Yes

Antifreeze set Allows to set the room temperature for activation of the anti-freeze function 0 ÷ 10 °C 5 °C

With the external probe present it denes the minimum ow temperature corresponding to operation with maximum external temperature

Without the external probe it denes the maximum ow that can be set by the user.

With the external probe present it denes the maximum ow temperature corresponding to operation with minimum external temperature

With the external probe present, it denes at what maximum external temperature

the system must operate at the minimum ow temperature

With the external probe present, it denes at what minimum external temperature

the system must operate at the maximum ow temperature

voltar.com.ua

Menu Service -> ermoreg. Parameters

It enables you to set operation of the control panel as modulating on/o: Set “Yes”, the

ow temperature will be varied depending on the room temperature set. Set “No”, the

ow temperature will be kept constant until the desired room temperature is reached.

N.B.: if an outdoor temperature probe is present, the ow temperature will be set

depending on the relative functioning curve

It establishes the system reaction speed according to the type of system present.

Example:

5 system with little heat inertia

10 system with normal dimensions with radiators

20 system with a lot of heat inertia (e.g. oor-standing system)

voltar.com.ua

voltar.com.ua

voltar.com.ua

4 ÷ 20 °C 7 °C

10 ÷ 25 °C 12 °C

20 ÷ 45 °C 20°C

20 ÷ 45 °C 35 °C

voltar.com.ua

Yes / No Yes

1 ÷ 20 10

voltar.com.ua

14

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

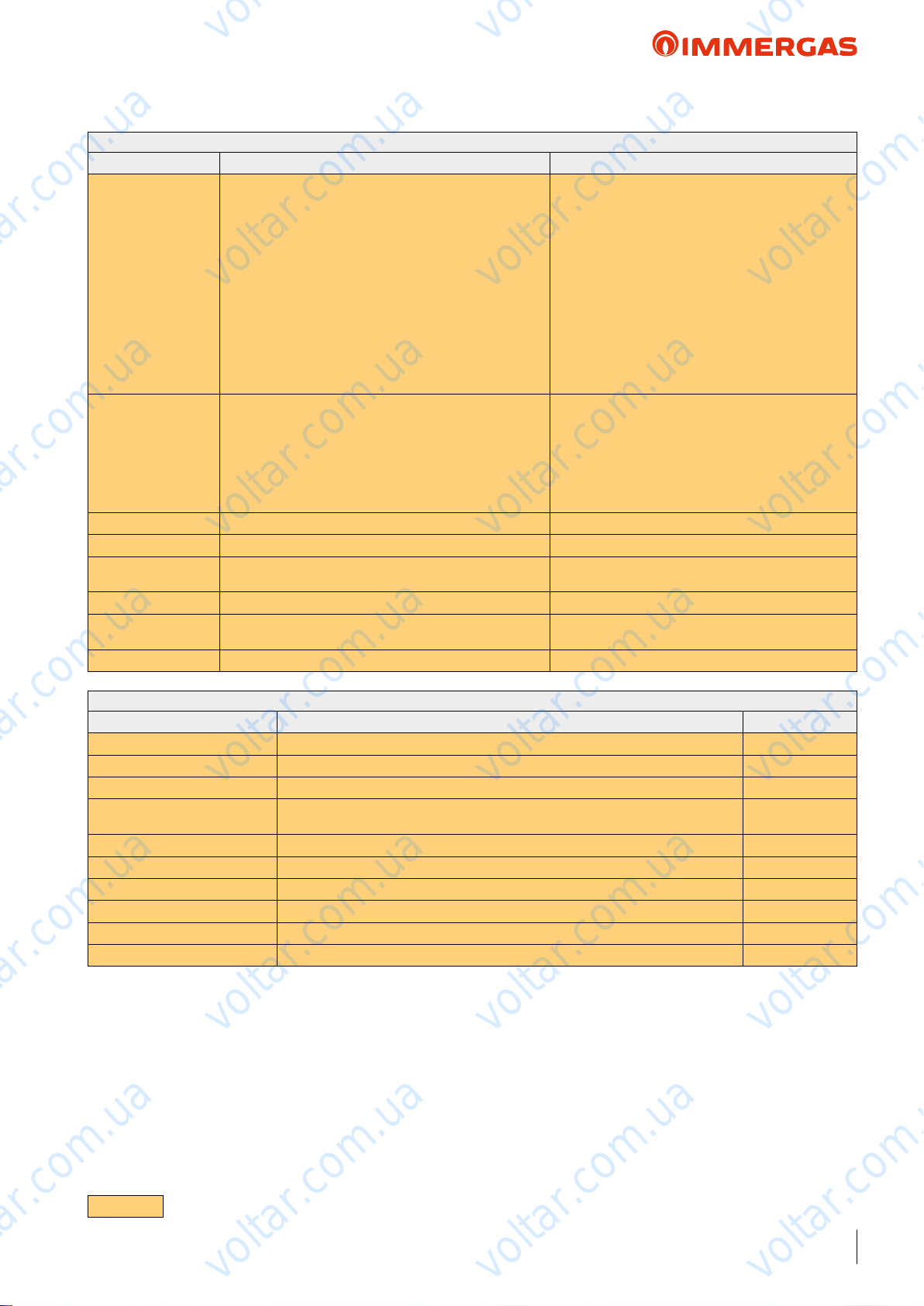

Menu Service -> Integration

Menu item Description Range Default

- None

- Sys.

Electrical integration

Contemp. Temp.

intgr.

Min. temp. of inte-

gration

Waiting time integra-

tion

Counter reset H.P. Reset the number of operating hours of the heat pump Yes / No No

Integration device It establishes the type of integration in the system

Min. Temp. of inte-

gration

Contemp. Temp.

integration

Waiting time integra-

tion

Counter Reset H.P. Reset the number of operating hours of the heat pump Yes / No No

It establishes the type of integration in the system: “Sys.” enables the system integration, “San” the DHW integration, “San+Sys.” enables both integrations

voltar.com.ua

Temperature threshold below which integration is activated and the heat pump

maintained on.

Temperature threshold below which integration is activated and the heat pump is

switched o.

Standby to reach the set value before activating integration when outdoor temperature is below the previously set temperature values (minimum integration temperature and simultaneous integration temperature).

Temperature threshold below which integration is activated and the heat pump is

switched o

voltar.com.ua

A value that is equal to, or higher than, the minimum integration temperature must

be set.

Activate central heating integration when the outdoor temperature is below the set

value, the set intake requested has not been reached, and the heat pump remains

active

Standby to reach the set value before activating integration when outdoor temperature is below the previously set temperature values (minimum integration temperature and simultaneous integration temperature)

voltar.com.ua

voltar.com.ua

- N.A.

- N.A.

- N.A.

- San

- San + Sys.

-20 ÷ +15 °C -20 °C

-20 ÷ +15 °C -20 °C

5 ÷ 120’ 60’

- None

- Electrical resistance

-20 ÷ +30 °C -20 °C

0 ÷ 60 °C 20°C

0 ÷ 600’ 60’

voltar.com.ua

voltar.com.ua

None

None

Menu Service -> Heat pump

Menu item Description Range

Flow temperature Instant outlet temperature from the system

Flow temp. system calc. Flow temperature requested by the generators

Comp. discharge temp. Current heat pump compressor temperature 0 ÷ 100 °C

Comp. suction temp. Compressor inlet temperature -20 ÷ 100 °C

BPHE refrigerant temp. Coolant temperature inside the plate heat exchanger -20 ÷ 100 °C

Coil refrigerant temp. Battery temperature -20 ÷ 100 °C

Outdoor Air Temp. Room temperature -20 ÷ 100 °C

Max freq. compressor Maximum frequency in current operating conditions 0 ÷ 200 Hz

Requested frequency Frequency requested by the control board 0 ÷ 200 Hz

Actual frequency Current compressor frequency 0 ÷ 200 Hz

Compressor runtime Number of hours of operation of the compressor

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 6 - 8 - 12 - 16 ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

15

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

Menu Service -> Heat pump

0 = O

1 = Standby

2 = Cooling

3 = Central heating

4 = Extra central heating

5 = Extra cooling

System mode Indicates the system's operating mode

voltar.com.ua

Flow switch Indicates circulation inside the hydraulic circulator On / O

Flag anomalies H

Flag anomalies L

Communication status

Indicates any multiple anomalies on the heat pump

Indicates the communication status between the control panel and heat

pump

2 or more than 2 = communication OK

0 = communication problem

voltar.com.ua

6 = Central heating reduction

7 = Cooling reduction

8 = Antifreeze protection

9 = Defrosting

10 = High temperature protection

11 = Surveillance time

12 = Anomaly

voltar.com.ua

voltar.com.ua

voltar.com.ua

Menu item Description Range

0 = No manual forcing

1 = “On” heat pump circulator

2 = “On” alarm outlet on clamp N° 5

Manual

N.B: Before exiting this menu, remember to bring the value to “0” (zero) for correct operation.

3 = “On” external circulator on clamp N° 4

4 = Alarm/defrosting outlet on clamp N° 11

5 = Outlet for integration resistance on clamp N° 12

6 = DHW 3-way valve outlet on clamp N°10

Menu Service -> Manual

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

0 ÷ 6

voltar.com.ua

16

voltar.com.ua

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 6 - 8 - 12 - 16 ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

Menu Heat Pump

Menu item Description Range

Working parameters Sub-menu for working data -

State Sub-menu for operating state -

Auxiliary info Sub-menu with other operating data -

P.C.B. settings Sub-menu to congure the P.C.B.

voltar.com.ua

voltar.com.ua

Menu item Description Range

Flow temperature Instant outlet temperature from the system

Return temperature Instant inlet temperature to the system

Calculated system temperature

set

Compressor outlet temperature Current heat pump compressor temperature

Compressor intake temperature Compressor inlet temperature

Compressor intake sat. temper-

ature

Coolant temperature on ex-

changer

Coil temperature low part Coil temperature, low side

Coil temperature high part Coil temperature, high side

External Temperature External room temperature

PdC frequency Current compressor frequency

System mode Indicates the system's operating mode

voltar.com.ua

Flow temperature requested by the generator

Compressor inlet saturation temperature

Coolant temperature inside the plate heat exchanger

Menu Heat Pump -> Working parameters

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

0=O

1 = Cooling

2 = Central heating

4 = DHW

6 = Central heating integration

7 = Defrosting

24 = DHW met

100 = Anomaly

101 = Cooling anomaly

102 = Central heating anomaly

104 = DHW anomaly

106 = Integration anomaly

107 = Defrosting anomaly

voltar.com.ua

voltar.com.ua

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

17

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

Menu Heat Pump -> State

Menu item Description Range

0 = O

1 = Wait after ignition

2 = Minimum compressor on time

3 = Minimum compressor o time

voltar.com.ua

voltar.com.ua

System stat Indicates the current system mode

voltar.com.ua

4 = delay for mode change

voltar.com.ua

5 = Step 1 compressor

6 = Step 2 compressor

7 = Step 3 compressor

8 = Step 4 compressor

9 = Compressor stop delay

11 - Frequency reduction on

20 = Defrosting

39 = Minimum external temperature for central

heating

40 = Maximum external temperature for central

heating

41 = Maximum ow/return value in central heating

42 = Low external temperature in central heating

43 = Very high external temperature in central heating

44 = High external temperature (compressor limita-

voltar.com.ua

tion)

45 = Step 1 High temperature protection in central

heating

46 = Step 2 High temperature protection in central

heating

47 = Step 3 High temperature protection in central

heating

48 = Step 4 High temperature protection in central

heating

50 = Minimum external temperature for cooling phase

51 = Minimum machine inlet temperature for cooling

phase

52 = External temperature <15°C in cooling phase

53 = External temperature >26°C in cooling phase

54 = External temperature >40°C in cooling phase

voltar.com.ua

55 = Low saturation temperature

57 = Step 2 antifreeze protection in cooling

58 = Step 1 antifreeze protection in cooling

61 = External temperature <0°C and ow temperature

> 12°C in cooling phase

62 = External temperature <0°C in cooling phase

70 = Protection for lack of ow rate

80 = Protection for oil return

85 = Compressor o from inverter

91 = Central heating integration

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

18

voltar.com.ua

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

Menu Heat Pump -> State

Menu item Description Range

-1 = integration disabled

0 = O

1 = Integration on

2 = Integration on

3 = Integration on during defrosting

Integration status Indicates the operating mode of the part of integration

DHW state Indicates the operating mode during DHW request

voltar.com.ua

voltar.com.ua

4 = Integration on for heat pump anomaly

5 = Integration on for low external temperature

12 = Integration o for DHW request

13 = Capacity Limit

50 = Integration not allowed

51 = No CH request

100 = Integration anomaly

-1 = DHW disabled

0 = DHW enabled

1 = DHW not active (request for central heating or

cooling)

2 = ree-way DHW drive

100 = DHW anomaly

voltar.com.ua

voltar.com.ua

Flow switch Indicates circulation inside the hydraulic circulator On/o

Input status On/o Indicates the input state for the on/o control On/O

DHW Request

Input status reduction Indicates the input state for the reduction control On/O

Fault

(Current alarm code)

Fault Inverter Inverter anomaly code

Menu item Description Range

Overheating temp. Indicates the overheated gas temperature

Overheating target temp. Indicates the overheated gas required temperature

Inverter Temp. Indicates the inverter temperature

Max freq. compressor

Requested frequency Indicates the frequency requested from the compressor

Fan speed Top Indicates the upper fan speed

Fan speed Low Indicates the lower fan speed

Circulator speed Indicates the pump speed

Water control point Temperature control set

Water temp. control Reference probe for the temperature control set

voltar.com.ua

Indicates the presence of a heat request by the DHW

storage

Current anomaly code

Menu Heat Pump -> Auxiliary info

voltar.com.ua

Indicates the maximum frequency that can be reached by the compressor with the

present conditions

voltar.com.ua

voltar.com.ua

On/O

voltar.com.ua

voltar.com.ua

voltar.com.ua

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

19

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

Menu Heat Pump -> P.C.B. settings

Menu item Description Range

- Central heating

Unit Type It establishes whether the machine is of reversible type

voltar.com.ua

Unit Size It establishes the Unit power

Power Supply

integration

voltar.com.ua

It denes the Unit power supply voltage 230Vac - 400Vac

voltar.com.ua

voltar.com.ua

- Cooling

- Central heating + Cooling

- 6 KW

- N.A.

- 8 KW

- N.A.

- N.A.

- N.A.

- 12 KW

- N.A.

- N.A.

- N.A.

- 16 KW

- N.A.

- 18 KW

- N.A.

- N.A.

- 21 KW

voltar.com.ua

voltar.com.ua

voltar.com.ua

Menu Service -> Test switch Max. press.

Menu item Description Range

0 = O

1 = Test required

N.B. the following states are managed by

the machine DO NOT USE

Test method for high pressure switch.

Test pressure switch

N.B. to run the test, set the value to 1 and wait for the test result

voltar.com.ua

Menu Service -> Manual

Menu item Description Range Default

Forcing of the heat pump operation

Manual operation

N.B. all controls on the ow and return sensors are disabled with these

voltar.com.ua

modes.

voltar.com.ua

voltar.com.ua

2 = AP Test in progress

3 = AP Test performed correctly

4 = AP Test failed for maximum time

reached

5 = AP Test failed for ow switch error

6 = AP Test failed for low water temperature

7 = AP Test failed for inverter error

0 = O

1 = Test cooling

2 = Test central heating

3 = Test cooling with

ramp

4 = Test central heating

with ramp

voltar.com.ua

0

voltar.com.ua

Circulator speed Pump speed forcing 0% ÷100% 0%

Flow switch Indicates circulation inside the hydraulic circulator O/On

ree way DHW Force the output for the DHW 3-way control O/On O

N.B. PARAMETERS ONLY VALID FOR AUDAX TOP 18 - 21 ErP

20

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

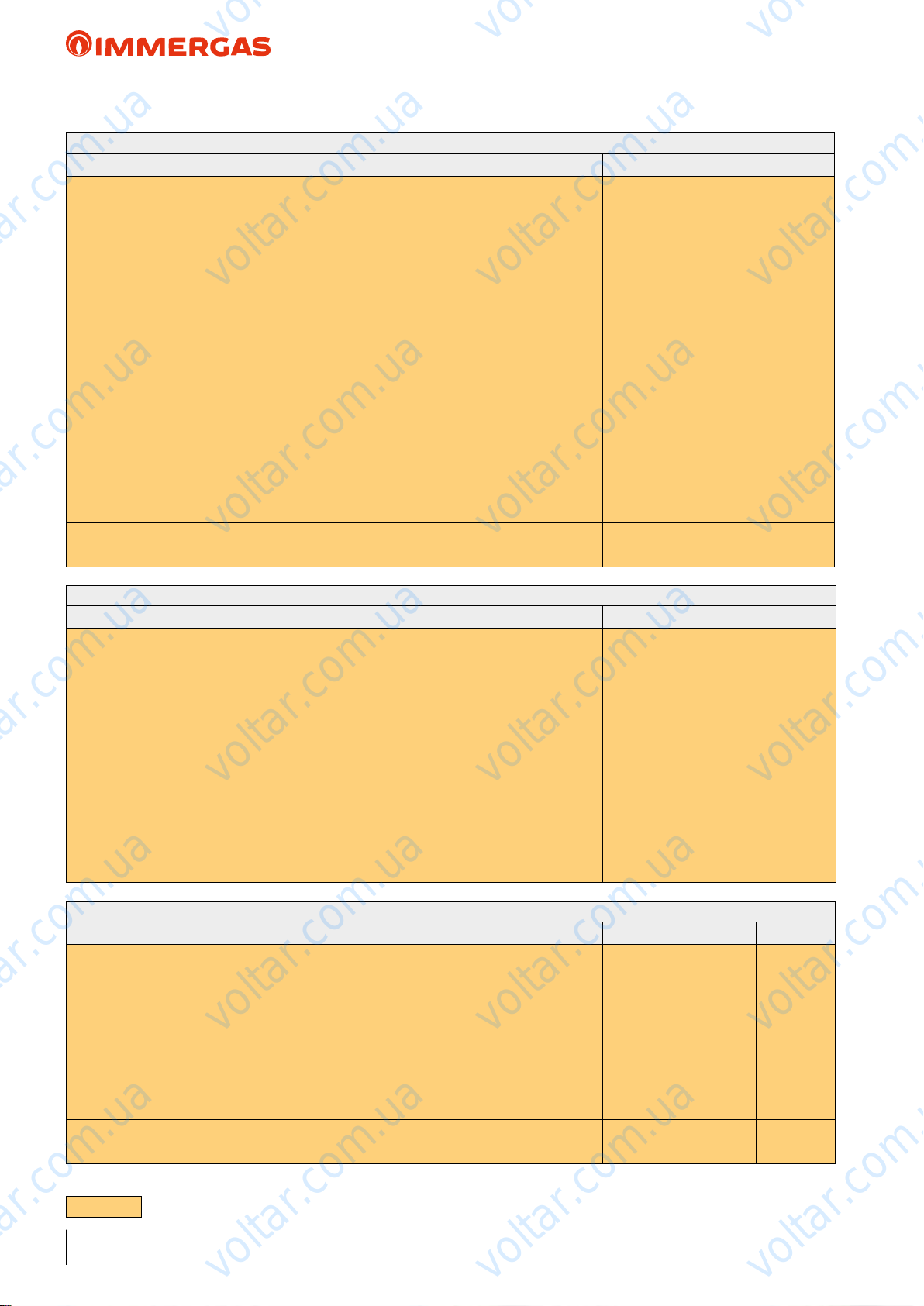

6 AUDAX TOP 6 8 12 16 ErP DIMENSIONS AND CONNECTIONS

voltar.com.ua

voltar.com.ua

System return = 1"M

voltar.com.ua

Condensate drain pipe and pre-cut holes in the

base. If draining is carried out through the drain pipe,

connect the drain tting (A) supplied, and use the

drain pipe (internal diameter: 16 mm) available on the

market. In the event of installation in very cold zones

or zones subject to heavy snow where the condensate

drain pipe can freeze, check the draining capacity of

the pipe. Draining capacity increases when the pre-cut

holes at the base, which collect condensate, are open

(open the pre-cut holes outwards with the aid of a

hammer with smooth edges).

N.B.: e gure on the side shows the measurements

to use to secure the machine (600 x 363). You must

insert the vibration-dampening devices supplied with

the product between AUDAX TOP ErP and the

support base.

voltar.com.ua

System ow = 1"M

voltar.com.ua

voltar.com.ua

600 051051

37

B

voltar.com.ua

363

400

voltar.com.ua

voltar.com.ua

430

voltar.com.ua

A

AUDAX TOP

ErP

6 kW

single phase

8 kW

single phase

12 kW

single phase

16 kW

three phase

A B C D E F G H L

908 821 326 350 87 356 466 40 60 61

voltar.com.ua

908 821 326 350 87 356 466 40 60 69

908 1363 326 350 174 640 750 44 69 104

908 1363 326 350 174 640 750 44 69 116

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

21

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

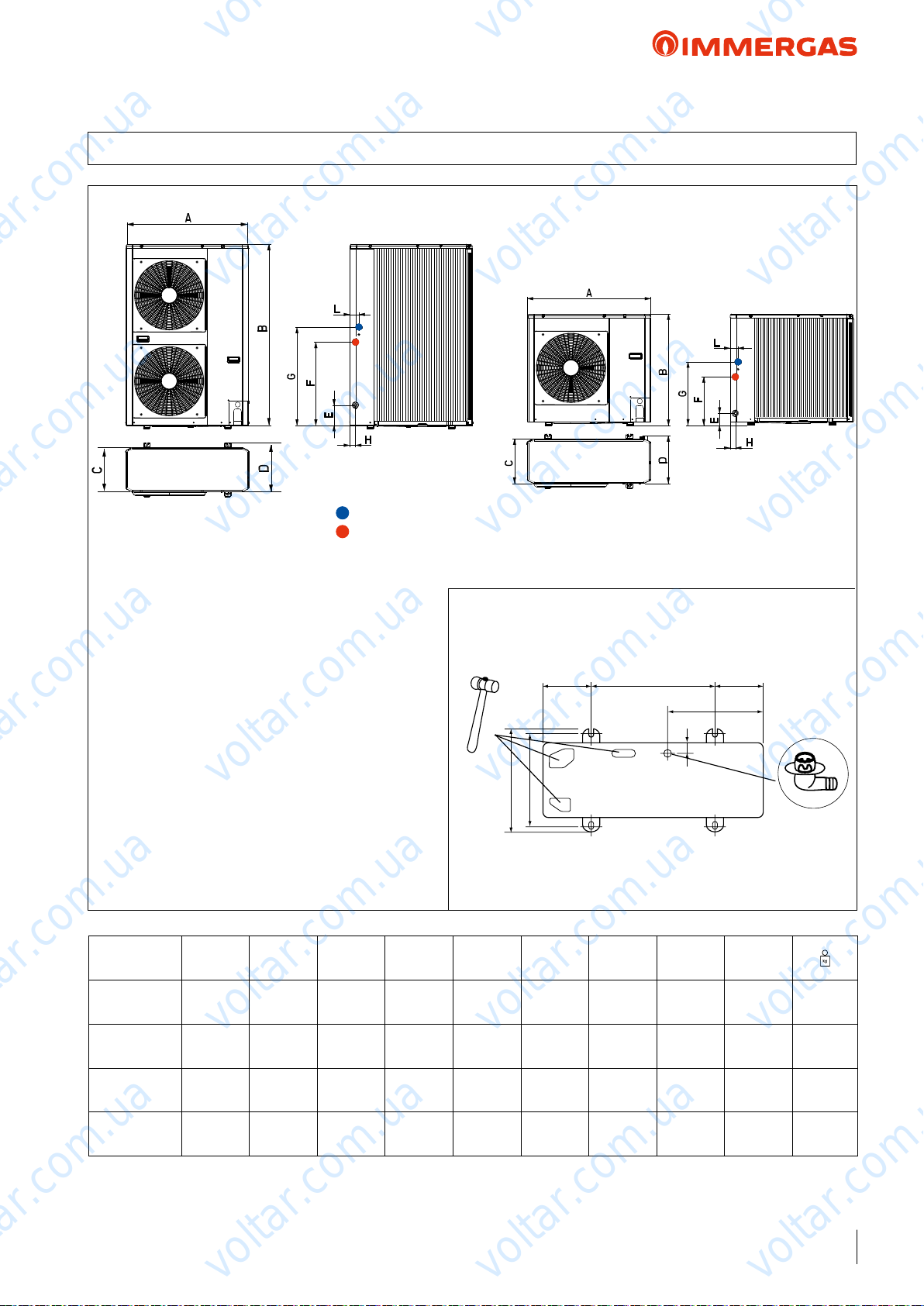

6.1 AUDAX TOP 18 21 ErP DIMENSIONS AND CONNECTIONS

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

Slots for condensate drain. Any condensate is drained

through the slots created under the nned barrier. In

the event of installation in very cold zones or zones

subject to heavy snow where the condensate can freeze,

take the necessary precautions to prevent any frozen

zones from causing falls or accidents.

N.B.: e following gure shows the measurements

to use to secure the machine (660 x 535). You must

insert the vibration-dampening devices supplied with

the product between AUDAX TOP 18 - 21 ErP and

the support base. Immergas proposes a kit made up of

4 vibration-dampening feet (optional) code 3.027654.

voltar.com.ua

System return = 1"1/4 M *

voltar.com.ua

System ow = 1"M

*1” M Reduction standard supplied

voltar.com.ua

voltar.com.ua

voltar.com.ua

22

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

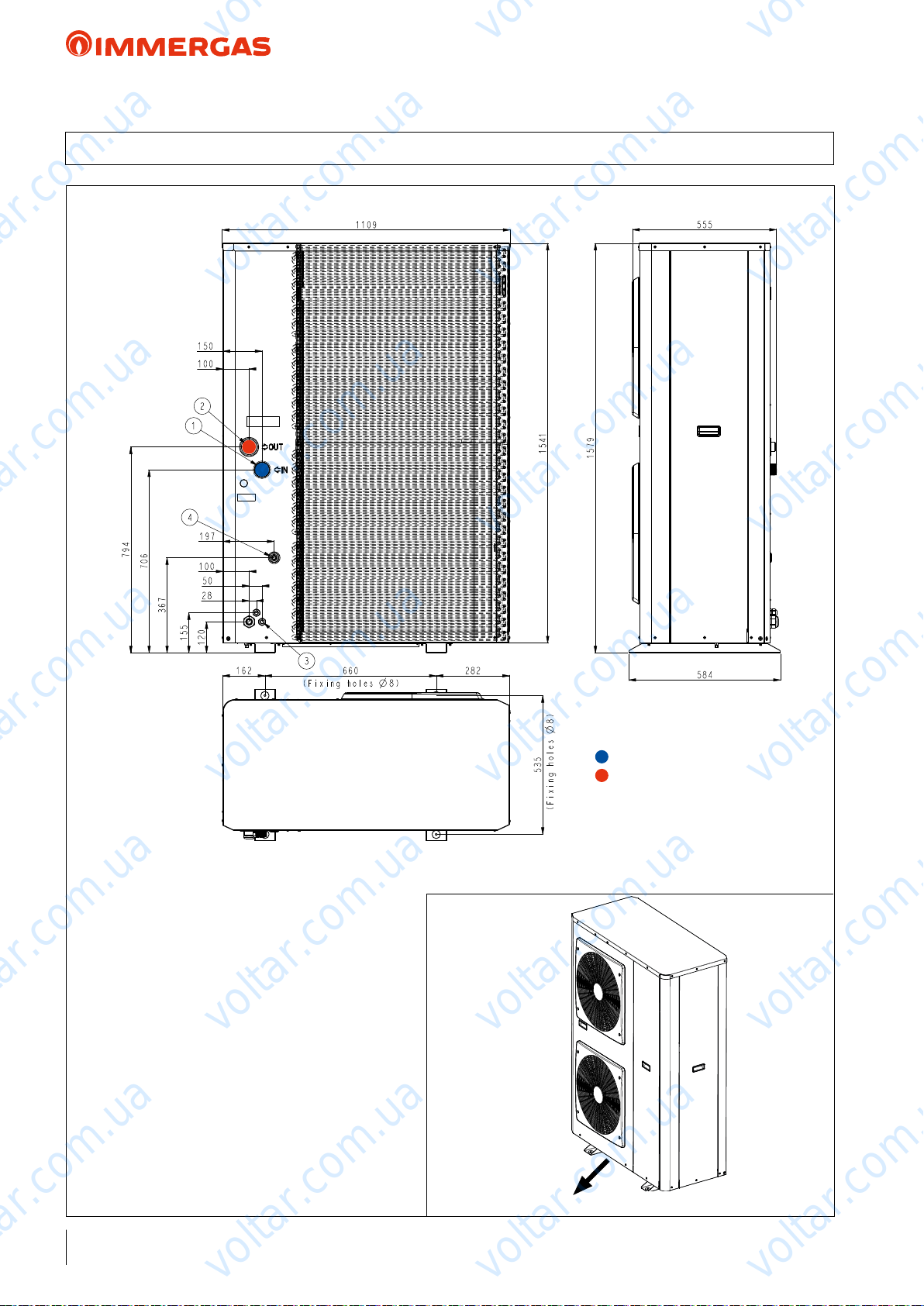

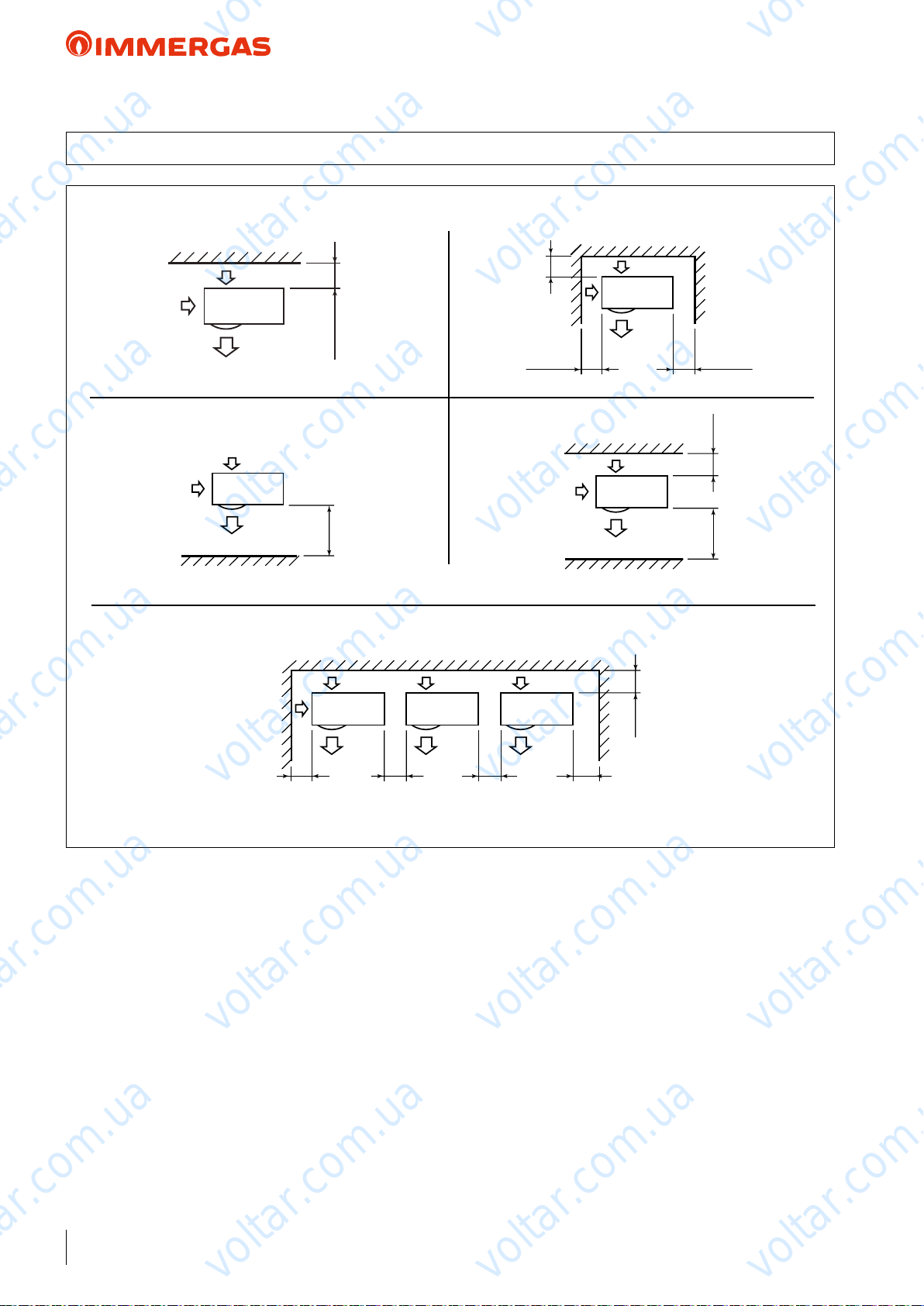

7 AUDAX TOP 6 8 12 16 ErP MINIMUM INSTALLATION DISTANCES

150

voltar.com.ua

500

voltar.com.ua

200

voltar.com.ua

voltar.com.ua

150

500

voltar.com.ua

150150

300300

300

voltar.com.ua

200

150

1000

1000

voltar.com.ua

voltar.com.ua

003051

1000

voltar.com.ua

1000

voltar.com.ua

200

300

300

1000

voltar.com.ua

voltar.com.ua

300

000200510001

voltar.com.ua

voltar.com.ua

200

voltar.com.ua

23

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

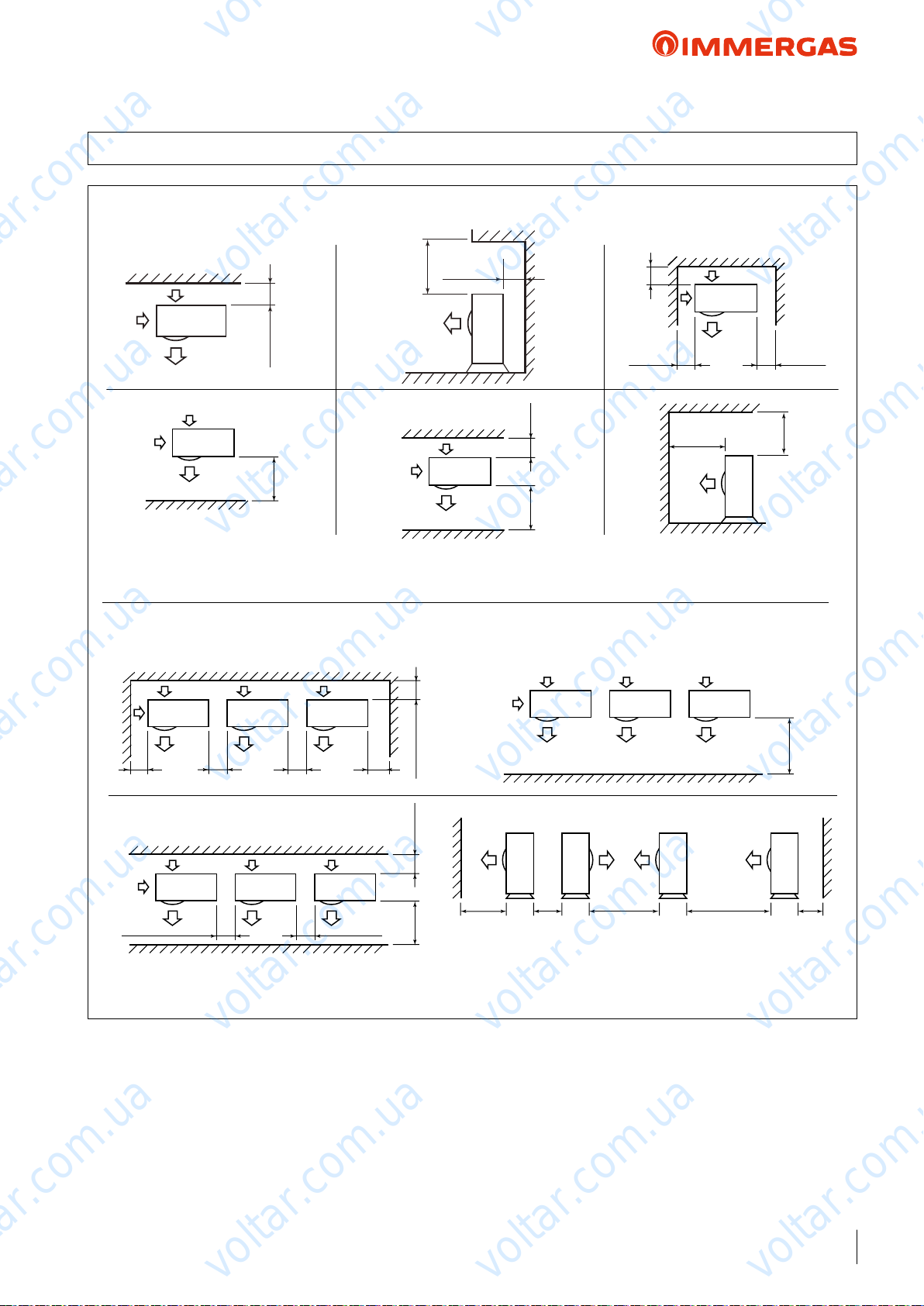

7.1 AUDAX TOP 18 21 ErP MINIMUM INSTALLATION DISTANCES

voltar.com.ua

voltar.com.ua

200

voltar.com.ua

1000

voltar.com.ua

300

5000200

200

voltar.com.ua

1000

voltar.com.ua

voltar.com.ua

voltar.com.ua

Place of installation:

e place of installation is very important and must be established by the system's designer or by a specically qualied

person, and must consider the technical requirements, standards

and laws in force.

• e unit must be installed outdoors only;

• It is recommended to avoid:

- positioning in basement windows

- obstacles or barriers that cause recirculation of exhaust air;

- places with aggressive atmospheres;

- limited spaces or anyhow in places where sound levels from

the appliance can be enhanced through reverberations or

resonance;

- positioning in corners where there is an accumulation of dust,

leaves and anything else that can reduce the appliance's eciency due to blocked passageways;

- prevent exhaust air from the device from coming into the rooms

through doors or windows, thus disturbing people;

voltar.com.ua

300

voltar.com.ua

500 500500200

• e appliances must:

- be placed on a level surface that is able to withstand its weight;

- be placed on a slab that is hard enough and which does not

transfer any vibrations to the underlying or adjacent rooms;

- use the vibration-dampening supports supplied with the

machine.

• If the unit is installed in zones subject to heavy snow, it will

voltar.com.ua

be necessary to raise the machine by at least 200 mm above

the normal level reached by the snow, or alternatively use the

wall-support bracket (optional).

• If deectors are present to protect the unit against strong winds,

these deectors must be studied so as to avoid obstructing the

normal air circulation.

voltar.com.ua

voltar.com.ua

24

voltar.com.ua

voltar.com.ua

voltar.com.ua

6

5

2

4

1

7

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

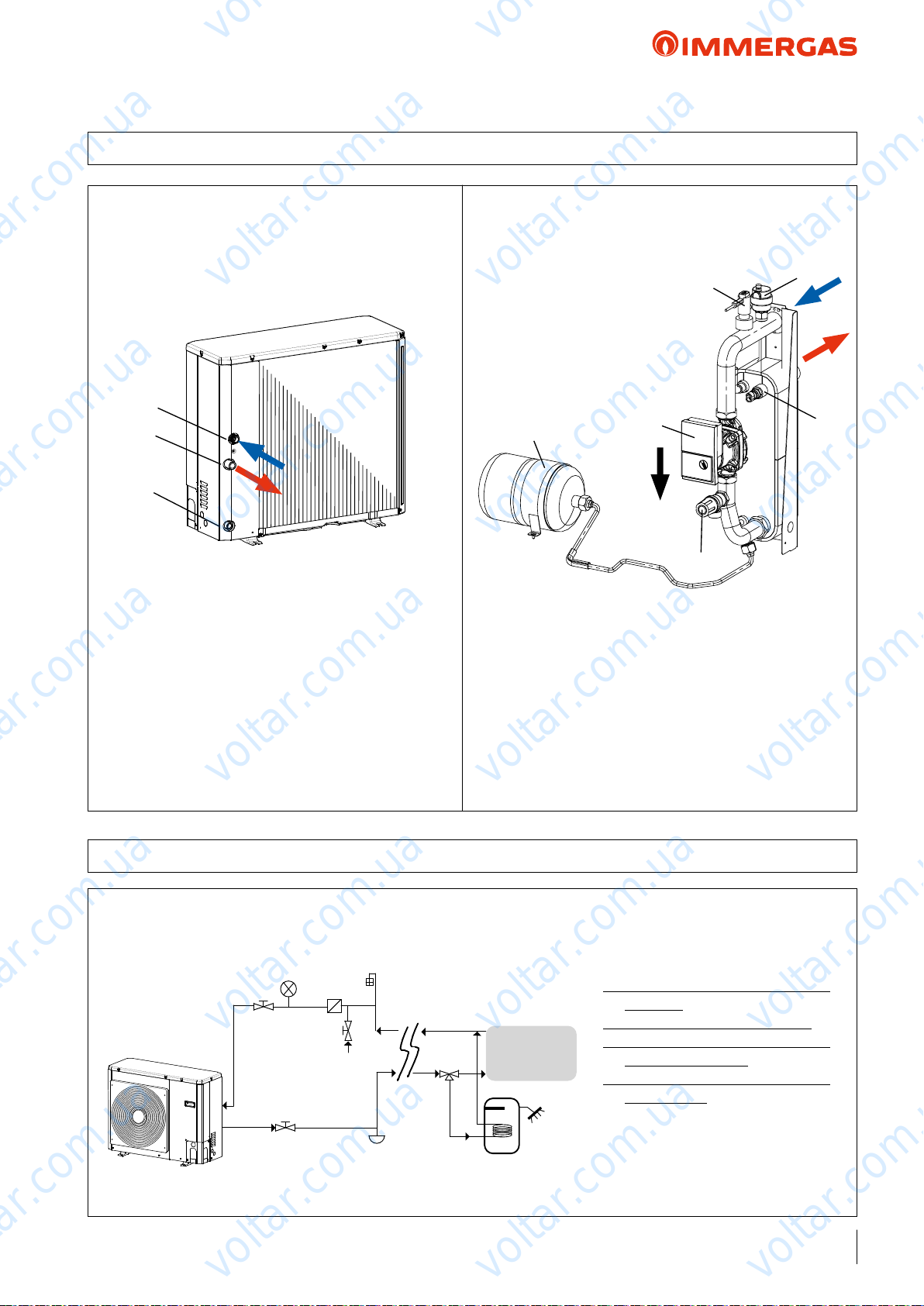

8 AUDAX TOP 6 8 ErP HYDRAULIC CIRCUIT COMPONENTS

voltar.com.ua

voltar.com.ua

1

2

3

voltar.com.ua

KEY:

1 - System return tting 1"M

2 - System ow tting 1"M

3 - Water drain

voltar.com.ua

voltar.com.ua

7

5

2

voltar.com.ua

3

KEY:

1 - Automatic air vent valve

2 - Flow switch

3 - Safety valve (outlet 1/2’)

4 - Temperature probe

5 - Circulation pump

7 - Expansion vessel

voltar.com.ua

1

voltar.com.ua

4

voltar.com.ua

voltar.com.ua

8.1 AUDAX TOP 6 8 ErP HYDRAULIC DIAGRAM

e diagram is purely indicative and not limited to the hydraulic circuit.

Also see the example on page 90-91

3

1

voltar.com.ua

1

2

6

4

3

voltar.com.ua

voltar.com.ua

7

5

8

voltar.com.ua

9

KEY:

1 - Shut-o valve

2 - Water line lters (standard)

3 - Pressure gauge (not supplied - to be

provided)

4 - Filling valve (NOT Automatic)

5 - System draining valve (in the lowest

points of the circuit)

6 - Air vent valve (in the highest points

of the circuit)

7 - 3-way valve

8 - DHW storage tank

9 - Internal utility

voltar.com.ua

25

voltar.com.ua

1

2

3

3

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

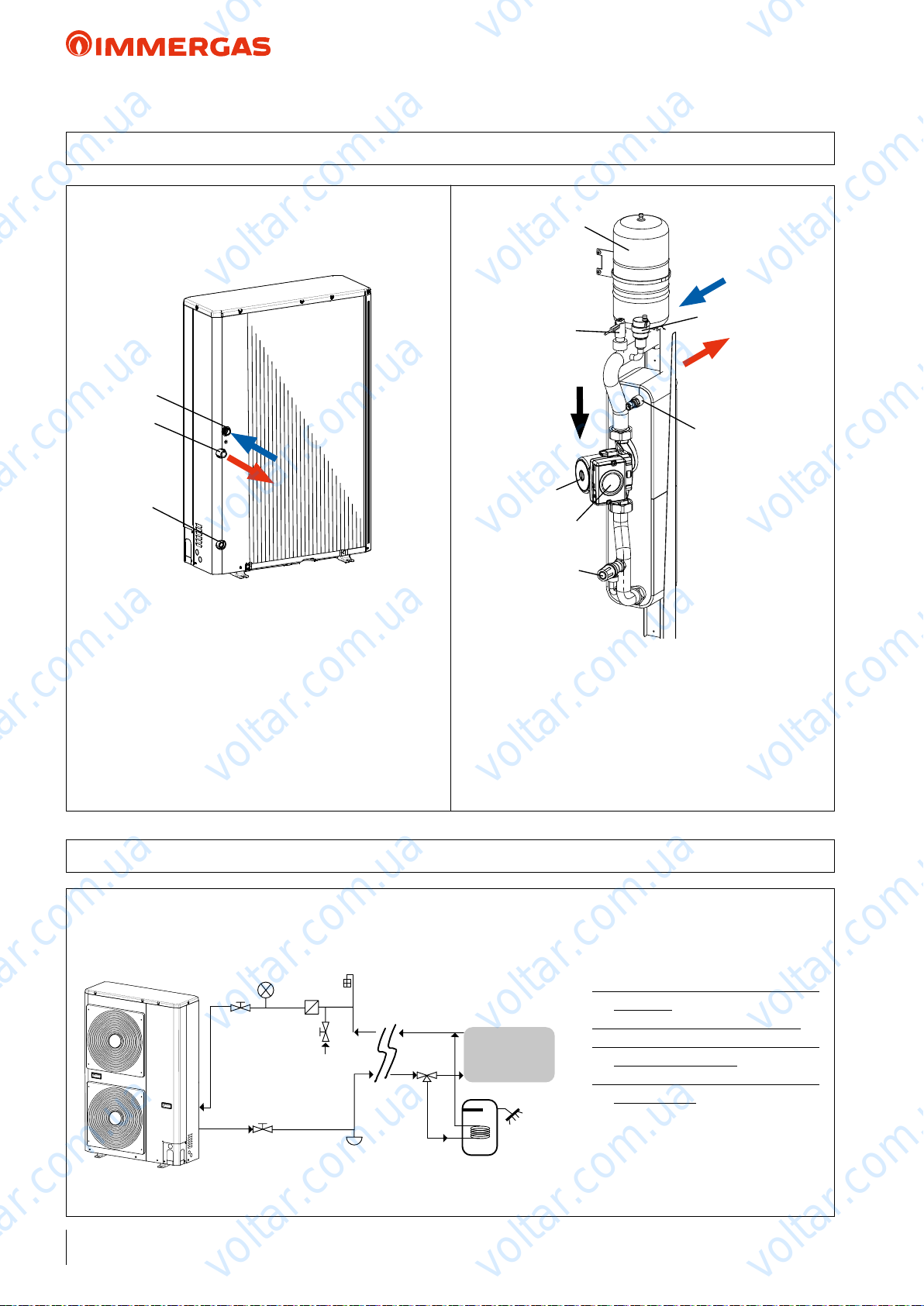

8.2 AUDAX TOP 12 16 ErP HYDRAULIC CIRCUIT COMPONENTS

7

voltar.com.ua

voltar.com.ua

1

2

3

voltar.com.ua

KEY:

1 - System return tting 1"M

2 - System ow tting 1"M

3 - Water drain

voltar.com.ua

voltar.com.ua

2

6

voltar.com.ua

KEY:

1 - Automatic air vent valve

2 - Flow switch

3 - Safety valve (outlet 1/2’)

4 - Temperature probe

5 - Circulation pump

7 - Expansion vessel

5

3

1

4

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

8.3 AUDAX TOP 12 16 ErP HYDRAULIC DIAGRAM

e diagram is purely indicative and not limited to the hydraulic circuit.

Also see the example on page 90-91

26

1

voltar.com.ua

1

2

6

4

3

7

5

voltar.com.ua

voltar.com.ua

9

8

voltar.com.ua

KEY:

1 - Shut-o valve

2 - Water line lters (standard)

3 - Pressure gauge (not supplied - to be

provided)

4 - Filling valve (NOT Automatic)

5 - System draining valve (in the lowest

points of the circuit)

6 - Air vent valve (in the highest points

of the circuit)

7 - 3-way valve

8 - DHW storage tank

9 - Internal utility

voltar.com.ua

voltar.com.ua

1

2

3

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

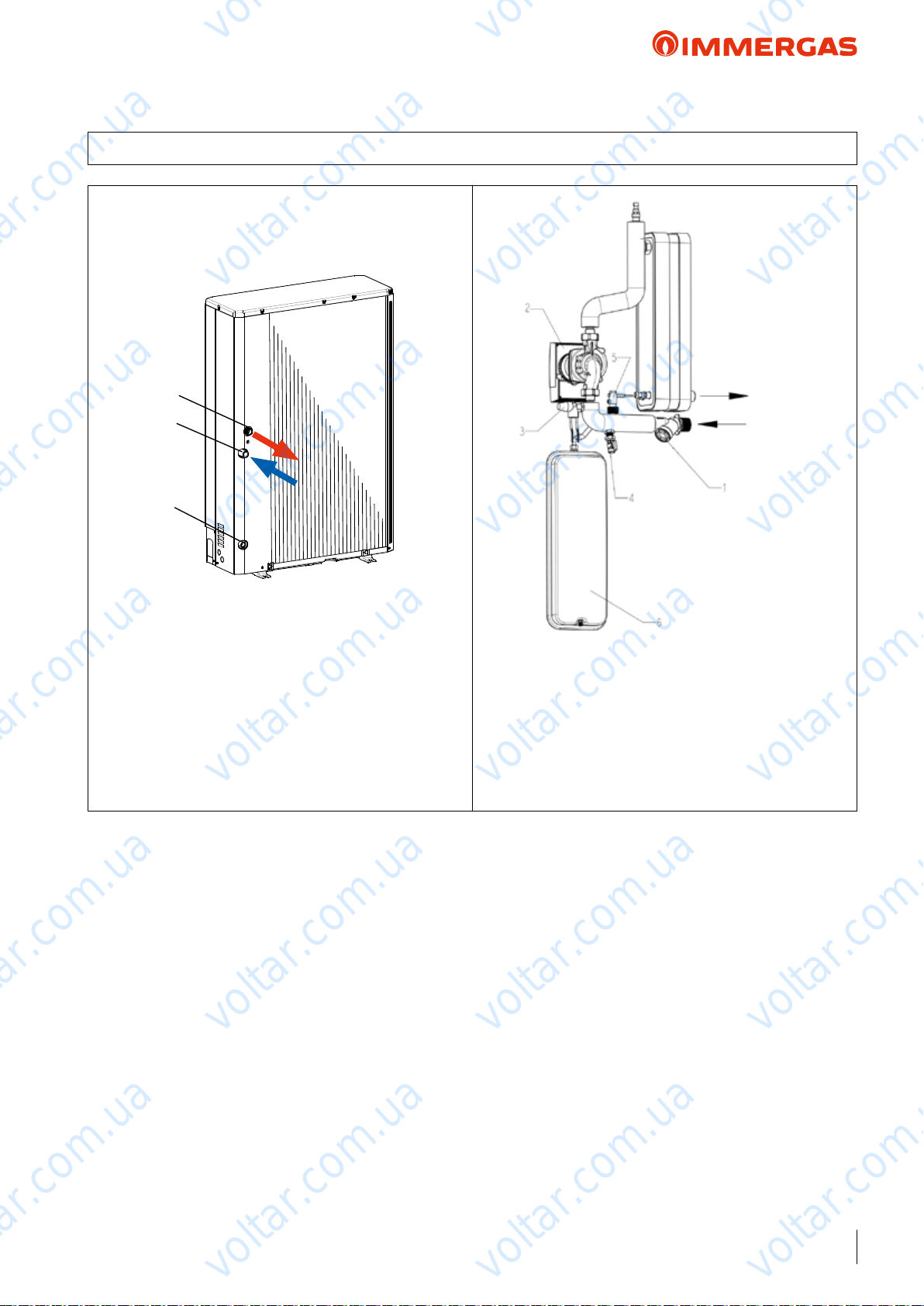

8.4 AUDAX TOP 18 21 ErP HYDRAULIC CIRCUIT COMPONENTS

voltar.com.ua

voltar.com.ua

1

2

3

voltar.com.ua

KEY:

1 - System ow tting 1''M

2 - System return tting 1"1/4 M*

3 - Water drain

*1”M Reduction standard supplied

voltar.com.ua

voltar.com.ua

OUTLET

INLET

voltar.com.ua

KEY:

1 - Mesh lter

2 - Circulation pump

3 - Safety valve

4 - Water drain valve

5 - Blade ow switch

voltar.com.ua

6 - Expansion vessel

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

voltar.com.ua

27

voltar.com.ua

X2

10

15

20

25

30

35

40

45

50

55

60

65

70

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

X2

Y2

AUDAX TOP 8-12-16

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP ErP

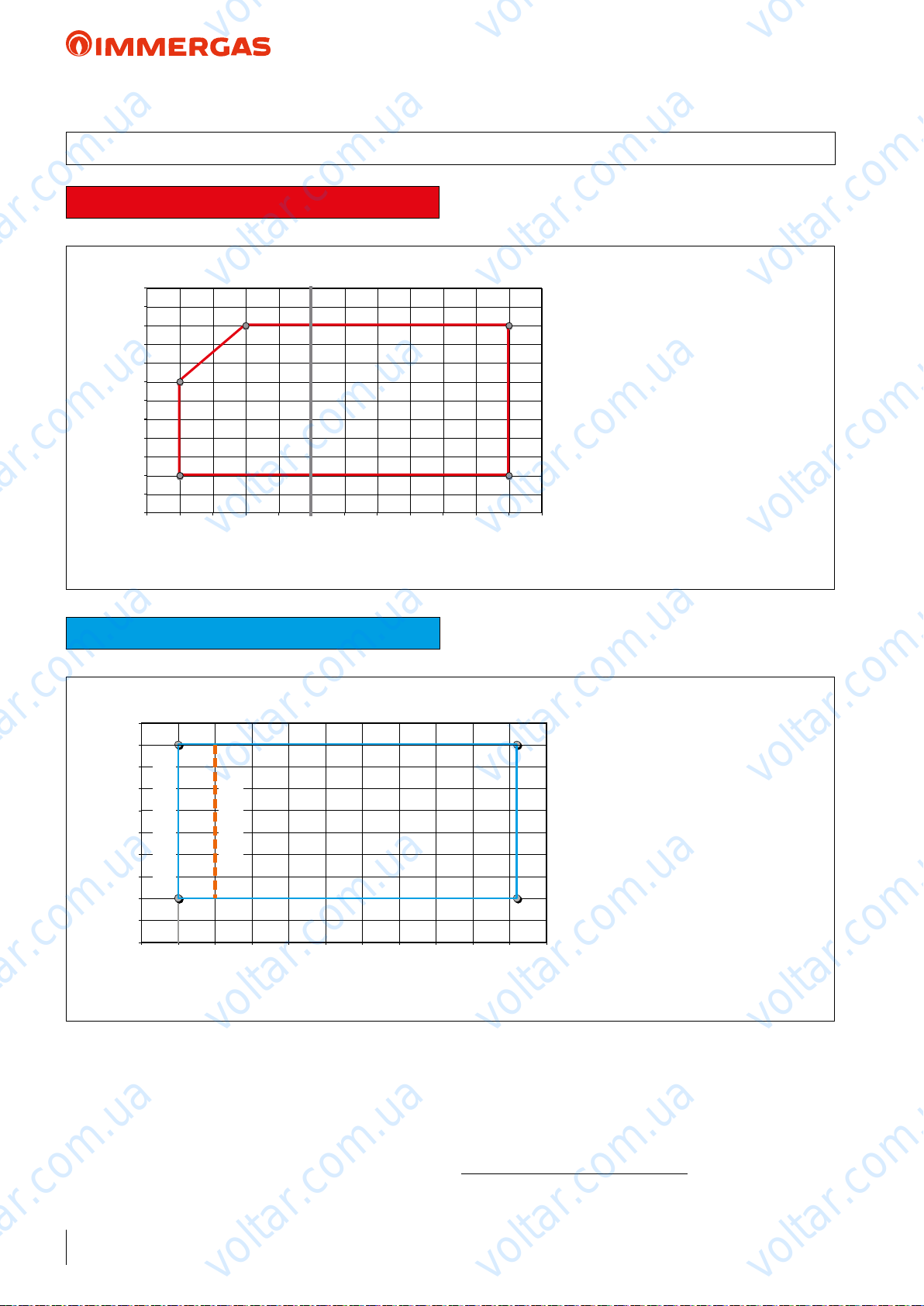

9 AUDAX TOP 6 8 12 16 ErP OPERATING LIMITS AND ANTIFREEZE FUNCTION

Central heating

70

65

60

55

50

45

40

Y2

35

30

25

20

15

10

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

Y1

20

18

16

14

12

10

8

6

4

2

0

-5

voltar.com.ua

voltar.com.ua

Cooling

voltar.com.ua

AUDAX TOP 6

0

105

15 20 25 30 35

voltar.com.ua

KEY:

Y2 - Flow water temperature (°C)

X2 - Outdoor air temperature (°C)

voltar.com.ua

KEY:

Y1 - Flow water temperature (°C)

voltar.com.ua

40

45

X1 - Outdoor air temperature (°C)

50

voltar.com.ua

voltar.com.ua

voltar.com.ua

X1

voltar.com.ua

NOTE: AUDAX TOP ErP is equipped with antifreeze protection up to -10 °C with supply voltage. If AUDAX TOP

ErP is installed in areas having temperatures below 0 °C, it is

recommended to provide special antifreeze systems in order to

guarantee the machine's integrity, especially the water-gas heat

exchanger, when there is a blackout.

For example, insert top quality, non-hazardous antifreeze liquid

into the heating system. In this case, the instructions of the

manufacturer of this liquid must be followed scrupulously re-

28

voltar.com.ua

voltar.com.ua

garding the percentage necessary with respect to the minimum

temperature at which the system must be kept.

An aqueous solution must be made with potential pollution class

of water 2 (EN 1717:2002).

With no supply voltage and if no antifreeze liquid has been

inserted, you must drain the water from the machine.

Avoid using automatic lling systems.

voltar.com.ua

voltar.com.ua

voltar.com.ua

10

15

20

25

30

35

40

45

50

55

60

65

70

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

X2

Y2

AUDAX 18 TOP ErP

AUDAX 21 TOP ErP

voltar.com.ua

voltar.com.ua

voltar.com.ua

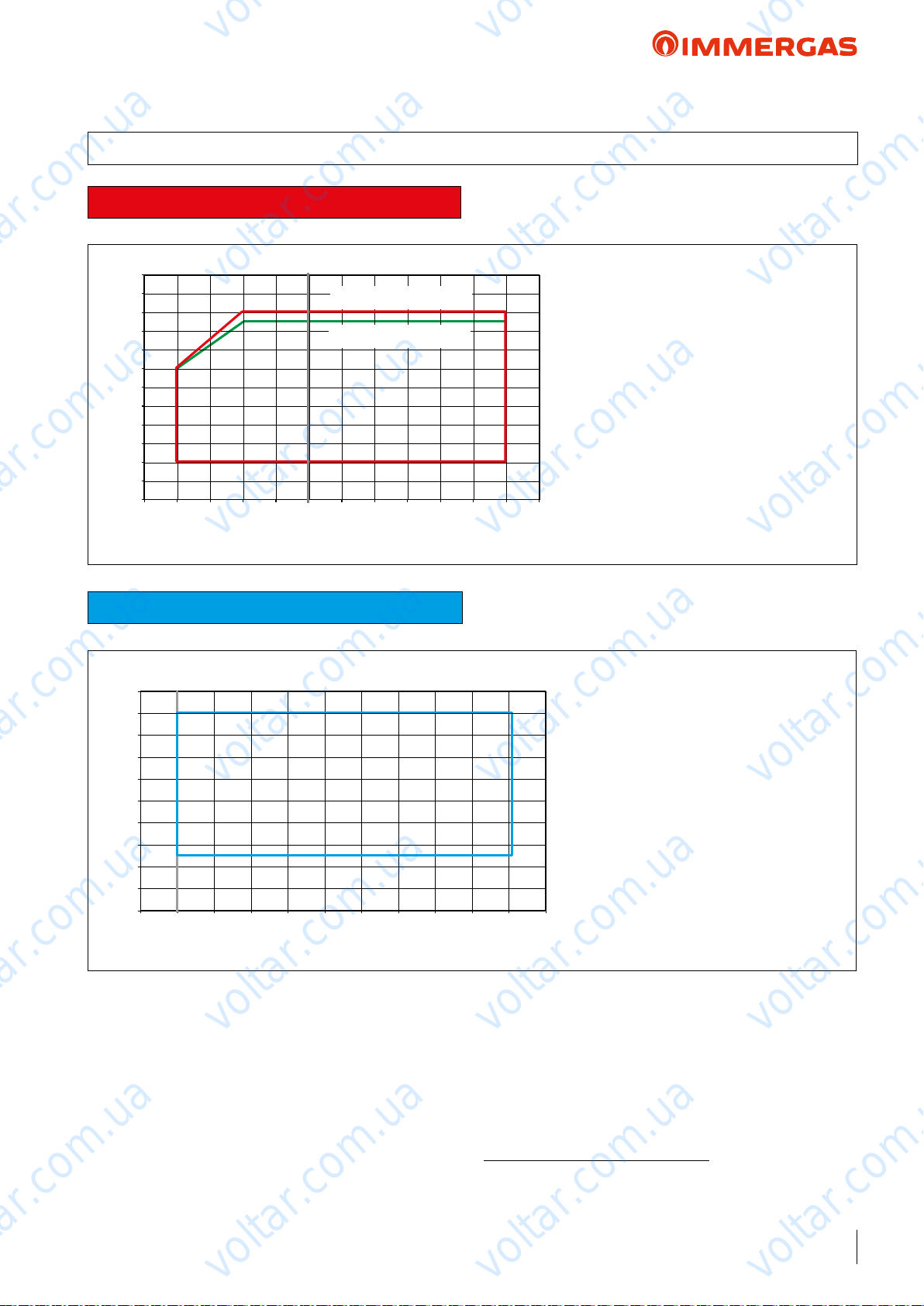

AUDAX TOP ErP

9.1 AUDAX TOP 18 21 ErP OPERATING LIMITS AND ANTIFREEZE FUNCTION

Central heating

70

65

60

55

50

45

40

Y2

35

30

25

20

15

10

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35

Y1

20

18

16

14

12

10

8

6

4

2

0

-5

0

voltar.com.ua

voltar.com.ua

Cooling

AUDAX 18 TOP ErP

AUDAX 21 TOP ErP

X2

voltar.com.ua

105

15 20 25 30 35

X1

voltar.com.ua

KEY:

Y2 - Flow water temperature (°C)

X2 - Outdoor air temperature (°C)

voltar.com.ua

KEY:

Y1 - Flow water temperature (°C)

X1 - Outdoor air temperature (°C)

voltar.com.ua

40

50

45

voltar.com.ua

voltar.com.ua

voltar.com.ua

NOTE: AUDAX TOP 18-21 ErP is equipped with antifreeze

protection comprising an electrical resistance to protect the plate

exchanger which is the most critical component with regard to

freezing. When the electrical resistance activates so does the

pump inside the AUDAX TOP 18-21 ErP, in this way, with

power supply voltage, the machine is protected up to -10°C.

If AUDAX TOP 18-21 ErP is installed in areas having temperatures below 0 °C, it is recommended to provide special antifreeze

systems in order to guarantee the machine's integrity, especially

the water-gas heat exchanger, when there is a blackout.

For example, insert top quality, non-hazardous antifreeze liquid

into the heating system.

voltar.com.ua

voltar.com.ua

In this case, the instructions of the manufacturer of this liquid

must be followed scrupulously regarding the percentage necessary

voltar.com.ua

with respect to the minimum temperature at which the system

must be kept.

An aqueous solution must be made with potential pollution class

of water 2 (EN 1717:2002).

With no supply voltage and if no antifreeze liquid has been

inserted, you must drain the water from the machine.

Avoid using automatic lling systems.

voltar.com.ua

voltar.com.ua

29

voltar.com.ua

voltar.com.ua

voltar.com.ua

AUDAX TOP 6 ErP

10 AUDAX TOP 6 ErP TECHNICAL DATA

Central heating circuit

Power in CH mode with water set at 35 °C

Power in CH mode with water set at 45 °C

Power in CH mode with water set at 55 °C

CH mode COP with water set at 35 °C

CH mode COP with water set at 45 °C

CH mode COP with water set at 55 °C

Min/max heat power with water set at 35 °C

Min/max heat power with water set at 45 °C

Min/max heat power with water set at 55 °C

Flow temperature range °C 20 / 60

Outdoor temperature heating operation limits °C -20 / 30

voltar.com.ua

(1)

kW 5.76

(2)

kW 5.76

(3)

kW 5.43

(1)

4.28

(2)

3.05

(3)

2.77

(1)

kW 1.08 / 6.14

(2)

kW 1.06 / 6.04

(3)

kW 1.02 / 5.58

voltar.com.ua

voltar.com.ua

voltar.com.ua

Cooling circuit

Power in cooling mode with water set at 18 °C

Power in cooling mode with water set at 7 °C

Cooling mode EER with water set at 18 °C

Cooling mode EER with water set at 7 °C

Min/max cooling capacity with water set at 18 °C

Min/max cooling capacity with water set at 7 °C

Flow temperature range °C 4 / 18

Outdoor temperature Cooling operation limits °C 5 / 46

General data

Max system operating pressure bar 3

Head available on the system with 1500 l/h flow rate kPa (m H2O) 40 (4.08)

Expansion vessel capacity l 2

Water circuit content l 1.0

C.H. sound power level dB(A) 62

Appliance electric protection rating IP X4

Electric supply voltage V - Hz 230 - 50

Permitted voltage range V 207 - 253

Maximum absorbed power W 2000

Maximum absorbed current A 11

Fuse inserted A 16 - Type B

Refrigerant fluid load (R410A)* g 1350

Heat Pump weight kg 61

voltar.com.ua

voltar.com.ua

voltar.com.ua

(1)

kW 7.04

(2)

kW 4.73

(1)

(2)

(1)

kW 1.20 / 7.49

(2)

voltar.com.ua

kW 0.73 / 5.33

voltar.com.ua

voltar.com.ua

voltar.com.ua

3.70

3.00

voltar.com.ua

voltar.com.ua

* Hermetically sealed system.

THE REPORTED DATA REFERS TO THE FOLLOWING CONDITIONS (in compliance with EN 14511)

ROOM C.H. MODE (°C) COOLING MODE (°C)

Room Antifreeze WATER (F/R)

Room Antifreeze WATER (F/R)

Room Antifreeze WATER (F/R)

30

(1)

- AIR (db/wb) 35/30 - 7/6 18/23 - 35 (db)

(2)

- AIR (db/wb) 45/40 - 7/6 7/12 - 35 (db)

(3)

- AIR (db/wb) 55/47 - 7/6

voltar.com.ua

voltar.com.ua

:

voltar.com.ua

Loading...

Loading...